Combined dresser and its manufacturing method and chemical mechanical polishing method

A manufacturing method and trimmer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as height differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

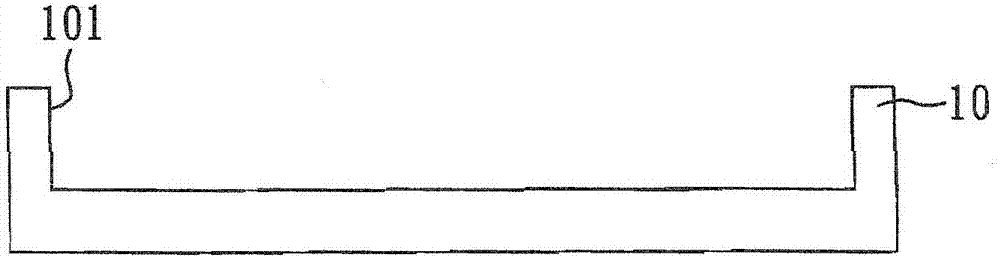

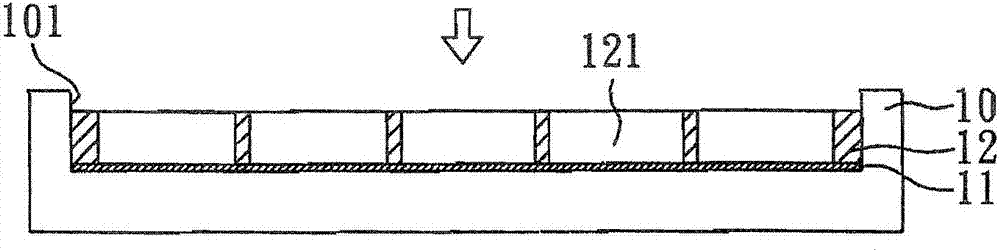

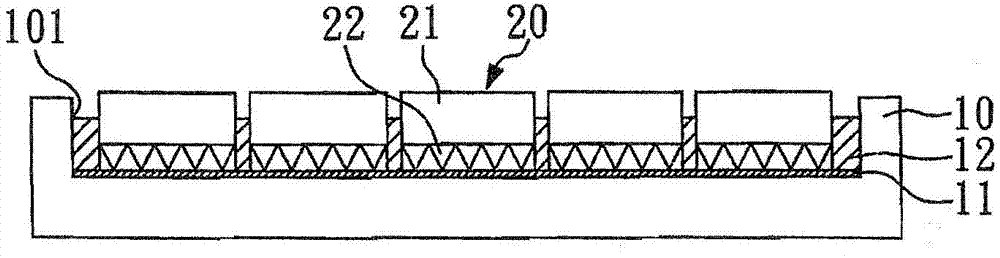

[0063] refer to Figure 1A to Figure 1G , a schematic flow chart of its manufacturing combined trimmer.

[0064] First, if Figure 1A As shown, a first mold 10 is provided, and the first mold 10 has an opening 101 . Next, if Figure 1B As shown, a temporary adhesive layer 11 is formed on the surface of the opening 101 of the first mold 10, and then a second mold 12 is placed on the surface of the temporary adhesive layer 11, so that the second mold 12 is placed on the opening of the first mold 10 101 , so the temporary adhesive layer 11 is sandwiched between the second mold 12 and the first mold 10 , wherein the second mold 12 has a plurality of holes 121 . In this preparation example, the temporary adhesive layer 11 is a double-sided adhesive tape.

[0065] like Figure 1C and Figure 1G As shown, a grinding unit 20 is set in each hole 121 of the second mold 12, wherein each grinding unit 20 includes a plurality of grinding particles 22 (each grinding particle 22 has at...

preparation example 2

[0073] refer to Figure 2A to Figure 2G , which is a schematic flow chart of manufacturing a combined trimmer.

[0074] First, if Figure 2A As shown, a second mold 12 is provided, the second mold 12 has 12 holes 121 , and the holes are arranged on the outer ring of the second mold 12 . Next, if Figure 2B As shown, the second mold 12 is placed on the surface of a first mold 10 .

[0075] like Figure 2C As shown, in each hole 121 of the second mold 12 , a grinding unit 20 is provided, wherein the working surface of the grinding unit 20 (the surface with the sharp point of grinding) faces the surface of the first mold 10 . In this preparation example, the grinding unit 20 is similar to that described in preparation example 1. Then, if Figure 2D As shown, glue is dispensed on the opposite side of the sharp point of each grinding unit 20 to form an adhesive layer 23 with adjustable thickness. Next, if Figure 2E As shown, a bottom substrate 24 is flatly pressed on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com