Electrode mixture paste coating method and coater

A coating method and mixture technology, which are applied in electrode collector coating, electrode manufacturing, alkaline battery electrodes, etc., can solve the problems of reduced coating dimensional accuracy and inability to improve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In water with a wet ball mill, the composition formula MmNi 3.55 co 0.75 mn 0.4 Al 0.3 The shown hydrogen storage alloy was pulverized to an average particle diameter of 30 µm to obtain a hydrogen storage alloy powder. After immersing the hydrogen storage alloy powder in an alkaline aqueous solution for surface treatment, 10 kg of a carboxymethyl cellulose aqueous solution having a solid content ratio of 1.5% and 0.4 kg of Ketjen black were added to 100 kg of the hydrogen storage alloy powder. After kneading, 1.75 kg of an aqueous solution of styrene-butadiene copolymer rubber particles having a solid content ratio of 40% was added and stirred to prepare electrode mixture slurry 6 .

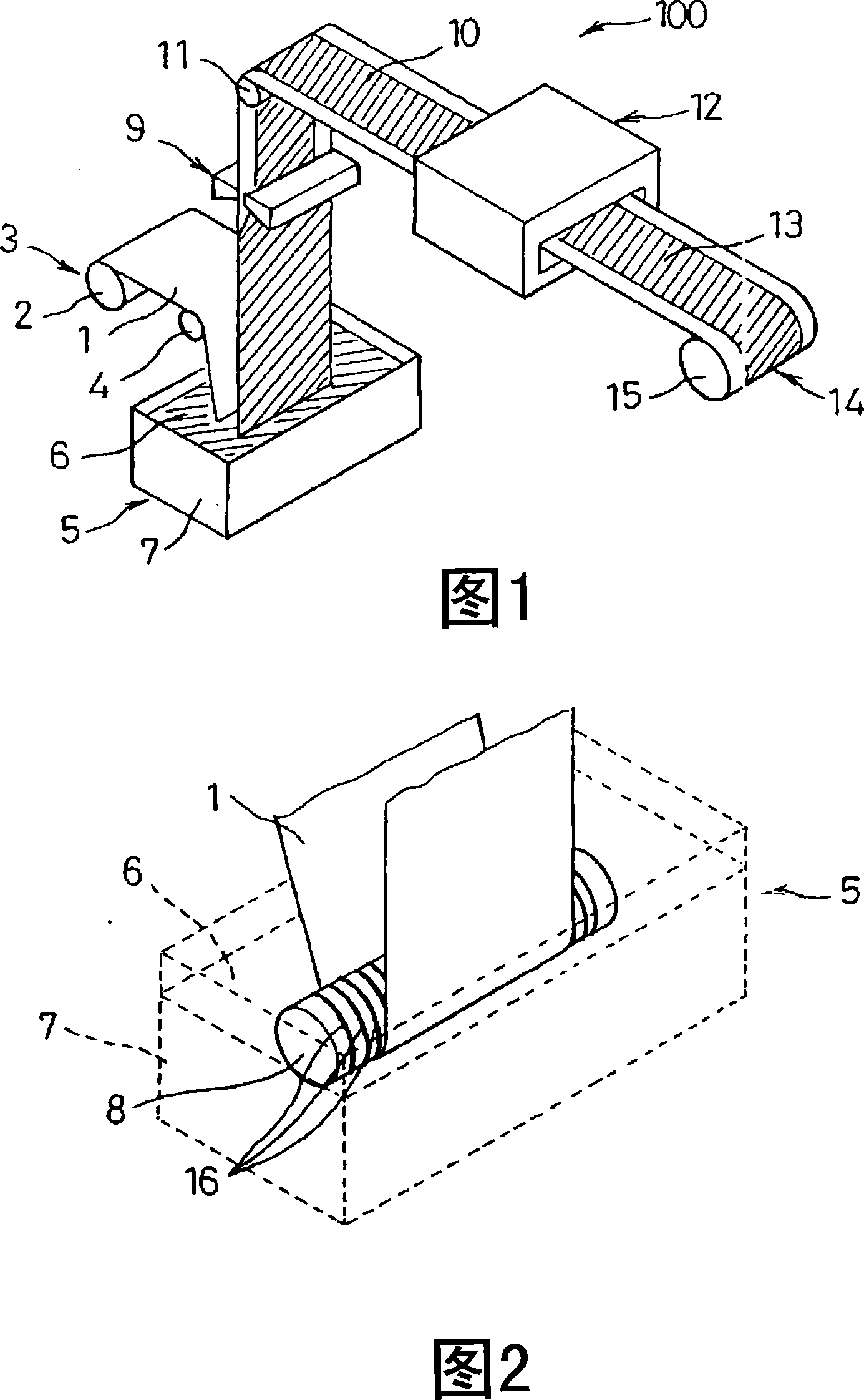

[0029] The core material 1 (the total length of the core material coil 2 is 200 m) is composed of a nickel-plated iron punching metal with a thickness of 60 μm, a width of 300 mm, a punching diameter of 1 mm, and an opening ratio of 42%. On both sides, the electrode mixture slurry 6 was ...

Embodiment 2~5

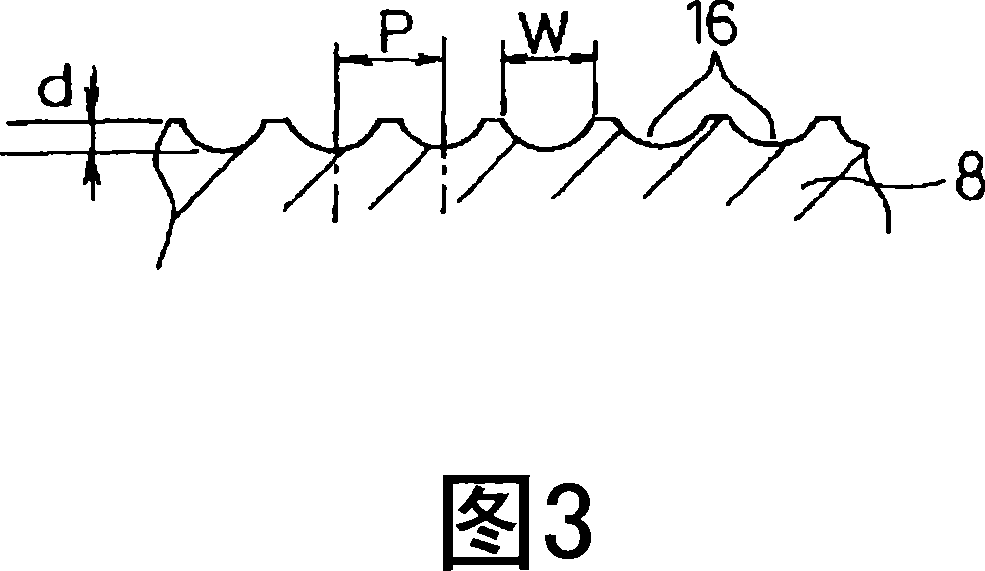

[0032] For Example 1, the pitch interval P of the grooves 16 formed on the surface of the roller 8 is set to 50mm (Example 2), 25mm (Example 3), 7mm (Example 4), and 5mm (Example 5), The electrode mixture slurry 6 was coated on the core material 1 in the same manner as in Example 1 except that the groove width w was set to the groove pitch interval P×0.8.

[0033] On the core material 1, the electrode mixture slurry 6 is coated in a range of 200m, and then at the rearmost part of the electrode slurry coating sheet 10 (the position where the coating is completed), measure the distance from one end of the core material 1 to the electrode mixture. The size of the application part of the slurry 6. As a result, with respect to the initial setting value of 20 mm, the offset amounts were 1.6 mm (Example 2), 0.7 mm (Example 3), 0.3 mm (Example 4), and 1.0 mm (Example 5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com