An integrated environmental protection treatment system for shield dregs

A technology for environmental protection and dregs, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of waste of inorganic raw materials, prone to landslides, landslides, land and resources damage, etc., to improve sand washing accuracy and efficiency. efficiency, improving the quality of finished sand washing, and improving the efficiency of slag treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

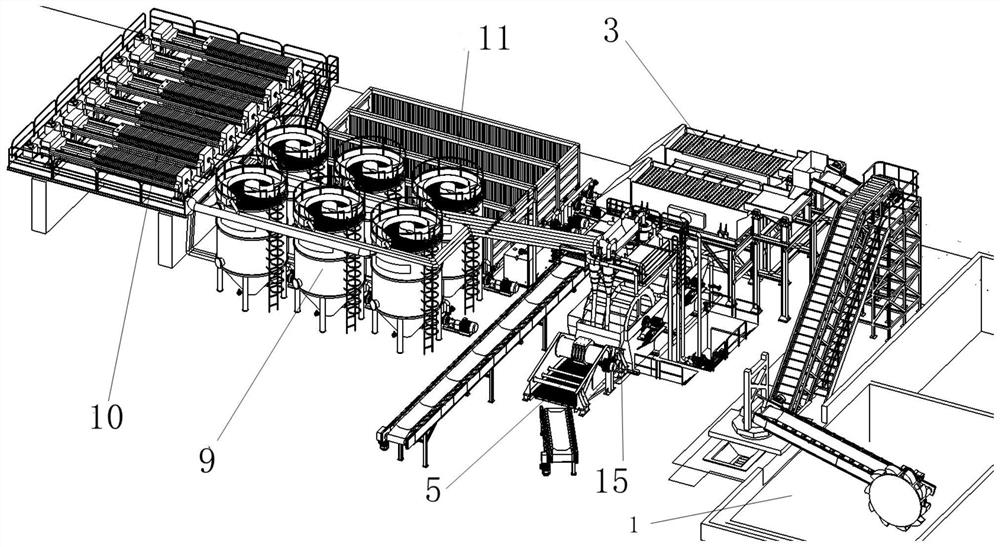

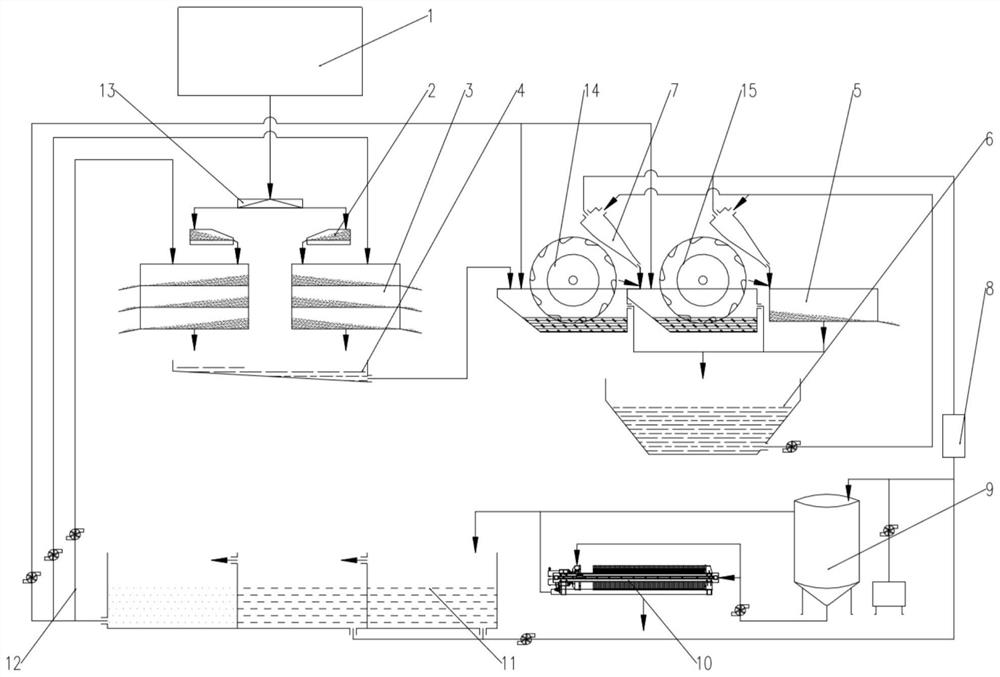

[0052] An integrated environmental protection treatment system for shield slag includes a regulating slag pit 1 for storing shield slag, the regulating slag pit 1 is connected with a feeder 2 through a feeding device, and the feeder 2 is far away from One side of the feeding device is connected with a vibrating screen 3, and the bottom of the vibrating screen 3 is fixedly connected with a multi-stage sand washing device through the under-screen chute 4, and the side of the multi-stage sand washing device away from the under-screen chute 4 is connected with a The dewatering screen 5, the dewatering screen 5 and the multi-stage sand washing device are respectively connected with the sand washing overflow pool 6, and the sand washing overflow pool 6 is connected with several cyclones 7 through a pressurized pump. The overflow ports of 7 are respectively connected with a liquid separation box 8, the liquid outlet of the liquid separation box 8 is fixedly connected with several floc...

Embodiment 2

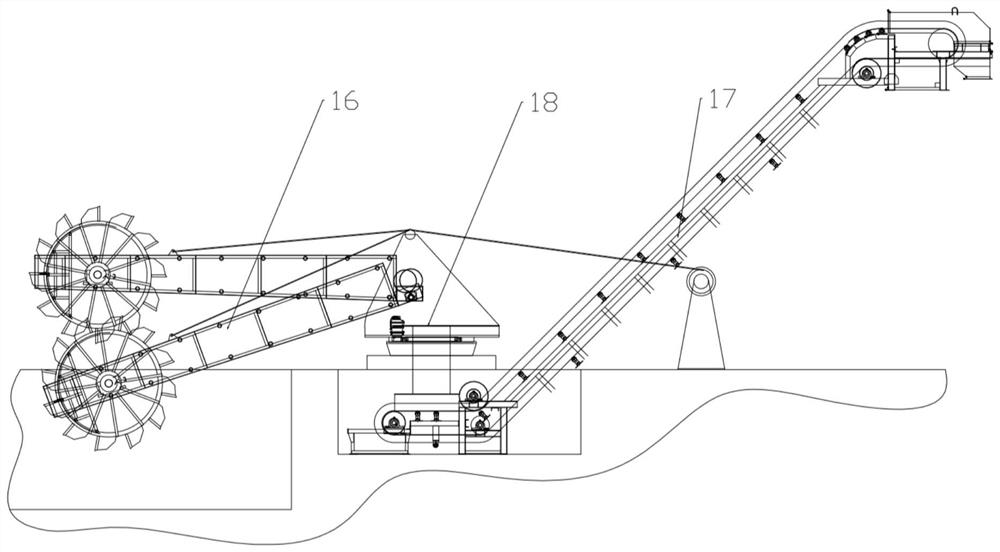

[0062] The feeding device includes a bucket wheel reclaimer 16, a large-angle belt conveyor 17 and a screening device 18. One end of the bucket wheel reclaimer 16 is located in the adjustment slag pit 1, and the The other end is set above the screening device 18 , one end of the high-angle belt conveyor 17 is set at the discharge port of the screening device 18 , and the other end of the high-angle belt conveyor 17 is connected to the feeder 2 .

[0063] When the slag is dry, low in water content and poor in fluidity, a bucket wheel reclaimer is used to reclaim the slag. The cost of a bucket wheel reclaimer is low. The power of the bucket wheel reclaimer is 60KW. The hoist assists the bucket wheel reclaimer to work within 60° in the horizontal direction and 20° in the vertical direction. The reclaiming depth is 2.75m from the plane where the muck pit is located. Within one hour, the bucket wheel reclaimer transports 200m3 of muck, and the muck passes through The screening devi...

Embodiment 3

[0075] The multi-stage sand washing device includes a first sand washing machine 14 and a second sand washing machine 15. The first sand washing machine 14 is connected to the underscreen chute 4 through a feeding mud pipe. The first sand washing machine 14 One end away from the feeding mud pipe is connected to the second sand washer 15 through the No. 1 logistics chute 19 , and the end of the second sand washer 15 away from the first sand washer 14 passes through the No. 2 logistics chute 20 The dewatering screen 5 is fixedly connected, and the dewatering screen 5, the first sand washing machine 14 and the second sand washing machine 15 are respectively connected with the sand washing overflow pool 6, and the interior of the sand washing overflow pool 6 is fixed. A stirring device 21 is provided.

[0076] The screening mud flows from the underscreen chute 4 to the feeding mud pipe and passes into the first sand washing machine 14 , and passes through the first sand washing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com