Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve sand washing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

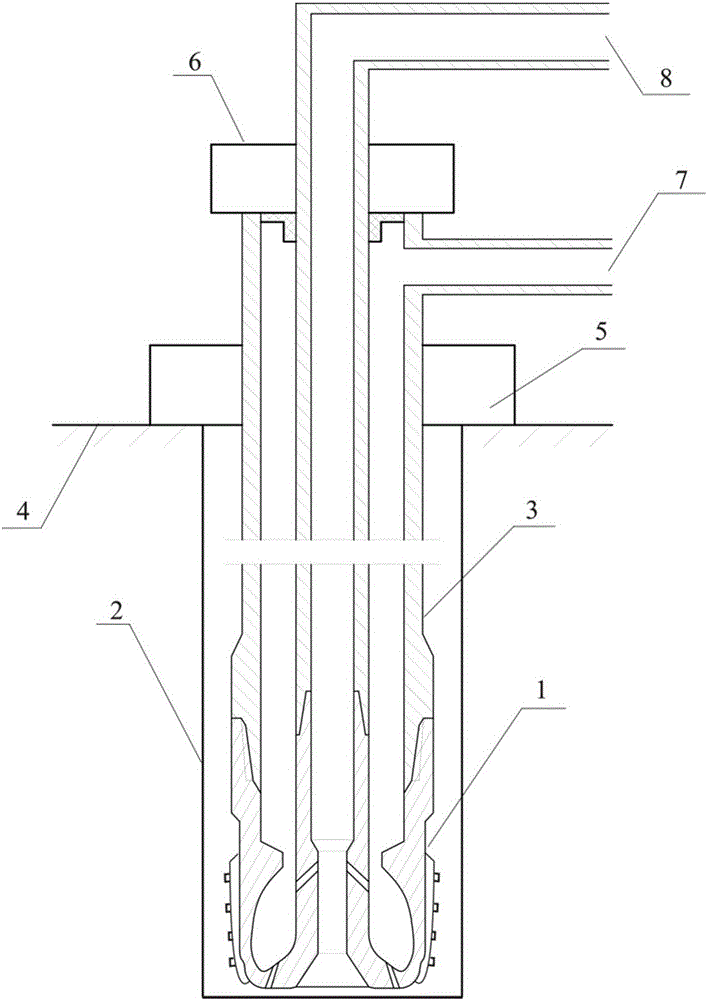

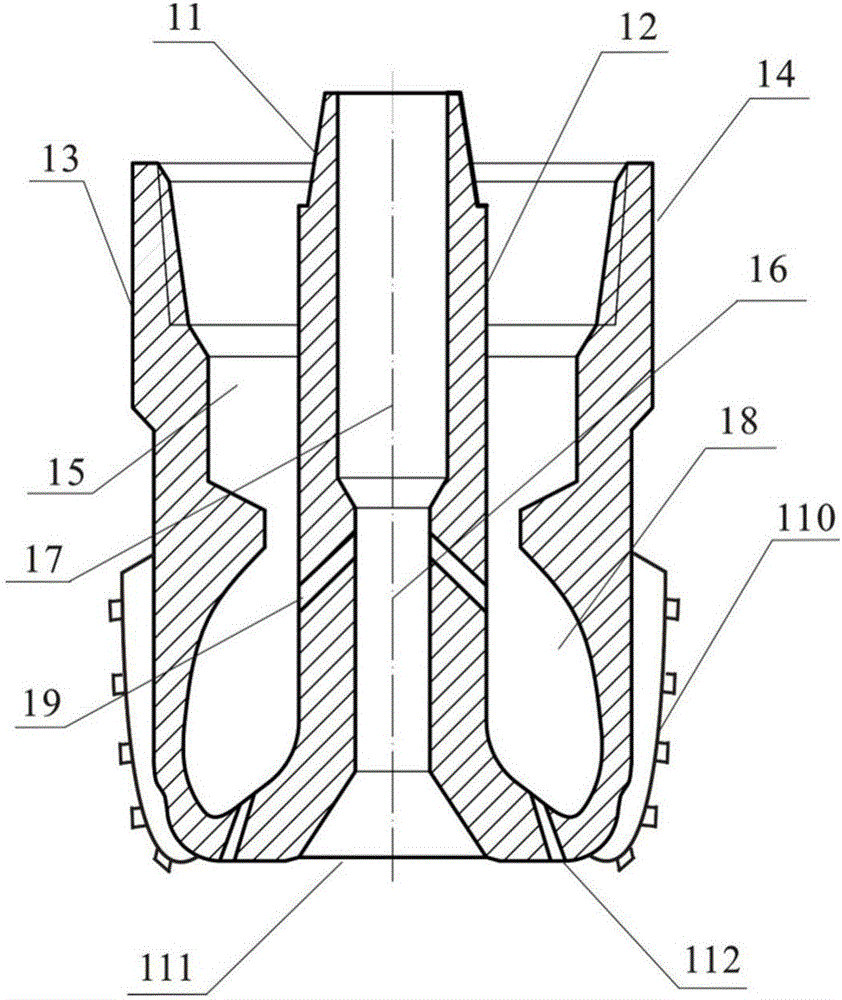

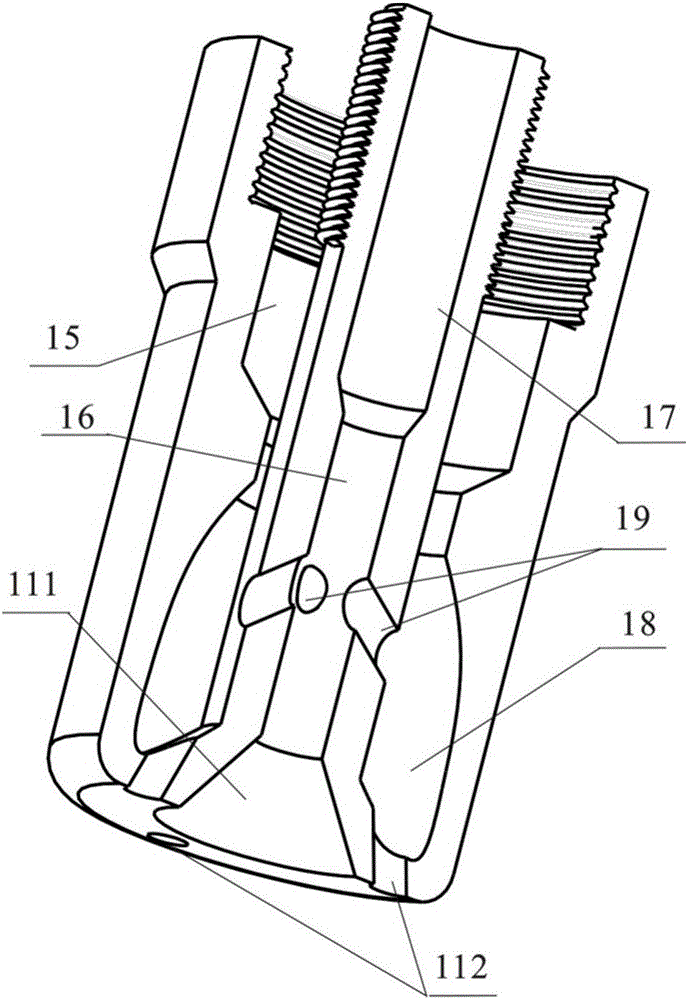

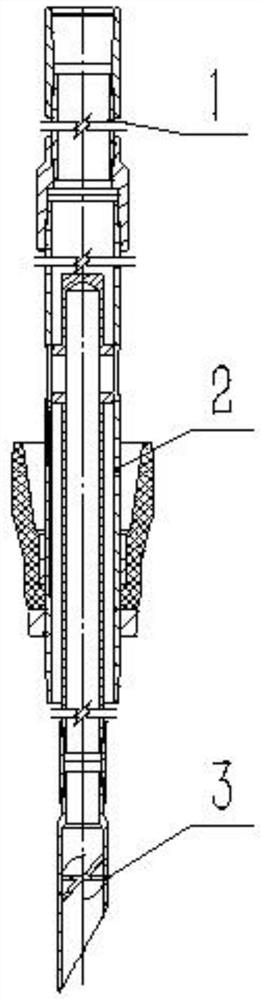

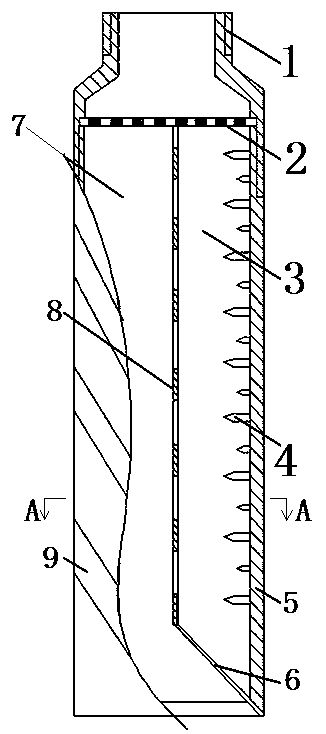

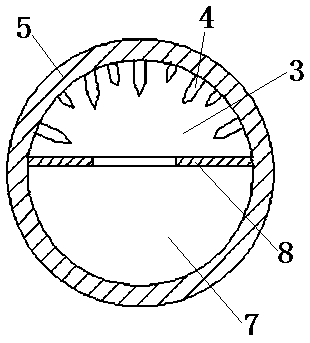

Drilling type continuous sand blasting device

InactiveCN106437570AGood for carrying sandImprove sand cleaning efficiencyDrill bitsDrilling rodsSand blastingSpray nozzle

The invention provides a drilling type continuous sand blasting device, comprising a sand blasting drill bit, a dual-wall drilling pillar, a rotational sealing well head, a rotational driving device, a sand blasting fluid manifold, and a sand carrying fluid manifold; the sand blasting drill bit includes a drill bit body and an inner drill bit body; the rotational driving device drives the dual-wall drilling pillar to rotate so as to drive the sand blasting drill bit to rotate and cut the hardware sand pillar at the bottom; a high-pressure shocking cavity with a multi-curve cavity is formed between the inner wall of the lower end of the drill bit body and the outer wall of the internal drill bit; a part of sand flushing fluid in the high pressure shocking cavity can provide suction negative pressure through a high pressure jet flow generated from a backward jet flow nozzle; thus on the one hand, normal circulation sand carrying of a low pressure well can be guaranteed; on the other hand, the settled sand at the bottom is isolated from the well bottom, so as to benefit sand carrying; the other part of sand blasting fluid is sprayed from the drill bit nozzle, asymmetry jet flow is formed, thus it is good for making the strewing sand at the well bottom enter the sand carrying suction cavity and improving the sand carrying efficiency. The device can guarantee the safety of oil gas well while effectively complete the cleaning work of the hard sand pillar of the low-pressure oil well.

Owner:SOUTHWEST PETROLEUM UNIV

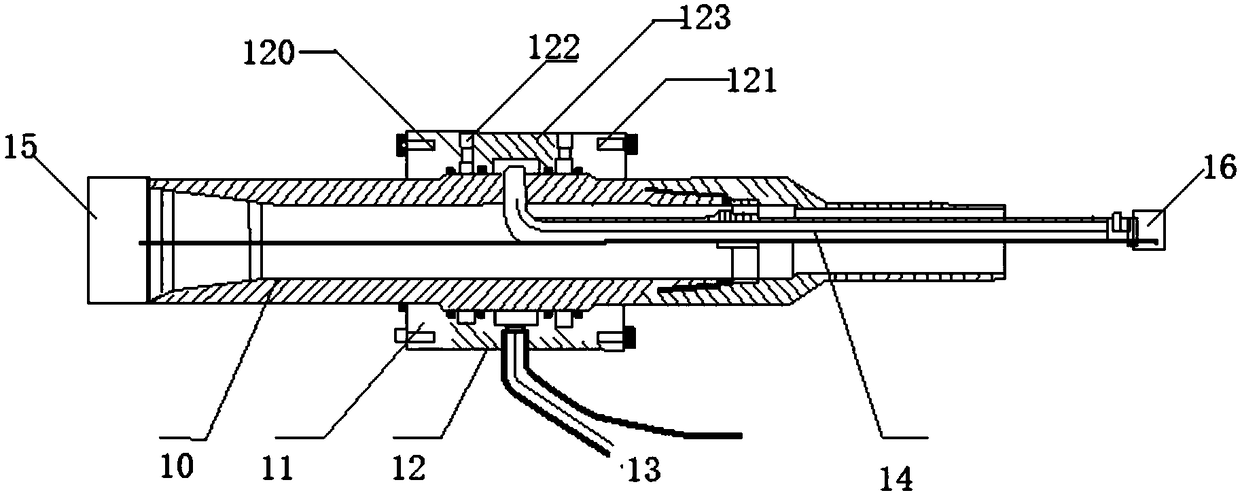

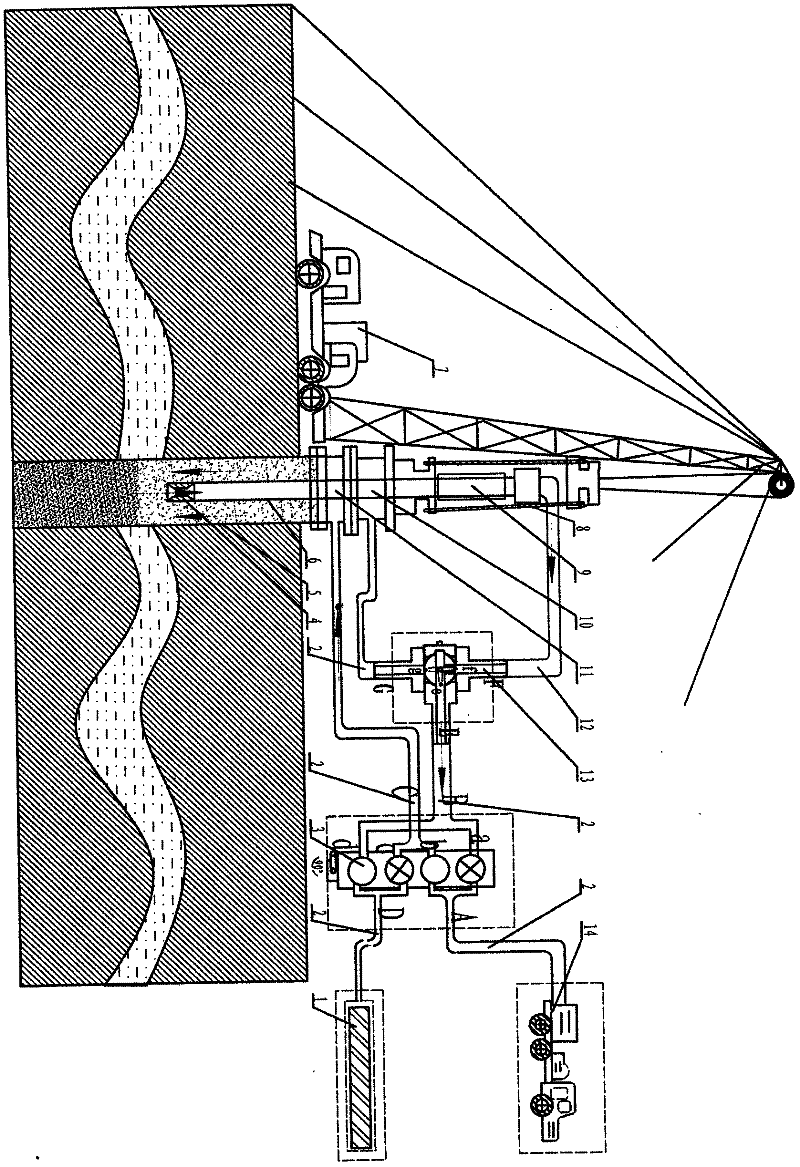

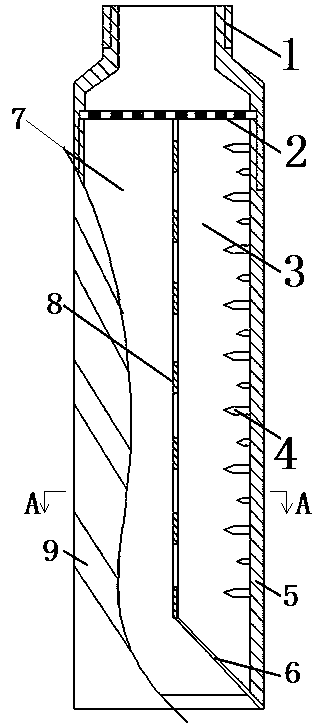

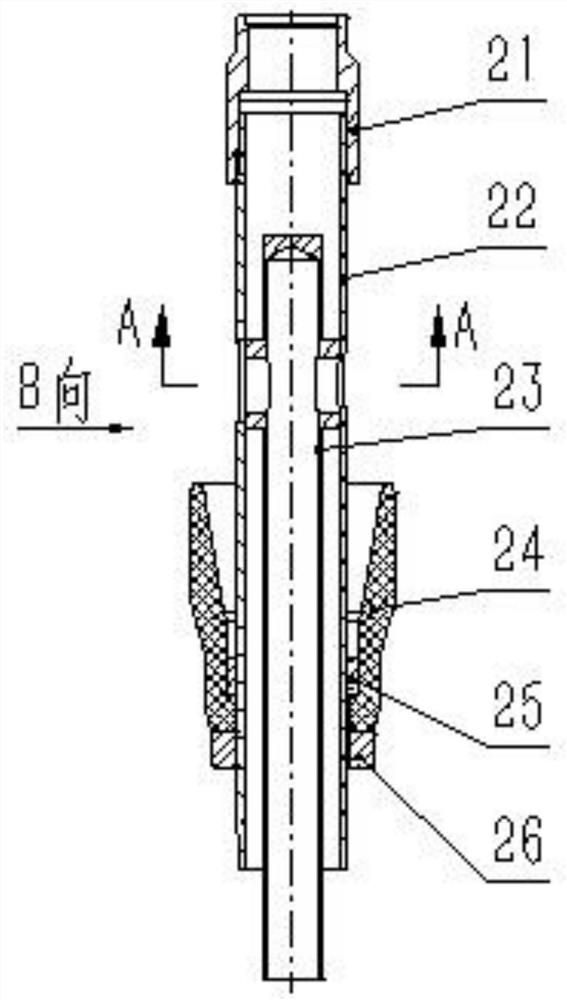

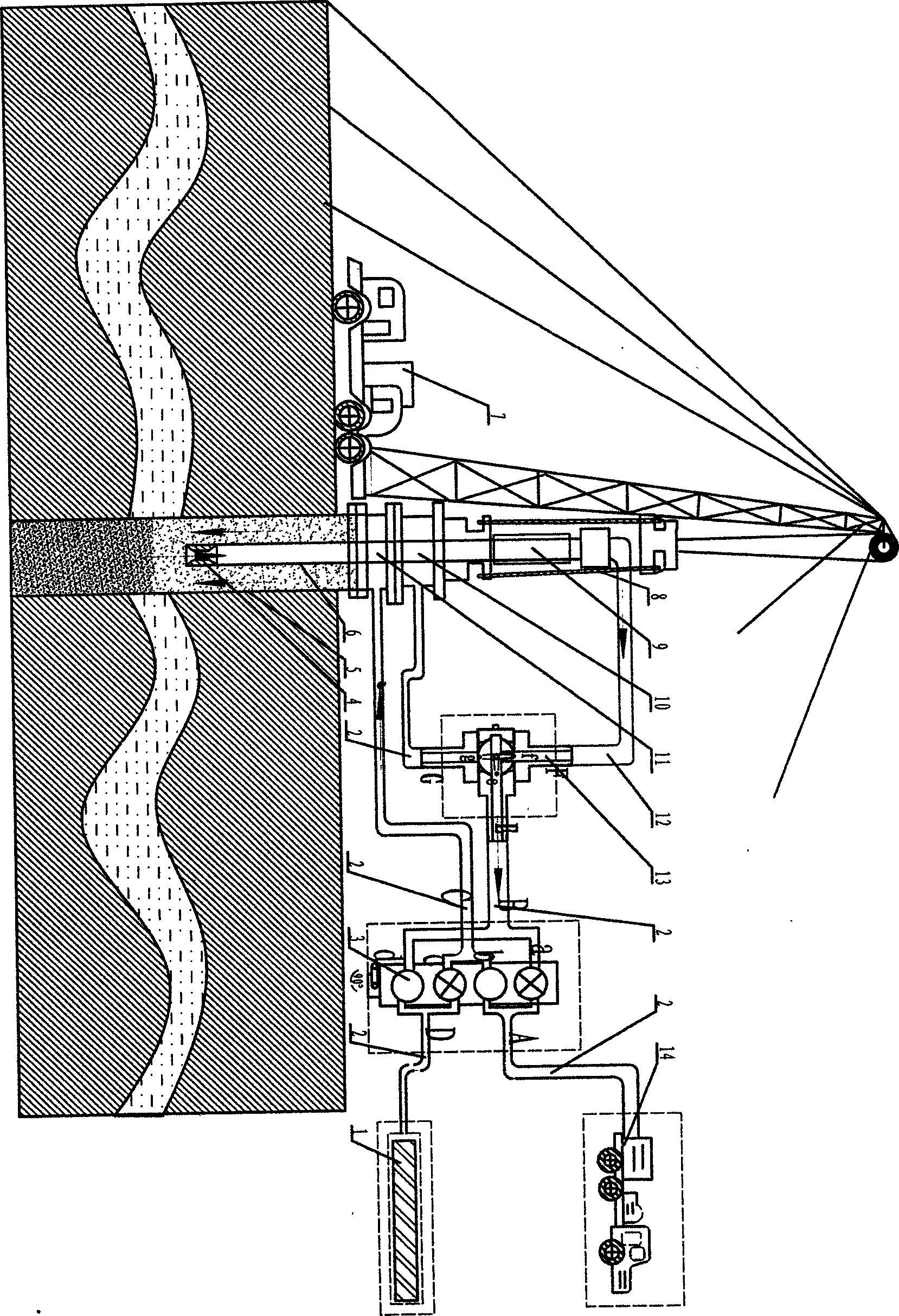

Gas lift reverse circulation sand washover well washing process and equipment for sandstone geothermal well

PendingCN108104749AStrong circulation suction abilityBeneficial to appearCleaning apparatusFlushingLiquid storage tankAir compressor

The invention provides a gas lift reverse circulation sand washover well washing process and equipment for a sandstone geothermal well. The process comprises the following steps: in a sand washover process, compressing gas in a gas storage tank by an air compressor to form compressed gas; feeding the compressed gas into a gas injection tube from a high-pressure pipeline through a gas feeding tubevia a cavity between an internal body and an external body; then delivering the compressed gas from a gas injection tubular column and a gas mixing tubular column to a gas mixer and mixing the compressed gas with sand washover liquid to generate a gas lift effect; and raising gas, liquid and solid three-phase liquid flow lifted by gas from a sand washover oil tube and then enabling the gas, liquidand solid three-phase liquid flow to enter the internal body of a double-walled gas injector and a water eye of a lower joint so as to reach a ground liquid storage tank via the high-pressure pipeline. The equipment comprises the double-walled gas injector, the gas injection tubular column, the gas mixing tubular column, a sand washover nib and a sand washover drill bit. By a gas lift reverse circulation sand washover technology, a circular suction ability is high, raising of well bottom or water layer settled sand is facilitated, moreover, the sand washover liquid flow can carry large dirtysand particles, repeated breakage of the dirty sand particles is reduced, and therefore, the sand washover efficiency is improved.

Owner:中石化绿源地热能(陕西)开发有限公司

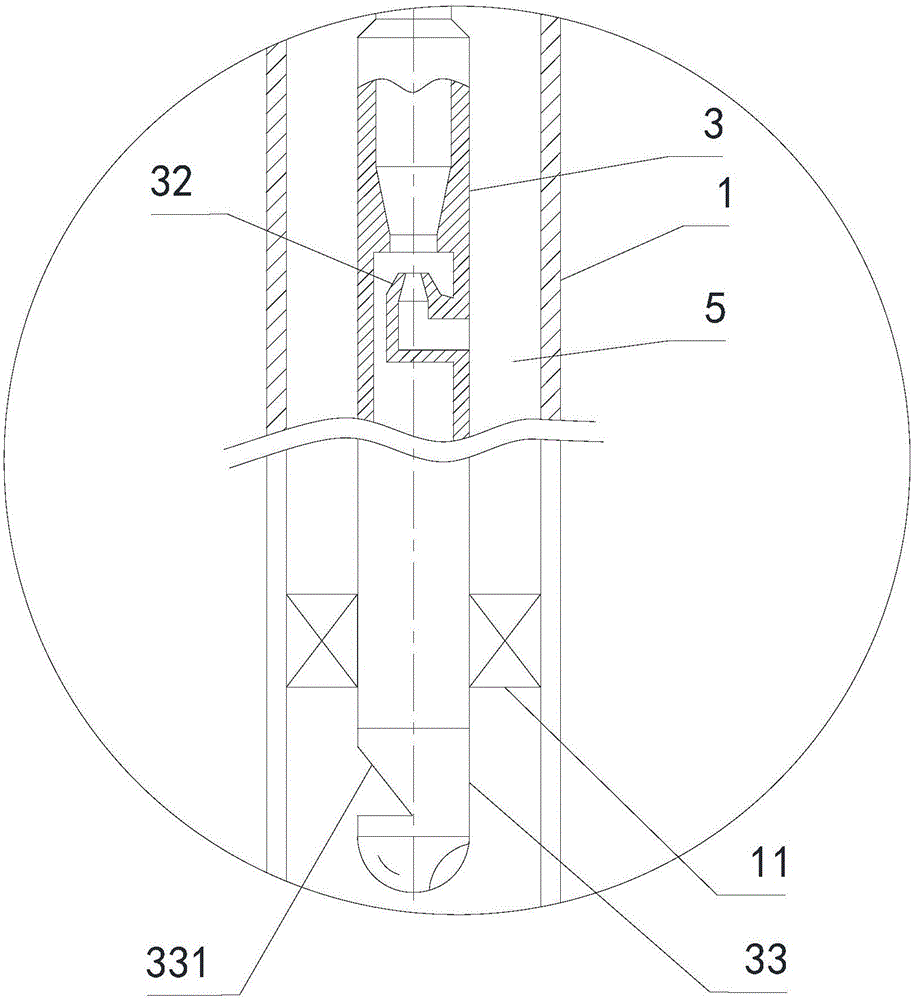

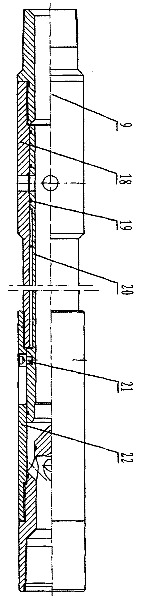

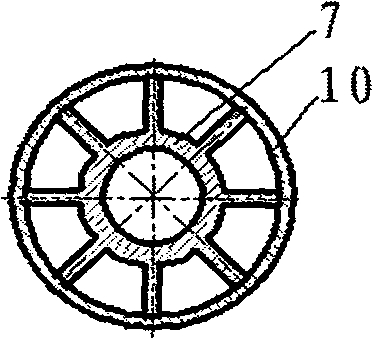

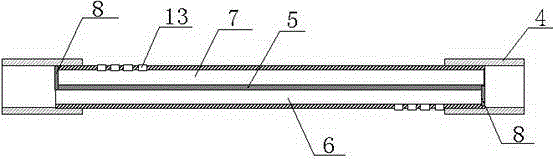

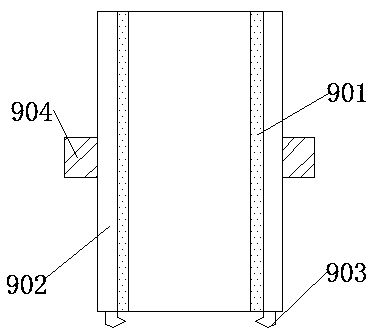

Sand washing concentric tube for low-pressure absorption well and assembling method of sand washing concentric tube

The invention provides a sand washing concentric tube for a low-pressure absorption well and an assembling method of the sand washing concentric tube. A tubular column comprises an inner sand washing tube body and an outer sand washing tube body, and the inner sand washing tube body is placed in the outer sand washing tube body; an annular cavity is formed between the inner sand washing tube body and the outer sand washing tube body in a distance manner; the upper end of the outer sand washing tube body is fixedly sleeved with a special-shaped coupling, and a penetrating hole is formed in an upper sealing joint; the upper sealing joint is fixedly sleeved with the upper end of the inner sand washing tube body through the penetrating hole; a plurality of protruding ribs are arranged on the outer wall of the upper sealing joint at intervals, extend to the inner wall face of the special-shaped coupling in the radial direction and are fixedly connected with the special-shaped coupling; and the inner sand washing tube body and the outer sand washing tube body are connected into a whole through the special-shaped coupling and the upper sealing joint. The sand washing concentric tube can carry out sand washing work simply, conveniently, safely and efficiently.

Owner:PETROCHINA CO LTD

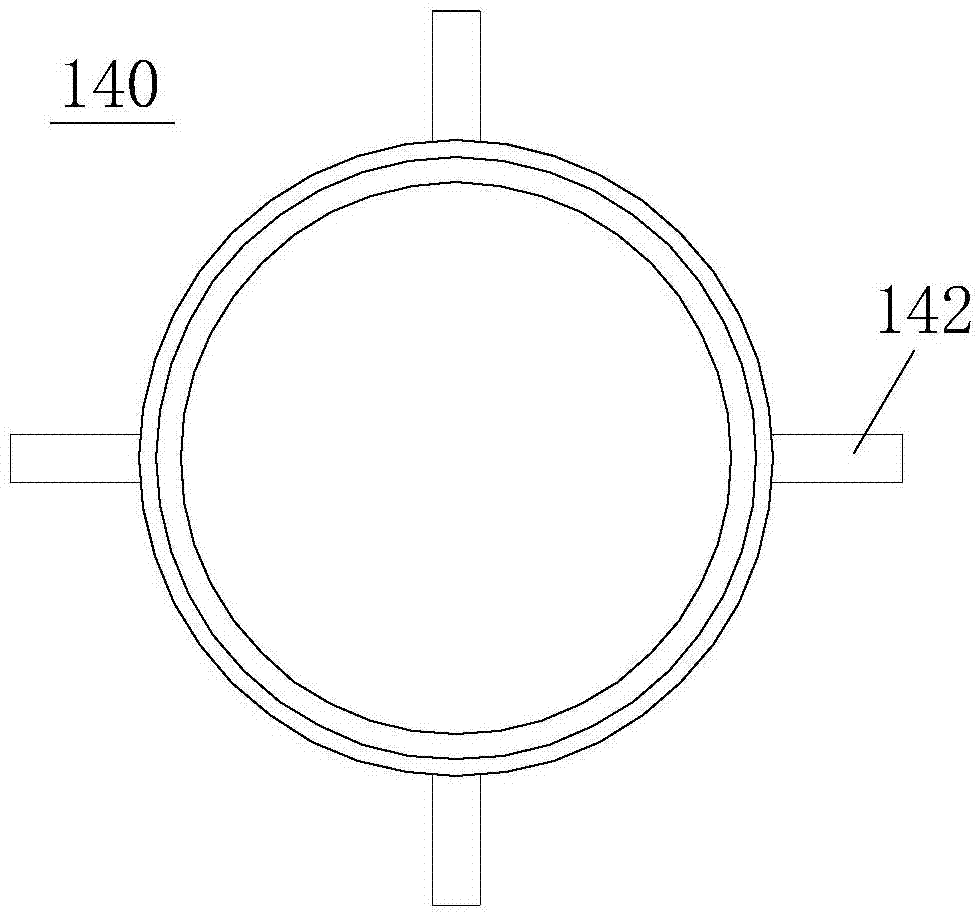

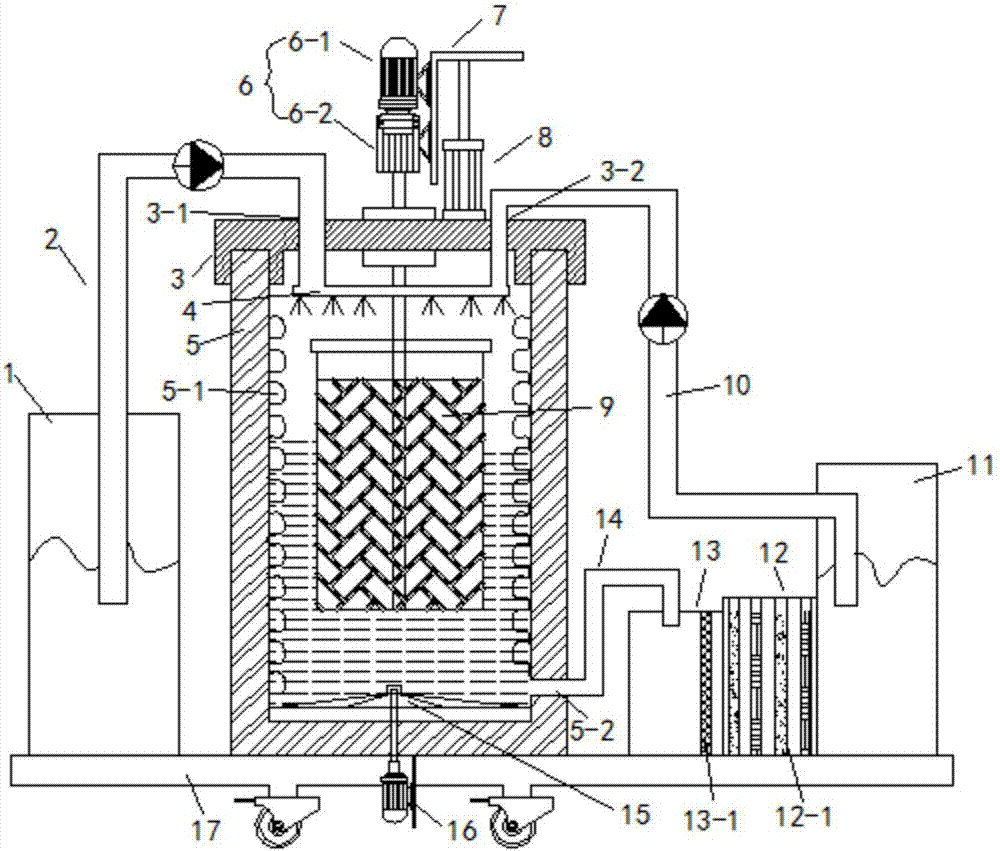

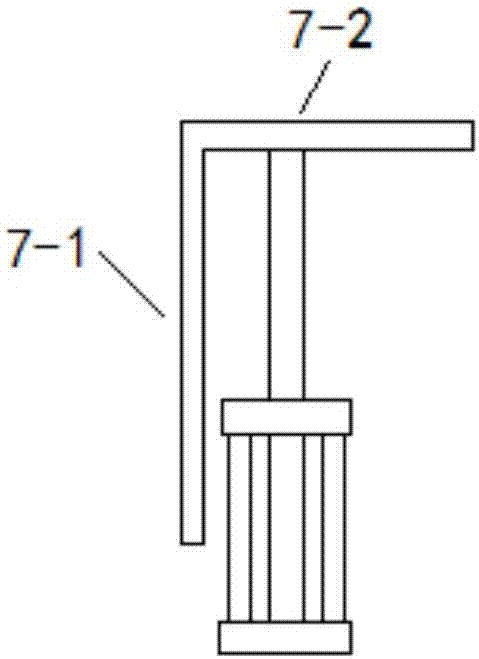

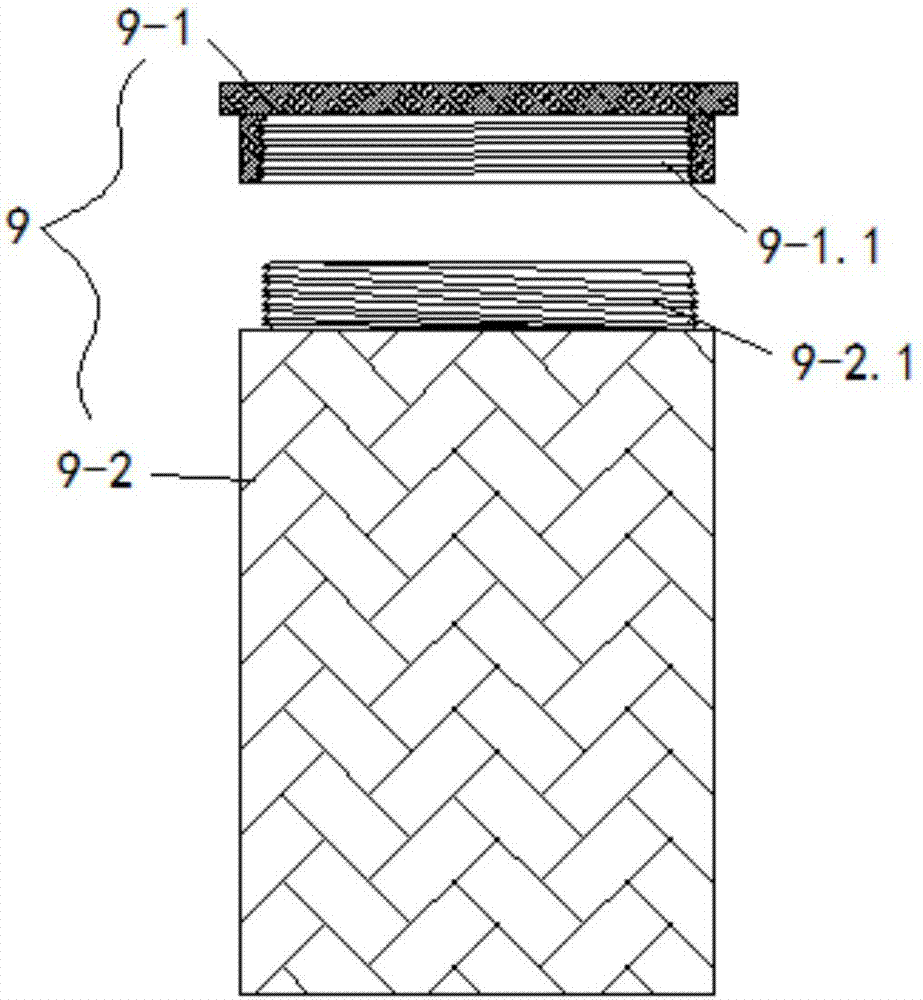

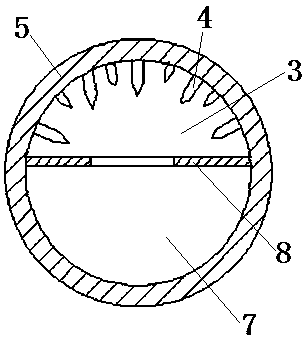

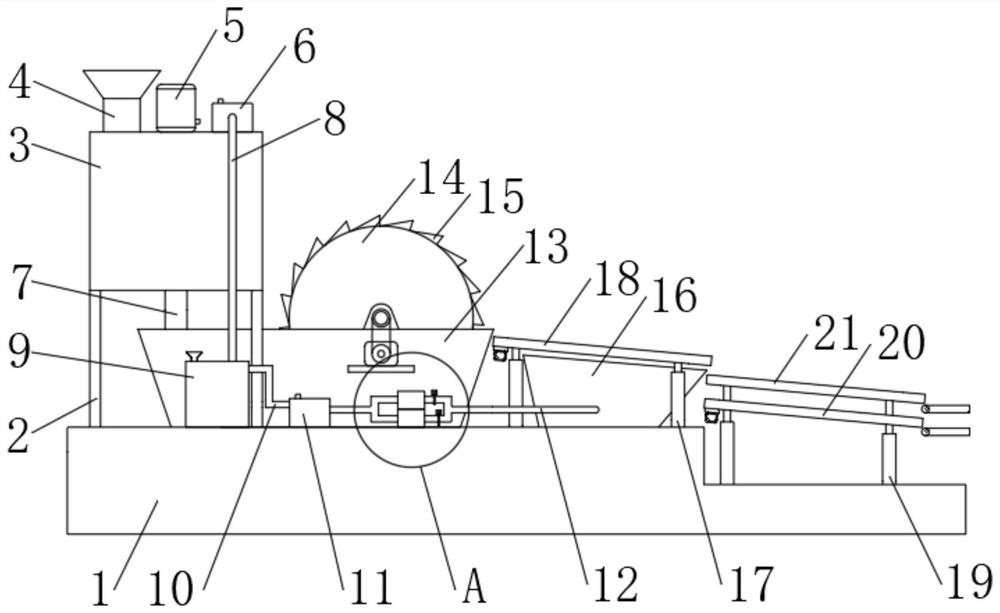

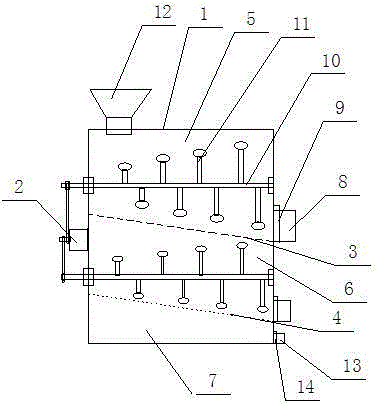

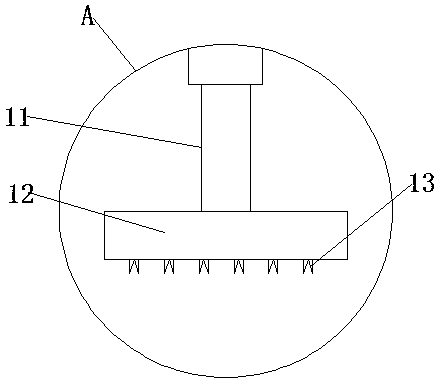

Movable well logging sand washing device

InactiveCN107398341AImprove sand washing efficiencyImprove sand washing effectHollow article cleaningTreatment involving filtrationEngineeringOil field

The invention discloses a movable well logging sand washing device and relates to the technical field of oil field well logging equipment. The movable well logging sand washing device comprises a movable base, a sand cleaning pond located on the movable base, and a sand containing barrel located in the sand cleaning pond; the sand cleaning pond is provided with a cover plate which is provided with a water inlet in an excavating manner; the water inlet is communicated with an annular water spraying pipe located in the sand cleaning pond, and the inner diameter of the annular water spraying pipe is larger than the outer diameter of the sand containing barrel; the lower end of the pond wall of the sand cleaning pond is provided with a water outlet; the cover plate is provided with a rotating driving assembly and a lifting driving assembly driving the rotating driving assembly to move up and down; and the output end of the rotating driving assembly penetrates the cover plate, extends into the sand cleaning pond, and penetrates the top of the sand containing barrel to be fixedly connected with the top and the bottom of the sand containing barrel. According to the movable well logging sand washing device, the two driving assemblies are used for driving the sand containing barrel to rotate up and down in the sand cleaning pond containing clean water, rock debris and a mud mixture in the sand containing barrel are made to be separated to achieve the sand washing purpose, and the sand washing effect is ideal.

Owner:成都捷科菲友信息技术有限公司

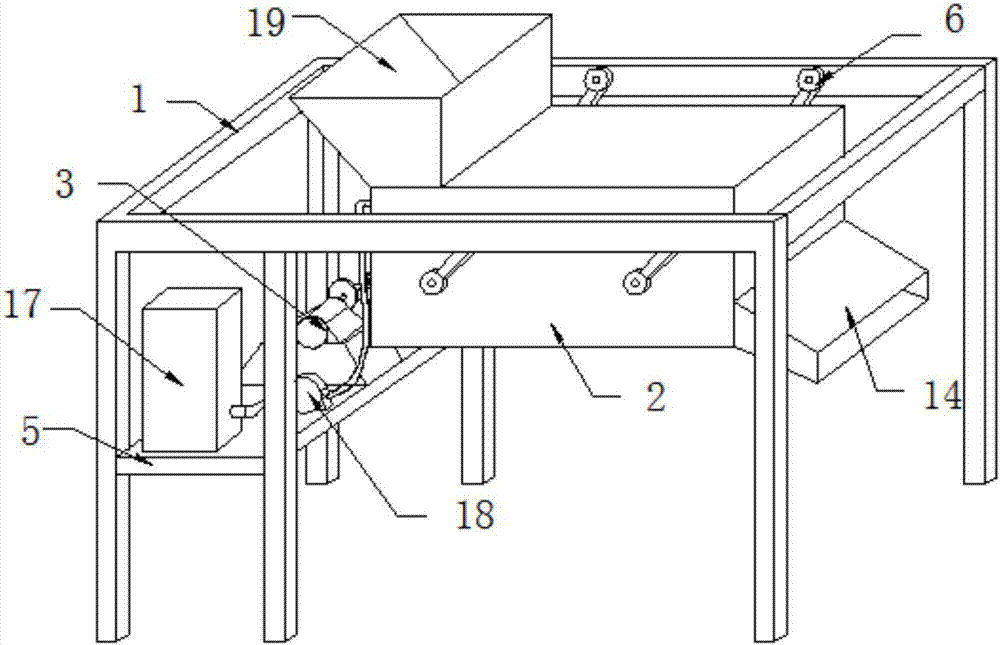

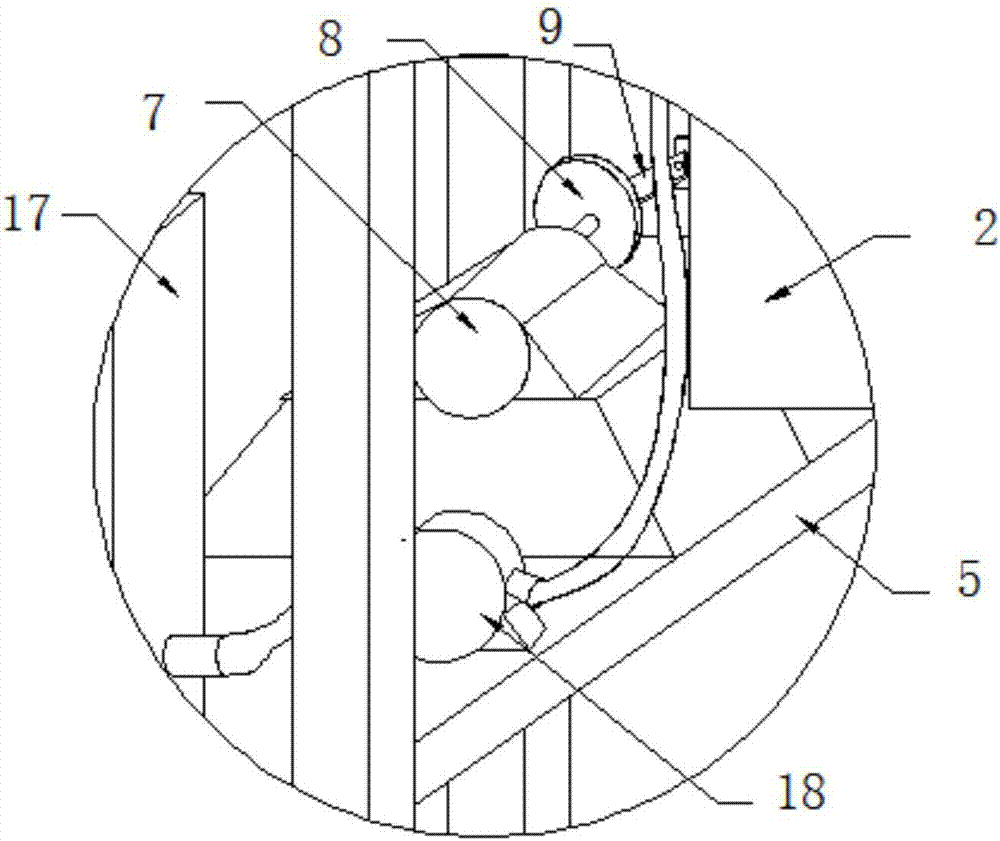

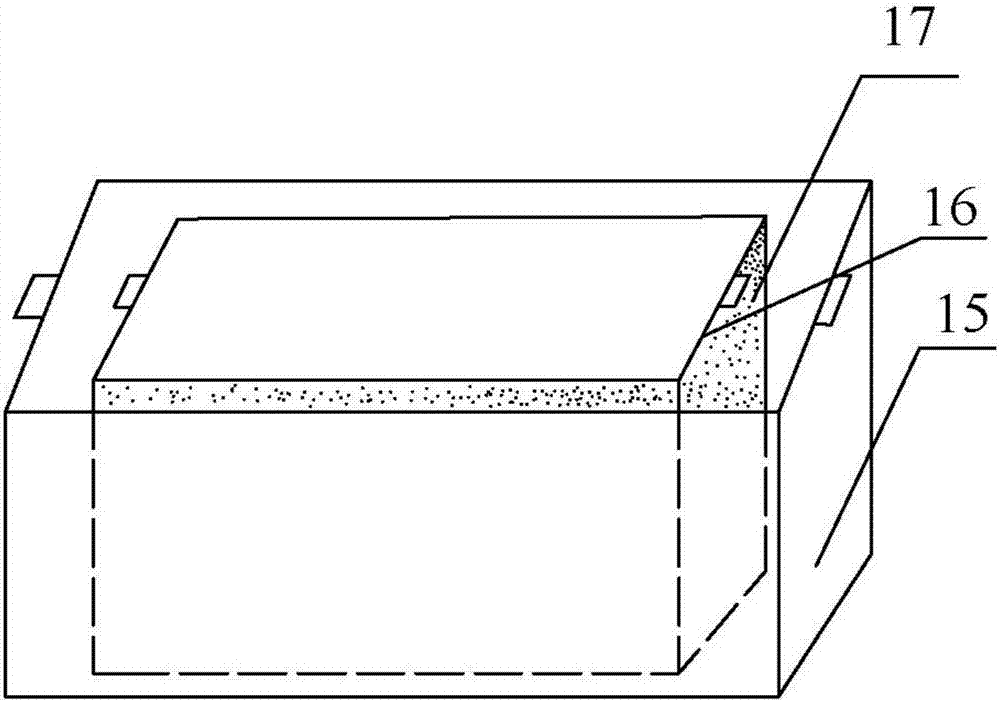

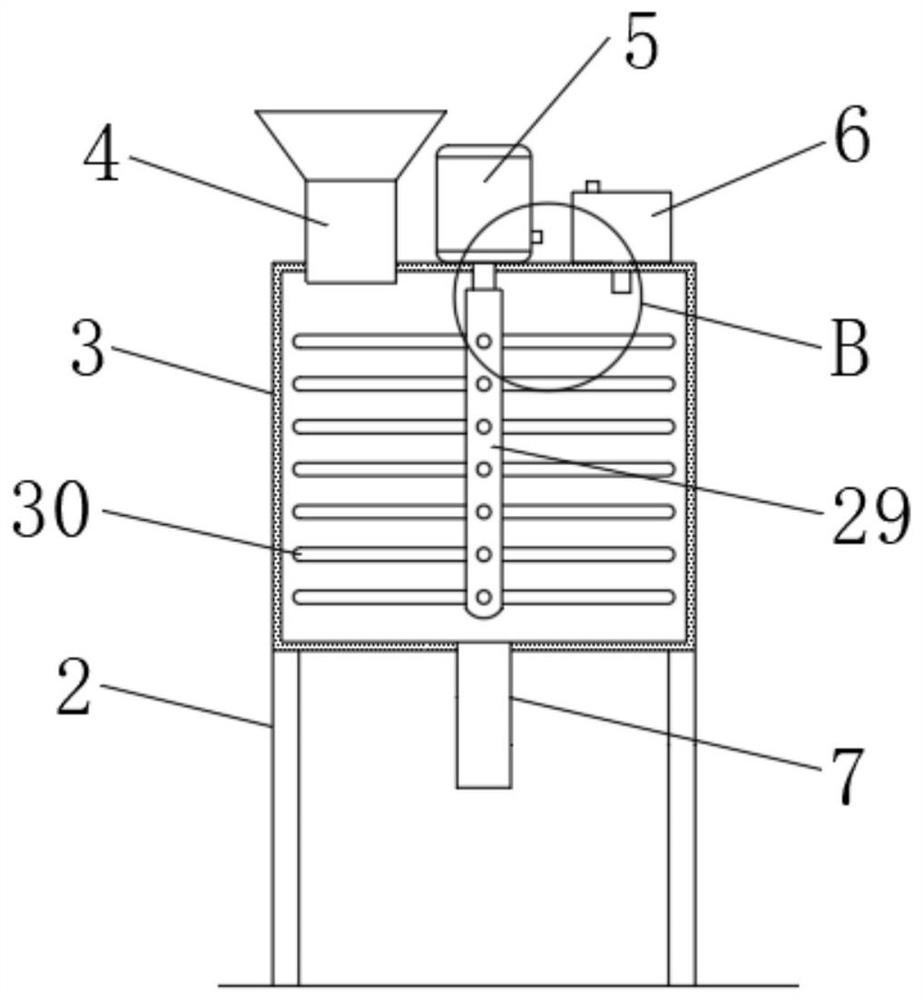

Gravel sand-washing device capable of conducting automatic cleaning

InactiveCN107042217AAutomate cleaningAvoid affecting the cleaning effectHollow article cleaningCleaning using liquidsEngineeringHand washing

The invention discloses a gravel sand-washing device capable of conducting automatic cleaning. The gravel sand-washing device comprises a bottom frame, a washing box, an oscillation device and an automatic cleaning device. A device installation plate is arranged on one side of the bottom frame. The two opposite sides of the washing box are each provided with a pair of swing connection pieces. The washing box is connected with the other side of the bottom frame through the four swing connection pieces. The oscillation device comprises a motor, an eccentric wheel and a connection arm. The motor is arranged at one end of the device installation plate. The eccentric wheel is arranged on an output shaft of the motor. The two ends of the connection arm are connected with the eccentric wheel and the washing box correspondingly. A washing and screening plate is arranged in the cleaning box. According to the gravel sand-washing device, sand washing is conducted on gravel through an oscillation type method, the sand washing efficiency can be higher, and the effect can be better; and by means of the added automatic cleaning device, fine sand dirt accumulated at the bottom of the washing box can be automatically removed, and it is avoided that because the too much fine sand dirt is stacked in the washing box, the washing effect of the device is influenced.

Owner:CHONGQING LYUDAOYUAN BUILDING MATERIAL CO LTD

Grit matrix cleaning device and method

PendingCN107321588ALabor savingImprove scientific research efficiencySievingScreeningResearch efficiencyEngineering

The invention discloses a grit matrix cleaning device and relates to the technical field of sand culture. The grit matrix cleaning device comprises a bracket, a driving device and a filter box. The bracket is movably connected to a stirring container, a stirring shaft is arranged in the stirring container, stirring blades are arranged on the stirring shaft, the top of the stirring container is opened, and a movable screen is arranged on the top opening of the stirring container; the driving device is arranged on the bracket, and the output end of the driving device is connected to one end of the stirring shaft; the filter box comprises a first box body and a second box body, the first box body can be placed in the second box body, and a water outlet hole is formed in the side wall of the first box body. The invention also discloses a grit matrix cleaning method of the grit matrix cleaning device. According to the grit matrix cleaning device and the grit matrix cleaning method, large grit can be removed and soluble nutrients attached to the surface are cleaned, so that a cleaned grit soil matrix meets demands on scientific research tests such as nutrient stress and grade size uniformity of a culture matrix, and therefore, the scientific research efficiency is increased greatly.

Owner:FUJIAN AGRI & FORESTRY UNIV

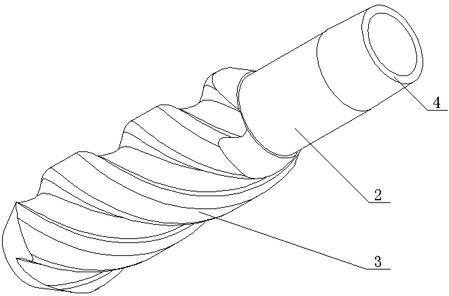

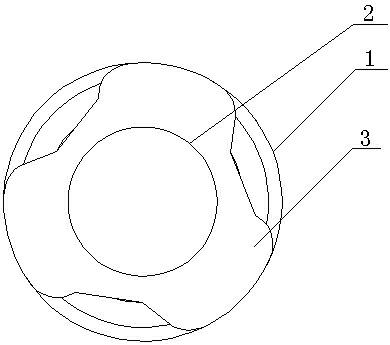

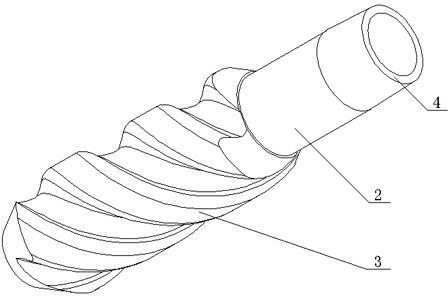

Cyclone sand washing device

The invention relates to the field of oil-gas field mining machines, in particular to a cyclone sand washing device used in sand washing operation of a horizontal well of an oil-gas field. The cyclone sand washing device is characterized in that a sand washing device body is arranged at the bottom in a sleeve, and a spiral groove is arranged outside the sand washing device body; the sand washing device body is placed in the position of a horizontal sand settling section at the bottom in the sleeve or the position within 0.5m to the sand surface of a straight well section of the sleeve; a connecting head is arranged at the upper end of the sand washing device body; the sand washing device body is hollow, and open pipy structures are arranged at two ends of the sand washing device body; and the outer diameter of the spiral groove is smaller than the inner diameter of the sleeve. The invention provides the cyclone sand washing device which is high in sand washing efficiency and can thoroughly clear sand settled at the bottom of the sleeve.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

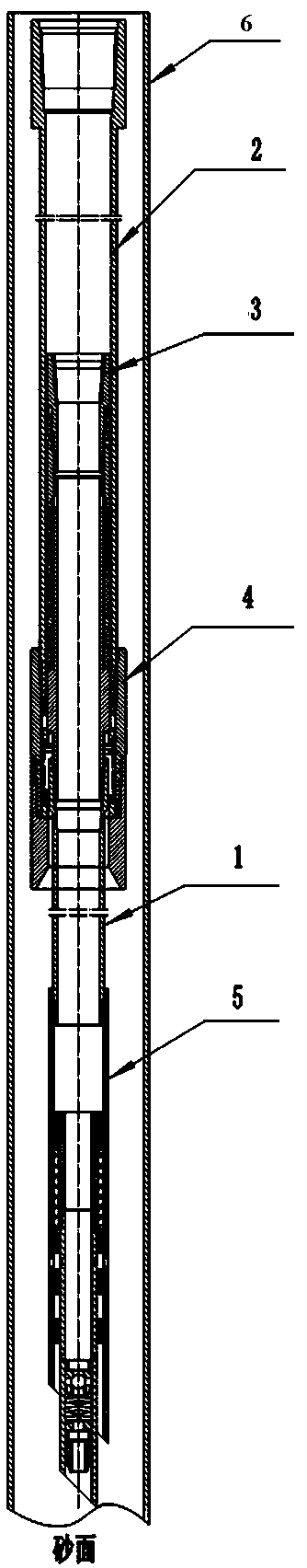

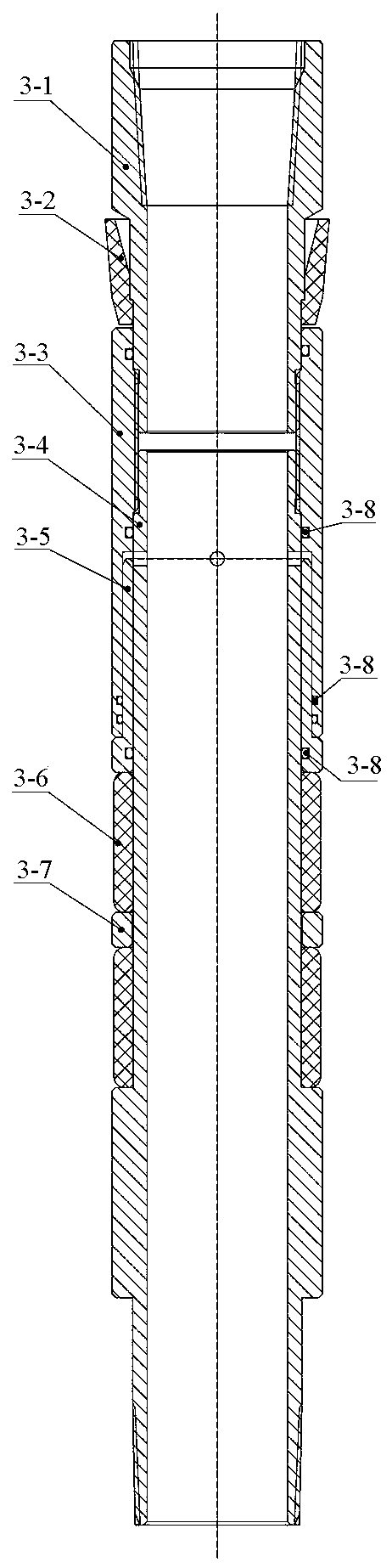

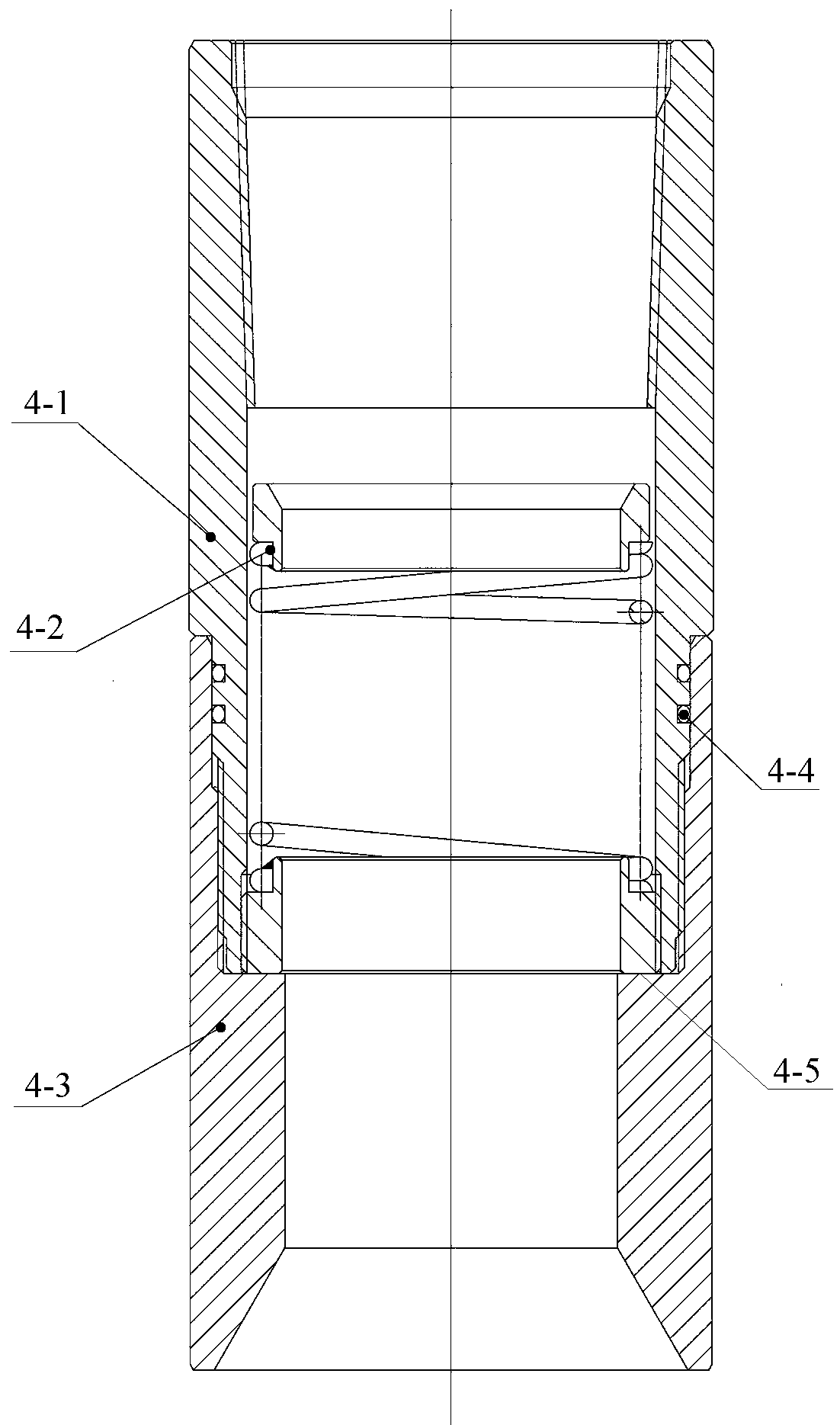

Continuous negative pressure sand washing device and system thereof

PendingCN106677727ARealization of continuous negative pressure sand washingNot easy to polluteFlushingEngineeringOil well

The invention relates to the technical field of sand washing of oil fields and oil wells, particularly to a continuous negative pressure sand washing device and a system thereof. The continuous negative pressure sand washing device comprises a sleeve, a liner pipe and a sand washing pipe, and the sleeve, the liner pipe and the sand washing pipe are sequentially arranged from outside to inside. The sand washing pipe is provided with a flow guiding hole, a flow jetting pump and a sand washing head from top to bottom. The lower end of the liner pipe is slidably sealed with the sand washing pipe; liquid outlet cavities are formed between the liner pipe and the sand washing pipe; an inner pipe cavity of the sand washing pipe communicates with the liquid outlet cavities through the flow guiding hole; the sleeve and the sand washing pipe are slidably sealed through first sealing pieces; a liquid injecting cavity is formed among the first sealing pieces, the liner pipe, the sand washing pipe and the sleeve; and liquid in the liquid injecting cavity is sprayed into the inner pipe cavity of the sand washing pipe through the flow jetting pump and carries the liquid from the sand washing hole. The continuous negative pressure sand washing system comprises the continuous negative pressure sand washing device and an operating machine. According to the continuous negative pressure sand washing device and the system, the technical problems that in the prior art, the construction efficiency of sand bailing operation is low and oil layers are prone to be polluted by sand washing are solved.

Owner:西安迈克斯石油技术有限公司

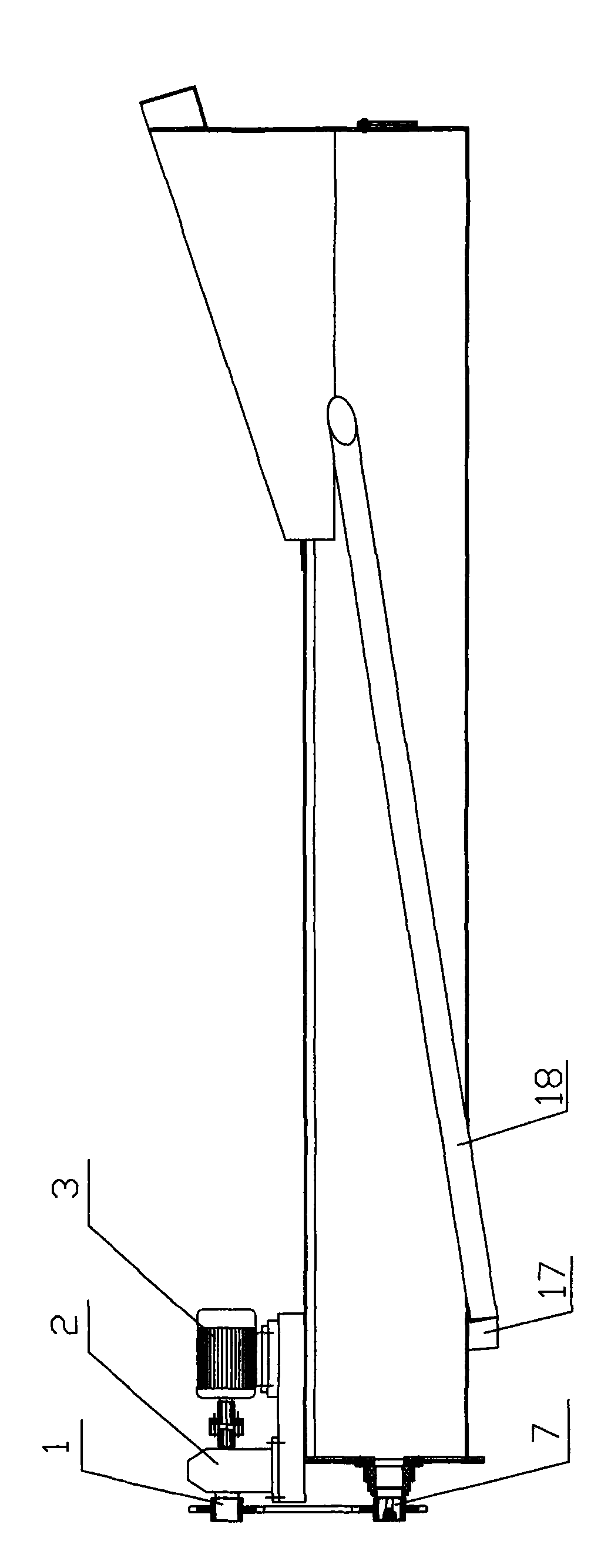

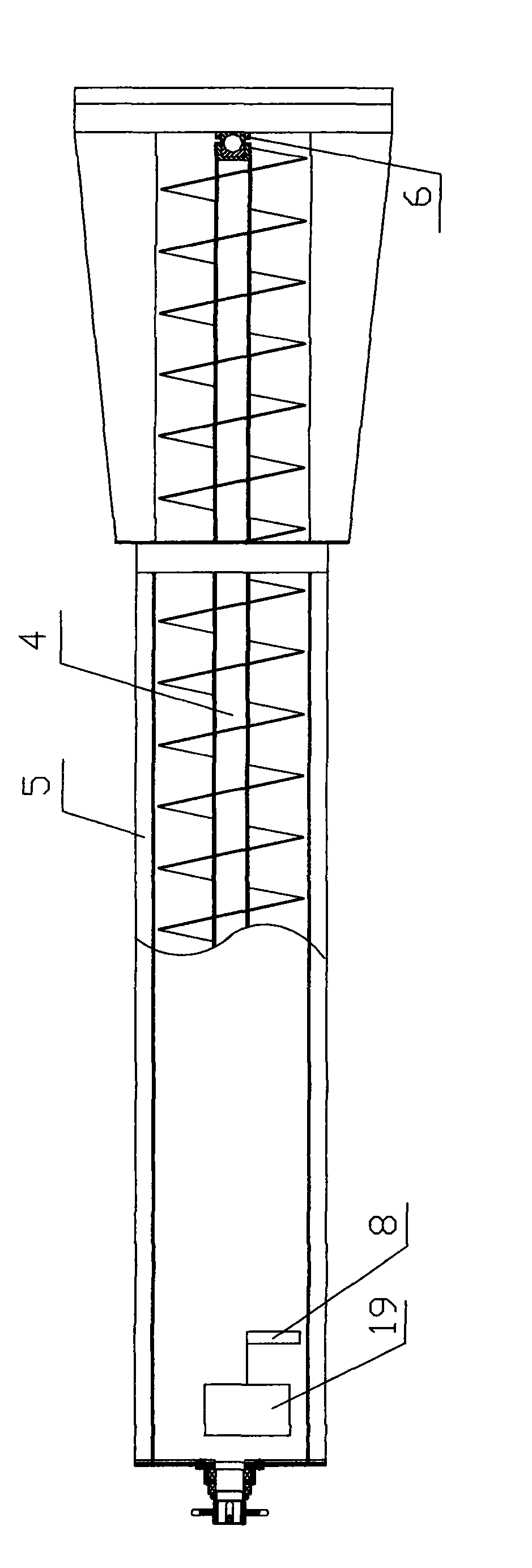

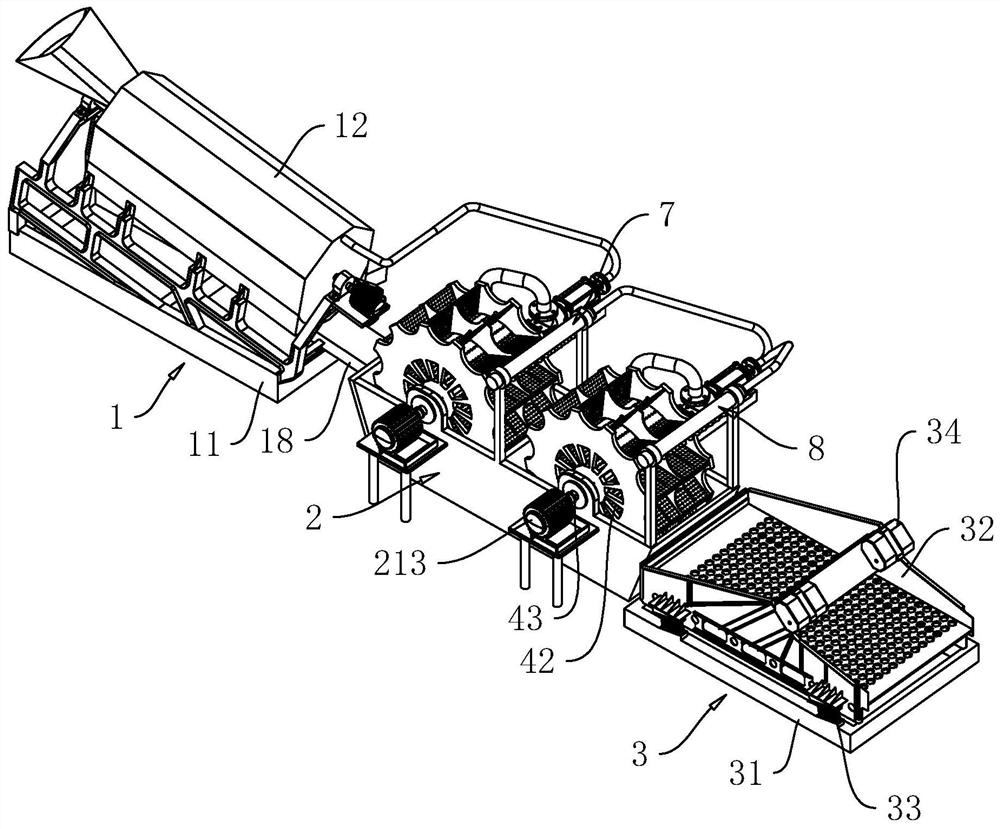

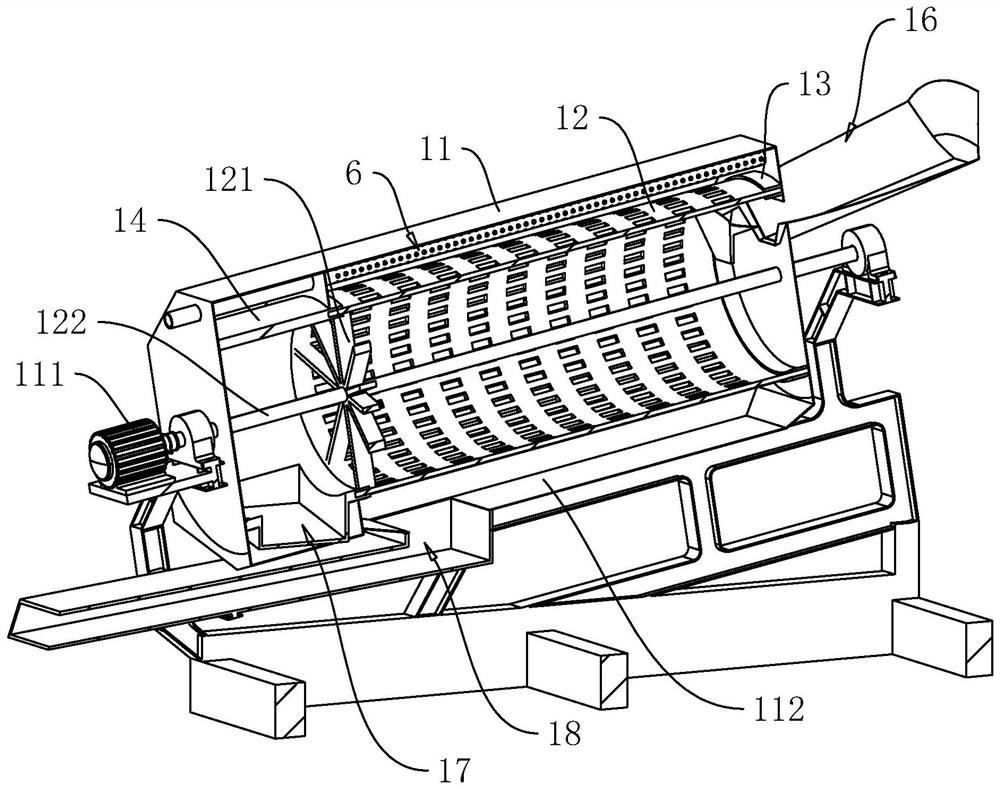

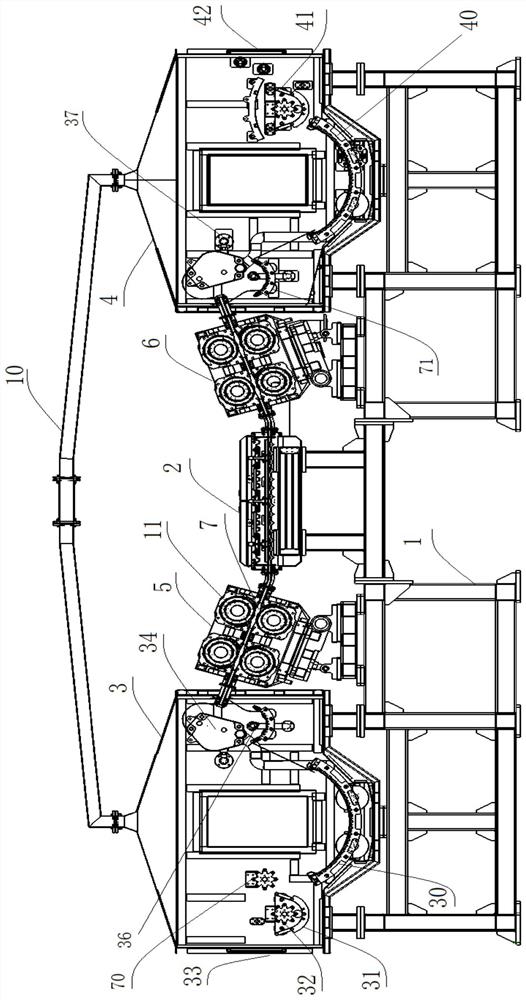

Manufactured-sand water-washing device and technique

A manufactured-sand water-washing device comprises a sand washing machine and a fine-sand collecting machine; the sand washing machine comprises a transmission device, a shell and a main shaft system which is fixed in the shell; the front end of the shell is provided with a discharge opening, the rear end of the shell is provided with a sand washing tank; the upper part of the sand washing tank is provided with a mud discharge opening; the mud discharge opening of the sand washing machine is connected with an inlet of the fine sand collecting machine; and the fine-sand collecting machine comprises a sand draining pump, a sand pulp concentrator, a high-efficiency dewatering screen, a material storing box and a material returning box. The invention also discloses a manufactured-sand water-washing technique. The device and the technique have the following beneficial effects that with the adoption of the combination of the sand washing machine and the fine-sand collecting machine, mud water discharged from the sand washing machine is subjected to a secondary treatment by the fine-sand collecting machine, and fine sand subjected to the secondary treatment is doped in the water-washed sand which is directly obtained by the sand washing machine, so that not only is the yield of the finished product sand increased, but also the quality of the finished product sand is optimized; and the fine sand in the mud water is re-collected, and thus, the discharge amount is reduced by 15% and the cleaning cycle of a settling pond is prolonged.

Owner:青岛磊鑫新型建材有限公司

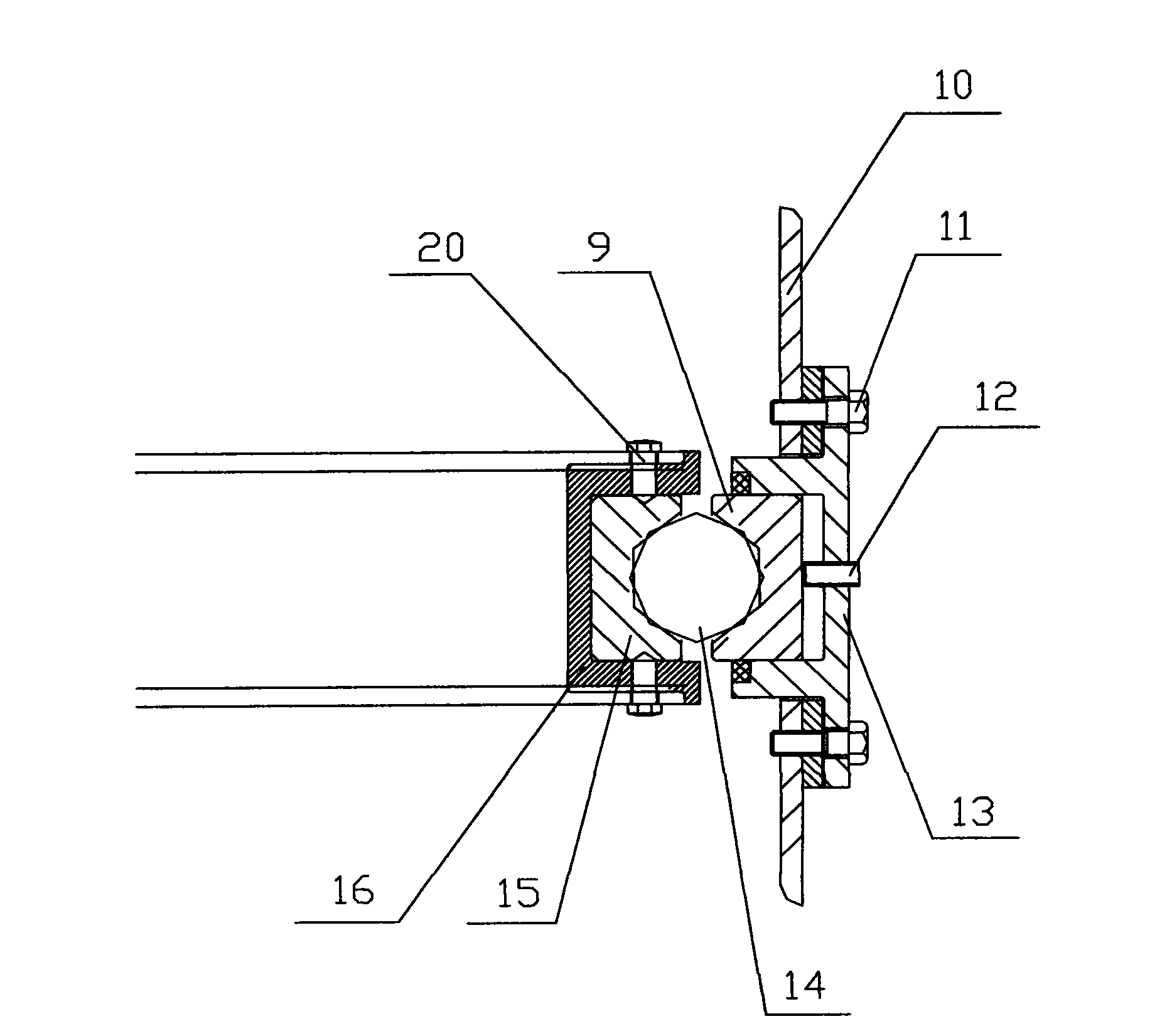

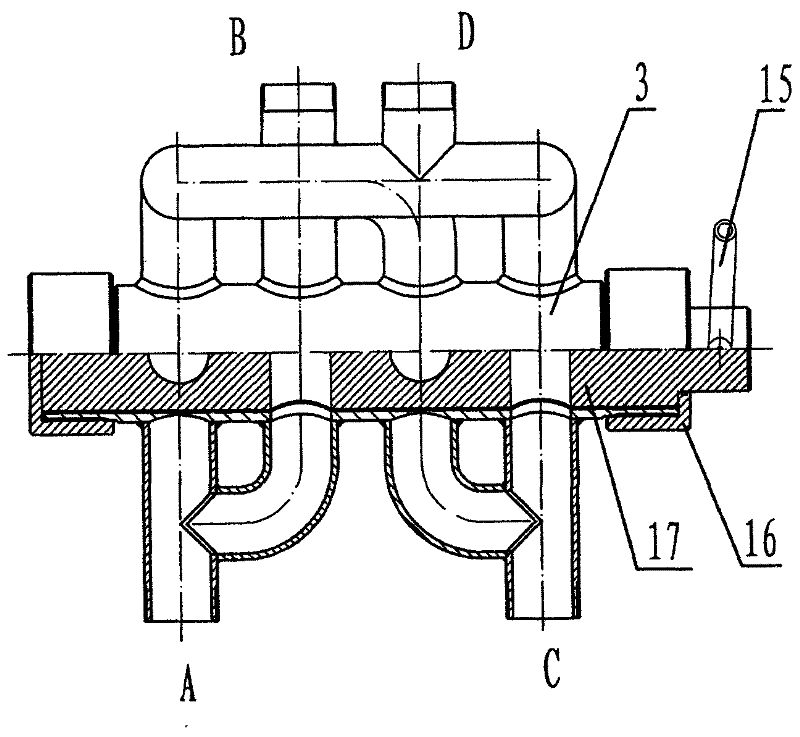

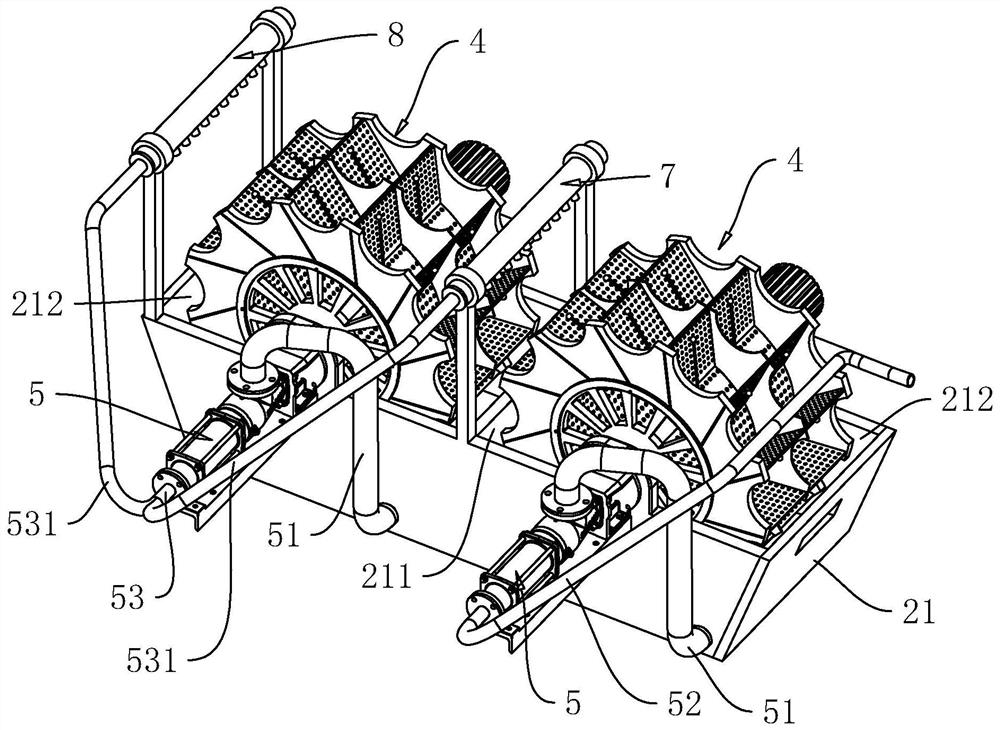

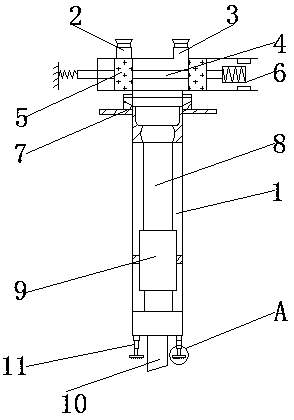

Continuous positive and negative integrated sand washing device for oil well

ActiveCN102383750ASatisfy sand washing requirementsImprove sand washing effectFlushingOil waterEngineering

The invention relates to a continuous positive and negative sand washing device for an oil-water well, in particular to a continuous positive and negative integrated sand washing device for an oil well. The device consists of an operation machine, pipelines, a sand washing pipe, an elevator, a pump truck and the like, wherein a self-sealing wellhead is arranged at the upper end of a big four-way joint of the wellhead; the lower end of a sand washing pipe column is provided with a sand washer, and the upper end of the sand washing pipe column is provided with a reversing valve; the sand washing pipe column enters a well casing under the well through the self-sealing wellhead and the big four-way joint; a three-way valve is connected with a water hose and the self-sealing wellhead and is connected with a positive and negative sand washing regulation and control valve bank; the positive and negative sand washing regulation and control valve bank is in threaded connection with the pipelines respectively connected onto the pump truck, a foul solution cylinder, the three-way valve and the big four-way joint; the three-way valve realizes continuous sand washing operation in the process of carrying out continuous single-length sand washing and carrying out subsequent single-length sand washing by cooperation of the opening and closing of pairs of pipe lines with the reversing valve and the self-sealing wellhead; and the positive and negative sand washing regulation and control valve bank completes conversion by adjusting and aligning with four holes which are vertical in pairs on a valve core and eight holes on a valve body, so that the positive and negative continuous sand washing operation is realized.

Owner:PANJIN GUANGTUO PETROLEUM TECH

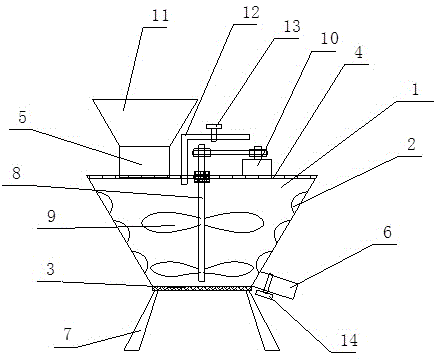

Simple sand washing machine

The invention discloses a simple sand washing machine, which comprises a sand washing cylinder, the sand washing cylinder is in the shape of an inverted truncated cone, a stirring sand washing device is arranged in the sand washing cylinder, and the sand washing cylinder is provided with a There are protrusions, the bottom is provided with a sand washing filter plate, the top is provided with a support plate, the support plate is provided with a sand inlet and a water inlet, the bottom of the sand washing cylinder is provided with a sand outlet, and the sand washing cylinder The bottom is provided with outriggers. The invention has the advantages of simple structure and convenient use.

Owner:HENGYANG SHUANGYAN TRANSPORTATION MACHINERY

Reverse circulation sand washing device

The invention relates to a borehole operation tool, and specifically relates to a reverse circulation sand washing device. The reverse circulation sand washing device comprises a barrel; during sand washing, a sand washing solution passing through the middle of the barrel and the sand washing device is used for impacting the barrel so as to form a sand mixing solution; the sand mixing solution enters into a sand washing passage under the guide of a guide plate; a part of the sand mixing solution in the sand washing passage directly passes through a first filter so as to enter into a sand washing pipe column, and the part of the sand mixing solution is used for taking away tiny impurities; the other part of the sand mixing solution is used for taking large impurities into a crushing cavitythrough holes in a partition board; large sand enters into the crushing cavity along the radial direction of the barrel and collides with crushing teeth inside the crushing cavity; after the tiny impurities are formed by crushing the large sand, the small impurities enter into the sand washing pipe column through a second filter, so that the large impurities inside the sand mixing solution are crushed through the crushing cavity; and therefore, the sand washing device is avoided from being blocked by the impurities, repeated cleaning of the sand washing device is avoided, and the sand washingefficiency is improved.

Owner:中石化石油工程技术服务有限公司 +1

Environment-friendly and energy-saving screening and sand washing all-in-one machine

InactiveCN111790512AAchieve cleaningRealize screeningFiltration separationWet separationWater resourcesEnvironmental engineering

The invention provides an environment-friendly and energy-saving screening and sand washing all-in-one machine, and relates to the technical field of ore processing equipment. The environment-friendlyand energy-saving screening and sand washing all-in-one machine comprises a base, wherein stirring blades which are uniformly distributed from top to bottom are fixedly connected to the outer diameter of a rotating shaft; a second sieve plate is fixedly connected in a third vibration frame; a water collecting tank is fixedly connected to the top of the base below a first vibration frame; a firstfilter is fixedly connected to the top of the base on one side of the rear end of a cleaning box; and a second filter is fixedly connected to the top of the first filter. According to the machine, automatic cleaning and screening of sand and stone can be realized through the cleaning box and the third vibration frame so that more production requirements can be met, the sand and stone can be scattered and prevented from caking through the stirring blades, the sand and stone and water can be mixed more uniformly, so that the cleaning effect of the sand and stone is better, the water can be filtered and reused through the first filter or the second filter, the waste of water resources is greatly reduced, and the machine is worthy of being popularized vigorously.

Owner:江西石城县南方有色选矿设备制造有限公司

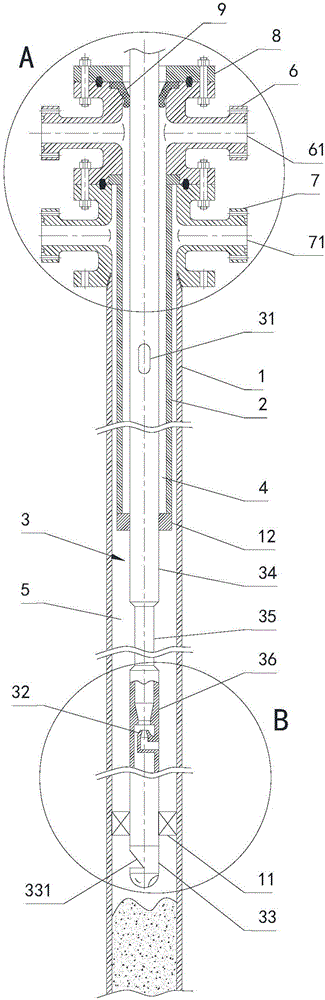

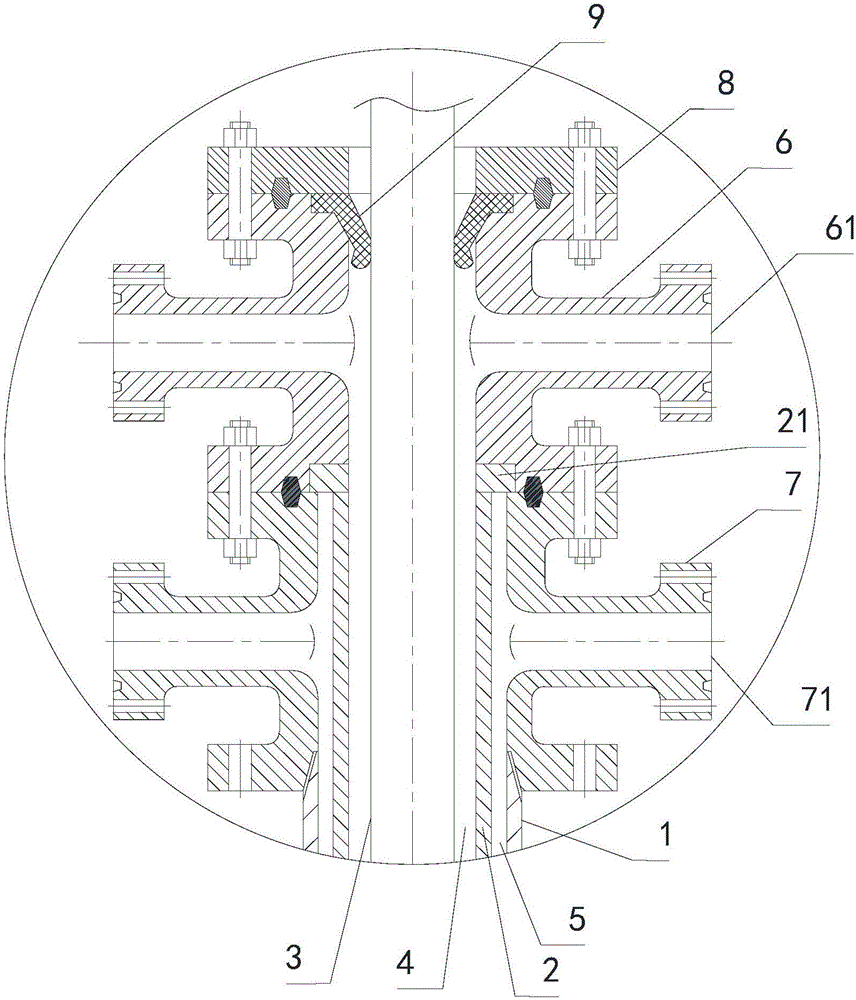

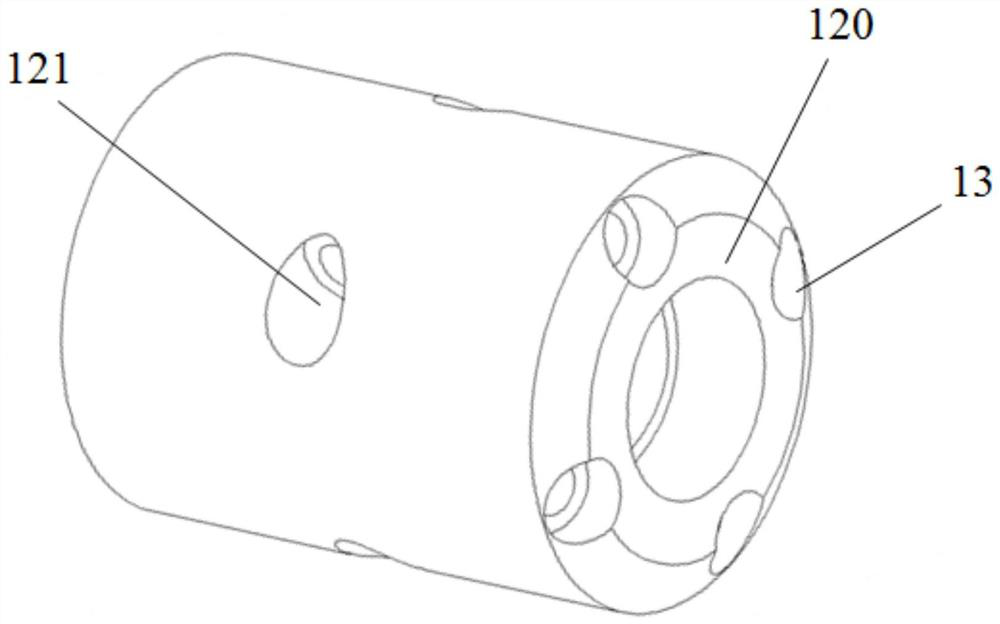

Rotational flow sand washing process pipe column

PendingCN112459735AIncrease flushing powerImprove sand washing efficiencyDrilling rodsFlushingHydrologyMechanical engineering

The embodiment of the invention discloses a sand washing pipe column and a sand washing method, the sand washing pipe column comprises a liquid flow reverser and a cyclone, and the lower end of the liquid flow reverser is connected with the cyclone. A descending channel for sand washing liquid to pass through and an ascending channel for returned liquid to pass through are formed in the liquid flow reverser. The upper part of the descending channel is communicated with an external space through a first opening in the side surface of the liquid flow reverser, and the lower part of the descending channel is communicated with a flow channel in the cyclone. An opening is formed in the lower part of the ascending channel. The cyclone is configured to convert the sand washing liquid flowing outof the descending channel from linear flow into rotational flow. The liquid flow reverser further comprises a blocking device, and the blocking device is located on the outer side of the sand washingpipe column and arranged to divide an annular space between sleeves into which the sand washing pipe column descends into an upper space and a lower space. The upper space is communicated with the descending channel.

Owner:CHINA OILFIELD SERVICES

Sand washing method and special tool

ActiveCN106368630BAchieving an annulus sealMeet construction requirementsFlushingSealing/packingEngineeringWater well

Owner:CHINA PETROLEUM & CHEM CORP +1

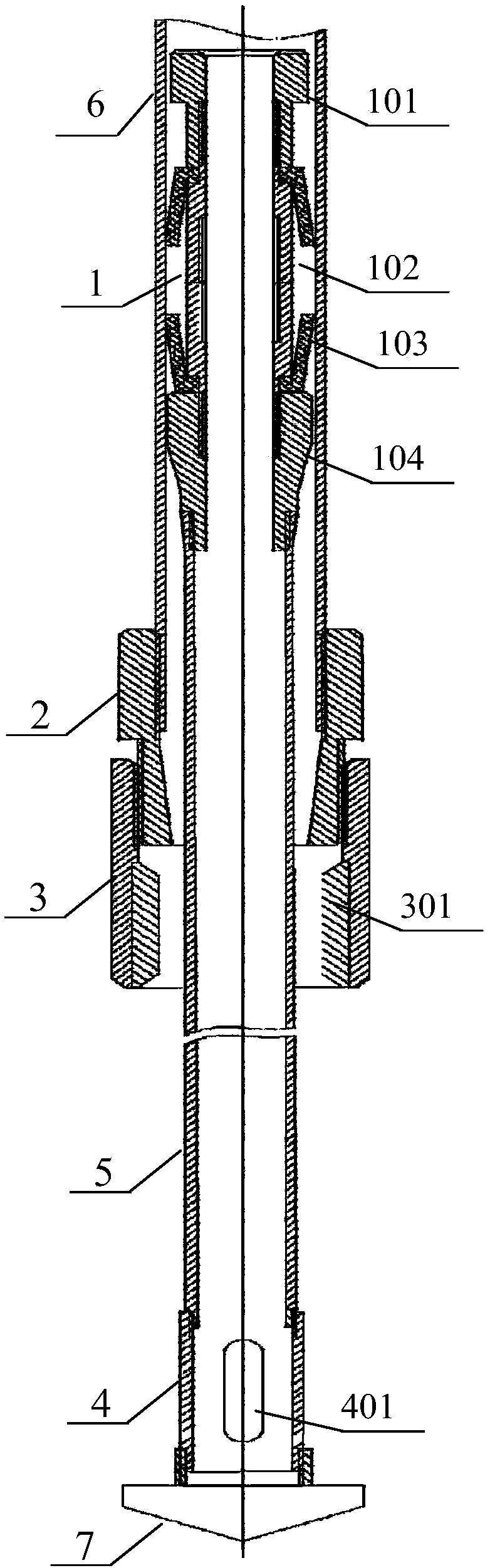

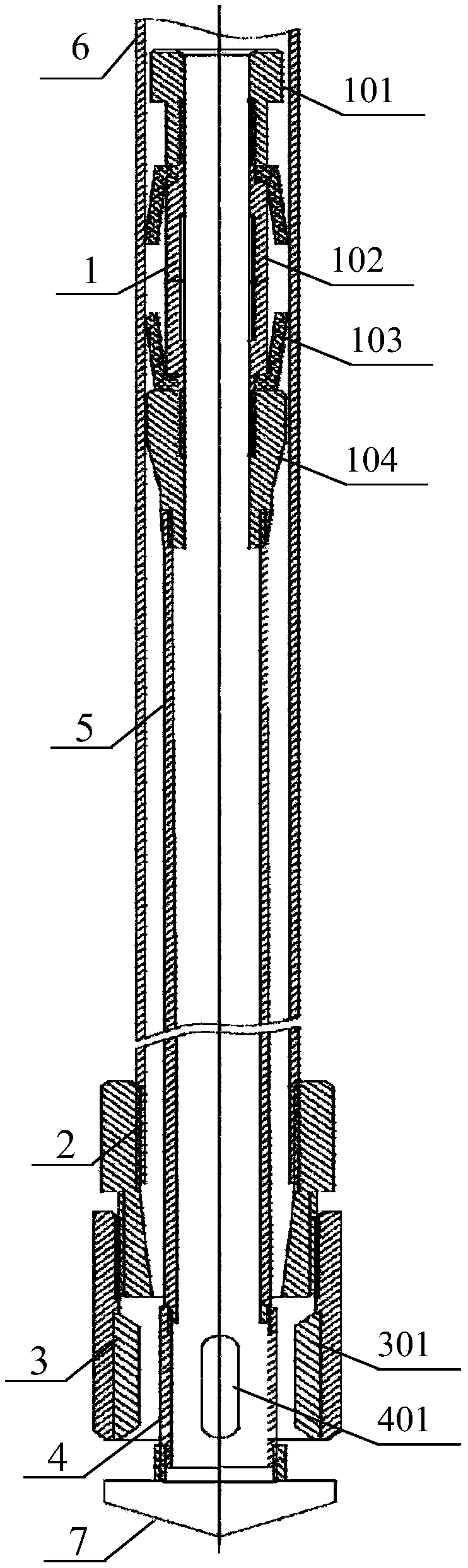

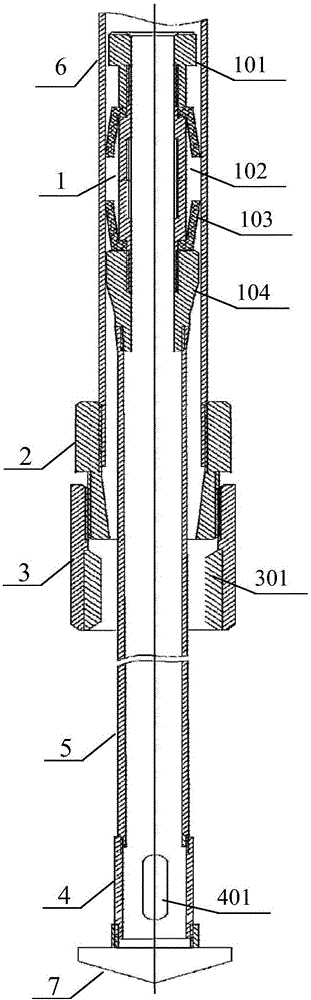

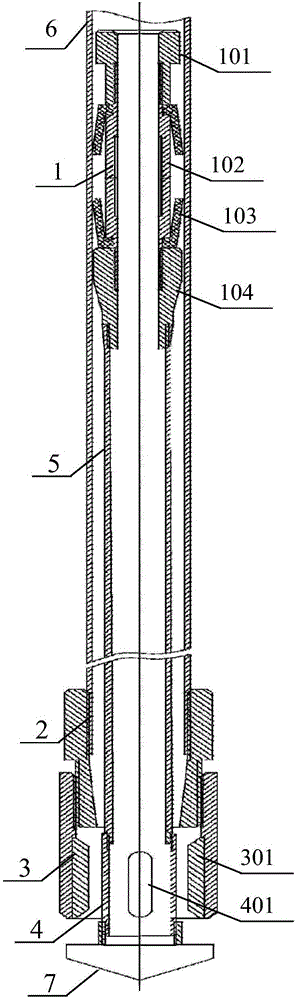

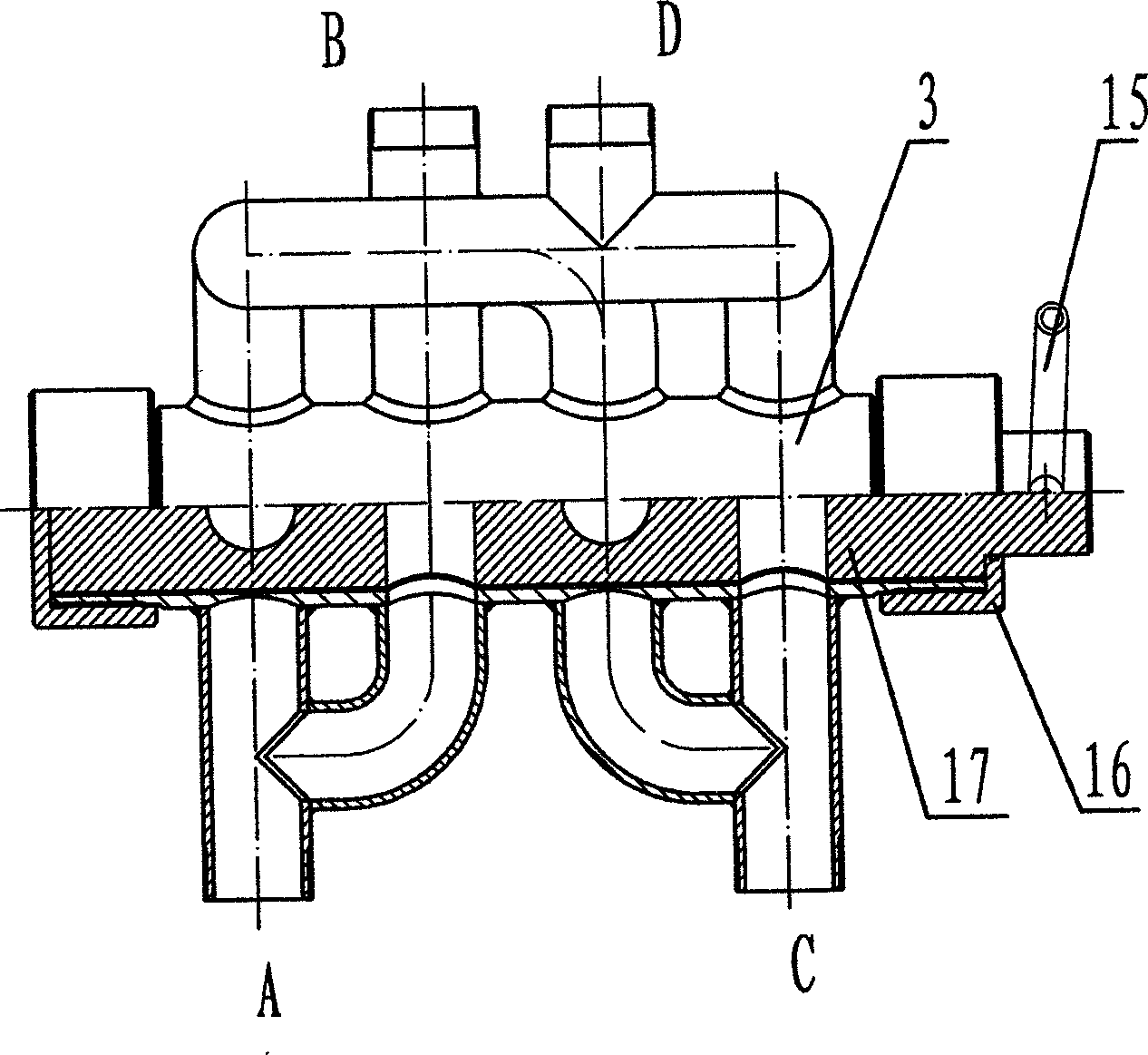

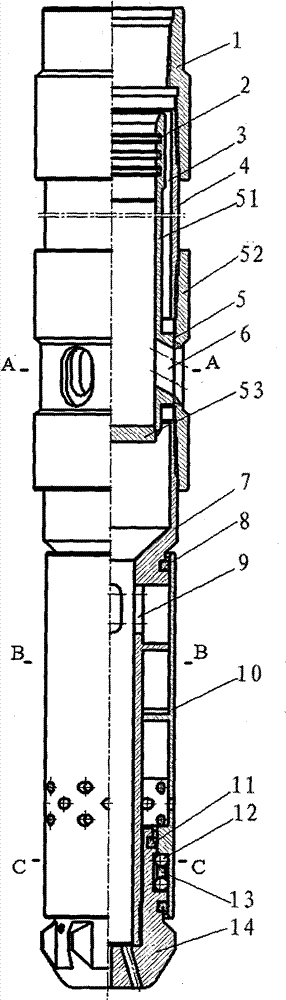

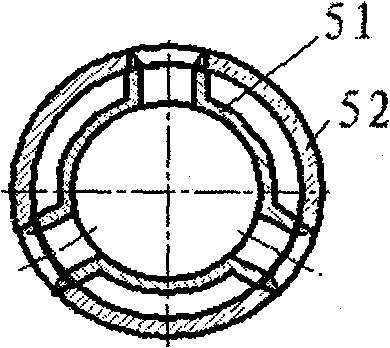

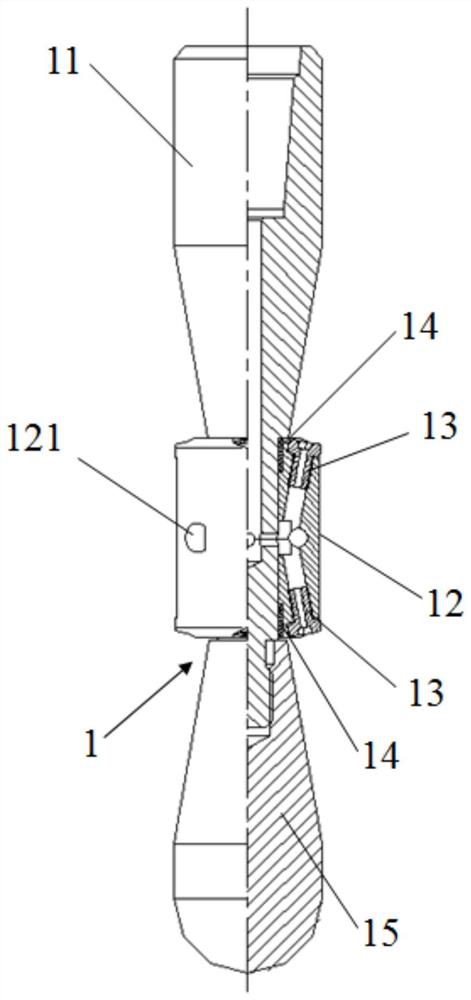

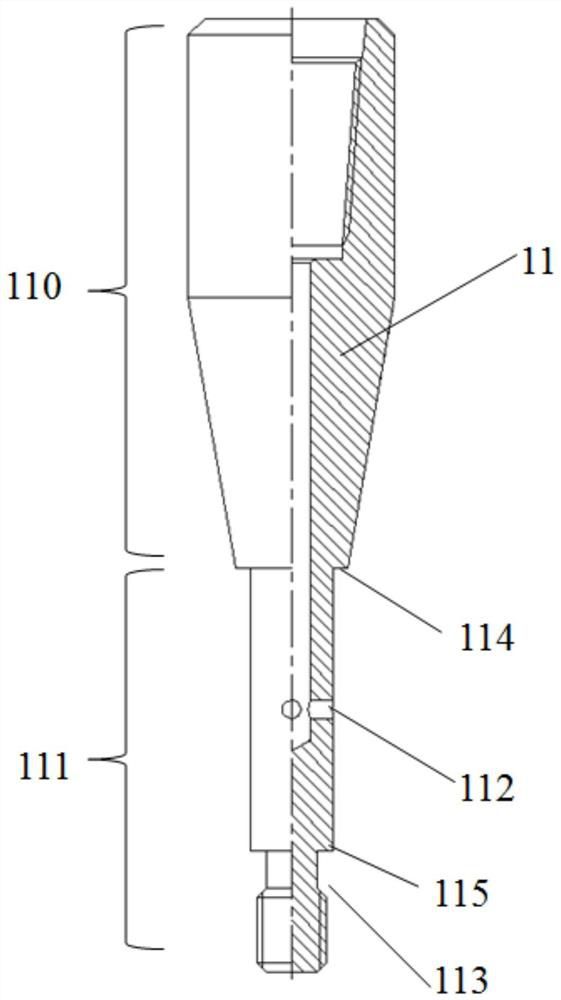

Method and special tool for sand flushing

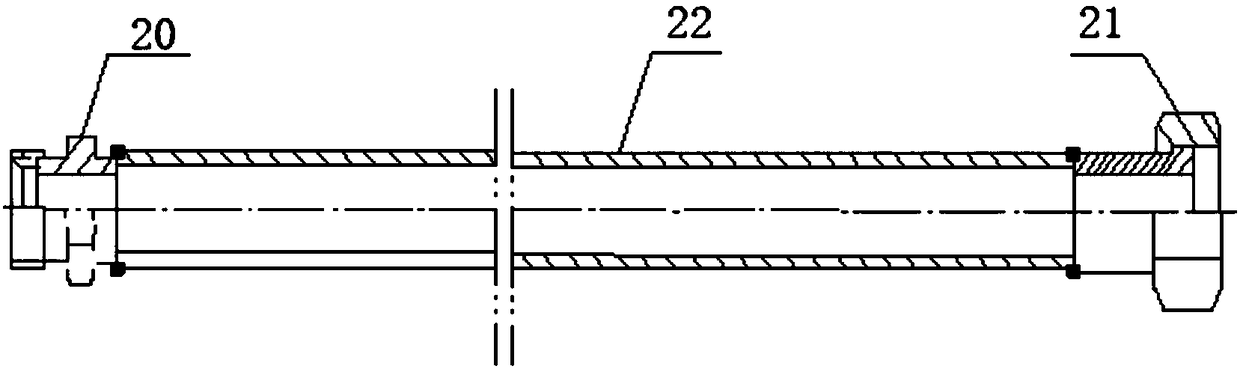

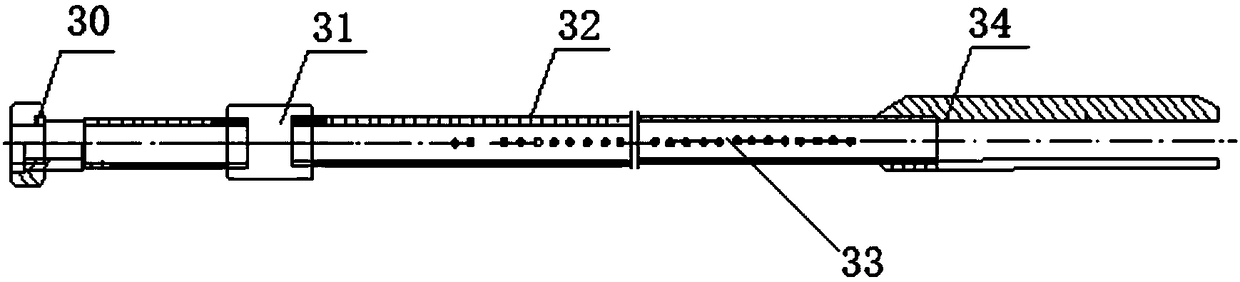

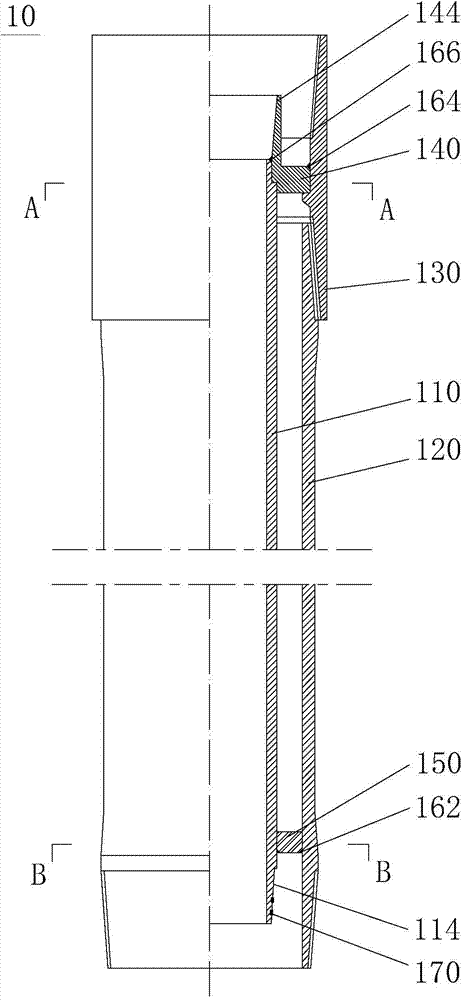

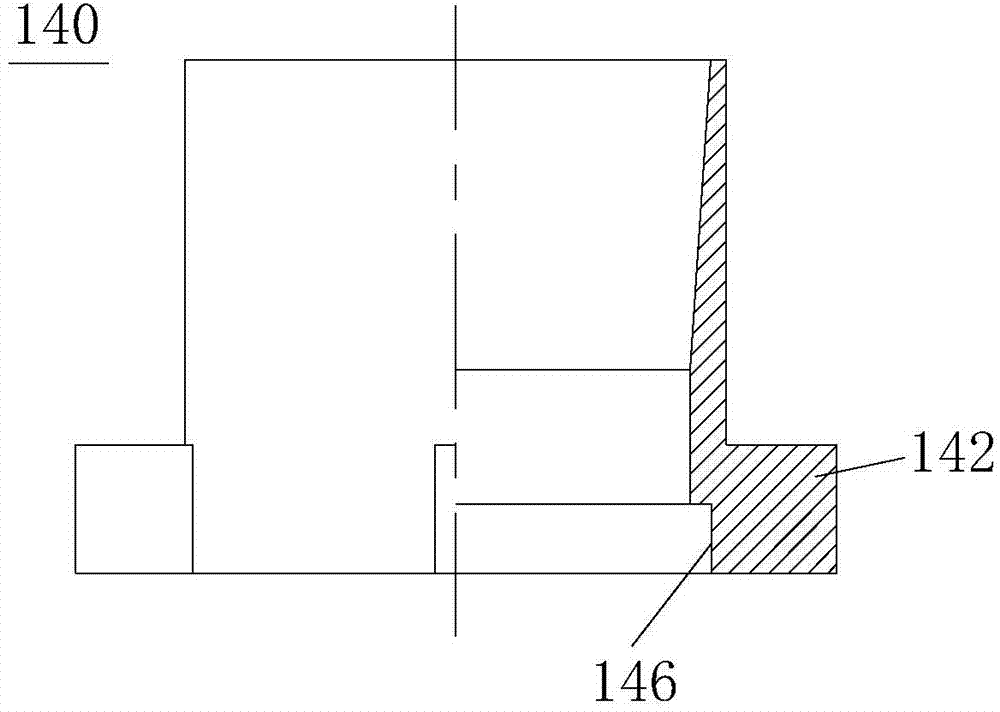

ActiveCN106368630AAchieving an annulus sealMeet construction requirementsFlushingSealing/packingEngineeringWater well

The invention relates to a method and special tool for sand flushing, and belongs to the technical field of well repairing work. The method and special tool for sand flushing are suitable for sand flushing construction of a pitshaft of an oil-gas well. The special tool for sand flushing comprises an outer pipe and a sand flushing inner pipe. The outer pipe is formed by sequentially connecting an oil pipe, a suspension pup joint and a rotary outer cylinder in a threaded mode. The sand flushing inner pipe is formed by sequentially connecting a sealing pup joint, a flushing pipe, a rotary inner cylinder and a drill bit in a threaded mode. According to the method and special tool for sand flushing, the annular space between the flushing pipe and the outer pipe is sealed through the sealing pup joint, a sand flushing fluid circulating channel between the outer pipe and the sand flushing inner pipe is established, and direct-circulating and reverse-circulating sand flushing construction in the sliding state of the flushing pipe is achieved; and rotating power for matching between the outer pipe and the ground is transmitted through the rotary inner cylinder and the rotary outer cylinder, the sand flushing drill bit is driven to rotate, and thus the rotary-drilling sand flushing construction requirement under a complex well condition is met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Condensed sand carrying agent used for under-pressure oil gas well

The invention discloses a condensed sand carrying agent used for an under-pressure oil gas well, and the condensed sand carrying agent is applied to the sand wash of the oil gas well in an oil gas field. The condensed sand carrying agent is characterized by comprising the following components in percentage by weight: 1-1.5% of xanthan gum, 20-25% of efficient foaming agent LF-II, 0.5-1% of potassium chloride, 0.2-0.5% of sodium carbonate, 5-8% of high-water-loss plugging agent, 0.5-1% of phenol, 0.3-0.5% of epoxy chloropropane, 0.5-0.8% of ethanol, 5-7% of carboxymethyl starch, 0.5-1% of sodium hydrogen carbonate and the rest of clear water, and the sum of the percentages of all the components is a hundred percent. The condensed sand carrying agent has the effects that the condensed sand carrying agent has favorable water solubility; when the concentration is lower, a water-soluble glue solution shows the characteristics of a plastic fluid; when the concentration is higher, a system shows the characteristics of a pseudoplastic fluid; the pollution to an underground stratum does not exist; the condensed sand carrying agent is applicable to the sand wash under a pressure and the work in an under-pressure gas well; and the problem that the seepage loss is big is solved. The solution dosage is only 50% of that of a conventional routine sand washing solution, and the pollution of a sand carrying solution to the stratum is reduced.

Owner:PETROCHINA CO LTD

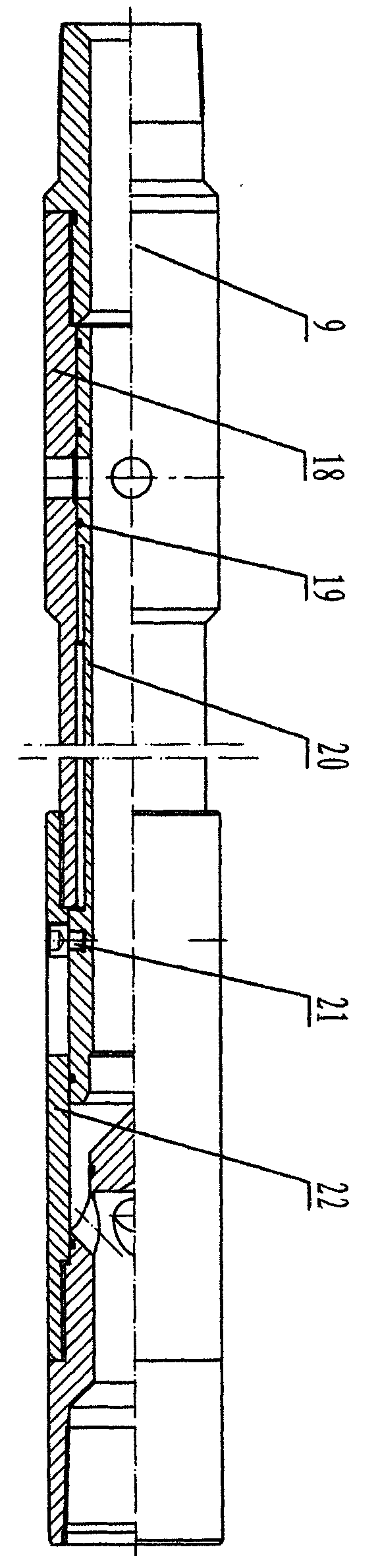

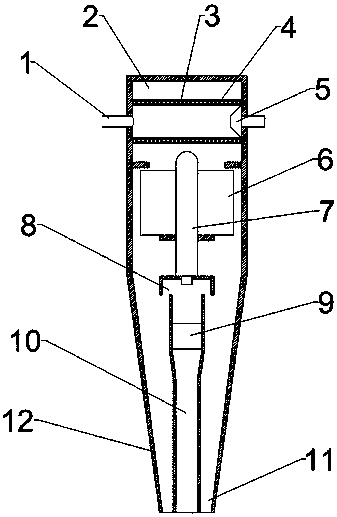

Continuous sand blasting tool

PendingCN110863786AWith vibration functionContinuous sand washingCleaning apparatusFlushingSand blastingGeotechnical engineering

The invention relates to a continuous sand blasting tool which includes an internal oil pipe and an external oil pipe. The continuous sand blasting tool is characterized in that the upper end of the internal oil pipe is provided with a compensation type sand blasting sealing tool, the lower end of the external oil pipe is provided with a buffer sand blasting suspension tool, and the lower end of the internal oil pipe is provided with a sitting type strong jet flow sand blasting tool; the compensation type sand blasting sealing tool includes an upper joint I, a central tube, a piston and a sealing sleeve, a packing cup is arranged between the upper joint I and the sealing sleeve, and a piston slides freely on the central tube; the buffer sand blasting suspension tool includes an upper jointII and a lower joint, the upper joint II and the lower joint are connected by threads, and a spring component is arranged in an inner cavity formed by the upper joint II and the lower joint and in front of a plug; and the sitting type strong jet flow sand blasting tool includes an outer tube, a sealing sleeve and a pen tip, the lower end of the pen tip is sequentially in threaded connection to aconstant pressure ball seat, an inner spring seat I, an inner spring seat II and a sand blasting opening. The device can avoid sand blocking and pump blocking, speeds up the process of sand blasting,reduces use of sand blasting liquid and improves the sand blasting efficiency.

Owner:LIAONING XINHUA INSTR CO LTD

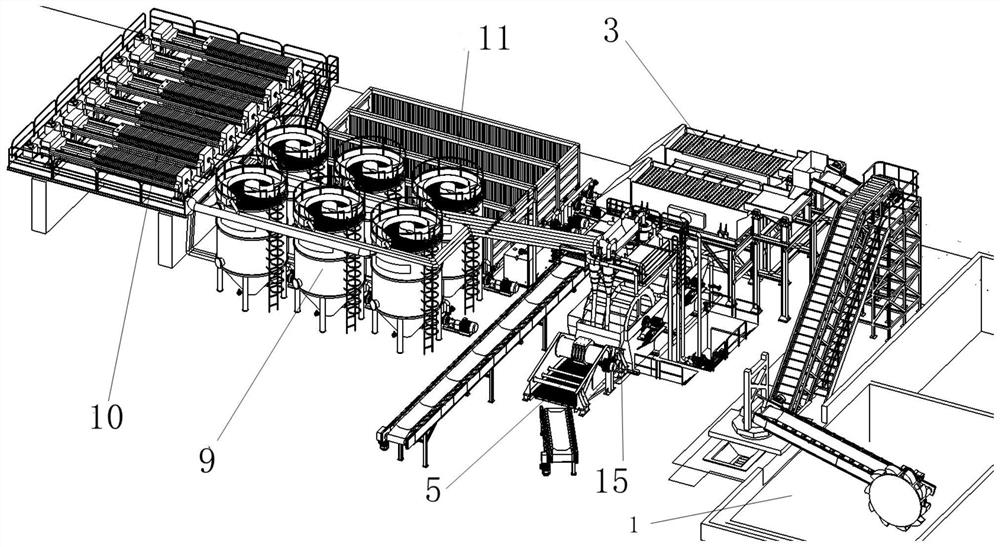

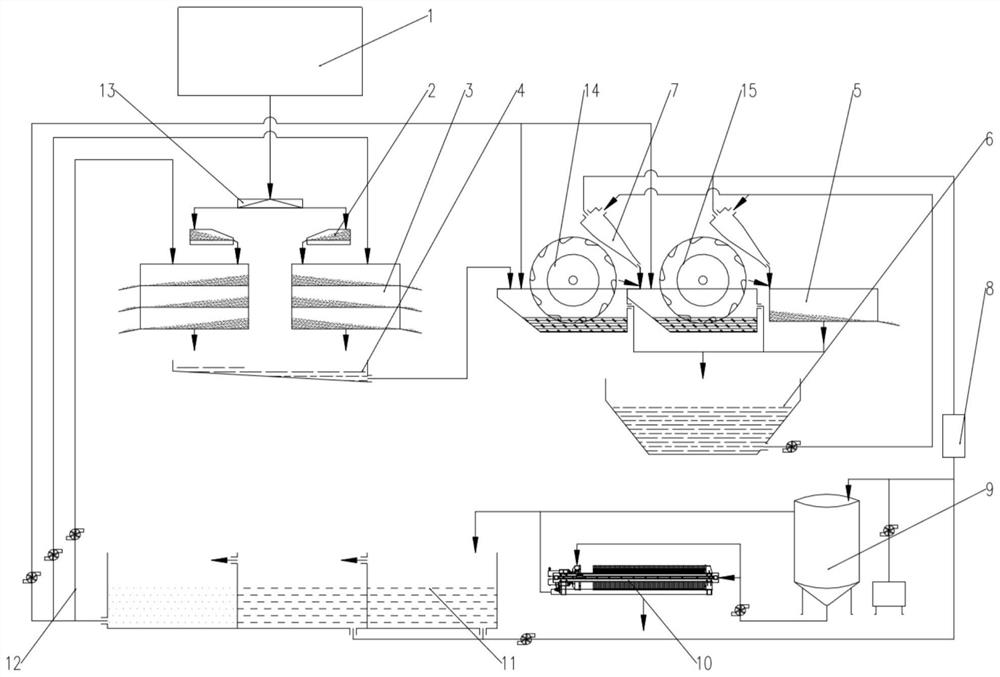

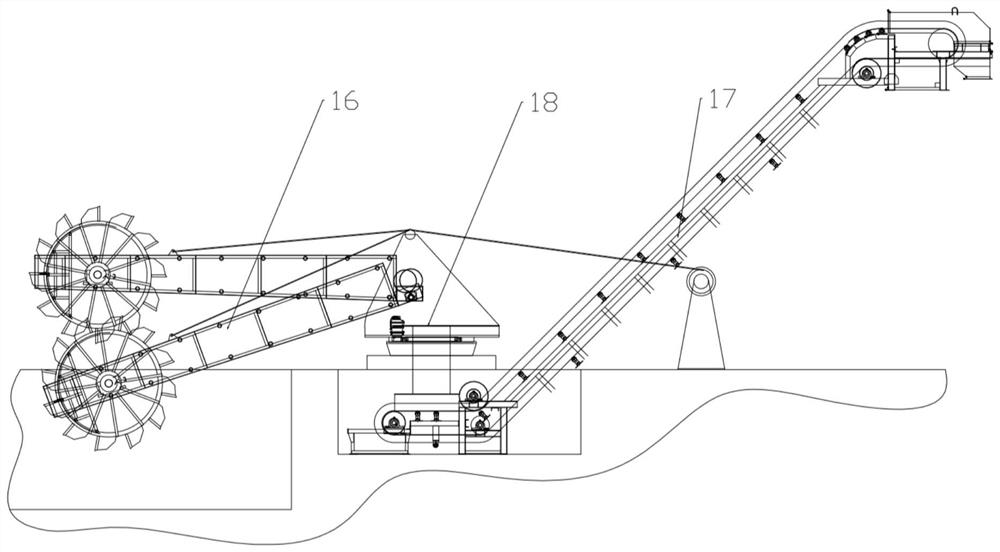

Waste building mud sand washing treatment system

InactiveCN114029159AAccelerated disengagementImprove sand washing efficiencySievingScreeningWater wheelEnvironmental engineering

The invention relates to a waste building mud sand washing treatment system. The system comprises a washing machine; the washing machine comprises a sand washing tank, water wheels and a first spraying frame; the sand washing tank is at least provided with two water washing tanks connected end to end; the water wheels are arranged in the two water washing tanks respectively, the axis directions of the water wheels are perpendicular to the arrangement direction of the water washing tanks, wheel shafts of the water wheels are rotationally connected to the sand washing tank and can rotate in the same direction, and a plurality of sand bailing tanks with leaking holes are evenly formed in the circumferential surfaces of the water wheels; and the first spraying frame is arranged above the sides, close to each other, of the two water washing tanks, and spraying heads of the first spraying frame can spray water to the sides, close to each other, of the two water wheels at the same time. With the waste building mud sand washing treatment system adopted, the sand washing efficiency can be improved.

Owner:青岛建一混凝土有限公司

Continuous positive and negative integrated sand washing device for oil well

ActiveCN102383750BSatisfy sand washing requirementsImprove sand washing effectFlushingOil waterEngineering

The invention relates to a continuous positive and negative sand washing device for an oil-water well, in particular to a continuous positive and negative integrated sand washing device for an oil well. The device consists of an operation machine, pipelines, a sand washing pipe, an elevator, a pump truck and the like, wherein a self-sealing wellhead is arranged at the upper end of a big four-way joint of the wellhead; the lower end of a sand washing pipe column is provided with a sand washer, and the upper end of the sand washing pipe column is provided with a reversing valve; the sand washing pipe column enters a well casing under the well through the self-sealing wellhead and the big four-way joint; a three-way valve is connected with a water hose and the self-sealing wellhead and is connected with a positive and negative sand washing regulation and control valve bank; the positive and negative sand washing regulation and control valve bank is in threaded connection with the pipelines respectively connected onto the pump truck, a foul solution cylinder, the three-way valve and the big four-way joint; the three-way valve realizes continuous sand washing operation in the process of carrying out continuous single-length sand washing and carrying out subsequent single-length sand washing by cooperation of the opening and closing of pairs of pipe lines with the reversing valve and the self-sealing wellhead; and the positive and negative sand washing regulation and control valve bank completes conversion by adjusting and aligning with four holes which are vertical in pairs on a valve core and eight holes on a valve body, so that the positive and negative continuous sand washing operation is realized.

Owner:PANJIN GUANGTUO PETROLEUM TECH

Sand separating and washing machine

The invention discloses a sand separating and washing machine. The sand separating and washing machine comprises a sand washing barrel and a driving motor; a coarse sand washing mesh screen and a fine sand washing mesh screen are arranged in the sand washing barrel from top to bottom, the coarse sand washing mesh screen and the fine sand washing mesh screen are parallel, are both obliquely arranged and partition the sand washing barrel into a coarse sand washing cavity, a fine sand washing cavity and a residue storing cavity from top to bottom, and stirring sand washers are arranged in the coarse sand washing cavity and the fine sand washing cavity respectively and driven by the driving motor. According to the sand separating and washing machine, the structure is simple, and not only can sand be efficiently washed, but also the sand can be separated according to the sand particle size.

Owner:HENGYANG SHUANGYAN TRANSPORTATION MACHINERY

Vortex sand washing device

The invention discloses a vortex sand washing device which comprises an upper connector, a tubing pup joint, a conversion body, a sand washing core tube, a revolving body and a sand washing head, wherein the upper connector is connected with the tubing pup joint, the conversion body, the sand washing core tube, the revolving body and the sand washing head in sequence; an annulus is formed betweenthe upper part of the inner pup joint of the conversion body and the cavity of the tubing pup joint; the lower end of the inner pup joint of the conversion body is provided with a stopper; a flow channel is arranged axially between the inner pup joint and the outer pup joint of the conversion body; the revolving body is arranged outside the sand washing core pipe and the sand washing head; and a bearing hoop is arranged between the lower cavity of the revolving body and the sand washing head. The vortex sand washing device adopts a double-tube structure, thus providing different channels for washing and upward-returning of sand washing fluid, and is characterized by high adaptability, high sand washing efficiency, high sand washing and well cleaning speed, good effect, high operation success rate and the like, thus being adapted to sand washing operation of common oil gas wells, especially to sand washing operation of highly-deviated wells and horizontal wells.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

Horizontal Well Cyclone Sand Washer

ActiveCN104047557BImprove sand washing efficiencyShorten the construction periodFlushingHorizontal wellsWasher

Owner:XIAN ZHONGFU KAIHONG GASOLINEEUM TECH +3

Flushing head, negative pressure sand washing device with flushing head and using method of negative pressure sand washing device

PendingCN114198036AIncrease sand return speedImprove sand return efficiencyFlushingMechanical engineeringWaste management

The invention discloses a flushing head, a negative pressure sand washing device with the flushing head and a using method of the negative pressure sand washing device, the flushing head comprises a connecting pipe, a rotating pipe sleeve, a plurality of nozzles and a guiding head, and the negative pressure sand washing device comprises a pipe core assembly, a sleeve assembly and the flushing head. According to the flushing head, the negative pressure sand washing device with the flushing head and the using method of the negative pressure sand washing device, negative pressure sand washing and gas injection sand returning are conducted on an oil and gas well which is low in formation pressure and prone to leakage, the sand washing efficiency is improved, the sand returning effect is improved, and due to the fact that liquid is returned to the ground again, pollution to the formation is avoided.

Owner:CNOOC TIANJIN BRANCH +1

Oil well flow back liquid sand removing device

InactiveCN108561112AReduce labor intensityIncrease productivityFluid removalAutomatic controlFiltration

The invention relates to an oil well flow back liquid sand removing device, and belongs to the technical field of oil field machinery. The invention develops the novel flow back liquid sand removing device which integrates the functions of sedimentation, filtration and sand recovery, the device can recover all fracturing flow back liquid, crude oil and sand in the field, so that recovered liquid can be reused, the intensity of a sand removing process is reduced, the production efficiency is improved to the largest extent, and energy saving and environmental protection are achieved; a lining adopts a polyurethane wear-resistant composite material grinding machine lining plate, and has the elasticity of a rubber-like substance and the characteristics of a rigid lining plate, in addition, thewear resistance of the lining is high, corrosion resistance is good, so that the composite material lining plate has unique wear properties, a combination mode of static and dynamic rotational flow sand catchers is formed, wear-resistant polyurethane is used as the lining material, an automatic control system is adopted, and the device has the advantages of wide adaptability, high sand washing efficiency, strong wear resistance and the like, and is of great significance for thickened oil sand removal and sump oil recovery.

Owner:陈琪峰

Sand-flushing well-cleaning agent for oil well

ActiveCN102399545BImprove sand washing efficiencyDrilling compositionCleansing AgentsSodium nonylphenol polyoxyethylene ether sulfate

The invention relates to a sand-flushing well-cleaning agent for an oil well applied to an oil field, which comprises the following components in percentage by weight: 12.5-13.5% of nonyl phenol polyoxyethylene ether sodium sulfate, 6.5-7.0% of fatty acid single glycollic amide polyoxyethylene ether sulfate, 10.5-11.0% of alkyl phenol polyoxyethylene ether (10) sodium sulfate, 5.5-6.0% of alkyl phenol polyoxyethylene ether carboxylate, 4.5-5.0% of ammonium bicarbonate and the rest of water. The sand-flushing well-cleaning agent disclosed by the invention has the effects that 0.5-1.0% of sand-flushing well-cleaning agent for the oil well is added in the water to obtain sand-flushing well-cleaning agent for an oil well liquid; and after the sand-flushing well-cleaning agent is utilized for sand-flushing well-cleaning construction, the sand flushing efficiency can be improved by 50-73%.

Owner:PETROCHINA CO LTD

Sand washing tool

PendingCN110593784AClear division of laborImprove sand washing efficiencyCleaning apparatusFlushingWater flowEngineering

The invention discloses a sand washing tool which comprises an equipment main body, stop blocks, a sand washing pipe and a sand washing pen point, wherein the upper end of the equipment main body is provided with a sand washing liquid inlet; the side end of the sand washing liquid inlet is provided with a sand outlet; a regulating rod is arranged inside the equipment main body near the sand washing liquid inlet; the stop blocks are fixedly connected onto the outer surface of the regulating rod; a coil is arranged at the tail end of the regulating rod; the upper end of the equipment main body is provided with a well sealing device; and the sand washing pipe is arranged at the lower end of the well sealing device. The coil and the stop blocks are arranged in the sand washing tool; when the coil is electrified, the stop blocks are moved, and the sand washing liquid inlet is further opened; water enters the sand washing pipe through the sand washing liquid inlet; water flow can impact sandat the well bottom; the sand upwards moves through the circulation of the sand washing liquid; when the coil is deenergized, the sand outlet is opened; the stop blocks block the sand washing liquid inlet; the sand and the sand washing liquid in an oil well are discharged out from the sand outlet at the same; the work division is clear; the integral sand washing efficiency is improved; and the sand washing and the sand outlet can be performed at the same time.

Owner:东营市三和石油装备有限公司

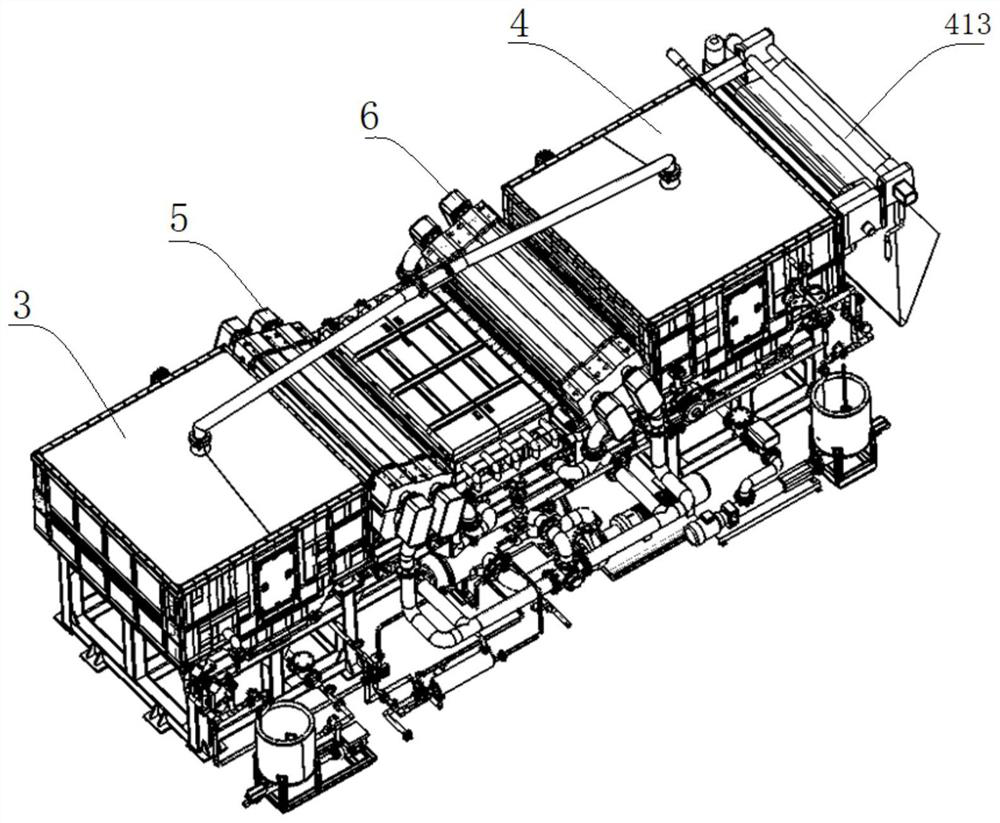

An integrated environmental protection treatment system for shield dregs

ActiveCN112844809BRealize reduced transportationAchieving processing powerWet separationFlocculationSlag

The invention discloses an integrated environmental protection treatment system for shield slag, belongs to the technical field of shield construction, and solves the problem of unsatisfactory treatment and recovery effect of shield slag in the prior art. Screening, sand washing, swirling, sand washing again, flocculation, pressure filtration, flocculation, etc., to obtain coarse sand, fine sand, mud cake and water, meet the requirements of material reuse and outbound transportation, and realize the reduction of shield muck It has the characteristics of integrated layout, modular installation, industrial production and intelligent control; the present invention has strong adaptability, and the system has multi-level configuration, multi-level accessories and various layout forms. It can meet the requirements of different projects on processing capacity, processing capacity, site layout and geological conditions.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

Reverse Circulation Sand Washer

ActiveCN107724979BAvoid cloggingAvoid cleaningFlushingMechanical engineeringGeotechnical engineering

The invention relates to a borehole operation tool, and specifically relates to a reverse circulation sand washing device. The reverse circulation sand washing device comprises a barrel; during sand washing, a sand washing solution passing through the middle of the barrel and the sand washing device is used for impacting the barrel so as to form a sand mixing solution; the sand mixing solution enters into a sand washing passage under the guide of a guide plate; a part of the sand mixing solution in the sand washing passage directly passes through a first filter so as to enter into a sand washing pipe column, and the part of the sand mixing solution is used for taking away tiny impurities; the other part of the sand mixing solution is used for taking large impurities into a crushing cavitythrough holes in a partition board; large sand enters into the crushing cavity along the radial direction of the barrel and collides with crushing teeth inside the crushing cavity; after the tiny impurities are formed by crushing the large sand, the small impurities enter into the sand washing pipe column through a second filter, so that the large impurities inside the sand mixing solution are crushed through the crushing cavity; and therefore, the sand washing device is avoided from being blocked by the impurities, repeated cleaning of the sand washing device is avoided, and the sand washingefficiency is improved.

Owner:中石化石油工程技术服务有限公司 +1

Sand washing machine

PendingCN112593359AAvoid damageQuality assuranceTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentProcess engineeringPower apparatus

The invention relates to the technical field of cloth dyeing and finishing, and discloses a sand washing machine which comprises a rack, wherein a middle flow channel is formed in the rack; a left cloth storage box is installed on the left side of the middle flow channel of the rack, and a right cloth storage box is installed on the right side of the middle flow channel; and a left spraying powerdevice is installed between the left cloth storage box and the middle flow channel of the rack, and a right spraying power device is installed between the right cloth storage box and the middle flow channel. When in actual use, the left spraying power device and the right spraying power device drive cloth to move back and forth between the left cloth storage box and the right cloth storage box, sand washing can be continuously conducted on the cloth, the cloth does not need to be replaced halfway, and the cloth sand washing efficiency is improved.

Owner:三谷东瑞先进技术研究(无锡)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com