Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Fast strapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

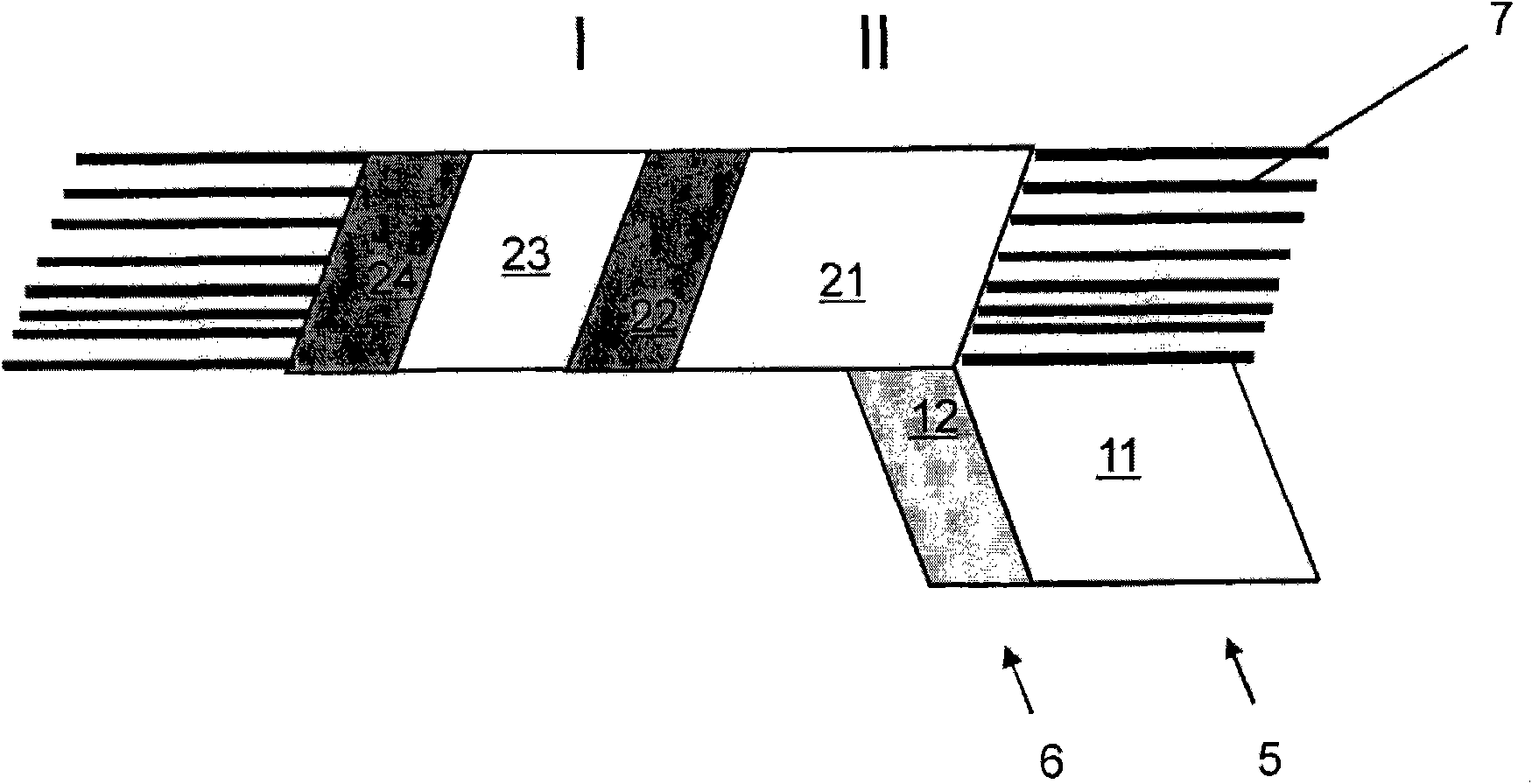

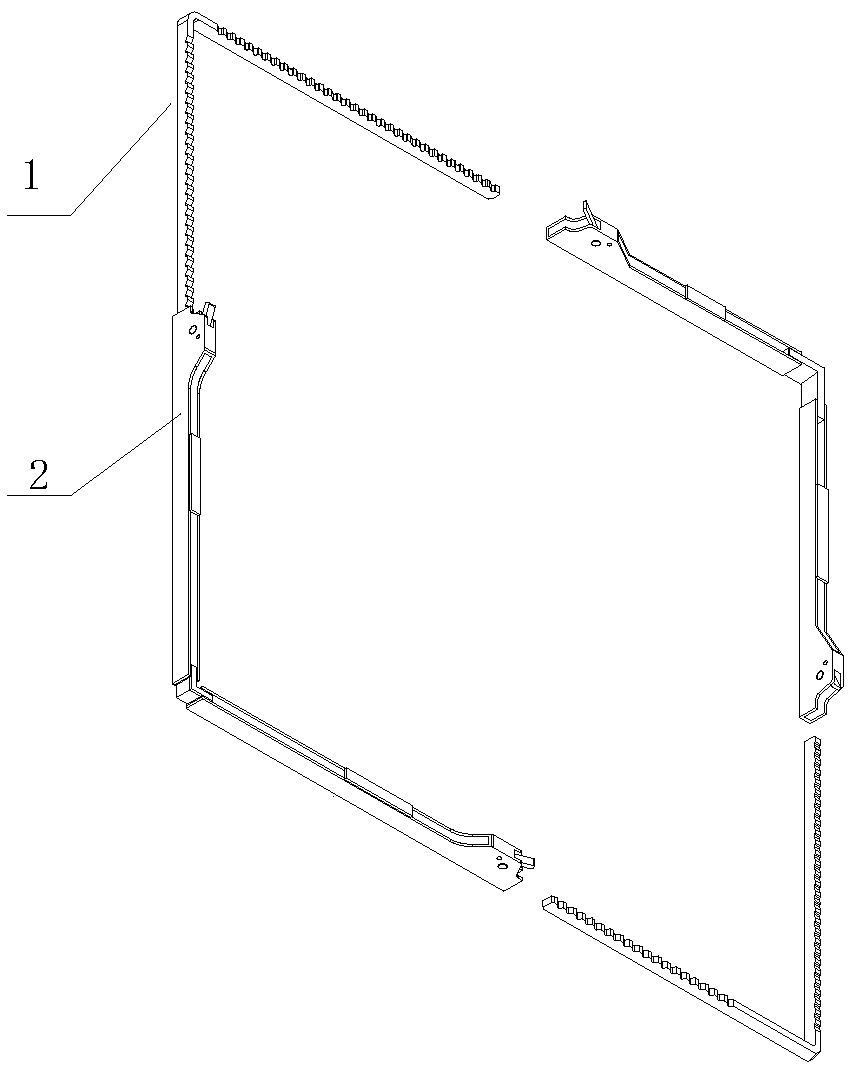

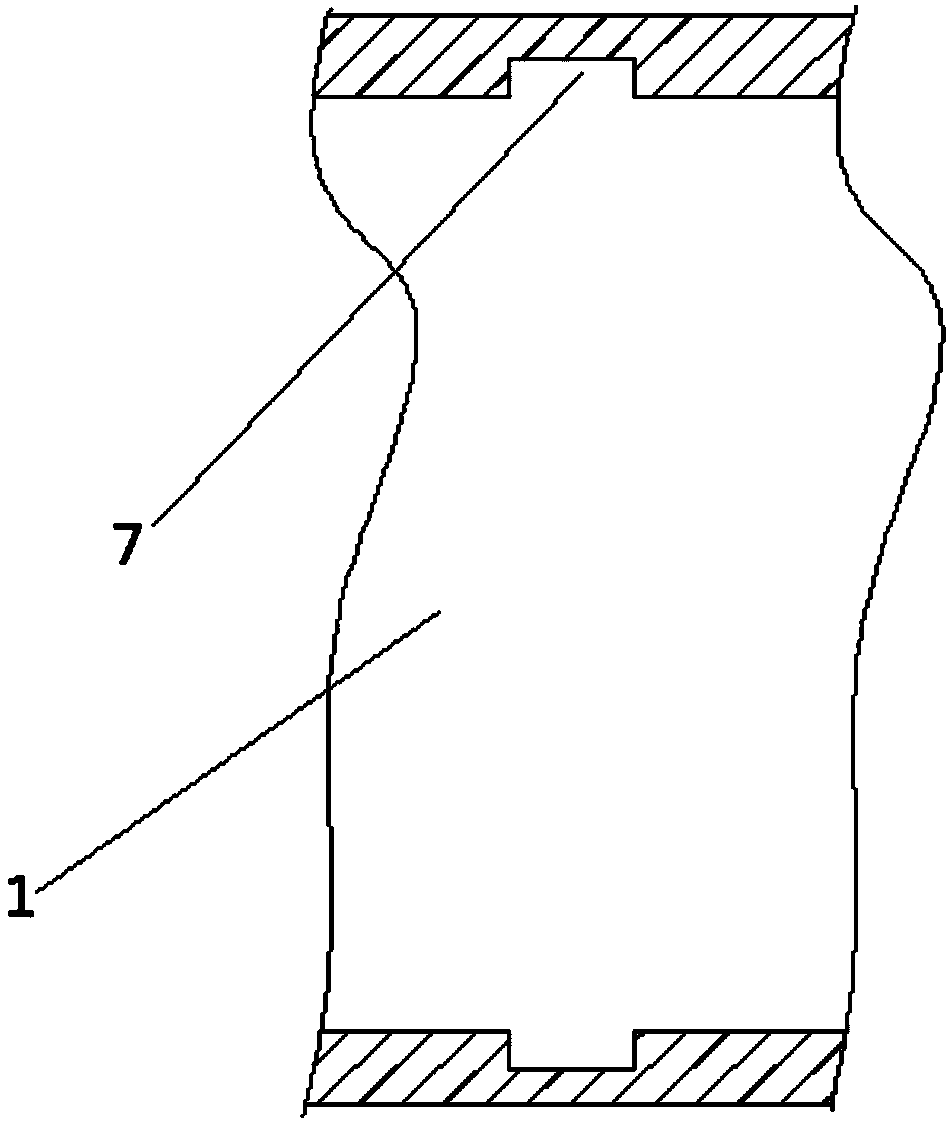

Adhesive tape and use thereof

InactiveCN101654600AFast strappingEasy to tieFilm/foil adhesivesFlexible elementsBand shapeEngineering

The invention provides an adhesive tape with a strap-shaped substrate material, which is used for wrapping a longitudinally extending object, particularly a conductor bundle or cable bunch. At least one side of the substrate material is spread with a special pressure-sensitive adhesive. The tape is characterized in that: the substrate material is formed by embossed PVC thin films; and the embosseddepth is 0.01 to 8mum, preferably 0.1 to 3mum.

Owner:TESA SE

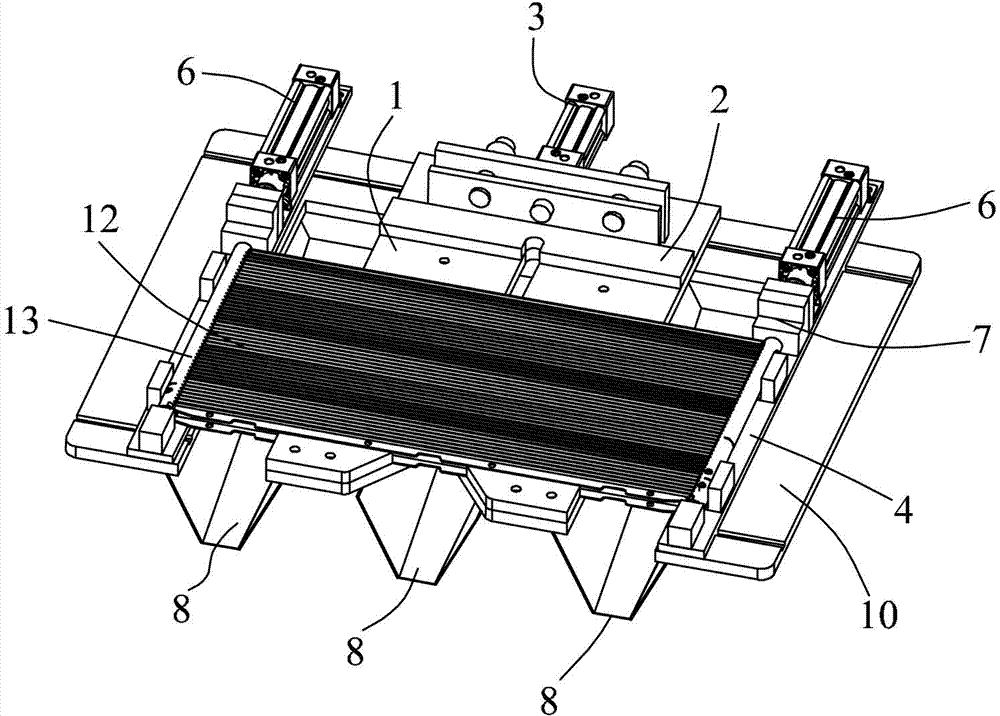

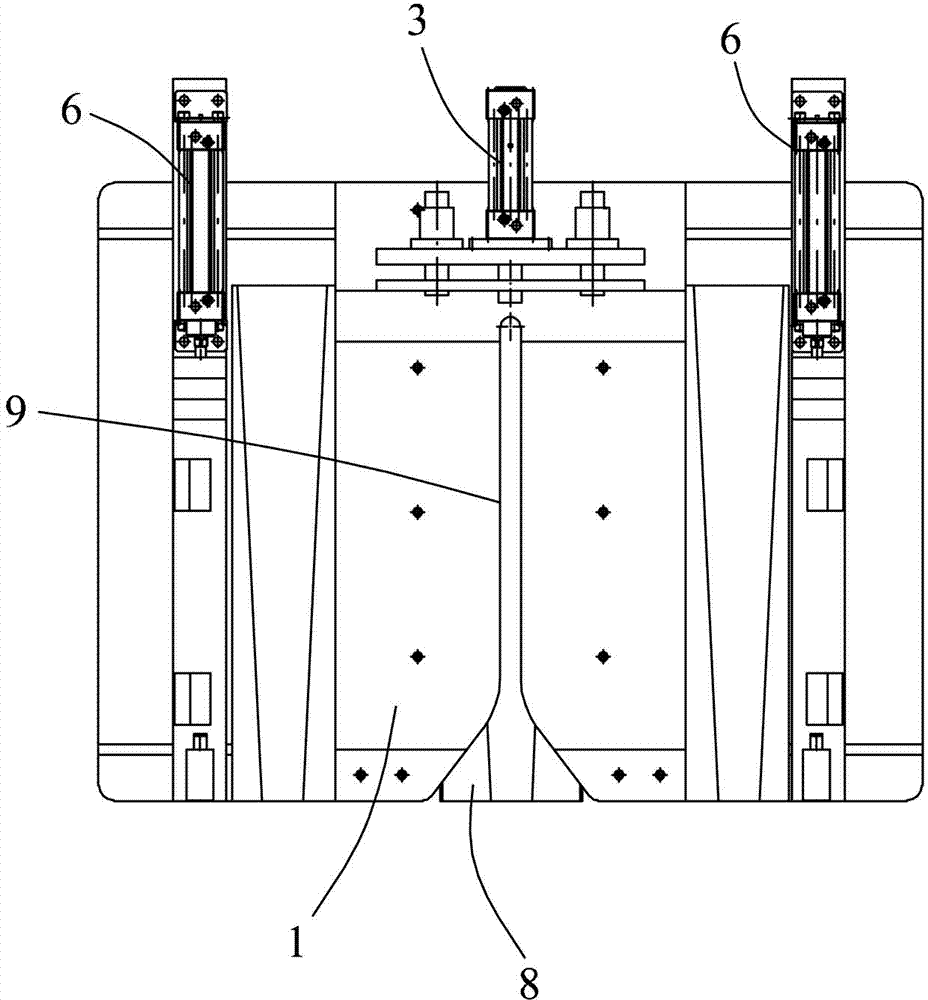

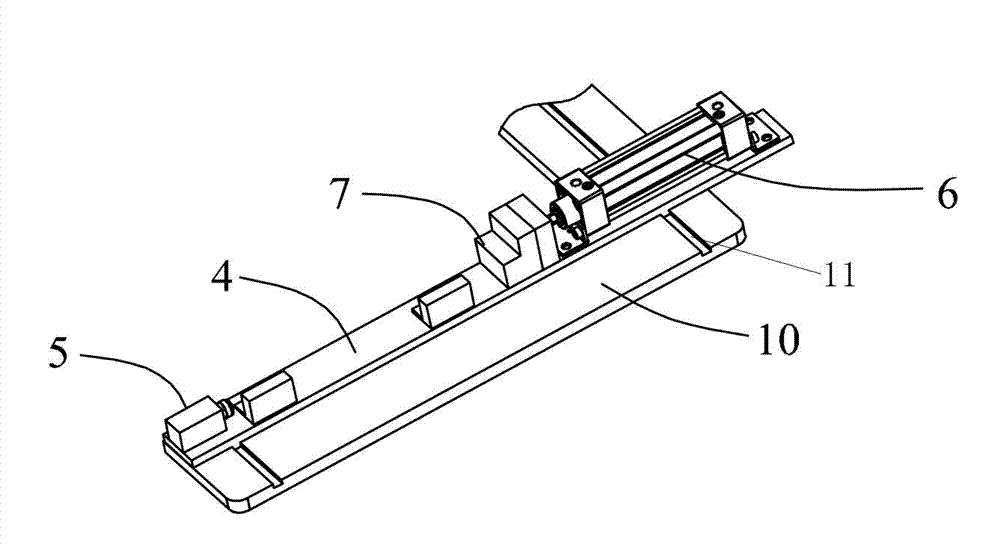

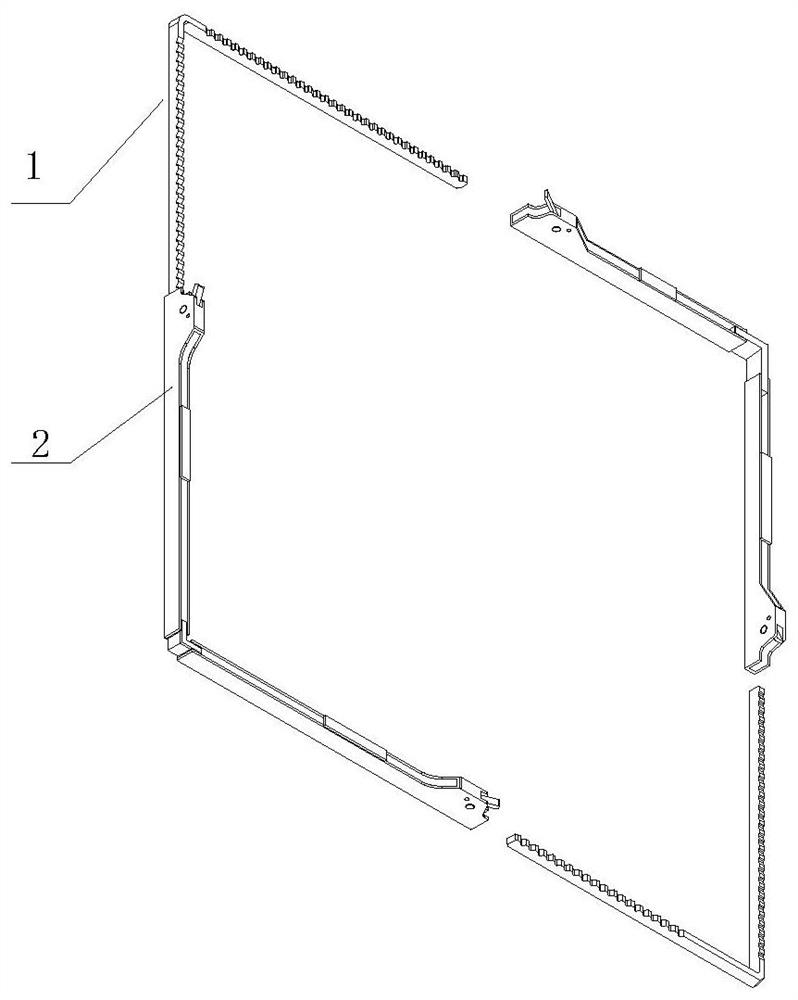

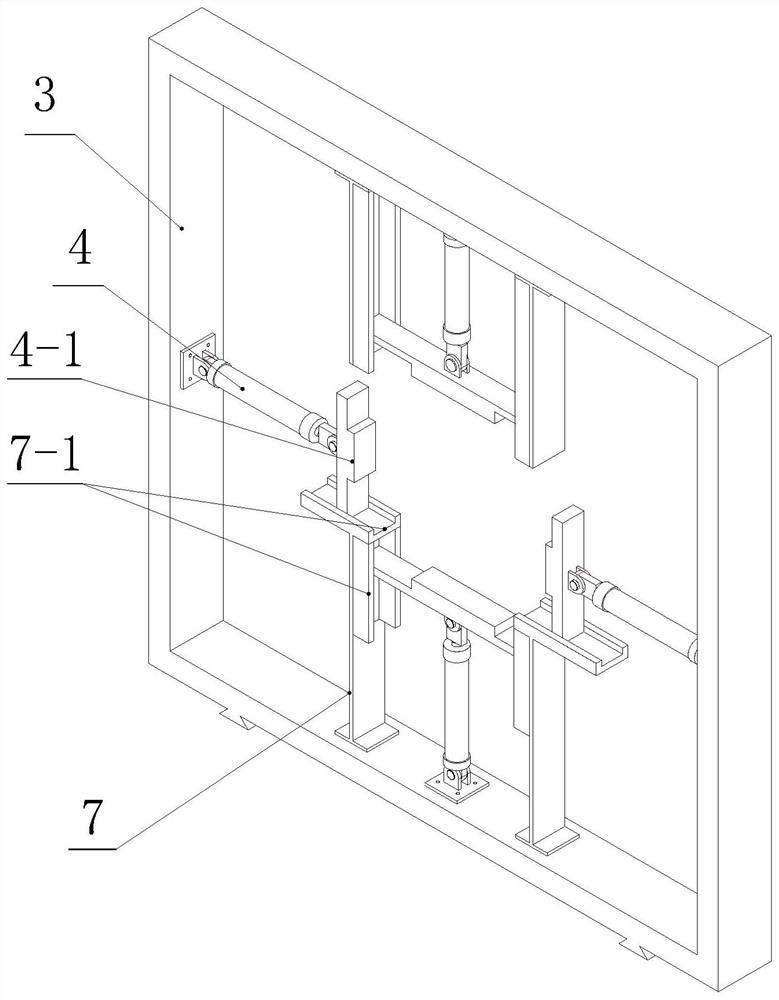

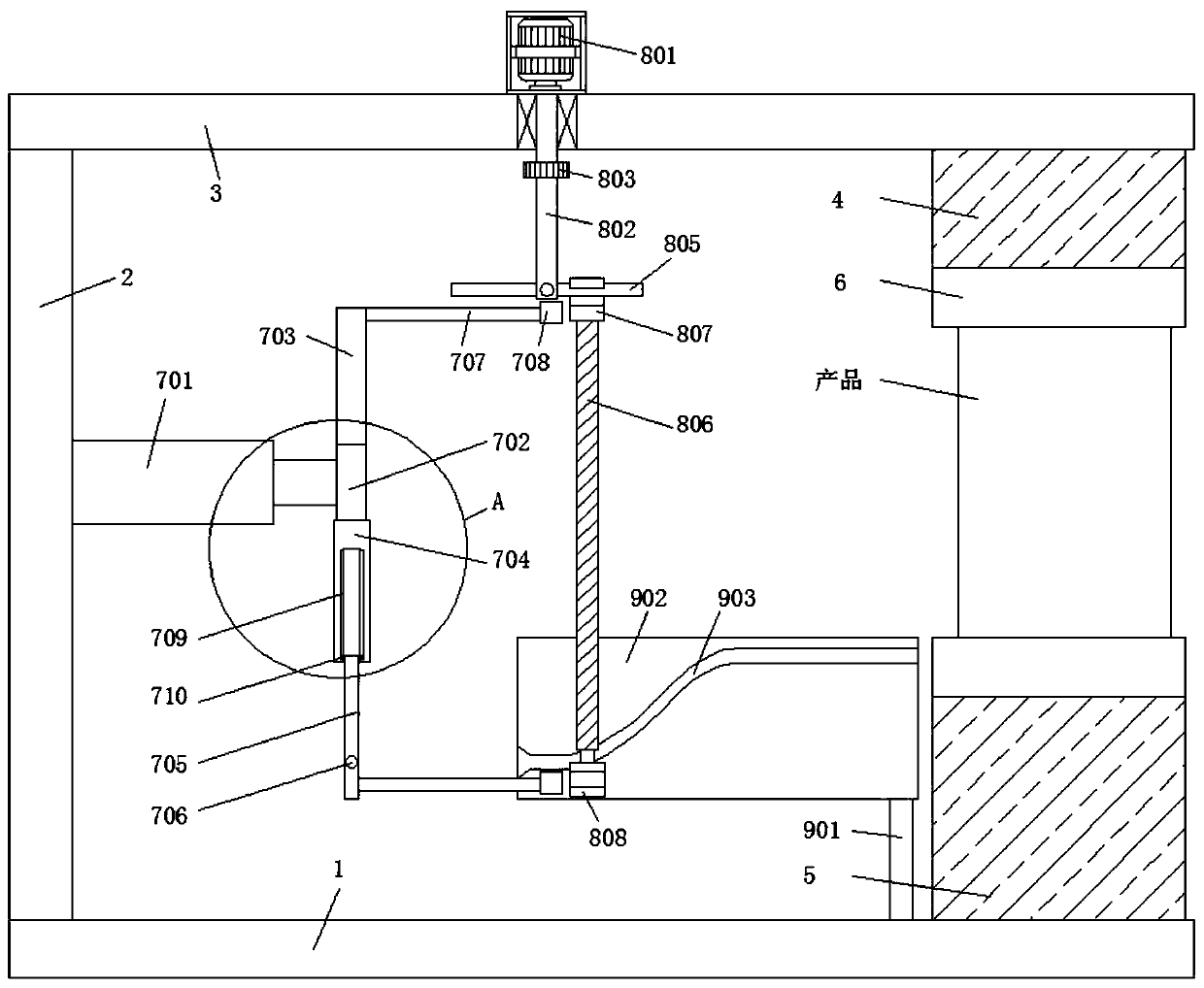

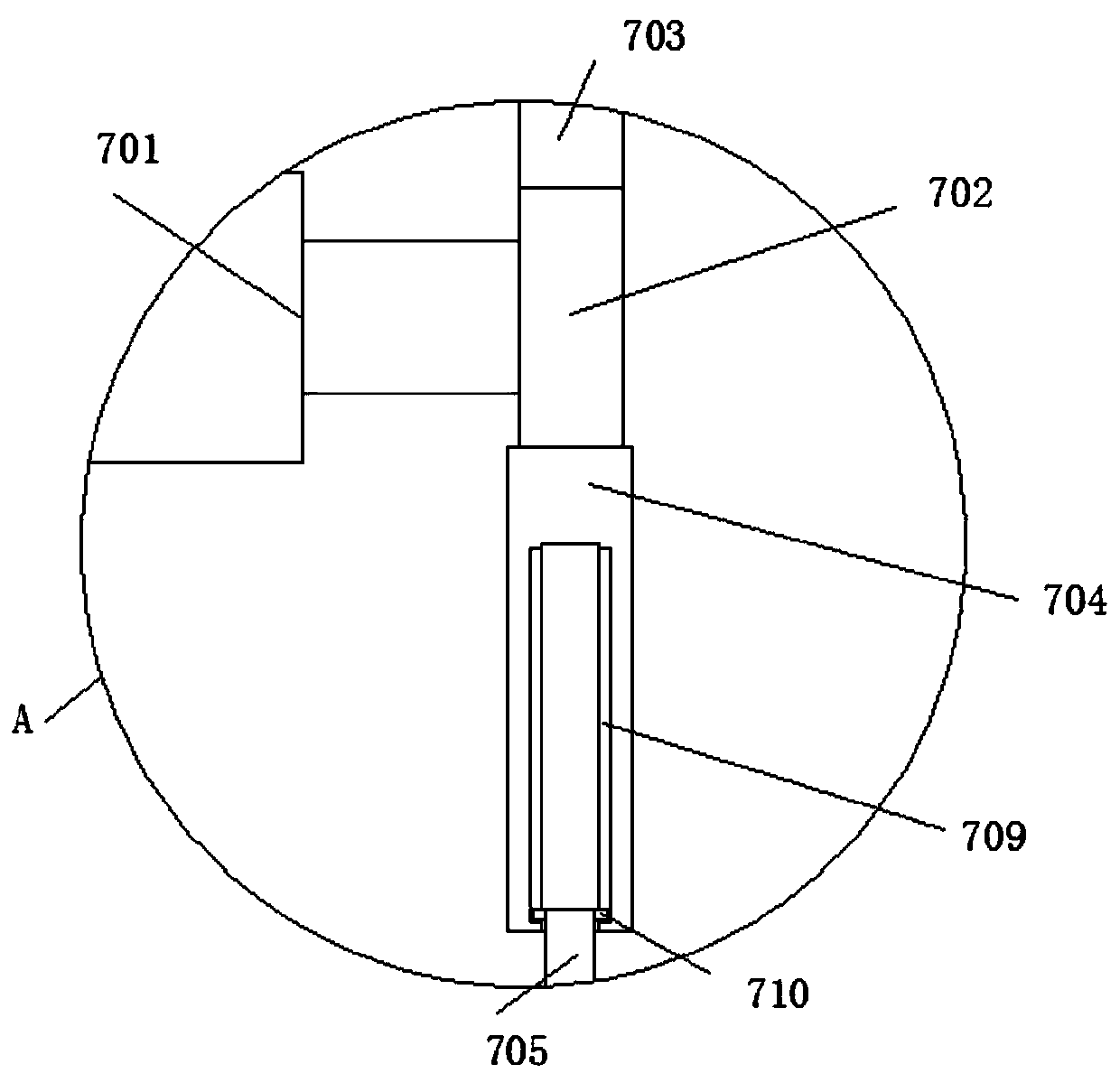

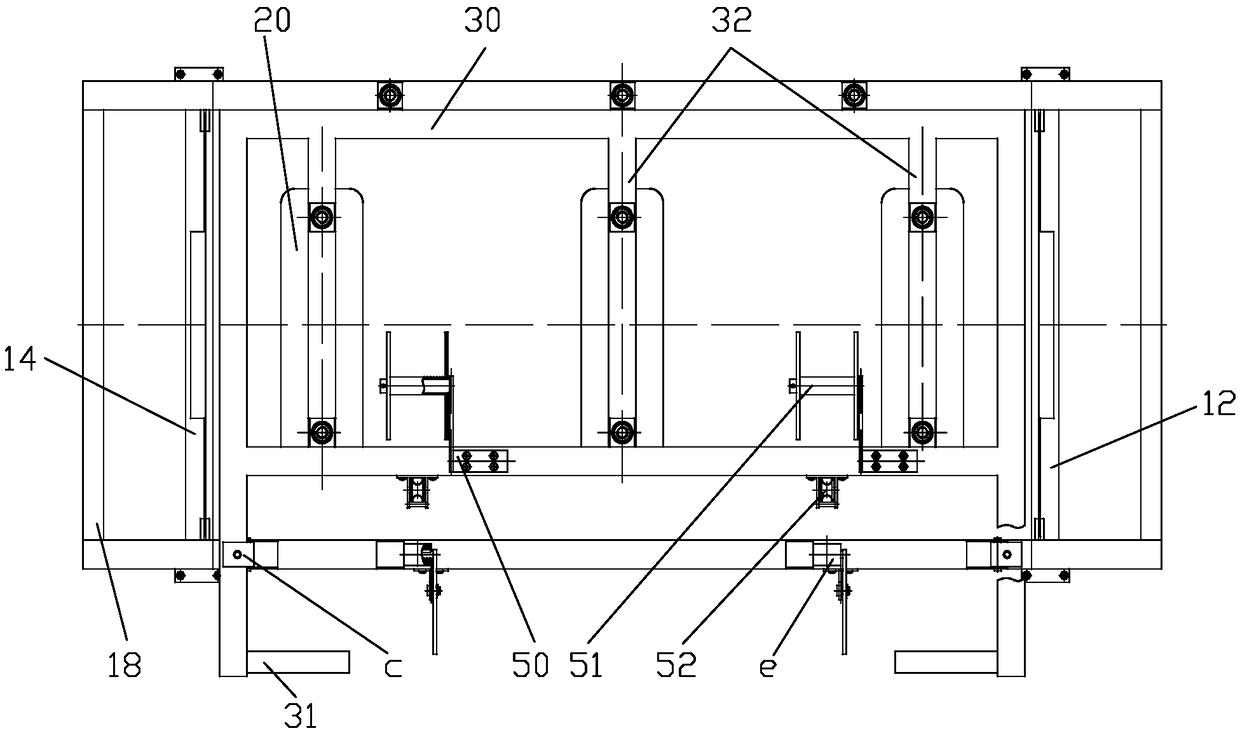

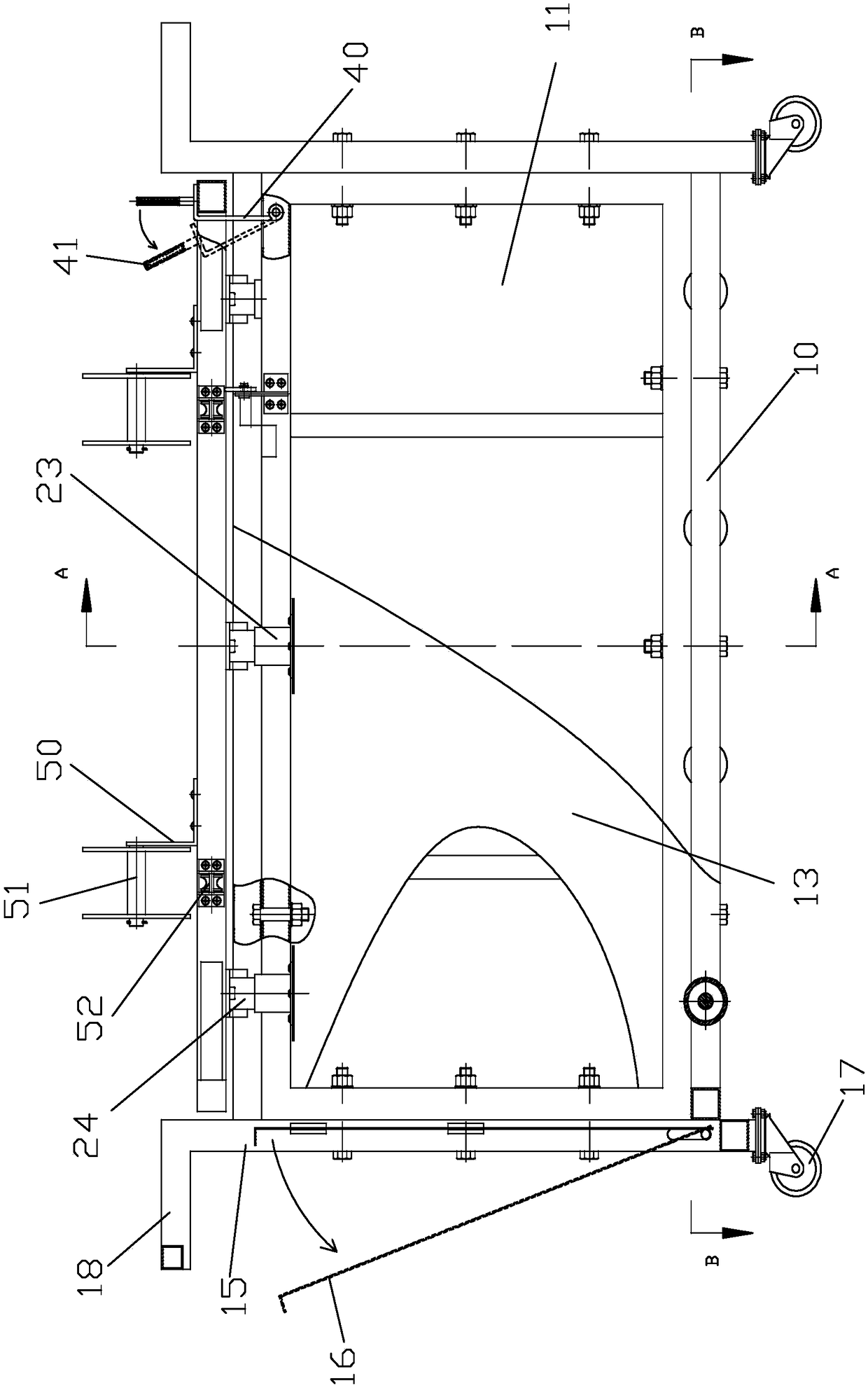

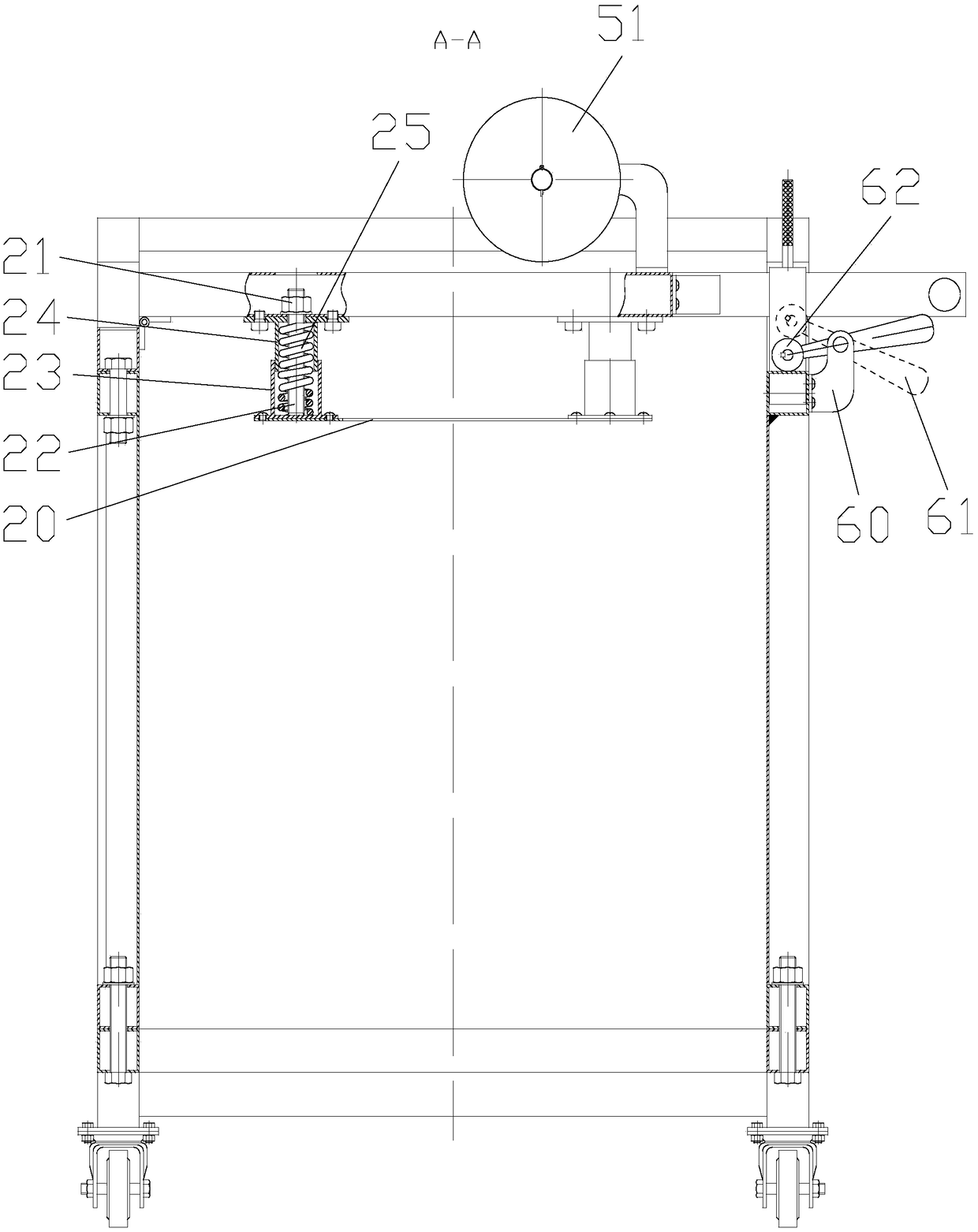

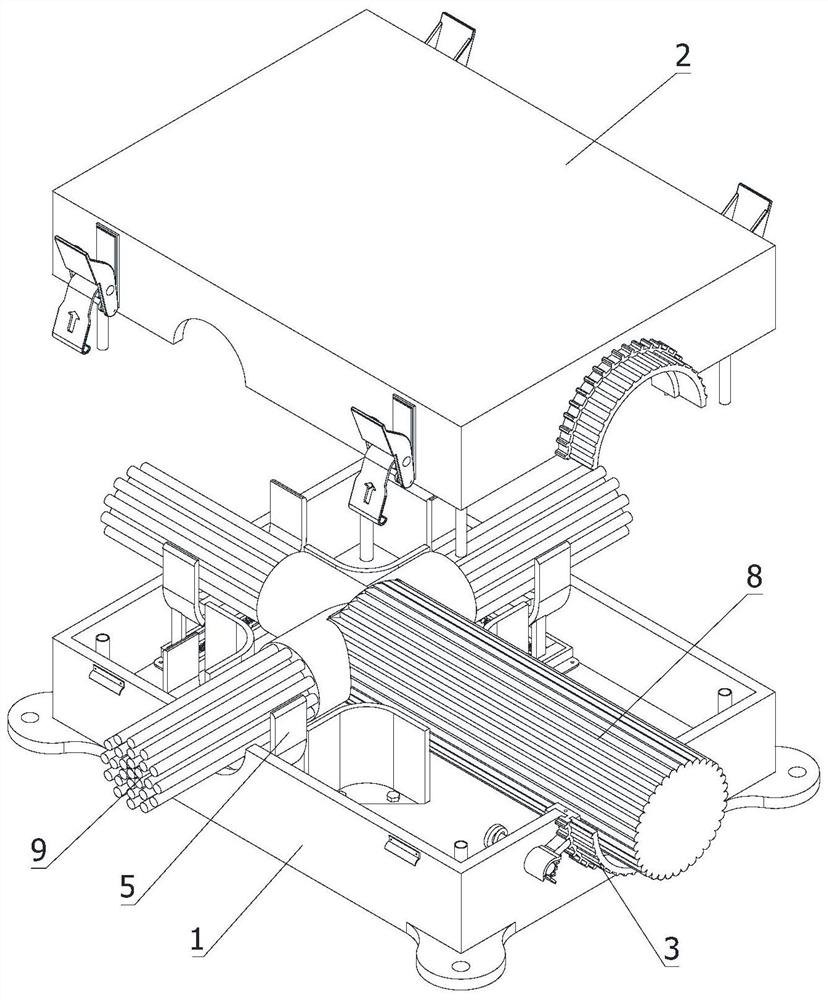

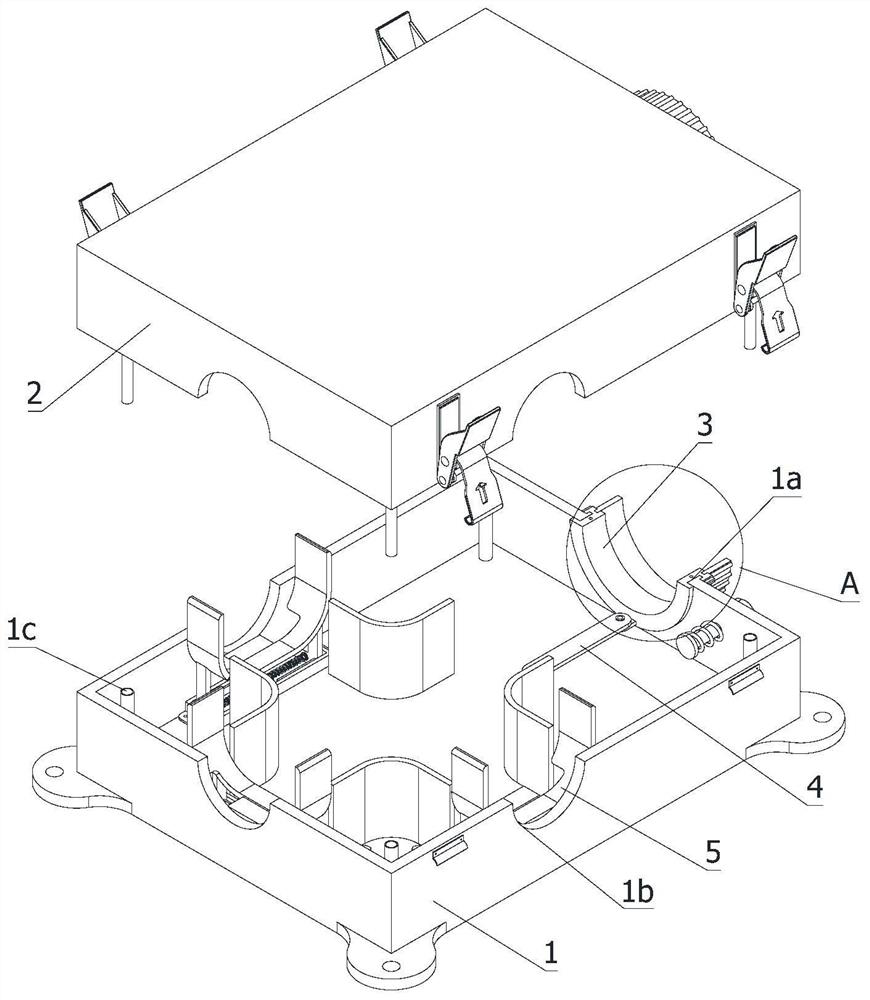

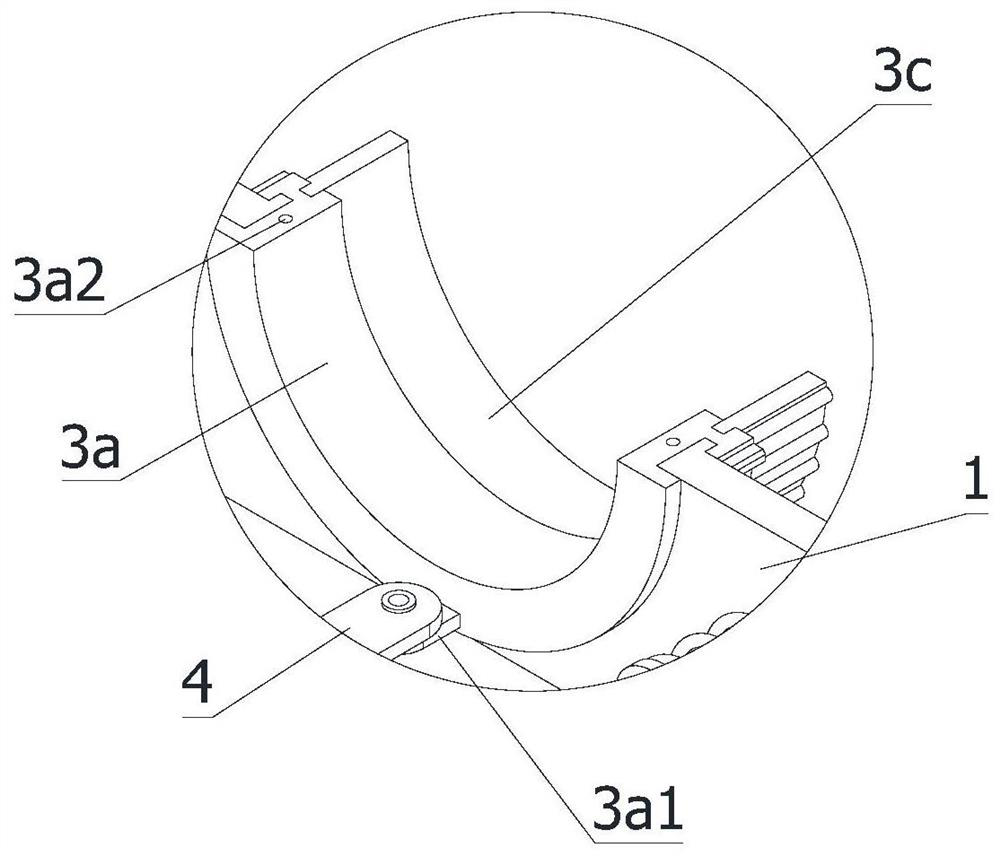

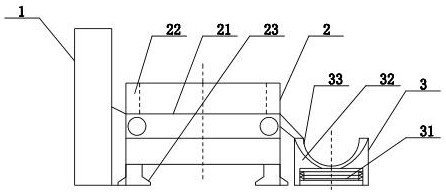

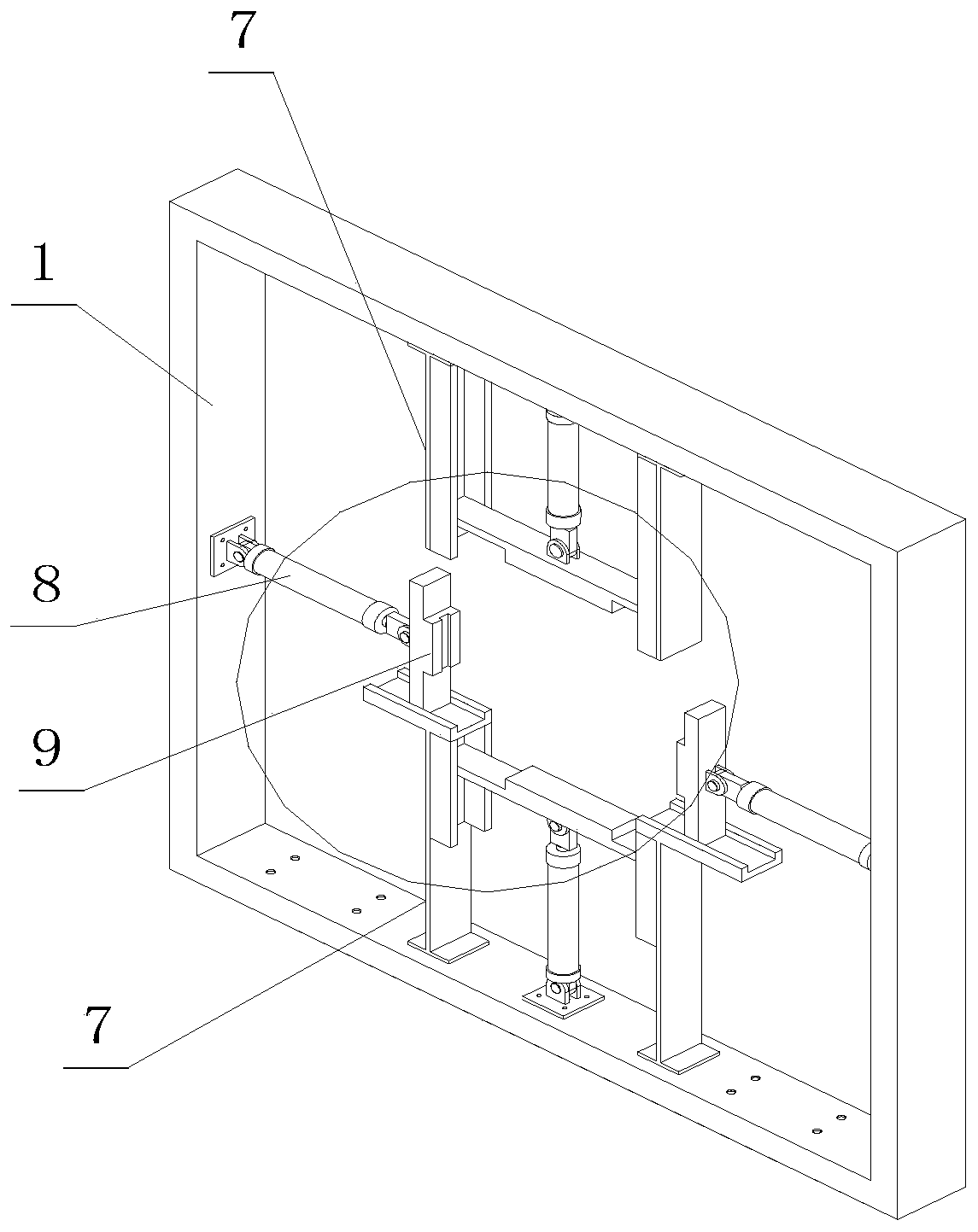

Installation tooling of condenser

InactiveCN103192345ACompact structureQuick installationWelding/cutting auxillary devicesWork holdersMechanical engineering

Owner:GREAT WALL MOTOR CO LTD

Fruit culture method adopting double-layer paper sheathing bag

InactiveCN104303929AReduce manual labor intensityImprove stabilityCultivating equipmentsPlant protective coveringsWaxFruit tree

The invention discloses a fruit culture method adopting a double-layer paper sheathing bag. The method comprises the following steps that a, an outer layer paper bag and an inner paper bag are adopted for forming the double-layer paper sheathing bag, wherein the inner layer paper bag is made of white wax paper, the lower part of the inner layer paper bag is provided with a bonding region, after fruiting on fruit trees, the double-layer paper sheathing bag is sheathed on each young fruit, in addition, the upper part of the double-layer paper sheathing bag is folded for curling the double-layer paper sheathing bag, and then, a winding wire is used for simultaneously binding the inner layer paper bag and the outer layer paper bag onto the fruit stem of the young fruit; b, after the fruit grows to the coloring period, the binding wire on the outer layer paper bag is untied, the outer layer paper bag is removed, and the inner layer paper bag is remained for protecting the fruit coloring; c, after the fruit rapes, the inner layer paper bag is picked and sold along with the ripen fruit. The fruit culture method provided by the invention mainly solves the following two technical problems including the falling or edge folding problem as the inner layer paper bag is easily influenced by climates in the fruit coloring period in the prior art and the problem of difficulty in fruit re-packaging through a measure that the inner layer paper bag is with the fruit when the fruit is colored, picked and sold.

Owner:徐世慧

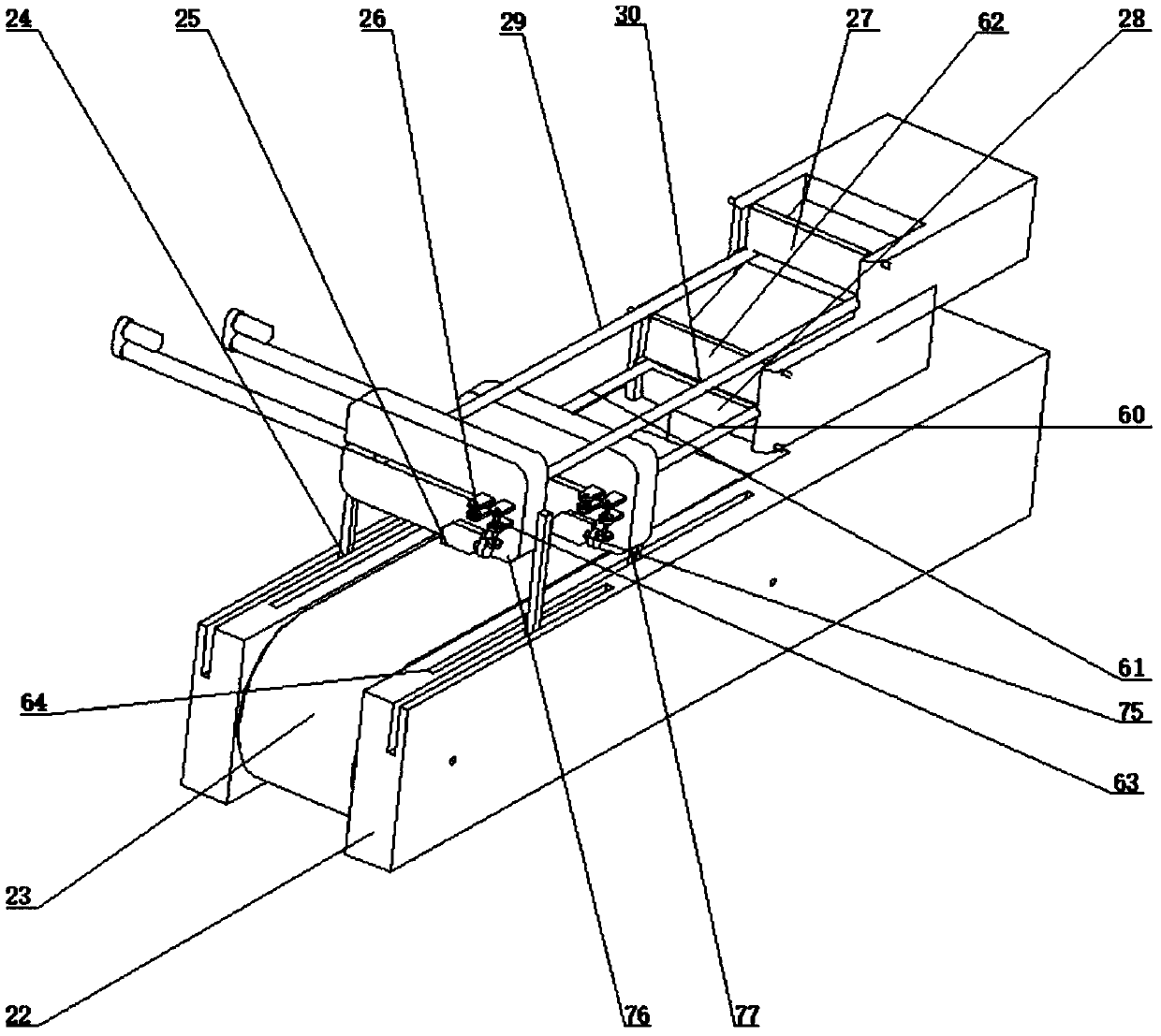

Automatic crab binding machine

ActiveCN109625382AEasy to manufactureEasy to transportBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention discloses an automatic crab binding machine which comprises a feeding mechanism, fixing mechanisms, a binding mechanism, a knotting mechanism and a sorting mechanism. The fixing mechanisms are arranged on the two sides of the feeding mechanism. A clamping device is arranged at one ends of the fixing mechanisms. The clamping device is located above the feeding mechanism. The binding mechanism is arranged at the tail end of the feeding mechanism. The knotting mechanism is arranged above the tail end of the binding mechanism, and the tail end of the binding mechanism is connected with the sorting mechanism. The automatic crab binding machine has the beneficial effects that the binding efficiency is improved, the binding quality is improved, the manual cost is reduced, worker injuries are reduced, and in addition, the automatic crab binding machine is standard, accurate and durable.

Owner:JIANGSU UNIV OF SCI & TECH

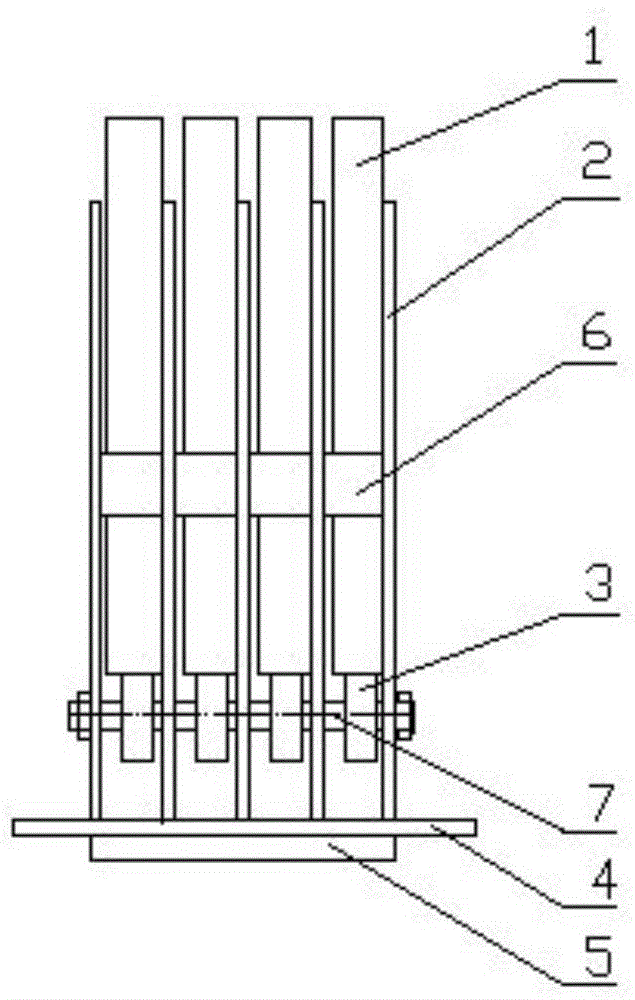

A binding steel belt storage rack

The invention relates to a binding steel belt storage rack. A square bottom plate is fixedly mounted to a base; separation plates are fixedly, vertically and uniformly mounted on the bottom plate at intervals; the two sides of the separation plates are connected via baffles; the bottom portions of the two side edges of each separation plate are provided with grooves in mirror symmetry; rolling shafts in mirror symmetry are connected with the separation plates after penetrating the grooves; rollers are arranged between the separation plates and on the rolling shafts; the two ends of each rolling shaft are fastened via nuts; binding steel belts are arranged between every two adjacent separation plates, located on the rollers and supported by the rollers. The binding steel belt storage rack is compact in design, enables a plurality of bundles of binding steel belts to be stored and used at the same time, can store binding belts of different models, facilitates use of operators and reduces the binding belt replacing efficiency.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

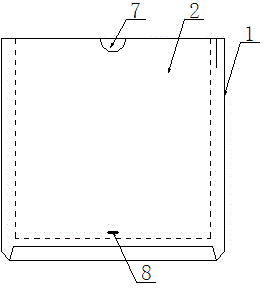

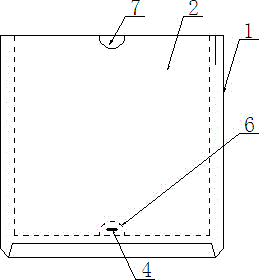

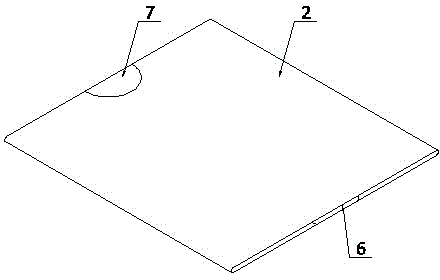

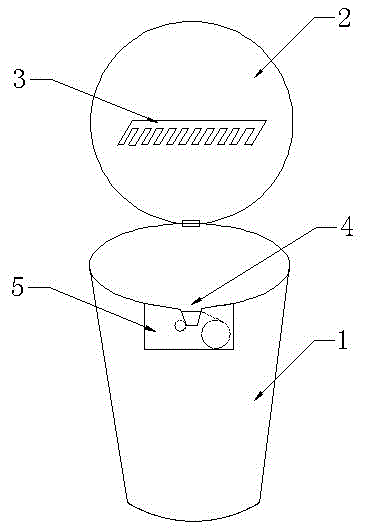

Comb-carried garbage can capable of achieving automatic bundling

The invention belongs to the field of living goods and particularly relates to a comb-carried garbage can capable of achieving automatic bundling. The comb-carried garbage can comprises a can body and a can cover hinged to the can body. A comb structure is arranged in the middle of the inner face of the can cover, comb teeth are downward, an opening is formed in the edge of a can opening of the can body, and a plastic bag bundling device is installed inside the opening. The comb-carried garbage can is simple in structure, can easily clear away hair and attachments on a bristle brush and rapidly bundle plastic bags, and is convenient to use, practical and suitable for being widely applied and popularized.

Owner:宋易遥

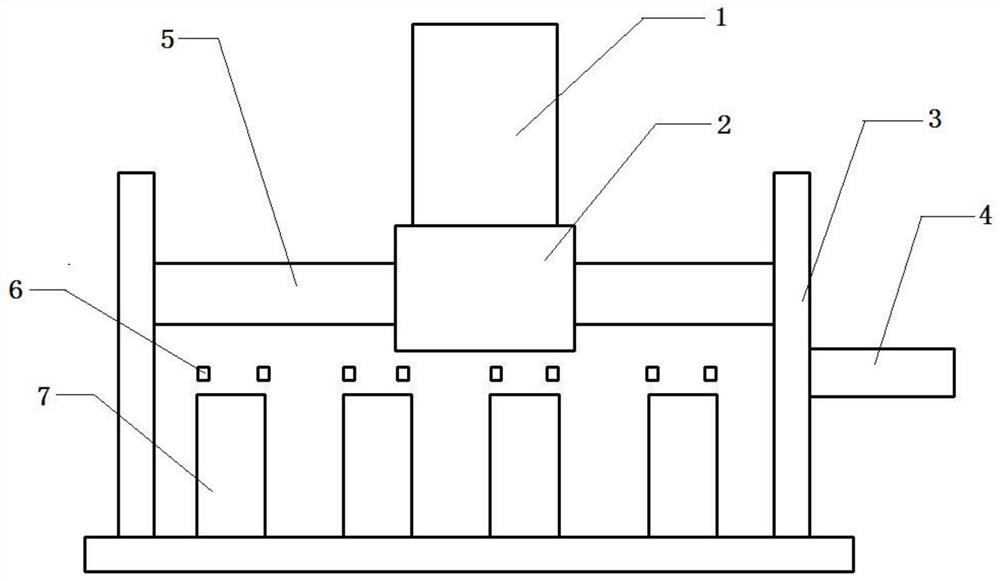

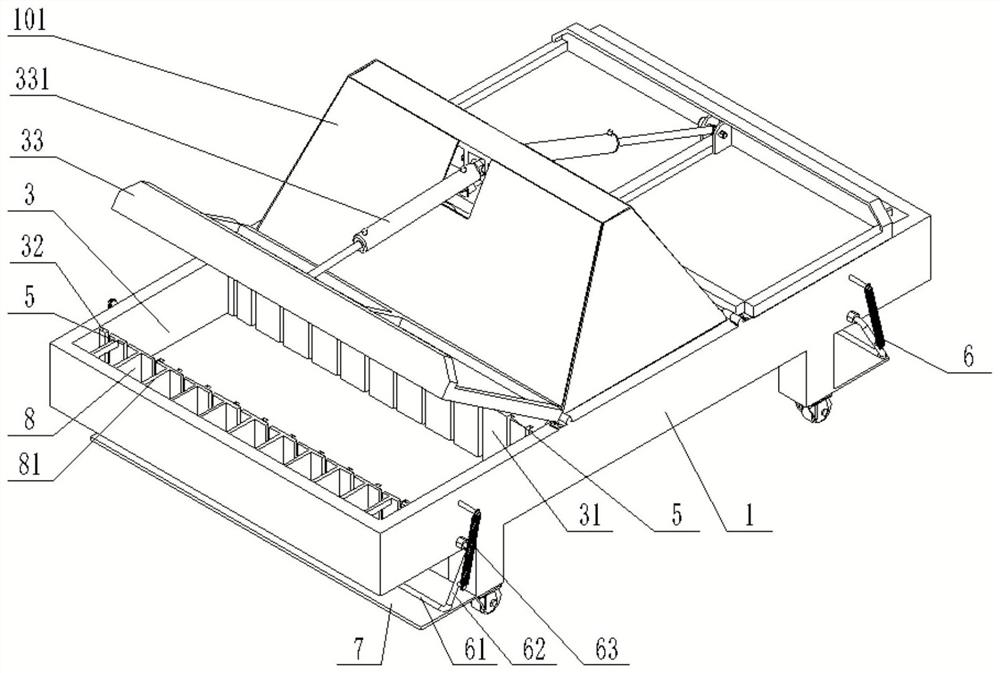

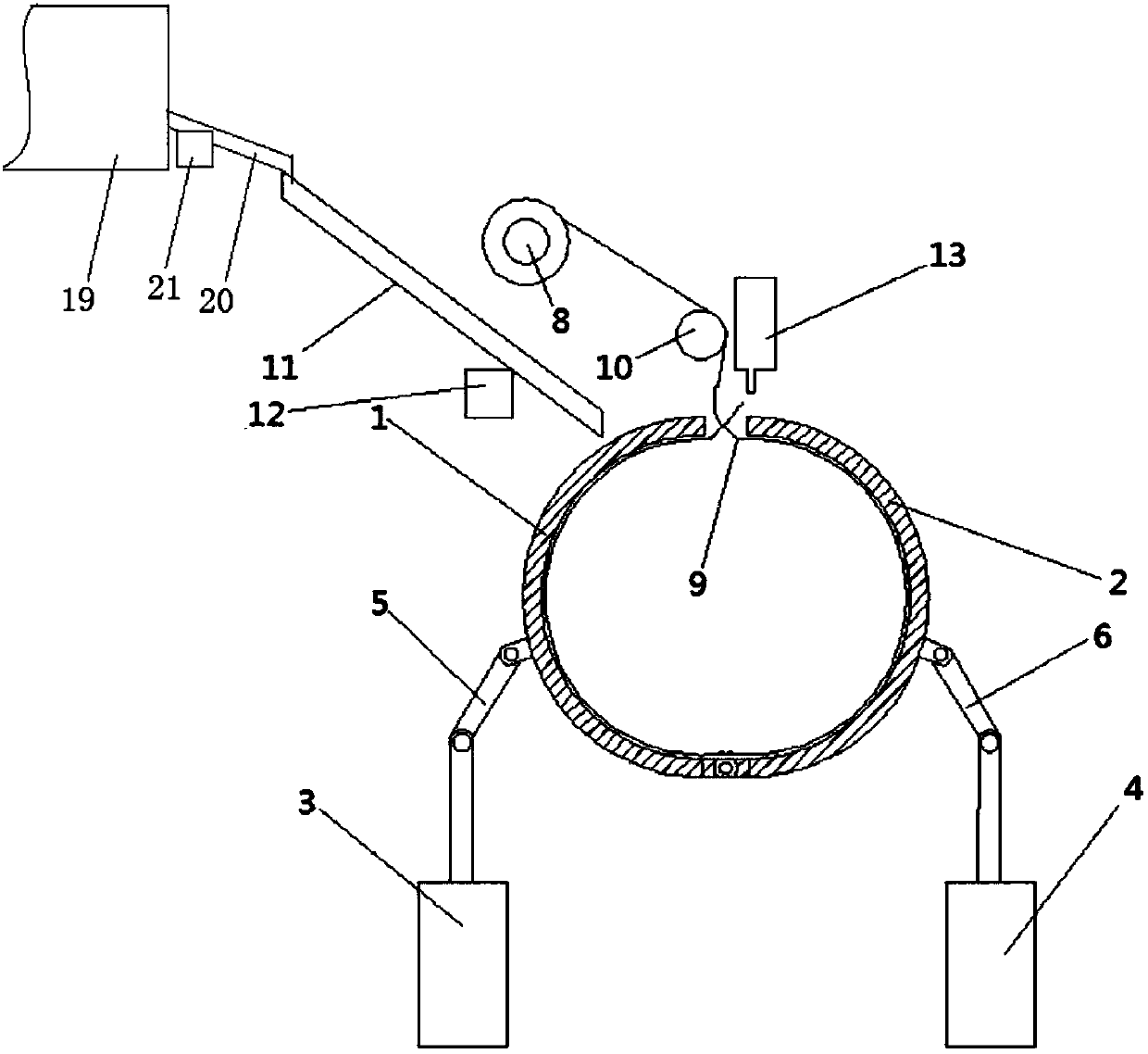

Energy-saving type structural steel bundling device

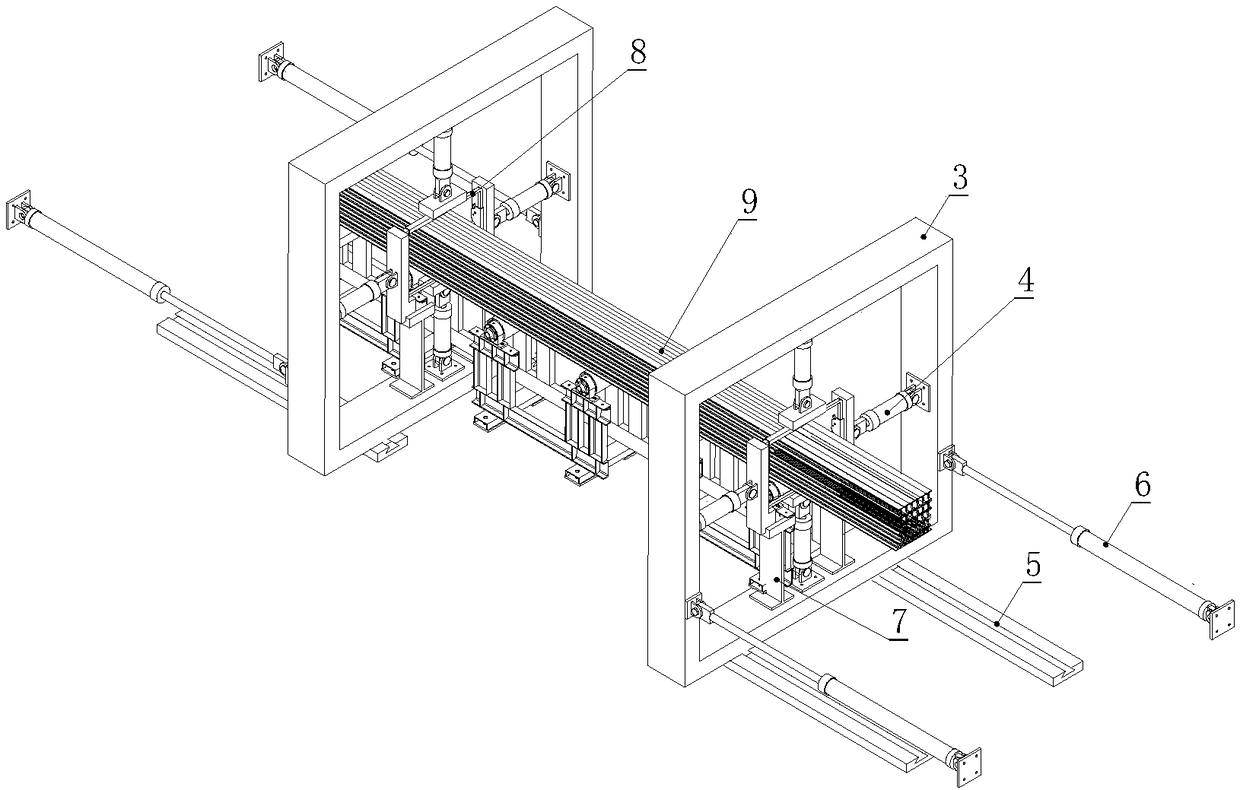

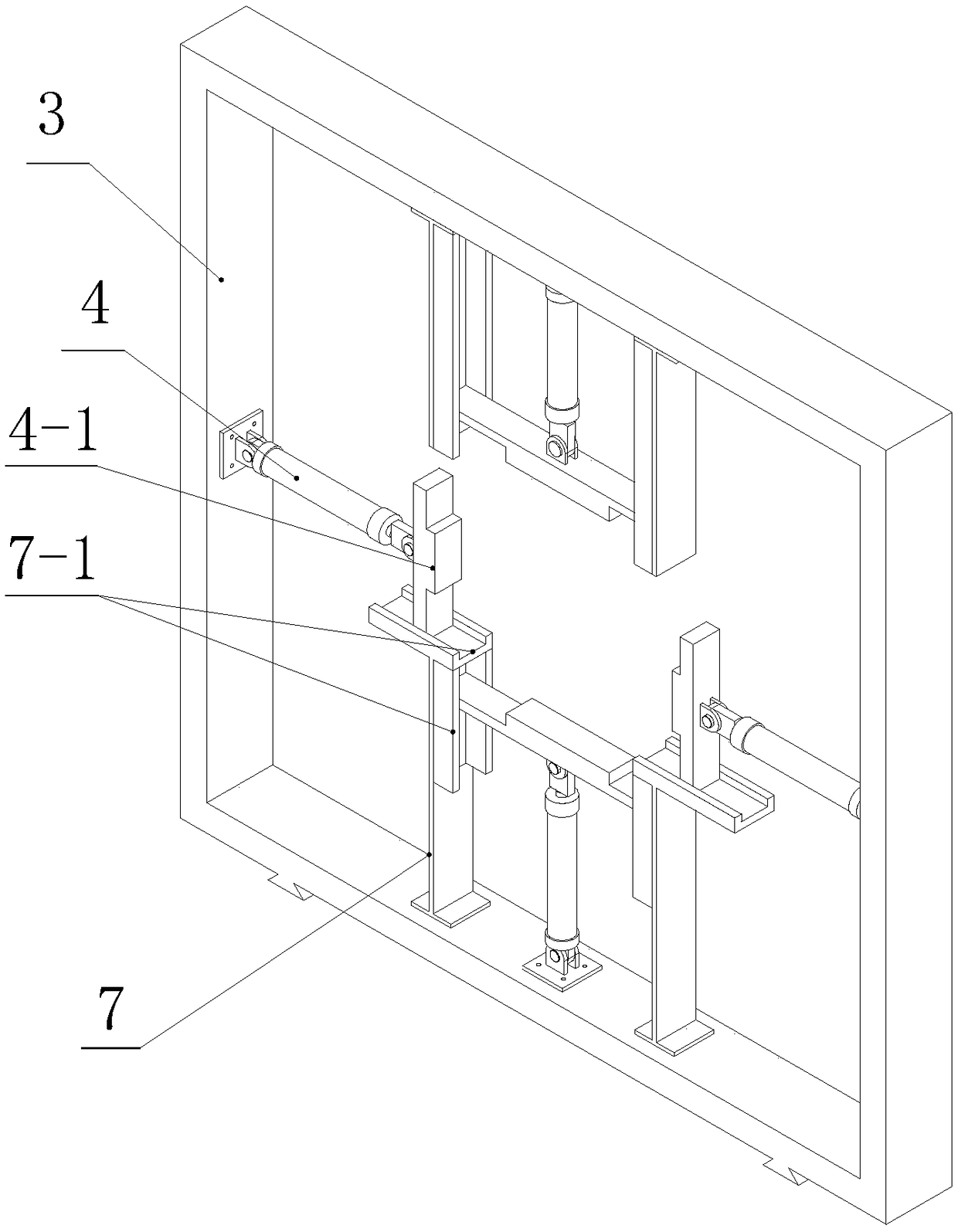

ActiveCN108706123ATo achieve the purpose of bundlingFast strappingBundling machine detailsVertical plane

The invention provides an energy-saving type structural steel bundling device. The energy-saving type structural steel bundling device comprises a bundling frame, a support moving device and a jackingpushing device. The support moving device is arranged at the bottom of the bundling frame. The jacking pushing device comprises a plurality of jacking pushing mechanisms which are arranged in the bundling frame and are arranged in the same vertical plane in the circumferential direction. Each jacking pushing mechanism comprises a jacking pushing rod and a jacking pushing block arranged at the endportion of the jacking pushing rod, and the vertical plane is perpendicular to the bundling frame moving direction. The jacking pushing directions of the jacking pushing rods face the center of the bundling frame. According to the energy-saving type structural steel bundling device, structural steel packaging is fast, tidiness and attractiveness are achieved, and the work efficiency is improved.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

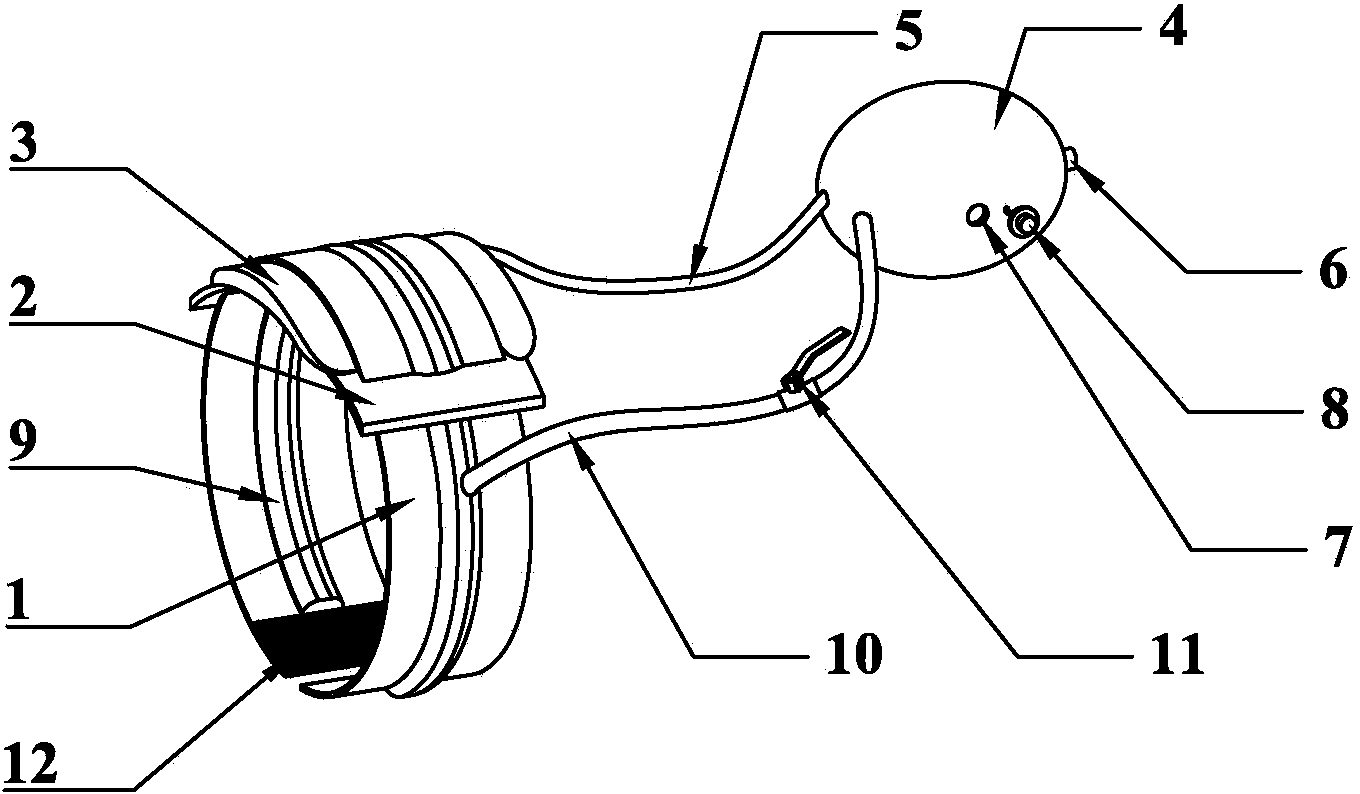

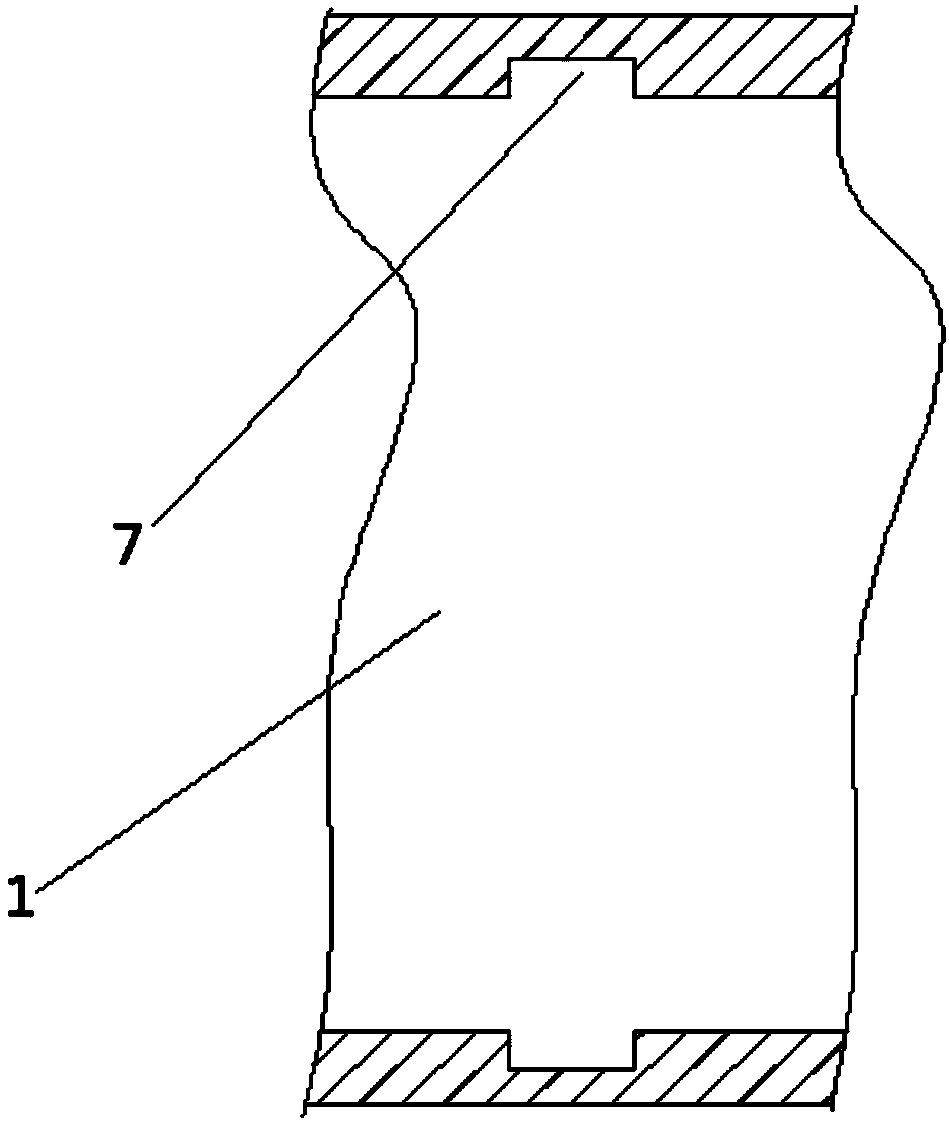

Upper arm tourniquet for ulna/radius fracture operation

The invention relates to an upper arm tourniquet for the ulna / radius fracture operation. A tourniquet needs to be bound on an upper arm in the forearm fracture operation process in the orthopaedics department; at present, the binding of a rubber pipe applied to the field can not last for a long time, the tightness degree can be known only through feeling, and once the tightness degree is not appropriate, the operation needs to be repeated again. The upper arm tourniquet comprises a tourniquet body which is a high-resillence strip-shaped soft belt made of polyurethane, and a plurality of vent holes are formed in the tourniquet body. The upper arm tourniquet further comprises a hard adjustment plate, an inflation bag and an extrusion sacculus, wherein the hard adjustment plate is in an arc shape, long groove holes are formed in the two ends of the hard adjustment plate respectively, the tourniquet body is in an annular shape and penetrates through the long groove holes, the inflation bag is arranged between the tourniquet body and the hard adjustment plate and is connected with the extrusion sacculus through an inflation hose, and a ball valve is arranged on the extrusion sacculus. The upper arm tourniquet is high in binding and detaching speed, and can be used for long-time continuous hemostasis especially the ulna / radius fracture operation in the orthopaedics department.

Owner:QINGDAO MUNICIPAL HOSPITAL

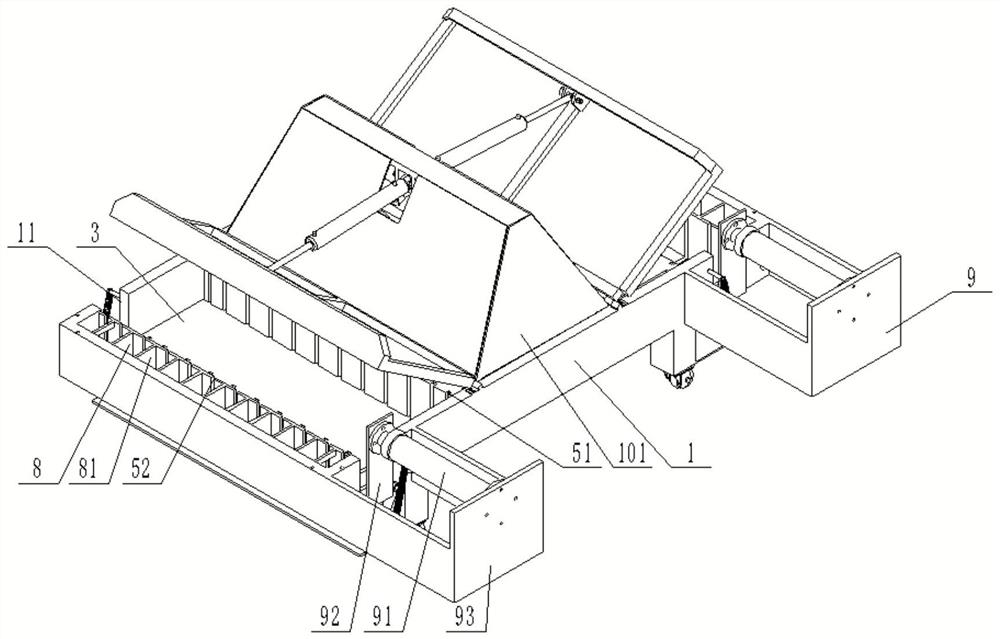

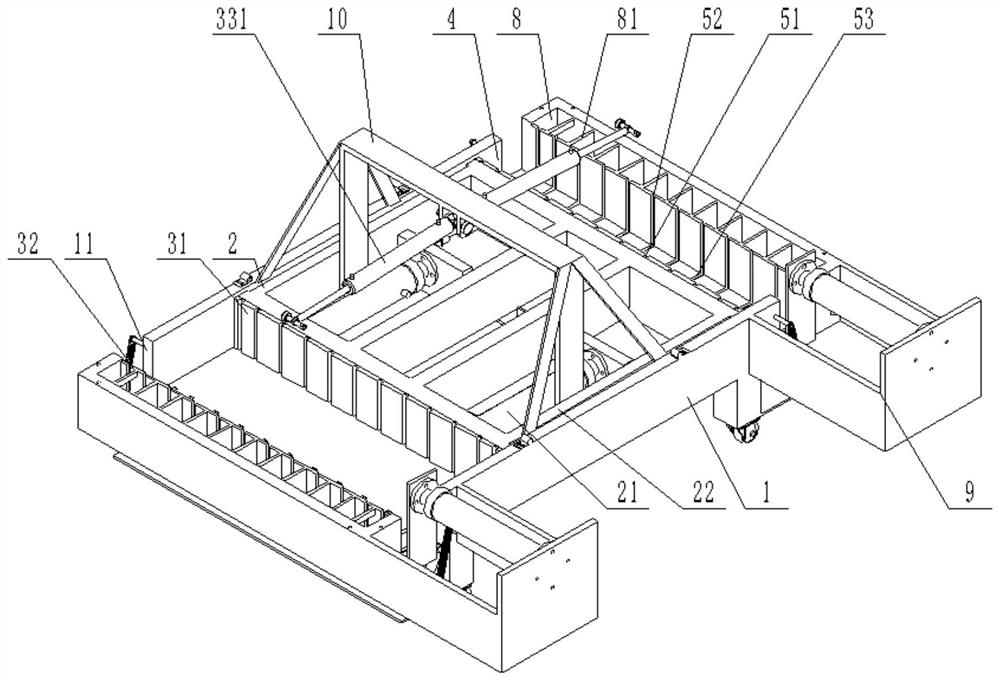

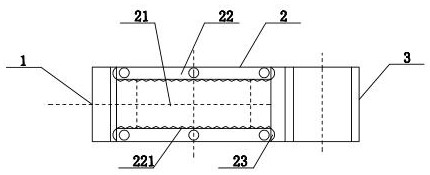

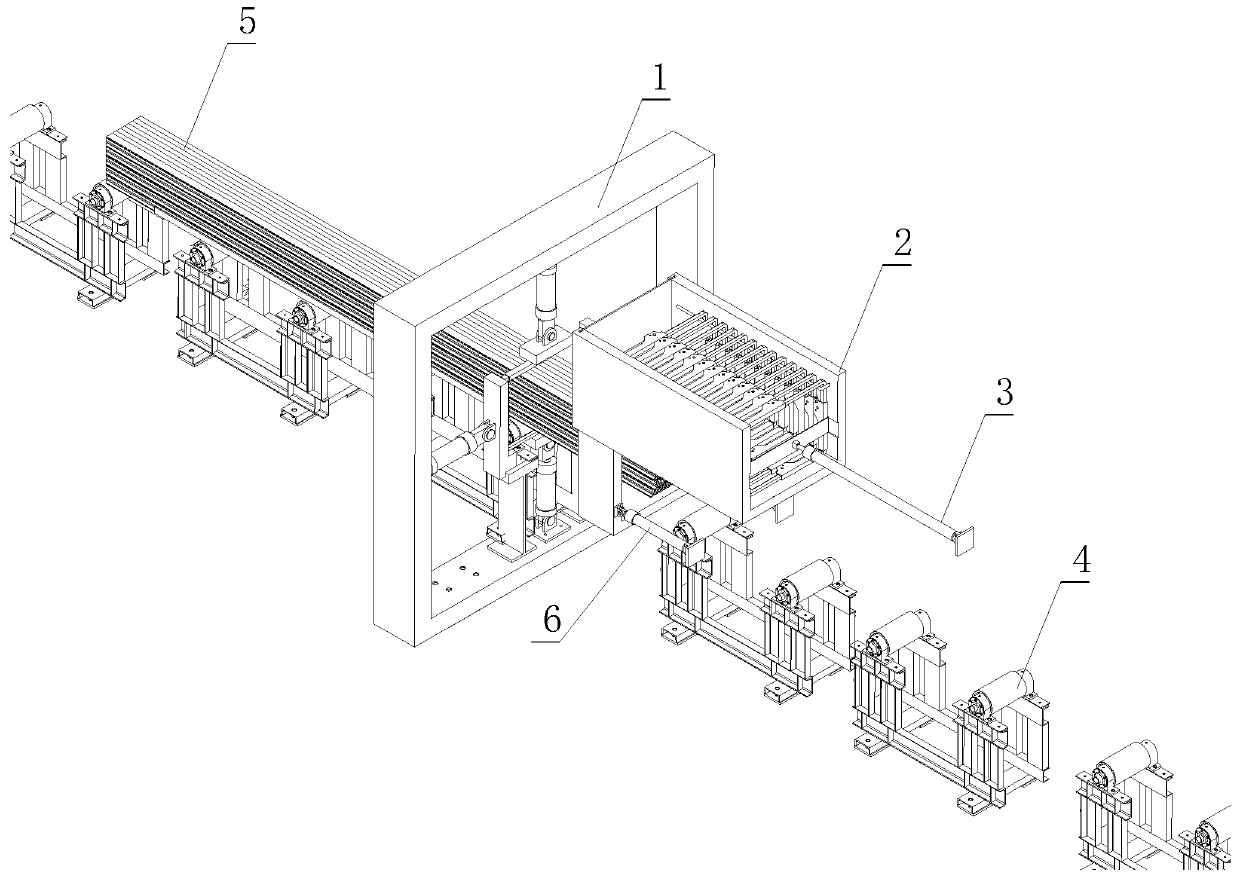

Energy-saving and automatic profile steel packaging device and process

ActiveCN108910121APlay a transport functionTo achieve the purpose of bundlingBinding material applicationBundling machine detailsVertical planeEngineering

Owner:HUATIAN NANJING ENG & TECH CORP MCC

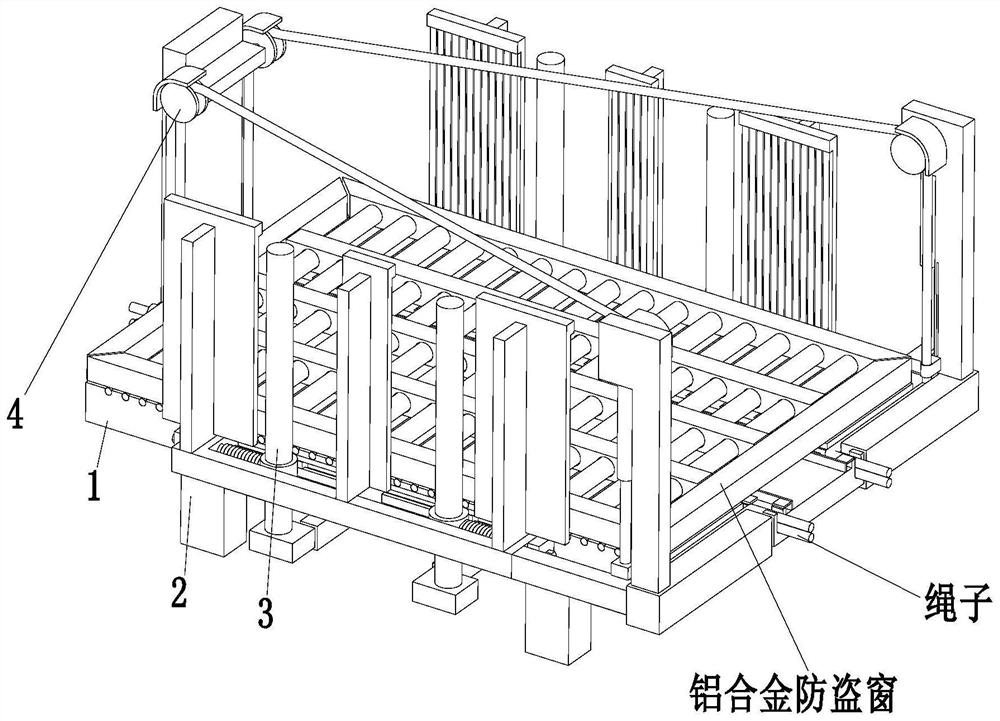

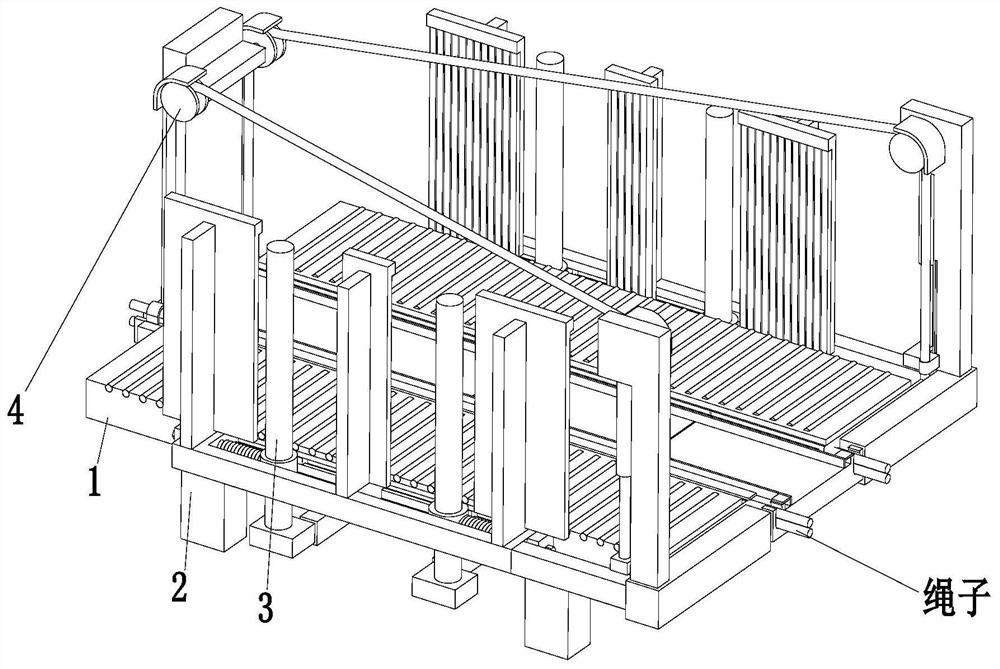

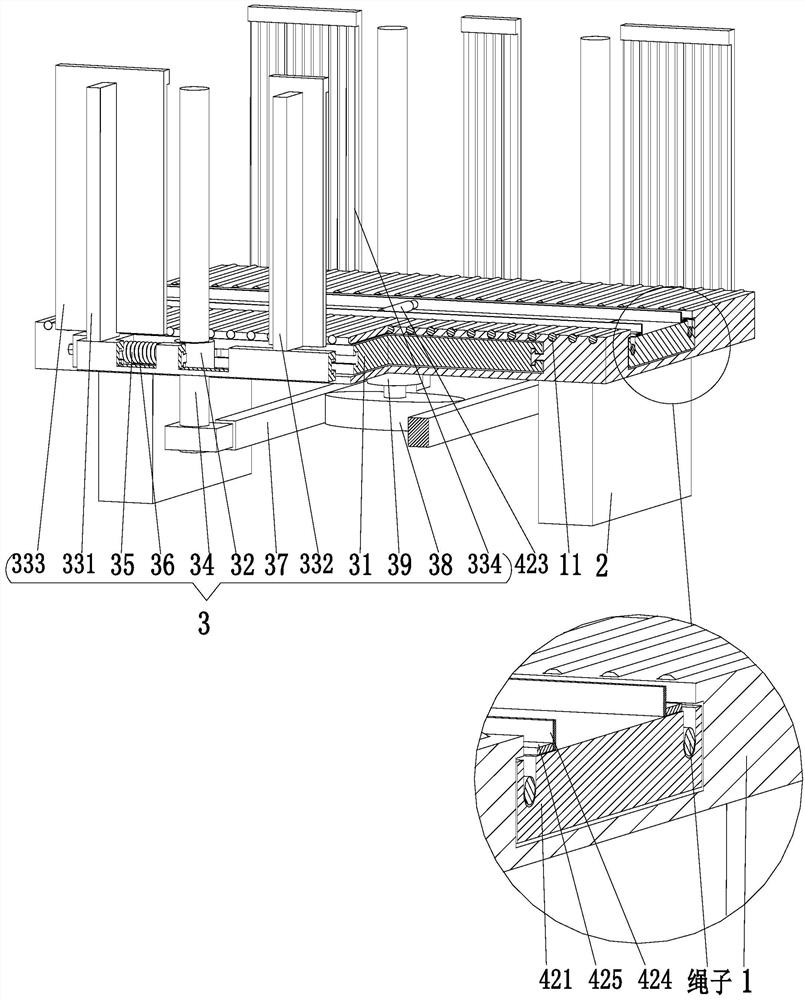

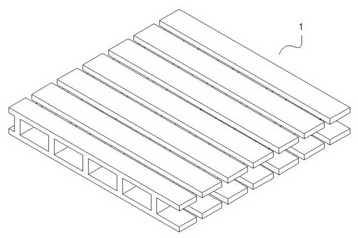

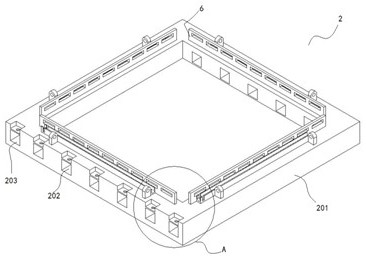

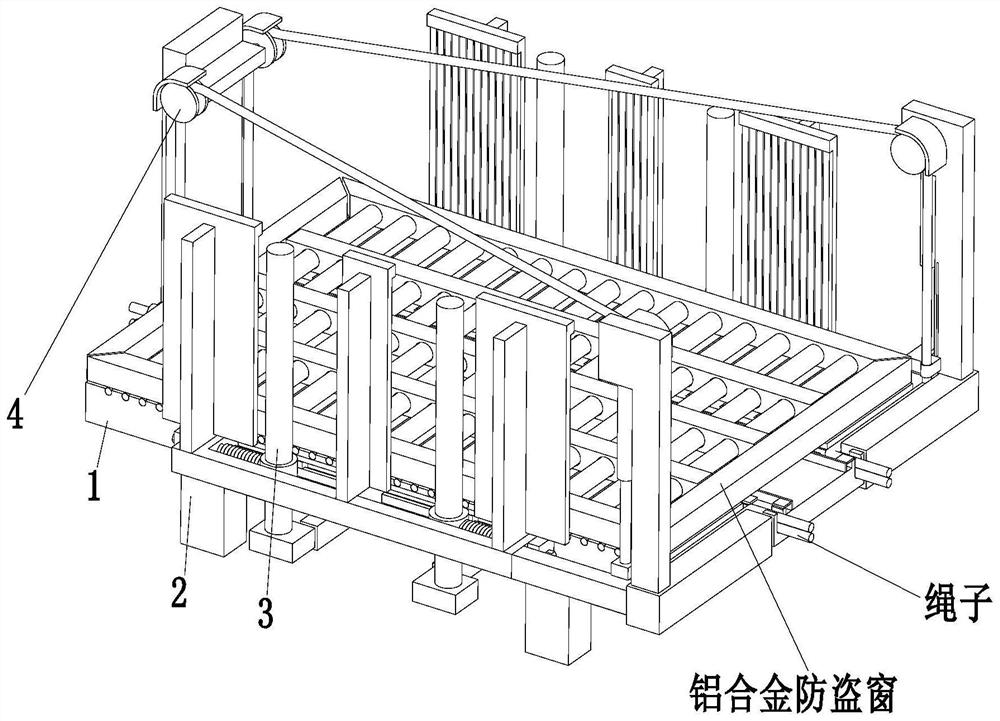

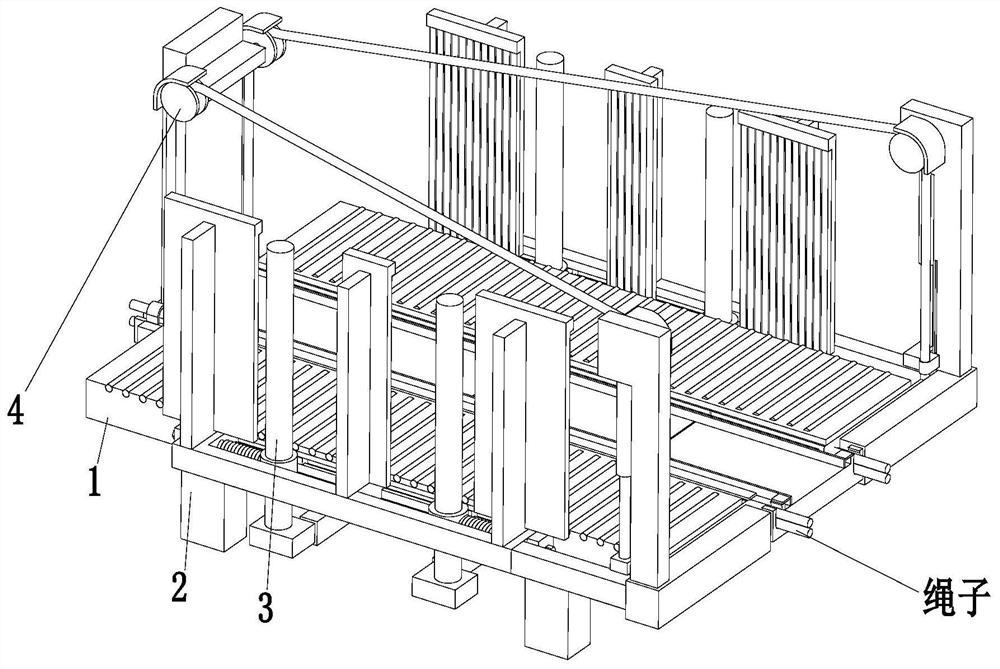

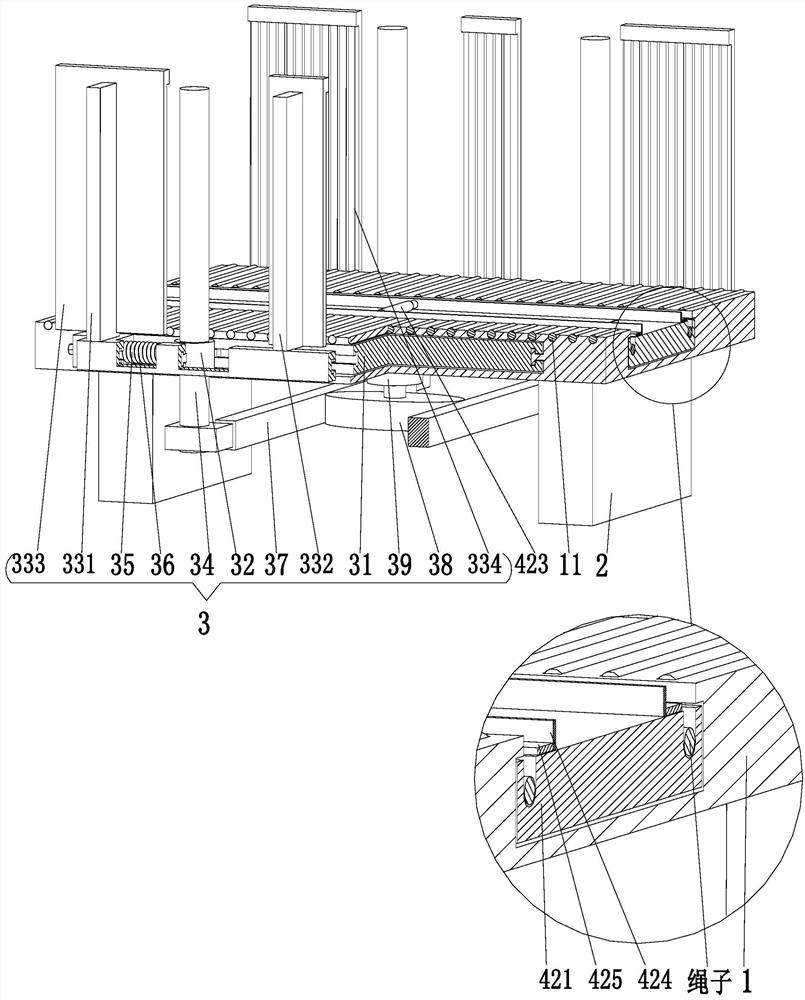

Intelligent palletizer for forming and manufacturing al-alloy door and window

ActiveCN111645927AAvoid prone to collapse and other problemsImprove stacking efficiencyBinding material applicationPalletizerStructural engineering

The invention relates to an intelligent palletizer for forming and manufacturing an al-alloy door and window. The intelligent palletizer comprises a placing plate, support blocks, righting mechanismsand guiding mechanisms; the support blocks are symmetrically mounted on the lower end face of the placing plate; the righting mechanisms are mounted at the front and rear ends of the placing plate; and the guiding mechanisms are mounted at the left and right ends of the placing plate. The intelligent palletizer can solve the following problems when an al-alloy security window is stacked and bundled: the al-alloy security windows on a forklift need to slowly be aligned with the placed al-alloy security windows, and the stacking efficiency is low; the al-alloy security windows are likely to deviate during the placing process, as a result, the corners of the al-alloy security windows are likely to collide with pedestrians or other al-alloy security windows, and the deviated al-alloy securitywindows can easily cause that the stacked al-alloy security windows collapse to cause quality and safety hidden dangers; and after stacking the al-alloy security windows, ropes need to be manually thrown to bundle the stacked al-alloy security windows, and the bundling efficiency is low.

Owner:惠民县天阳金属材料有限公司

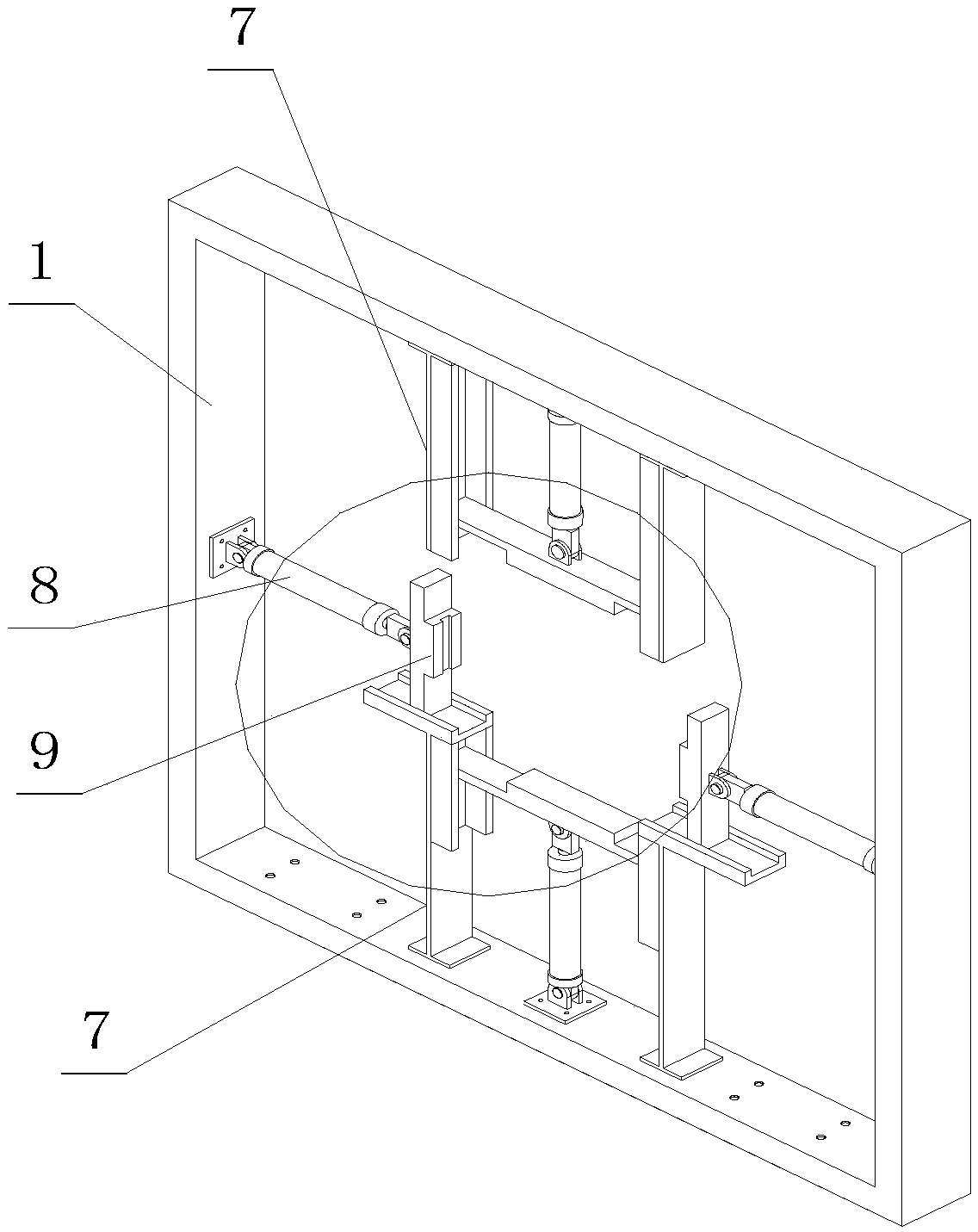

Energy-saving section steel strapping device

ActiveCN108706123BTo achieve the purpose of bundlingFast strappingBundling machine detailsVertical planeEngineering

The invention provides an energy-saving type structural steel bundling device. The energy-saving type structural steel bundling device comprises a bundling frame, a support moving device and a jackingpushing device. The support moving device is arranged at the bottom of the bundling frame. The jacking pushing device comprises a plurality of jacking pushing mechanisms which are arranged in the bundling frame and are arranged in the same vertical plane in the circumferential direction. Each jacking pushing mechanism comprises a jacking pushing rod and a jacking pushing block arranged at the endportion of the jacking pushing rod, and the vertical plane is perpendicular to the bundling frame moving direction. The jacking pushing directions of the jacking pushing rods face the center of the bundling frame. According to the energy-saving type structural steel bundling device, structural steel packaging is fast, tidiness and attractiveness are achieved, and the work efficiency is improved.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

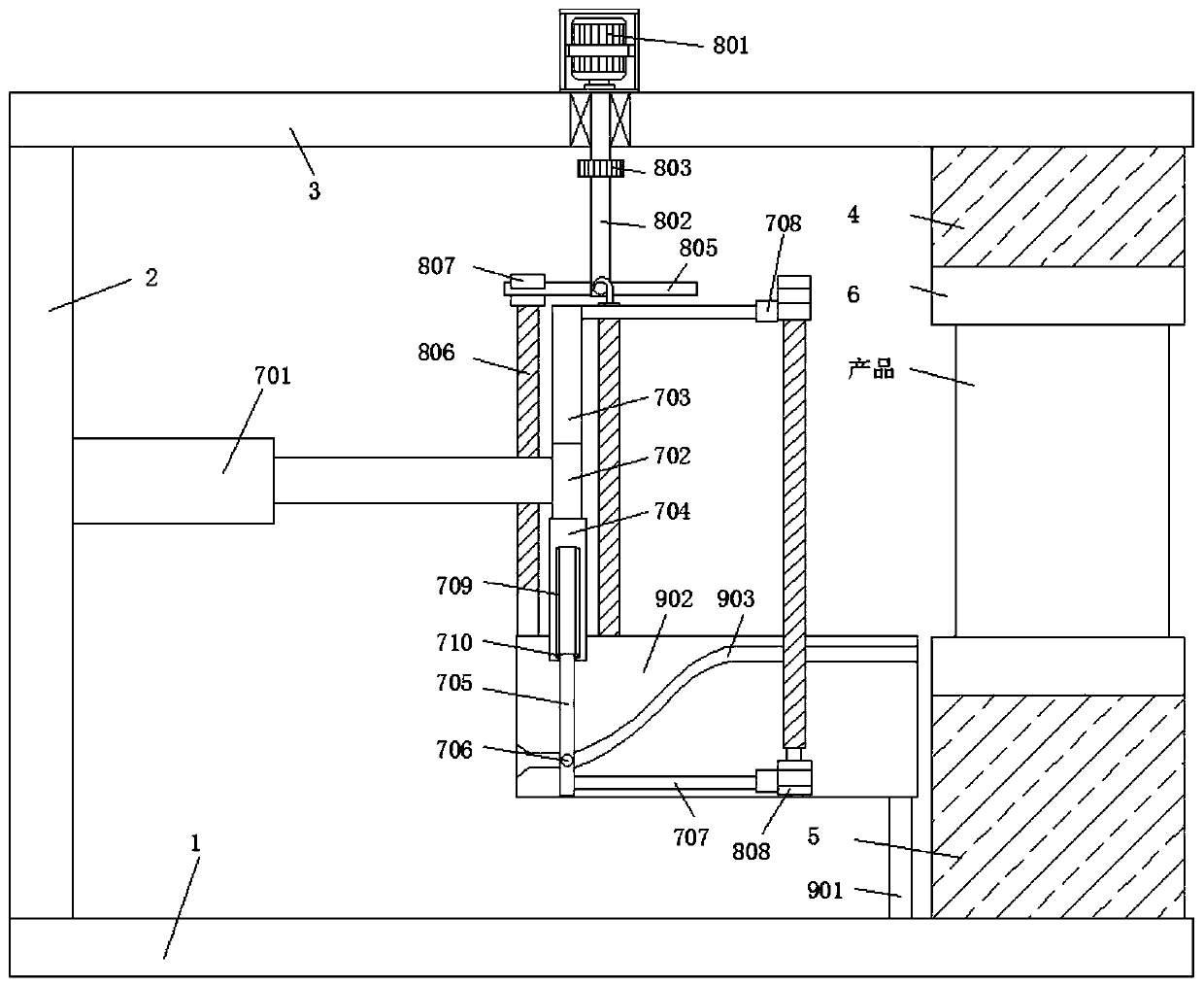

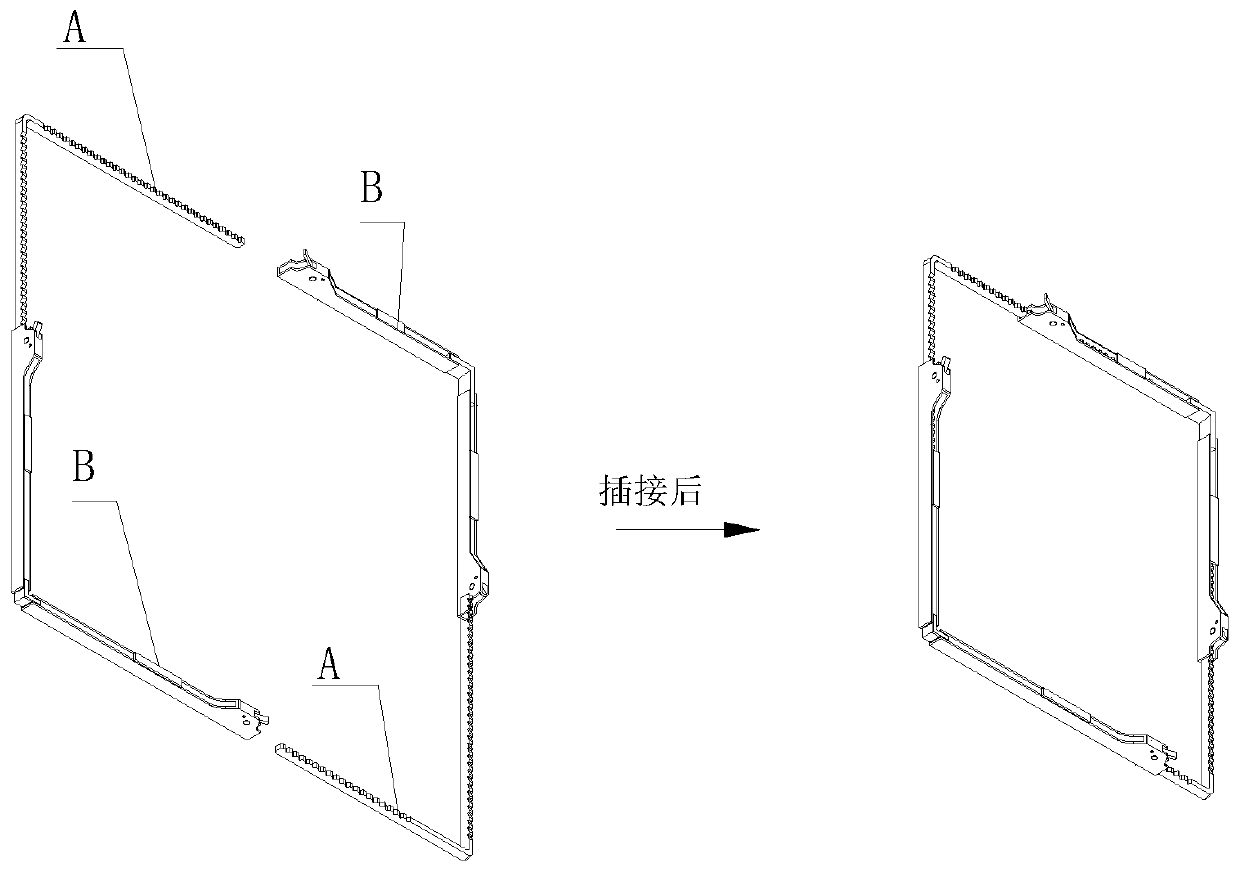

Product packaging strapping machine

InactiveCN111056059AImprove efficiencyEasy to wrapBundling machine detailsEngineeringStructural engineering

The invention relates to the technical field of product packaging, and particularly discloses a product packaging strapping machine. The product packaging strapping machine comprises a bottom plate, wherein a supporting plate is fixedly connected to the left side of the top of the bottom plate, a top plate is fixedly connected to the top of the supporting plate, a top supporting block and a bottomsupporting block are fixedly connected to the top plate and the bottom plate respectively, and long grooves are uniformly arranged in the top supporting block and the bottom supporting block; the product packaging strapping machine further comprises an inserting mechanism, a rotating mechanism and a limiting mechanism, wherein the inserting mechanism is arranged on the right side of the supporting plate and comprises a telescopic rod, and the telescopic rod is fixedly connected to the right side of the supporting plate; and the rotating mechanism is arranged on the top plate and comprises a motor, wherein the motor is fixedly connected to the top of the top plate. According to the product packaging strapping machine, through cooperative arrangement of a magnet, a hook and a hanging ring,the hook and the hanging ring can be attracted to the magnet, so that the hook and the hanging ring are driven by the telescopic rod to move to the right side of the long grooves, and a strapping tapecan be conveniently wound around a product.

Owner:柏晓珏

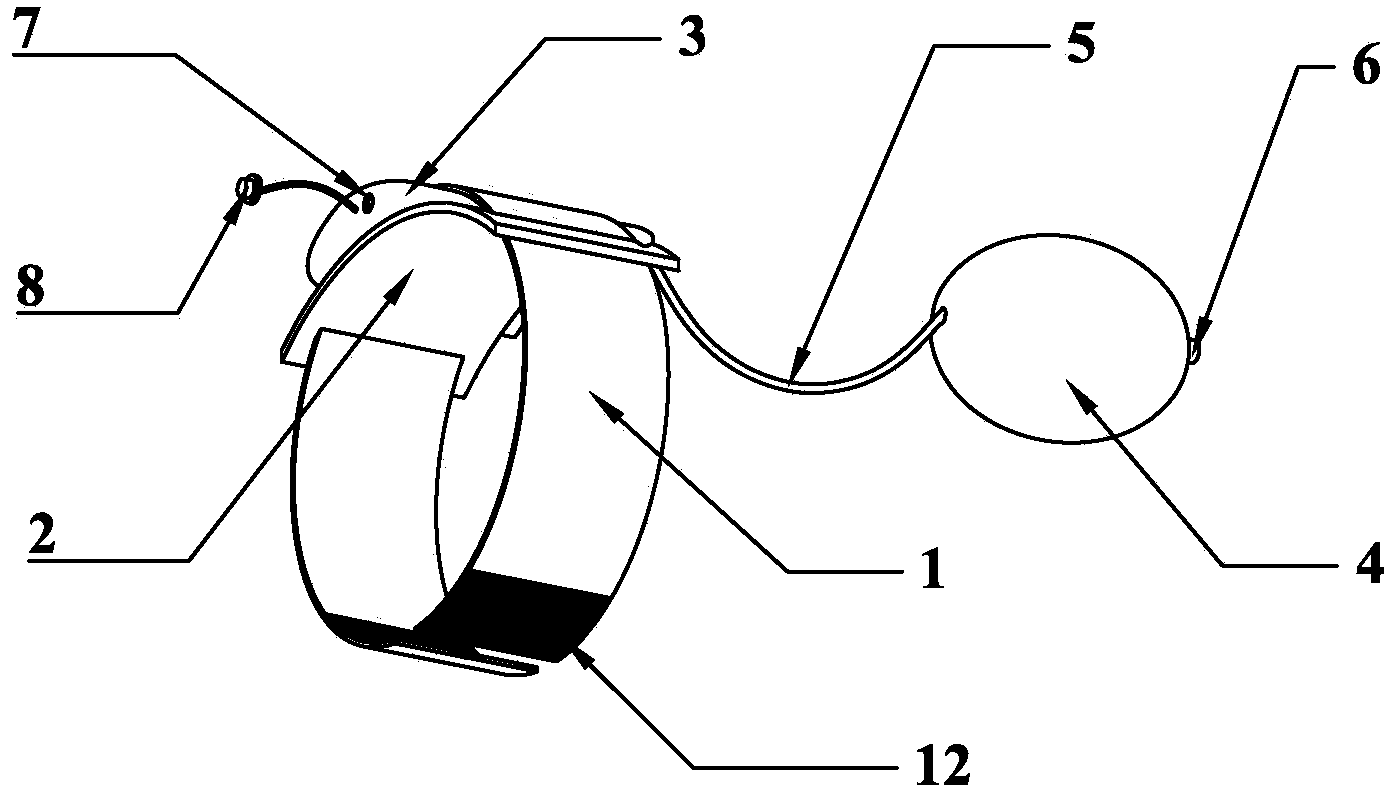

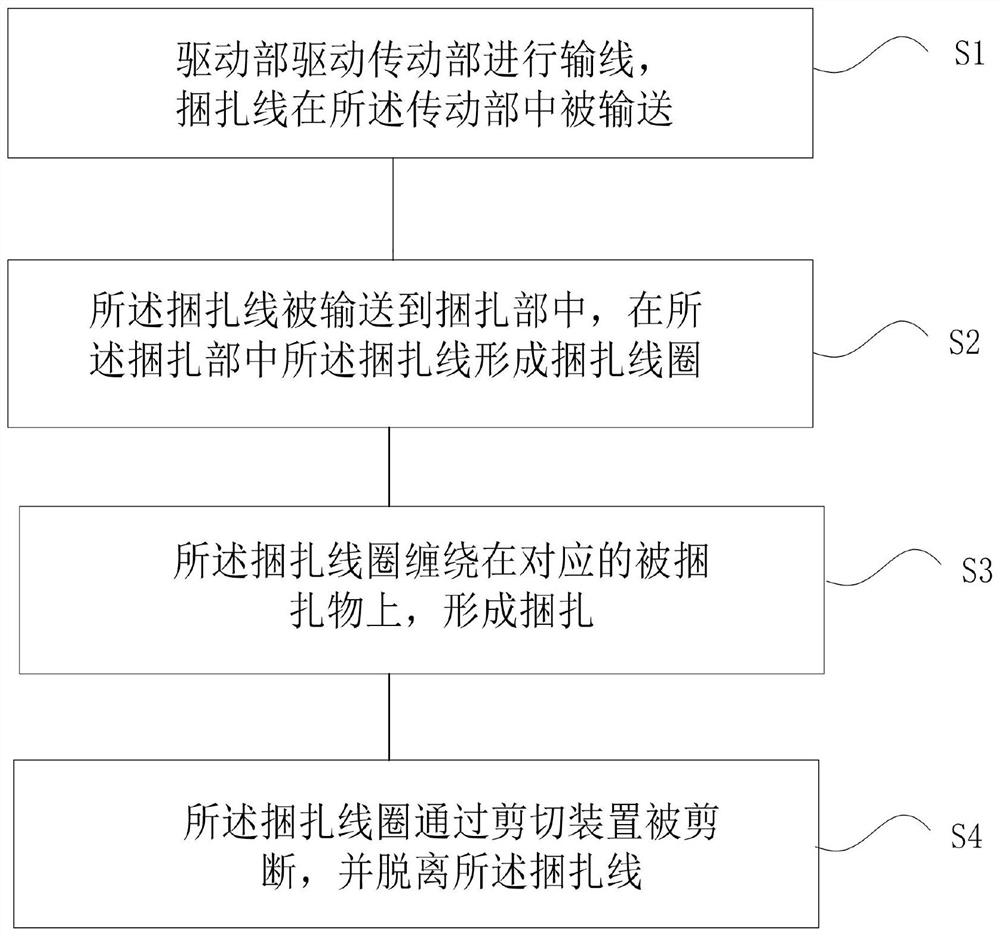

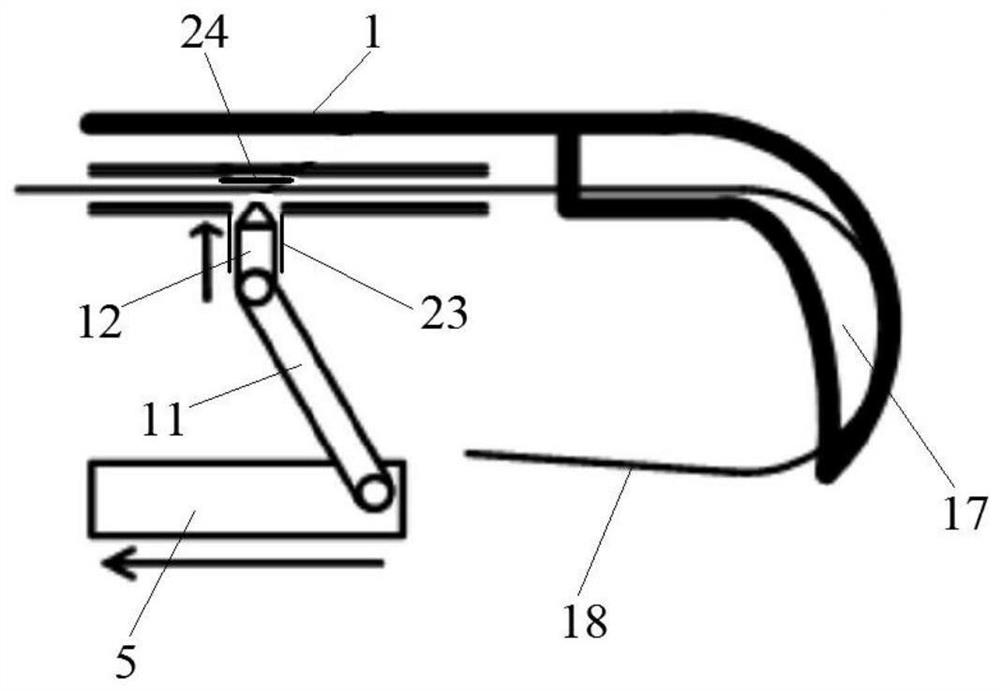

Binding method of intelligent binding machine

InactiveCN112449934AImprove practicalityQuick cutCultivating equipmentsPlant supportsStrappingControl engineering

The invention discloses a binding method of an intelligent binding machine. The method comprises the steps that a driving part drives a transmission part to convey a line, and the strapping line is conveyed in the transmission part, wherein the binding line is conveyed into a binding part, and a binding coil is formed by the binding line in the binding part; the binding coil is wound on a corresponding bound object to form binding; and the binding coil is sheared off through a shearing device and is separated from the binding line. The method has the advantages that plant vines can be rapidlyand conveniently bound, the binding efficiency is high, and the method can be universally used.

Owner:NINGBO XINYI WEIYE IMPORT & EXPORT CO LTD

Rapid packing machine

InactiveCN109051023AFast strappingEasy to shipBinding material applicationBundling machine detailsWaste treatment

The invention relates to the technical field of waste resource recycling and processing equipment, in particular to a rapid packing machine. The machine comprises a waste containing box with a top endopening and a waste abutting-pressing cover whose rear end part is connected with the rear side of the top end opening of the waste containing box in a turnover mode, the front side of the top end opening of the waste containing box is provided with a tensioning lock used for locking the waste abutting-pressing cover on the waste containing box, a rope guiding mechanism used for winding binding ropes is further arranged on the front side of the waste abutting-pressing cover, and a rope pressing mechanism used for fixing ends of the binding ropes is arranged at a position on the front side ofthe top end opening of the waste containing box and in the same straight line with each rope guiding mechanism. According to the machine, packaging waste with different specifications and different shapes can be quickly compacted, bound and packaged based on specified size so as to provide convenience for waste conveying or stacking, and meanwhile, the waste treatment efficiency is greatly improved; and the structure of the machine is simple and compact, operation is convenient and rapid and strong practical value and market popularization value are achieved.

Owner:青海天纵网络技术有限公司

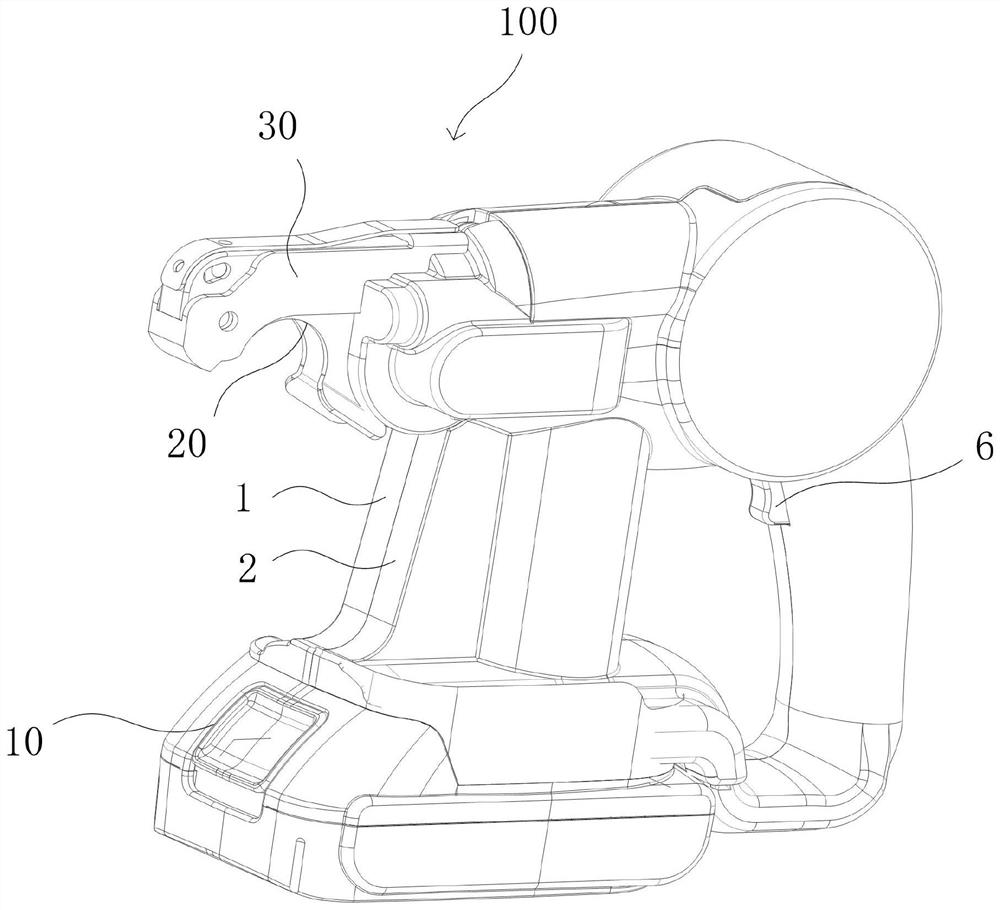

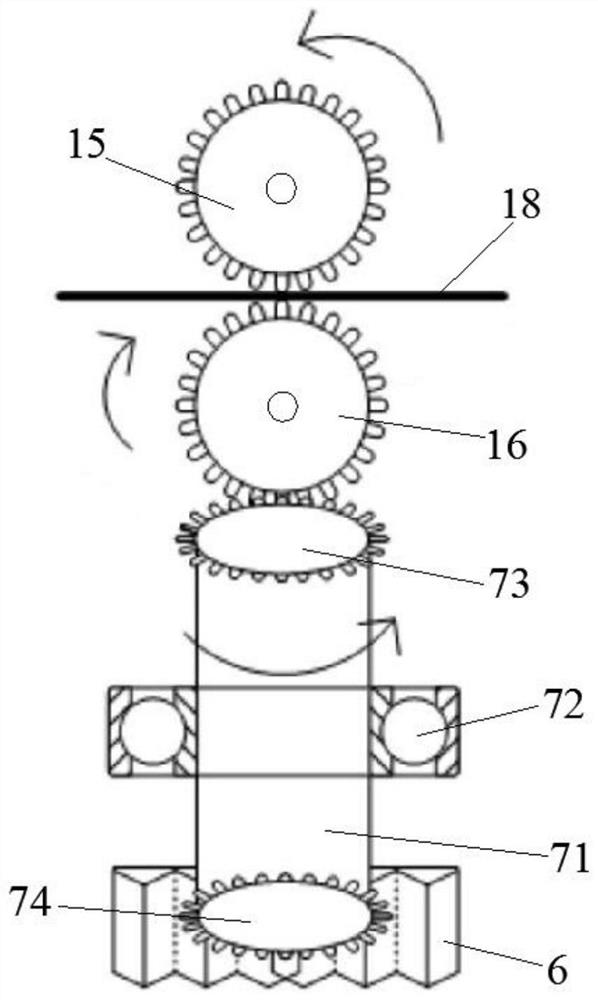

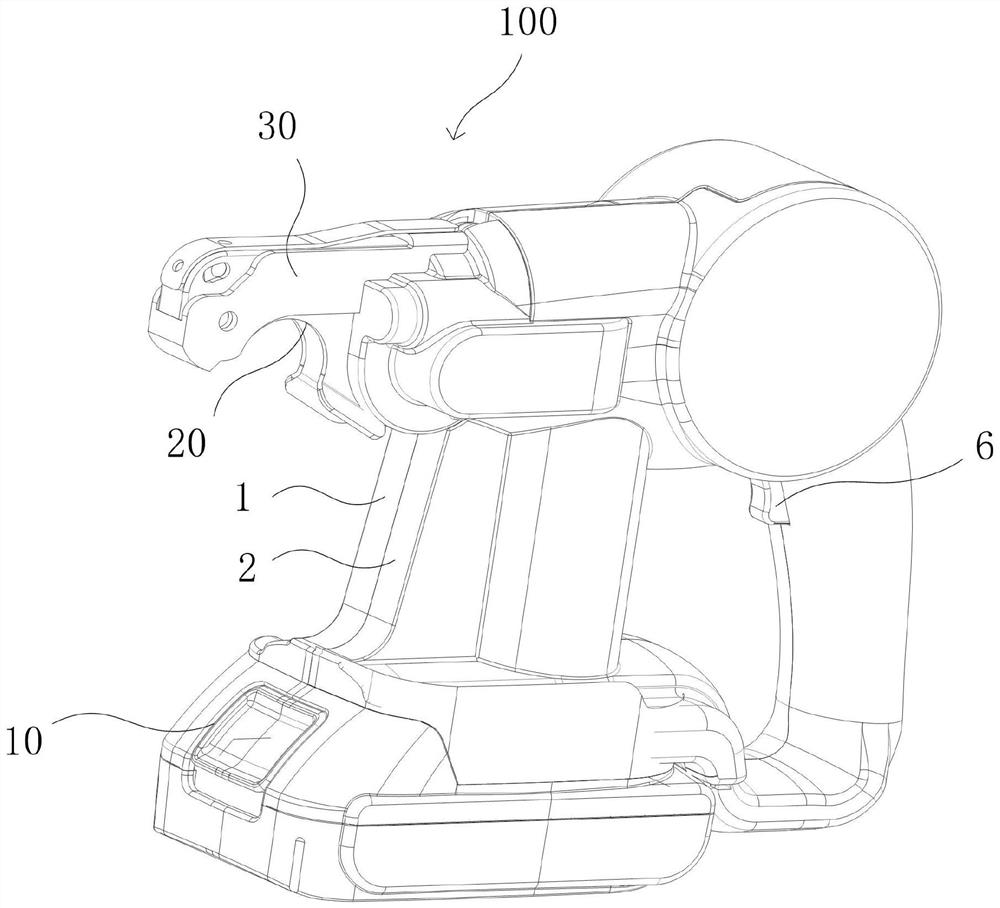

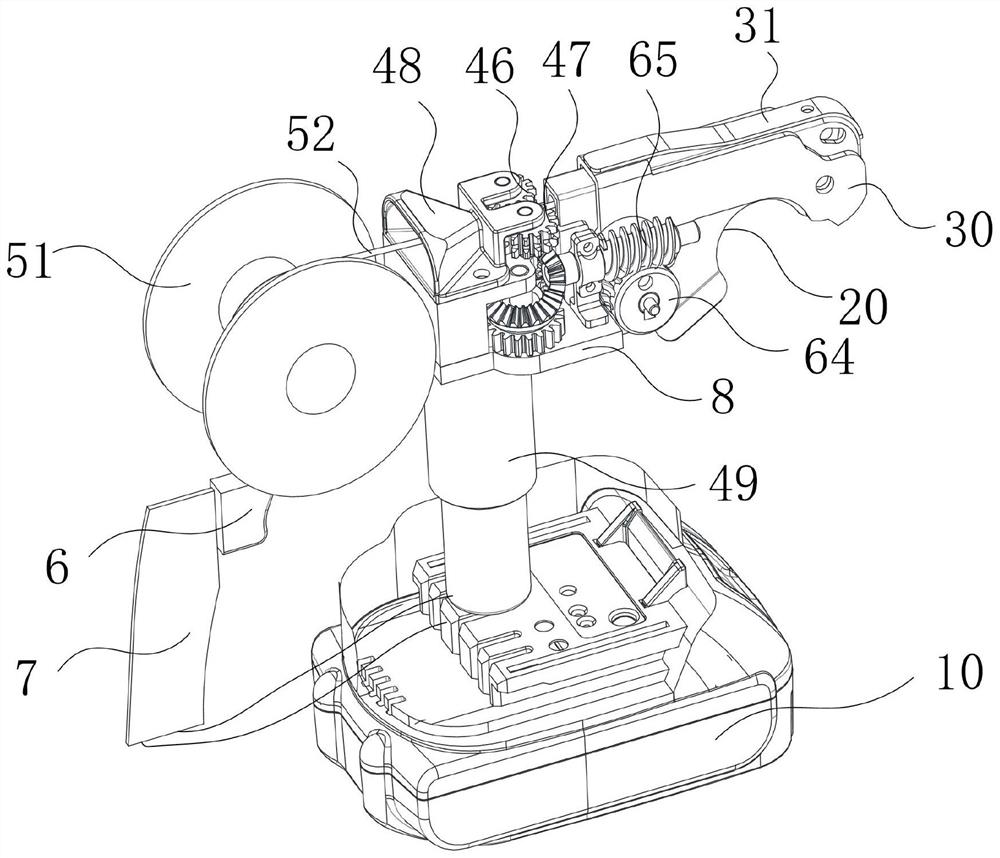

Binding machine

PendingCN112243794AFast strappingRealize bundlingCultivating equipmentsStructural engineeringMechanical engineering

The invention discloses a binding machine. The binding machine comprises a driving part, a transmission part, a binding part and a shearing part. The transmission part is driven by the driving part, and binding and shearing of a binding wire are completed through forward and reverse rotation of the transmission part; the binding part is in transmission connection with the transmission part, and inthe binding part, the binding wire is wound to form a binding coil; and the shearing part comprises a shearing transmission part and a shearing knife which are in transmission connection with the transmission part, and the shearing knife is driven by the shearing transmission part to shear off the binding coil from the binding wire. The binding part can quickly bind plant vines, and the arrangedbinding part can change the conveying path of the binding wire, so that the binding wire used for binding can be automatically wound to form a hanging ring shape to be wound on the surfaces of the vines, and binding is achieved; the binding efficiency is improved, and the labor intensity is reduced; and the arranged shearing part can be used for quickly shearing the binding wire, so that the working efficiency is improved, and the situation that scissors or other sharp edges are manually taken for shearing in the traditional process is avoided.

Owner:NINGBO XINYI WEIYE IMPORT & EXPORT CO LTD

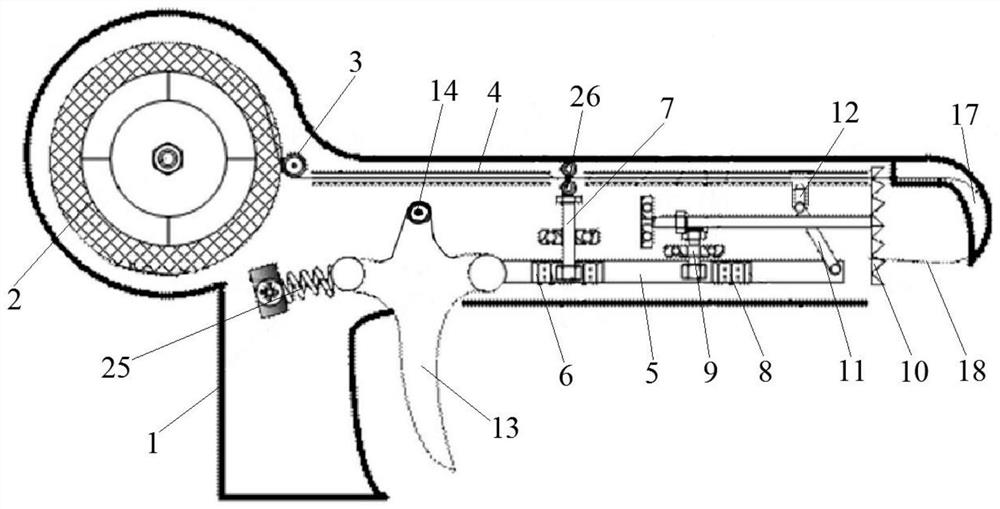

A portable cable binding fixture

ActiveCN111029974BFast strappingConsistent strengthApparatus for laying cablesStrappingTransmission channel

A portable cable binding fixer, belonging to the technical field of cable laying, comprising a housing, in which an iron wire transmission channel is provided, a forward conveying device is provided in the middle of the iron wire transmission channel, a cutter is provided at the front of the iron wire transmission channel, and the iron wire transmission channel There is a binding disc at the front end of the channel, a trigger is installed in the housing, and the trigger is connected to a transmission rod. The transmission rod is connected to the forward conveying device through the forward transmission mechanism. The transmission rod is connected to the binding disc through the binding transmission mechanism. connect. The trigger drives the transmission rod to slide, the forward transmission mechanism drives the forward conveying device, and the iron wire is conveyed forward; the transmission rod drives the binding plate through the binding transmission mechanism to realize the bundling of cables, and the transmission rod drives the cutter through the connecting rod to cut the iron wire. The structure is simple , easy to use, high bundling efficiency, through the fixed mechanical transmission action, the bundling force is consistent, to ensure that the cables are not damaged during bundling, and the construction quality is guaranteed.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

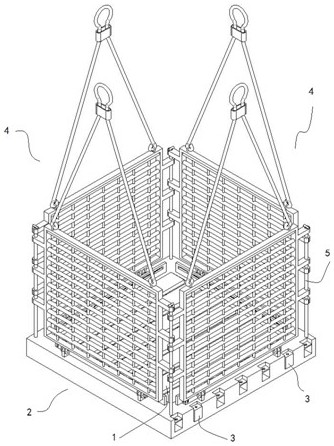

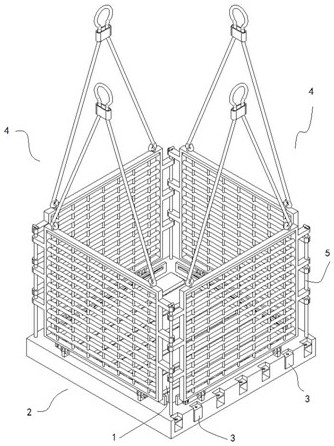

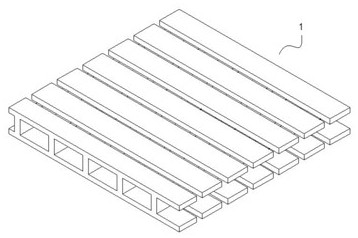

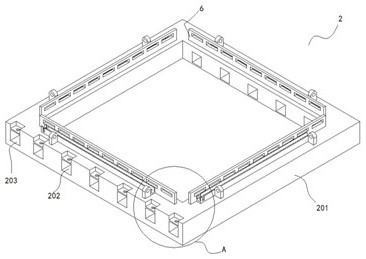

A construction material binding device

InactiveCN111762423BEnsure stabilityPrevent fallingRigid containersArchitectural engineeringStructural engineering

The invention discloses a building material bundling device, and relates to the technical field of building material bundling tools. The building material bundling device comprise a tray, and furthercomprises a bottom suspending frame for allowing the tray to be mounted and two inserted supporting rods. Side protection hanging bars are rotationally mounted on the four sides of the upper surface of the bottom suspending frame through two hinge seats correspondingly. Every two circumferential adjacent side protection hanging bars are connected through inserted link pins. The bottom suspending frame comprises a rectangular frame with four aequilate edges. Five rectangular through holes penetrating to the outer side face of the other side of the rectangular frame are evenly distributed and formed in one side face of the rectangular frame. Two rectangular containing through holes for containing the inserted supporting rods are formed in the positions, on side frames at the two ends, of thesame side face of the rectangular frame. According to the building material bundling device, a supporting plate and the bottom suspending frame are fast connected through the two inserted supportingrods, building materials on the supporting plate are tied and bundled through two crossed elastic tighteners, and the building materials are prevented from falling off through the four side protectionhanging bars.

Owner:陈艳

A kind of bismuth crystal production equipment

ActiveCN108048904BFast strappingPolycrystalline material growthFrom frozen solutionsCruciblePhysical chemistry

Owner:安徽省恒伟铋业有限公司

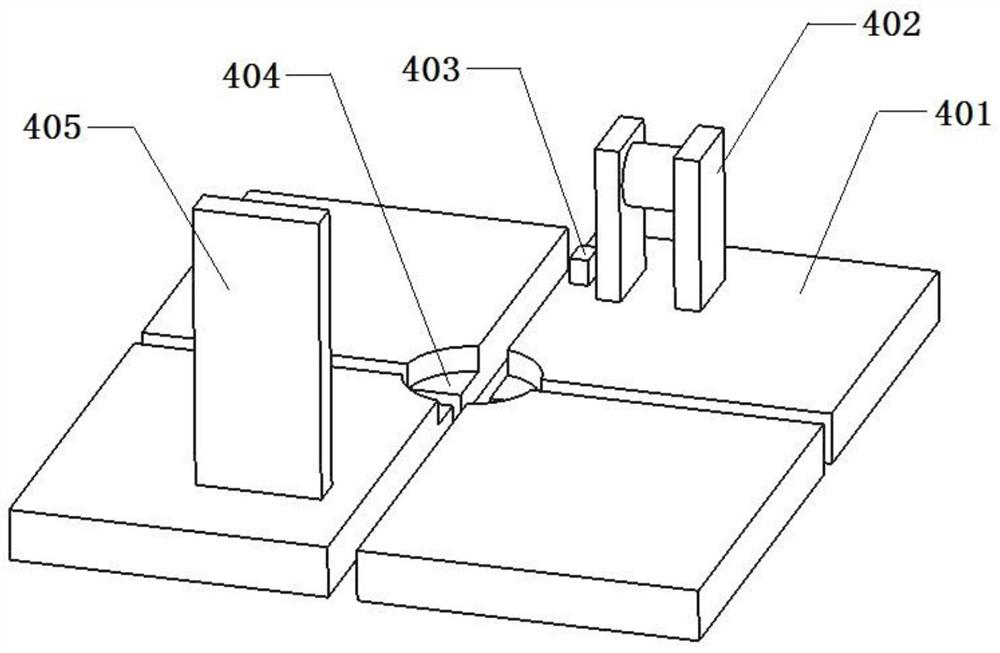

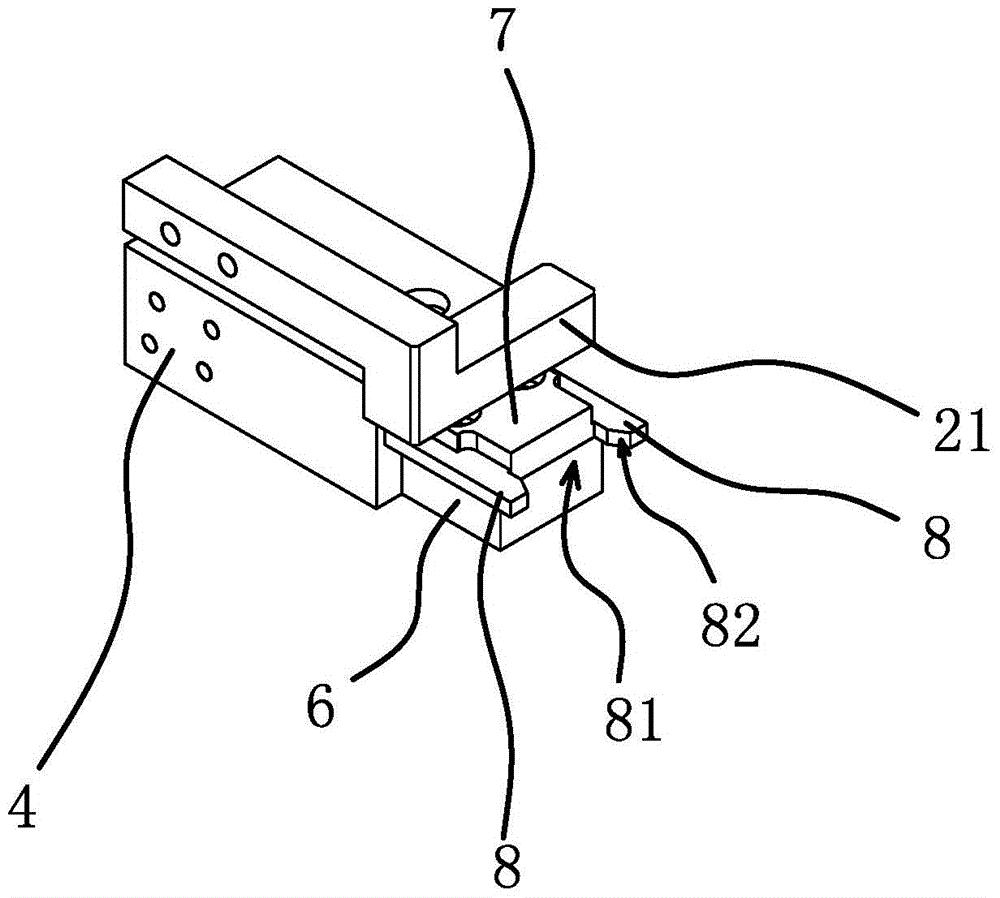

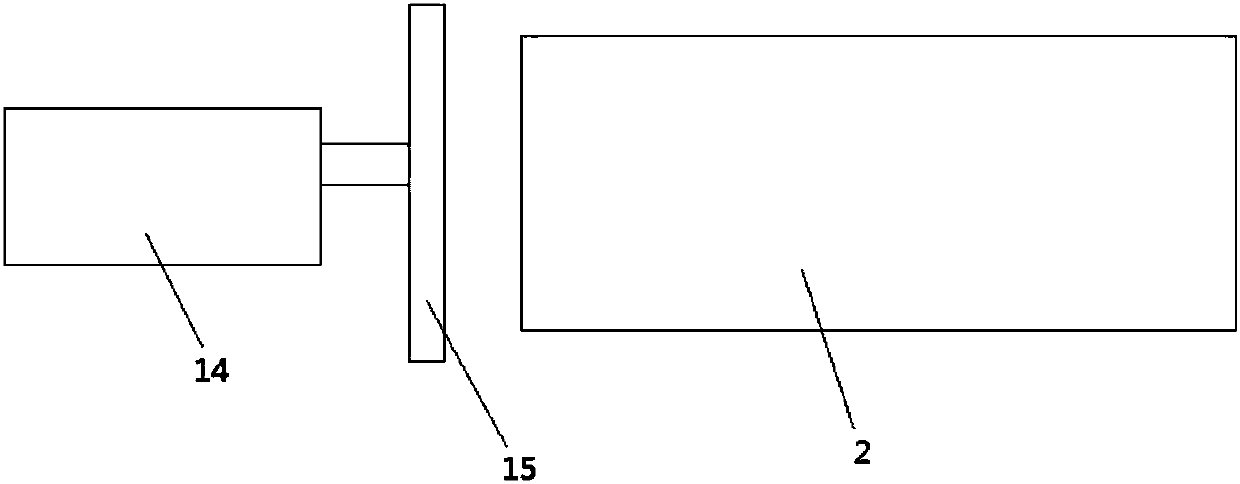

A cable tie binding heat sealing mechanism on an infusion set assembly machine

ActiveCN104554869BFast strappingMake sure the tie is tightInfusion devicesAssembly machinesInfusion setEngineering

The invention provides a ribbon bundling heat sealing mechanism for an infusion set assembly machine, belongs to the technical field of medical instruments and solves the technical problems that an existing infusion set assembly machine is low in efficiency as an infusion set is manually bundled and the like. The ribbon bundling heat sealing mechanism for the infusion set assembly machine comprises a first clamping component, a second clamping component and a heating component, the first clamping component is capable of clamping one end of a ribbon, the second clamping component is capable of clamping the other end of the ribbon, the two ends of the ribbon can be fitted, abutted and fixedly connected in a heat sealing manner by the heating component, and the first clamping component and the second clamping component can move relatively, can be abutted and are parallel to the heating component. The infusion set can be rapidly and tightly bundled by the ribbon, automated assembly line production can be realized, and production efficiency is improved.

Owner:MAIDER MEDICAL IND EQUIP

An intelligent palletizing machine for forming aluminum alloy doors and windows

ActiveCN111645927BInefficient stackingLow binding efficiencyBinding material applicationStructural engineeringAlloy

Owner:惠民县天阳金属材料有限公司

Cable arrangement device provided with branching assembly and used for electronic connector and method thereof

PendingCN114014104AImprove cleanlinessAvoid clutterFlexible lead accommodationStructural engineeringElectrical connector

The invention relates to the technical field of cable arrangement, in particular to a cable arrangement device provided with a branching assembly and used for an electronic connector and a method thereof, and aims to solve the problems that cables are easily wound together in a mess during use, and too much space is occupied due to the fact that the cables are very scattered during branching to affect the appearance. The device comprises: a cable arrangement box, a cover body and bus tightening assemblies, wherein the bus tightening assemblies are arranged at a first main wire hole and a first auxiliary wire hole respectively; an elastic band, wherein one end of the elastic band is connected with the interior of the cable arrangement box, and the other end of the elastic band is connected with the output end of the bus tightening assembly; a plurality of auxiliary wire tightening assemblies, wherein the plurality of auxiliary wire tightening assemblies are arranged in the cable arrangement box; and a plurality of auxiliary wire tightening driving pieces arranged in the cover body. According to the invention, by arranging the cable arrangement device, the tidiness of the cables is improved, branch lines are effectively processed, and disorder caused when the number of the cables is large is avoided.

Owner:深圳市宏利电子有限公司

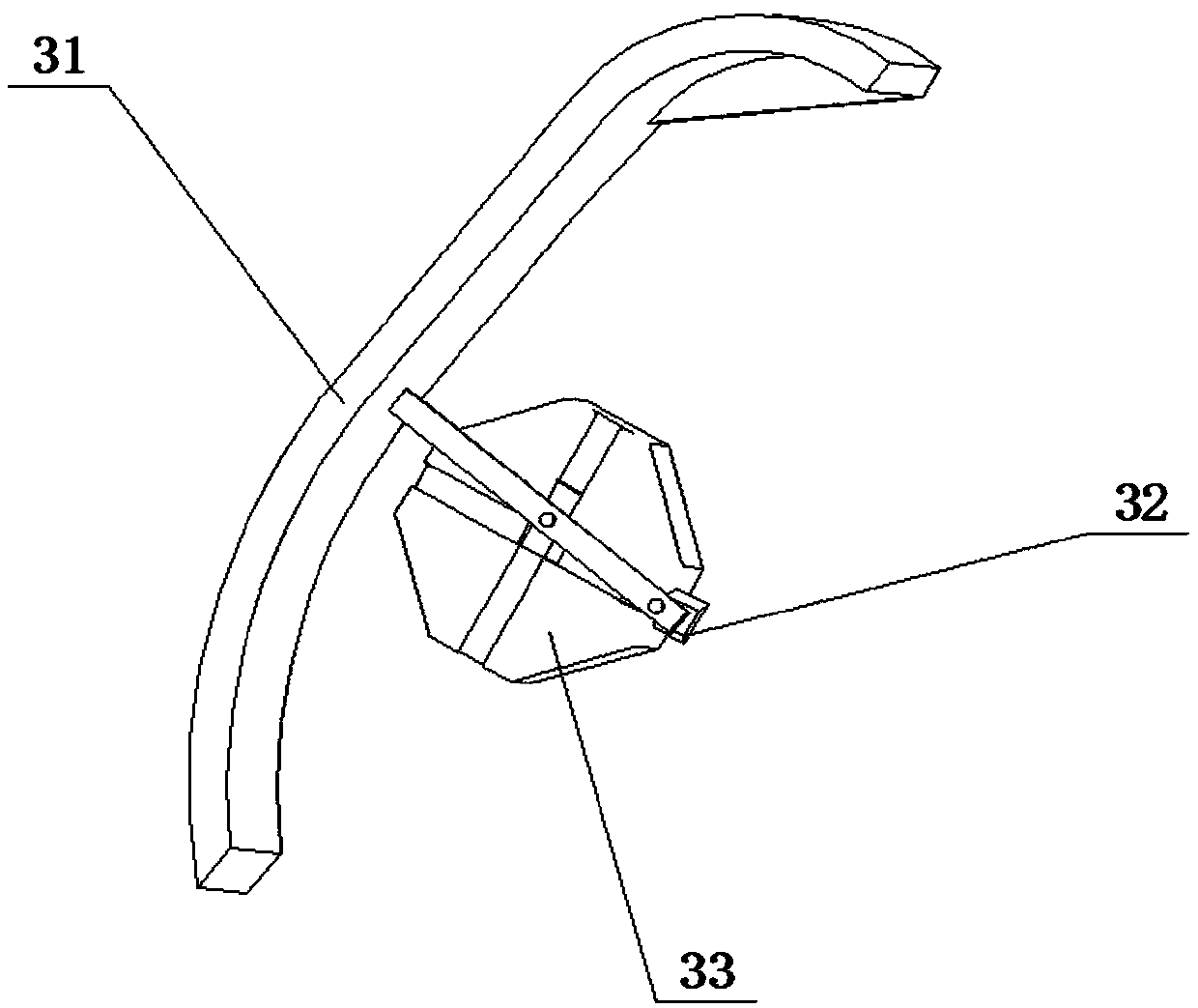

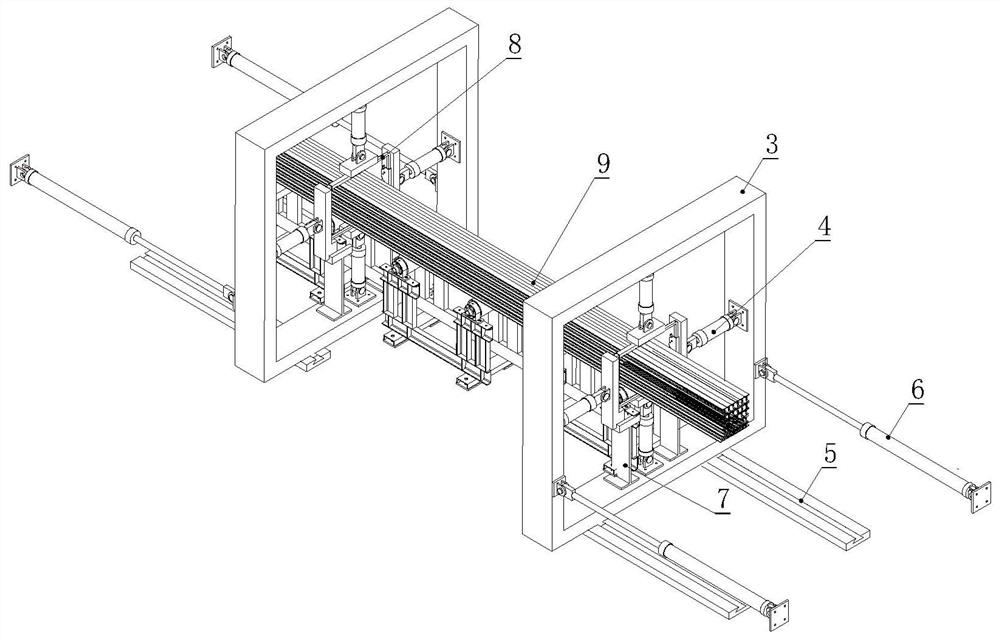

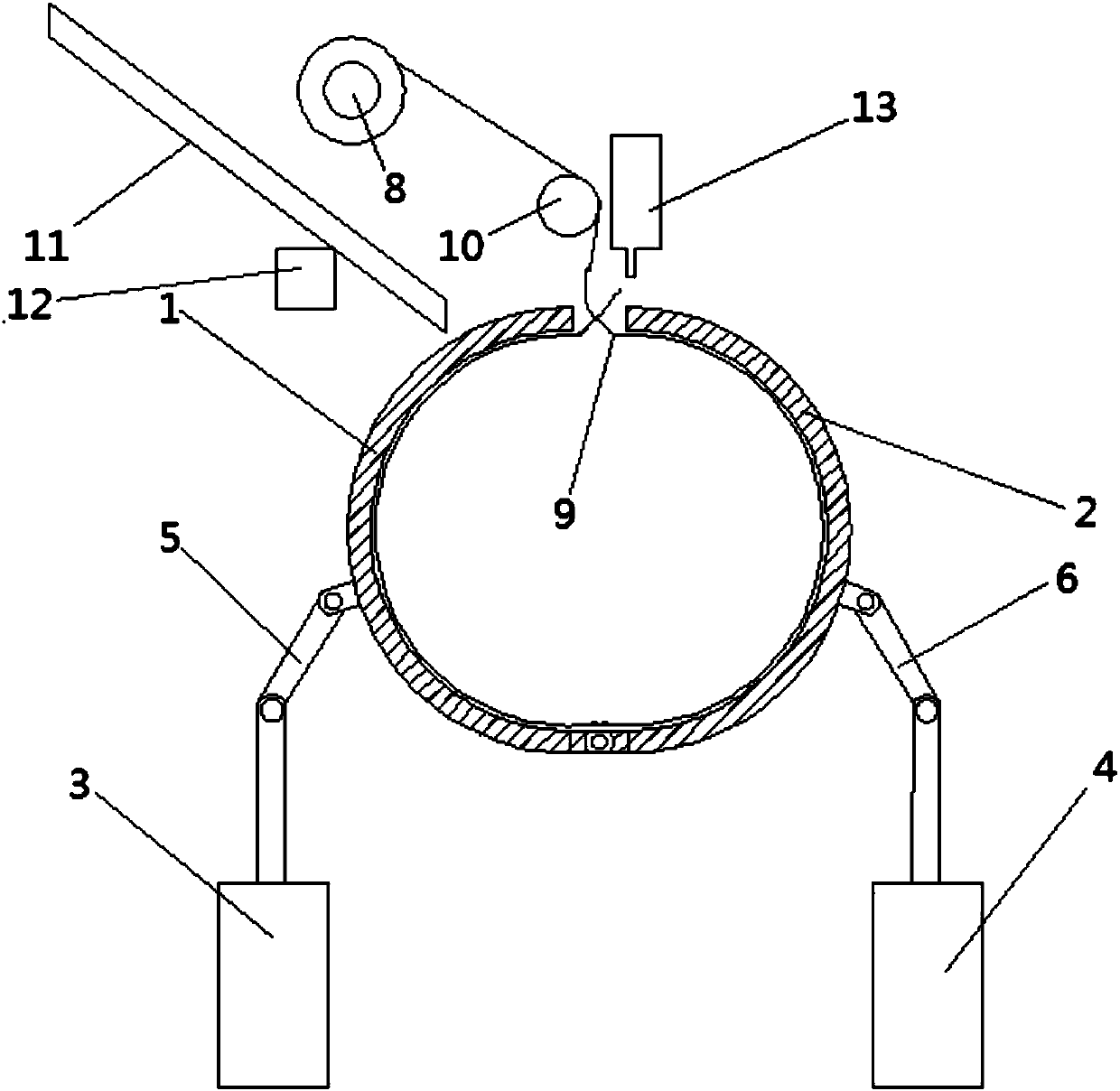

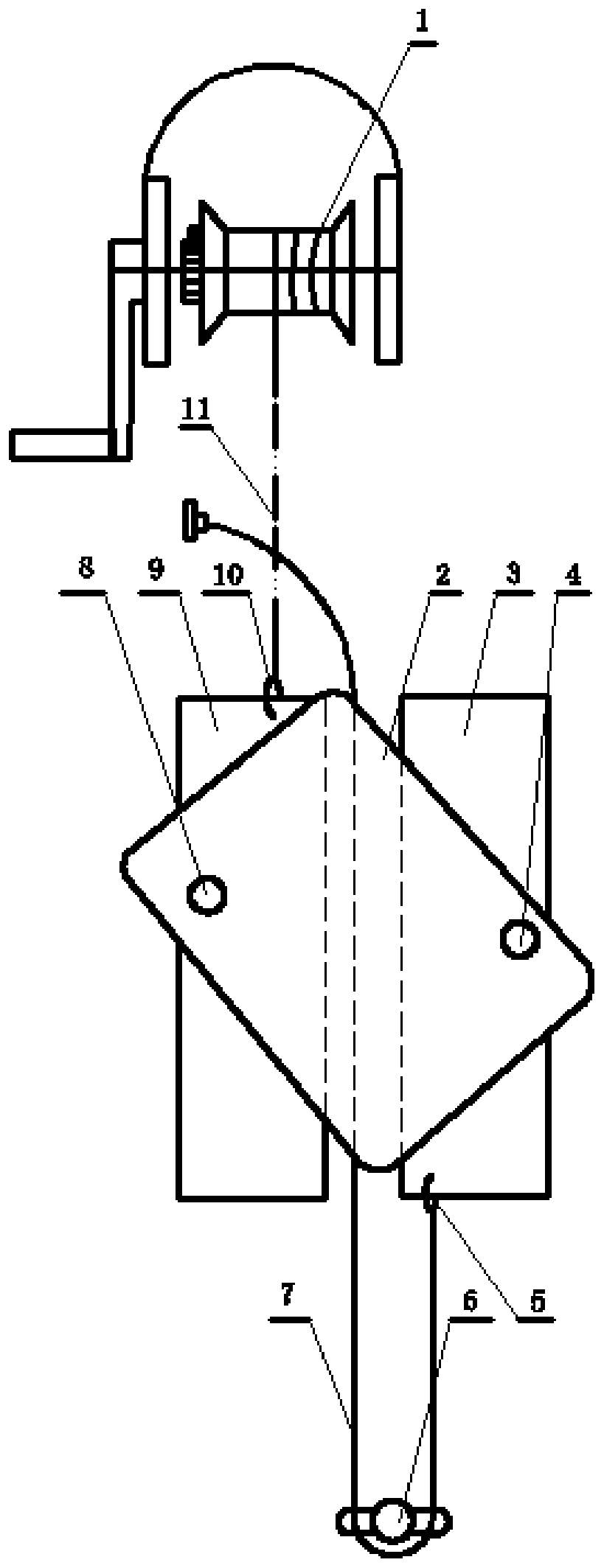

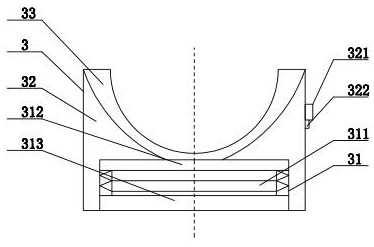

A quantitative paper tube code tube binding device

ActiveCN106144006BFast strappingIngenious structural designBinding material applicationPackaging automatic controlPulp and paper industryTube bending

The invention discloses a quantitative paper tube stacking and bundling device. The quantitative paper tube stacking and bundling device comprises a left side arc-shaped seat and a right side arc-shaped seat; the bottom ends of the two arc-shaped seats are in hinged connection; air cylinders are installed at the outer sides of the two arc-shaped seats; piston rods of the air cylinders are in hinged connection with the arc-shaped seats on two sides; arc-shaped clamping grooves are formed in the inner walls of the two arc-shaped seats; a motor wound with a rope is installed above the two arc-shaped seats; the rope winds across a fixed pulley in a traction mode, extends from the right side arc-shaped seat into the clamping groove of the left side arc-shaped seat, and the top end of the rope stretches out to the outside of the left side arc-shaped seat; after paper tubes enter the position between the two arc-shaped seats through a material guiding plate, the left side arc-shaped seat and the right side arc-shaped seat oppositely combine and form a circular shell body; the rope bundled on the paper tubes is disconnected in a fusing mode through a thermal cut-off; and a pushing plate driven by the air cylinder is arranged ahead and extends into the inner cavity of the circular shell body. The quantitative paper tube stacking and bundling device has the advantages that the structure is ingeniously designed; paper tubes are counted and quantitatively fed; the effect of fast stacking and bundling is achieved; the automation degree is high; time and labor are saved; and working efficiency is high.

Owner:日照新睿招商发展有限公司

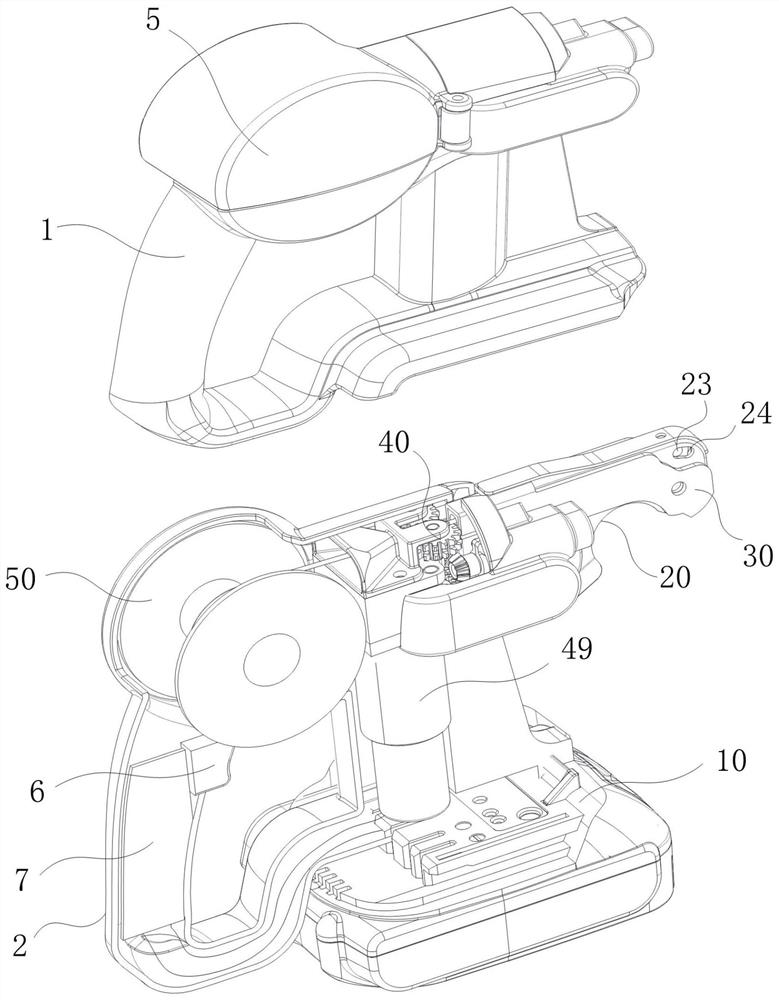

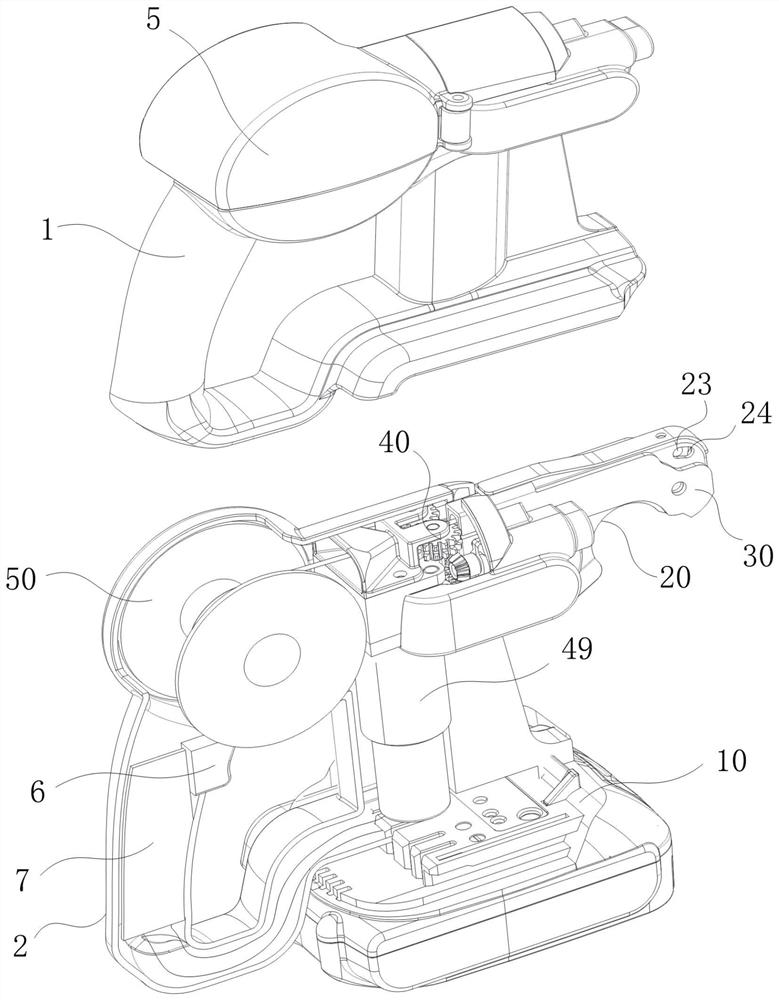

Binding machine

PendingCN112293142AFast strappingImprove bundling efficiencyCultivating equipmentsEngineeringMechanical engineering

The invention discloses a binding machine. The binding machine comprises a driving part, a binding part and a shearing part; the binding part is in driving connection with the driving part, the binding part further comprises a binding wire conveying piece, and the driving part drives a binding wire to pass through the binding wire conveying piece to the binding part to be wound to form binding coils; and the shearing part is in transmission connection with the driving part, and the binding coils are sheared off from the binding wire through the shearing part. The binding wire conveying piece is arranged in the binding part, so that the binding wire is conveniently conveyed to be wound to form the binding coils, so that the binding efficiency is improved; the binding diameter can be adjusted through the arranged binding part, and to-be-bound objects with different diameters can be rapidly adjusted and bound, so that the binding application range is wide; and the binding coils are sheared off from the binding wire through the shearing part, automatic shearing can be achieved, and the binding machine can be universally used.

Owner:NINGBO XINYI WEIYE IMPORT & EXPORT CO LTD

Straw baling forming machine

PendingCN113099856ARealize two-way pressing operationIncrease profitBalingMolding machineMechanical engineering

The invention provides a straw baling forming machine which comprises a working platform, a two-way stamping assembly horizontally and movably installed on the working platform and two straw forming assemblies arranged at the two ends of the two-way stamping assembly, wherein each straw forming assembly comprises a movable pressing plate arranged at the driving end of the two-way stamping assembly, a fixed pressing plate arranged opposite to the movable pressing plate and a bundling cover plate hinged to the working platform, and a straw forming cavity is defined by the movable pressing plate, the fixed pressing plate, the bundling cover plate and the working platform when the movable pressing plate moves to a preset position; and bundling grooves for allowing bundling wires to pass through bundling straw are formed in the circumferential bottom end and the two side ends of each straw forming cavity. The straw baling forming machine has the advantages of high baling efficiency, convenience in operation and the like.

Owner:湘潭县超豪农业发展有限公司

Quick locking and unlocking mechanism of steel wire rope

InactiveCN111483391AQuick releaseImprove work efficiencyLoad securingTransportation itemsEngineeringWire rope

The invention discloses a quick locking and unlocking mechanism of a steel wire rope. The quick locking and unlocking mechanism is characterized in that the mechanism is provided with a rectangular left clamping plate and a rectangular right clamping plate which have the same size and are butted in parallel; an upper pressing plate and a lower pressing plate correspondingly cover the two clampingplates up and down; a left clamping plate connecting shaft, a right clamping plate connecting shaft, a left clamping plate connecting hole and a right clamping plate connecting hole are arranged on two sides and close ends of the left clamping plate, the right clamping plate, the upper pressing plate and the lower pressing plate respectively; and the right clamping plate connecting hole is fixedlyconnected with a traction steel wire rope. Goods can be rapidly bound and disassembled, high-efficiency work is achieved, and the work efficiency is greatly improved.

Owner:胡永成

A quantitative paper tube cutting yard tube binding device

ActiveCN106144004BFast strappingIngenious structural designBinding material applicationPackaging automatic controlPulp and paper industryTube bending

The invention discloses a cutting, stacking and bundling device for quantitative paper tubes. The device comprises a paper tube cutting machine, a left arc-shaped seat and a right arc-shaped seat; a counting device is arranged on one side of a discharging port of the paper tube cutting machine; bottom ends of the two arc-shaped seats are in hinged connection; air cylinders are arranged on outer sides of the two arc-shaped seats; arc-shaped clamping grooves are formed in inner walls of the two arc-shaped seats; a motor with a rope winding around is arranged above the two arc-shaped seats; the rope is pulled to wind around a fixed pulley and then extends into the arc-shaped clamping groove in the left arc-shaped seat from the right arc-shaped seat; the top end of the rope extends out of the left arc-shaped seat; after the paper tubes enter the space between the two arc-shaped seats by the aid of a guiding plate, the left arc-shaped seat and the right arc-shaped seat are combined to form a round casing, ropes bundling the paper tubes are connected and fused by the aid of a thermal fuse; and push plates driven by the air cylinders are arranged on front sides and extend into an inner cavity of the round casing. The device is ingenious in structural design, capable of counting and quantitatively discharging the paper tubes and cutting, stacking and bundling the paper tubes quickly, high in automation degree, time-saving, effort-saving and high in working efficiency.

Owner:日照新睿招商发展有限公司

Building steel bar bending equipment

InactiveCN111804849AQuick cutQuick collectionPackaging automatic controlMetal working apparatusConstruction engineeringRebar

The invention discloses building steel bar bending equipment, and relates to the technical field of steel bar production. The equipment comprises a cutting device, a conveying device and a collectingdevice; the conveying device is arranged on the right side of the cutting device, the collecting device is arranged below the conveying device, and the conveying device comprises a first conveying belt, second conveying belts and fixed seats; the number of the second conveying belts is two, the two second conveying belts are respectively and vertically arranged at the two ends of the first conveying belt, the number of the fixed seats is four, the four fixed seats are respectively and correspondingly arranged at the periphery of the first conveying belt, and the collecting device comprises a damping device, a weighing device and a placing box; and the weighing device is arranged above the damping device, and the placing box is positioned at the top of the weighing device. The equipment hasthe beneficial effects that the equipment is simple in structure, steel bars can be quickly cut off, collected and bundled, the automation degree of steel bar collection is improved, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:邵世恩

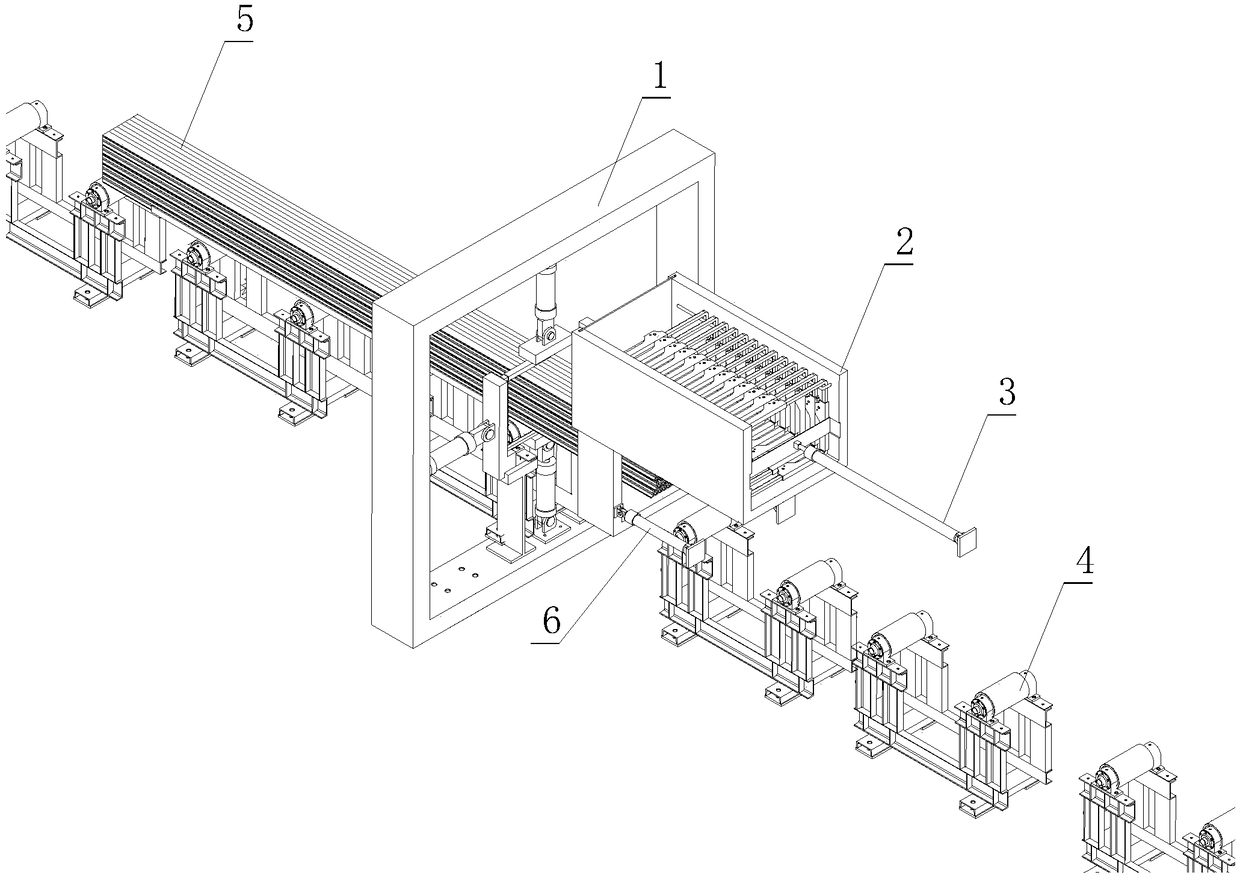

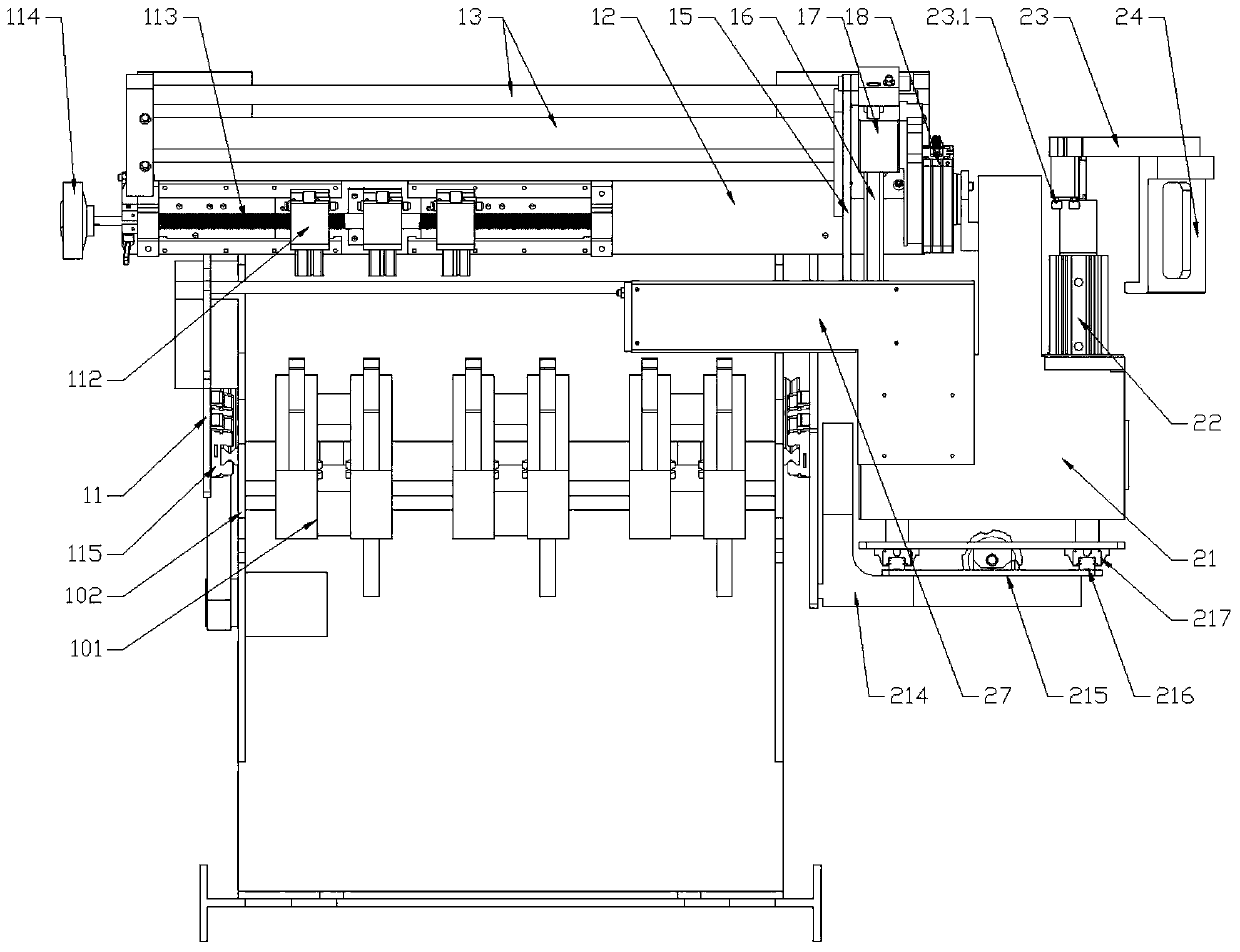

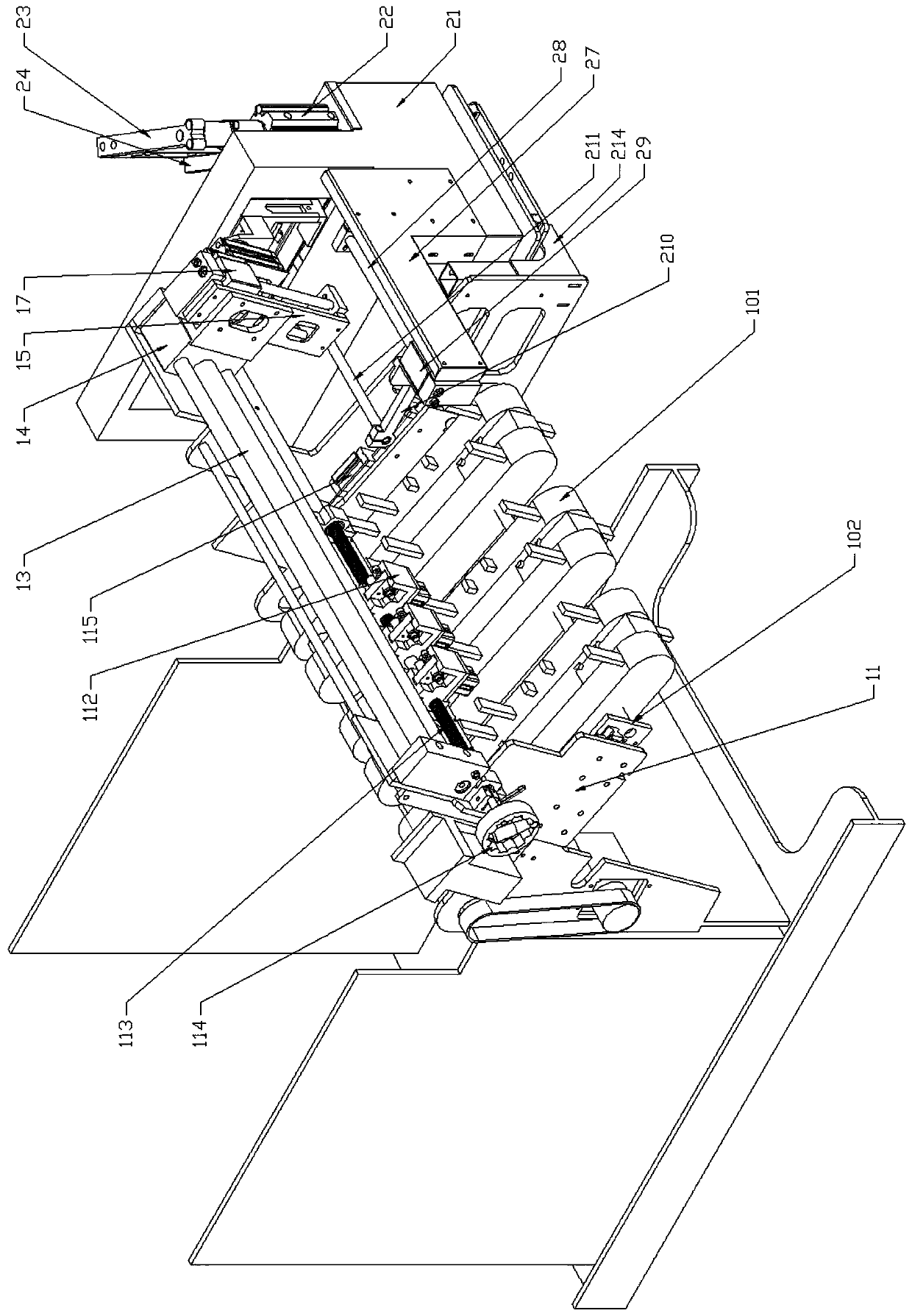

An energy-saving section steel automatic packing device and process

ActiveCN108910121BPlay a transport functionTo achieve the purpose of bundlingBinding material applicationBundling machine detailsVertical planeMechanical engineering

The invention provides an energy-saving and automatic profile steel packaging device. The device comprises a binding frame, a stacked-profile-steel conveying device, a clamp conveying device and a pushing device and is characterized in that the pushing device comprises a plurality of pushing rods and pushing blocks, the pushing rods are circumferentially arranged in the binding frame and located on the same vertical plane, the pushing blocks are arranged at the ends of the pushing rods, and the pushing direction of the pushing rod face the center of the binding frame; the bottom of the bindingframe is provided with a support platform for placing clamps; the stacked-profile-steel conveying device comprises conveying rollers passing the binding frame and a stacked-profile-steel conveying rack, the conveying rollers are vertical to the binding frame and penetrate the frame the clamp conveying device is arranged on one side of the vertical plane and comprises a clamp conveying box, a clamp conveying mechanism and a clamp box pushing mechanism, the clamp conveying box is located above the conveying rollers, and the bottom of the clamp conveying box is provided with a clamp conveying port. The energy-saving and automatic profile steel packaging device has the advantages that stacked profile steel can be continuously automatically bound, the stacked profile steel is neat and attractive, and high work efficiency is achieved.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

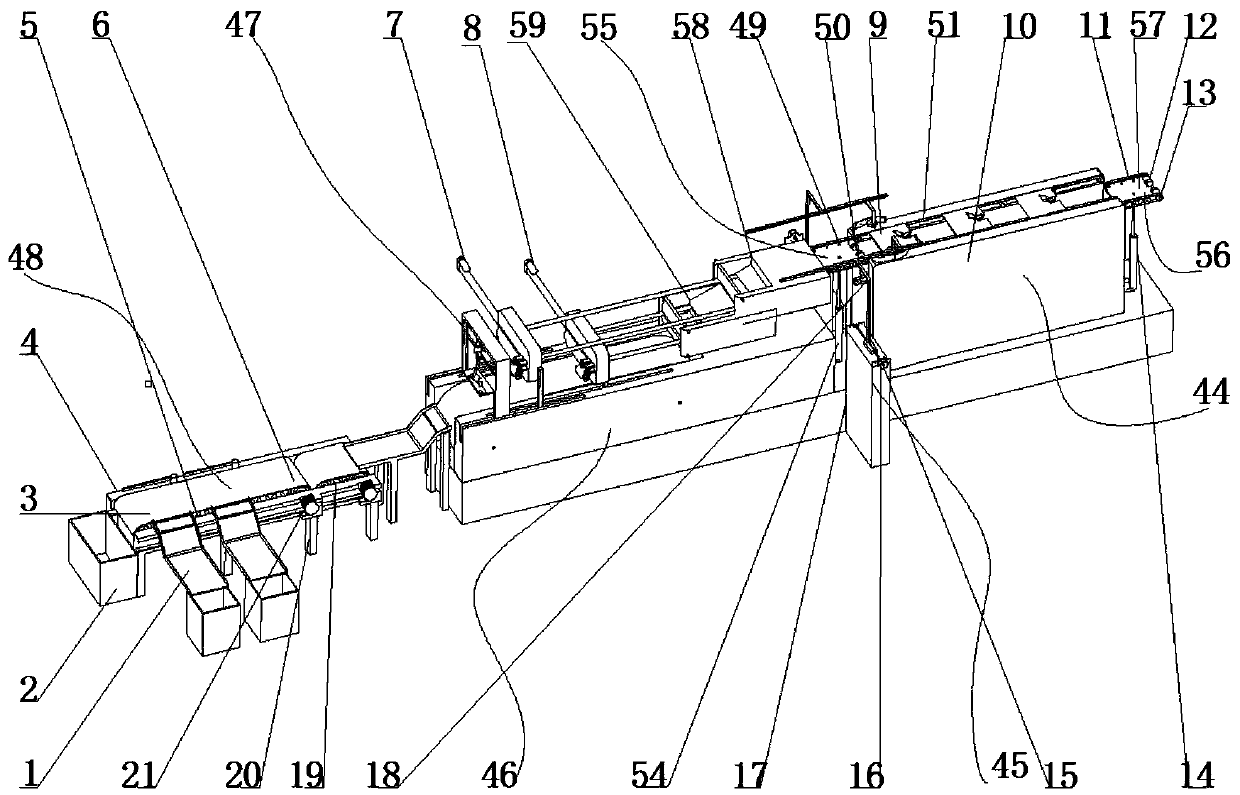

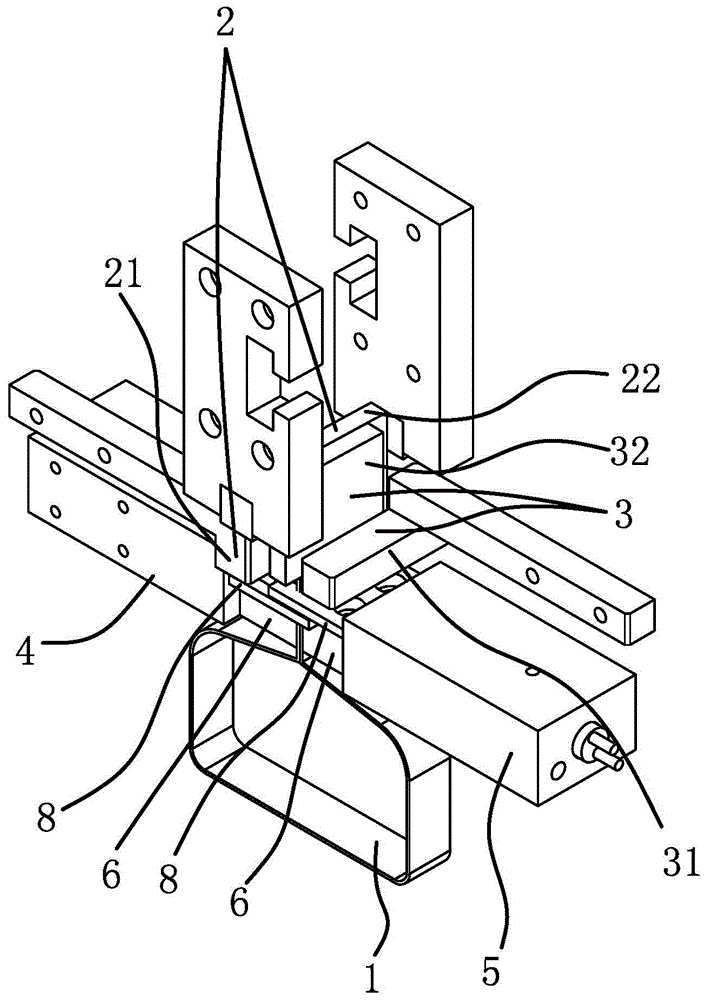

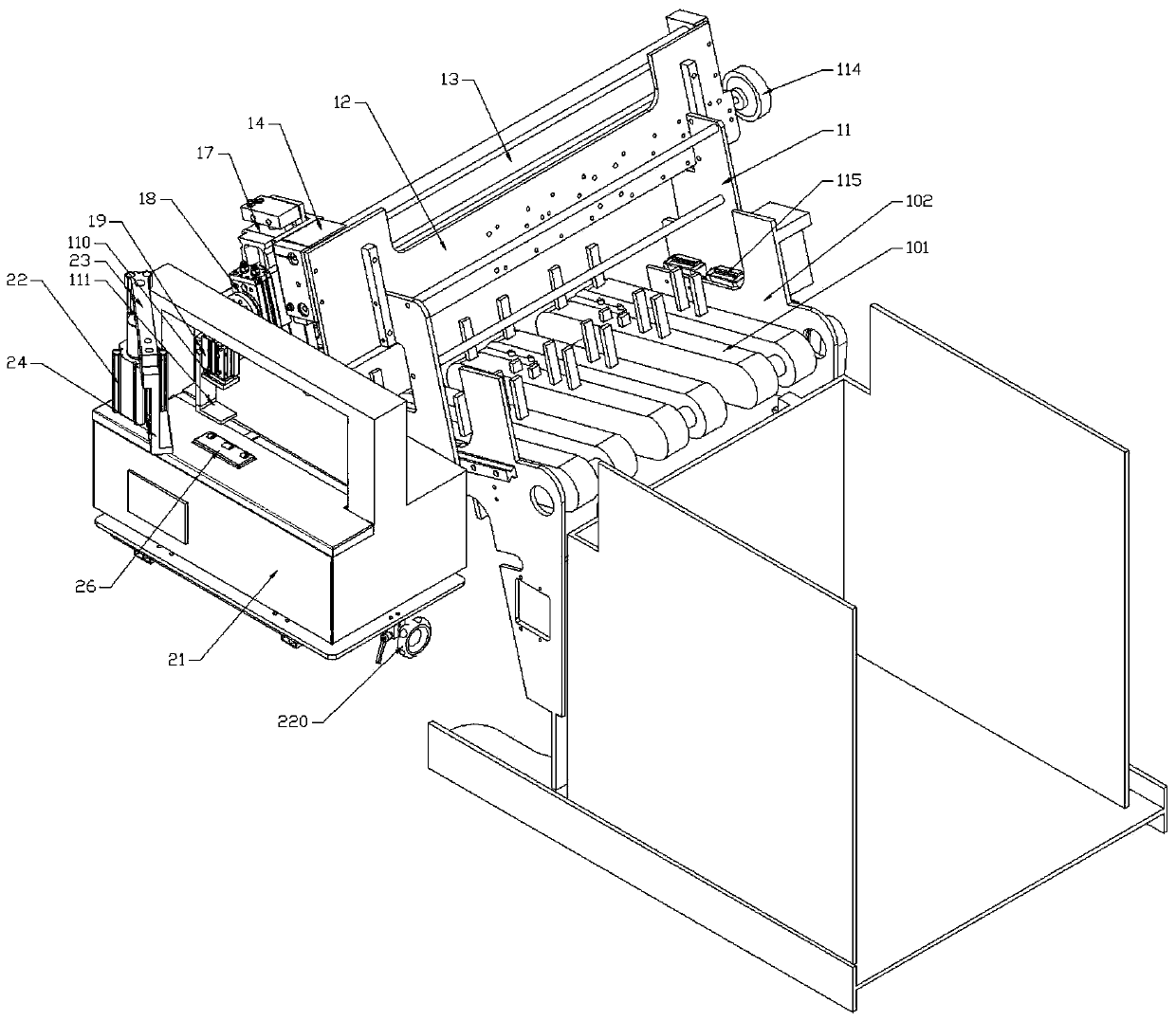

Material grabbing and strapping mechanism of bag management machine

PendingCN111114886AFast strappingHigh degree of automationBinding material applicationWall plateManufacturing engineering

A material grabbing and strapping mechanism of a bag management machine comprises a material grabbing mechanism and a strapping mechanism which are installed on the rear portion of the bag managementmachine. The material grabbing mechanism comprises material grabbing wallboards. A horizonal movement installation plate is arranged between the material grabbing wallboards. Horizontal movement guideshafts are arranged on the horizontal movement installation plate. A horizontal movement cylinder is arranged on the horizontal movement guide shafts. A lifting installation plate is arranged on thehorizontal movement cylinder. Lifting guide shafts are arranged on the lifting installation plate. A lifting cylinder is arranged on the lifting guide shafts. A rotation cylinder is arranged on the lifting cylinder. A material grabbing cylinder is arranged on the rotation cylinder. The movable end of the material grabbing cylinder is connected with an upper material grabbing plate. A lower material grabbing plate is arranged on one side of the material grabbing cylinder. The strapping mechanism comprises a strapping machine. A strapping tape groove is formed in a work table of the strapping machine. A strapping cylinder is arranged outside the strapping tape groove. The movable end of the strapping cylinder is connected with one end of a transverse rod, and the other end of the strapping cylinder is connected with a pressing block. The material grabbing and strapping mechanism can be well connected with a bag manufacturing and managing machine to achieve rapid strapping of packaging bags, the automation degree is high, and the labor cost is greatly reduced.

Owner:浙江创派智能科技有限公司

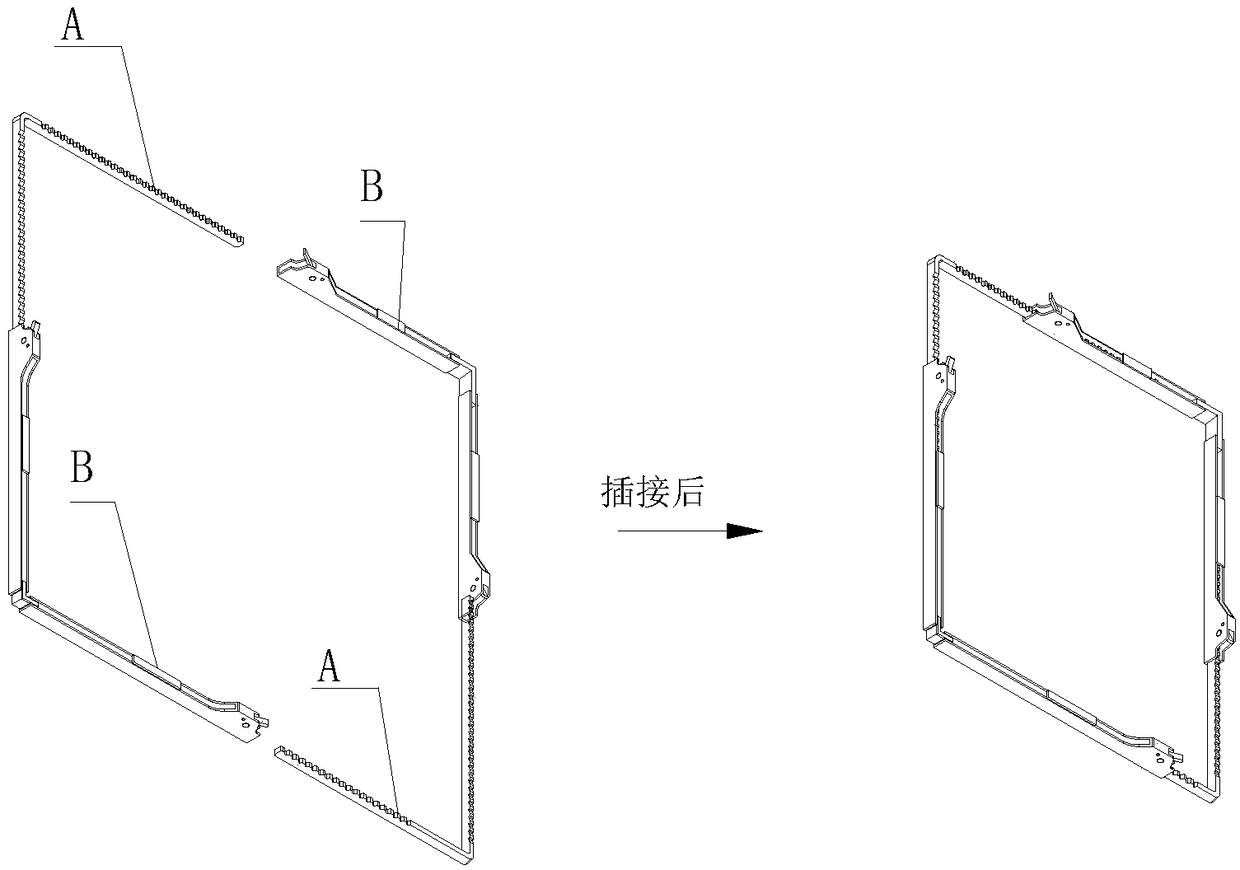

Building material bundling device

InactiveCN111762423AEnsure stabilityPrevent fallingRigid containersArchitectural engineeringStructural engineering

The invention discloses a building material bundling device, and relates to the technical field of building material bundling tools. The building material bundling device comprise a tray, and furthercomprises a bottom suspending frame for allowing the tray to be mounted and two inserted supporting rods. Side protection hanging bars are rotationally mounted on the four sides of the upper surface of the bottom suspending frame through two hinge seats correspondingly. Every two circumferential adjacent side protection hanging bars are connected through inserted link pins. The bottom suspending frame comprises a rectangular frame with four aequilate edges. Five rectangular through holes penetrating to the outer side face of the other side of the rectangular frame are evenly distributed and formed in one side face of the rectangular frame. Two rectangular containing through holes for containing the inserted supporting rods are formed in the positions, on side frames at the two ends, of thesame side face of the rectangular frame. According to the building material bundling device, a supporting plate and the bottom suspending frame are fast connected through the two inserted supportingrods, building materials on the supporting plate are tied and bundled through two crossed elastic tighteners, and the building materials are prevented from falling off through the four side protectionhanging bars.

Owner:陈艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com