A double stacking device for wood-plastic substrate production line

A stacking device and production line technology, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of inconvenient production management, etc., and achieve the effect of simple structure, convenient connection, and reliable material absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

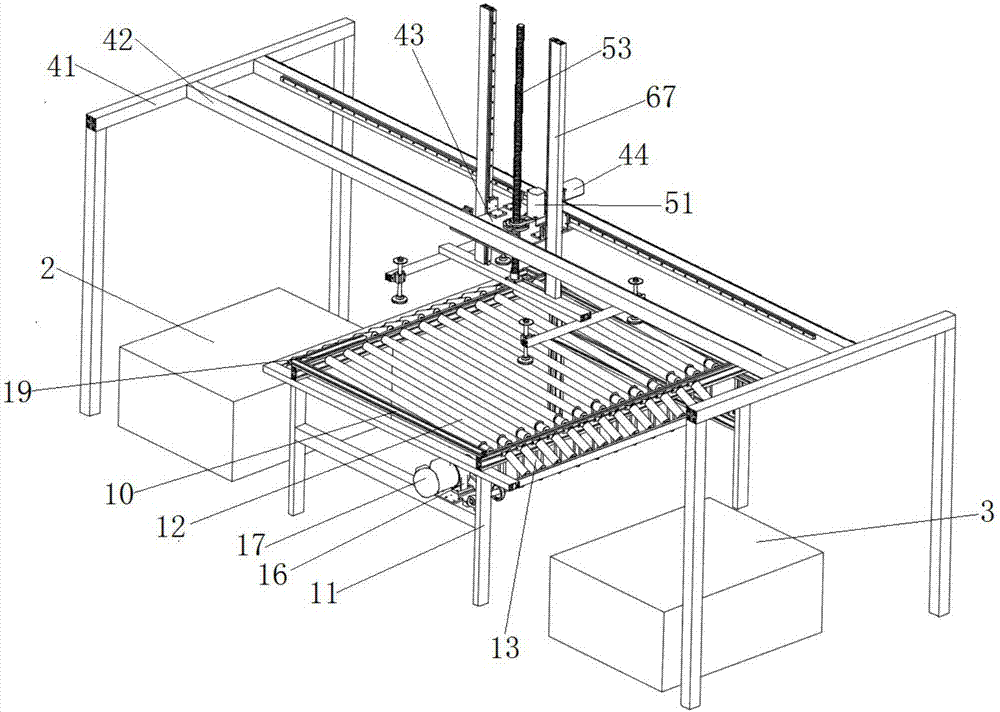

[0032] combine figure 1 , figure 2 with image 3 , a double stacking device for a wood-plastic substrate production line in this embodiment, including a roller transport mechanism, a double stacking manipulator, and stacking positions 1 and 2 placed perpendicular to the transport direction of the supporting roller transport mechanism. 3. Stacking position 1 2 and stacking position 2 3 are relatively located on the left and right sides of the roller transport mechanism. During work, stacking position 1 2 is stacked and then stacked at stacking position 2 3;

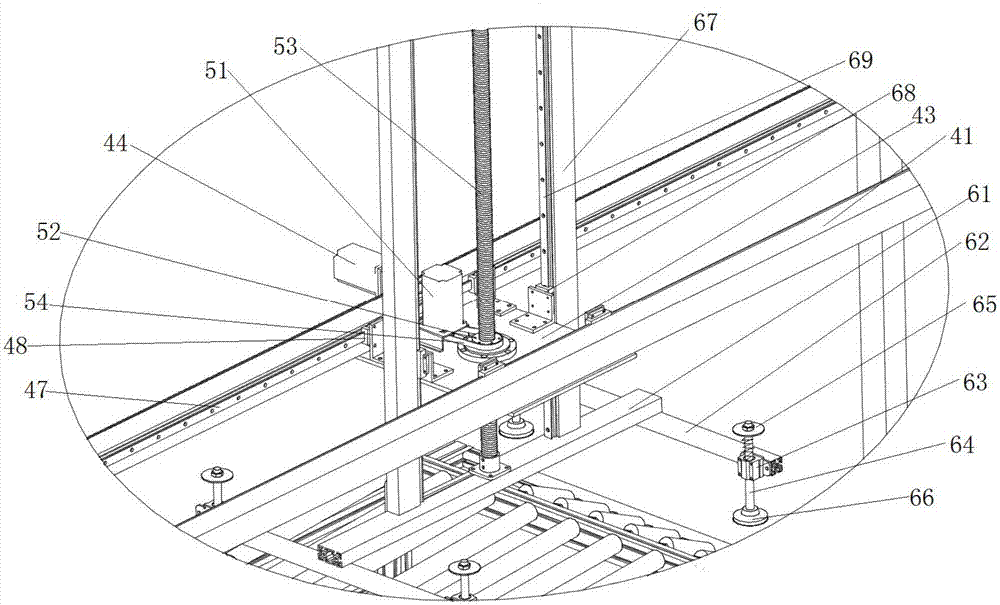

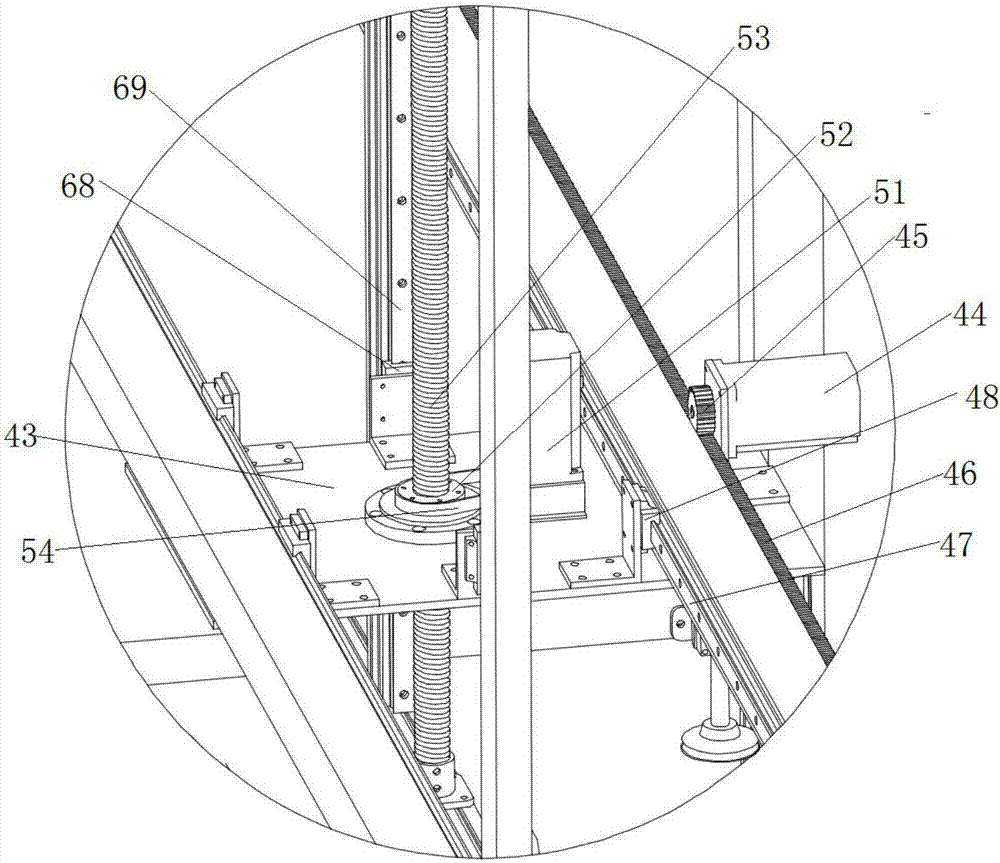

[0033] Roller transport mechanism (see Figure 4 with Figure 5shown) includes a main frame 11, several central idlers 12 and power components, several central idlers 12 are parallel to each other and are respectively rotatably connected to the main frame 11, and several central idlers 12 are respectively provided with several A side roller 13. Specifically, in this embodiment, the lower part of the main frame 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com