Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Avoid transit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

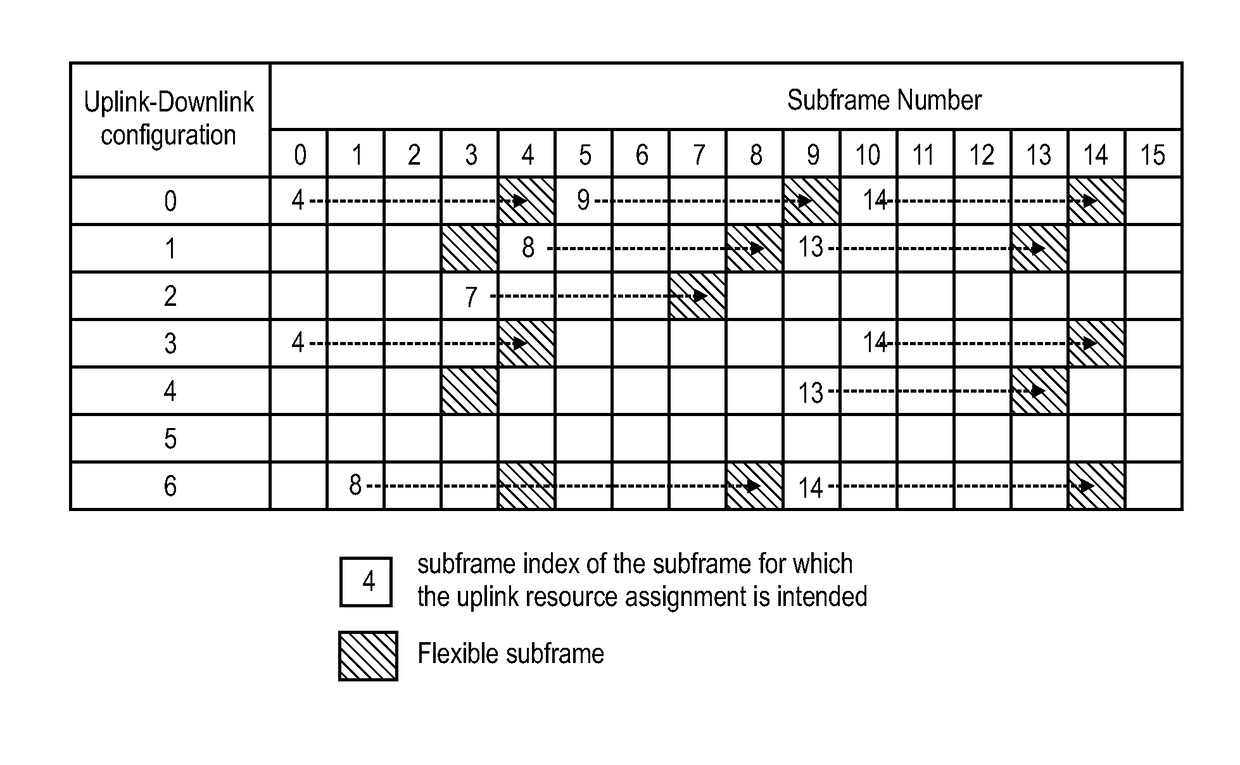

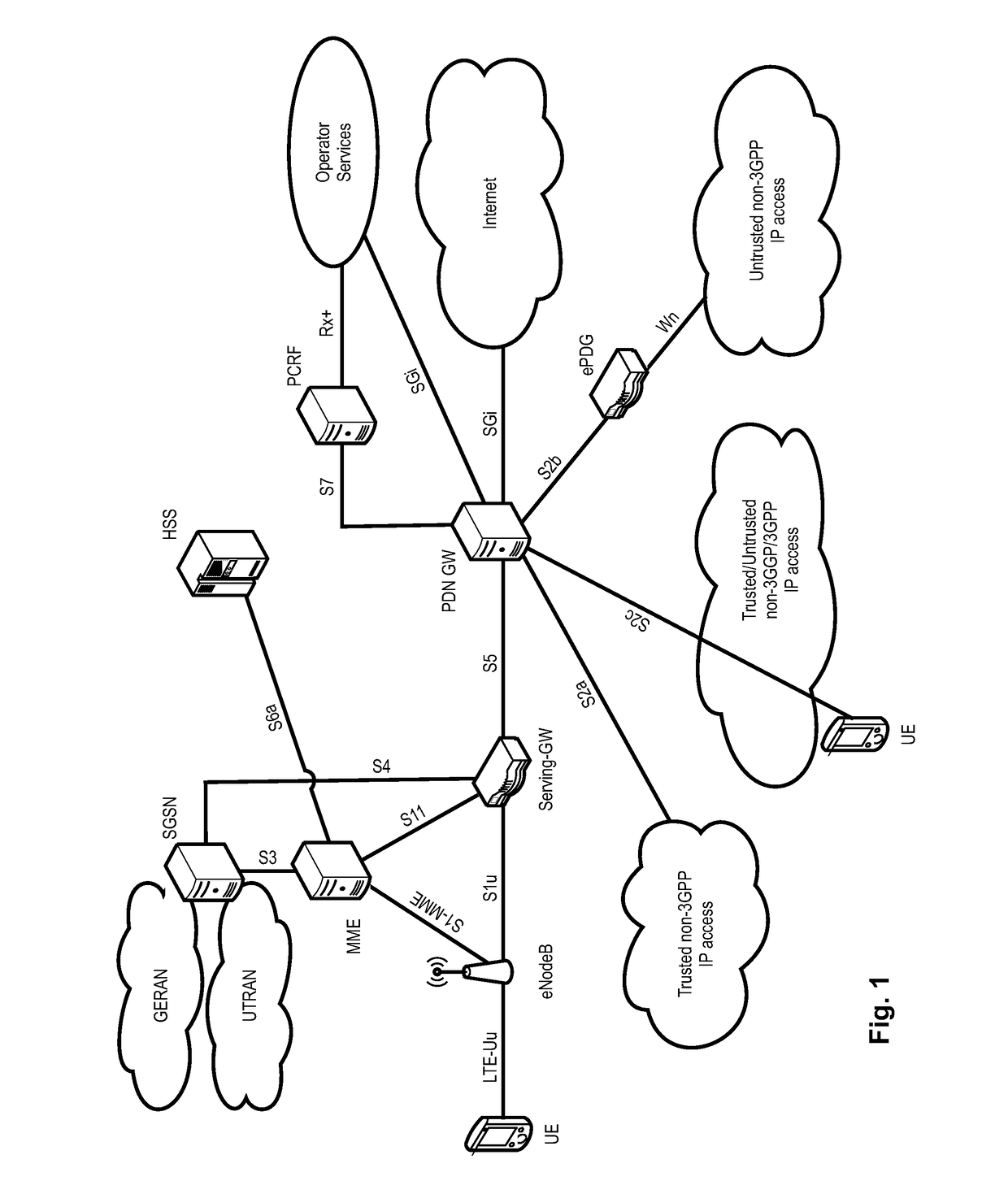

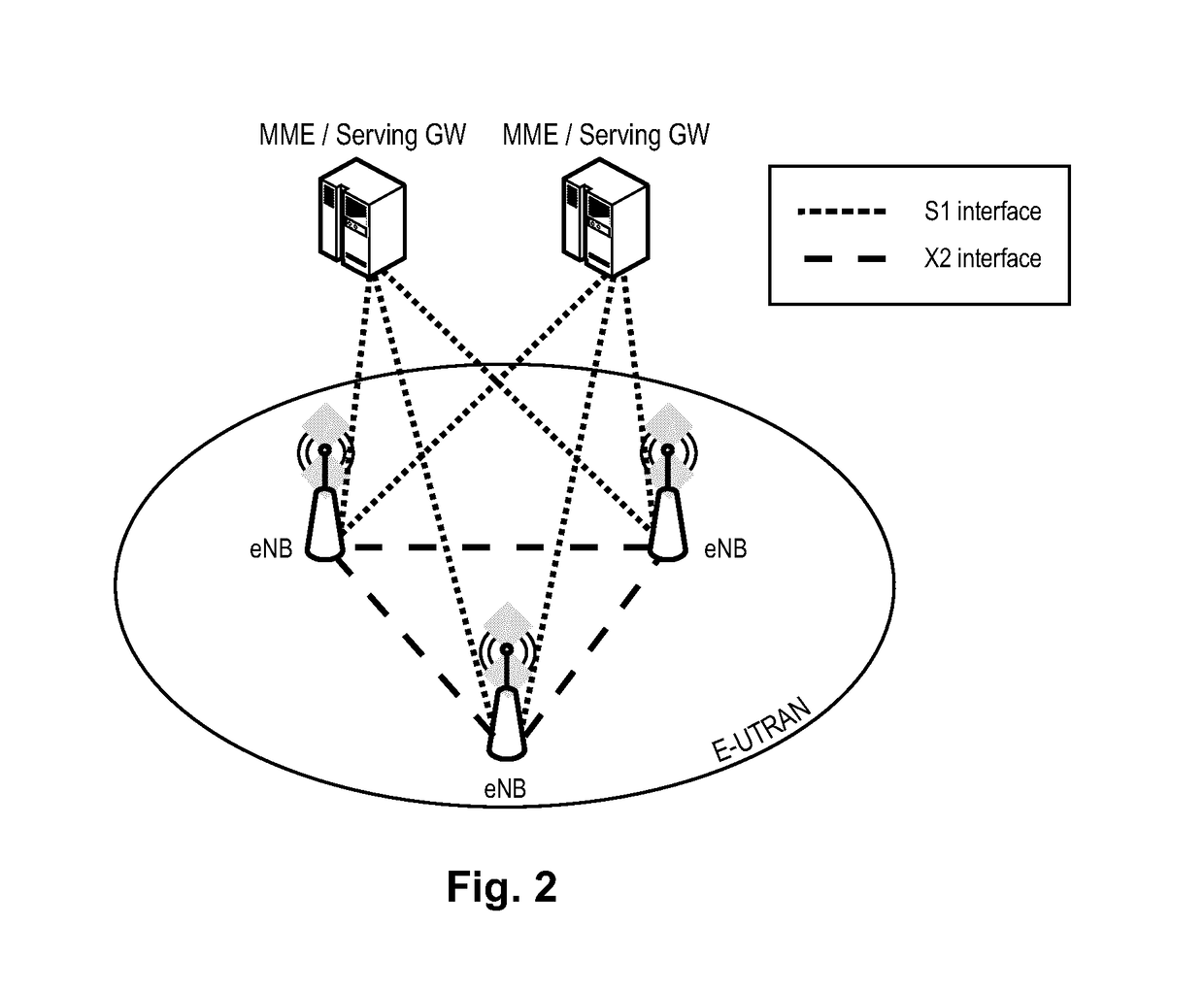

Flexible TDD uplink-downlink configuration with flexible subframes

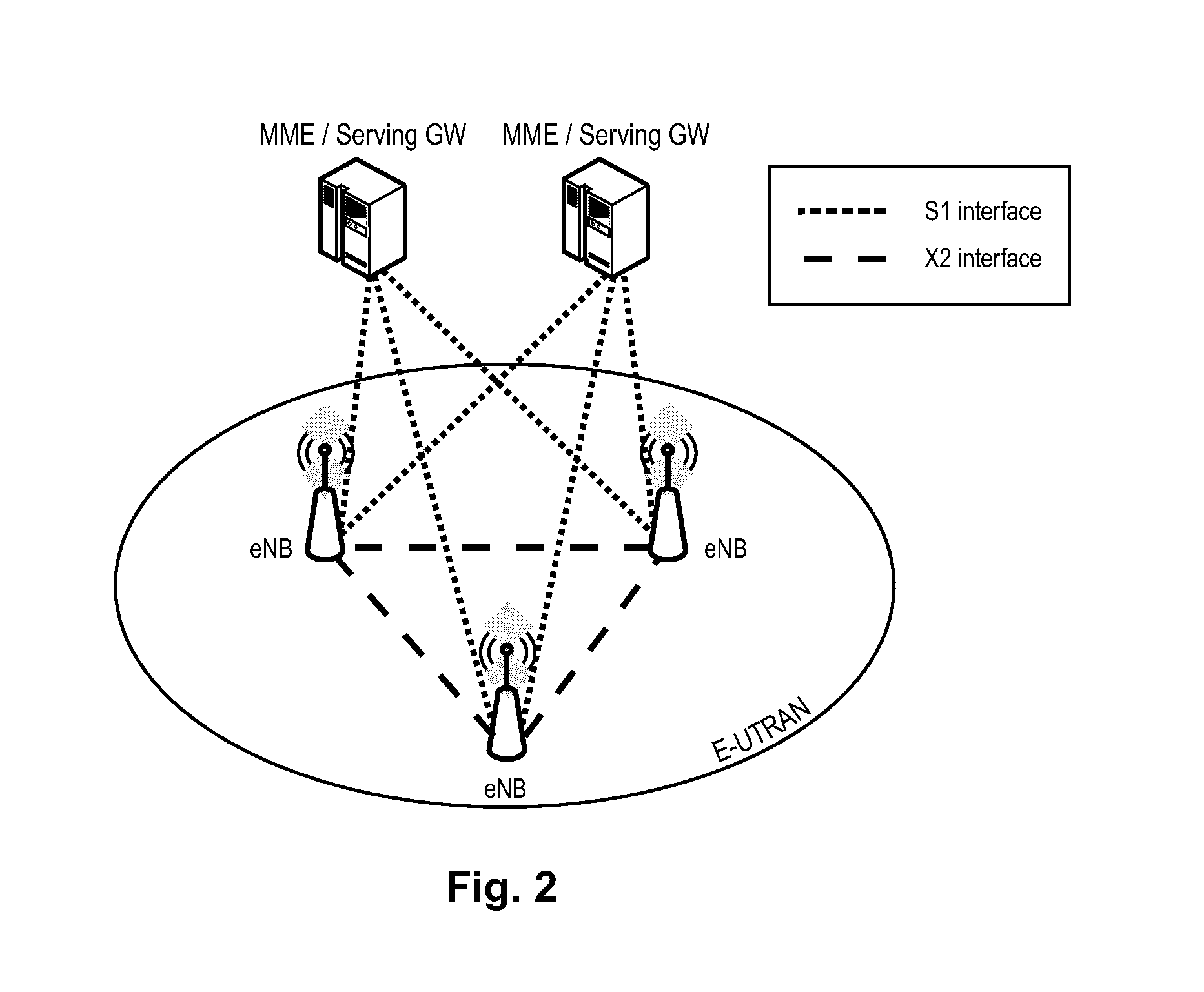

ActiveUS20160080133A1Adapt wellAvoid transitError preventionTransmission path divisionData transmissionRandom access

The invention relates to a method for communicating based on a flexible TDD configuration by introducing flexible subframes, selectively usable as a downlink or uplink subframe in a manner avoids a transition from a (non-)flexible downlink subframe n to a (non-)flexible uplink subframe n+1. Furthermore, the invention allows reducing the number and types of uplink transmissions that would be pending for a flexible subframe, by defining HARQ uplink feedback timings based on the HARQ uplink feedback timings for the static TDD configurations such that HARQ uplink feedback is never transmitted in a flexible subframe, and also by releasing configurations for periodic uplink transmissions such as, SPS-scheduled uplink data transmissions, periodic CSI report, uplink sounding, random access, and scheduling requests.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

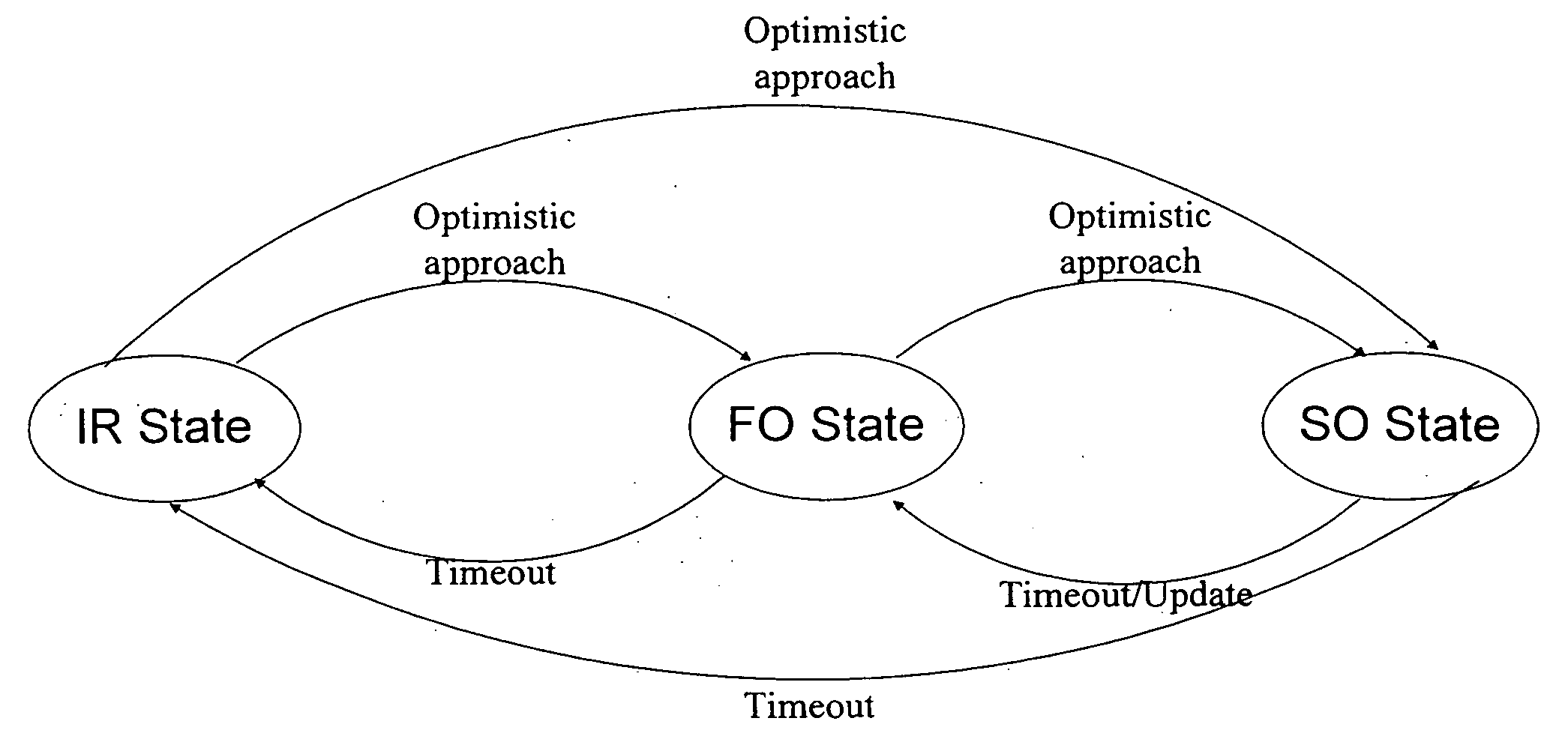

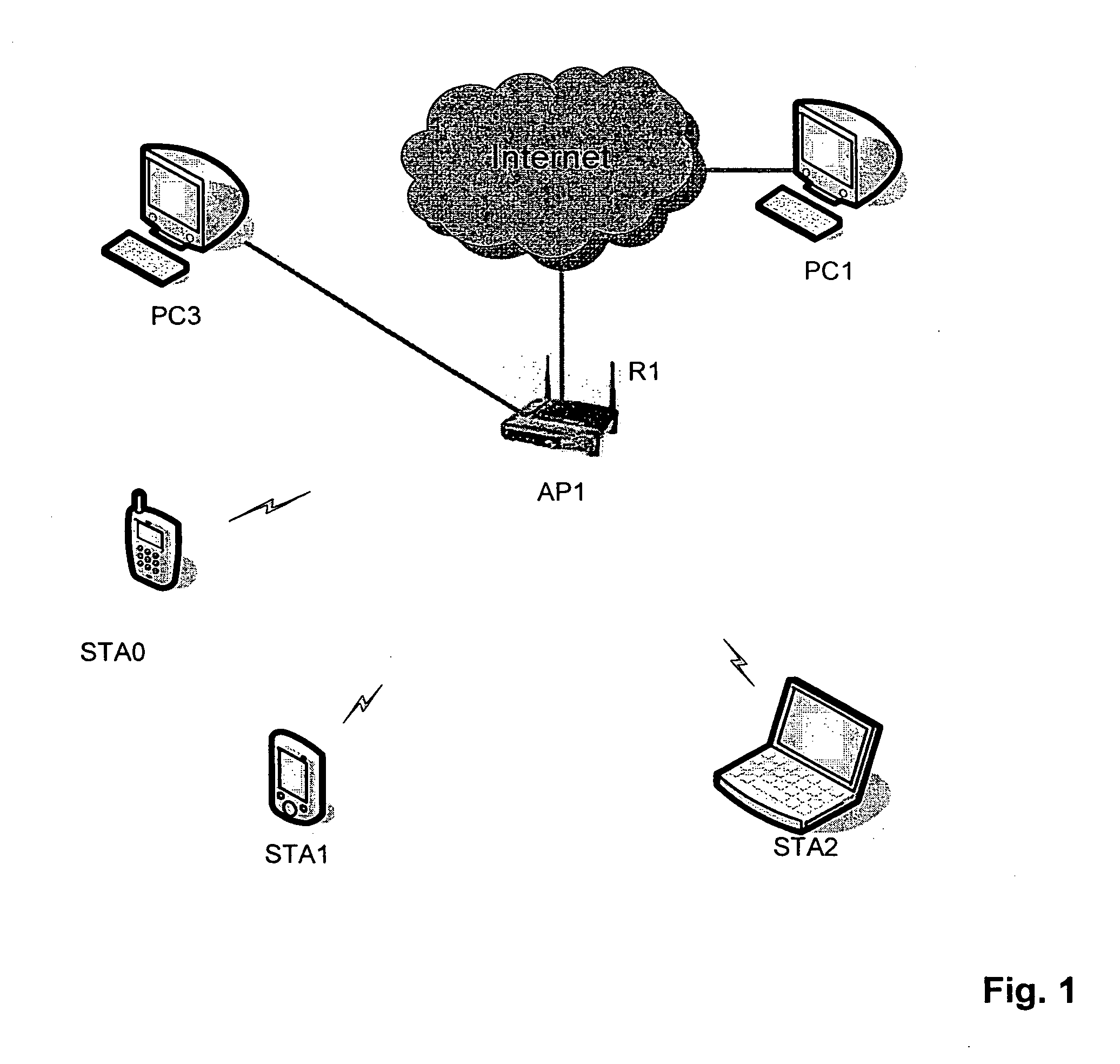

Method for the exchange of data packets in a network of distributed stations, device for compression of data packets and device for decompression of data packets

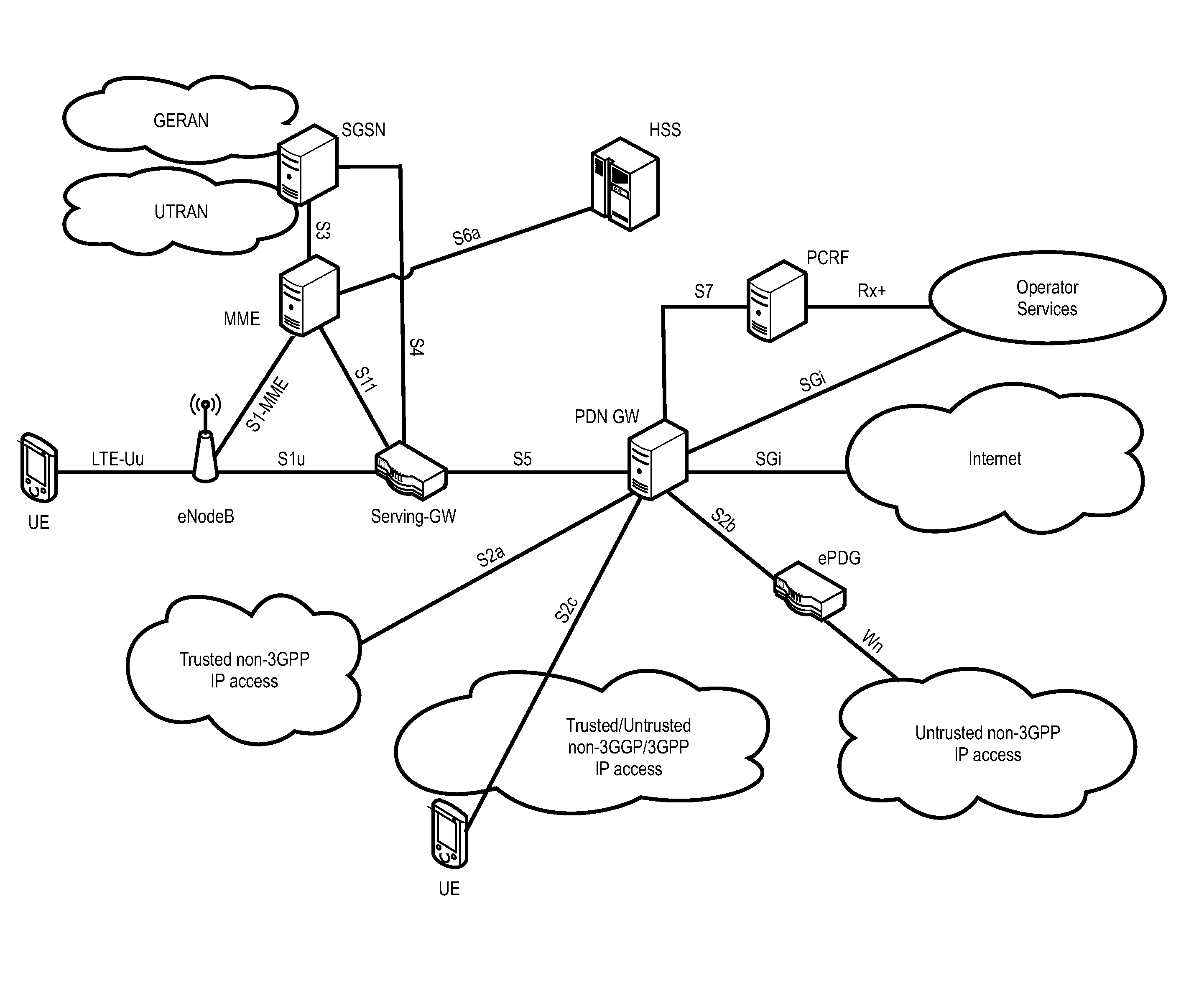

InactiveUS20070165635A1Avoid possibilityAvoid transitSpecial service provision for substationNetwork traffic/resource managementRobust Header CompressionNetwork communication

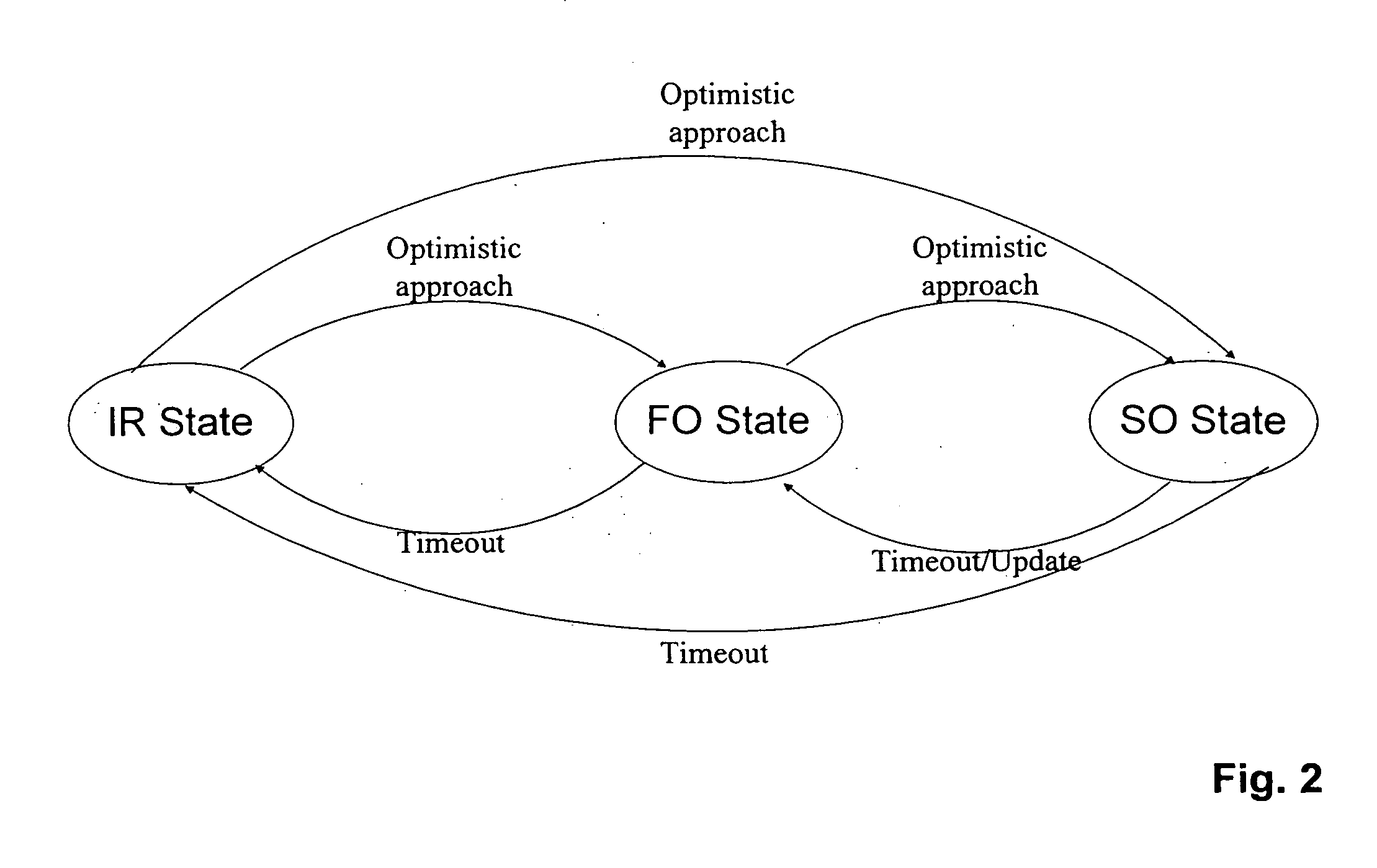

The invention is related with network communication, in particular wireless networking. In order to improve bandwidth utilization, a header compression protocol is implemented in most wireless network systems, such as robust header compression ROHC for WLAN systems. When using multicast groups for data communication problems with ROHC are related with relative late initiation of stations that newly enter the multicast group. The invention proposes an improved state machine for the compressor in order to overcome this drawback. It is also proposed an improvement for the decompressors which omit sending positive acknowledgements in order to further improve compression efficiency. The invention also concerns an accordingly improved method for the exchange of data packets in a network of distributed stations.

Owner:THOMSON LICENSING SA

Skewless differential switch and DAC employing the same

InactiveUSRE37619E1Minimizes complexity of switchReduces spurious switchingTransistorElectric signal transmission systemsControl signalDigital-to-analog converter

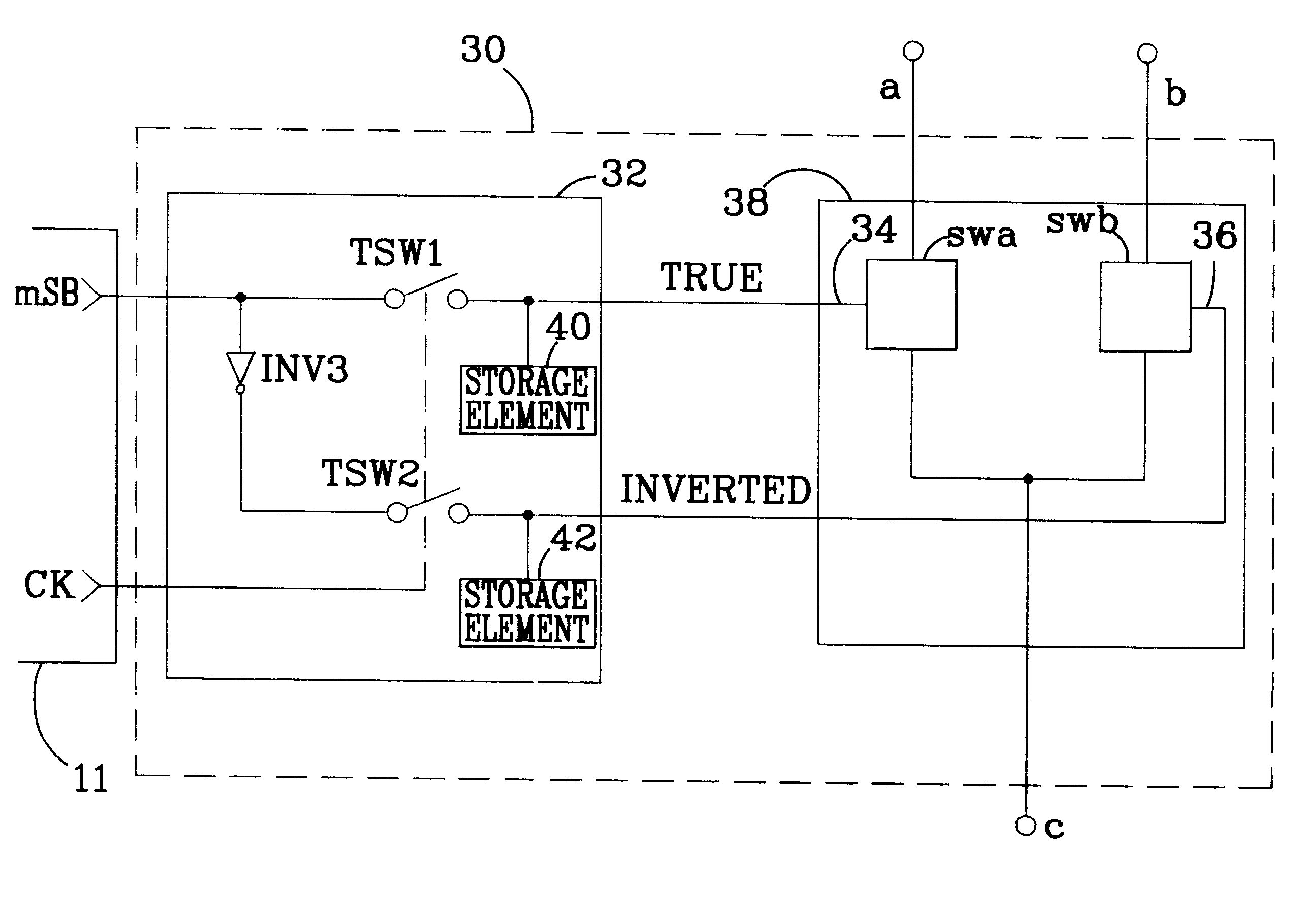

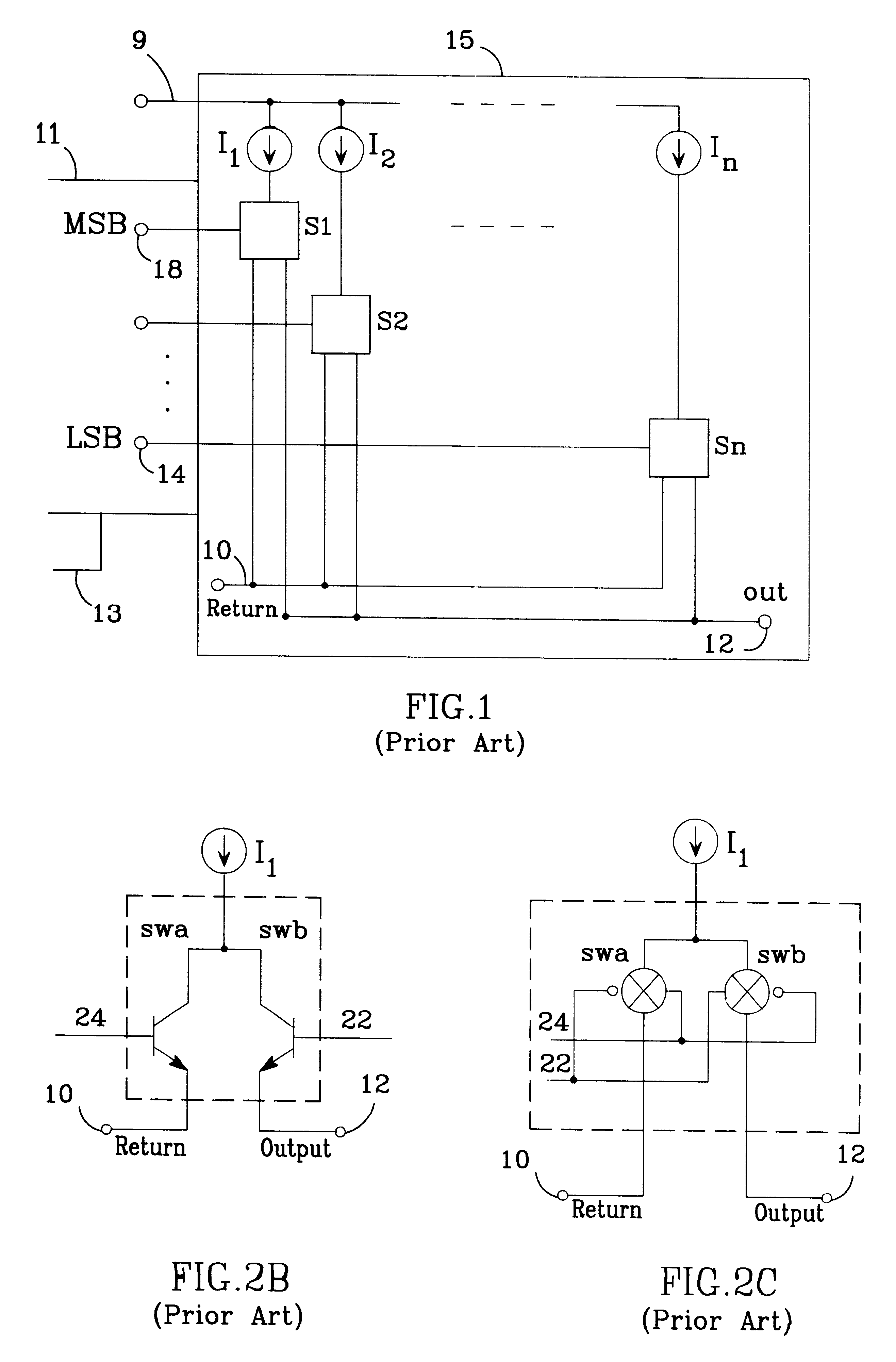

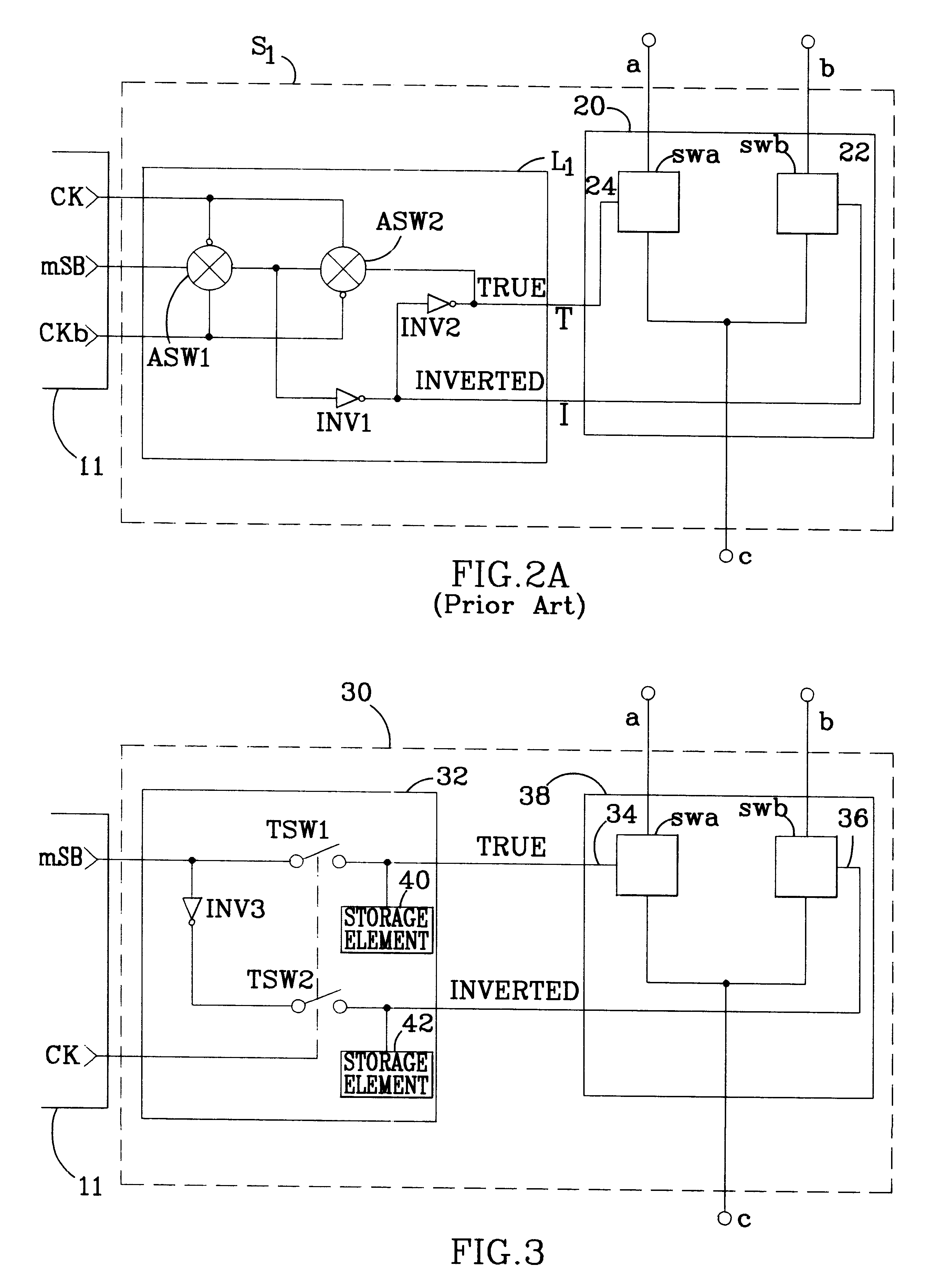

A differential switch accepts a binary control signal and its complement (which may be skewed with respect to the control signal) and latches both signals simultaneously. The latched output signals drive the control terminals of a differential switch pair which connects one of two terminals to a third terminal, depending upon the state of the control terminals. The differential switch may optionally include an inverter which complements the binary control signal, thus eliminating the need for external inversion of the control signal. The switch is particularly applicable for use in a digital to analog converter.

Owner:ANALOG DEVICES INC

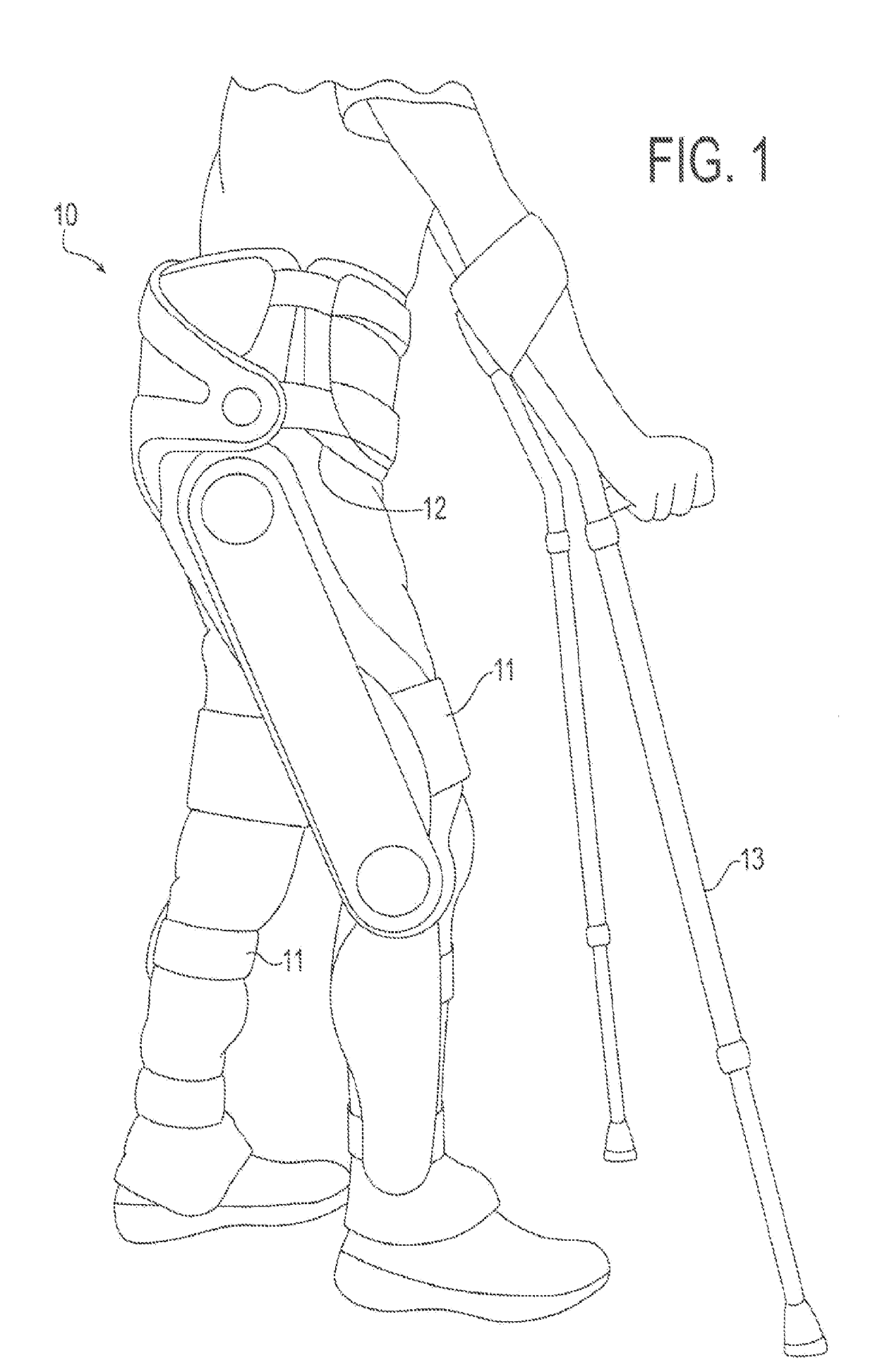

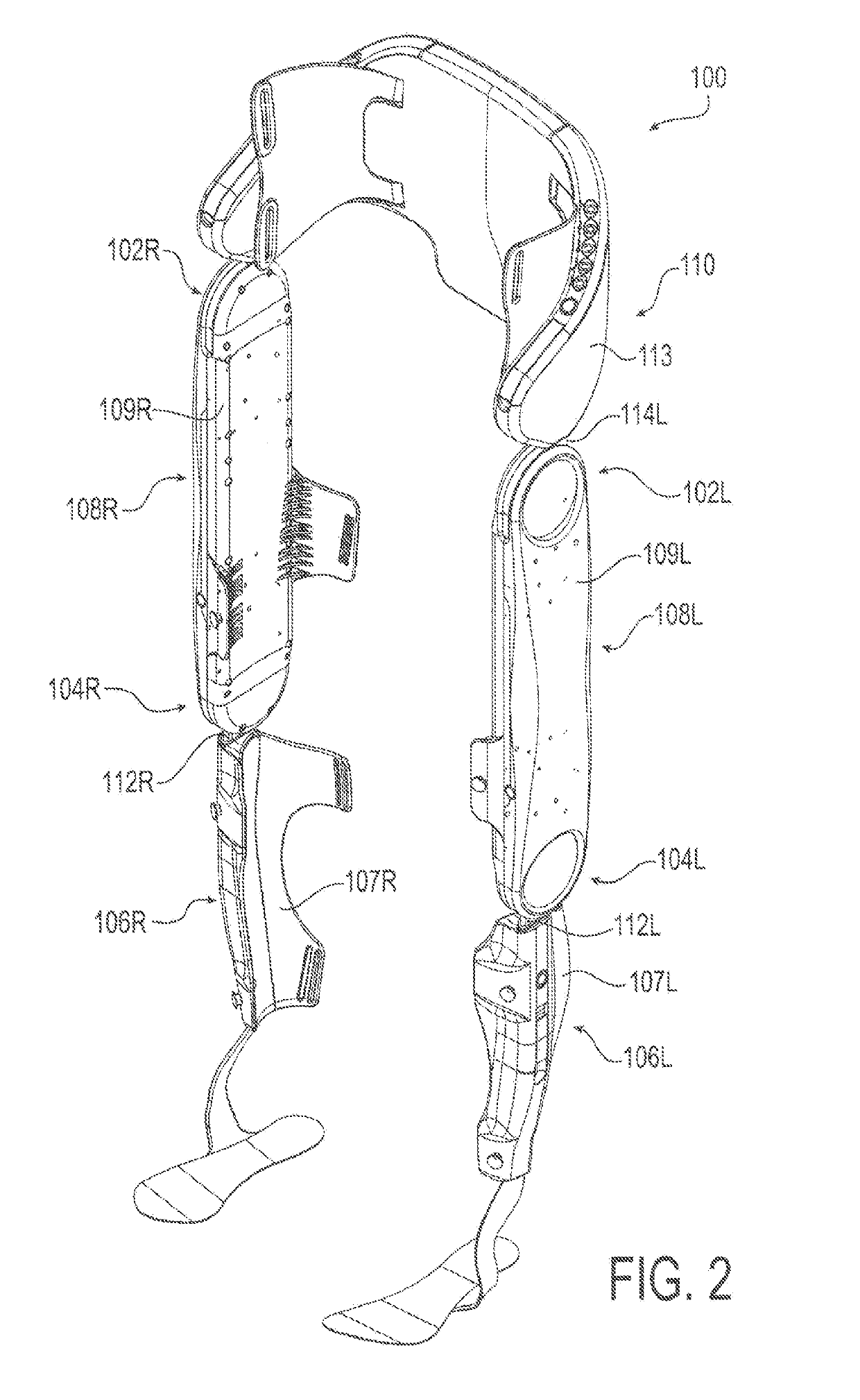

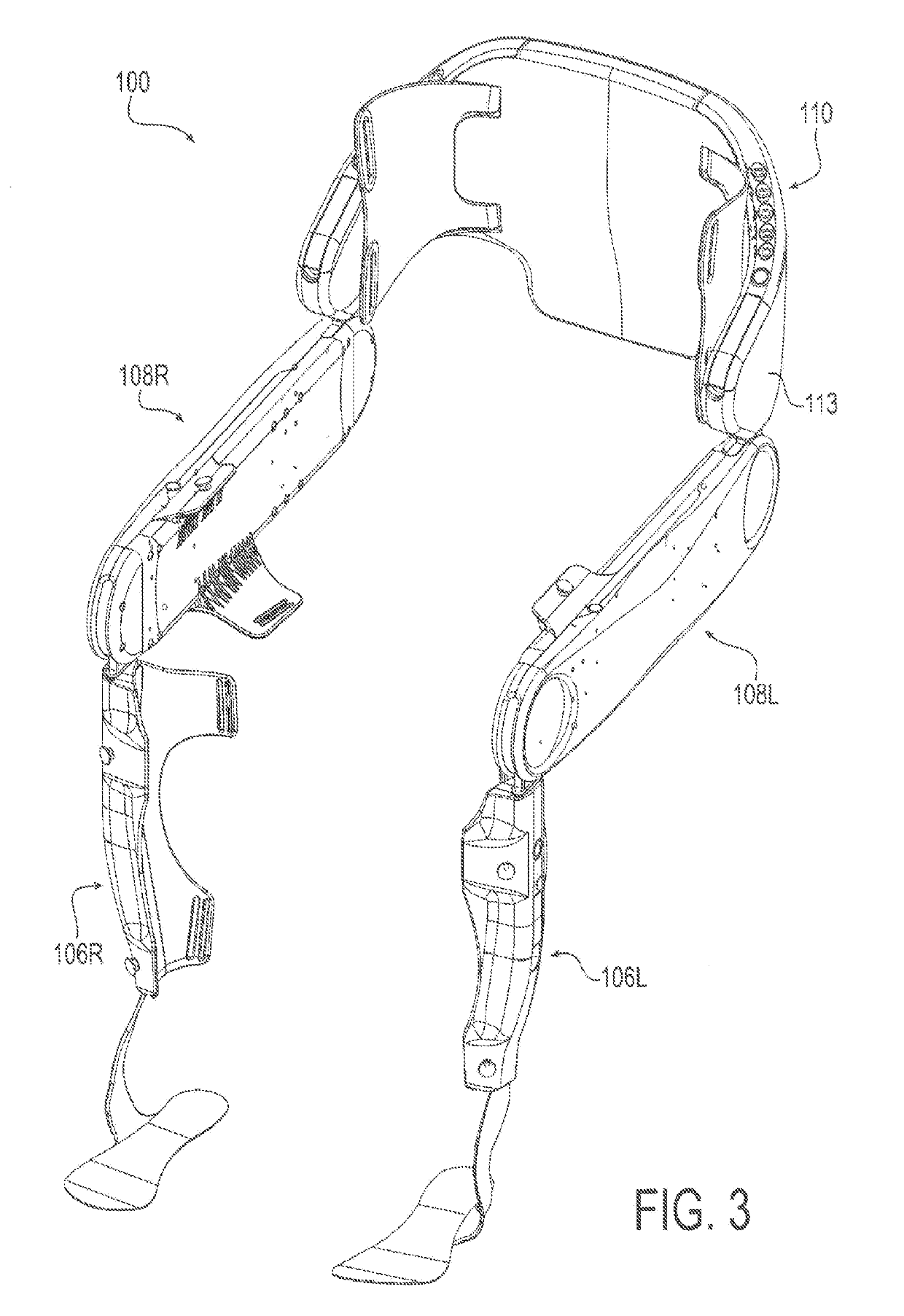

Safety monitoring and control system and methods for a legged mobility exoskeleton device

ActiveUS20190105777A1Avoid unnecessaryAvoid state transitionsProgramme controlProgramme-controlled manipulatorJoint componentElectronic controller

A method of controlling a mobility device and related device including at least one drive component that drives at least one joint component is described. The control method may include executing a control application with an electronic controller to perform: receiving sensor information from sensors corresponding to a state and / or mode of the mobility device; analyzing the sensor information and determining a control mode of operation based on the sensor information; generating a control signal to output an alert via electronic indicators corresponding to the determined control mode; and controlling at least one drive component of the mobility device to selectively configure and modulate at least one joint component in accordance with the determined control mode of operation. Different alerts may be outputted by the electronic indicators depending on the nature or severity of the alert condition, accompanied by respective device control operations in accordance with the alert condition.

Owner:EKSO BIONICS HLDG INC

Flexible TDD uplink-downlink configuration with flexible subframes

ActiveUS9768942B2Reduce distractionsEasy to adaptError prevention/detection by using return channelTransmission path divisionUplink transmissionData transmission

The invention relates to a method for communicating based on a flexible TDD configuration by introducing flexible subframes, selectively usable as a downlink or uplink subframe in a manner avoids a transition from a (non-)flexible downlink subframe n to a (non-)flexible uplink subframe n+1. Furthermore, the invention allows reducing the number and types of uplink transmissions that would be pending for a flexible subframe, by defining HARQ uplink feedback timings based on the HARQ uplink feedback timings for the static TDD configurations such that HARQ uplink feedback is never transmitted in a flexible subframe, and also by releasing configurations for periodic uplink transmissions such as, SPS-scheduled uplink data transmissions, periodic CSI report, uplink sounding, random access, and scheduling requests.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

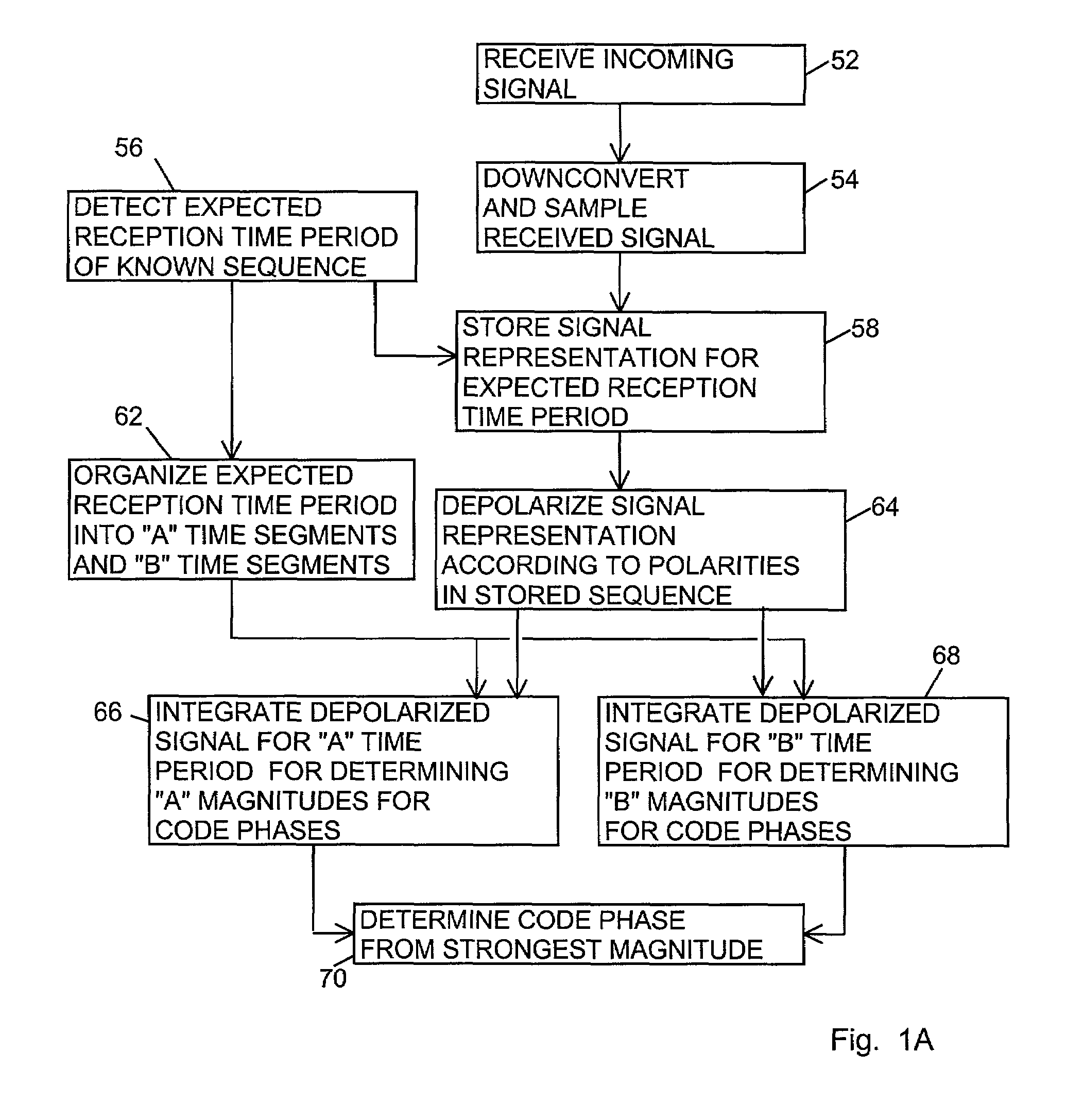

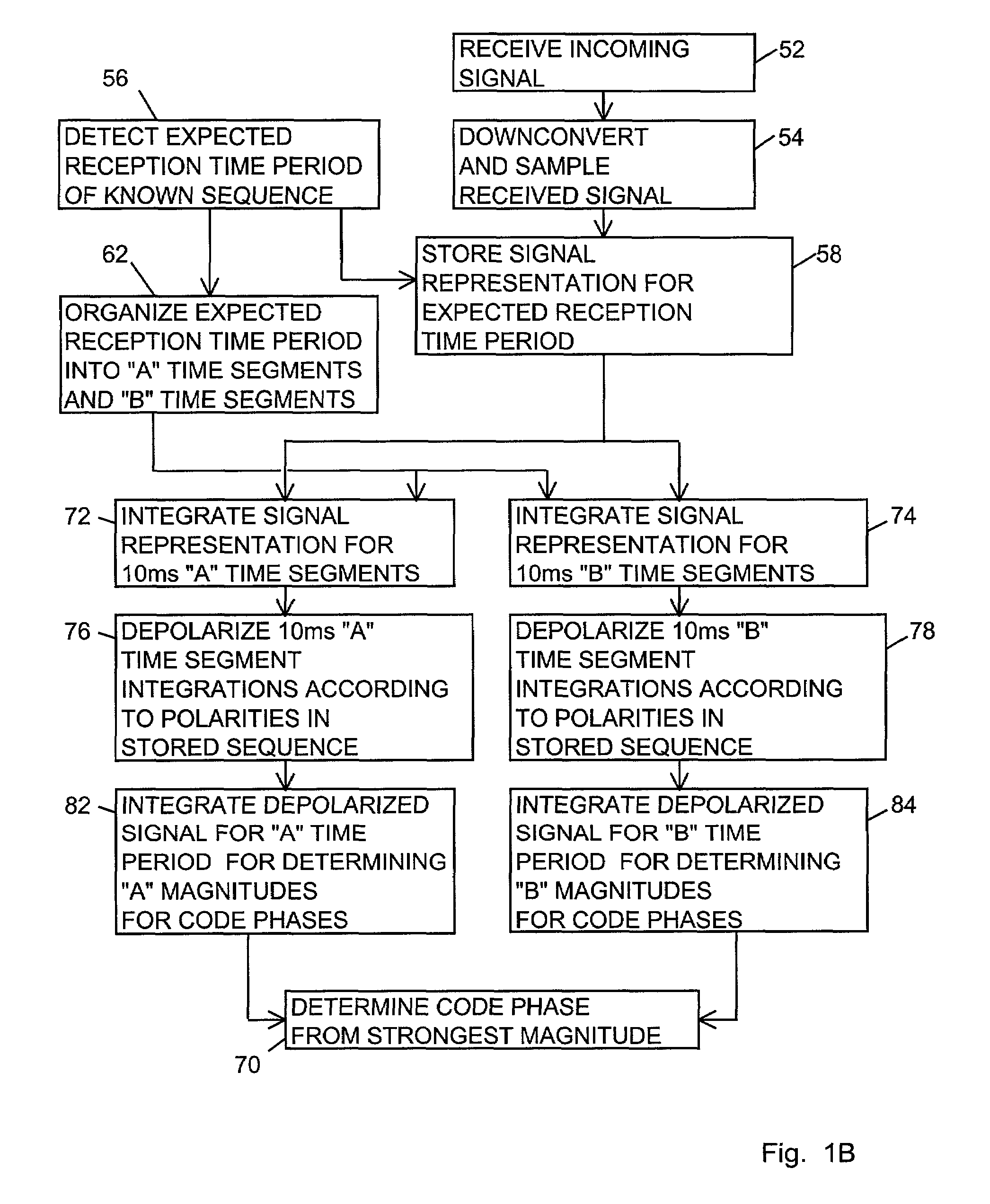

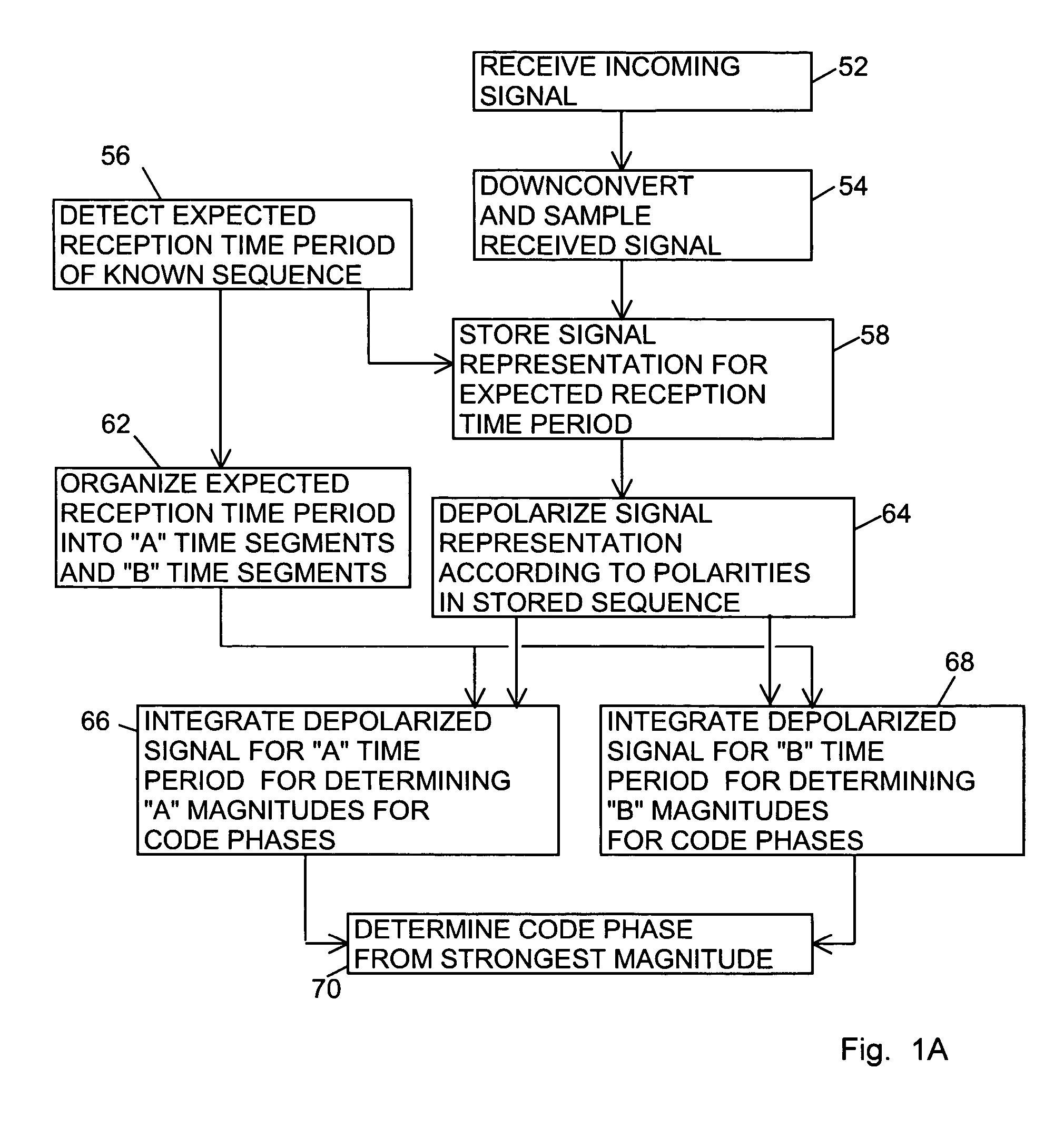

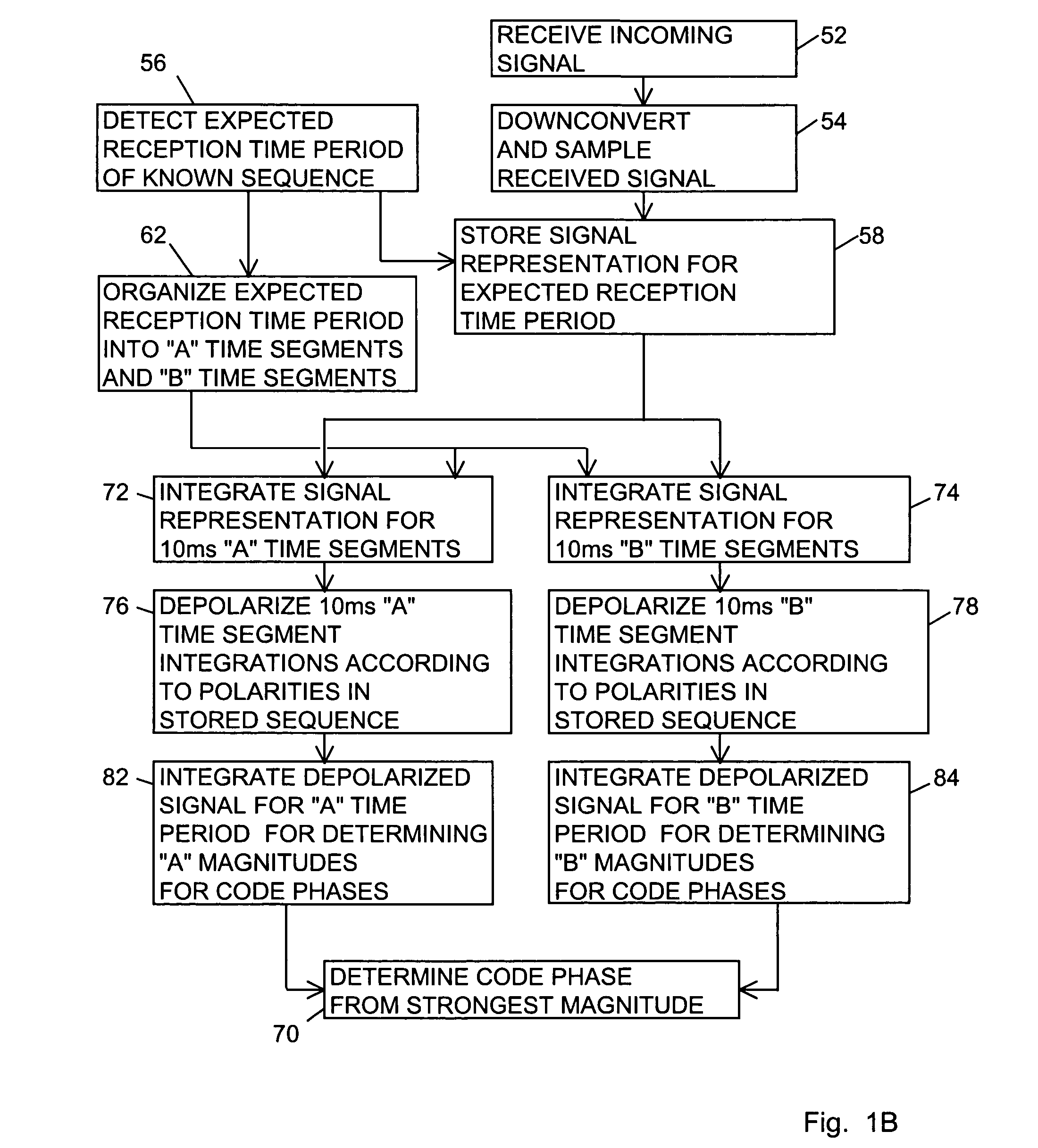

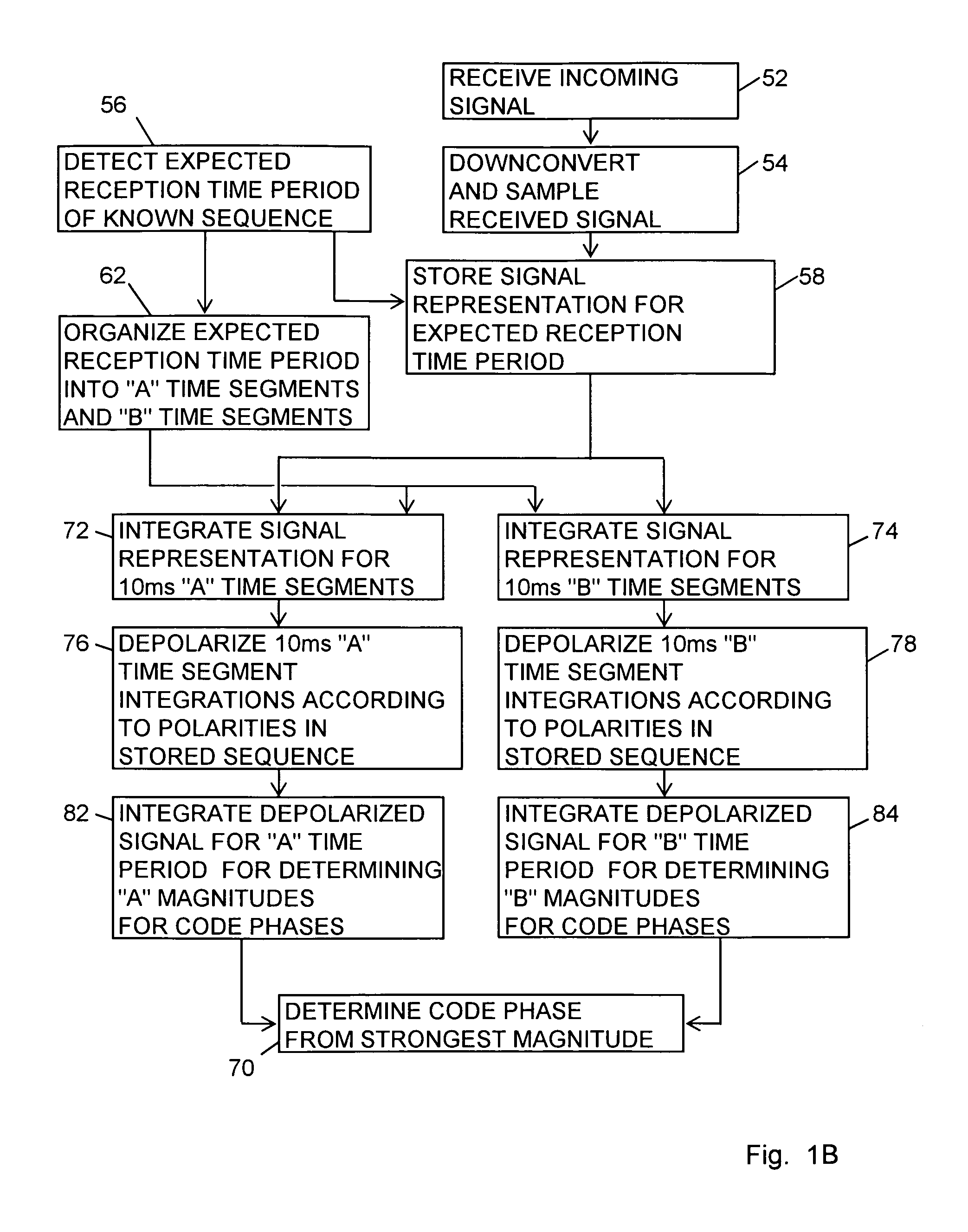

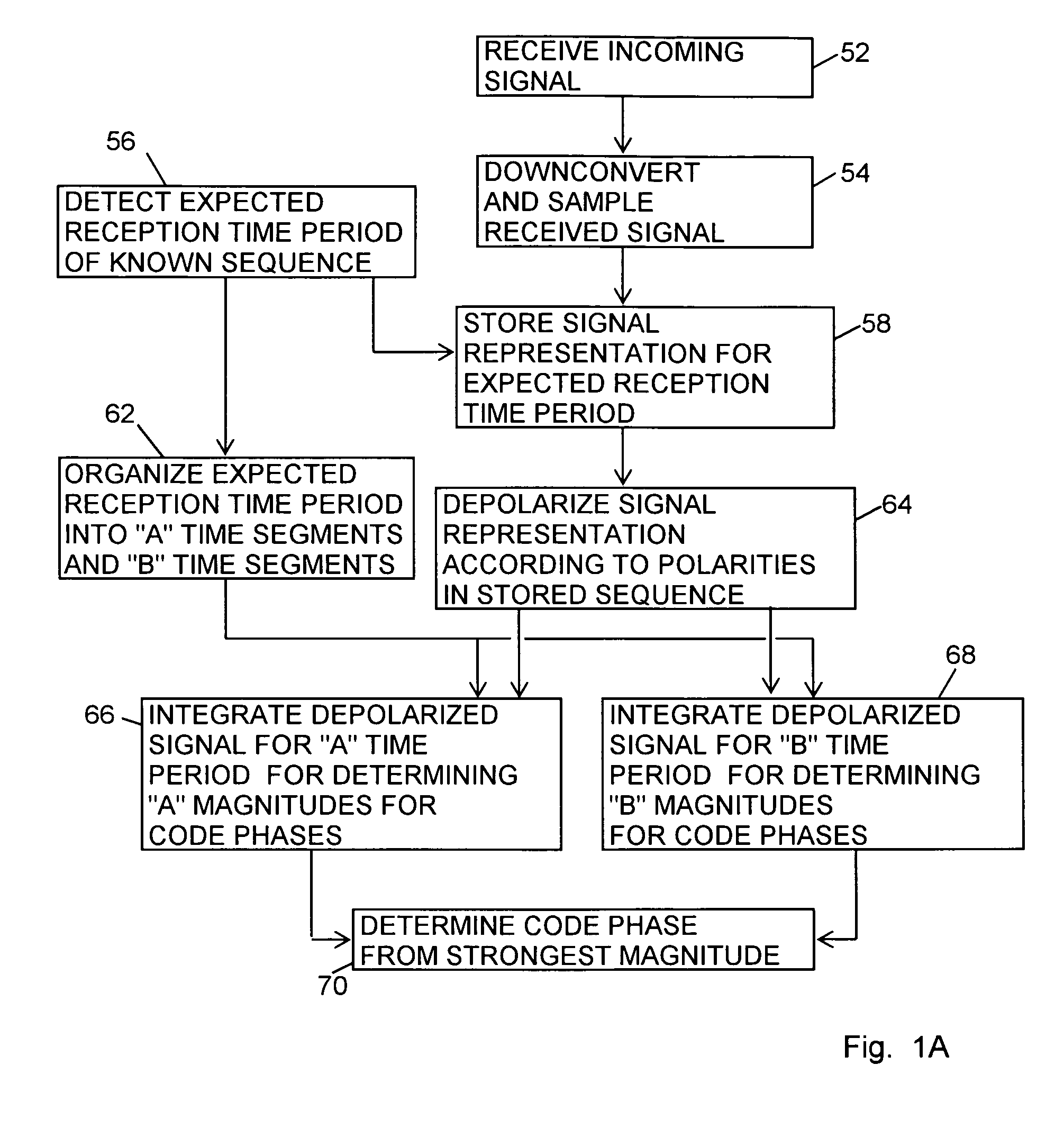

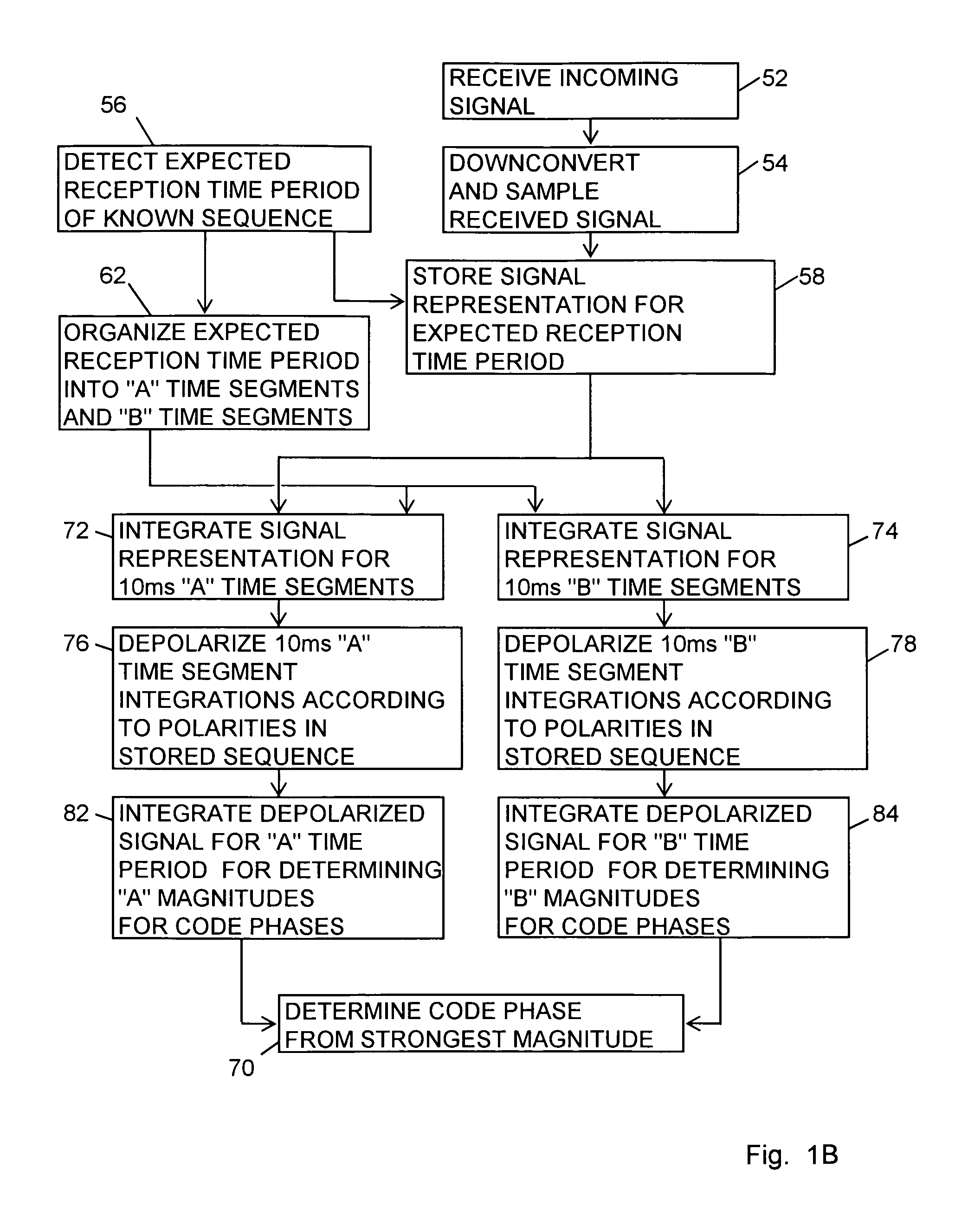

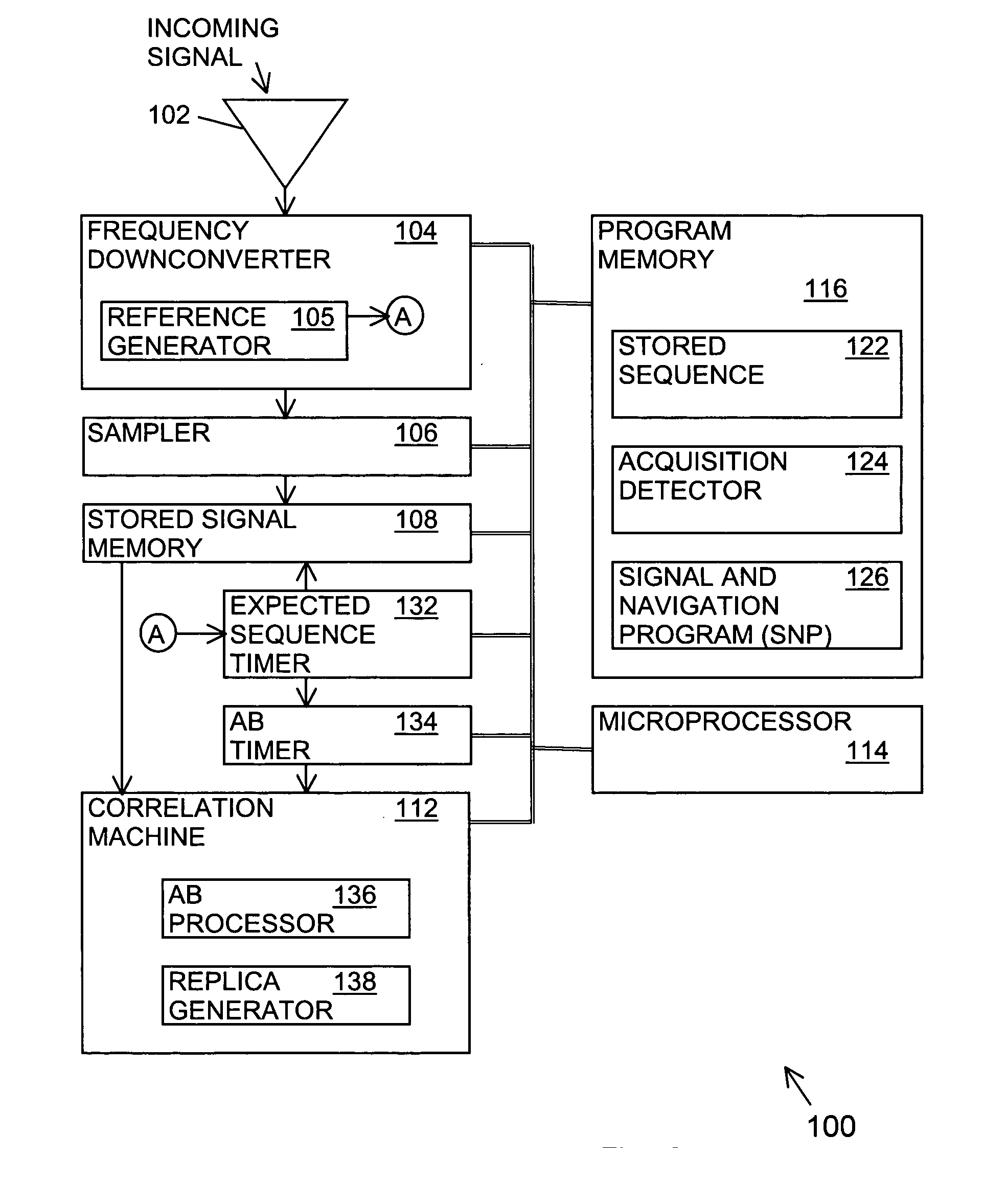

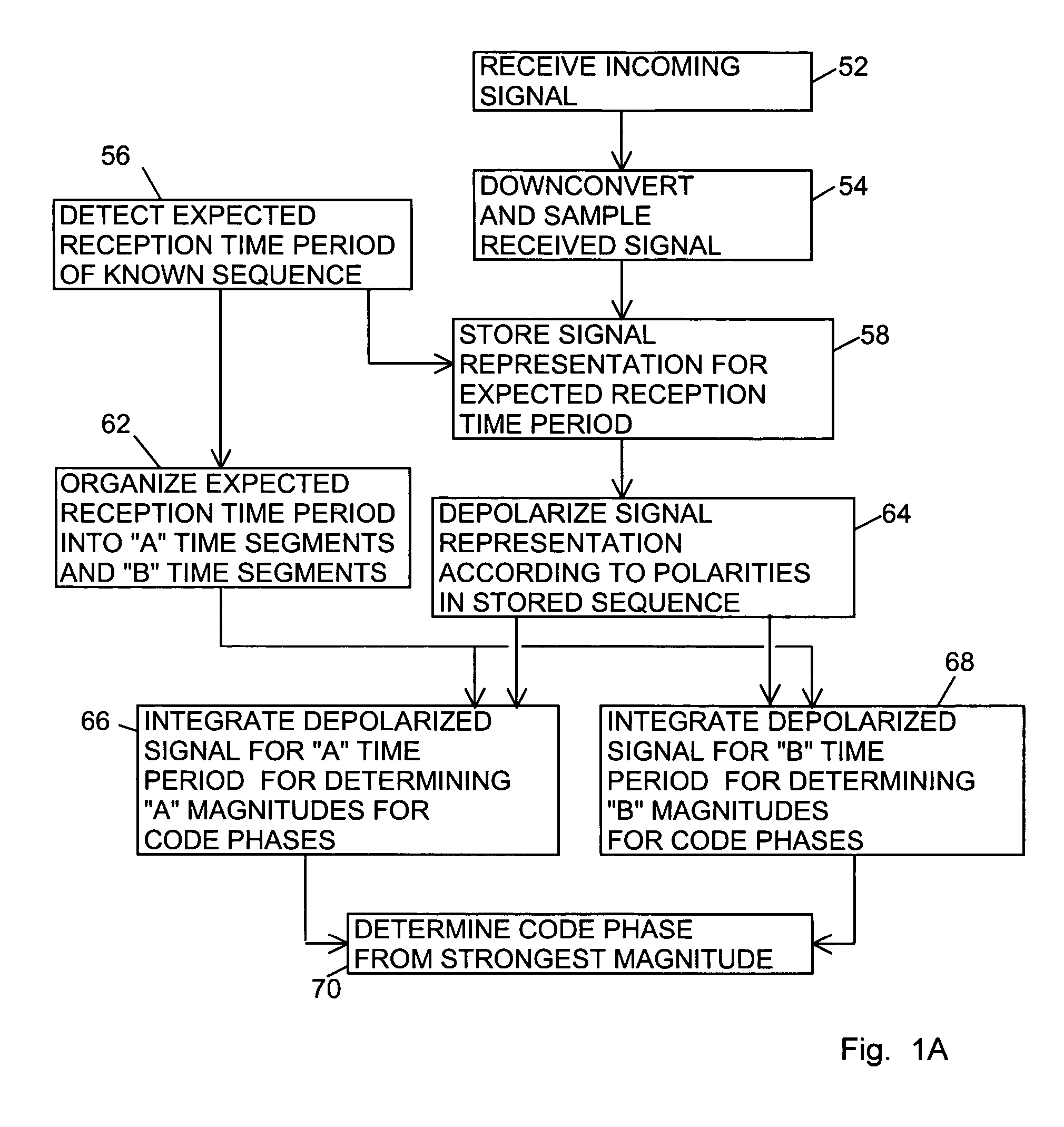

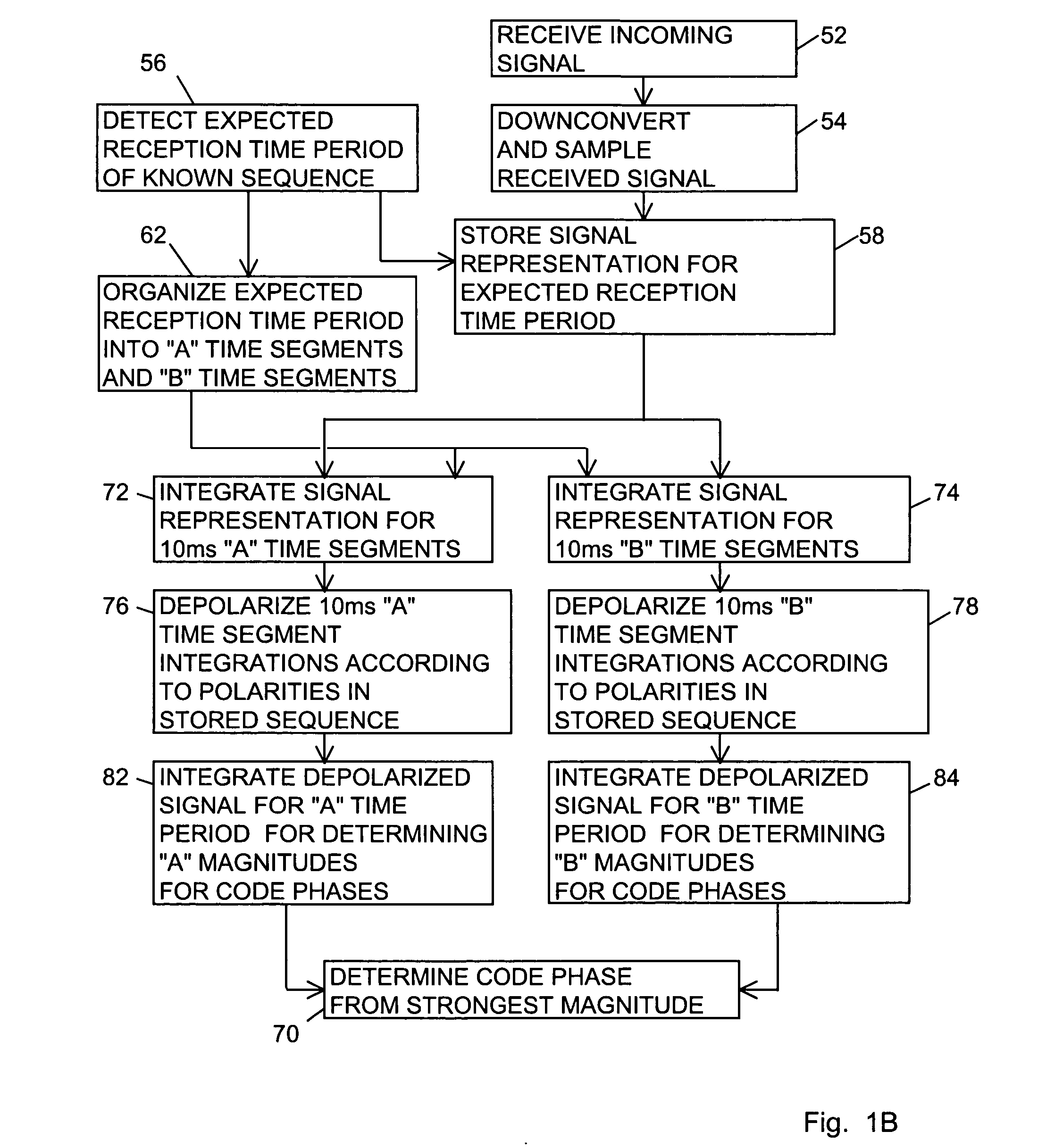

Signal receiver using coherent integration in interleaved time periods for signal acquisition at low signal strength

ActiveUS6990140B2Avoid transitEasy to followModulated-carrier systemsBeacon systemsTime segmentGps receiver

A GPS receiver and method using alternating “A” and “B” integration time segments. The polarities of certain GPS data bits are known beforehand and their expected reception times are known. The GPS signal in 10 millisecond “A” time segments and “B” time segments is depolarized according to the known polarities. The depolarized GPS signal during an “A” time period made up of all the “A” time segments is integrated for providing an “A” time period magnitude for each code phase. Likewise, the depolarized GPS signal during a “B” time period made up of all the “B” time segments is integrated for providing a “B” time period magnitude for each potential GPS code phase. The strongest of the time period magnitudes is compared to a correlation threshold for selecting a code phase for signal acquisition.

Owner:TRIMBLE NAVIGATION LTD

Signal receiver having signal acquisition at low signal strength using interleaved time segments

InactiveUS7197064B2Avoid transitEasy to followBeacon systemsSatellite radio beaconingTime segmentGps receiver

A GPS receiver and method using alternating “A” and “B” integration time segments. The polarities of certain GPS data bits are known beforehand and their expected reception times are known. The GPS signal in 10 millisecond “A” time segments and “B” time segments is depolarized according to the known polarities. The depolarized GPS signal during an “A” time period made up of all the “A” time segments is integrated for providing an “A” time period magnitude for each code phase. Likewise, the depolarized GPS signal during a “B” time period made up of all the “B” time segments is integrated for providing a “B” time period magnitude for each potential GPS code phase. The strongest of the time period magnitudes is compared to a correlation threshold for selecting a code phase for signal acquisition.

Owner:TRIMBLE NAVIGATION LTD

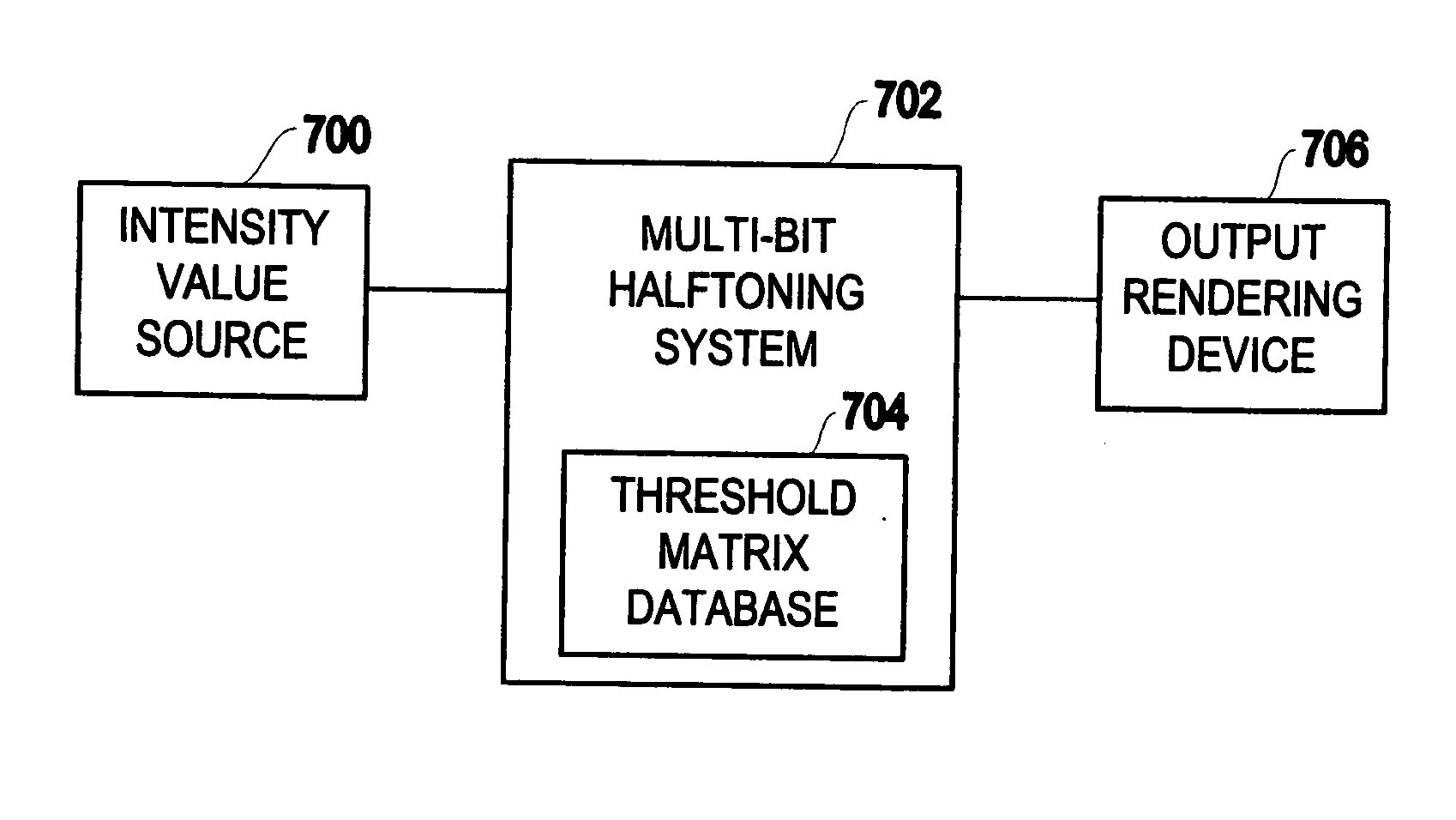

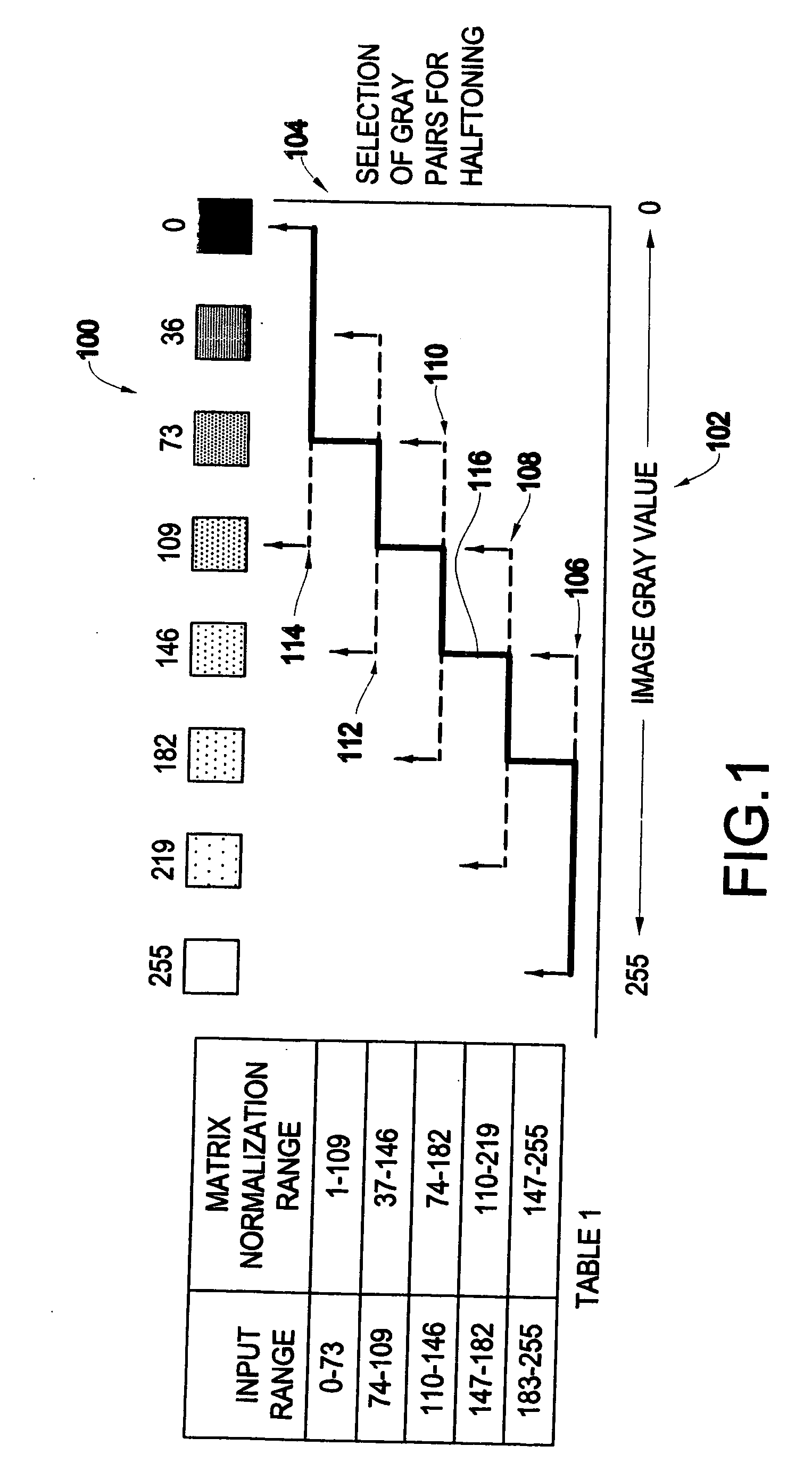

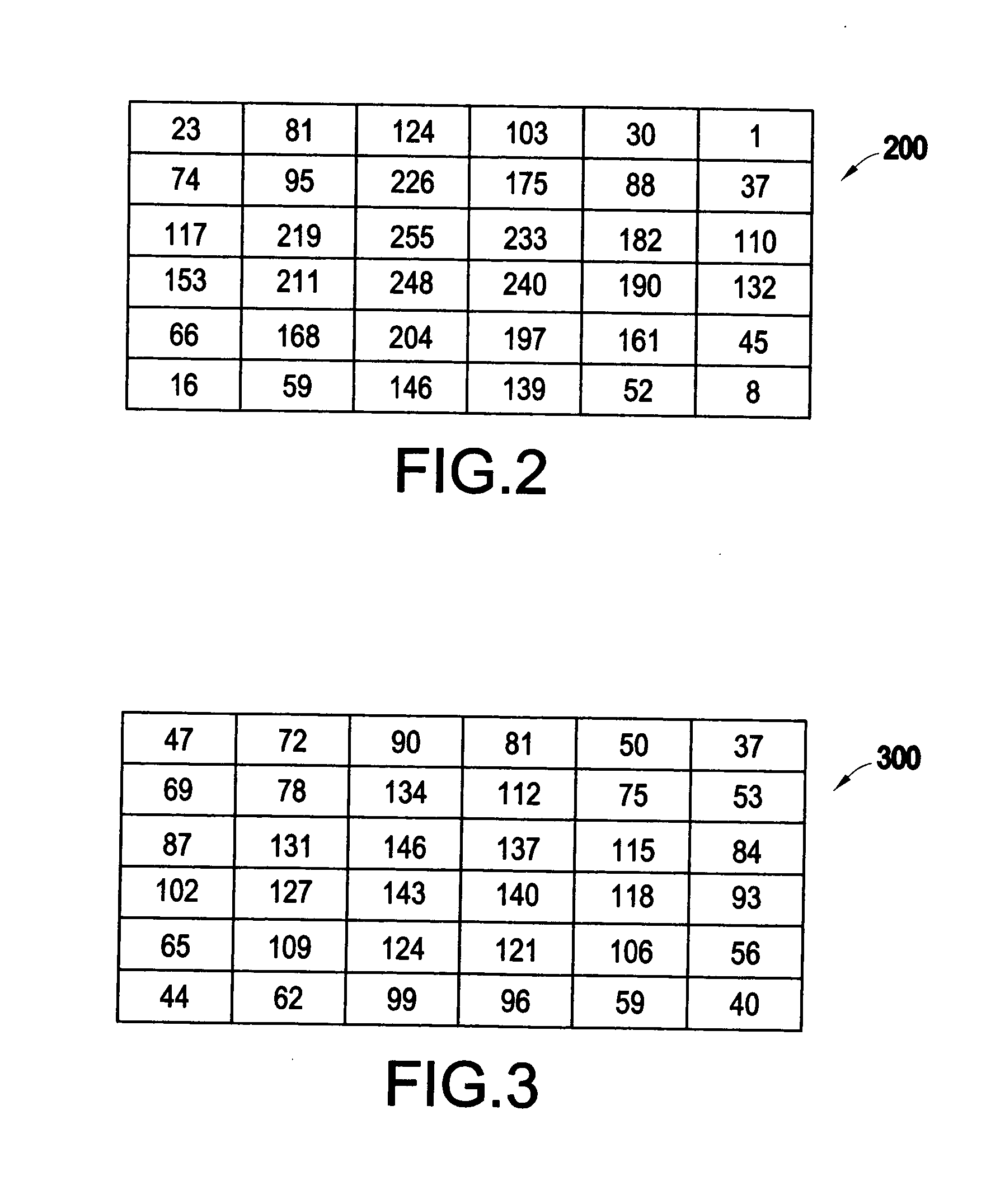

System and method for multi-bit halftoning

InactiveUS20060244981A1Less difficultyConsistent patternDigitally marking record carriersDigital computer detailsHueComputer science

Owner:IBM CORP

Signal receiver using data bit search in alternating time segments

ActiveUS20090285268A1Large signal processing gainIncrease probabilitySatellite radio beaconingTransmissionTime segmentTrial and error

A GNSS receiver and method using alternating “A” and “B” time segments for a reception time length of two or more data bits. The GNSS signal in an “A” time period comprising the “A” time segments is integrated for determining “A” magnitudes corresponding to code phase increments and the GNSS signal in a “B” time period comprising the “B” time segments is integrated for determining “B” magnitudes corresponding to code phase increments. A trial-and-error data bit search is performed for depolarizing data bit senses. The code phase increment showing the largest correlation level is used for acquisition of the GNSS signal and / or determination of the location where the GNSS is being received.

Owner:TRIMBLE NAVIGATION LTD

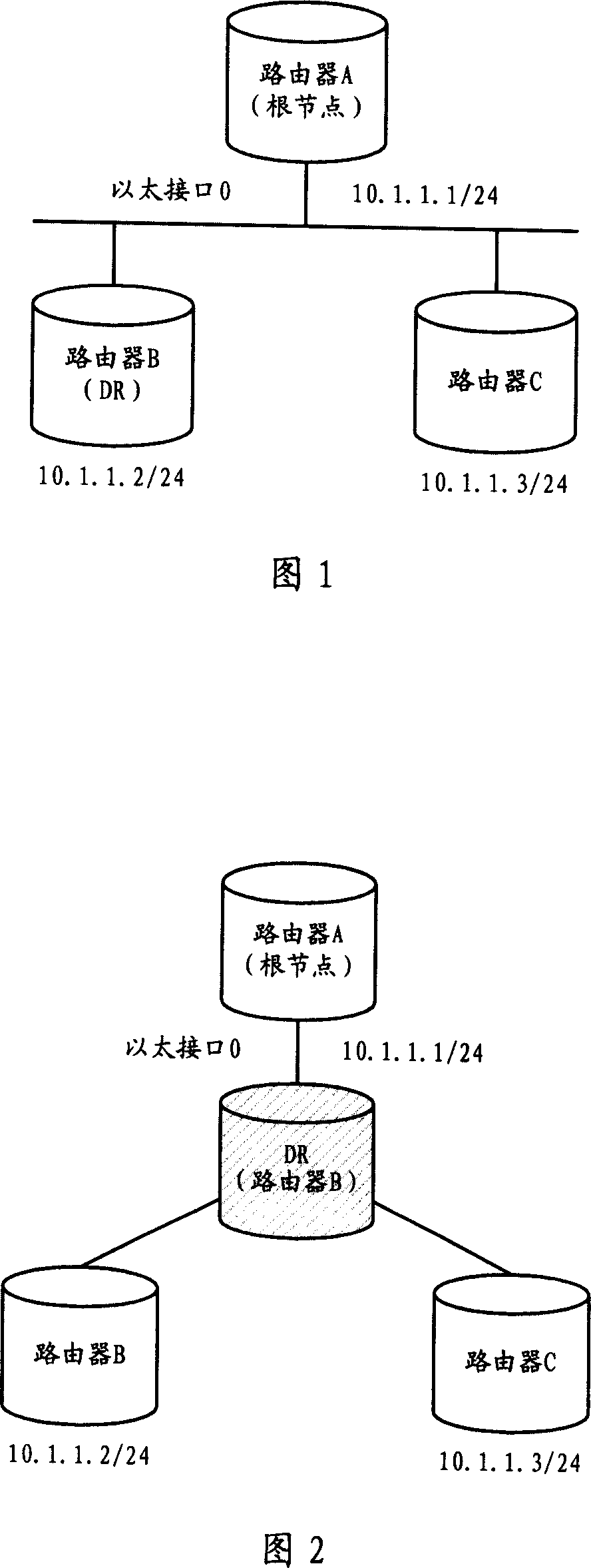

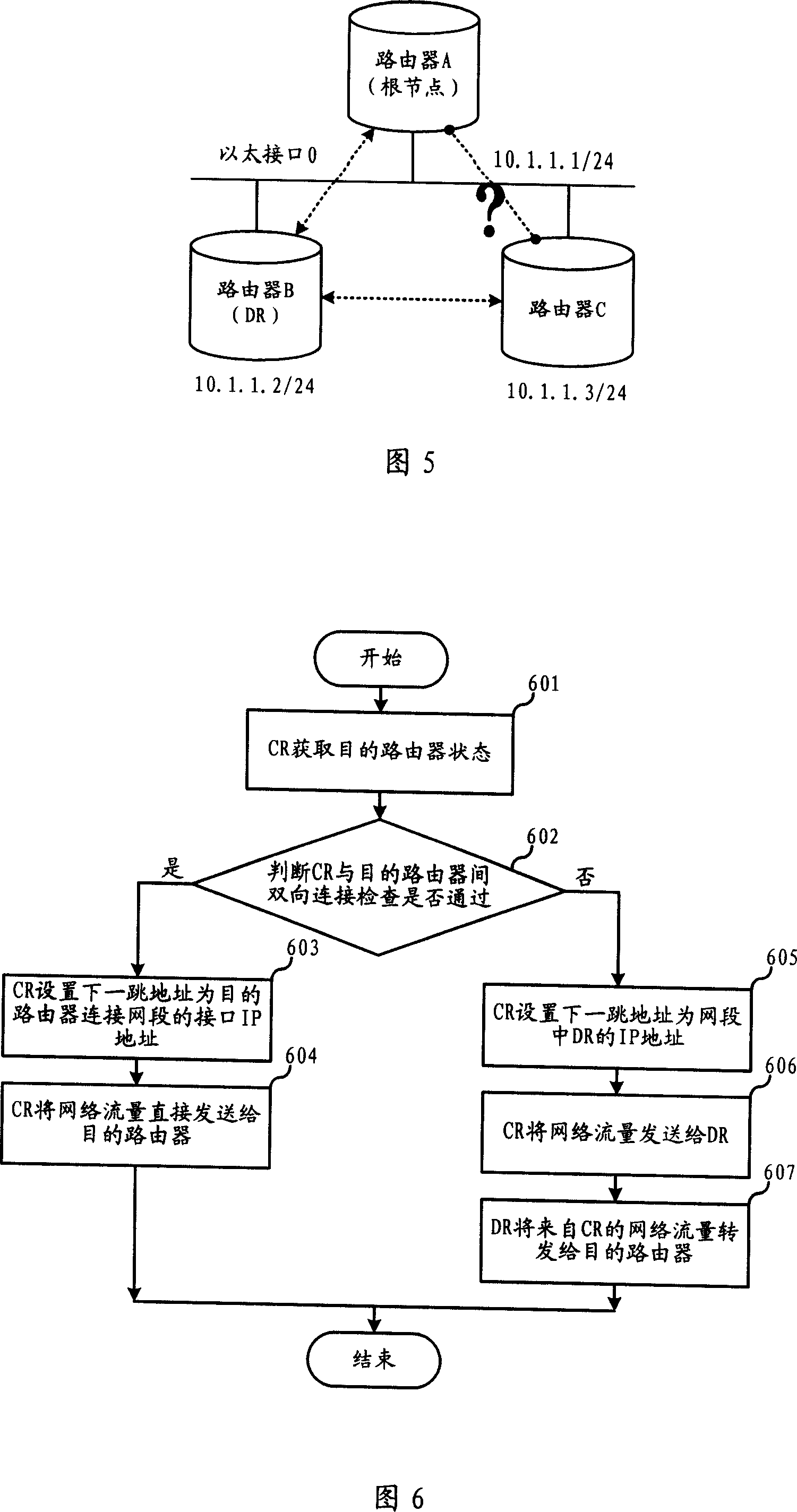

Route selection method and device in minimum path priority protocol

ActiveCN101087240AGuarantee unimpededThere will be no routing black holesData switching networksTraffic volumeIp address

The invention relates to route technique in communication system, discloses route selection method and device in priority protocol of shortest path and it can avoid the black hole to ensure the unblocked network. In the invention, when calculates the topology of broadcasting network or the NBMA network, the calculating router checks the both-way communication according to the state of target router, if the check is passed, the next jumping address of target router is set as the IP interface address of NBMA network or broadcasting network, and the network flow is sent to target router directly. If the check is not passed, the next jumping address that the calculating router to target router is set as the IP address of appointed router in NBMA network or broadcasting network, and the network flow to target router is transferred by appointed router.

Owner:HUAWEI TECH CO LTD

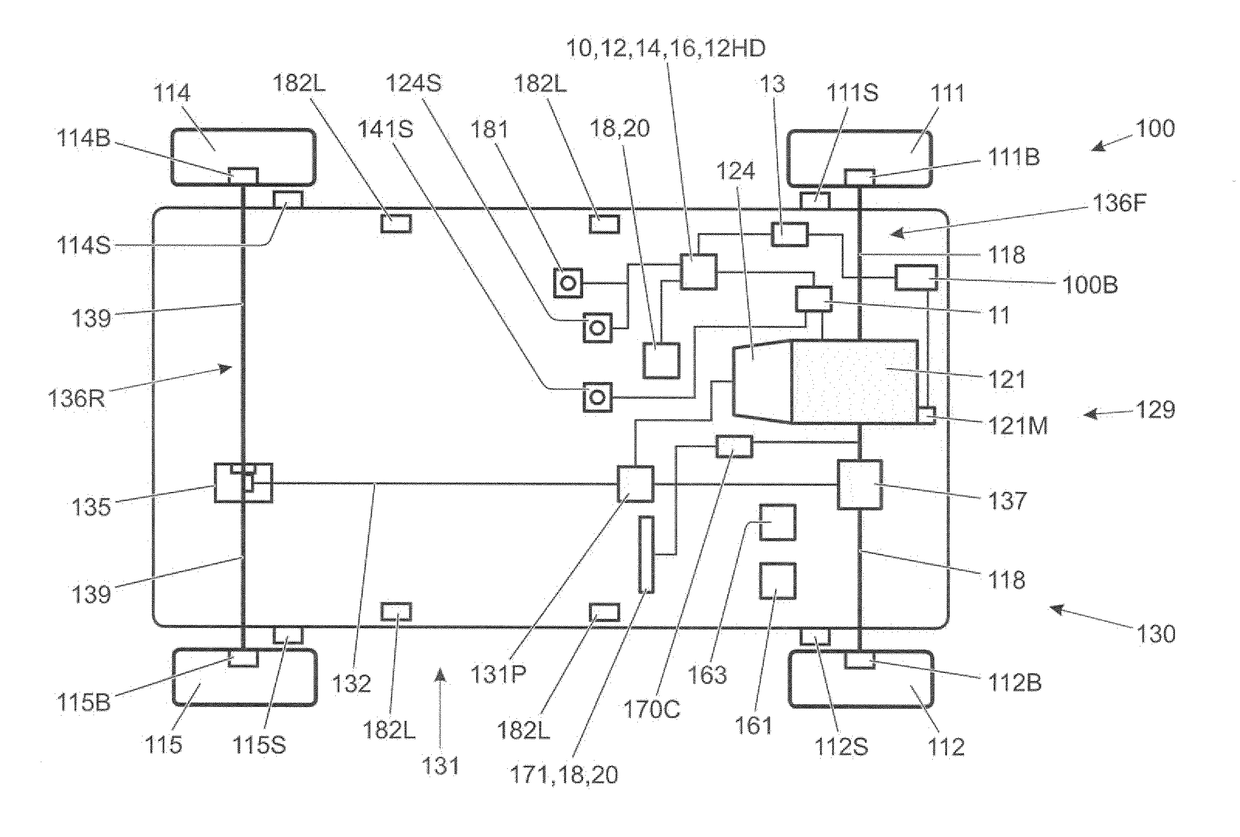

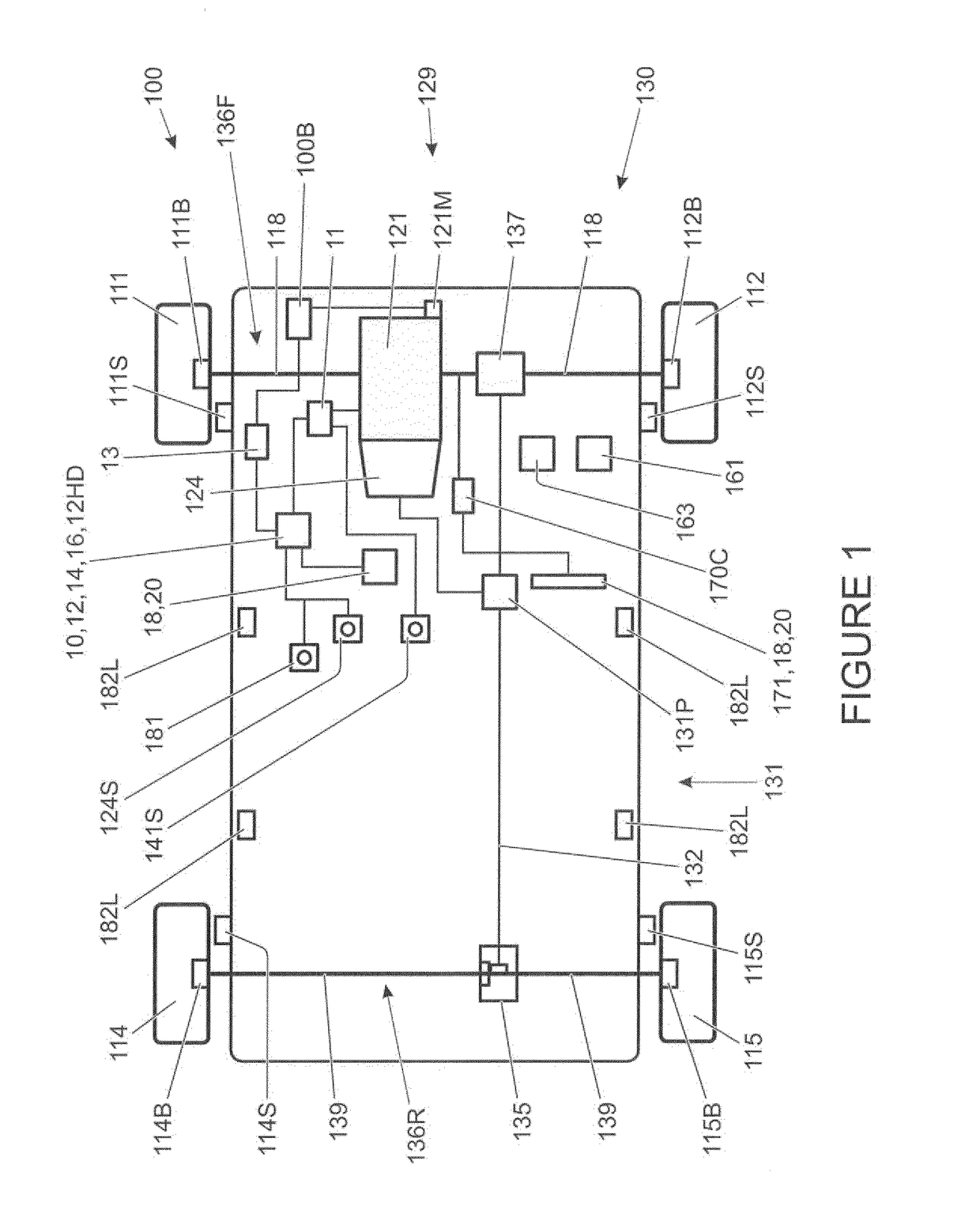

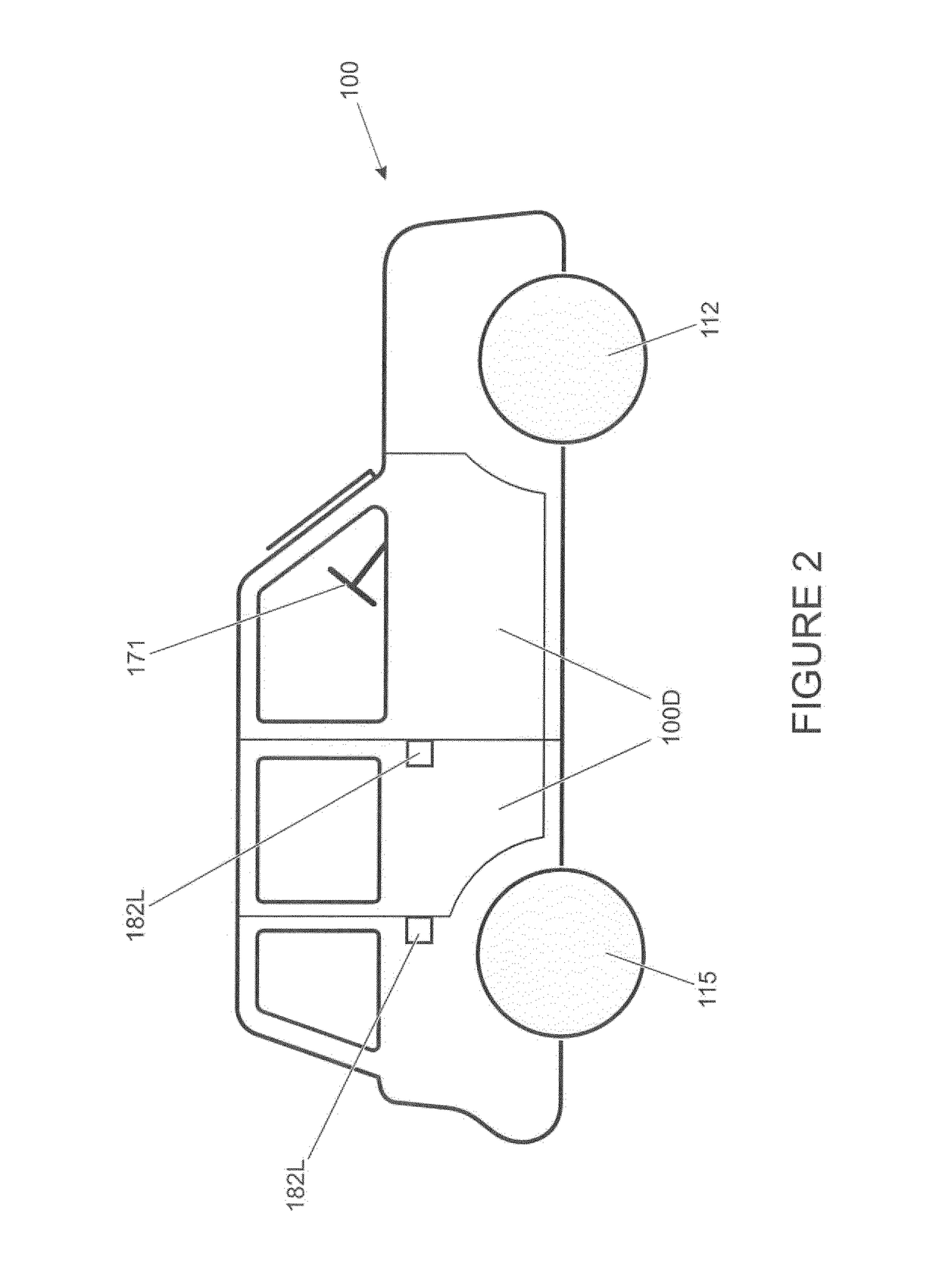

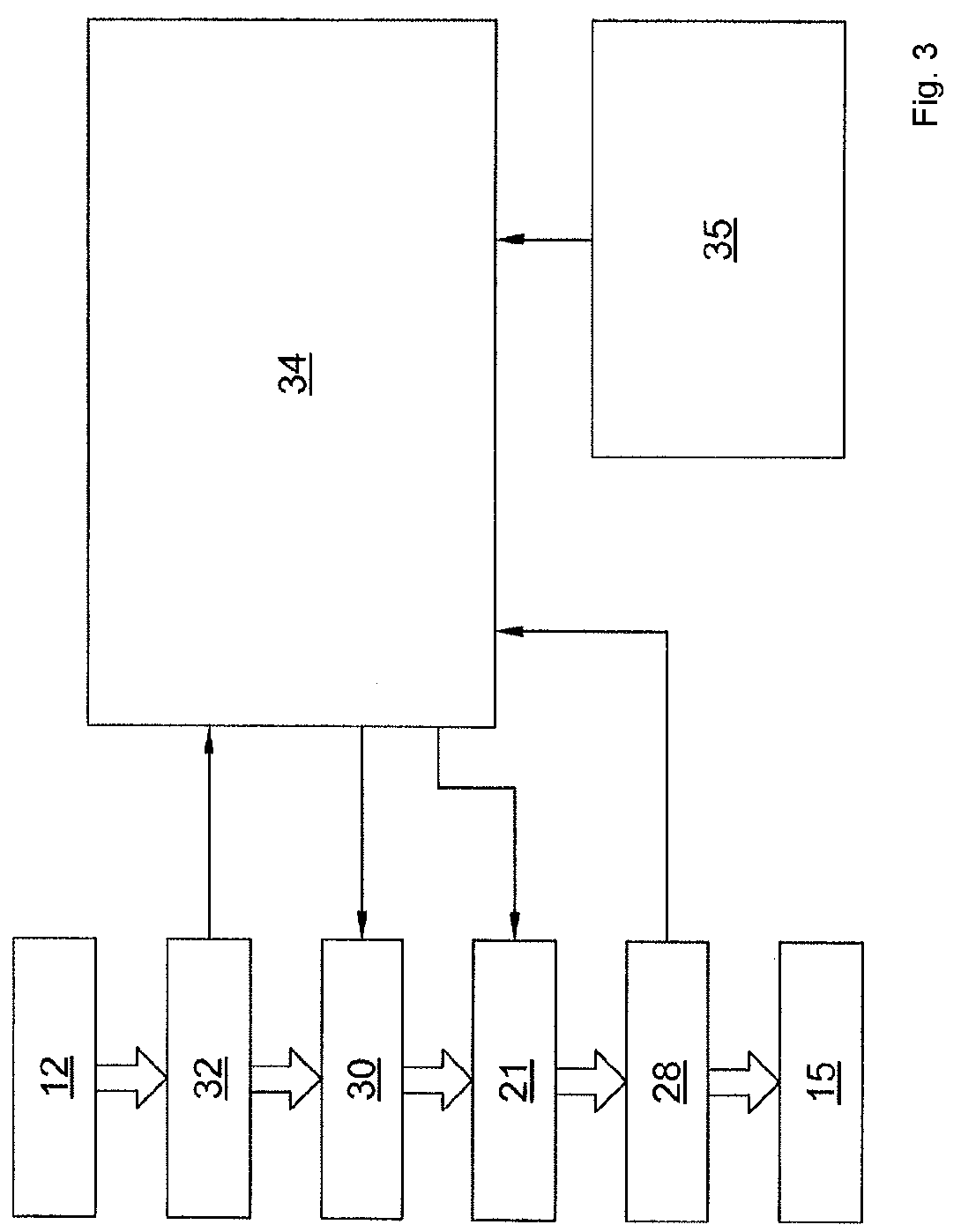

Control system and method

A system comprising: a first controller operable to assume one of a plurality of respective states, in a first state the first controller being configured to generate a first controller powertrain signal in order to cause a powertrain to develop drive torque and cause a vehicle to operate in accordance with a target speed value; and a second controller configured to receive from the first controller a state signal responsive to the state assumed by the first controller and the first controller powertrain signal. The second controller is configured to cause a powertrain to deliver an amount of drive torque according to the first controller powertrain signal in dependence on the state signal.

Owner:JAGUAR LAND ROVER LTD

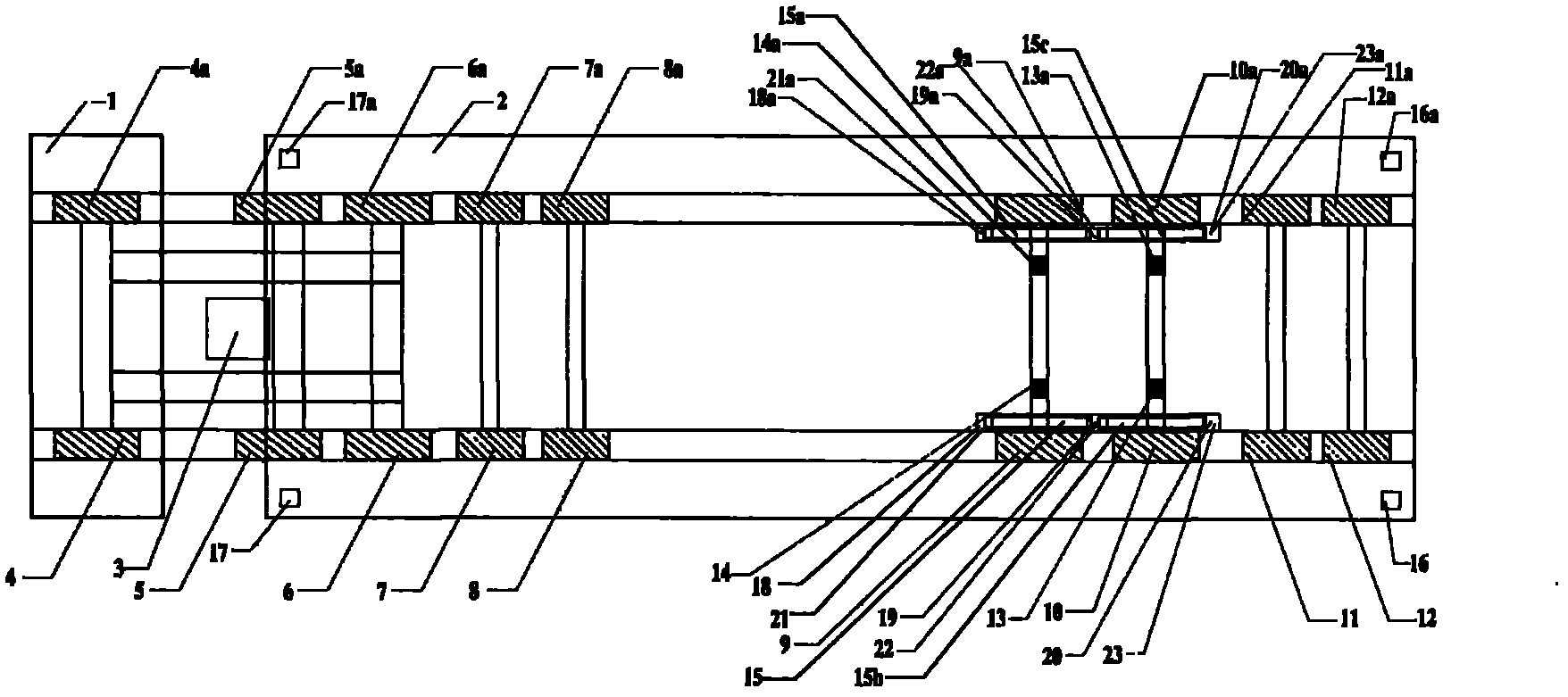

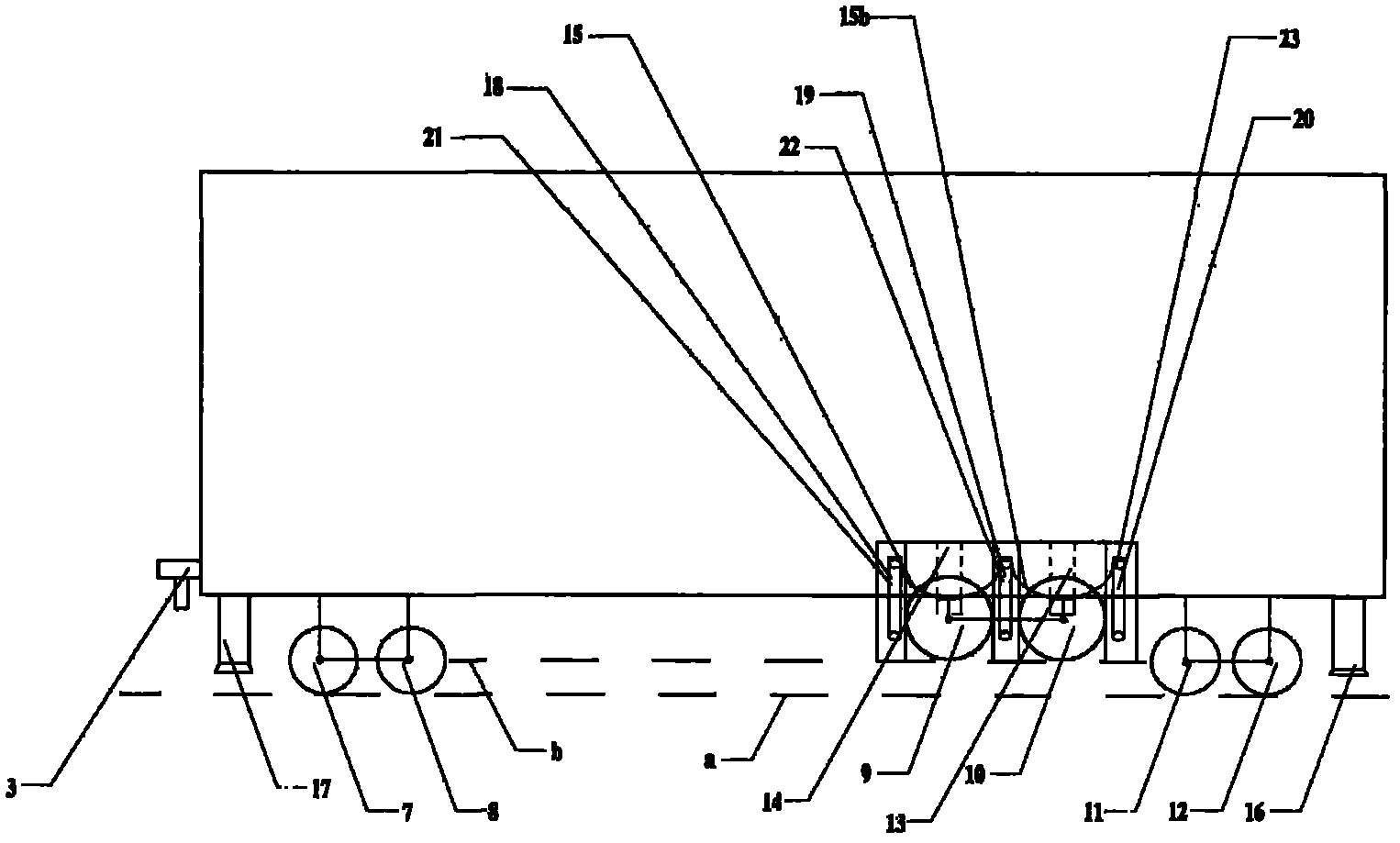

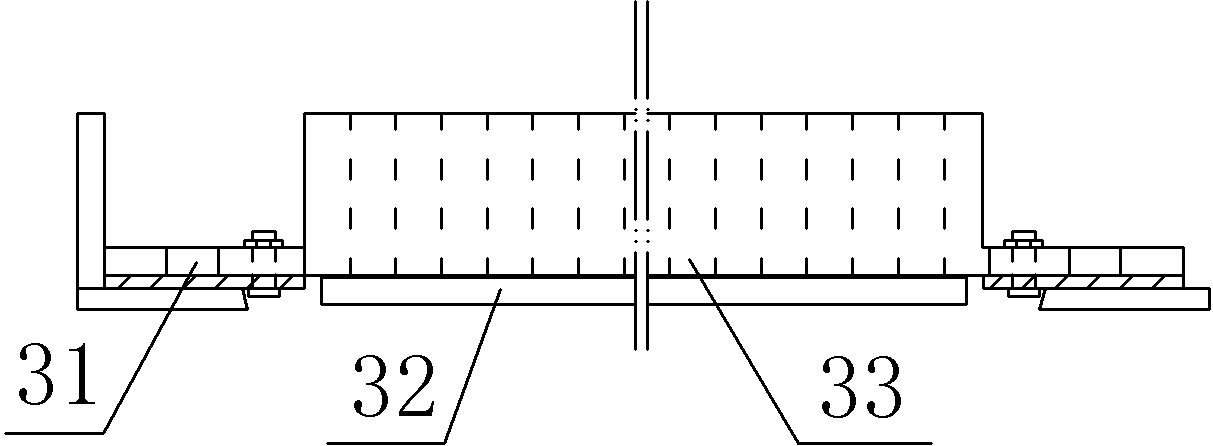

Dual-purpose trailer for highways and railways

InactiveCN102700370AReduce shipping costsShort transit timeRail and road vehiclesWagons/vansTransit timeAutomotive engineering

The invention relates to the field of automotive vehicles, in particular to a dual-purpose trailer for highways and railways. The trailer comprises a carriage utilizing a train skin body as a trailer body, and automobile wheels arranged at the bottom of the train skin body and is characterized in that the carriage utilizes the train skin as the trailer body; the bottom of the dual-purpose trailer for the highways and the railways provided by the invention is provided with automobile wheels and train wheels, so that the trailer can run on a rail and the friction factor between the train wheels and the rail is smaller, and therefore by utilizing the dual-purpose trailer for the highways and the railways provided by the invention, the transportation cost is low and the transportation time is shorter; and the bottom of the dual-purpose trailer for the highways and the railways provided by the invention is provided with the automobile wheels, so that after arriving at the station, the dual-purpose trailer for the highways and the railways is directly used as road transportation till arriving at the destination, and the procedure of transfer of cargoes is omitted, i.e., the transfer time is reduced, the loading and unloading expenses for transfer are omitted, and the transportation cost is further lowered.

Owner:朱瑞彪

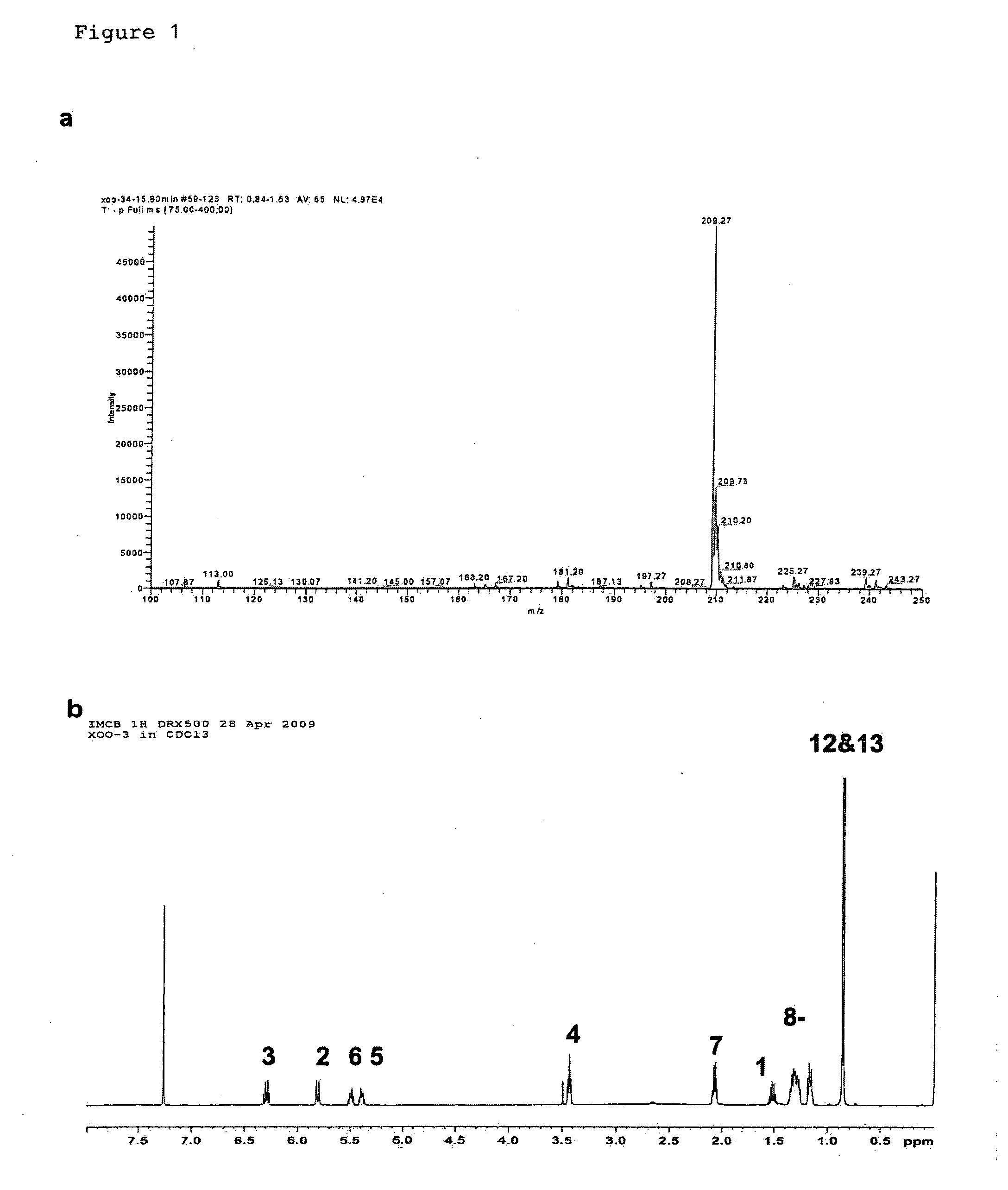

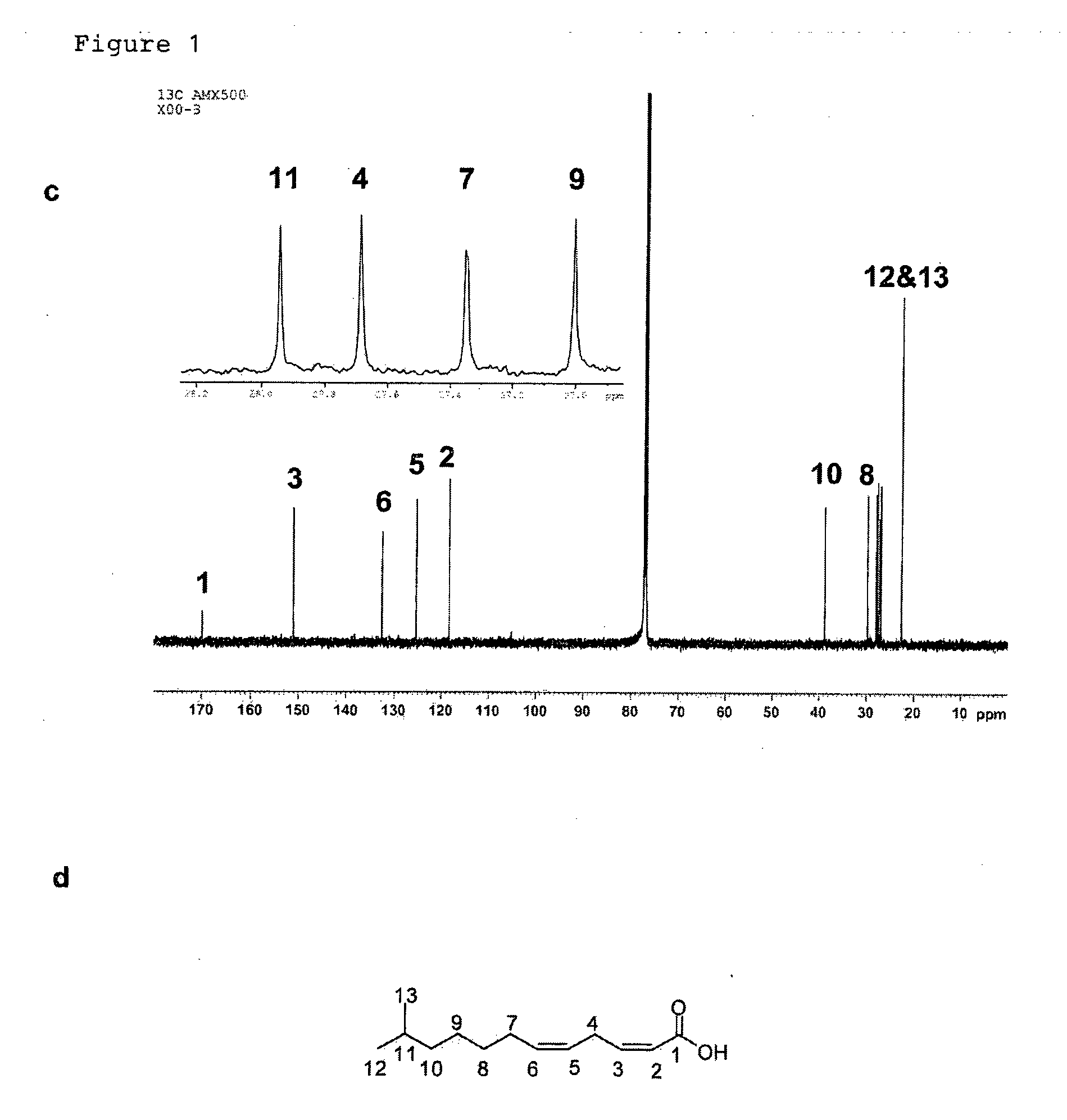

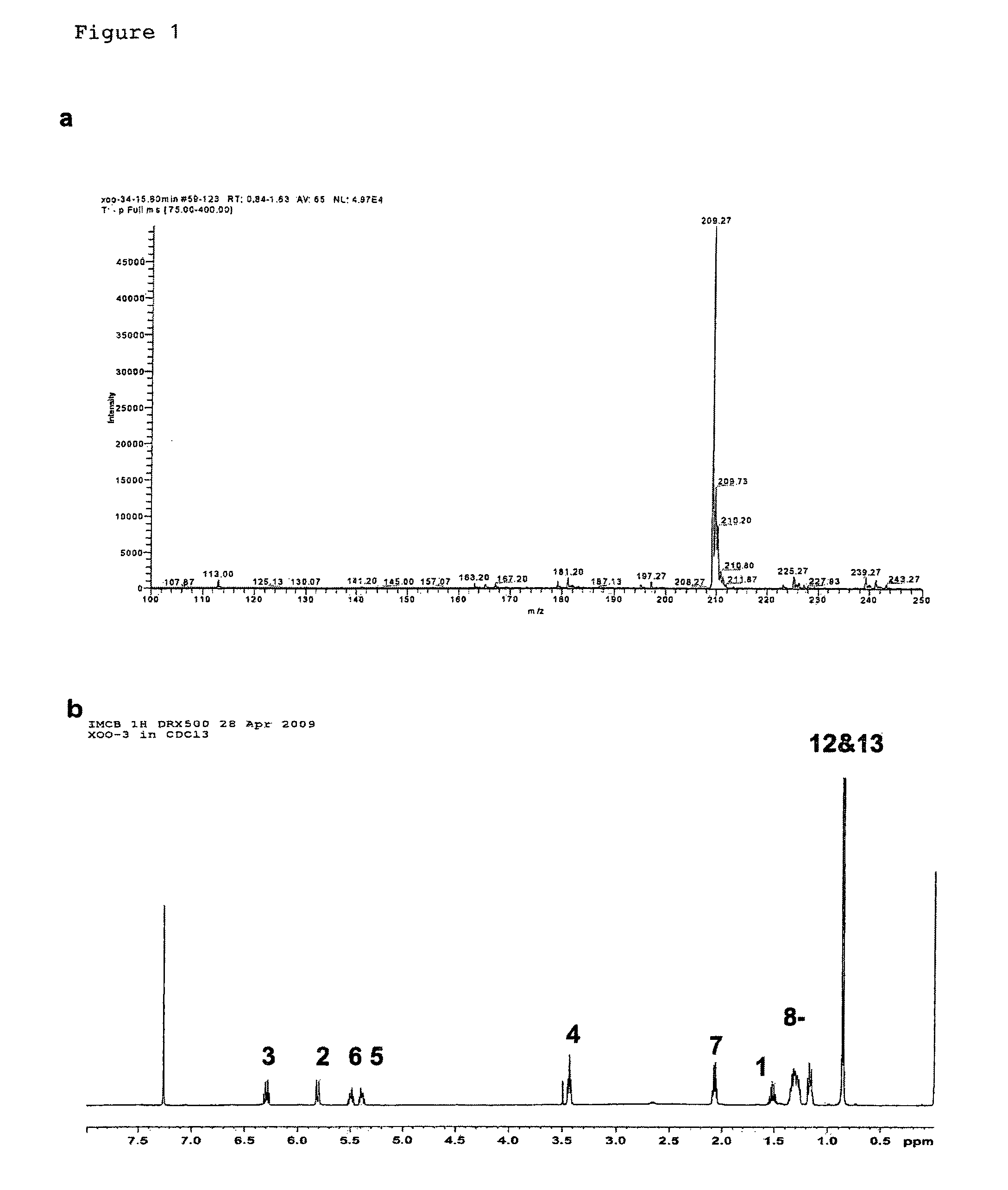

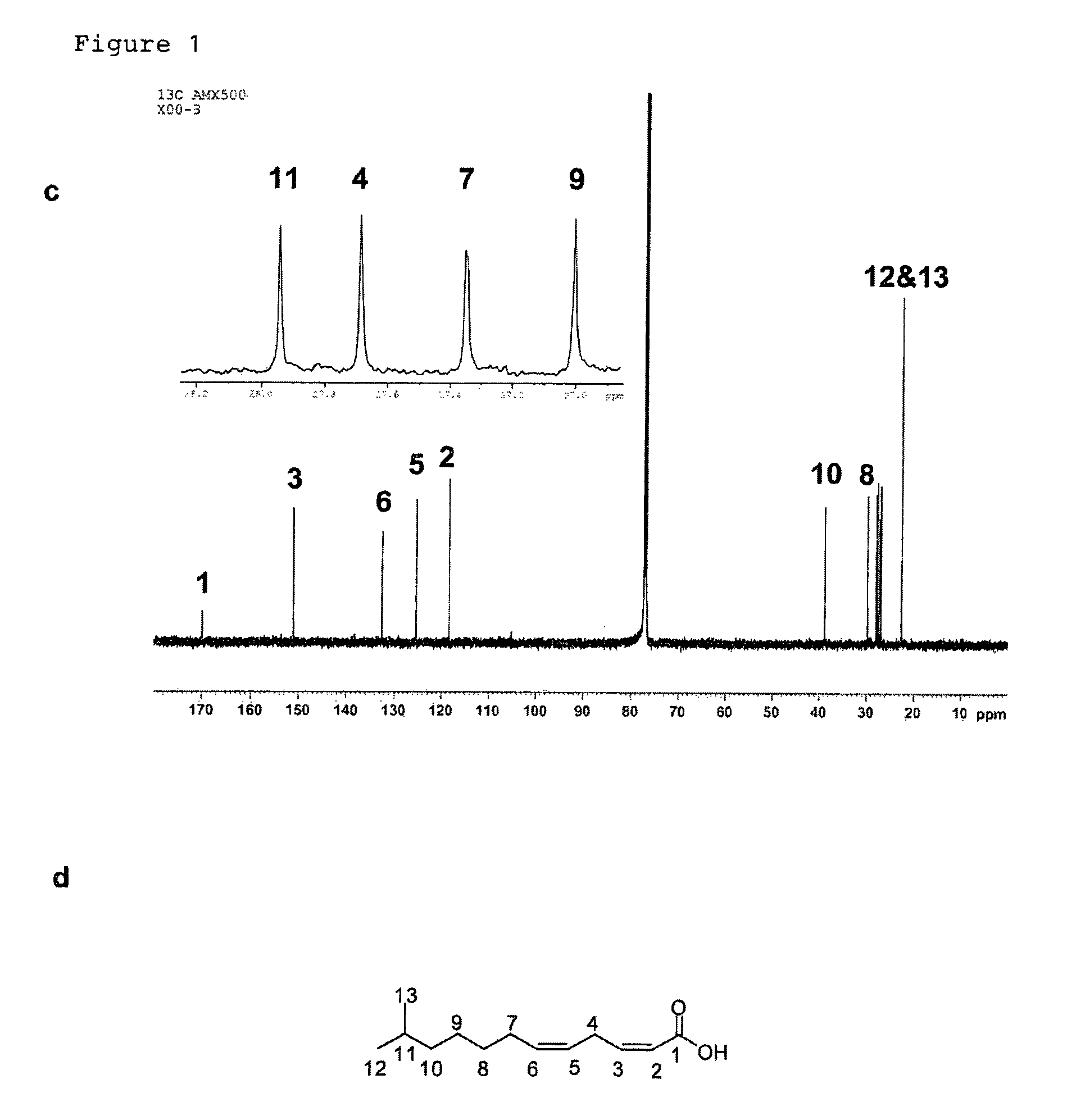

Novel antimicrobial compounds and uses thereof

InactiveUS20130131172A1Inhibit biofilm formationInhibits biofilm formationAntibacterial agentsBiocideChemical compoundAntimicrobial compound

The present invention relates to novel antimicrobial compounds, methods of their production as well as uses thereof.

Owner:ASTRAL QS TECH PTE LTD

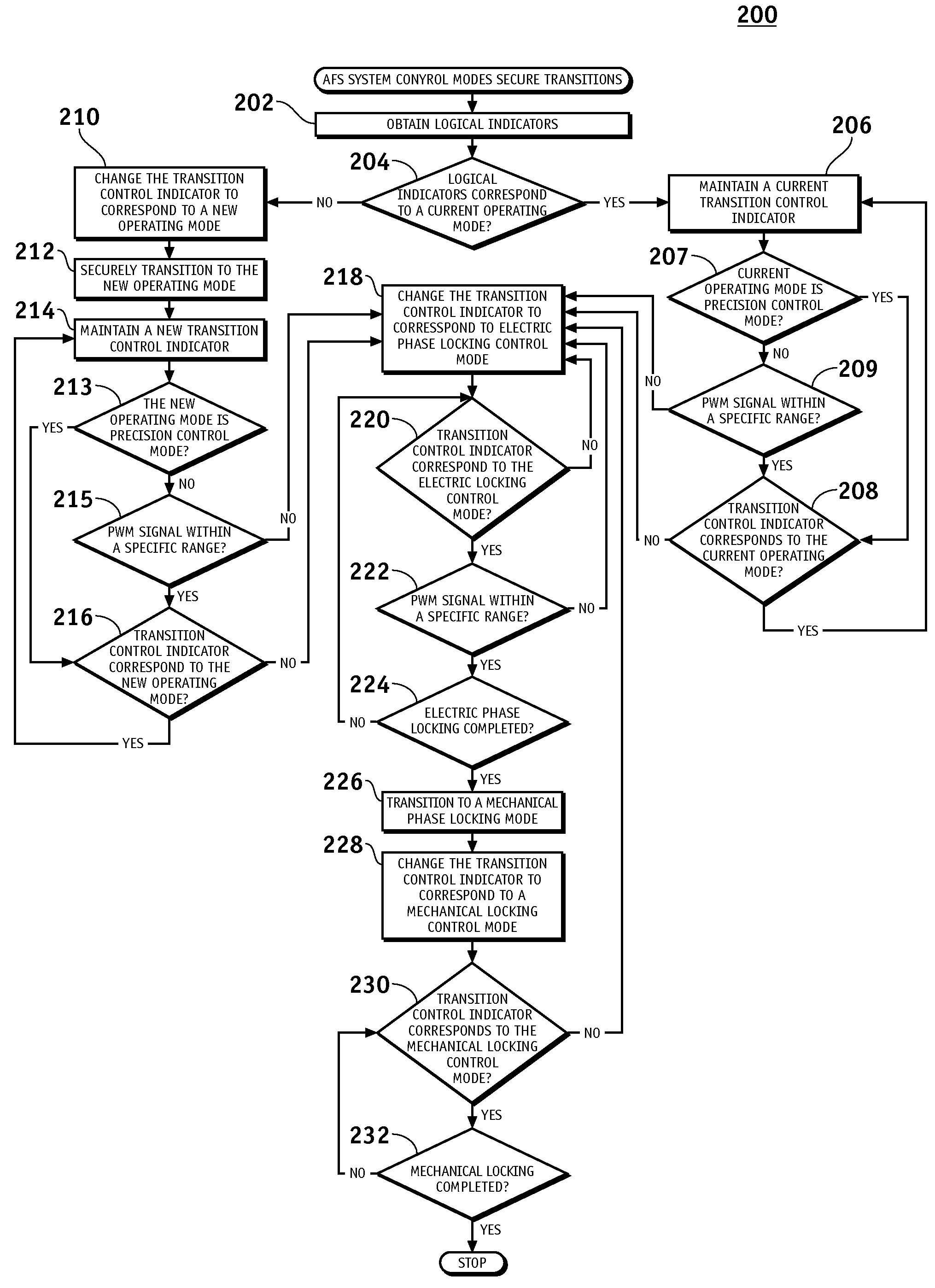

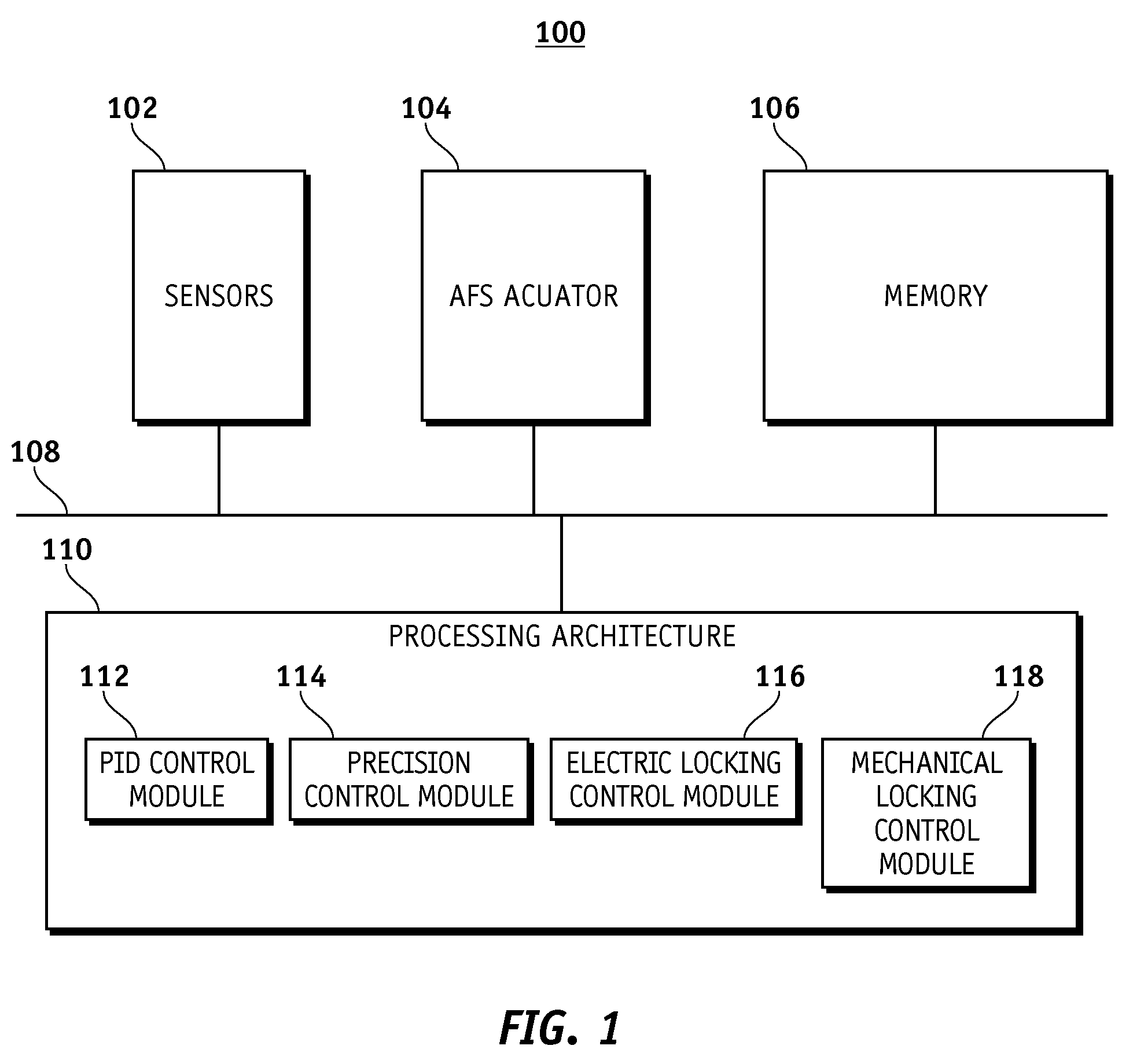

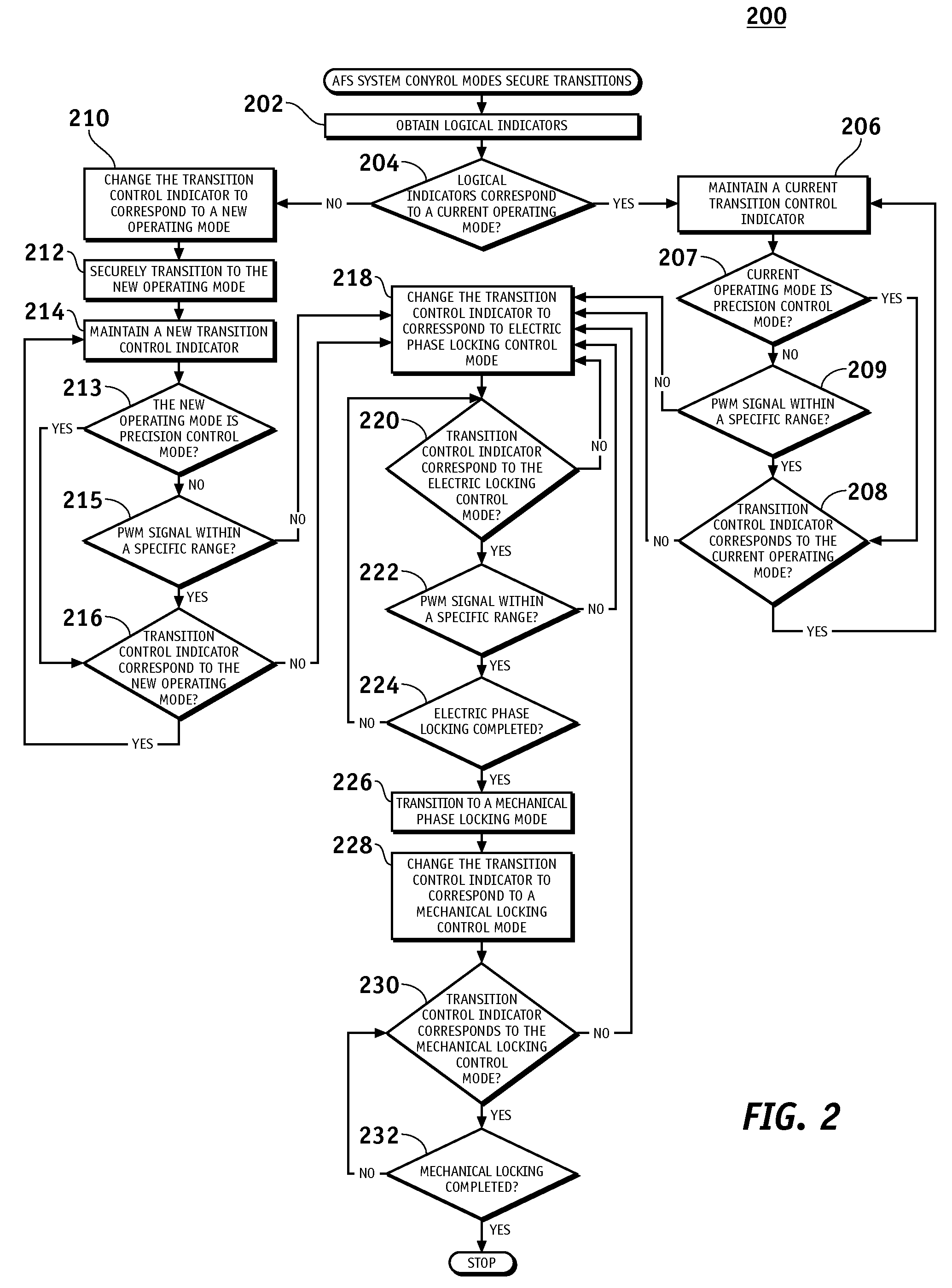

Secure control mode transition methods for an active front steer system

InactiveUS7634340B2Avoid transitSteering initiationsDigital data processing detailsSteering controlEngineering

A system and method for secure and restricted transitions between steering control modes for a vehicle with active front steering is disclosed. Possible operating control modes include precision, electric phase locking, and proportional integral derivative (PID) modes. Each operating control mode is monitored and the operational status of the modes are checked before transitioning. For security, the system can prevent transitions from PID to precision control mode and restrict electric phase locking mode to transition only to a mechanical locking mode.

Owner:GM GLOBAL TECH OPERATIONS LLC

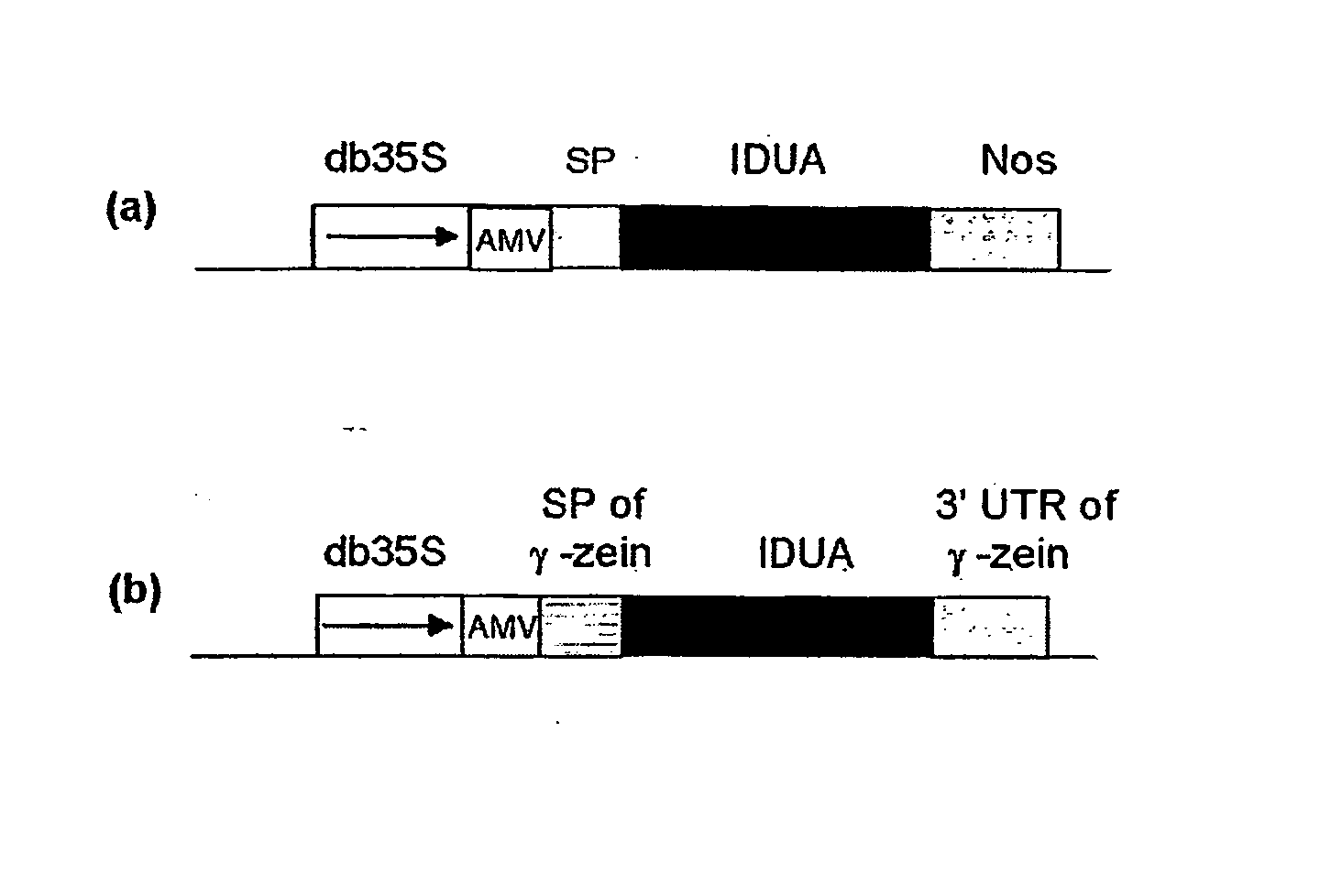

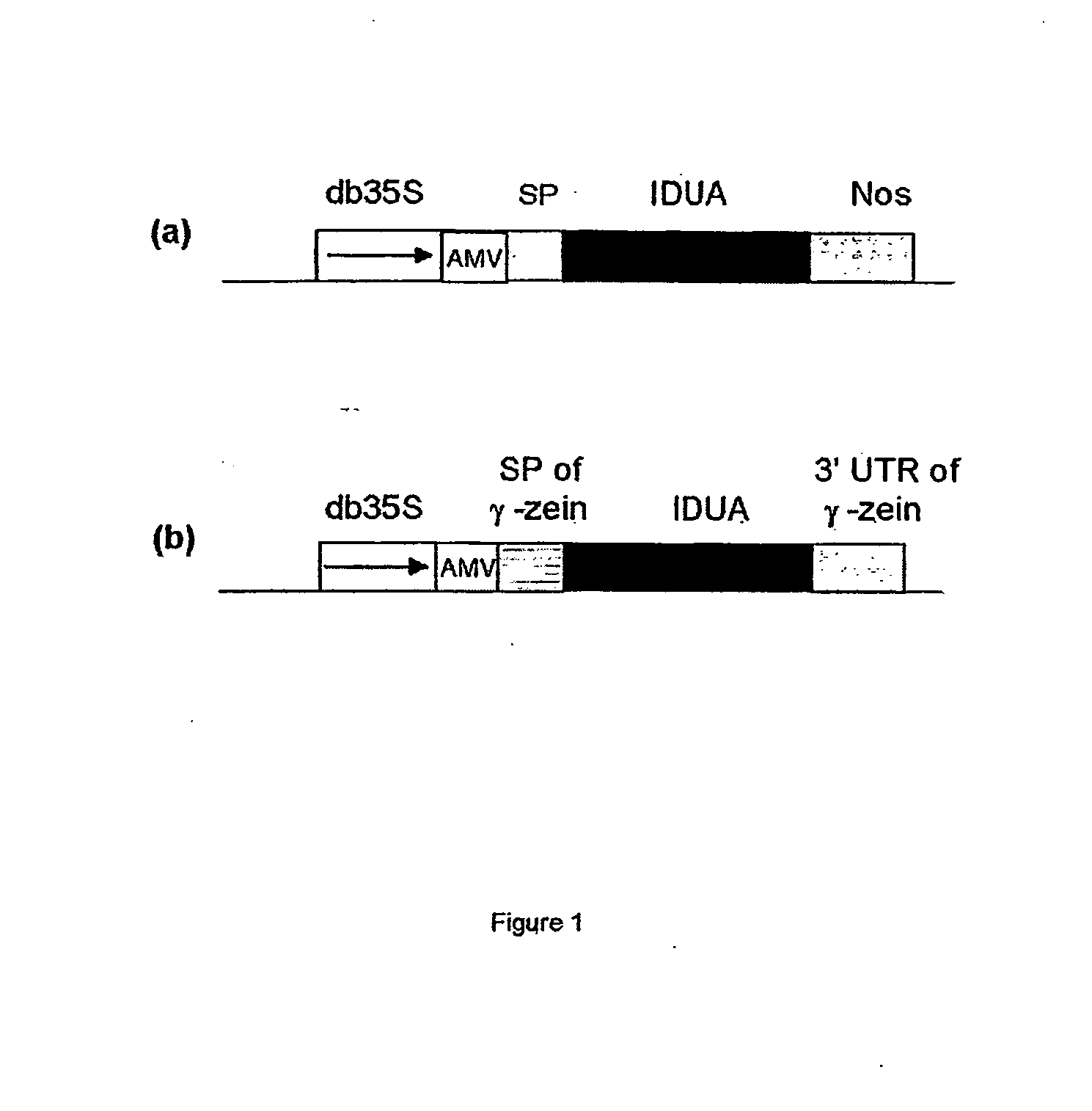

Production Of A Protein Localized To The Endoplasmic Reticulum Protein Bodies In A Transgenic Plant And Seed

InactiveUS20080034455A1Avoid it happening againFacilitates prolamin localizationSugar derivativesFermentationHeterologousReticulum cell

A nucleotide sequence is provided for expression of a heterologous protein of interest that is localized to the endoplasmic reticulum protein bodies in transgenic plants, plant cells, and seeds. Said nucleotide sequence comprises a promoter, the 5′ untranslated region from the maize γ-zein gene, the γ-zein signal peptide sequence, a sequence encoding a heterologous protein of interest, and the 3′ untranslated region from the maize γ-zein gene, operatively linked.

Owner:SIMON FRASER UNIVERSITY

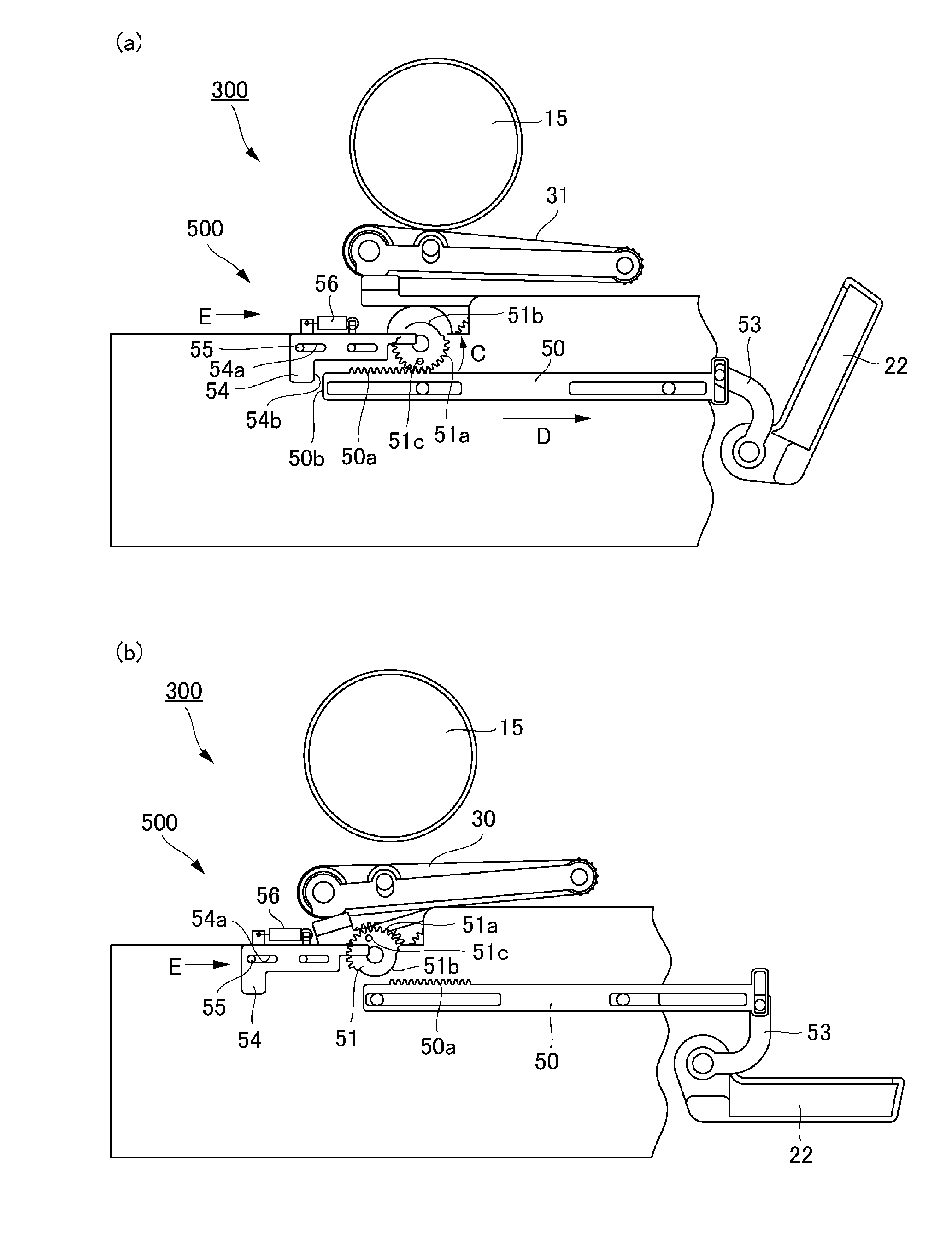

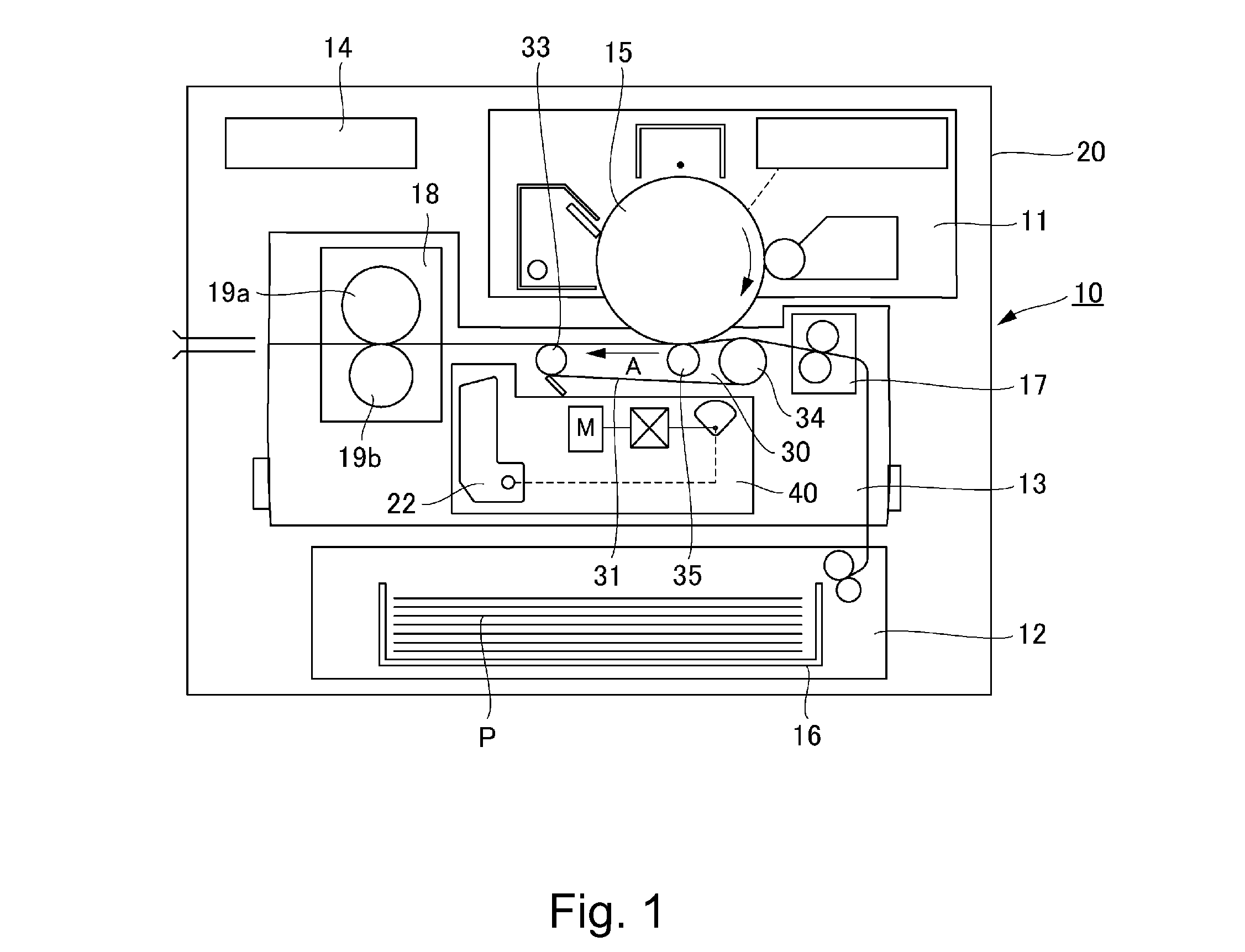

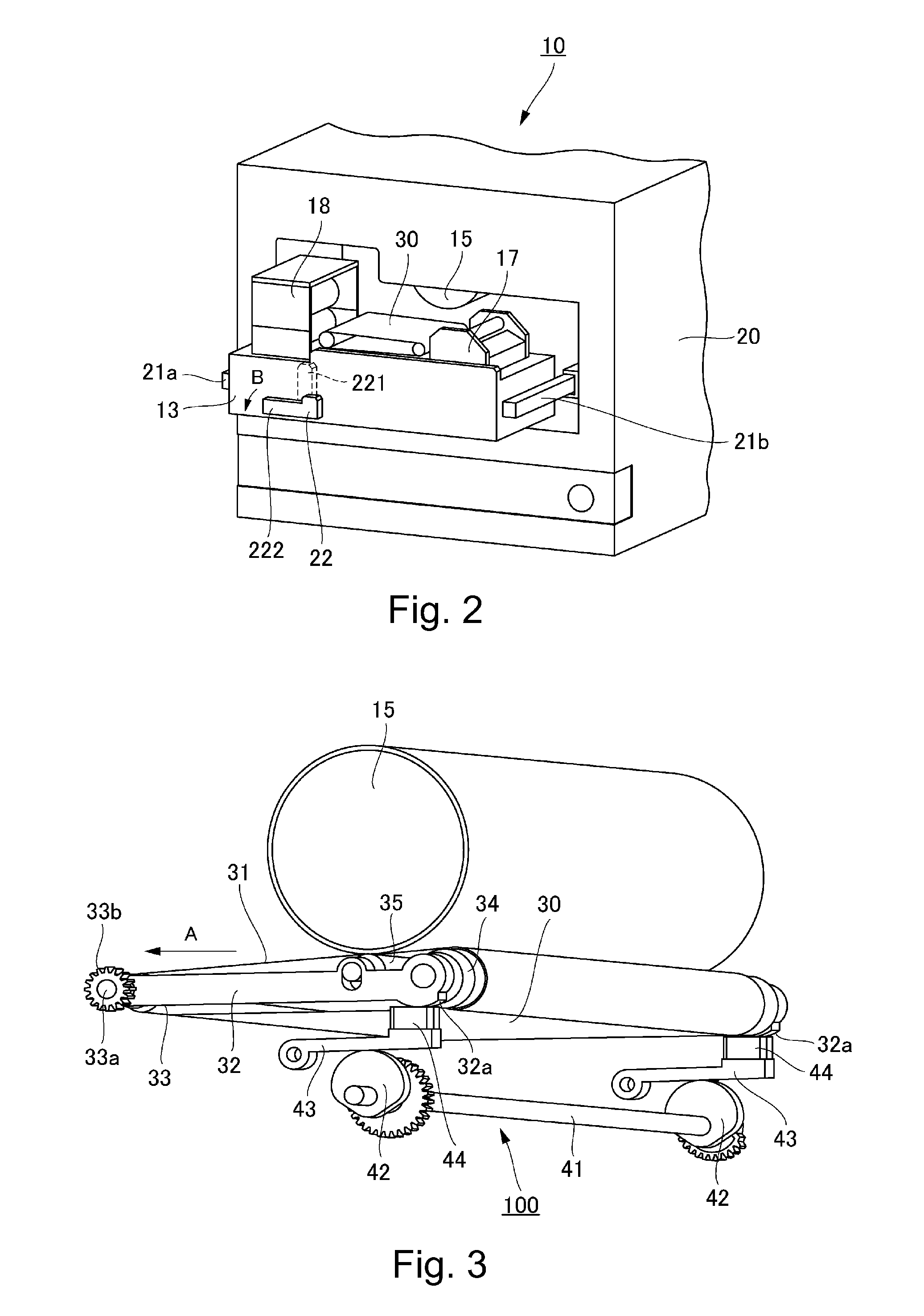

Image forming apparatus

An image forming apparatus includes an image bearing member forming a toner image, a belt member transferring the toner image, a cam transiting the belt member and the image bearing member between a contact state and a spaced state, and an operating lever for moving the belt member and the image bearing member between the contact state and the spaced state. In addition, a first member has a first engaging portion that moves in interrelation with movement of the cam and transmits a driving force of moving the operating lever to the cam, and a second member has a second engaging portion which engages with the first engaging portion and slidably movable to the first engaging portion. A third member regulates movement of the cam by abutting the second member when the operating lever is moved.

Owner:CANON KK

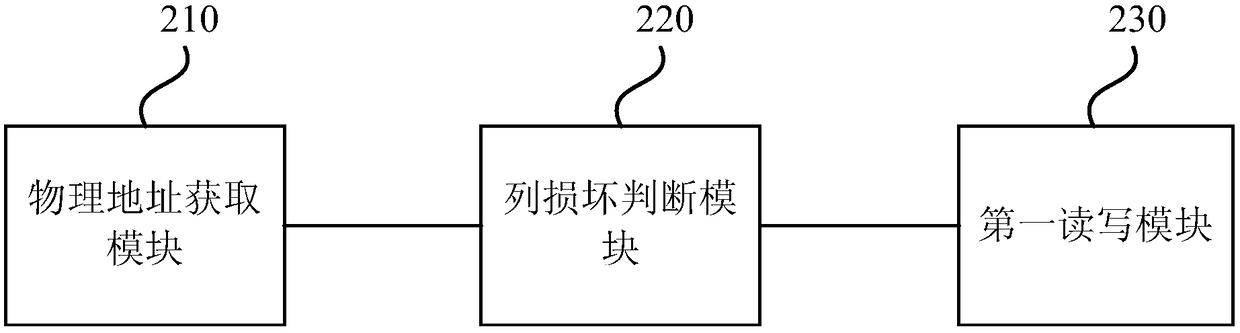

Column replacement method and device based on NAND flash memory and NAND storage device

InactiveCN108536389AAccelerateAvoid transitInput/output to record carriersRead-only memoriesPhysical addressHigh Readings

An embodiment of the invention discloses a column replacement method and device based on NAND flash memory and a NAND storage device. The method is applied to the NAND storage device; the NAND storagedevice includes a core array, a redundant array, a core array latch, a redundant array latch and a bad address latch; the bad address latch is used for storing a bad address lookup table; the bad address lookup table stores column addresses of bad columns in the core array. The method comprises: upon data writing, acquiring physical addresses of data to be written; judging whether columns, in thecore array, corresponding to the physical addresses of the data to be written are damaged according to the physical addresses of the data to be written and the bad address lookup table; if yes, writing, through the redundant array latch, the data to be written into the redundant array according to the physical addresses of the data to be written. The column replacement method and device based onNAND flash memory and the NAND storage device according to an embodiment of the invention can provide higher reading-writing speed.

Owner:GIGADEVICE SEMICON (BEIJING) INC

System for controlling conference circuit in packet-oriented communication network

InactiveUS7486629B2Simplify the migration processReduce development costsSpecial service provision for substationMultiplex system selection arrangementsTerminal equipmentConference control

To control a conference circuit between multiple terminal devices in a packet-oriented communication network, circuit-oriented conference control signaling is transmitted via a packet-oriented transport protocol between a first terminal device and a communication server of the communication network. Setting up of packet-oriented media channels between the terminal devices and a packet-oriented conference mixing device is initiated by the communication server depending on the conference control signaling.

Owner:UNIFY GMBH & CO KG

Door locking system

InactiveUS20210238882A1Reduce riskUnintentional locking of the door can also be preventedWing handlesKeyhole guardsSoftware engineeringMechanical engineering

A door locking system for opening and closing a door lock in a door. The door locking system includes a first door handle unit with a first door handle and a second door handle unit with a second door handle. The first door handle and the second door handle are pivotable about a common pivot axis. The door locking system comprises a coupling device with an axially aligned polygonal pin which has two pin pieces. The respective pin piece is connected to the respective door handle in a pivotably fixed manner.

Owner:KARCHER

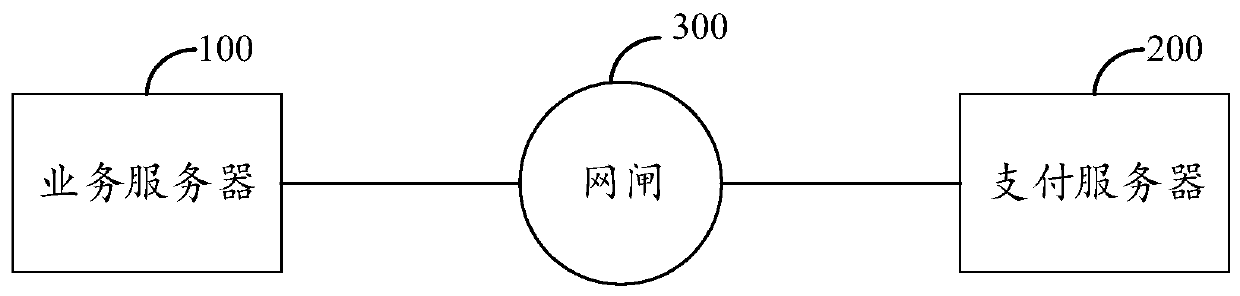

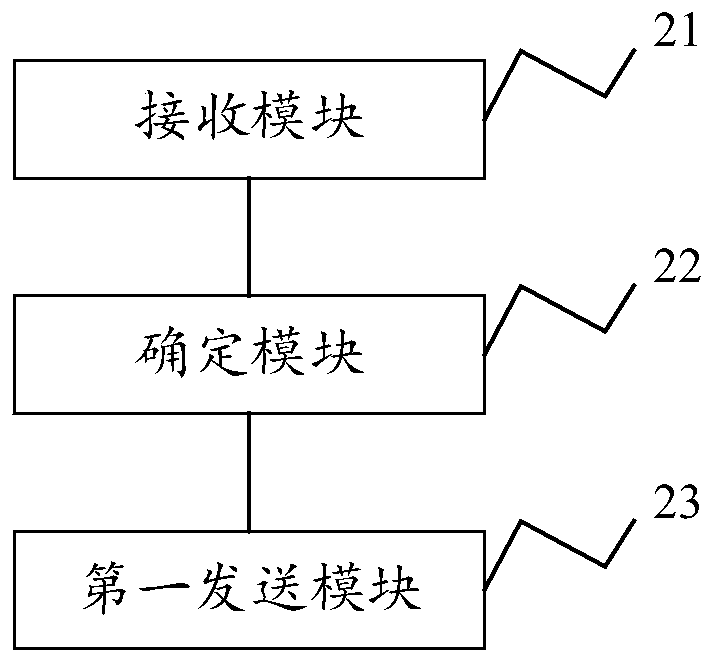

Payment message notification system, service server and payment server

ActiveCN111371847AAvoid transitGuaranteed real-timePayment architectureMessaging/mailboxes/announcementsInternet communicationPayment

The invention discloses a payment message notification system, a service server and a payment server, the system comprises the service server and the payment server, and the service server is connected with the payment server through a gateway; the business server is used for packaging collection information based on a communication address of a payee and sending the collection information to a payer, so that the payer carries out payment by using the collection information. And the payment server is used for sending a payment result to the payee by using a communication protocol correspondingto the communication address. According to the payment message notification system provided by the invention, the notification of the payment message is changed from cross-intranet communication to full-internet communication on the basis of not modifying a gatekeeper ferry system, so that the real-time performance is ensured.

Owner:HANGZHOU DT DREAM TECH

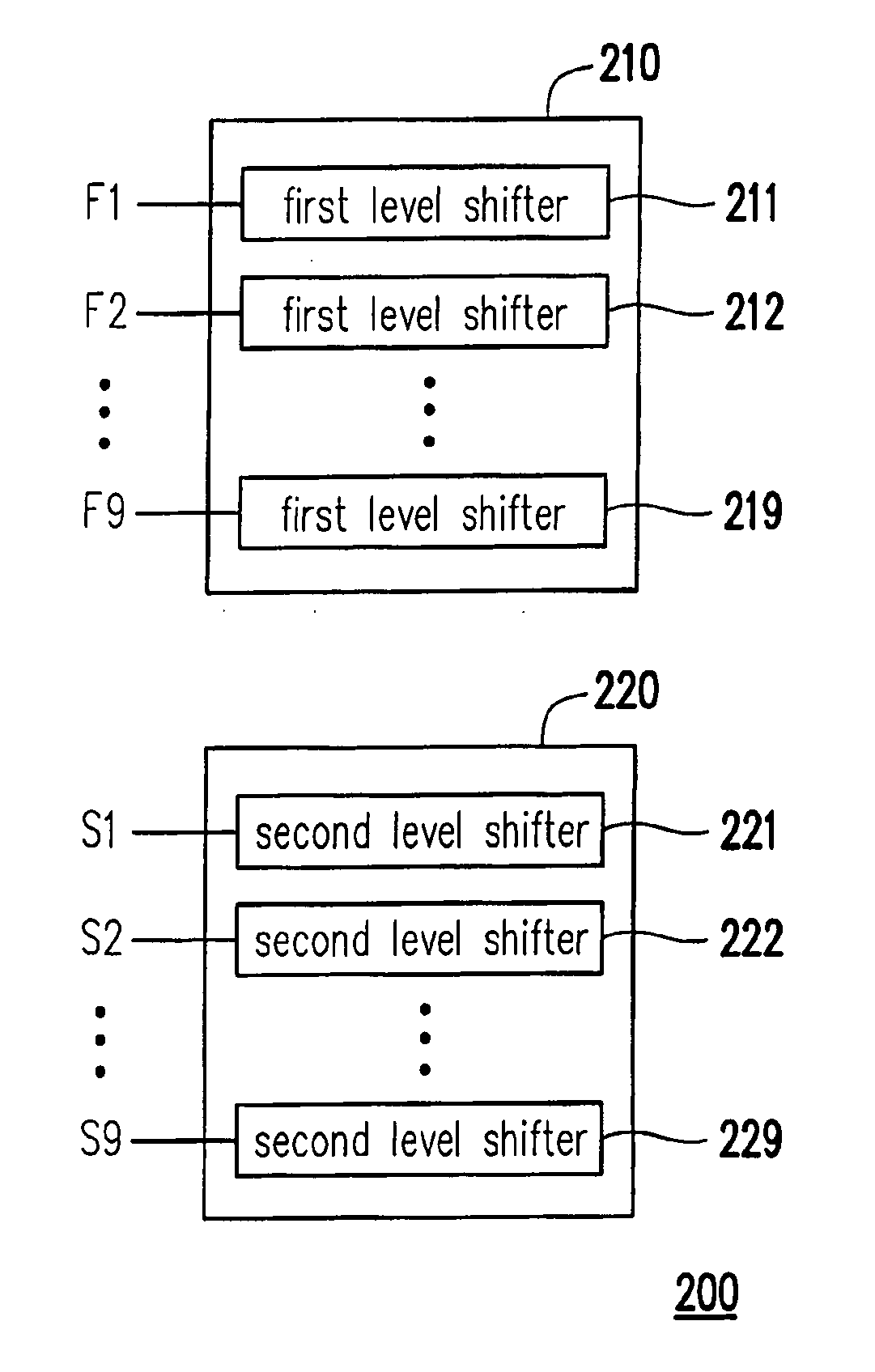

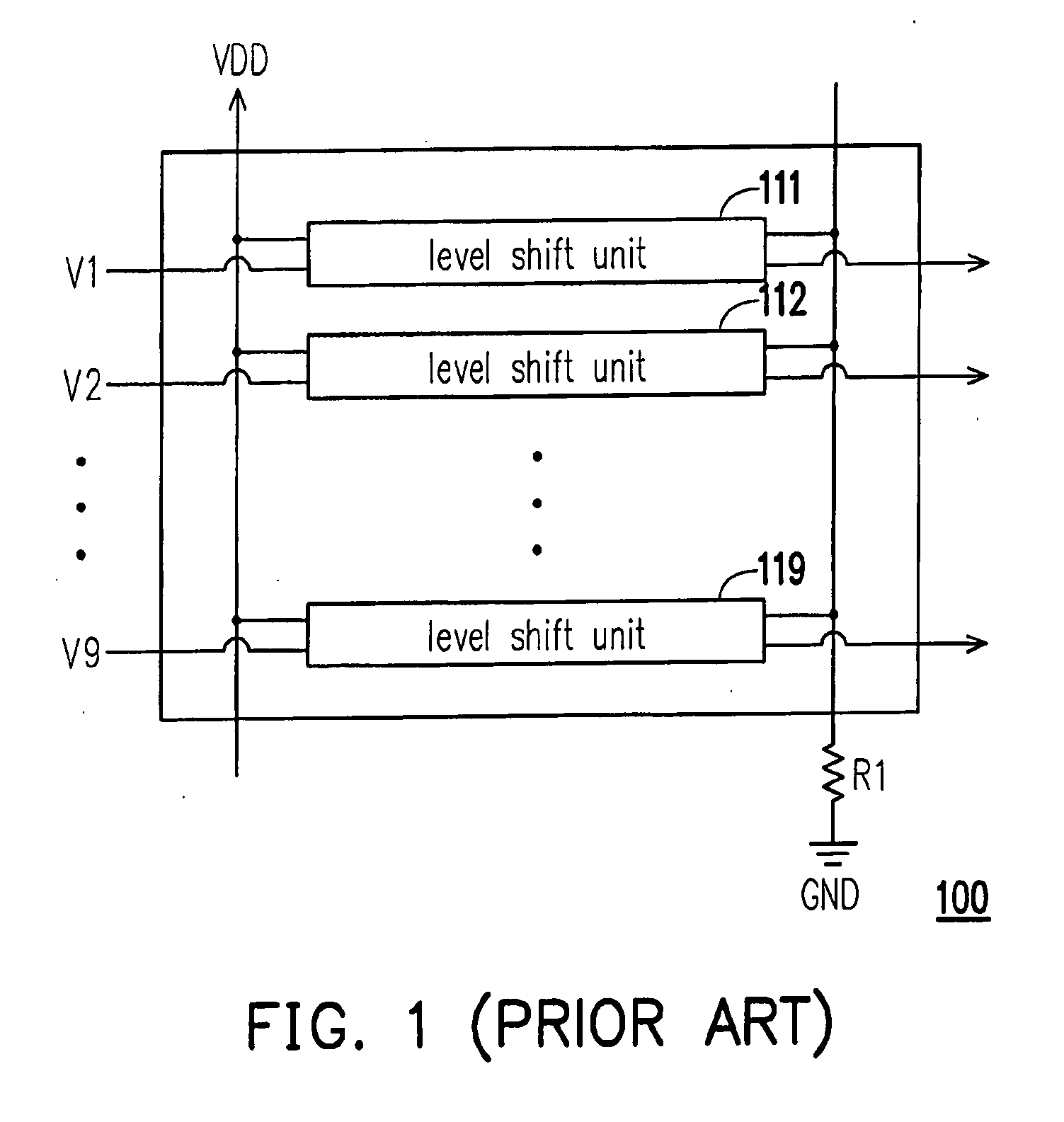

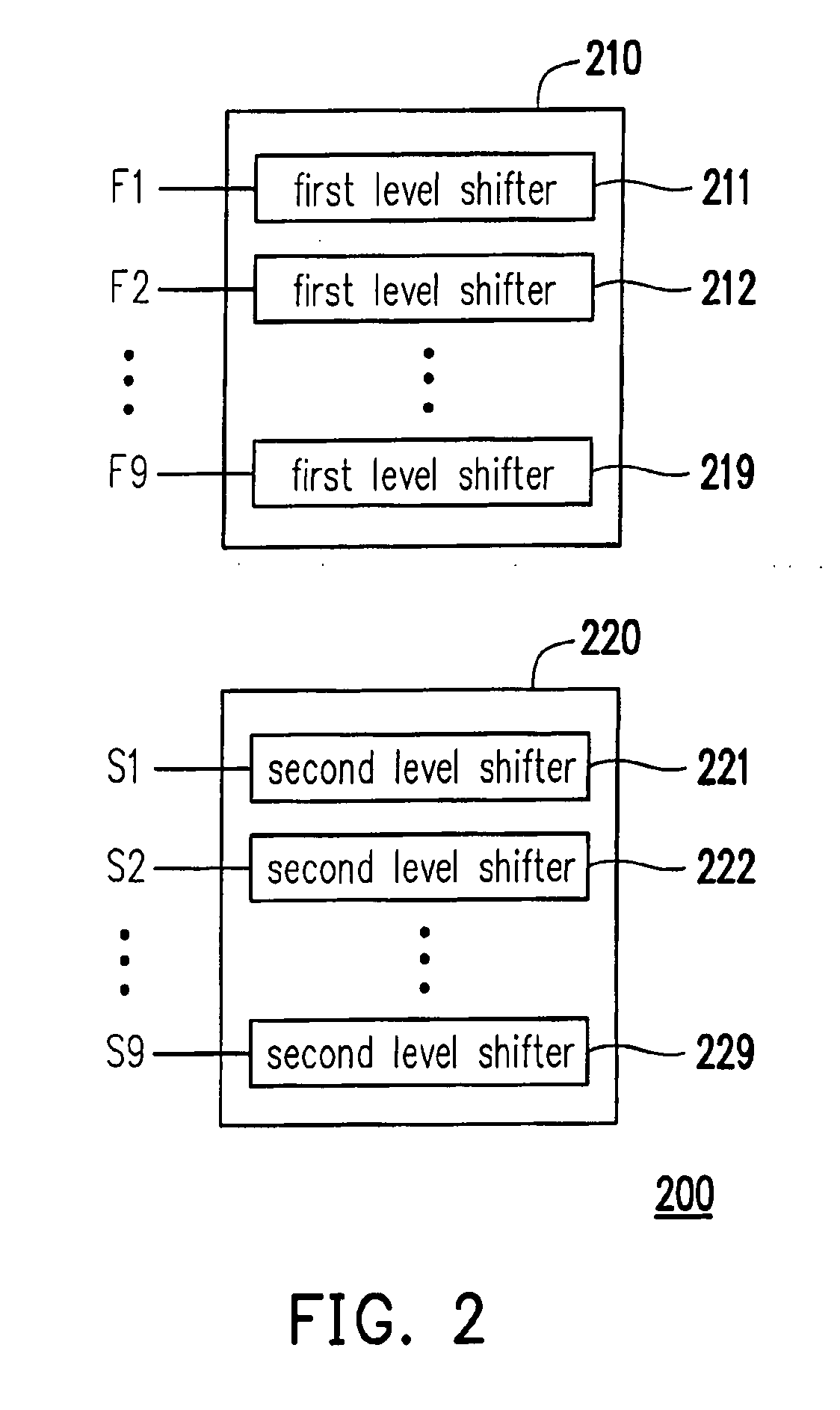

Level shifter concept for fast level transient design

InactiveUS20090091367A1Avoid transitMaintain abilityPulse automatic controlStatic indicating devicesEngineeringLevel converter

A driver including a first level shifter group and a second level shifter group is provided. The first level shifter group includes at least one first level shifter to receive a first input signal. The second level shifter group includes at least one second level shifter to receive a second input signal. The driver sequentially enables the first level shifter group and the second level shifter group to sequentially transfer voltage levels of the first input signal and the second input signal.

Owner:HIMAX TECH LTD

Signal receiver using data bit search in alternating time segments

ActiveUS7940834B2Avoid transitEasy to followSatellite radio beaconingTransmissionTime segmentTrial and error

A GNSS receiver and method using alternating “A” and “B” time segments for a reception time length of two or more data bits. The GNSS signal in an “A” time period comprising the “A” time segments is integrated for determining “A” magnitudes corresponding to code phase increments and the GNSS signal in a “B” time period comprising the “B” time segments is integrated for determining “B” magnitudes corresponding to code phase increments. A trial-and-error data bit search is performed for depolarizing data bit senses. The code phase increment showing the largest correlation level is used for acquisition of the GNSS signal and / or determination of the location where the GNSS is being received.

Owner:TRIMBLE NAVIGATION LTD

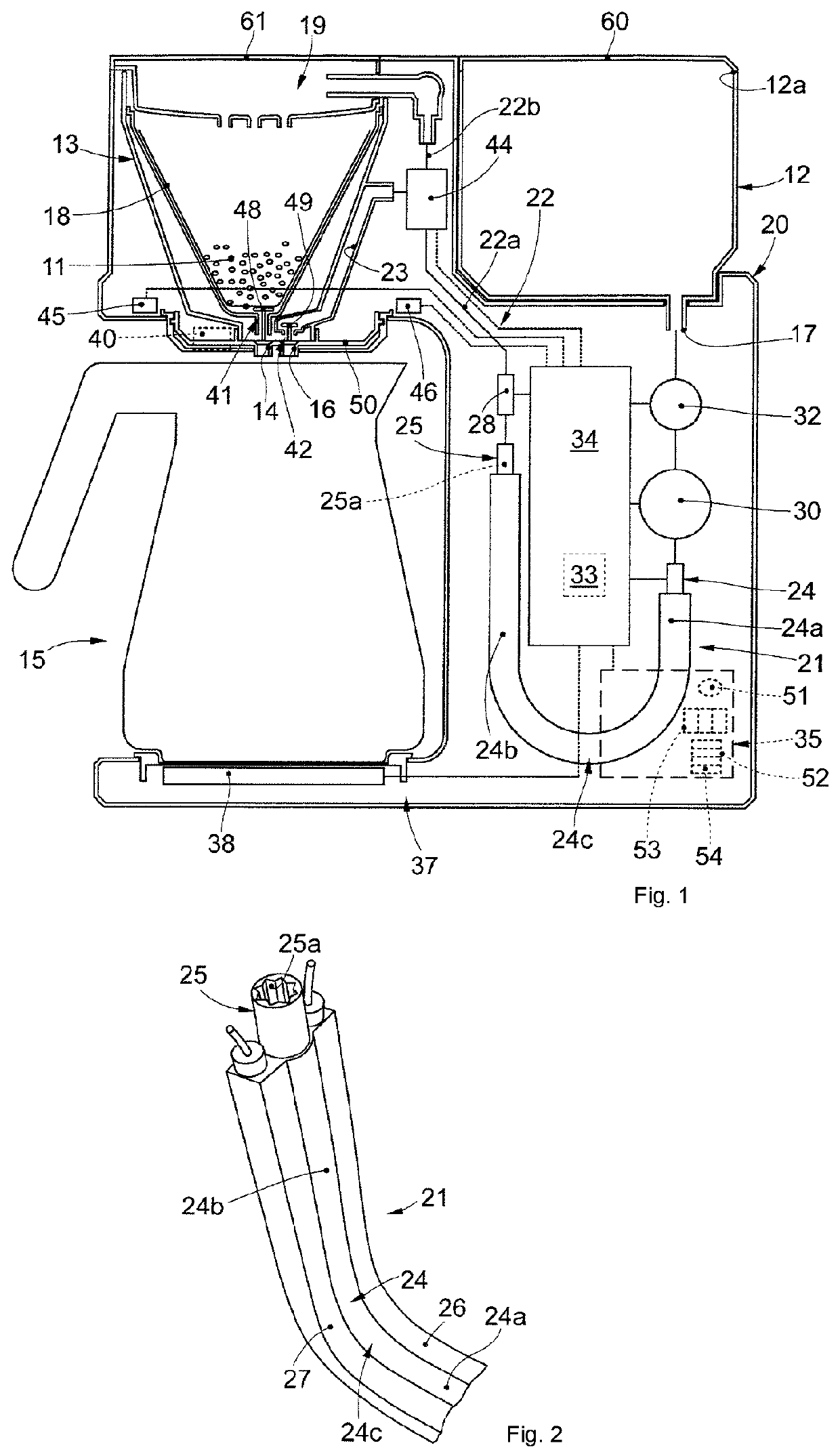

Machine for preparing beverages and method of control

A machine for preparing beverages includes at least one tank for the water, fluidly connected, by means of a circuit, to a filtering container suitable to contain an aromatic mixture to be brewed, a pump to feed the water from said tank to said circuit, a heating device to heat the water in transit, and a control and command unit functionally connected to a user interface comprising commands suitable to select the characteristics of said beverage to be prepared.

Owner:DELONGHI APPLIANCES S R L CON UNICO SOCIO

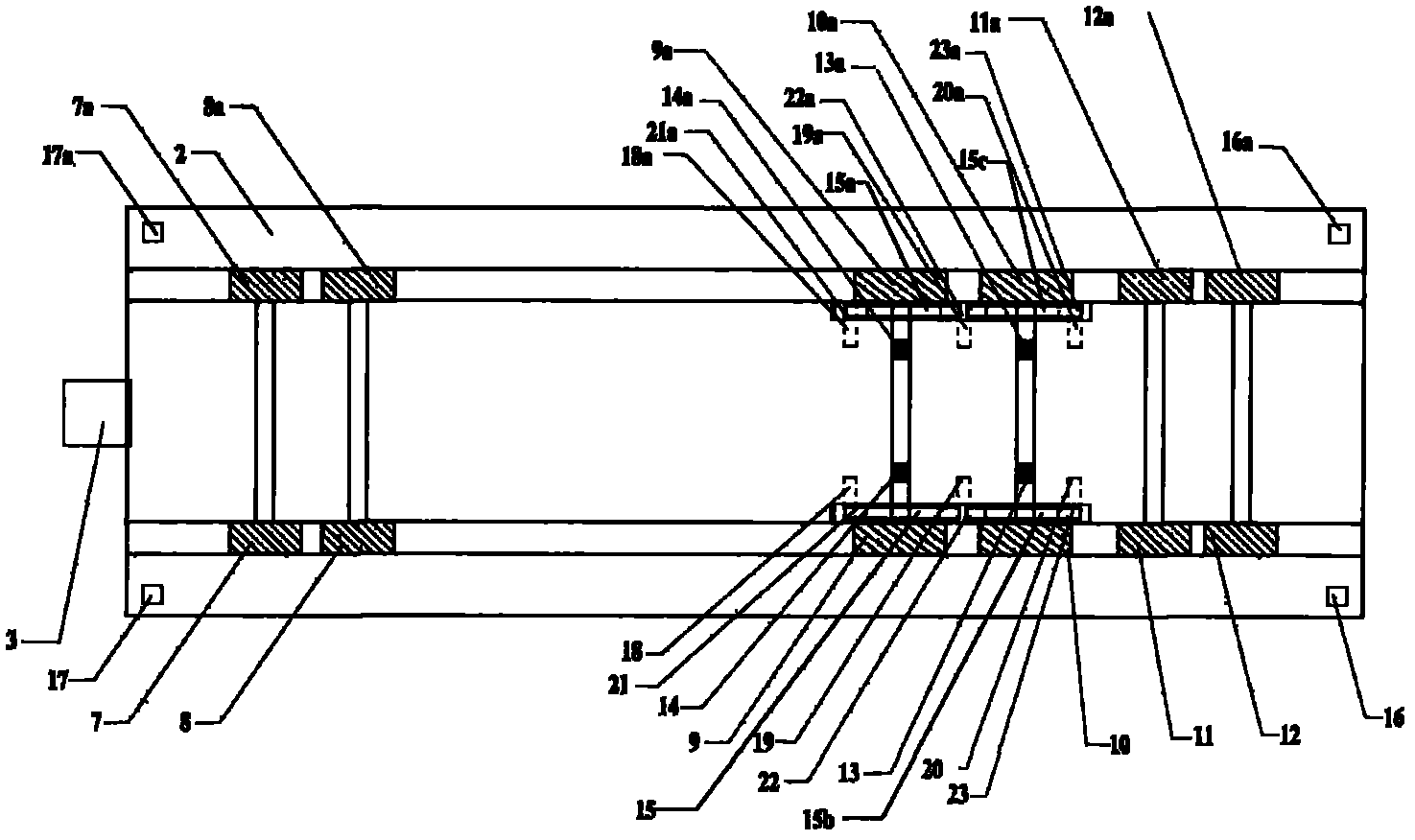

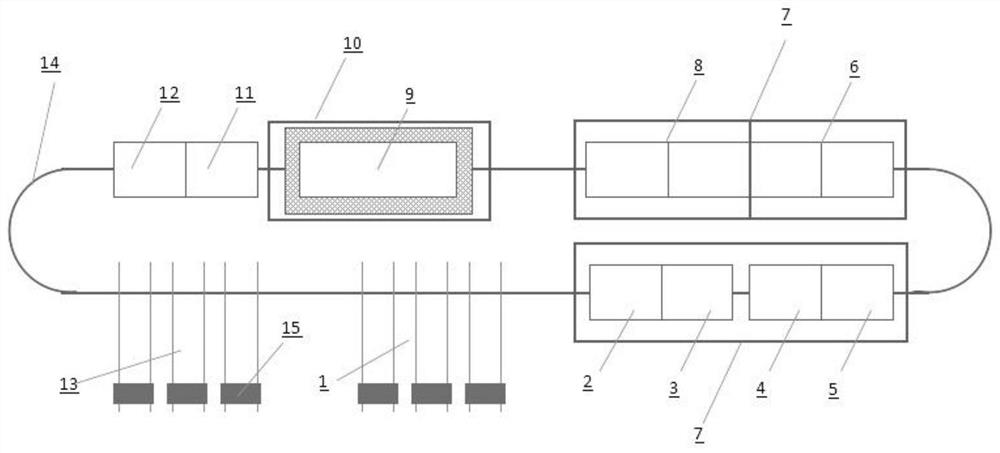

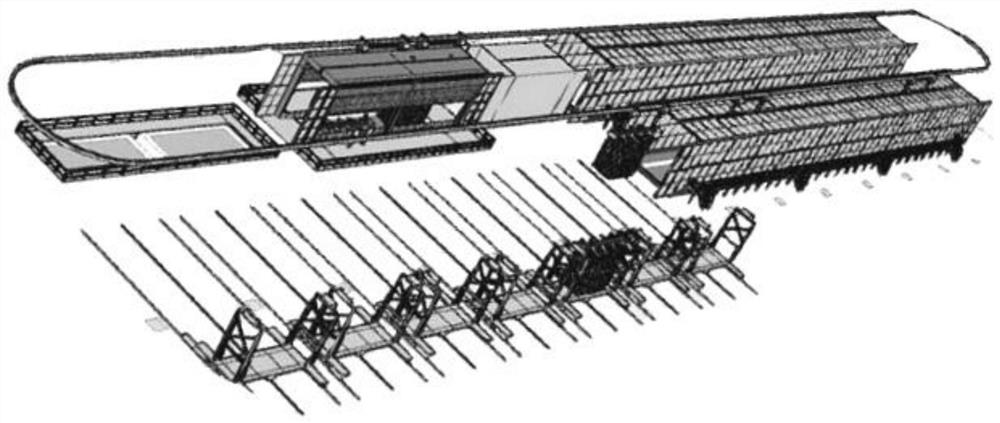

Batch hot-dip efficient environment-friendly continuous plating process and equipment

PendingCN112941447AIncrease productivitySimple operation processHot-dipping/immersion processesContinuous operationProcess engineering

The invention relates to a batch hot-dip efficient environment-friendly continuous plating process and equipment. The process involves a feeding area, a pre-treatment area, a dip plating area, a post-treatment area and a discharging area in sequence according to the process flow. The continuous plating process adopts an annular track, the annular track is provided with an electric conveying device, and transfer is of no need in the whole process flow. Material conveying at all the areas is completed on the same annular track, multiple sets of electric hoists with different starting moments are arranged in the feeding area, the materials on the different electric hoists enter the annular track according to the time difference, and continuous circulating plating of batched pieces is achieved. According to the batch hot-dip efficient environment-friendly continuous plating process and equipment, the annular plating process is adopted, so that the continuous operation without stopping and turning back is realized, the operation process is simplified, the waiting time of batch zinc plating is shortened, the continuous production from feeding to discharging is realized, the production efficiency is greatly improved, the advantages of energy conservation, consumption reduction, high production efficiency, small occupied area, energy conservation and emission reduction, environmental protection and the like are achieved, and the production benefits of an enterprise are increased.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

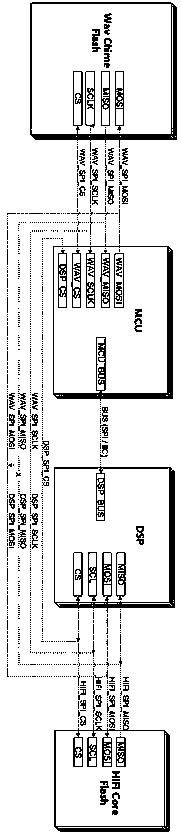

Novel automobile audio Digital Chime player

ActiveCN111524540AIngenious structural designStable and reasonable structureRecord information storageDigital storageComputer hardwareSound quality

The invention relates to a novel automobile audio Digital Chime player, which belongs to the technical field of automobile electronics and comprises an MCU, a DSP, a first Flash and a second Flash, the MCU is connected with the DSP and the first Flash, and the DSP is connected with the first Flash and the second Flash. During initialization, the DSP serves as a host, the second Flash serves as a slave computer, the HiFi processing program of the second Flash is loaded into the HiFi kernel of the DSP; after initialization, communication between the DSP and the second Flash is cut off, the DSP mounts the SPI data channel to the SPI data channel between the MCU and the first Flash, the MCU is a host, the first Flash is a slave, the DSP is switched from the host to the slave, and dual-slave data transmission is achieved. According to the player, the tone quality of the Chime can be effectively improved, diversified sound effects can be customized freely, and dependence on a specific DSP chip module is overcome.

Owner:YANFENG VISTEON ELECTRONICS TECH NANJING

Signal receiver having signal acquisition at low signal strength using interleaved time segments

InactiveUS20060034353A1Avoid transitEasy to followBeacon systemsSatellite radio beaconingTime segmentGps receiver

A GPS receiver and method using alternating “A” and “B” integration time segments. The polarities of certain GPS data bits are known beforehand and their expected reception times are known. The GPS signal in 10 millisecond “A” time segments and “B” time segments is depolarized according to the known polarities. The depolarized GPS signal during an “A” time period made up of all the “A” time segments is integrated for providing an “A” time period magnitude for each code phase. Likewise, the depolarized GPS signal during a “B” time period made up of all the “B” time segments is integrated for providing a “B” time period magnitude for each potential GPS code phase. The strongest of the time period magnitudes is compared to a correlation threshold for selecting a code phase for signal acquisition.

Owner:TRIMBLE NAVIGATION LTD

Automatic production line and process of inner joint holder

ActiveCN111761461ARealize automatic feedingEasy to detectGrinding machinesGrinding feedersProduction lineMachine

The invention provides an automatic production line and a process of an inner joint holder. The automatic production line comprises a feeding system, a window processing system, an outer circle processing system, an inner diameter processing system, a turning system and a conveying unit; holders to be processed are gradually conveyed to the turning system for detection after being sorted by the feeding system, wherein the holder with a positioning surface facing down is directly conveyed to a first feeding unit, and the holder with a positioning surface facing up can realize automatic feedingand detection of the positioning surface by adding the automatic feeding and the turning system before a grinding window process as well as the holder with the positioning surface facing up is conveyed to the window processing system for grinding window processing after being turned automatically; and the holder is conveyed to the outer circle processing system and a subsequent inner hole processing system by a lifting unit, so as to realize one person operating a plurality of machines, reduce labor intensity, improve production efficiency, and reduce the turnover cycle of workpieces.

Owner:ZHEJIANG KAIDI AUTOMOTIVE PARTS IND

Antimicrobial compounds and uses thereof

InactiveUS8785680B2Inhibits biofilm formationReduced expression levelAntibacterial agentsBiocideAntimicrobial compoundStereochemistry

The present invention relates to novel antimicrobial compounds, methods of their production as well as uses thereof.

Owner:ASTRAL QS TECH PTE LTD

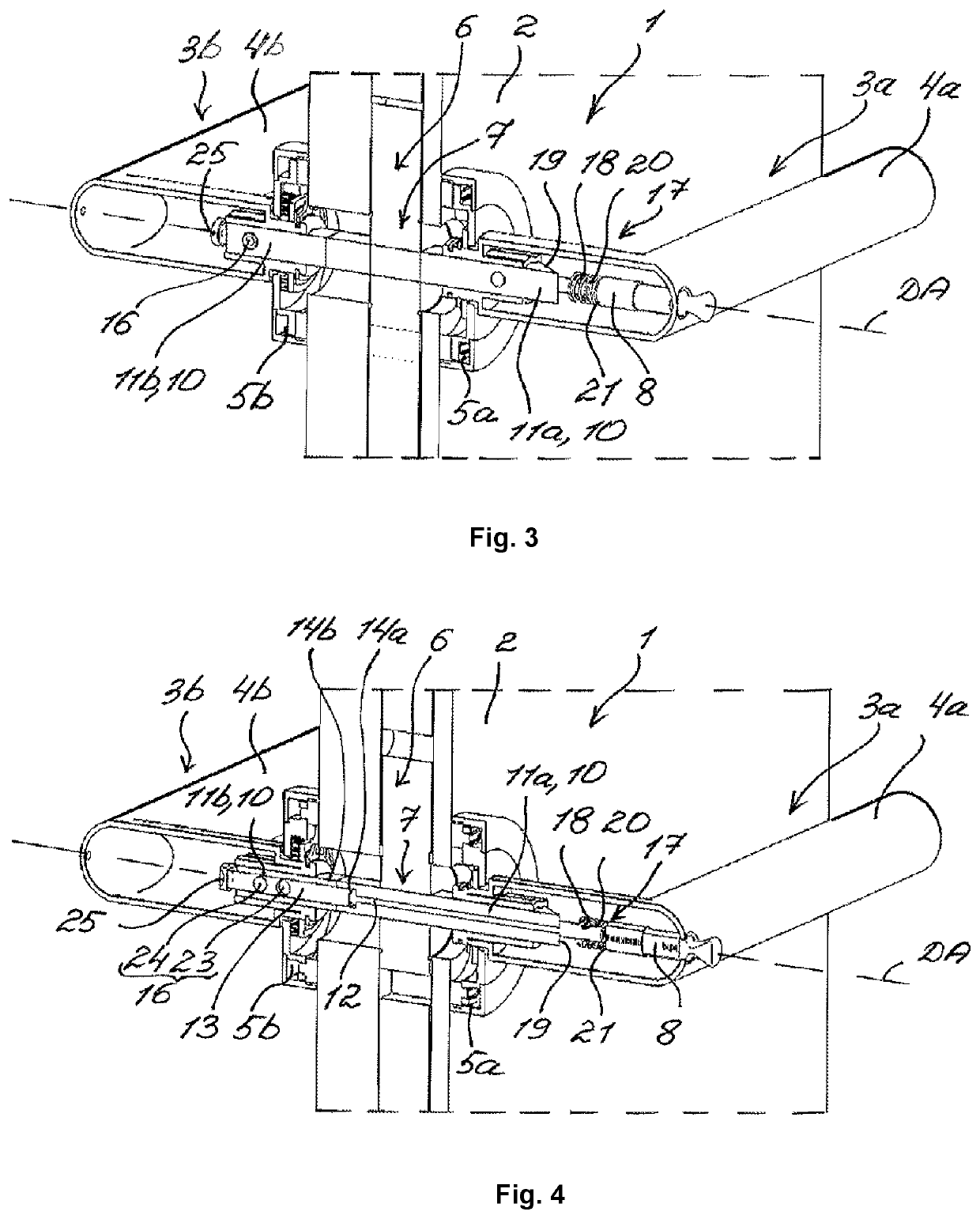

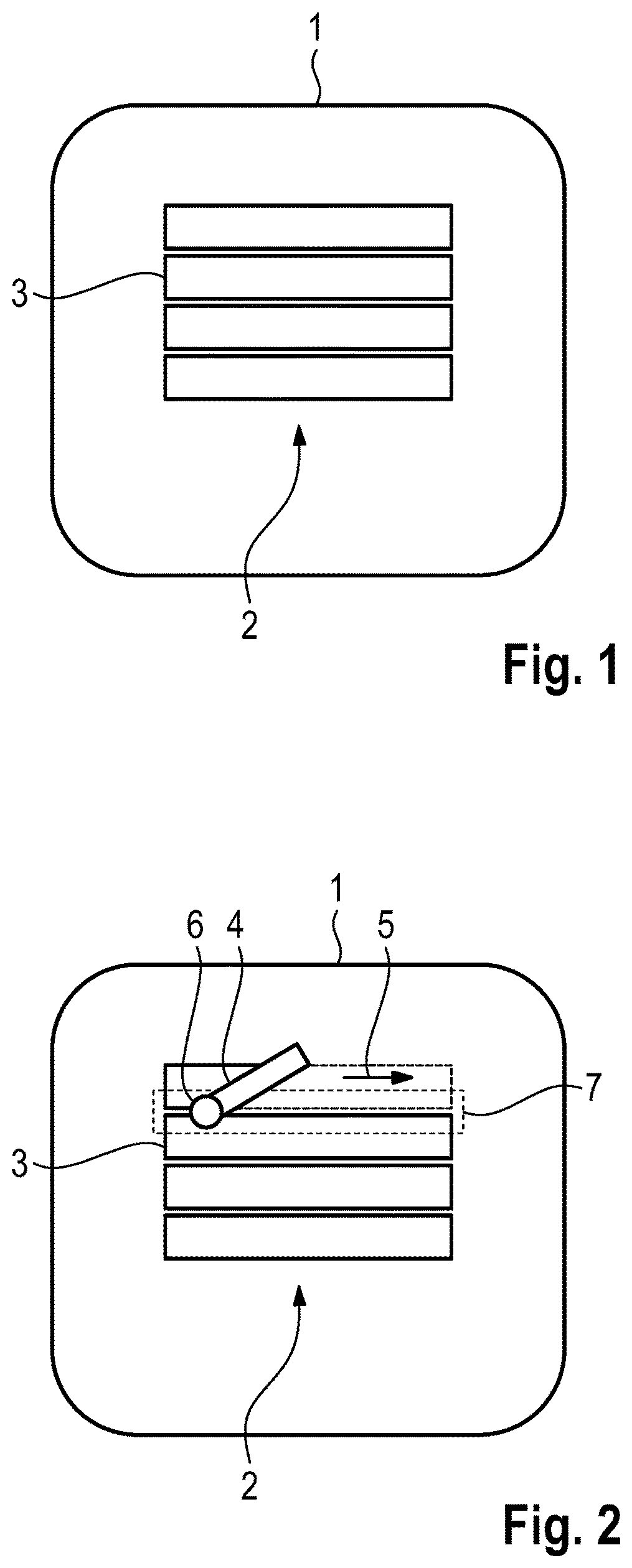

Method for printing a surface with a printed pattern and associated printing device

ActiveUS20200238729A1Easy inputAvoid transitDuplicating/marking methodsPattern printingPhysicsEngineering

A method for printing a surface (1) with a printed pattern (2) includes printing a first partial structure (3) of the printed pattern (2), printing a second partial structure (3) of the printed pattern (2) at a distance from the first printed structure (3) and treating at least one region (7) between the first printed structure (3) and the second printed structure (3), and the irradiating the region (7) between the first printed structure (3) and the second printed structure (3) with electromagnetic waves and / or soundwaves.

Owner:DR ING H C F PORSCHE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com