Terminal structure of smart label connector and manufacturing method

A smart label and terminal structure technology, which is applied to the parts, connections, fixed/insulated contact components of the connecting device, etc., can solve the problems that the label connector cannot meet the assembly requirements, cannot guarantee the quality of communication, and the terminals are easy to be damaged. Not easy to deform, meet the requirements of use, strong insertion force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

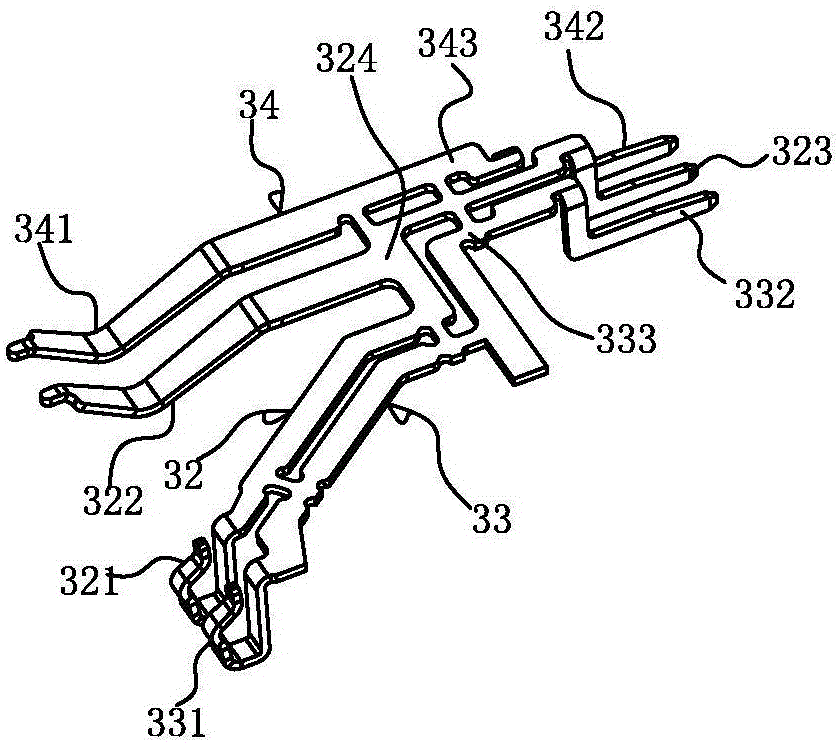

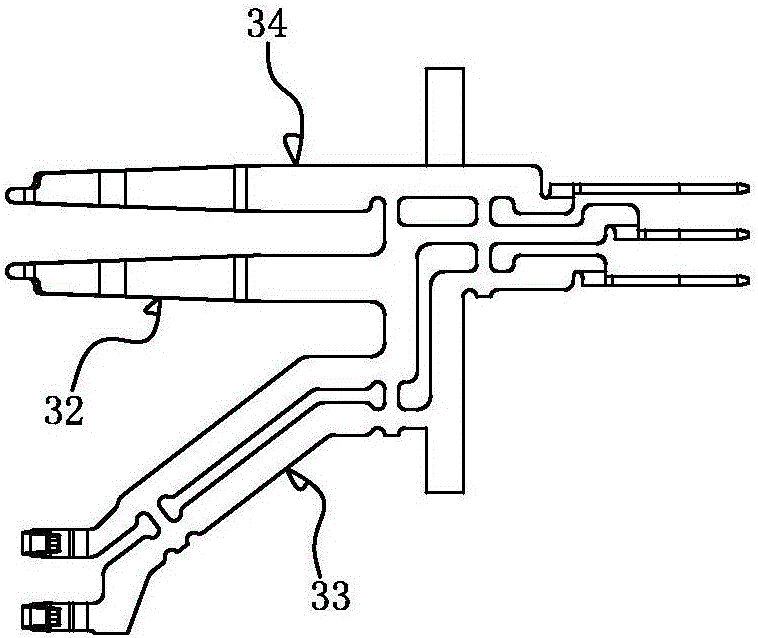

[0051] See Figure 1-3 As shown, it is a terminal structure of a smart label connector, which includes a power terminal 32 , a ground terminal 33 and a signal terminal 34 .

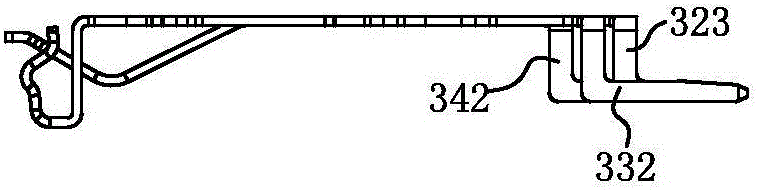

[0052] Specifically, combining Figure 4 As shown, the power terminal 32 includes a first body part 324 integrally fixed in the terminal base 1, and the first elastic contact arm 321, the second elastic contact arm 322 and the first elastic contact arm 322 formed on the front end of the first body part 324. The first contact portion 323 is bent and formed at the rear end of the first main body portion 324 , wherein the first elastic contact arm 321 extends obliquely outward relative to the second elastic contact arm 322 , ie forms a bifurcated structure.

[0053] The end of the first elastic contact arm 321 is formed with a first raised portion 3211 and a first bent portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com