Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Improve insertion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

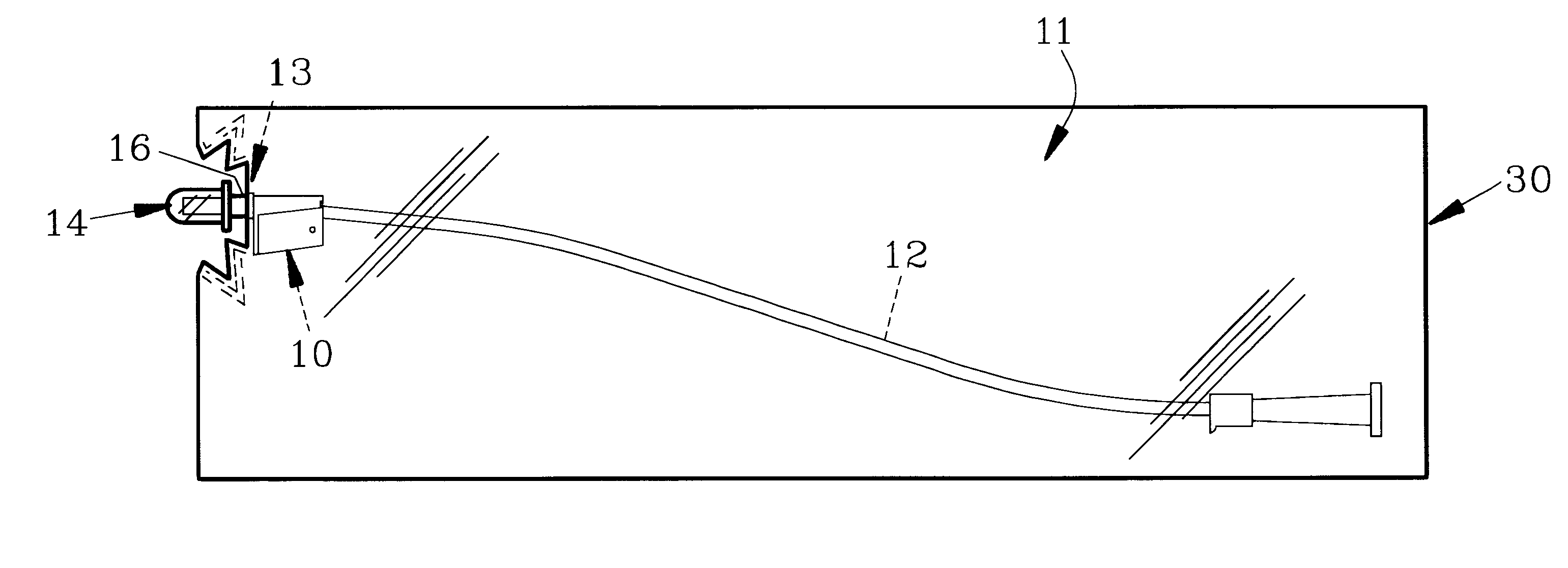

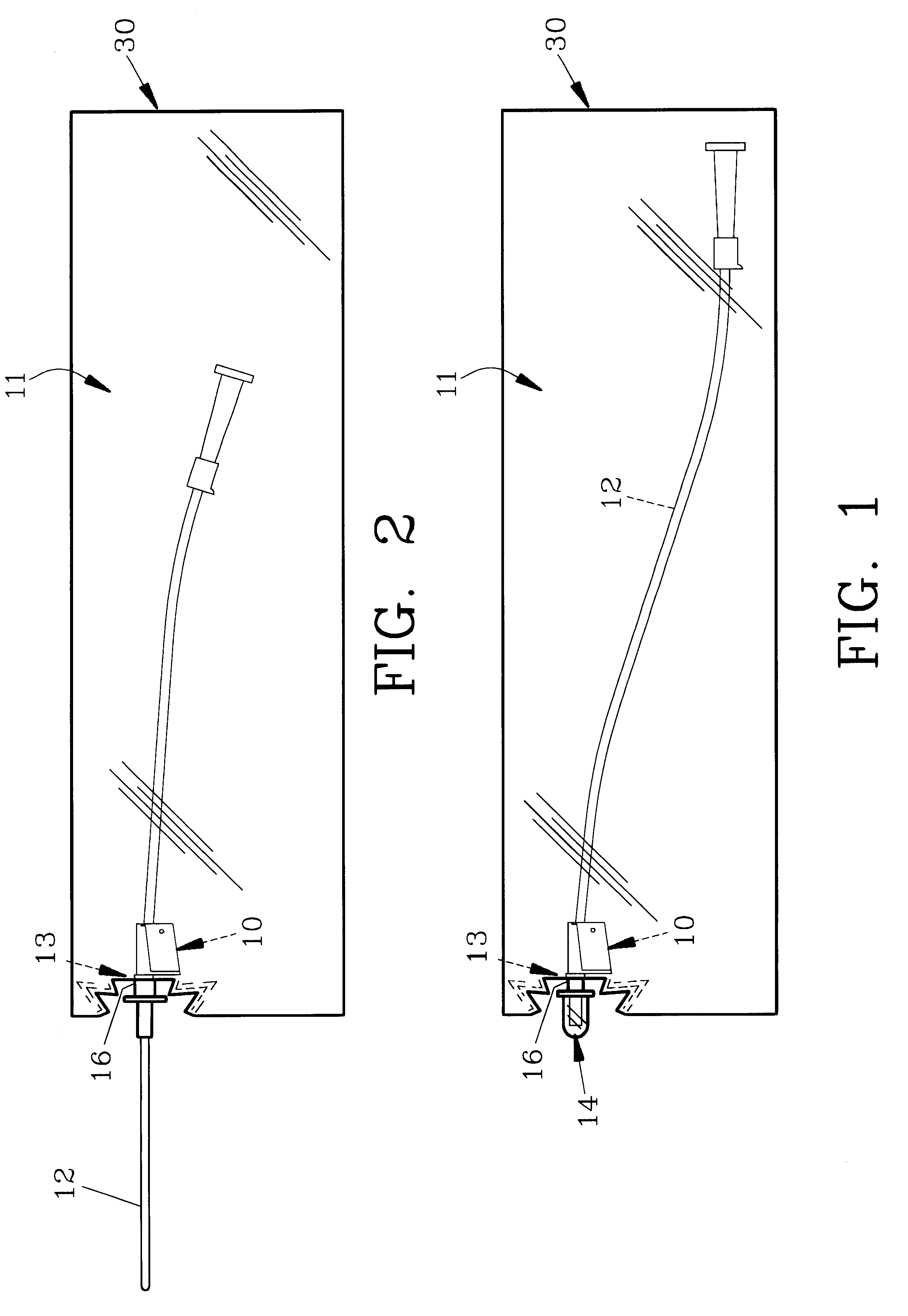

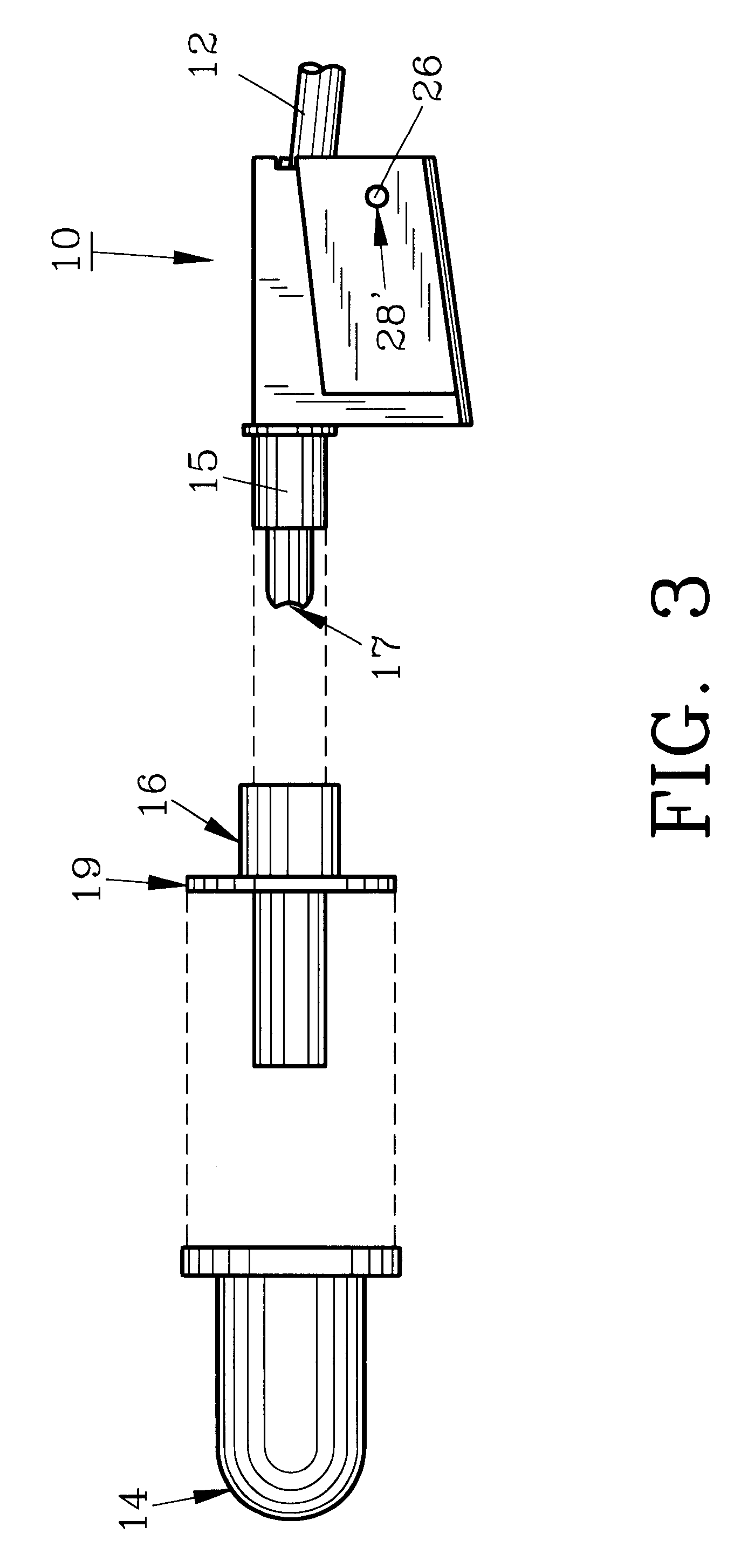

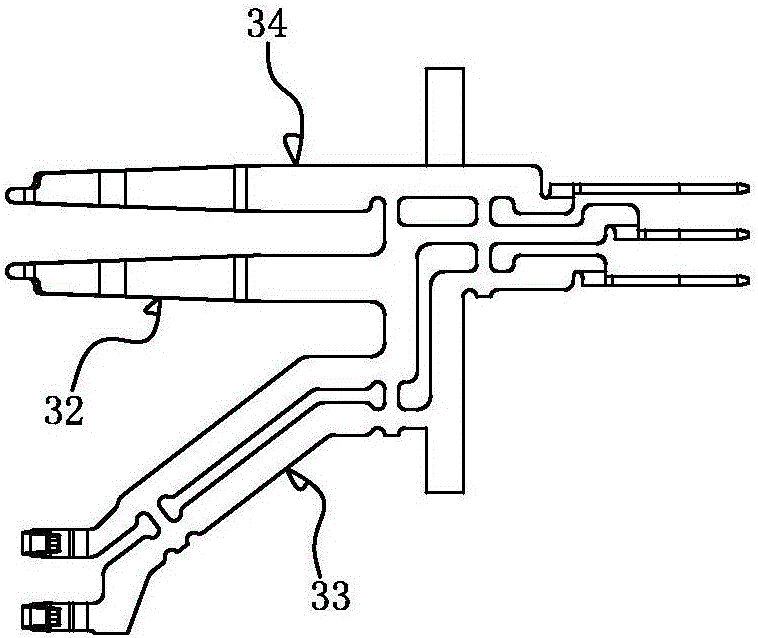

Catheter movement control device and method

InactiveUS6391010B1Minimize and eliminate manual touchingImprove insertion forceMedical devicesCatheterCatheter insertionMovement control

A catheter movement control device is provided which allows forward, extending movement of the catheter tube contained within a flexible package to the exterior thereof as required during insertion. The method of use includes moving the catheter tube through the control device to exit the catheter package where it is inserted into the urethra. If resistance is encountered during insertion a stop member firmly engages the catheter tube to prevent rearward movement of the catheter tube under normal urging.

Owner:MEDICAL TECH OF GEORGIA

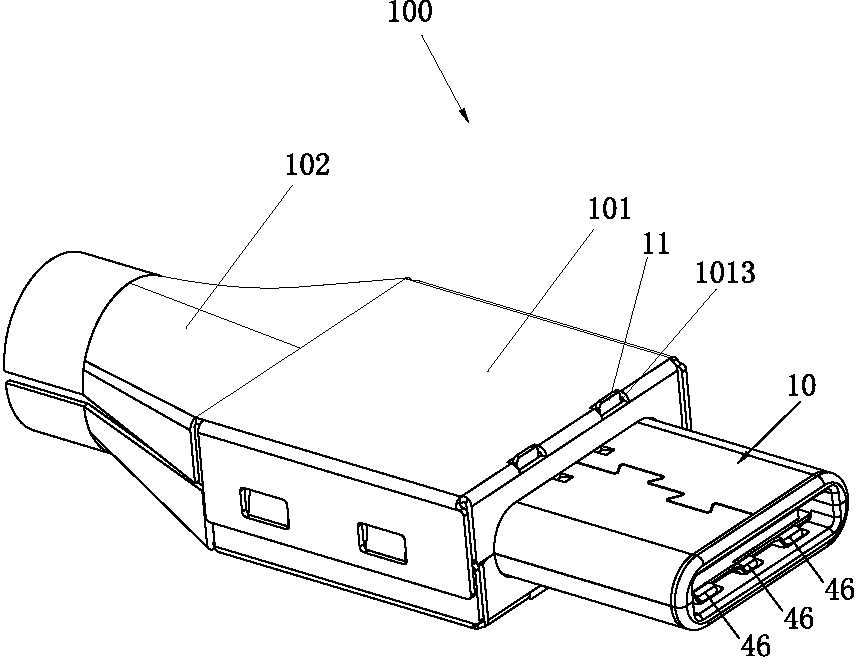

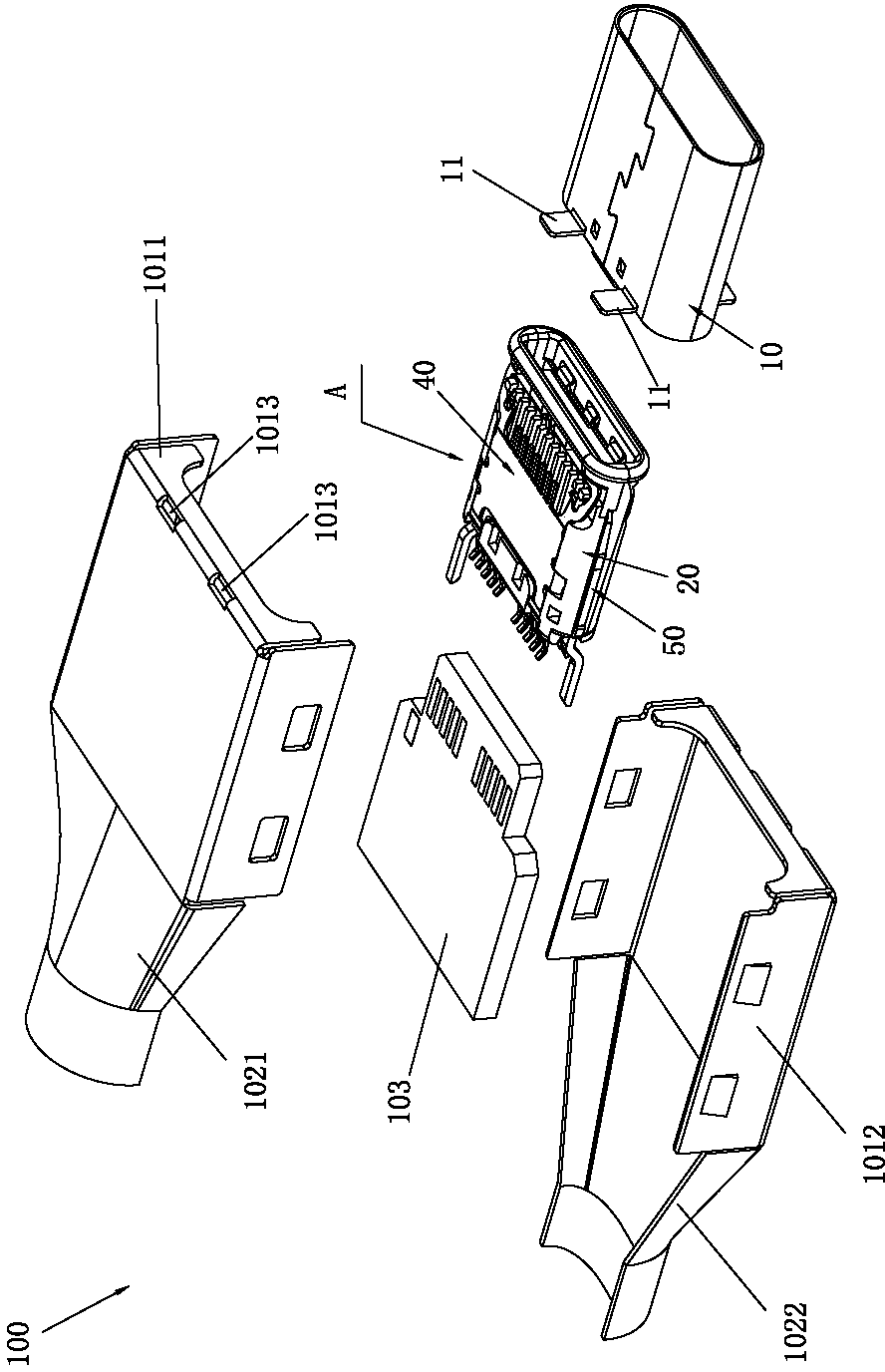

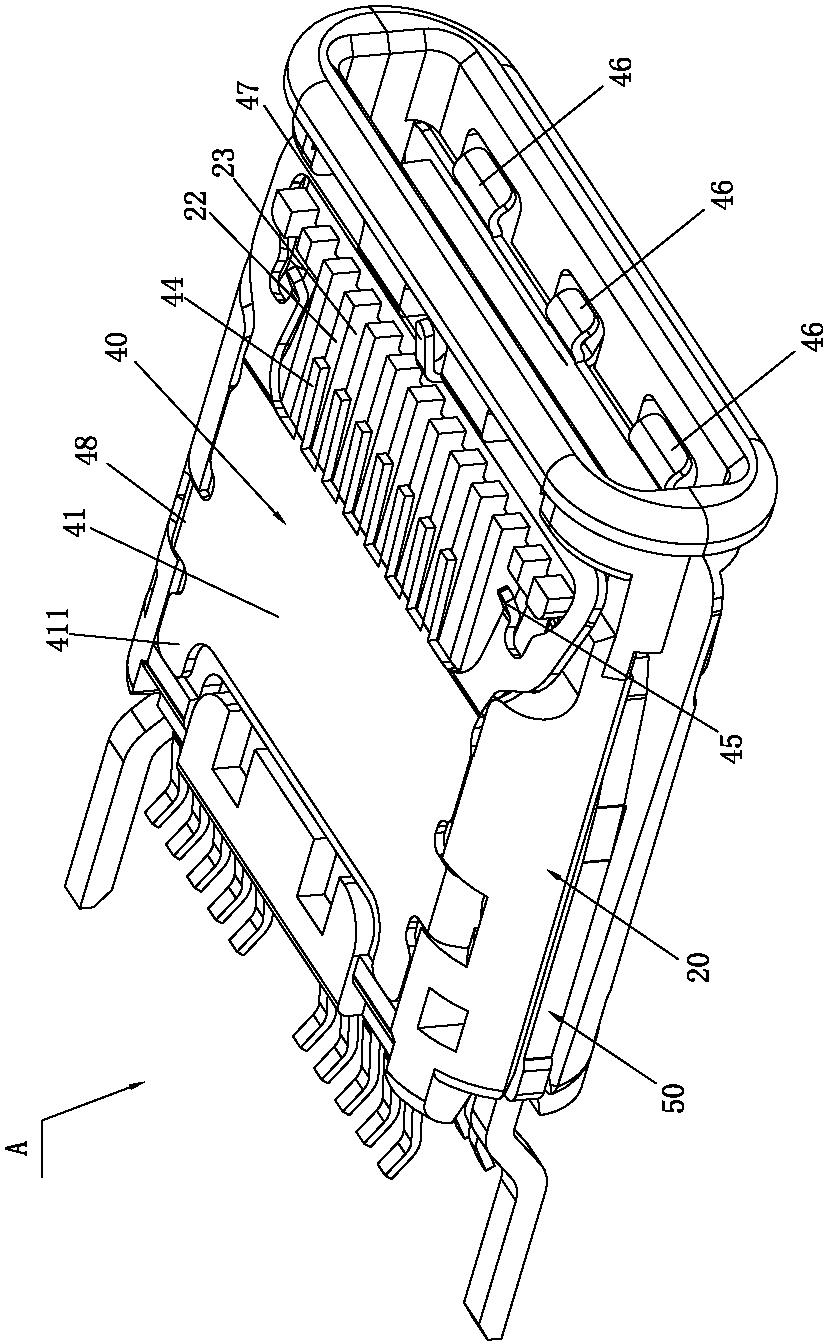

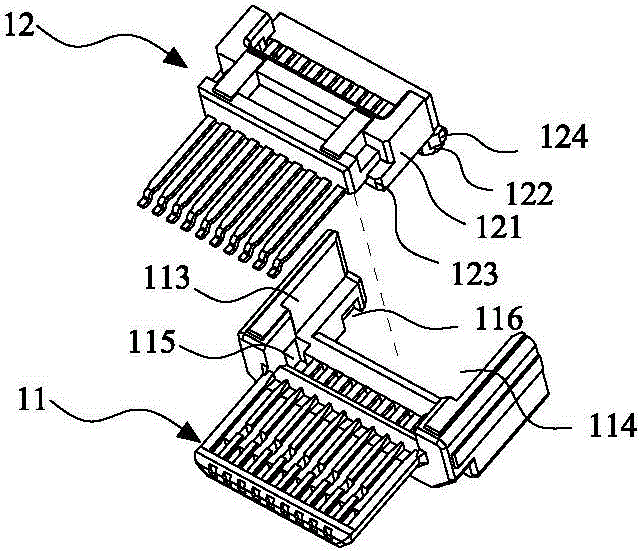

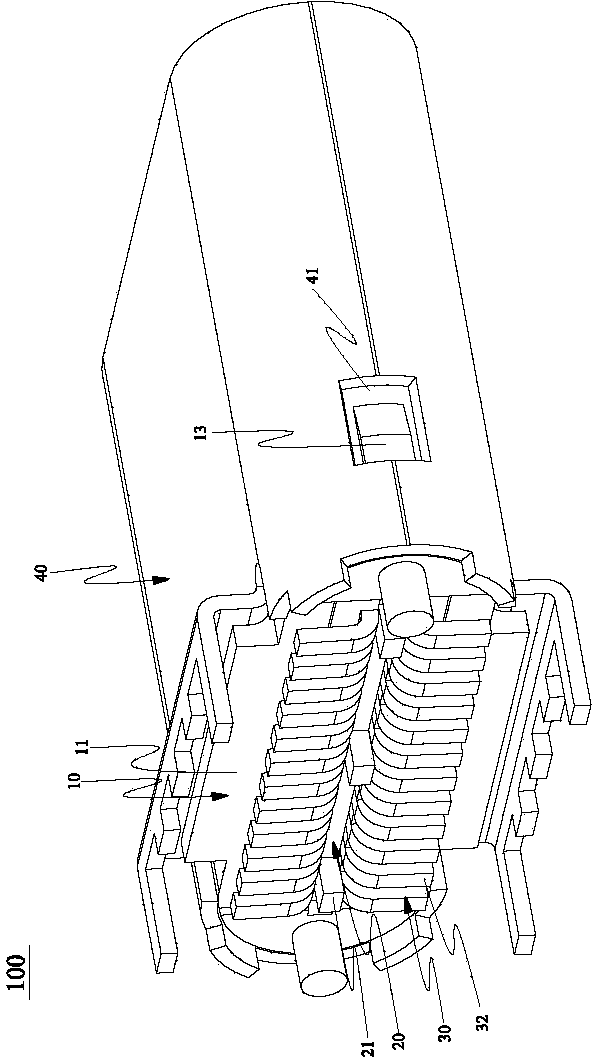

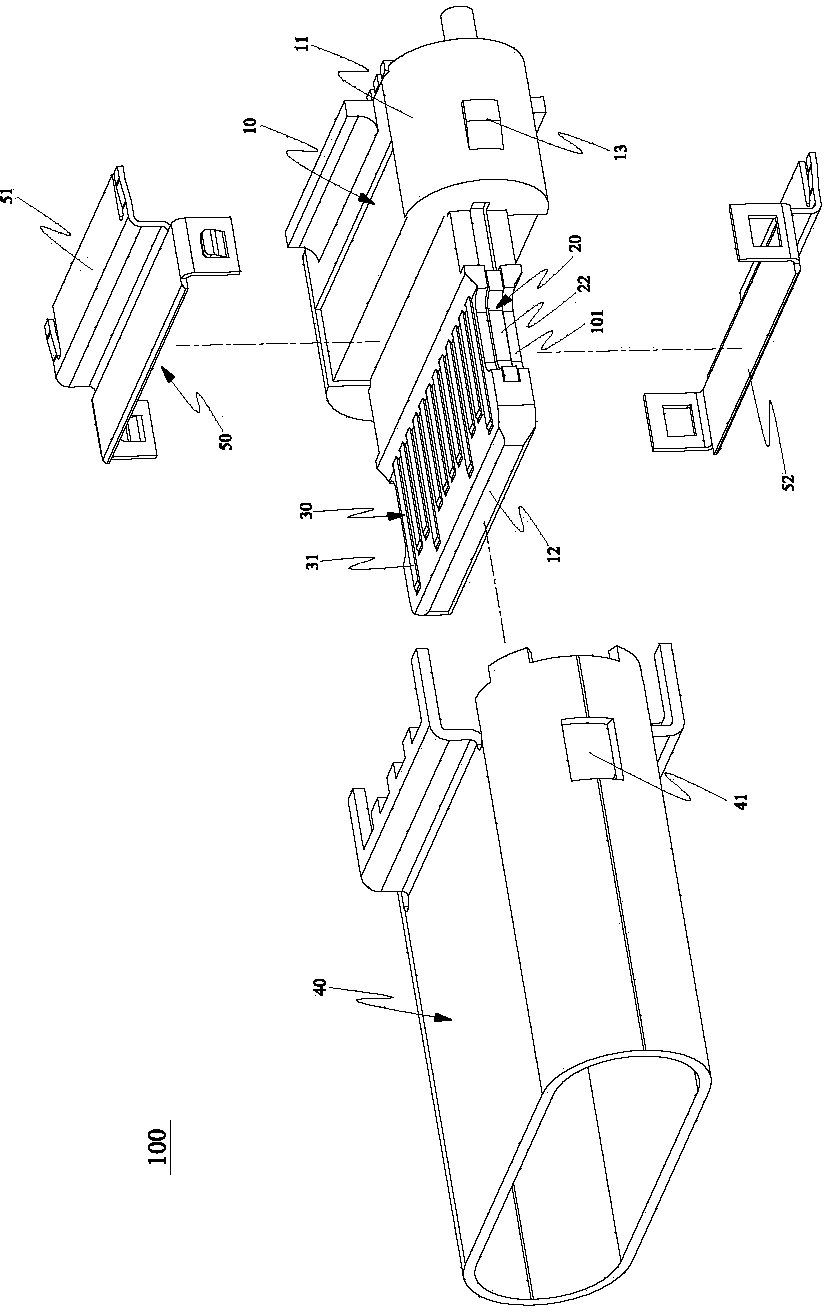

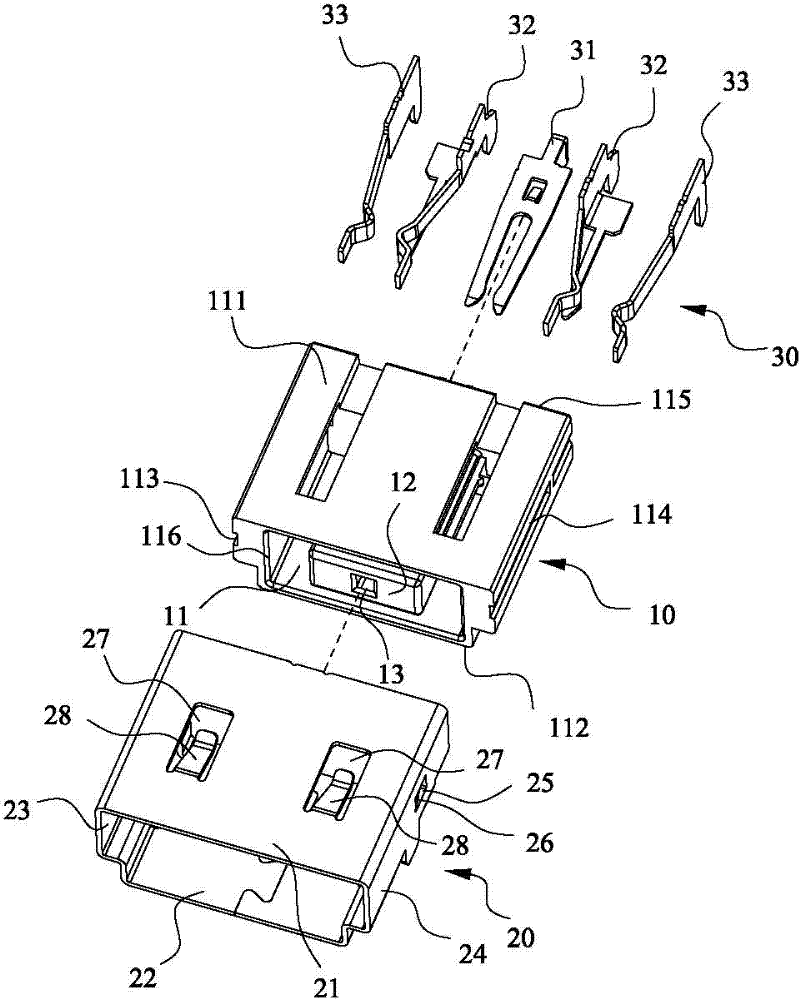

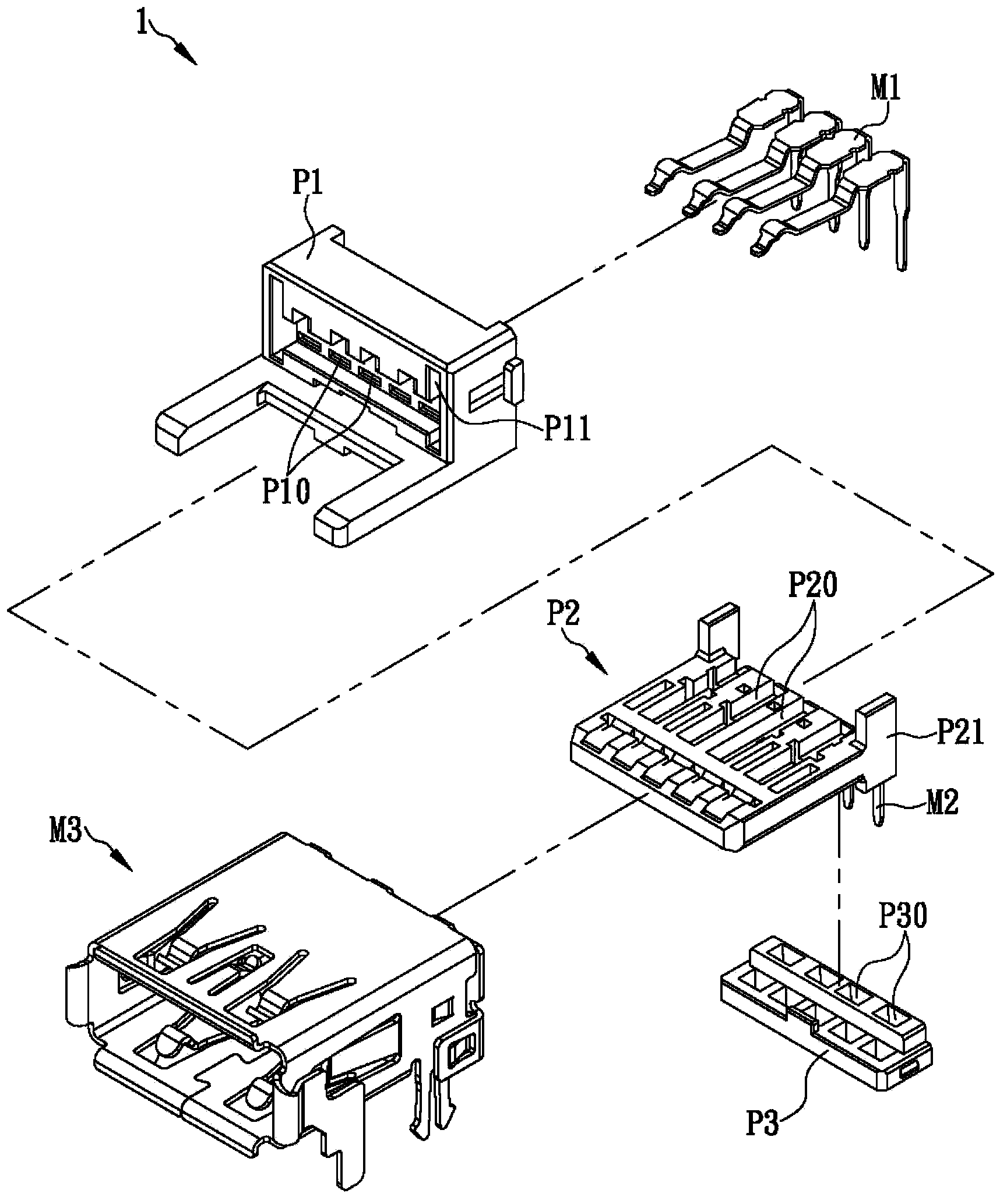

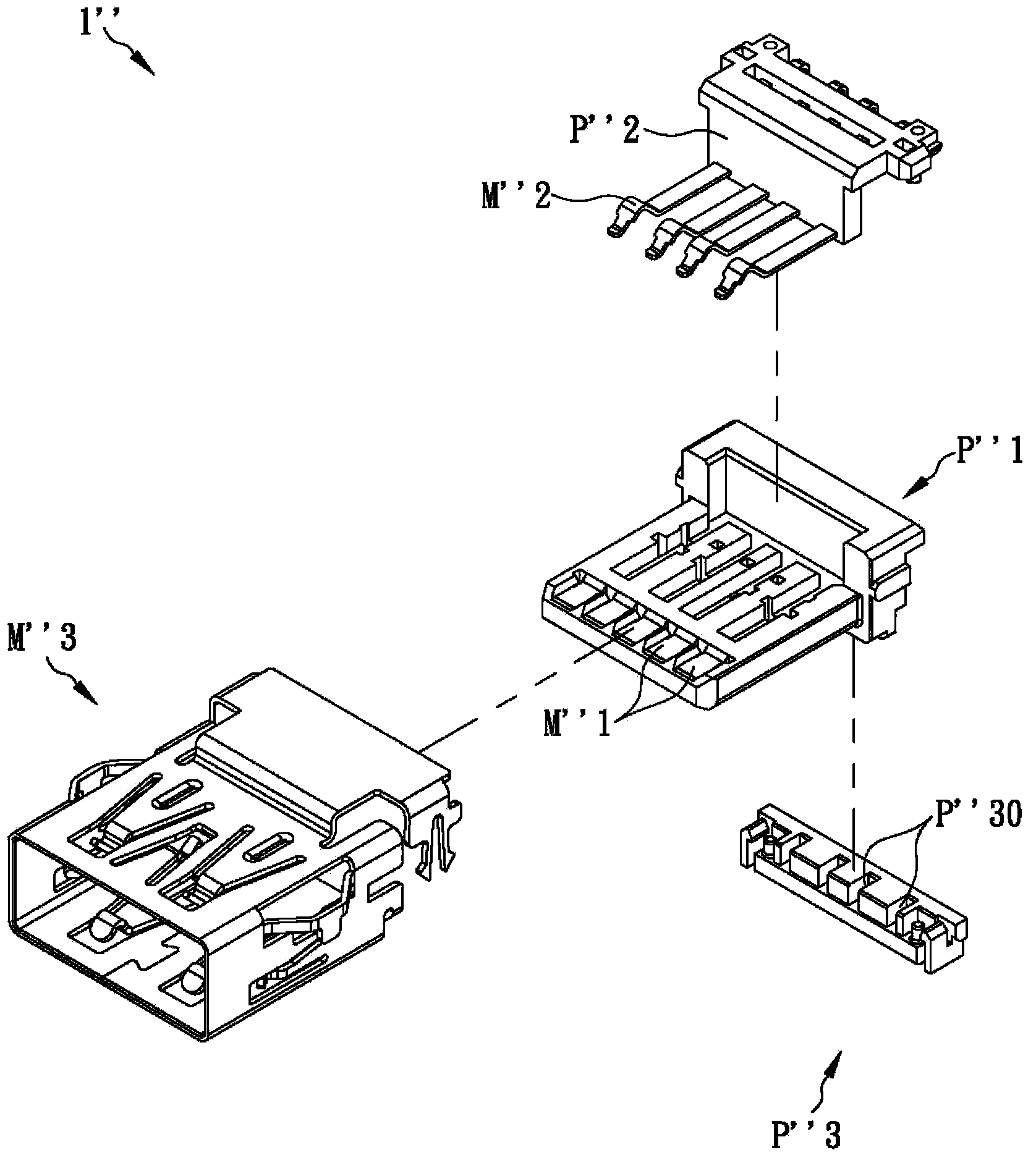

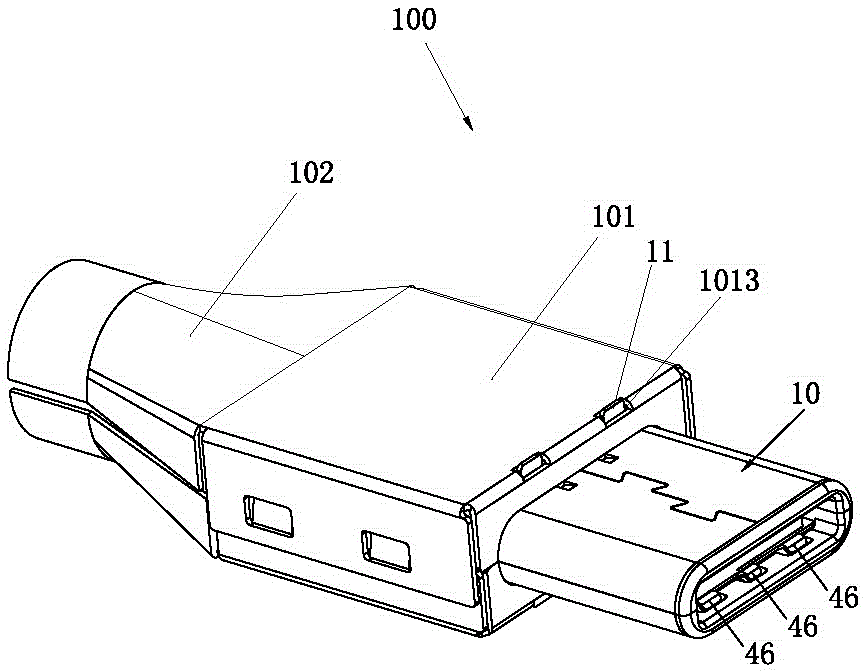

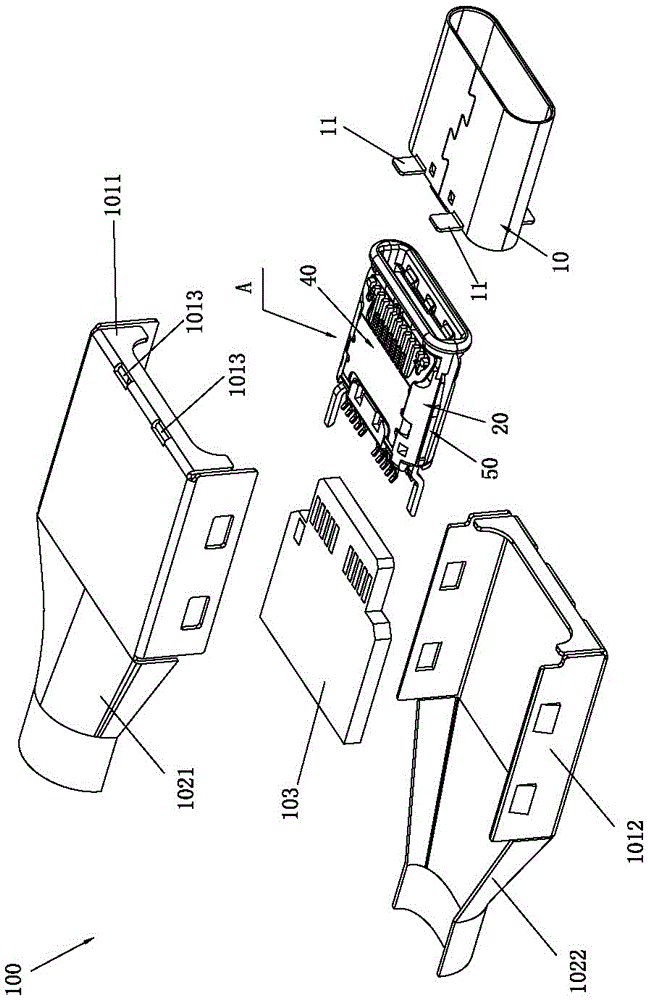

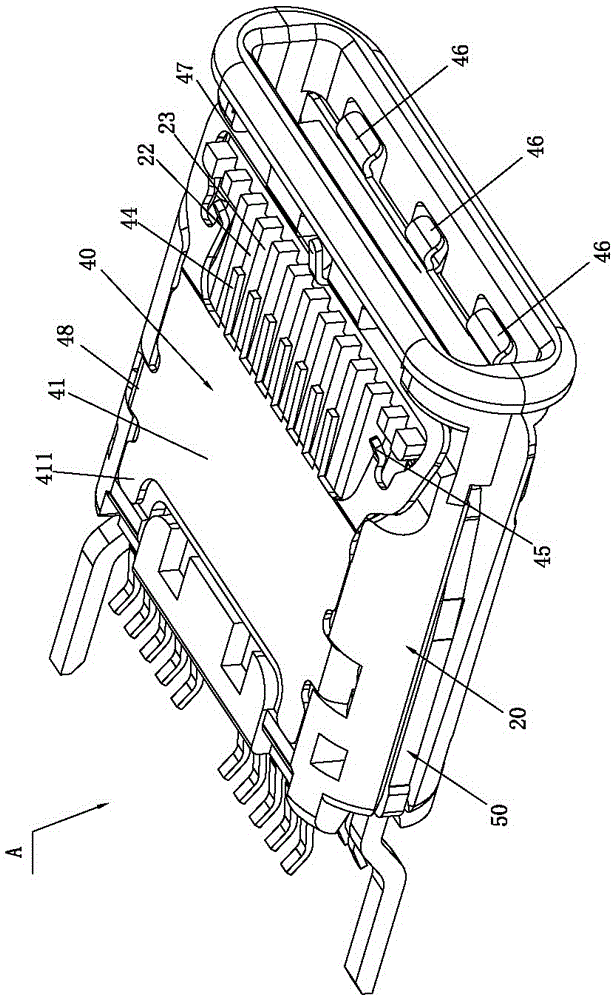

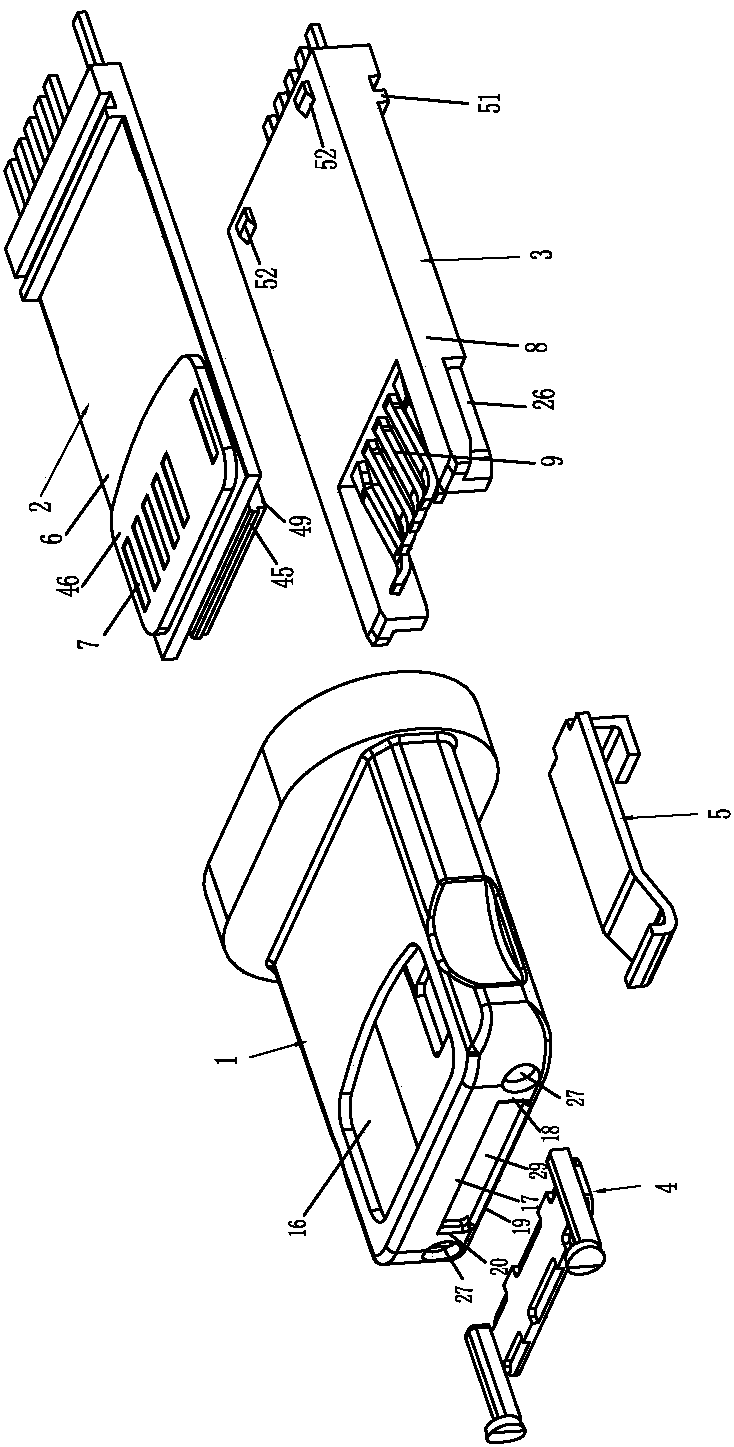

Connector plug, connector socket and connector combination of connector plug and connector socket

ActiveCN104241975AReduce distractionsImprove shielding effectCoupling contact membersEngineeringContact mode

The invention discloses a connector plug, a connector socket and a connector combination of the connector plug and the connector socket. The plug and the socket respectively comprise an insulating body, two rows of contact terminals, two baffles and a shielding shell. The plug is internally provided with the upper baffle and the lower baffle for the contact terminals, and the socket is internally provided with the upper baffle and the lower baffle for the contact terminals, the baffles of the contact terminals are conducted with the corresponding shielding shells in a contact mode so as to improve the shielding effect and to ensure that contact transmission is stable. The socket baffles are provided with contact elastic sheets, when the plug and the socket are combined, the contact elastic sheets make elastic contact with the socket baffles to form a shielding protection loop, the signal interference between the different rows of contact terminals is further avoided, and the plugging force of the connector combination can be enhanced. The connector plug and the connector socket are internally and respectively provided with hook plates and partition plates to separate the two rows of contact terminals, the hook plates and the partition plates are conducted with the corresponding shielding shells in a contact mode, inverted hook parts of hooks are buckled in the concave parts of the partition plates, and the inverted hook parts are conducted with the concave parts of the partition plates in a contact mode.

Owner:SHENZHEN LITKCONN TECH

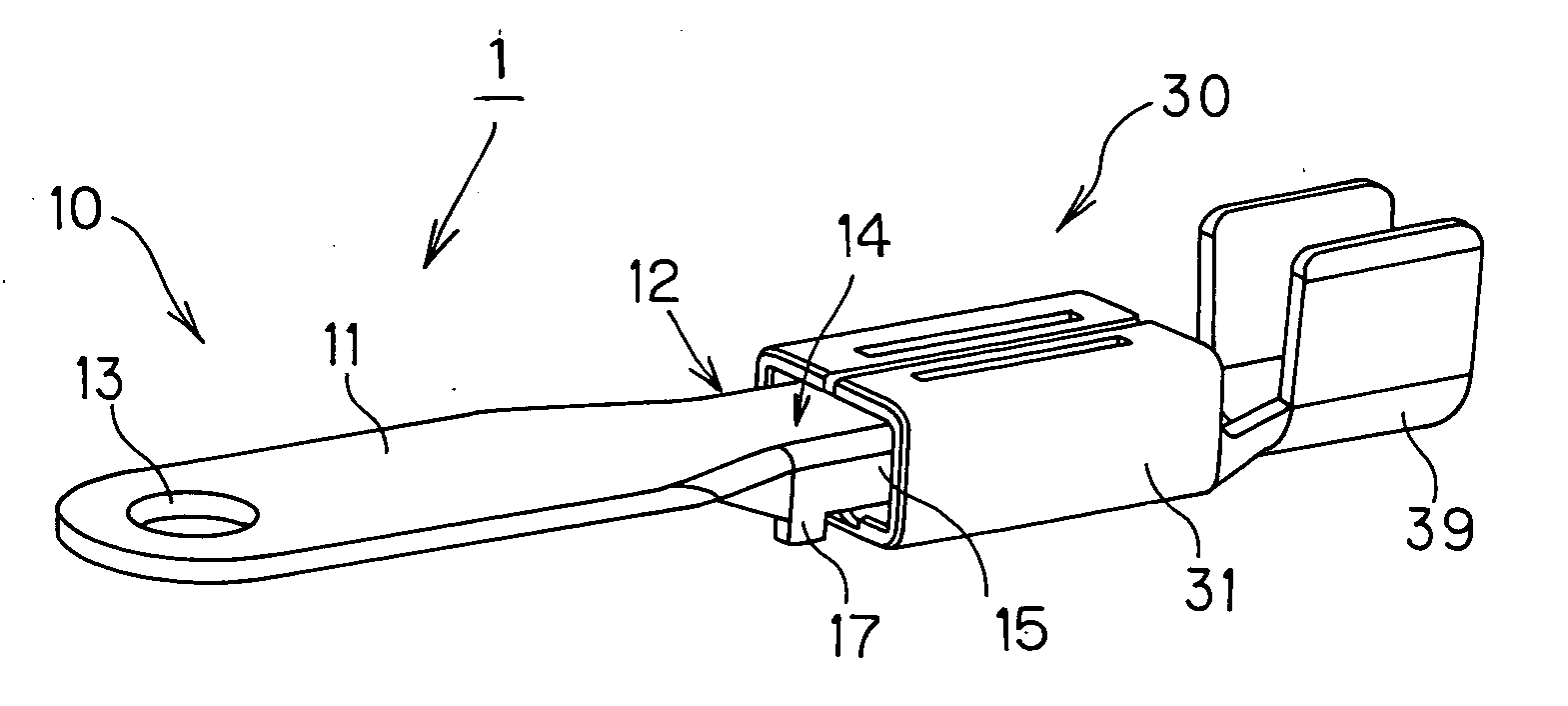

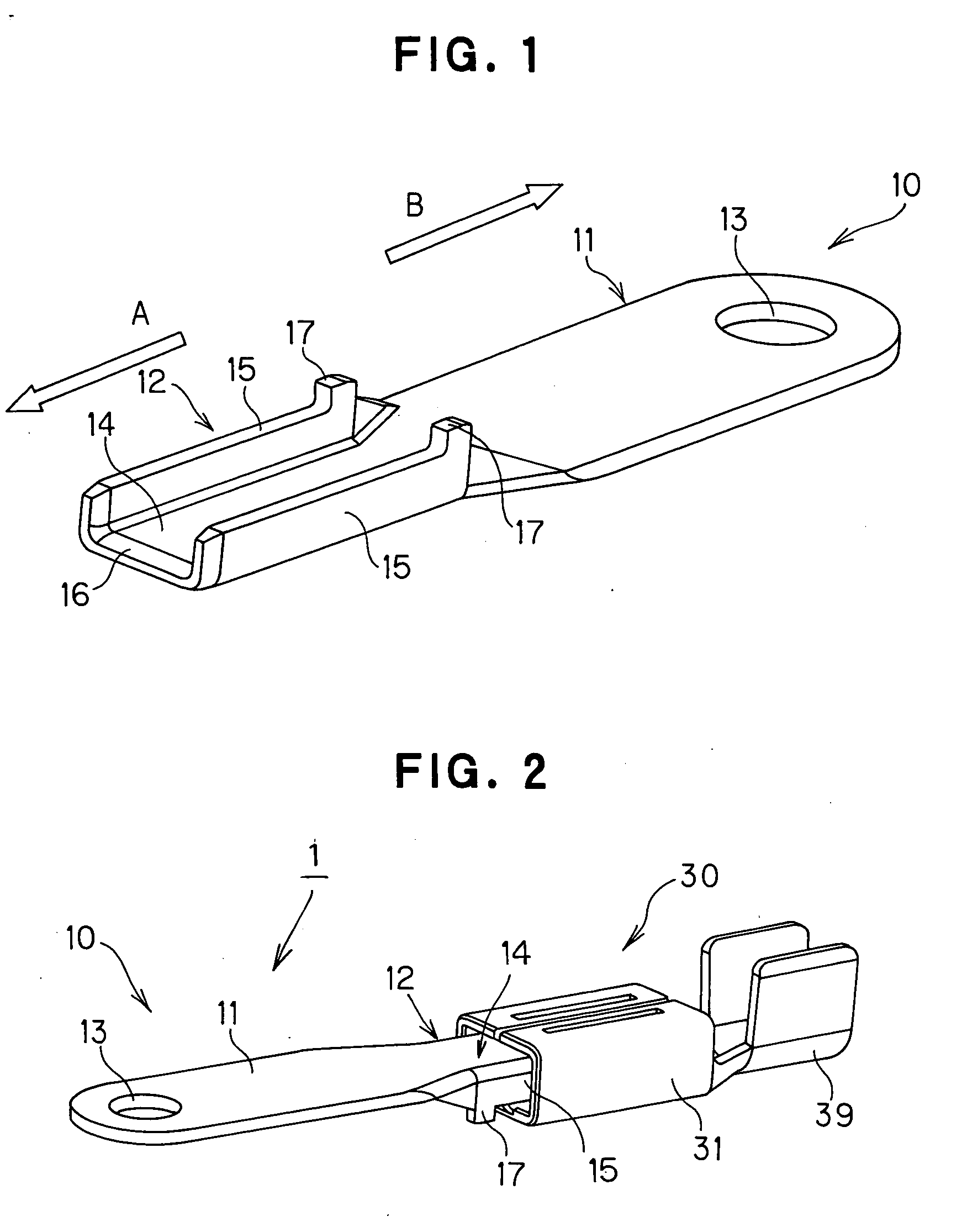

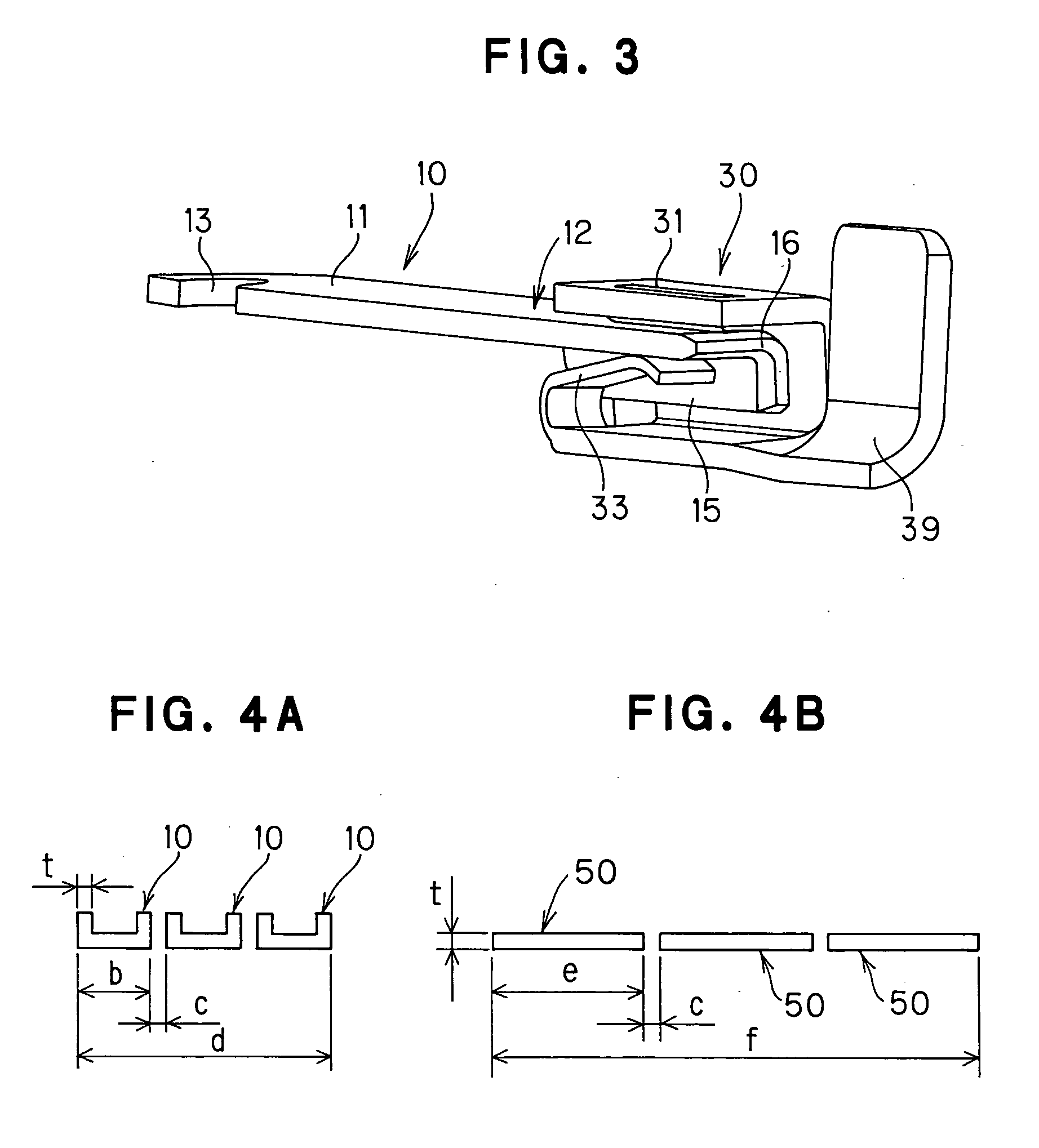

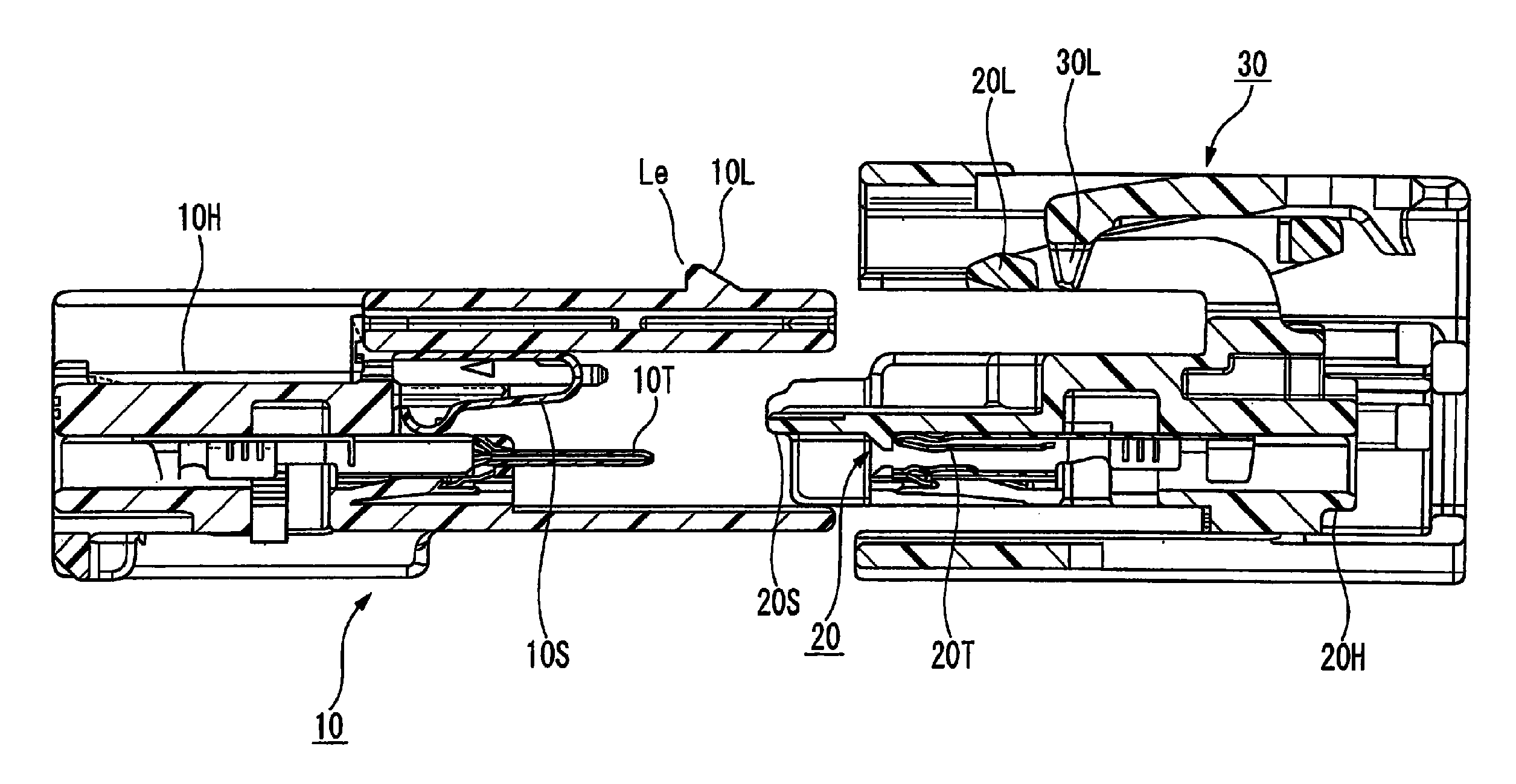

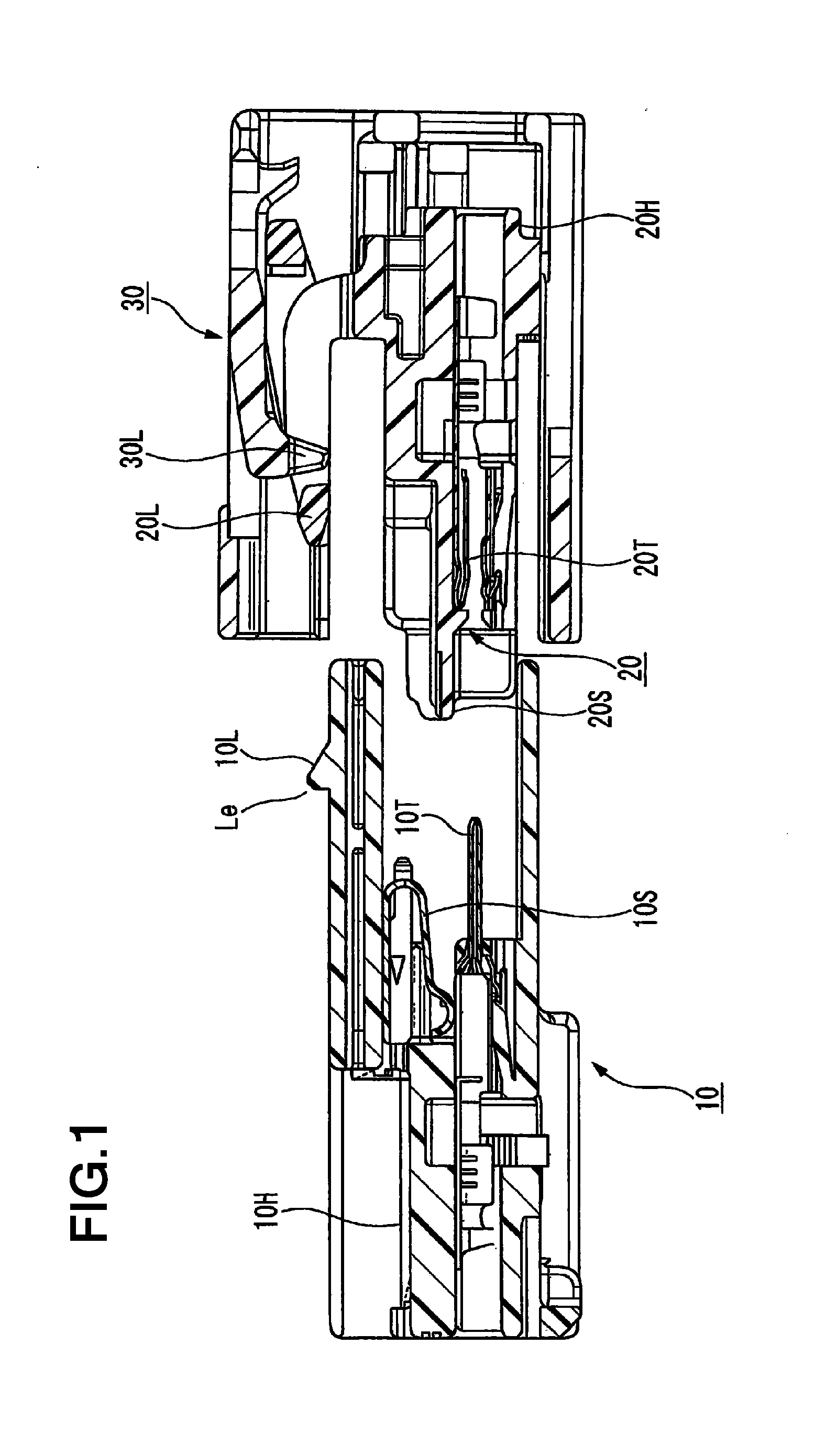

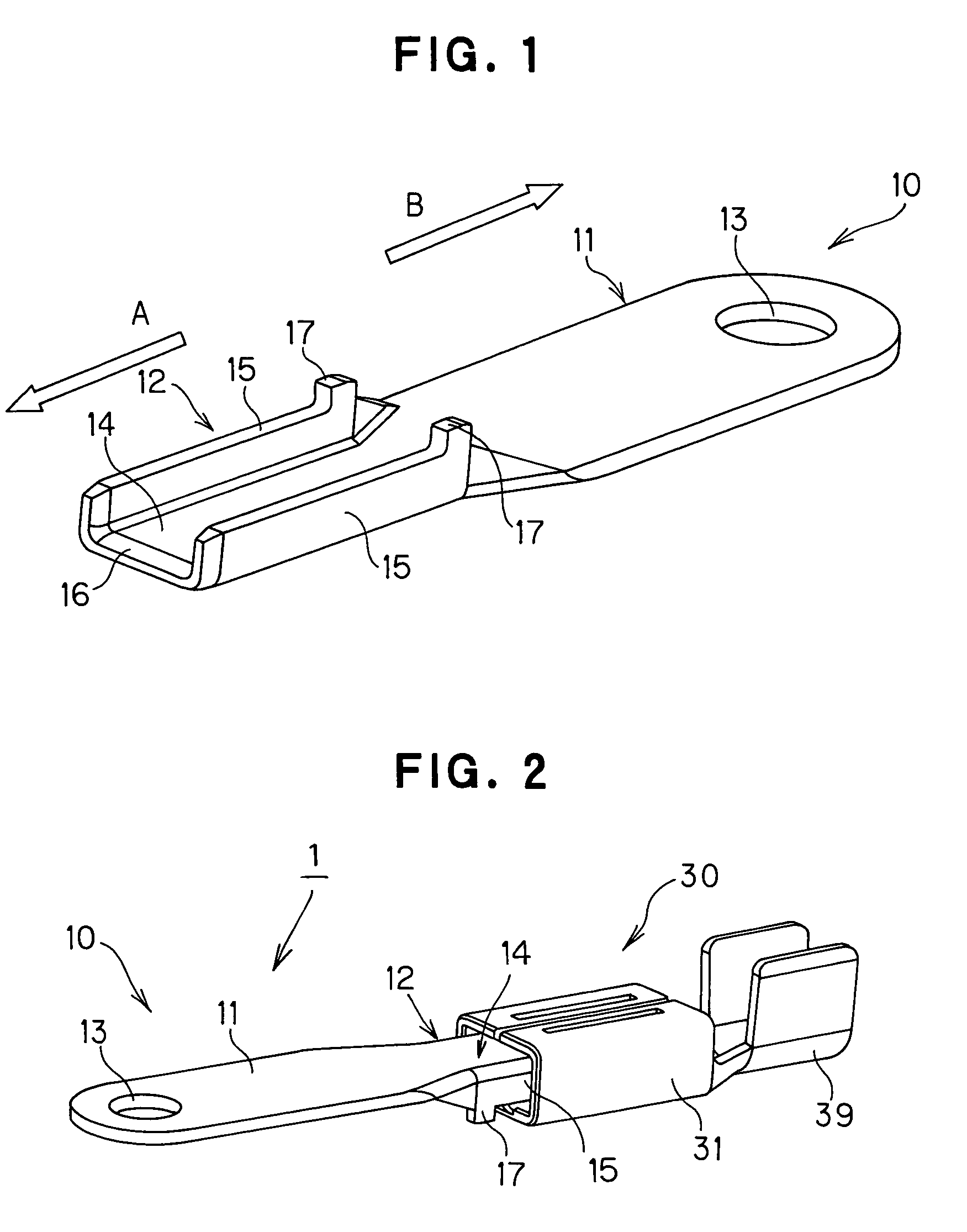

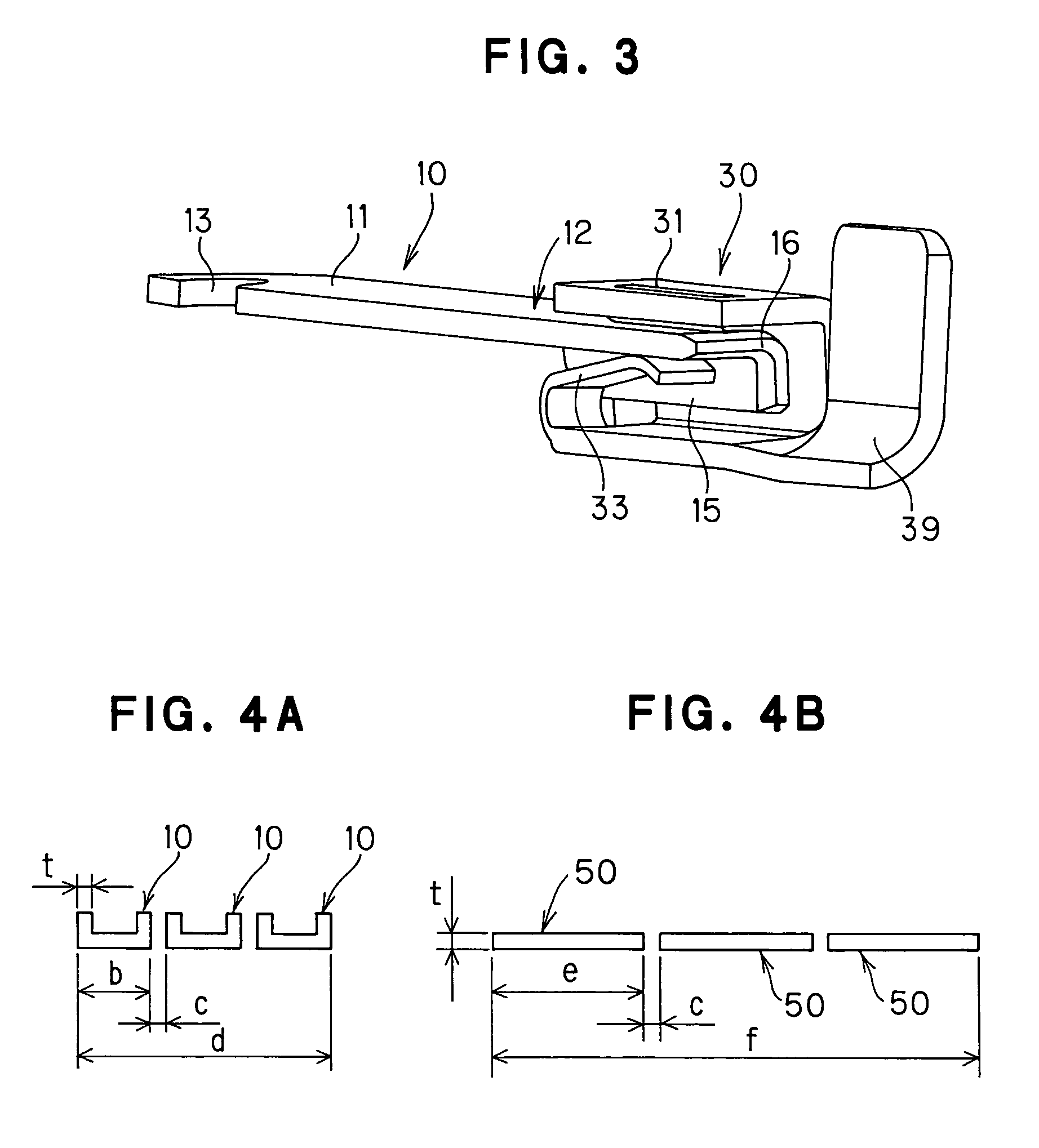

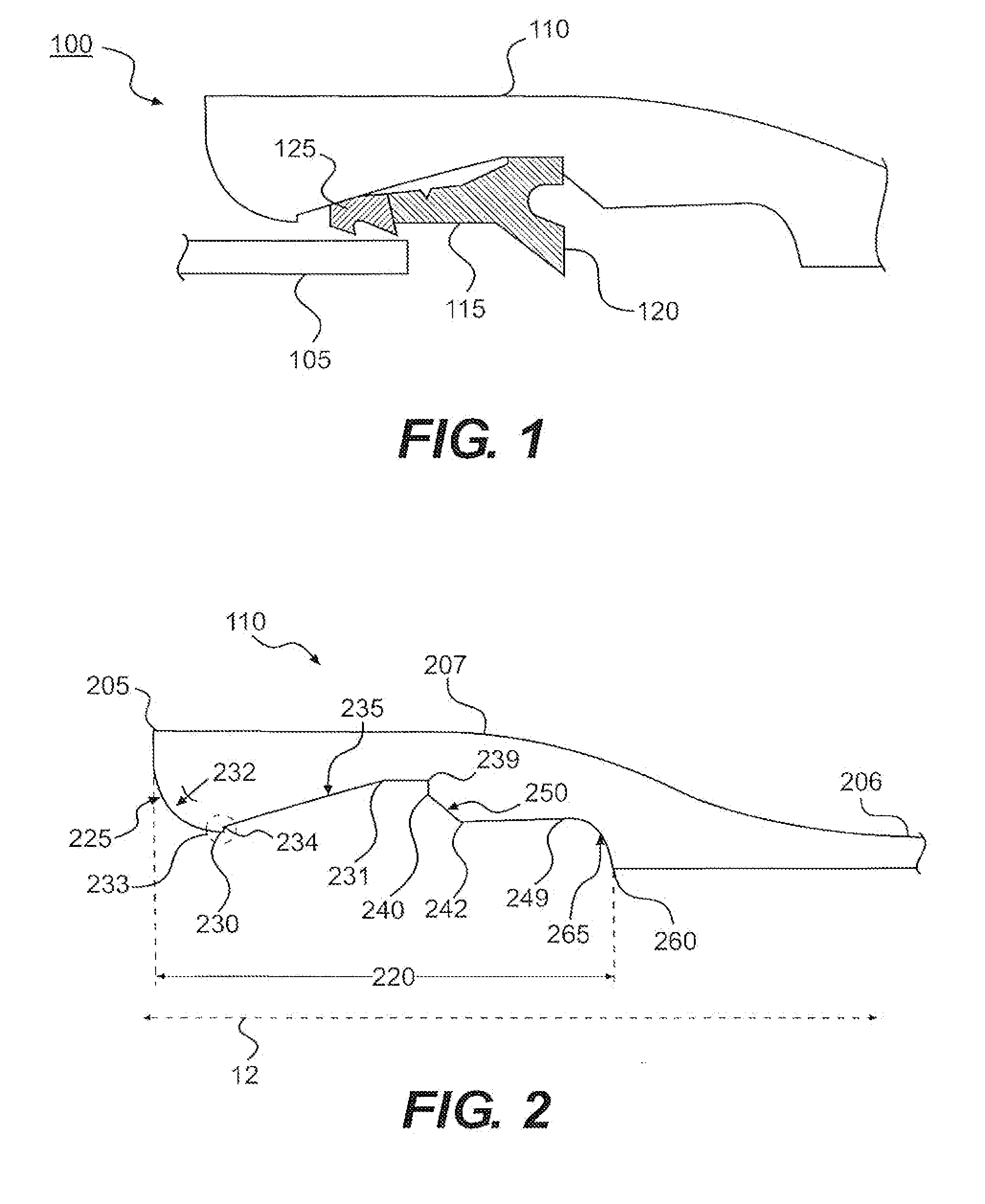

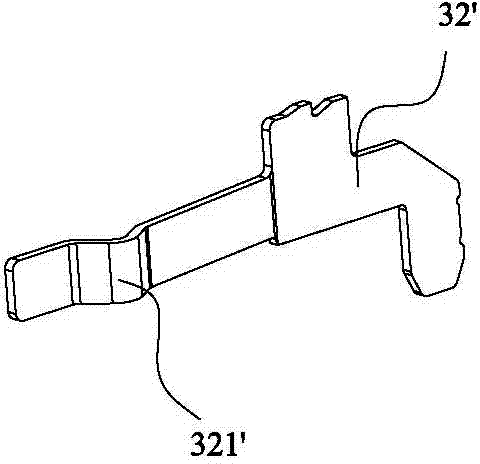

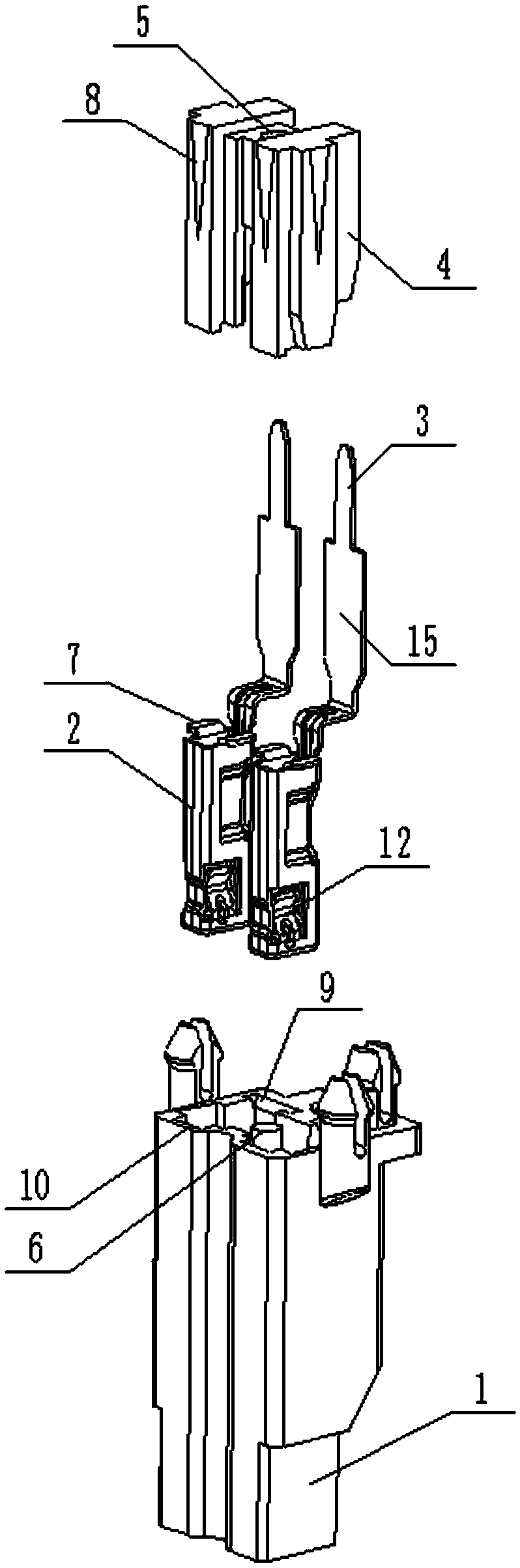

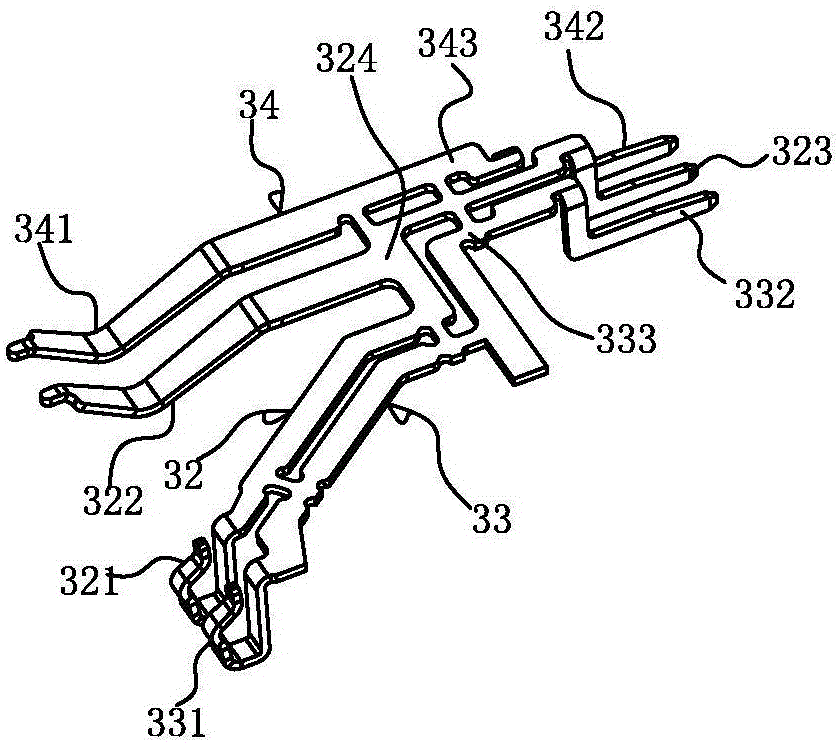

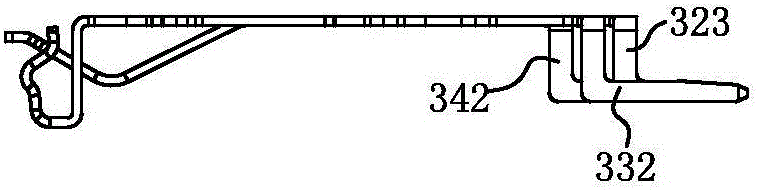

Connector structure having a male terminal and a female terminal

InactiveUS20070149050A1Improve cooling effectFirmly connectedSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

A male terminal 10 has a wire connecting portion 13 at one end to be connected to an electric wire, and an inserting contact portion 12 at another end to be inserted into a female terminal 30. A plate member of the inserting contact portion 12 is bent to have a U-shape cross section. The female terminal 30 has a terminal energizing portion 31 composed of a high conductivity material having a frame structure for accommodating the male terminal 10, a terminal box 32 composed of a material having a strength higher than that of the high conductivity material of the terminal energizing portion 31 for covering the terminal energizing portion 31, and a spring 33 located within the terminal energizing portion 31 for fixing the male terminal 10. The spring 33 is formed integrally with the terminal box 32.

Owner:HITACHI METALS LTD

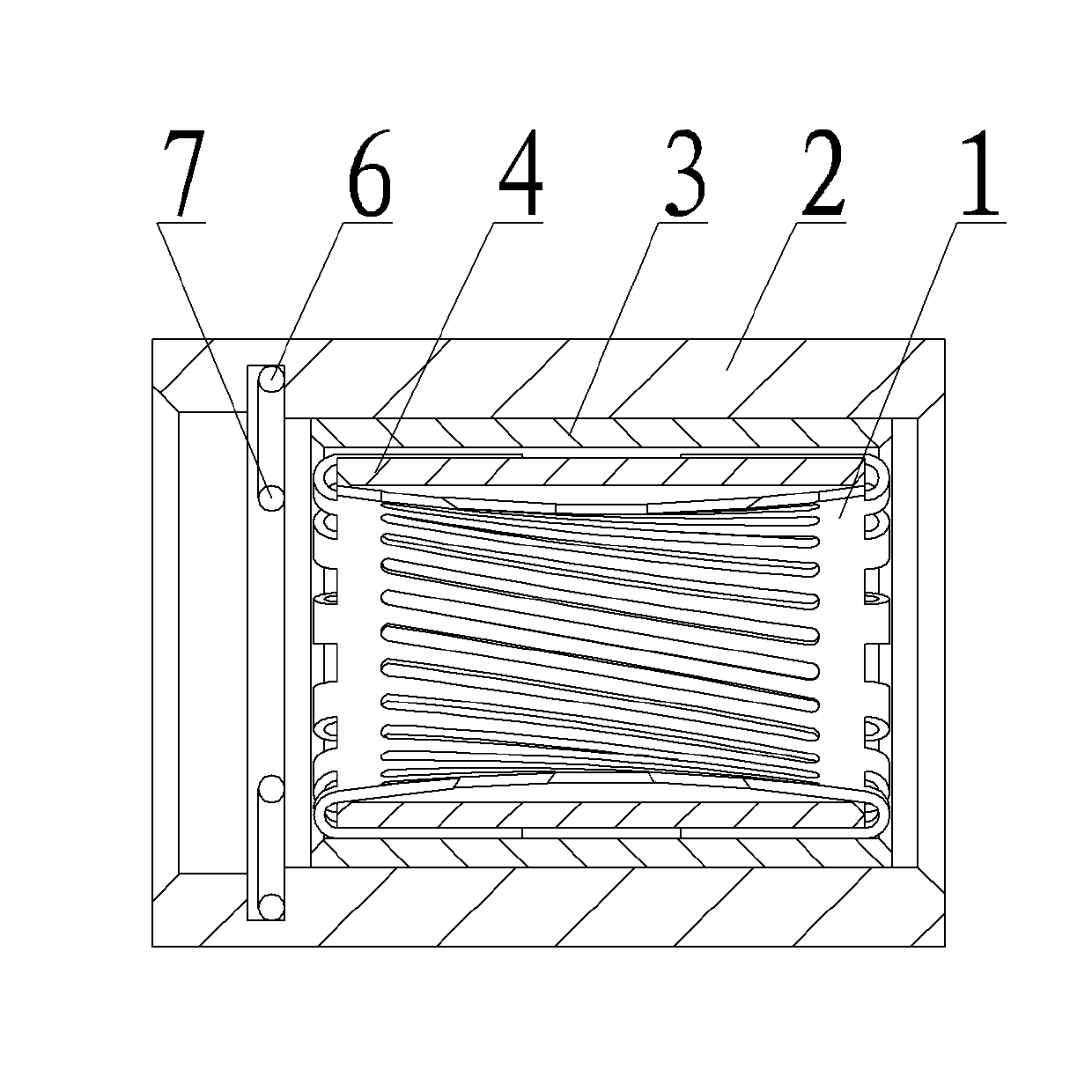

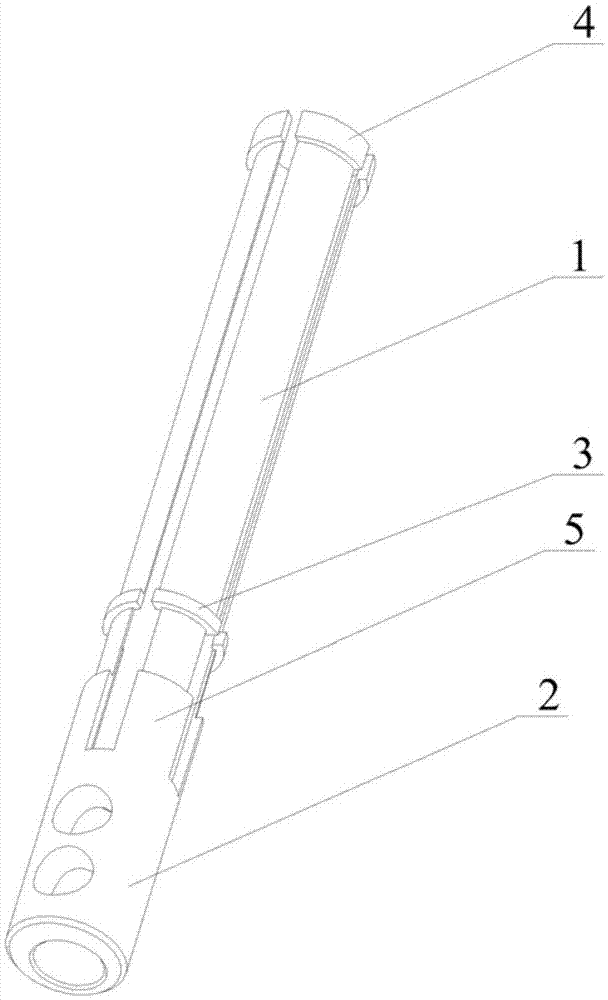

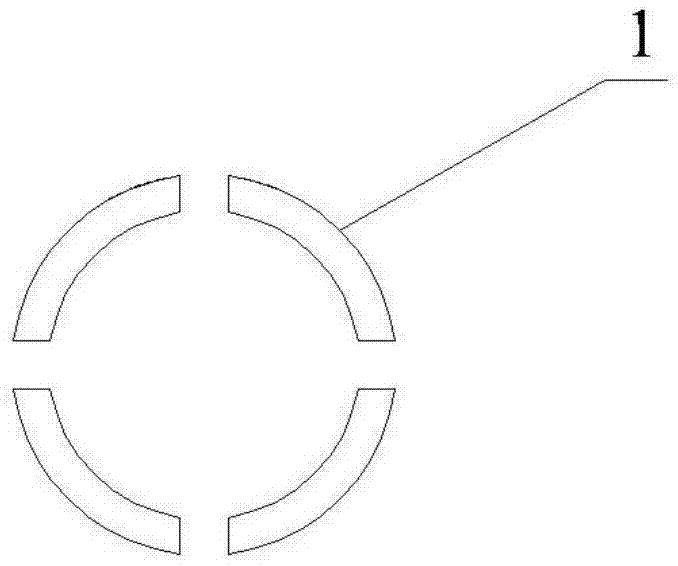

Crown spring cage tyep pin and jack component and jack thereof

InactiveCN102005663AImprove insertion forcePlug firmlyCoupling contact membersBiomedical engineering

The invention relates to a crown spring cage tyep pin and jack component and a jack thereof. the crown spring cage tyep jack comprises an inner sleeve, wherein an outer sleeve is sleeved outside the inner sleeve, a crown spring penetrates through the inner bore of the inner sleeve; two parallel elastic clamping strips are symmetrically arranged on the port part of the inner bore of the outer sleeve; and the distance between the two elastic clamping strips is less than the minimum internal diameter of the crown spring. The crown spring cage tyep pin and jack component comprises a pin and a jack, wherein the jack contains the inner sleeve; the outer sleeve is sleeved outside the inner sleeve, the crown spring penetrates through the inner bore of the inner sleeve; the two parallel elastic clamping strips are symmetrically arranged on the port part of the inner bore of the outer sleeve, the distance between the two elastic clamping strips is less than the internal diameter of the crown spring; and the pin contains a needle-like connection-peg, and the circumference surface of the needle-like connection-peg is provided with a clamping structure which fits with the two elastic clamping strips in a clamping manner. The elastic clamping strips are arranged on the port part of the jack; and during plugging, the clamping structure on the pin fits with the elastic clamping strips in the clamping manner, thus the reliable plugging of the pin and the jack can be realized and the pin is difficult to separate from the jack.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

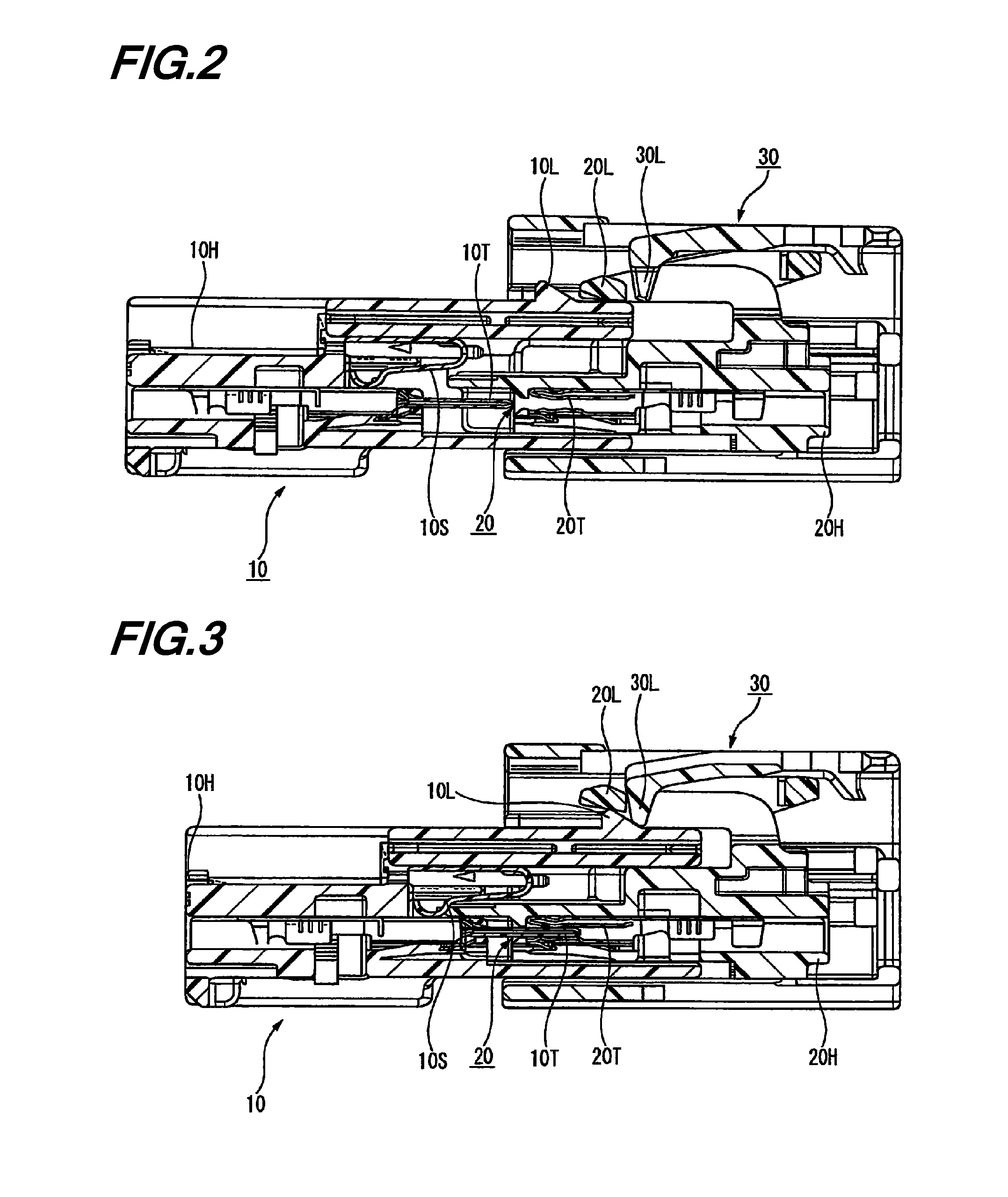

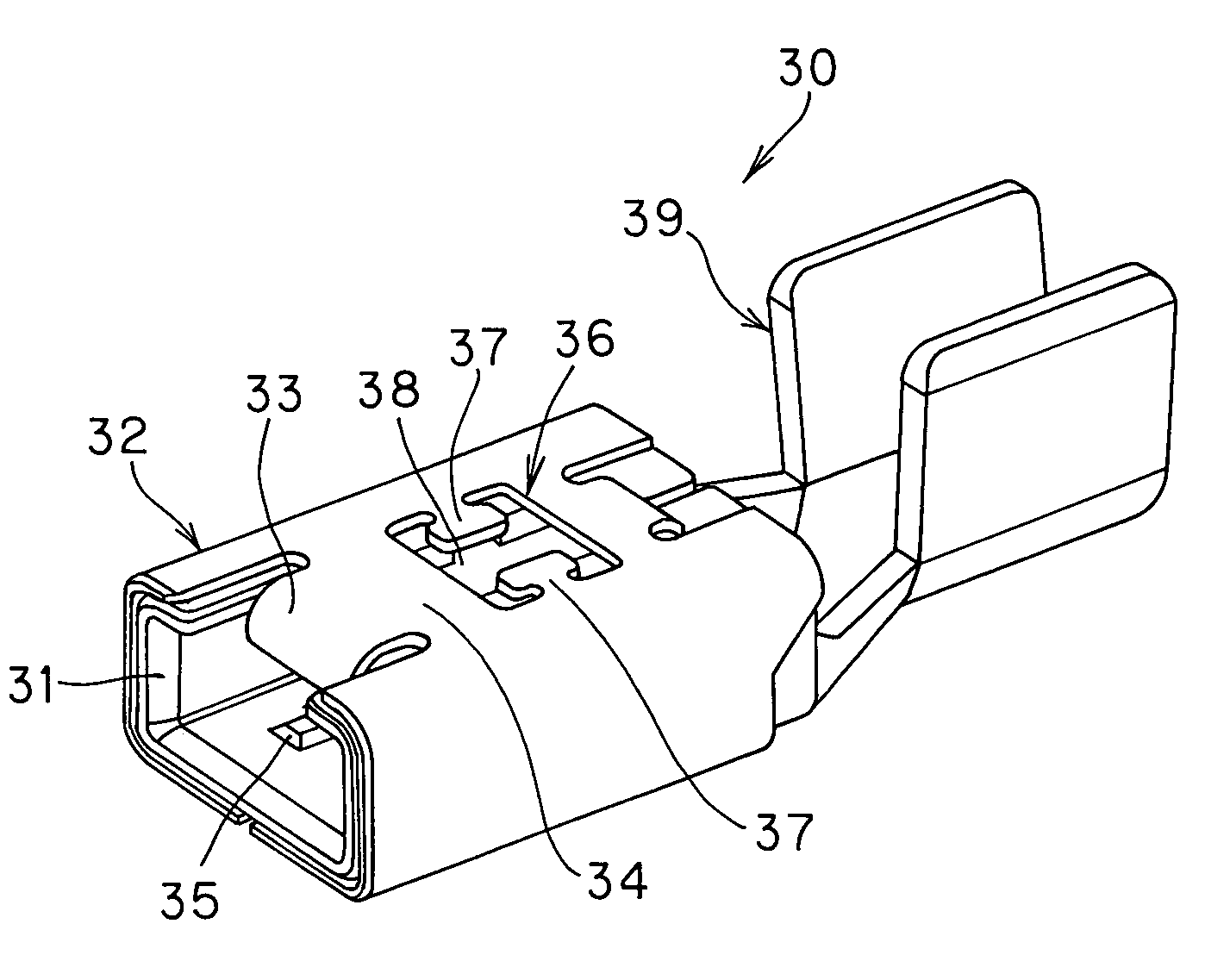

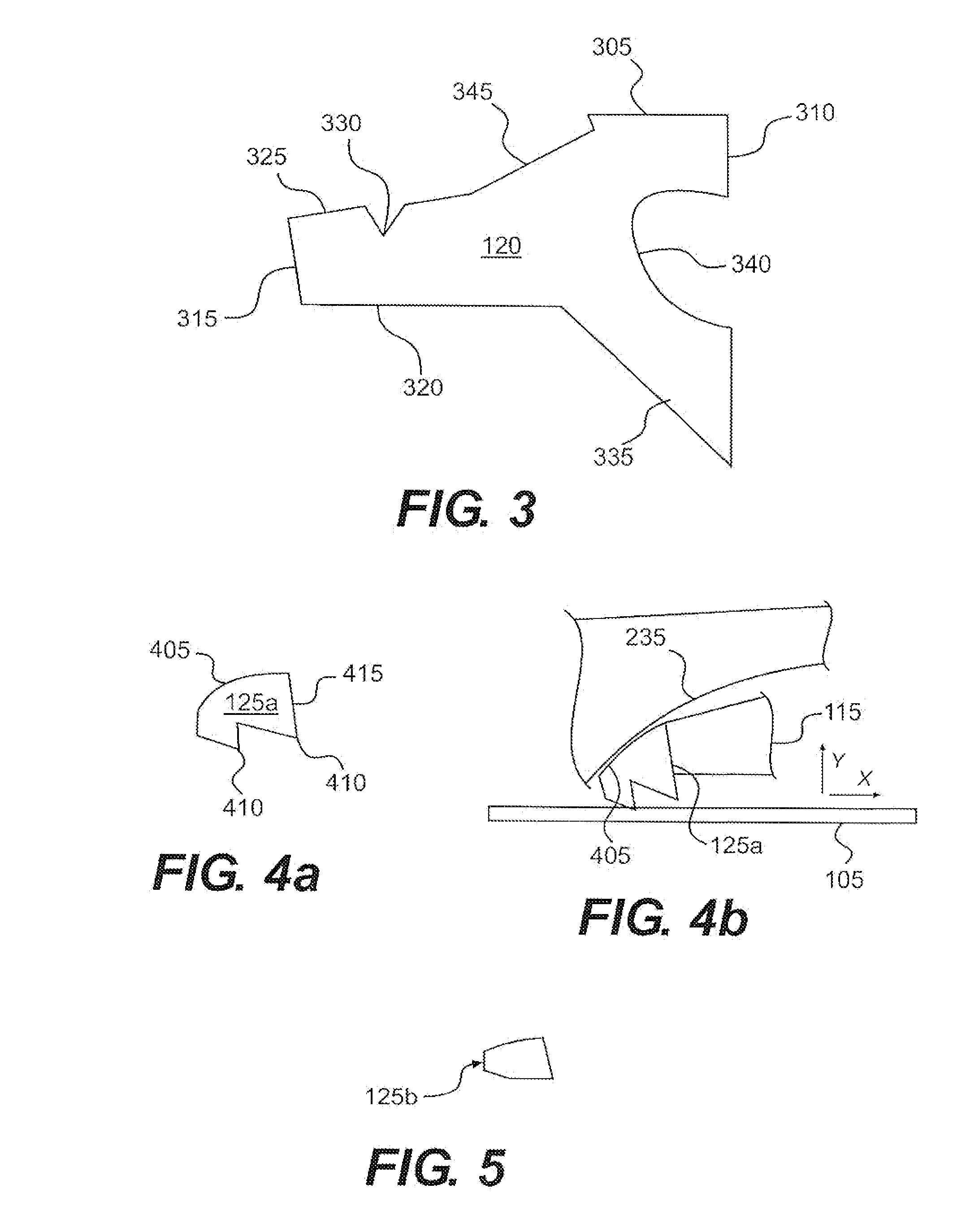

Incomplete fitting prevention connector

ActiveUS20130210266A1Preventing increase in insertion forceImprove insertion forceIncorrect coupling preventionEngineeringRestoring force

An incomplete fitting prevention connector includes a first connector, a second connector that is fitted to the first connector, and a connector position assurance lock that is slidably mounted to an outer side of the second connector. The first connector includes a male beak, a short spring and a terminal The second connector includes a female lock passing over the male beak and a short-circuit removal plate part inserted between the short spring and the terminal A draw-in slanted surface is formed at a leading end of the male beak, a restoring force for returning the female lock to its original position serves as a driving force for fitting the connector when the female lock reaches the draw-in slanted surface, and the insertion force of the short-circuit removal plate part applied between the short spring and the terminal is reduced.

Owner:YAZAKI CORP

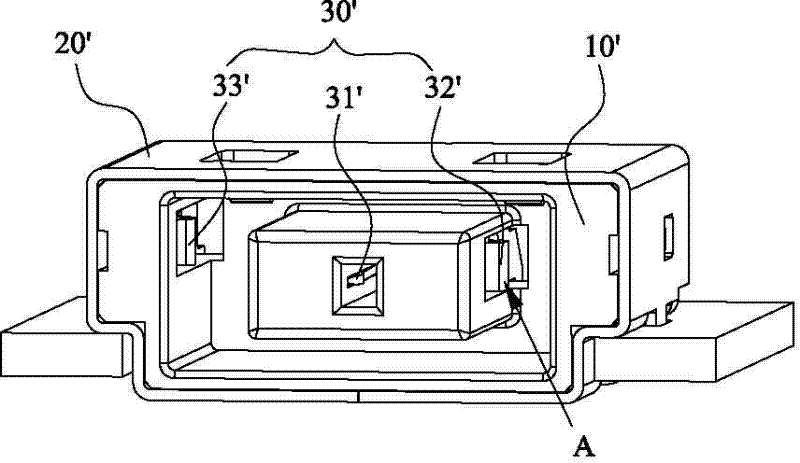

Connector structure with a u-shaped cross section having a male terminal and a female terminal

InactiveUS7594832B2Improve cooling effectFirmly connectedSecuring/insulating coupling contact membersCoupling contact membersEngineeringMechanical engineering

A male terminal 10 has a wire connecting portion 13 at one end to be connected to an electric wire, and an inserting contact portion 12 at another end to be inserted into a female terminal 30. A plate member of the inserting contact portion 12 is bent to have a U-shape cross section. The female terminal 30 has a terminal energizing portion 31 composed of a high conductivity material having a frame structure for accommodating the male terminal 10, a terminal box 32 composed of a material having a strength higher than that of the high conductivity material of the terminal energizing portion 31 for covering the terminal energizing portion 31, and a spring 33 located within the terminal energizing portion 31 for fixing the male terminal 10. The spring 33 is formed integrally with the terminal box 32.

Owner:HITACHI METALS LTD

Fool-proof electric connector

ActiveCN102723641AEffective contactImprove insertion forceIncorrect coupling preventionCoupling protective earth/shielding arrangementsElectricityEngineering

The invention discloses a fool-proof electric connector, which comprises an insulating body, a shielding shell and a plurality of conductive terminals, wherein the conductive terminals are accommodated in the insulating body; the shielding shell covers the insulating body to form an insertion port; an avoidance notch is formed on the shielding shell; a fool-proof elastic piece is arranged in the avoidance notch; the avoidance notch comprises a first hollow-out cavity which is vertically formed and a second hollow-out cavity which is transversely formed; the first hollow-out cavity is communicated with the second hollow-out cavity; the fool-proof elastic piece comprises an elastic arm, a guide arm and a fool-proof arm; the elastic arm is formed by forward and inclined extension from the inner part of the rear end of the first hollow-out cavity along integrated vertical direction; the guide arm is formed by extension from a free tail end of the elastic arm, bending and protrusion; the fool-proof arm is formed by transverse extension from the side wall face of the elastic arm; the elastic arm and the guide arm are suspended in the first hollow-out cavity; a guide face of the guide arm extends into the insertion port; the fool-proof arm is suspended in the second hollow-out cavity; and a pressing part of the fool-proof arm extends into the insertion port.

Owner:DONGGUAN TECONN ELECTRONICS TECH CO LTD

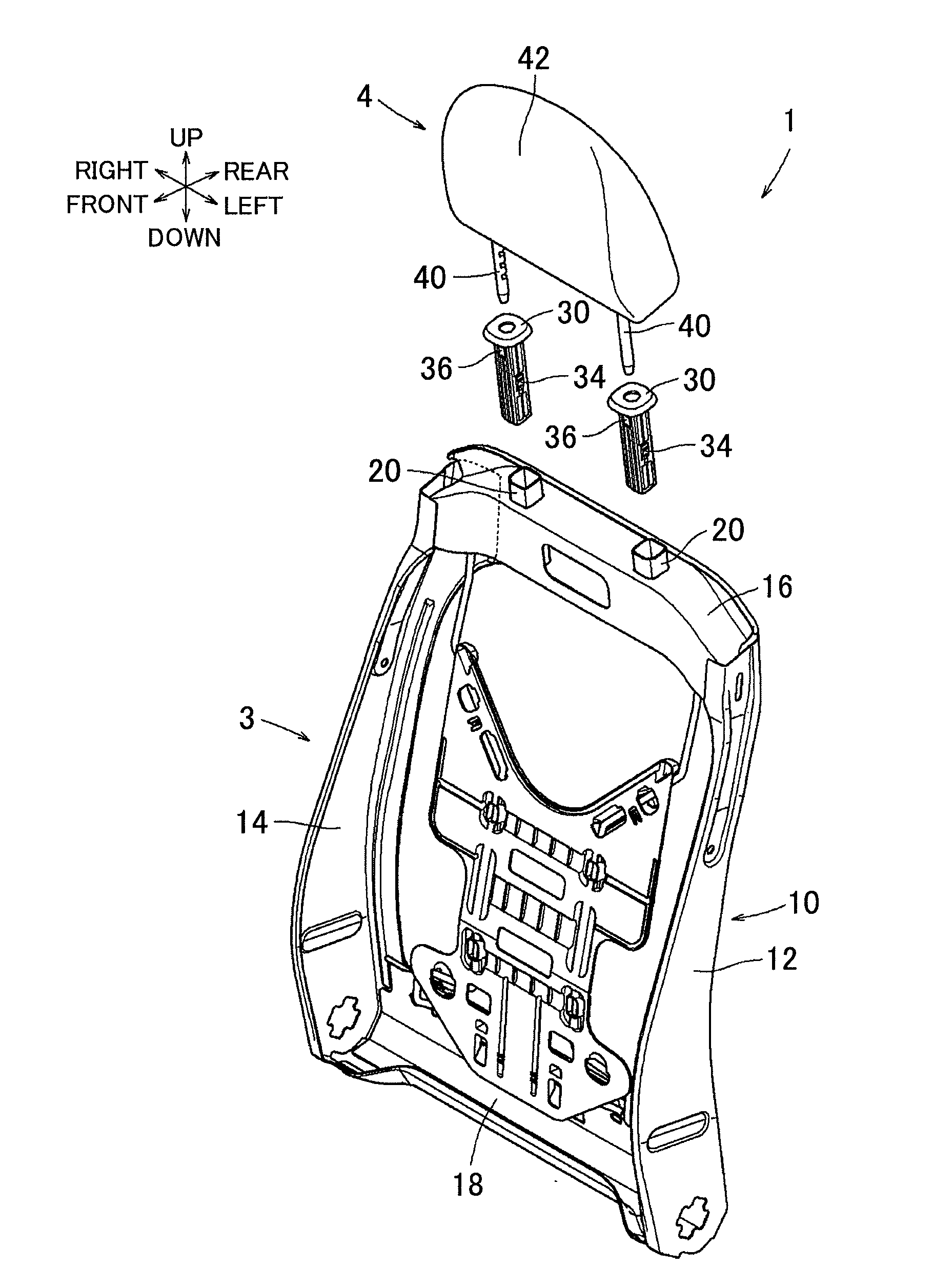

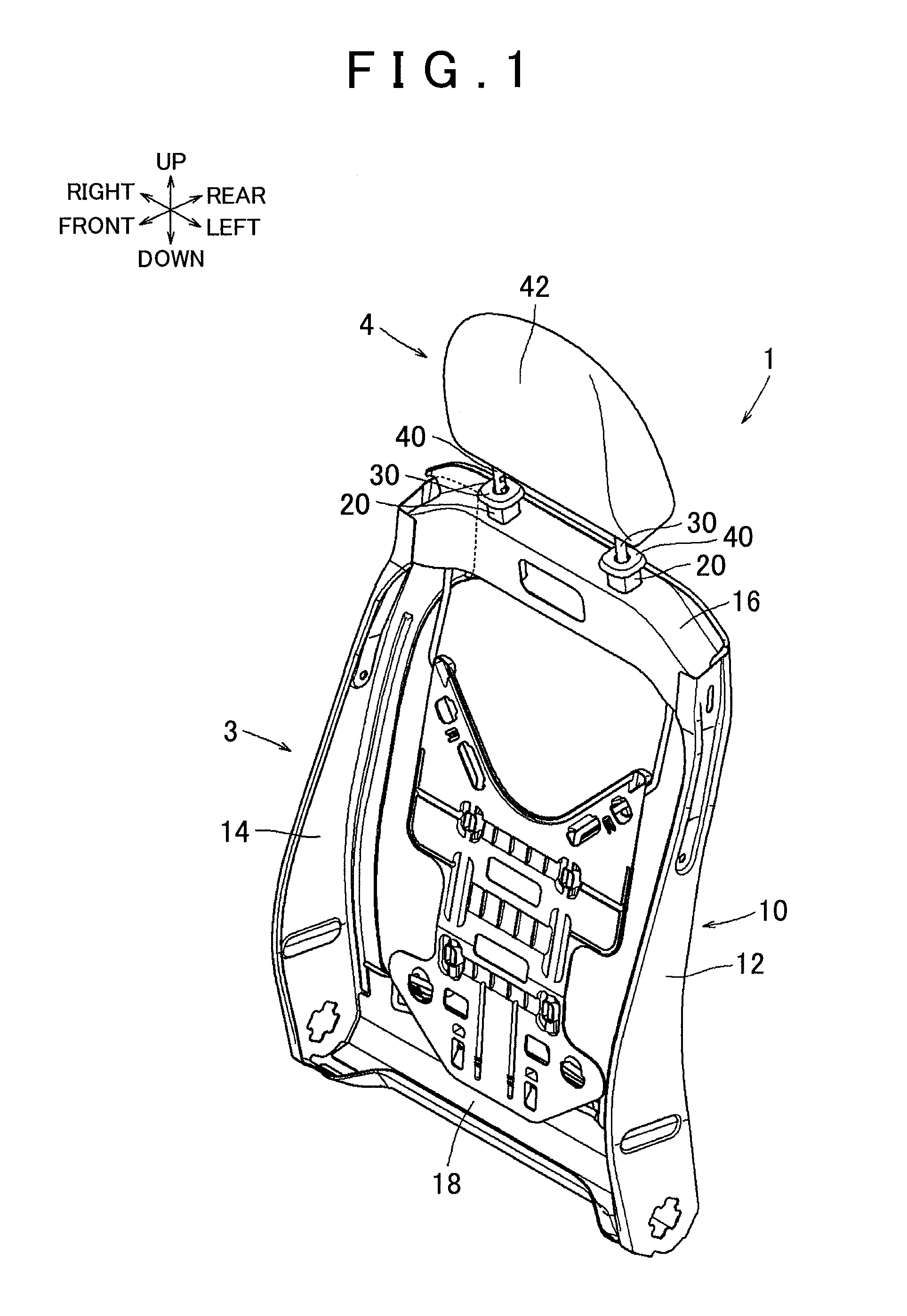

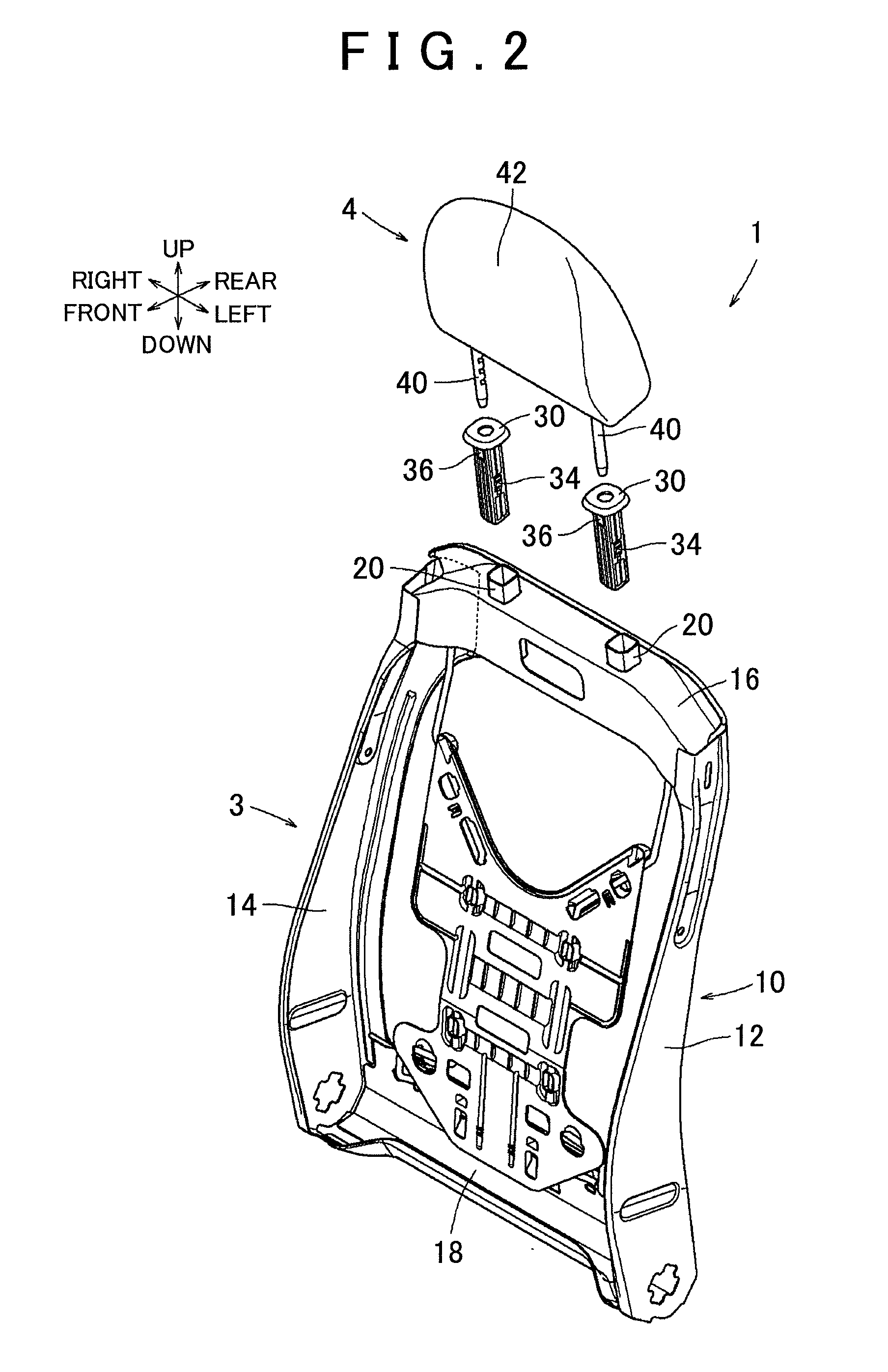

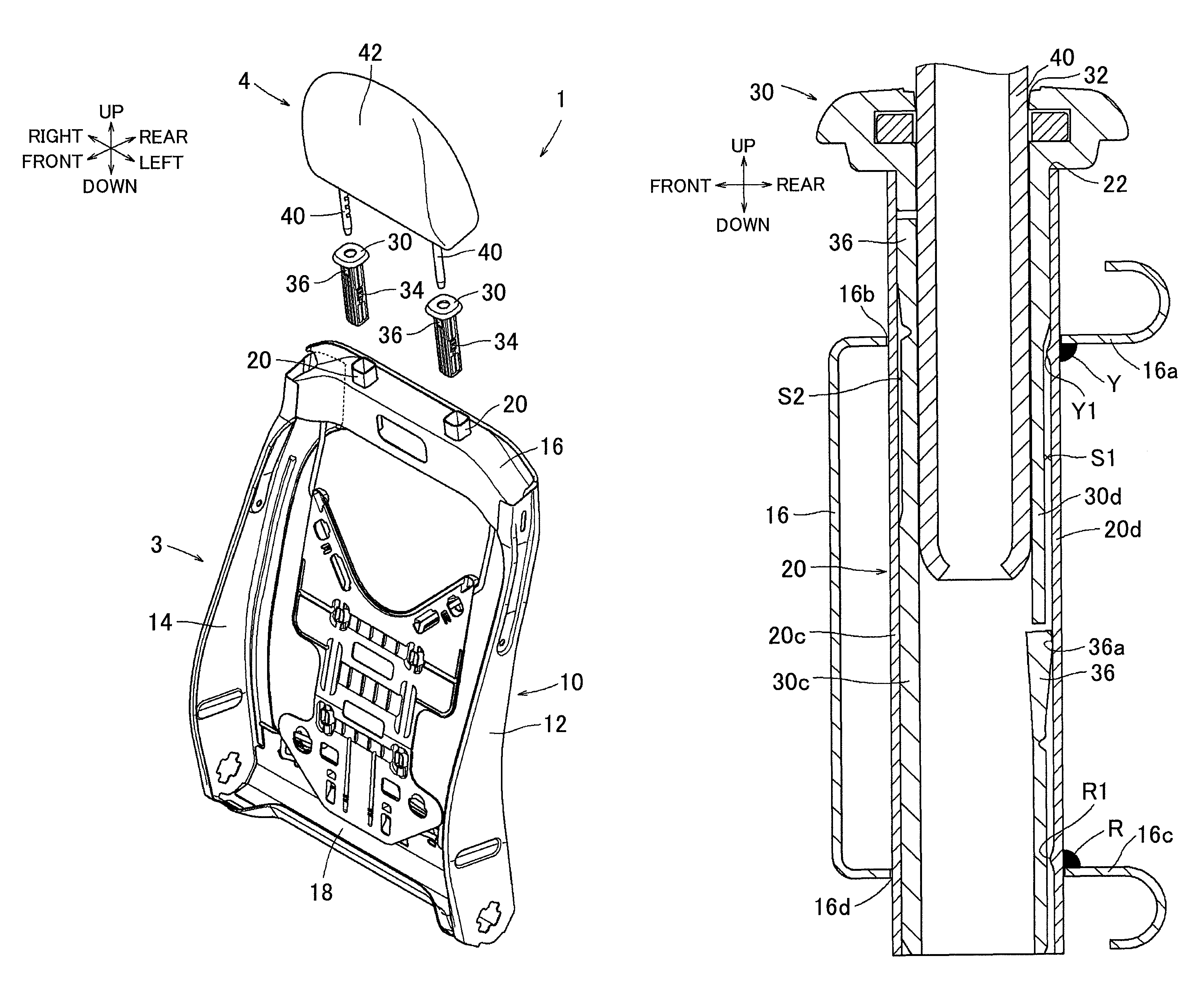

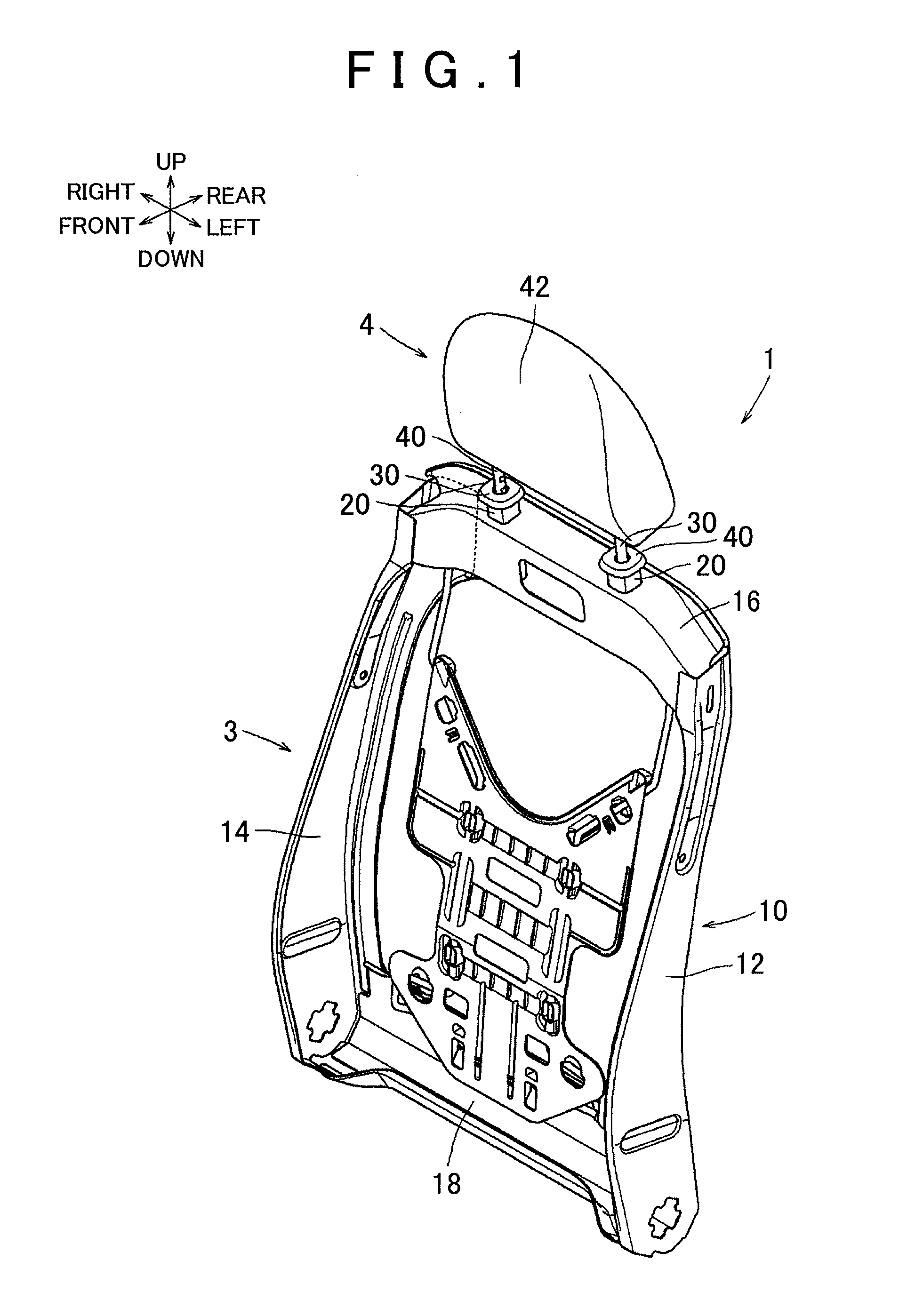

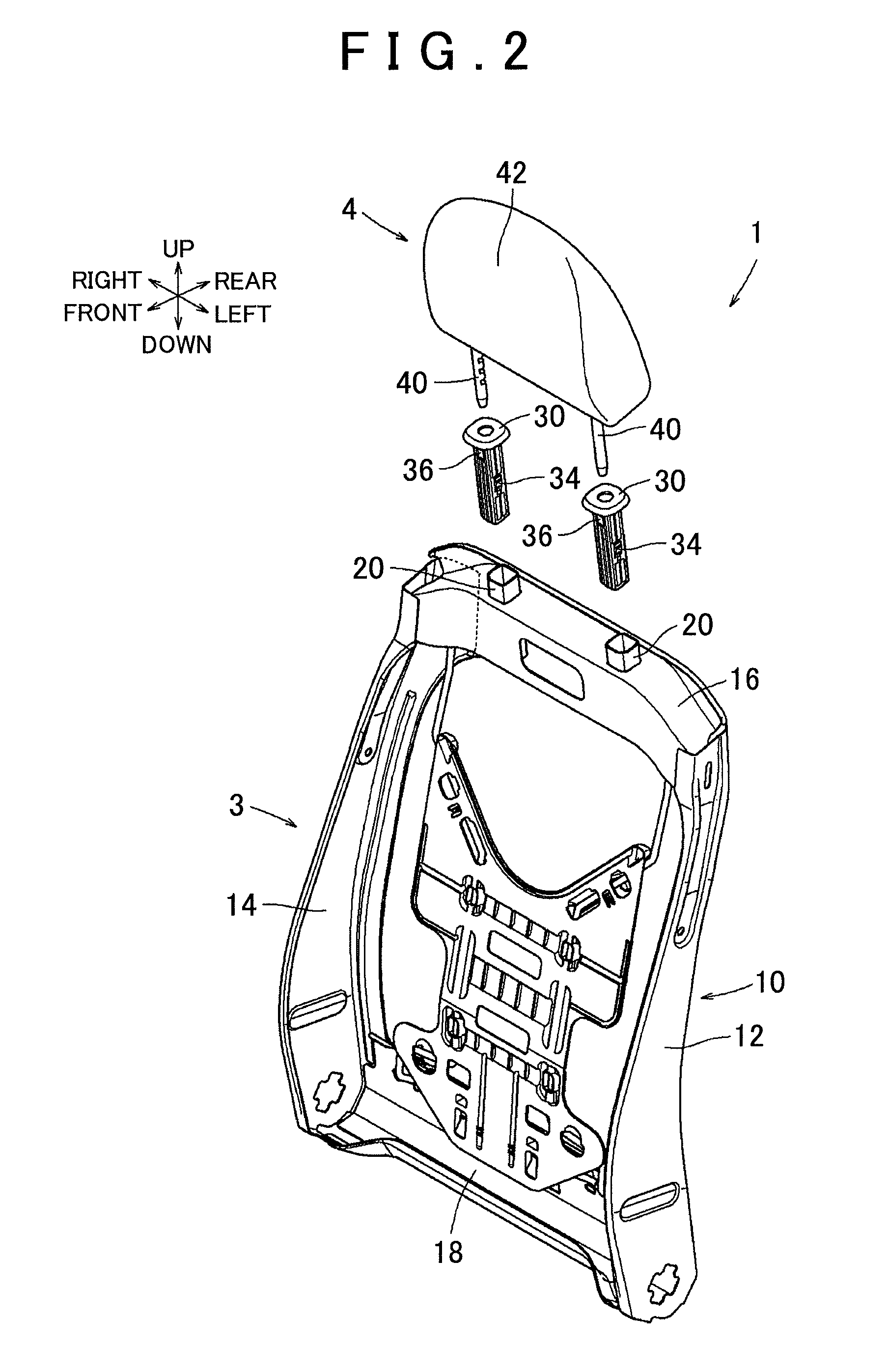

Headrest mounting structure vehicle seat

ActiveUS20150306994A1Suppress increase in insertion forcePrevent rattlingOperating chairsDental chairsEngineeringMechanical engineering

Owner:TOYOTA BOSHOKU KK

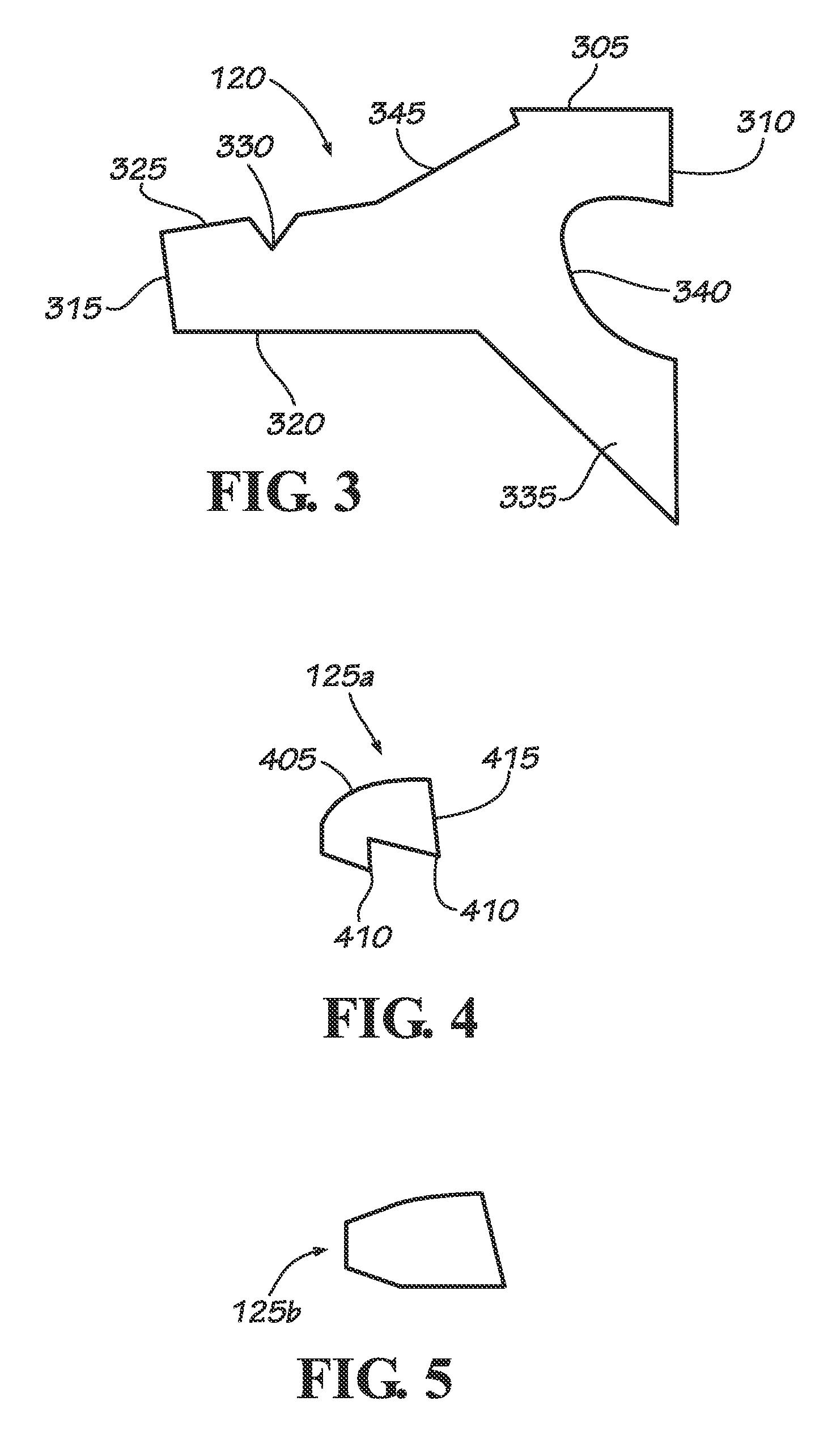

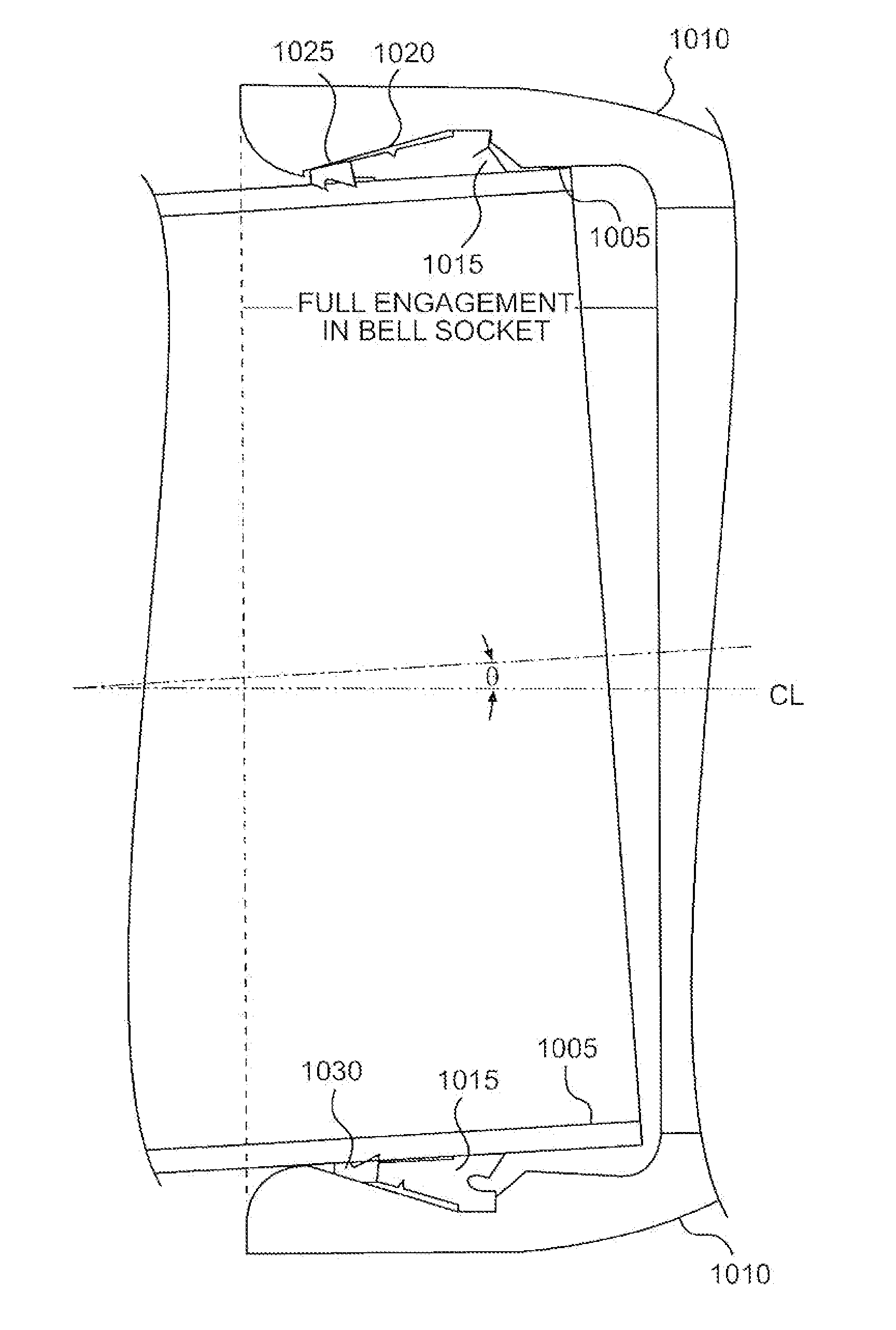

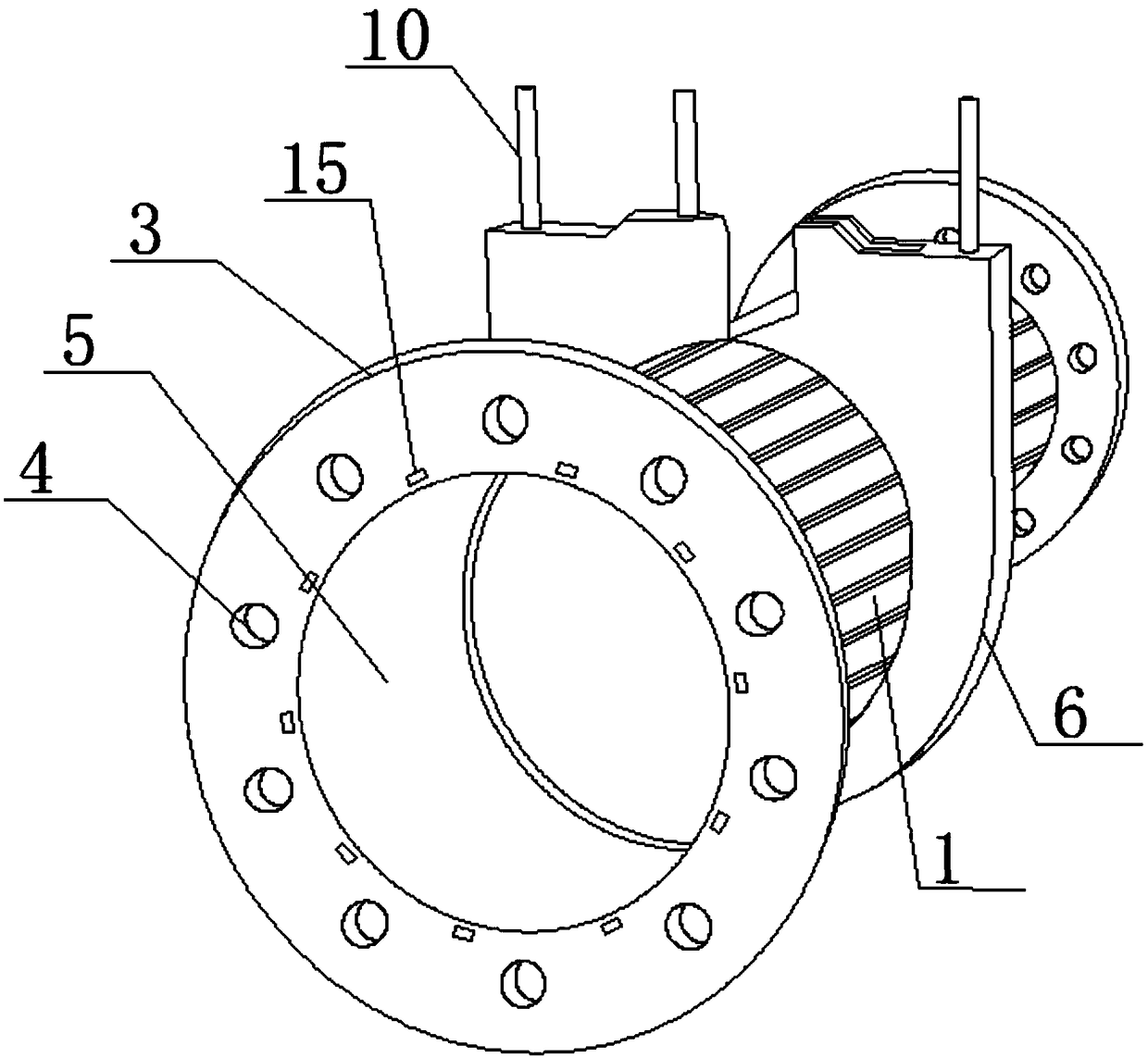

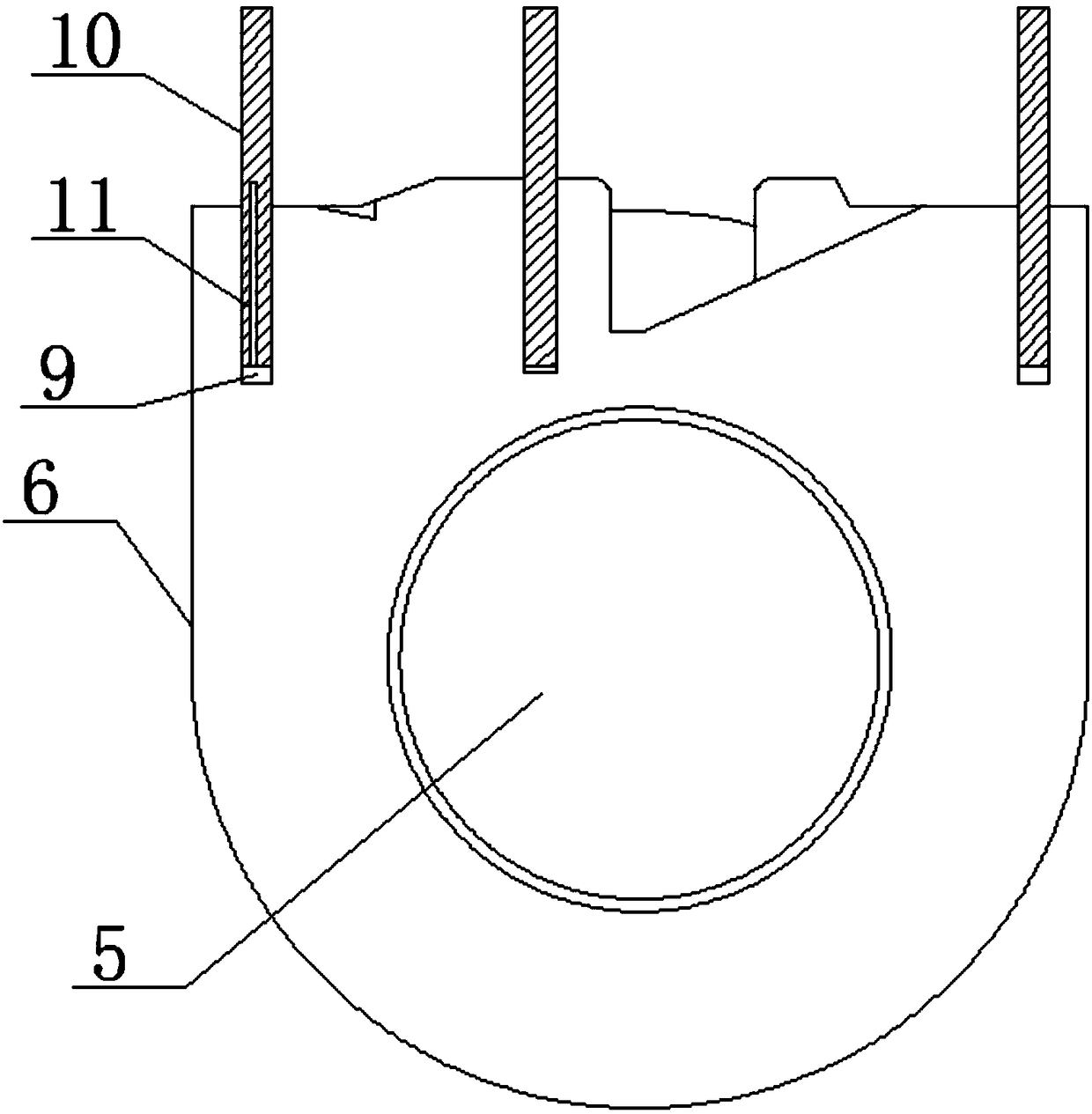

Gasket for parabolic ramp self restraining bell joint

ActiveUS20120280497A1Improve insertion forceIncrease forceSleeve/socket jointsFluid pressure sealed jointsAxial forceCoupling system

Gaskets for use with a bell and spigot coupling system are disclosed herein. The gasket comprises an elastomeric member having a front edge, a first section, and a second section. Axial forces generated by the insertion of the spigot to the first section of the elastomeric member displace the first section of the elastomeric member in an axial and radial direction.

Owner:MUELLER INT LLC

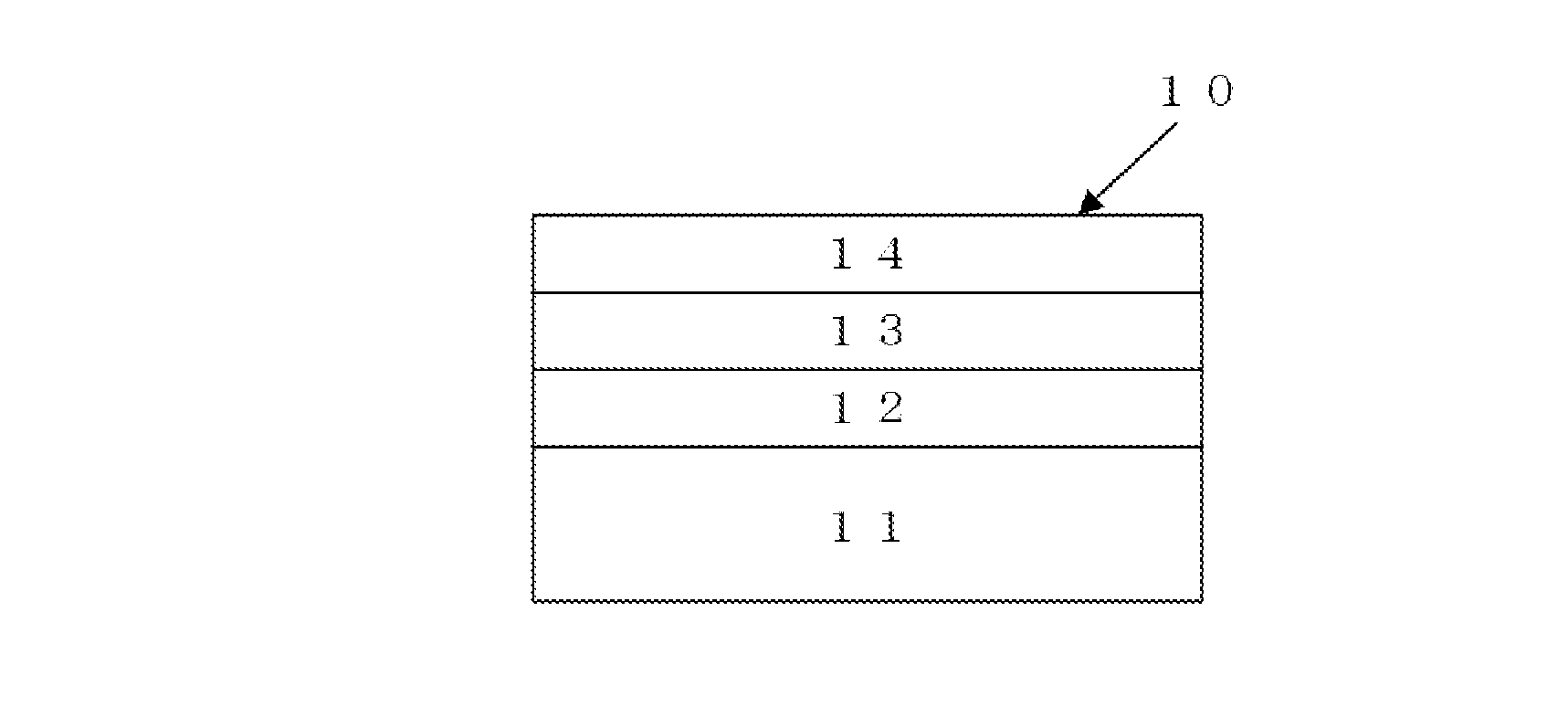

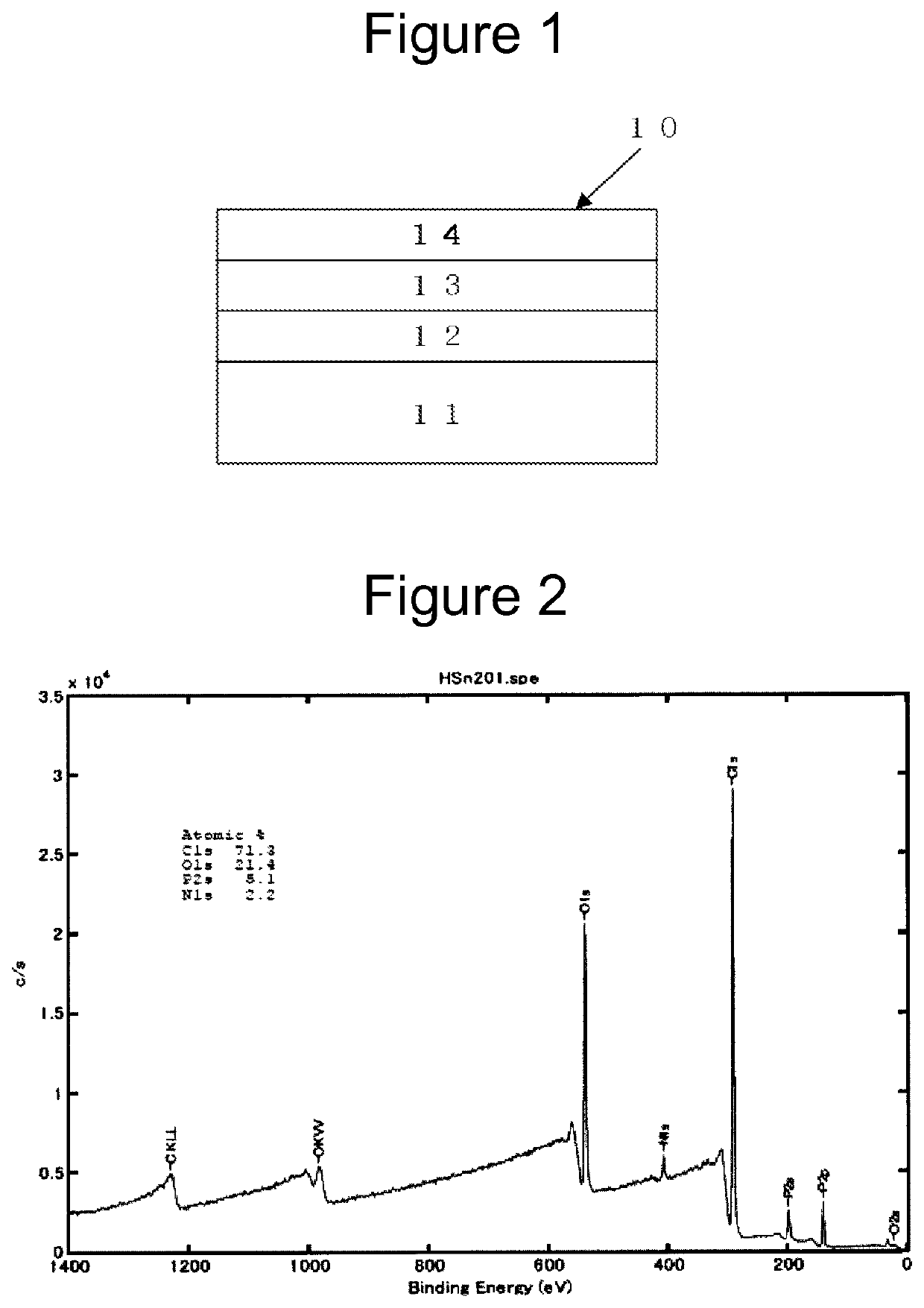

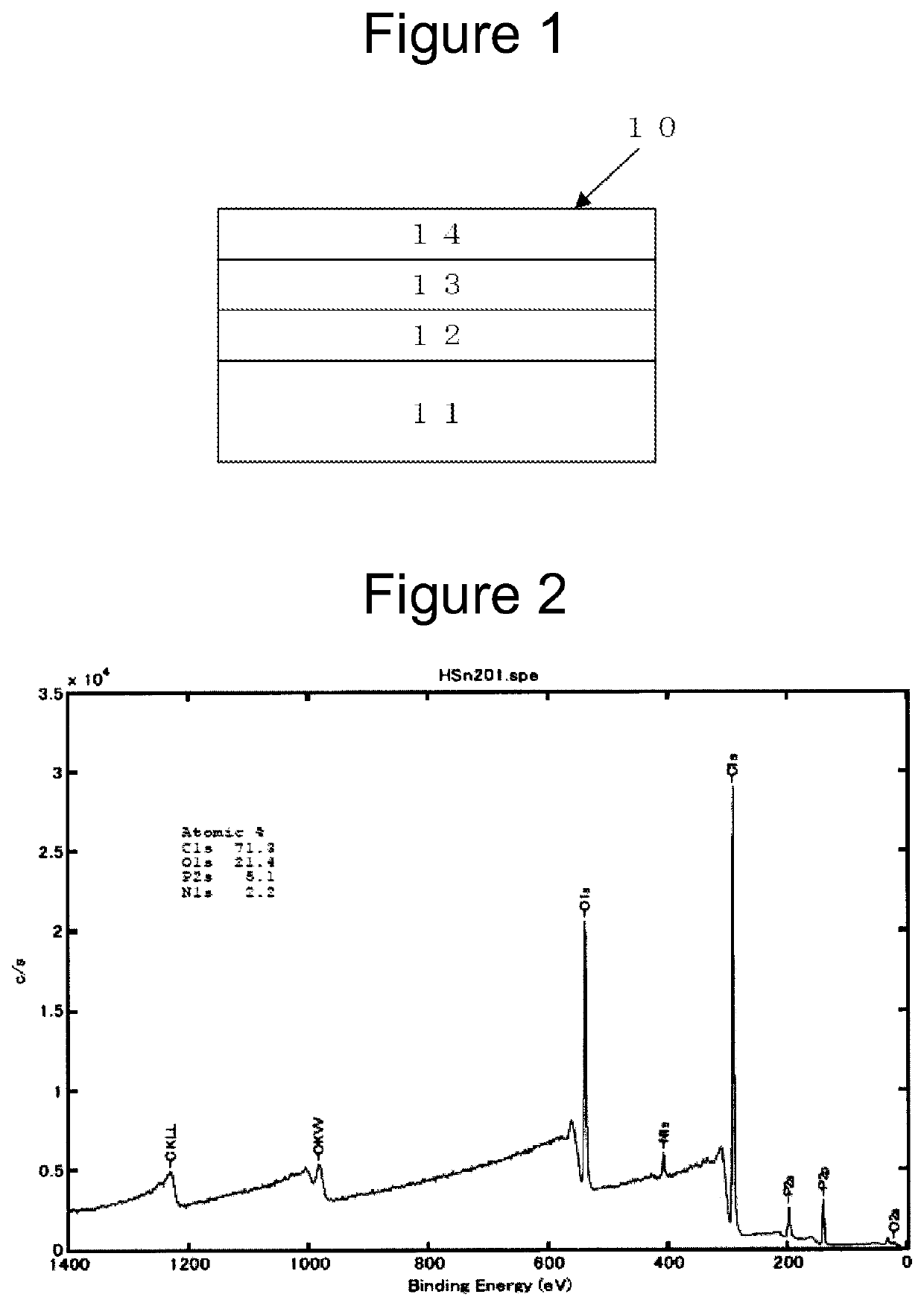

Metallic Material For Electronic Components And Method For Producing Same, And Connector Terminals, Connectors And Electronic Components Using Same

ActiveUS20150147924A1Low degreeIncreased durabilityElectrically conductive connectionsSingle bars/rods/wires/strips conductorsMetallic materialsAlloy

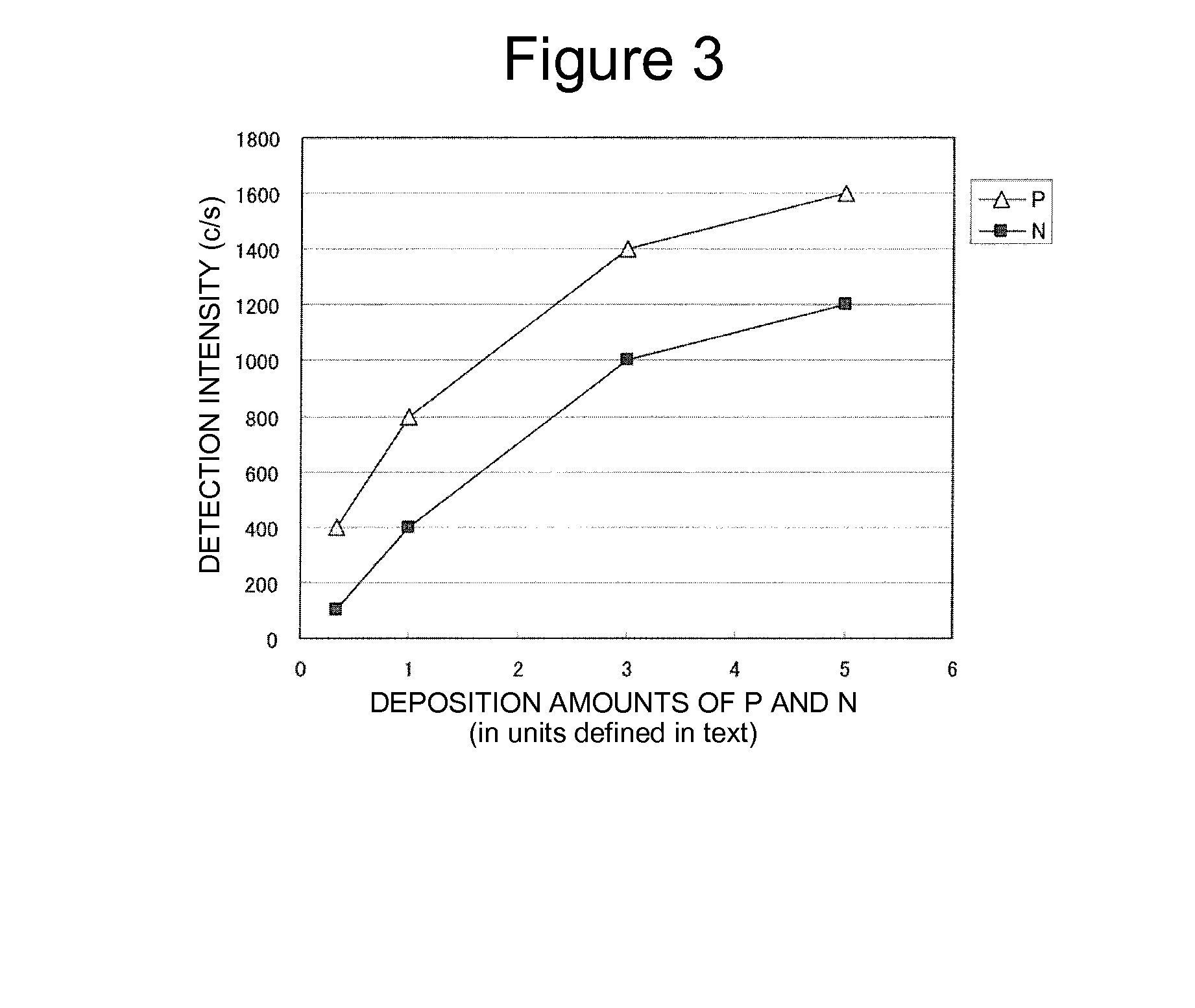

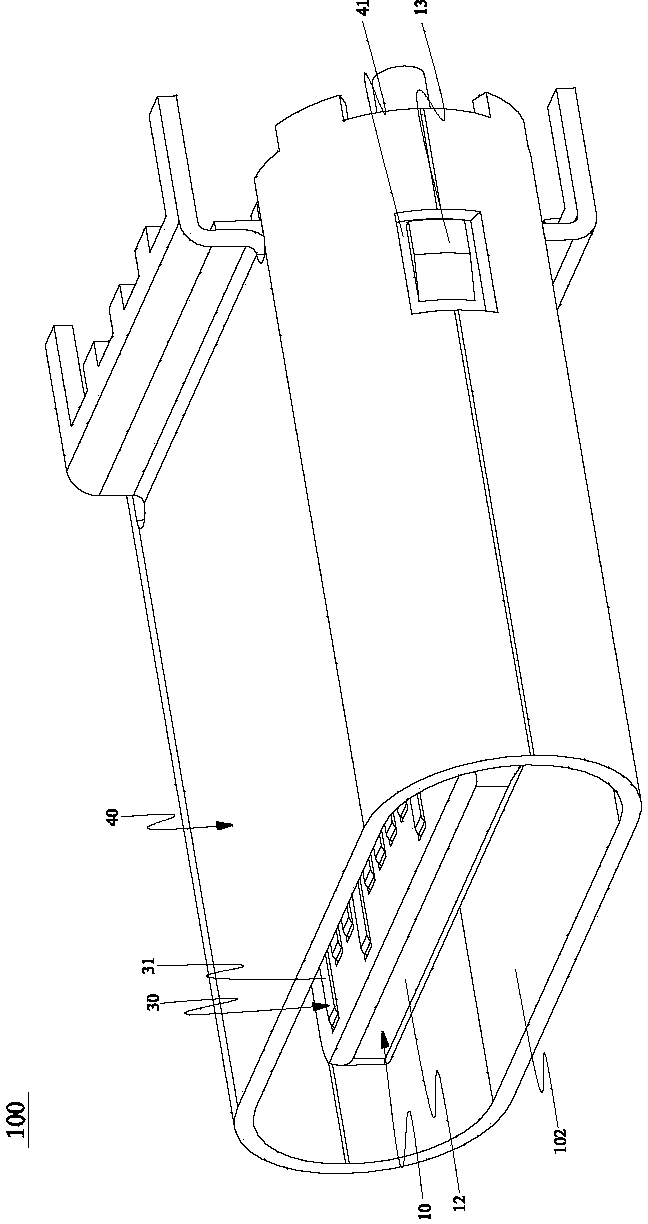

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer including an alloy constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir, and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; and an upper layer formed on the intermediate layer, the upper layer being constituted with one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.02 μm or more and less than 0.80 μm; and the thickness of the upper layer is 0.005 μm or more and less than 0.30 μm.

Owner:JX NIPPON MINING& METALS CORP

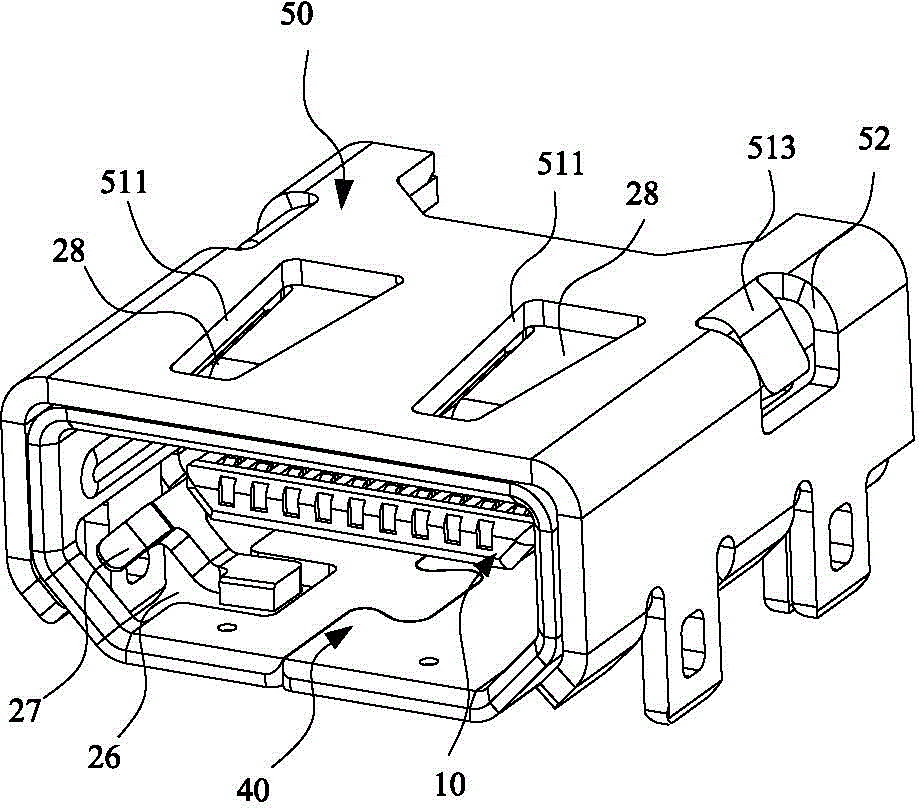

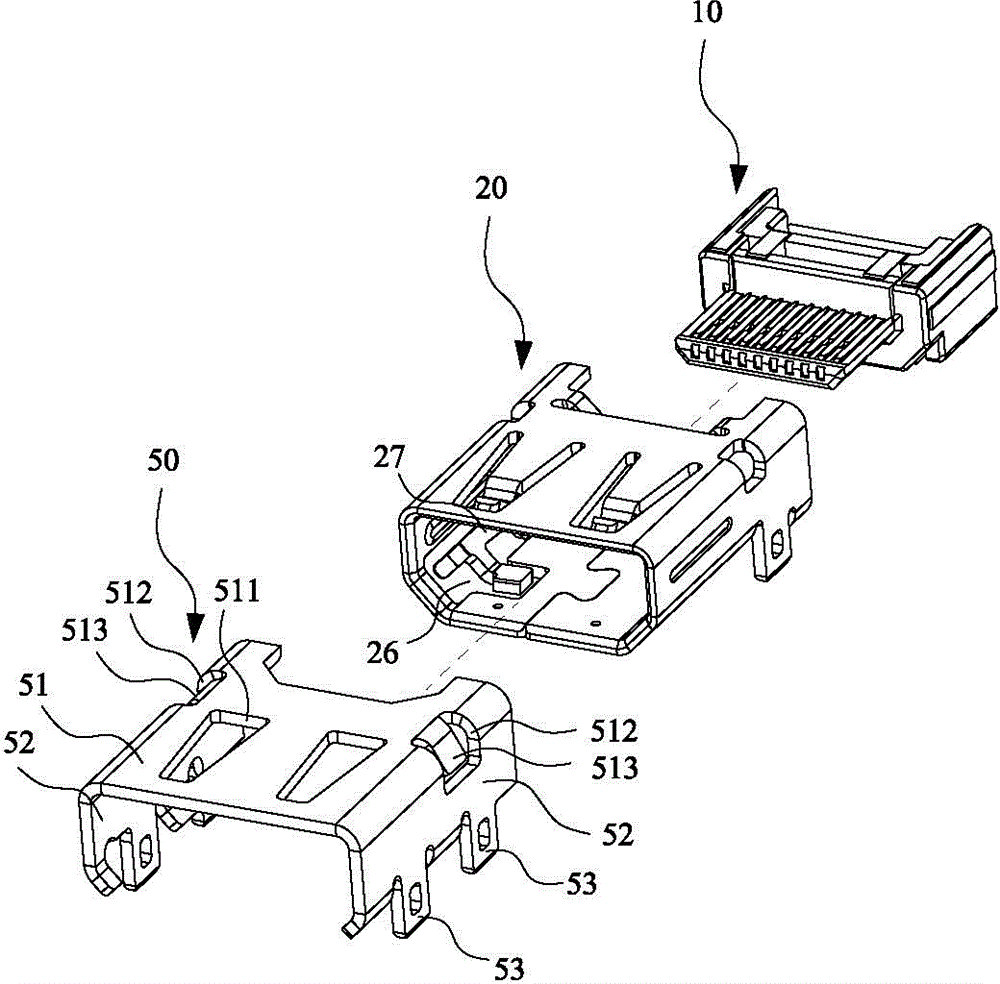

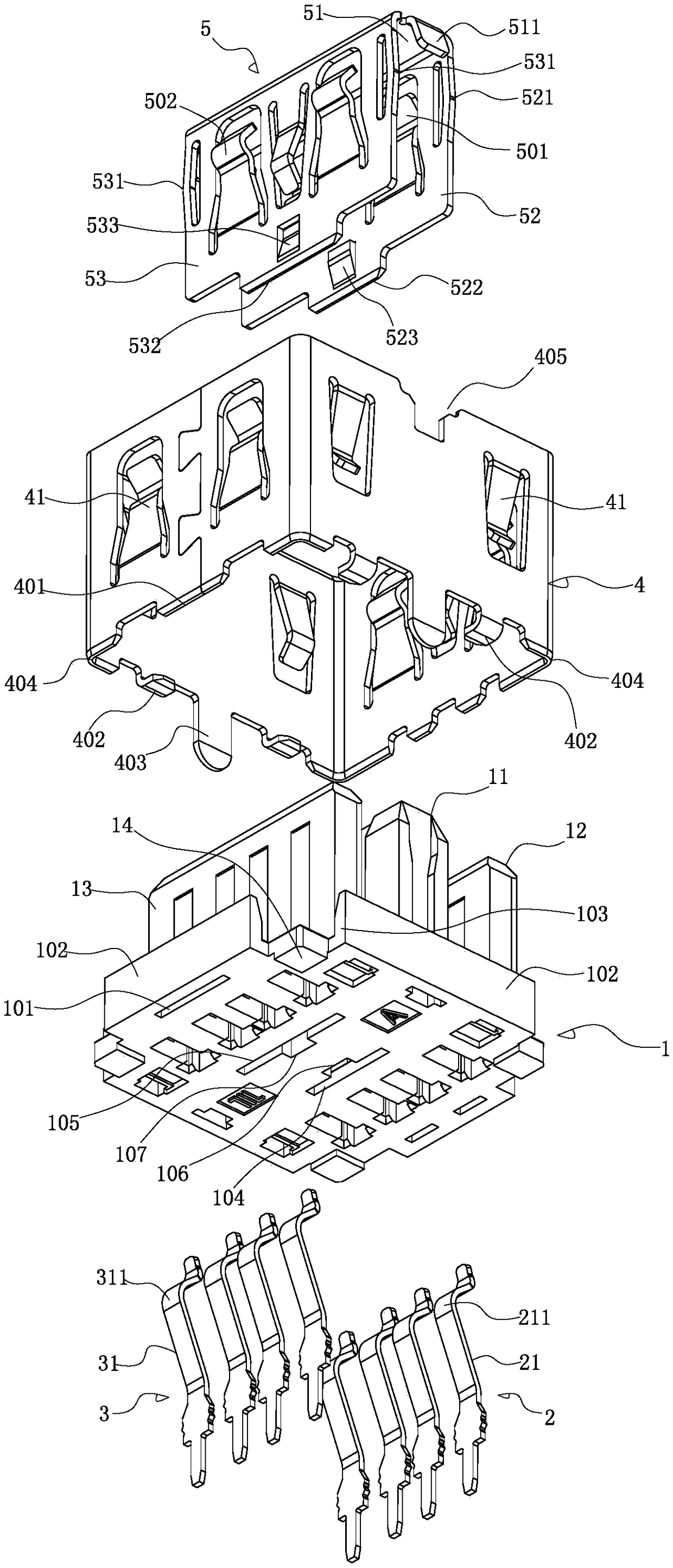

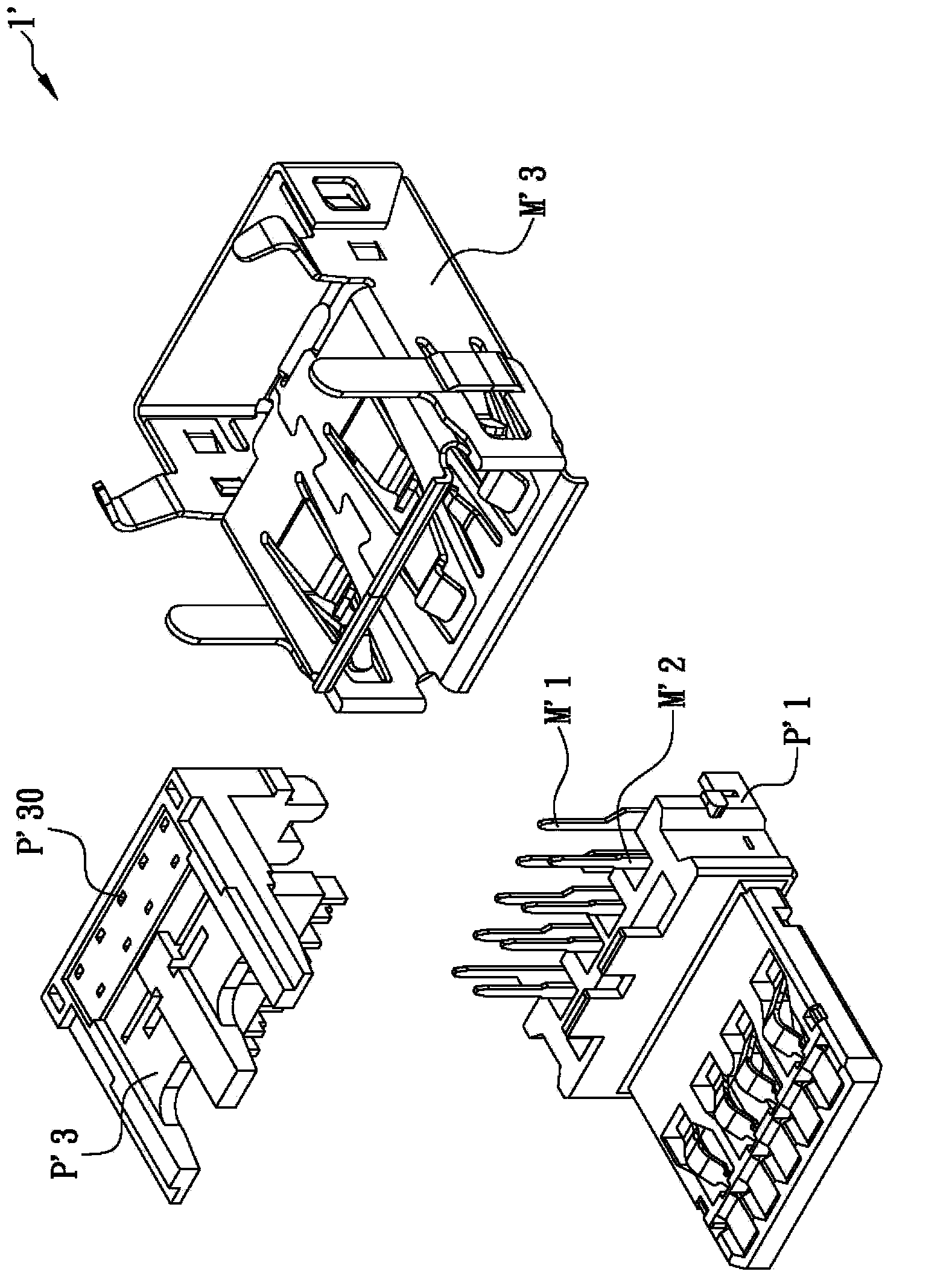

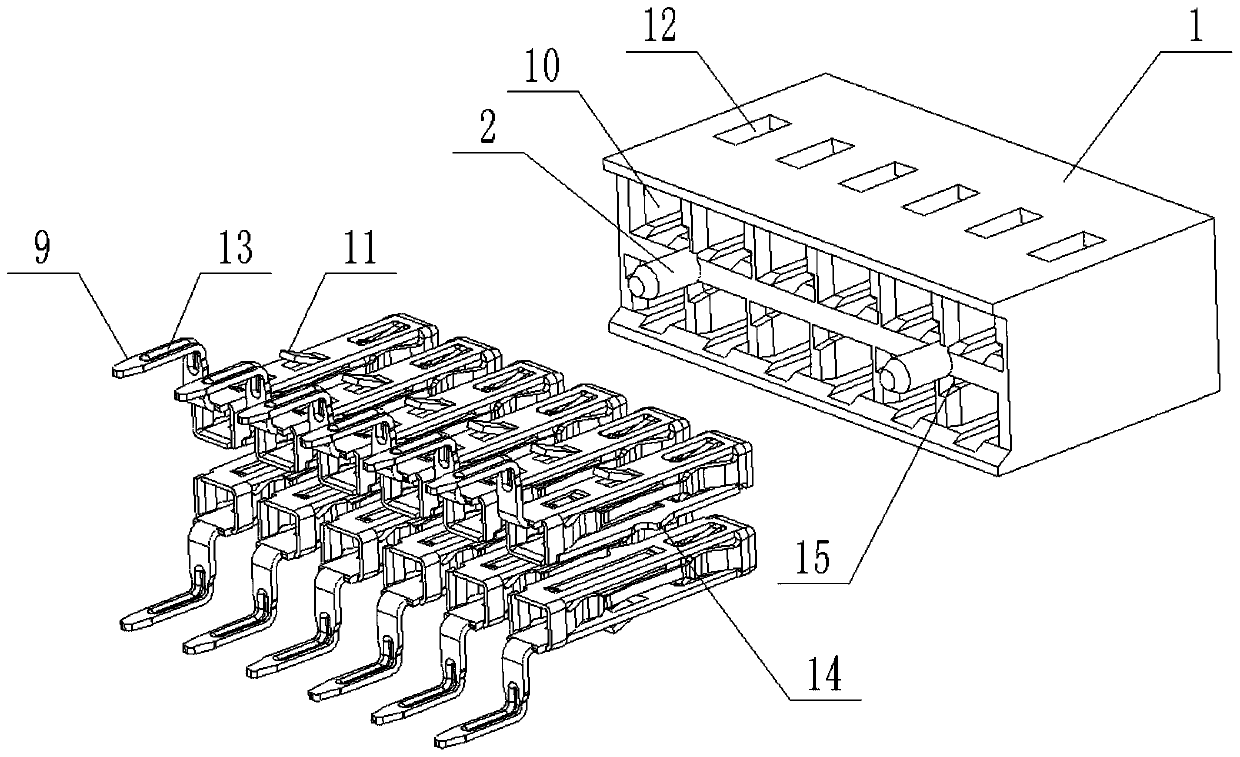

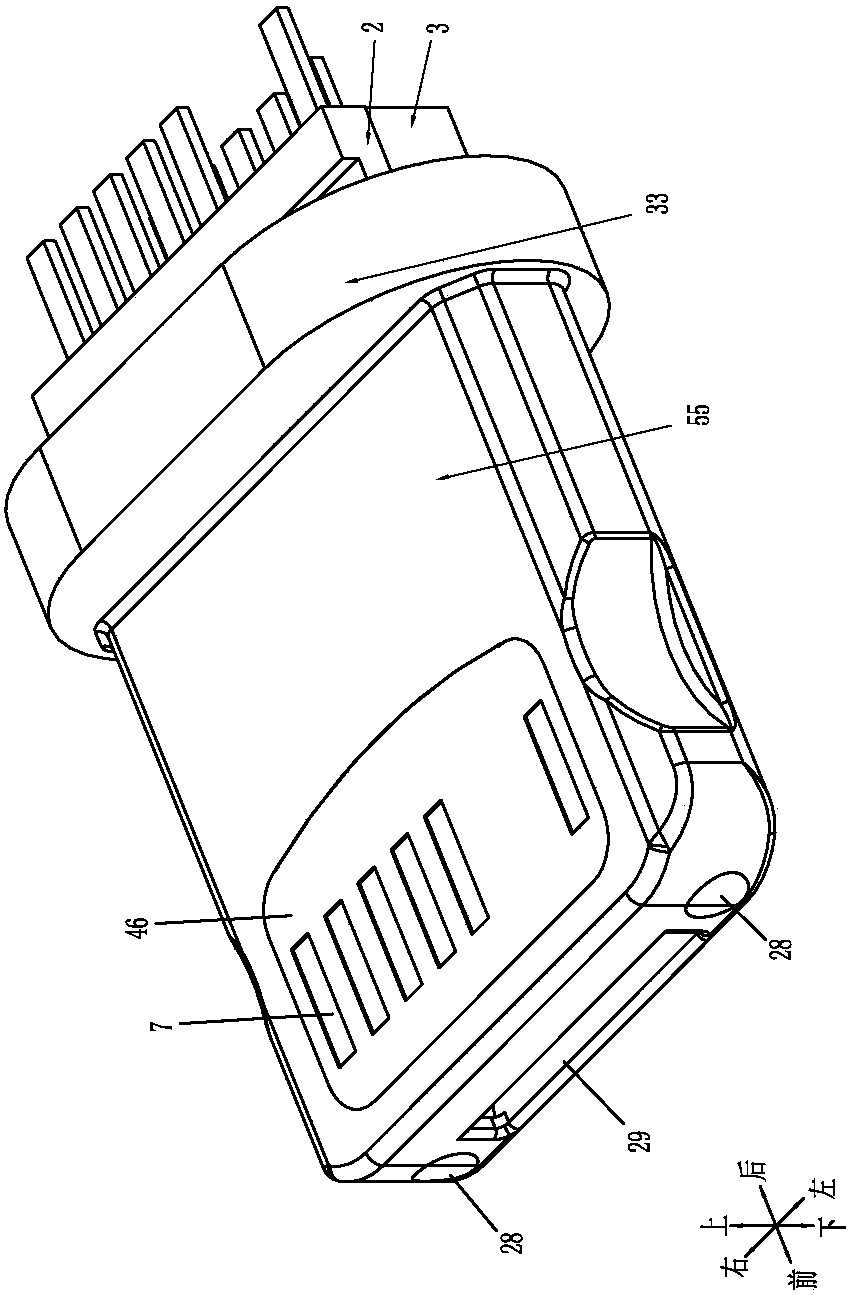

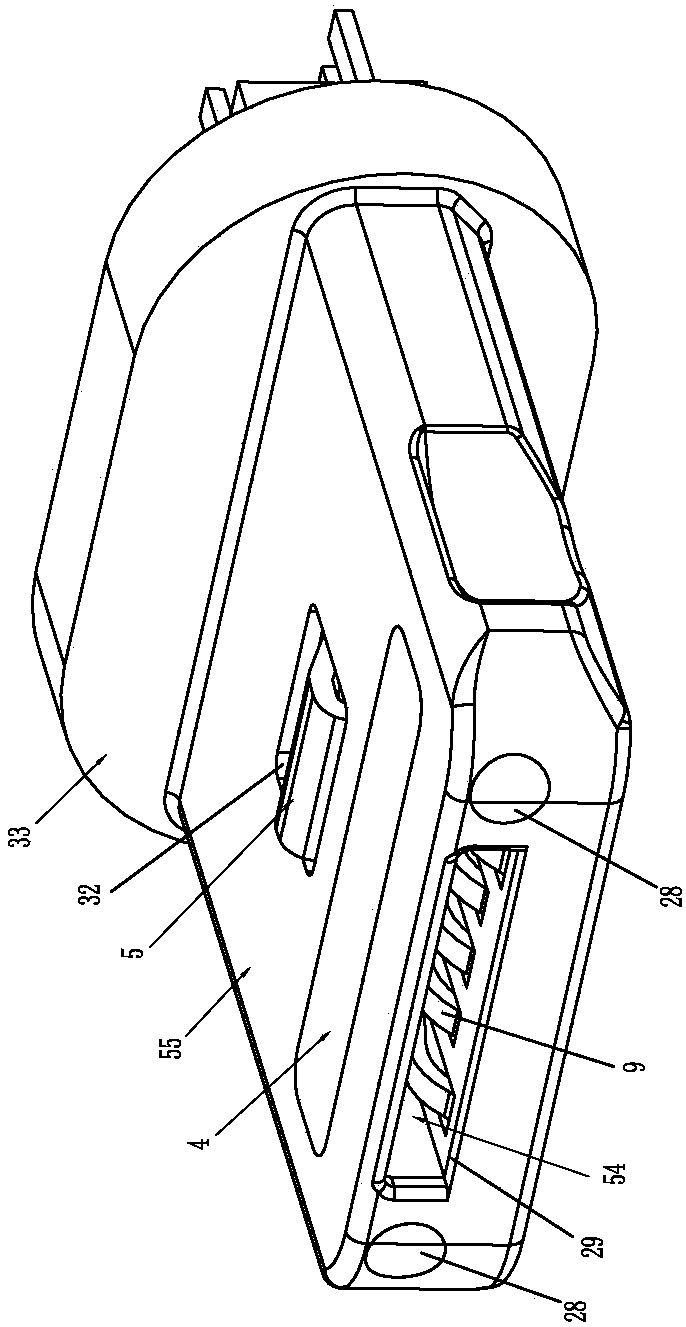

Socket connector, plug connector and combination structure thereof

ActiveCN104092059AGuaranteed stabilityImprove insertion forceTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectromagnetic interferenceHigh frequency

The invention discloses a socket connector, a plug connector and a combination structure thereof. The socket connector includes a first insulating body, a first shielding sheet, two rows of first contact terminals and a first shielding casing. The plug connector includes a second insulating body, a second shielding sheet, two rows of second contact terminals, at least one contact spring sheet and a second shielding casing. Through arrangement of the contact spring sheets in the plug connector, contact faces of the first shielding sheet are cooperated to expose side faces of a first clapper and during mutual-insert combination, the front ends of the contact spring sheets elastically abut against the contact faces so that a grounding circuit is formed through the contact connection and thus electromagnetic interferences, between the upper and lower rows of the contact terminals, caused when high-frequency signals are transmitted can be well shielded and the stability of transmission of the high-frequency signals is ensured better; and at the same time, the plug-in and plug-out forces of the connectors can be strengthened effectively and because the contact spring sheets and the contact faces are all made of metal materials, a demand of long plug-in and plug-out service lives of the connectors is met and the service life of the product is longer. The socket connector, the plug connector and the combination structure thereof are also capable of satisfying positive and reverse plug-in and plug-out.

Owner:DONGGUAN TECONN ELECTRONICS TECH CO LTD

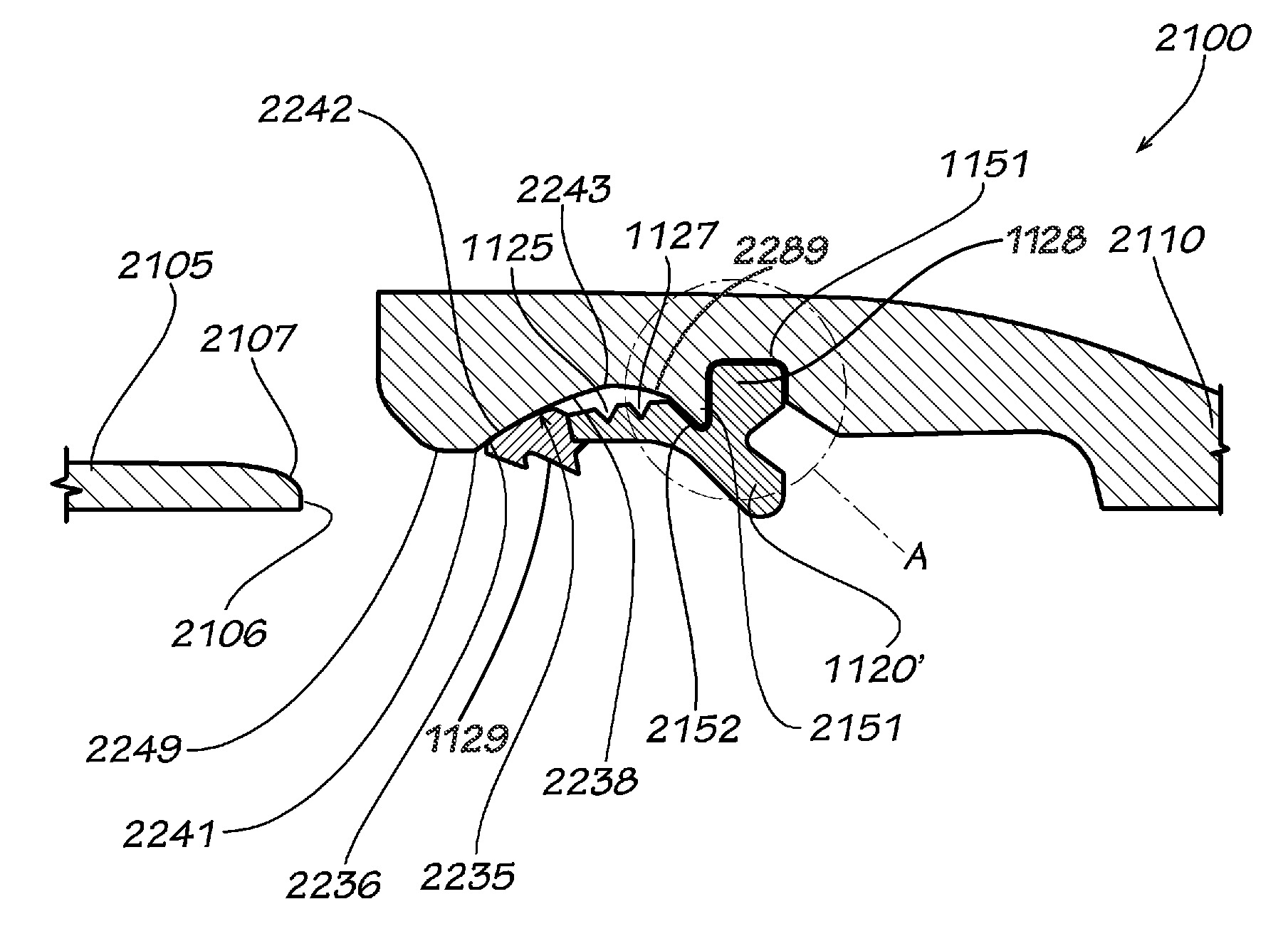

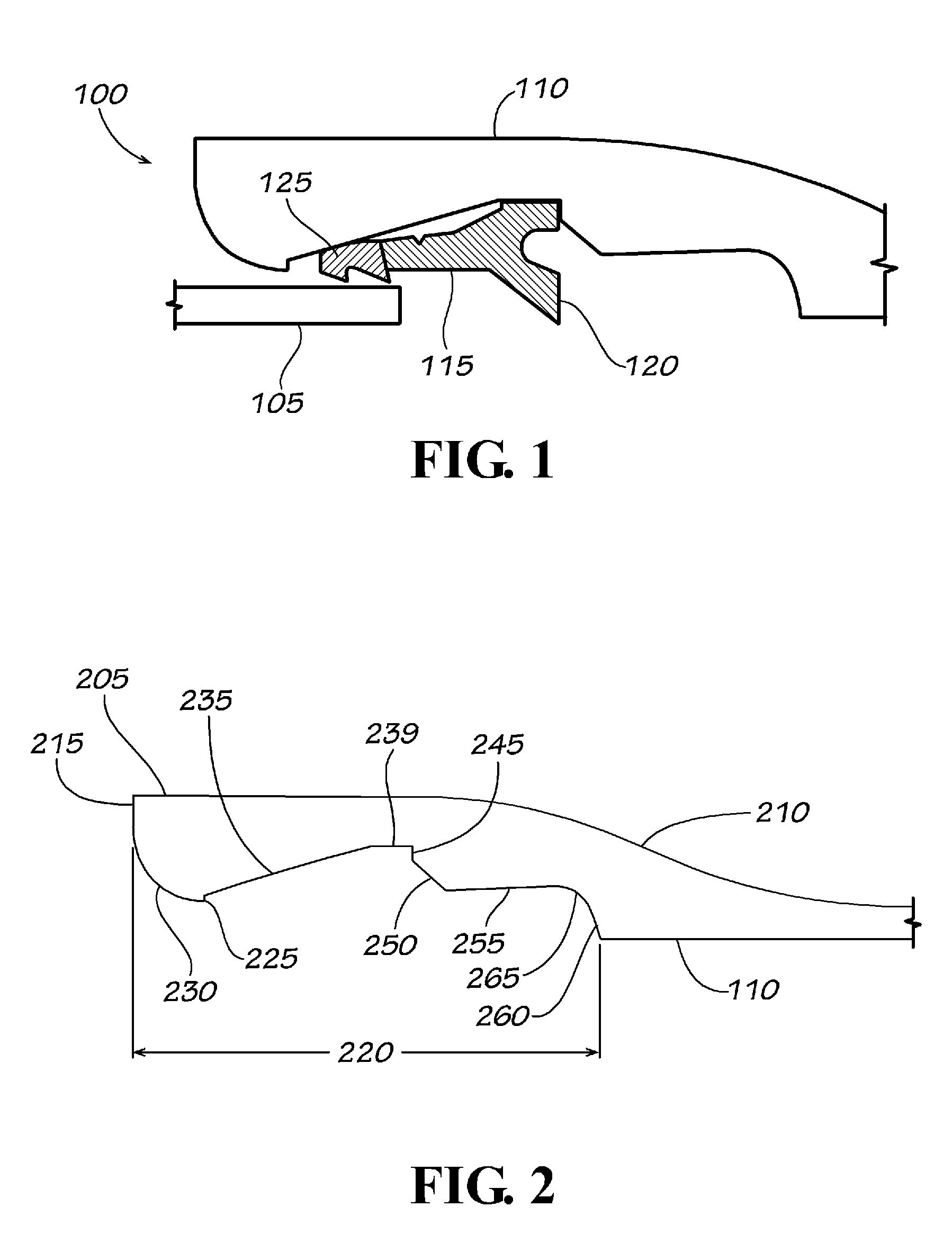

Simplified low insertion force sealing device capable of self restraint and joint deflection

ActiveUS20110084478A1Improve insertion forceLess likely to lose restraint and pressureSleeve/socket jointsFluid pressure sealed jointsLow insertion forceEngineering

A conduit coupling system, sealing device, bell and method of use are disclosed herein. The system comprises at least two piping components, and a sealing device. A first component has a bell and a second component has a spigot, the spigot is adapted to mate with the bell. The bell comprises a first end and a second end, the first end coupled to the first component. The bell has a concave annular inner surface and a diameter of the annular inner surface adjacent to the first end of the bell is greater than a diameter of the annular inner surface adjacent to the second end of the bell. The sealing device comprises a locking segment comprising a convex outer surface and a K-type gasket coupled to a locking segment or a non-restraining anti-extrusion segment. The sealing device is adapted to fit between the bell and the spigot.

Owner:MUELLER INT LLC

Heat treatment process for jack of electric connector

ActiveCN102347581AEasy to closeIncrease elasticityContact member manufacturingFurnace temperatureElectricity

The invention discloses a heat treatment process for a jack of an electric connector, which comprises the following steps that: a special opening-shrinking tool is adopted to carry out hole-shrinking on the jack; after the furnace temperature for heat treating reaches 290+ / -10 DEG C, the opening-shrinking tool and the embedded jack are fed into a furnace to be subjected to heat treatment; after the furnace temperature rises to 290+ / -10 DEG C again, timing is started; and heat preservation is carried out at the furnace temperature of 290+ / -10 DEG C for 3 hours, and then discharging and air cooling are carried out. According to the invention, the opening-shrinking effect of the opening part of the jack is favorable without a clearance, the jack is stressed evenly, the insertion and extraction force of the jack is no less than 2.45N, the connecting requirement of the electric connector is met, the connection is firm, the time is saved, the efficiency is high, and the signal is stable.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH

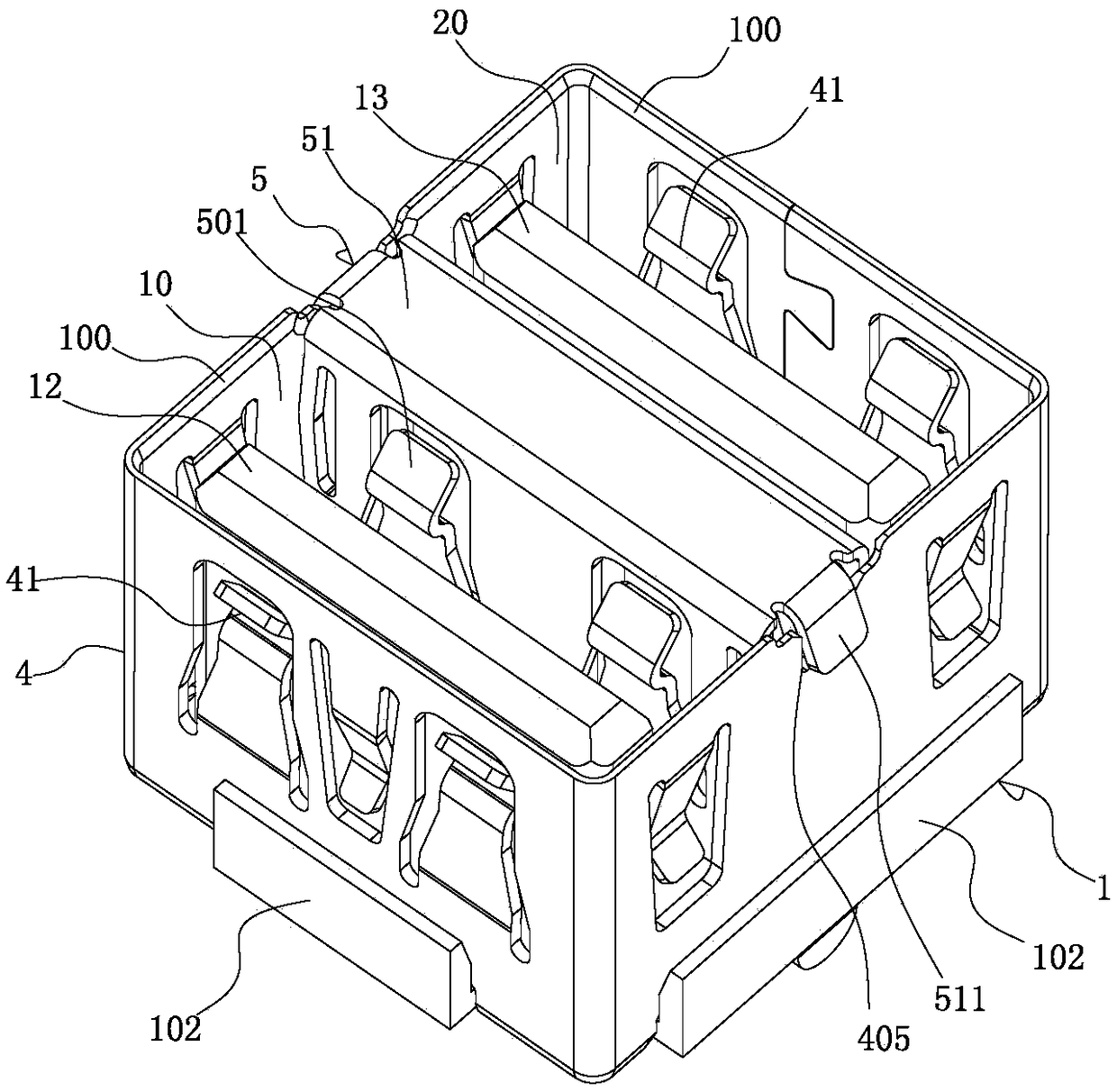

Electric connector and connector assembly

ActiveCN106848752APrevent prolapseLarge stopping forceCoupling device detailsTwo-part coupling devicesEngineeringElectrical and Electronics engineering

The invention relates to an electric connector and a connector assembly. The electric connector comprises an insulator and at least one contacting piece with the front-and-back inserting direction, contacting-piece installing holes for allowing the contacting pieces to be installed from back to front are formed in the insulator, and a contacting-piece stopping structure for limiting the forward moving range of the contacting pieces is arranged on the insulator; the electric connector also comprises a contacting-piece pressing plate, backward contacting piece stopping faces are arranged on the containing pieces, a pressing-plate installing channel for allowing the pressing plate to be installed from right to left in a guided mode is formed in the insulator, avoiding channels are formed in the contacting-piece pressing plate, pressing-plate stopping faces for being matched with the contacting piece stopping faces on the corresponding contacting pieces in a contacting-and-stopping mode are arranged at the portions, on the peripheries of the avoiding channels, on the contacting-piece pressing plate, and the contacting-piece pressing plate is fixed in the a pressing-plate installing channel through a fixing structure. By means of the electric connector and the connector assembly, the problem that in the prior art, as the contacting pieces are limited by pouring glue to move, the electric connector is complex in assembling technology is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

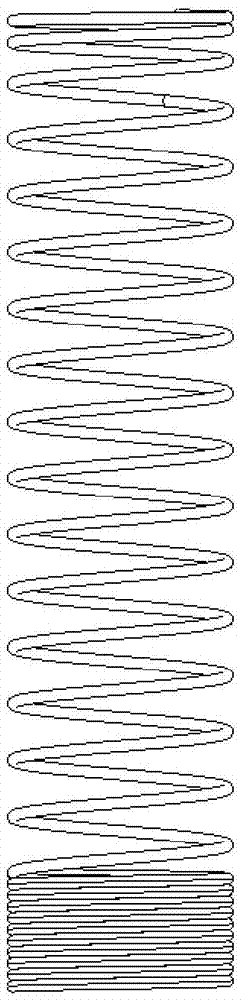

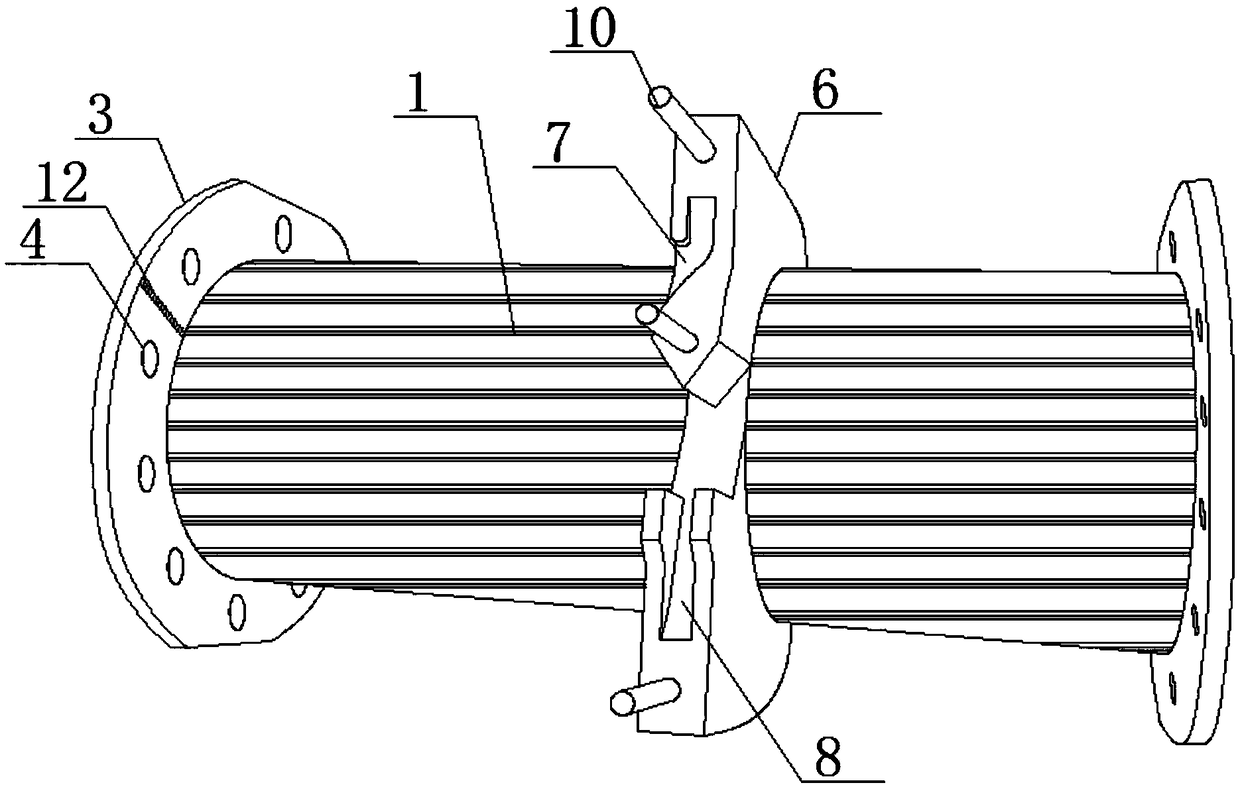

Cylindrical surface contact connection assembly

InactiveCN106898900AGood for deformation and shrinkageEasy to expandCoupling contact membersCoil springEngineering

The invention relates to a cylindrical surface contact connection assembly, which includes a terminal, a deformation arm and a plurality of arc-shaped contact pieces; the terminal is a cylindrical structure; the top of the arc-shaped contact piece is a free end, and the center forms a cylindrical shape The cavity; the bottom of the arc-shaped contact piece is connected to the terminal through the deformation arm as an integral structure; the outer side of the arc-shaped contact piece is provided with a spring. The present invention newly adds the extended part of the cylindrical socket as the deformation part, and arranges a coil spring or a spring leaf at the front end of the deformation part, so that the inner diameter of the front end of the deformation part is smaller than the cylindrical plug, so that the insertion part of the cylindrical plug fully contacts.

Owner:XIAN BLUE DIAMOND ELECTRONICS

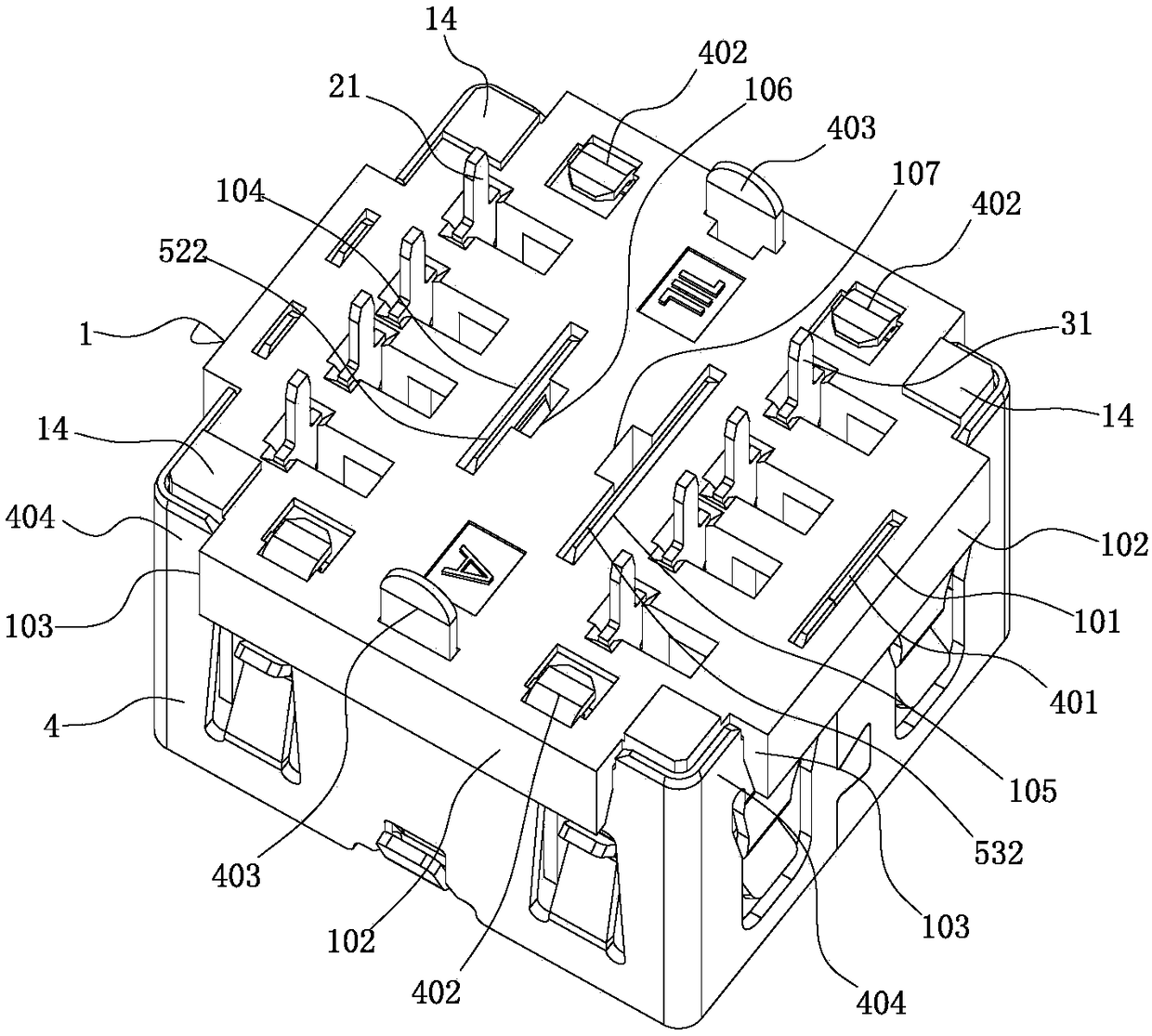

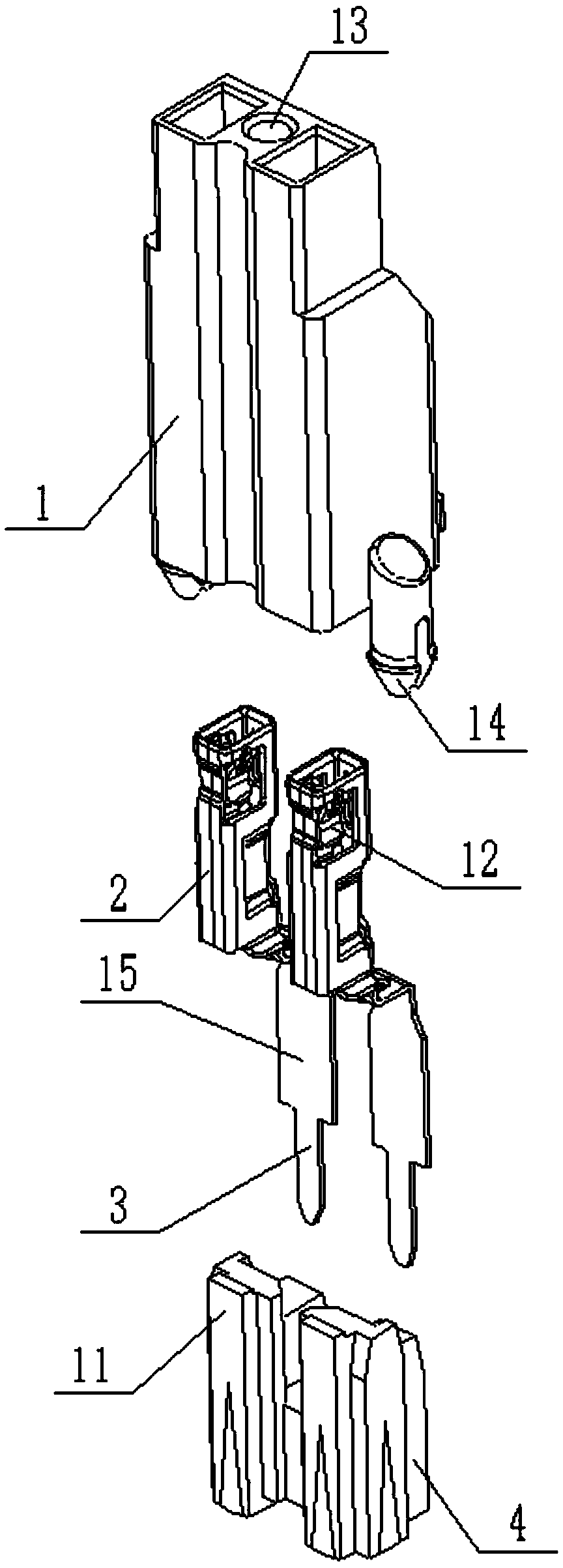

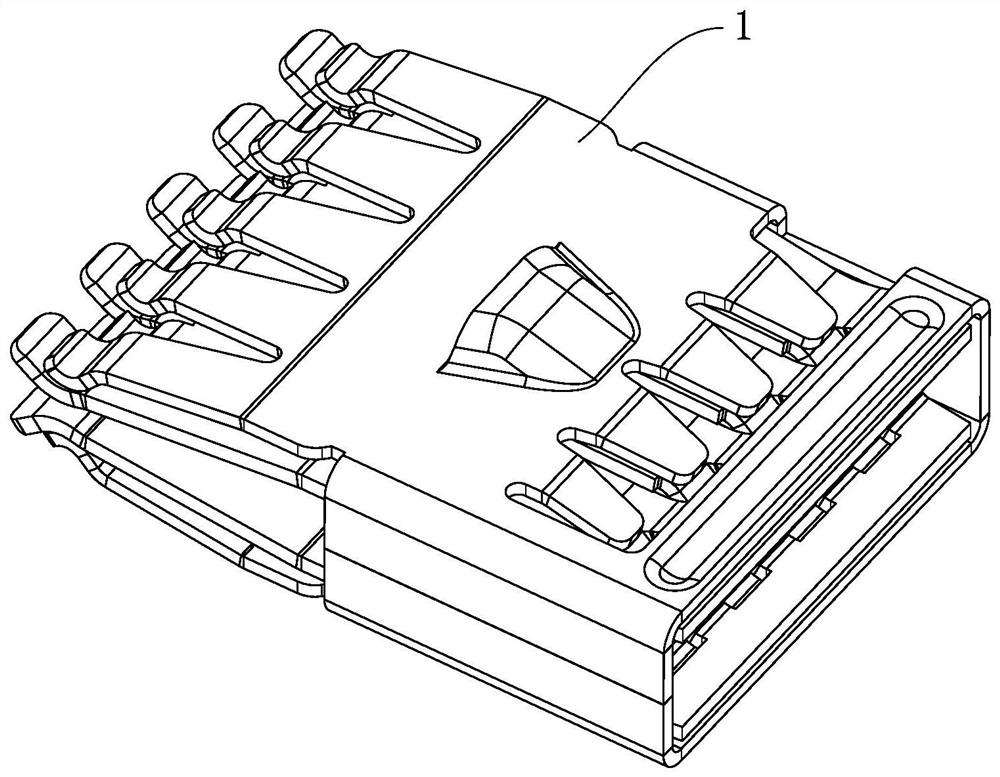

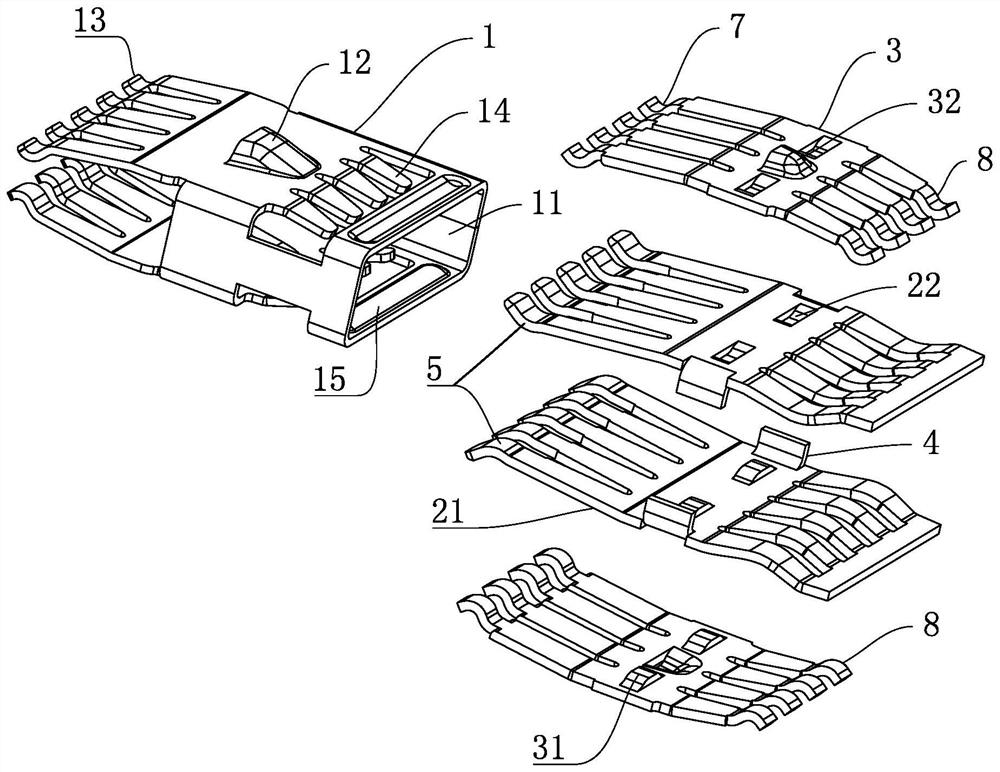

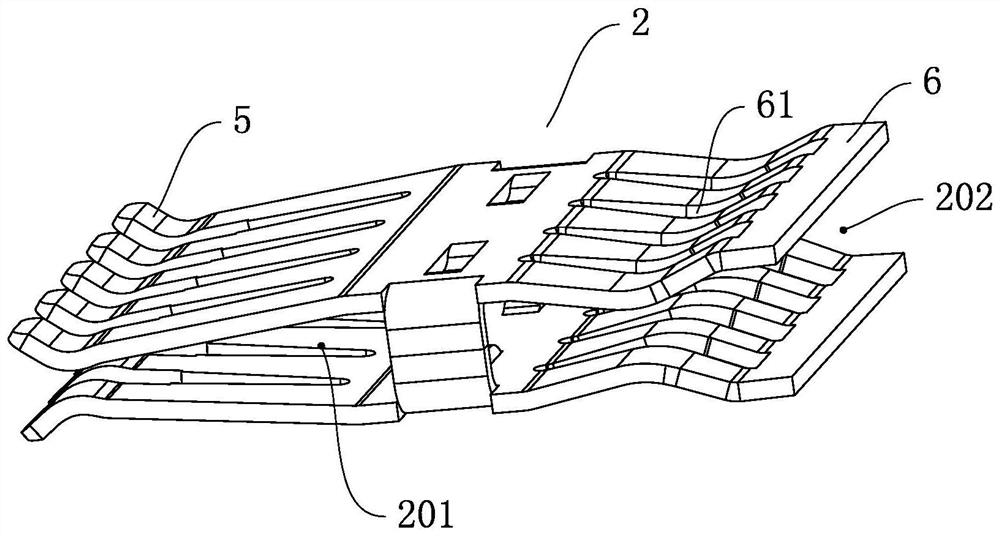

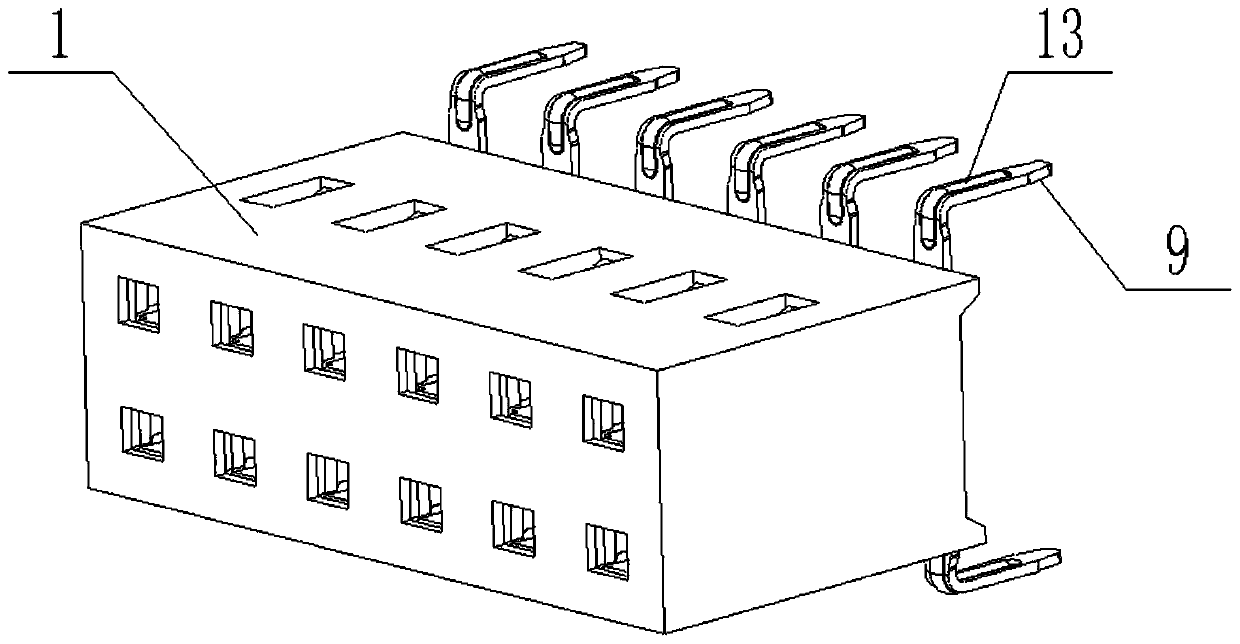

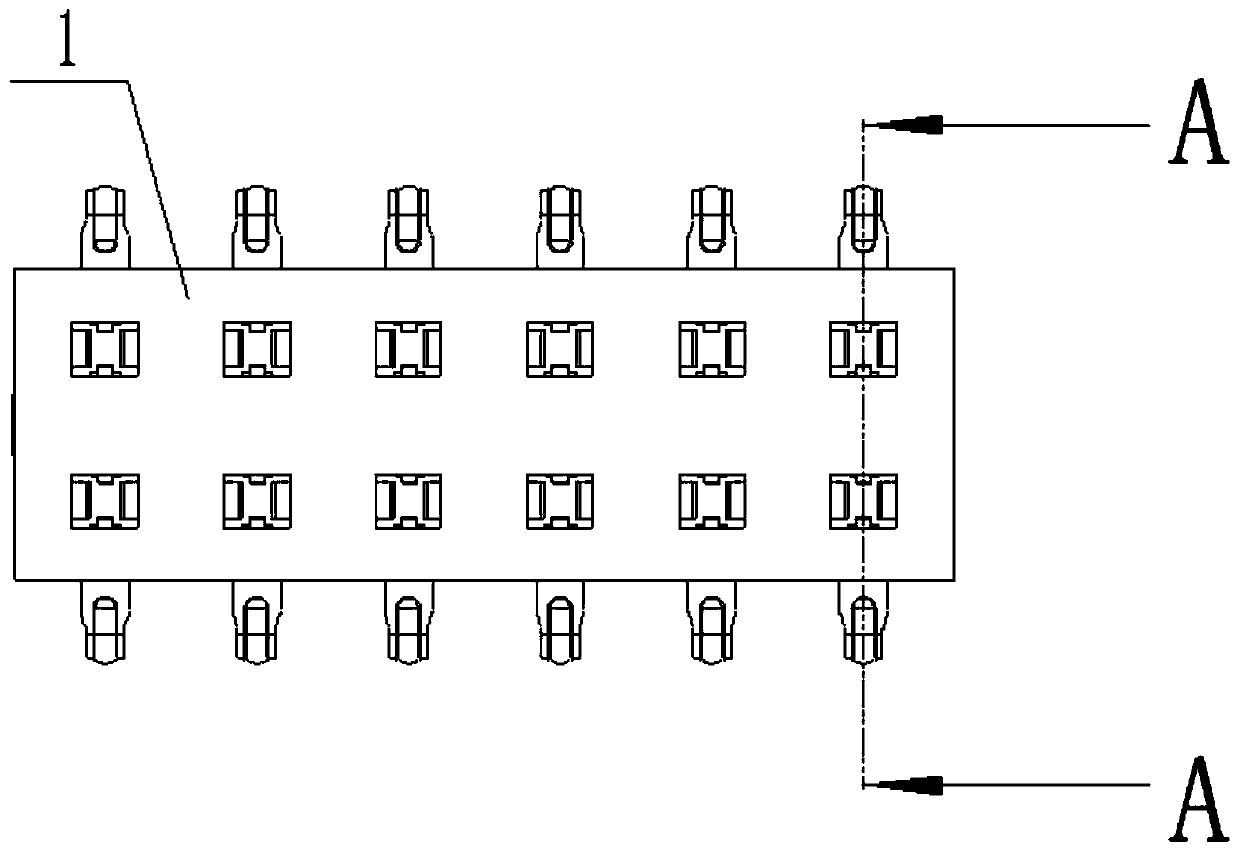

Ultra-thin vertical double-layer USB connector

PendingCN108736222AInsert firmlyStable structureEngagement/disengagement of coupling partsCouplings bases/casesEngineeringUSB

The invention discloses an ultra-thin vertical double-layer USB connector, comprising: an insulating body, having an intermediate partition, a first clapper and a second clapper; a first terminal group, inserted on the insulating body; a second terminal group, inserted on the insulating body; a metal casing, sleeved on the outer periphery of the insulating body; and a metal jacket, sleeved on theintermediate partition and fixedly connected with the metal casing, wherein a first insertion groove is formed between one side of the metal jacket and the metal casing and the first clapper, a firstelastic pressing arm is formed on one side of the metal jacket, and the first elastic pressing arm is disposed in the first insertion groove; a second insertion groove is formed between the other sideof the metal jacket and the metal casing and the second clapper, a second elastic pressing arm is formed on the other side of the metal jacket, and the second elastic pressing arm is disposed in thesecond insertion groove; and a third pressing arm formed by the metal casing is placed in the first insertion groove and / or the second insertion groove. The invention has few parts, simple structure,convenient assembly and low cost.

Owner:DONGGUAN SANJI ELECTRONICS

Power socket connector and conductive terminals thereof

InactiveCN102354836AAvoid overheating and burnoutExtend the lifespanCoupling contact membersCouplings bases/casesBurning outHigh current

The invention discloses a power socket connector. The power socket connector comprises: an insulation body; a shielding housing, which coats an outer surface of the insulation body; and a terminal set, which is installed in the insulation body. The terminal set includes a central contact terminal and conductive terminals, which are at two sides of the central contact terminal; a vertical type elastic contact part and a horizontal type elastic part are arranged on the same conductive terminal; and the vertical type elastic contact parts and the horizontal type elastic parts are respectively connected to an L-shaped holding portion through a vertical connection portion and a horizontal connection portion. Therefore, when a butted power plug is inserted into the power socket connector, the vertical type elastic contact parts and the horizontal type elastic parts simultaneously make contacts with the butted power plug, so that an area for passing of a high current is enlarged and stability of current conduction is improved; besides, an occurrence of burning out of the connector due to high temperature can be avoided, wherein the high temperature is caused by insufficient of contact points during current flowing; and thus the product security during high currents can be ensured, hidden troubles are eliminated, and operating life of the connector is also extended.

Owner:SUYING ELECTRCNICS (DONG GUAN) CO LTD

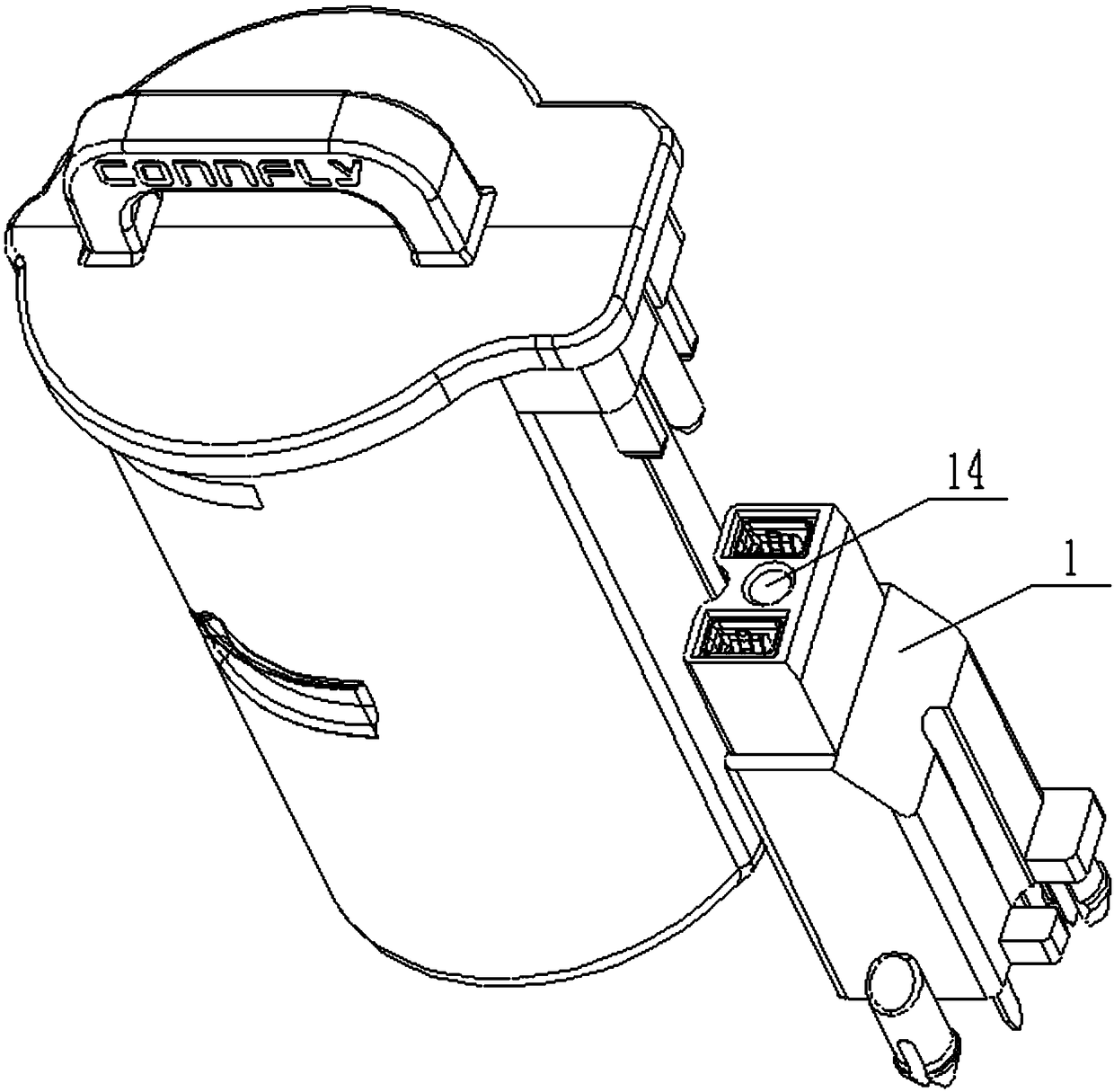

Plug-in connector

InactiveCN108987965AImprove insertion forceImprove plug lifeCoupling contact membersEngineeringMechanical engineering

Owner:NINGBO CONNFLY ELECTRONIC CO LTD

A plastic skeleton structure with pins for inductive coils

ActiveCN109215982AAvoid the risk of being pushed outImprove insertion forceTransformers/inductances coils/windings/connectionsPositive pressureInductor

The invention relates to the technical field of inductors, in particular to a plastic skeleton structure with pins for inductive coils. Through the vertical exhaust groove arranged at the lower end ofthe pin, As that pin is insert, no positive pressure is formed in the air in the pin hole, As that gas in the pinhole enter with the pin, Gas escapes from the vertical exhaust slot, there is no positive pressure gas in the hole, so that that insertion and extraction force is increase, At that same time, the high-temperature gas doe not run out along the vertical exhaust slot when soldering the tin instantaneously, avoiding the risk of pins being pushed out, through the heat dissipation groove and the heat dissipation hole, and the heat dissipation hole is communicated with the heat dissipation groove, As that coil is wound around the core, A heat dissipation hole (a) is arranged so as to better dissipate heat for the coil in operation. A partition plate is sleeved on the core, and a clipblock on the partition plate is stuck in the heat dissipation groove, so that the partition plate can be moved around the core again to meet different use requirements.

Owner:WUXI JINGLEI ELECTRONICS

Terminal structure of smart label connector and manufacturing method

ActiveCN105762543AGuaranteed StrengthIncreasing the thicknessSecuring/insulating coupling contact membersCoupling contact membersEngineeringBiomedical engineering

The invention discloses a terminal structure of a smart label connector and a manufacturing method. The terminal structure includes a power supply terminal, a grounding terminal and a signal terminal, wherein the power supply terminal includes a first main body part, first elastic touch arms, second elastic touch arms and a first contact part, and the first elastic touch arms obliquely extend outward relative to the second elastic touch arms; the grounding terminal includes a second main body part, elastic conducting arms and a second contact part, and elastic conducting arms are parallelly distributed beside the first elastic touch arm; the signal terminal includes a third main body part, elastic plugging arms and a third contact part, the elastic plugging arms are parallelly distributed beside the second elastic touch arm; and the first, second and third contact parts are the same in structure, the thickness of first, second and third golden fingers in the first, second and third contact parts is larger than that of the first, second and third main body parts, and the width of the first, second and third golden fingers is the same as that of the first, second and third main body part. By adoption of the terminal structure provided by the invention, a smart label connector can be made thinner.

Owner:DONGGUAN YUQIU ELECTRONICS CO LTD

Method for locating connecting terminal by using repeat buried injection technology

InactiveCN103840350AIncreased plugging forceSignal transmission is stableContact member assembly/disassemblySizingEngineering

The invention relates to a method for locating a connecting terminal by using a repeat buried injection technology. The method is used for generating a signal connector and comprises the following steps that multiple first connecting terminals are located in a first mould, a first sizing material is injected to enable the first sizing material to form a first seat body after solidification, and the first seat body is formed on the first connecting terminals; then, the first seat body is located on a second mould, multiple second connecting terminals are located to one side of the first seat body; a second sizing material is injected in the second mould to enable the second sizing material to form a second seat body after solidification, the second seat body and the first seat body are combined in a seamless mode and are formed on the second connecting terminals, and then the signal connector is formed through the combination. In this way, through the buried injection technology, the locating strength of the connecting terminals can be improved effectively, and the production qualified rate and the product efficiency of the signal connector can be improved.

Owner:GUIMA SCI & TECH

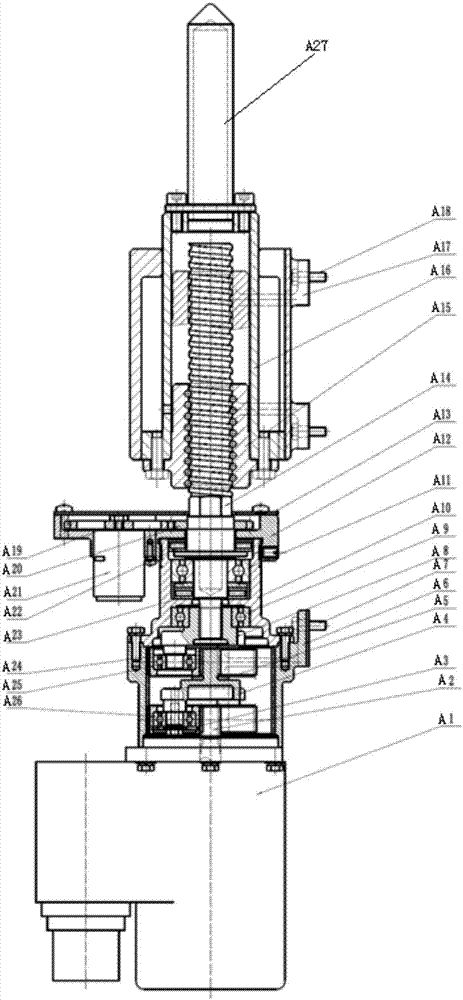

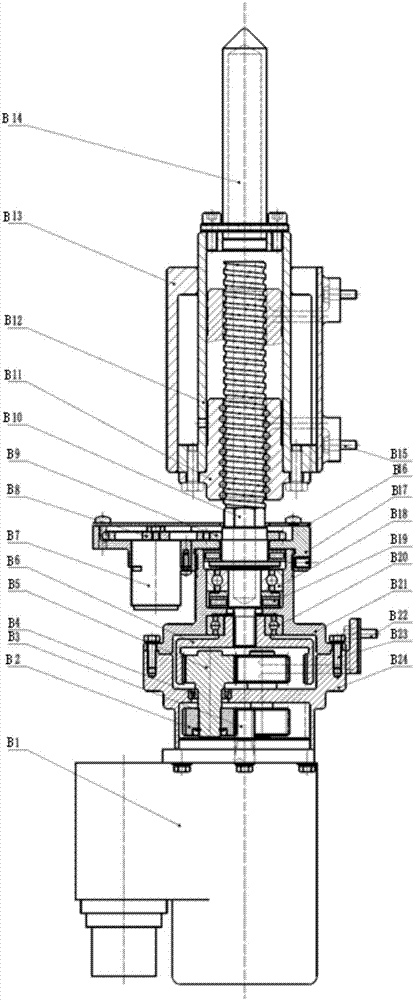

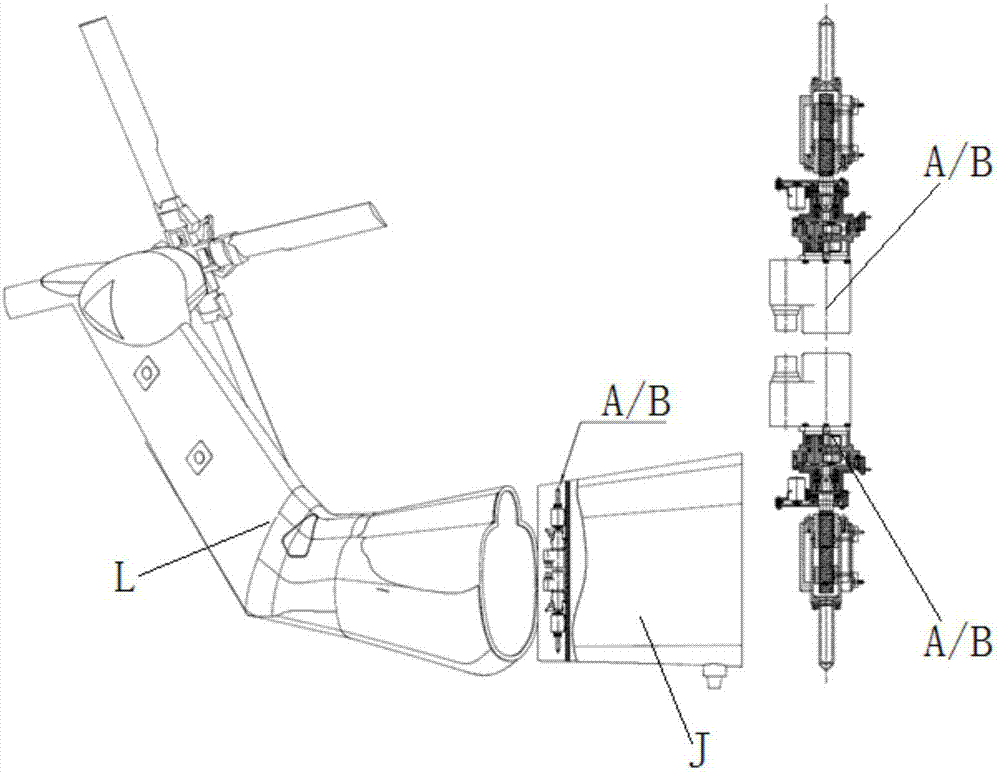

Electric transmission device of split helicopter tail inclined beam pin locking mechanism and pin locking mode

ActiveCN107575547AReduce the risk of task completionImprove insertion forceGearingAir-flow influencersSplit pinMotor drive

The invention provides an electric transmission device of a split helicopter tail inclined beam pin locking mechanism and a pin locking mode. Firstly, the rotating speed of a motor is lowered througha gear transmission pair to achieve the purposes of reducing the speed and increasing the torque; and finally, the torque is converted to the linear thrust of a pin locking nut through a ball screw pair to realize quick locking and unlocking of a tail inclined beam. meanwhile, the use and the maintenance of the device are considered; and under the condition of failures, the manual locking and unlocking can be realized. The pin locking device adopts upper and lower sets of split pin locking devices; and each motor drives one locking pin, so that each locking pin can be singly acted to reduce the task risk. The vibration of the tail inclined beam of a helicopter can be effectively reduced in flight, so that the abnormal actions of the tail inclined beam due to vibration are prevented, the guarantee time before and after flight is shortened, and the unfolding and folding reliability of the tail inclined beam of the helicopter is improved.

Owner:CHONGQING UNIV +1

A connector plug, a connector socket and a connector combination thereof

ActiveCN104241975BReduce distractionsImprove shielding effectCoupling contact membersContact modeContact Transmission

Owner:SHENZHEN LITKCONN TECH

Metallic material for electronic components and method for producing same, and connector terminals, connectors and electronic components using same

ActiveUS10594066B2Low degreeIncreased durabilitySingle bars/rods/wires/strips conductorsPhosphatisationMetallic materialsEngineering

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer including an alloy constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir, and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; and an upper layer formed on the intermediate layer, the upper layer being constituted with one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.02 μm or more and less than 0.80 μm; and the thickness of the upper layer is 0.005 μm or more and less than 0.30 μm.

Owner:JX NIPPON MINING & METALS CORP

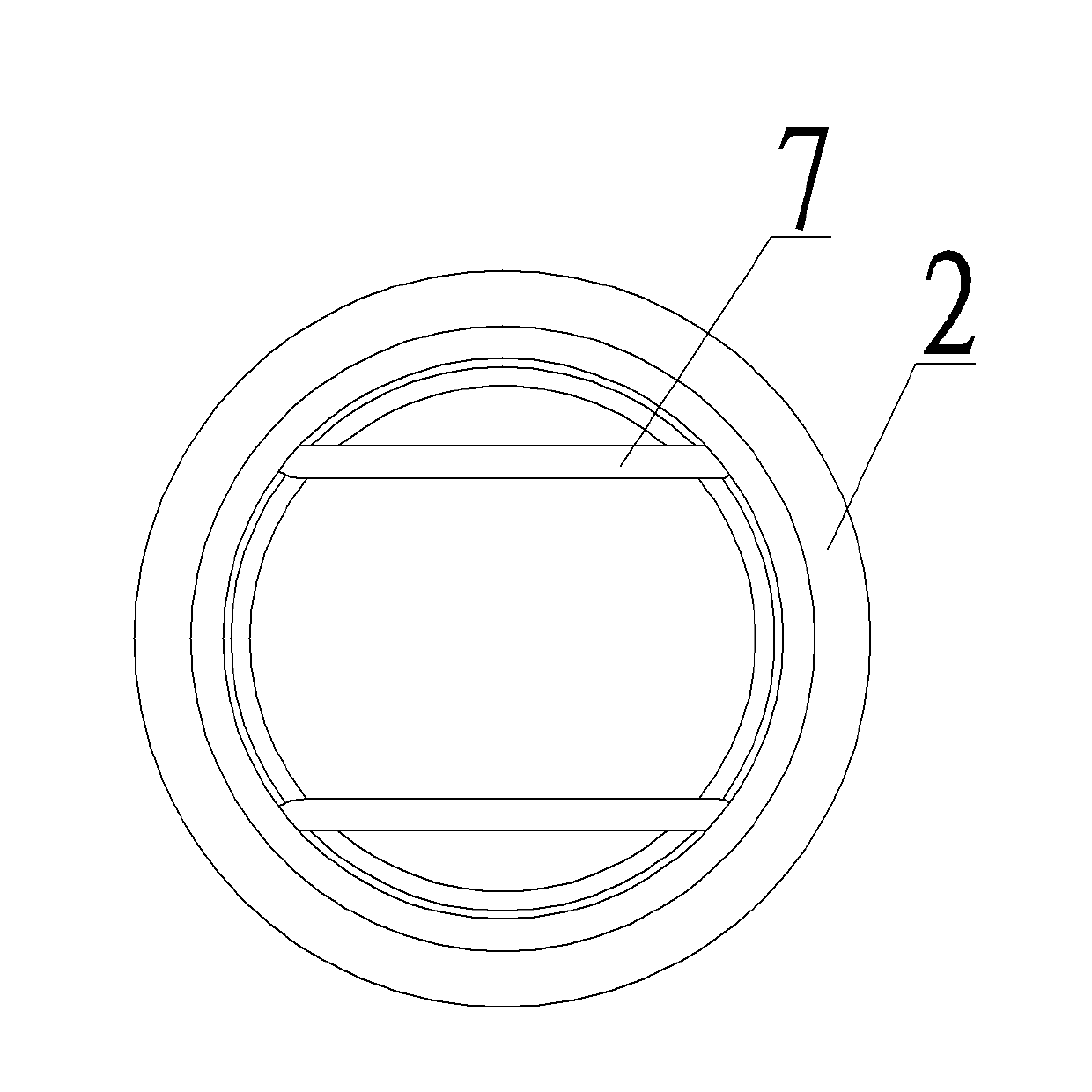

Reed-type radio frequency coaxial connector

InactiveCN102709766AExpand the pin rangeImprove insertion forceCoupling contact membersTwo-part coupling devicesElectrical conductorEngineering

The invention discloses a reed-type radio frequency coaxial connector, comprising a shell body and an inner conductor arranged in the shell body; a connecting device is arranged in the inner conductor, and the connecting device is a reed structure; the reed structure comprises two mutually matched spring pieces and rod bodies, the spring pieces are connected at the front ends of the rods; two mutually matched spring pieces are formed to be a pluggable zone. The pluggable zone formed by the two mutually matched spring pieces is matched with the shape of a contact pin. Two mutually matched spring pieces are formed to be a plug hole which is small in the aperture of the front end and is large in the aperture of the middle part. The contact pin of the reed-type radio frequency coaxial connector is wide in scale, long in service life and low in cost.

Owner:镇江南方电子有限公司

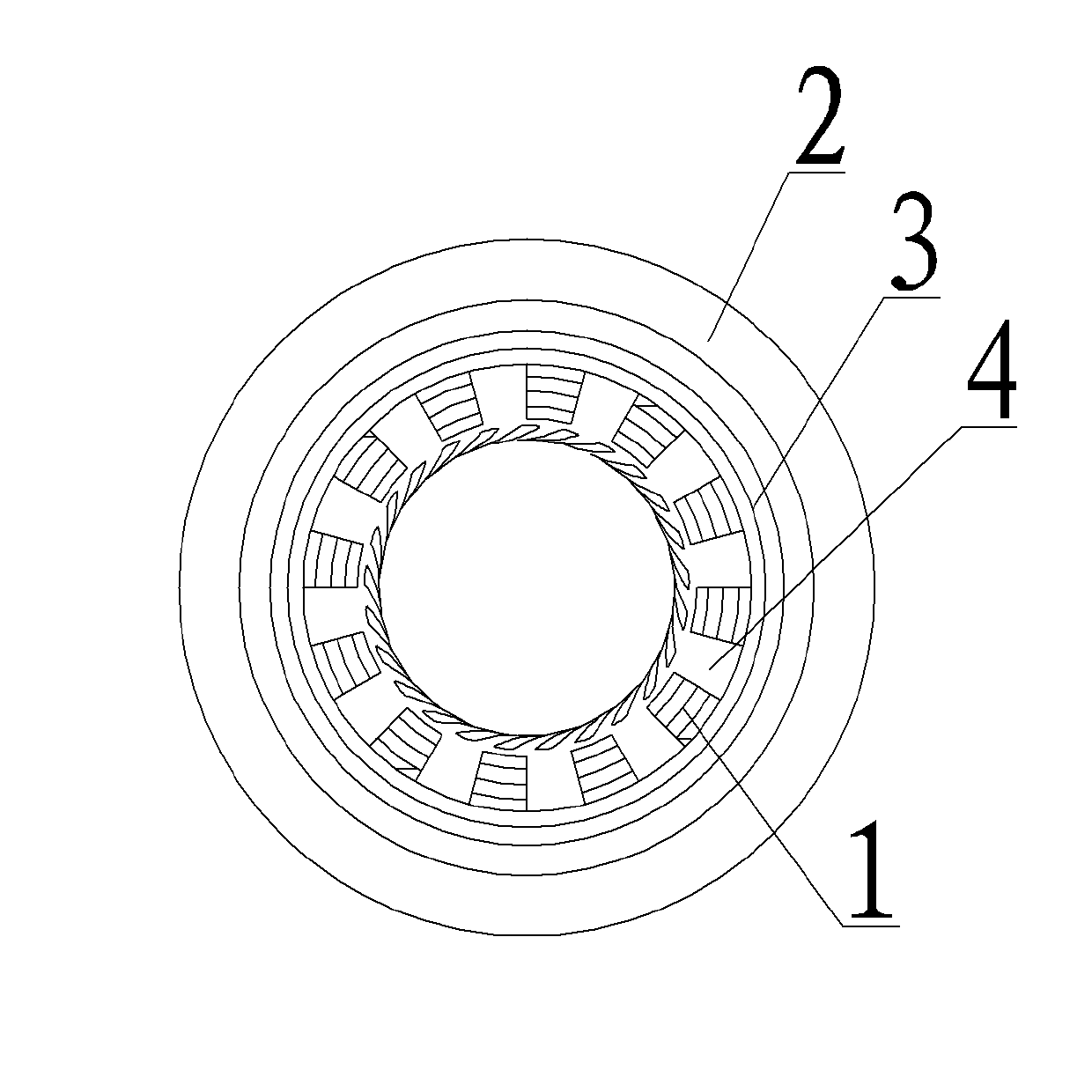

A chip contact socket structure

ActiveCN111541083BIncrease elasticityImprove conductivitySecuring/insulating coupling contact membersCoupling contact membersElectrical connectionEngineering

A chip contact socket structure, including a circlip, a chip contact assembly installed in the circlip socket and both front and rear ends are used for mating with the adapter chip pin, and symmetrically installed on the chip contact For the reeds on the upper and lower surfaces of the component, the front end of the sheet contact assembly is oppositely provided with a plurality of first claws arranged at intervals along the width direction of the sheet contact assembly, and the rear end is oppositely provided with a conductive clip; the front end of the reed has a The second spring claw between the first spring claws and the second spring claw is in conductive contact with the blade pin, and the rear end has a third spring claw which is placed in the through hole opened on the conductive clip and is in conductive contact with the blade pin. The present invention adopts the steel-clad copper type double reed structure, which is convenient for processing and assembling. Compared with the existing single reed structure, the contact point and contact retention force with the adapter pin are increased, and the electrical connection is improved. Stability, especially suitable for high frequency vibration environment.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Headrest mounting structure vehicle seat

Owner:TOYOTA BOSHOKU KK

A female connector

ActiveCN108539470BImprove contact stabilityImprove contact reliabilitySecuring/insulating coupling contact membersEngineeringMechanical engineering

Owner:NINGBO CONNFLY ELECTRONIC CO LTD

Metallic material for electronic components and method for producing same, and connector terminals, connectors and electronic components using same

ActiveUS10826203B2Low degreeIncreased durabilityLine/current collector detailsSingle bars/rods/wires/strips conductorsMetallic materialsEngineering

The present invention provides metallic materials for electronic components, having low degree of whisker formation, low adhesive wear property and high durability, and connector terminals, connectors and electronic components using such metallic materials. The metallic material for electronic components includes: a base material; a lower layer formed on the base material, the lower layer being constituted with one or two or more selected from a constituent element group A, namely, the group consisting of Ni, Cr, Mn, Fe, Co and Cu; an intermediate layer formed on the lower layer, the intermediate layer being constituted with one or two or more selected from a constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir; and an upper layer formed on the intermediate layer, the upper layer being constituted with an alloy composed of one or two or more selected from the constituent element group B, namely, the group consisting of Ag, Au, Pt, Pd, Ru, Rh, Os and Ir and one or two selected from a constituent element group C, namely, the group consisting of Sn and In; wherein the thickness of the lower layer is 0.05 μm or more and less than 5.00 μm; the thickness of the intermediate layer is 0.01 μm or more and less than 0.50 μm; and the thickness of the upper layer is 0.02 μm or more and less than 0.80 μm.

Owner:JX NIPPON MINING & METALS CORP

Dual-purpose connector plug and assembly method thereof

InactiveCN105914515BEasy to useAvoid damageContact member assembly/disassemblyTelephony connectorsDual purposeUSB

The invention discloses a dual-purpose connector plug and an assembling method thereof. The dual-purpose connector plug comprises a metal housing, a Lightning interface terminal module and a Micro-USB interface terminal module. A first abdicating hole is formed in the top wall of the metal housing. A first terminal contact part of the Lightning interface terminal module is exposed from the first abdicating hole. A plug-in port is formed in the front end wall of the metal housing. The plug-in port penetrates backwards through the inner part of an accommodating cavity so as to form a plug-in cavity. A second terminal contact part of the Micro-USB interface terminal module is exposed in the plug-in cavity in a protruding manner. A second abdicating hole is formed in the bottom wall of the metal housing. An insulator is arranged in the second abdicating hole, and in this way, an insulating area corresponding to another surface of contact terminals in a Lightning socket is formed on the bottom wall of the metal housing, so that the short circuit problem of the metal housing and the Lightning socket of the dual-purpose connector plug is effectively solved, the damages caused to the electronic products using the Lightning socket are avoided, and the usage performance of the dual-purpose connector plug is improved; in addition, the structure is simple, the design is ingenious and reasonable, and the assembling is convenient, rapid, stable and reliable.

Owner:KENSONIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com