Deformed steel bar surface flaw repairing process

A technology for surface defects and rebars, which is applied in the field of repairing the surface defects of rebars, can solve the problems of easy missed inspection, difficulty in inspection, low inspection efficiency, etc., so as to avoid false inspections, improve inspection efficiency and accuracy, and improve repair strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

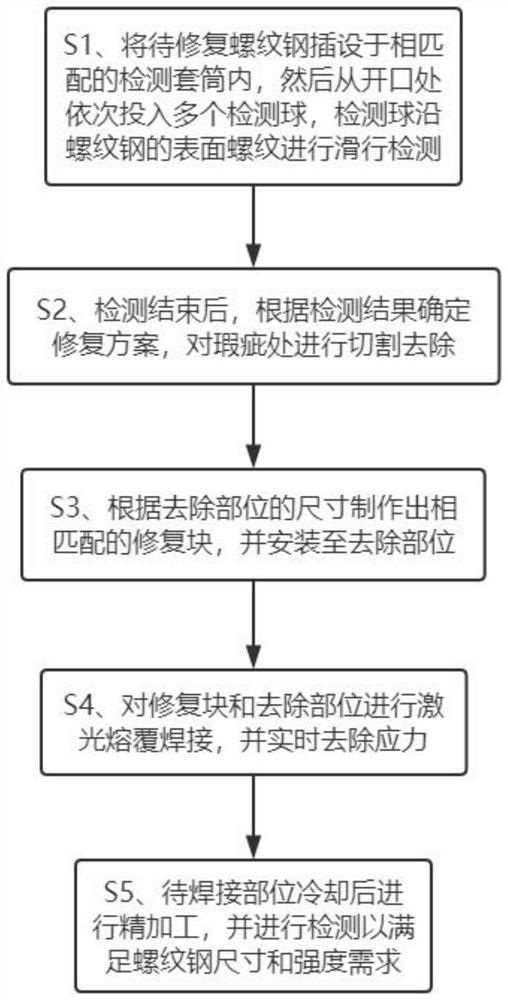

[0045] see Figure 1-2 , a rebar surface defect repair process, comprising the following steps:

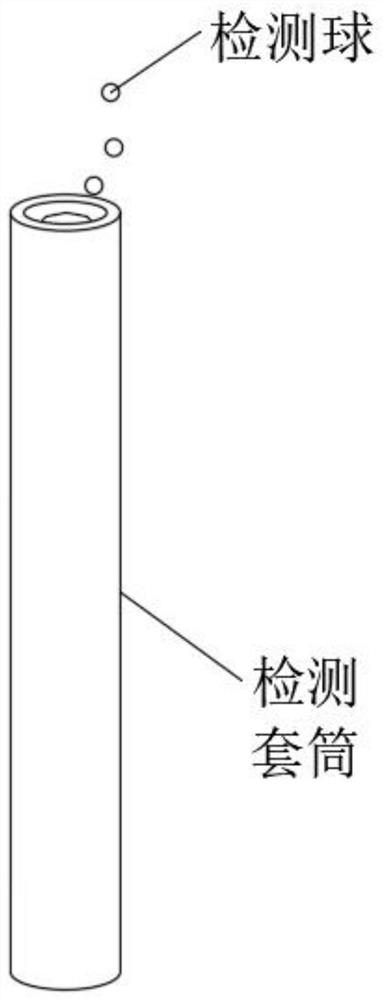

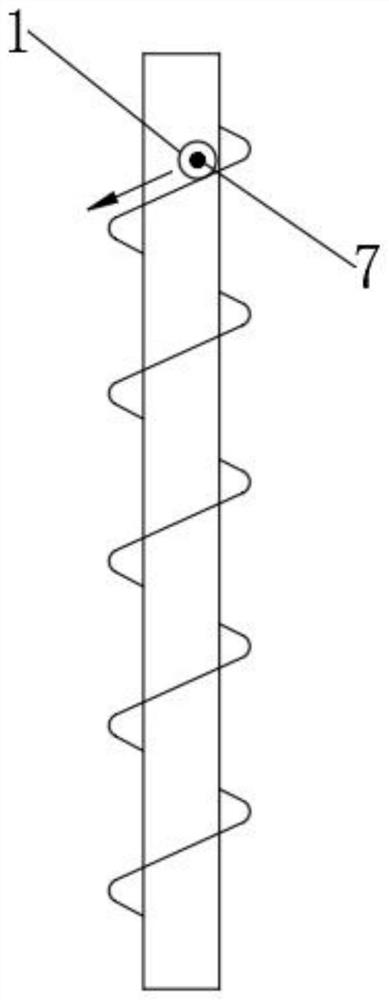

[0046] S1. Insert the rebar to be repaired in the matching detection sleeve, and then put a plurality of detection balls in sequence from the opening, and the detection balls slide along the surface thread of the rebar for detection;

[0047] S2. After the inspection, determine the repair plan according to the inspection results, and cut and remove the defects;

[0048] S3. Make a matching repair block according to the size of the removed part, and install it to the removed part;

[0049] S4. Laser cladding welding is performed on the repair block and the removed part, and the stress is removed in real time;

[0050] S5. After the welding part is cooled, finish machining and inspection to meet the size and strength requirements of the rebar.

[0051] In step S4, the cladding material is selected from iron-based and cobalt-based alloys, the laser power is 1500-2500W, the inert g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com