Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Ensure planarity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

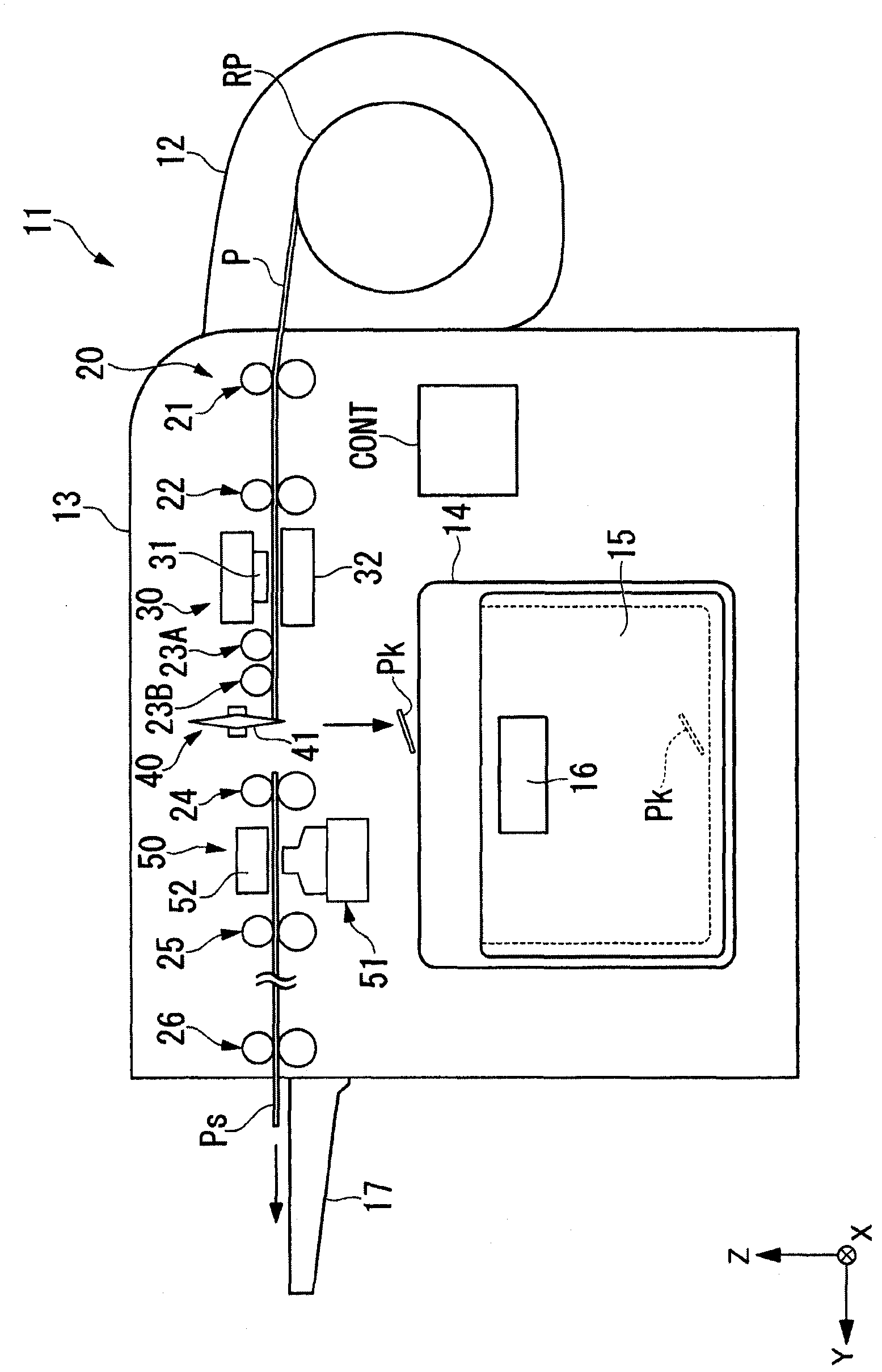

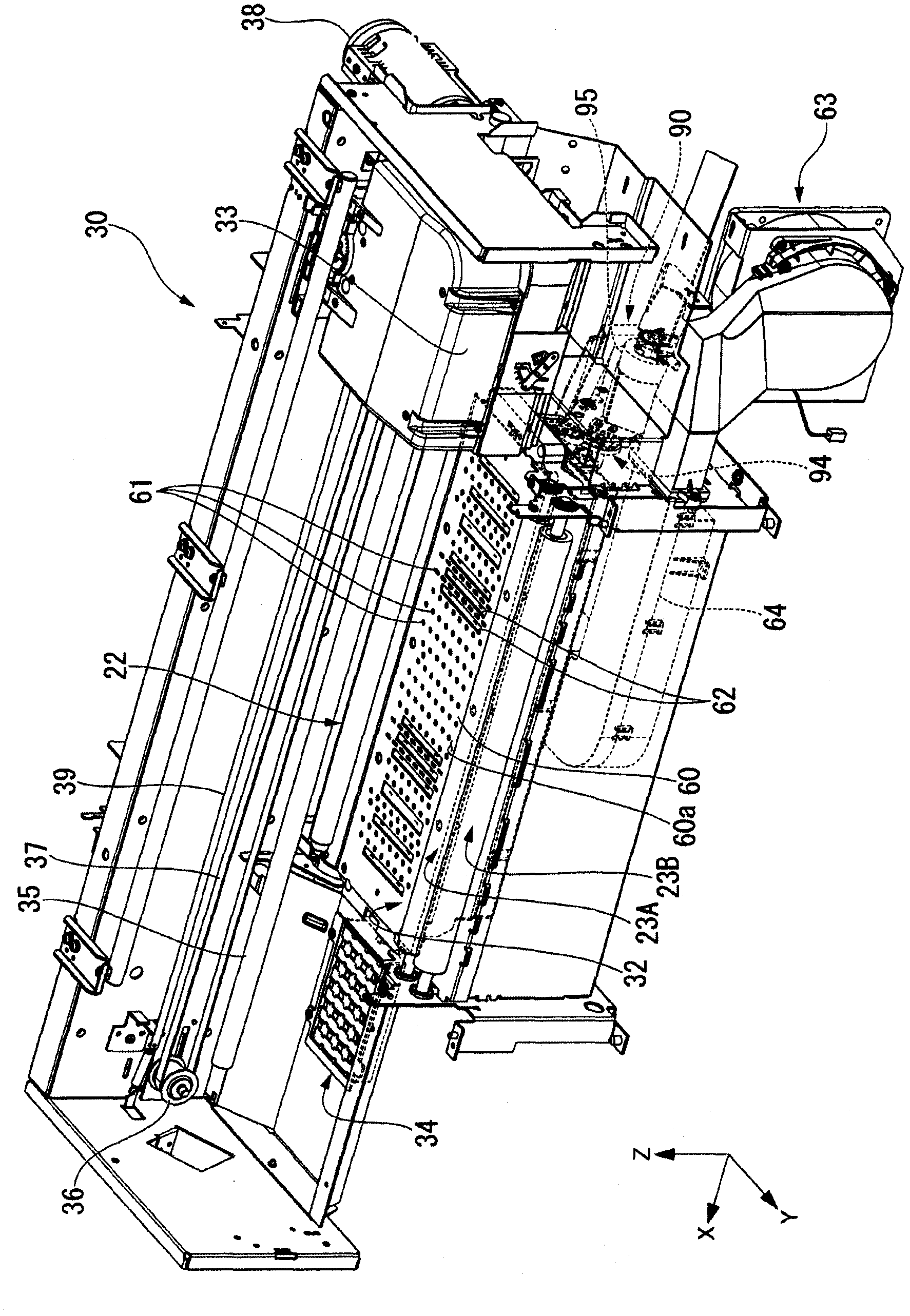

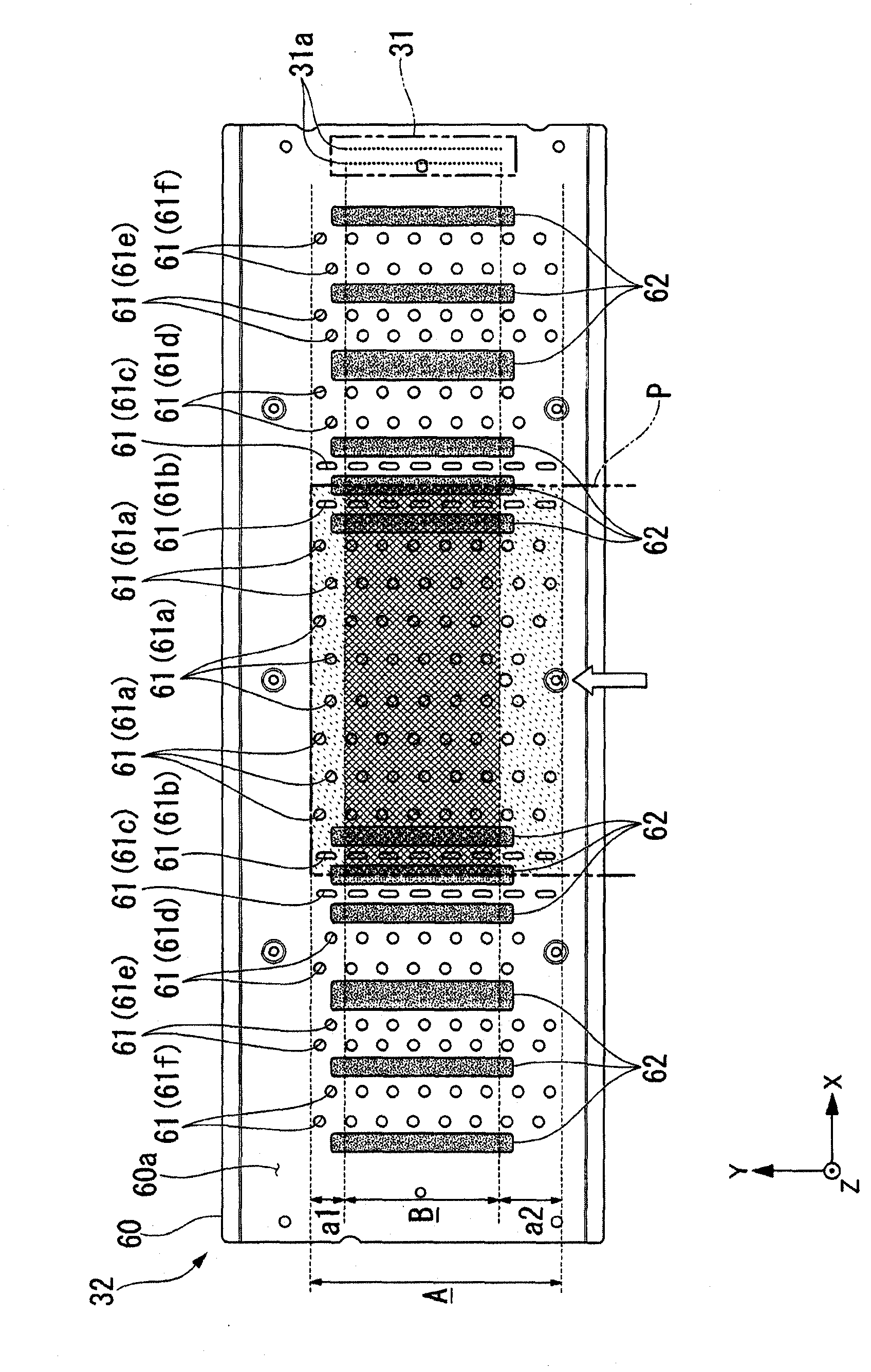

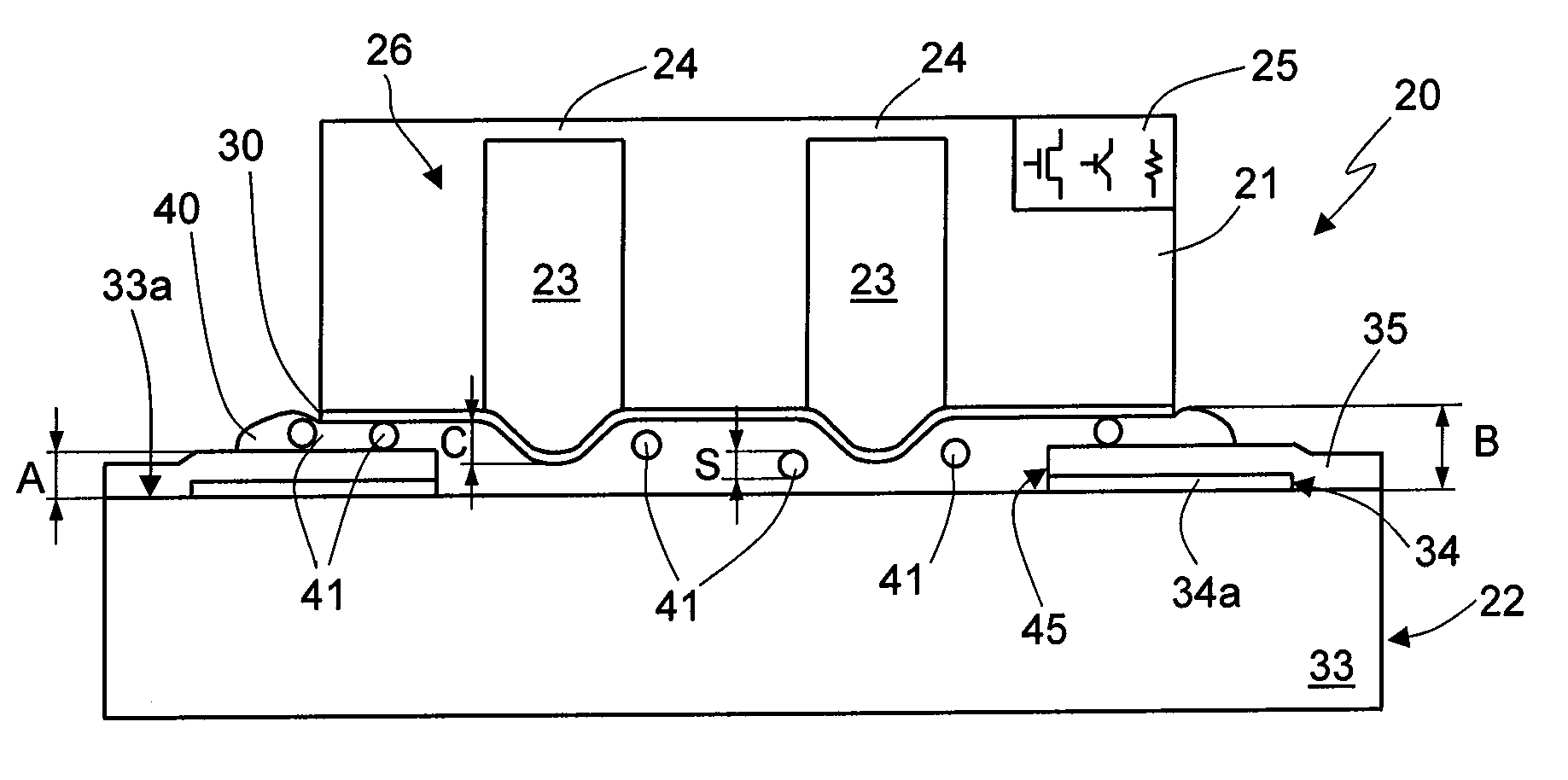

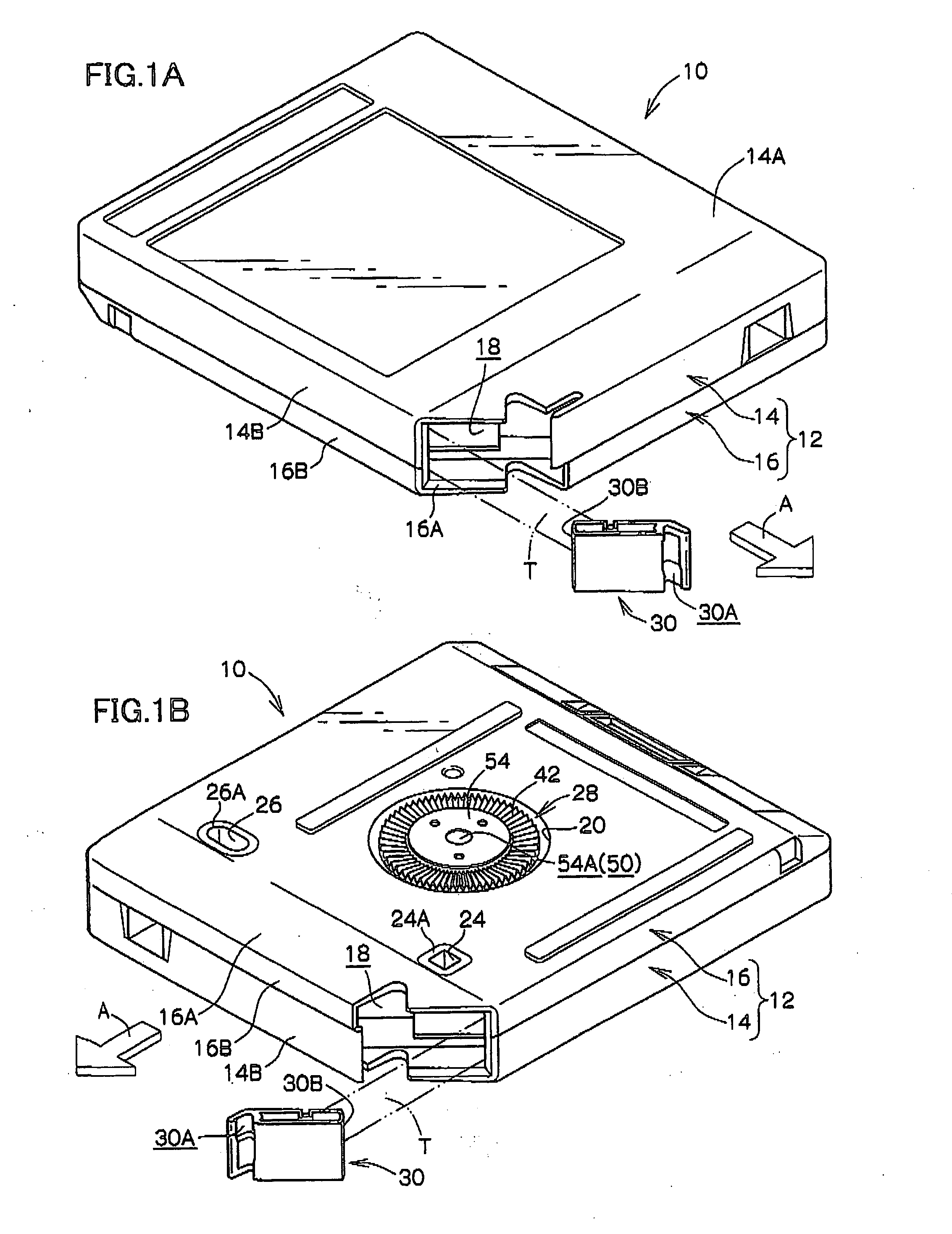

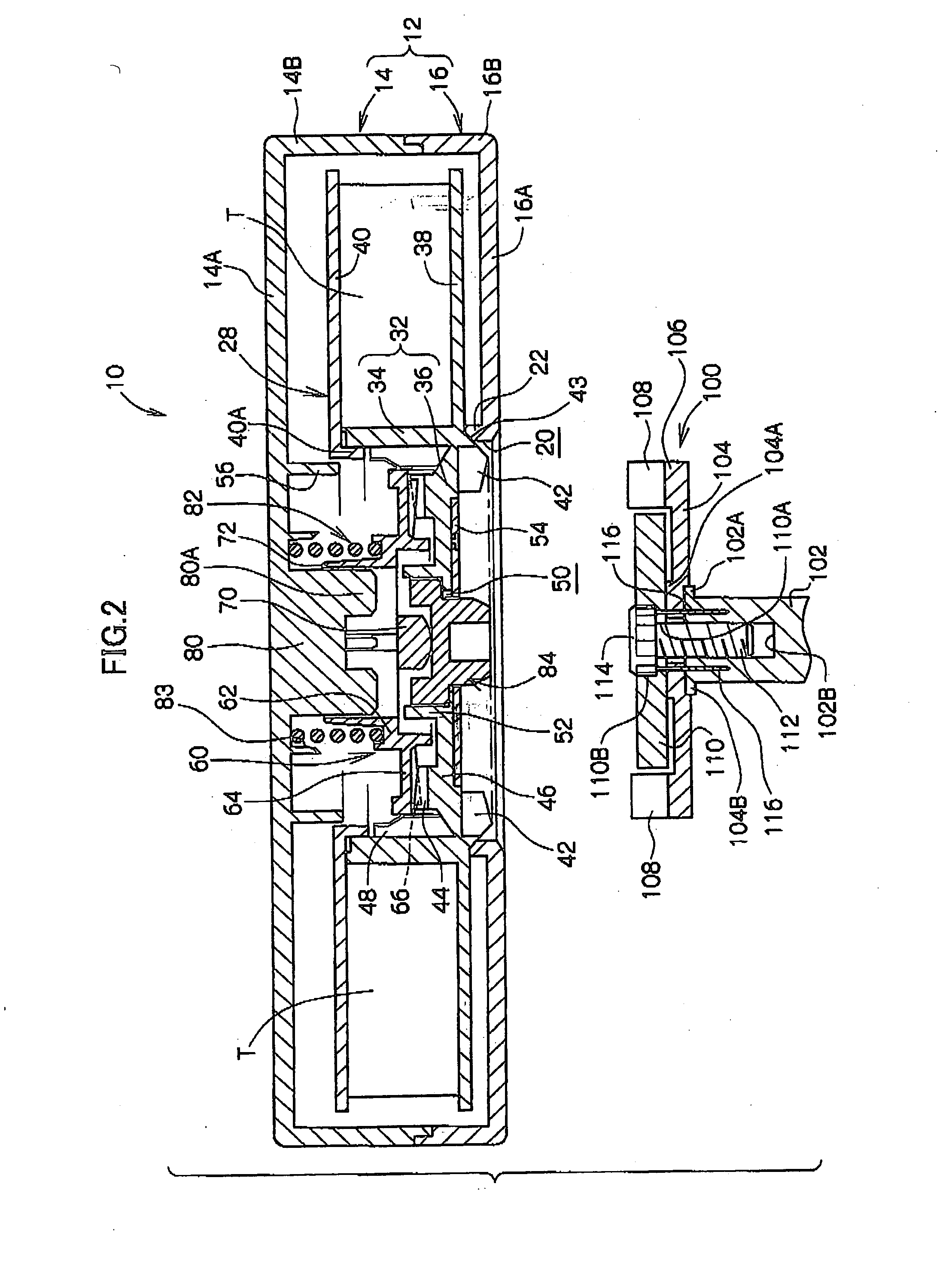

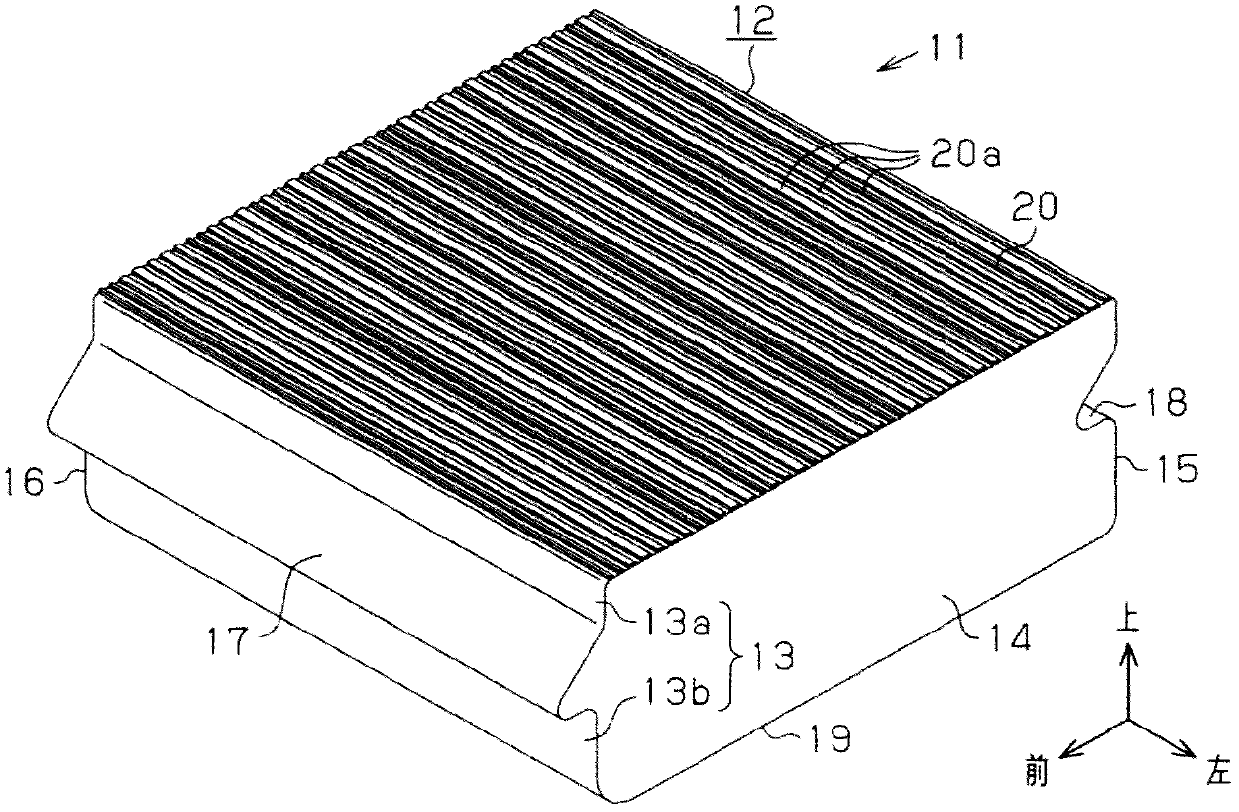

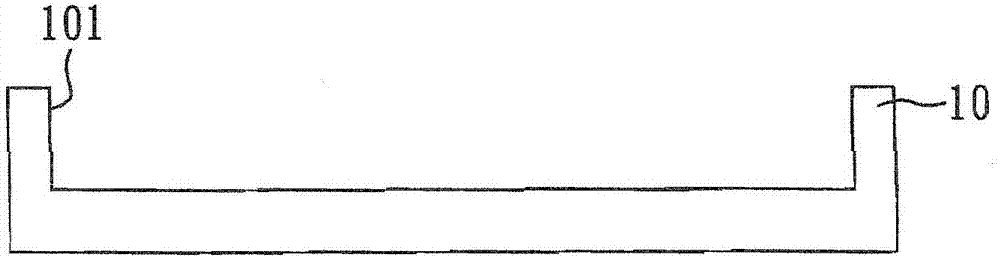

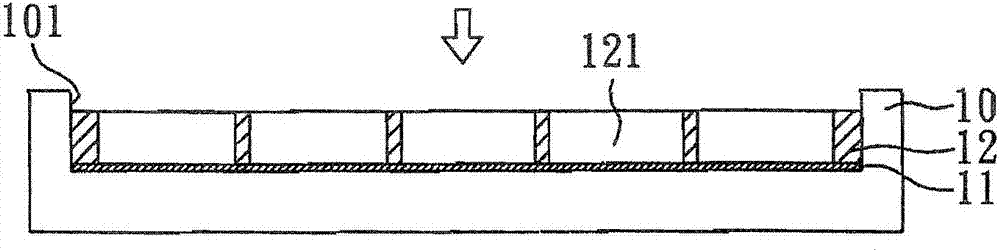

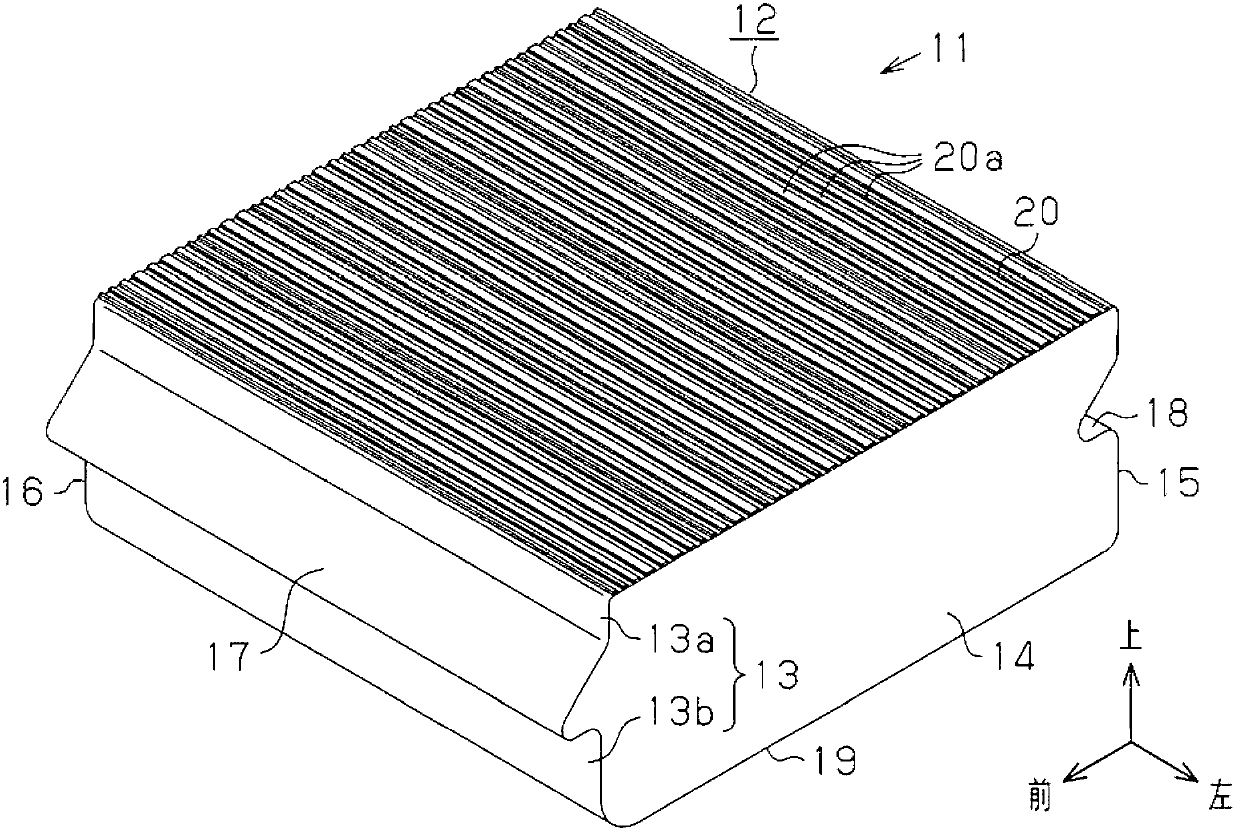

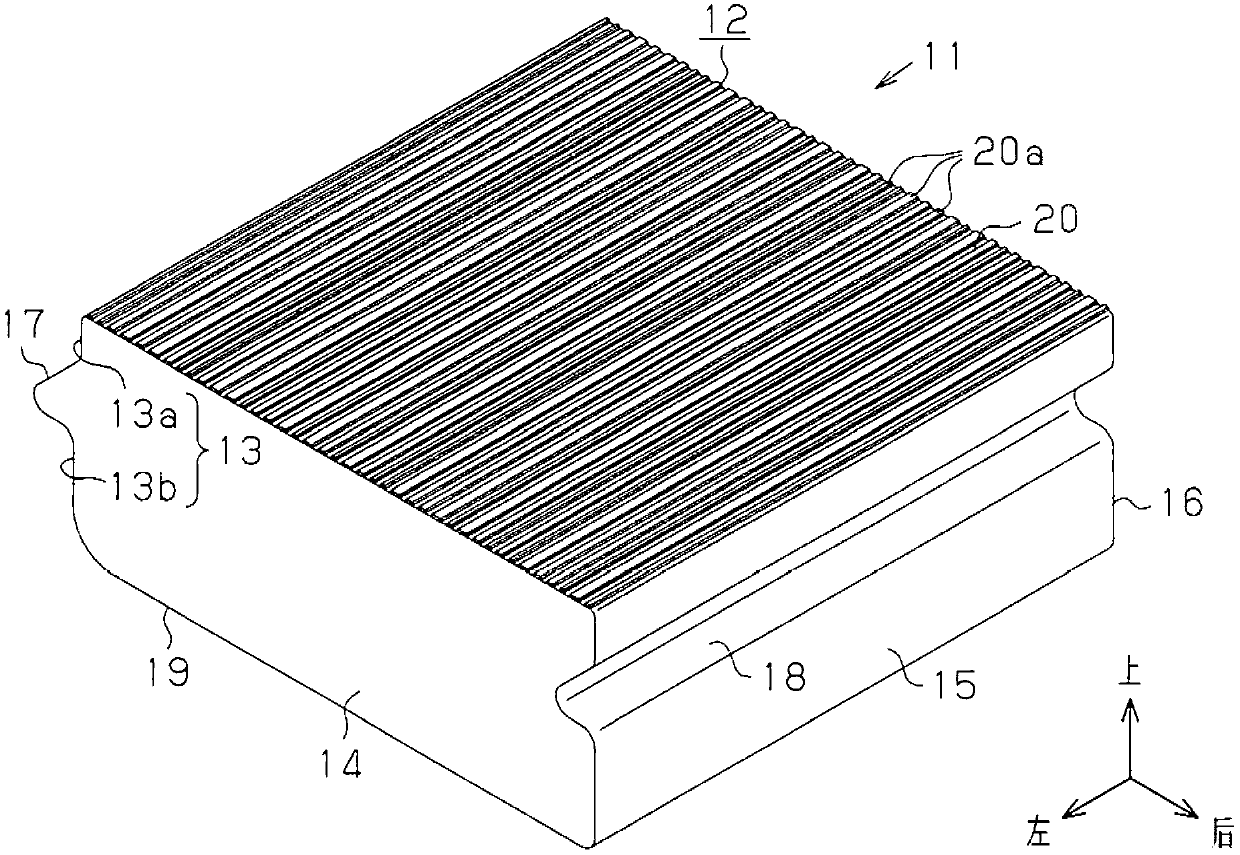

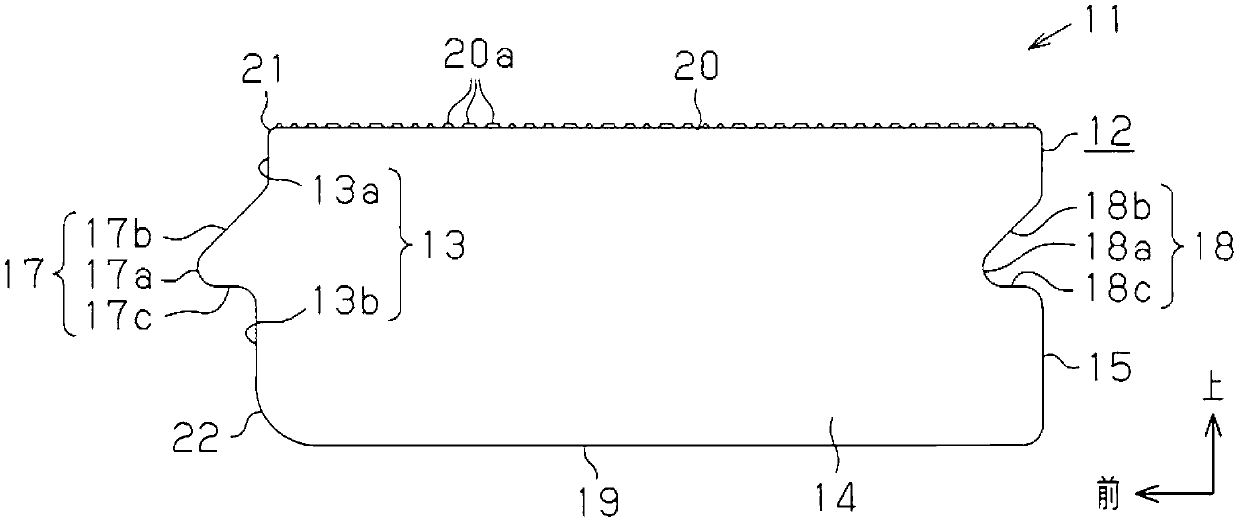

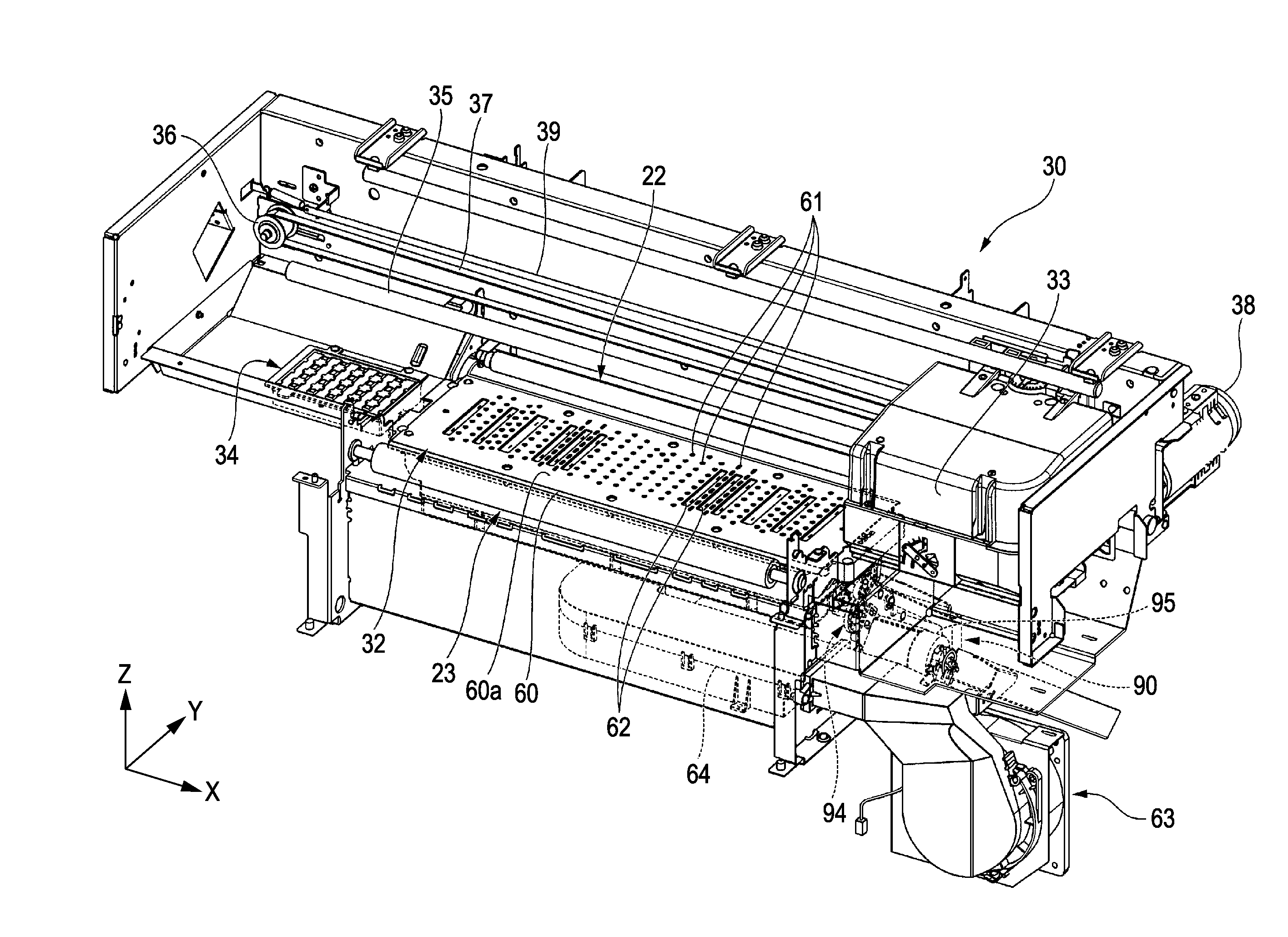

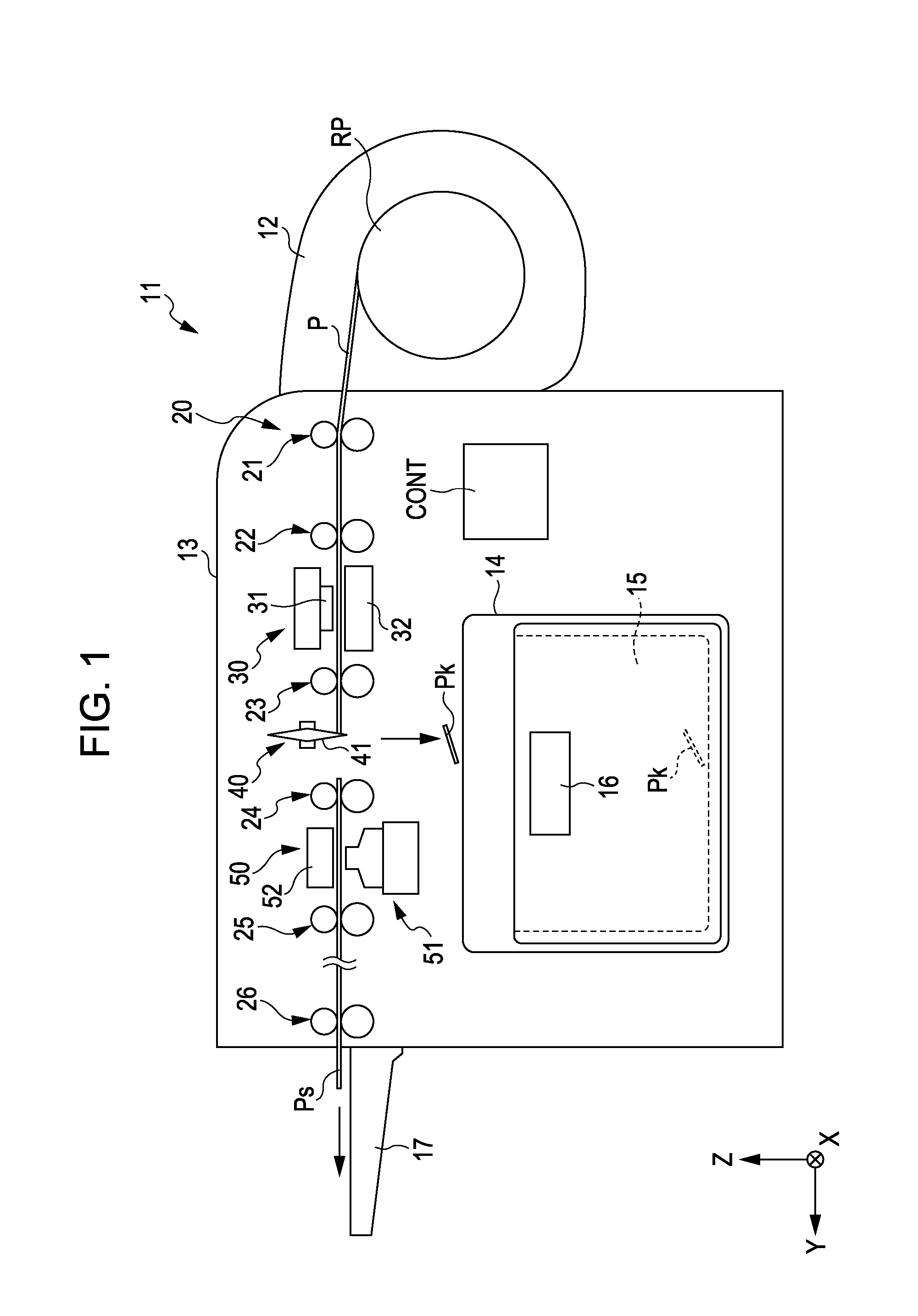

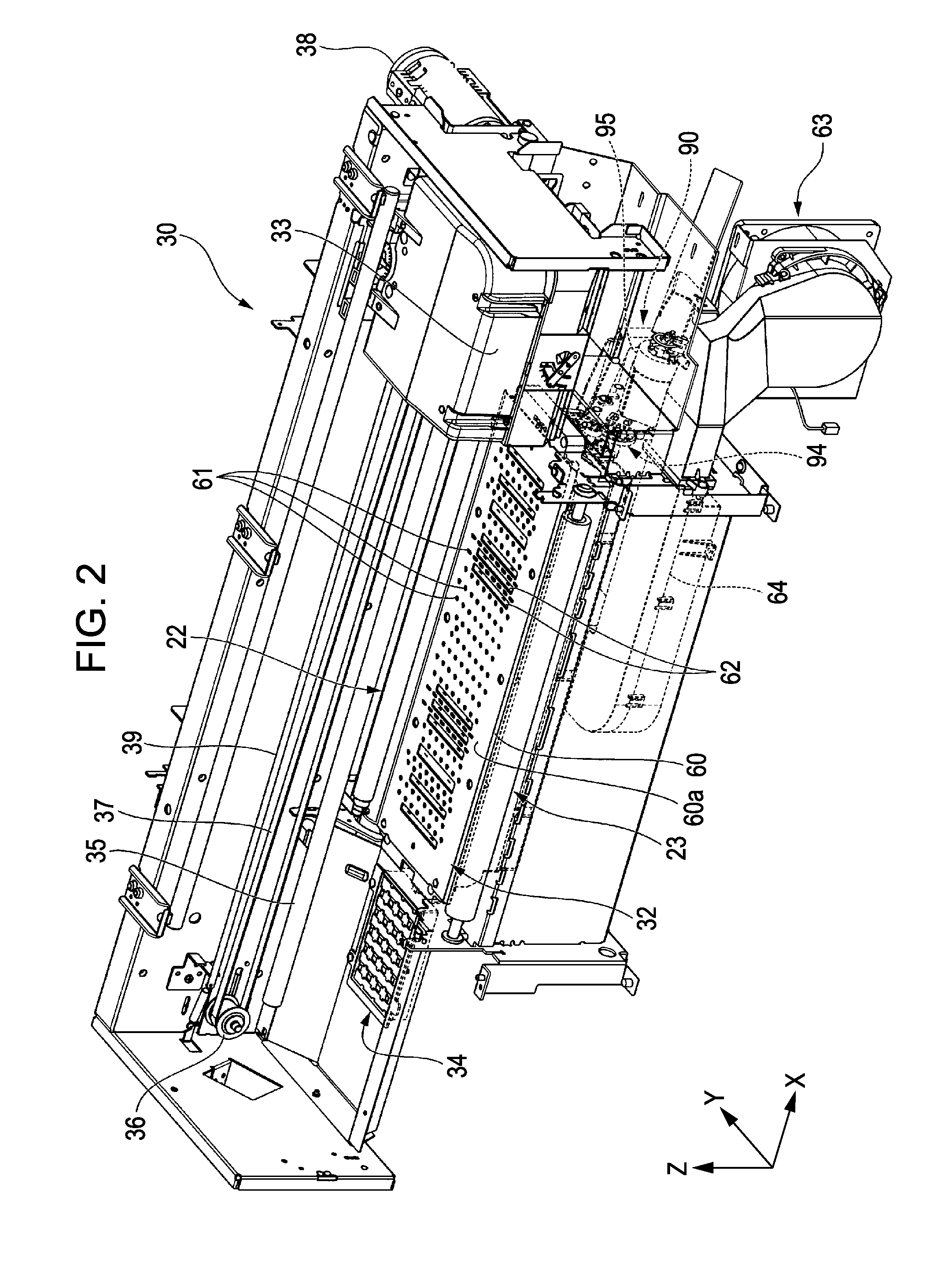

Recording apparatus

ActiveUS20120069076A1Improve flatnessSuppress printing qualityOther printing apparatusEngineeringRecording media

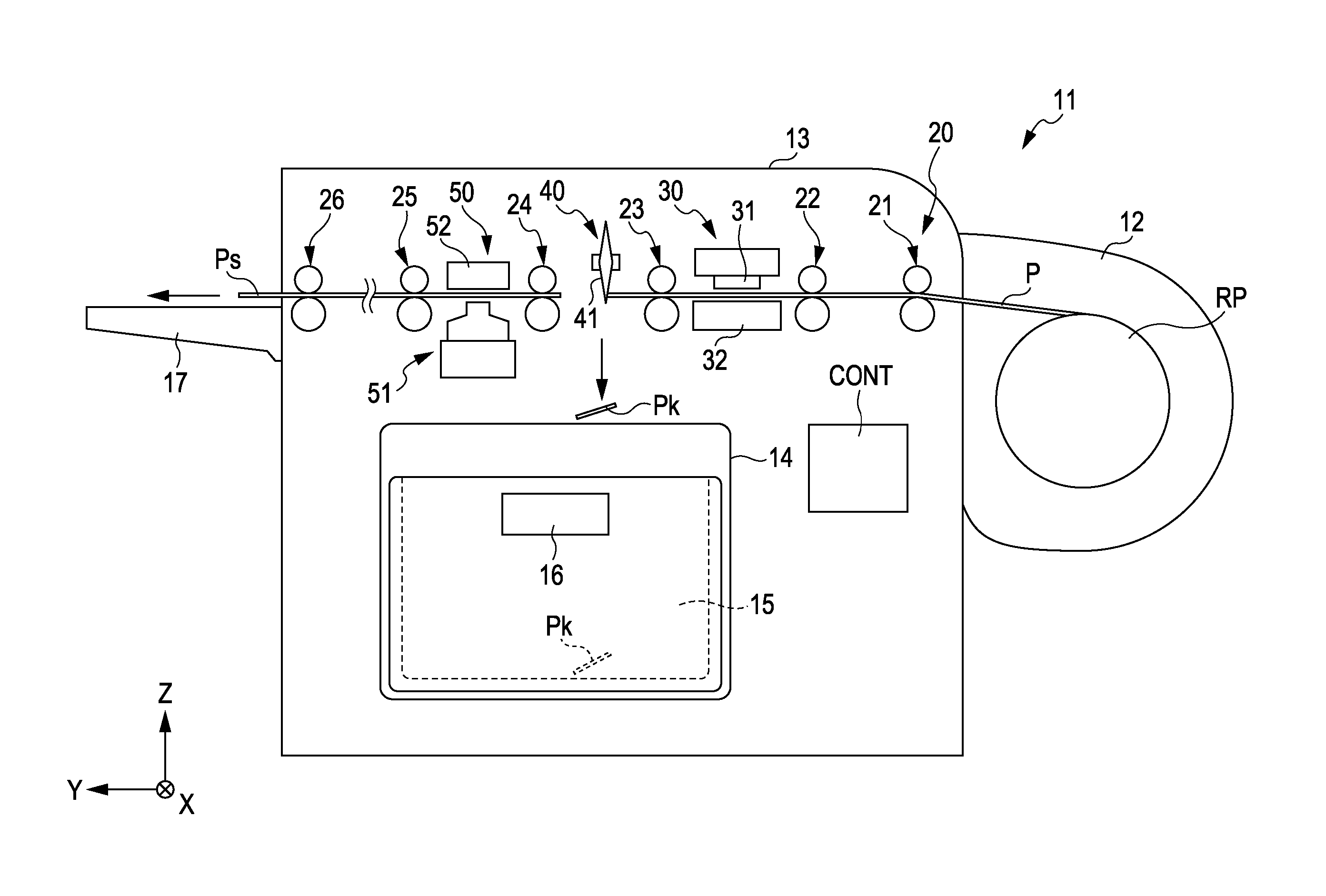

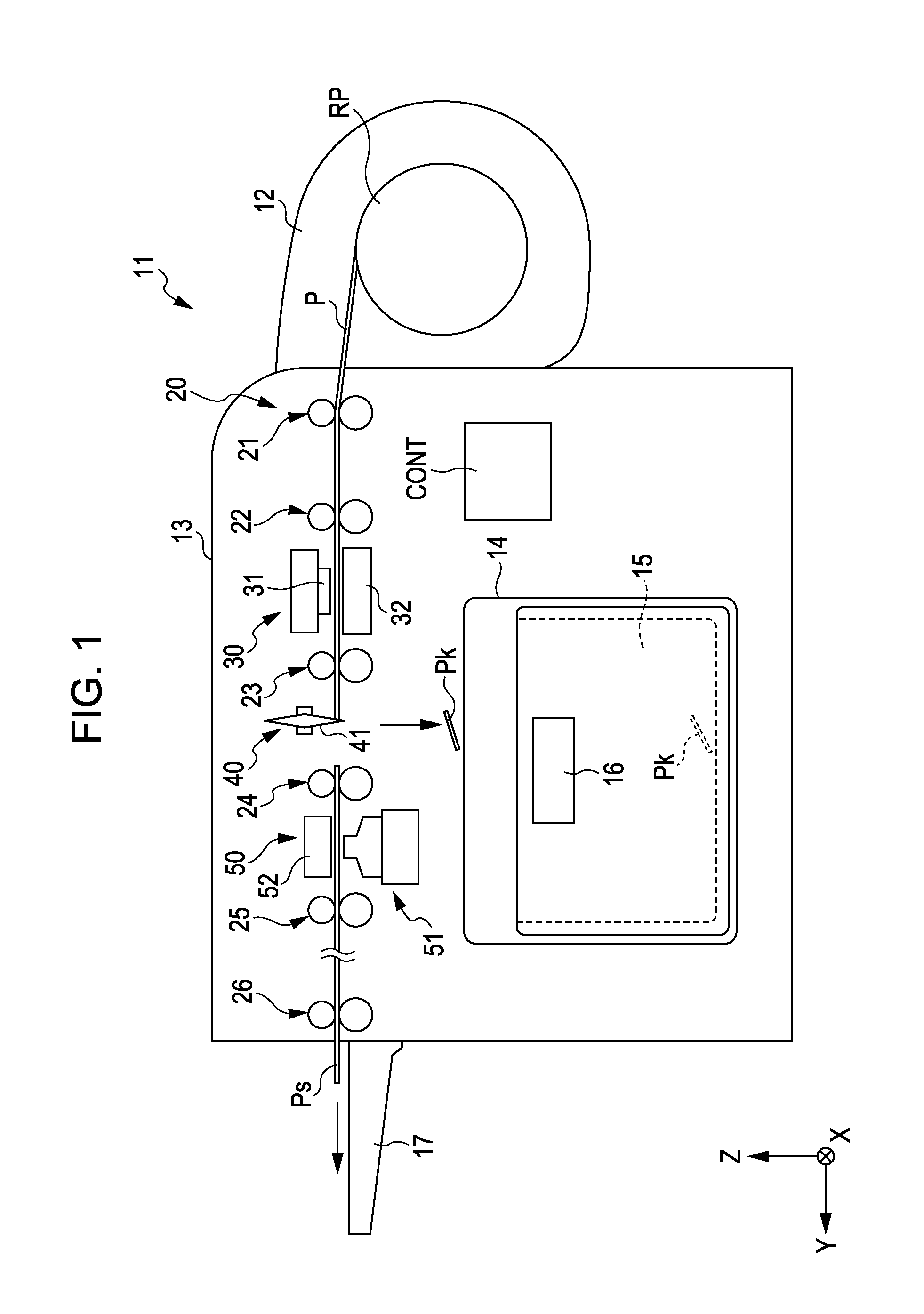

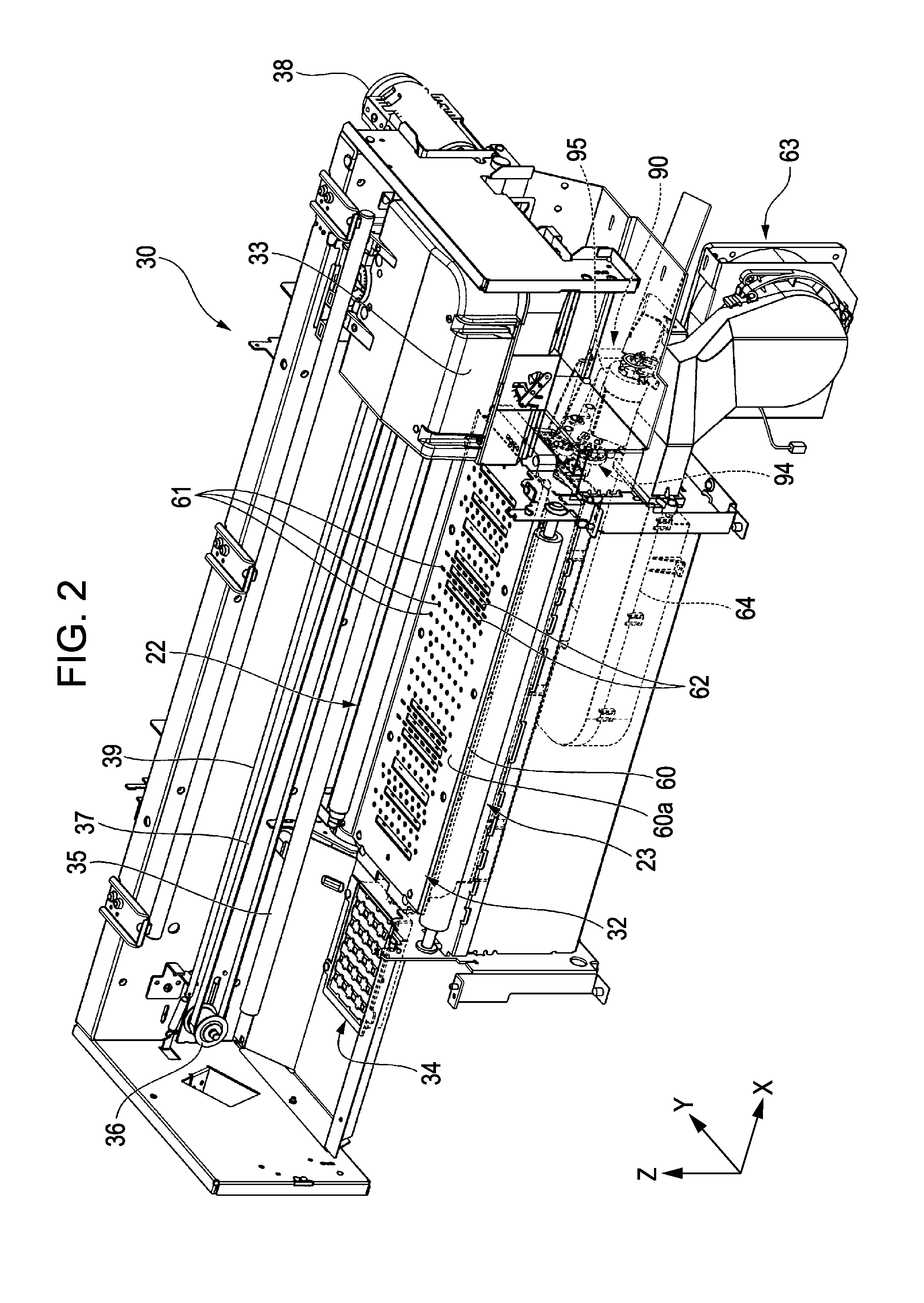

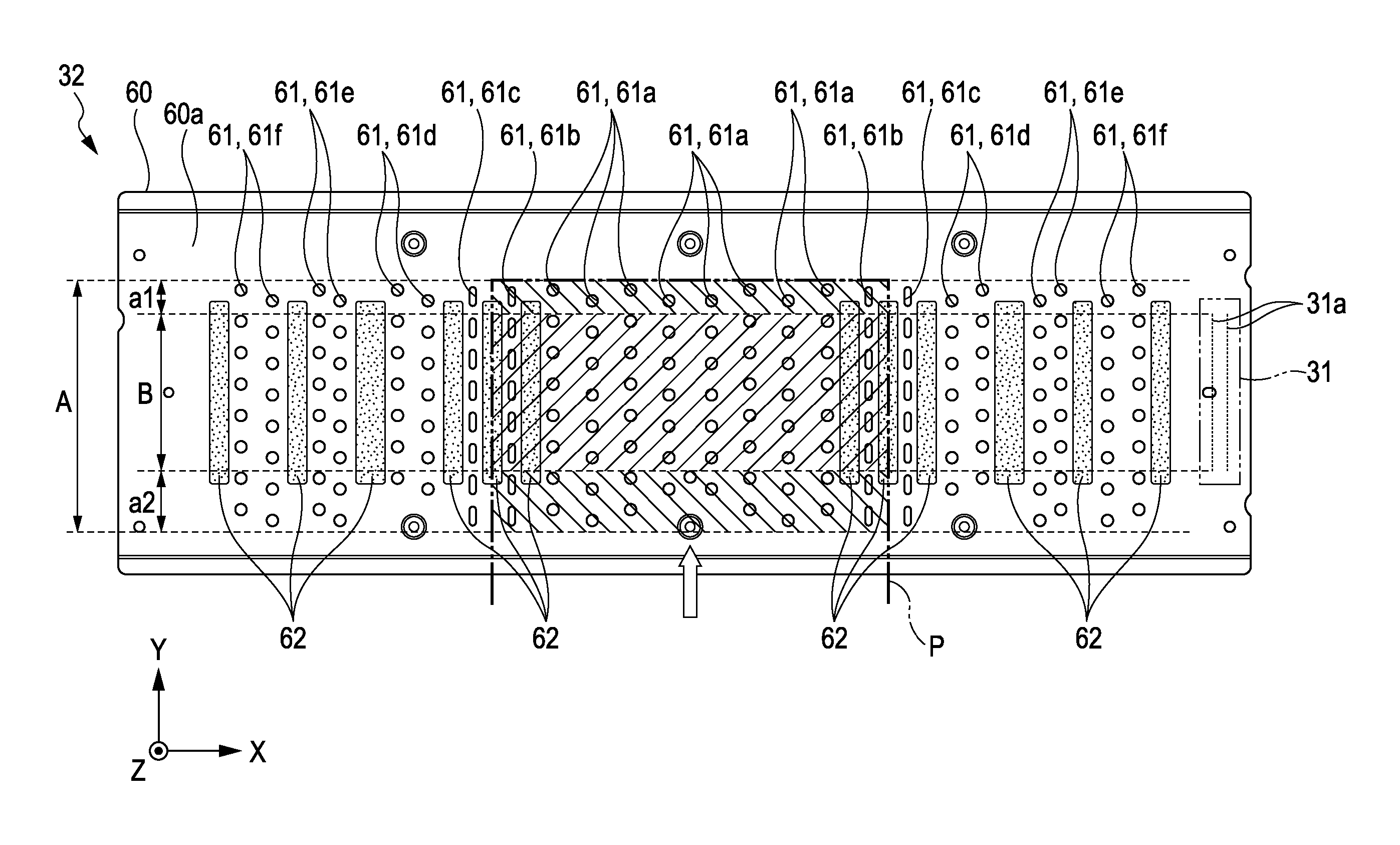

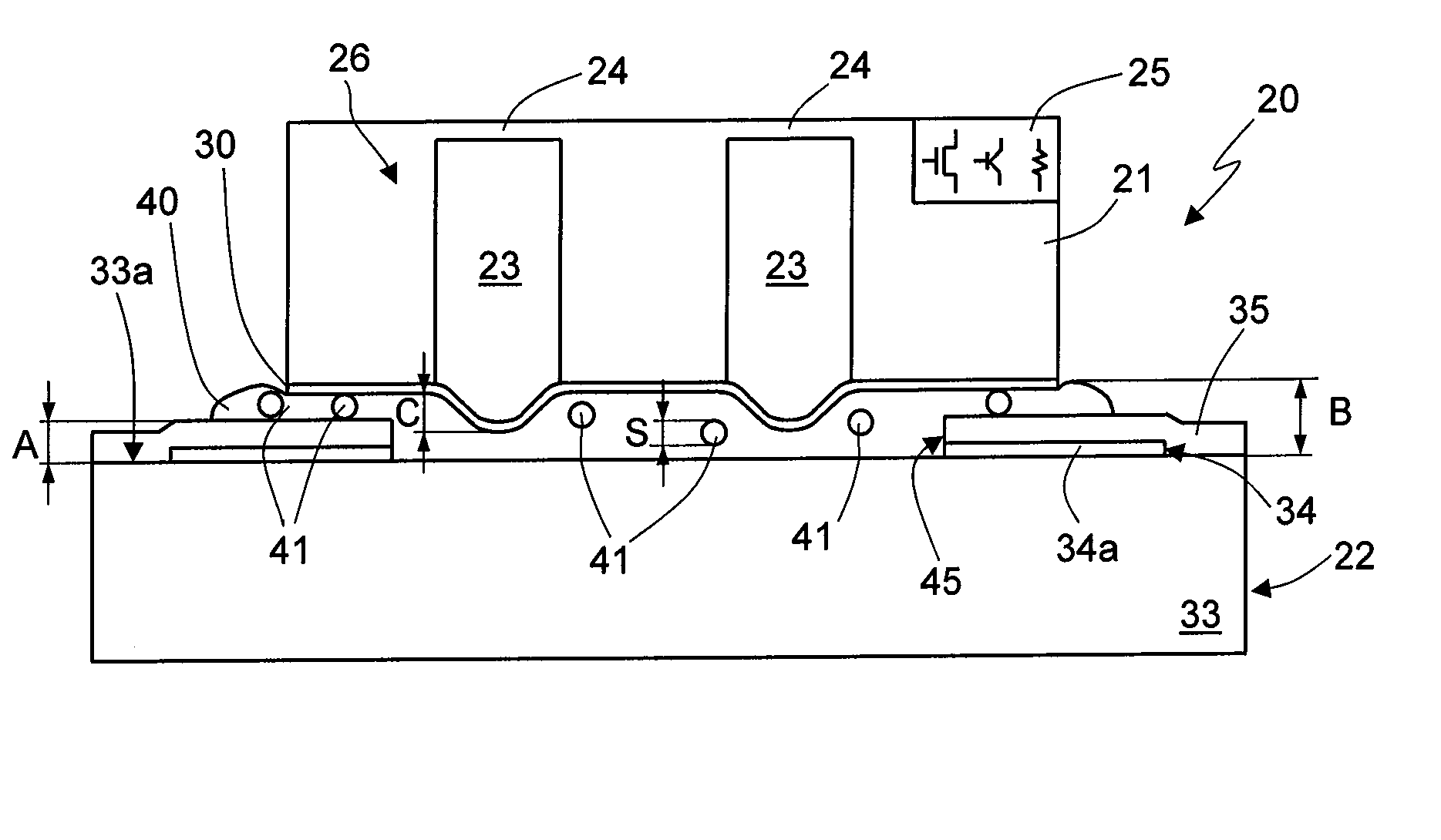

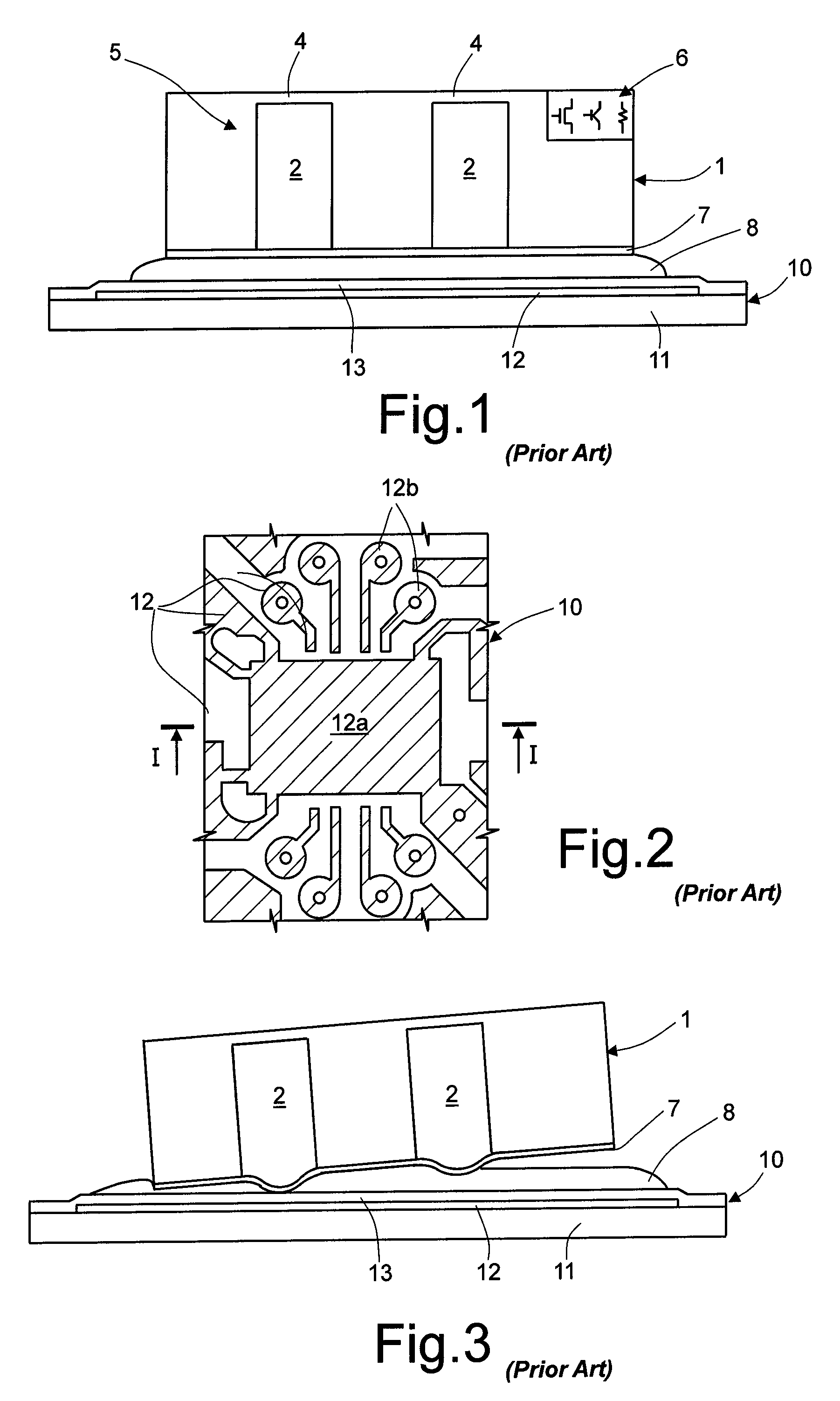

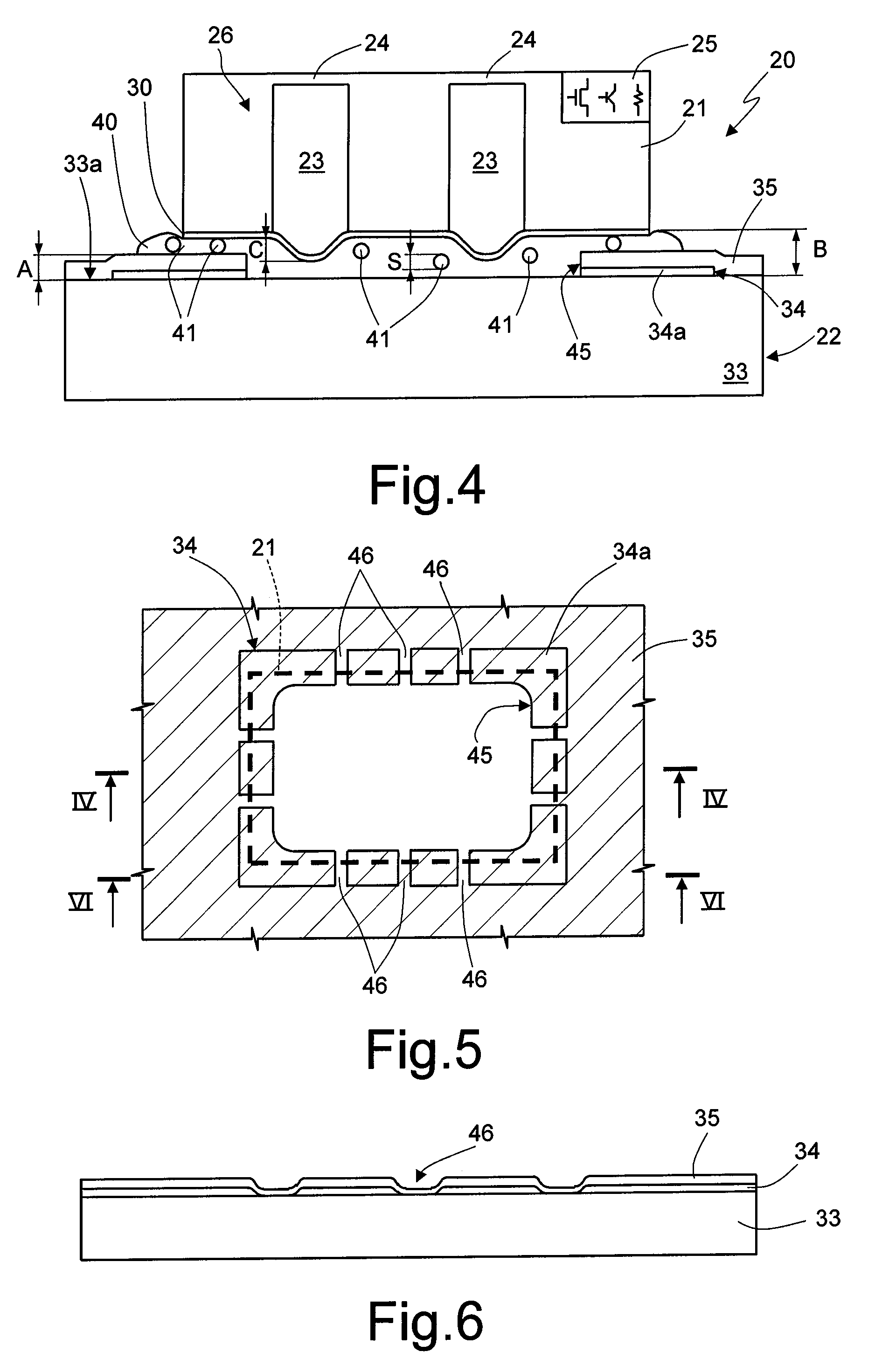

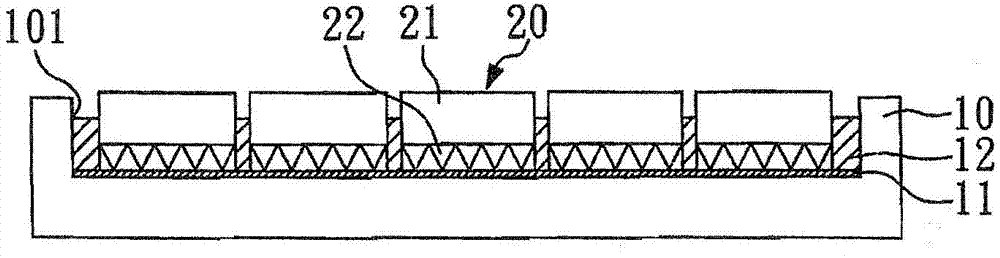

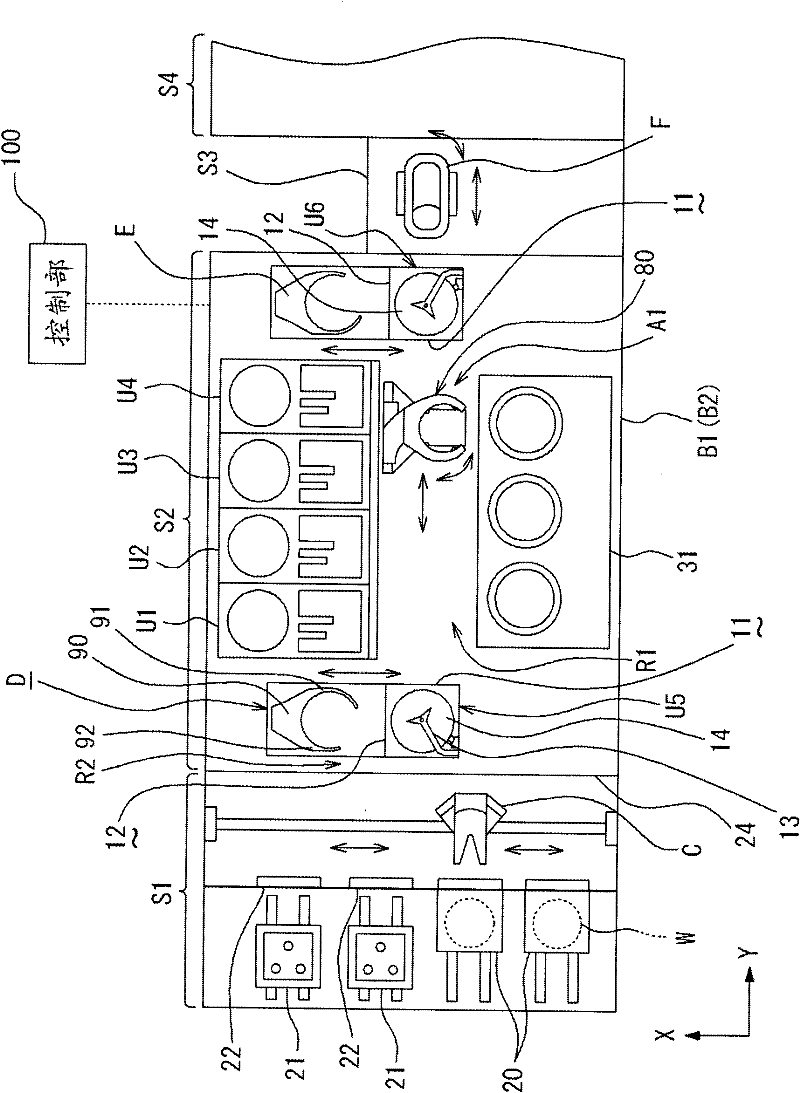

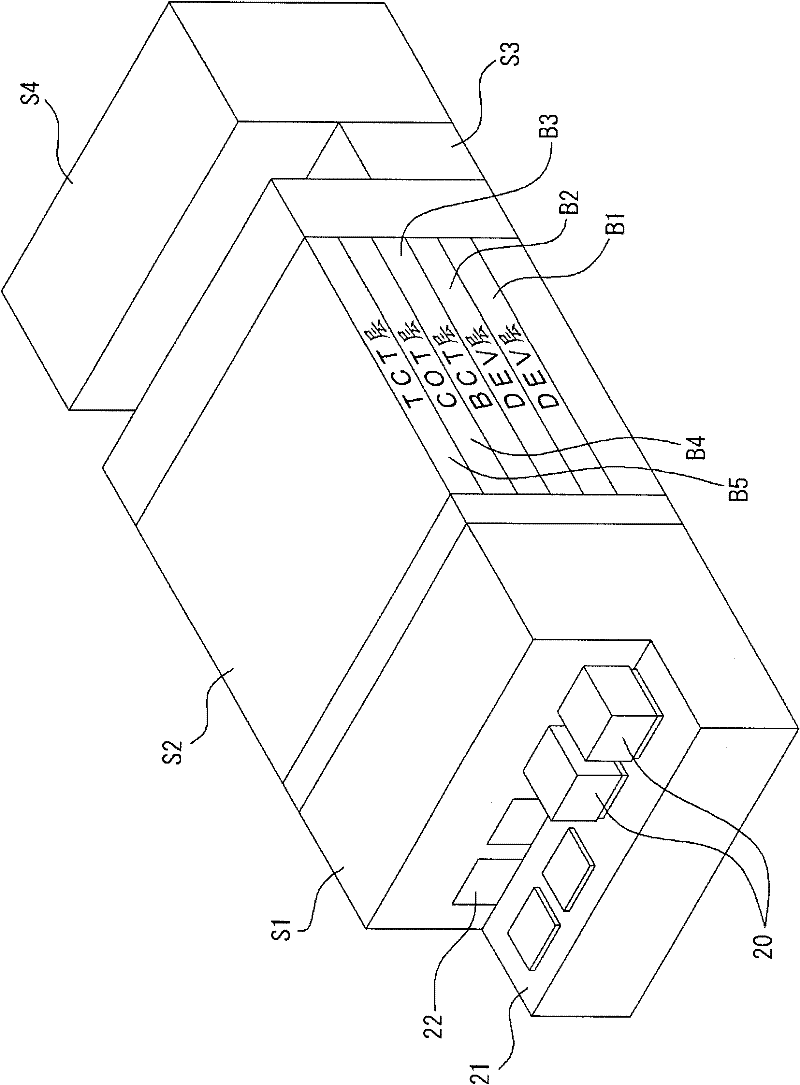

A recording apparatus includes a supporting member on which a plurality of suction holes for sucking a recording medium are formed on a supporting face for supporting the recording medium, a transportation device which transports the recording medium along the supporting face, a recording head which ejects fluid on the recording medium supported by the supporting face so as to perform printing, and a control device which makes the recording head execute the printing when a front end of the recording medium in the transportation direction reaches to a position at which the front end of the recording medium covers the suction holes formed at downstream-most positions in the transportation direction on the supporting face.

Owner:SEIKO EPSON CORP

Recording apparatus

ActiveUS8398200B2Suppress printing qualityPlanarityOther printing apparatusEngineeringRecording media

A recording apparatus includes a supporting member on which a plurality of suction holes for sucking a recording medium are formed on a supporting face for supporting the recording medium, a transportation device which transports the recording medium along the supporting face, a recording head which ejects fluid on the recording medium supported by the supporting face so as to perform printing, and a control device which makes the recording head execute the printing when a front end of the recording medium in the transportation direction reaches to a position at which the front end of the recording medium covers the suction holes formed at downstream-most positions in the transportation direction on the supporting face.

Owner:SEIKO EPSON CORP

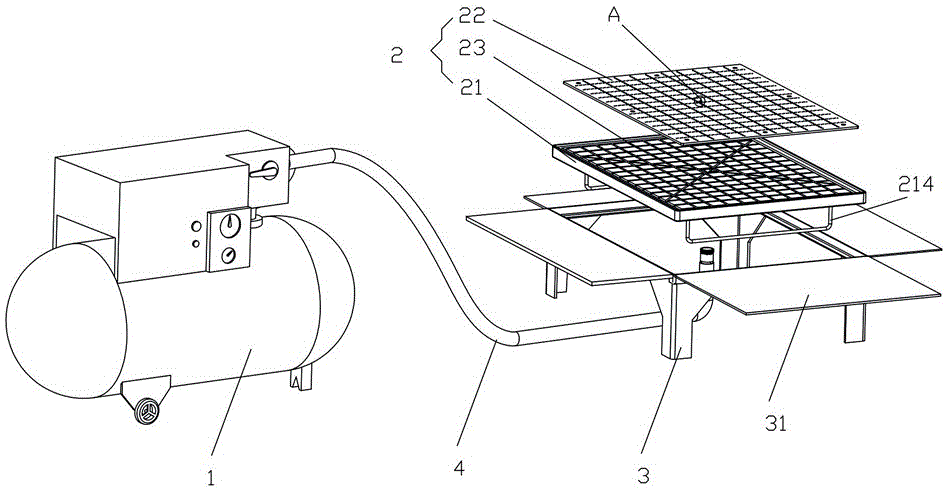

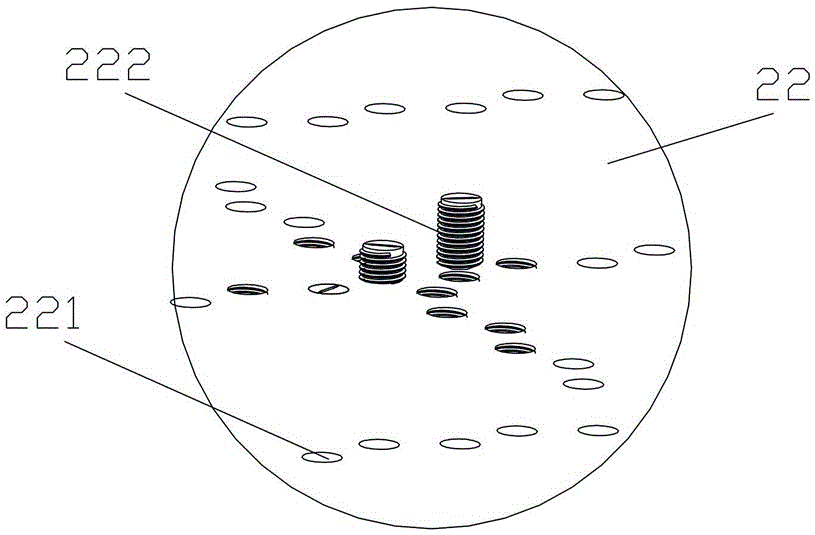

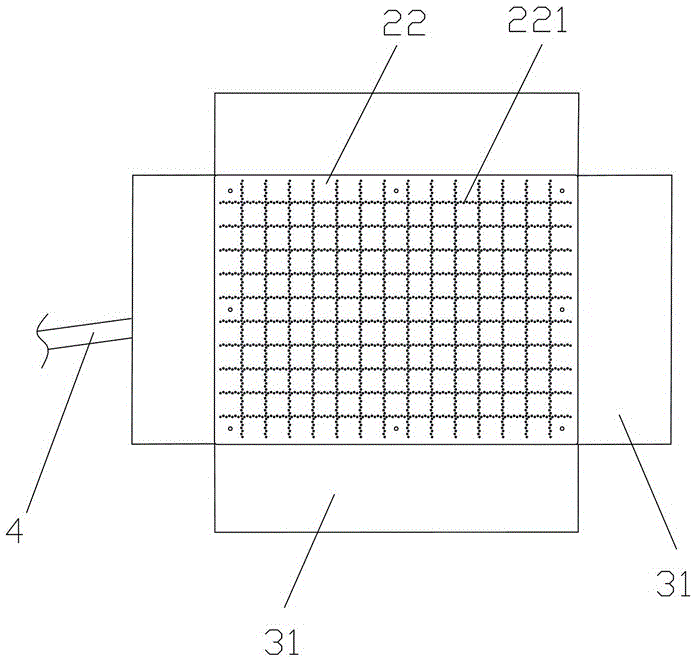

Negative-pressure adsorption welding device and negative-pressure adsorption welding method

InactiveCN106141519ANot prone to distortionImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a negative-pressure adsorption welding device which comprises a negative-pressure producing assembly and negative-pressure adsorption plate assemblies; the negative-pressure adsorption plate assemblies comprise a bottom negative-pressure adsorption plate assembly and a top negative-pressure adsorption plate assembly; negative-pressure adsorption chambers are formed between the negative-pressure plate assemblies and the adsorption plate assemblies; the negative-pressure production assembly communicates with the negative-pressure adsorption chambers for extracting air in the negative-pressure adsorption chambers to form vacuum negative pressure; a plurality of negative-pressure adsorption holes are formed in the adsorption plate assemblies for fixing to-be-welded parts onto the adsorption plate assemblies in a negative-pressure adsorption manner to carry out welding operation when vacuum negative pressure is formed in the negative-pressure adsorption chambers. The invention further discloses a negative-pressure adsorption welding method. The negative-pressure adsorption welding device is reasonable in design, is convenient and quick to operate, is small in welding deformation and is capable of reducing working cost and improving working efficiency.

Owner:株洲天瑞精密钣金有限公司

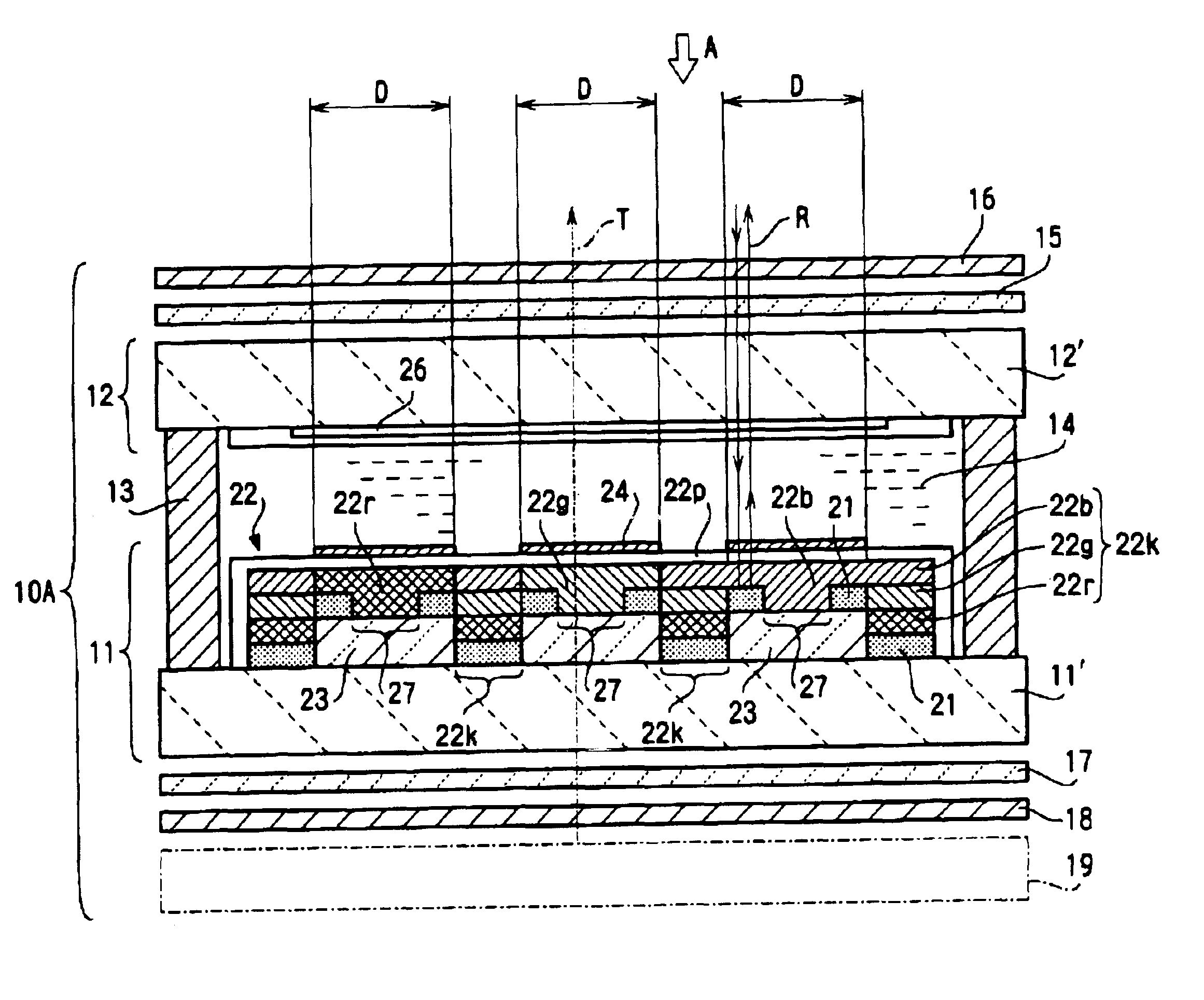

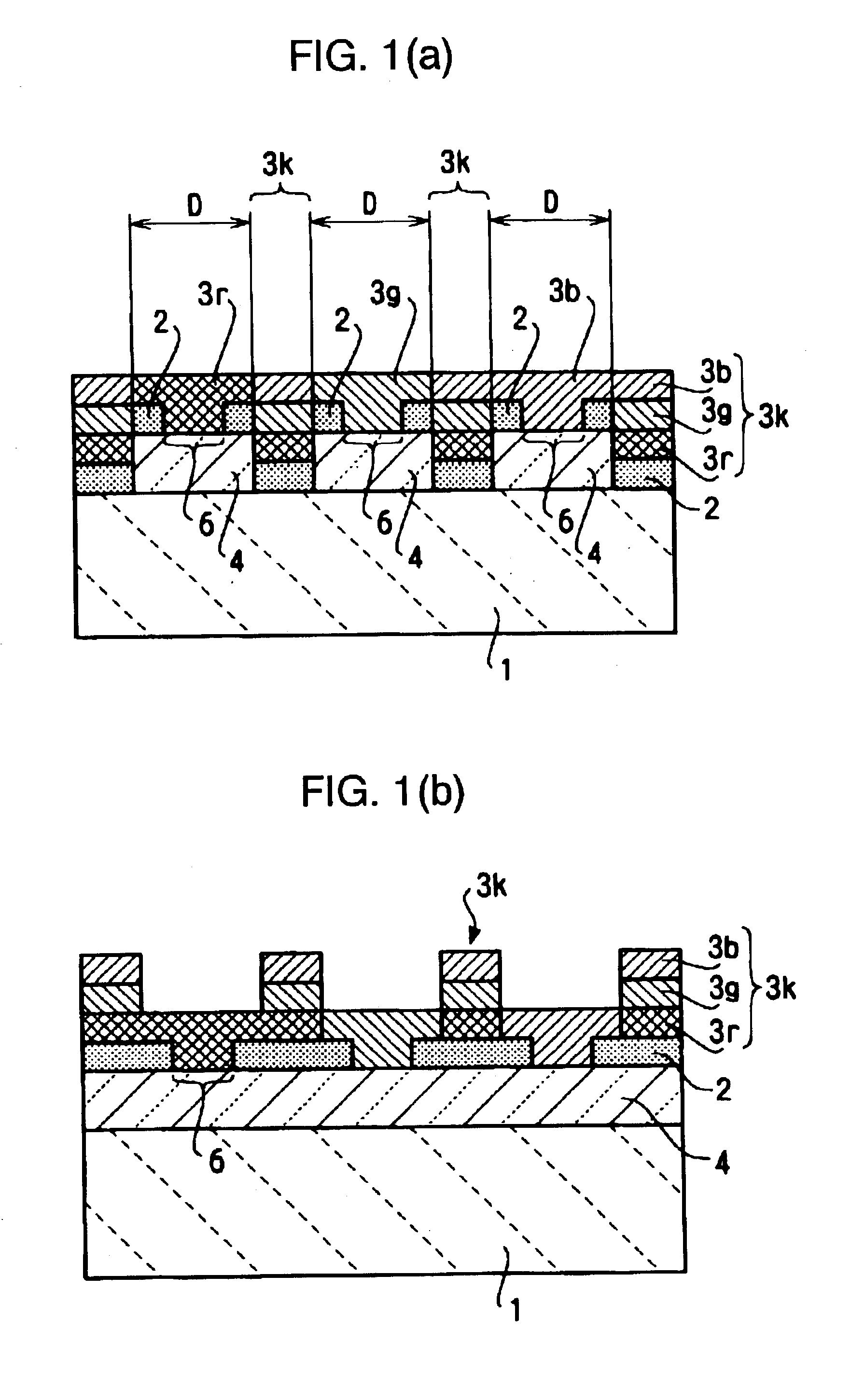

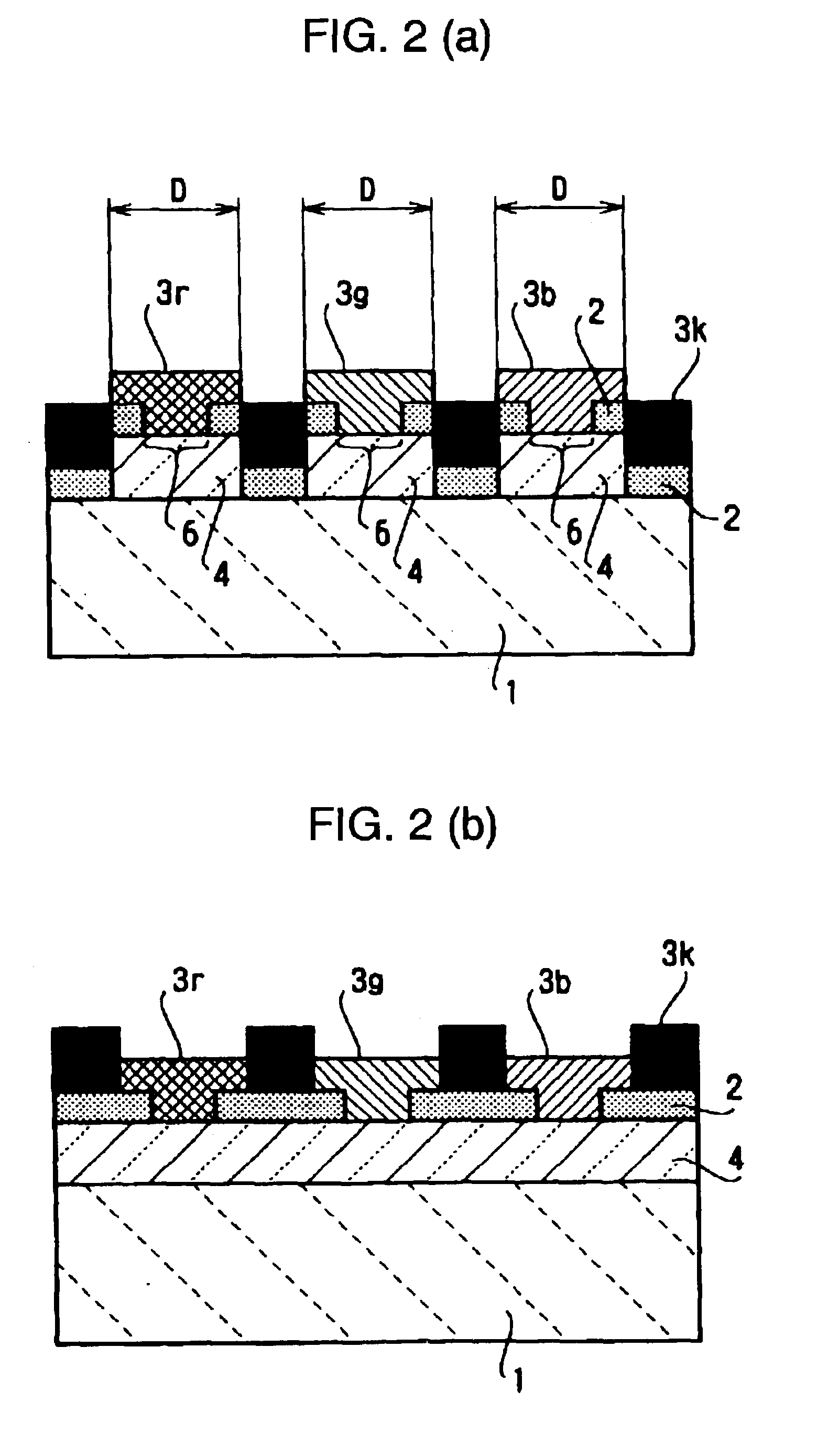

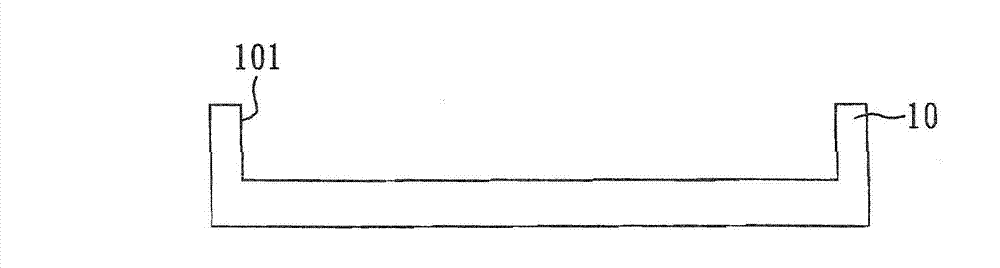

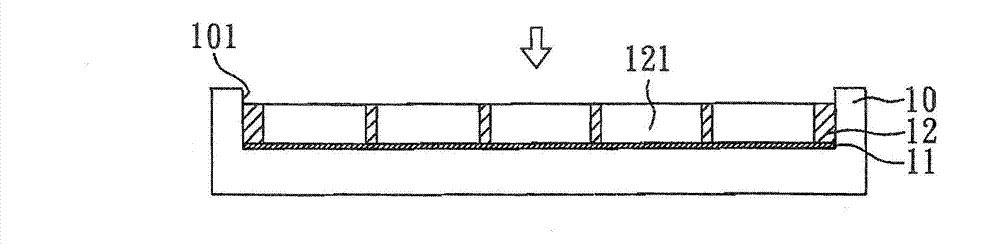

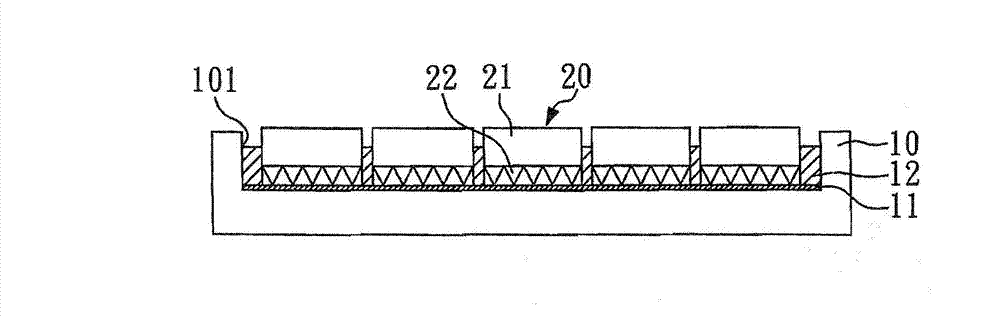

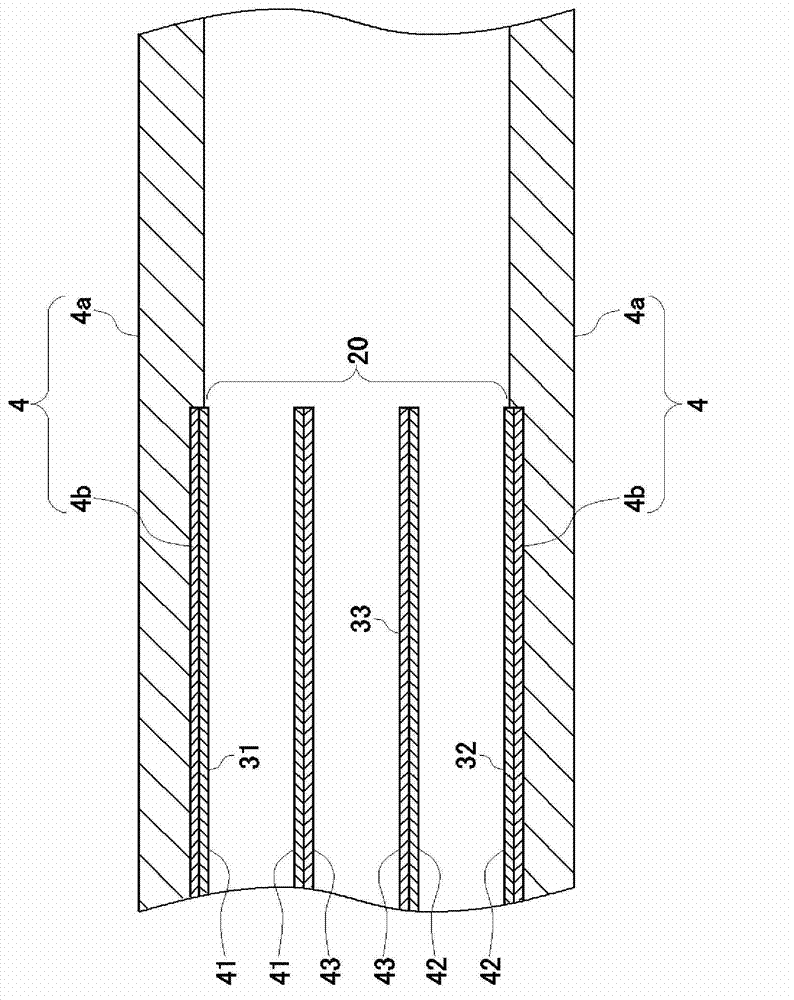

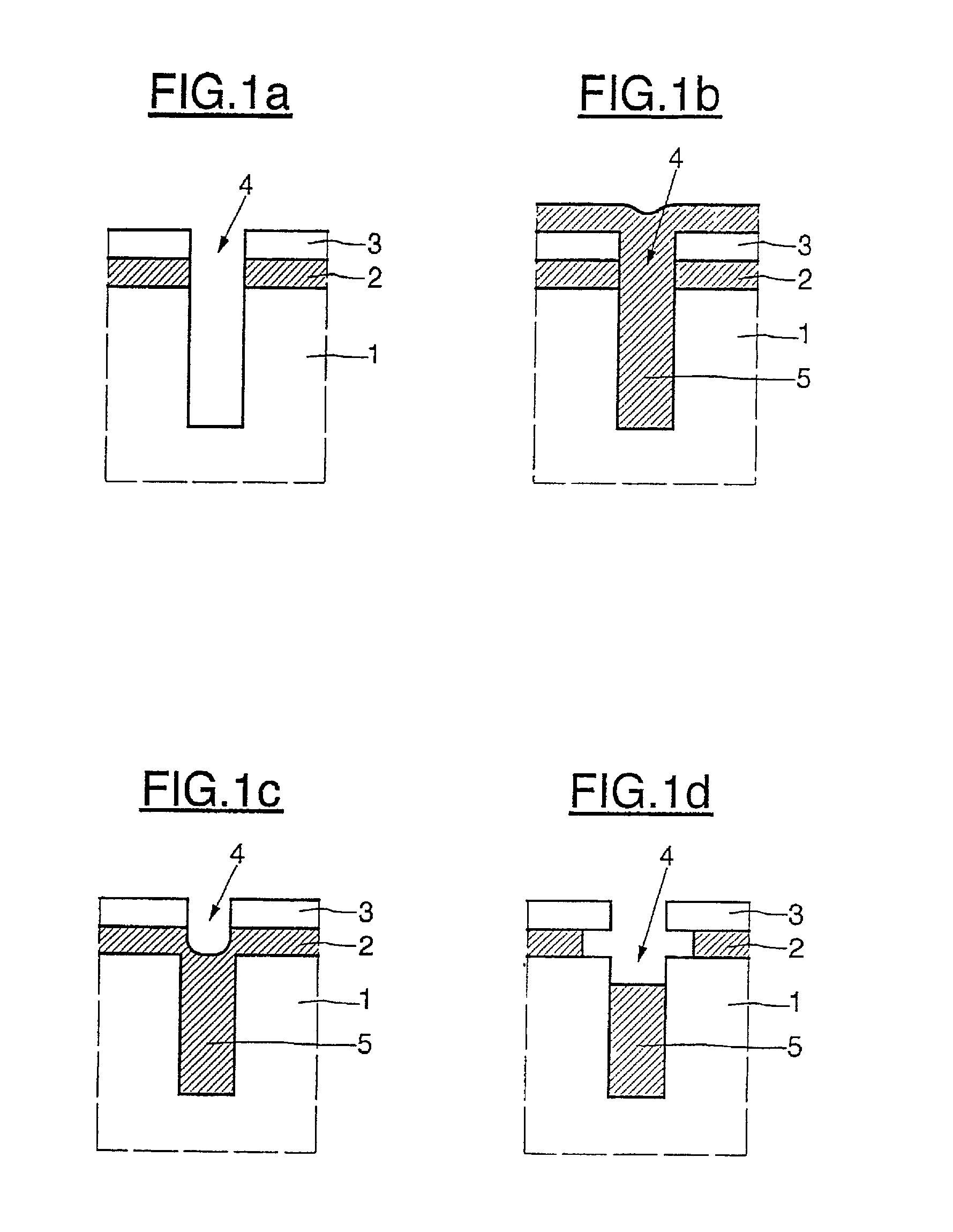

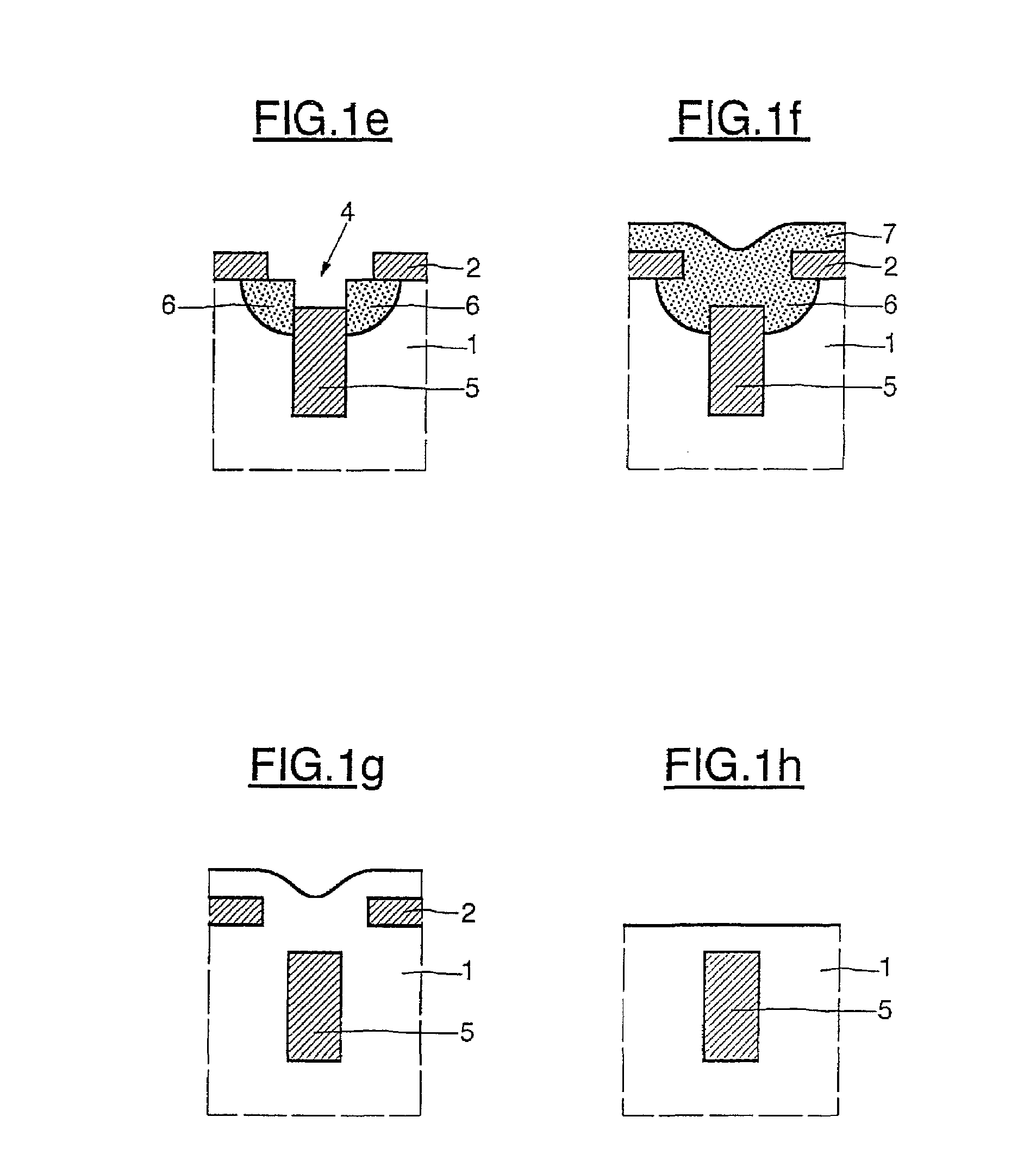

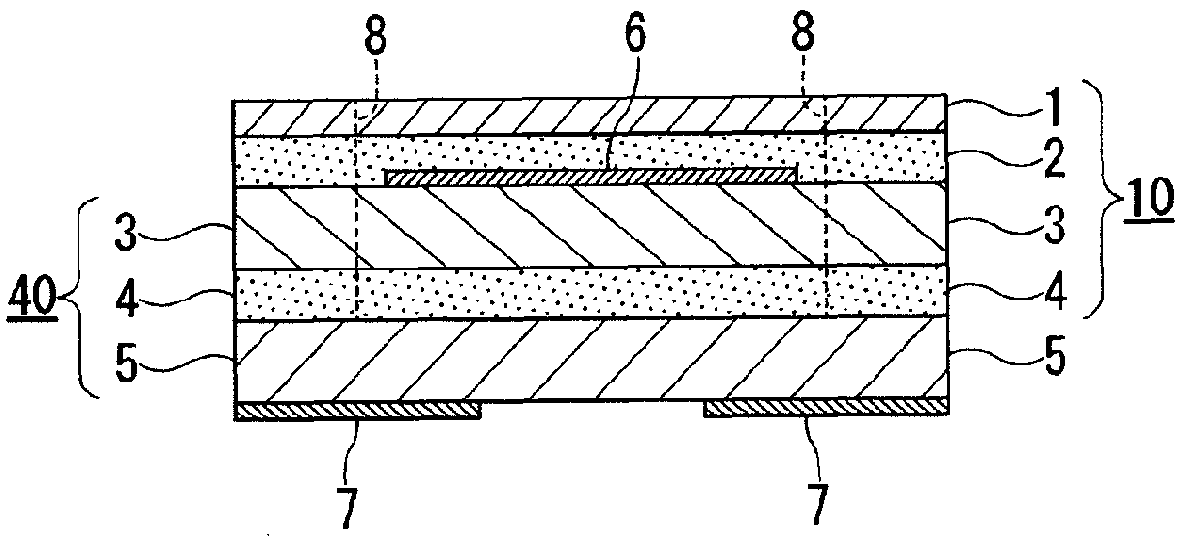

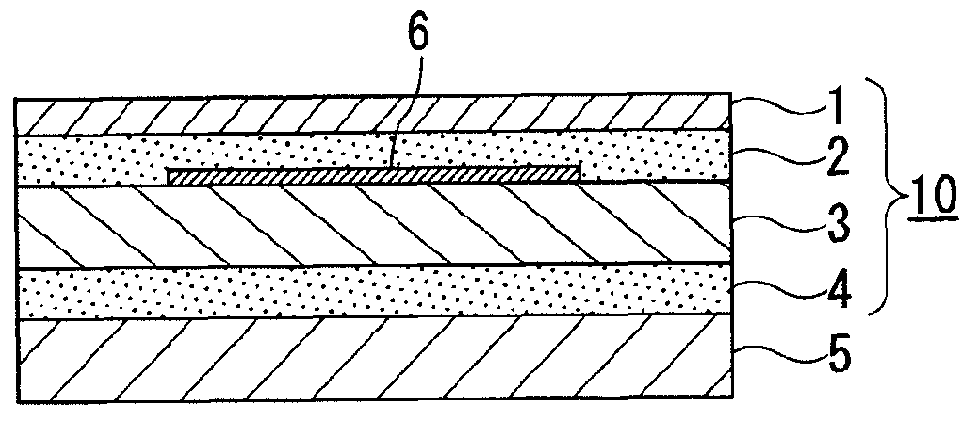

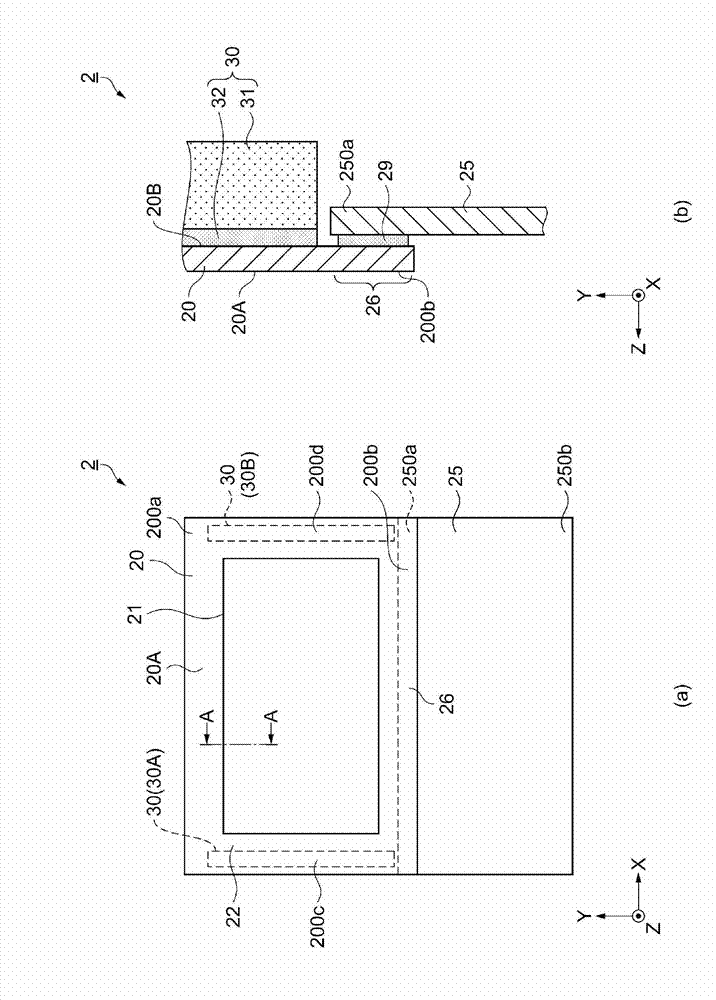

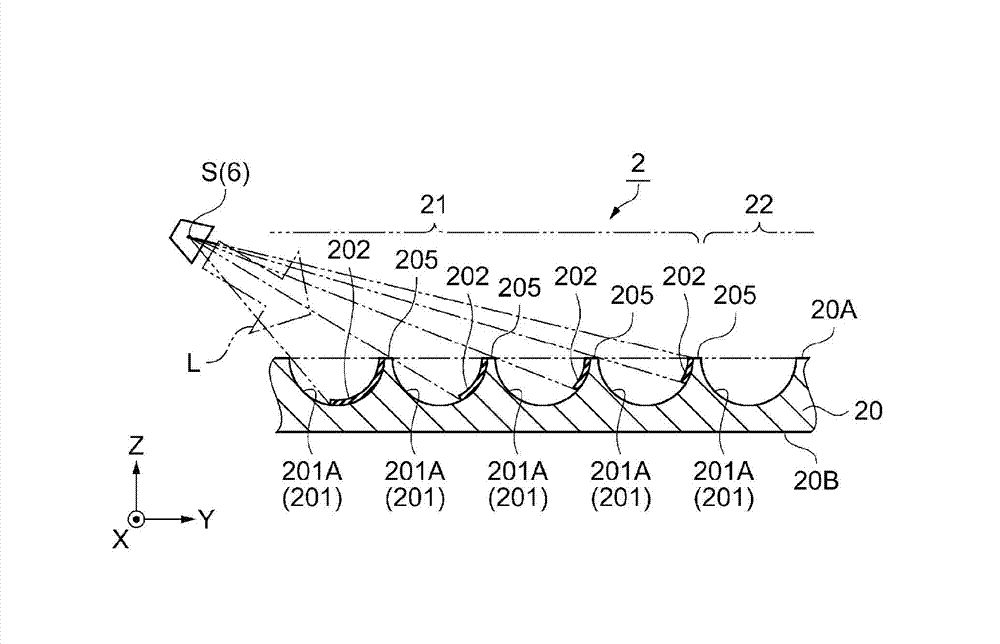

Substrate for electrooptical device, method for manufacturing the substrate, electrooptical device, method for manufacturing the electrooptical device, and electronic apparatus

InactiveUS6867831B2Small dispersionEnsure planarityNon-linear opticsIdentification meansEngineeringReflective layer

A substrate for an electrooptical device includes a base 1 having a plurality of display dots D, an underlayer 4 formed on the base 1, a reflective layer 2 formed on the underlayer 4, and color layers 3r, 3g, and 3b formed on the reflective layer 2. The underlayer 4 is provided at regions corresponding to the display dots D, but is not provided at regions between the display dots D. In addition, concave areas are provided at regions between the display dots D, and a light-shielding layer 3k is provided to fill the concave areas. Accordingly, the light-shielding layer 3k, and the-color layers 3r, 3g, and 3b are level with each other.

Owner:BOE TECH GRP CO LTD

Recording apparatus

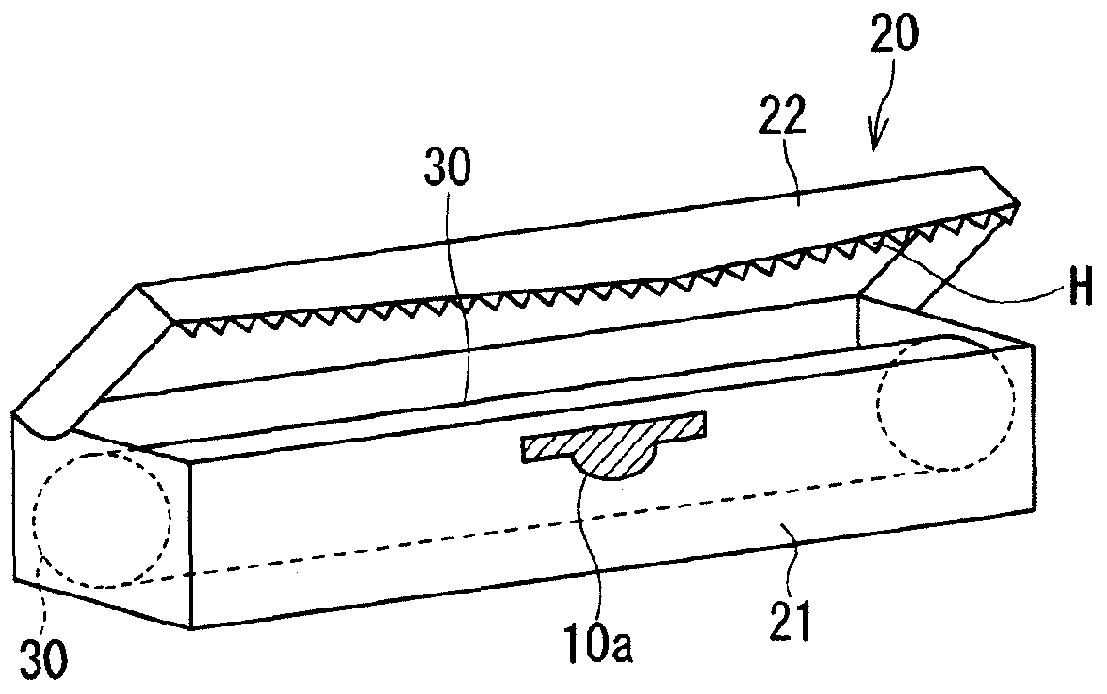

ActiveCN102555533AEnsure planaritySuppresses deterioration of printing qualityTypewritersOther printing apparatusSupport surfaceRecording media

The invention provides a recording apparatus, including: a support member in which a plurality of suction holes that apply suction to a recording medium are formed in a support surface that supports the recording medium; a transport device that transports the recording medium along the support surface; a recording head that prints onto the recording medium supported by the support surface by ejecting a fluid; and a regulating member, provided downstream from the suction holes formed in the location that is furthest downstream in the transport direction, that suppresses the recording medium from lifting off the support surface by more than a predetermined height.

Owner:SEIKO EPSON CORP

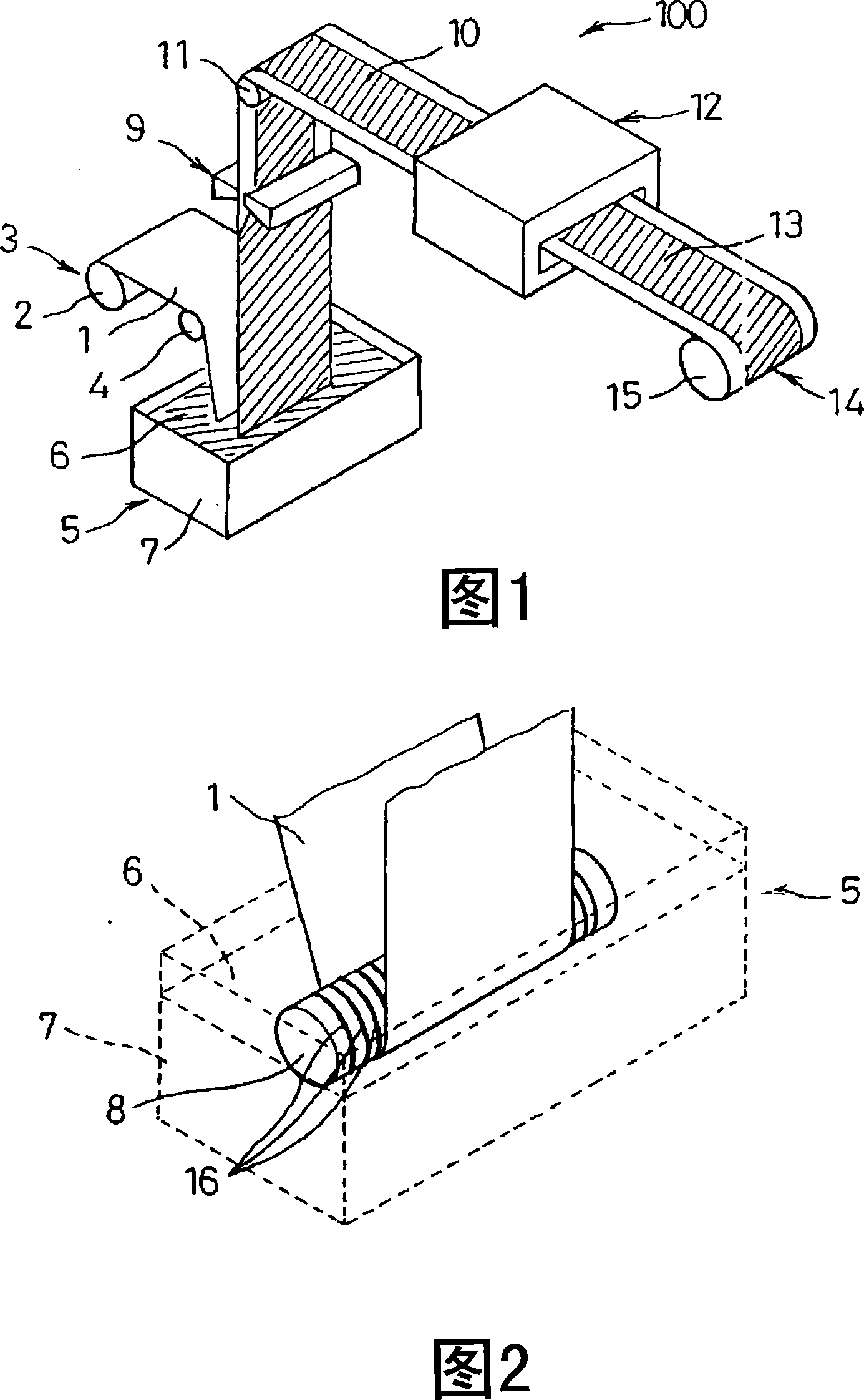

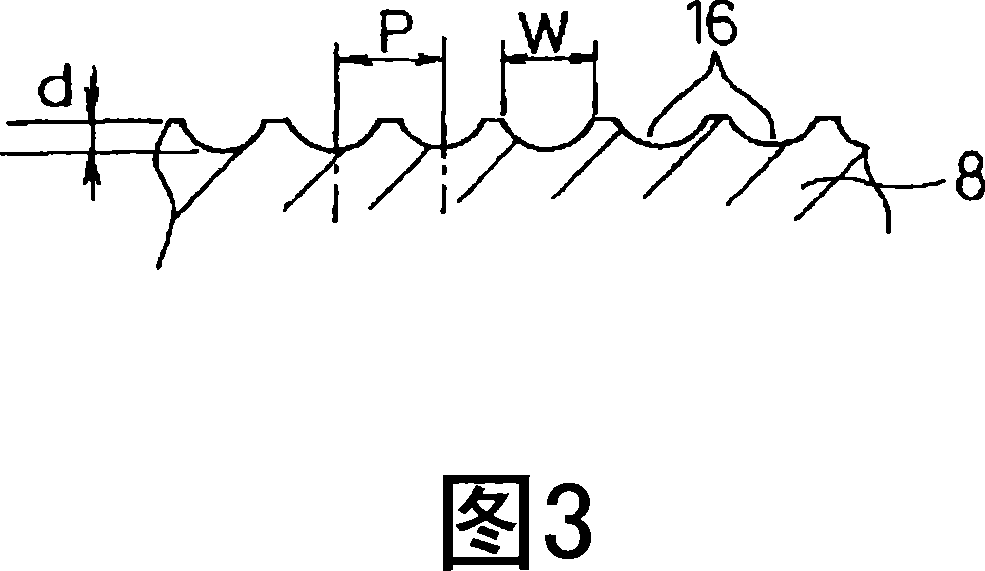

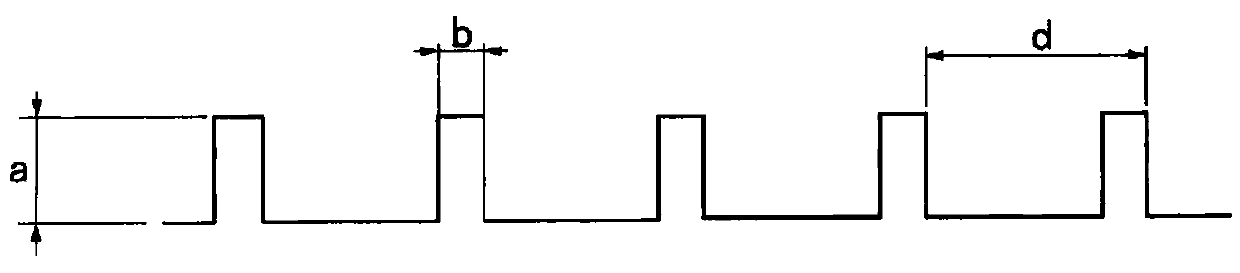

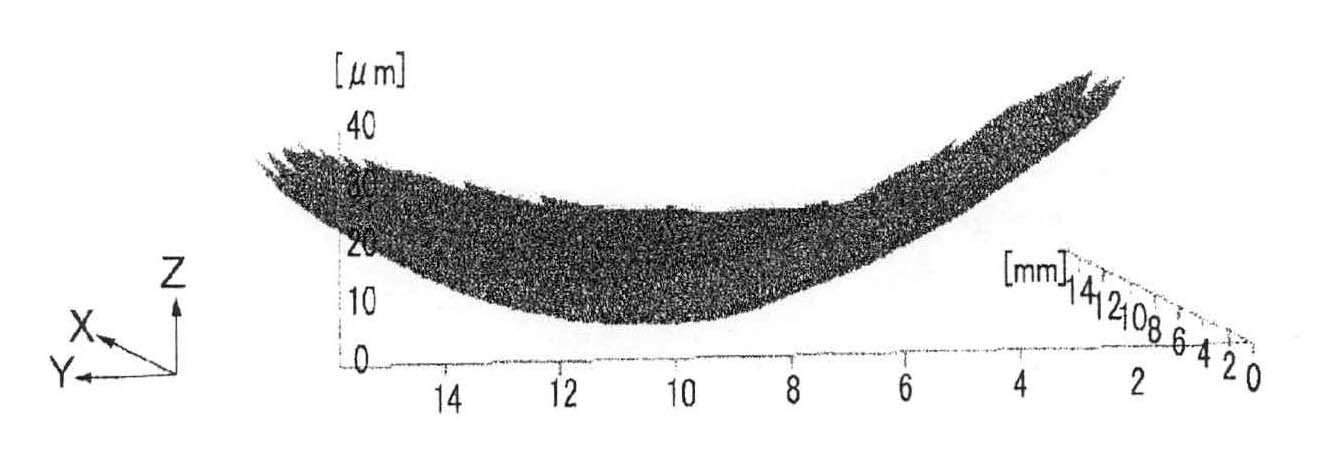

Combined trimmer and manufacturing method and chemical mechanical polishing method thereof

InactiveCN103367242ALow costBest removal rateSemiconductor/solid-state device manufacturingMicrometerEngineering

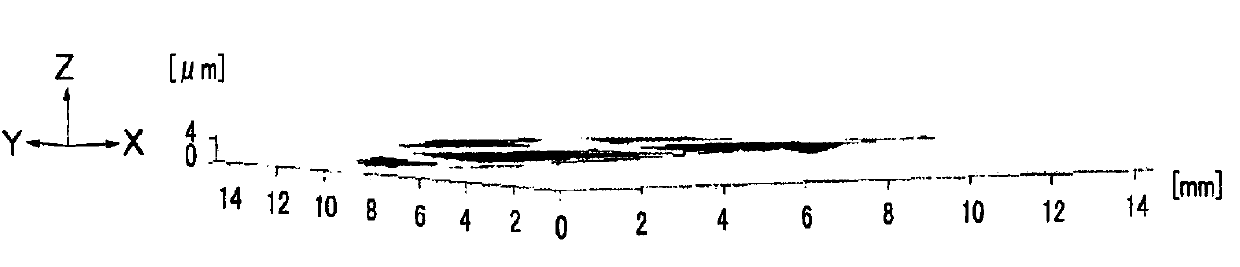

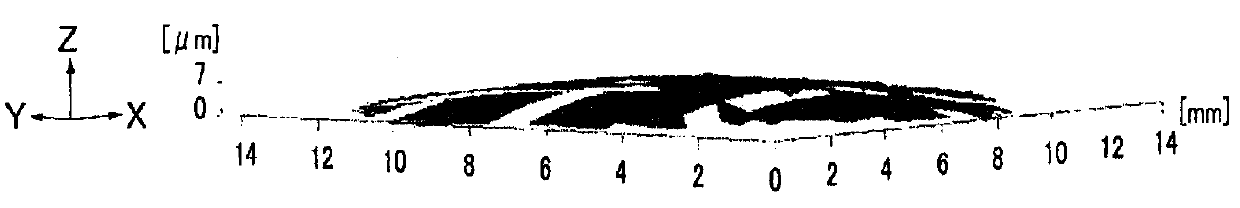

The present invention is about a combined trimmer, comprising: a bottom substrate; a plurality of grinding units arranged at a surface of the bottom substrate, wherein the each grinding unit comprises a plurality of grinding sharp points and a binding agent layer for fixing the grinding sharp points; and an adhesive layer with an adjustable thickness for fixing the grinding units to the surface of the bottom substrate, wherein height difference between a first high point and a second high point in the grinding sharp points protruded from a predetermined plane is less than 10 micrometer, height difference between the first high point and a tenth high point is less than 20 micrometer, height difference between the first high point and a hundredth high point is less than 40 micrometer, and the height of the first high point protruded from the binding agent layer is greater than 50 micrometer. The present invention is also about a manufacturing method and a chemical mechanical polishing method of the combined trimmer.

Owner:RITEDIA CORPORATION

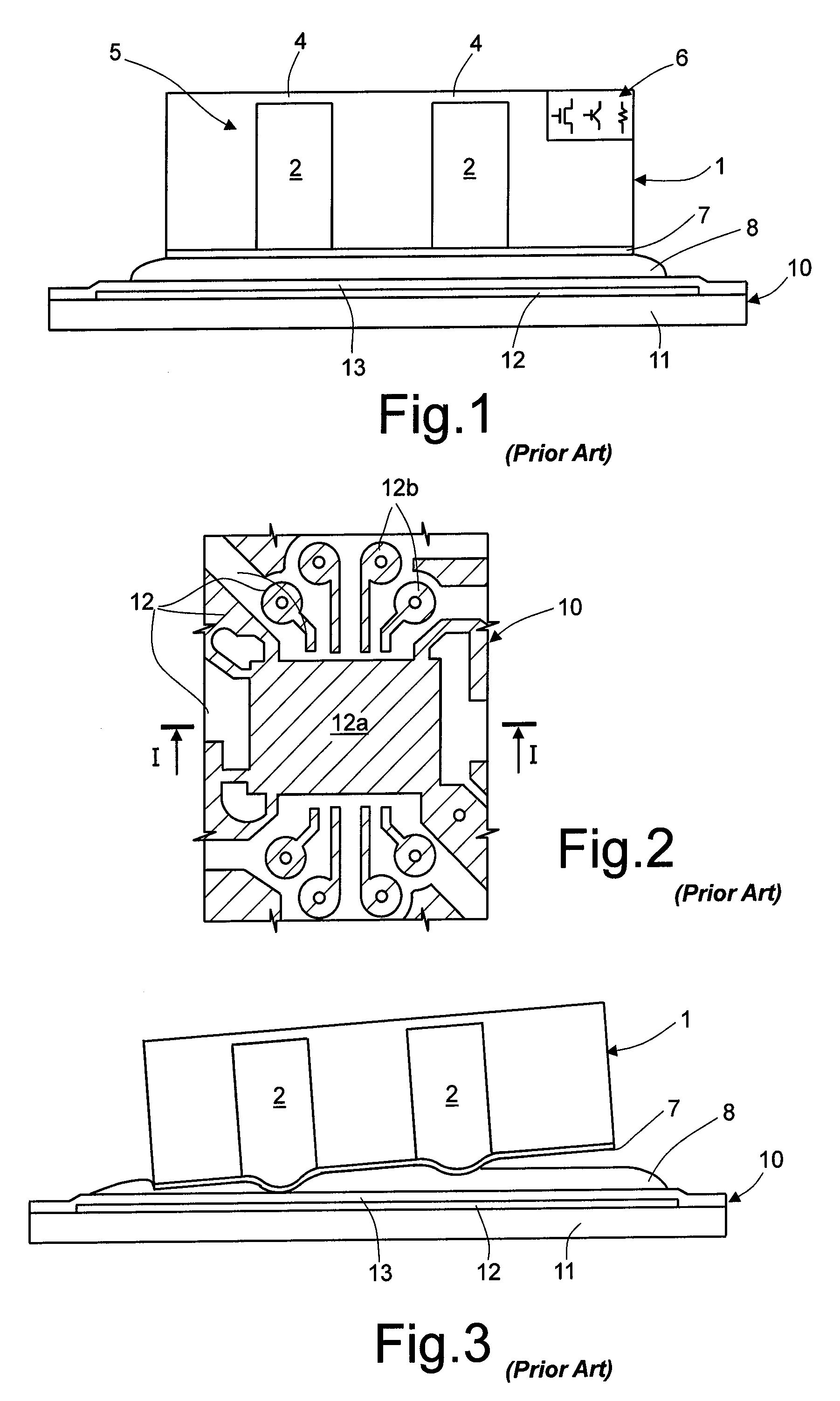

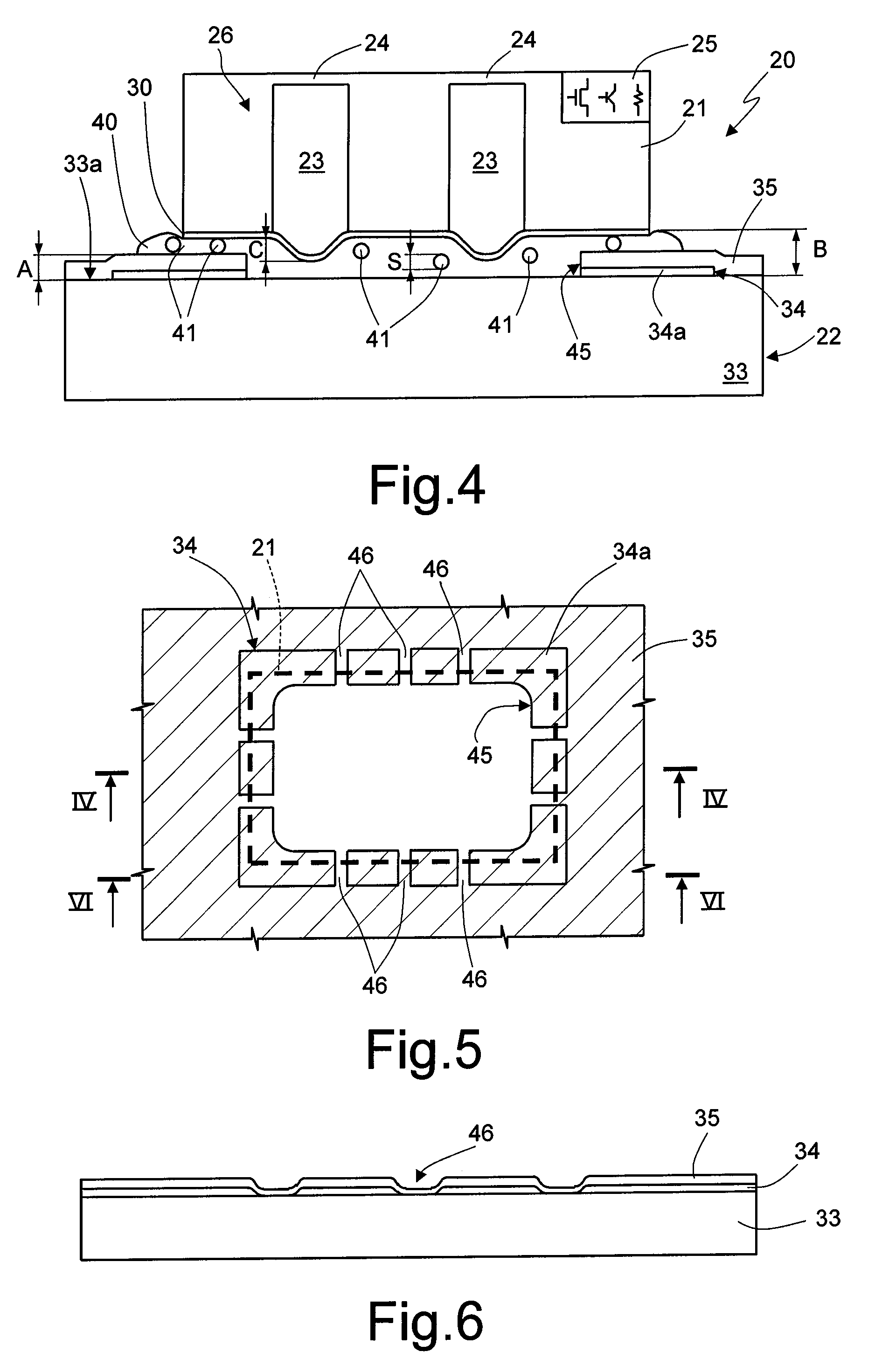

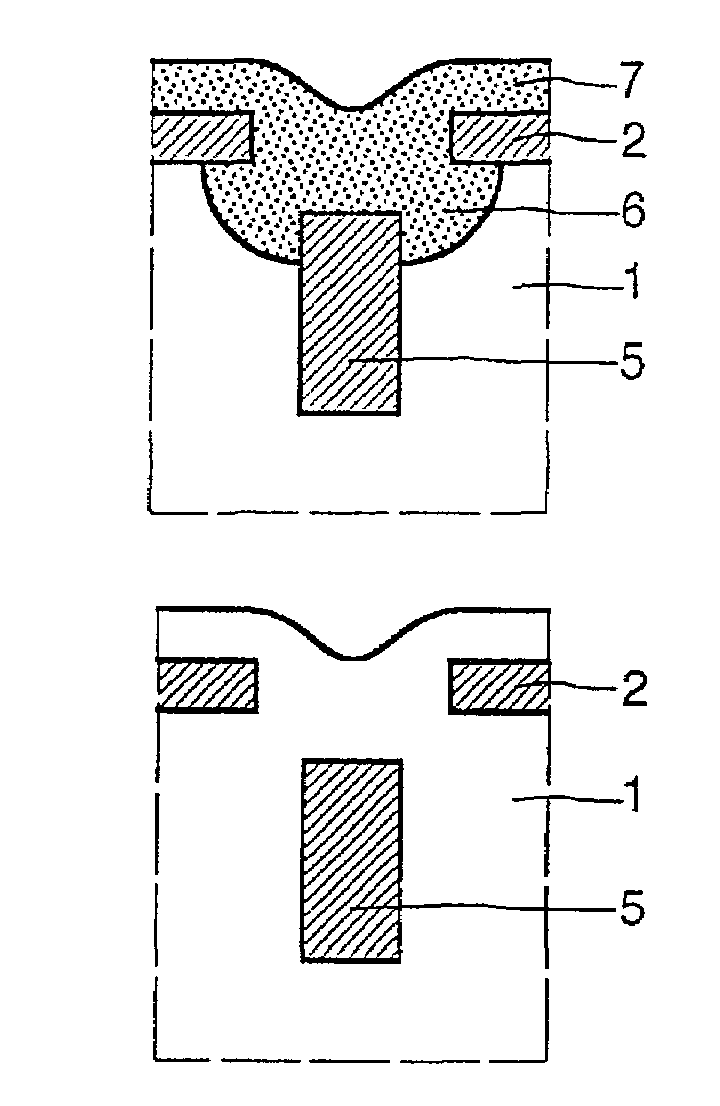

Electronic MEMS device comprising a chip bonded to a substrate and having cavities and manufacturing process thereof

InactiveUS8981498B2Preventing raising and tiltingEnsure planarityDecorative surface effectsSemiconductor/solid-state device manufacturingHeat treatedElectrical and Electronics engineering

An electronic MEMS device is formed by a chip having with a main face and bonded to a support via an adhesive layer. A cavity extends inside the chip from its main face and is closed by a flexible film covering the main face of the chip at least in the area of the cavity. The support has a depressed portion facing the cavity and delimited by a protruding portion facing the main face of the chip. Inside the depressed portion, the adhesive layer has a greater thickness than the projecting portion so as to be able to absorb any swelling of the flexible film as a result of the expansion of the gas contained inside the cavity during thermal processes.

Owner:STMICROELECTRONICS SRL

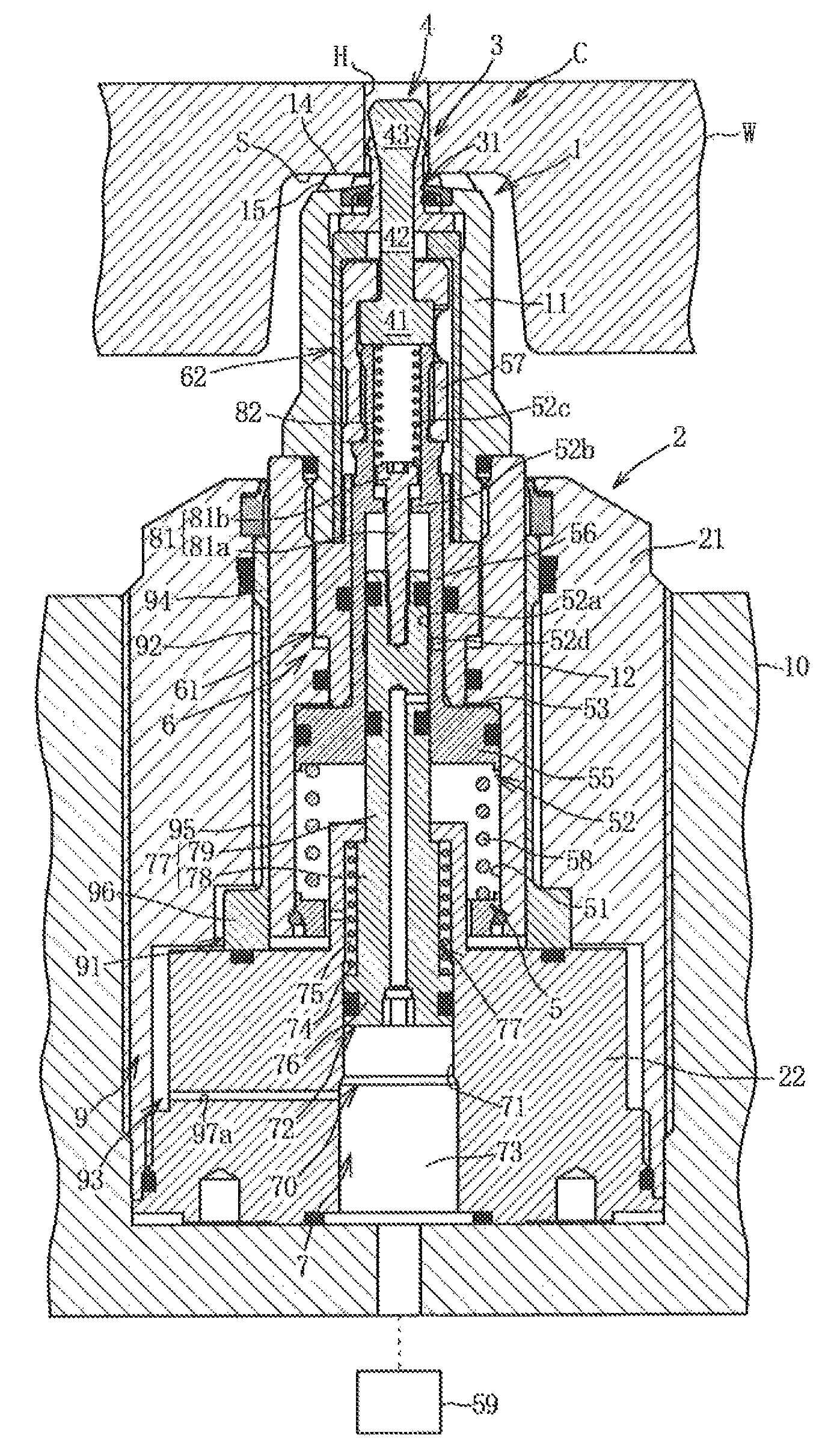

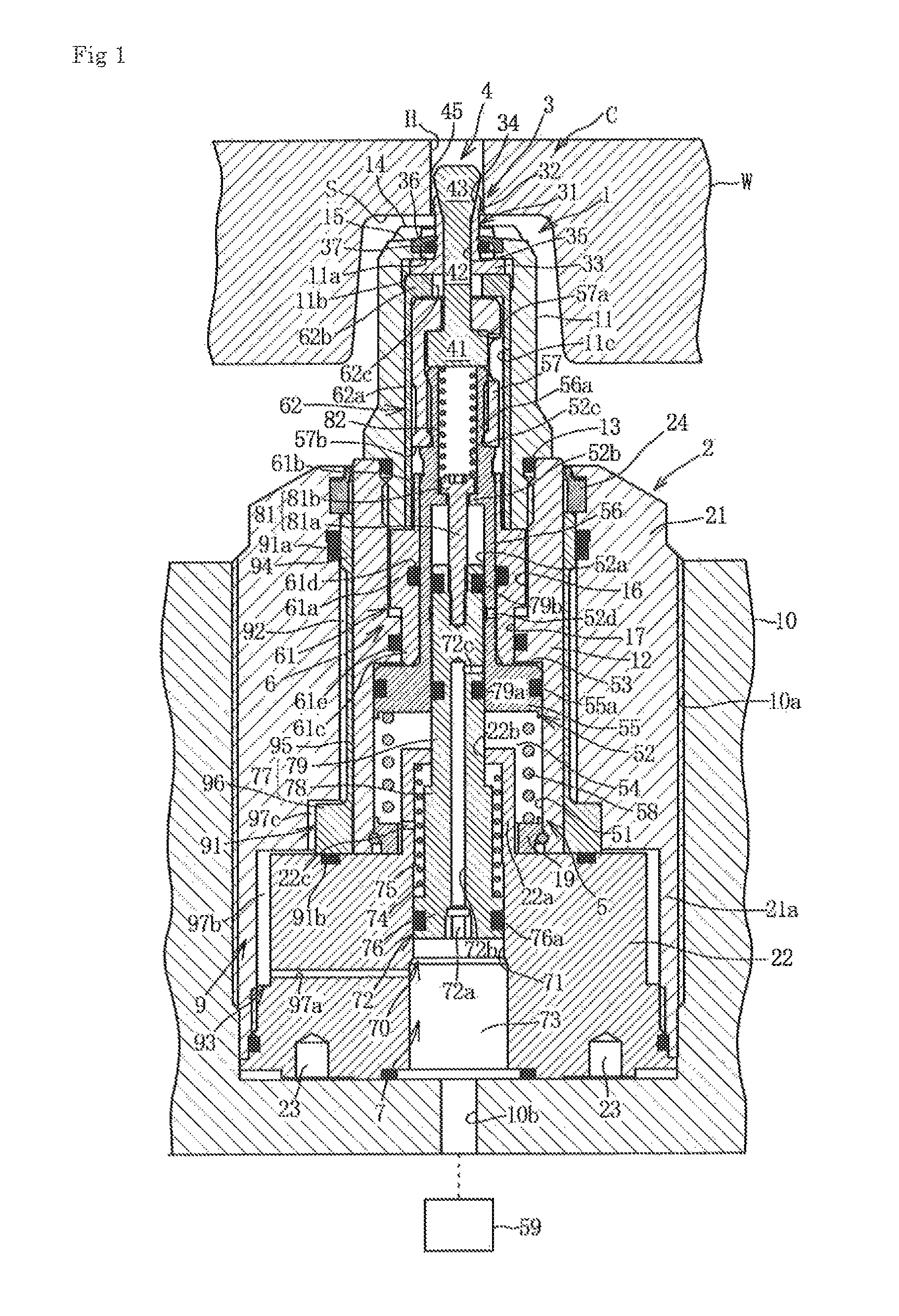

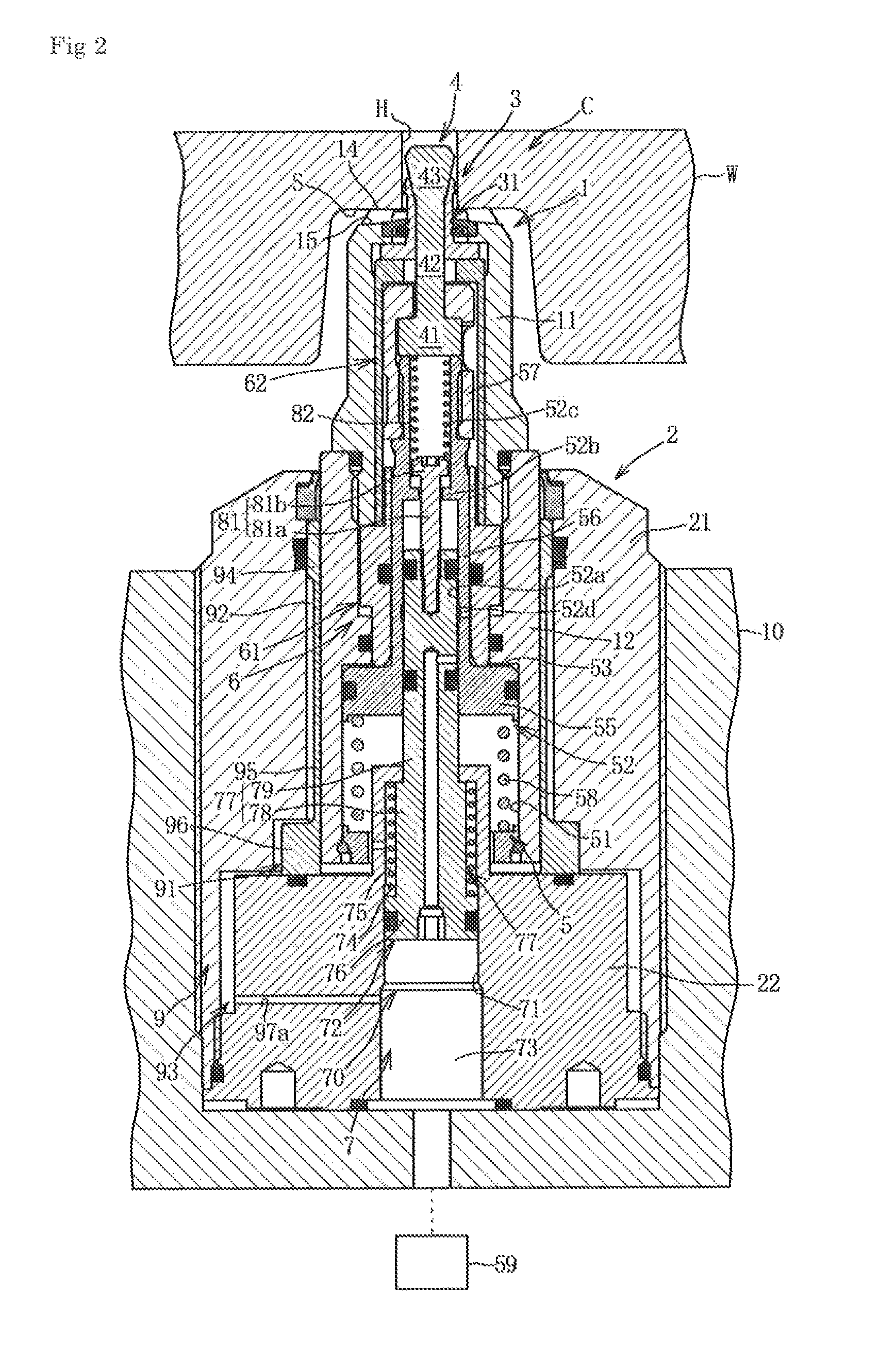

Clamp device

ActiveUS9242324B2Reliable lockingReduce the overall diameterLarge fixed membersPositioning apparatusLocking mechanismEngineering

A grip member is inserted into an insertion hole of a cylindrical clamp body and is capable of extending outwards to grip the inner circumferential surface of an aperture of an article. A clamp rod is engaged with the grip member; a driving mechanism capable of driving the clamp rod forwards and backwards; a seating surface formed at the top end of the cylindrical clamp body; a case member supporting the cylindrical clamp body movably forwards and backwards; a driving mechanism capable of raising an lowering the cylindrical clamp body; and a lock mechanism having a cylindrical member into which the cylindrical clamp body is inserted so as to slide freely and capable of locking the outer circumferential surface of the cylindrical clamp body by elastically deforming the cylindrical member so as to reduce its diameter.

Owner:PASCAL ENG

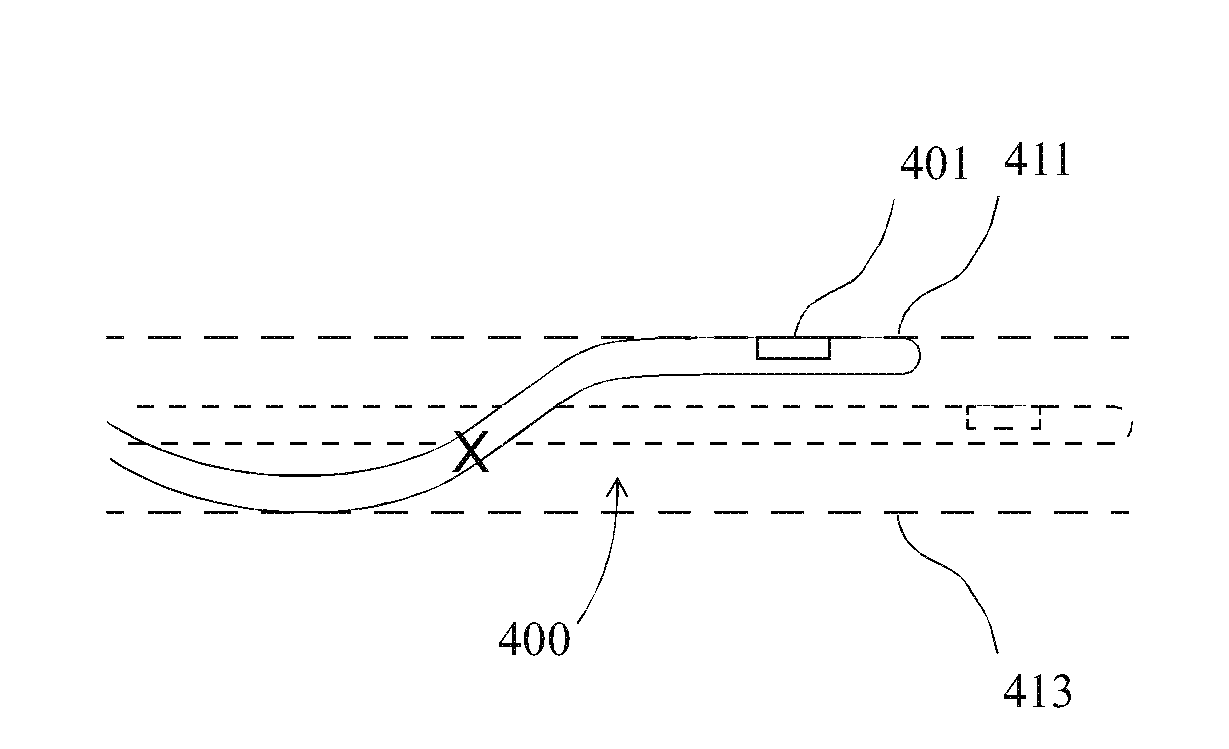

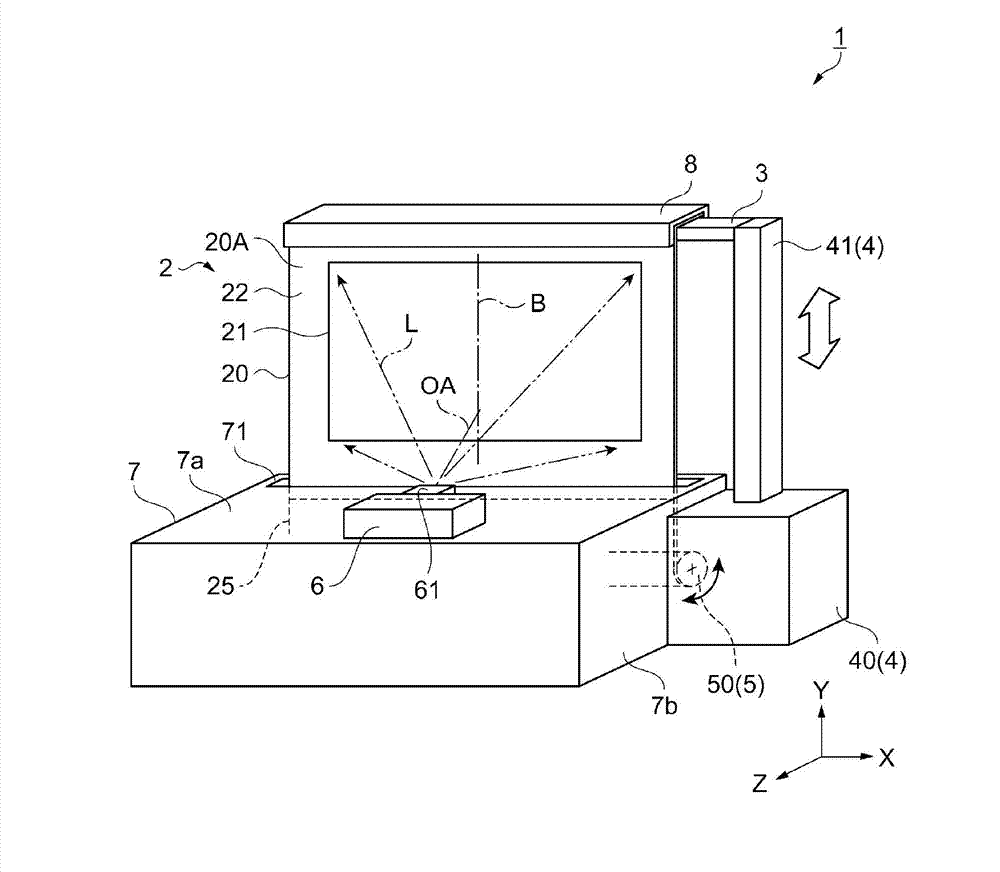

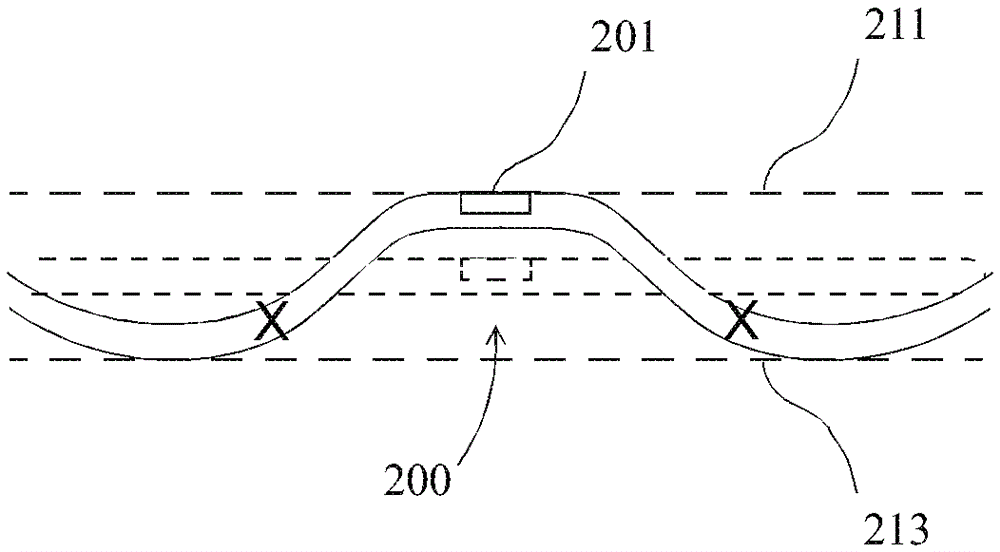

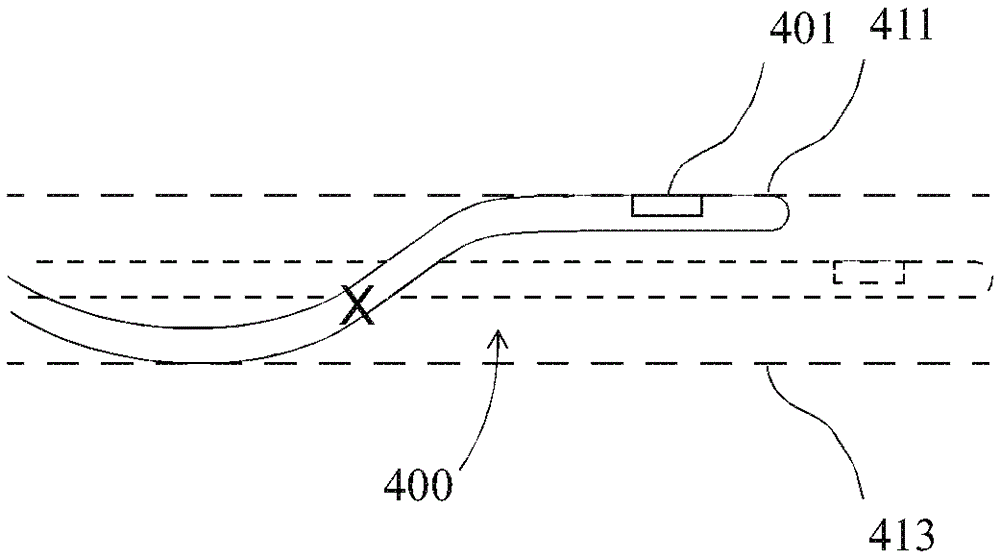

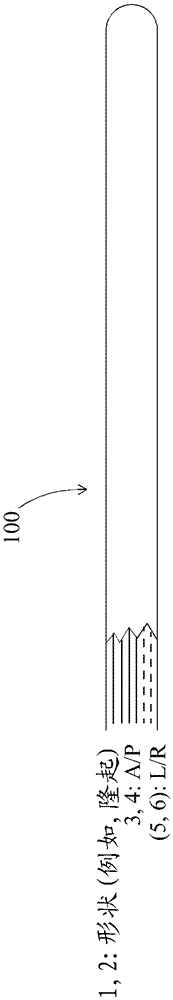

Shape-controllable catheters and catheter systems

ActiveCN102641138AHardness maintained or increasedLess discomfortGuide wiresSurgeryHardnessCatheter device

The present invention relates to a shape-controllable catheters and catheter systems. Shape-controllable catheters (100, 200, 300, 400, 500) are provided that are versatile in application and that, in human-imaging applications, minimize or reduce patient discomfort. One such catheter is provided with at least one control wire (121, 123) that extends inside the catheter and a control mechanism (611, 613) for tensioning the control wire to produce in the catheter a humped shape or a cantilevered configuration. Hardness of the catheter may be varied along the length thereof to facilitate desired bending. For example, hardness may be reduced in bend areas. Hardness may be maintained or increased in other areas for performance reasons, for example to maintain planarity of an imaging array.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Electrode mixture paste coating method and coater

InactiveCN101167207AEnsure emissionsEnsure planarityAlkaline accumulator electrodesElectrode collector coatingThin metalViscosity

Owner:PANASONIC CORP

Electronic MEMS device comprising a chip bonded to a substrate and having cavities and manufacturing process thereof

InactiveUS20120286381A1Preventing raising and tiltingEnsure planaritySemiconductor/solid-state device manufacturingForming microstructural systemsEngineeringHeat treated

An electronic MEMS device is formed by a chip having with a main face and bonded to a support via an adhesive layer. A cavity extends inside the chip from its main face and is closed by a flexible film covering the main face of the chip at least in the area of the cavity. The support has a depressed portion facing the cavity and delimited by a protruding portion facing the main face of the chip. Inside the depressed portion, the adhesive layer has a greater thickness than the projecting portion so as to be able to absorb any swelling of the flexible film as a result of the expansion of the gas contained inside the cavity during thermal processes.

Owner:STMICROELECTRONICS SRL

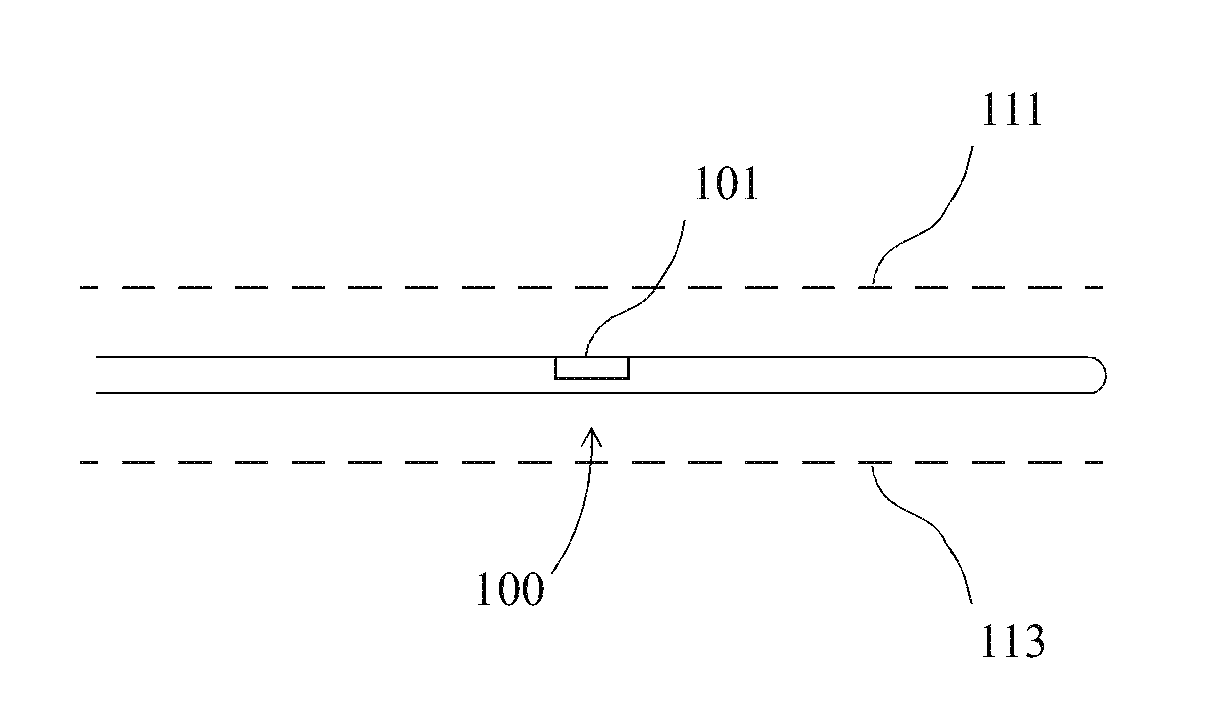

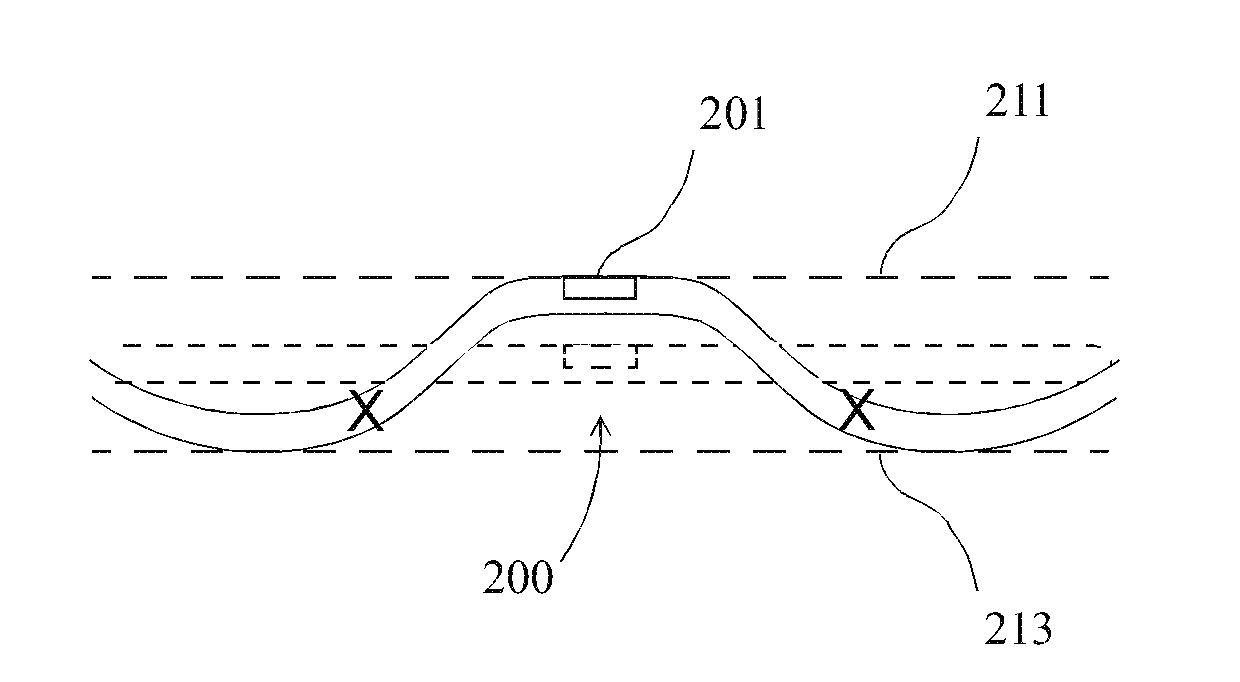

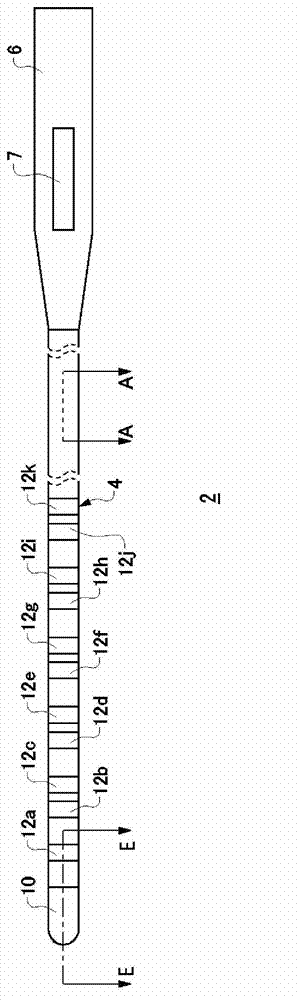

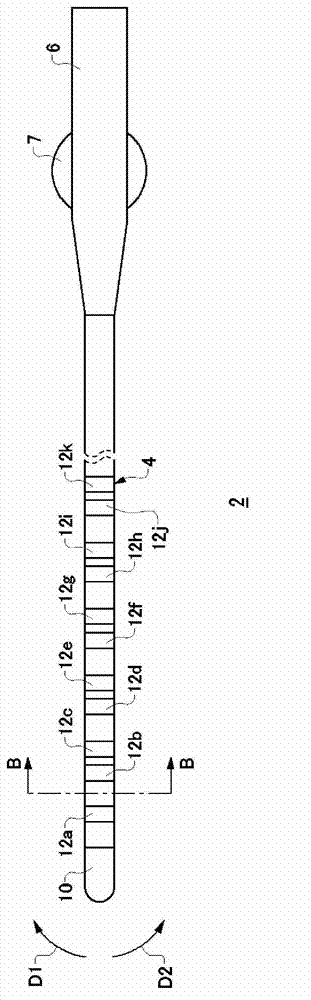

Catheter

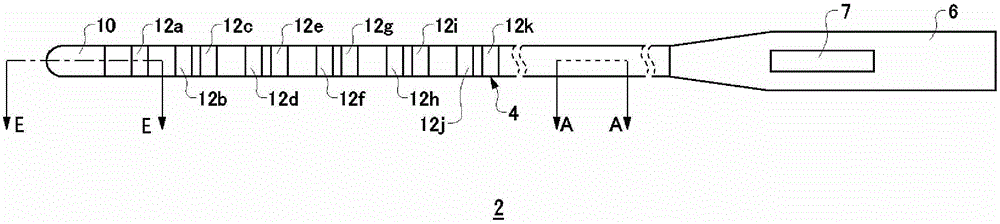

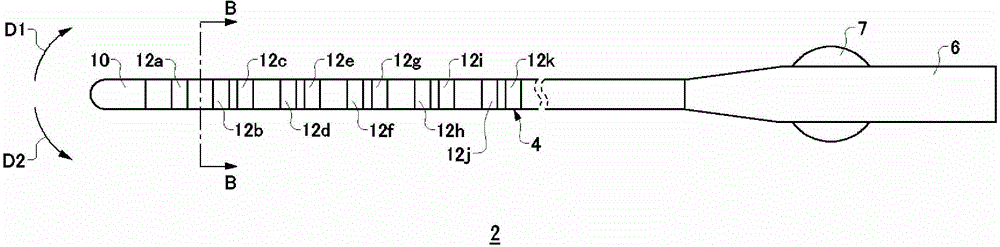

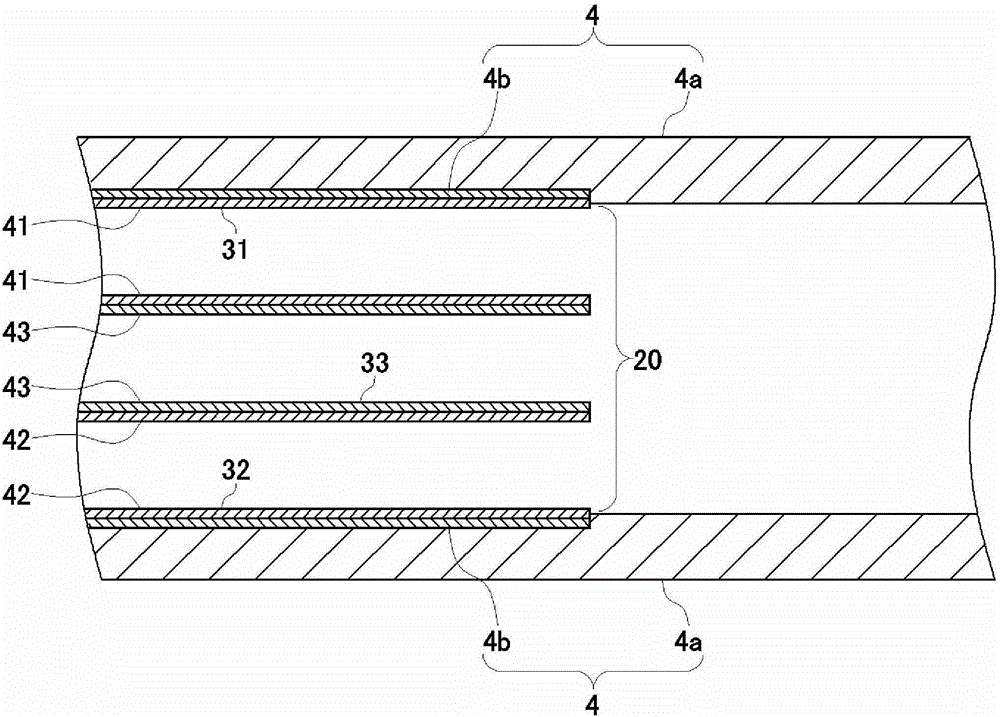

ActiveCN103079626AEnsure planarityIncrease the number ofElectrocardiographyMulti-lumen catheterEngineeringCatheter device

Disclosed is a catheter provided with: a tube member (4); a pair of bar springs (22a and 22b) provided inside the tube member (4) along the central axis (X1) thereof, one of said bar springs being offset from the central axis (X1) and the other being offset from the central axis (X1) in the opposite direction; control-wire insertion passages (31 and 32) provided inside the tube member (4) along the central axis (X1) thereof, located respectively on one side (H1) and the other side (H2) of a virtual plane (H) that passes through the central axes (X2 and X3) of the two bar springs (22a and 22b); and control wires (50a and 50b) slidably inserted into the control-wire insertion passages (31 and 32), one end of each control wire being connected near the distal end of the tube member (4).

Owner:JAPAN LIFELINE CO LTD

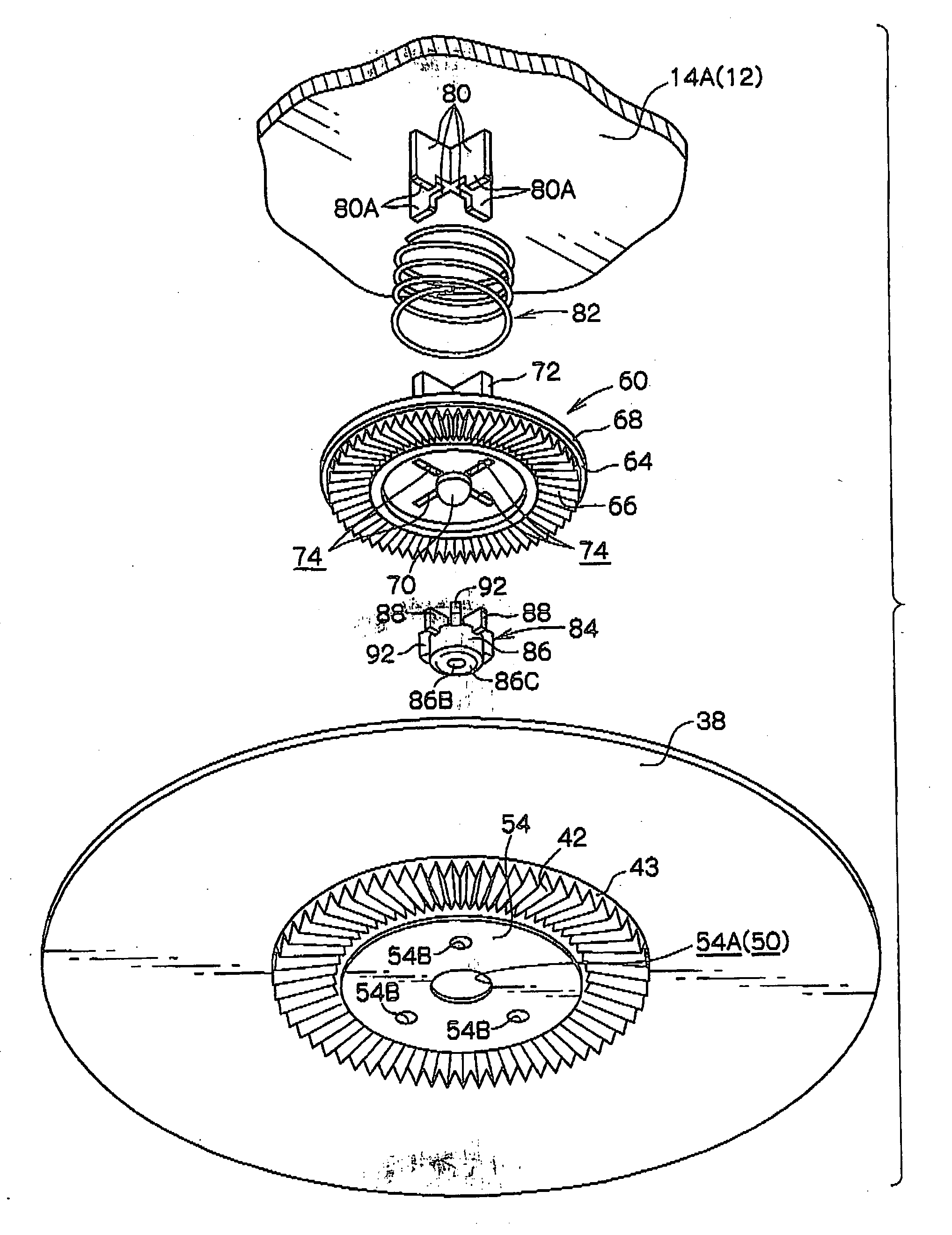

Reel

InactiveUS20070246598A1Ensure planarityRecord information storageDriving by direct/indirect member actionEngineeringMechanical engineering

Owner:FUJIFILM CORP

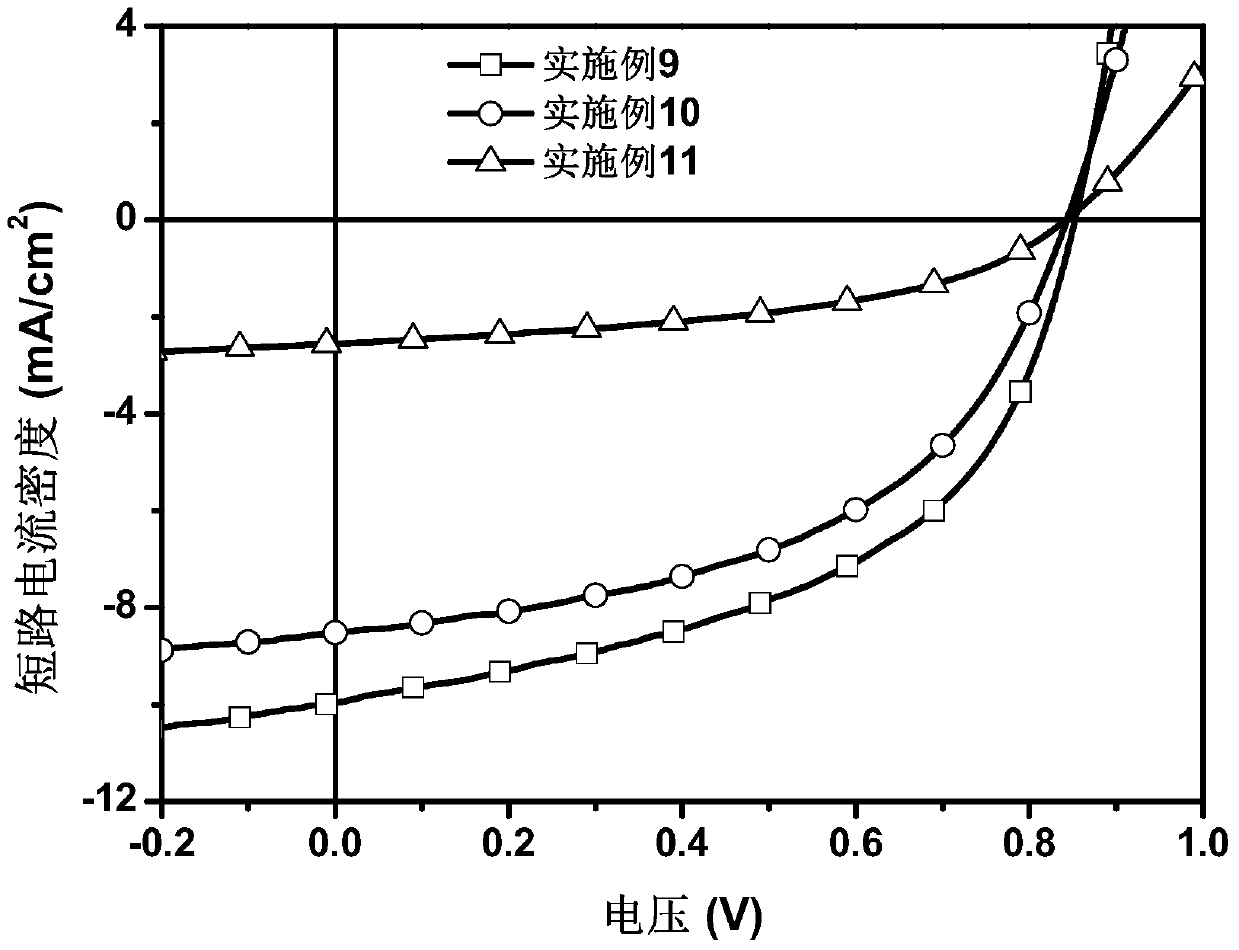

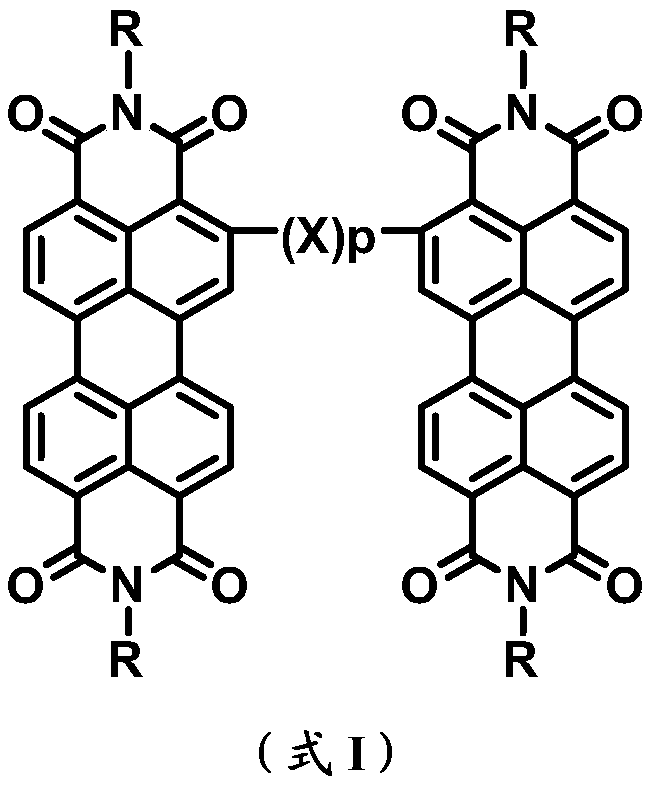

Ortho-bridged perylene diimide dimer, preparation method and application thereof in organic photovoltaic devices

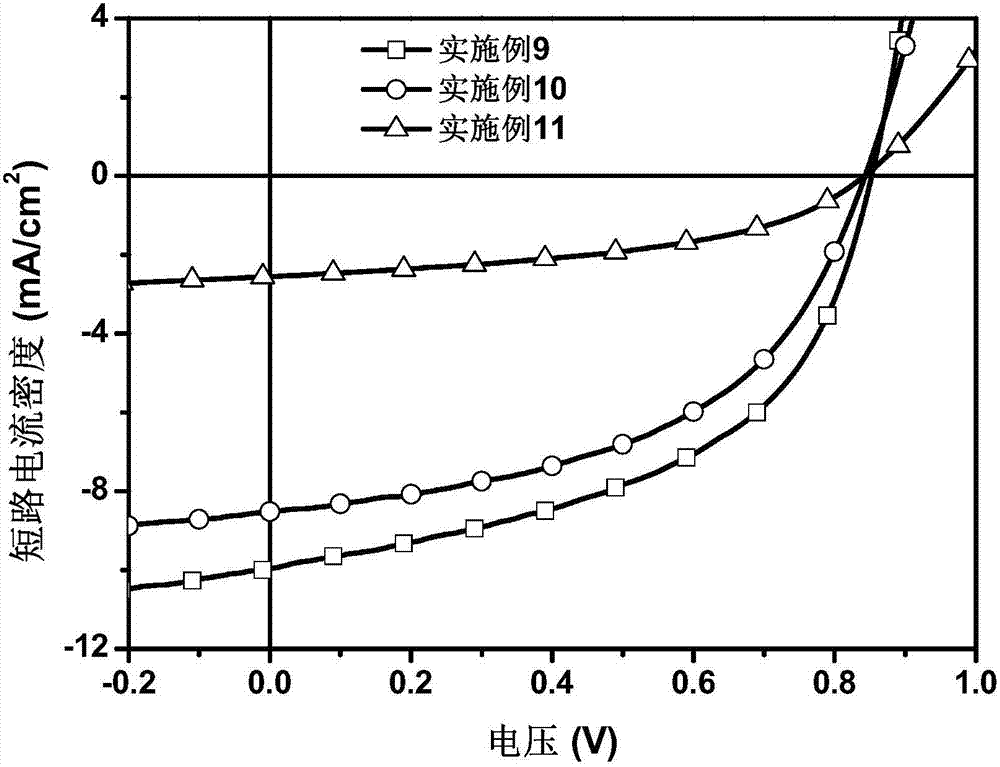

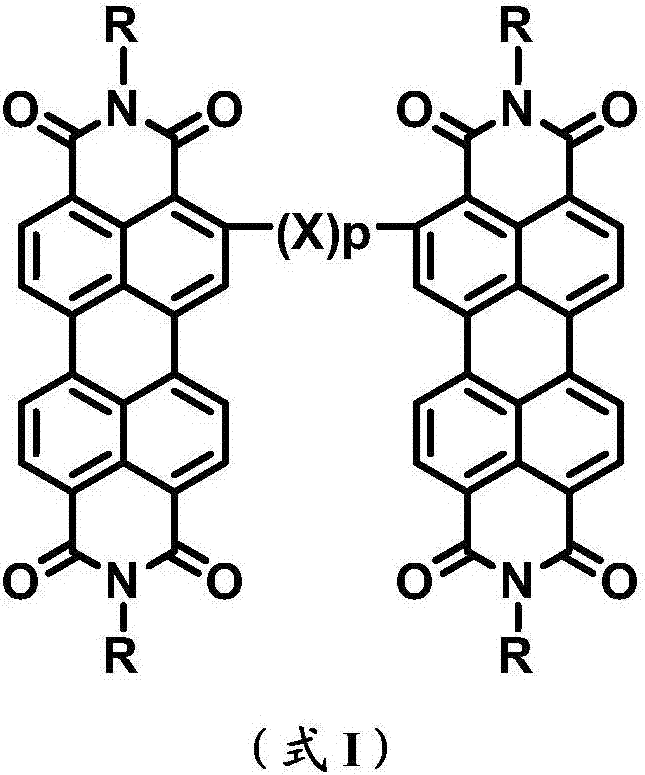

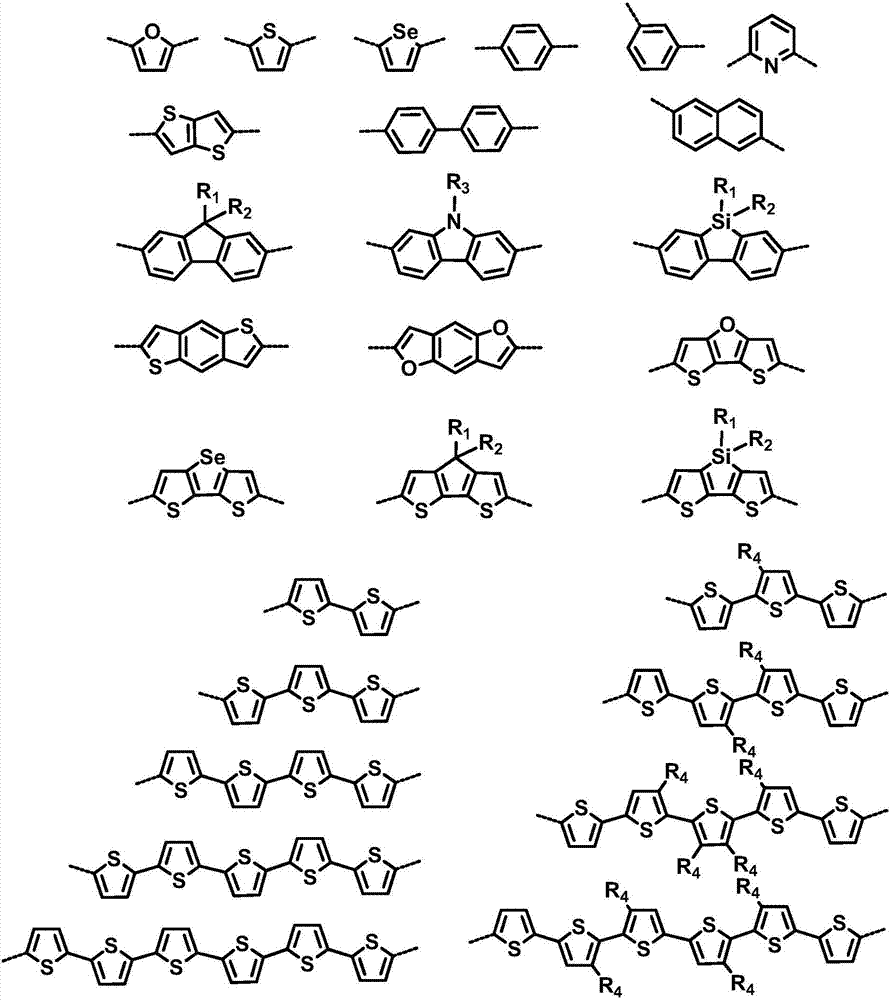

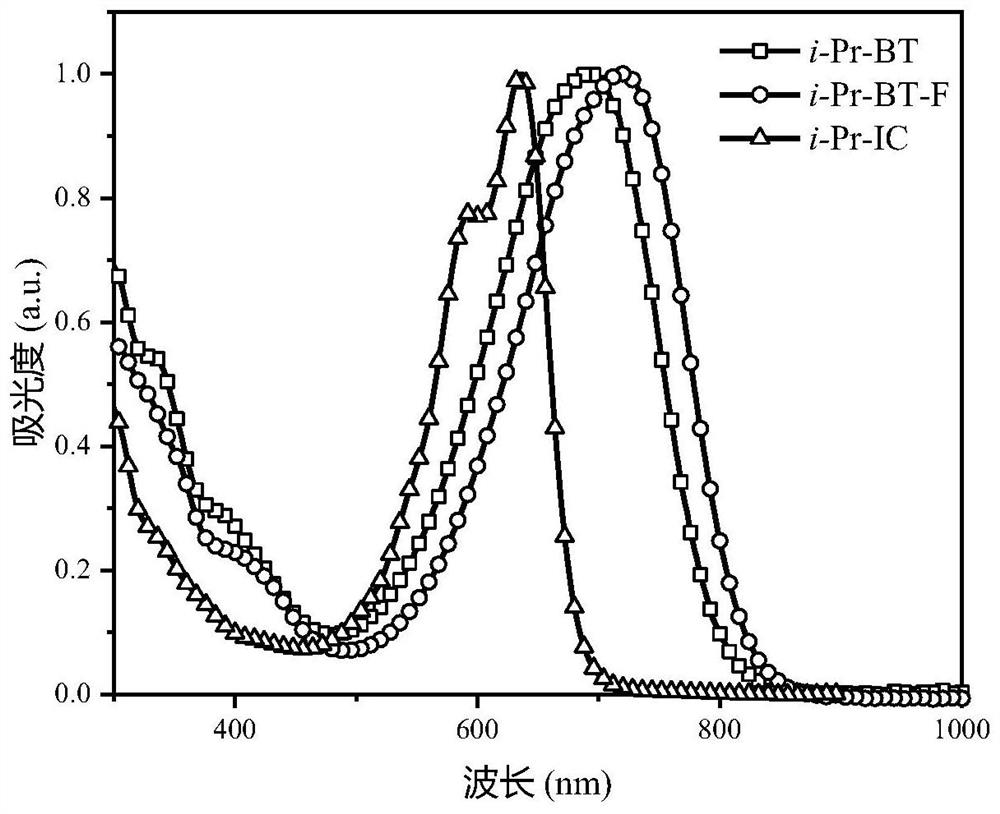

ActiveCN107304218AReduce excessive aggregationAvoid deformationGroup 4/14 element organic compoundsSolid-state devicesOrganic solar cellElectron donor

The invention provides an ortho-bridged perylene diimide dimer (formula I), a preparation method and an application thereof in the organic photovoltaic field. The invention further relates to an organic solar cell of the compound and a preparation method of the organic solar cell. Compared with a PDI monomer molecule, a formed twisted dimer structure is capable of effectively weakening excessive aggregation among PDI molecules, so that the phase size is reduced. Meanwhile, by virtue of ortho-bridging, the deformation of a PDI inner core caused by waist bridging can be avoided, so that certain planarity and relatively strong pi-pi accumulation can be maintained, and relatively high electronic mobility can be obtained. The PDI dimer is taken as a receptor material and is combined with an electron donor polymer so as to prepare the organic solar cell, so that very high photoelectric conversion efficiency is realized.

Owner:INST OF CHEM CHINESE ACAD OF SCI

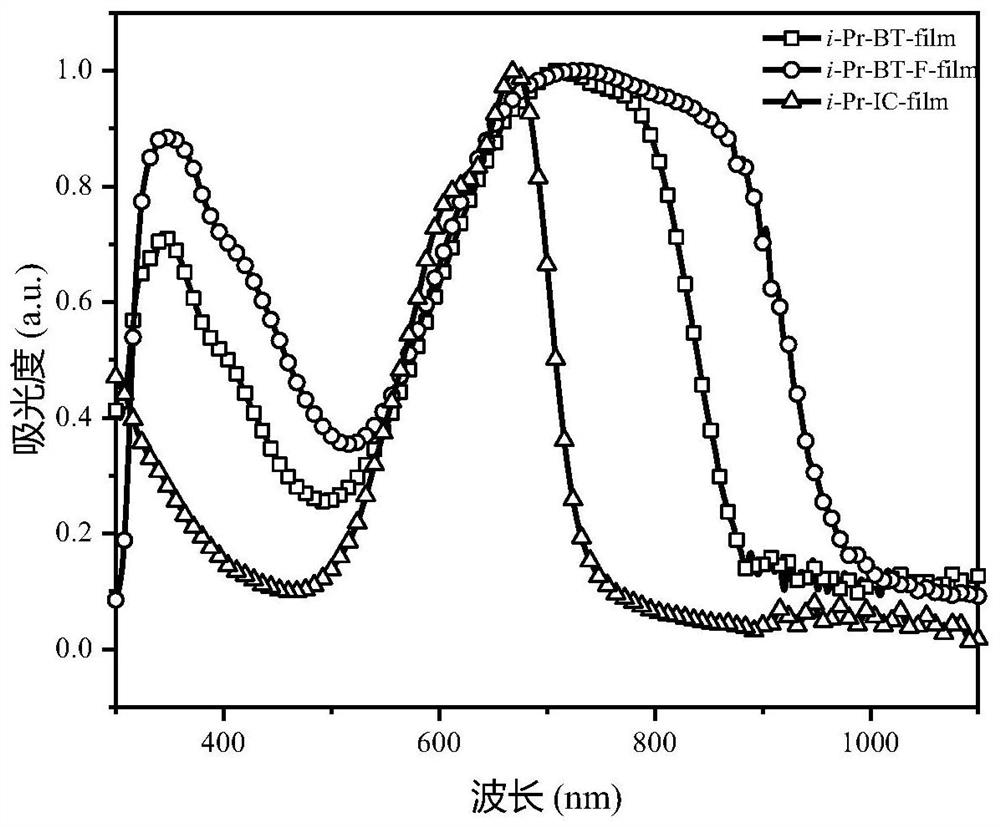

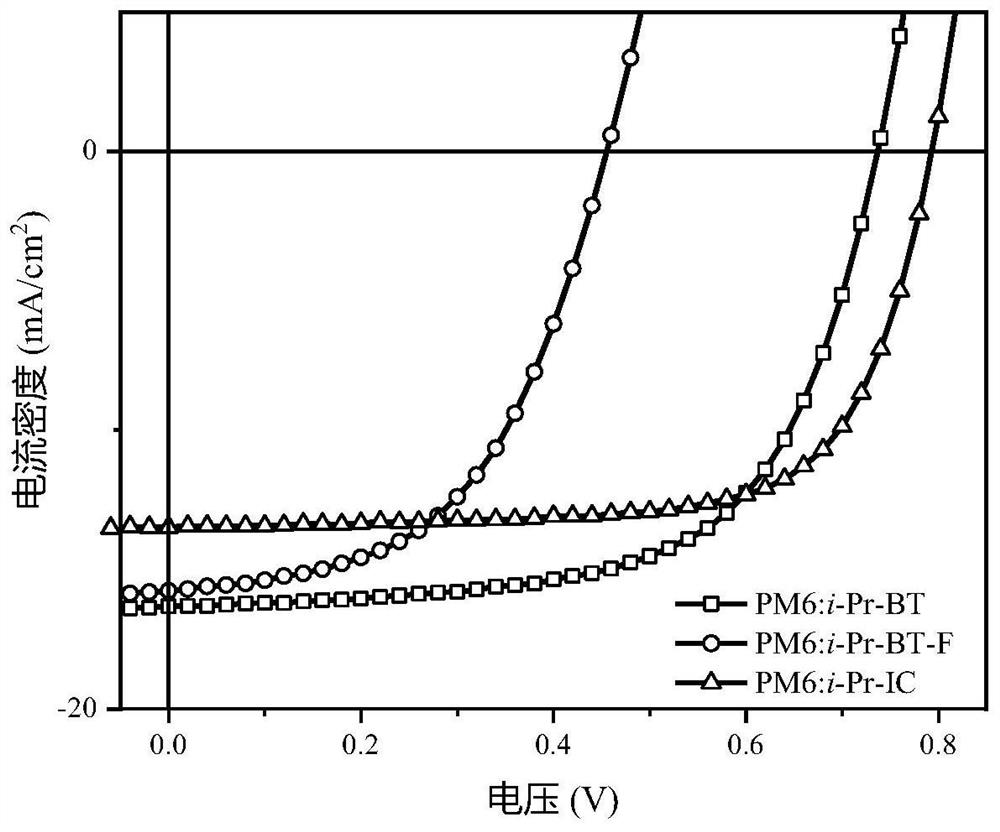

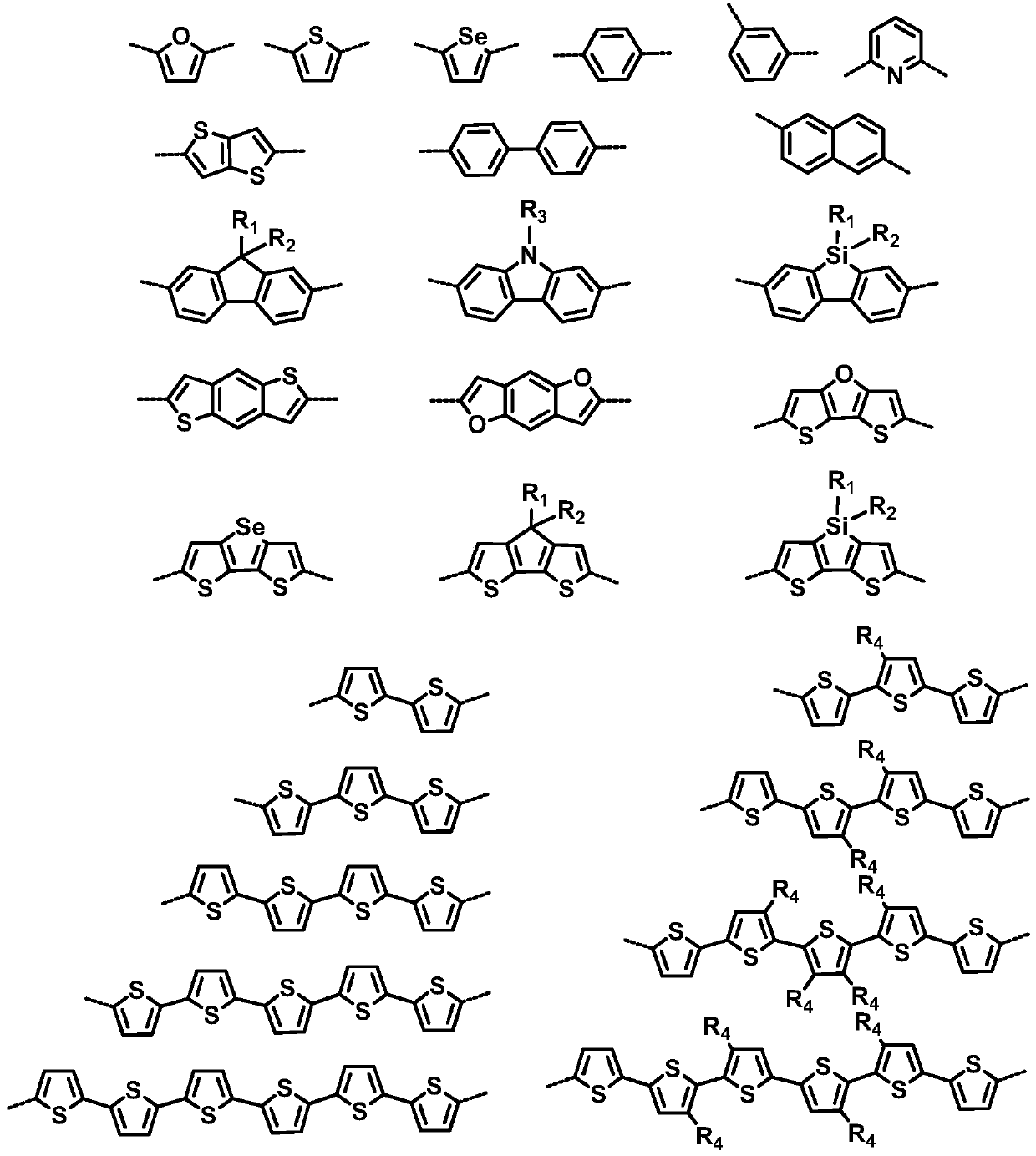

Non-fullerene acceptor material as well as preparation method and application thereof

ActiveCN113429383AImprove developmentImprove solubilityOrganic chemistrySolid-state devicesAcceptorMolecular materials

The invention discloses a non-fullerene acceptor material as well as a preparation method and application thereof. The non-fullerene acceptor material has a structure as shown in a formula (I). The non-fullerene acceptor material provided by the invention can have a non-condensed ring structure, and can maintain the planarity of a molecular host while ensuring the dissolving property, so that organic photovoltaic material molecules can be flexibly constructed by using a non-condensed ring structure unit, the material solubility is good, the light absorption range can be expanded to a near-infrared region, the electron mobility is high, and the development of novel efficient donor and acceptor materials is facilitated.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Process for fabricating a single-crystal substrate and integrated circuit comprising such a substrate

InactiveUS7060596B2Ensure planarityEnsure surfaceSolid-state devicesSemiconductor/solid-state device manufacturingChemical compositionSingle crystal substrate

An initial single-crystal substrate 1 having, locally and on the surface, at least one discontinuity in the single-crystal lattice is formed. The initial substrate is recessed at the discontinuity. The single-crystal lattice is amorphized around the periphery of the recess. A layer of amorphous material having the same chemical composition as that of the initial substrate is deposited on the structure obtained. The structure obtained is thermally annealed in order to recrystallize the amorphous material so as to be continuous with the single-crystal lattice of the initial substrate.

Owner:STMICROELECTRONICS SRL

Block

InactiveCN103132417AGood constructionEasy constructionSingle unit pavingsClimate change adaptationEnvironmental geologyMechanical engineering

The invention provides a block with a convex portion formed on the front side surface and a concave portion formed in the back side surface in a shape corresponding to that of the convex portion. A shape inclined to a front-lower direction in a front-and-back direction is formed on an upper side profile of the convex portion extending from the front end of the convex portion to a based end on the upper surface of the convex portion and on an upper side profile of the concave portion extending from the inner end of the concave portion to an opening of the concave portion on the upper surface of the concave portion, on a longitudinal section shape formed when the bottom surface of the block is disposed at the lower side and the block is cut along a vertical plane along a front-and-back direction. A shape not inclined to a front-upper direction in the front-and-back direction is formed on a lower side profile of the convex portion extending from the front end of the convex portion to the based end on the upper surface of the convex portion and on a lower side profile of the concave portion extending from the inner end of the concave portion to the opening of the concave portion on the lower surface of the concave portion, on the longitudinal section shape. According to the invention, the block which has excellent application property and can well maintain joint planarity of adjacent blocks after being laid can be obtained.

Owner:UNISON CO LTD

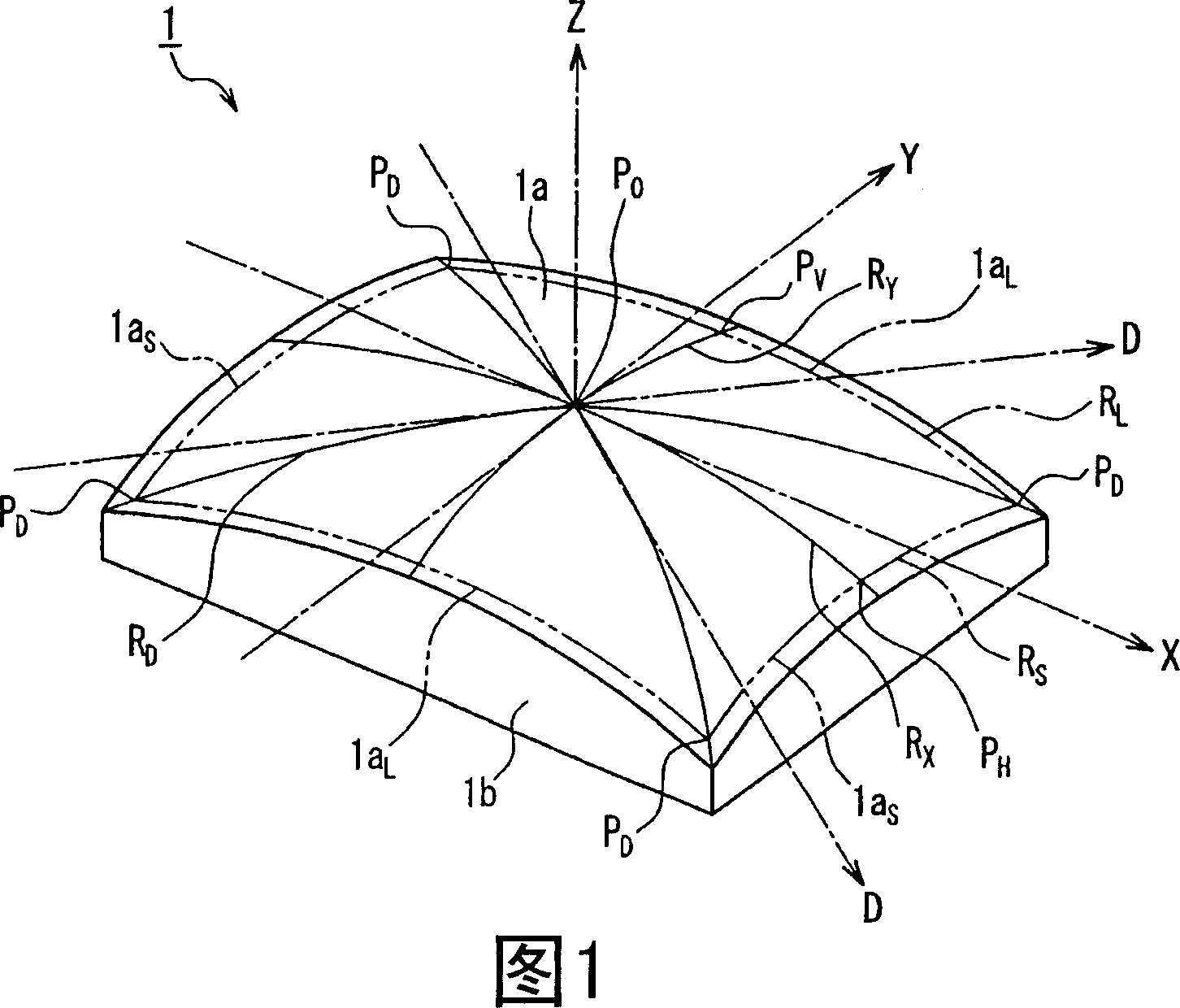

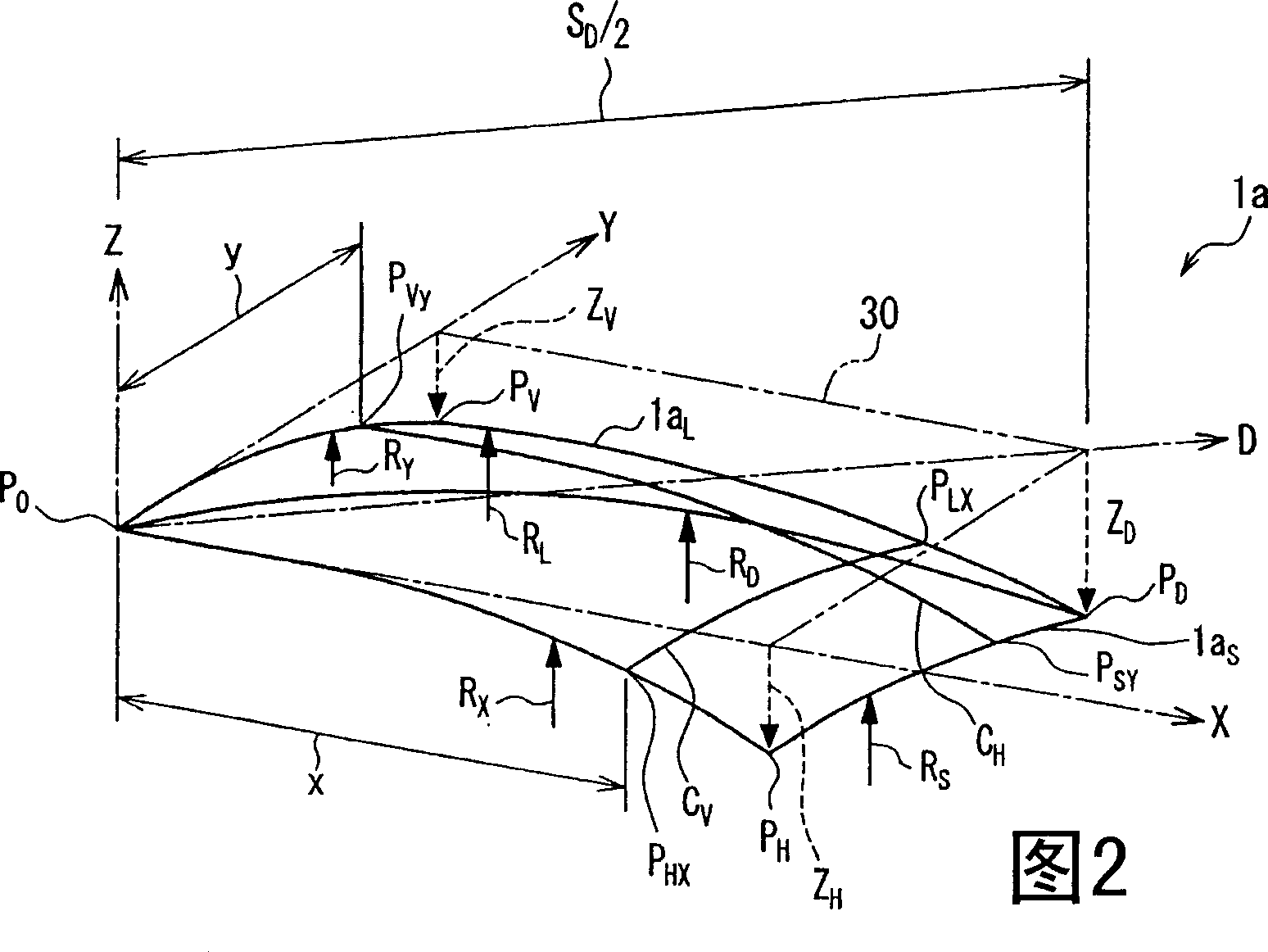

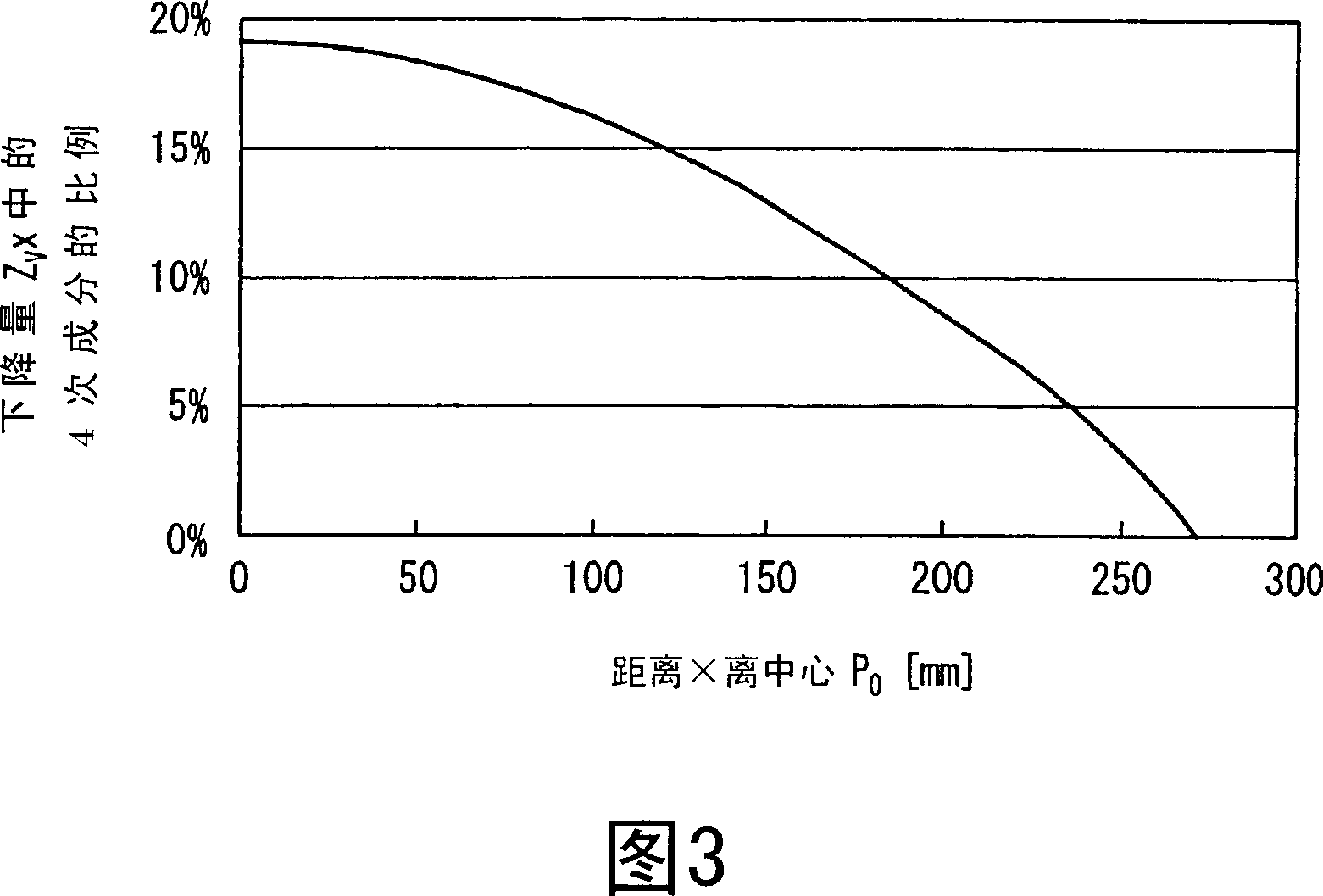

Color picture tube

InactiveCN1975977AIncrease surface retention strengthReduce uniformityCathode-ray/electron-beam tube vessels/containersVisibilityEngineering

The radii of curvature RD, RS and RL along a diagonal axis, a short side and a long side of an outer surface of a useful portion of a panel whose inner surface is provided with a phosphor screen satisfy RD>=10 m, RS>RD, and RL>RD. This makes it possible to provide a color picture tube that has an excellent visibility and is not susceptible to the deterioration in color purity due to doming, while including a shadow mask with excellent formability and strength.

Owner:MATSUSHITA TOSHIBA PICTURE DIS

A kind of ortho-bridged perylene diimide dimer and its preparation method and application in organic photovoltaic devices

ActiveCN107304218BReduce excessive aggregationAvoid deformationGroup 4/14 element organic compoundsSolid-state devicesOrganic solar cellImide

The invention provides an ortho-bridged perylene diimide dimer (formula I), a preparation method thereof and an application thereof in the field of organic photovoltaics. The invention also relates to organic solar cells of such compounds and methods for their preparation. Compared with PDI monomer molecules, the formed twisted dimer structure can effectively weaken the excessive aggregation between PDI molecules, thereby reducing the phase size. At the same time, the deformation of the PDI core caused by bridging at the waist can be avoided through the bridging at the adjacent position, so that it can maintain a certain planarity and strong π-π stacking, and obtain higher electron mobility. Using the PDI dimer as an acceptor material and combining it with an electron-donating polymer, an organic solar cell is prepared, and a high photoelectric conversion efficiency is achieved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Combined dresser and its manufacturing method and chemical mechanical polishing method

InactiveCN103367242BLow costBest removal rateSemiconductor/solid-state device manufacturingMicrometerEngineering

The present invention is about a combined trimmer, comprising: a bottom substrate; a plurality of grinding units arranged at a surface of the bottom substrate, wherein the each grinding unit comprises a plurality of grinding sharp points and a binding agent layer for fixing the grinding sharp points; and an adhesive layer with an adjustable thickness for fixing the grinding units to the surface of the bottom substrate, wherein height difference between a first high point and a second high point in the grinding sharp points protruded from a predetermined plane is less than 10 micrometer, height difference between the first high point and a tenth high point is less than 20 micrometer, height difference between the first high point and a hundredth high point is less than 40 micrometer, and the height of the first high point protruded from the binding agent layer is greater than 50 micrometer. The present invention is also about a manufacturing method and a chemical mechanical polishing method of the combined trimmer.

Owner:RITEDIA CORPORATION

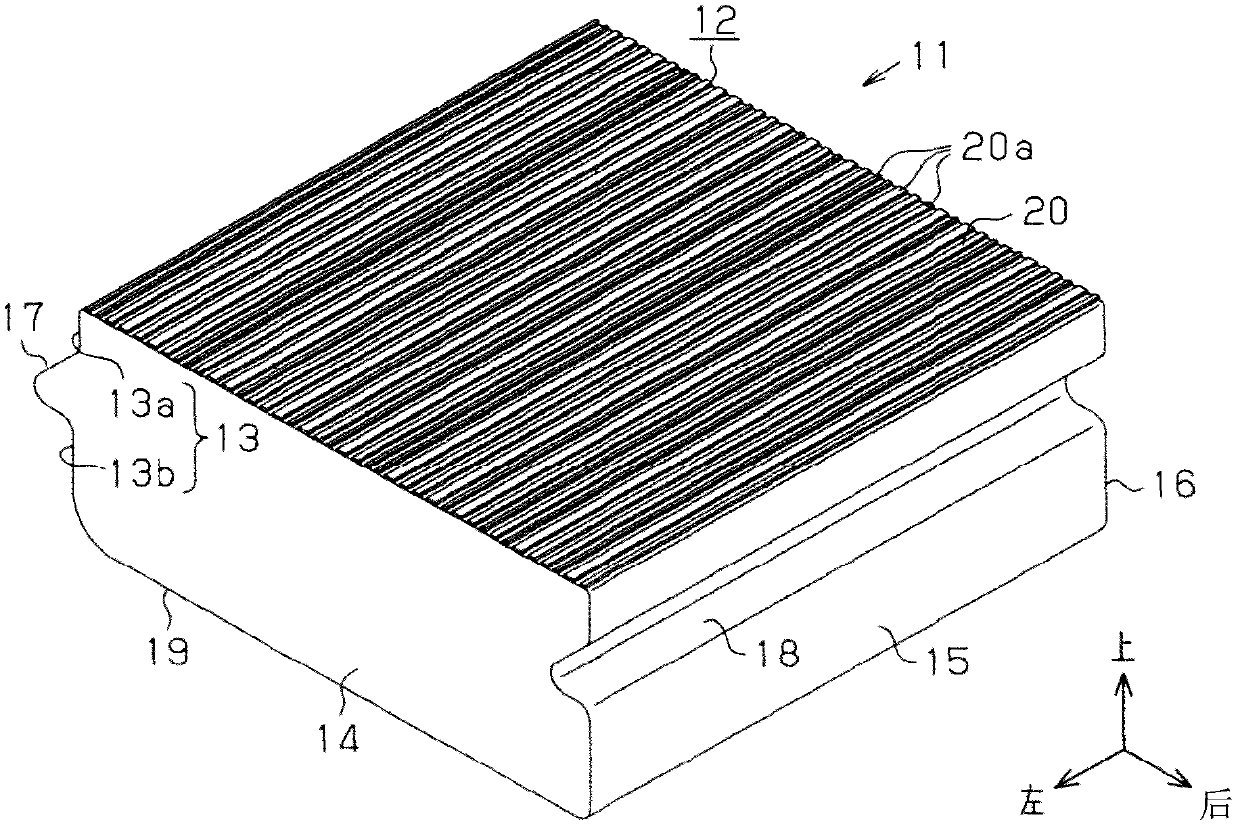

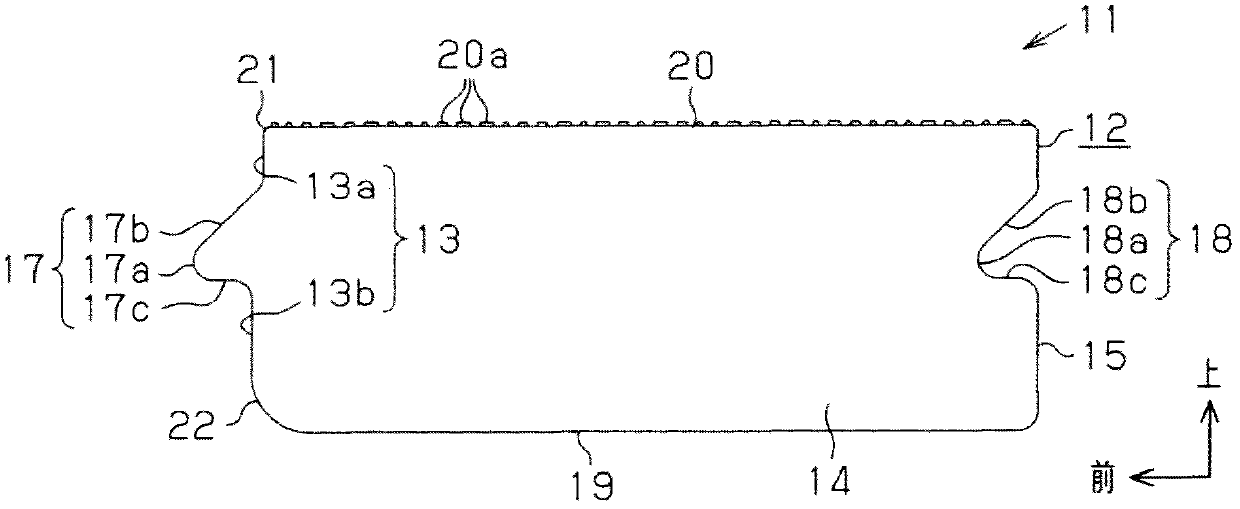

Wrap film container and label adapted for use for the container and used for film holding section

InactiveUS8389091B2Stable and continuous film-holding powerFormed stably and easilyDispensing apparatusSynthetic resin layered productsEngineeringMechanical engineering

A wrapping film container, including: an elongated container body for housing therein a rolled self-tacky wrapping film, an opening provided to the container body along a longitudinal direction of the container body for pulling out a portion of the wrapping film therethrough, cutting means for cutting the pulled-out portion of the wrapping film and a film-holding section provided on a front face of the container body for preventing re-winding to an inside of the container, wherein the film-holding section comprises a laminate structure including a pressure-sensitive adhesive layer, a substrate layer, an adhesive layer and a self-tacky film layer, disposed sequentially from the container body side. The film-holding section is efficiently formed on the front face of the container body by using a label for forming film-holding section of a wrapping film container having a laminate structure including a self-tacky film layer, an adhesives layer, a base material layer, a pressure-sensitive adhesive layer and a separator layer, disposed sequentially from one side thereof, and exhibits a stable and consistent film-holding power.

Owner:KUREHA KAGAKU KOGYO KK

Building block

InactiveCN103132424AEnsure planaritySuppresses roughening of the surface stateSingle unit pavingsClimate change adaptationEngineeringShape formation

A building block has good workability when being paved on flat sand cushion layer, and can maintain planarity of gap between adjacent blocks after paving. When the bottom surface of the block is downward, a convex portion is formed on the front side, a concave portion with a shape corresponding to the concave portion is formed on the back side, and a cross-section shape is formed by cutting along the direction of protruding direction of the convex portion and the deboss direction of the concave portion. A forward downward inclined shape is formed from the top of the convex portion to the bottom of the concave portion. In the protruding direction of the convex portion and the deboss direction of the concave portion, a non-forward upward inclined shape is formed from the top of the convex portion to the bottom of the concave portion.

Owner:UNISON CO LTD

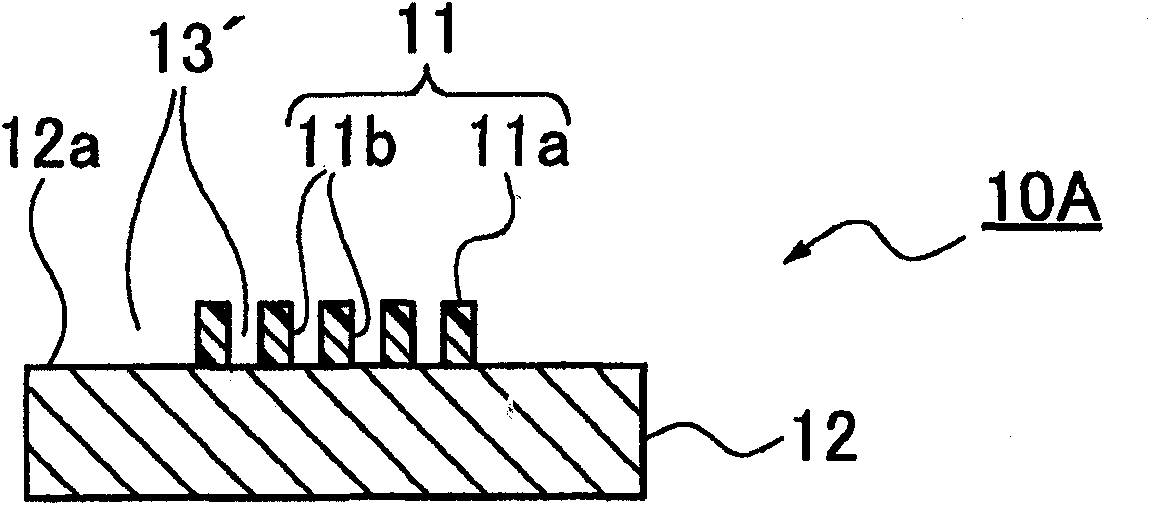

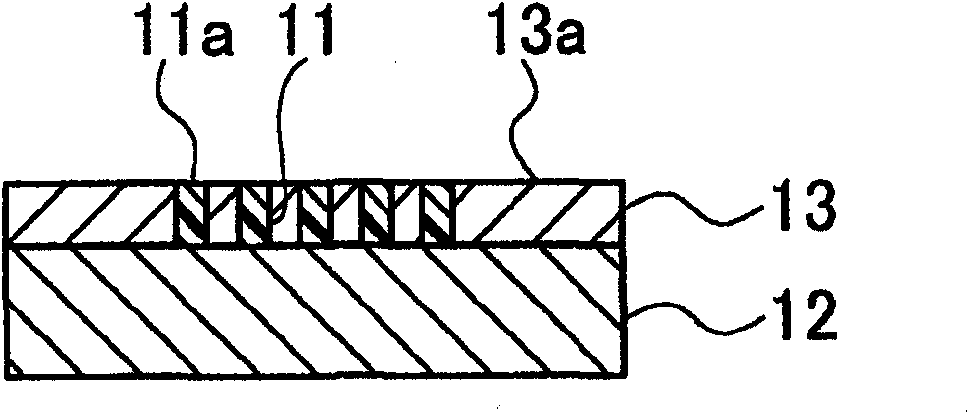

Molding die, and molding die manufacturing method

ActiveCN102112280BGuaranteed durabilityEnsure planarityRecord information storageOptical record carrier manufactureResistSurface structure

Owner:KURARAY CO LTD

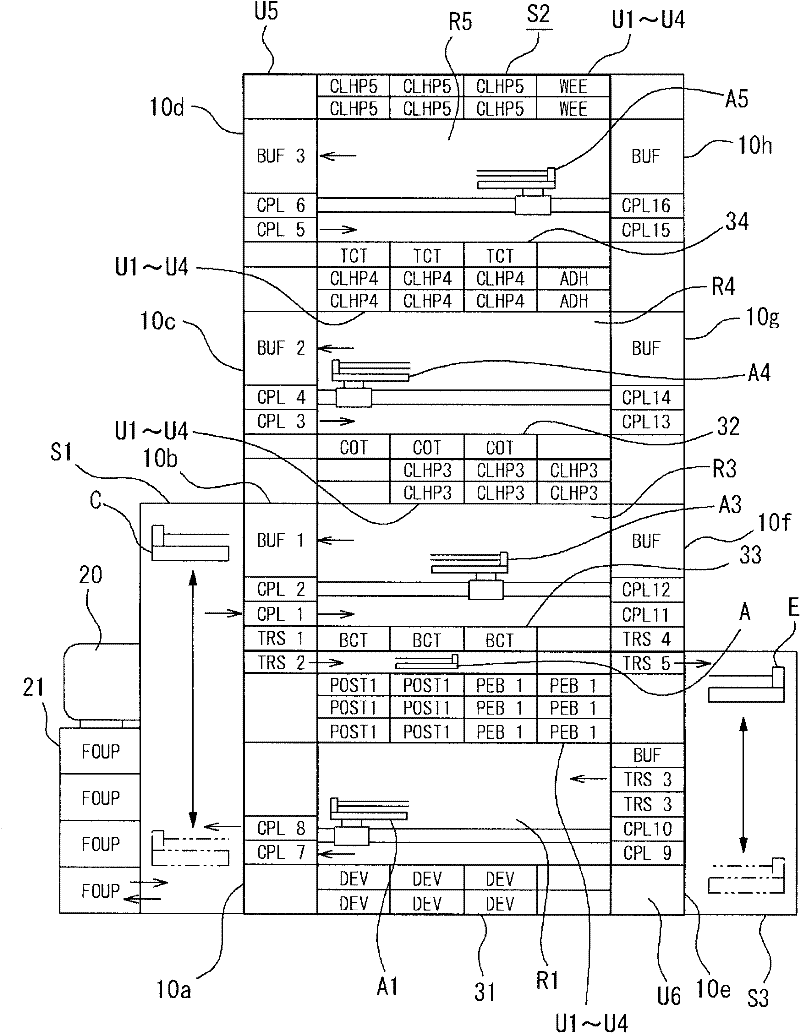

Substrate heat processing apparatus

ActiveCN101840847BGood effectIncrease the number of storageSemiconductor/solid-state device manufacturingPhotosensitive material processingProduction rateMiniaturization

The present invention provides a substrate heat processing apparatus, which can reduce the configuration space of a heat processing plate as possible thereby realizing the miniaturization of device, increasing the number of accommodated substrates and increasing the freedom and productivity of the heat medium flow. The substrate heat processing apparatus is provided with a heat processing plate such as a cooling plate (14), which is used for carrying a semiconductor wafer (W) and performing heat processing to the wafer to a preset temperature, wherein, the cooling plate (14) is provided with a cooling plate body (64). The cooling plate body (64) is obtained through laminating a plurality of thin plates (1) composed of heat-conductive material through a mode such as diffusion joint mode, and is provided with a supplying flow path (61a) and discharging flow path (62a) of the heat medium, a refrigerant flow path (63) and adsorption holes (64f), which are provided through laminating the thin plates (1).

Owner:TOKYO ELECTRON LTD

Molding die, and molding die manufacturing method

ActiveCN102112280AGuaranteed durabilityEnsure planarityRecord information storageOptical record carrier manufactureResistSurface structure

Disclosed is a molding die having a molding face, to which a finely irregular surface structure based on a mother mold is transferred, so that the molding die is durable and can retain the flatness of the molding face. Also disclosed is a method for manufacturing molding dies (10, 20) having the finely irregular surface on a molding face (10a). The method comprises: a mother mold forming step of applying a finely-ridged resist structure (11) based on a resist to an energization part (12a) by using an energization substrate (12) having the energization part (12a) on at least one surface thereof, to thereby form a mother mold (10A); a metal structure forming step of depositing a metal having a thickness corresponding to the height of the resist structure (11), on the energization part (12a), to thereby form a metal structure (13); an energization film forming step of forming an energization film (14) on the surface of the resist structure (11); a reinforcing layer forming step of forming a reinforcing layer (15) on the energization film (14) by a plating treatment; and a mother mold removing step of removing the mother mold (10A) to thereby form the mold having the finely irregular patterns based on the metal structure (13).

Owner:KURARAY CO LTD

Catheter

ActiveCN103079626BEnsure planarityIncrease the number ofElectrocardiographyMulti-lumen catheterEngineeringCatheter device

Disclosed is a catheter provided with: a tube member (4); a pair of bar springs (22a and 22b) provided inside the tube member (4) along the central axis (X1) thereof, one of said bar springs being offset from the central axis (X1) and the other being offset from the central axis (X1) in the opposite direction; control-wire insertion passages (31 and 32) provided inside the tube member (4) along the central axis (X1) thereof, located respectively on one side (H1) and the other side (H2) of a virtual plane (H) that passes through the central axes (X2 and X3) of the two bar springs (22a and 22b); and control wires (50a and 50b) slidably inserted into the control-wire insertion passages (31 and 32), one end of each control wire being connected near the distal end of the tube member (4).

Owner:JAPAN LIFELINE CO LTD

Screen and screen unit

Owner:SEIKO EPSON CORP

Recording apparatus

InactiveUS20130195537A1Suppress printing qualityPlanarityOther printing apparatusRecording mediaElectrical and Electronics engineering

A recording apparatus includes a supporting member on which a plurality of suction holes for sucking a recording medium are formed on a supporting face for supporting the recording medium, a transportation device which transports the recording medium along the supporting face, a recording head which ejects fluid on the recording medium supported by the supporting face so as to perform printing, and a control device which makes the recording head execute the printing when a front end of the recording medium in the transportation direction reaches to a position at which the front end of the recording medium covers the suction holes formed at downstream-most positions in the transportation direction on the supporting face.

Owner:SEIKO EPSON CORP

Shape-Controllable Catheters and Catheter Systems

ActiveCN102641138BHardness maintained or increasedLess discomfortGuide wiresSurgeryControl systemHardness

The present invention relates to shape controllable catheters and catheter systems. A shape-controllable catheter (100, 200, 300, 400, 500) is provided that is versatile in application and minimizes or reduces patient discomfort in human imaging applications. One such catheter is provided with: at least one control wire (121, 123) extending inside the catheter; and a control mechanism (611, 613) for tensioning the control wire to create a raised shape or cantilevered structure. The stiffness of the catheter can vary along its length to induce the desired bend. For example, the stiffness can be reduced in the bending region. Stiffness may be maintained or increased in other areas for performance reasons, eg, to maintain planarity of the imaging array.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

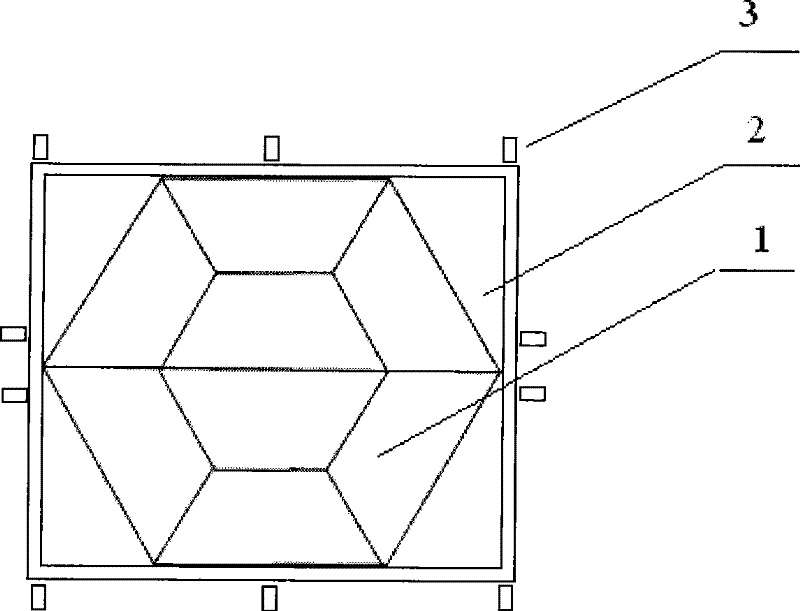

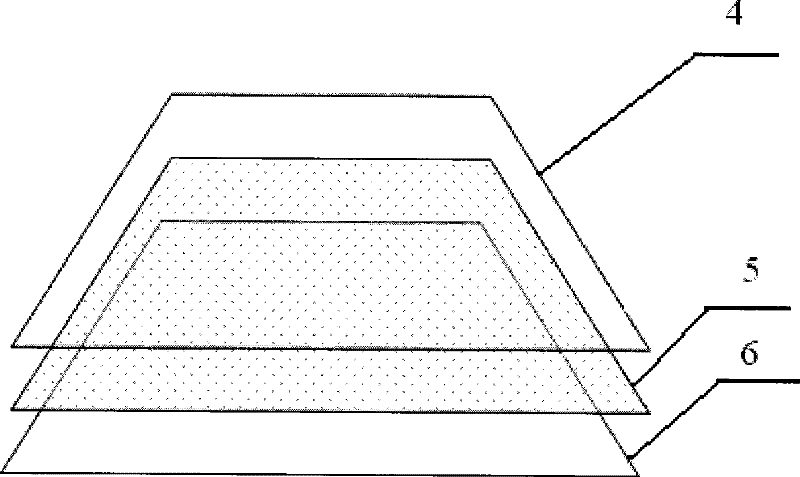

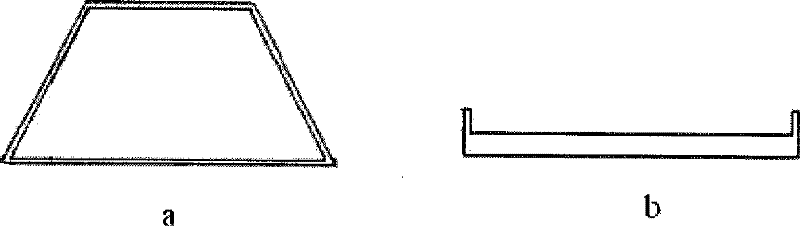

Large-sized artificial nuclide plane source calibration device and gamma ray spectrometer calibration method thereof

ActiveCN101666881BEnsure planarityReduce verification workloadX-ray spectral distribution measurementRadiation intensity measurementGamma ray spectrometerIsosceles trapezoid

The invention provides a large-sized artificial nuclide plane source calibration device and an optimized calibration method for calibrating a machine-mounted / vehicle-mounted gamma ray spectrometer by using the device. In the device, the design that eight isosceles trapezoids are combined to form a regular hexagon plane source realizes the conversion of a limited plane source into an unlimited (saturated) plane source through gapless joint; a rigid supporting plate structure ensures the planarity of the plane source; the uniform mesh distribution on filter paper and the use of quantitative liquid filler for filling raw liquid ensure the design activity of the plane source and the uniformity of activity distribution; the sealing of the plane source by adhesive resin ensures that source spots are free from damages and the long-term stability of the activity of the plane source; and the establishment of an angle response model provides a feasible technical evidence for the reduction of detection workload in a follow-up detection process, and the calibration method can be used to calculate a calibration factor when no obvious change occurs in the angle response model.

Owner:核工业航测遥感中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com