A binding steel belt storage rack

A storage rack and steel belt technology, applied in the field of strapping steel belts and steel belt storage racks, can solve problems such as troublesome operation by workers, loose ends of steel belts, and laborious pulling of steel belts, so as to achieve easy pulling and reduce replacement. The frequency of strapping, the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

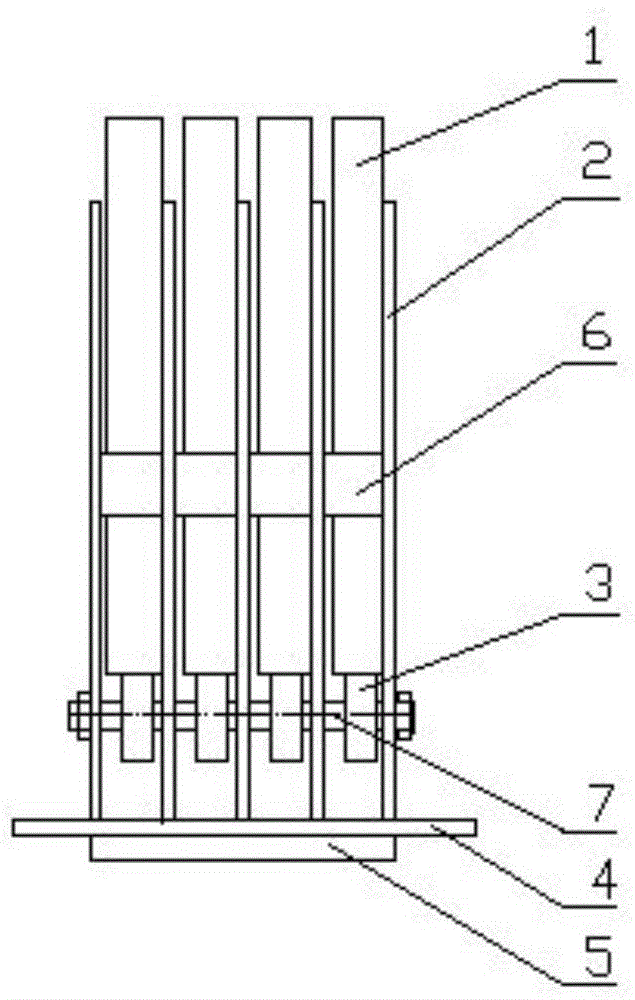

[0022] A bundled steel belt storage rack, a square bottom plate 4 is welded on a base 5, the bottom plate is perpendicular to the direction of the bottom plate, vertically and evenly spaced and welded with partitions 2, the partitions are rectangular, the length of the long side of the partition and the long side of the bottom plate equal, the distance between two adjacent partitions is greater than the width of the binding steel strip 1, the two sides of the adjacent two partitions are connected by baffles 6, and there are mirror-symmetrical grooves on the bottom of each side of each partition. Groove is rectangular, and the roller 7 of mirror image symmetry passes through groove and connects each dividing plate, and the distance between the rollers is less than the diameter of the outer ring of the strapping steel strip, and roller 3 is set between the two dividing plates of the roller, and the roller The two ends are fastened by nuts, and the binding steel belt is placed bet...

Embodiment 2

[0024] A bundled steel strip storage rack, the difference from Example 1 is (1) no baffles are provided on both sides of the partition (2) no U-shaped groove is opened in the upper middle of the partition, instead, each There is a hole in the middle of each partition, and a rotating shaft passes through the hole to connect the partition and the strapping steel belt placed between the partitions. The two ends of the shaft are fastened with nuts. When the steel belt needs to be replaced, the nut can be unscrewed. , It is also very convenient to pull out part of the shaft and take out the steel belt from the side.

Embodiment 3

[0026] A kind of binding steel belt storage rack, the difference with embodiment 1 is that base is changed into the four corners of bottom surface of square bottom plate and universal wheels are installed, so it is more convenient to move this binding steel belt storage rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com