Tire tread structure of pneumatic tire of motorcycle

A technology for pneumatic tires and motorcycles, which is applied to motorcycle tires, motorcycles, tire treads/tread patterns, etc., and can solve the problem of low smooth edge effect of large-span pattern main grooves 21, difficulty in discharging stones, and poor traction performance. Unsatisfactory problems, to achieve the effect of improving wetland grip performance, improving drainage performance, and facilitating stone removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

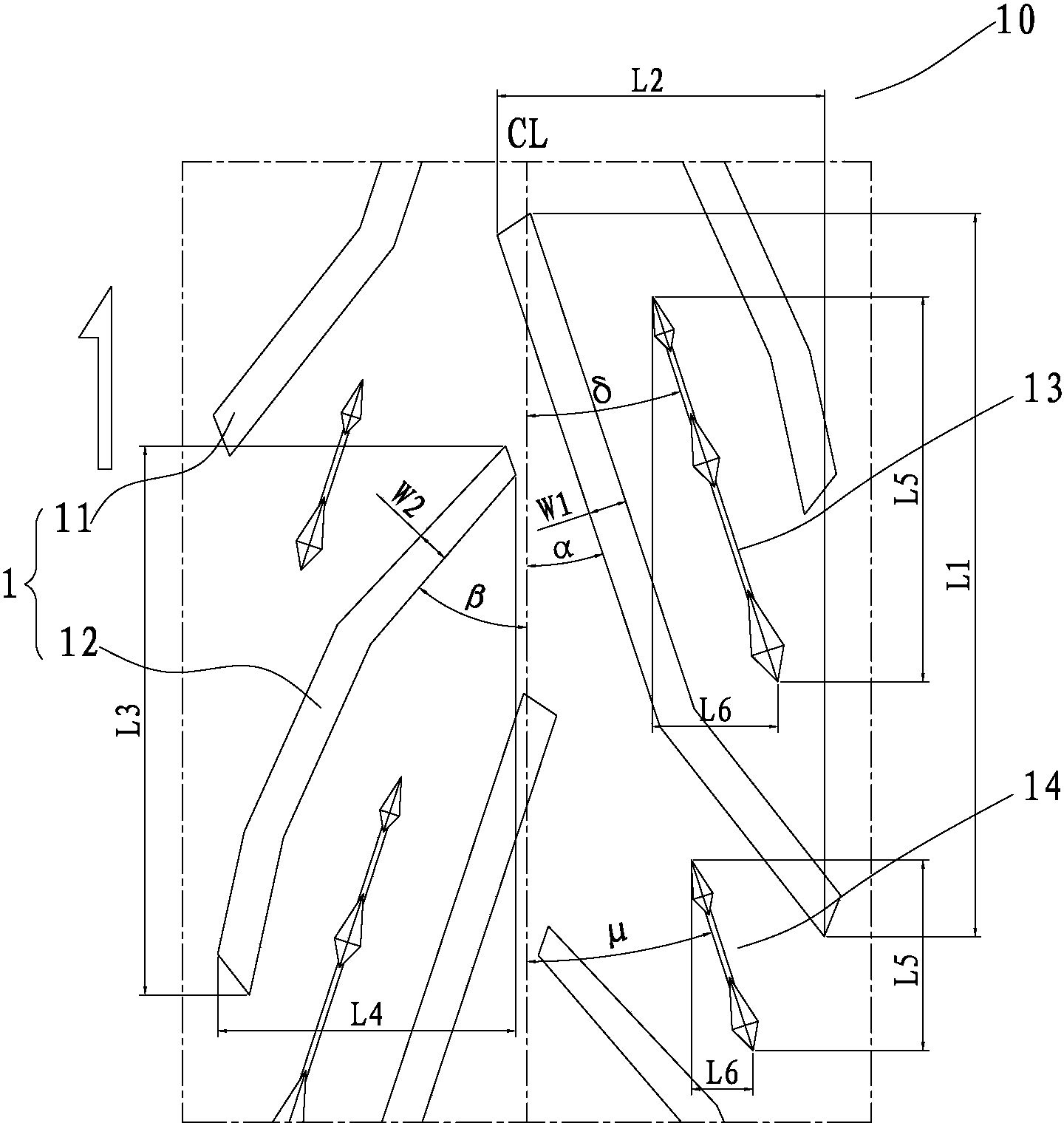

[0029] Such as Figure 1 to Figure 6 As shown, the present invention discloses a motorcycle pneumatic tire tread structure, CL is the center line of the tread, and the tread 10 includes several pattern main groove groups 1 arranged symmetrically and alternately with the center of the tread, each pattern main groove Group 1 includes the first pattern main groove 11 and the second pattern main groove 12, both of which are large-span and high longitudinal pattern main grooves inclined from the inside of the tread to the outside, wherein the inner end of the first pattern main groove 11 can be Across the center of the tread; in addition, a first fine diamond pattern auxiliary groove 13 is provided between the pattern main groove groups 1, and between the first pattern main groove 11 and the second pattern main groove 12 of each pattern main groove group 1 A second fine diamond pattern auxiliary groove 14 is provided.

[0030] Such as figure 1 , the ratio of the lateral length L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com