Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Increase heat supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

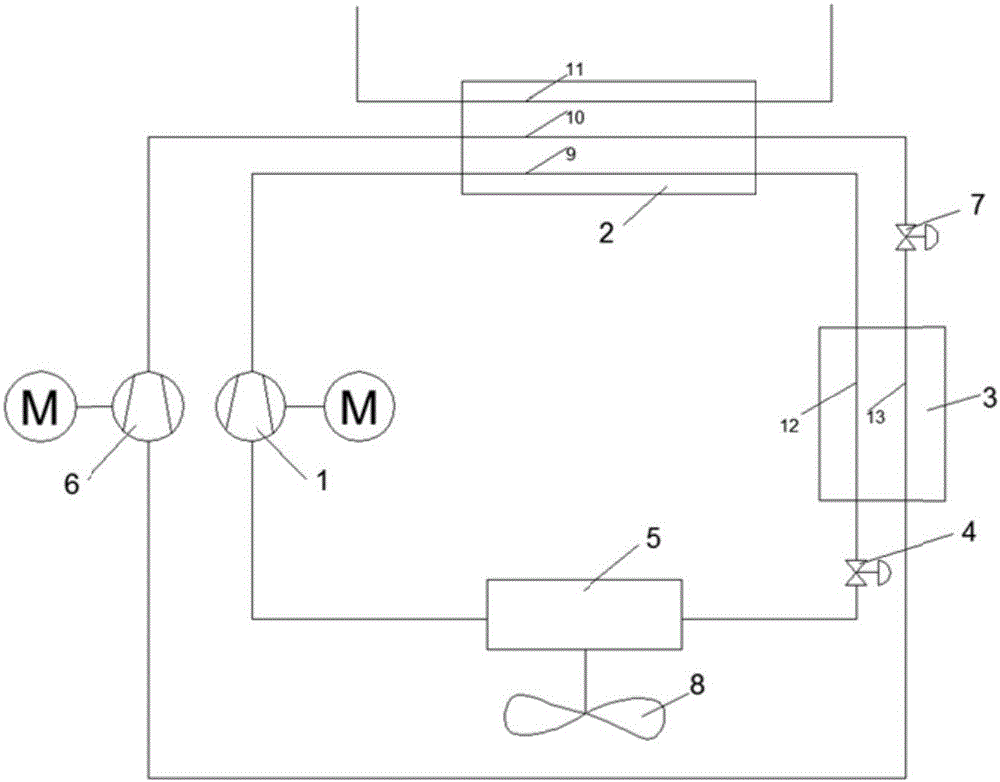

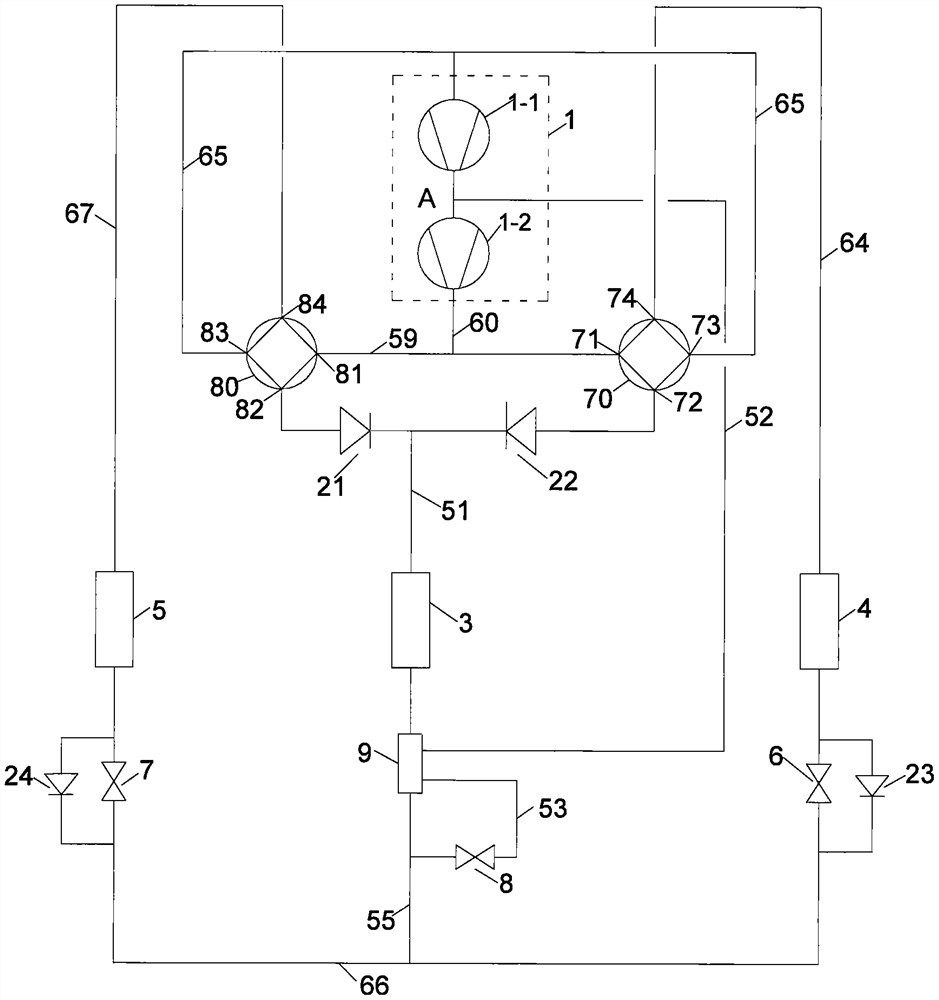

Defrosting control method for air conditioner

InactiveCN104633835ASolve the problem of releasing cold energyImprove comfortMechanical apparatusSpace heating and ventilation safety systemsMain branchFour-way valve

The invention provides a defrosting control method for an air conditioner. The air conditioner comprises a compressor, a four-way valve, an indoor heat exchanger, a first throttling device, outdoor heat exchangers, a refrigerant pipeline, a second throttling device, a first two-way valve and a second two-way valve. When defrosting begins, the second two-way valve is closed, and the first two-way valve is opened, a refrigerant sprayed by the compressor is divided into two branches at the second connecting point of the first two-way valve, wherein the main branch comprises the large part of refrigerant which flows to the first part heat exchanger of the outdoor heat exchangers to be used for defrosting, flows to the second part heat exchanger through the second throttling device to absorb heat and finally flows through the four-way valve to return into the compressor; the auxiliary branch comprises the other small part of refrigerant which flows through the indoor heat exchanger to exchange heat and flows through the first throttling device to join the main branch. In the defrosting process, the small part of the refrigerant flows to the indoor heat exchanger, an indoor unit has certain heat and does not have cold radiation, the problem that the indoor unit releases the refrigerating capacity to an indoor unit in the defrosting process of the air conditioner is solved, and the comfortable feeling of a user is improved.

Owner:GREE ELECTRIC APPLIANCES INC

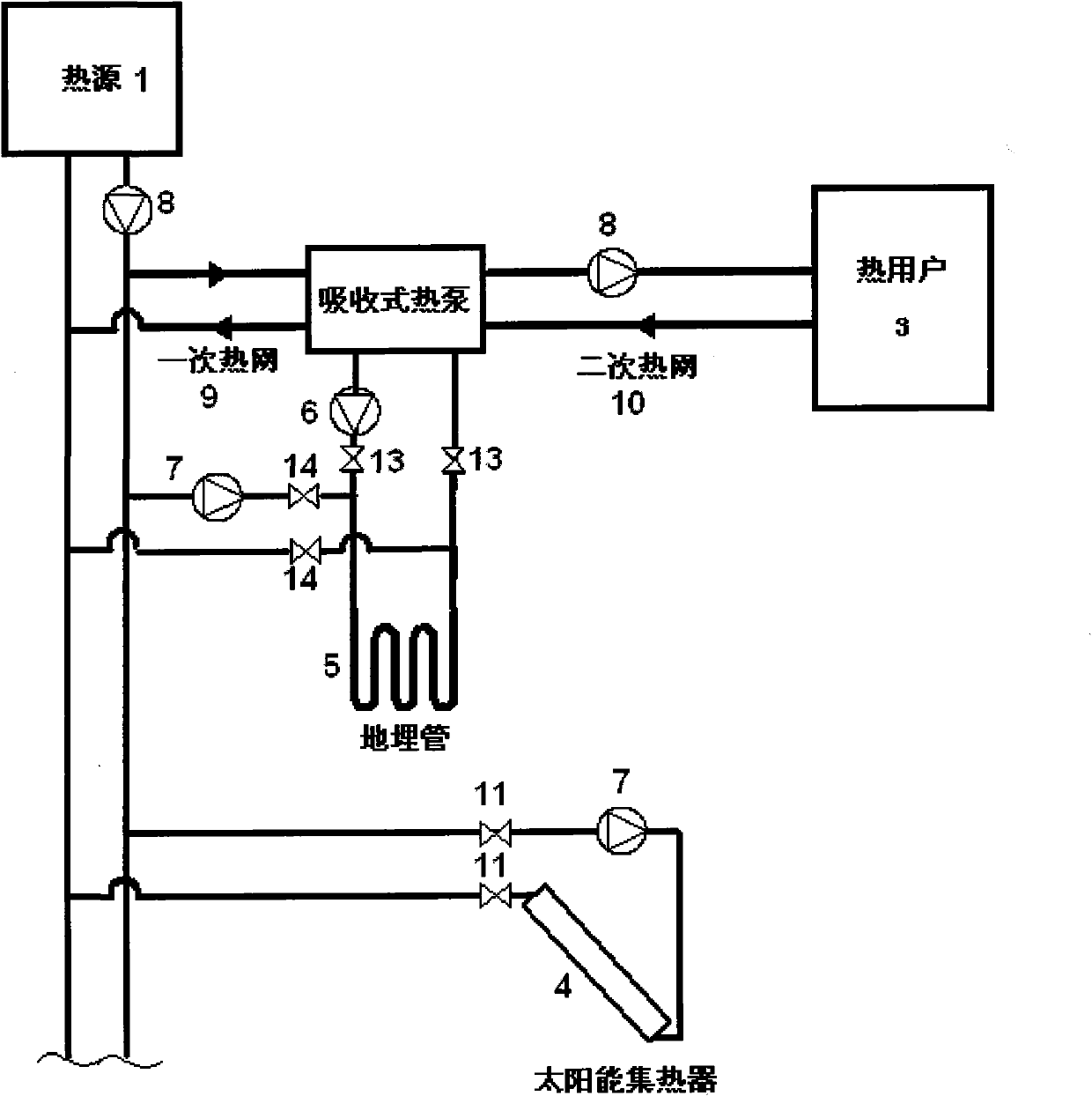

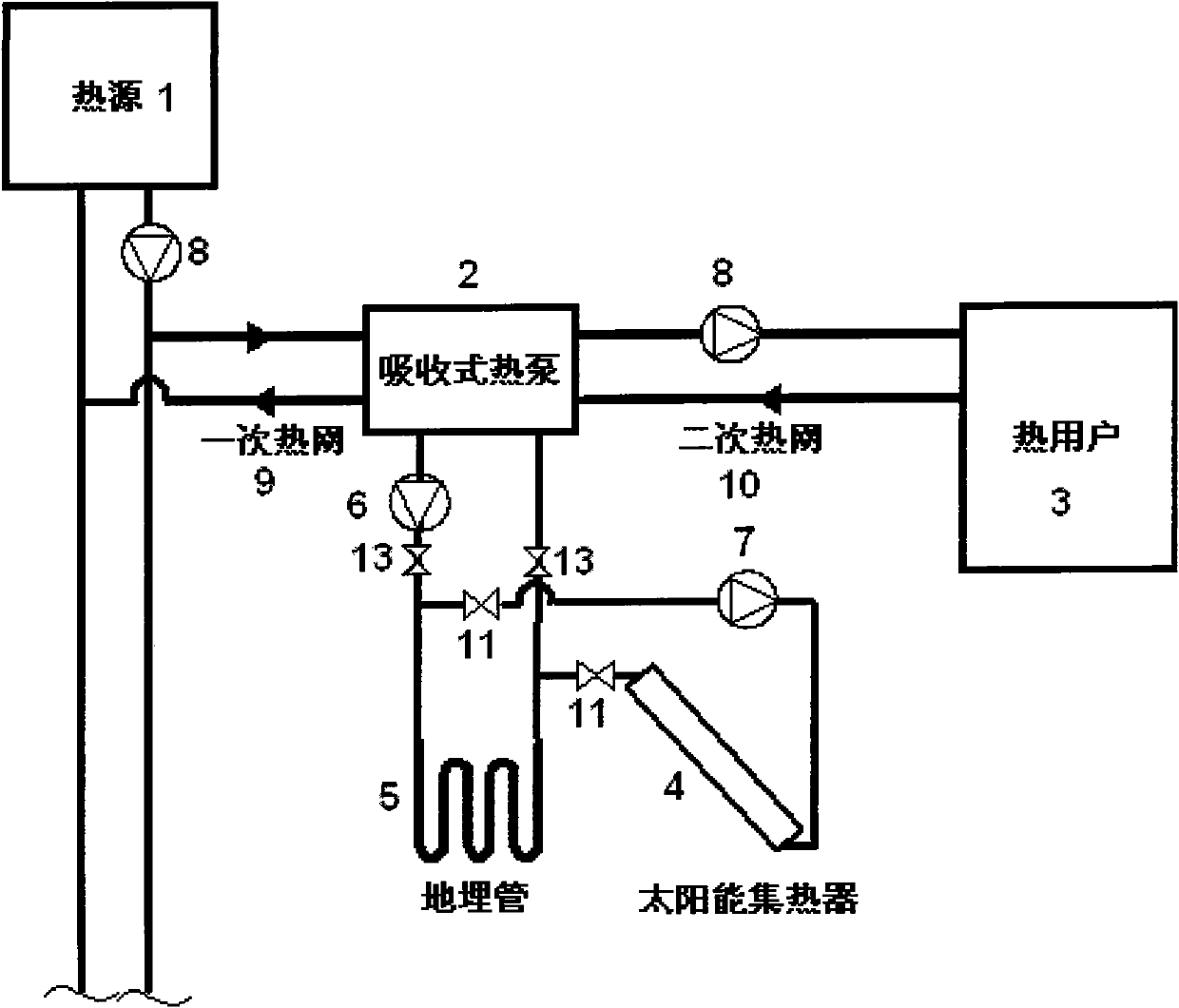

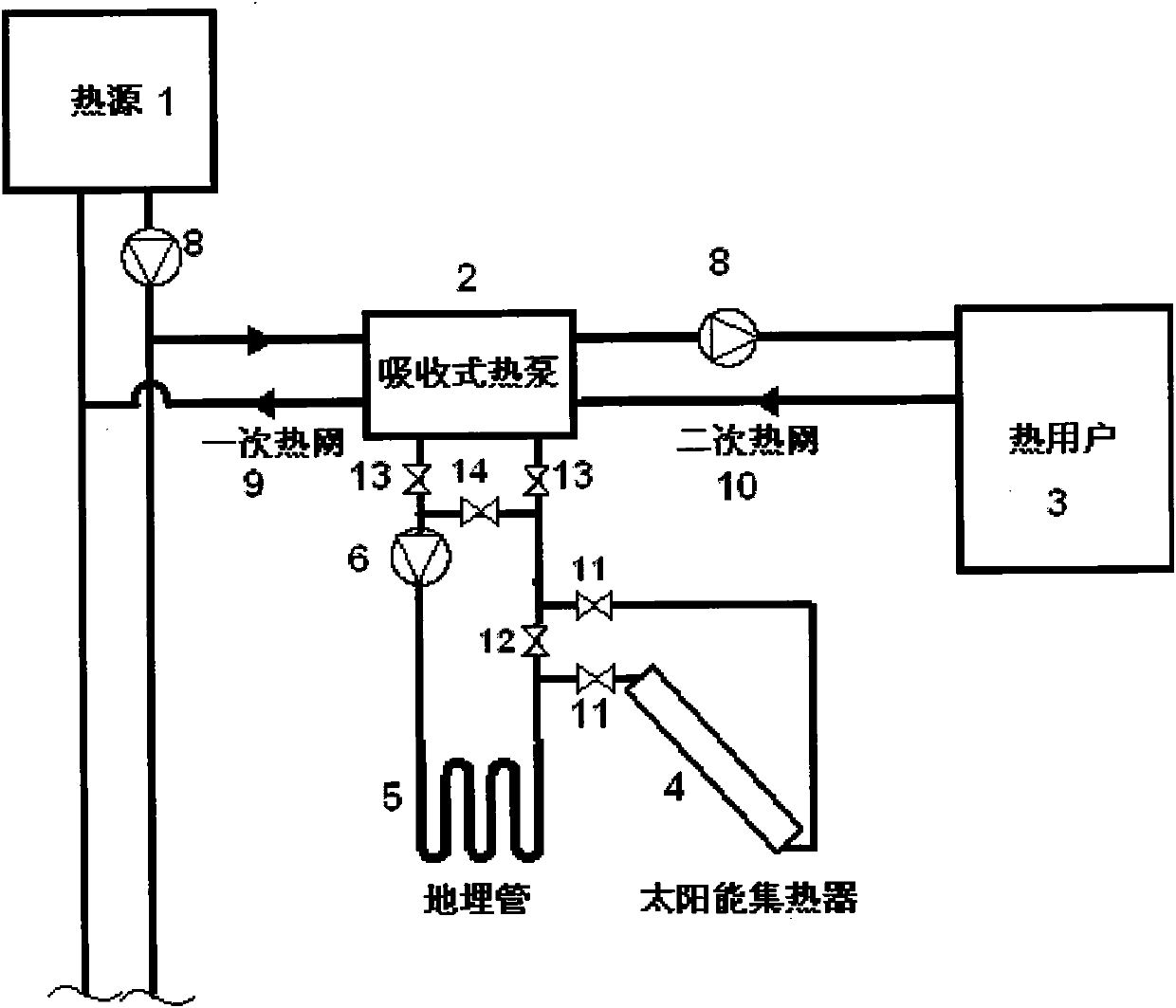

Solar energy and geothermal energy assistant centralized heating system

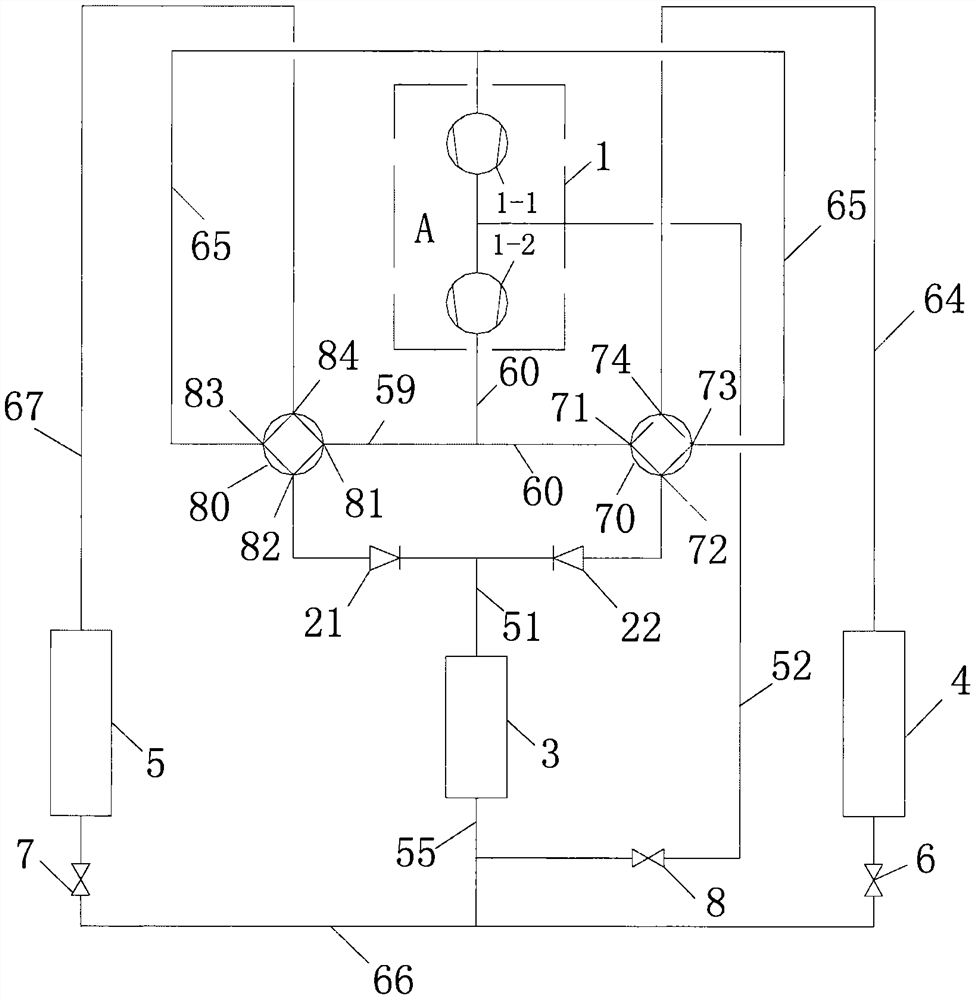

ActiveCN101922753AIncrease heat supplyIncrease profitHeat pumpsSolar heat devicesHeating seasonEngineering

The invention discloses a solar energy and geothermal energy assistant centralized heating system belonging to the technical field of centralized heating. A heating station is provided with a geothermal source adsorption heat pump unit, a centralized heating system once-network high-temperature hot water drives the adsorption heat pump, a soil source serves as the low-order heat source of the adsorption heat pump, heating medium adsorbs heat from earth and releases heat in a heat-pump evaporator, and adsorbed geothermy is used for secondary network heat supply. In order to restore soil temperature, the system adopts solar energy to serve as an assistant heat source; in the heating season, solar energy and geothermal energy mutually supplements; in the non-heating season, solar energy is independently used to recharge heat into ground so as to restore soil temperature and keep the soil temperature balanced in the whole year. The system takes the adsorption heat pump to replace a water-water heat exchanger and improves system heat supply amount by recovering environment heat; a solar energy soil heat accumulation mode is used for improving the utilization ration and system stability of the solar energy heat collector; and heat network water is used for driving the heat pump, thus saving a great quantity of electric power consumption, and lowering operation cost.

Owner:TSINGHUA UNIV +1

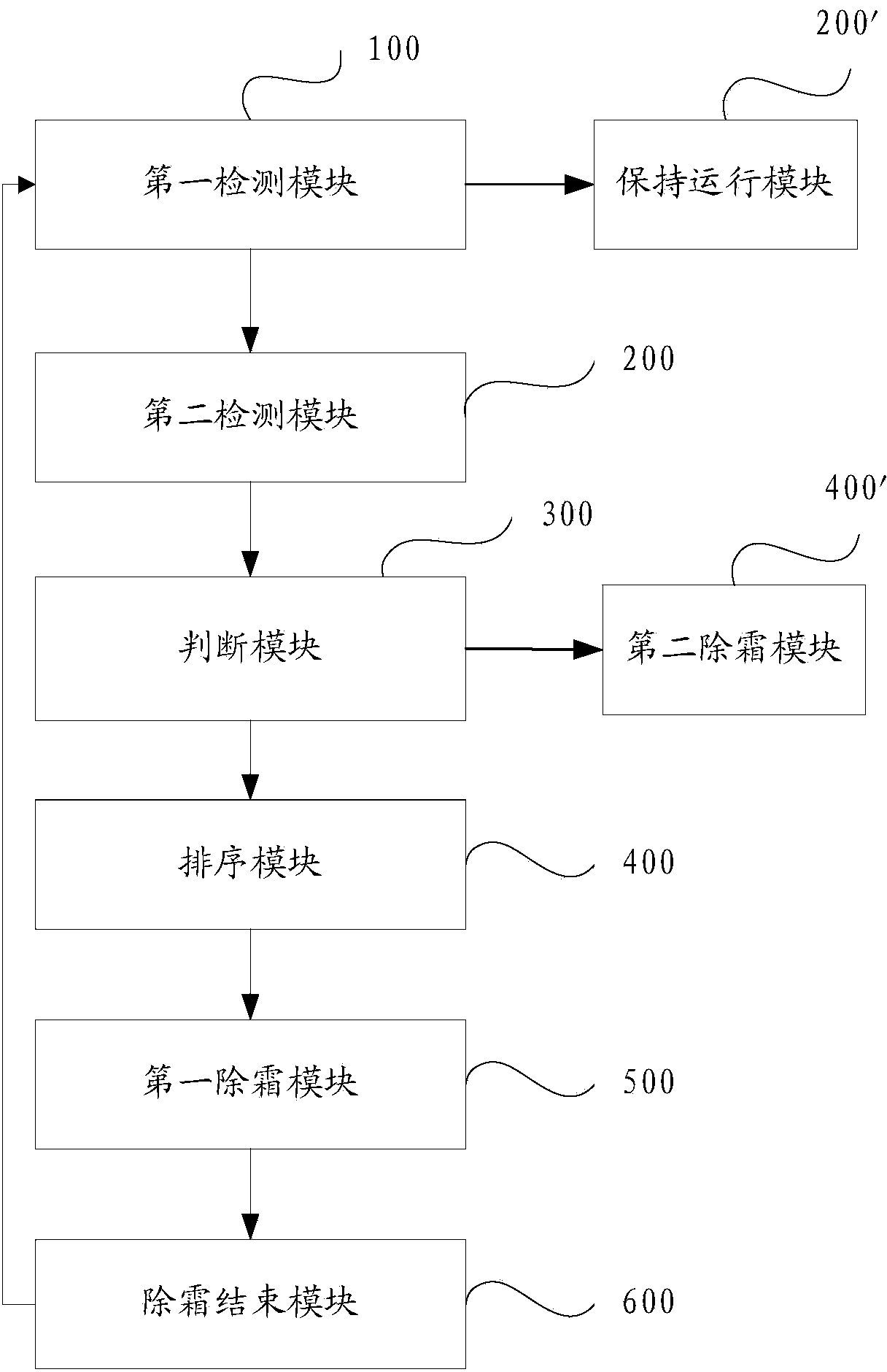

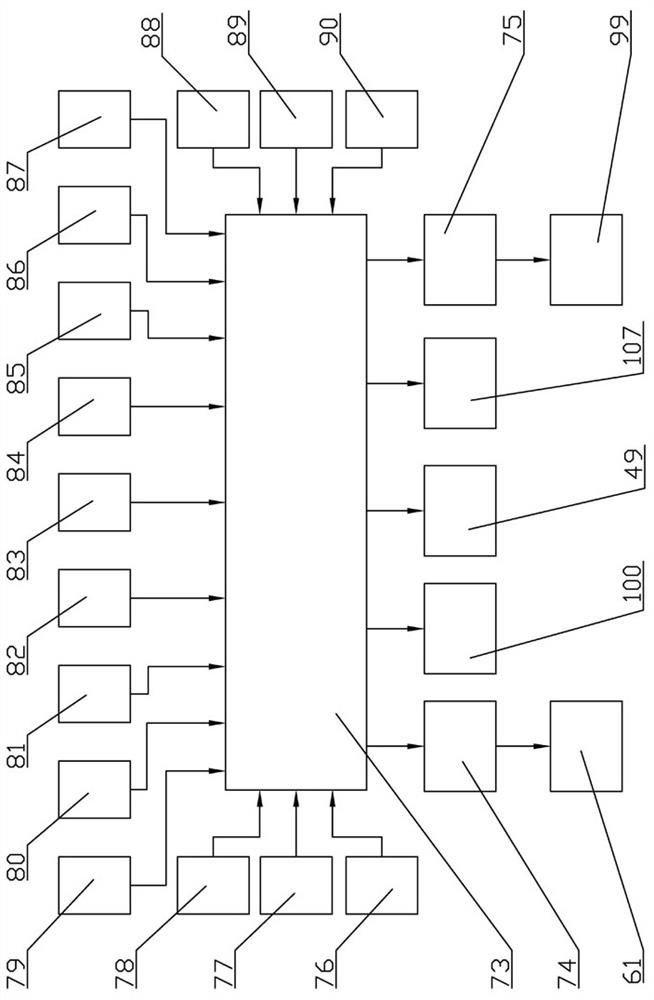

Defrosting control method and system of heat pump air-conditioning unit

InactiveCN104180570AImprove reliabilityReduce the frequency of start and stopSpace heating and ventilation safety systemsSpace heating and ventilation control systemsThermodynamicsProcess engineering

The invention provides a defrosting control method and system of a heat pump air-conditioning unit. The defrosting control method is used for defrosting multiple pipeline systems of the air-conditioning unit and comprises the following steps: whether pipeline systems meeting defrosting requirements exist is detected, if yes, the quantity of the pipeline systems meeting the defrosting requirements is detected; whether the percentage of the quantity of the pipeline systems meeting the defrosting requirements in the total quantity of the pipeline systems is larger than a preset percentage or not is determined; if yes, the pipeline systems meeting the defrosting requirements are sorted according to total run time of corresponding compressors; and a preset quantity of pipeline systems in the pipeline systems meeting the defrosting requirements are in a defrosting mode, and other pipeline systems are in a heating mode. According to the defrosting control method and system, in the defrosting process, part of the pipeline systems defrost, the other pipeline systems perform heating, so that heating continuity for users is guaranteed, the use comfort of the users is improved, the heating pipeline systems provide heat for the defrosting pipeline systems, and the defrosting efficiency is increased.

Owner:GREE ELECTRIC APPLIANCES INC

Phosgene-complementary disc-type sterling solar power generation device

InactiveCN102128149AIncrease heat supplyRated steady stateFrom solar energySolar thermal energy generationThermodynamicsSolar power

The invention discloses a phosgene-complementary disc-type sterling solar power generation device, and relates to the technical field of solar thermal power generation, aiming at solving the problem that the existing sterling solar power generation device can not stabilize the output power during the strong and weak changes of the sunlight. The device comprises a light collecting disc, an absorber, a sterling power generator set, a heater and a combustor, wherein the light collecting disc is supported by a base and is used for collecting the sunlight; the absorber is arranged above the light collecting disc through a support and is used for absorbing focused energy; the sterling power generator set is used for converting the heat energy into electric energy; the absorber is connected with the heater of the sterling power generator set; the heater is used for transferring the focused solar energy to the sterling power generator set; and the combustor is connected with the heater, and is used for performing auxiliary heating on the sterling power generator set. The phosgene-complementary disc-type sterling solar power generation device provided by the invention is suitable for solar power generation, the combination of solar energy and natural gas or marsh gas is adopted for generation, the sterling solar power generation device is ensured to be used in case of no sunlight or insufficient sunlight, and the utilization ratio and economical efficiency of the device can be improved.

Owner:SHANGHAI MICROPOWERS

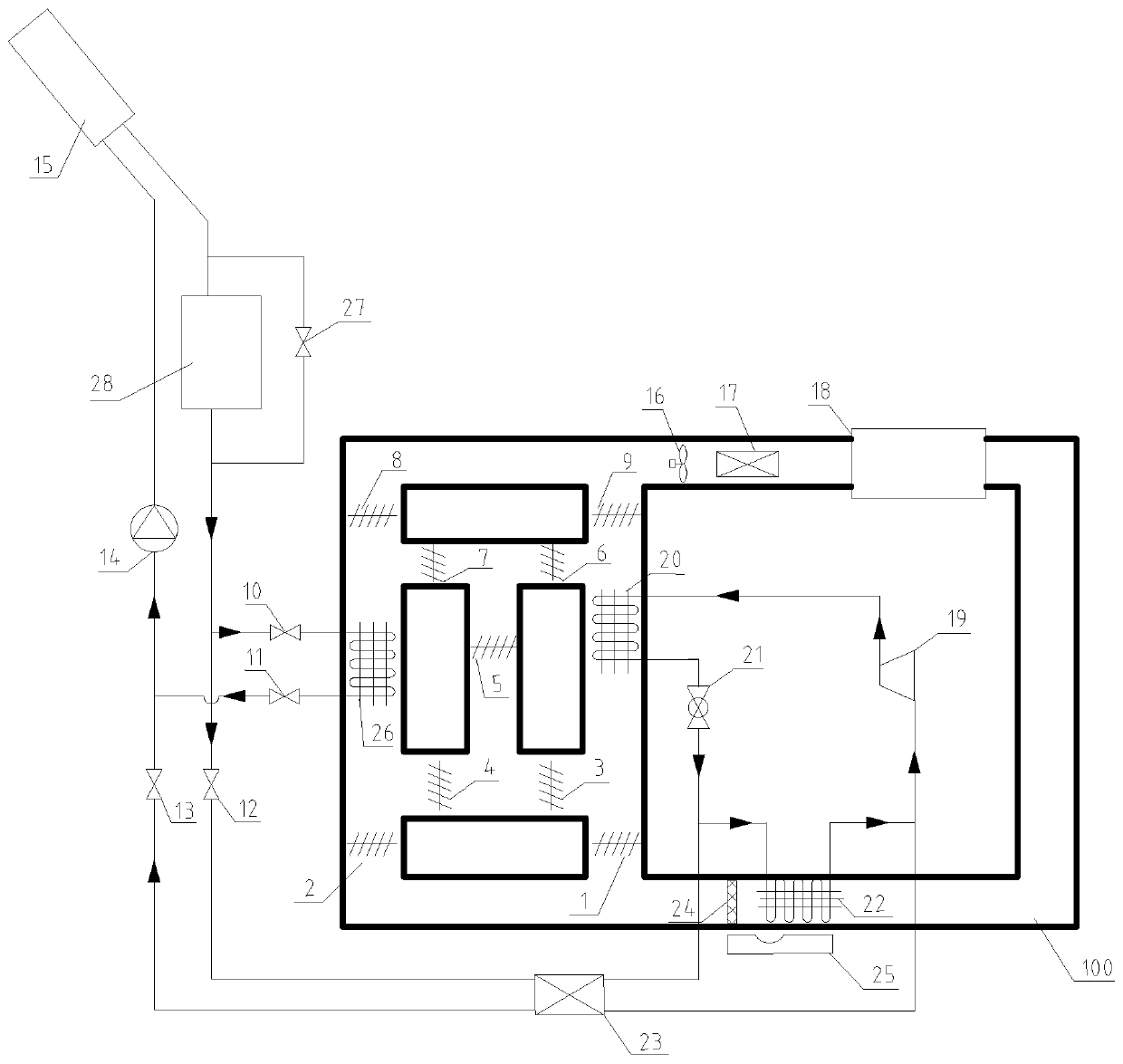

Transcritical CO2 compound heat pump and control method thereof

InactiveCN106440441AImprove performanceIncrease profitMechanical apparatusHeat pumpsFailure rateEvaporation

The invention discloses a transcritical CO2 compound heat pump and a control method thereof. The transcritical CO2 compound heat pump comprises a CO2 main path compressor, an air cooling-air cooling recombiner, a supercooling-evaporation recombiner, an evaporator and a CO2 auxiliary compressor, wherein the air cooling-air cooling recombiner comprises a CO2 main path, a CO2 auxiliary path and a water path; and the supercooling-evaporation recombiner comprises a CO2 main path supercooling section and a CO2 auxiliary evaporation section. According to the invention, the transcritical CO2 compound heat pump comprises two working modes according to the return water temperature, the application range of a unit is wider, and daily requirements are met; the transcritical CO2 compound heat pump only has one refrigerant and water heat exchanger, and compared with a conventional transcritical CO2 compound heat pump with three water and refrigerant heat exchangers, the transcritical CO2 compound heat pump has the advantages that a circulating water path is a single loop with one inlet and one outlet, the system is simple, and the failure rate is decreased; and an auxiliary loop adopts an inverter compressor, a heat pump water heater system can stably and reliably operate for a long time under the conditions of wider load and temperature, the power consumption is reduced, and the starting current of the compressor can be decreased.

Owner:XI AN JIAOTONG UNIV

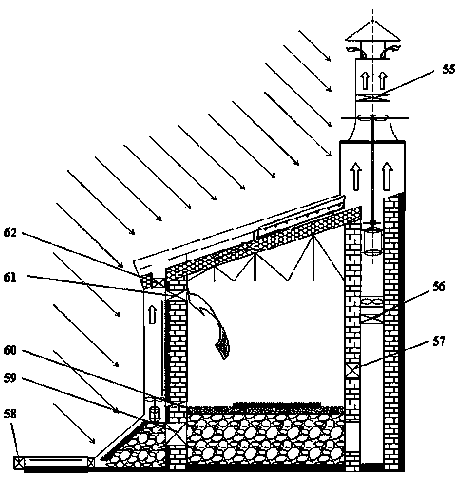

Solar energy and building integrated hot air power generation, ventilation and heating system

ActiveCN103835447AImprove utilization efficiencyEfficient and reasonable useRoof covering using slabs/sheetsSolar heating energyBuilding integrationThermal water

A solar energy and building integrated hot air power generation, ventilation and heating system comprises a house body. The house body comprises a foundation, walls, doors, windows and a solar hot air power generation, ventilation and heating system body. The solar hot air power generation, ventilation and heating system body comprises a solar energy ground collector, a solar energy outer wall collector, a solar energy roof collector, a solar hot air power generator, a solar heating device, a solar ventilating device and a solar hot air water heating device. The solar hot air power generation, ventilation and heating system has the advantages that the features of solar energy is effectively used, solar energy hot air is used for heating domestic hot water, ventilating, cooling, power generating and heating, solar energy air collectors are integrated with a building, the system is low in cost, safe, reliable, good in stability and capable of comprehensively utilizing solar energy all the year round, and the domestic hot water supply, winter heating, summer power generation, ventilation and cooling of the single building in northern areas can be achieved.

Owner:山西奥通光热技术有限公司

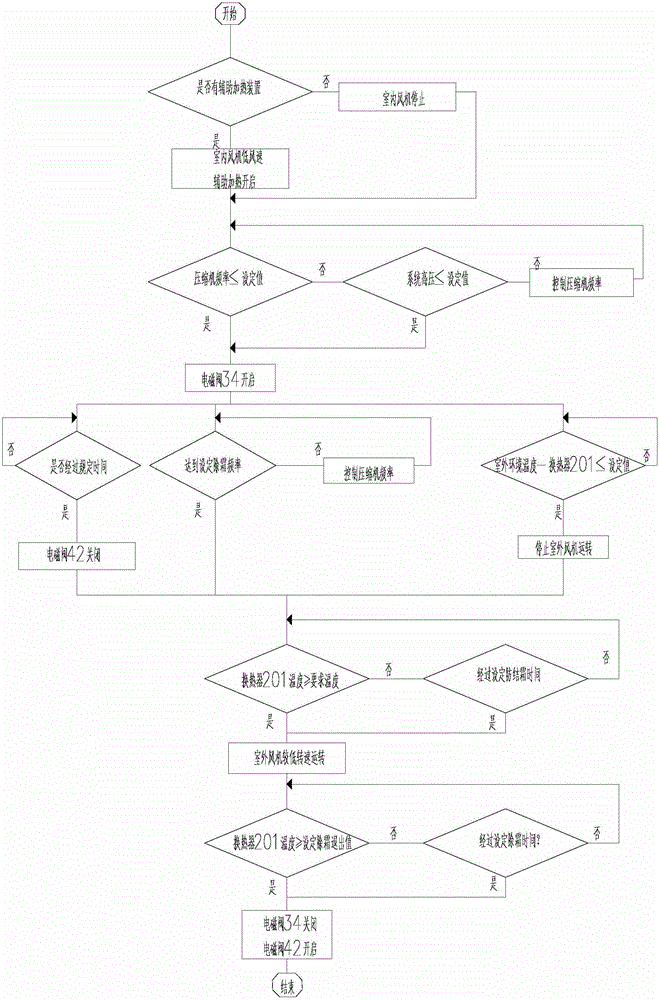

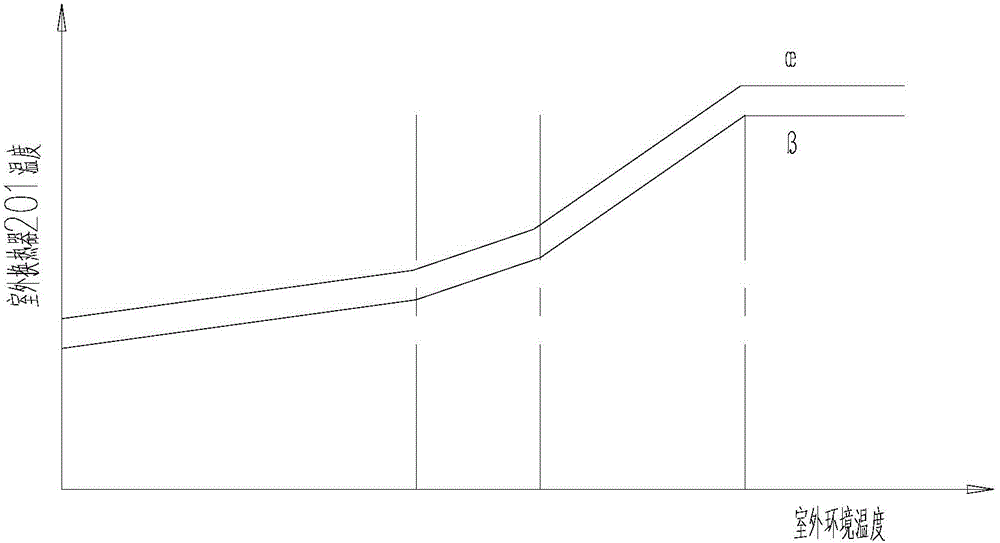

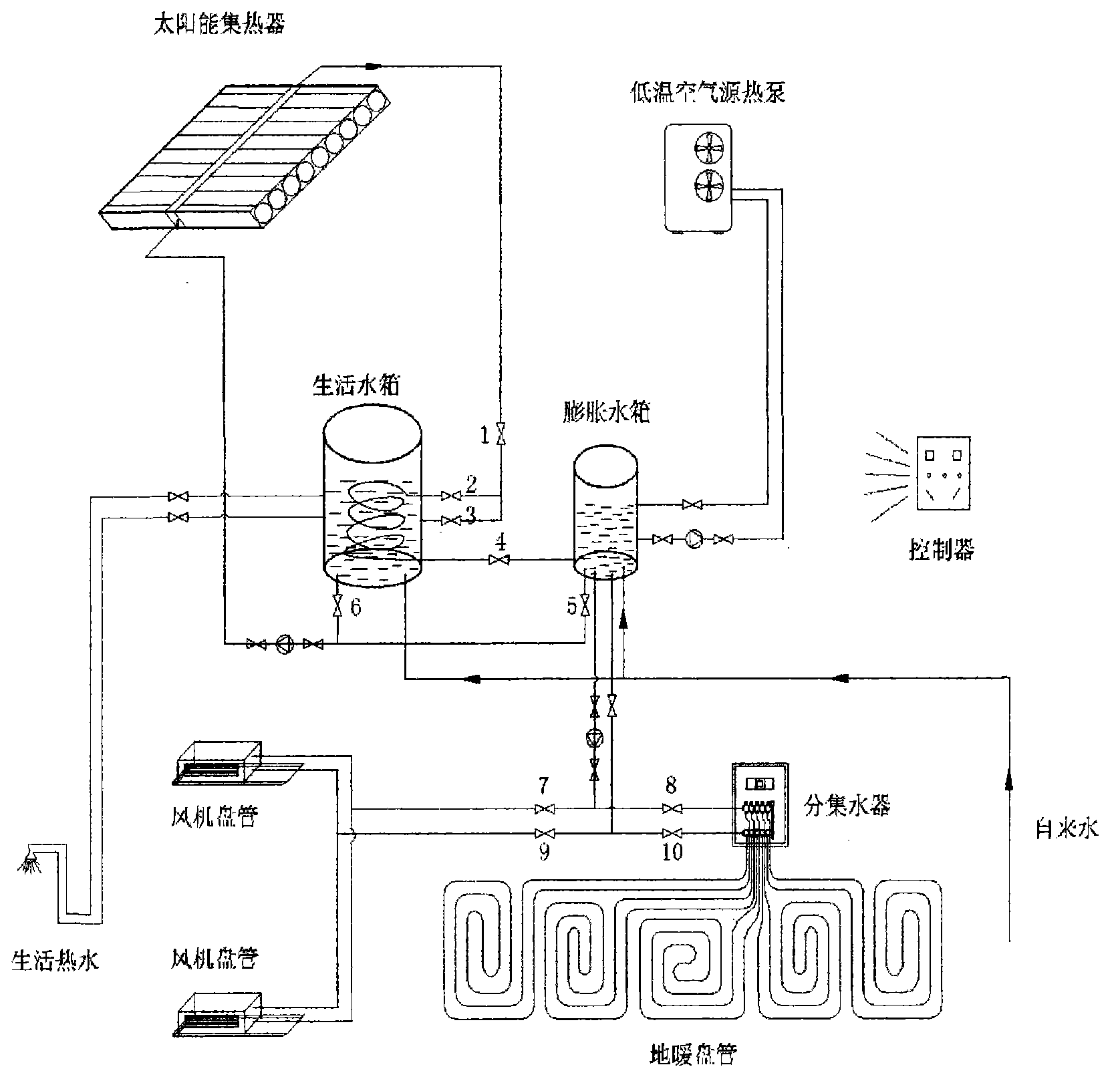

Solar energy and air-source heat pump heating and water heating complementary system and method

InactiveCN104180420AImprove heat supply and thermal efficiencyGuaranteed stable operationLighting and heating apparatusCentral heating systemHeating systemHeating efficiency

The invention discloses a solar energy and air-source heat pump heating and water heating complementary system and method. The system comprises an air-source heat pump, wherein an indoor unit of the air-source heat pump and an insulation water tank form a closed water path, the indoor unit of the air-source heat pump and a floor heating system form a closed water path, and a solar heat collector is used for supplying heat to the insulation water tank through a heat exchange pipeline II and supplying heat to a heat exchanger and a water receiving tray of an outdoor unit of the air-source heat pump through a heat exchange pipeline I, so as to defrost; a central controller is used for controlling the opening / closing of various electromagnetic valves and setting various temperatures. According to the solar energy and air-source heat pump heating and water heating complementary system and method, disclosed by the invention, the problem that the volume of hot water for living supplied by solar energy in winter and rainy days is insufficient can be solved by an air-source heat pump system, and the heat supply amount and heat efficiency are greatly increased; in addition, heat supplied by the solar energy is used for removing the icing of the heat exchanger and the water receiving tray of the outdoor unit of the air-source heat pump, so that the stable operation of the air-source heat pump is guaranteed.

Owner:赵建忠

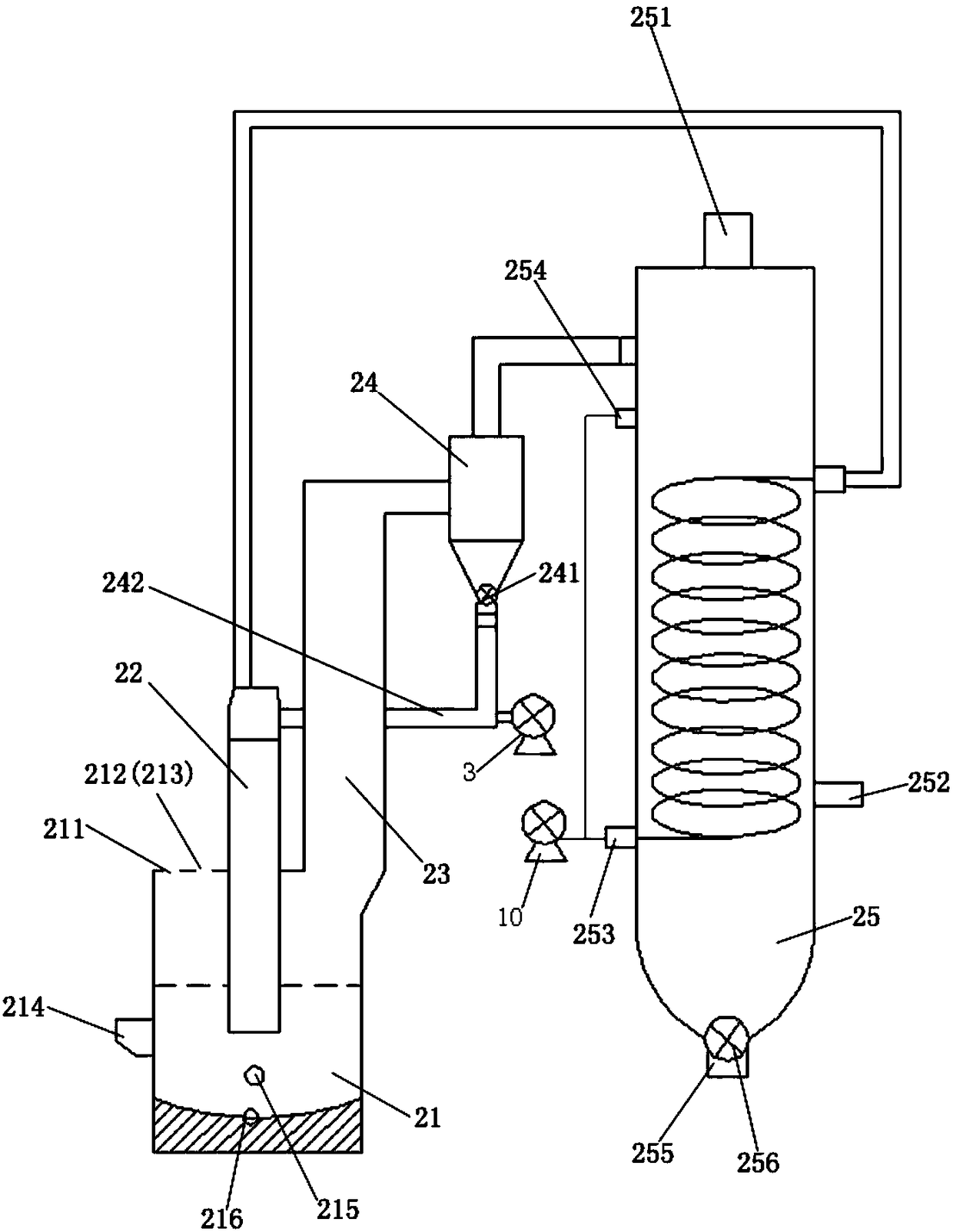

Recycling treatment device and method of waste circuit boards

ActiveCN106591585AHigh recovery rateEliminates the possibility of synthesisProcess efficiency improvementPrinted circuit boardCarbon particle

The invention provides a recycling treatment device and method of waste circuit boards. The recycling treatment device of waste circuit boards mainly comprises a crushing machine, a self-reduction smelting furnace, a Roots blower and an exhaust gas treatment device. The self-reduction smelting furnace is mainly composed of a smelting furnace body, a smelting spray gun, a vertically lifting flue, a cyclone separator and a combustion heat exchange tower, wherein the top of the smelting furnace body is provided with a charging port, a heat preservation gun port and a sampling port; the vertically lifting flue is connected with an inlet of the cyclone separator; an outlet of the cyclone separator is connected with the combustion heat exchange tower; an air heat exchanger is arranged inside the combustion heat exchange tower; and a hot air outlet is formed in the upper portion of the combustion heat exchange tower and connected with a smelting spray gun entering the smelting furnace through a pipeline. Through equipment transformation, process optimization and combination of recycled carbon particles as a reduction agent and recycled high-temperature process gas as heat, the recycling rate of valuable metal is effectively increased, the smoke volume of a system is reduced, energy is saved, and pollution is reduced.

Owner:中节能工程技术研究院有限公司

Multi-energy complementary heat pump drying device suitable for low-temperature working condition

PendingCN111457711ARaise the evaporation temperatureGuaranteed uptimeSolar heating energyMechanical apparatusEngineeringMechanical engineering

The invention discloses a multi-energy complementary heat pump drying device suitable for a low-temperature working condition. The device comprises a refrigerant loop, a water loop and an air loop. When the device operates, especially under the low-temperature working condition in winter, hot water prepared by solar energy is sent to a second evaporator to heat a refrigerant to provide an auxiliary heat source for a heat pump, the total heat production amount of the heat pump is increased, and the technical problem that the heat pump is low in efficiency under the low-temperature working condition is solved; and in addition, solar energy is provided for independent heat supply, a heat pump condenser and a gas-water heat exchanger are simultaneously or independently put into operation to heat and dry air, and the purpose of drying in multiple modes and multiple energy sources is achieved. The invention provides a novel multi-energy complementary drying system suitable for the low-temperature working condition based on solar energy and the heat pump, through combined utilization of the heat pump and the solar energy, the operation efficiency of heat pump drying is further improved, electric energy consumption is reduced, and pollutant emission is reduced.

Owner:YANTAI UNIV

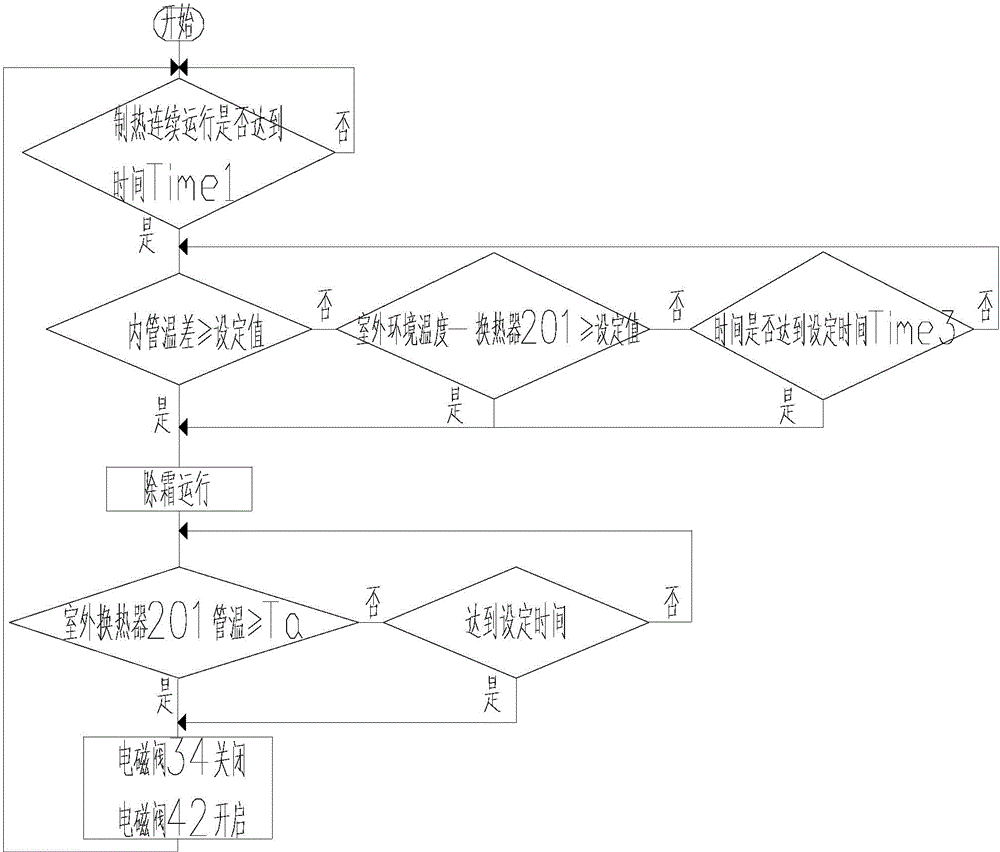

Continuous heating and defrosting air source heat pump control method

PendingCN111649511AShorten defrosting timeRun fastCorrosion preventionEfficient regulation technologiesEngineeringMechanical engineering

The invention discloses a continuous heating and defrosting air source heat pump control method. Low-voltage protection of a heat pump system is actively shielded during the period of defrosting, andthe low-voltage protection is started after the defrosting period; when any group of outdoor heat exchangers of all outer heat exchangers meets a defrosting condition and enters a defrosting state, acontroller records pre-defrosting opening values of all main electronic expansion valves matched with a first group of outdoor heat exchangers to be defrosted at the same specified time before a four-way valve is switched; the first group of outdoor heat exchangers enters the defrosting state after the four-way valve is switched; and the main electronic expansion valves opening matched with the first group of outdoor heat exchangers is a specified defrosting opening, and remaining main electronic expansion valves are respectively regulate opening according to outlet superheat degree of the outdoor heat exchangers matched with the main electronic expansion valves in the defrosting period of the first group of outdoor heat exchangers. The method is characterized in that heat can be providedin the defrosting, the operation of the heat pump is more stable, the defrosting time can be shortened, and the heating load of the heat pump is improved.

Owner:刘雄

Thick material layer sintering production method

The invention discloses a thick material layer sintering production method. According to the method, an upper layer sintering mixture and a lower-layer sintering mixed material of a sintering machinecan be sintered at the same time through twice material spreading and twice ignition, so that the thickness of a sintered material layer is improved, the yield of sintered ore is improved, and sintering indexes are improved; after primary material spreading and before secondary ignition, special carbon pellets are placed, so that heat supply and mineralization time of an upper material layer can be increased, the quality of upper-layer sintered ore is improved, and the sintered ore return amount is reduced; and the hypoxia problem of a lower sintered material layer is solved, the lower sintered material layer is fully mineralized, and the quality of lower-layer sintered ore is improved.

Owner:ANGANG STEEL CO LTD

Chemical conveying pipe for heat supply

InactiveCN108916521AAvoid connectionLow input costPipe heating/coolingPetroleum engineeringInvestment cost

The invention discloses a chemical conveying pipe for heat supply. The chemical conveying pipe for heat supply comprises a pipe body, a fixed cover, an annular bracket, a joint cable and a protectivecover; an inner wall protecting layer is welded on the inner wall of the pipe body; the fixed cover is welded at the middle part of the periphery of the pipe body; heaters are fixedly connected between the inner wall of the fixed cover and the periphery of the pipe body and near two ends through bolts; heat conveying ends of the heaters both penetrate through the pipe body, and are embedded to theinner wall protecting layer; and the heat conveying ends of the heaters are of annular structures. The fixed cover is arranged at the middle part of the periphery of the pipe body; the heaters are arranged between the fixed cover and the pipe body; and each heater is electrically connected through the joint cable in each pipe body, so that circulating substances in the pipe body are heated afterelectrification, the unnecessary sensor connection is prevented, the production cost is reduced, the assembly efficiency is improved, the investment cost of medium and small enterprises is greatly reduced, and the defects in the prior art are made up.

Owner:FOSHAN KUIFENG BUSINESS CONSULTATION SERVICES CO LTD

Method for increasing yield of super-thick material layer sintering

The invention relates to a method for increasing the yield of super-thick material layer sintering. Hot pressing pellets with the alkalinity being the same as that of a sintering mixture are distributed into the sintering mixture, so that ventilation holes are formed in an upper sintering material layer during ignition sintering. The method comprises the steps that 55-70 wt% of iron concentrate and 30-45 wt% of soft coal are fully uniformly mixed, then quick lime is added into the iron concentrate and the soft coal to form a mixture, the binary alkalinity of the mixture is made to be the same as the alkalinity of the sintering mixture, the ratio of CaO to SiO2 is 1.8-2.4, 2-5 wt% of water is added into the mixture, and the mixture is fully stirred and uniformly mixed in a mixer; a uniformly mixed mixture is subjected to hot pressing forming through a ball press machine, wherein the forming pressure is 20-30 MPa, the hot pressing temperature is 350-550 DEG C, the hot pressing time is 8-15 min, and the diameters of obtained hot pressing pellets are 8-12 mm; and the hot pressing pellets are distributed into the sintering mixture layer through a distribution device arranged between a sintering distributor and an ignitor, wherein the amount of the hot pressing pellets distributed into the edge sintering mixture is 1-2.5 times that of the hot pressing pellets distributed into the middle sintering mixture, and the depth of the hot pressing pellets distributed into the sintering material layer is 20-200 mm.

Owner:ANGANG STEEL CO LTD

Air supply temperature adjusting system and adjusting method, computer readable storage medium and electronic equipment

InactiveCN112032991AMeet temperature requirementsIncrease heat supplyMechanical apparatusSpace heating and ventilation safety systemsTemperature controlTemperature conditioning

An air supply temperature adjusting system provided by the invention comprises an air source, a flow regulating valve, a heating device and a controller; the air source is used for providing to-be-conveyed gas; the flow regulating valve is arranged at an outlet of the gas source and is used for regulating the output flow of the to-be-conveyed gas; the heating device is arranged on a gas path of the to-be-conveyed gas and used for adjusting the temperature of the to-be-conveyed gas; and the controller is used for adjusting the opening degree of the flow adjusting valve and the output power of the heating device according to the obtained temperature of the to-be-conveyed gas, so that the gas in a ready state meets the requirement of gas equipment on the gas temperature. The heating device can carry out heating on the gas output from the flow regulating valve, and heating is carried out on the to-be-conveyed gas according to the opening degree of the flow regulating valve and the output power of the heating device, so that the gas in the ready state meets the requirement of the gas equipment on the gas temperature. According to an adjusting method, a computer readable storage medium and electronic equipment, adjusting can be carried out on the gas flow and the temperature required by the gas equipment by means of the air supply adjusting system.

Owner:北京瑞尔腾普装备科技有限公司

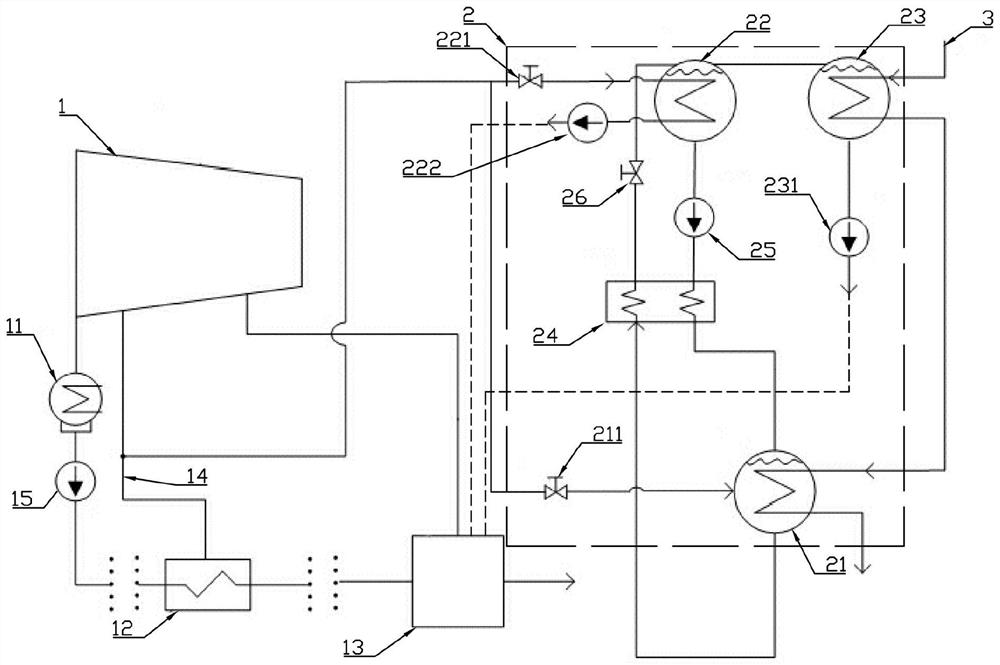

Combined heat and power generation system and method provided with absorption heat pump

ActiveCN114754400AReduce usable energy lossAdjustable steam volumeHeating fuelHeat pumpsCogenerationAbsorption heat pump

The invention relates to a combined heat and power generation system and method provided with an absorption heat pump. The combined heat and power generation system comprises a steam turbine, a heater, a deaerator and the absorption heat pump. The steam turbine is communicated with the heater through a steam extraction pipeline, the absorption heat pump comprises an absorber, a generator and a condenser, heat supply network return water in a heat supply network loop is firstly input into a condenser heat exchanger to be heated for the first time, and then the heat supply network return water heated for the first time is input into an absorber heat exchanger to be heated for the second time to reach the temperature of heat supply network water supply. The absorber steam extraction valve and the generator steam extraction valve are adjusting valves and can adjust the amount of steam input into the absorber and the generator. When the heat supply amount needs to be adjusted, the temperature of the solution in the absorber can be changed by directly changing the steam extraction amount of the steam extraction valve of the absorber, the temperature of the heat supply network water supply output from the heat exchanger of the absorber is changed, and the heat supply amount is increased or reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD +1

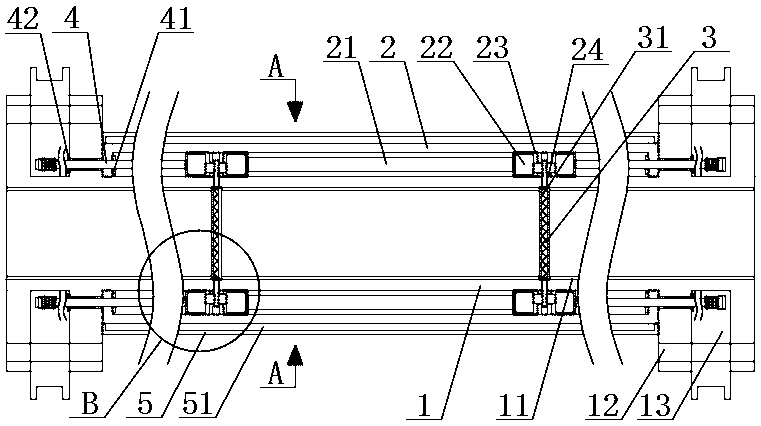

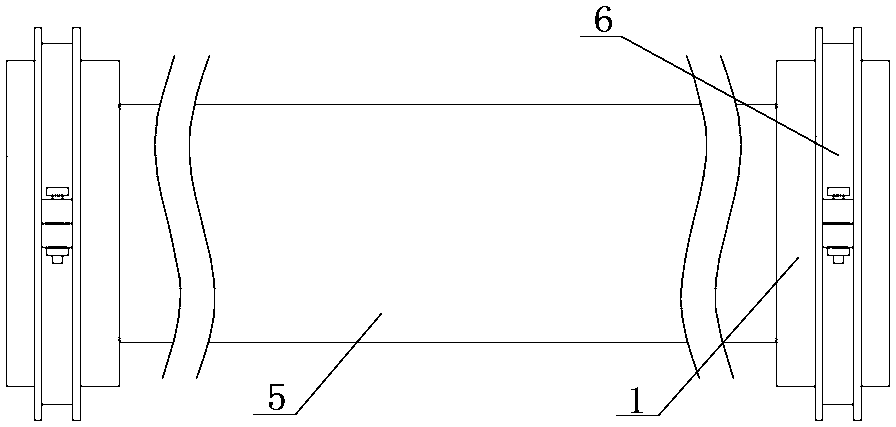

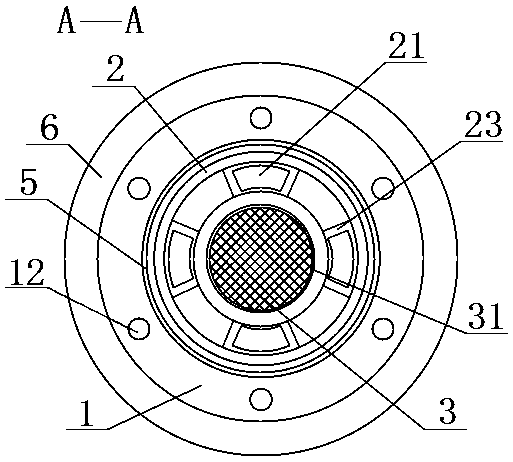

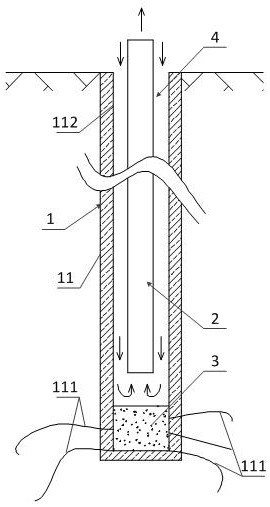

Deep geothermal well structure and transformation method for waste geothermal well

ActiveCN111664601ALess investmentIncrease investment to gain heatLighting and heating apparatusGeothermal energy generationGeophysicsGeothermal heating

The invention provides a deep geothermal well structure and a transformation method for a waste geothermal well. The deep geothermal well structure comprises a deep geothermal well body and a heat exchanger, wherein the deep geothermal well body comprises the waste geothermal well, and a plugging layer is arranged on the inner wall of the waste geothermal well; the heat exchanger is arranged in the length direction of the deep geothermal well body, a gap is reserved between the heat exchanger and the inner wall of the deep geothermal well body to enable an annular channel to be formed betweenthe heat exchanger and the deep geothermal well body, a heat exchange medium flows in the annular channel and exchanges heat with rock stratums around the deep geothermal well body, and the heat exchange medium flows into the heat exchanger from the tail end of the heat exchanger so as to be pumped to the ground along the heat exchanger for heating. According to the deep geothermal well structure,an existing waste geothermal well structure is transformed and utilized, the investment is reduced, only heat is collected, water is not collected, the economic value is generated while underground water and the environment are protected, and the unit investment heat taking amount of the geothermal heating technology and the geothermal heating economy are improved.

Owner:广东中科光年数智科技有限公司

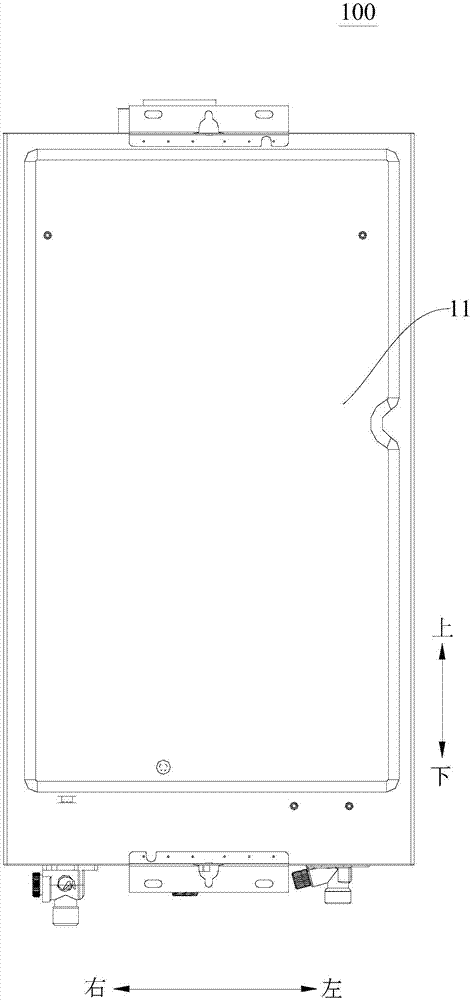

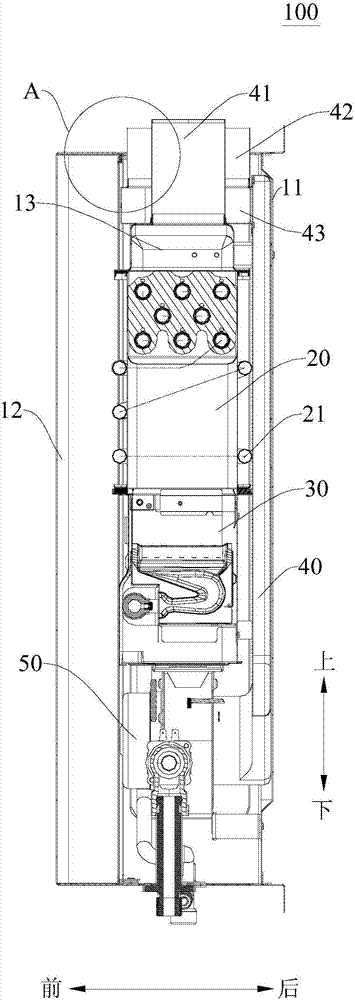

Liquid crystal display module capable of uniformly heating at low temperature

InactiveCN109491118AIncrease heat supplyImprove uniformityNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display module capable of uniformly heating at a low temperature, which comprises a front end functional component (12), a liquid crystal display screen (13),a rear end functional component (14), a structural frame (11) and a heater; a mounting groove is arranged on the structural frame (11), the front end functional component, the liquid crystal display screen (13) and the rear end functional component (14) are sequentially overlapped, two ends are tapped into the structural frame (11), the heater is in close contact with the liquid crystal display screen (13), and the heat is supplied according to the heat demand of the liquid crystal display (13). The liquid crystal display module capable of uniformly heating at the low temperature solves the problem that the response time of a display at the low temperature can be greatly increased in the prior art, and heating under a special environment is achieved.

Owner:中航华东光电有限公司

High-low pressure cylinder cutting thermoelectric decoupling mode and system based on exhaust steam built-in group injection

PendingCN111828115AEliminate cold junction lossesImprove flow capacitySteam useCombined combustion mitigationElectrolysisCogeneration

The invention provides a high-low pressure cylinder cutting thermoelectric decoupling mode and system based on exhaust steam built-in group injection, and belongs to the technical field of combined heat and power generation and centralized heating. A combined heat and power generation system is provided with an injection decoupling device for high-low pressure cylinder cutting, wherein a high-pressure driving steam inlet of an external high-pressure cylinder cutting injector is connected with a new steam pipe; a low-pressure inlet is connected with a high-pressure cylinder exhaust steam cold re-heating pipe; a medium-pressure exhaust steam port is connected with a boiler reheater inlet; a hot re-heating pipe is provided with a steam extraction port; a built-in low-pressure group injectionpipe bundle is arranged in an exhaust steam communicating pipe between a low-pressure cylinder and a condenser; a high-pressure driving steam inlet of the built-in low-pressure group injection pipe bundle communicates with a hot re-heating steam extraction port or a medium-pressure exhaust steam port; a low-pressure inlet is opened in the exhaust steam communicating pipe; medium-pressure exhaust steam is arranged in a front area of an exhaust steam inlet of the condenser; and a cooling water inlet and a cooling water outlet of the condenser communicate with a heat supply network return water inlet pipe and a heat supply network return water outlet pipe correspondingly and achieve heat supply network return water heating. According to the high-low pressure cylinder cutting thermoelectric decoupling mode and system based on exhaust steam built-in group injection, the near-full load heat supply and power generation adjusting capacity of a steam turbine can be achieved, the cold end loss is eliminated, and the thermal power operation flexibility is improved.

Owner:TSINGHUA UNIV +3

A device and method for recycling waste circuit boards

ActiveCN106591585BHigh recovery rateEliminates the possibility of synthesisProcess efficiency improvementPollutionCarbon particle

The invention provides a recycling treatment device and method of waste circuit boards. The recycling treatment device of waste circuit boards mainly comprises a crushing machine, a self-reduction smelting furnace, a Roots blower and an exhaust gas treatment device. The self-reduction smelting furnace is mainly composed of a smelting furnace body, a smelting spray gun, a vertically lifting flue, a cyclone separator and a combustion heat exchange tower, wherein the top of the smelting furnace body is provided with a charging port, a heat preservation gun port and a sampling port; the vertically lifting flue is connected with an inlet of the cyclone separator; an outlet of the cyclone separator is connected with the combustion heat exchange tower; an air heat exchanger is arranged inside the combustion heat exchange tower; and a hot air outlet is formed in the upper portion of the combustion heat exchange tower and connected with a smelting spray gun entering the smelting furnace through a pipeline. Through equipment transformation, process optimization and combination of recycled carbon particles as a reduction agent and recycled high-temperature process gas as heat, the recycling rate of valuable metal is effectively increased, the smoke volume of a system is reduced, energy is saved, and pollution is reduced.

Owner:中节能工程技术研究院有限公司

Built-in single-section circulating multilayer drying kiln

PendingCN113237311AIncrease heat supplyReduce humidityDrying gas arrangementsDrying machines with progressive movementsThermodynamicsHeat conservation

The invention discloses a built-in single-section circulating multilayer drying kiln. The built-in single-section circulating multilayer drying kiln comprises a kiln body, a heat supply main pipe and a moisture removal main pipe, wherein the inner side wall of the kiln body is covered with a heat preservation layer, a plurality of conveying rollers are arranged in the kiln body, a heat supply lower branch pipe and a heat supply upper branch pipe are arranged on and below each conveying roller correspondingly, a bidirectional draught fan is installed at the top of the kiln body, an air outlet of the draught fan is formed inside the kiln body and is connected to a heat supply side pipe extending to the side wall of the kiln body, the heat supply lower branch pipe and the heat supply upper branch pipe are both connected to the heat supply side pipe, a heat preservation partition plate is further arranged in the kiln body, a partition space is formed between the heat preservation partition plate and the upper wall of the kiln body, and an air inlet of the draught fan is formed in the partition space. According to the built-in single-section circulating multilayer drying kiln, ceramic tiles on the conveying rollers can be quickly dried, meanwhile, it can be guaranteed that the temperature of the transverse section of the kiln is consistent, moisture heat energy can be further released again after moisture matches with heat supply gas to be sucked into the draught fan, and the heat preservation effect of the heat preservation layer match, so that the purposes of saving energy and reducing consumption are achieved.

Owner:FOSHAN JINBAILI ELECTROMECHANICAL

Automatic control water bath evaporation unit

ActiveCN102698445AGuaranteed thermal stabilityEvenly distributedEvaporator accessoriesWater bathsAutomatic control

The invention relates to an automatic control water bath evaporation unit which is characterized in that a heating cavity is internally provided with a plurality of heating inlets and heating outlets, the plurality of heating inlets are respectively connected with an outlet of a heater, the plurality of heating outlets are respectively connected with a backflow port, a first temperature controller and a second temperature controller are arranged between the outlet of the heater and the plurality of heating inlets of the heating cavity and between the plurality of heating outlets and the backflow port respectively; the first temperature controller and the second temperature controller are both connected with a PLC (programmable logic controller) module, the heater is connected with the PLC module, and the PLC controls the starting and stopping of the heater. The beneficial effects are as follows: the PLC module is used to monitor in real time the temperature of a medium entering the heating cavity and flowing out of the heating cavity so as to turn on and turn off the heater, so that the heating stability of the heating cavity is guaranteed, energy sources are also saved at the same time, the medium is more uniformly distributed due to the plurality of heating inlets and outlets in the heating cavity, and a dead area is prevented from being produced in the heating cavity, so that the heating effect is much more balanced, the coefficient of heat conduction is increased, and the concentration benefit is improved.

Owner:温兄控股集团股份有限公司

Energy-saving heating device and method of use

ActiveCN111197785BReduce water consumptionIncrease heat supplyLighting and heating apparatusScale removal and water softeningWater processingCorrosion

The present invention relates to the field of heating and ventilation technology, and is an energy-saving heating device and its use method. The former includes a boiler, a primary energy-saving device, a secondary energy-saving device, a chimney, a condenser, a primary-side primary water pump, a primary-side secondary water pump, Condensed water tank, primary net water tank, secondary net water tank and primary side make-up water pump; the latter includes the following steps: water injection; operation; condensate water collection; data collection and analysis; adjustment; water replenishment. The structure of the invention is reasonable and compact. By installing a water treatment device, strong corrosion of the pipes in the condensed water can be avoided. By installing a primary side water supply pump, the condensed water can be reinjected into the pipe network to supplement the water loss in the pipe network. Reduce the water consumption during the operation of the heating system and reduce maintenance costs. By setting the pressure equalizing valve, the heat supplied by the boiler can be quickly increased, avoiding the situation of slow temperature rise and large heat loss in the entire pipe network, and reducing high-temperature flue gas. The impact of emissions on the environment and reduce operating costs.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

High-temperature particle waste heat recycling device and method for waste incineration power plant

PendingCN114046516AIncrease output powerRealize Cascade RecyclingCombined heat and power systemsSpace heating and ventilation detailsOrganic Rankine cycleIncineration

The invention discloses a high-temperature particle waste heat recycling device and method for a waste incineration power plant. The high-temperature particle waste heat recycling device comprises a waste heat boiler, wherein the waste heat boiler is communicated with the bottom of an incinerator of the waste incineration power plant, and the waste heat boiler is used for exchanging heat with high-temperature particles at the bottom of the incinerator of the waste incineration power plant through a heat exchange medium; a heat exchange medium outlet of the waste heat boiler is communicated with an inlet of a first steam turbine, an outlet of the first steam turbine is communicated with a first inlet of a first heat exchanger, a first outlet of the first heat exchanger is connected with a first inlet of a third heat exchanger, and a first outlet of the third heat exchanger is connected with a heat exchange medium inlet of the waste heat boiler to form a steam Rankine cycle; and a second outlet of the first heat exchanger is connected with a second inlet of a second heat exchanger, a second outlet of the second heat exchanger is communicated with an inlet of a second steam turbine, and an outlet of the second steam turbine is communicated with a second inlet of the first heat exchanger to form an organic Rankine cycle.

Owner:HUANENG CLEAN ENERGY RES INST +1

A deep geothermal well structure and reconstruction method for abandoned geothermal wells

ActiveCN111664601BIncrease heat gain from unit investmentLess investmentLighting and heating apparatusGeothermal energy generationThermodynamicsGeothermal heating

The invention provides a deep geothermal well structure and a reconstruction method for an abandoned geothermal well. The deep geothermal well structure includes: a deep geothermal well body and a heat exchanger; wherein, the deep geothermal well body includes an abandoned geothermal well, and a plugging layer is arranged on the inner wall of the abandoned geothermal well; the heat exchanger is arranged along the length direction of the deep geothermal well body It is set, and there is a gap between the heat exchanger and the inner wall of the deep geothermal well body, so that an annular passage is formed between the heat exchanger and the deep geothermal well body, and the heat exchange medium flows in the annular passage and is connected with the deep geothermal well body. It exchanges heat with the rock formation, and flows from the end of the heat exchanger into the heat exchanger to be pumped along the heat exchanger to the ground for heating. The present invention transforms and utilizes the existing abandoned geothermal well structure, which not only reduces investment, but also only collects heat without collecting water, thereby generating economic value while protecting groundwater and the environment, and improving the unit investment of geothermal heating technology to obtain heat and geothermal energy Heating economy.

Owner:广东中科光年数智科技有限公司

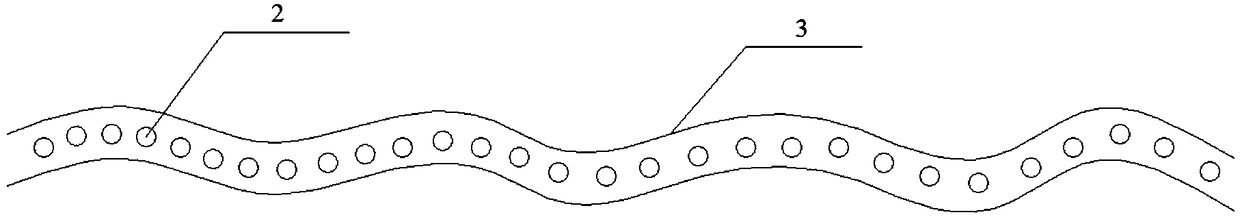

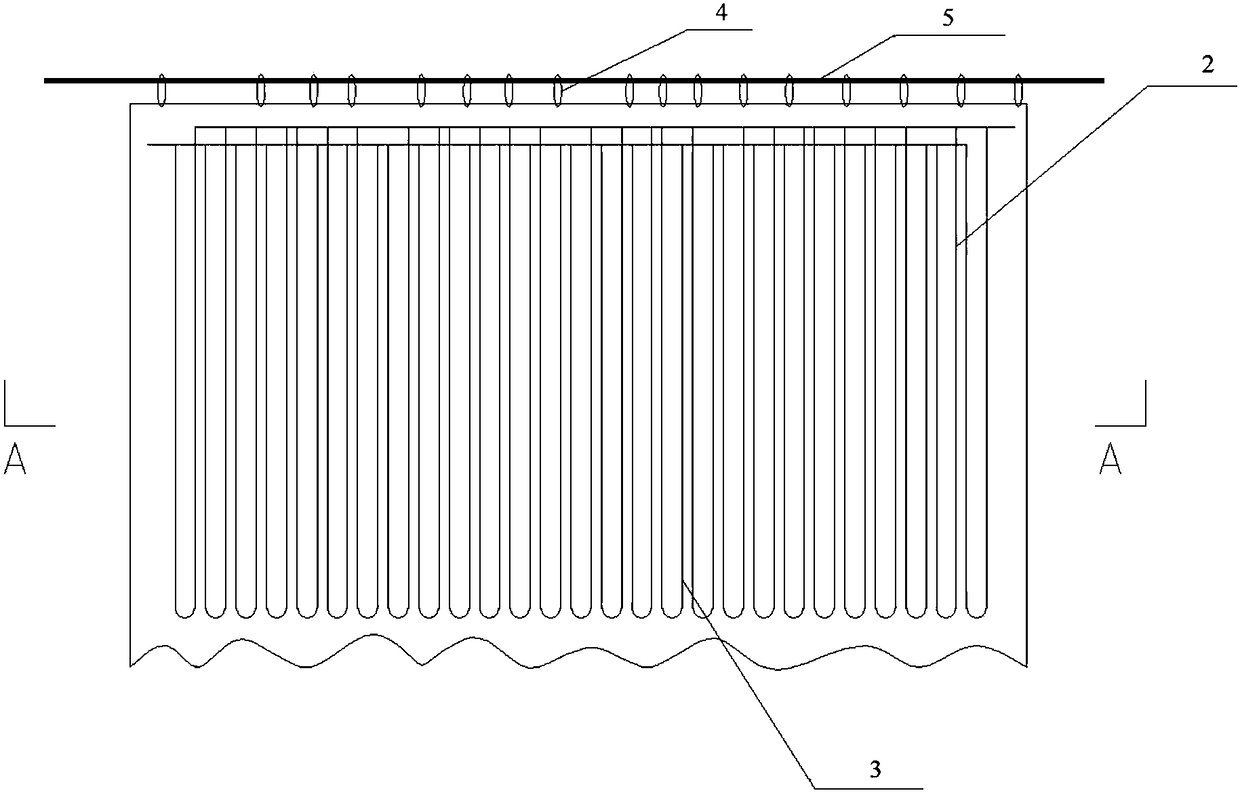

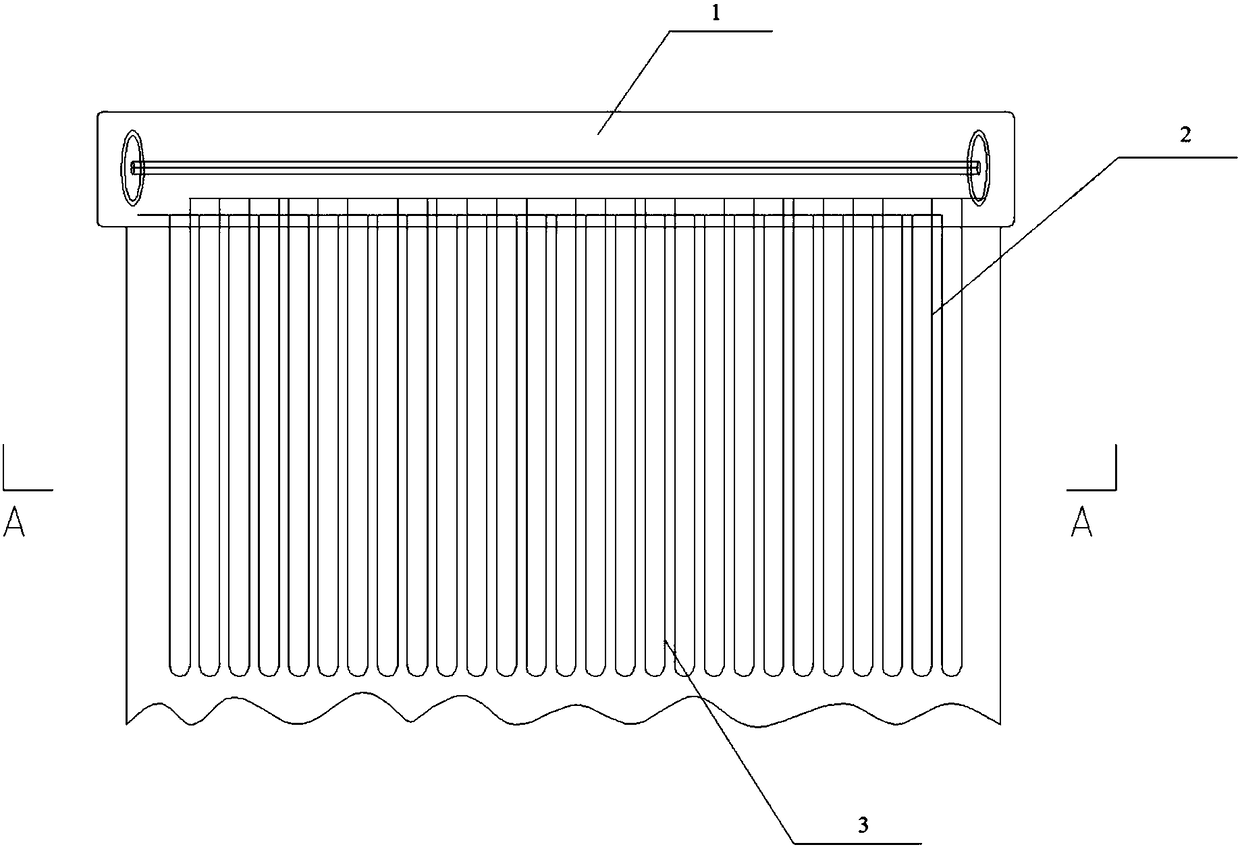

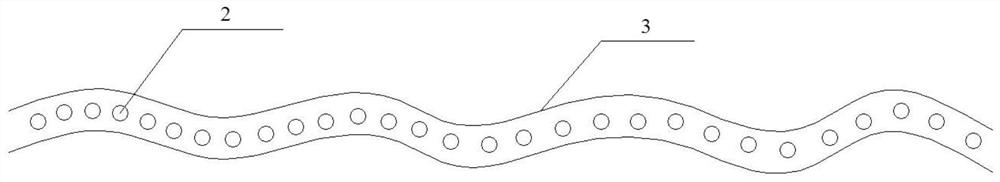

Flexible radiating end, preparation method and use thereof

ActiveCN108948736AEasy and reasonable installationConducive to reasonable configurationDewEngineering

A flexible radiating end comprises a radiator and a refrigerant / heat medium pipe; wherein the refrigerant / heat medium pipe is in direct or indirect contact with the radiator. The flexible radiating end structure of the invention can make the installation and configuration of the radiation end of the traditional radiation type air conditioner more convenient and reasonable, can be arranged at any position according to the need, reduces or avoids the possibility of dew condensation, and improves the comfort. The flexible radiating end structure of the invention can be made into a curtain, formedinto a projection curtain, and can be used for furniture and the like.

Owner:中安瑞材(北京)科技有限公司

A kind of thick material layer sintering production method

The invention discloses a thick material layer sintering production method. According to the method, an upper layer sintering mixture and a lower-layer sintering mixed material of a sintering machinecan be sintered at the same time through twice material spreading and twice ignition, so that the thickness of a sintered material layer is improved, the yield of sintered ore is improved, and sintering indexes are improved; after primary material spreading and before secondary ignition, special carbon pellets are placed, so that heat supply and mineralization time of an upper material layer can be increased, the quality of upper-layer sintered ore is improved, and the sintered ore return amount is reduced; and the hypoxia problem of a lower sintered material layer is solved, the lower sintered material layer is fully mineralized, and the quality of lower-layer sintered ore is improved.

Owner:ANGANG STEEL CO LTD

Gas water heater

The invention discloses a gas water heater which comprises a shell, a heat exchanger, a burner used for heating the heat exchanger, an air return duct and a draught fan. The shell is provided with a smoke outlet and an air inlet. The heat exchanger is arranged in the shell. The burner is arranged in the shell and communicates with the smoke outlet. The air return duct is a sealed piece provided with only an air intake port and an air exhaust port, wherein the air return duct is arranged in the shell, the air intake port communicates with the air inlet, the air exhaust port communicates with the burner, and the draught fan is connected to the air return duct. According to the gas water heater provided by the embodiment of the invention, the sealing effect of the air return duct is improved, damage to the gas water heater caused by air leakage of the air return duct is avoided, the ventilation rate of the gas water heater is improved, and gas can be sufficiently burnt; and besides, the air return duct can isolate an air current from electric elements in the gas water heater to prevent the high-temperature air current from damaging the electric elements.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

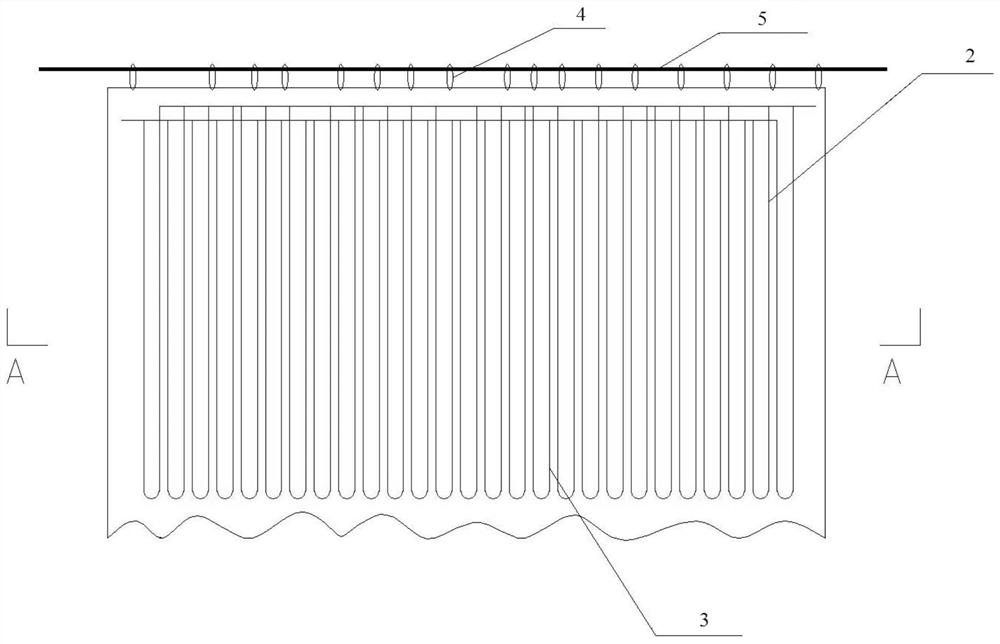

Sludge drying ground heating device

InactiveCN105936576AHigh thermal conductivityIncrease heat supplySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWater pipeEngineering

The invention puts forward a sludge drying ground heating device, which comprises a hot water pipe and a return pipe which are arranged at two sides of the drying ground. Steel radiators and PE heating pipes are connected between the hot water pipe at one side and the return pipe at the other side. The steel radiators are arranged within the drying ground of the upstream section during the sludge drying process. The PE heating pipes are arranged within the drying ground of the downstream section during the sludge drying process. In allusion to the characteristic that moisture evaporation velocity changes with sludge moisture content during the sludge drying process, the steel radiators are paved below sludge with high moisture content. By the utilization of the steel radiators' characteristic of high heat conductivity coefficient, supply of heat for sludge with high moisture content is increased, and evaporation of moisture is promoted. The PE heating pipes are paved below sludge with high moisture content. Loss of heat can be reduced under the precondition of satisfying heat supply.

Owner:山东福航新能源环保股份有限公司

A flexible radiation terminal and its preparation method and application

Owner:中安瑞材(北京)科技有限公司

Combined cooling, heating and power waste incineration waste heat utilization device and method

PendingCN114046508AIncrease output powerImprove output power and energy utilization efficiencyClimate change adaptationSteam useOrganic Rankine cycleRefrigeration plant

The invention provides a combined cooling, heating and power waste incineration waste heat utilization device and method. The combined cooling, heating and power waste incineration waste heat utilization device comprises a waste incinerator, wherein the waste incinerator is provided with a household waste inlet and an air inlet; the waste incinerator is provided with a high-temperature flue gas outlet and a high-temperature slag outlet, and the high-temperature slag outlet and the high-temperature flue gas outlet are both connected to a steam Rankine cycle system; a low-temperature gas outlet formed in the steam Rankine cycle system is connected with a gas inlet of an organic Rankine cycle system; a waste heat outlet of the steam Rankine cycle system and a waste heat outlet of the organic Rankine cycle system are further connected with a heat exchange unit used for conducting heat exchange on heat supply network return water; and a low-temperature gas outlet of the heat exchange unit is connected with refrigeration equipment. According to the invention, heat in slag and flue gas at the bottom of the incinerator of the waste incineration power plant is recycled through a multi-stage heat recycling unit, then power is generated through the steam Rankine cycle and the organic Rankine cycle, and the output power of the waste incineration power plant is improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com