pneumatic tire

A technology of pneumatic tires and tires, which is applied to off-road vehicle tires, tire parts, tire treads/tread patterns, etc., can solve problems such as weakening rigidity, and achieve the effect of improving decorative effect and maintaining traction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

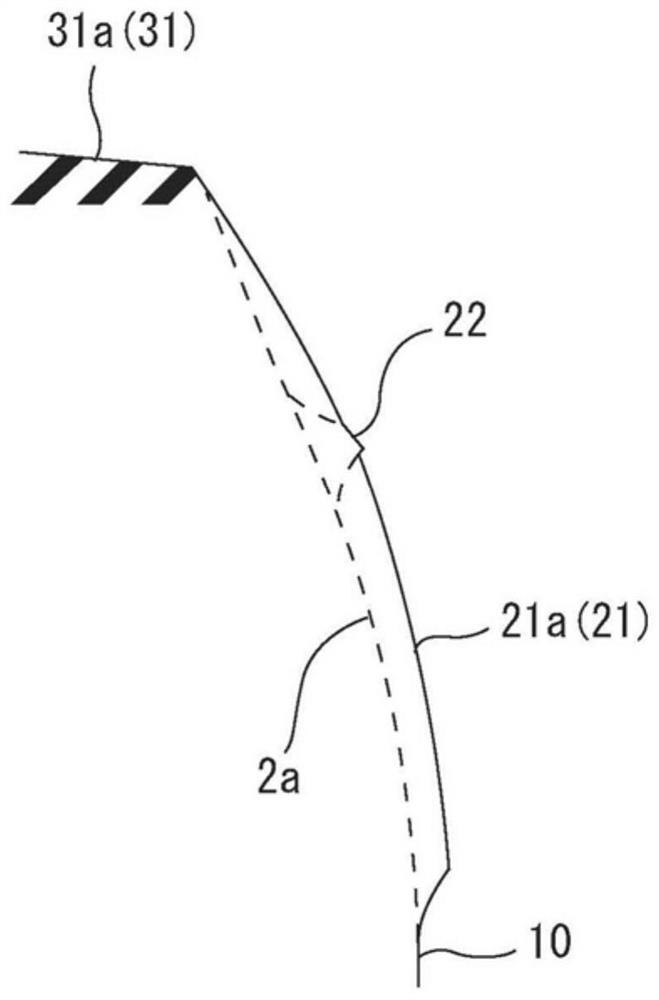

[0028] Hereinafter, the first embodiment of the present invention will be described with reference to the drawings. figure 1 Summary represents a half-cross-sectional view of a tire sub-line semi-cross-sectional view of 1 example of the pneumatic tire according to the present invention, which is equivalent to figure 2 A-a section. figure 2 It is a deployment diagram showing the shoulder area and the wall region of the pneumatic tire. in figure 2 In the left and right directions, the tire circumferential direction is performed in the lower direction of the tire width direction, and the inner direction is inside the tire width direction. Figure 3A ~ 3D It is expressed separately figure 2 A schematic view of the A-A, B-B, C-C, D-D section.

[0029] The inflatable tire T is a non-paving pavement of a non-paving pavement in a harsh pavement including a muddy location or a rock field. Such as figure 1 As shown, the pneumatic tire T is provided: a pair of bead portion 1, from each of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com