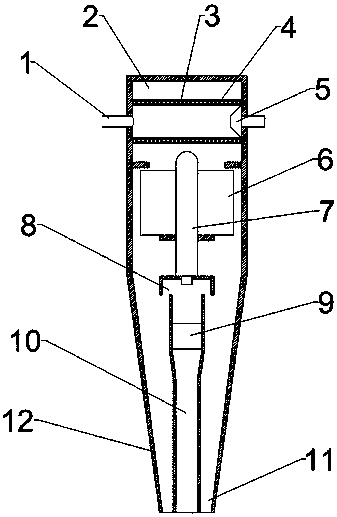

Oil well flow back liquid sand removing device

A technology for oil wells and feed chambers, which is used in wellbore/well components, production fluids, earth-moving drilling, etc. Lightening, improving production efficiency, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] First, the material liquid with sand is poured into the filter desanding device, and through the filtering effect of the hole tube 3 and the filter element 4, the large sand particles are first intercepted and deposited on the filter screen to form a filter cake, and the filter cake is then finer in the liquid phase. The suspended solid phase particles are intercepted, filtered to remove large sand particles, and then enter the feed chamber 2, and the impeller 6 is driven to rotate by the input kinetic energy of the external motor through the cyclone, thereby driving the liquid to change from static to rotary motion, so that the liquid rotates to generate powerful The centrifugal force, the rotating liquid moves down along the shell of the cyclone, so that the liquid obtains a certain static pressure, the liquid flow inside forms a three-dimensional spiral flow, the outer side is the outer swirling flow down the wall, and the inner side It is an upward internal swirl flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com