Horizontal Well Cyclone Sand Washer

A horizontal well and sand flushing technology, which is applied in the field of sand flushers, can solve the problems of inability to effectively carry formation sand, inability to effectively carry, and low construction efficiency, so as to enhance flushing and carrying capacity, reduce construction period and water consumption, and prevent Effect of stuck pipe accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

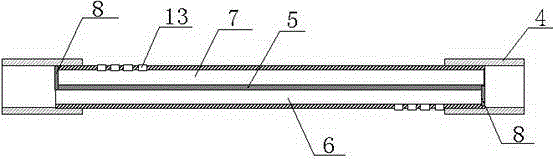

[0018] see figure 1 , a horizontal well swirl sand flusher, comprising a vector flushing pipe 1 and an isolated flushing pipe 2 connected by a tubing collar, the isolated flushing pipe 2 is located above the vector flushing pipe 1;

[0019] see image 3 , the vector flushing pipe 1 includes a tubing short that is provided with several vector nozzles 14 on the pipe body, and a female plug 3 with nozzles is provided at the end of the tubing short; the vector nozzles 14 are columnar nozzles and are arranged in a spiral, and each vector nozzle 14 is arranged on the pipe body through a circular pipe, and the axis of each vector nozzle 14 is 45° to the axis of the oil pipe short-circuit, and 30° to the tangent of the circular pipe.

[0020] see figure 2 , the other end of the isolation flushing pipe 2 is provided with a tubing collar, and the interior of the isolation flush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com