Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Draw reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

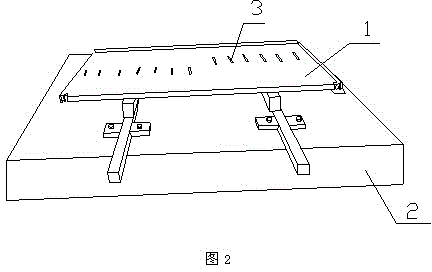

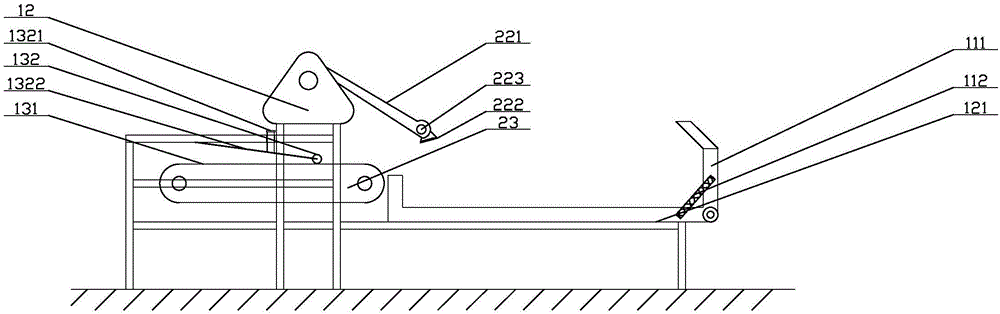

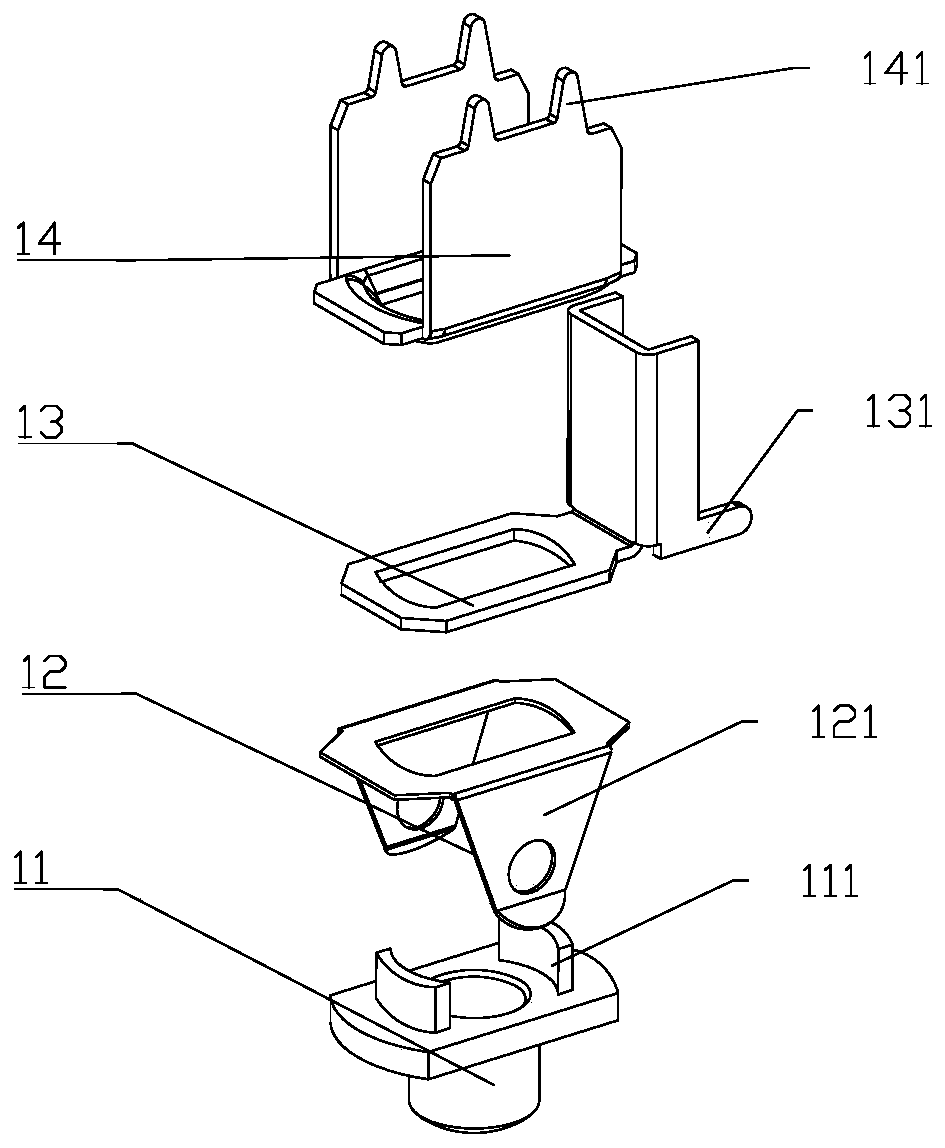

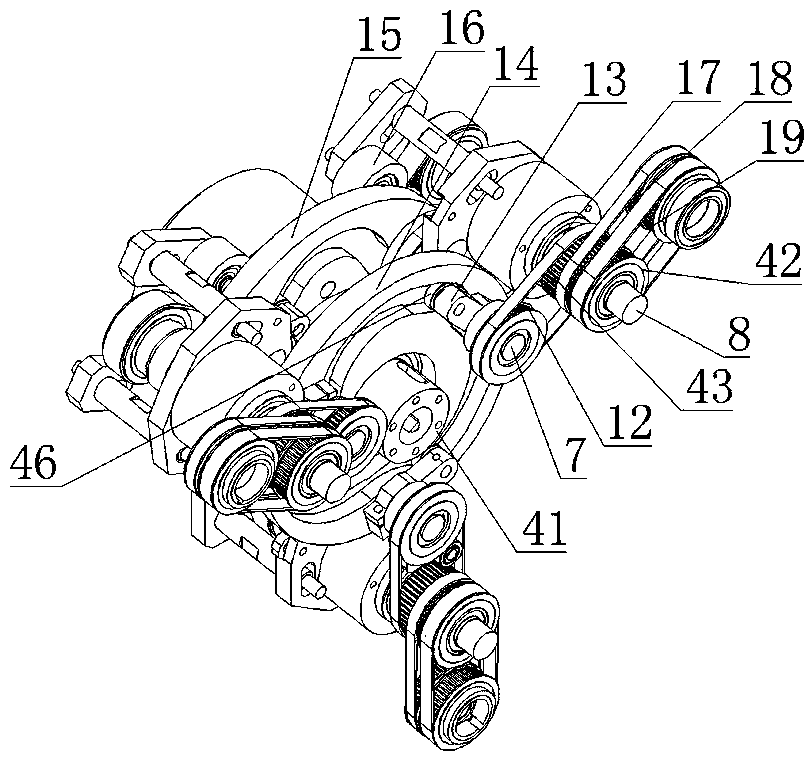

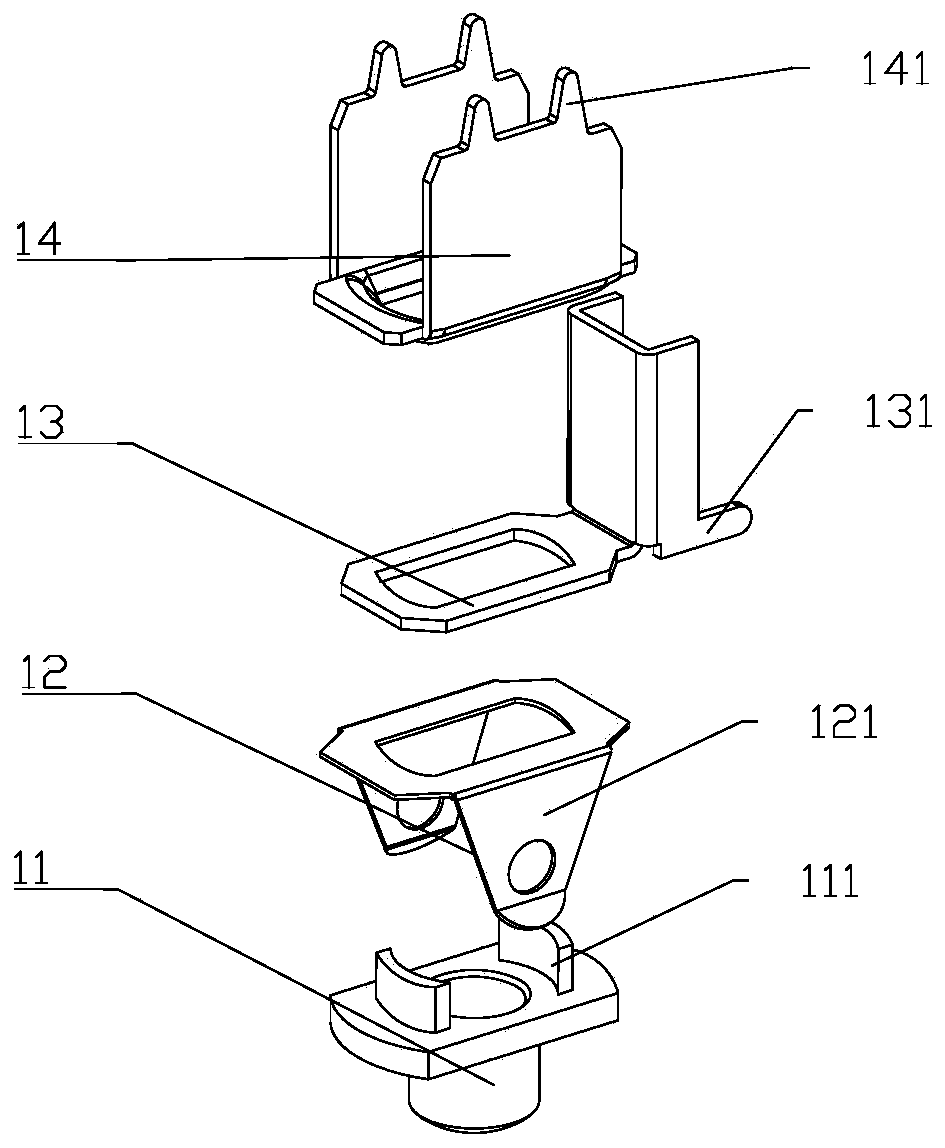

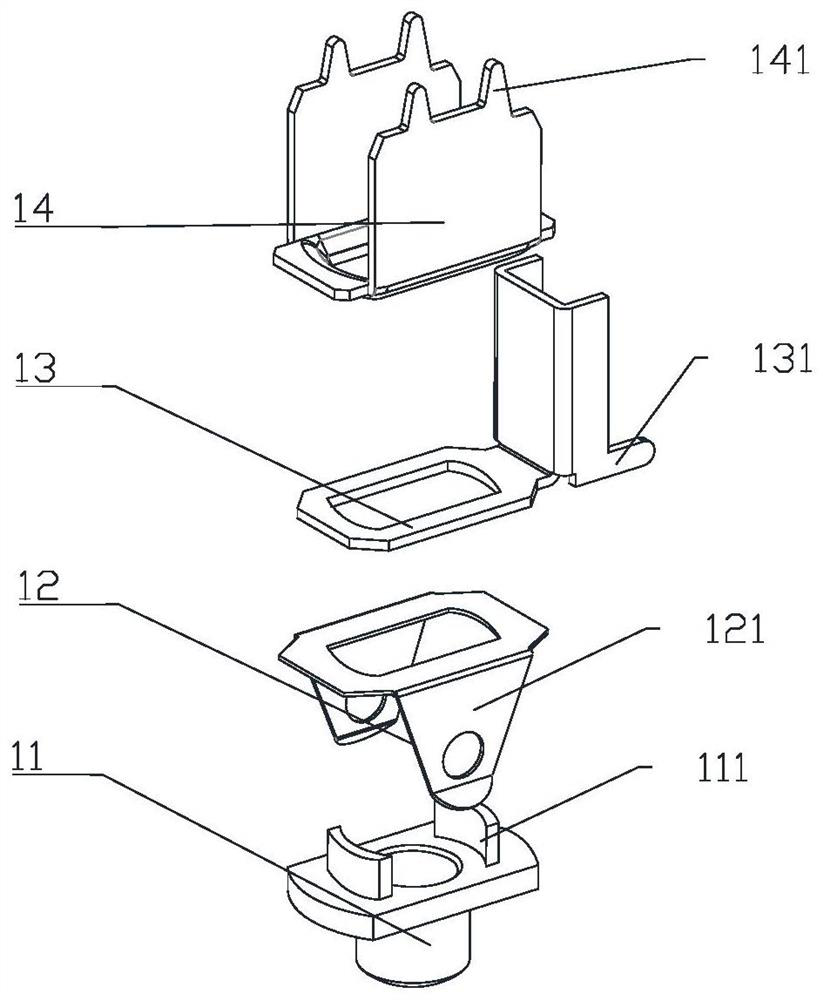

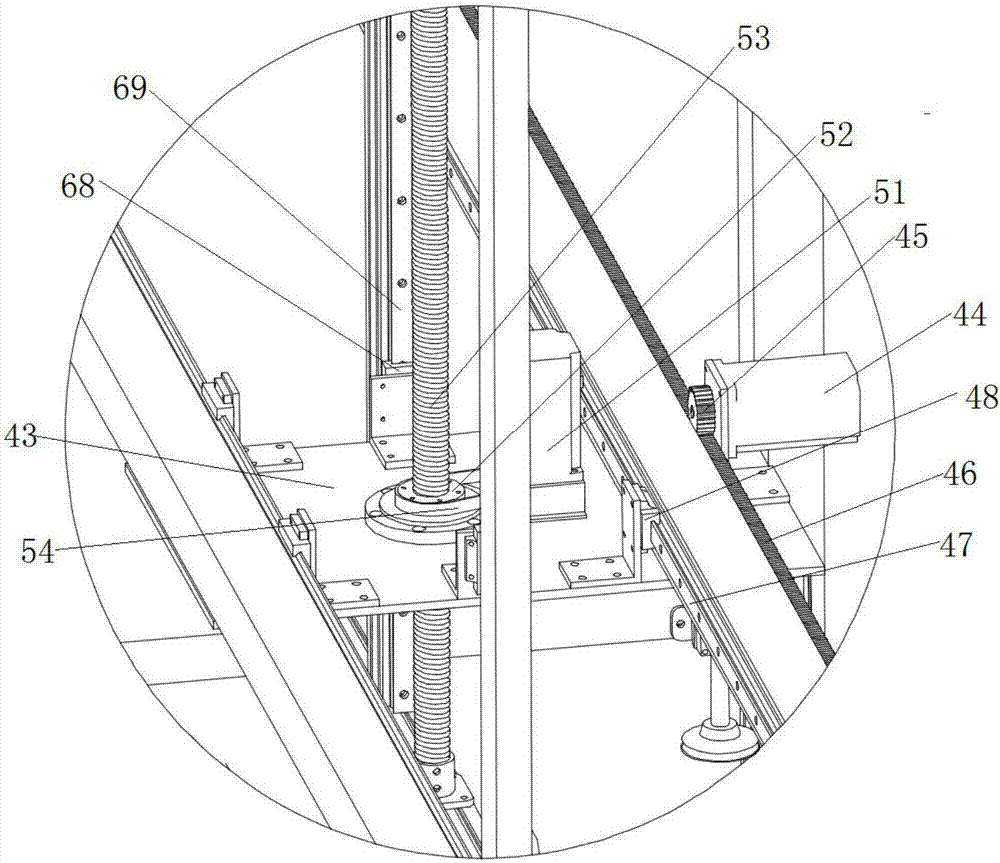

Heterogeneous bonding and forming device

ActiveCN103466542AAvoid deformationDraw reliablePrecision positioning equipmentSoldering apparatusBonding processEngineering

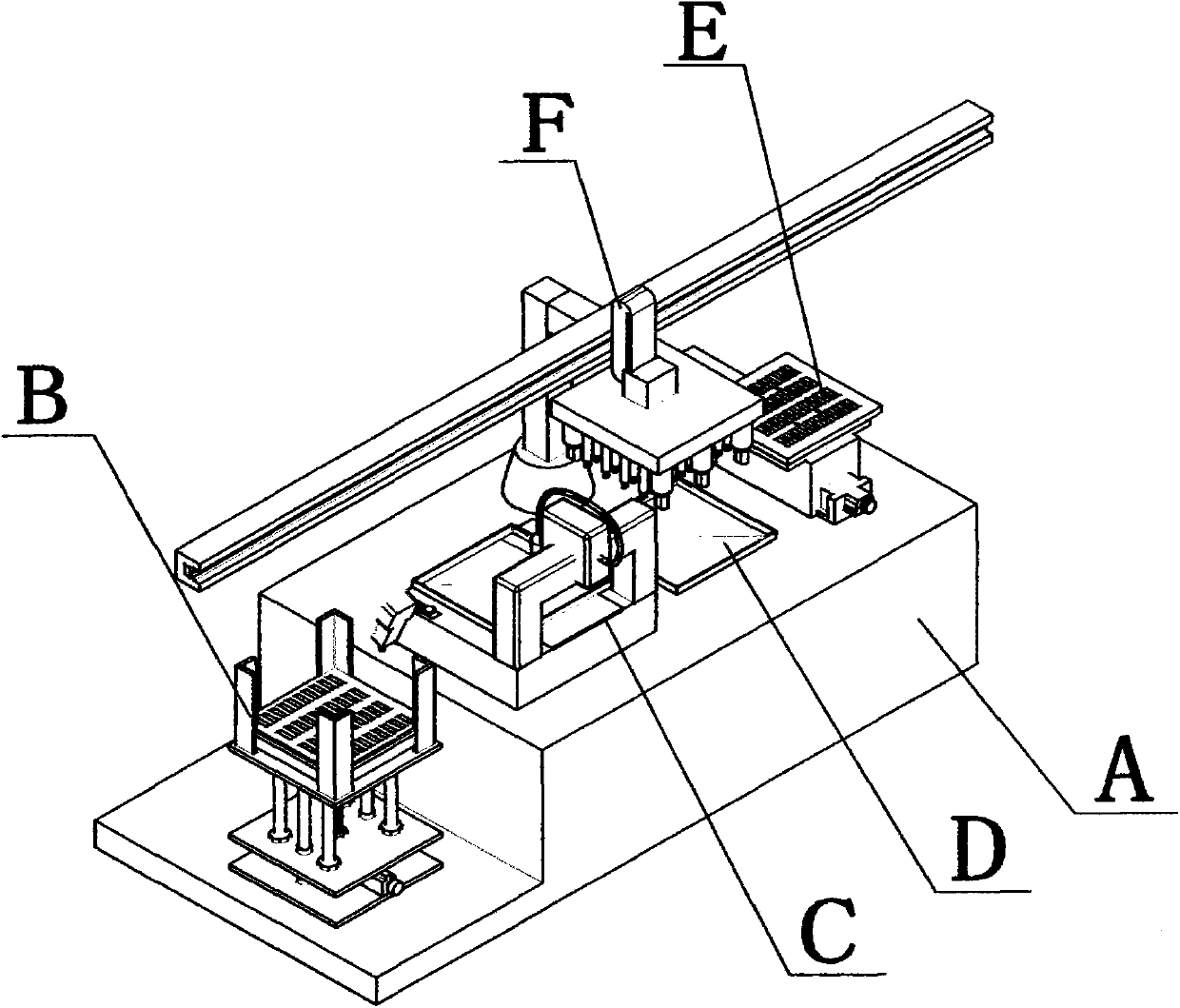

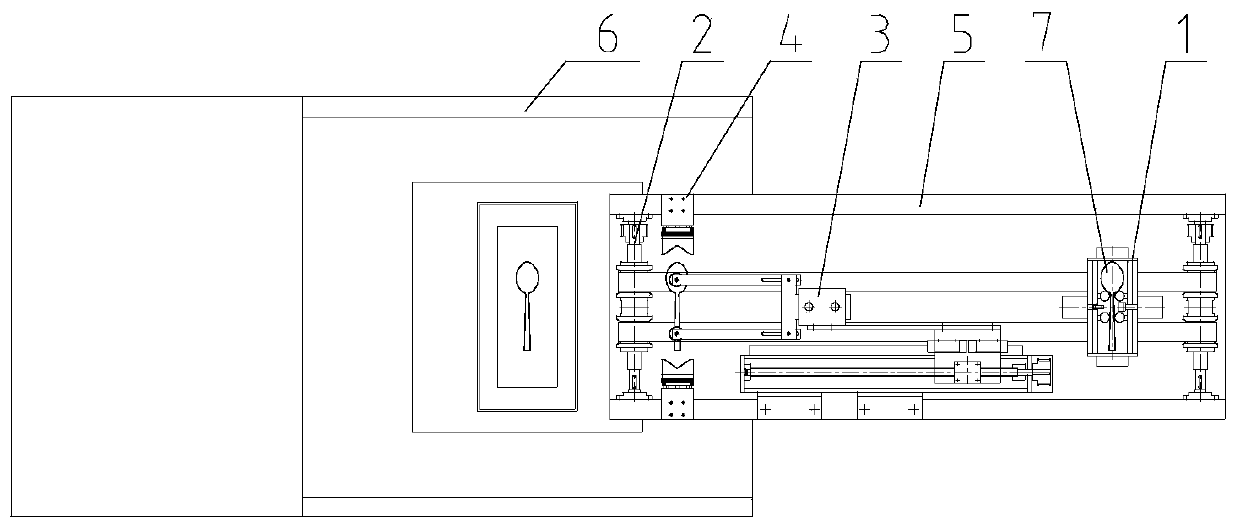

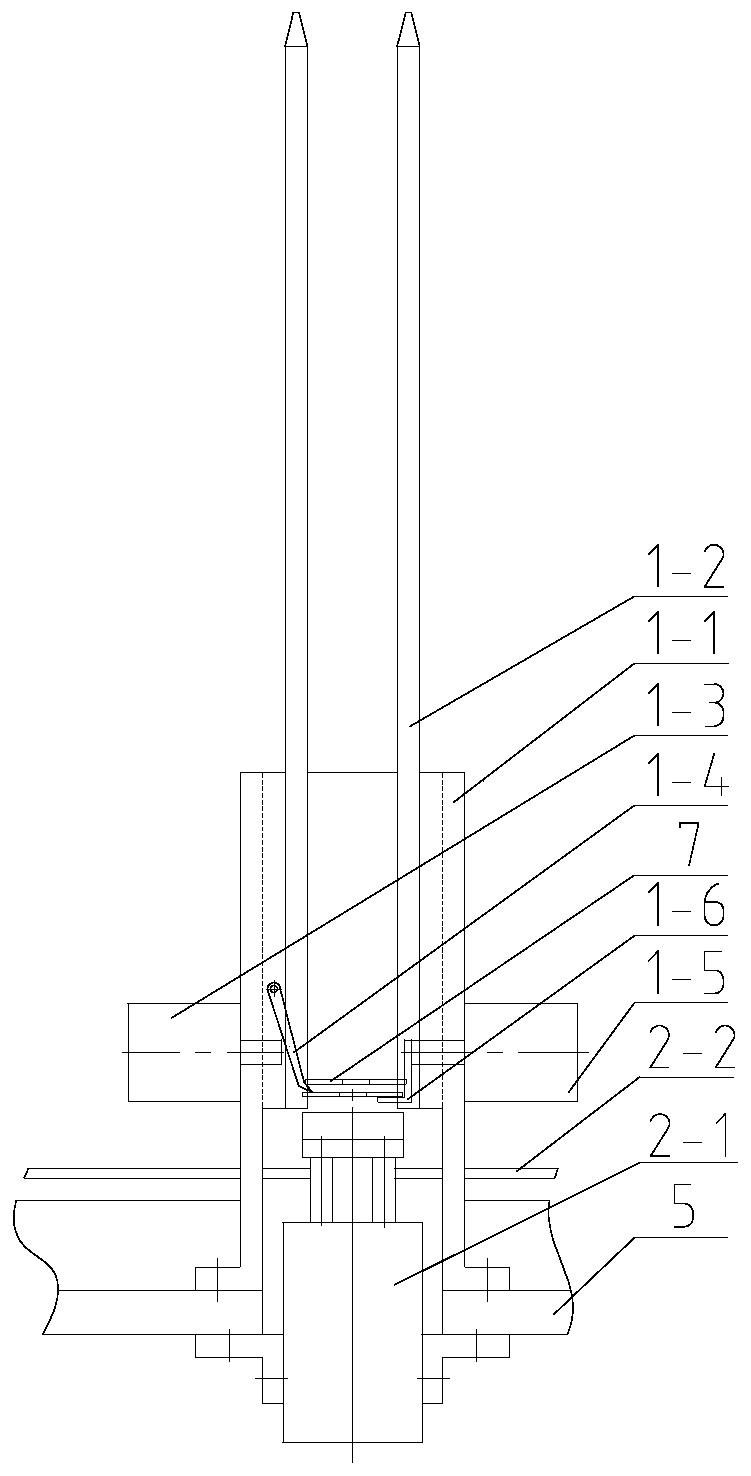

The invention discloses a heterogeneous bonding and forming device. The heterogeneous bonding and forming device comprises a worktable, wherein a lifting mechanism for lifting materials is fixedly arranged on the worktable, and a plate loading mechanism, a dispensing mechanism, a sheet loading mechanism and a bonding mechanism are arranged below the lifting mechanism; the plate loading mechanism comprises a material plate which is driven to move up and down by a motor and is used for placing a material M; the dispensing mechanism comprises a limiting trough longitudinally moving along the worktable to limit the material M, and a dispensing needle head transversely and vertically moving along the worktable is arranged above the limiting trough; the bonding mechanism comprises a positioning disc, a lead-in trough closed towards the bottom is arranged on at least one side of the positioning disc, and an inclined angle of the lead-in trough is 55-65 degrees; the sheet loading mechanism comprises a second material plate for placing a material N, and a push plate capable of moving up and down is arranged below the second material plate; the lifting mechanism comprises a vacuum chuck transversely and vertically moving along the worktable. By utilizing the lifting mechanism and an auxiliary positioning device, the difficulties of high-precision positioning, repeated positioning and high-precision controllability in a heterogeneous bonding process are greatly solved.

Owner:铜陵太阳岛农业科技有限公司

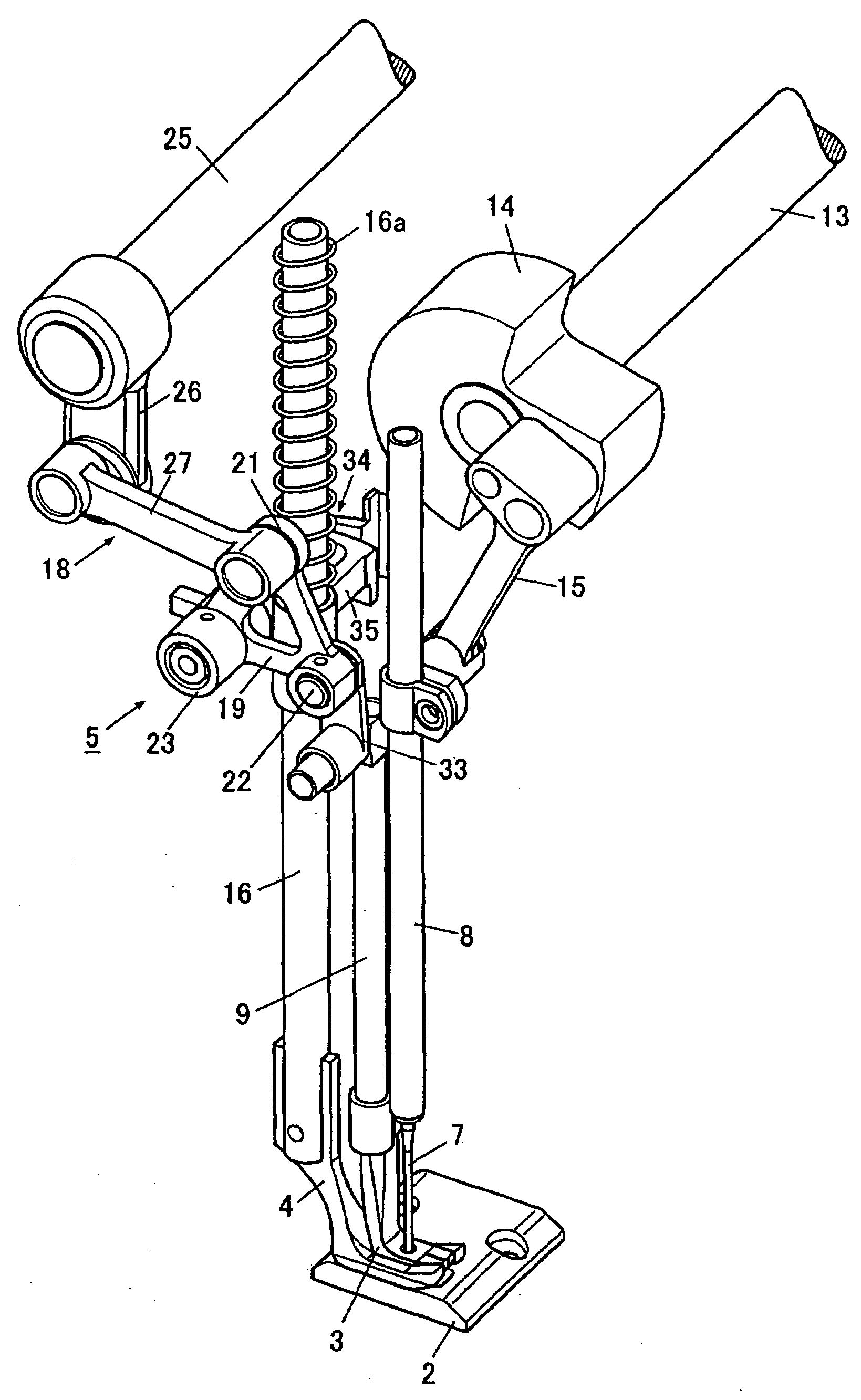

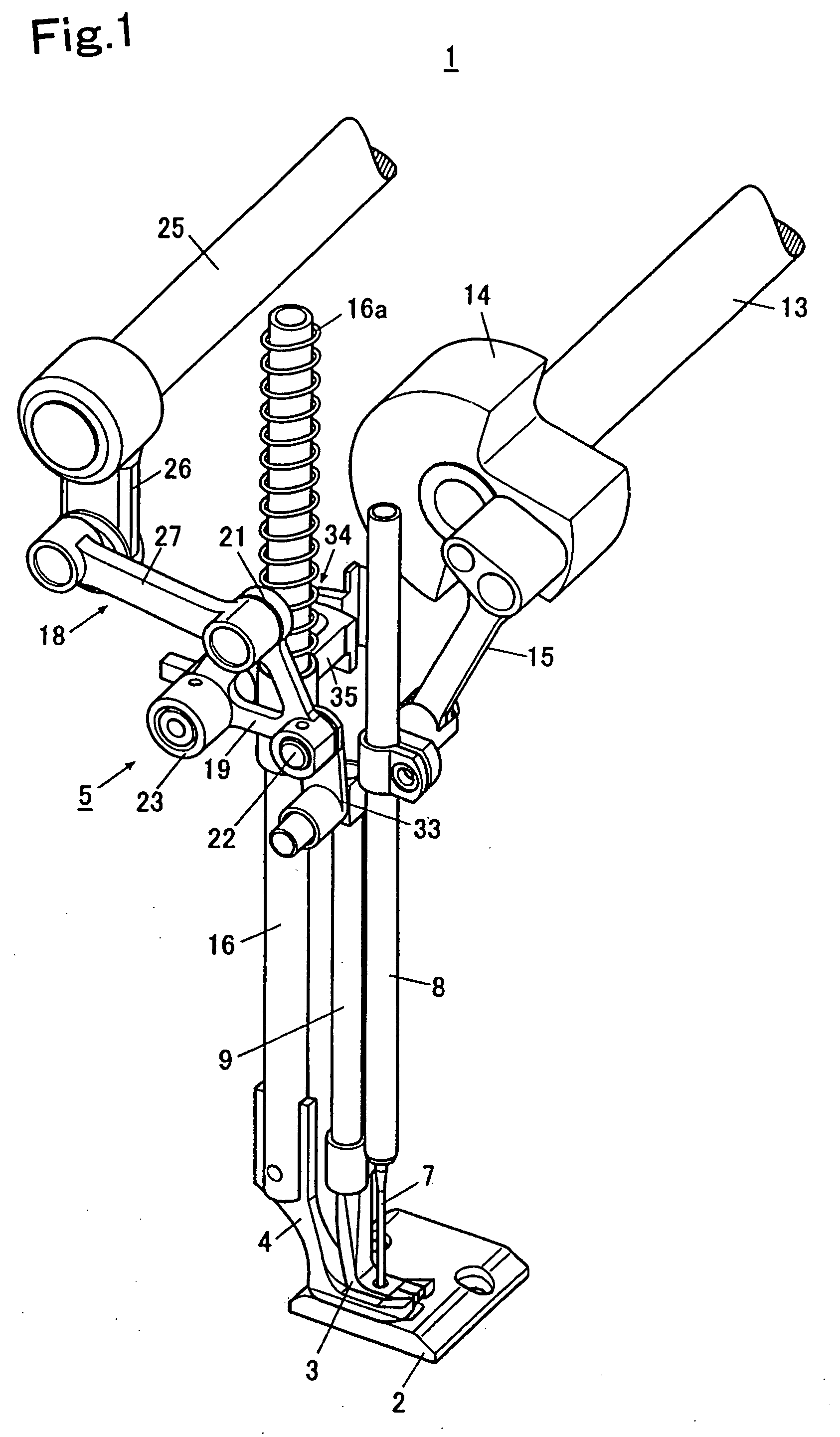

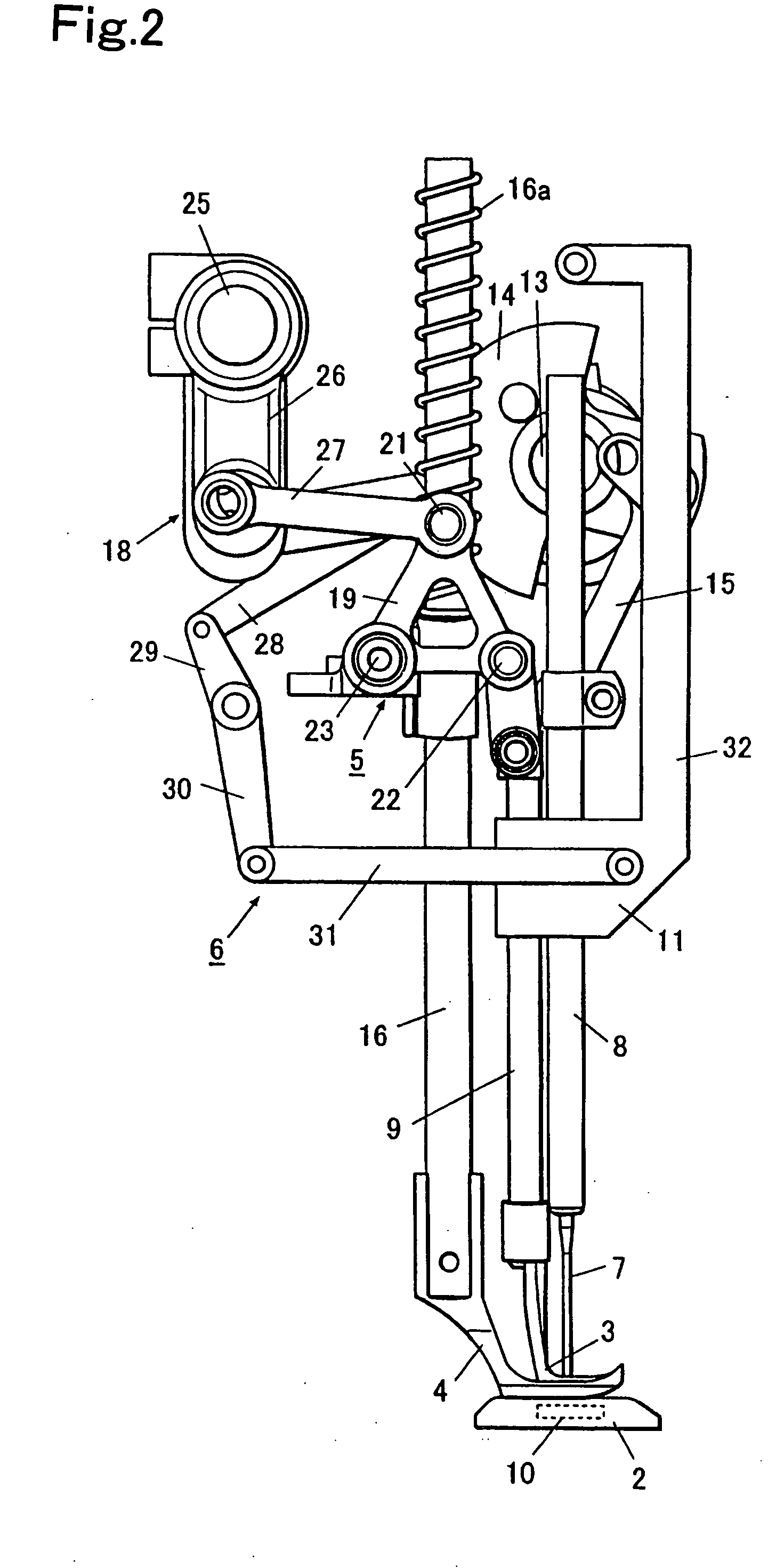

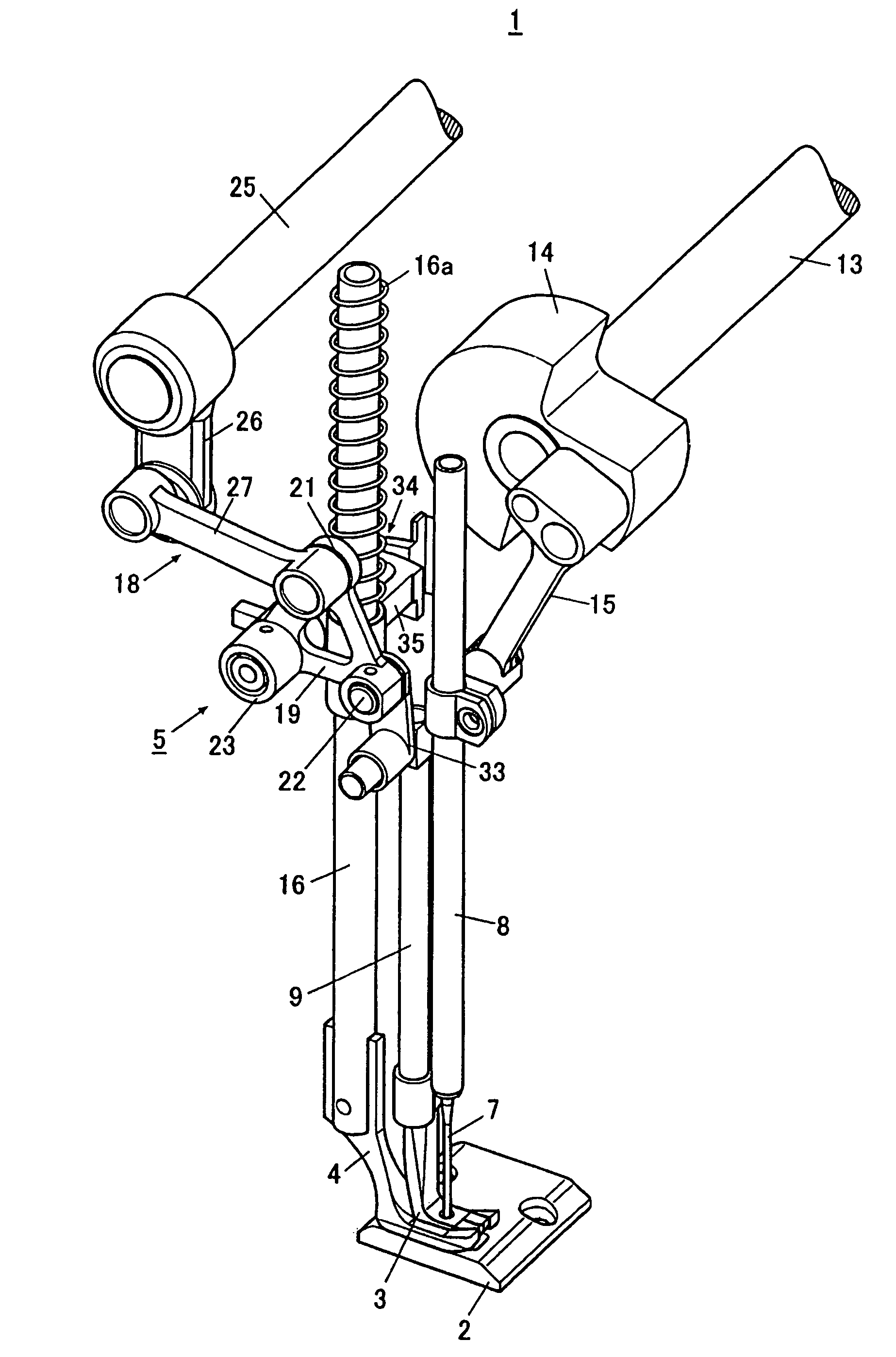

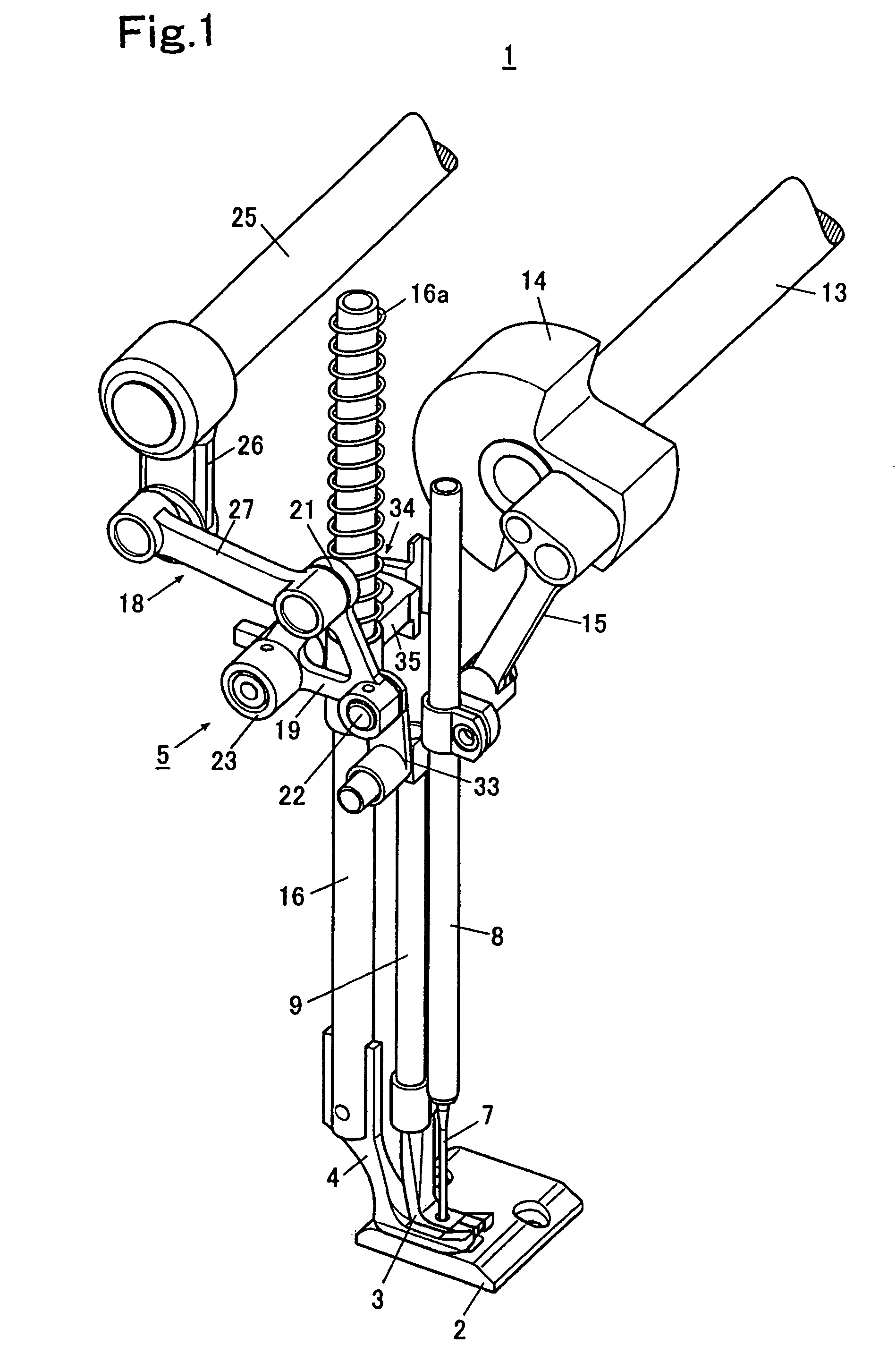

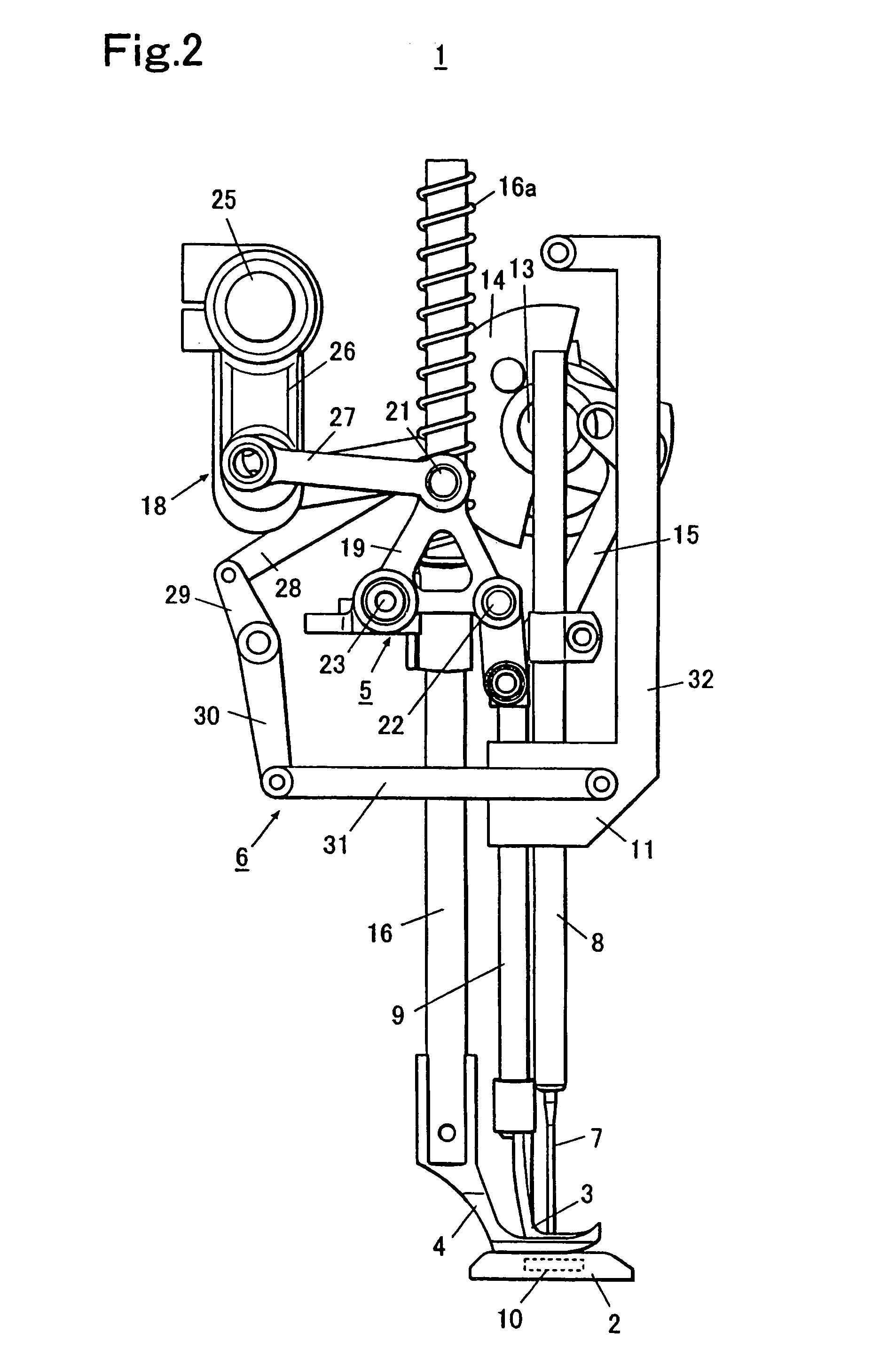

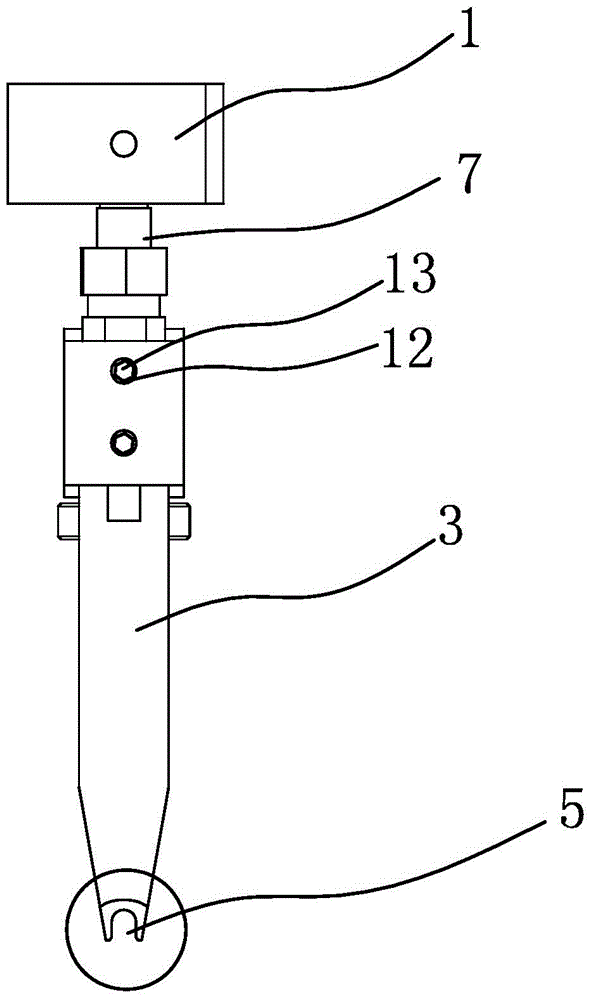

Sewing machine

A sewing machine includes a needle, a needle bar which supports the needle, an upper feeding foot operable to feed the workpiece interlockingly with an up and down movement of the needle bar, a presser foot operable to press the workpiece, a holding bar which supports the presser foot, an actuator including an operating member operable to be changed to a first state, a second state or a no-load state, and a connecting portion which couples the operating member and the holding bar. The holding bar is constantly biased downward by a biasing force. The actuator moves the presser foot up against the first biasing force when the operating member is in the first state, and moves the presser foot down when the operating member is in the second state.

Owner:JUKI CORP

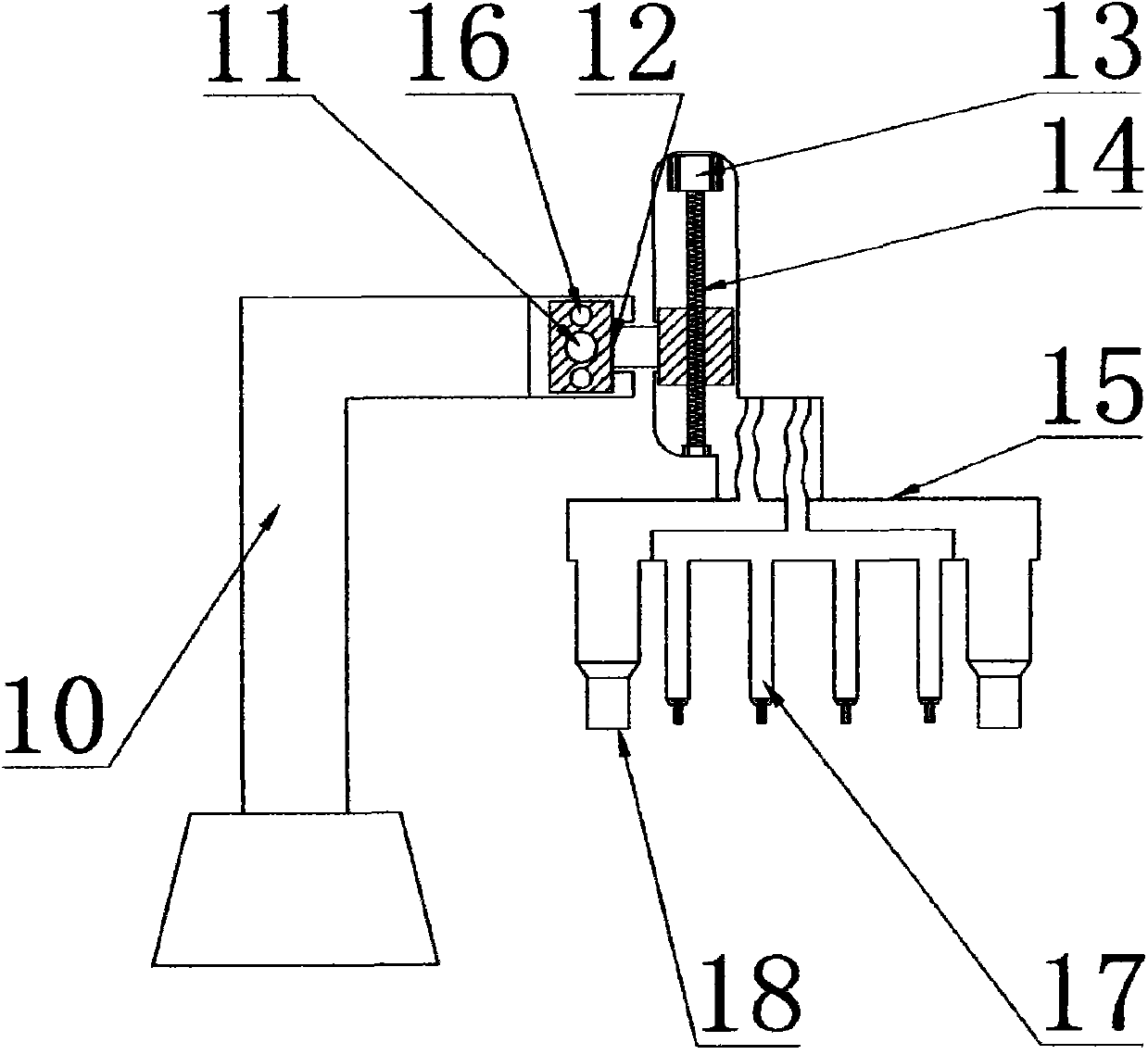

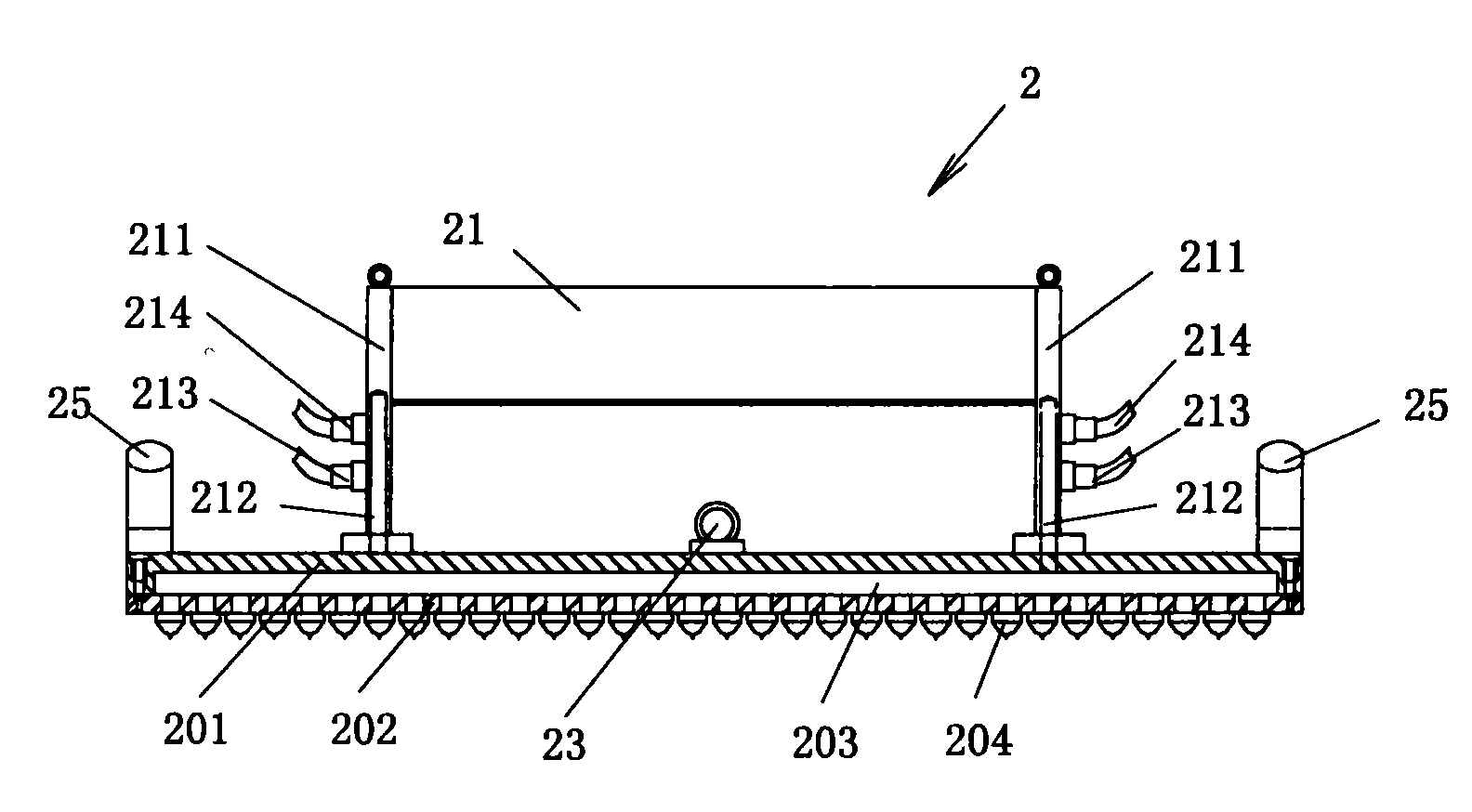

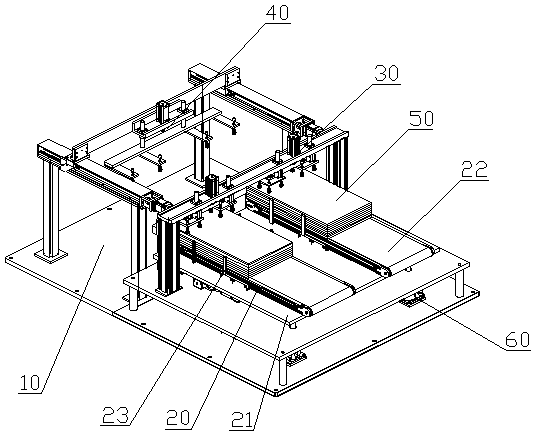

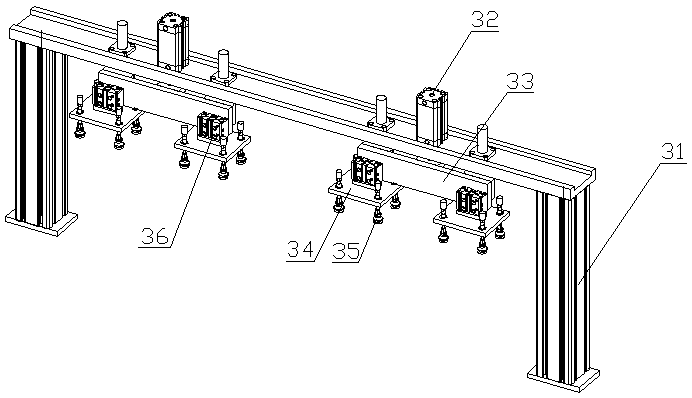

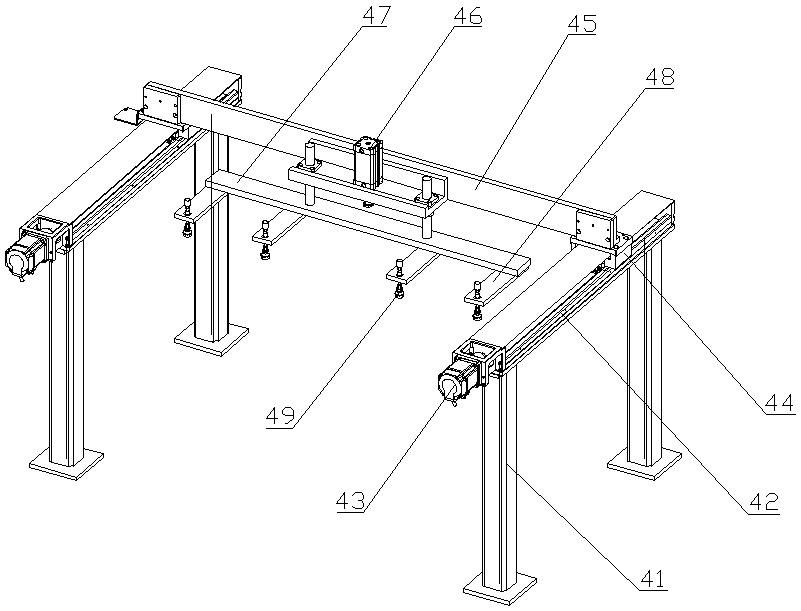

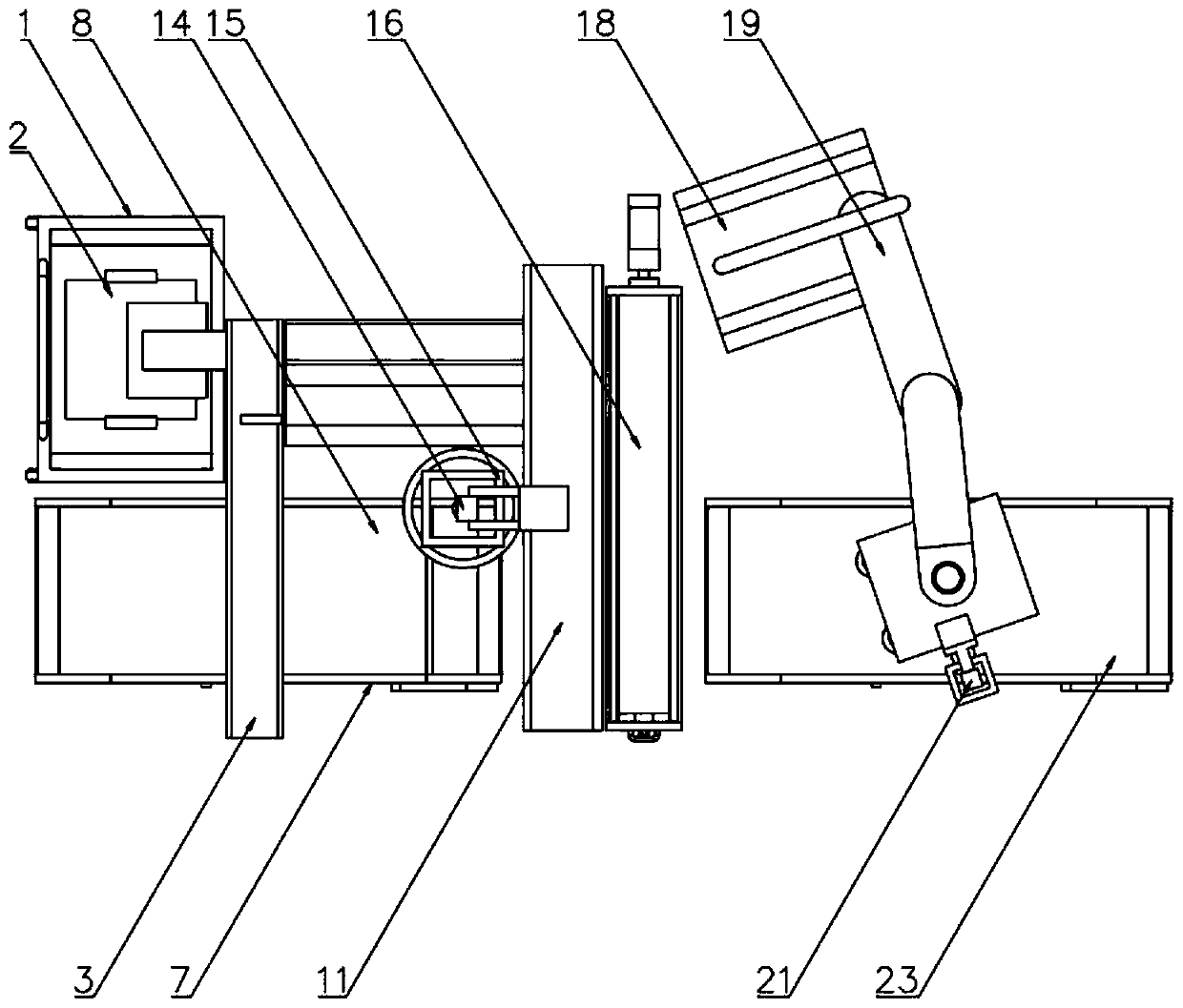

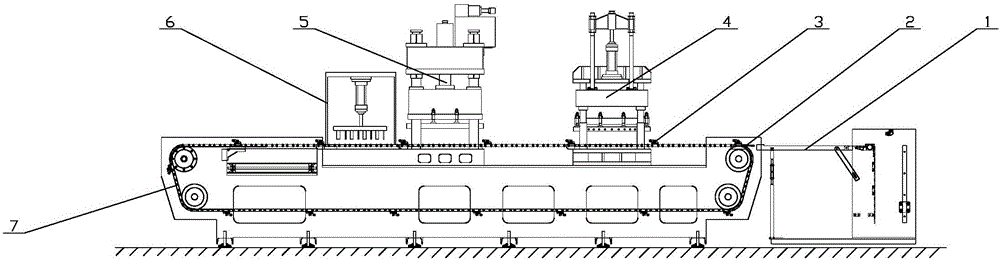

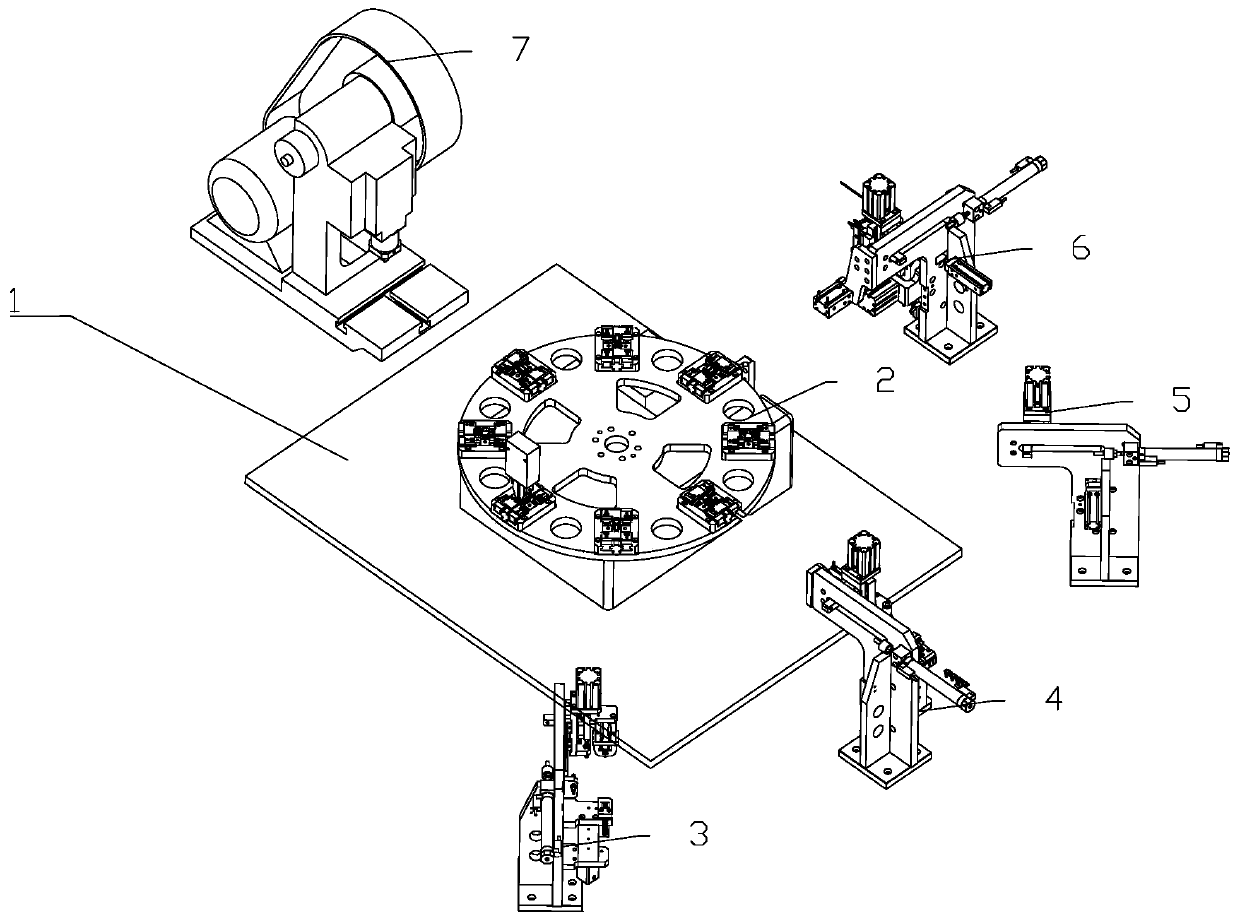

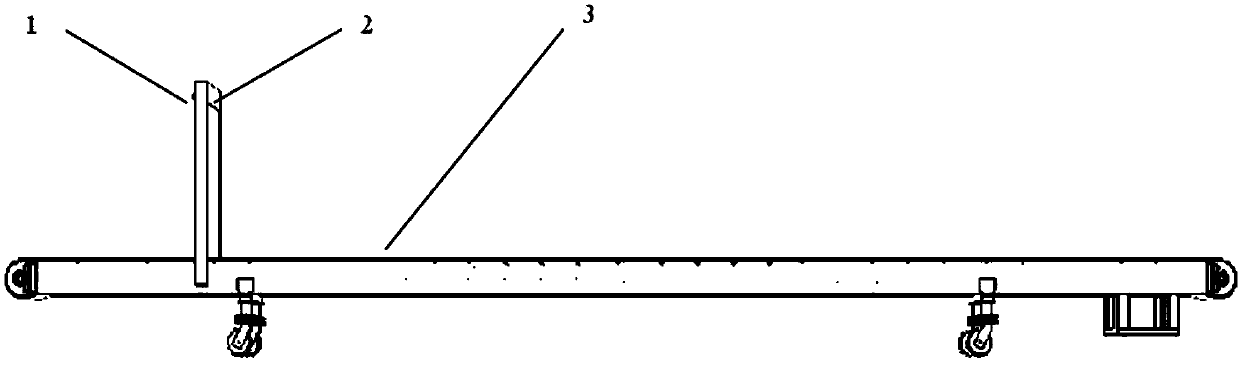

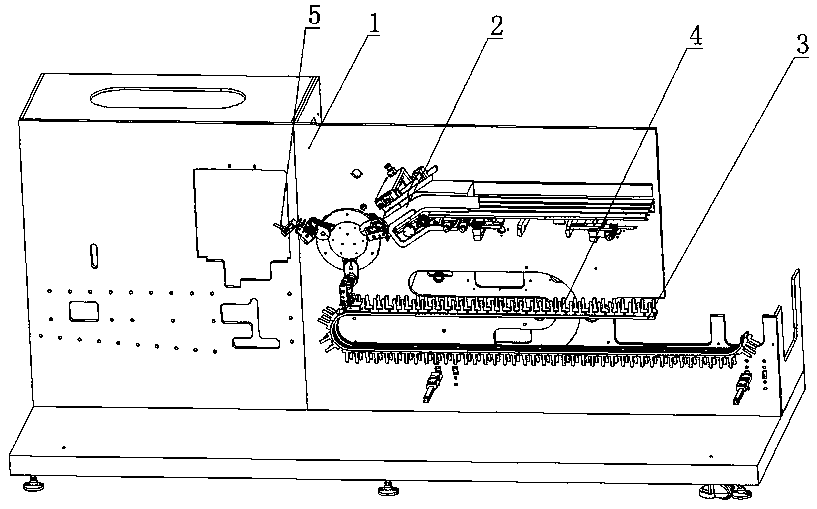

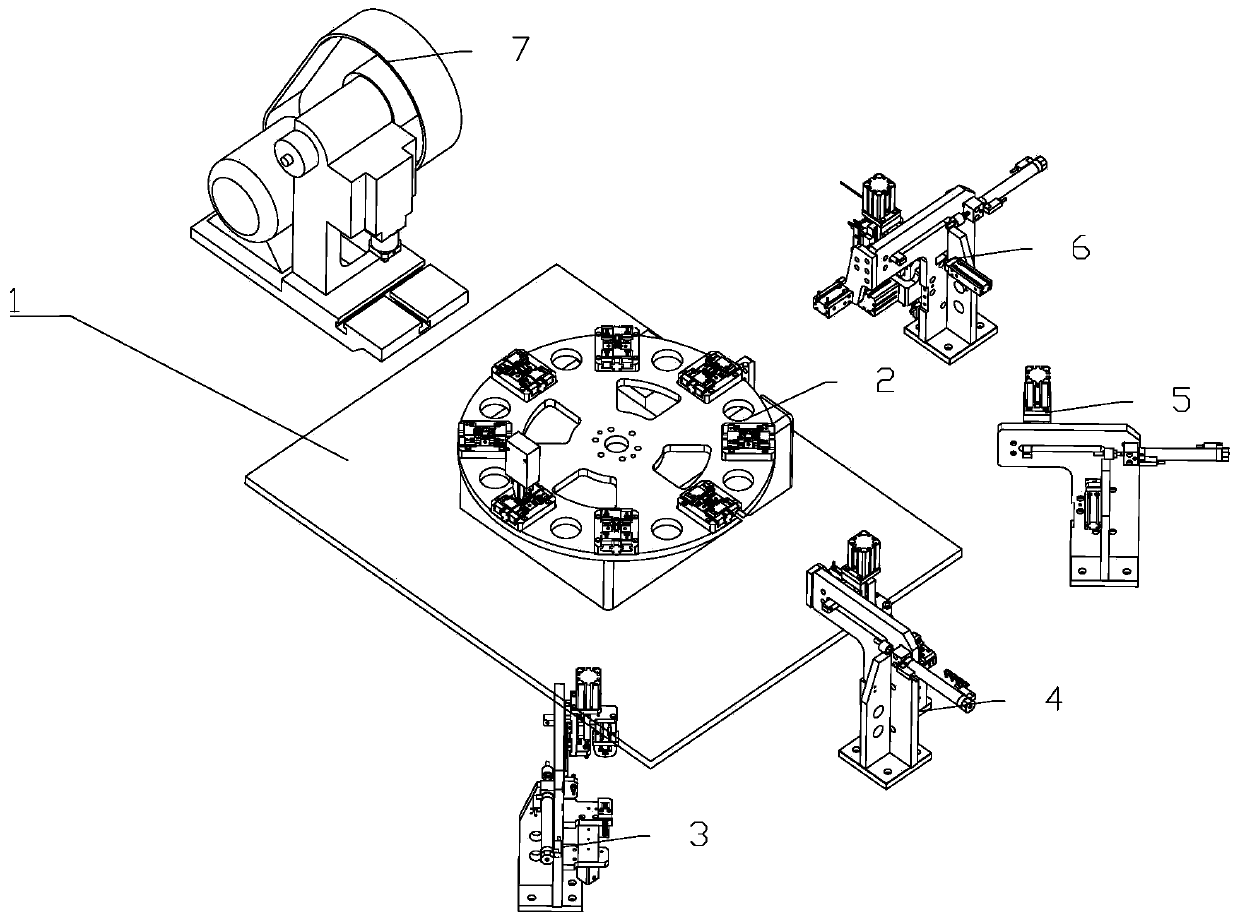

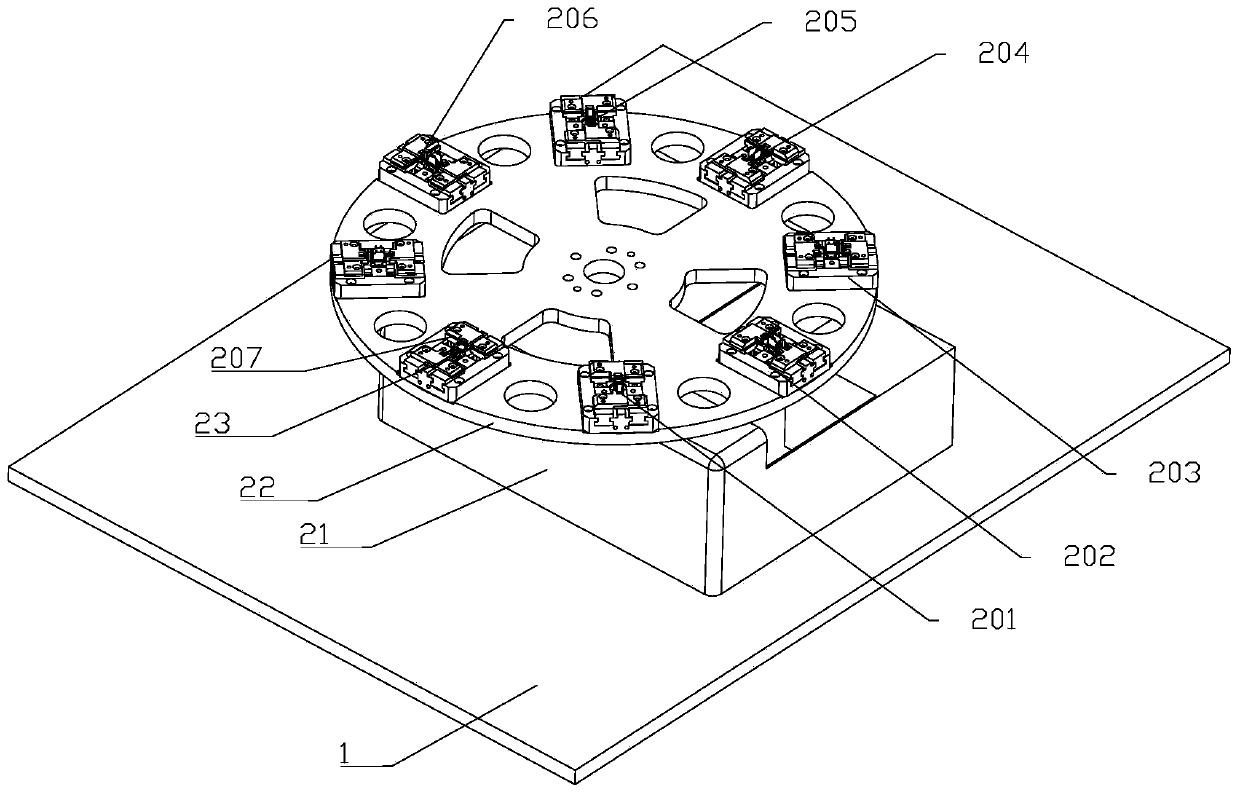

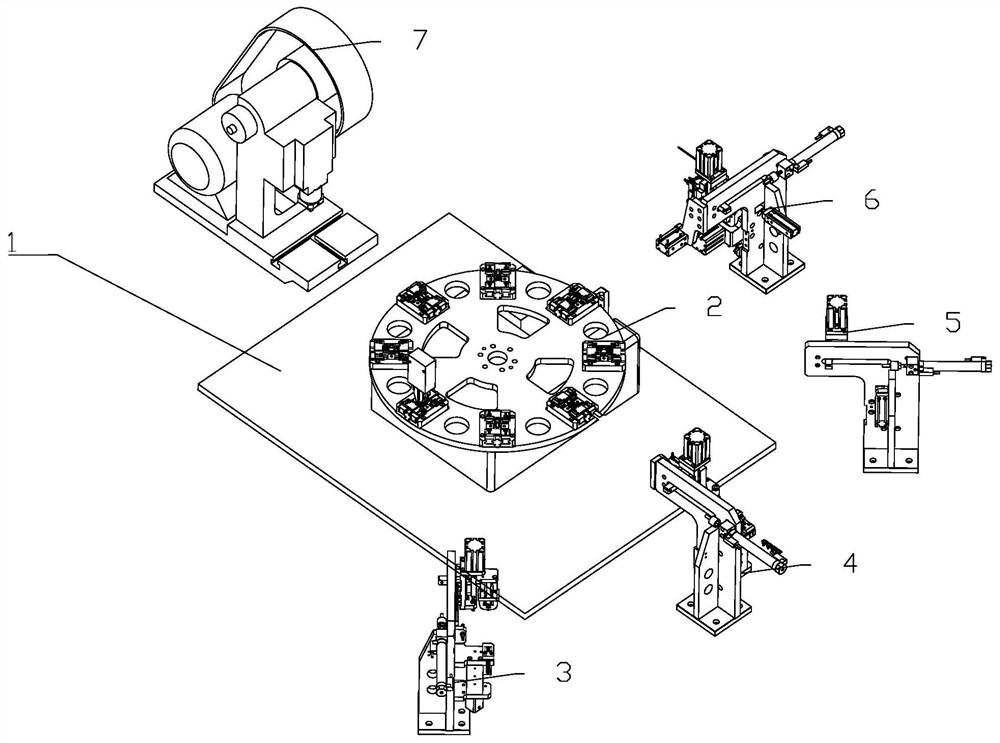

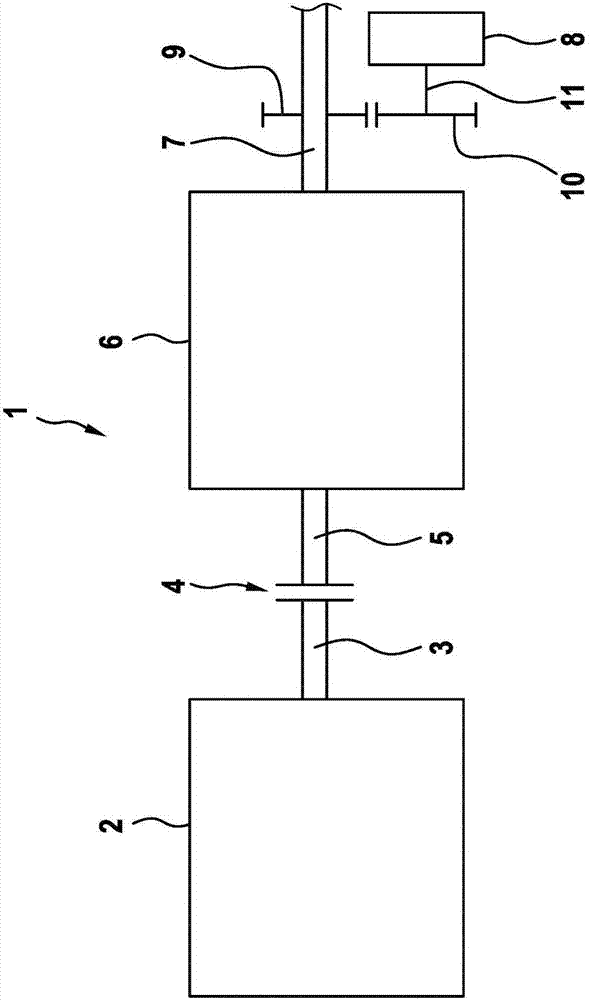

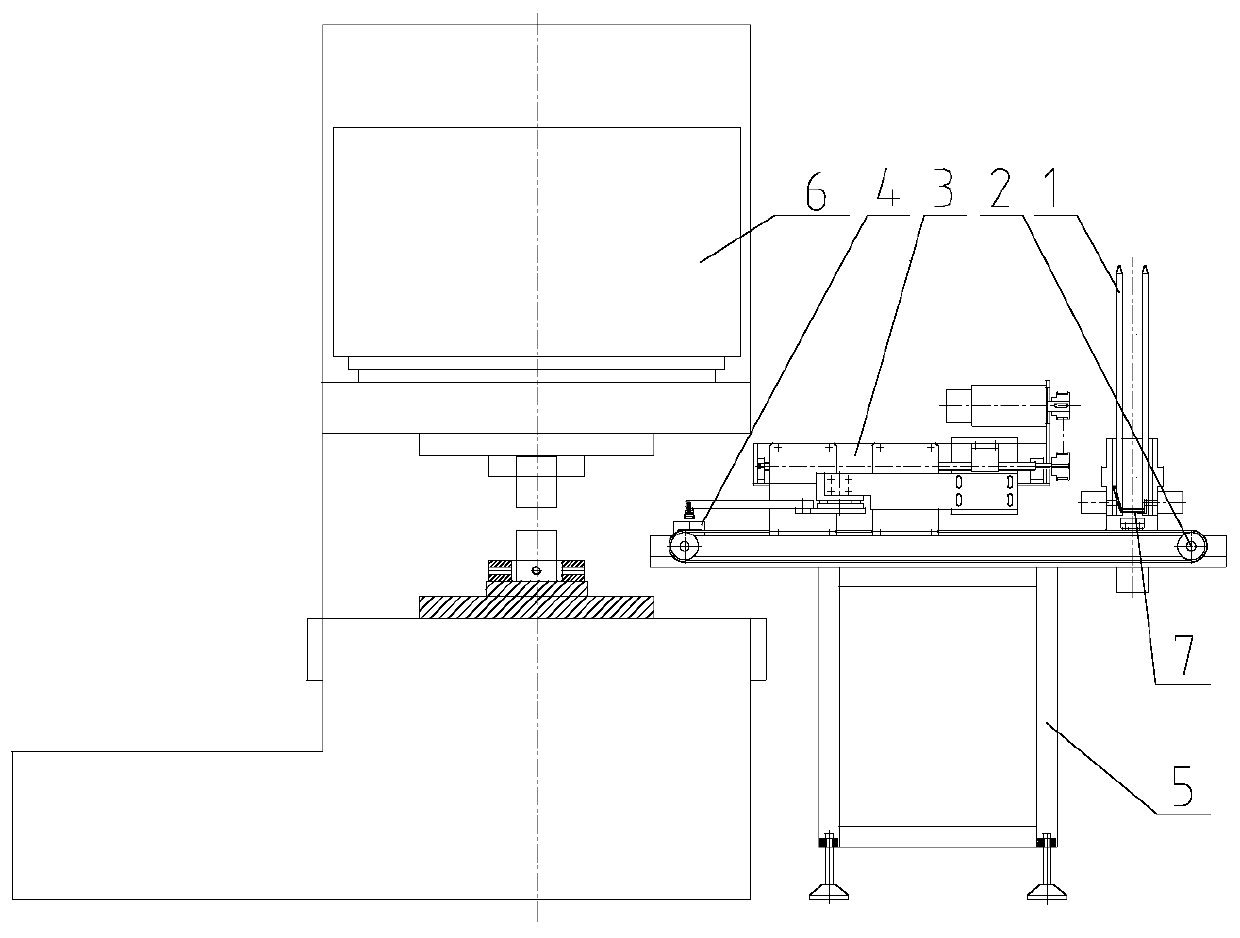

Assembling system for explosive-surface light and thin part of igniter

ActiveCN110821928ASolve the problem of manual assemblyDraw reliableLiquid surface applicatorsMaterial gluingRobot handEngineering

The invention discloses an assembling system for an explosive-surface light and thin part of an igniter, and belongs to the field of automatic assembling of igniters. The assembling system comprises afeeding and discharging module (1), a light and thin part assembling module (2), a glue solution coating module (3), a product circulation module (4), a product transferring module (5) and a module mounting base (6). According to the assembling system for the explosive-surface light and thin part of the igniter, automatic feeding and discharging are achieved through a feeding and discharging mechanical arm in the feeding and discharging module (1), and rapid and accurate assembling of the light and thin part is achieved through reliable negative-pressure suction and grab and positive-pressurepushing and placement by an anti-static suction head of the light and thin part assembling module (2); a multi-axis motion module in the glue solution coating module (3) is adopted to control the direction of a glue gun to complete glue extrusion; through joint cooperation of the modules, the explosive-surface light and thin part of the igniter is automatically assembled and the inner wall of a shell is automatically coated with a glue solution and checked; and the problems in manual assembling of the light and thin part of an existing igniter and manual coating of the glue solution on the inner wall of the shell are solved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

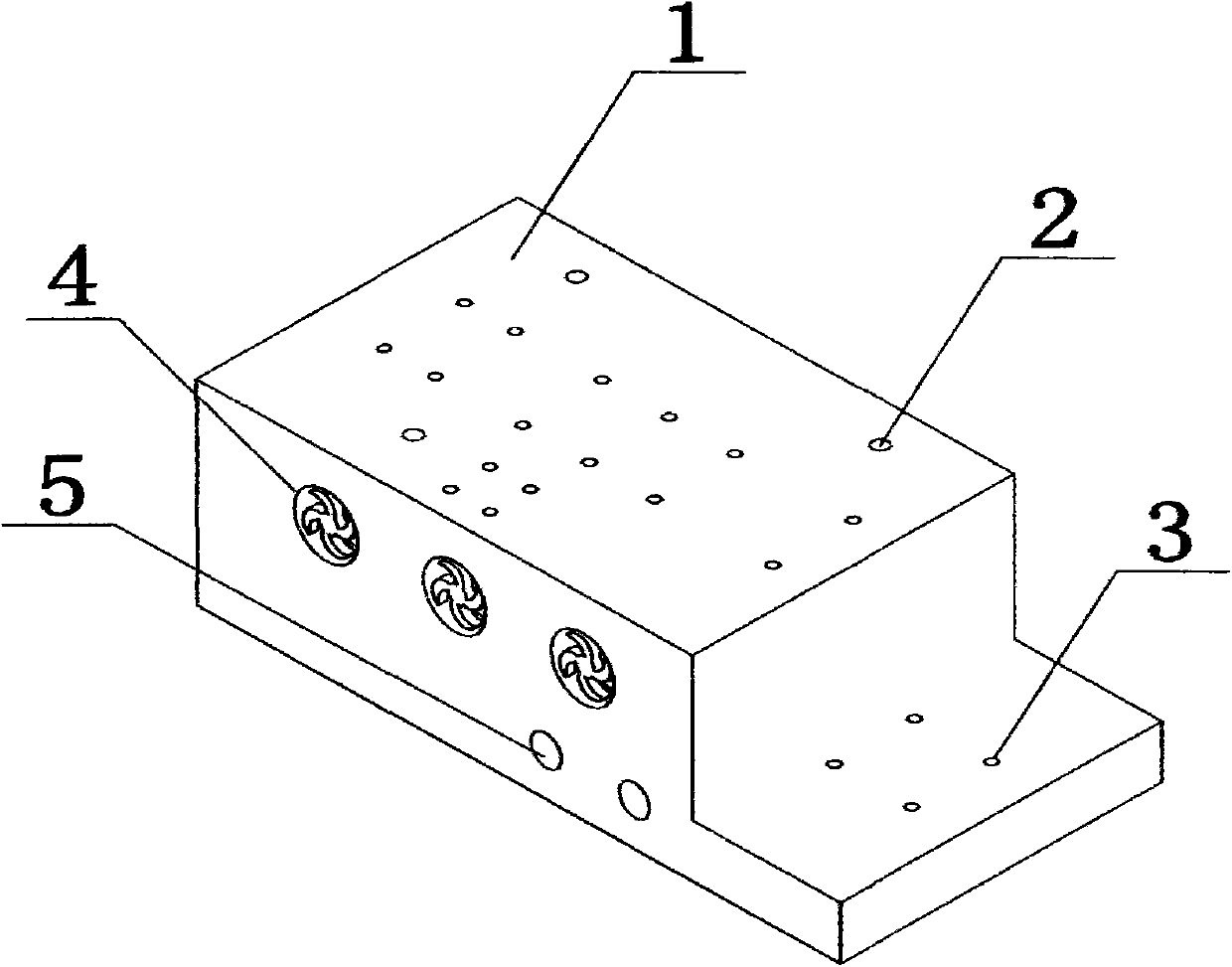

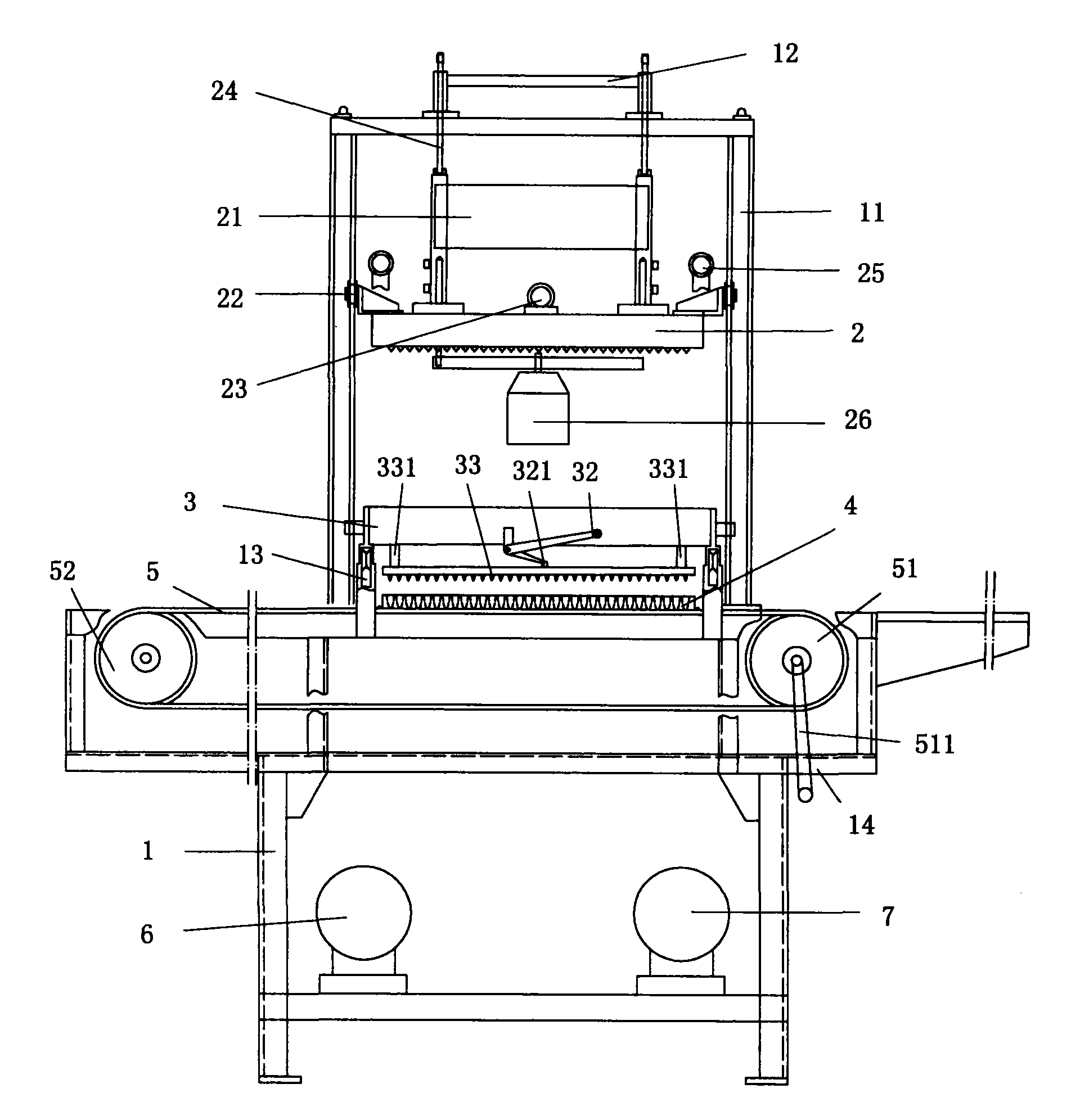

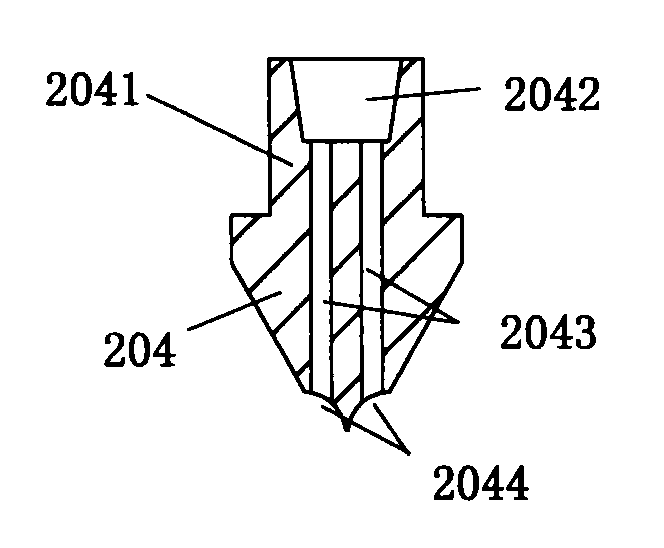

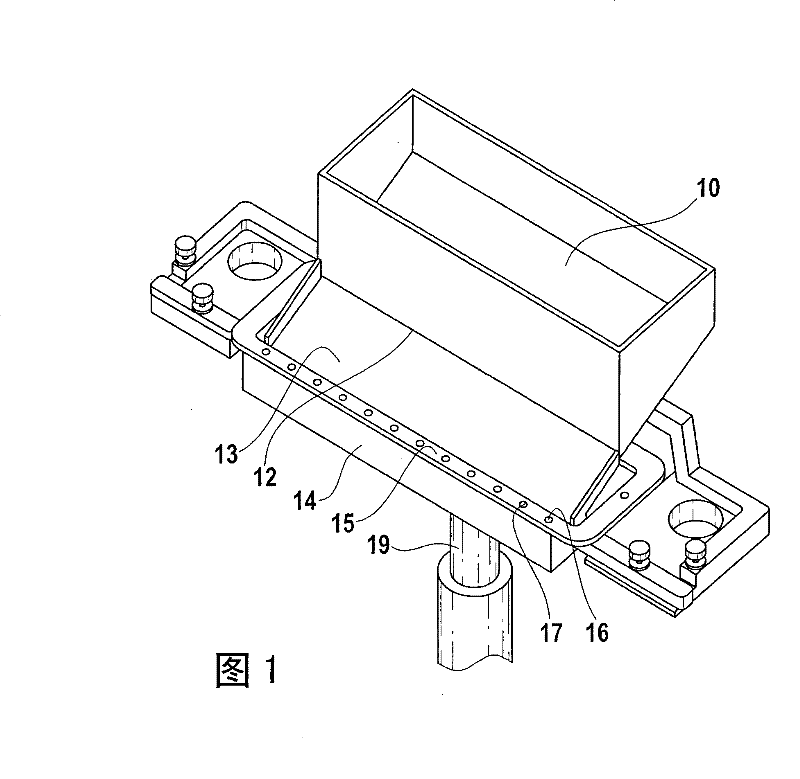

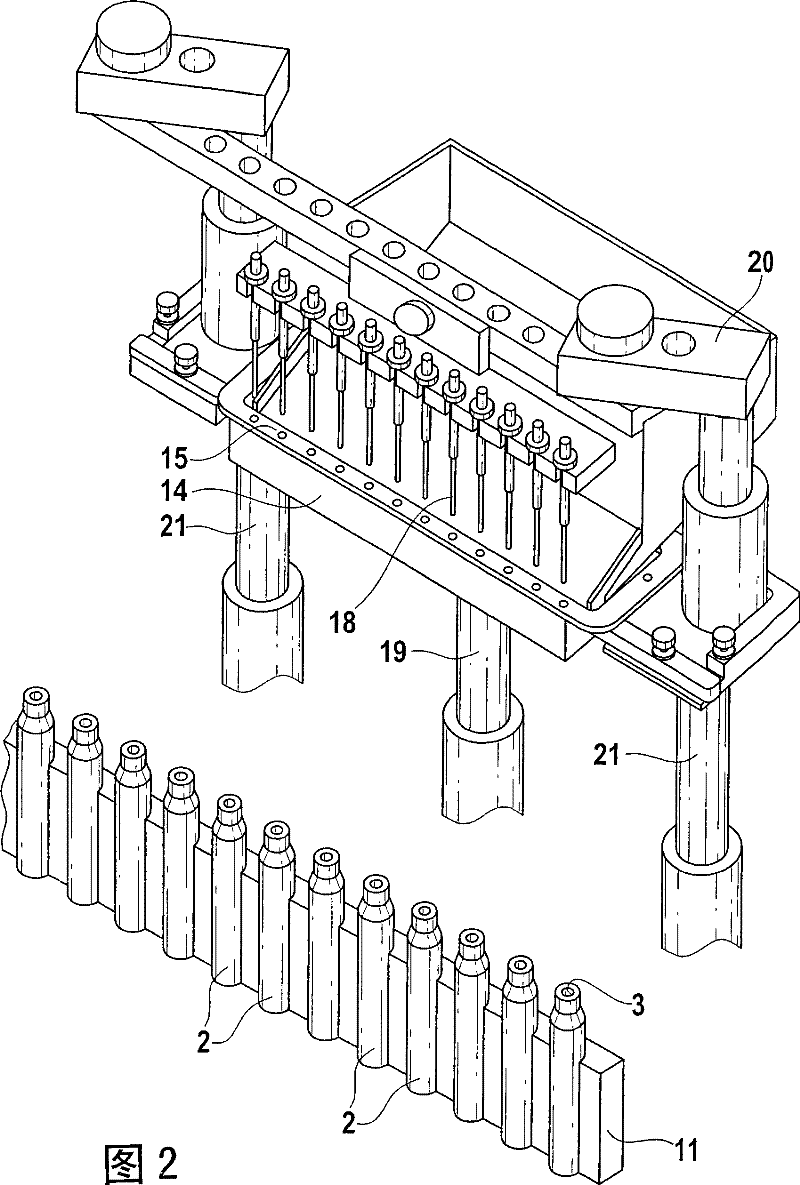

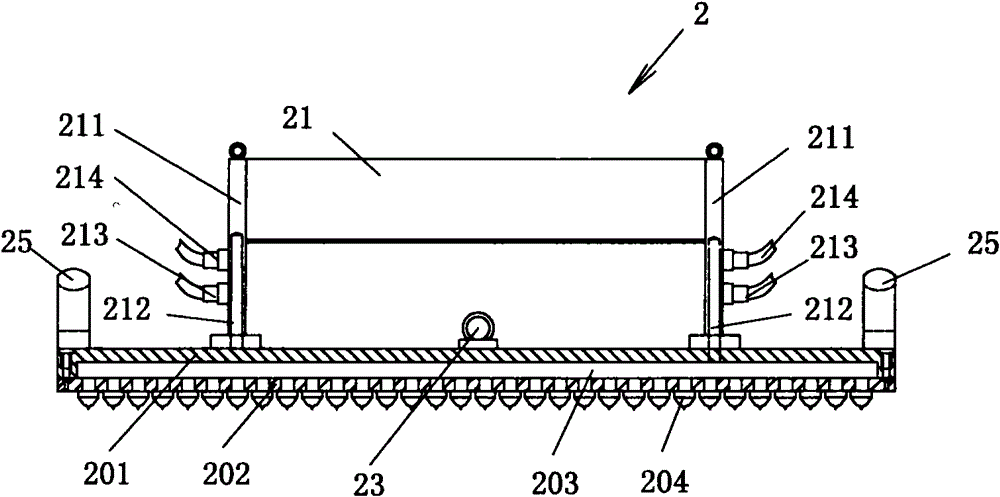

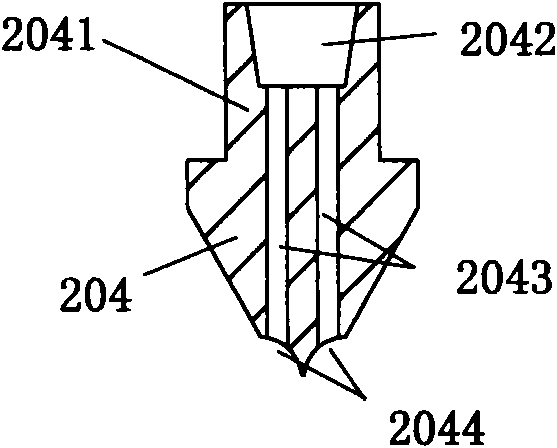

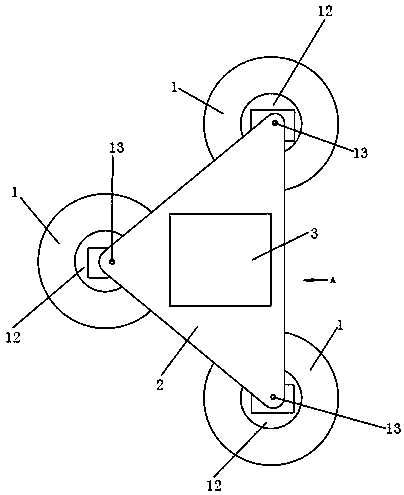

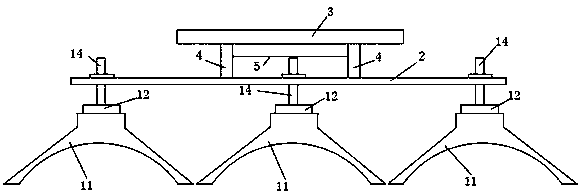

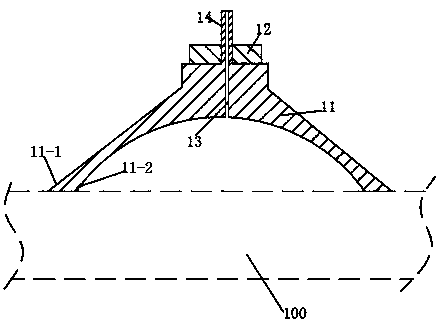

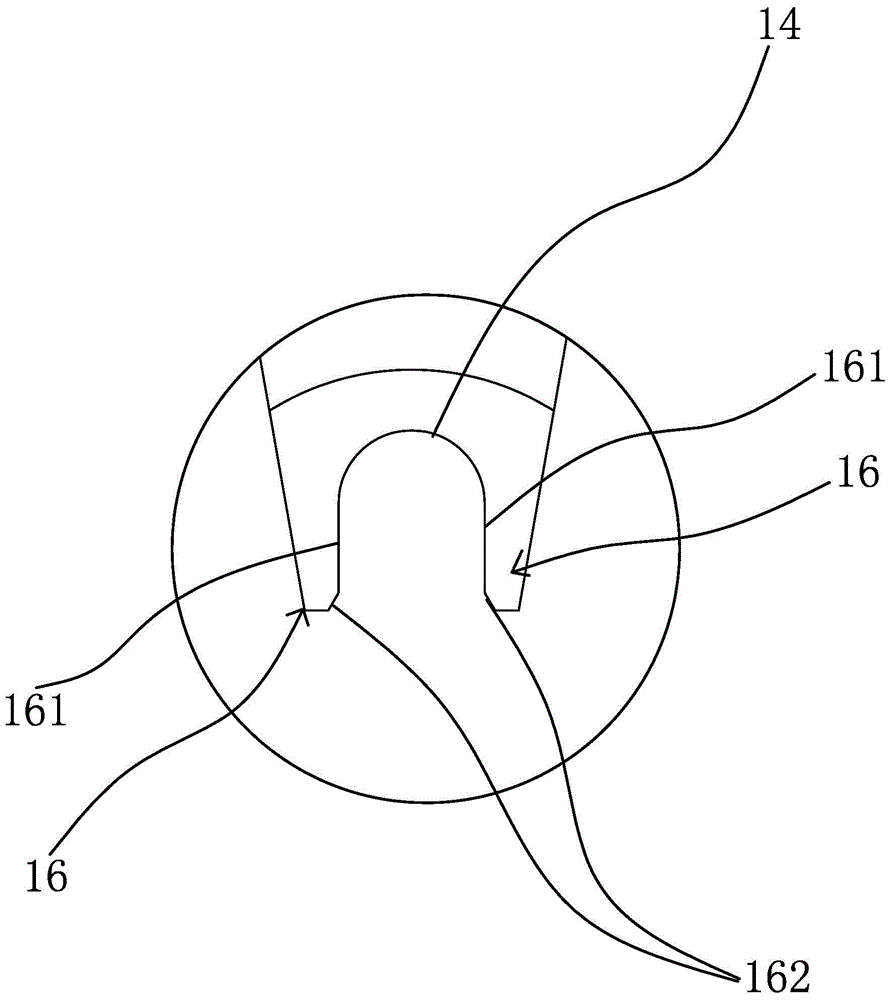

Pot body seed tray and pot body seeder

InactiveCN101773012AEasy to moveDraw reliableSeed depositing seeder partsSingle grain seedersSeederInterior space

The invention relates to a pot body seed tray and a pot body seeder, in particular to a pot body seed tray for accurately seeding in the pot body for cultivating rice seedling and a seeder adopting the seed tray. The invention solves the problems of low reliability for directly adsorbing seed by small holes of the seed tray, miss seedling and complex control structure of the seeder. In the pot body seeder, a stand is provided with a negative-pressure fan, a positive-pressure fan, a seed tray, a pot body seed tray and a pot body seed tray. A shell of the pot body seed tray and a bottom plate are spliced into a cavity; a vacuum pipe interface on the shell and a plurality of small holes on the bottom plate are respectively communicated with the inside space of the cavity; the vacuum pipe interface is connected with a vacuum control valve and the negative-pressure fan in series through a vacuum pipeline; the shell is provided with an air blowpipe interface communicated with the inside space of the cavity; the air blowpipe interface is connected with an air blow control valve and the positive-pressure fan in series through an air blow pipeline; each small hole of the bottom plate is provided with a sucker at least provided with a suction hole which is communicated with the inside space of the cavity and is provided with a slot at the external end.

Owner:张国梁

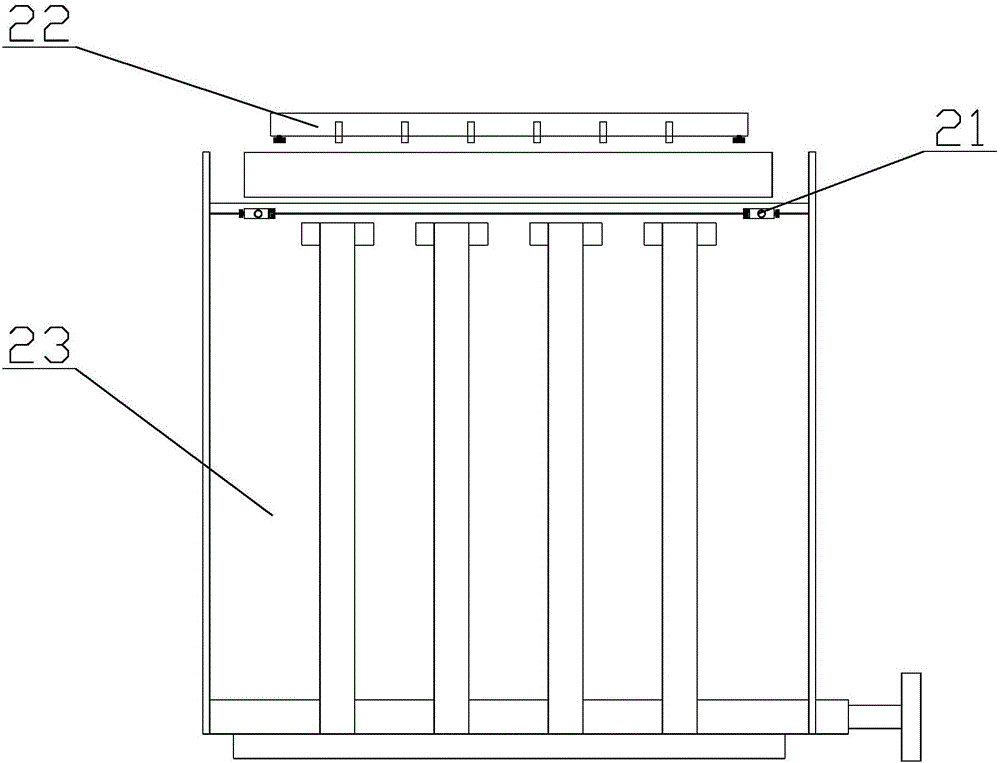

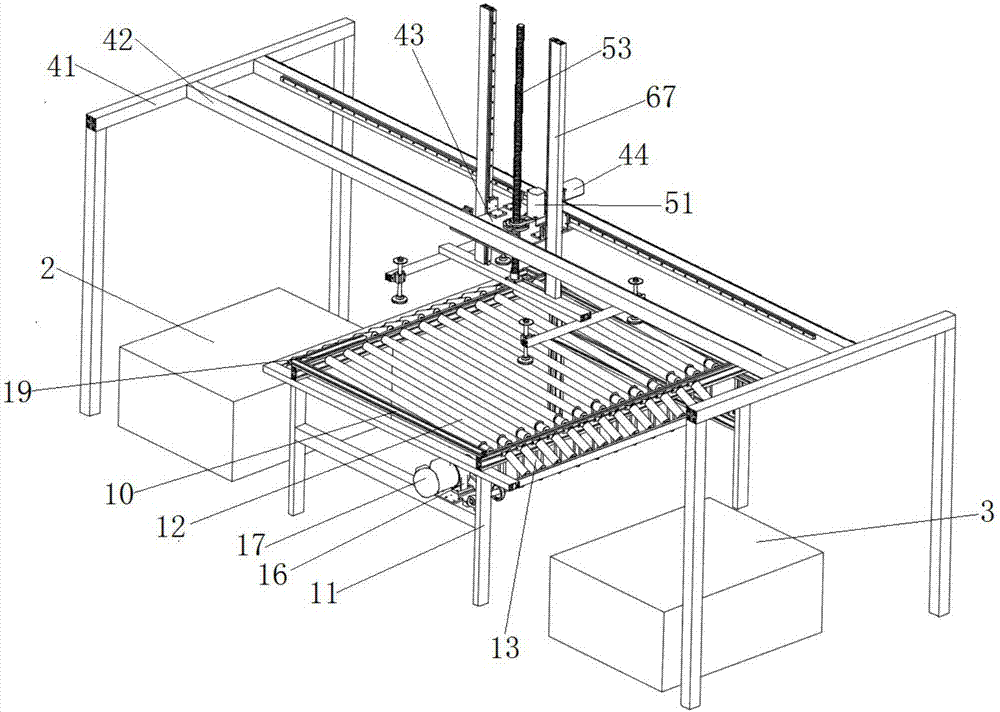

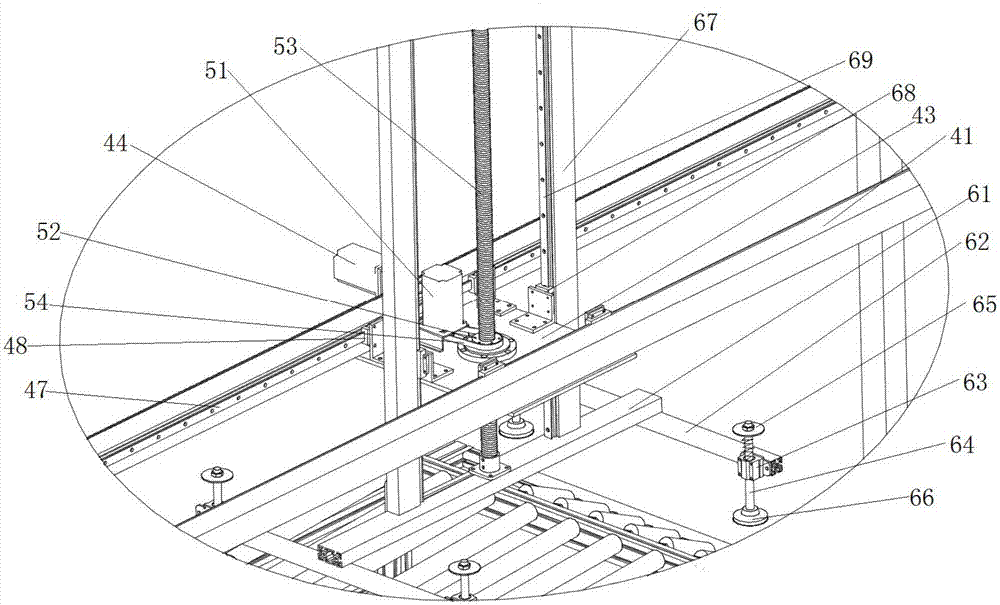

Large-size optical film automatic feeding device

PendingCN107697670AAvoid absorbingDraw reliableArticle feedersArticle separationEngineeringAssembly line

The invention belongs to the field of optical automation test and especially relates to a large-size optical film automatic feeding device which comprises a base, a feeding mechanism, an absorbing mechanism, a transporting mechanism and a control mechanism. The base is used for carrying the feeding mechanism above the base, and the feeding mechanism is arranged on the base so as to carry optical films and transmit the optical films to a first working station. The absorbing mechanism which can move up and down is arranged above the first working station so as to absorb the optical films in thefeeding mechanism and transmit the absorbed optical films to a second working station. The transporting mechanism which can move up and down is arranged at the rear end of the absorbing mechanism so as to absorb the optical films on the second working station and transmit the absorbed optical films to a third working station. The control mechanism is electrically connected with the feeding mechanism, the absorbing mechanism and the transporting mechanism respectively. When in use, operators only need to place stacked optical films on the feeding mechanism, bath feeding can be easily realized.The large-size optical film automatic feeding device is time-saving and labor-saving, high in working efficiency and smooth in operating process, and can be applied to assembly line work environment and has a broad market prospect.

Owner:SHENZHEN JINGCHUANG TECH CO LTD

Automatic detection processing production line for PCB

PendingCN110002182APrecise positioningConvenient, accurate and fast positioningMeasurement devicesSortingProduction lineAutomation

The invention relates to an automatic detection processing production line for a PCB. The automatic detection processing production line is sequentially provided with a feeding trolley, a feeding conveying single shaft assembly, a loading level flat belt production line and thickness measuring assembly, an OCR character scanning assembly, a cleaning assembly, a four-axis robot picking assembly anda discharging production line assembly. According to the production line, the operations of feeding, carrying, loading, conveying, code scanning, cleaning, discharging and the like can be completed,the automation degree is high, and the production and manufacturing efficiency is high.

Owner:惠州迪普恩科技有限公司

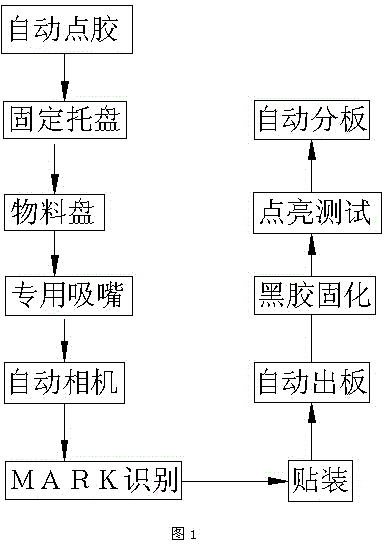

LED module light bar production system

InactiveCN104883869AMeet operational requirementsDraw reliableElectrical componentsRubber ringEngineering

The invention discloses a LED module light bar production system. The system comprises an automatic dispenser machine, a fixing tray, material discs, a dedicated suction nozzle, an automatic camera, MARK identification, an automatic chip mounter, an automatic plate feeding machine, black rubber solidification, a lightening test and an automatic plate splitting machine. A slotting on the material disc is in a horn hole shape. The fixing tray is installed on the automatic chip mounter. A positioning apparatus is arranged on the fixing tray. A sealing rubber ring is arranged on the dedicated suction nozzle. The material discs are made from an RF-4 material. An error between the material discs is + / -0.02mm. In the invention, through a high-efficient and accurate mounting mode of a LED energy saving light bar, problems that models and sizes of different lens shades are not unified and returning positions of the tray of the chip mounter are not unified so that a lens reject rate is high and a tiling position is deviated and so on are solved.

Owner:科思技术(滁州)有限公司

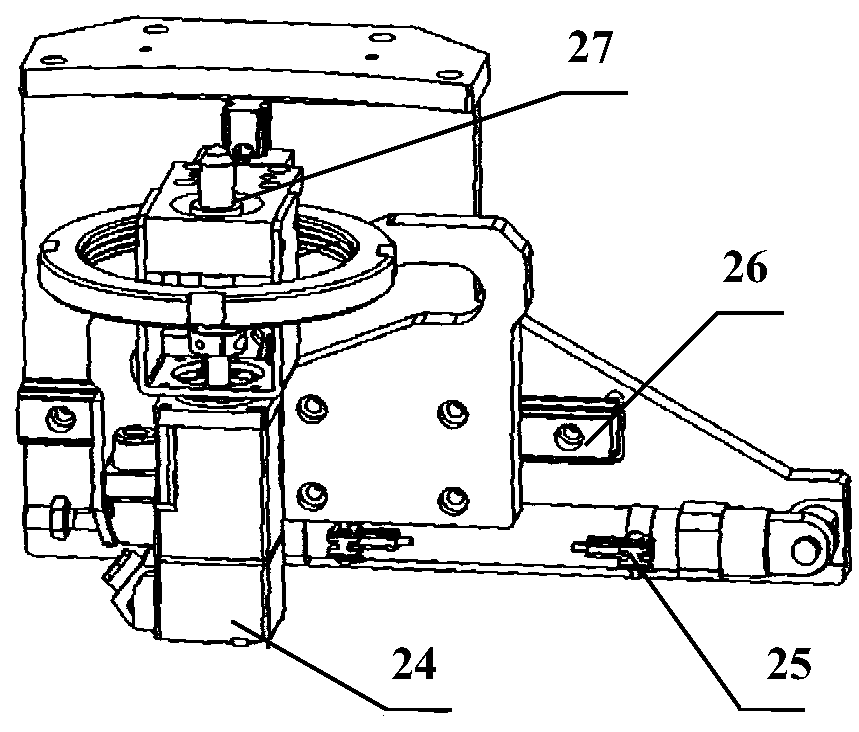

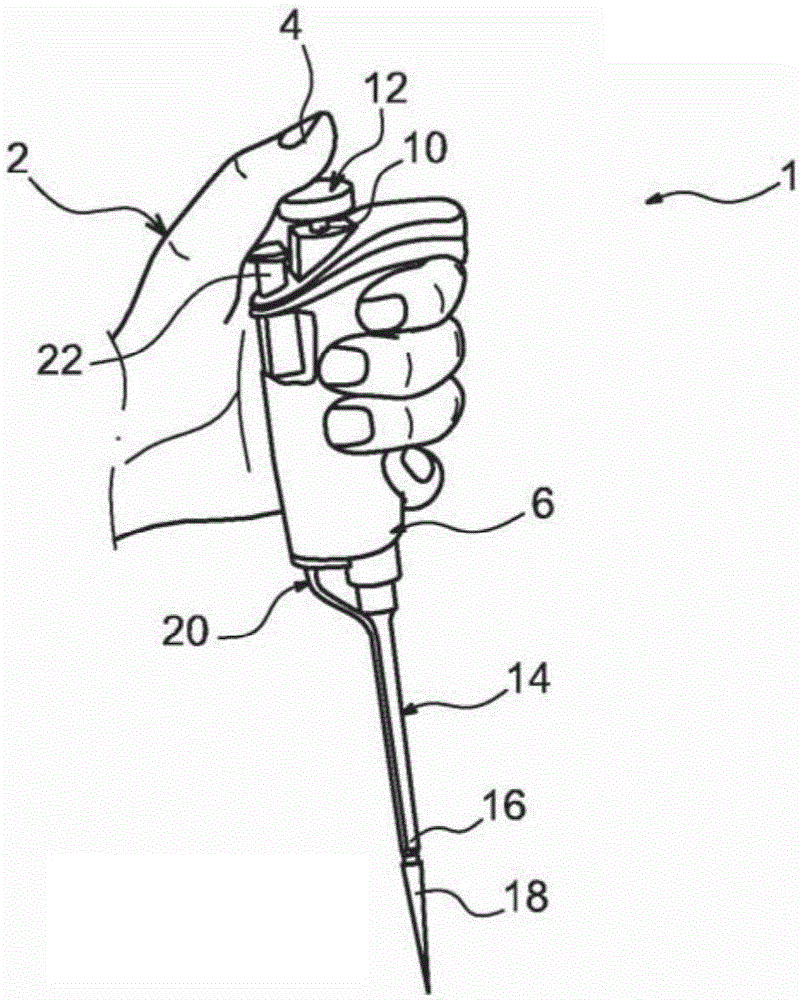

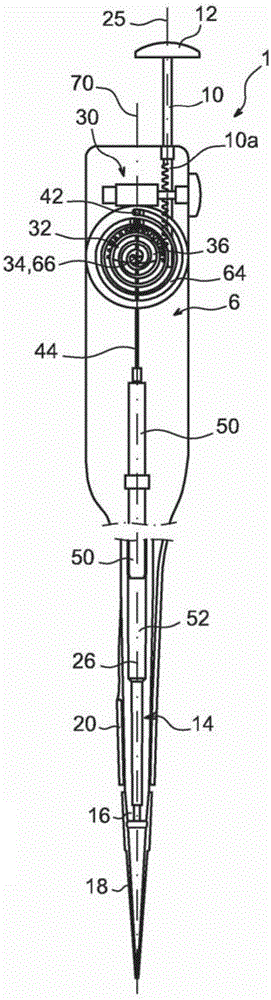

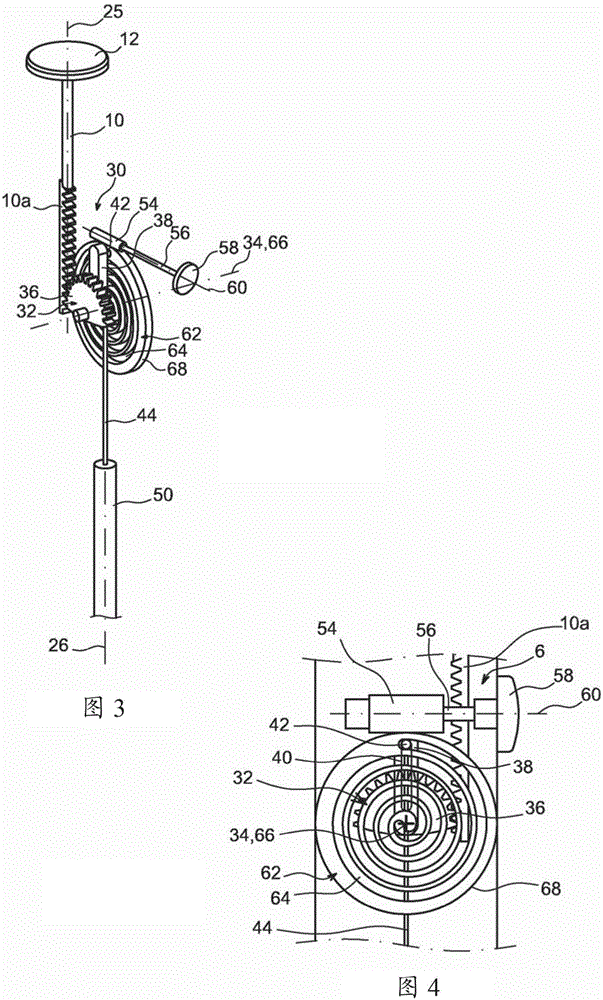

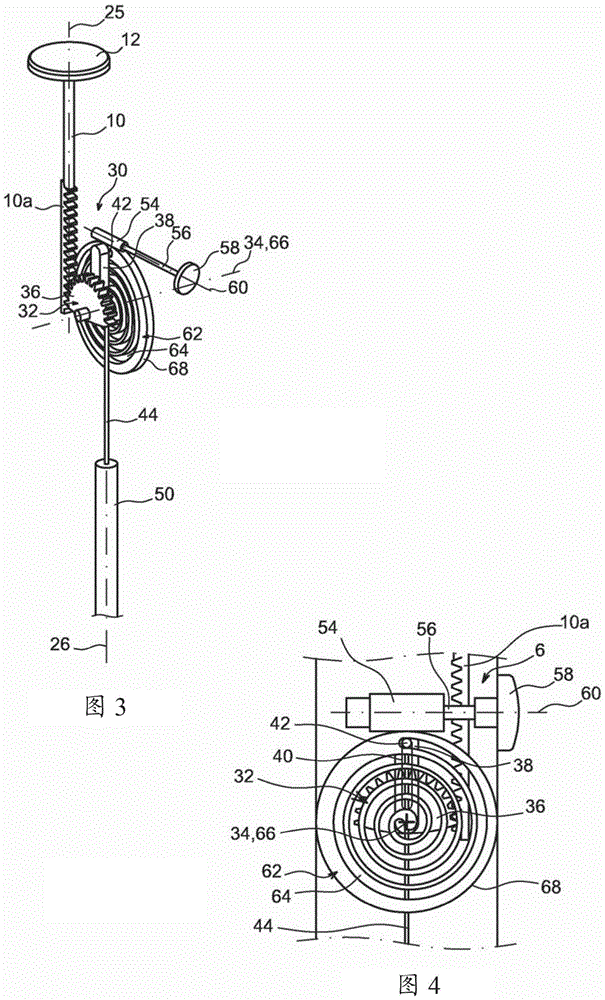

Pipetting system with improved control and volume adjustment

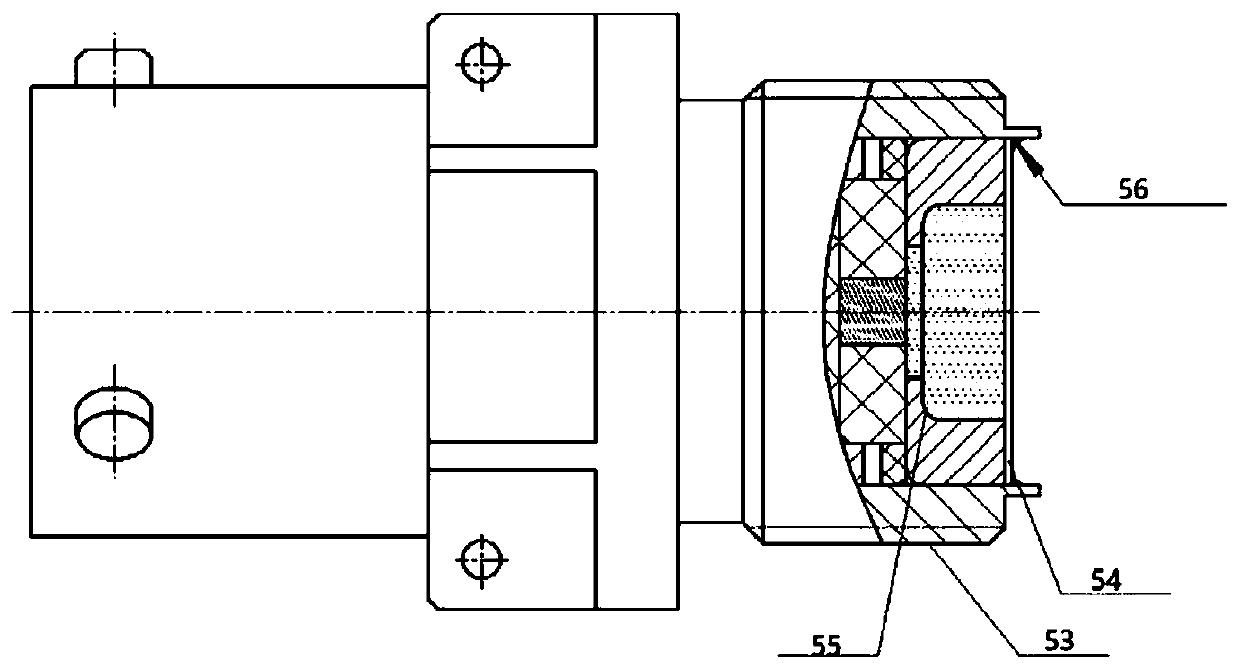

InactiveCN105073264AConstant suction strokeImprove suction smoothnessBurettes/pipettesMaterial analysisEngineeringMechanical engineering

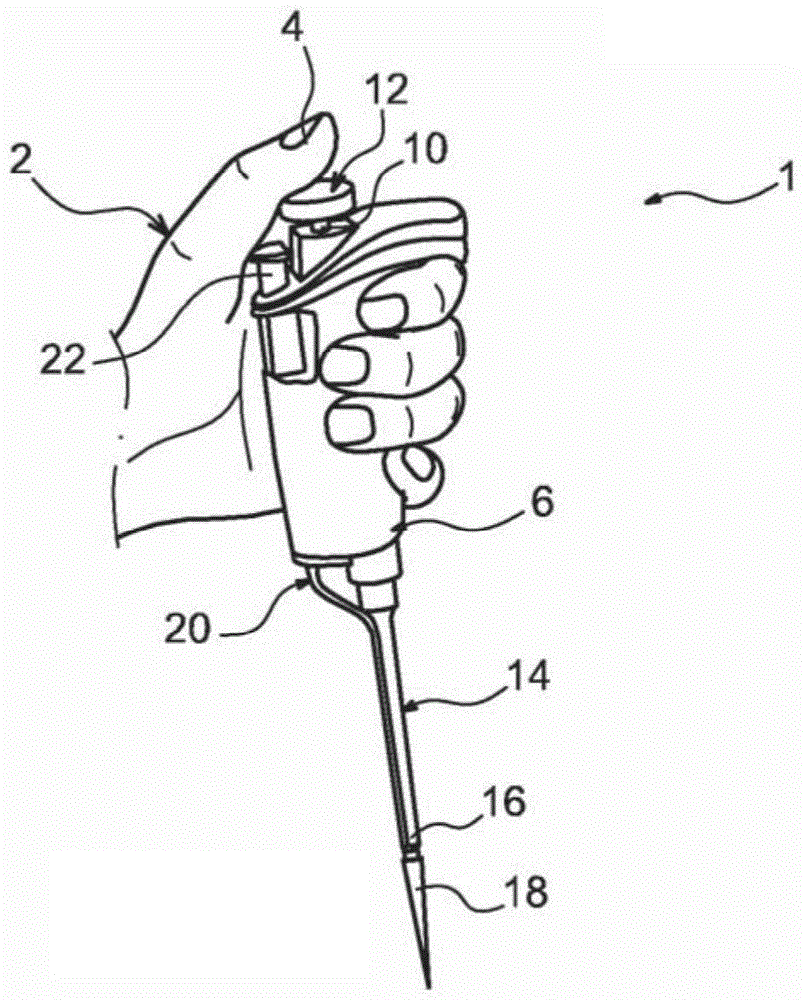

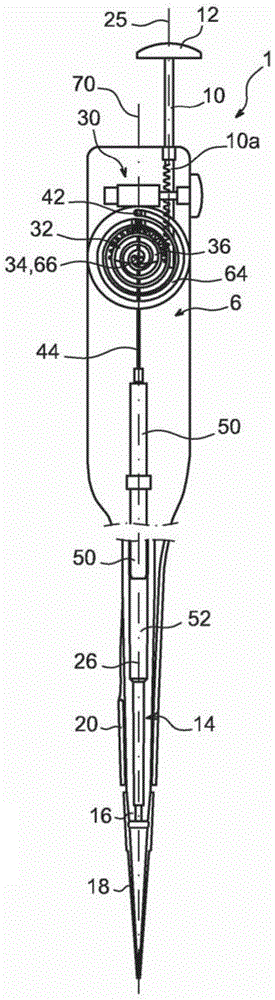

The invention concerns a device (30) for controlling pipetting and adjusting a volume to be collected, comprising: - a pipetting control member (10); - rotary actuating means (32) coupled to the control member; - a link member (42) slidably mounted on the actuating means, the link member being connected to a plunger (50); - volume adjustment means (54); - rotary means (62) defining, for the link member (42), a spiral-shaped guide path (64), the means (62) being coupled to the adjustment means (54) such that the actuation thereof causes the means (62) to rotate about a second axis (66) on which the path (64) is centred, this rotation resulting in the displacement of the link member (42) along the path (34) and the sliding of the member (42) relative to the actuating means (32).

Owner:GILSON SAS

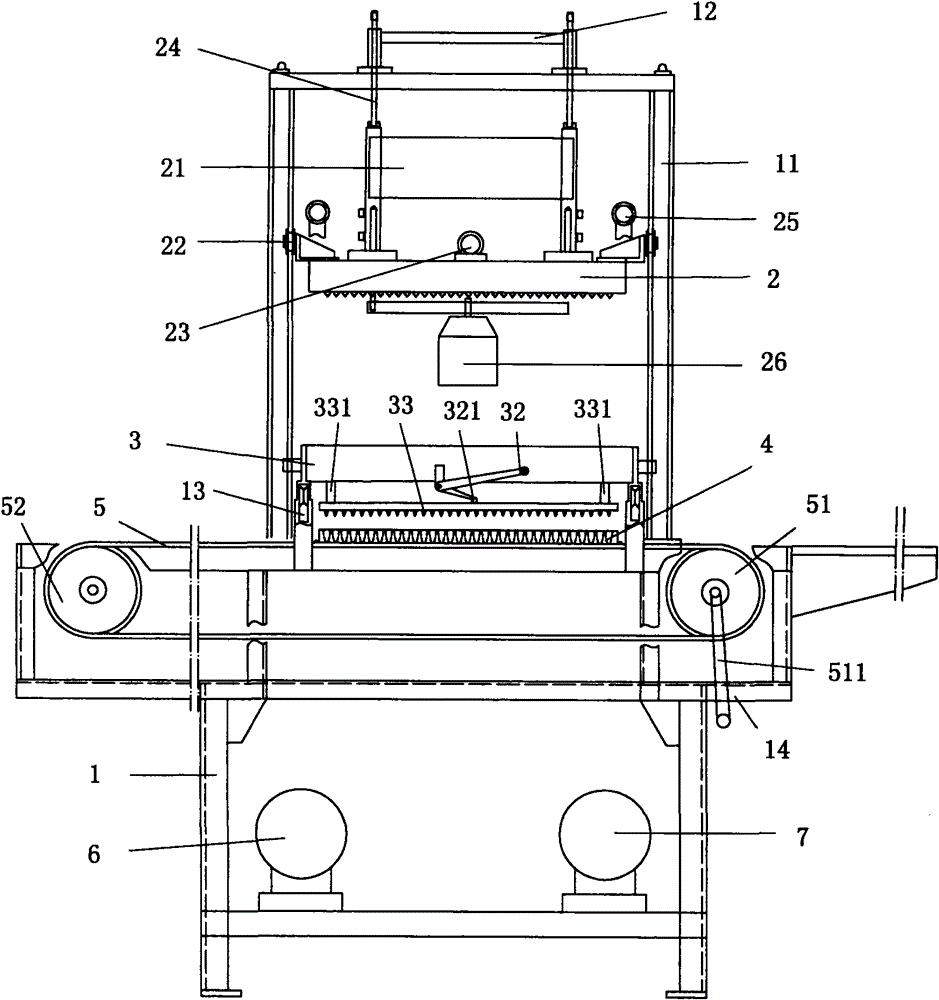

Full-automatic soft-line sectional die-cutting machine and operating method thereof

InactiveCN106739137ASave human effortReduce labor intensityPaper-makingBox making operationsMechanical engineeringEngineering

The invention relates to a packing box processing device, in particular to a full-automatic soft-line sectional die-cutting machine and an operating method thereof. The full-automatic soft-line sectional die-cutting machine is simple in structure and is characterized in that two procedures of indentation and slitter edge removal of a plastic sheet are finished during one-time clamping to realize high-precision processing and high processing efficiency. The full-automatic soft-line sectional die-cutting machine comprises a rack and a controller, wherein a closed-cycle chain conveyor is arranged on the rack, a plurality of clamping and conveying mechanisms are uniformly distributed in the conveying direction of the chain conveyor, and a support wheel part at the head ends of the rack and the chain conveyor is a feeding end; and adjustment holes are formed in the two ends of stiffeners, adjustable bolts are arranged in the adjustment holes, and a stop block is arranged on the rear side of each adjustment hole. The full-automatic soft-line sectional die-cutting machine has the advantages that dents and cut edges are integrally formed, the borders of the cut edges are smooth, the dents are equal in depth, the processing efficiency is high and the structure is simple.

Owner:YANGZHOU SU PACK NEW MATERIAL TECH CO LTD

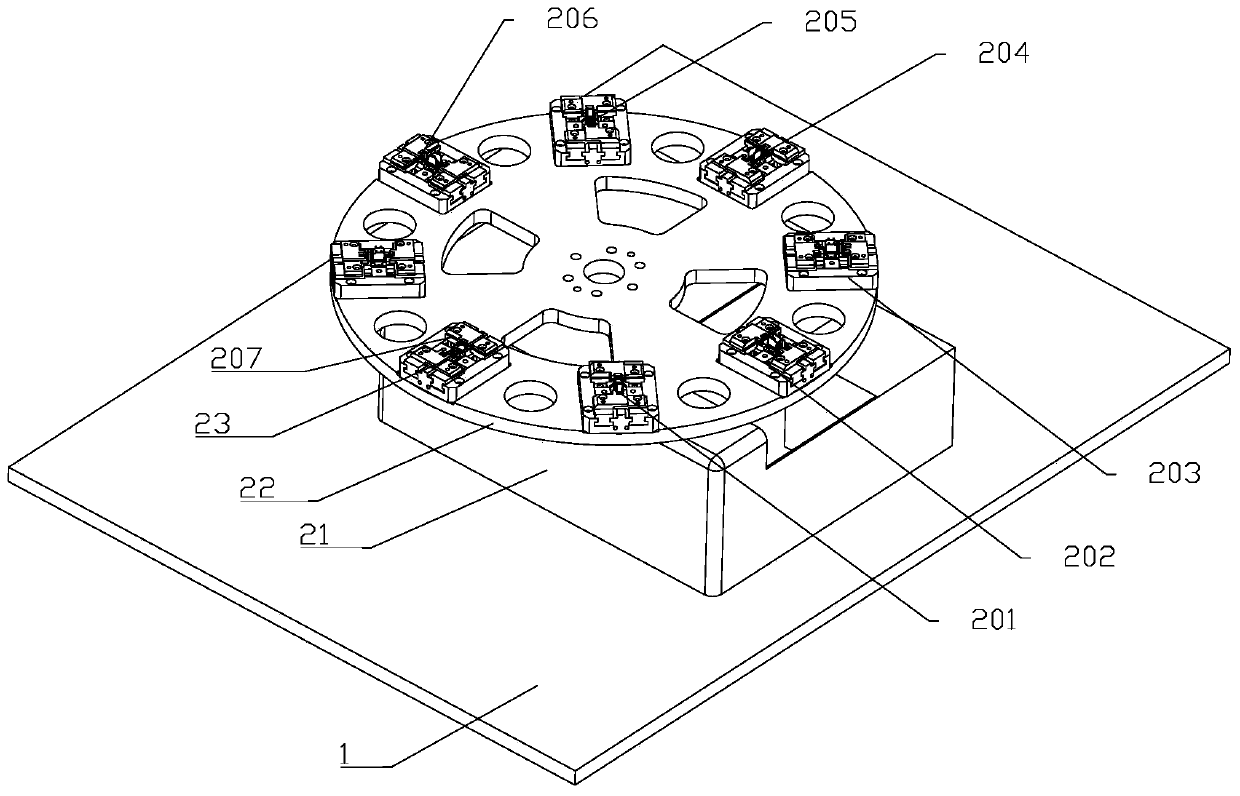

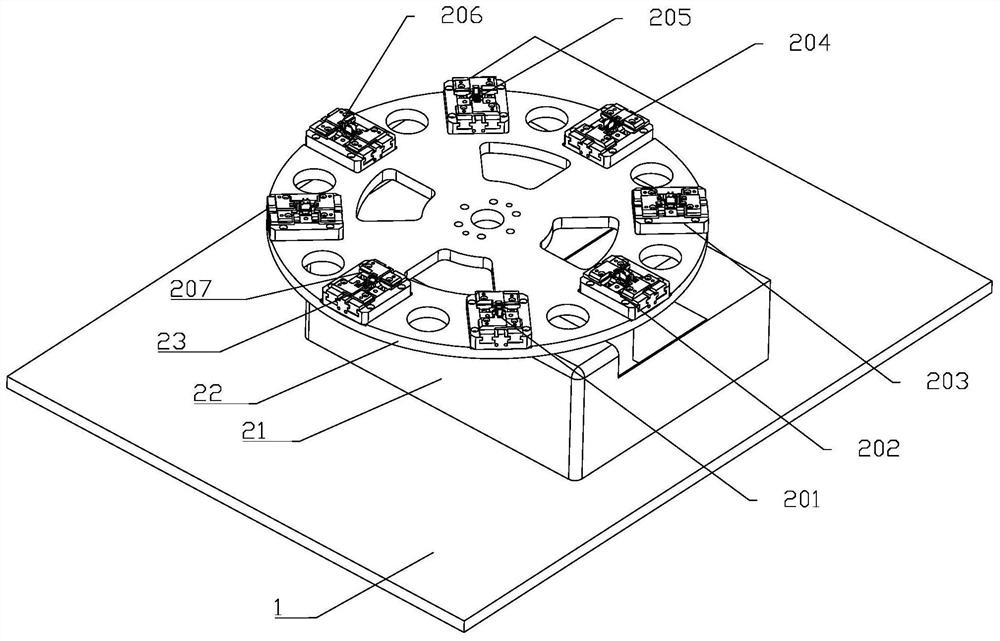

Wire connector and automatic production equipment and method thereof

ActiveCN111300034ACompact structureEfficient transportAssembly machinesMetal working apparatusElectrical connectorMechanical engineering

The invention relates to the technical field of electronic connector production and discloses automatic production equipment of a wire connector. The automatic production equipment comprises a rack aswell as a rotary table jig device, a wire connector feeding device, a locating plate feeding device, a lateral clamping piece feeding device, a bottom clamping piece feeding device, a detecting device, a stamping device and a discharging device which are mounted on the rack, wherein the rotary table jig device is mounted in the middle of the rack; the wire connector feeding device, the locating plate feeding device, the lateral clamping piece feeding device, the bottom clamping piece feeding device, the detecting device, the stamping device and the discharging device are sequentially connected to be arranged on the circumference of the rotary table jig device; and the rotary table jig device is efficient in transferring, can clamp and position a workpiece, is higher in precision, guides alocating plate to enable the locating plate to fall in a jig precisely, and keeps the workpiece position to improve the clamping precision and assembling precision.

Owner:陕西中昊佳成信息科技有限公司

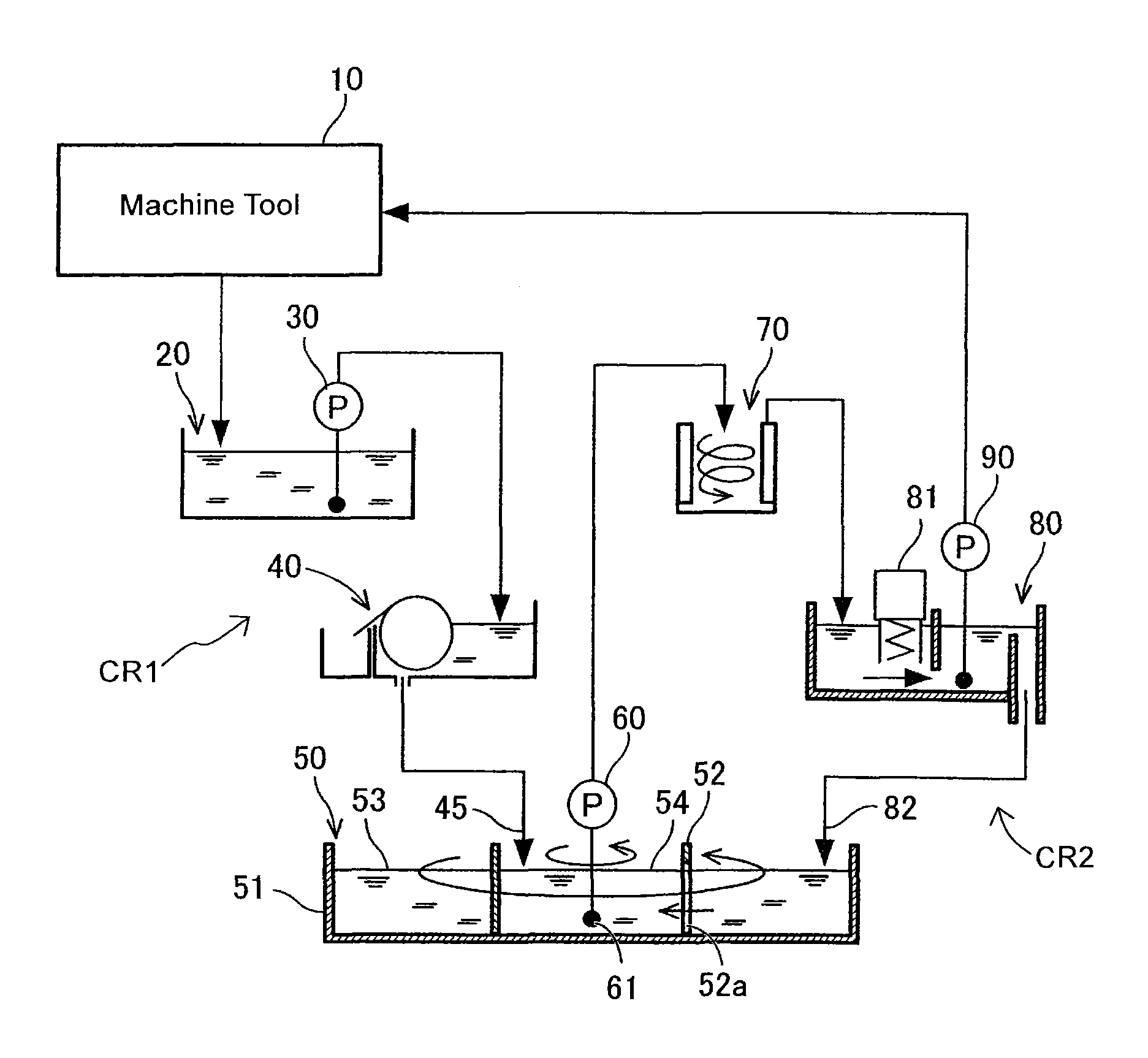

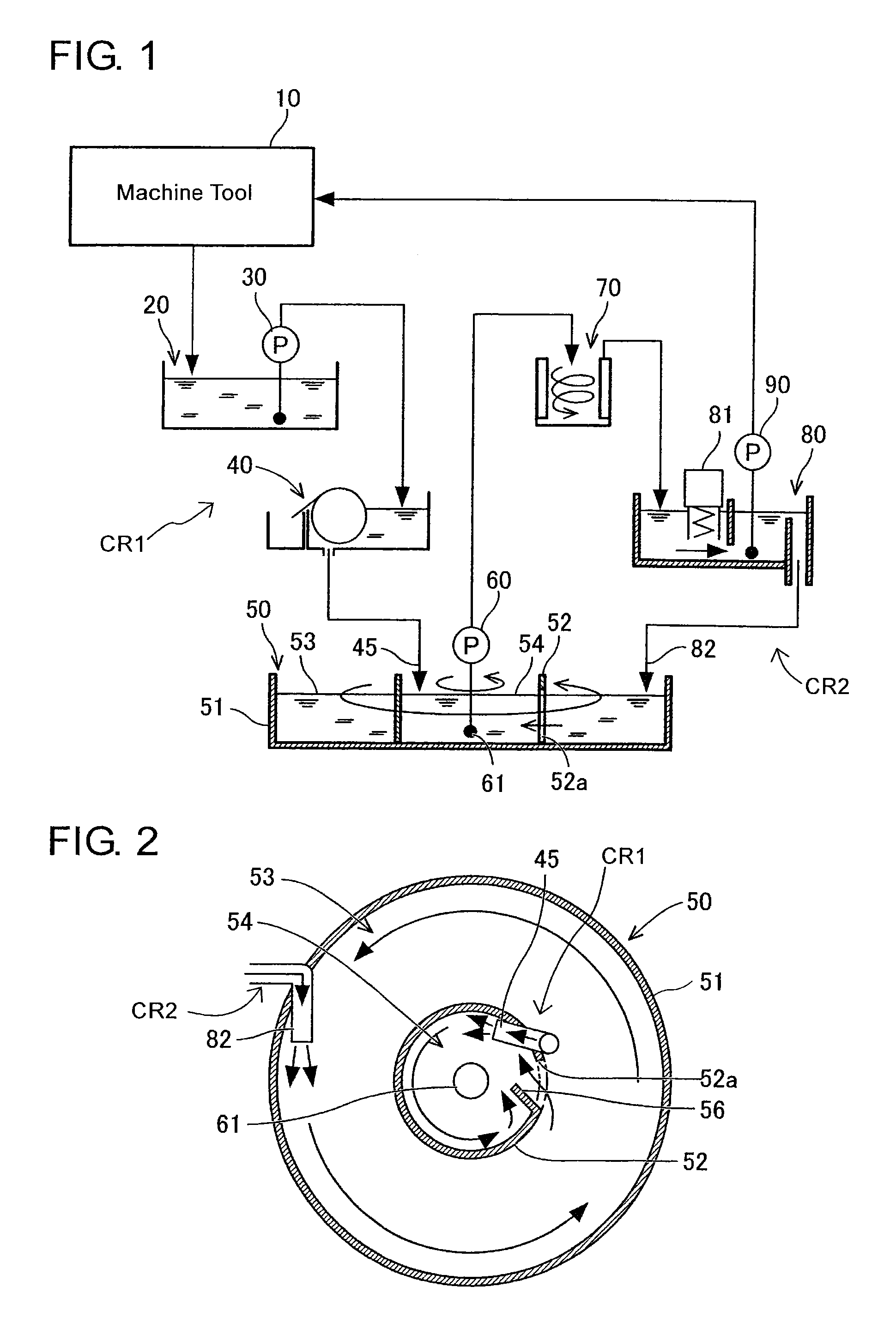

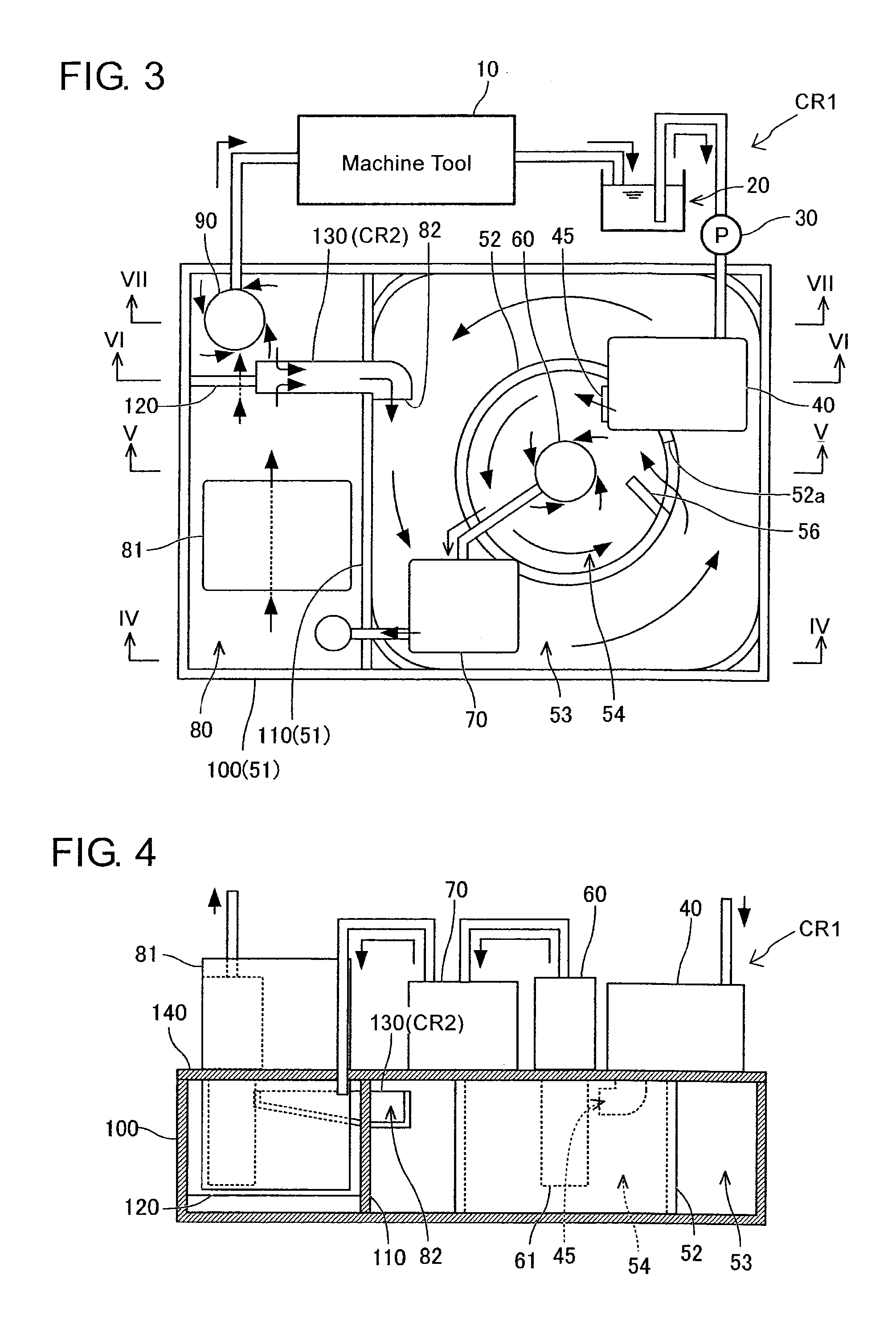

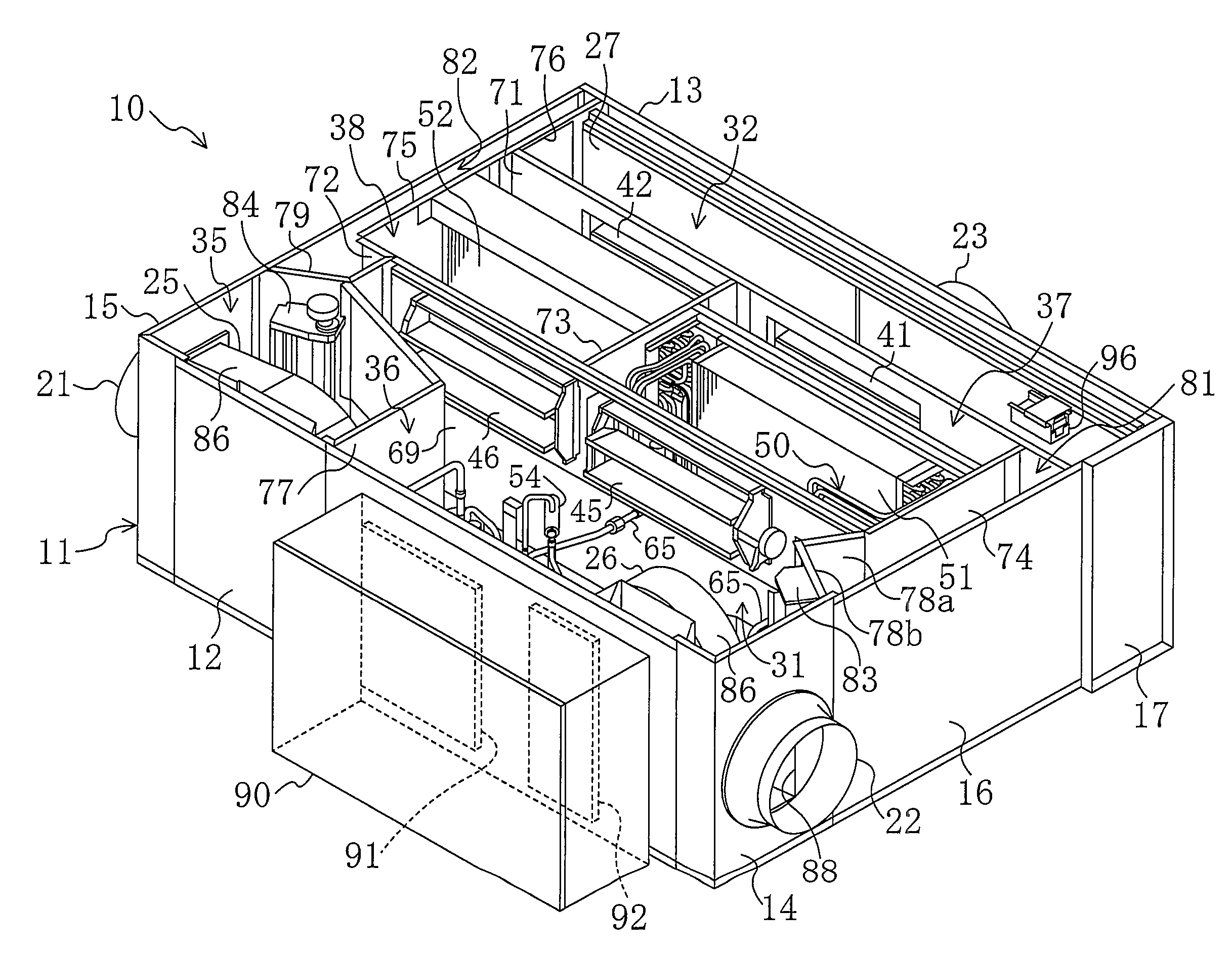

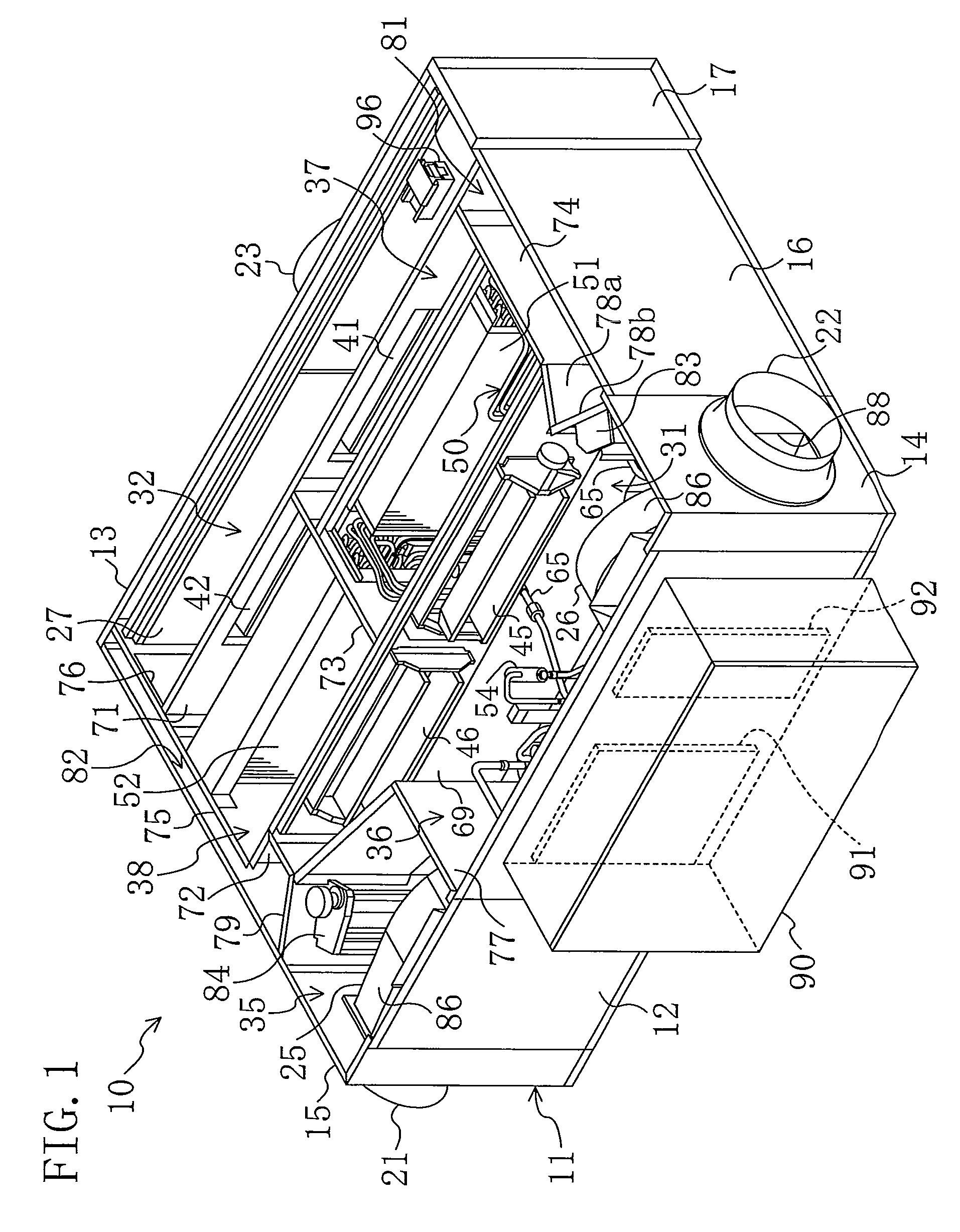

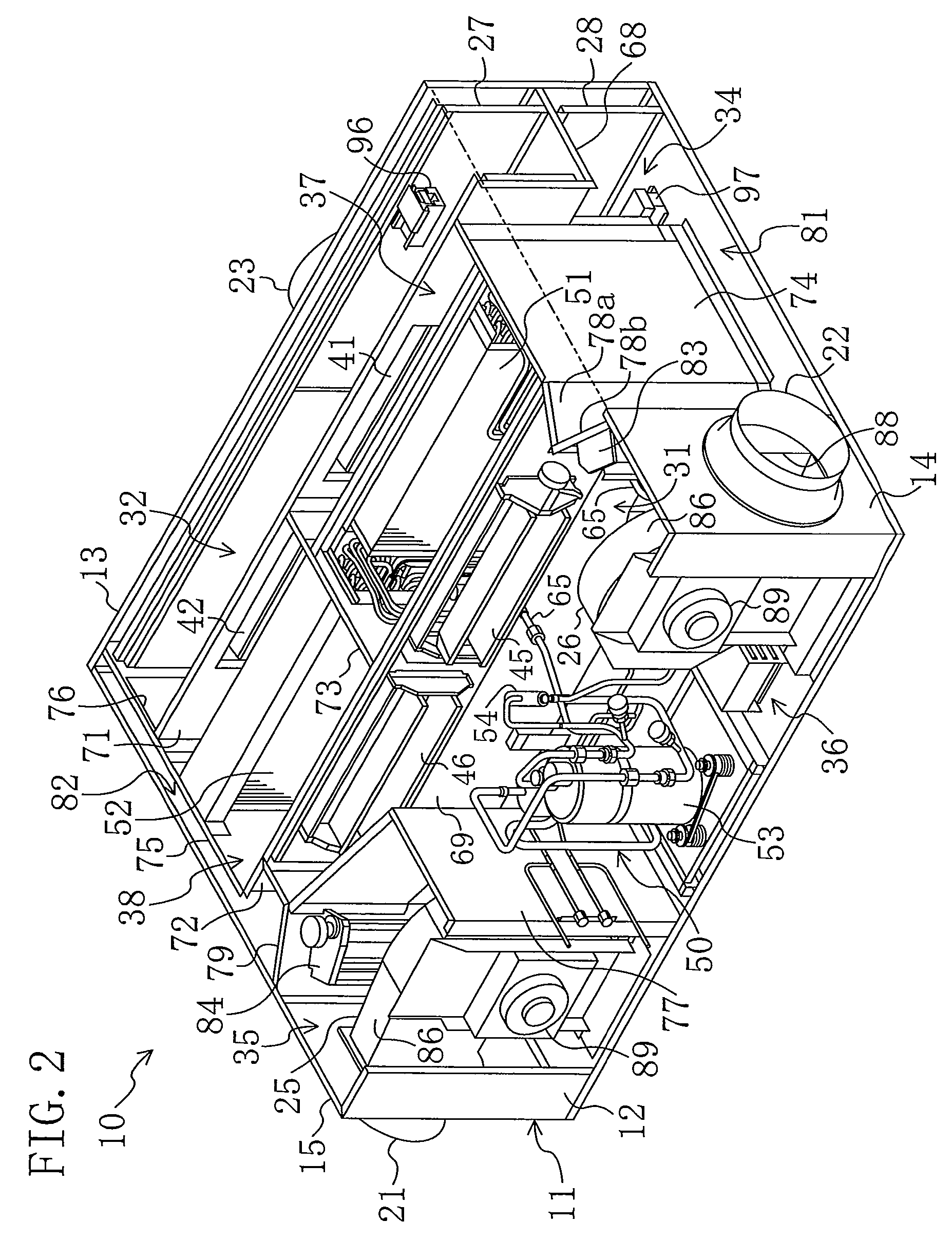

Coolant system

ActiveUS9393571B2Draw reliableReliable feedingFiltration separationMagnetic separationEngineeringDepth direction

In a coolant system, the interior of a reservoir frame storing the coolant discharged from a machine tool is partitioned by a partition member into an outer peripheral coolant tub and a central coolant tub. The partition member is formed with a silt that extends in the depth direction to make the outer peripheral coolant tub communicate with the central coolant tub. A suction port of a pump that feeds the coolant in the central coolant tub to a filtering device is arranged in the central coolant tub. The coolant discharged from the machine tool is supplied to the central coolant tub without passing through the outer peripheral coolant tub. At least a part of the coolant filtered by the filtering device is supplied to the outer peripheral coolant tub without passing through the central coolant tub.

Owner:JTEKT CORP +1

Humidity control apparatus

ActiveUS8827169B2Reduced space requirementsLimitation installation location is alleviatedSpace heating and ventilation safety systemsLighting and heating apparatusControl roomControl theory

Owner:DAIKIN IND LTD

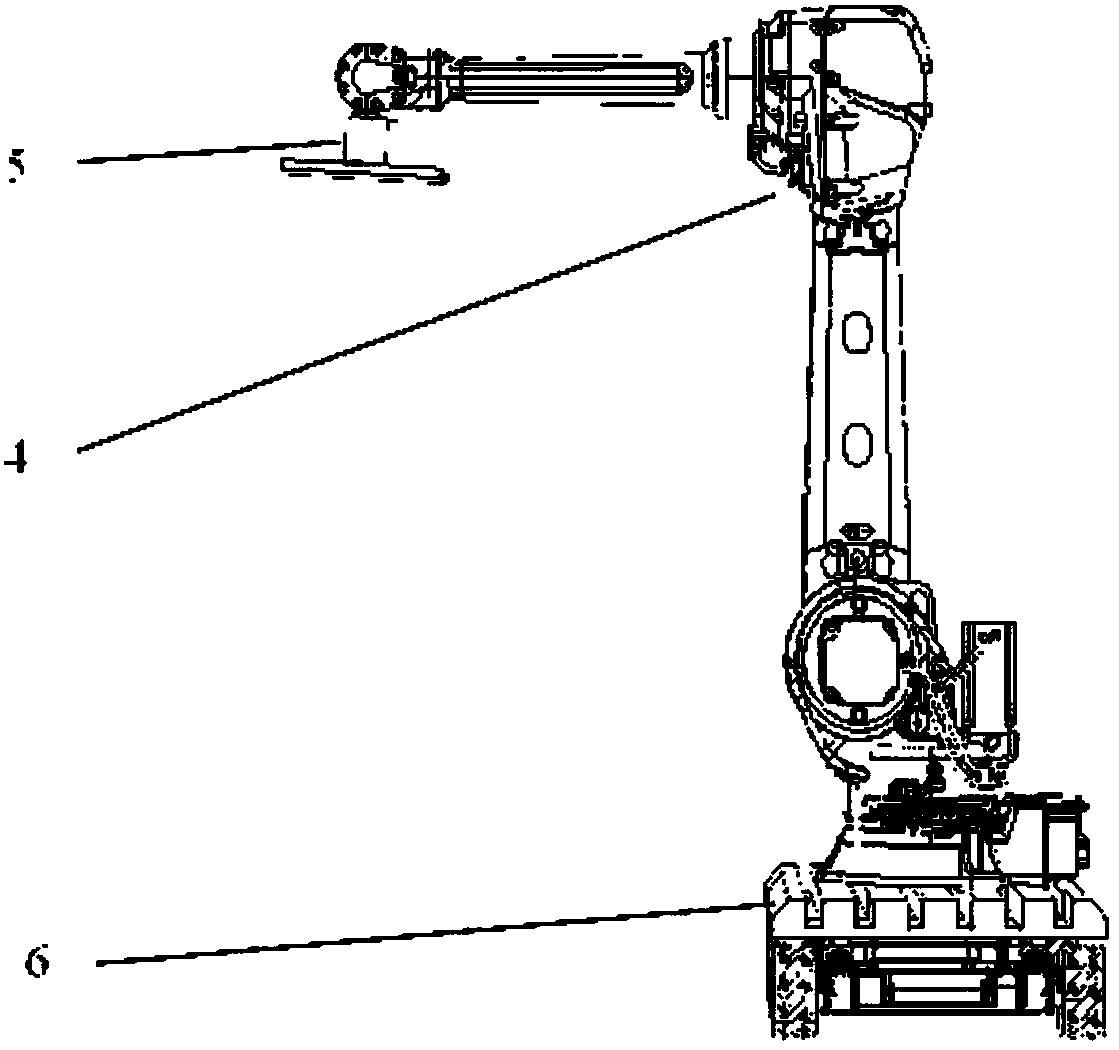

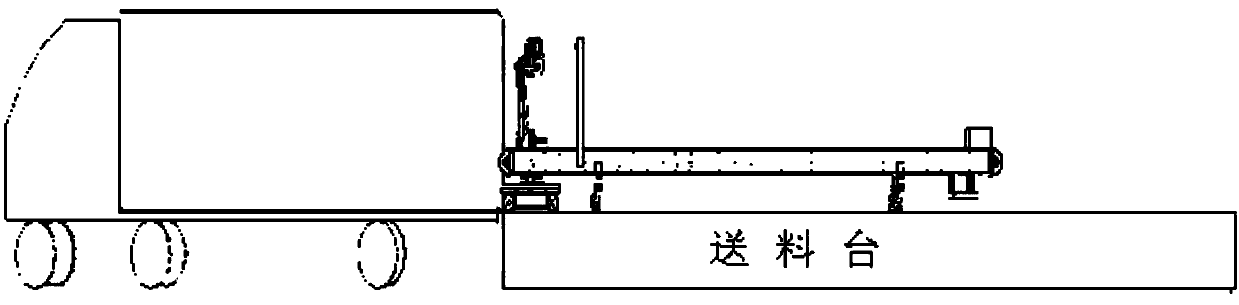

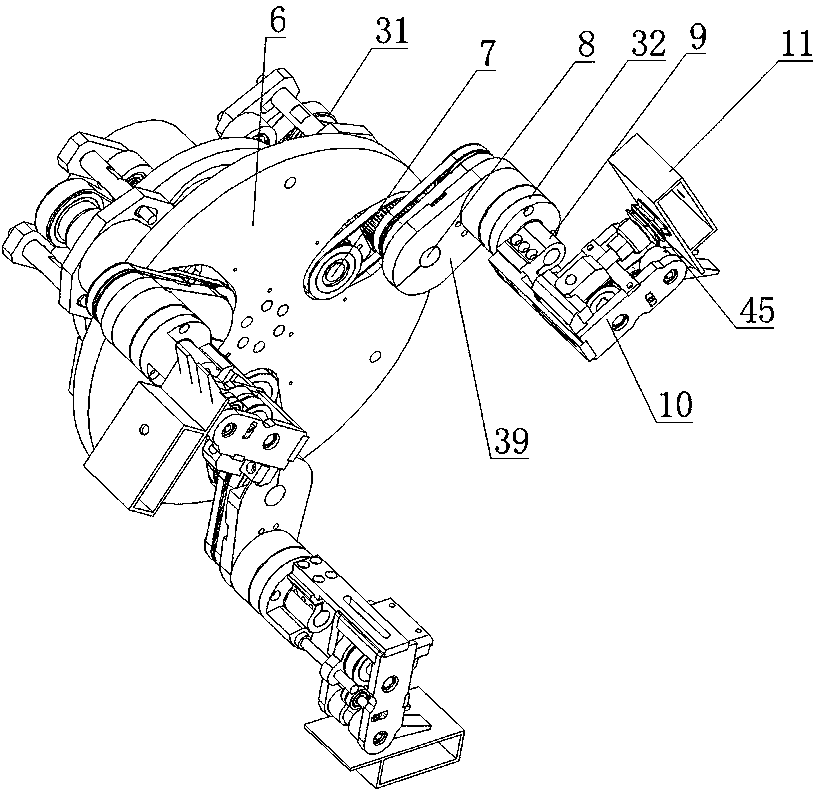

Automatic truck loading system and method based on machine vision

PendingCN107758363ADraw reliableFlexible packingImage enhancementImage analysisEngineeringVisual recognition

The invention discloses an automatic truck loading system and method based on machine vision. A movable telescopic machine, a 3D camera connected with a vision recognition system, a camera support arranged above the front section of the telescopic machine and used for fixing the 3D camera, a mechanical arm body, a robot system for transmitting information fed back by the vision recognition systemto control the action of the mechanical arm body, and a trolley used for carrying the mechanical arm body for movement. A suction cup clamp is arranged at the end portion of the mechanical arm body and used for conveying goods to the telescopic machine. The suction cup clamp is arranged at the end portion of the mechanical arm body and used for conveying the goods to the telescopic machine. In theoperation process, to make the mechanical arm body stable, the trolley is fixed to one side of the tail end of the telescopic machine and is driven by the telescopic machine to move. When the mechanical arm body cannot reach the position during operation, the front-back fixed position of the trolley on the telescopic machine can be adjusted till the mechanical arm body can work in the operation range.

Owner:SOUTH CHINA UNIV OF TECH

Box sucking and opening mechanism for packaging box

The invention discloses a box sucking and opening mechanism for a packaging box. The mechanism is mainly characterized in that first rotating shafts are arranged on a rotating disc at equal intervals,the first rotating shafts are provided with second rotating shafts correspondingly, the second rotating shafts are movably connected with rocker arms correspondingly, third rotating shafts are installed on the rocker arms correspondingly, the second rotating shafts and the third rotating shafts are sleeved with sleeves correspondingly, synchronizing wheels on the second rotating shafts can rotatewhile revolving around a large synchronizing wheel, synchronizing wheels on the second sleeves can rotate while revolving around the synchronizing wheels on the second rotating shafts correspondingly, synchronizing wheels on the third rotating shafts can rotate while revolving around the synchronizing wheels on the second sleeves correspondingly, and suction nozzles and swing rods are arranged onmounting frames on the third rotating shafts correspondingly. According to the mechanism, the flat paper box placed in a box storage frame can be sucked and rotated and then sucked by another suctionnozzle to be opened, finally, through swinging of the swing rods, the opened packaging box is straightened and falls onto a conveying belt, objects can be conveniently pushed into the packaging box to be packaged, and the mechanism has the characteristics of being scientific in structure and stable in work.

Owner:RUIAN HUAPU MACHINERY

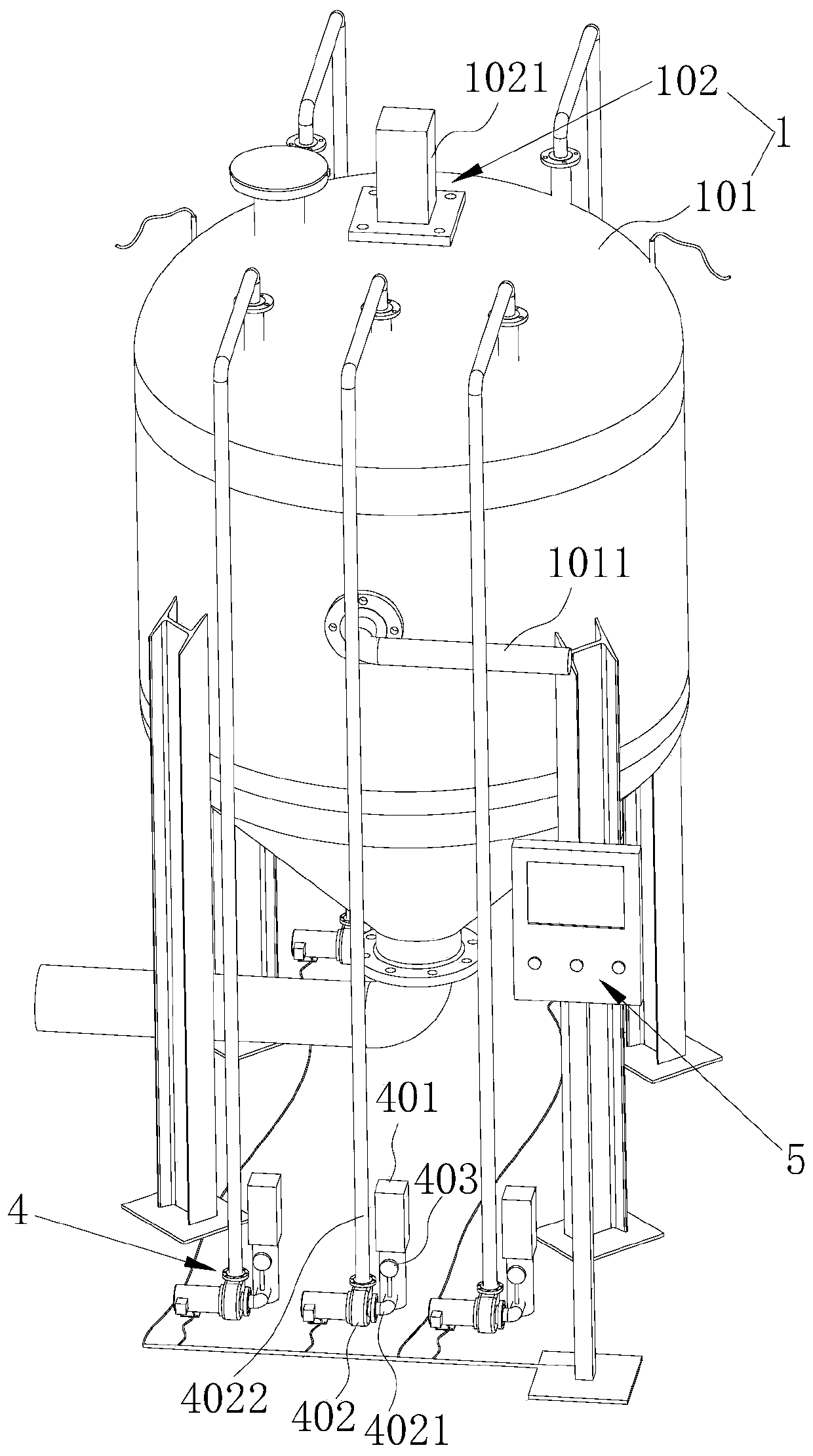

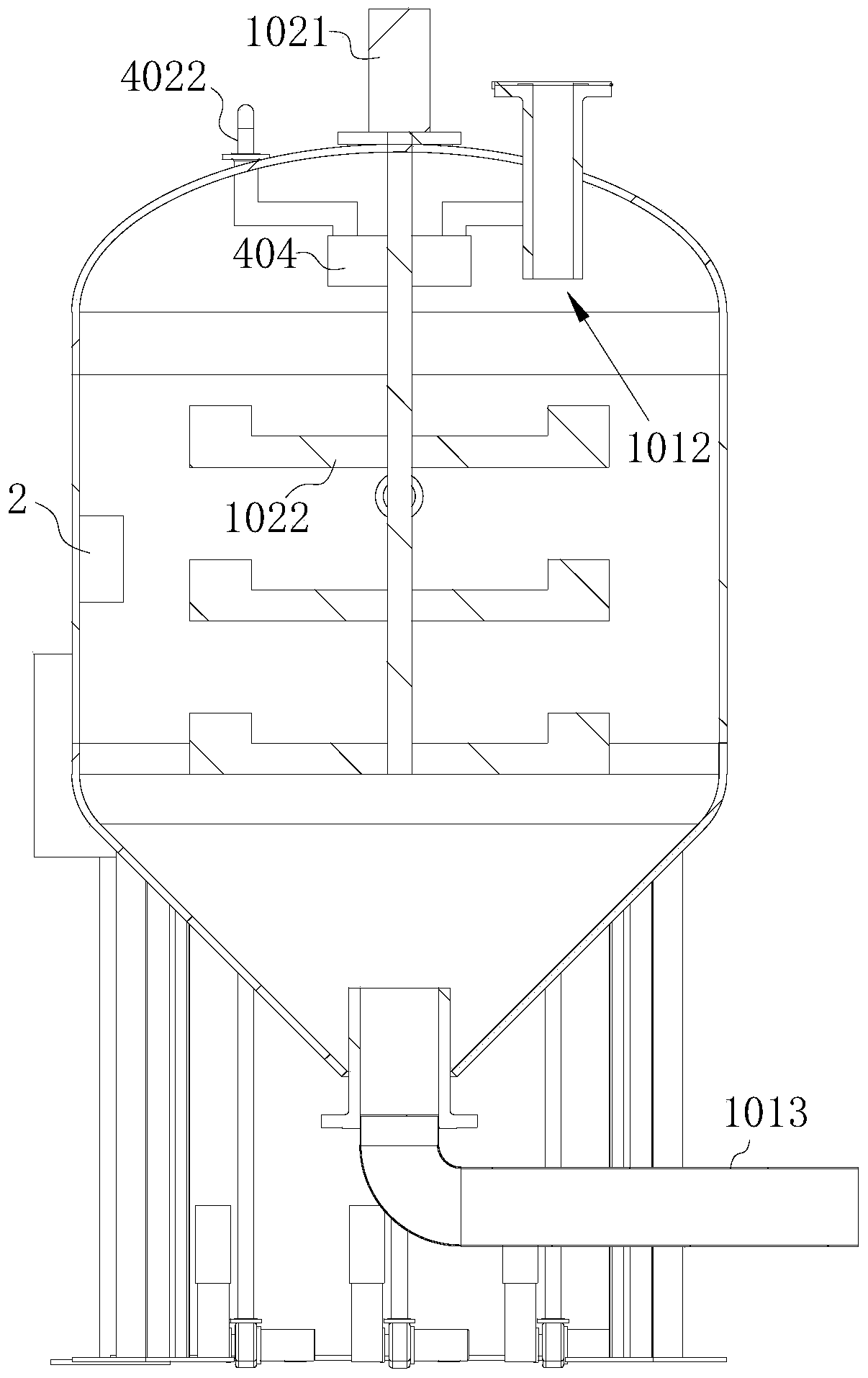

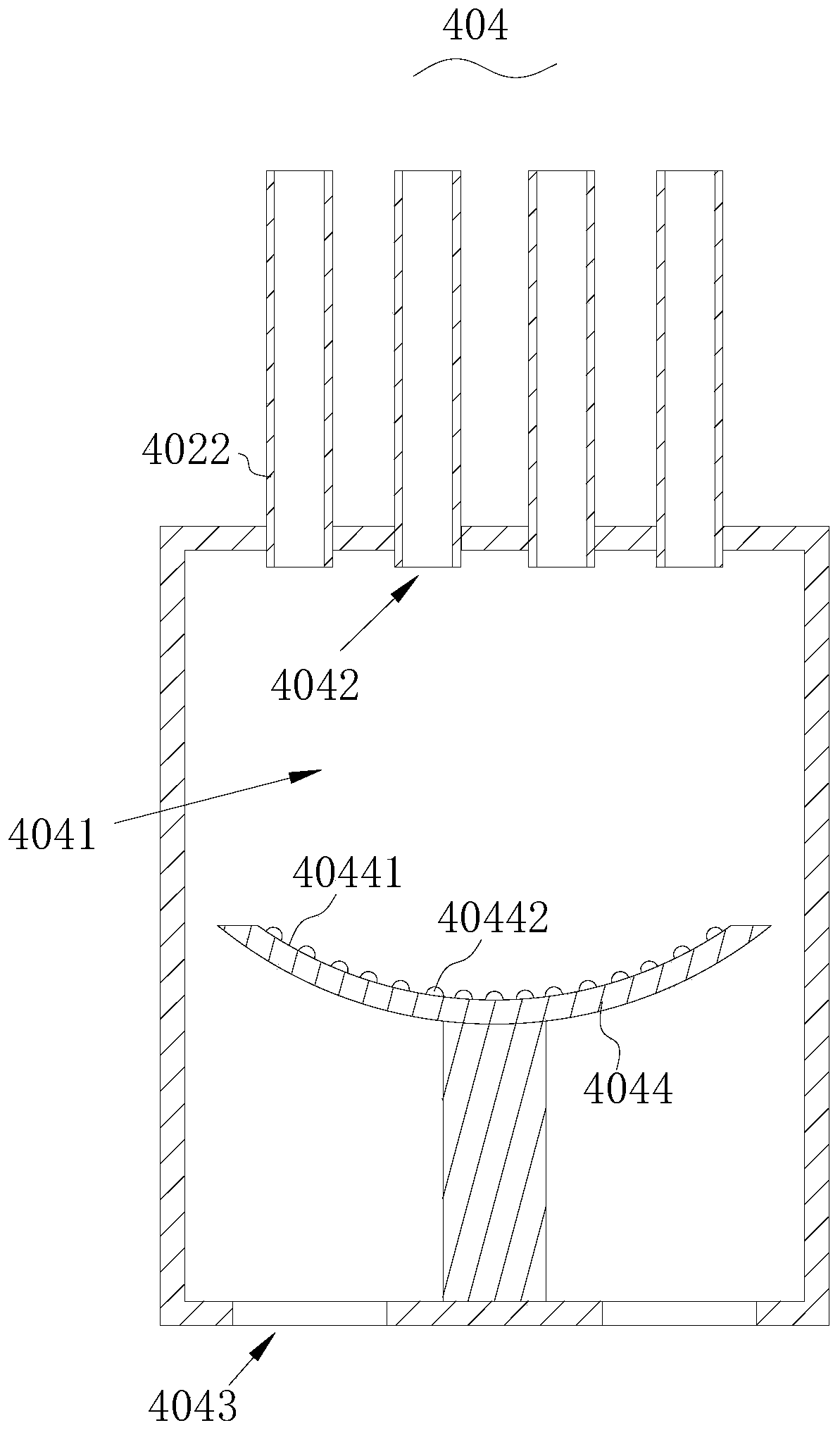

Disinfectant fluid production process

ActiveCN110523319AImprove real-time performanceIncrease productivityBiocideRotary stirring mixersNegative feedbackDisinfectant

The invention discloses a disinfectant fluid production process. According to the scheme, support-designed production equipment is adopted for production, preparation of liquid raw materials, mixing of solutions and online measurement of effective chlorine content and pH value of the obtained mixed solution are included, the effective chlorine content, pH value and other production parameters aremonitored in real time and effectively through an effective chlorine sensor and a pH meter in the production process, and the addition amount of corresponding liquid raw material components can be adjusted in a negative feedback mode through an electronic control device, so that the production efficiency of a disinfectant fluid and the quality of the product are improved.

Owner:广州亲安环保科技有限公司

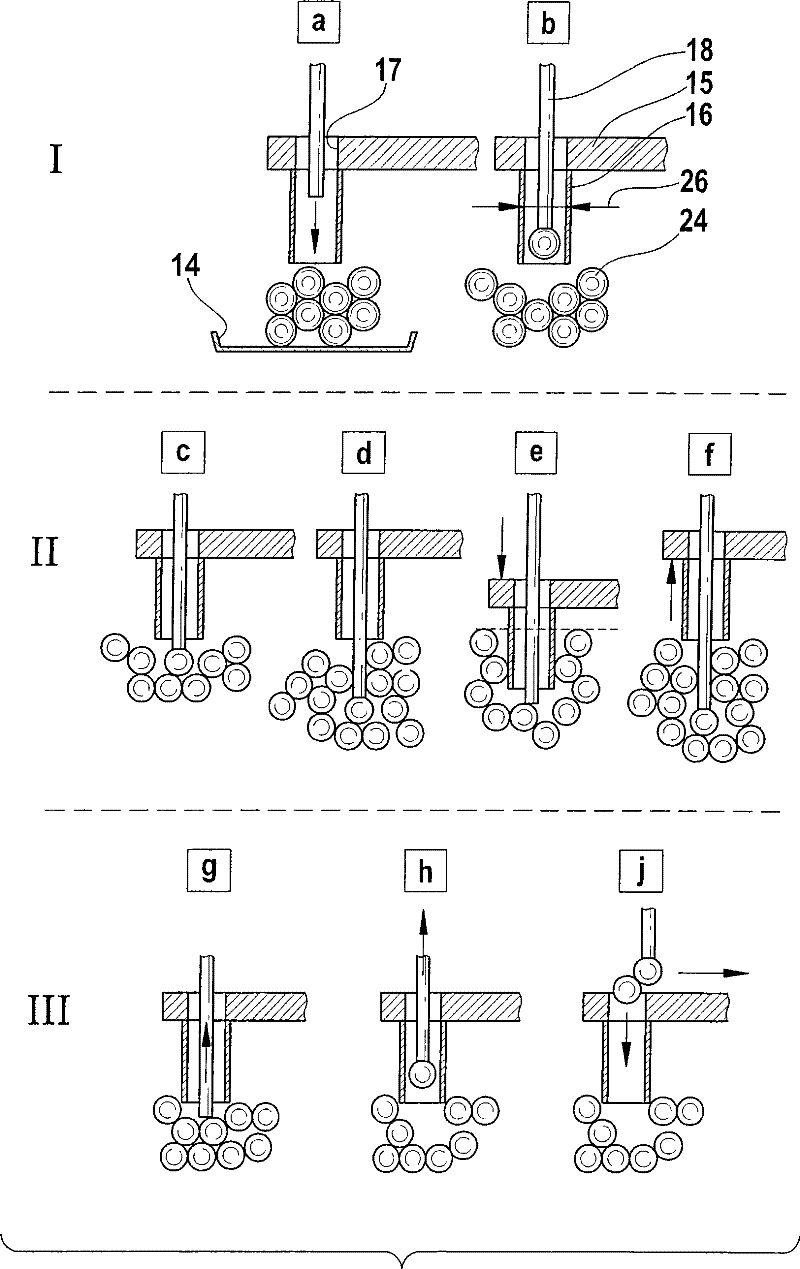

Device for transporting ball shaped component into container

ActiveCN101077729BAvoid pinchingReliable separationConveyorsLiquid materialSpherical shapedMechanical engineering

Owner:SYNTEGON TECHNOLOGY GMBH

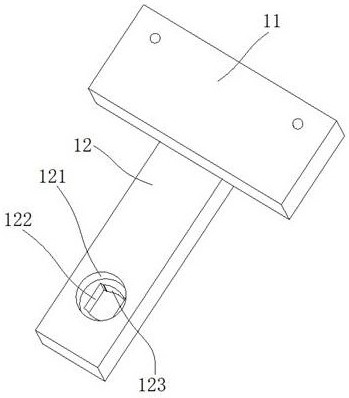

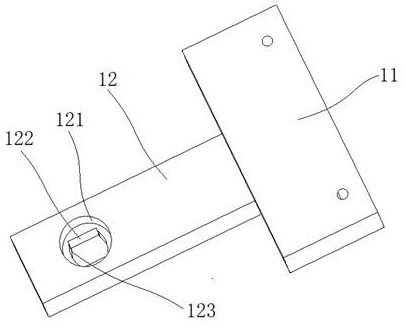

Automatic chip alignment device and alignment method

ActiveCN113835019BImprove conductivityImprove thermal conductivityElectronic circuit testingSemiconductor/solid-state device manufacturingEngineeringErbium lasers

The invention provides an automatic chip alignment device and an alignment method, which belong to the technical field of laser chip detection equipment. The chip automatic alignment device includes: a moving mechanism; an alignment piece, and the alignment piece has a correction plate; The first hole body is suitable for the chip to pass through, and a group of opposite sides of the first hole body is provided with avoidance grooves. The chip automatic alignment device provided by the present invention drives the alignment member to move forward, backward, left, and right in the first direction and the second direction by controlling the moving mechanism. The chip is adjusted in angle and position under the action of the side of the first hole, and an avoidance groove is provided on the first hole, and the avoidance groove can prevent the light-emitting point on the chip from touching the side of the first hole. Ensure that the chip is in an accurate position and angle during detection, avoid the phenomenon that the detection mechanism cannot accurately detect the corresponding position on the chip, and ensure the accuracy of the chip detection result.

Owner:HEBEI KTHAHCO TECH CO LTD

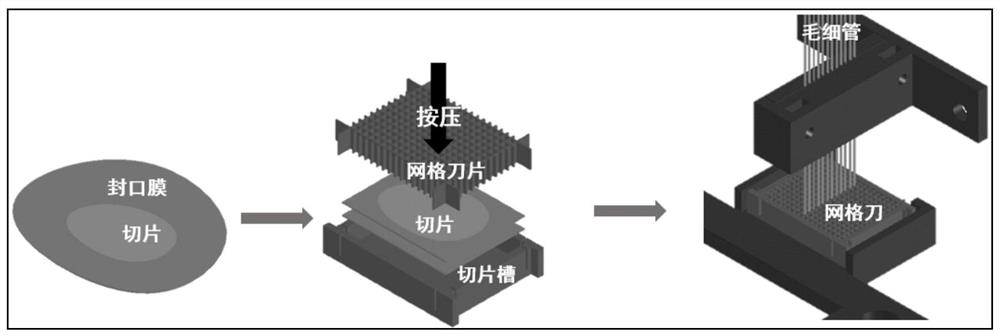

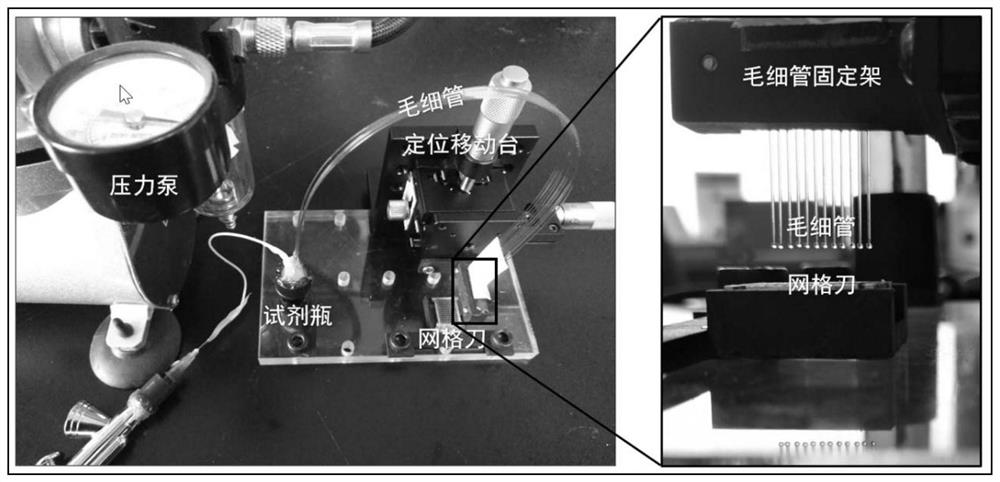

Molecular imaging method based on high-stability capillary electrophoresis separation analysis technology

ActiveCN113109409ARich separation patternsSeparate objects widelyMaterial analysis by electric/magnetic meansPhysicsNeutral molecule

The invention discloses a molecular imaging method based on a high-stability capillary electrophoresis separation analysis technology, and relates to multiple fields of analytical chemistry, life science, clinical medicine, medicine development, material science and the like. The molecular imaging method comprises the steps of sample pretreatment, high-stability capillary electrophoresis sample introduction, separation and analysis and molecular distribution image drawing. The sample pretreatment adopts a grid knife method, and comprises the steps of uniform segmentation, in-situ extraction, enrichment, derivation and the like. According to the method, the strong separation capability and abundant separation modes of capillary electrophoresis are utilized, imaging elements are abundant, and neutral molecules difficult to distinguish by mass spectrometry and components with the same mass-to-charge ratio can be imaged. The batch processing capacity of capillary array electrophoresis can accelerate the separation process and shorten the imaging analysis time. By means of the high-stability capillary electrophoresis technology, the peak position of the separated component can be stabilized, identification and positioning of the component are facilitated, and then a spatial distribution image of the stable peak component is constructed.

Owner:INST OF CHEM CHINESE ACAD OF SCI

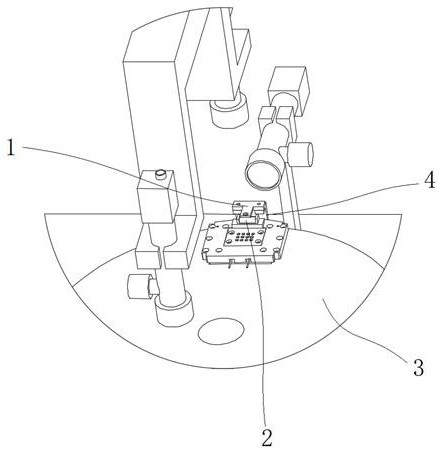

Positioning piece feeding device of wire connector production equipment

ActiveCN111299992ADraw reliablePrevent lodgingMetal working apparatusElectrical connectorMechanical engineering

The invention relates to the technical field of electronic connector production, and discloses a positioning piece feeding device of wire connector production equipment. The positioning piece feedingdevice comprises a support, a transverse moving air cylinder, a moving plate, a longitudinal moving air cylinder, a suction assembly, a material table, a discharging block, a jacking block, a jackingair cylinder, a first side pushing air cylinder, a push rod and a second side pushing air cylinder. According to the positioning piece feeding device, the suction assembly is used for sucking, carrying, taking materials for positioning and placing the materials for guiding, and the taking and placing precision is high.

Owner:SHANDONG LONGLI ELECTRONICS

Sewing machine

A sewing machine includes a needle, a needle bar which supports the needle, an upper feeding foot operable to feed the workpiece interlockingly with an up and down movement of the needle bar, a presser foot operable to press the workpiece, a holding bar which supports the presser foot, an actuator including an operating member operable to be changed to a first state, a second state or a no-load state, and a connecting portion which couples the operating member and the holding bar. The holding bar is constantly biased downward by a biasing force. The actuator moves the presser foot up against the first biasing force when the operating member is in the first state, and moves the presser foot down when the operating member is in the second state.

Owner:JUKI CORP

A wire connector and its automatic production equipment and method

ActiveCN111300034BThe equipment is compactCompact structureAssembly machinesMetal working apparatusEngineeringElectrical connector

The invention relates to the technical field of electronic connector production. An automatic production equipment for wire connectors, the equipment includes a frame and a turntable fixture device installed on the frame, a wire joint feeding device, a positioning piece feeding device, a side clamping piece feeding device, a bottom clamping piece feeding device, detection device, punching device and unloading device; the turntable jig device is installed in the middle of the frame, the wire joint feeding device, the positioning piece feeding device, the side clip feeding device, the bottom clip feeding device, the detection device, The stamping device and the unloading device are sequentially arranged on the periphery of the turntable jig device. The turntable jig device is efficient in transfer, can clamp and position the workpiece with higher precision; guide the positioning piece to facilitate accurate falling into the jig; maintain the position of the workpiece and improve the accuracy of the assembly of the clamping accuracy.

Owner:陕西中昊佳成信息科技有限公司

Pot body seed tray and pot body seeder

InactiveCN101773012BEasy to moveDraw reliableSeed depositing seeder partsSingle grain seedersPositive pressureEngineering

The invention relates to a pot body seed tray and a pot body seeder, in particular to a pot body seed tray for accurately seeding in the pot body for cultivating rice seedling and a seeder adopting the seed tray. The invention solves the problems of low reliability for directly adsorbing seed by small holes of the seed tray, miss seedling and complex control structure of the seeder. In the pot body seeder, a stand is provided with a negative-pressure fan, a positive-pressure fan, a seed tray, a pot body seed tray and a pot body seed tray. A shell of the pot body seed tray and a bottom plate are spliced into a cavity; a vacuum pipe interface on the shell and a plurality of small holes on the bottom plate are respectively communicated with the inside space of the cavity; the vacuum pipe interface is connected with a vacuum control valve and the negative-pressure fan in series through a vacuum pipeline; the shell is provided with an air blowpipe interface communicated with the inside space of the cavity; the air blowpipe interface is connected with an air blow control valve and the positive-pressure fan in series through an air blow pipeline; each small hole of the bottom plate is provided with a sucker at least provided with a suction hole which is communicated with the inside space of the cavity and is provided with a slot at the external end.

Owner:张国梁

Drive device for a motor vehicle

ActiveCN107076293ALower the liquid levelRaise the liquid levelGear lubrication/coolingGear wheelLubricant

Owner:AUDI AG

Automatic sucker manipulator device

PendingCN110860615AReduce labor intensitySimple structureMetal-working feeding devicesPositioning devicesRobot handWork injury

The invention relates to a feeding device, in particular to an automatic sucker manipulator device. The device comprises a shelf, a feeding mechanism, a sucking mechanism and a base, wherein the shelfis arranged on the base, and is used for storing workpieces and discharging one by one; the feeding mechanism is arranged on the base, is positioned under the shelf, and is used for bearing the workpieces falling from the shelf and forwards conveying; and the sucking mechanism is arranged on the base, and is used for sucking and conveying the workpieces conveyed by the feeding mechanism. The device is simple and compact in structure, small in size and convenient to operate, realizes precise control, improves the working efficiency, reduces the labor intensity of workers, and prevents occupational injury.

Owner:辽宁汇智机器人有限公司

Suction volume system with improved control and volume adjustment

InactiveCN105073264BConstant suction strokeImprove suction smoothnessBurettes/pipettesMaterial analysisAbsorption capacityEngineering

A device for controlling pipetting and adjusting a volume to be sampled, including a pipetting control member; rotary actuating means coupled to the control member; a linking member slidably mounted on the actuating means, the linking member being connected to a piston; volume adjusting means; rotary means defining, for the linking member, a spiral-shaped guiding path, the rotary means being coupled to the adjusting means so that their actuation causes a rotation of the means about a second axis which the guiding path is centered, this rotation leading to a displacement of the linking member along the path, and to a sliding of the member relative to the actuating means.

Owner:GILSON SAS

Vacuum clamping assembly for robot

The invention relates to a vacuum clamping assembly for a robot. The assembly comprises a plurality of adsorption bodies capable of sucking and transferring the same object to be clamped and a connecting plate which is used for connecting the plurality of adsorption bodies into a whole, a mounting platform is arranged above the connecting plate through a support, and the mounting platform is connected with a mechanical arm of the robot; each adsorption body comprises an annular suction nozzle capable of forming a negative pressure cavity and a reinforcing block extending from the upper end part of the annular suction nozzle to the direction of the connecting plate, a connecting pipe is embedded in the reinforcing block, and the connecting pipe penetrates through the connecting plate and isfixedly connected with the connecting plate; and a gas channel extending to the negative pressure cavity is arranged in each connecting pipe, each annular suction nozzle is in contact with the smoothupper surface of the object to be clamped, gas in each annular suction nozzle is pumped out by the corresponding gas channel, and a vacuum area used for adsorbing the object to be clamped is formed.The vacuum clamping assembly has the advantages of being simple in structure, convenient to use and reliable in suction.

Owner:XIAN DINGZI ELECTRONICS INFORMATION SCI & TECH

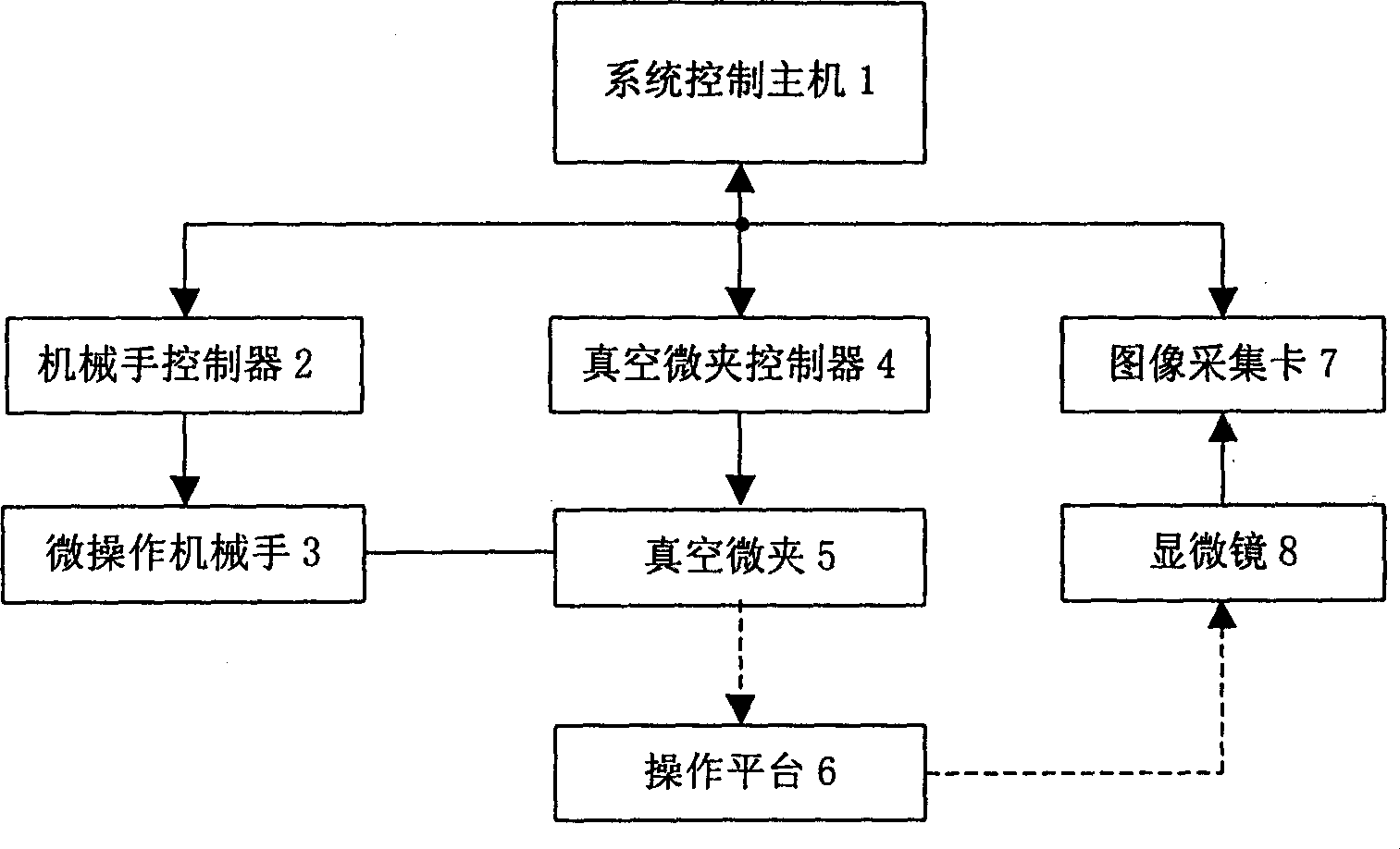

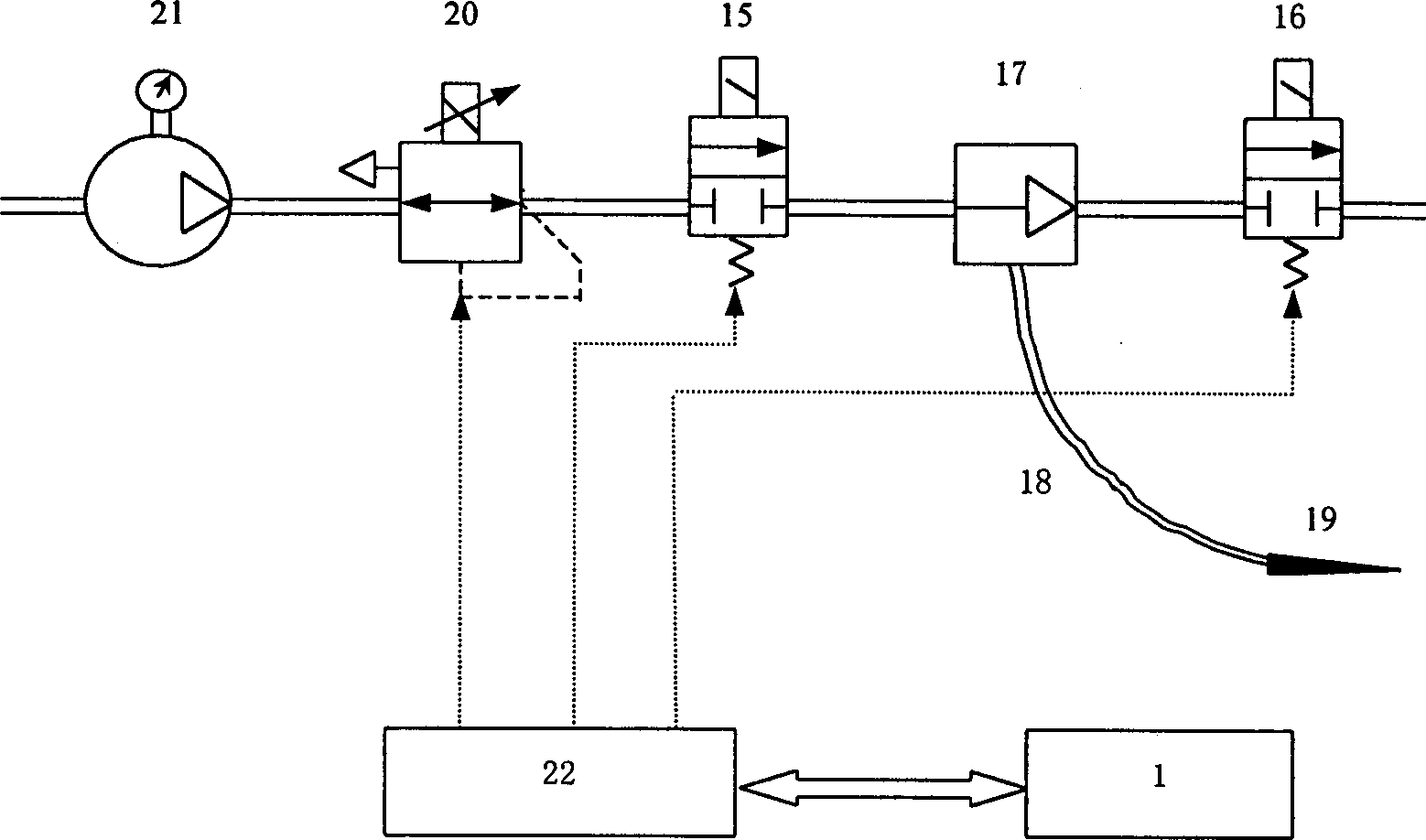

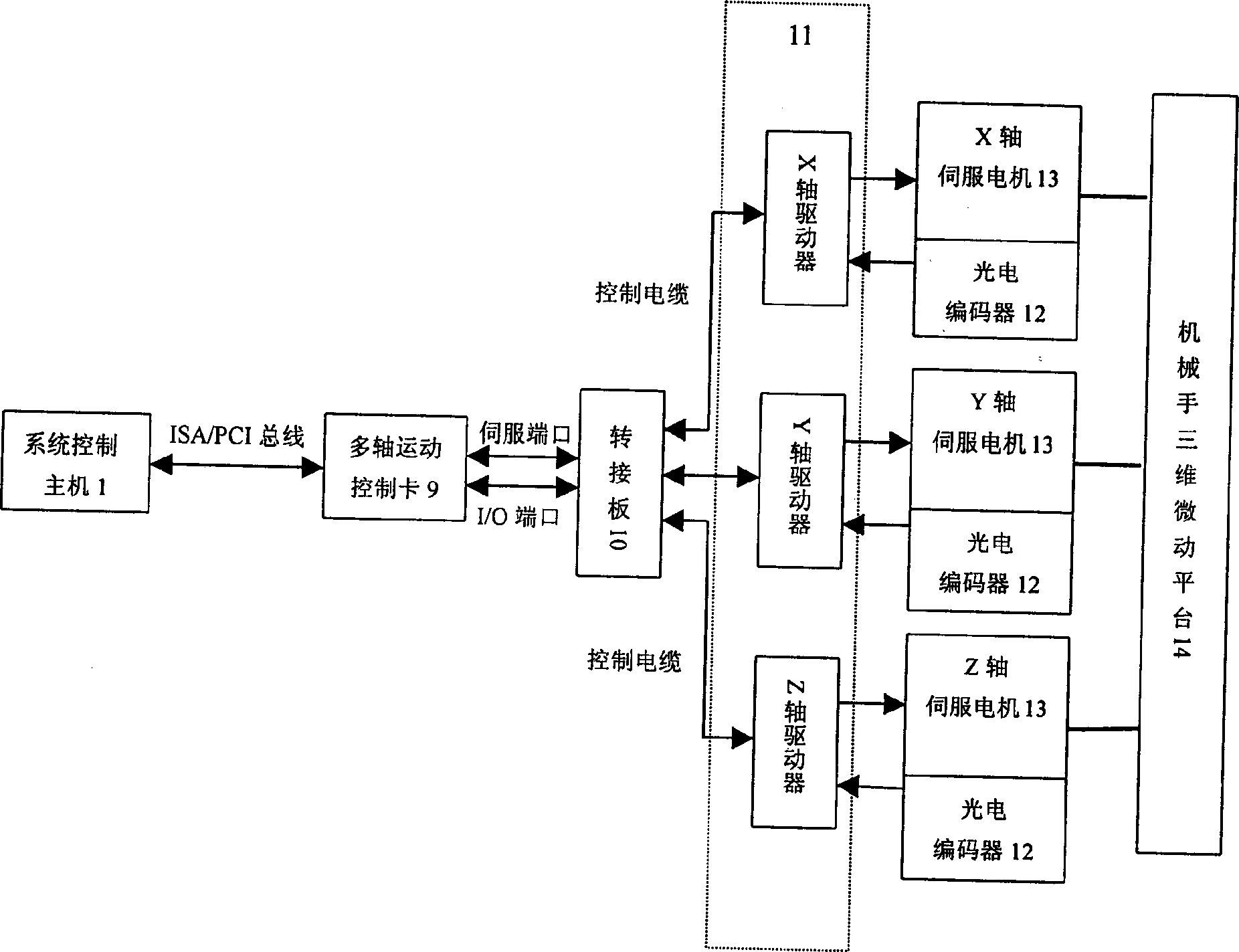

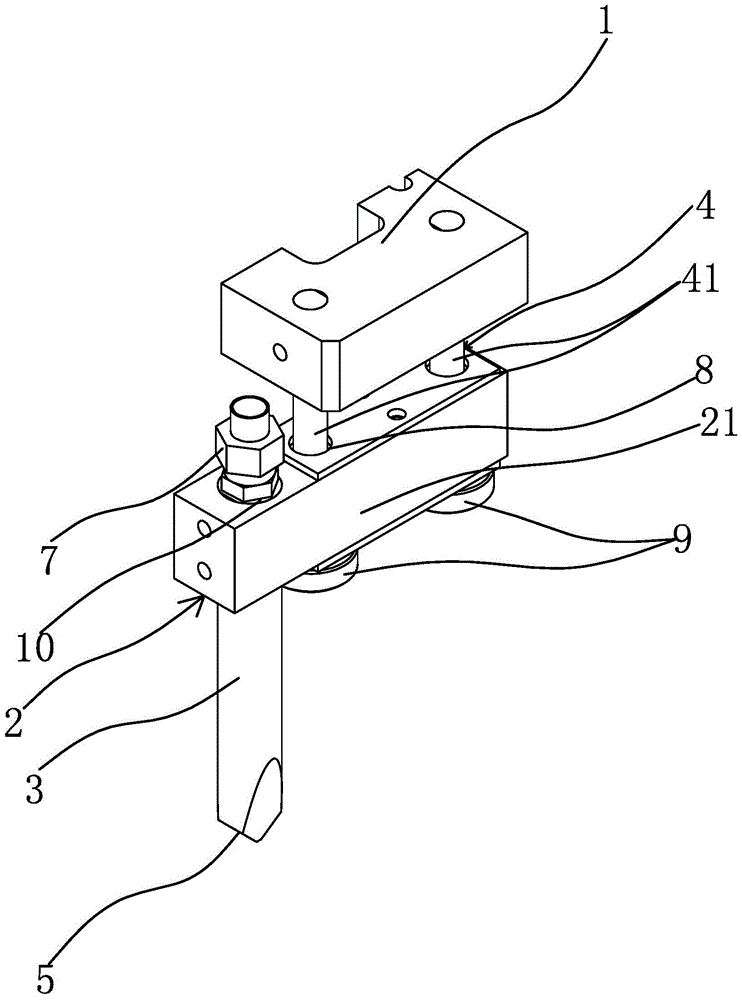

Microassembling robot system based on microvision

The present invention discloses micro assembly robot system based on microscopic vision sense and is composed of system control host unit, micro operating mechanical hand, vacuum microclamp, microscope with camera. Microoperating mechancal hand is composed of micromotion platform which has limit switch and zero position switch and is connected with servomotor having photoelectric coder, mechanical hand controller is composed of successively connected multi axle motion control clamp, transit board and driver the multiaxle motion control clamp is connected with host unit. The present invented system can conveniently and effectively proceed autoamtic and semi-autoamtic operation and assembly of submillimeter grade micro particle object.

Owner:HUAZHONG UNIV OF SCI & TECH

A suction structure for pipe feeding

The invention provides a suction structure for catheter feeding, and belongs to the technical field of mechanical devices. The suction structure for catheter feeding solves the technical problem that existing infusion set catheters are prone to deforming in the transfer process. The suction structure comprises an installing base and a pneumatic claw rod. A sliding mechanism which can make the pneumatic claw rod slide up and down in the vertical direction is arranged between the installing base and the pneumatic claw rod, a balance weight structure is fixedly connected to the pneumatic claw rod, an arc-shaped concave claw opening is formed in the lower end of the pneumatic claw rod, an air hole communicated with the claw opening is formed in the pneumatic claw rod, the claw opening is composed of two symmetrical claw pieces, and the outer side face of each claw piece is a slope which inclines from outside to inside. According to the suction structure for catheter feeding, the claw pieces of the claw opening form a wedge, and can be easily inserted into cumulate catheters to separate the catheters which cling to one another so that a target catheter can smoothly enter the claw opening, and the purpose of sucking catheters rapidly, accurately and reliably is achieved.

Owner:MAIDER MEDICAL IND EQUIP

A double stacking device for wood-plastic substrate production line

ActiveCN105600489BSafe lateral movementDraw reliableConveyorsStacking articlesProduction lineSufficient time

Owner:江苏坤美新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com