Lithium battery detection and repair equipment and repair method thereof

A technology for lithium batteries and equipment, applied in the field of lithium battery detection and repair equipment and its repair, can solve the problems of large workload and low efficiency in pressure measurement one by one, and achieve the effects of improving efficiency, convenient fixing, and simplifying connection operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

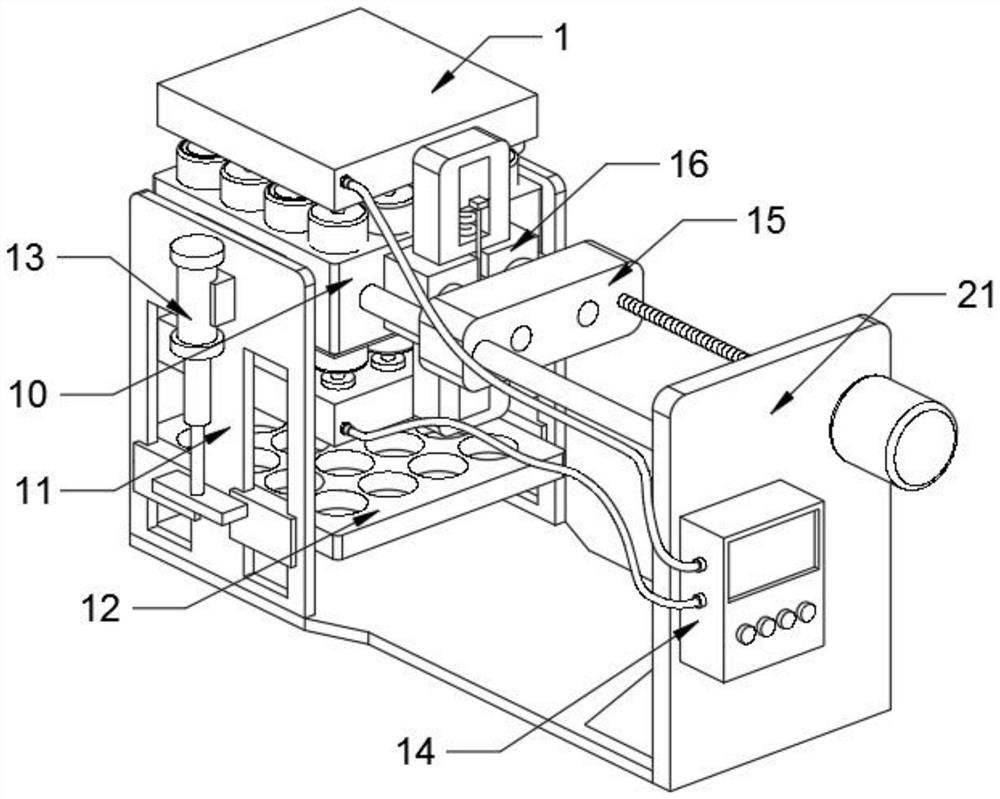

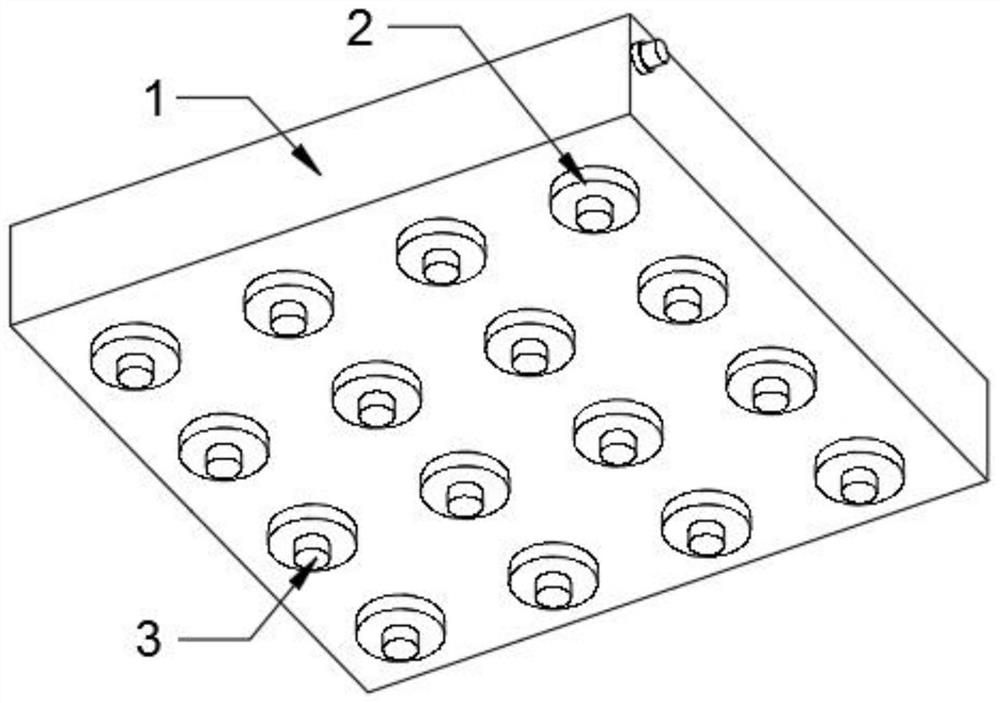

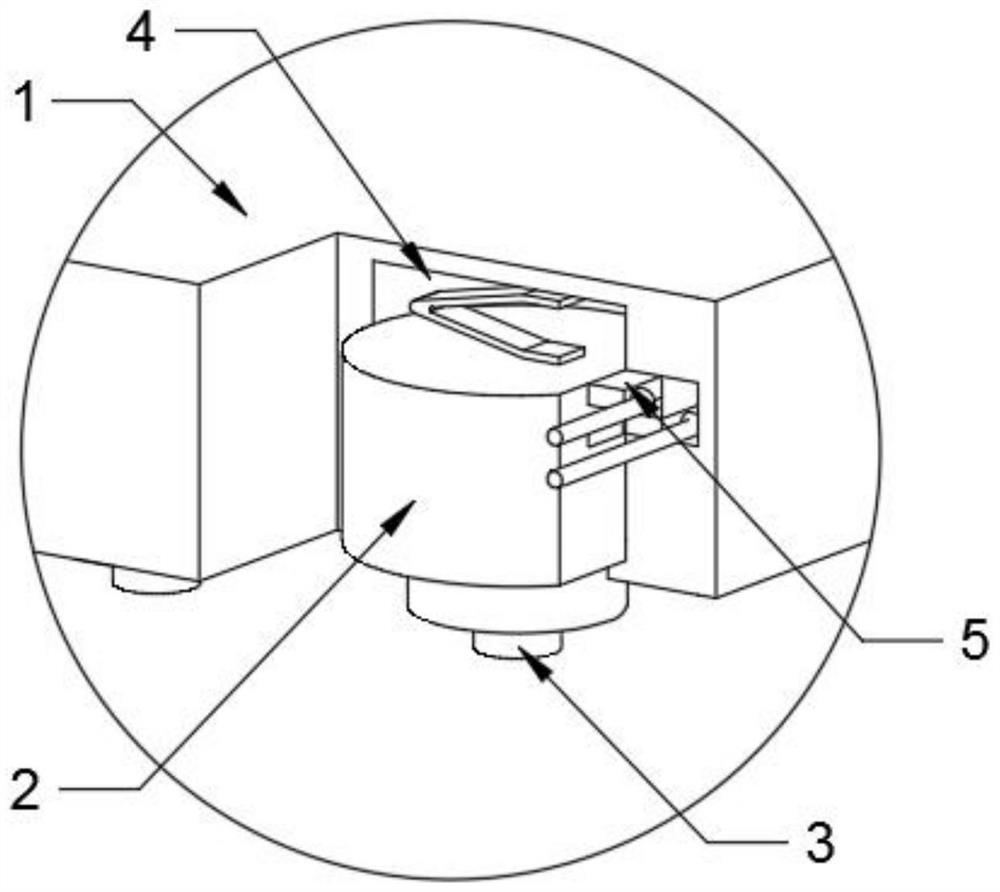

[0038] Such as Figure 1-5 As shown, a lithium battery testing and repairing equipment, the U frame 11 and the vertical plate 21 are fixed together to form a main frame, the limit assembly is fixed on the top of the U frame 11, and the closing mechanism is installed between the placement plate 10 and the vertical plate 21 Between them, two sets of pressure measuring pole plates are arranged above and below the placement plate 10, and connected to the closing mechanism. The pressure measuring pole plates include a plate body 1, and a plurality of electrode cavities 4 are evenly opened on the surface of the plate body 1, and the core The block 2 is installed inside the electrode cavity 4 through the shrapnel, and the end of the core block 2 protrudes from the end surface of the plate body 1, and the two sets of outer electrode sheets 5 are fixed on the inner wall of the electrode cavity 4, and the two sets of inner electrode sheets 6 are fixed on the inner wall of the electrode c...

Embodiment 2

[0043] Such as Figure 6-7 As shown, the limit assembly includes a placement plate 10, and a placement hole 17 is evenly opened on the surface of the placement plate 10. The placement hole 17 corresponds to the position of the electrode needle 3, and four air cavities 19 are opened on the side of the placement hole 17, and the air bag 20 Sealed in the air cavity 19, the extruded block 18 is penetrated from the air cavity 19 to the placement hole 17, and connected to the air bag 20, using a trachea to communicate with each air bag 20, and connecting the air inlet on the side of the placement plate 10;

[0044] Each single battery body is aligned through the placement hole 17, and the pipeline is connected to the gas supply equipment to introduce high-pressure gas into the air bag 20, so that the air bag 20 expands in the air cavity 19, so that the extrusion block 18 moves into the placement hole 17, The extrusion blocks 18 in four directions form a stable pressure on the cell b...

Embodiment 3

[0048] Such as figure 1 and Figure 8 As shown, the closing mechanism includes a moving block 15 and a traversing mechanism. The traversing mechanism includes a screw mandrel. The screw mandrel is rotated on the surface of the vertical plate 21, and the motor is connected to fix the slide bar and the screw mandrel on the surface of the vertical plate 21 in parallel. The rod slides through the moving block 15, the screw thread passes through the moving block 15, the base block 16 is placed between the moving block 15 and the placement plate 10, two groups of connecting columns 22 are fixed on the surface of the base block 16, and the connecting columns 22 Slide and insert with the moving block 15, connect the spring between the moving block 15 and the base block 16, open guide grooves symmetrically on the top and bottom of the base block 16, slide and install the slider 23 in the guide groove, and use elastic connection, Open a relief hole 25 at the center of the base block 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com