Vortex sand washing device

A technology of sand flushing and eddy current, which is applied in flushing wellbore, wellbore/well components, earth-moving drilling, etc. It can solve the problems of in-place, long time-consuming and failure of the process string, and achieve high operation success rate, flushing and other problems. High sand efficiency and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

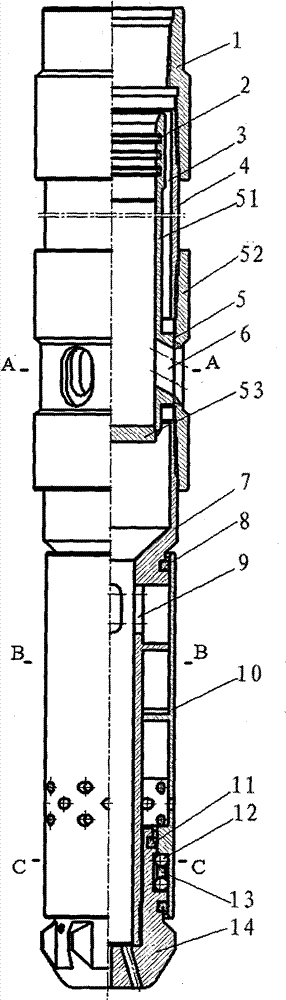

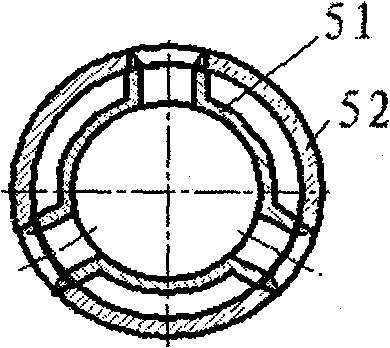

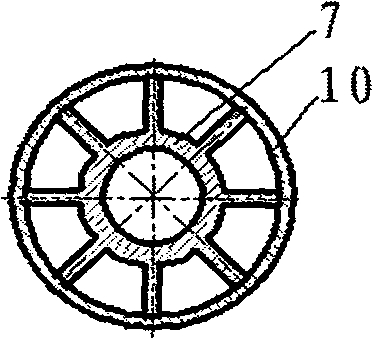

[0015] refer to Figure 1-Figure 4 , an eddy current sand washing device, comprising an upper joint, a short joint of oil pipe, a conversion body, a sand washing core pipe, a rotating body and a sand washing head. The upper joint 1 is sequentially connected with the tubing nipple 4, the conversion body 5, the sand washing core pipe 7, the rotating body 10 and the sand washing head 14; An annulus 3 is formed, and a plug 53 is installed at the lower end of the short joint 51 in the conversion body; there is a flow passage in the axial direction between the inner short joint 51 and the outer short joint 52 of the conversion body; the rotating body 10 is installed on the sand washing core pipe 7 and the outside of the sand washing head 14; a bearing hoop 13 is installed between the lower inner cavity of the rotating body 10 and the sand washing head 14, and a conversion hole 9 is arranged on the sand washing core pipe 7. A y-shaped sealing ring 11 is installed on the sand flushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com