Simple sand washing machine

A sand washing machine, simple technology, applied in the field of sand and gravel treatment, can solve the problems affecting sand gradation, many equipment, high power, etc., and achieve the effect of simple structure and high sand washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

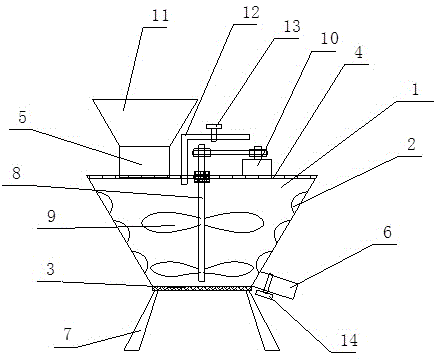

[0018] combine figure 1 A simple sand washing machine shown includes a sand washing cylinder 1, which is in the shape of an inverted truncated cone. The sand washing cylinder 1 is provided with a stirring sand washer, and the wall of the sand washing cylinder 1 is provided with a protrusion 2. The bottom is provided with a sand washing filter plate 3, the top is provided with a support plate 4, the support plate 4 is provided with a sand inlet 5 and a water inlet, the bottom of the sand washing cylinder 1 is provided with a sand outlet 6, and the bottom of the sand washing cylinder 1 is Legs 7 are provided.

[0019] In this embodiment, the agitating sand west device includes a stirring shaft 8 vertically arranged in the center of the sand washing cylinder 1 and a stirring blade 9 arranged on the stirring shaft 8. fixed.

[0020] In this embodiment, the stirring shaft 8 is provided with a driven pulley at the support plate 4 .

[0021] In this embodiment, a driving motor 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com