Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid mislabeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

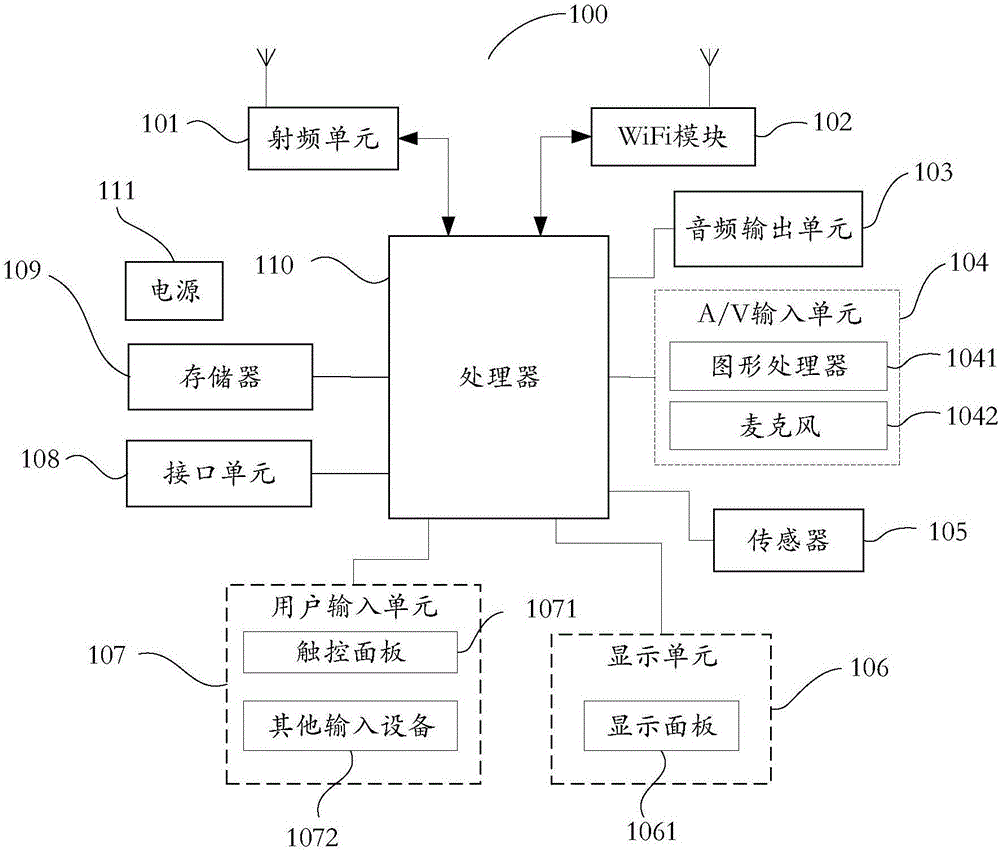

Configuration method and system, household appliance, mobile terminal and server

ActiveCN106211205ASimplify the build assembly processImprove simplicityConnection managementComputer terminalEmbedded system

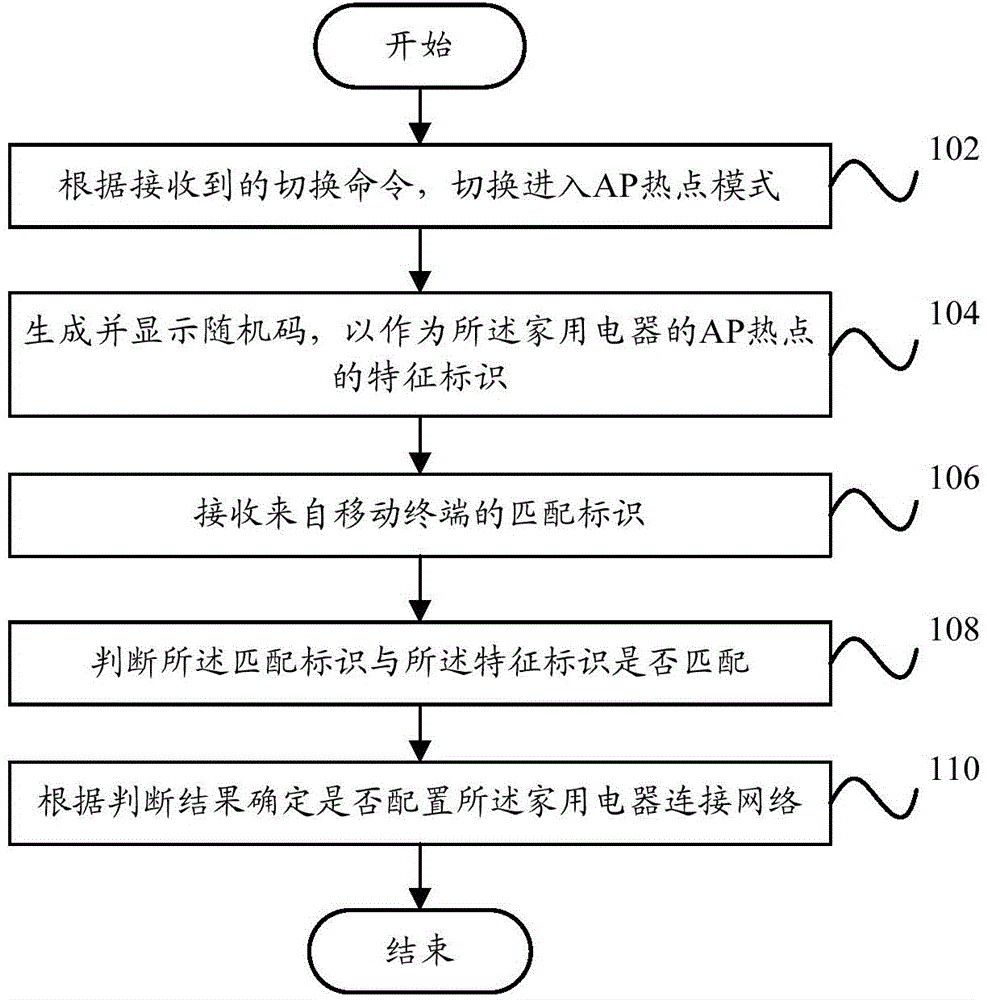

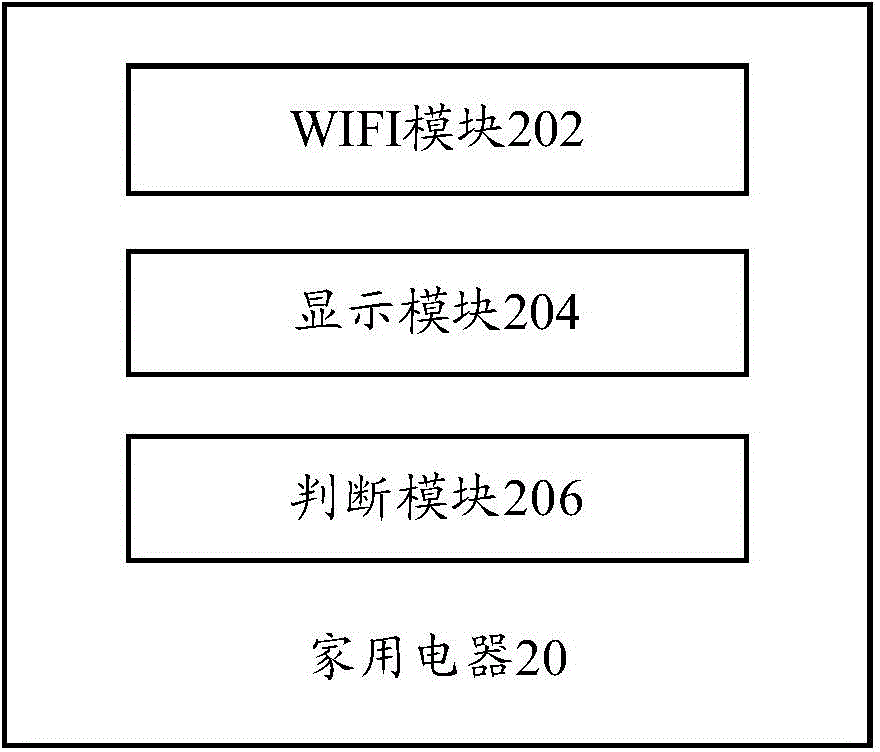

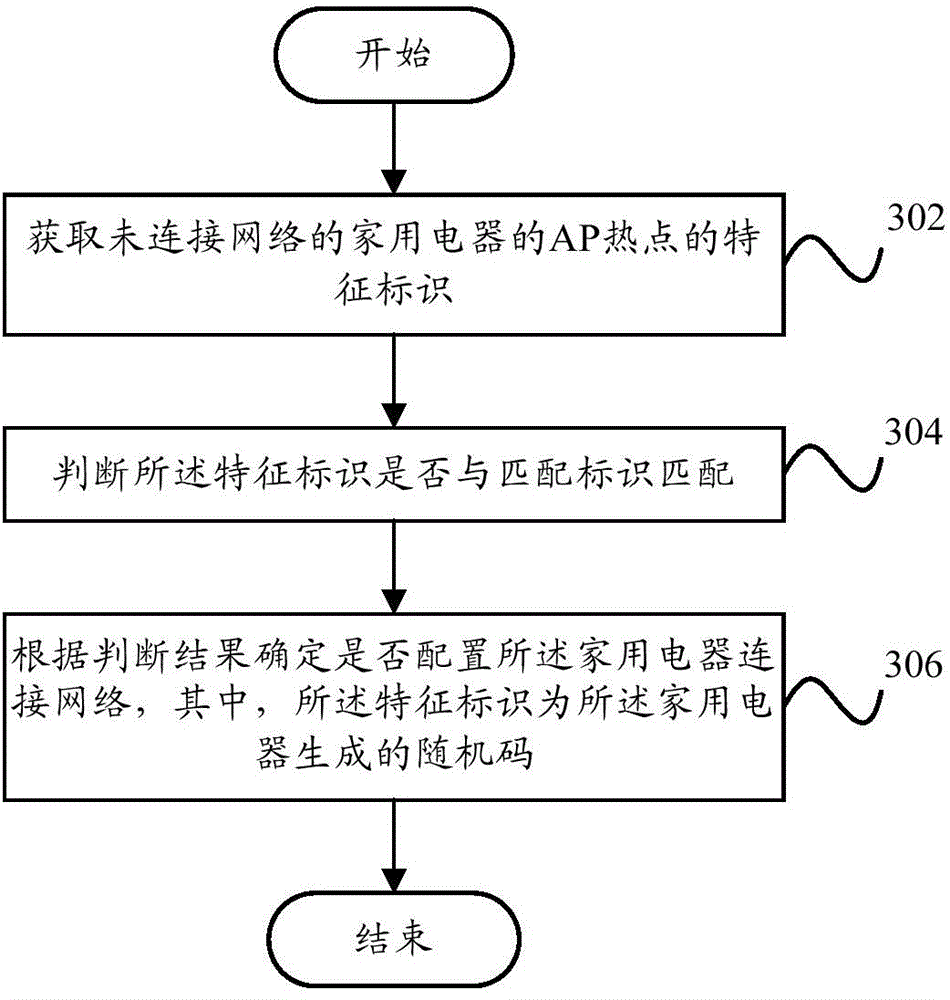

The invention provides a configuration method for connecting a household appliance with a network, the household appliance, a mobile terminal, a server and a configuration system for connecting the household appliance with the network. The configuration method comprises the steps of switching to enter an AP hotspot mode according to a received switchover command; generating and displaying a random code, and using the random code as a feature identifier of the AP hotspot of the household appliance; receiving a matching identifier from the mobile terminal; judging whether the matching identifier is matched with the feature identifier; and determining whether to configure the household appliance to be connected with the network according to a judgment result. According to the technical scheme of the method and system, the household appliance, the mobile terminal and the server of the invention, a configuring process of connecting the household appliance with the network can be started by pressing one key, the accuracy of a connection between the mobile terminal and the household appliance can be improved, and thus the simplicity of connecting the household with the network is improved, the user experience is enhanced, and meanwhile the production assembly process of the household appliance is simplified and the production efficiency is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Sign pasting device and sign pasting method using same

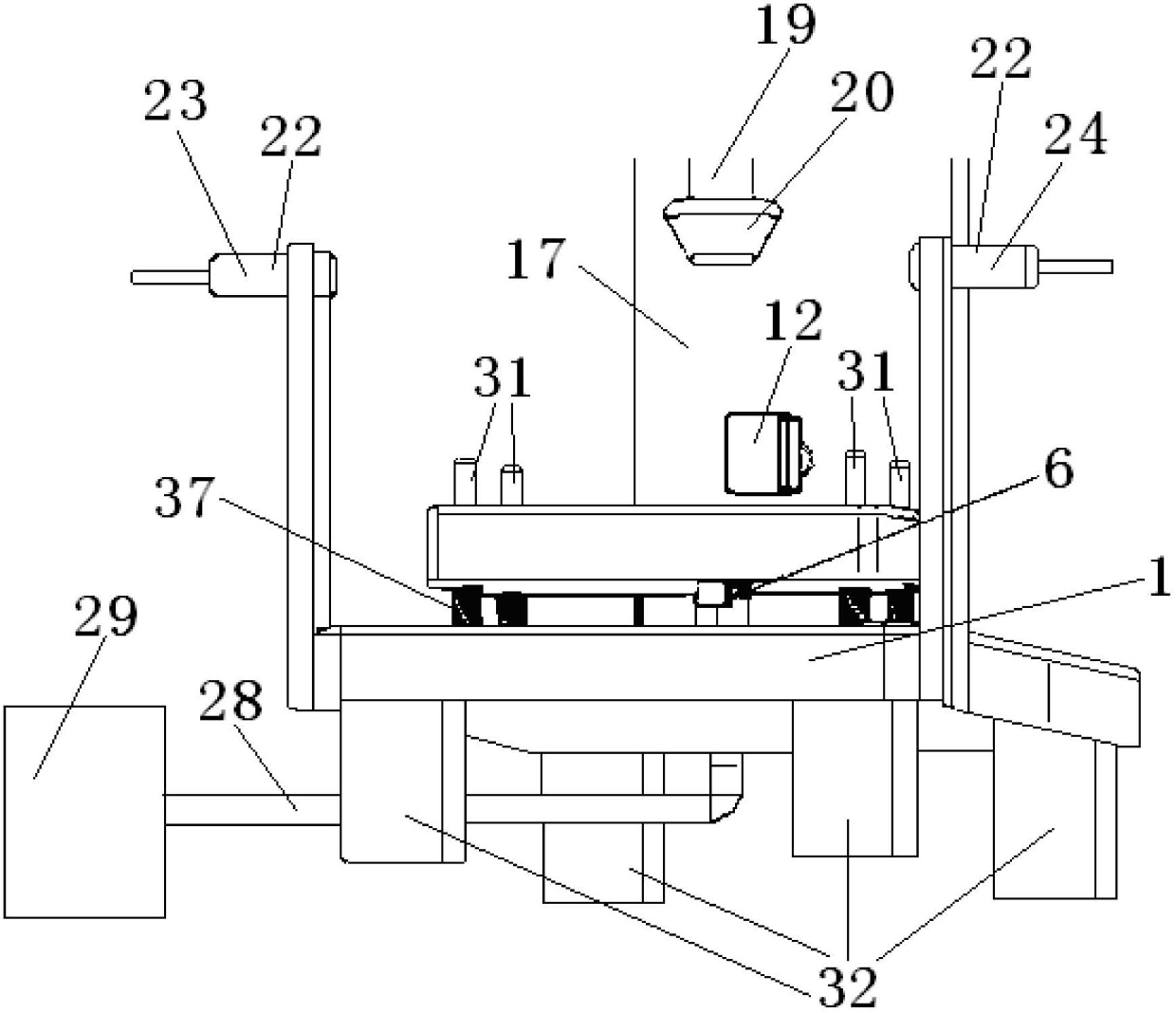

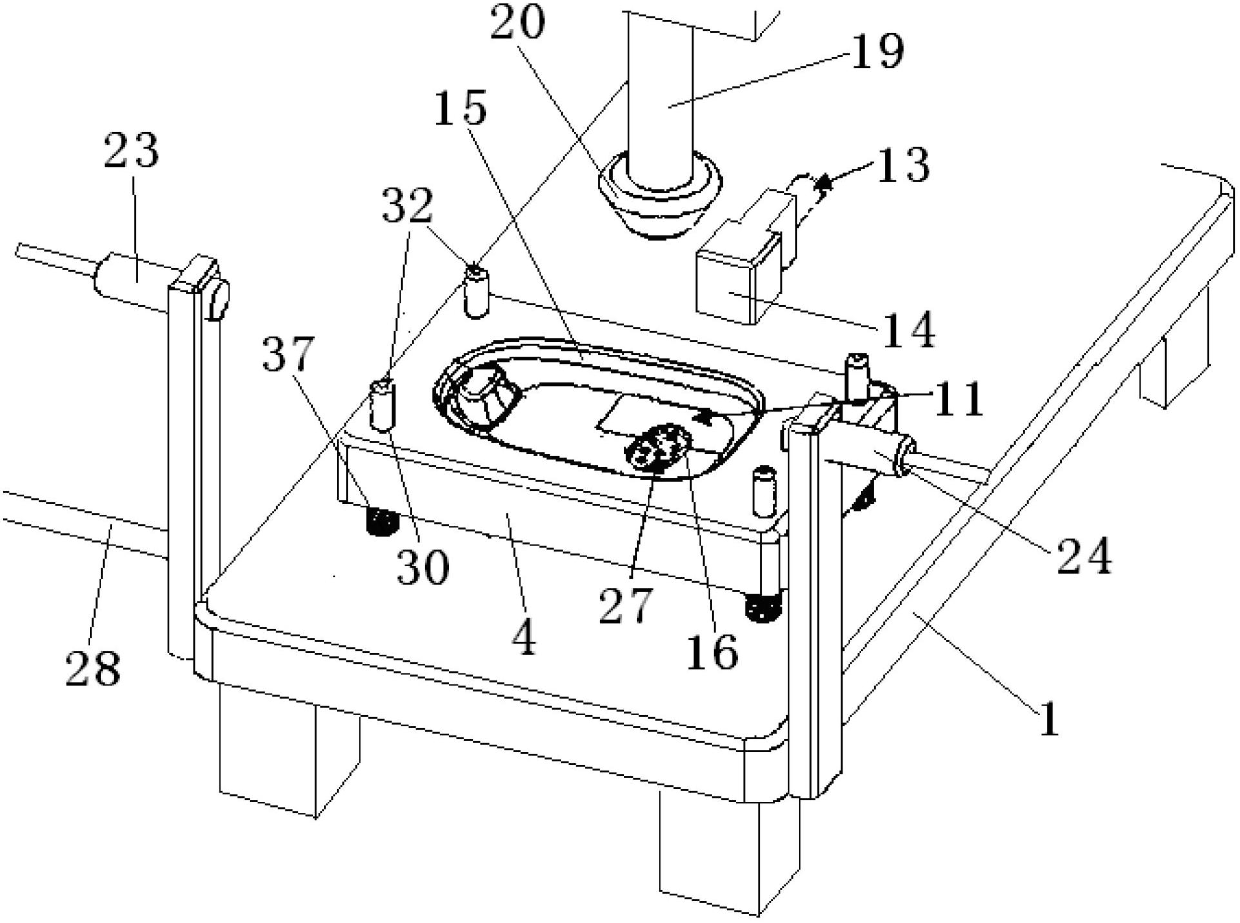

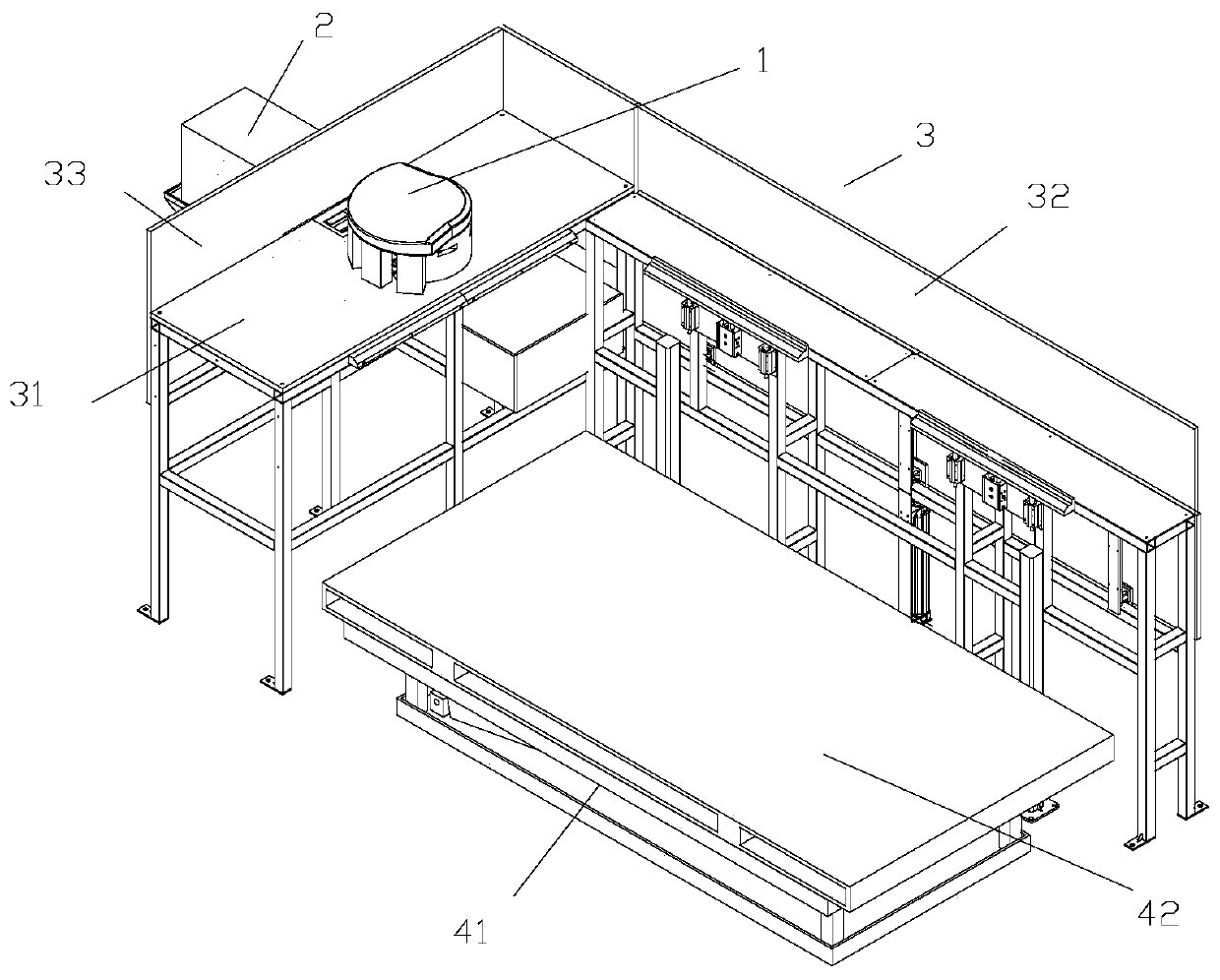

InactiveCN102673853AGuarantee paste qualityError-proofLabelling flat rigid surfacesLabelling machinesEngineeringElectric control

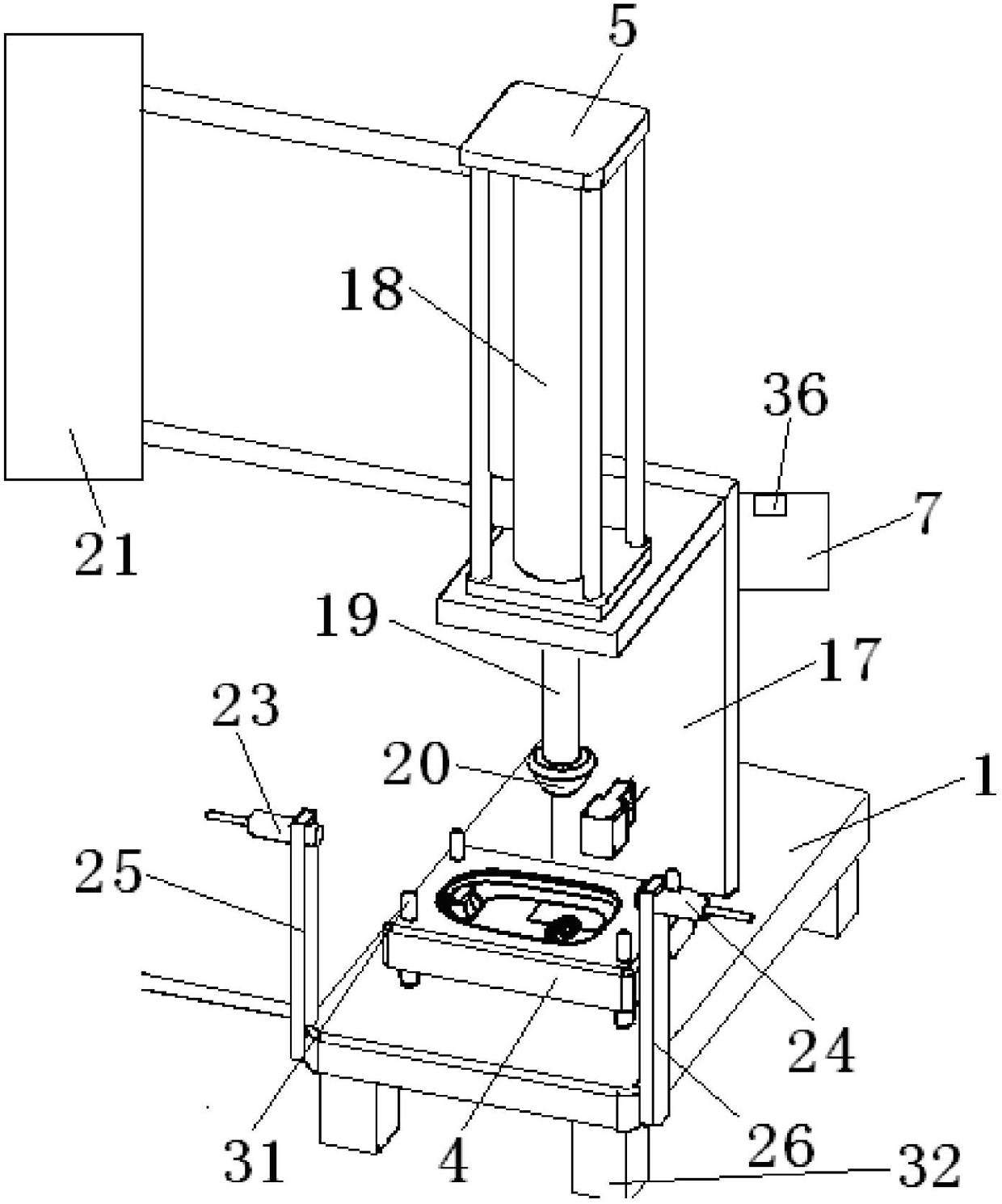

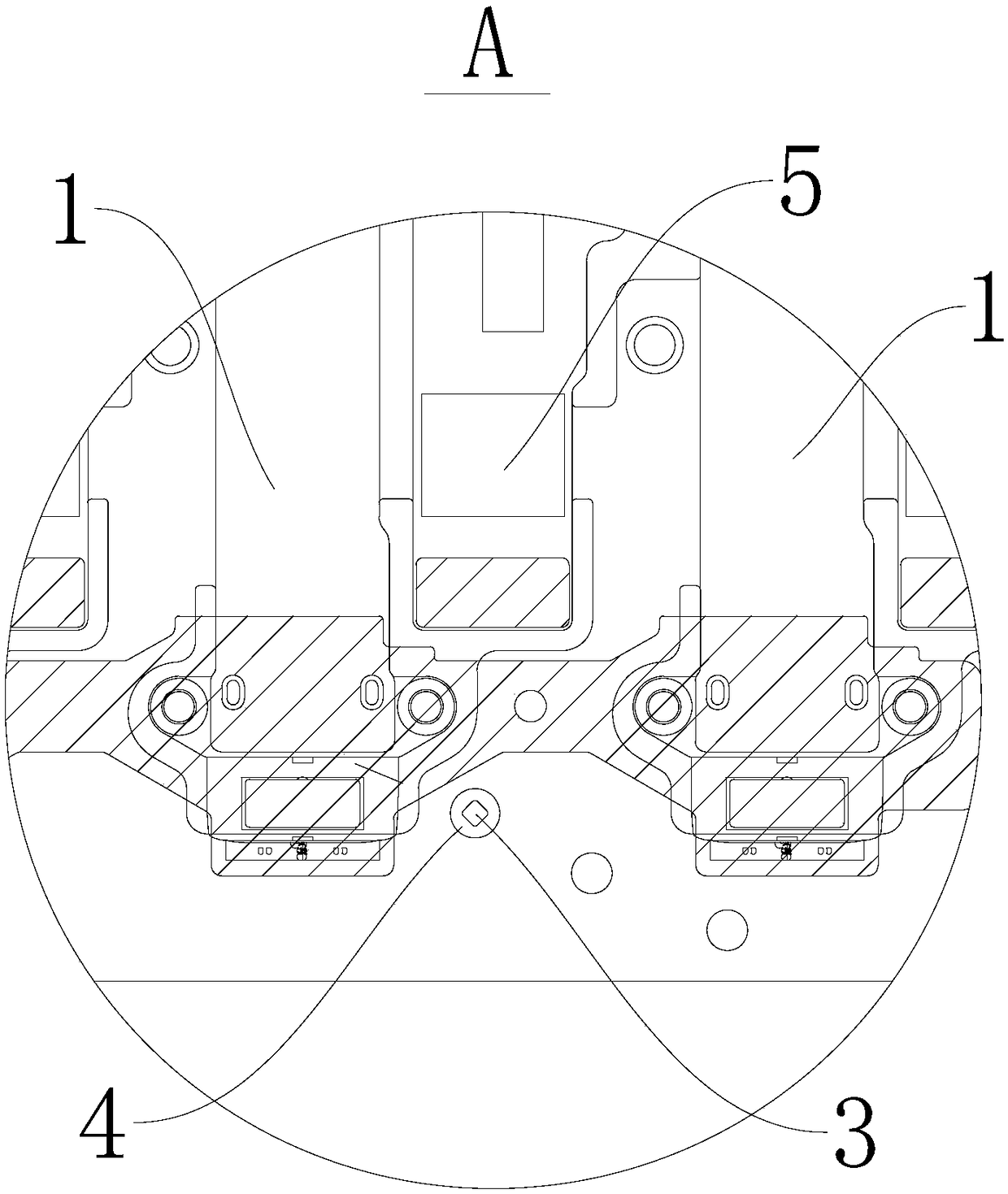

The invention provides a sign pasting device applied to the technical field of sign pasting, and further relates to a sign pasting method using the sign pasting device. The pasting device comprises bases (4) for placing a plastic part (3) to be pasted with a sign, wherein the bases (4) are arranged on a supporting platform (1); a press-fit component (5) is arranged above each base (4) and has a liftable structure; a photo sensor (6) is further arranged on the base (4) and is connected with an alarm component (36); and both the photo sensor (6) and the press-fit component (5) are connected with an electric control component (7). The sign pasting device has stable pressure during sign pasting, and has an error-proofing function so as to solve the problem of omissions and errors caused by visual fatigue of an operator; and furthermore, the sign pasting device is strongly universal and can adapt to the pasting of signs of different shapes on the plastic part.

Owner:震宇(芜湖)实业有限公司

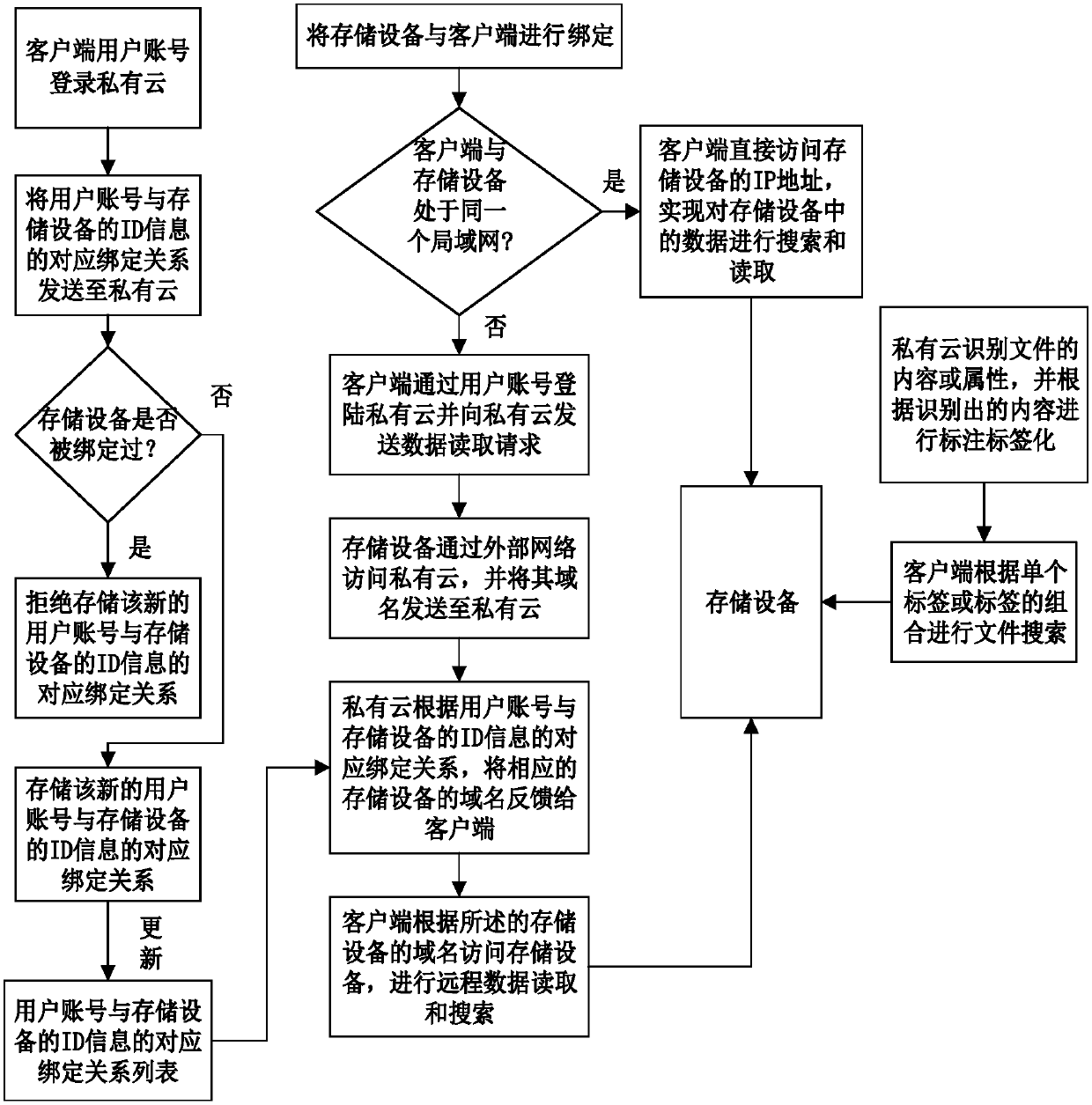

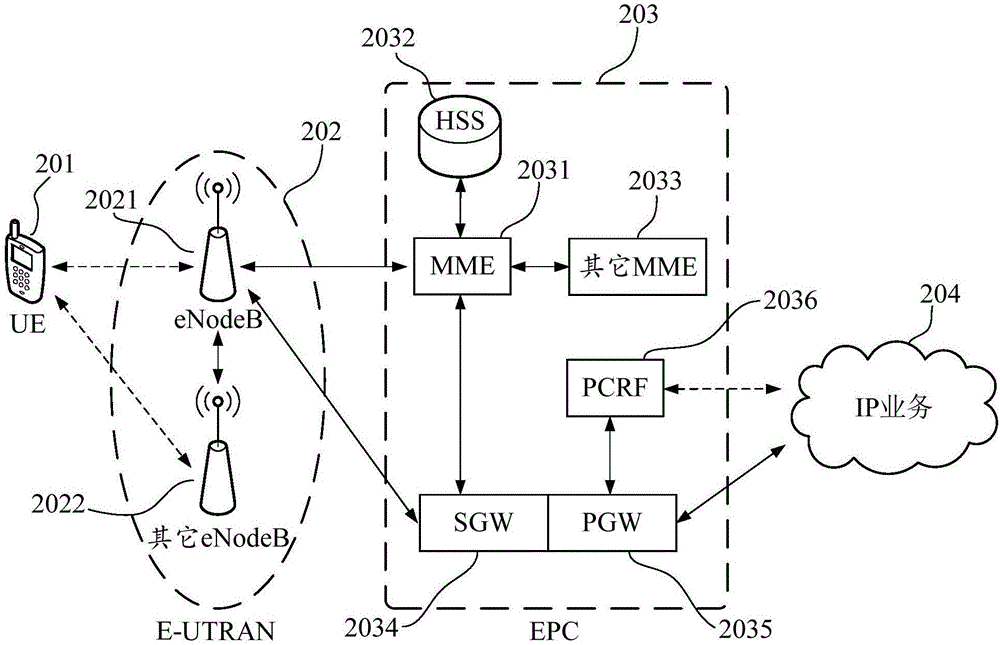

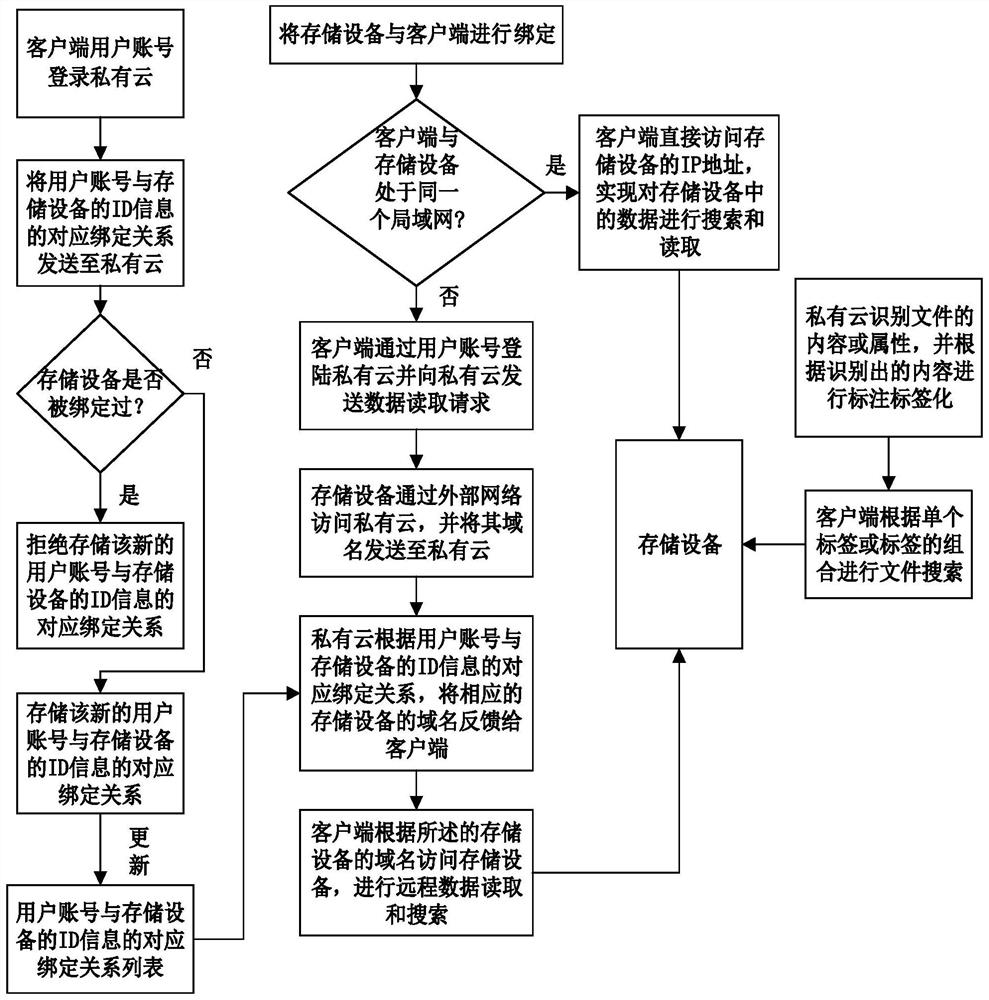

File search method and system

ActiveCN107766430ASearch intelligenceImprove search efficiencyTransmissionRedundant operation error correctionClient-sideSingle label

The invention discloses a file search method and system. The method comprises the following steps of: S1, recognizing content or an attribute of a file in storage equipment by a private cloud and carrying out labelling according to the recognized information, or when the file is backed up into the storage equipment, recognizing the content or the attribute of the file by utilizing the private cloud and carrying out labelling according to the recognized information, wherein private cloud platforms are operated on both the storage equipment and a client; S2, binding an ID of the storage equipment with a user account number; and S3, logging the private cloud platform by the client by utilizing the user account number, accessing the storage equipment through the private cloud platform, and after verification passes, carrying out file search according to a single label or combination of labels. According to the method and system, the content or the attribute of the file is recognized by utilizing the private cloud, and labelling is carried out according to the recognized information, so that file search can be carried out by utilizing a single label or combination of labels, intelligentfile search is realized by utilizing the private cloud and both the search efficiency and correctness are relatively high.

Owner:BEIJING CHUNHONG TECH CO LTD

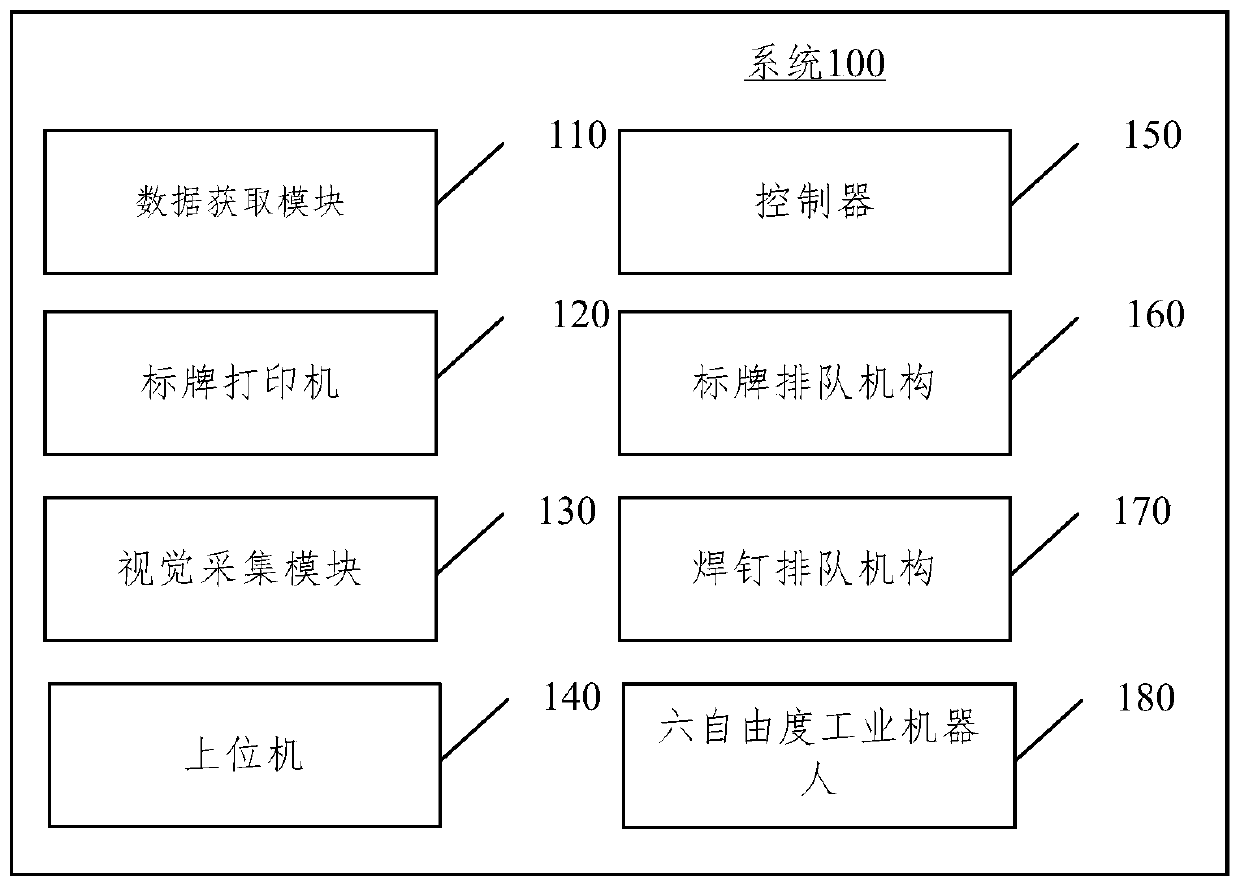

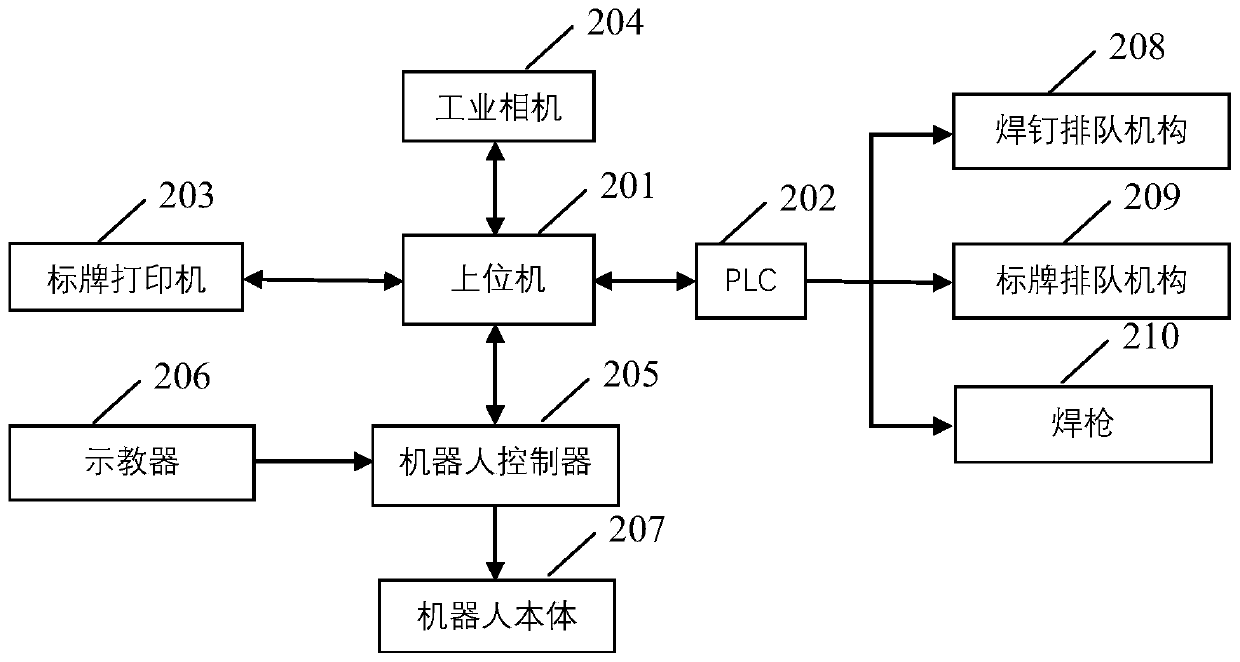

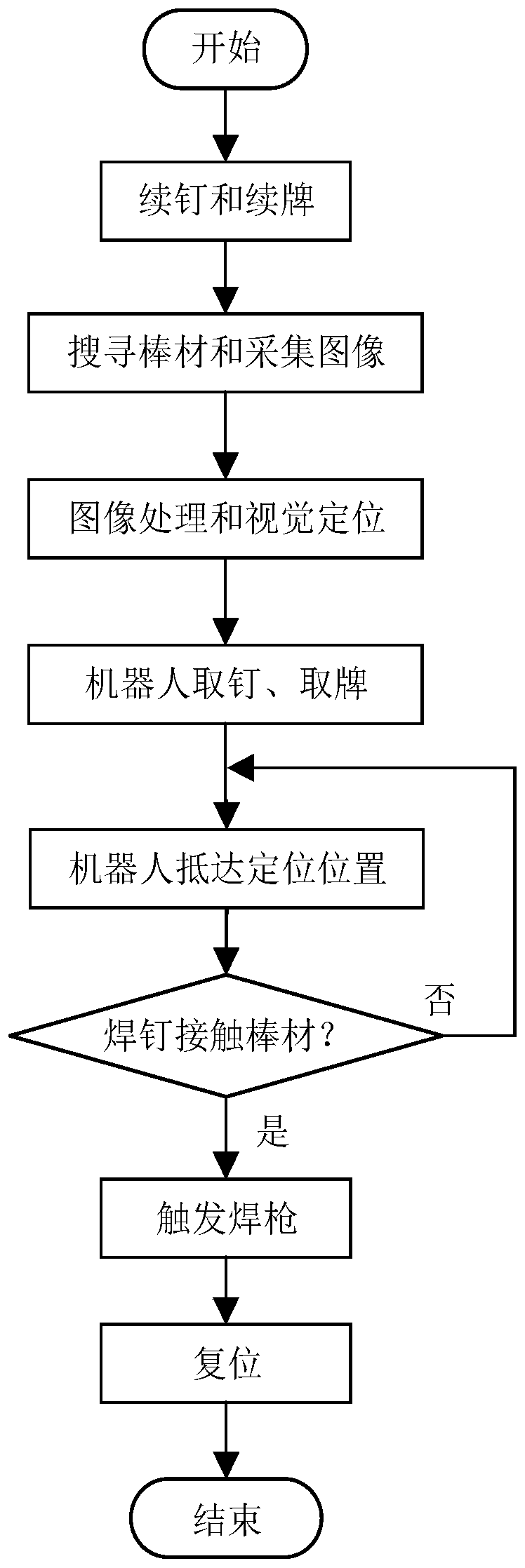

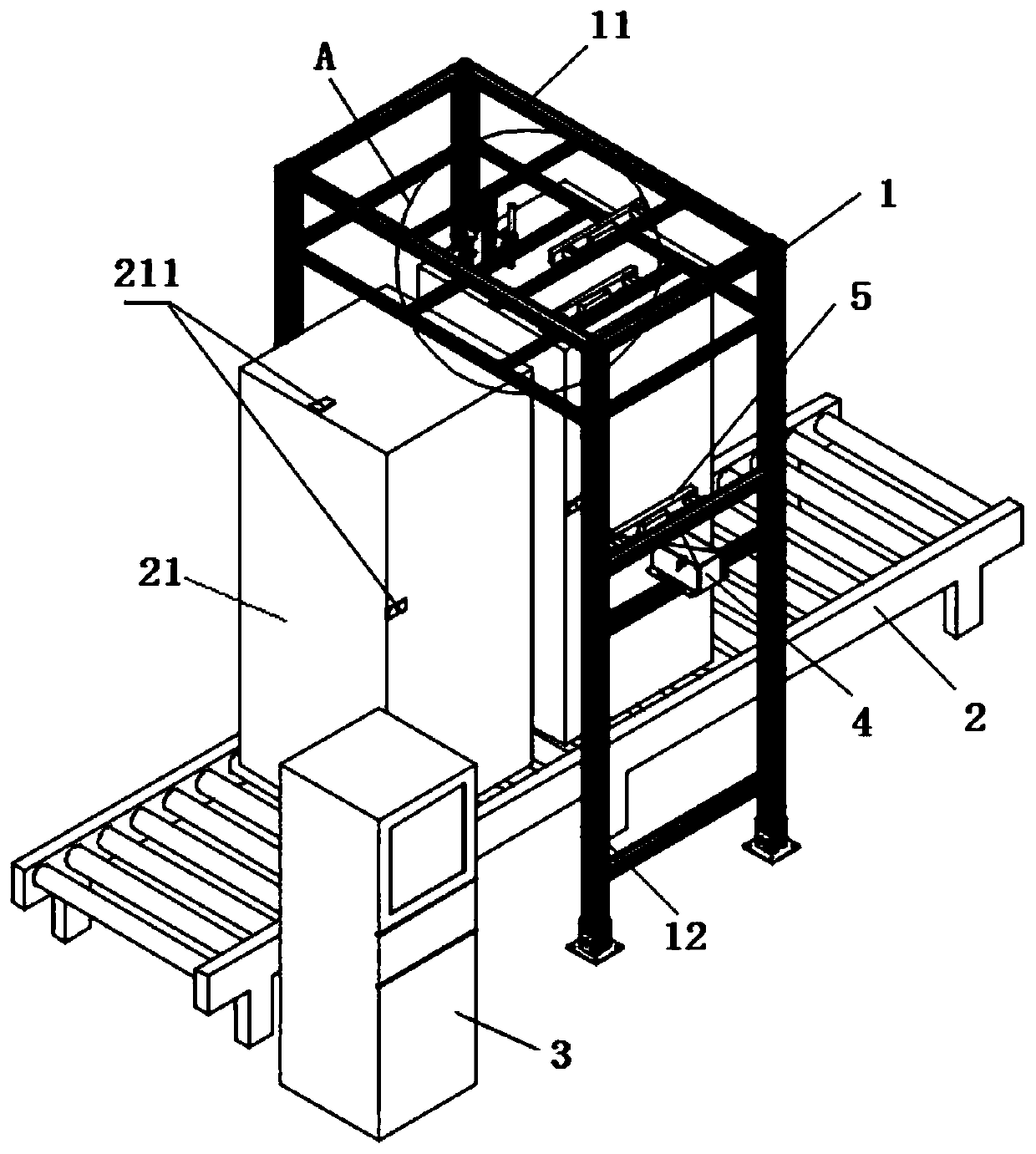

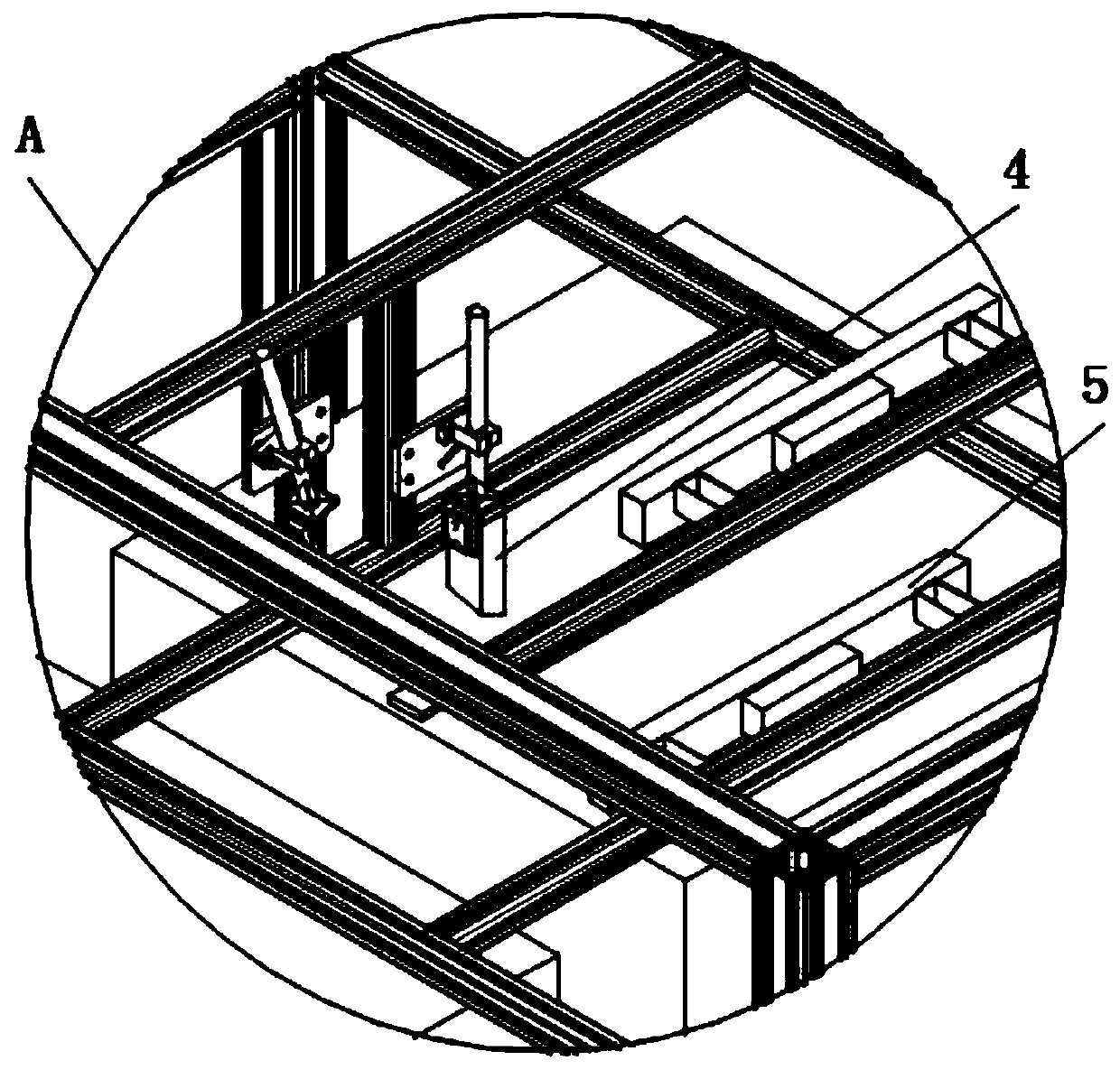

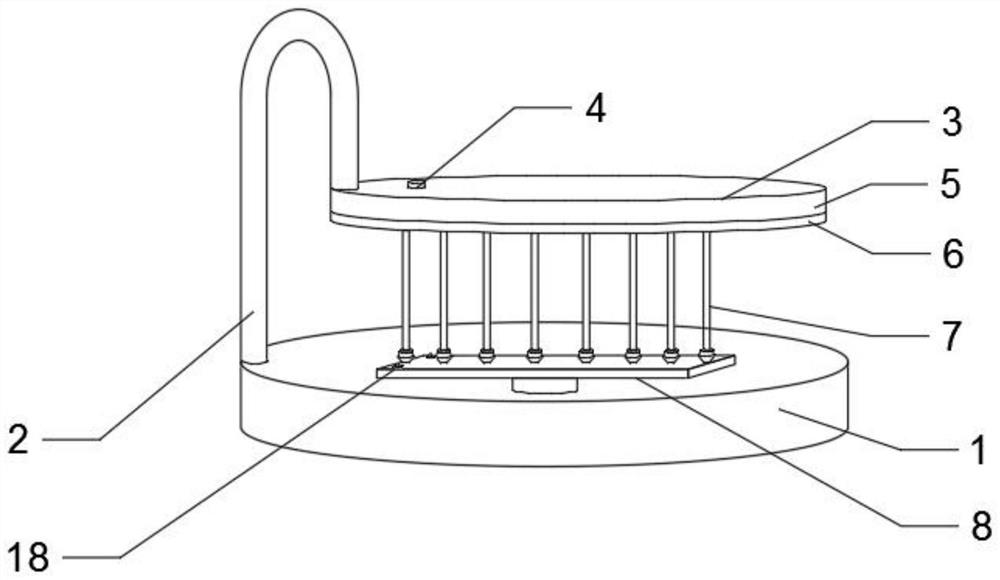

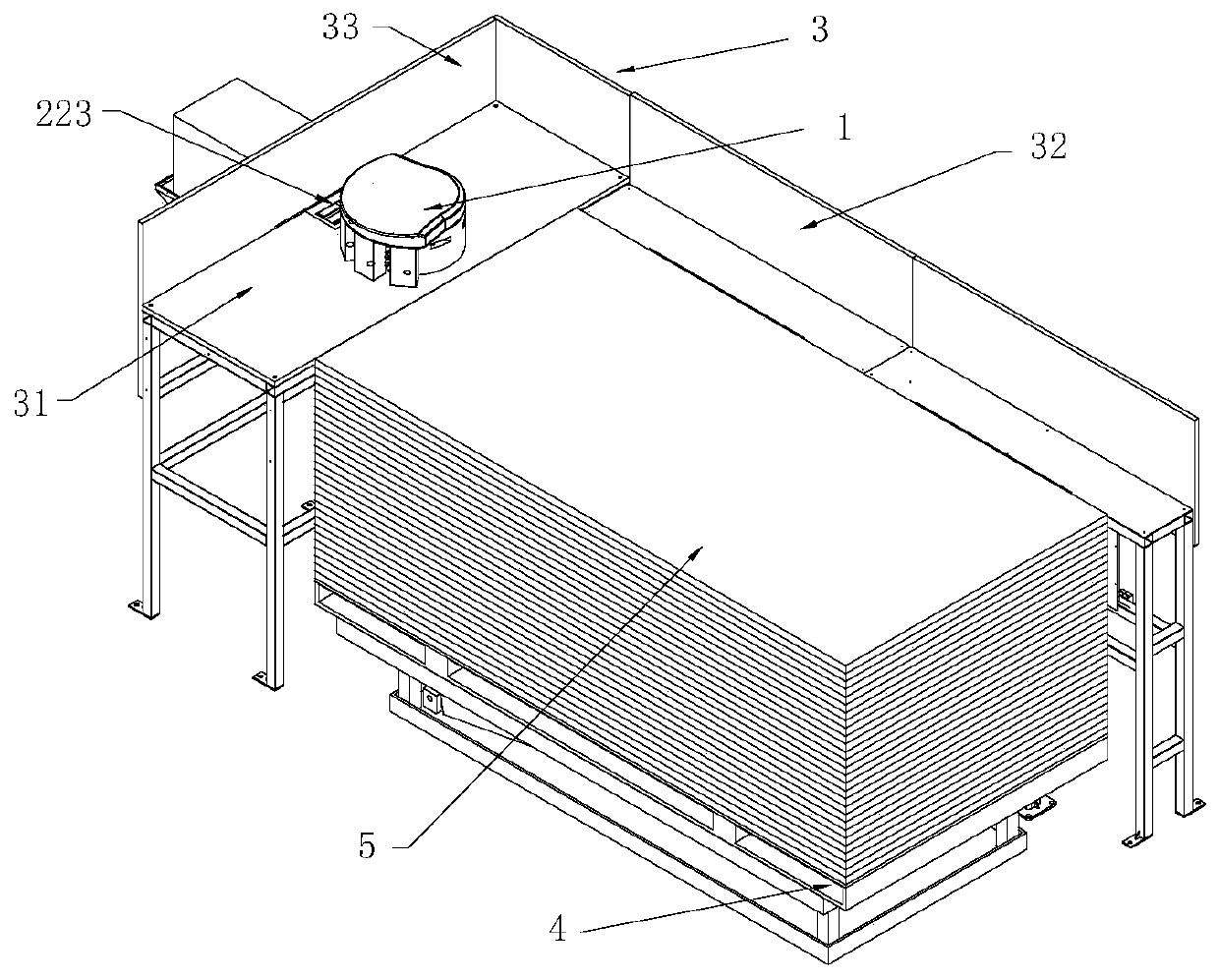

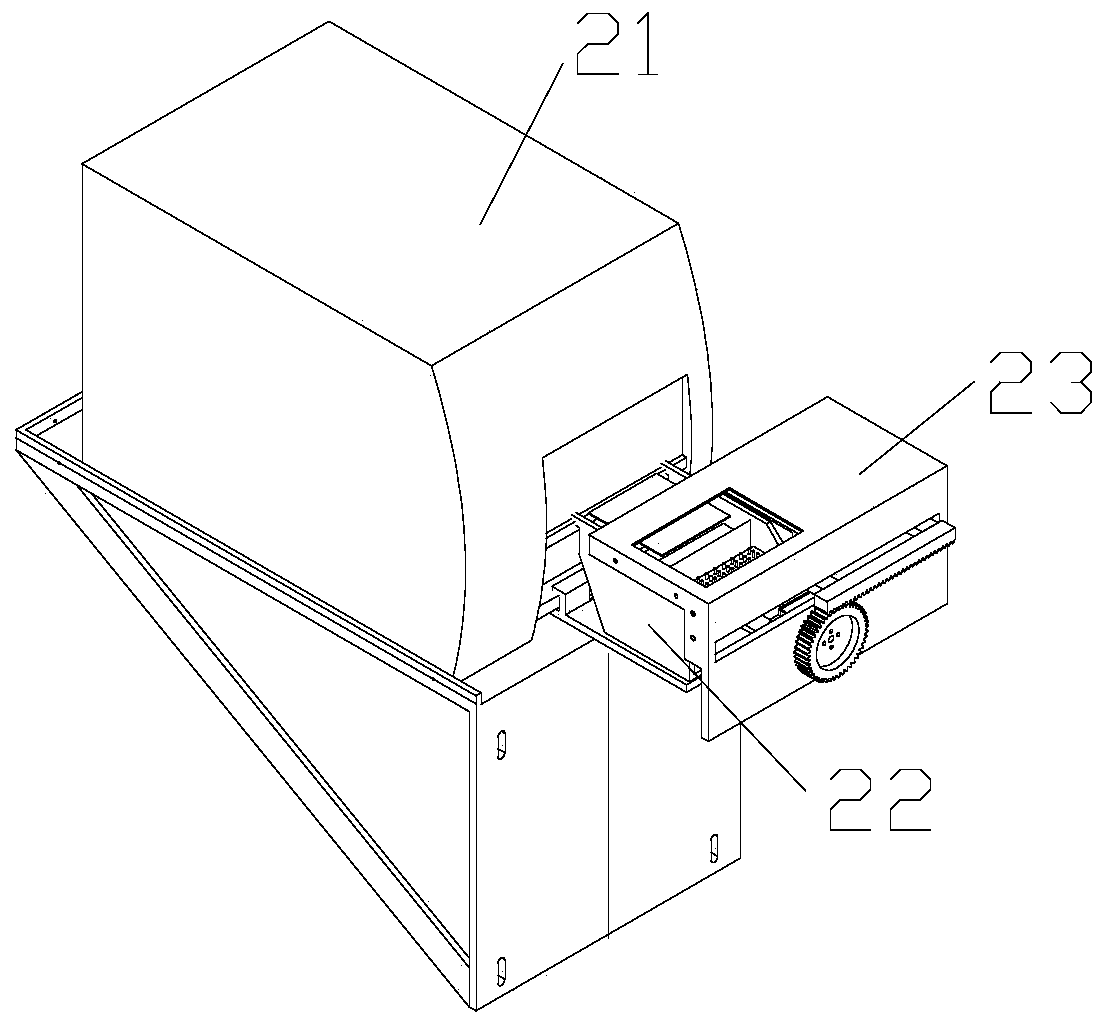

Bundled-bar label welding system based on machine vision

InactiveCN111055039AGuaranteed one-to-one correspondenceWork lessWelding/cutting auxillary devicesTypewritersMachine visionComputer printing

The invention relates to a bundled-bar label welding system based on machine vision. The system involves a data acquisition module, a label printer, a visual acquisition module, an upper computer, a controller, a label queuing mechanism and a welding stud queuing mechanism, wherein the data acquisition module is used for acquiring bar information of bundled bars with a label to be welded in real time; the label printer is used for printing the bar information on the label; the visual acquisition module is used for acquiring end face data information; the upper computer is used for generating astud continuing instruction and a label continuing instruction and determining a welding position according to the end face data information; the controller is used for generating a corresponding control signal according to the stud continuing instruction and the label continuing instruction; the label queuing mechanism is used for queuing printed labels in order and conveying the labels to a label output hole; the welding stud queuing mechanism is used for queuing a plurality of welding studs in sequence and conveying the welding studs to a welding stud output hole; and after a robot obtainsthe label and the welding nail, welding is conducted according to the welding position. According to the system, the phenomenon of wrong label pasting can be prevented, manual input and potential safety hazards are reduced through automatic stud continuing and label continuing, accurate positioning is achieved, the welding effect is attractive and neat, falling is not prone to happening, and theproduction efficiency is improved.

Owner:NORTHEASTERN UNIV +1

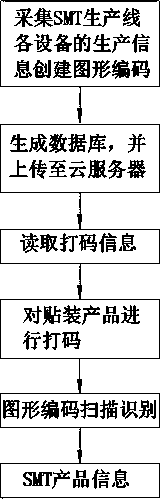

Code information tracing management method based on SMT on-line mount products

InactiveCN107679873AEffective traceability in real timeCoding technology increasesCo-operative working arrangementsCommerceGraphicsProduction line

The invention discloses a code information tracing management method based on SMT on-line mount products, and relates to the technical field of SMT mount equipment. The code information tracing management method based on SMT on-line mount products includes the following steps: 1) based on an operation control system of the SMT mount equipment, creating the unique graph code of the product on an SMT production line; 2) generating a graph code database of the product on the SMT production line, and synchronously uploading the product information, on the SMT production line, corresponding to thegraph code, to a cloud server to save; 3) performing graph code printing on a PCB circuit board which is conveyed to a code printing workbench, wherein after graph code printing is completed, the system enters the product production process; and 4) entering the system to scan the graph code through a smart phone or a hand PDA, automatically reading the product information, on the SMT production line, saved in the cloud server. The code information tracing management method based on SMT on-line mount products can use graph code to replace a paper label or stamp, thus improving the production efficiency and avoiding manual mis-pasting, error pasting, or error printing, and can realize automatic and intelligent information tracing of the products on the SMT production line.

Owner:中山市鸿菊自动化设备制造有限公司

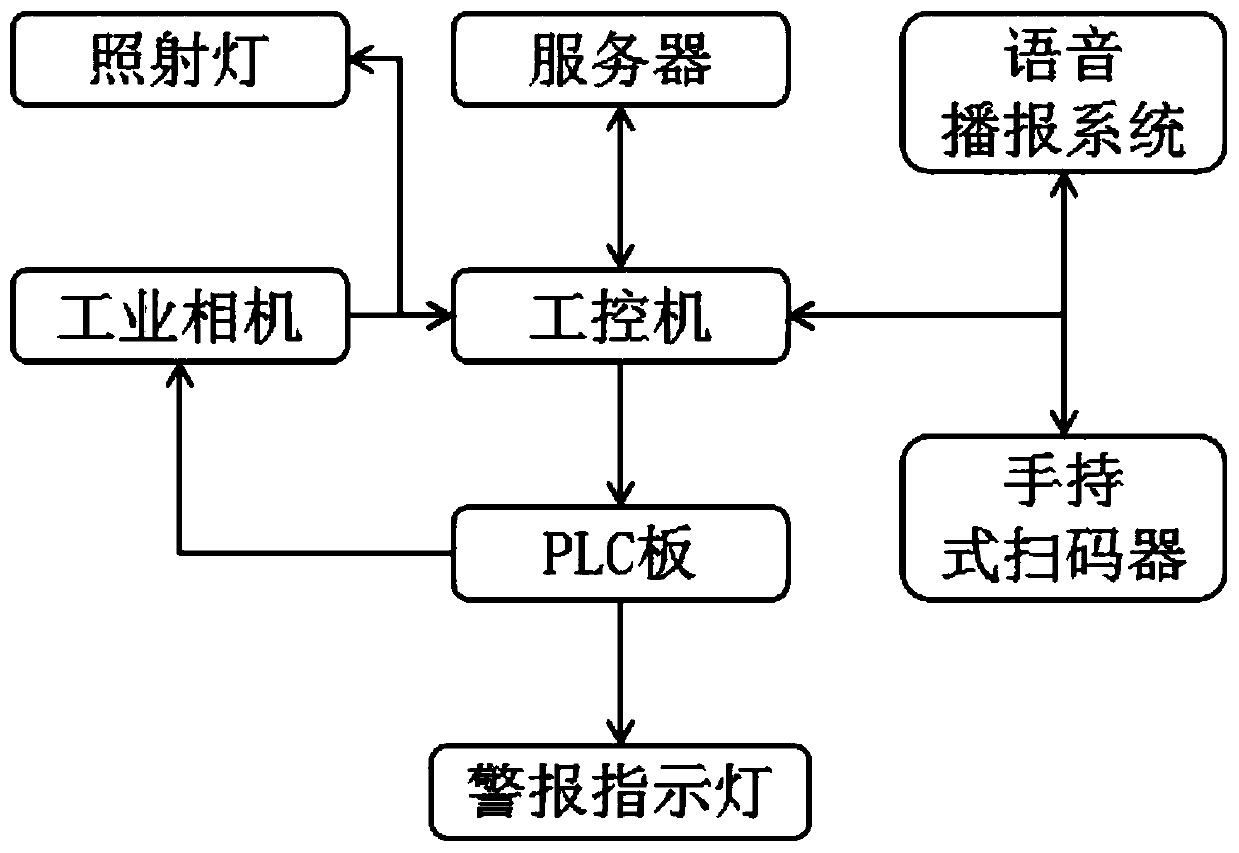

A packaging box label and bar code comparison identification device and method

InactiveCN109711496AImprove monitoring efficiencyAvoid mislabelingCo-operative working arrangementsEmbedded systemPersonal computer

The invention discloses a packaging box label and bar code comparison identification device and method, and relates to the technical field of label and bar code comparison. An industrial control box of the industrial personal computer is installed; two industrial cameras are mounted on a transverse frame of the portal frame; An industrial camera is also mounted on a vertical frame of the portal frame; Labels and bar codes are attached to the top and the side face of the packaging box conveyed on the conveying device; the industrial personal computer is electrically connected with the industrial camera and the illuminating lamp respectively; the industrial personal computer is also in communication connection with the server; the industrial personal computer is further electrically connected with the PLC board. And the PLC board is electrically connected with the industrial camera and the alarm indicator lamp respectively. According to the invention, the industrial camera collects labels and bar codes on packaging boxes and image information of the bar codes and transmits the image information to the industrial personal computer; Meanwhile, the industrial personal computer comparesthe identification result of the image information with the material data and the batch data downloaded from the server, monitors the problems of wrong pasting and missed pasting through the comparison result, improves the monitoring efficiency, avoids wrong pasting of labels and bar codes and bar codes, and reduces the economic loss.

Owner:CHANGHONG MEILING CO LTD

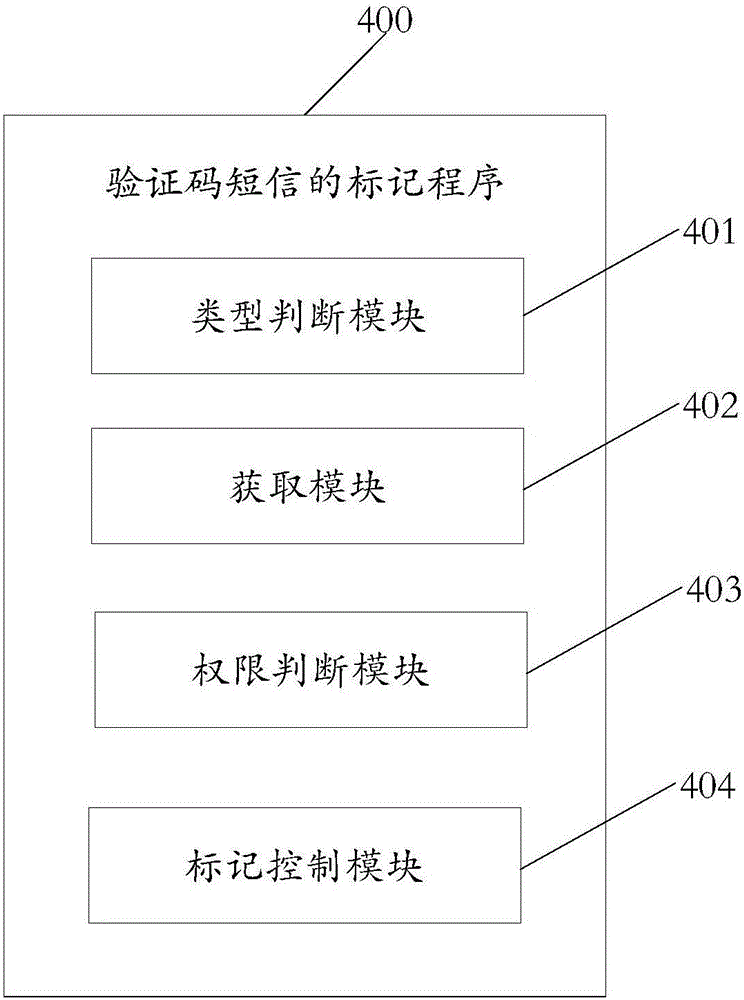

Marking method of verification code short message and mobile terminal

InactiveCN107182043AReduce stepsImprove experienceSubstation equipmentMessaging/mailboxes/announcementsComputer terminalText messaging

The invention discloses a mobile terminal which comprises a memory, a processor, and a marking program of a verification code short message. The marking program is stored in the memory and can run in the processor. When the marking program of the verification code short message is executed by the processor, the following steps are realized: judging whether a received short message is the verification code short message or not; obtaining an application corresponding to a sender server of the verification code short message if so; judging whether the application has permission to read the short message verification code or not; and marking the verification code short message as read if so. Compared with the prior art, the automatic marking of the verification code short message as read is realized, a user operation is saved, and a user experience is improved. At the same time, through judging whether the application has the permission to read the short message verification code or not and determining whether to mark the verification code short message as read or not according to a judgment result, a marking result is more accurate, and wrong marking in the time when the application can not read a verification code is avoided.

Owner:NUBIA TECHNOLOGY CO LTD

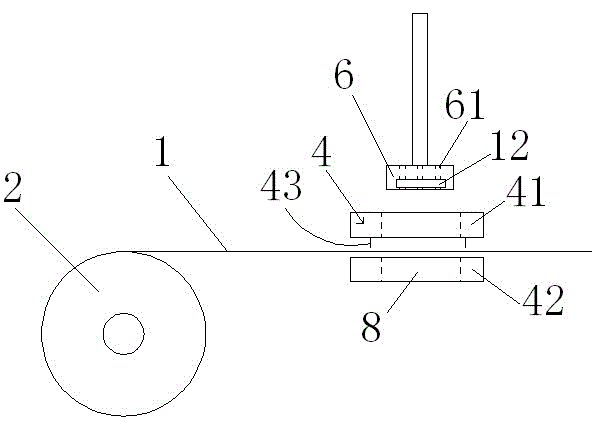

Labeling device for textiles

InactiveCN102975918AAvoid incompleteNo manual operationLabelling deformable materialsLabelling machinesMechanical engineeringTextile

The invention discloses a labeling device for textiles. The labeling device comprises a label tray (2), a cutting mould (4) and a pressure head (6) driven by an air cylinder, wherein the label tray (2) can rotate under the driving of a power device; the cutting mould (4) comprises an upper mould (41) and a lower mould (42), wherein a cutting blade (43) is arranged on the upper mould (41); a channel (8) through which the pressure head (6) can pass is formed in the upper mould (41) and the lower mould (42); a plurality of vacuum suction holes (61) are formed in the pressure head (6); the labeling device is characterized in that a scanner (12) is arranged on the pressure head (6). The labeling device provided by the invention has the advantages of simple structure, convenience in use and low wrong labeling rate.

Owner:WUJIANG YIJIU TEXTILE

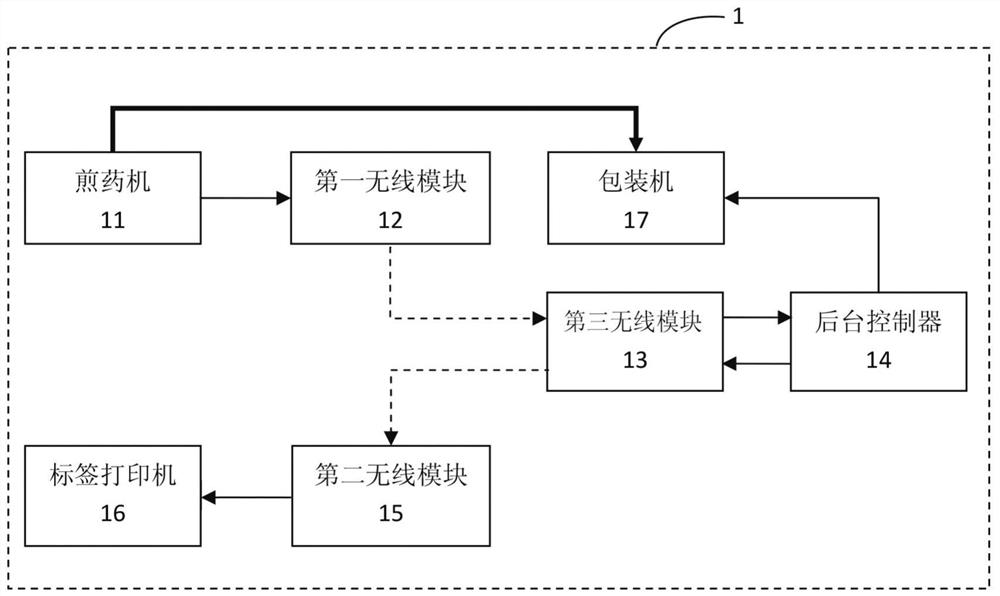

Drug label synchronous printing system

The invention discloses a drug label synchronous printing system. The drug label synchronous printing system includes a medicine decocting machine, a first wireless module, a background controller, asecond wireless module and a label printer. The medicine decocting machine is connected to the first wireless module in a wired mode, the first wireless module is connected to the background controller in a wireless mode, the background controller is connected to the second wireless module in a wireless mode, and the second wireless module is connected to the label printer in a wired mode. The drug label synchronous printing system can control the label printer to print corresponding drug labels while arranging drugs or packaging the drugs by a packaging machine after the medicine decocting machine completes medicine decocting, and the problem of ''misalignment'' in the labeling process of the drug labels is effectively avoided.

Owner:BEIJING DONGHUAYUAN MEDICAL EQUIP CO LTD

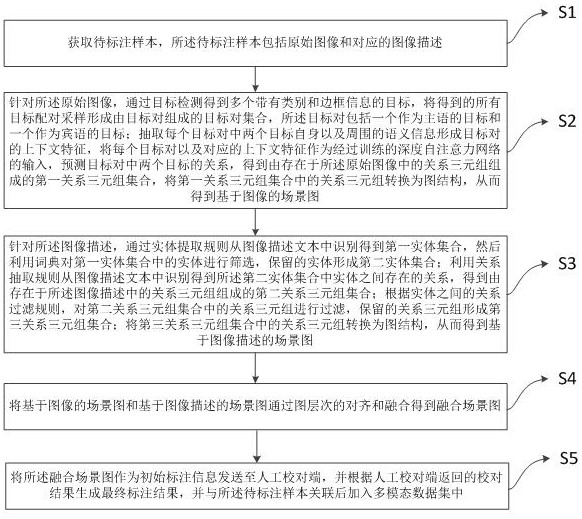

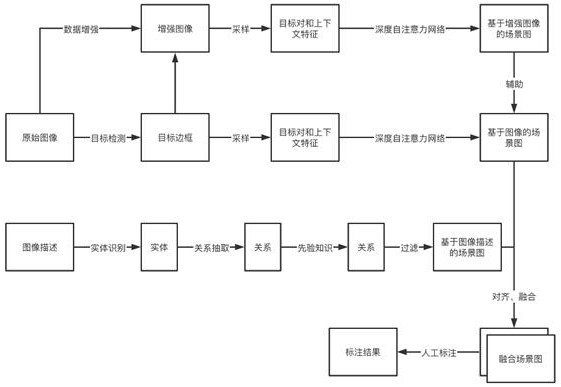

Multi-modal data set labeling method and device for AI practical training and electronic equipment

ActiveCN114708472AReduce label sizeReduce the difficulty of labelingCharacter and pattern recognitionNatural language data processingManual annotationImage based

The invention discloses a multi-modal data set labeling method and device for AI practical training and electronic equipment, and belongs to the field of computer vision. According to the invention, through a scene graph generation algorithm based on a deep learning technology and graph alignment fusion, a first type of scene graph is generated by using weak supervision information of image description, the first type of scene graph is further aligned and fused with a second type of scene graph generated based on an image, and finally a candidate initial scene graph is generated as a reference for manual annotation. And wrong labeling and missing labeling are avoided. According to the multi-modal data marking method and system, intelligent marking prompts can be provided for manual marking of the multi-modal data set, so that only the candidate scene graph needs to be optimized during manual marking, the marking scale and the marking difficulty are greatly reduced, and the marking efficiency of the multi-modal data can be effectively improved.

Owner:ZHEJIANG UNIV

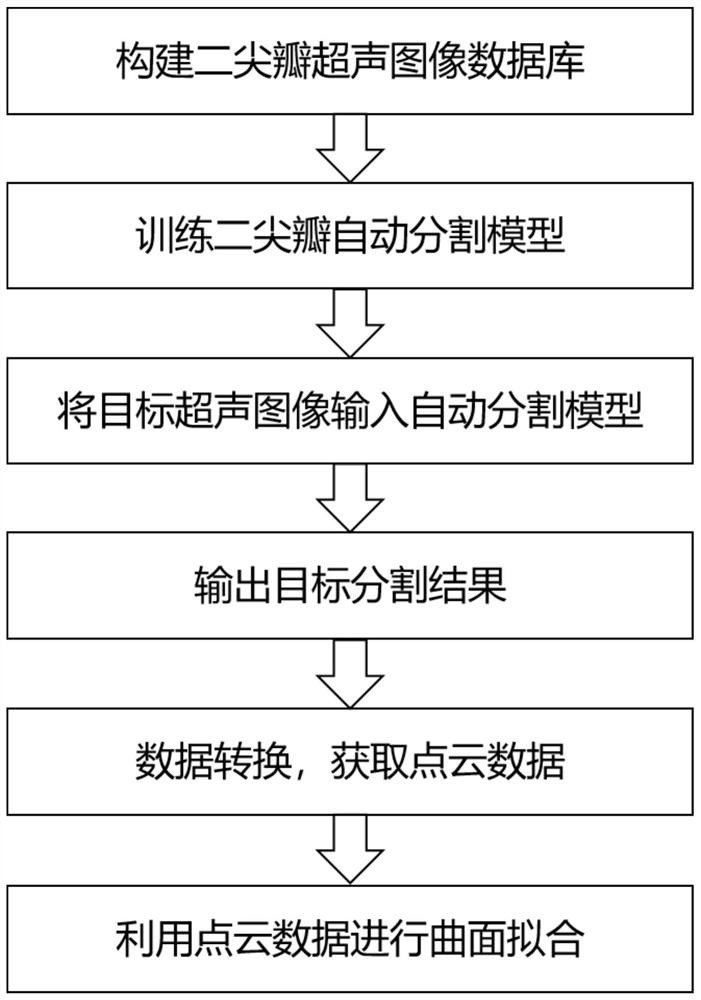

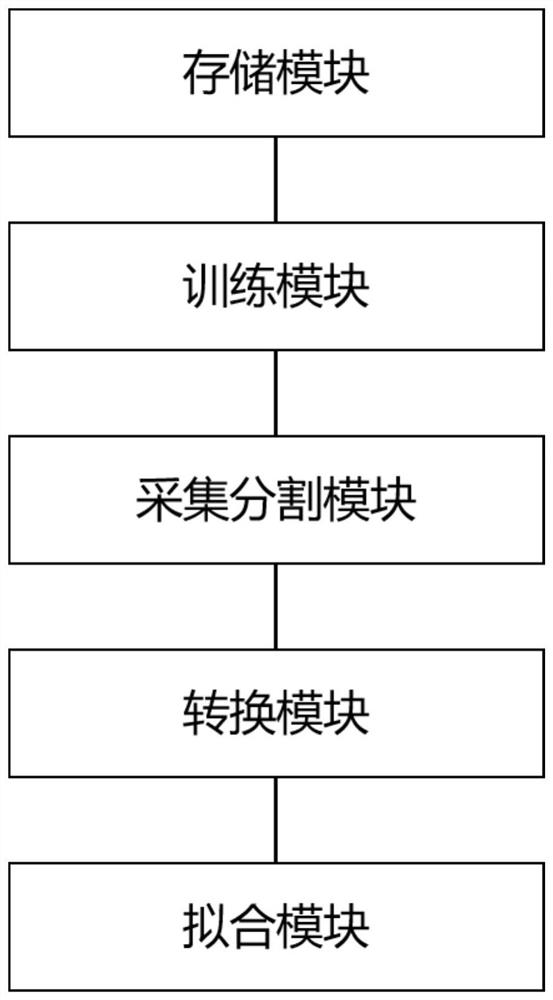

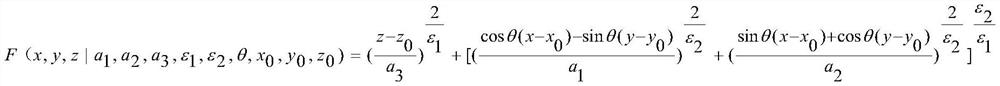

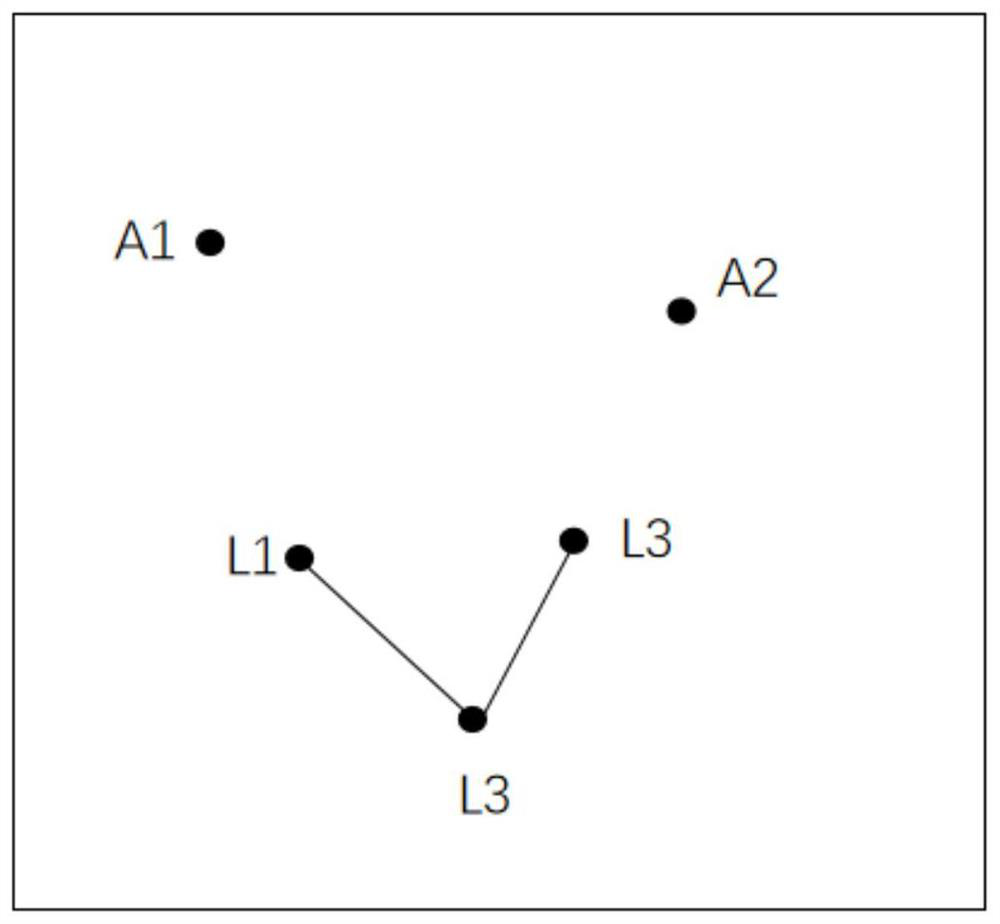

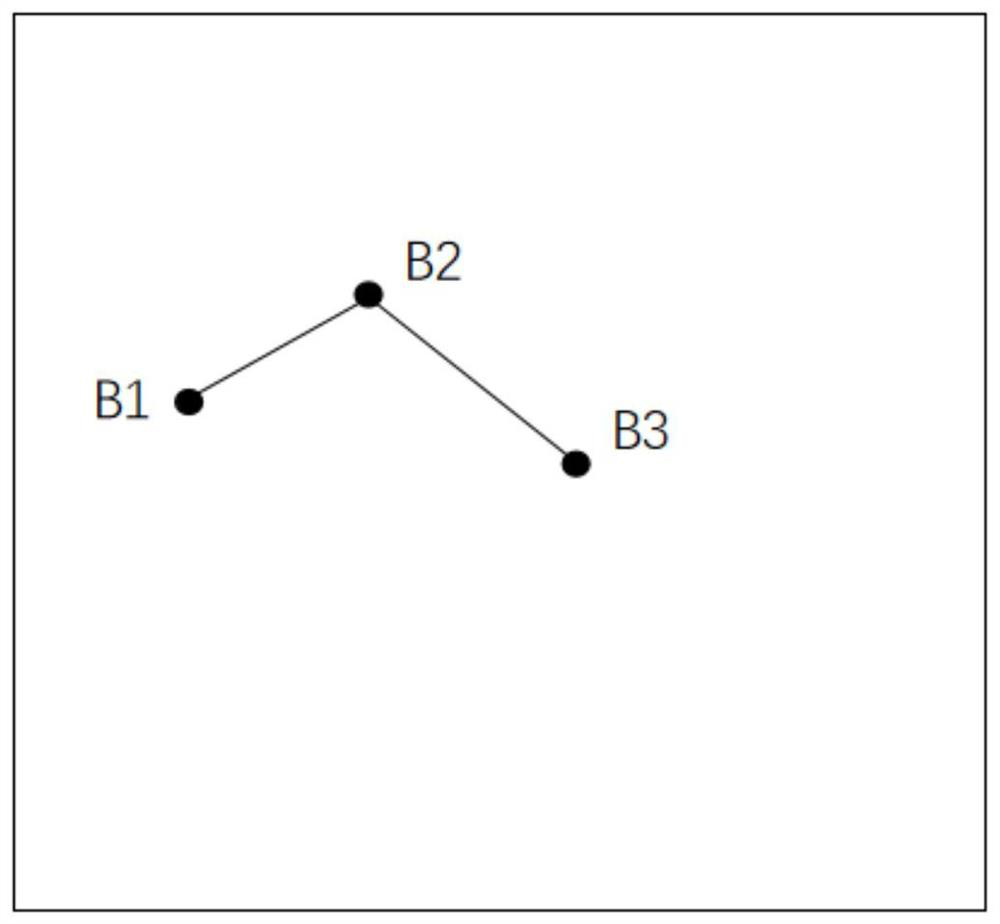

Personalized mitral valve automatic modeling method, system and equipment

ActiveCN112991522AImprove modeling efficiencyImprove accuracyDetails involving processing stepsImage enhancementData setEngineering

The invention discloses a personalized mitral valve automatic modeling method. The method comprises the following steps: constructing a mitral valve three-dimensional ultrasonic image database; inputting data in the mitral valve three-dimensional ultrasonic image database into a convolutional neural network as a training data set to obtain a trained mitral valve automatic segmentation model; acquiring a three-dimensional ultrasonic image of a target mitral valve, inputting the target ultrasonic image into the mitral valve automatic segmentation model, and outputting a target segmentation result; obtaining point cloud data through the target segmentation result; performing curved surface fitting according to the point cloud data to obtain a curved surface equation of the mitral valve, and obtaining a three-dimensional curved surface model of the mitral valve through the curved surface equation of the mitral valve. The invention also discloses a corresponding system and equipment. According to the method, automation of personalized mitral valve modeling is realized, and the modeling time is greatly shortened. The curved surface model obtained through automatic modeling can be subjected to three-dimensional zooming rotation checking, and can also be used for measuring the spatial position relation between mitral valve tissue structures.

Owner:SOUTH CHINA UNIV OF TECH

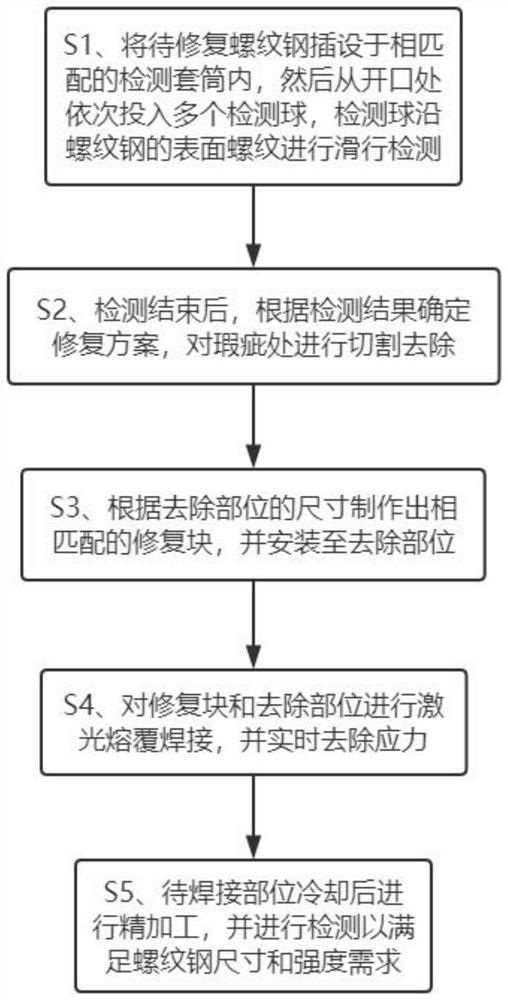

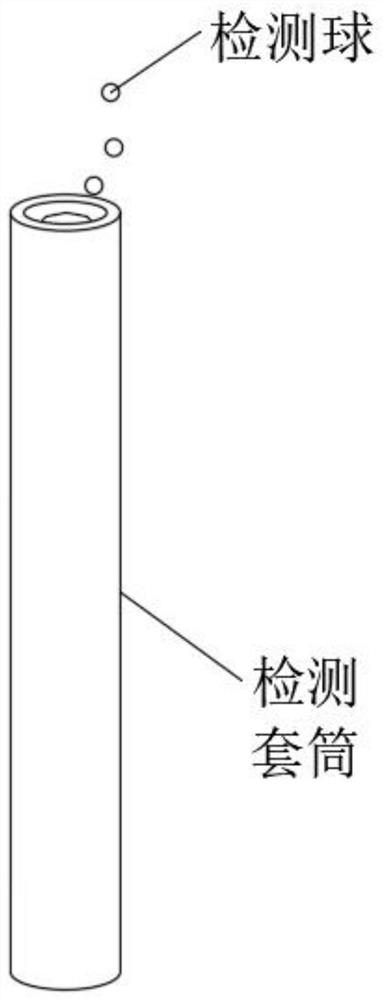

Deformed steel bar surface flaw repairing process

ActiveCN113478166AImprove detection and repair efficiencyImprove detection efficiencyMetallic material coating processesSS - Stainless steelSteel bar

The invention discloses a deformed steel bar surface flaw repairing process, and belongs to the technical field of stainless steel. A deformed steel bar can be detected by innovatively introducing a detection sleeve and detection balls. The deformed steel bar is only required to be inserted into the detection sleeve, and then a plurality of detection balls are sequentially put from an opening. The detection balls can automatically slide down along a thread on the surface of the deformed steel bar and detect flaws on the thread in the sliding-down process. Once the thread has a notch or deforms, the detection balls can adapt to the notch or the deformation so as to trigger the extrusion action on internal elastic oil absorption blocks, and marking liquid is released to mark the flaws. Meanwhile, the multiple detection balls are used for simultaneous detection, so that the detection efficiency and precision can be improved, and meanwhile the situation that the detection is broken due to the clamping condition can be avoided. The deformed steel bar is taken out after detection is finished, flaws can be repaired according to the marked position. The repair strength is improved through a laser cladding technology, and thus the detection and repair efficiency of the deformed steel bar is greatly improved.

Owner:北京天润恒远工贸有限公司

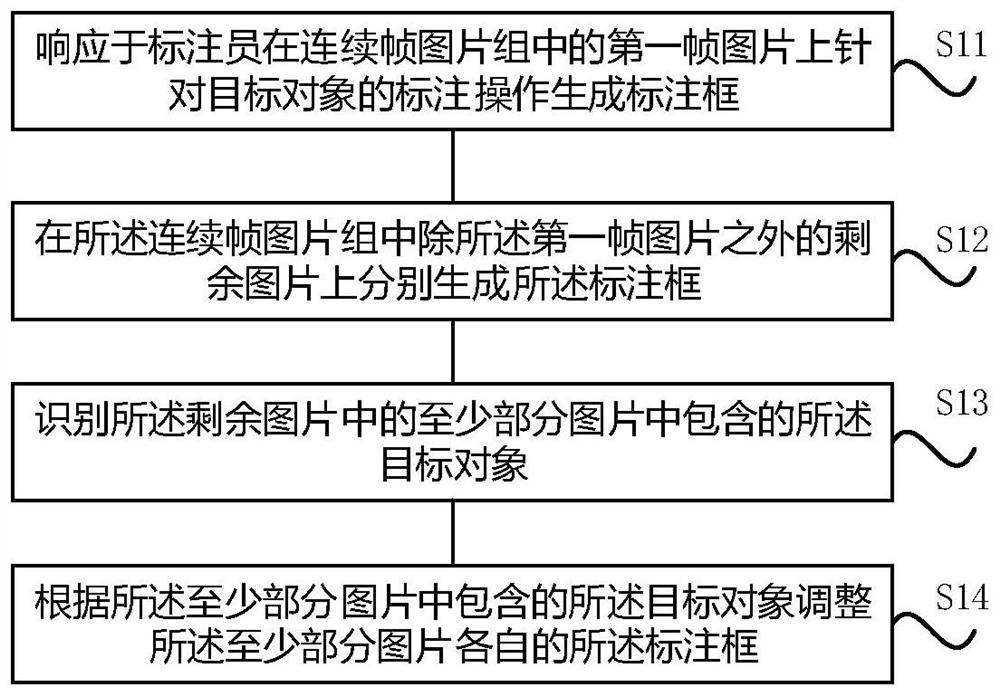

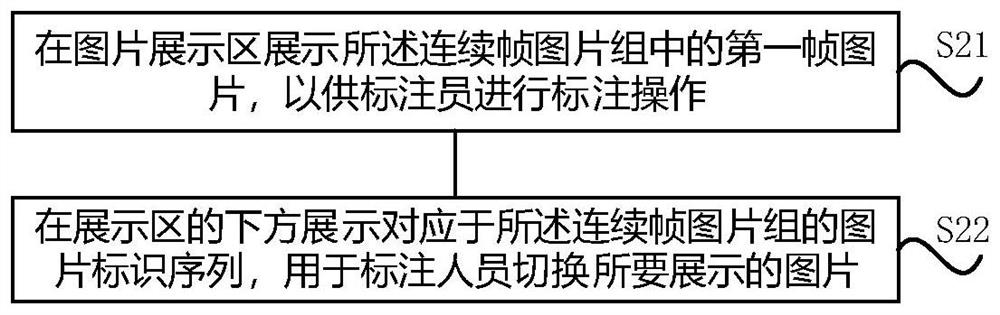

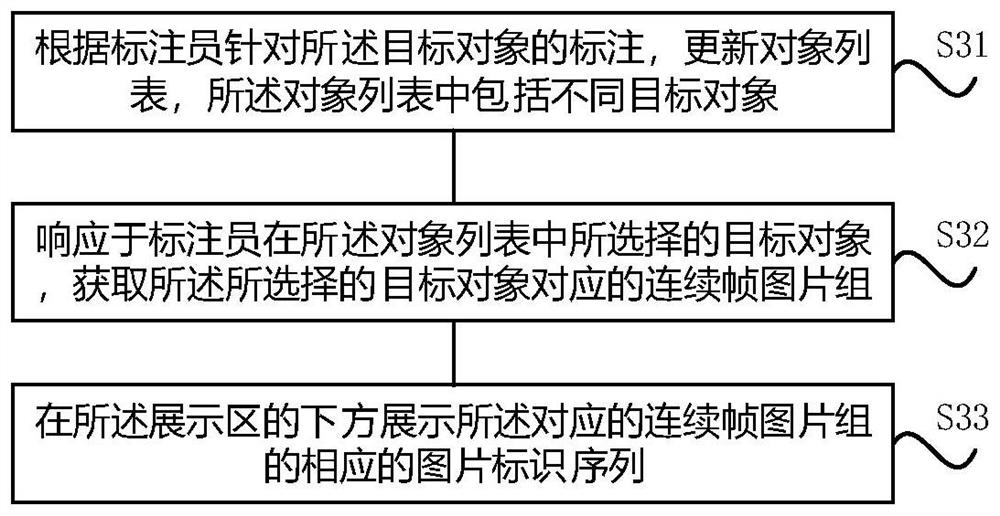

Continuous frame picture labeling method, electronic equipment and storage medium

PendingCN114241384AImprove labeling efficiencyAvoid mislabelingCharacter and pattern recognitionComputer visionEngineering

The invention discloses a continuous frame picture annotation method. The method comprises the following steps: generating an annotation box in response to an annotation operation of an annotator on a first frame picture in a continuous frame picture group for a target object; respectively generating the annotation boxes on the remaining pictures except the first frame picture in the continuous frame picture group; identifying the target object contained in at least part of the residual pictures; and according to the target object contained in the at least part of the pictures, adjusting the respective annotation boxes of the at least part of the pictures. In the whole process, an annotator only needs to manually complete annotation of the first picture, then the target object in the continuous frame picture group can be rapidly and accurately annotated based on automatic annotation box generation, automatic target object recognition and automatic adjustment, the annotation efficiency is improved, and the annotation time is shortened. And wrong labeling caused by excessive dependence on manpower is avoided.

Owner:北京安捷智合科技有限公司

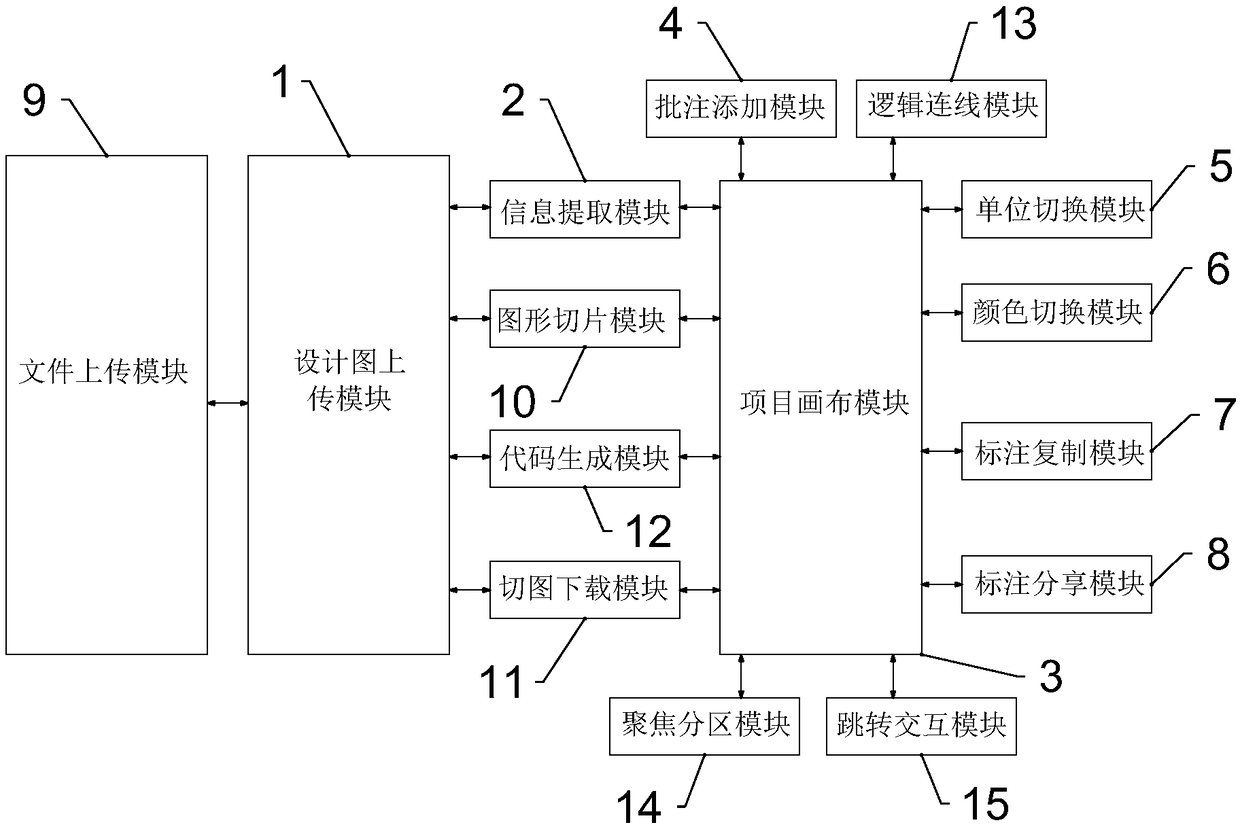

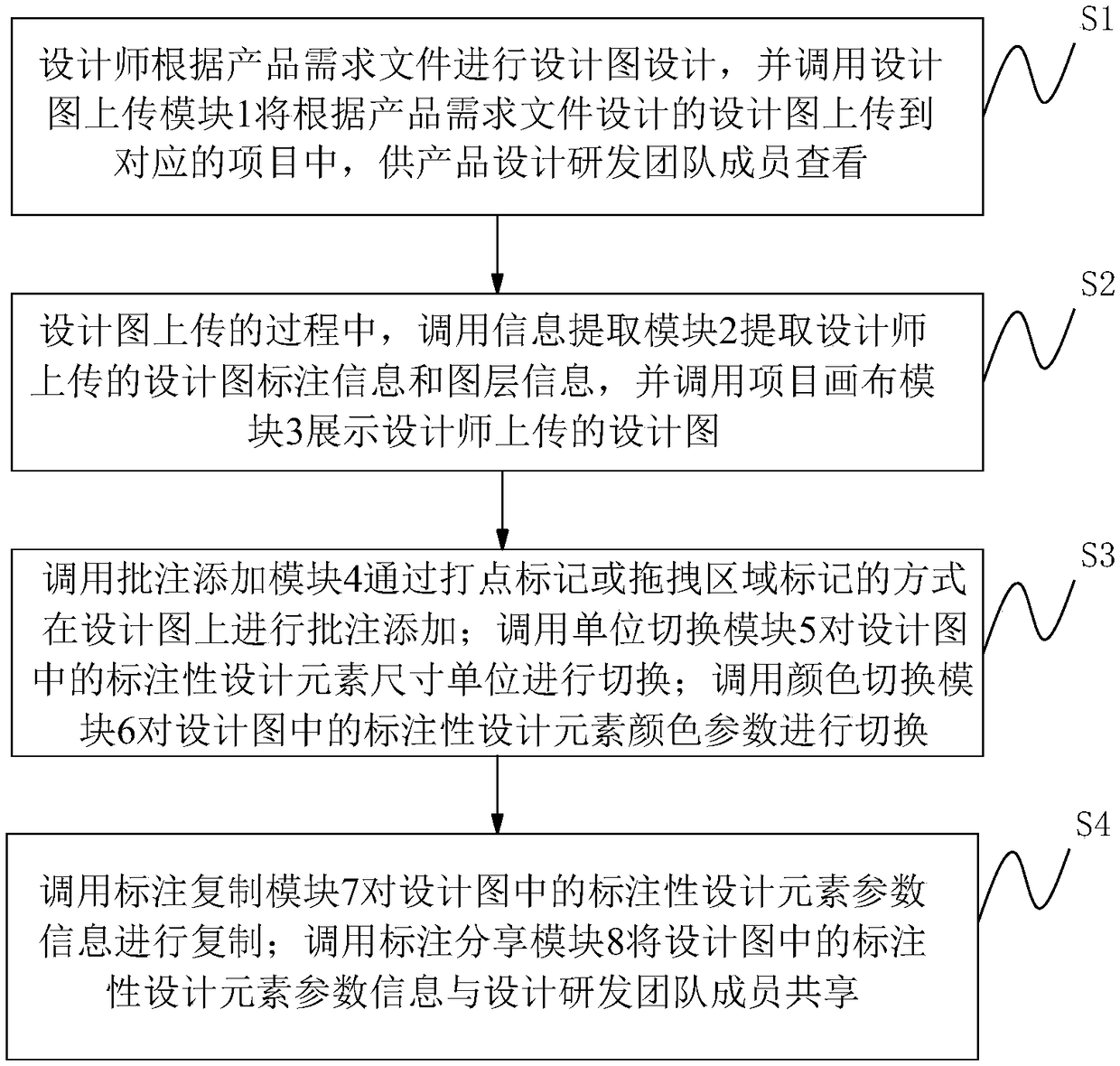

Design drawing design element information sharing device and method

InactiveCN109062573ASave time at workAvoid mislabelingSoftware engineeringDisplay designInformation sharing

The invention discloses a design drawing design element information sharing device and method. The designer carries out the design drawing design according to the product demand file, and invokes thedesign drawing uploading module to upload the design drawing designed according to the product demand file to the corresponding project for the members of the product design research and development team to view. Extract the designer's annotation information and layer information, and call the project canvas module to display the designer's uploaded design drawings; annotations are added to the design drawing by dotting or dragging area markers; Switching the dimension units of the labeled design elements in the design drawings; Switching the color parameters of labeled design elements in thedesign drawings; Duplicate the parameter information of annotated design elements in the design drawings; The annotation sharing module is called to share the parameter information of annotated designelements in the design drawing with the members of the design and development team. The invention can automate the manual labeling of the traditional machinery and improve the work efficiency of thedesigner.

Owner:北京知本源信息技术有限公司

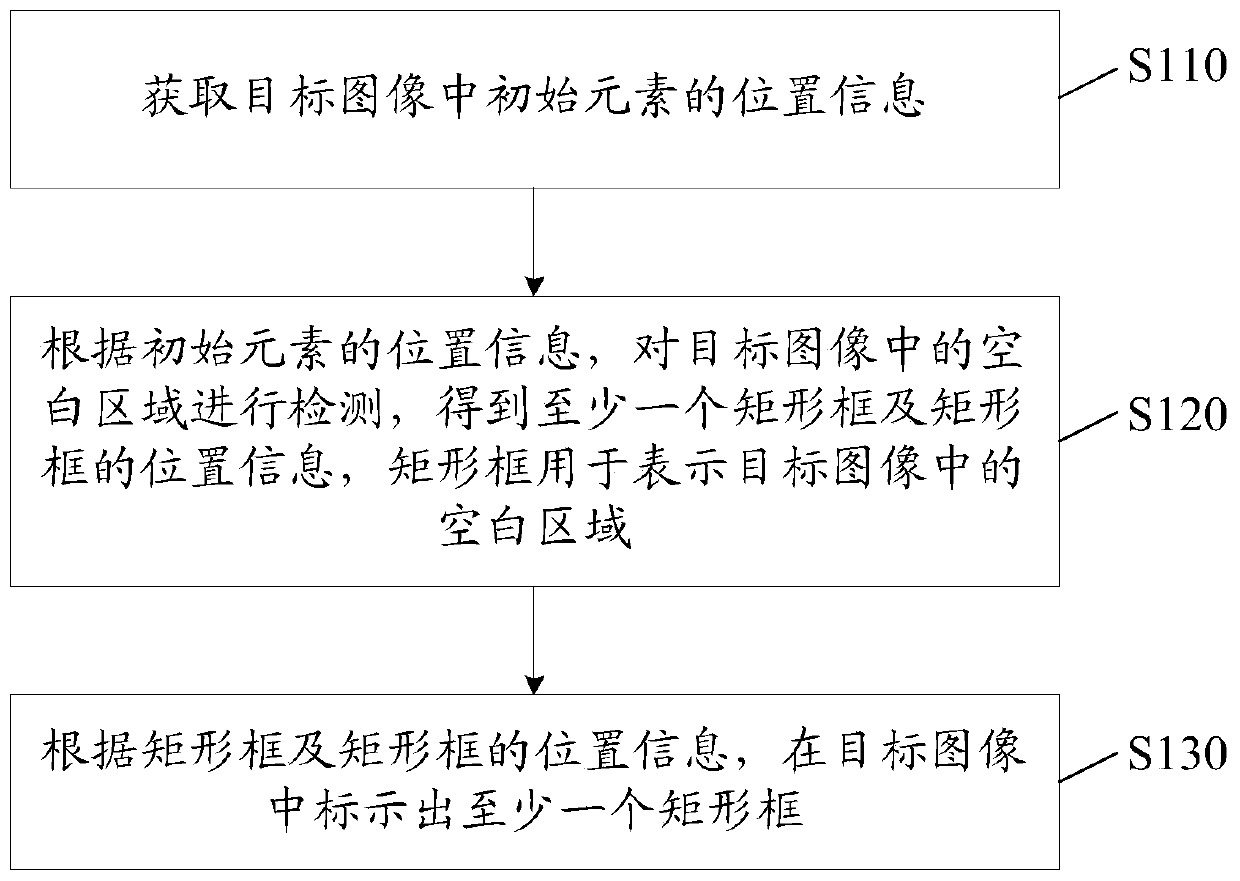

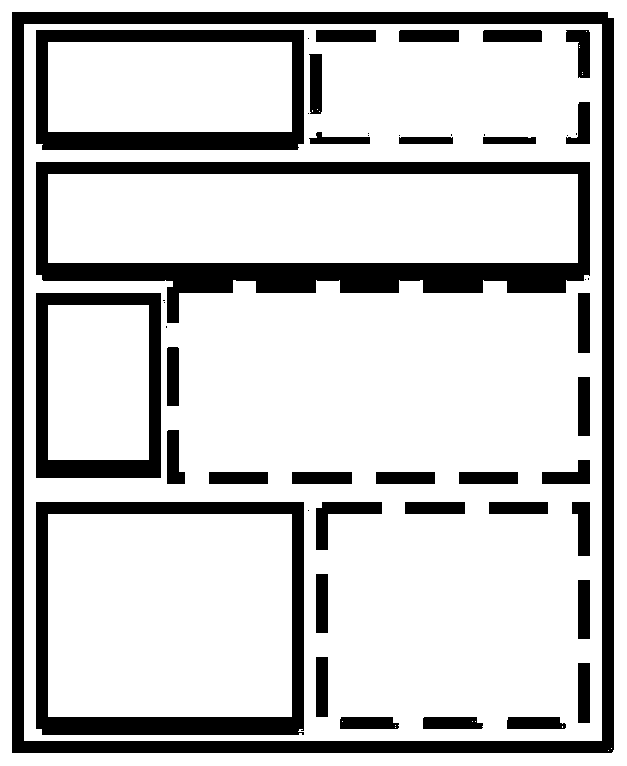

Image processing method and device

ActiveCN110675384AImprove labeling efficiency and labeling accuracyAvoid mislabelingImage enhancementImage analysisComputer graphics (images)Imaging processing

The invention provides an image processing method and device. The image processing method comprises the steps: obtaining the position information of an initial element in a target image; detecting a blank area in the target image according to the position information of the initial element to obtain at least one rectangular frame and position information of the rectangular frame, the rectangular frame being used for representing the blank area in the target image; and marking at least one rectangular frame in the target image according to the rectangular frame and the position information of the rectangular frame. According to the image processing method and device, the blank area in the target image is detected, and the rectangular frame representing the blank area is automatically markedin the target image, so that the marking efficiency and marking accuracy of the blank area in the image are effectively improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

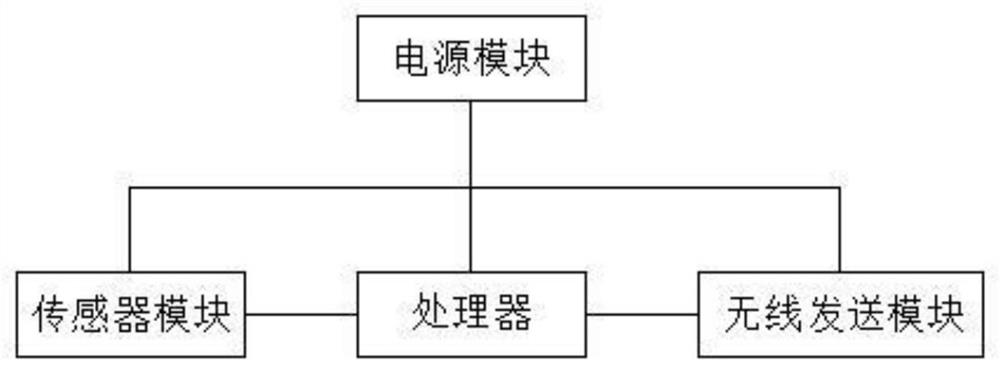

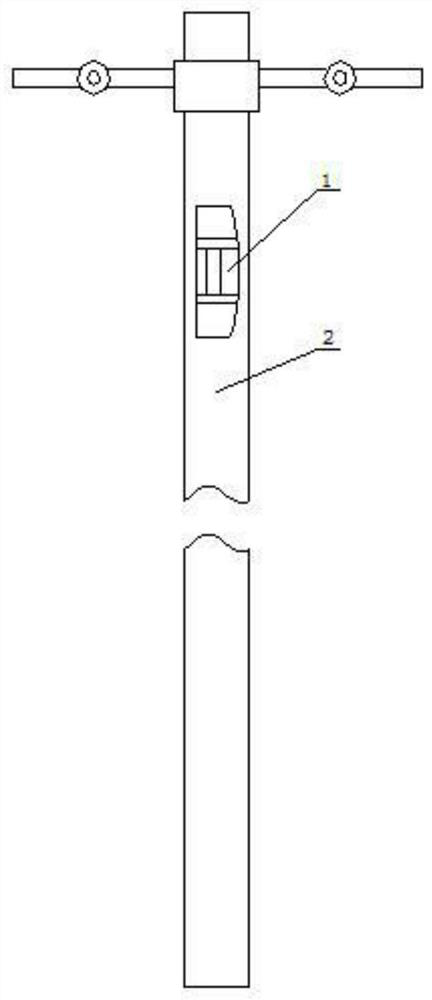

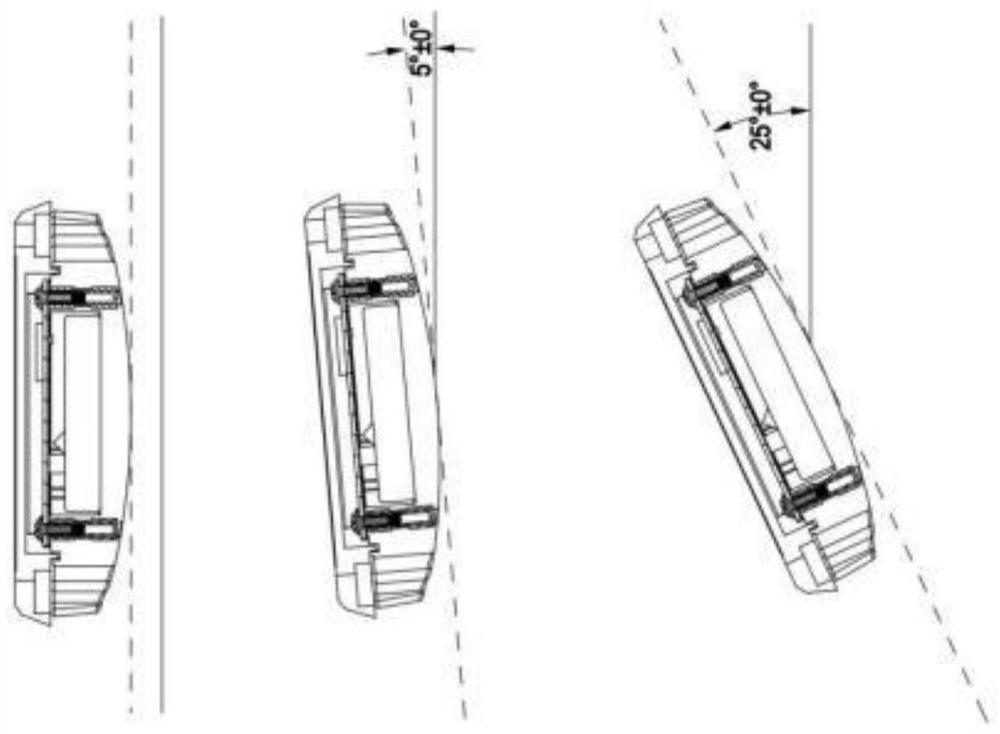

Tower inclination state monitoring device and monitoring method thereof

The invention belongs to the technical field of monitoring devices, and relates to monitoring of inclination angles, in particular to a tower inclination state monitoring device and a monitoring method thereof. The tower inclination state monitoring device comprises a device body, and the device body is integrally fixed to the exterior of a tower and used for monitoring the swing angle of the tower in the vertical direction; a sensor module, a processor and a wireless sending module are arranged in the device body. The signal output end of the sensor module is connected with the processor, thesignal output end of the processor is connected with an external platform through the wireless sending module, the device body is further provided with a power supply module, and the power supply module provides a load for the sensor module, the processor and the wireless sending module.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

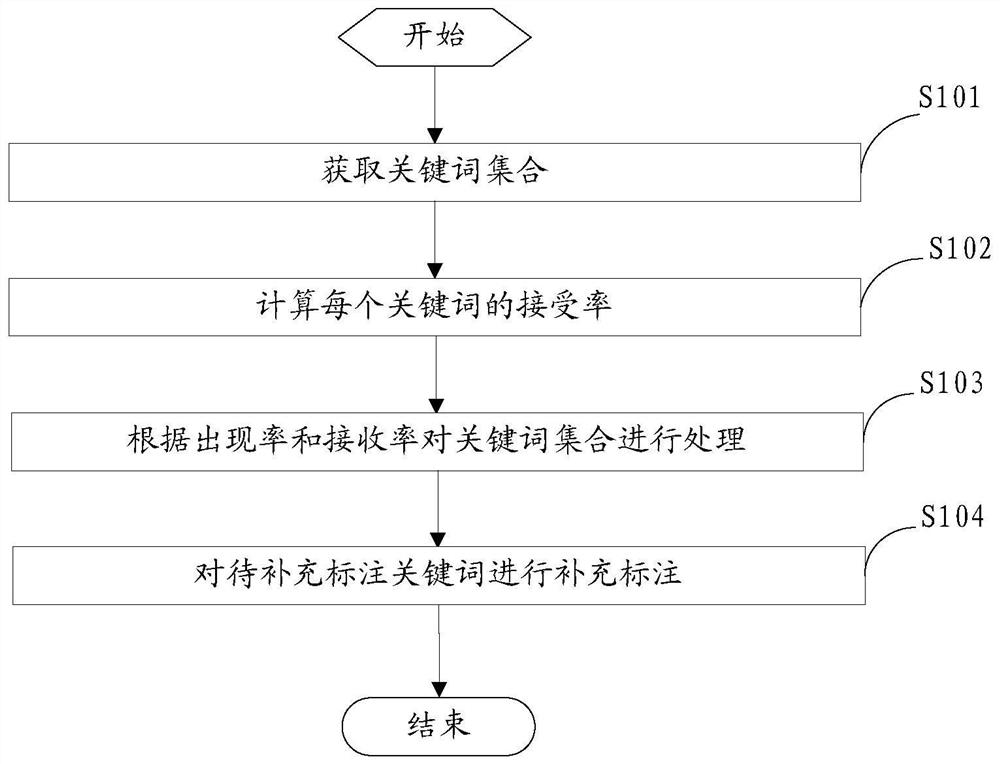

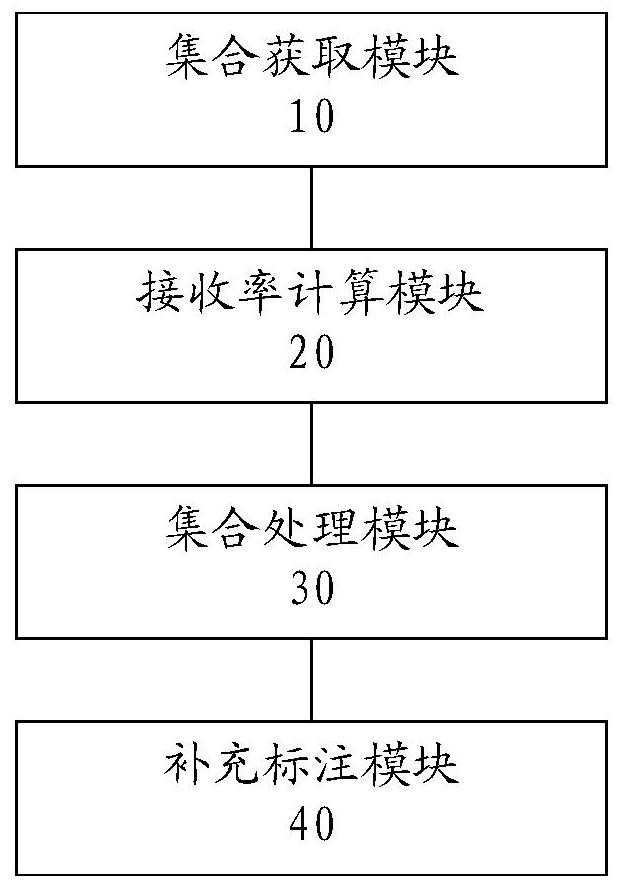

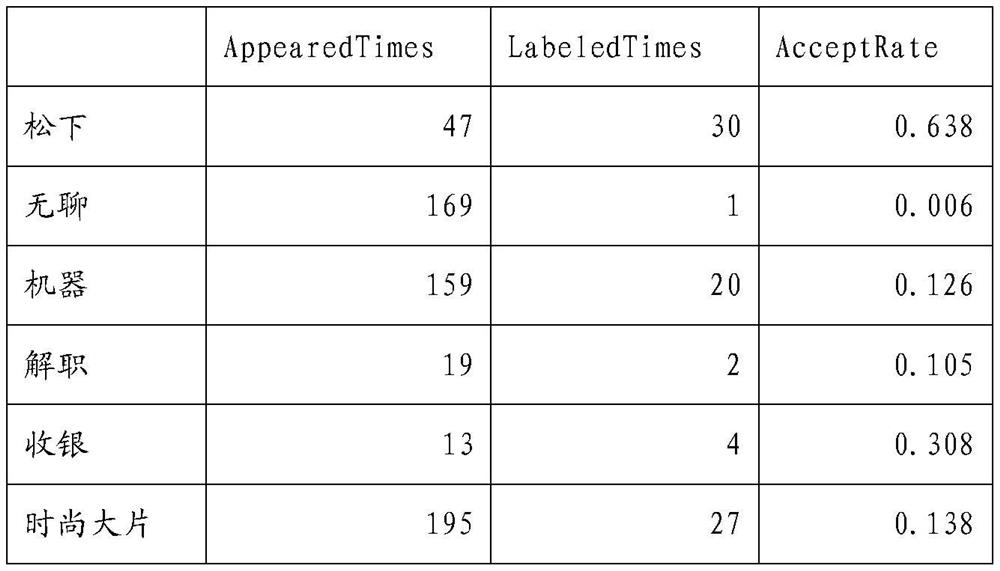

A keyword extraction method and device

ActiveCN107885722BHigh extraction rateAvoid being missedNatural language data processingSpecial data processing applicationsLabeled dataData mining

The embodiment of the present invention provides a keyword extraction method and device, the method and device are applied to natural language processing systems, specifically to obtain a keyword set, the keyword set includes a plurality of artificially marked keywords; calculate the keyword set The acceptance rate of each keyword in ; according to the frequency of occurrence and the acceptance rate, the keyword set is processed to obtain a set of keywords to be supplemented, and the set of keywords to be supplemented includes multiple keywords to be supplemented; the keywords to be supplemented are Make additional annotations. Supplementary labeling of keywords to be supplemented can increase the extraction probability of keywords with a high acceptance rate and prevent keywords from being missed. At the same time, it also means suppressing the extraction rate of keywords with low acceptance rates to prevent mislabeling. Through the above measures, the quality of labeled data is effectively improved, and the negative impact of low-quality labeled data on keyword extraction is avoided.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

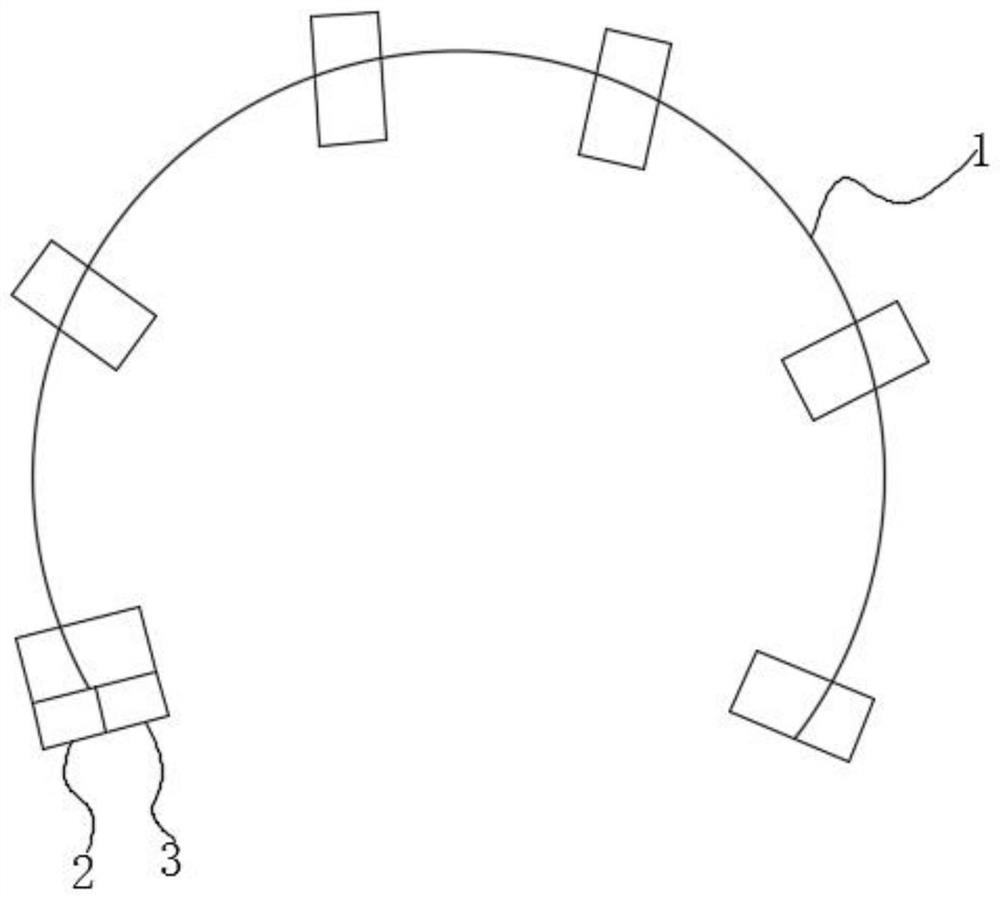

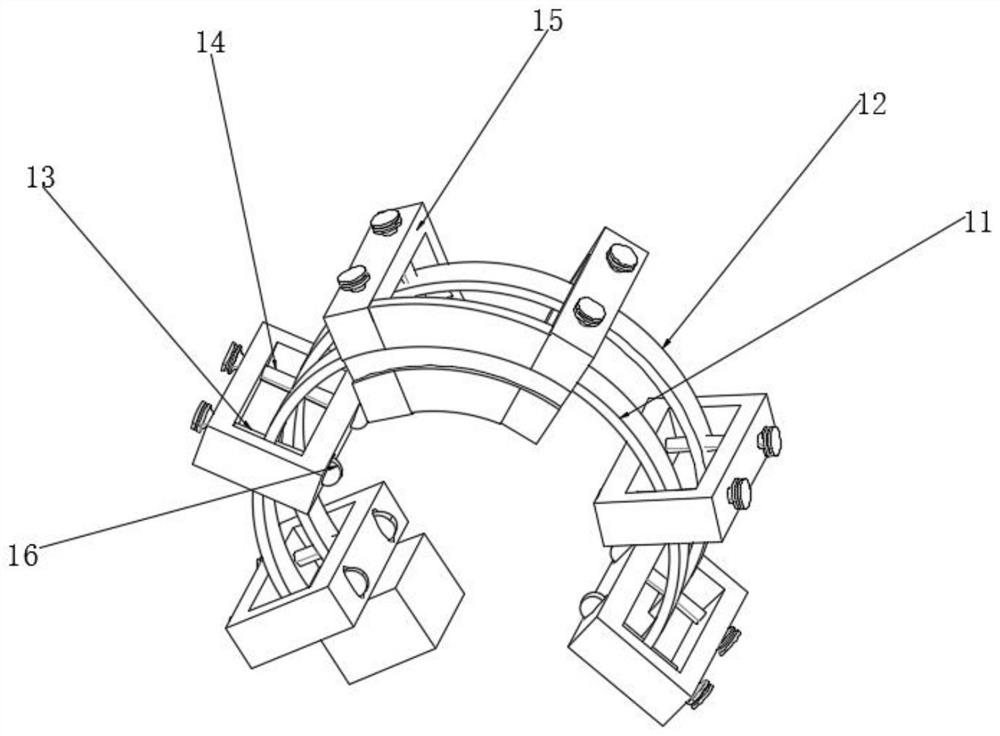

Electrical porcelain wall ultrasonic flaw detection measuring device and method

PendingCN113109448AAvoid missingAvoid mislabelingMaterial analysis using sonic/ultrasonic/infrasonic wavesStructural engineeringMechanical engineering

Owner:醴陵华鑫电瓷科技股份有限公司

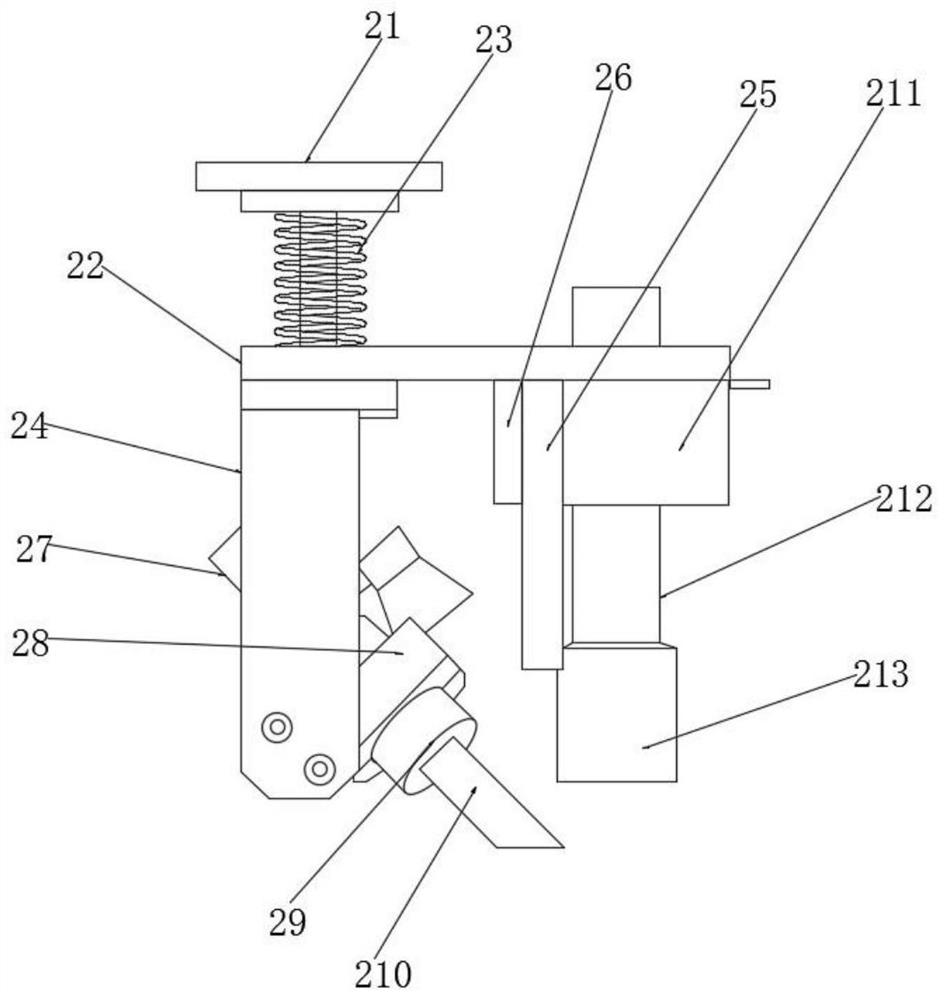

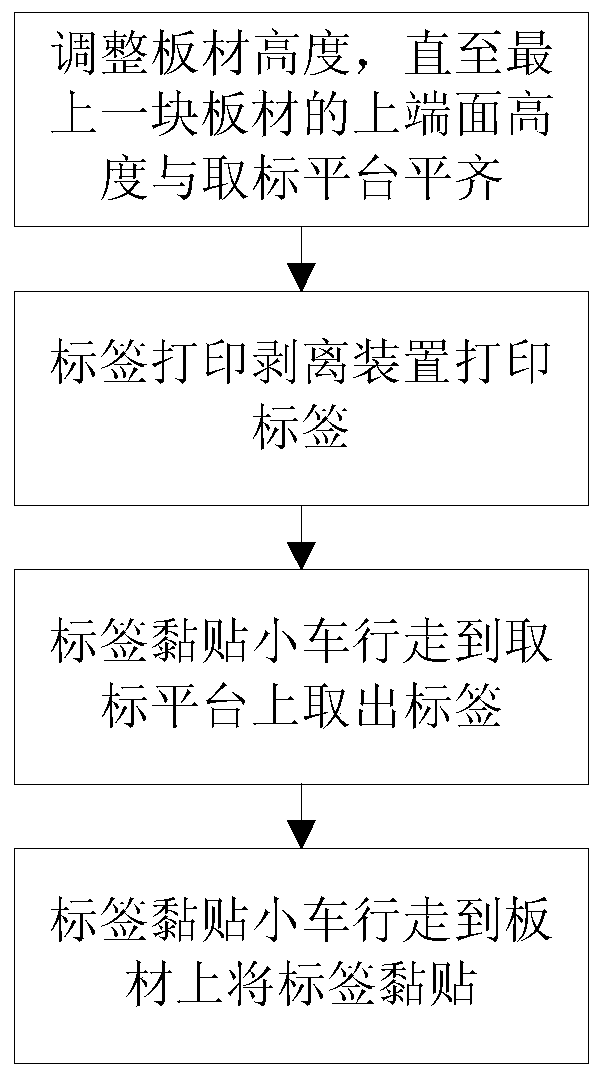

Method for pasting label of customized furniture plate

ActiveCN110615155AReduce manual labor intensityReduce labor costsLabelling flat rigid surfacesLabelling machinesEngineeringUltimate tensile strength

The invention provides a method for pasting a label of a customized furniture plate. The method is characterized in that a plate lifting device is arranged on one side of a label taking platform of arack; the plate is stacked on the plate lifting device to realize plate lifting; the height of the upper end surface of the uppermost plate is adjusted to be flush with the label taking platform, so that the label taking platform and the plate jointly form the moving plane of a label pasting trolley; a label printing stripping device prints the label, and the label is stripped from bottom paper and then placed on a label receiving platform; and the label pasting trolley walks to the label taking platform to take out the label on the label receiving platform and then walks to the plate to pastethe label. By the adoption of the method, label printing stripping and pasting automatic operation can be realized, the labor intensity of workers is reduced, the labor cost is reduced, the label pasting efficiency is improved, and the size of the equipment is favorably reduced.

Owner:无锡维尚家居科技有限公司 +1

A kind of pcb board mounting equipment and mounting method

ActiveCN111601466BGuaranteed accuracyGuaranteed uniformityPrinted circuit assemblingElectrical componentsElectric machineryProcess engineering

Owner:宿州高科智能科技有限公司

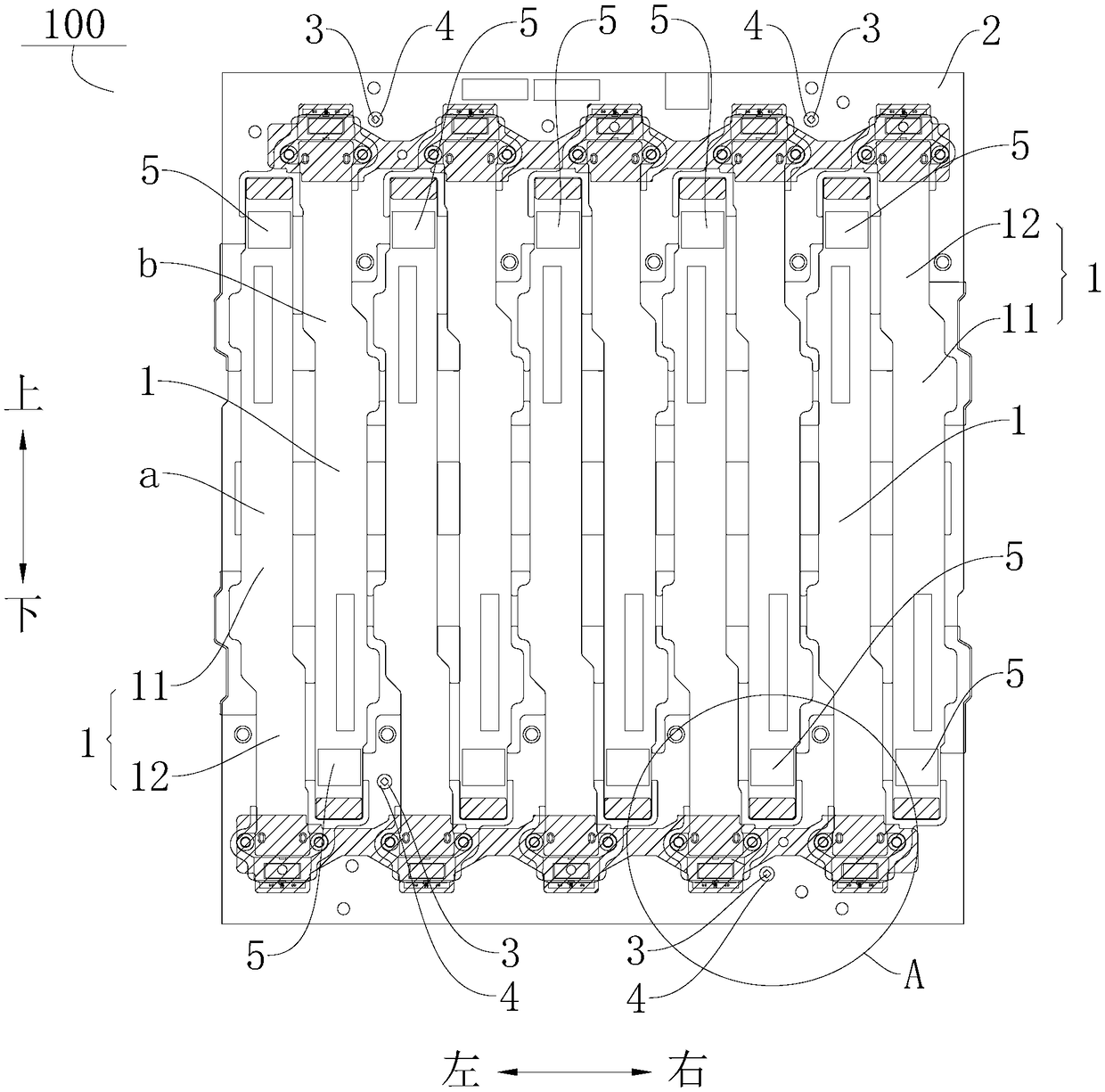

Circuit board

PendingCN108200718AAvoid wrong or missing stickersImprove placement quality and placement efficiencyInspection/indentification of circuitsElectrical and Electronics engineering

The invention discloses a circuit board. The circuit board includes a plurality of sub boards which are arranged side by side in a first direction; each sub board extends in a second direction perpendicular to the first direction; the plurality of sub boards are connected through connection plates; the circuit board has a first surface and a second surface which are opposite to each other; components are arranged on the first surface; a plurality of mark points for positioning the circuit board are arranged on the second surface; an information traceablity code is arranged on each sub board; and the information traceablity codes are positioned on the second surface. According to the circuit board, the plurality of mark points are arranged on the second surface of the circuit board, a labeling machine can read the mark points of the circuit board, and can complete accurate positioning of the circuit board; the labeling machine can complete pasting of information traceability codes according to a preset program by replacing workers; the problems of wrong pasting or leak pasting of the information traceability codes can be avoided, the pasting quality and the pasting efficiency of theinformation traceability codes of the sub board can be improved, the working load of workers can be reduced, and the assembly efficiency of the circuit board can be improved.

Owner:SHENZHEN HEYTAP TECHNOLOGY CO LTD

Certificate post seal system and certificate post seal method

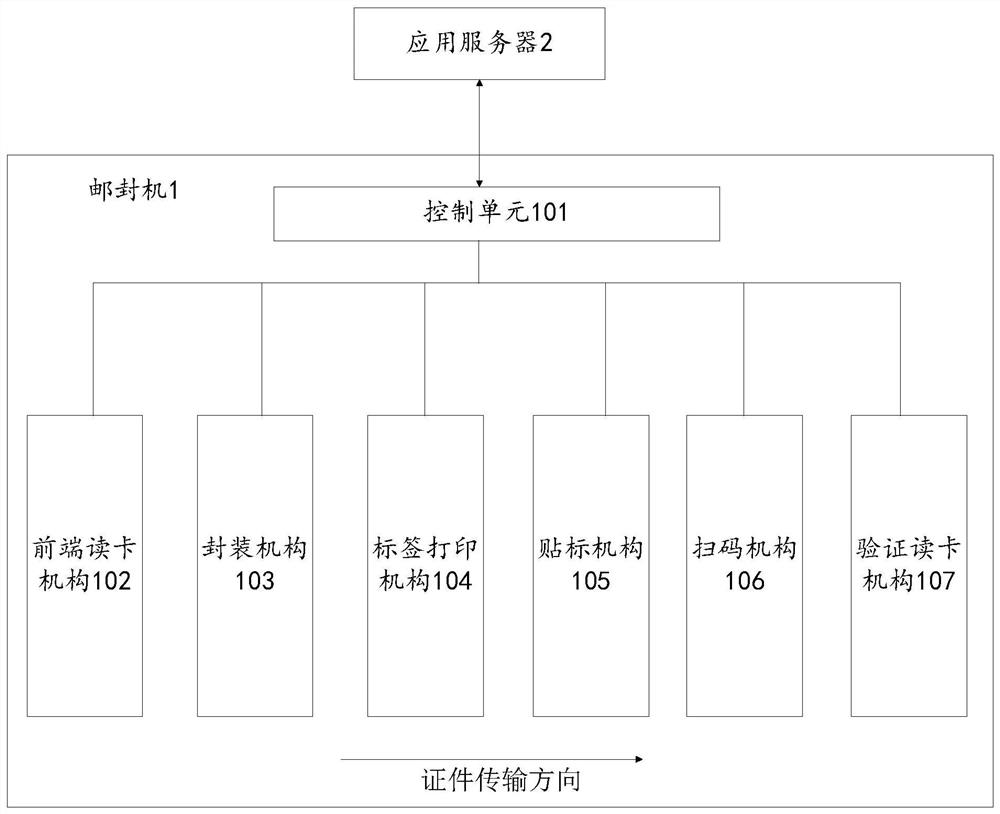

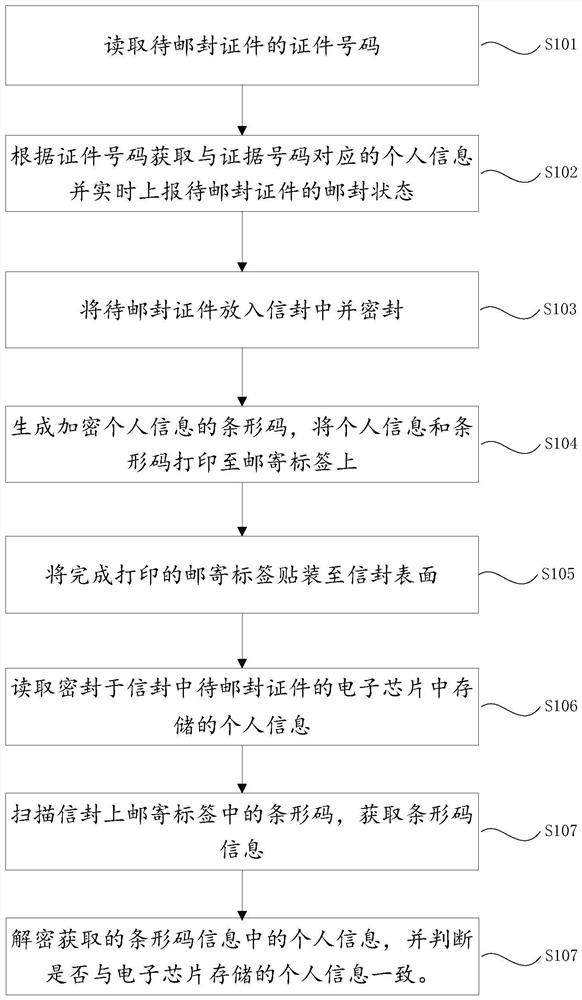

PendingCN112487463AImplement extractionImprove envelope efficiencyLabelling deformable materialsCo-operative working arrangementsApplication serverComputer printing

The invention discloses a certificate post sea system and a certificate post sea method, and the system comprises a post seal machine which comprises a control unit, and a front-end card reading mechanism, a packaging mechanism, a label printing mechanism, a labeling mechanism, a code scanning mechanism and a verification card reading mechanism which are electrically connected with the control unit; the control unit is used for controlling the front-end card reading mechanism to read the certificate number of the certificate to be posted, obtaining corresponding personal information from an application server according to the certificate number, controlling the packaging mechanism to put the certificate to be posted into the envelope, generating a bar code of the encrypted personal information, controlling a label printing mechanism to print the personal information and the bar code onto a mailing label, controlling a labeling mechanism to paste a mailing label to the surface of the envelope; controlling the verification card reading mechanism to read the personal information stored in the electronic chip, controlling a code scanning mechanism to scan the bar code information, anddecrypting the personal information in the acquired bar code information, and judging whether the personal information is consistent with the personal information stored in the electronic chip or not.The mail sealing efficiency and accuracy are improved.

Owner:AEROSPACE INFORMATION

Game map marking method and device, electronic equipment and storage medium

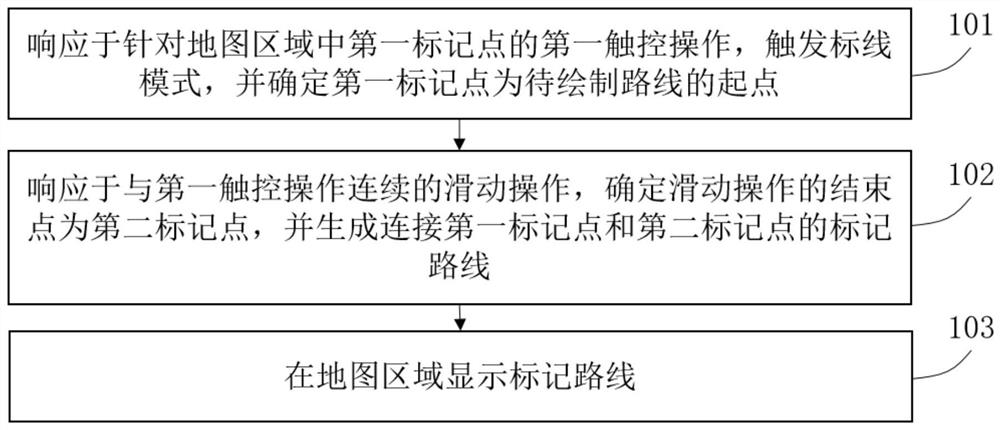

The invention provides a game map marking method and device, electronic equipment and a storage medium, and the method comprises the steps: responding to a first touch operation for a first marking point in a map region, triggering a marking mode, and determining the first marking point as a starting point of a to-be-drawn route; in response to a sliding operation continuous with the first touch operation, determining an end point of the sliding operation as a second mark point, and generating a mark route connecting the first mark point and the second mark point; and displaying the marked route in the map area. The corresponding marking mode can be started according to the operation acting on the map area, a mode switching control does not need to be configured, and the bearing burden of interface content can be reduced; and meanwhile, wrong marking caused by wrong selection of the mode switching control can be prevented, the convenience of user operation is improved, and the game experience of the user is further improved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

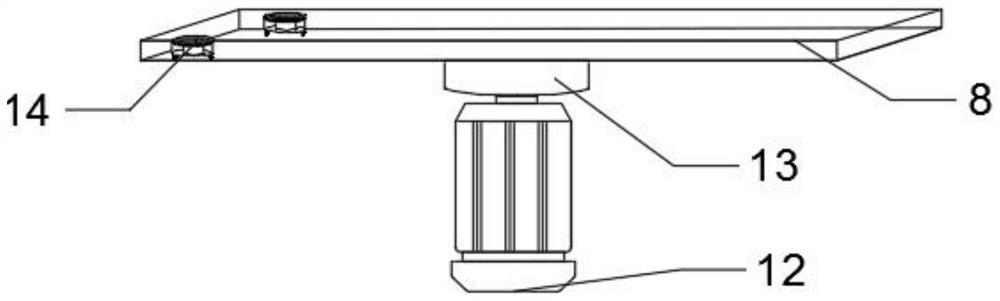

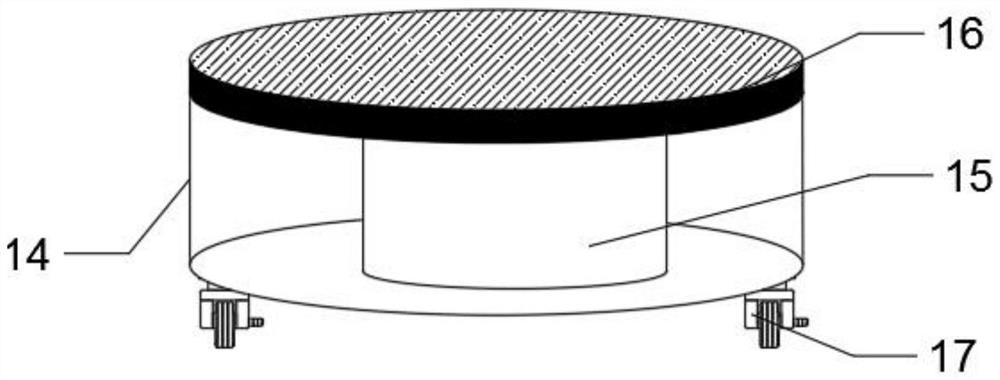

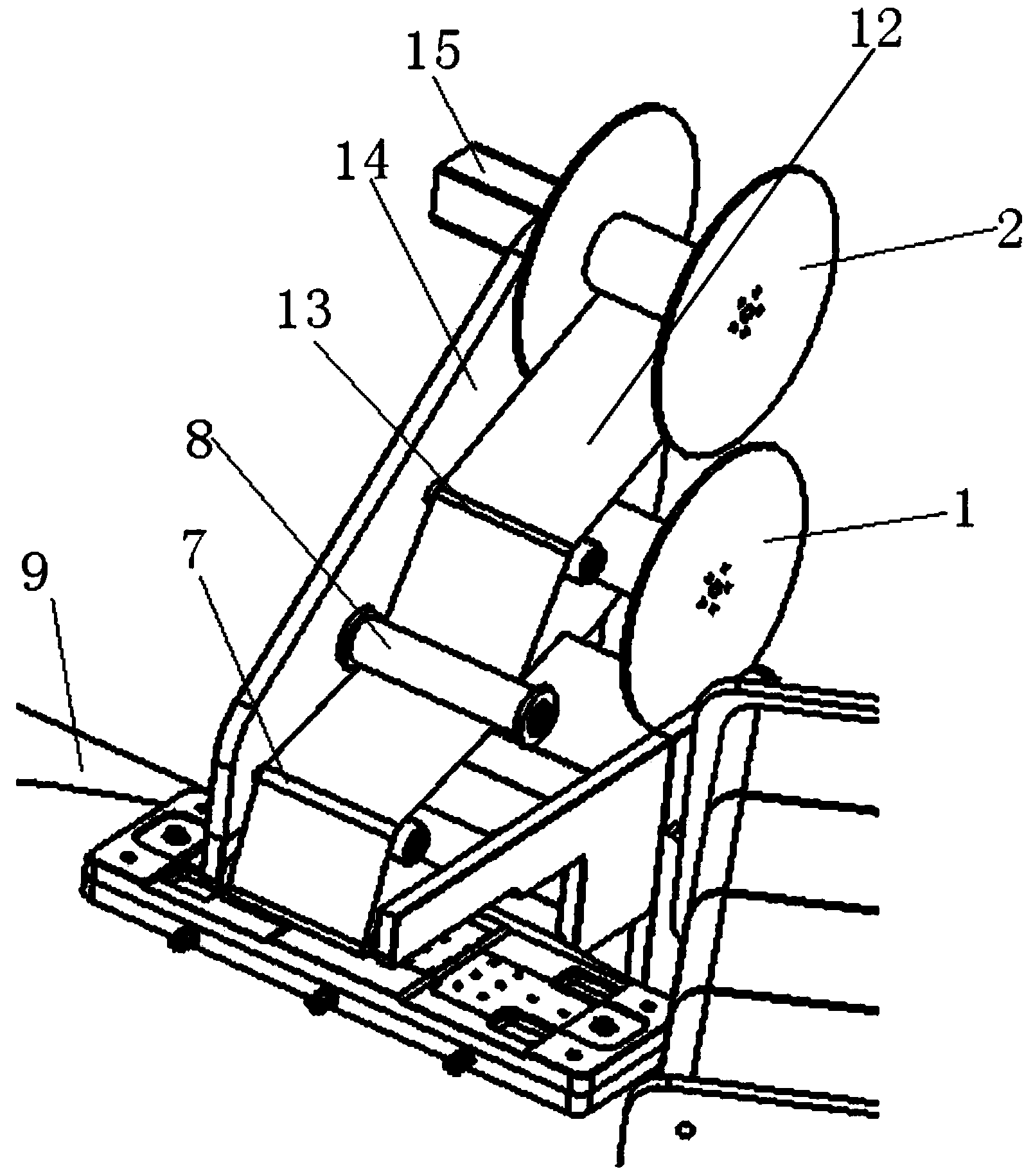

Bracket lifting type release paper laminating device

ActiveCN104385756BAchieve adsorptionRealize intelligent fitLamination ancillary operationsLaminationMiniaturizationMechanical engineering

The invention discloses a bracket lifting type release paper bonding device, which is characterized in that it comprises: a discharge roller (1), a receiving roller (2) and a separation roller (3), the release paper bonding device It is arranged on the support (14), and the lower part of the support (14) is provided with a cylinder for lifting. The invention provides a bracket-lifting type release paper bonding device, the bracket can be lifted up and down, the positioning is flexible and accurate, the positioning speed is fast, the working hours are effectively saved, and it also has the characteristics of full automation, intelligence and miniaturization, especially suitable for small Material placement.

Owner:KUSN MAIZHI FIXTURE TECH

Lift support type release paper fit device

ActiveCN104385756AAchieve adsorptionRealize intelligent fitLamination ancillary operationsLaminationControl engineeringMiniaturization

The invention discloses a lift support type release paper fit device. The lift support type release paper fit device is characterized by comprising a discharge roller (1), a collecting roller (2) and a separation roller (3), wherein the release paper fit device is arranged on a support (14); an air cylinder for lifting is arranged below the support (14). According to the lift support type release paper fit device provided by the invention, the support is liftable, the lift support type release paper fit device is flexible and accurate in positioning, and is high in positioning speed, labor time is effectively saved, and the lift support type release paper fit device also has the characteristics of full automation, intelligentization and miniaturization, and is especially suitable for fitting minitype materials.

Owner:KUSN MAIZHI FIXTURE TECH

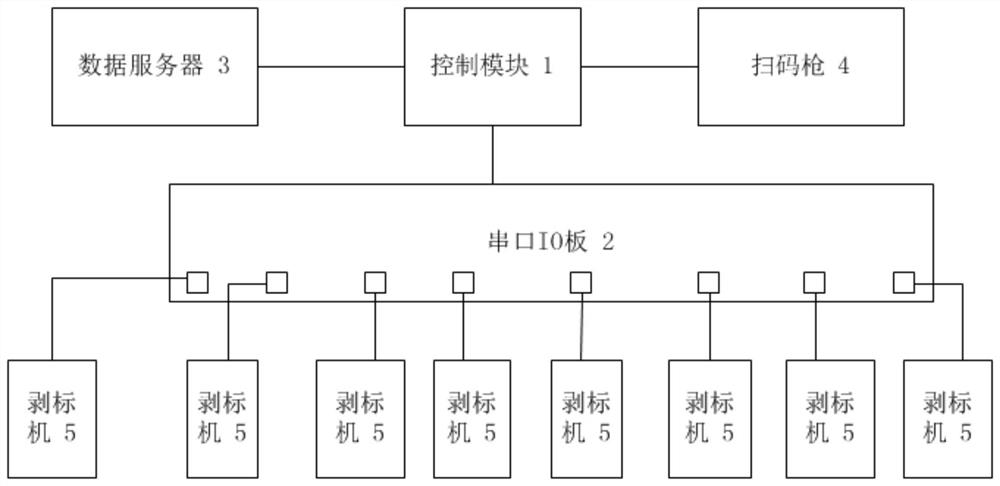

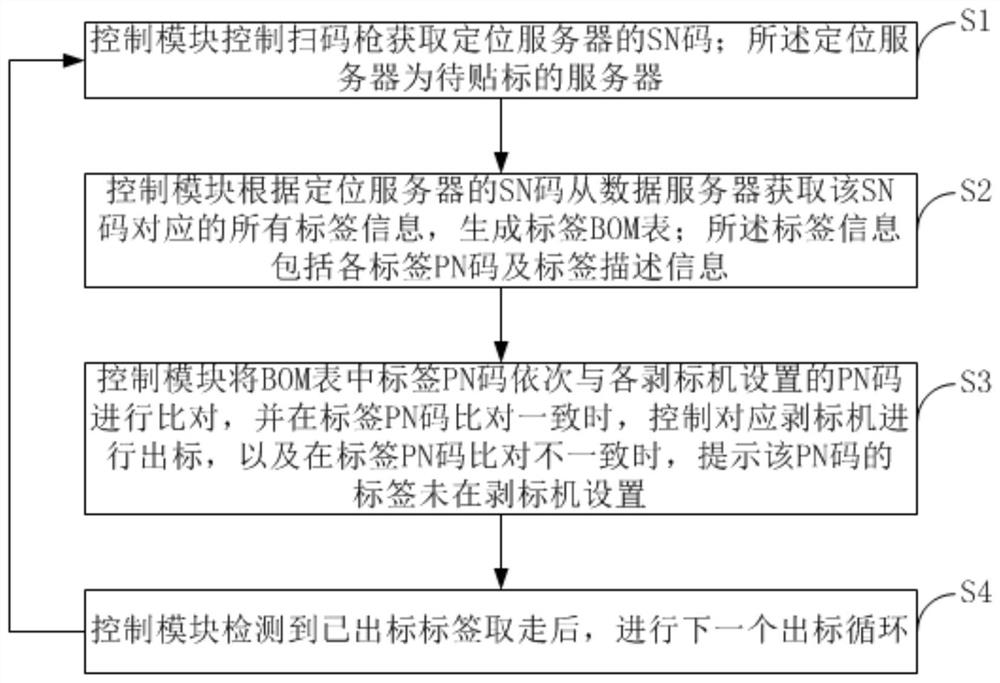

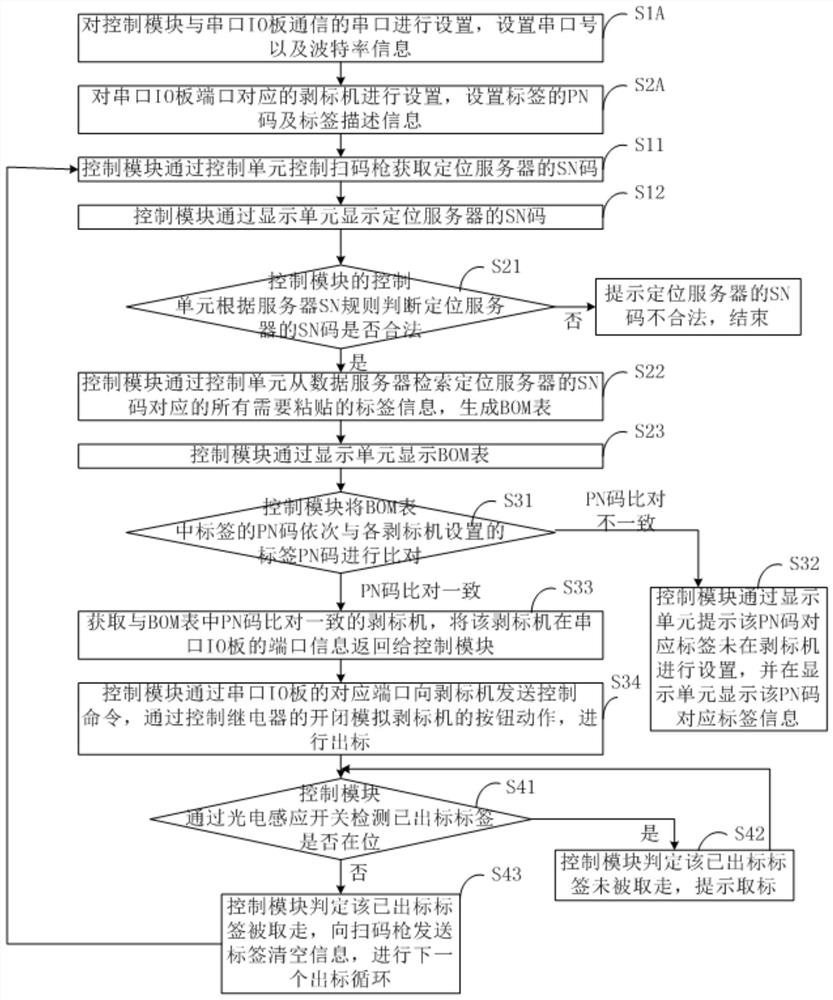

Fool-proof control system and method for server production labeling

InactiveCN111776396AAvoid missing labelsIncrease productivityLabelling machinesSerial portSoftware engineering

The invention provides a fool-proof control system and method for server production labeling. The control system comprises a control module; the control module is connected with a serial port IO board, a data server and a code scanning gun; and the serial port IO board is connected with a plurality of stripping machines. The control module controls the code scanning gun to acquire SN codes of positioning servers, and then obtains label PN codes and label description information corresponding to the SN codes of the positioning servers from the data server to generate a BOM table; and the control module sequentially selects the label stripping machines with the same label PN code setting for label discharging according to the label PN codes in the BOM table, and detects whether the discharged labels are taken away or not. According to the fool-proof control system and method, in the server assembling production process, all the labels of the positioning servers are obtained from the dataserver according to the SN codes of the scanned positioning servers, the label stripping machines are controlled to achieve sequential label discharge according to the label PN codes, the labels areensured to be taken away and pasted, missing labels and mistaken labels are avoided in the production process, and the production efficiency is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

A file search method and system

ActiveCN107766430BSearch intelligenceImprove search efficiencyMetadata still image retrievalTransmissionEngineeringSingle label

Owner:BEIJING CHUNHONG TECH CO LTD

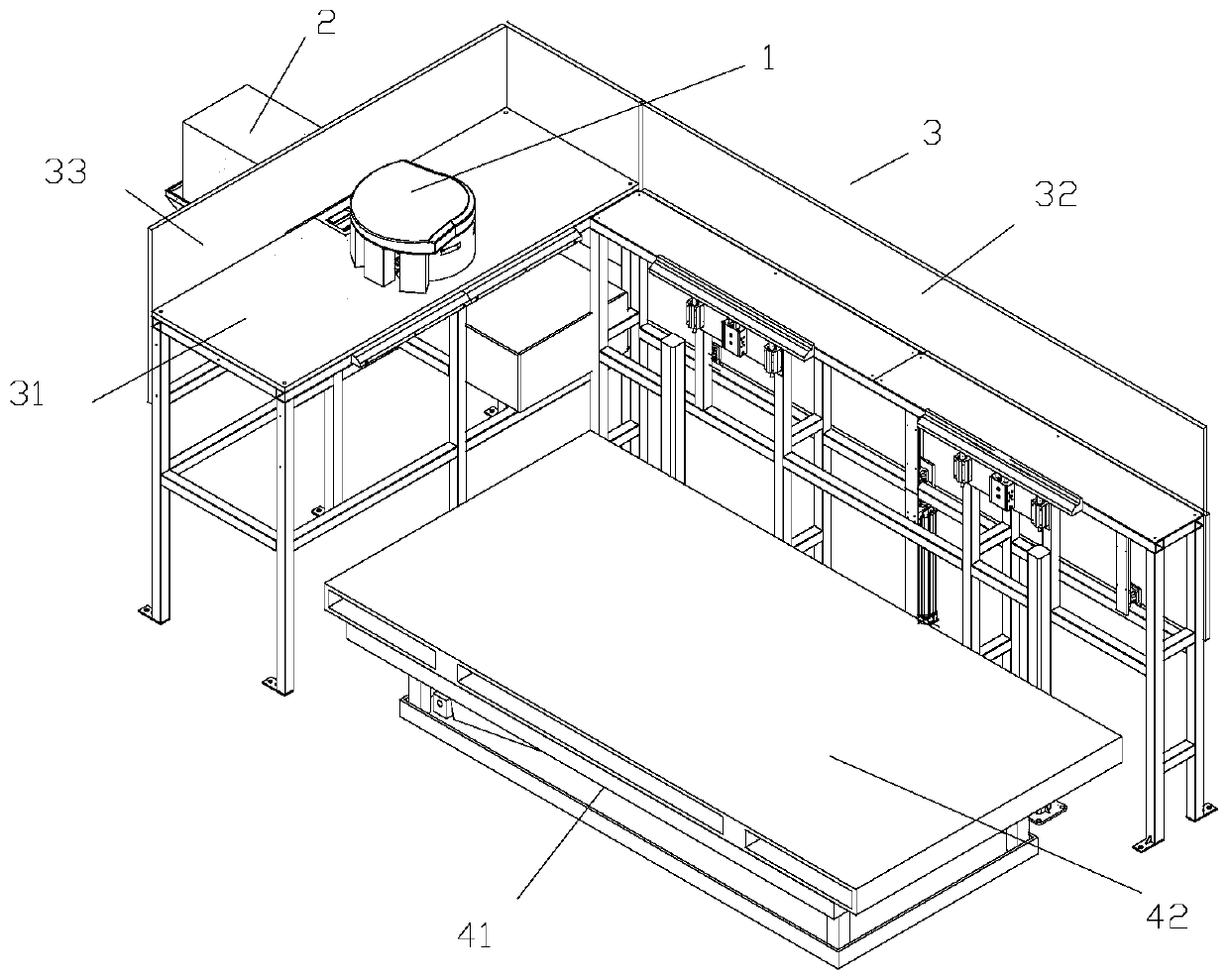

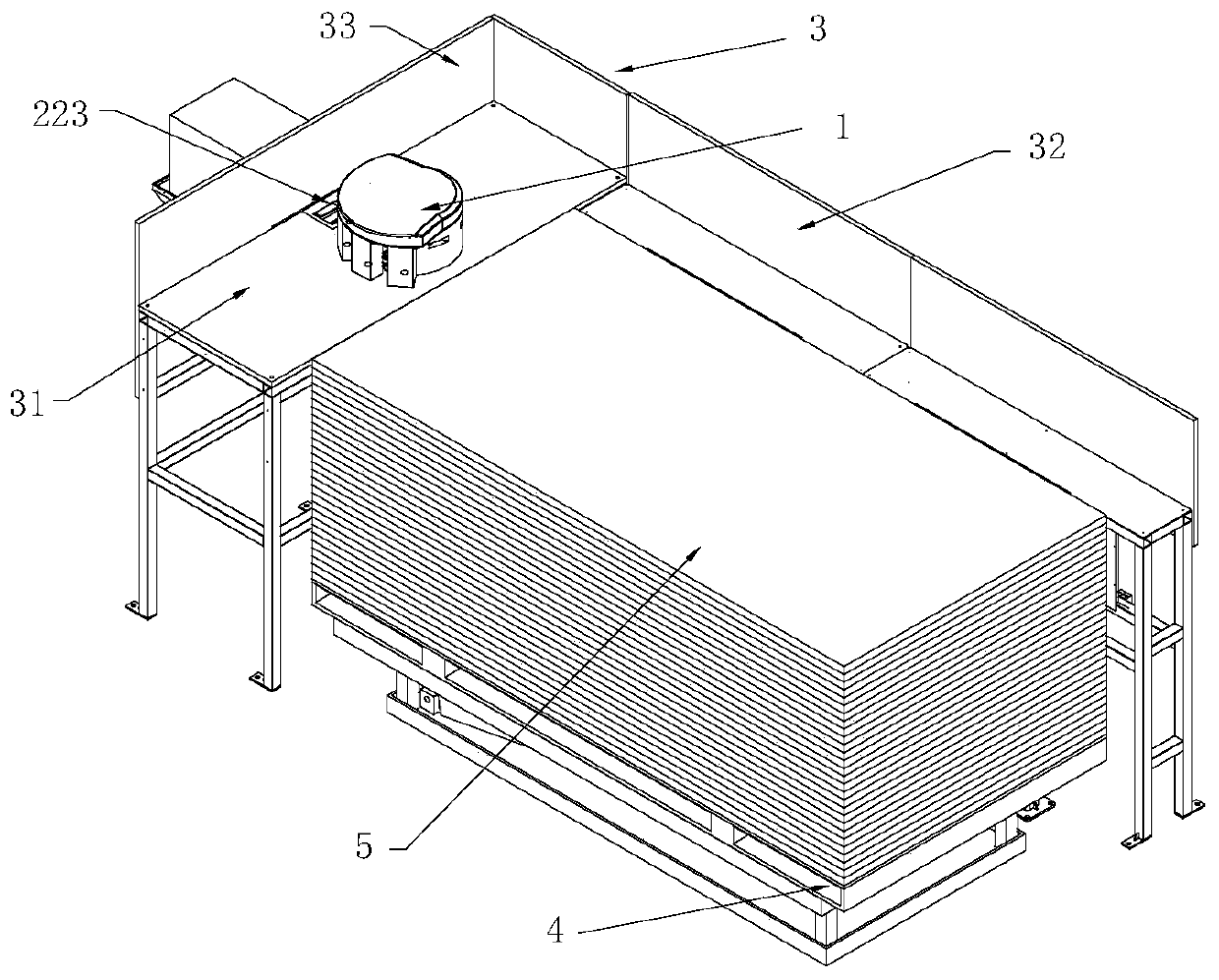

Equipment for sticking labels on panels of customized furniture

ActiveCN110615154AImprove pasting efficiencyAvoid mislabelingLabelling flat rigid surfacesLabelling machinesPaper sheetEngineering

The invention provides equipment for sticking labels on panels of customized furniture. The equipment for sticking the labels on the panels of customized furniture comprises a rack, a label printing stripping device, a panel lifting device and a label-sticking trolley. The label printing stripping device is used for printing the labels and placing the labels on a label-receiving platform after backing paper are stripped off the labels. The panel lifting device is used for storing the panels and adjusting the height of the panels. The label-sticking trolley is used for taking out labels on thelabel-receiving platform, running onto the panels with the labels and sticking the labels. A label-taking platform in which a label-sticking trolley movement plane is formed is arranged on the rack. The label-receiving platform is arranged in a manner that the label-receiving platform is located on the label-taking platform or close to the label-taking platform. The panel lifting device is locatedon one side of the label-taking platform. By means of the equipment for sticking the labels on the panels of customized furniture, the labor intensity of workers and the labor cost can be lowered; label-sticking efficiency is improved; the circumstance that labels are stuck mistakenly or omitted is avoided; and the equipment is small in volume, low in the cost and small in the area of the occupied operation site.

Owner:佛山维尚家具制造有限公司

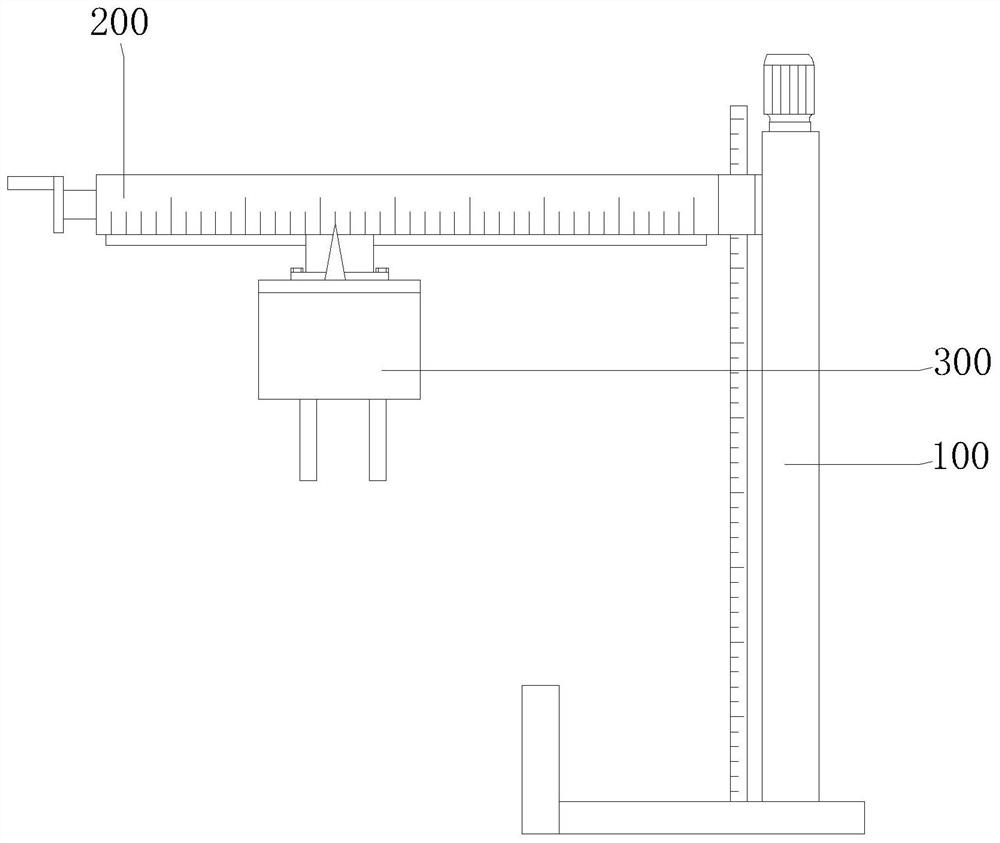

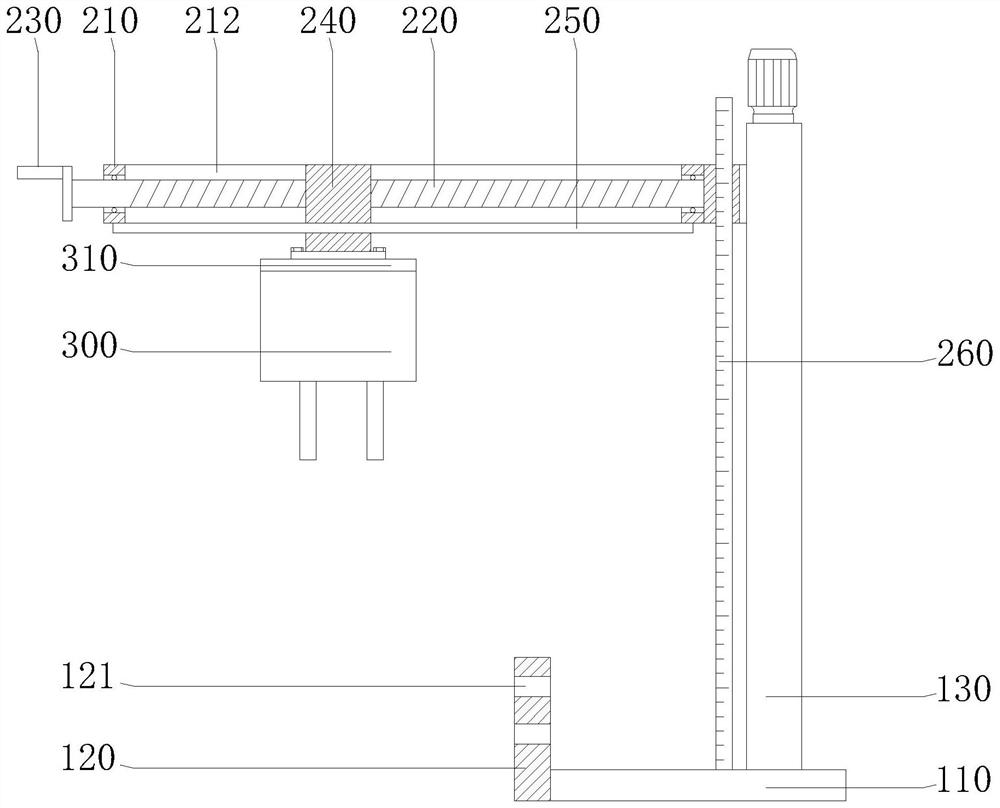

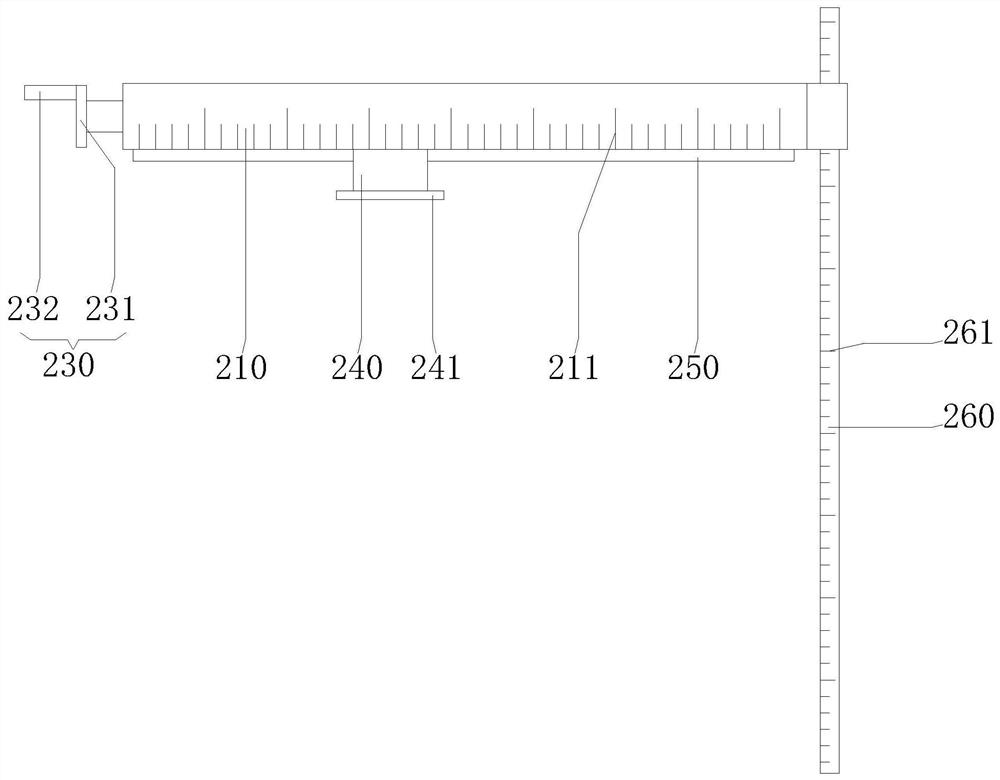

Engine moving marking mechanism

PendingCN113370671AAvoid mislabelingHigh precisionTypewritersPower drive mechanismsEngineeringMechanical engineering

The invention provides an engine moving marking mechanism, and belongs to the technical field of engine marking. The engine moving marking mechanism comprises a supporting assembly, a connecting assembly and a marking machine body, when in use, a connecting hole is connected to an engine through a bolt, then a rotating piece is rotated to drive a threaded rod to rotate, then the marking machine body can be moved to the position above the marking position of the engine, and then the marking machine body is started to mark a mark number on the engine, in the marking process, whether the position of the marking machine body is changed or not can be determined through first length scale marks, the marking machine body is fixed to the engine, whether the position of the marking machine body is changed or not can be more rapidly determined, the phenomenon that the marking machine body marks the mark number in a deviated mode can be effectively prevented, the marking accuracy of the marking machine body can be improved, and marking of the engine by the marking machine body is facilitated.

Owner:GUANGXI YUCHAI MASCH CO LTD

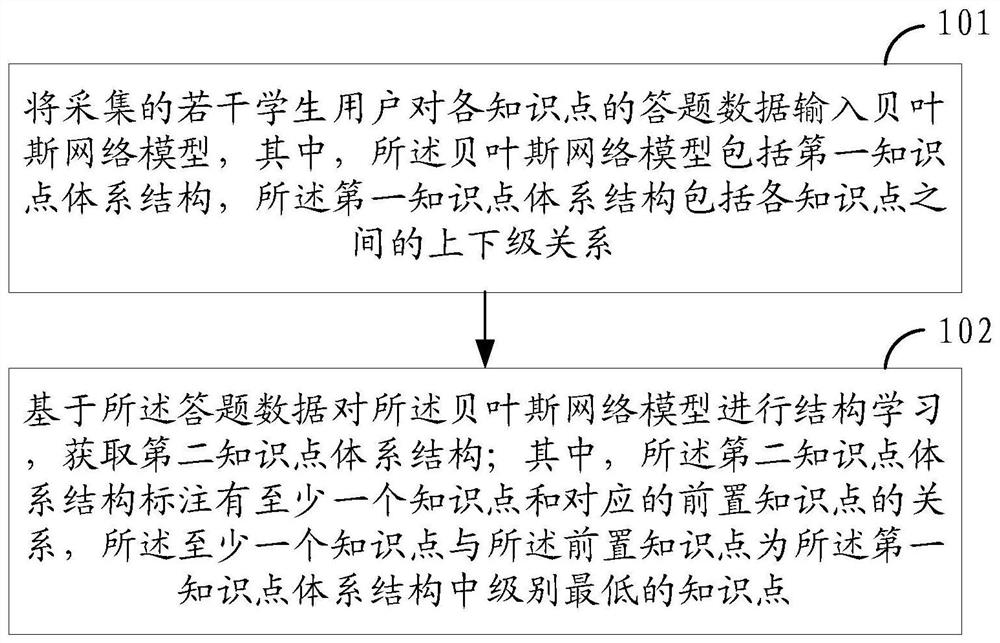

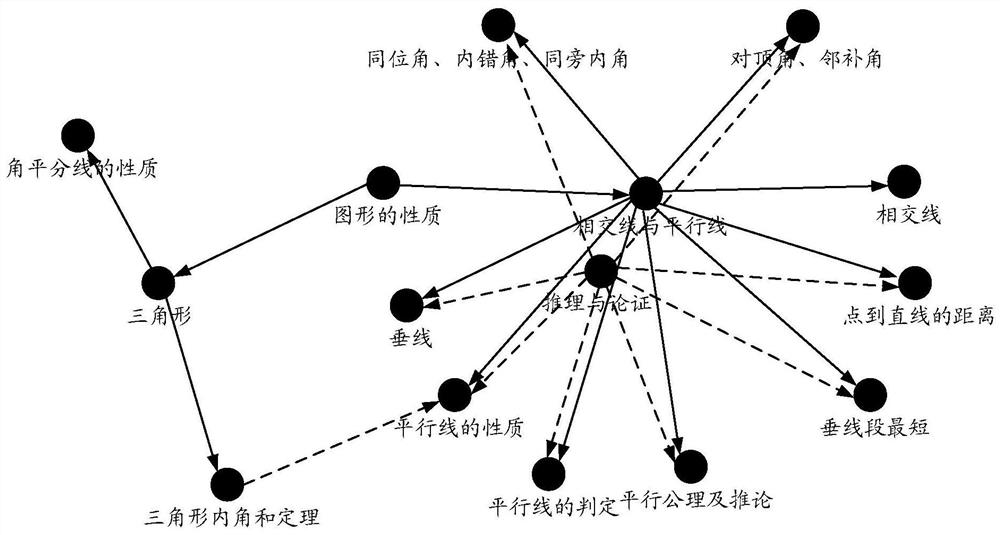

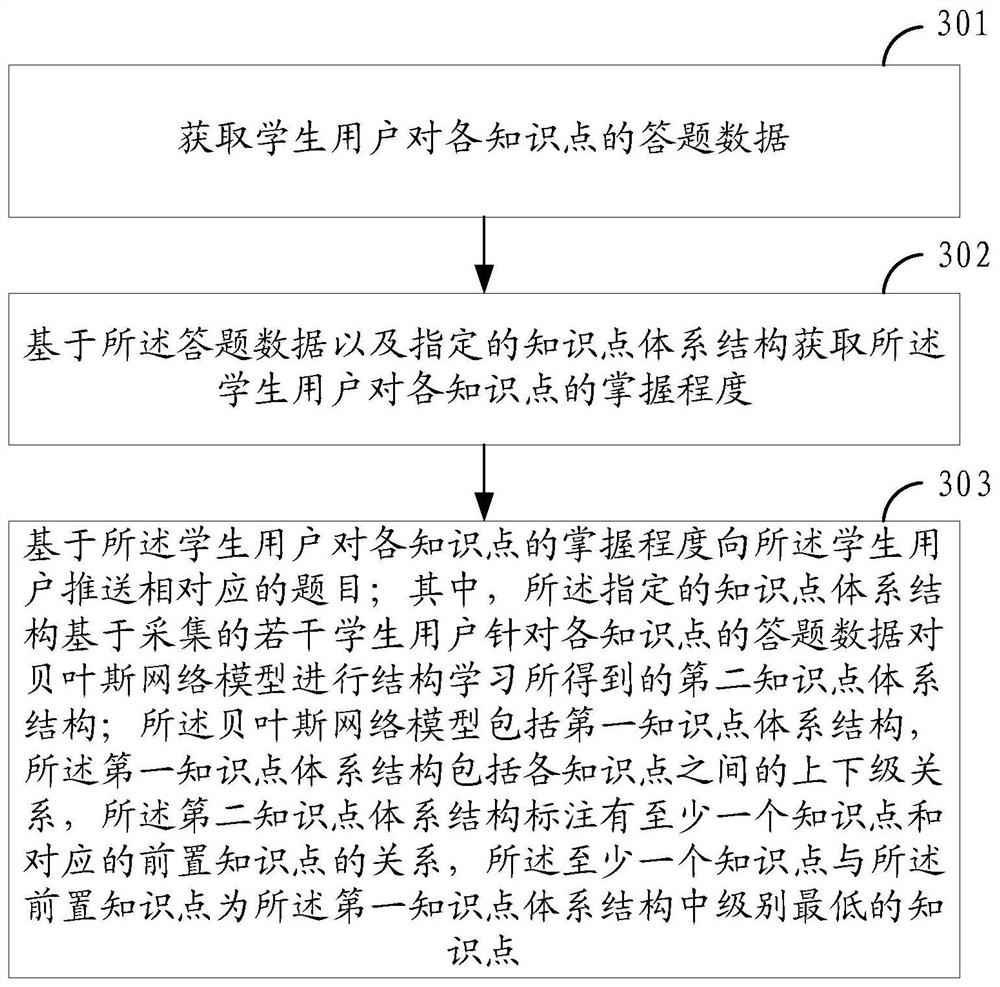

Preposed knowledge point labeling method and device, question pushing method and device, equipment and medium

PendingCN111897945AAvoid time costAvoid mislabelingDigital data information retrievalData processing applicationsStructure learningEngineering

The invention provides a preposed knowledge point labeling method and device, a question pushing method and device, equipment and a medium. The preposed-knowledge point labeling method comprises the following steps: inputting acquired answer data of a plurality of student users to each knowledge point into a Bayesian network model; performing structure learning on the Bayesian network model basedon the answer data to obtain a second knowledge point system structure, wherein the second knowledge point system structure is marked with a relationship between at least one knowledge point and the corresponding front knowledge point. In this way, marking of the front knowledge points of all the knowledge points can be automatically completed, on one hand, the time cost and the auditing cost of manual marking of teachers can be reduced, and on the other hand, compared with a method for obtaining the preposed knowledge points by performing similarity calculation based on text information of the knowledge points in related technologies, the technical scheme has the advantages that possible preposed relationships among the knowledge points are reversely deduced by utilizing the answer data of the students, so that the wrong labeling conditions of similar texts and no actual direct relationship are avoided, and the labeling accuracy is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com