Automatic system for friction stir welding internal defect on-line detection

A technology of friction stir welding and automation system, which is applied in the processing of detection response signals, measurement devices, and analysis of solids using sonic/ultrasonic/infrasonic waves. The effect of solving inefficiency and improving the efficiency of inspection and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

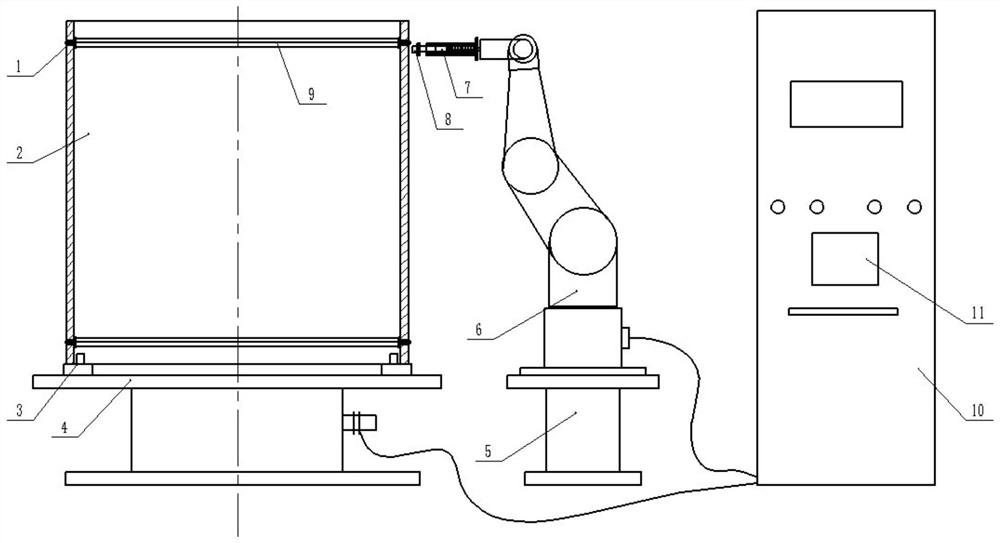

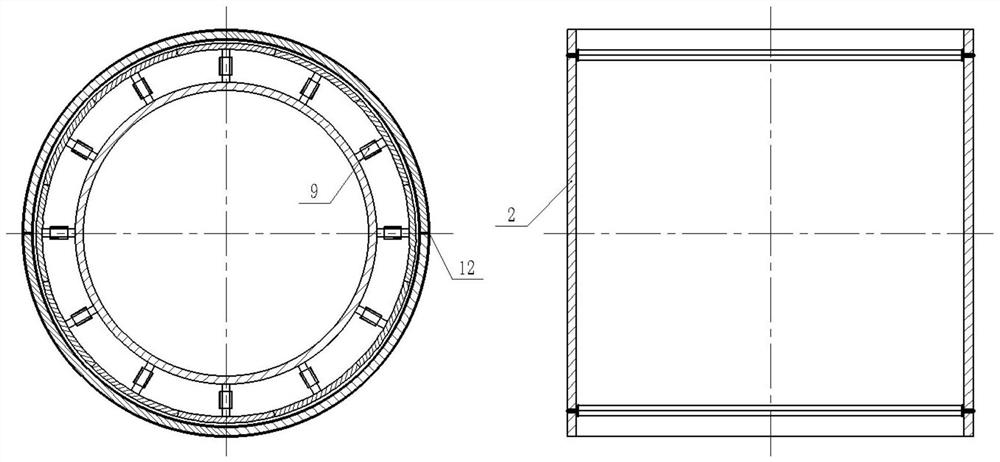

[0029] combine figure 1 , figure 2 , image 3 , an automatic system for on-line detection of internal defects in friction stir welding, consisting of a workpiece 2, a workpiece centering fixture 3, a rotary table 4, a robot base 5, a multi-axis robot 6, a flexible probe clamping coupling tool 7, and a phased array Ultrasonic probe module 8, workpiece internal support ring tooling 9, electric control cabinet subsystem 10, and phased array instrument 11 are composed.

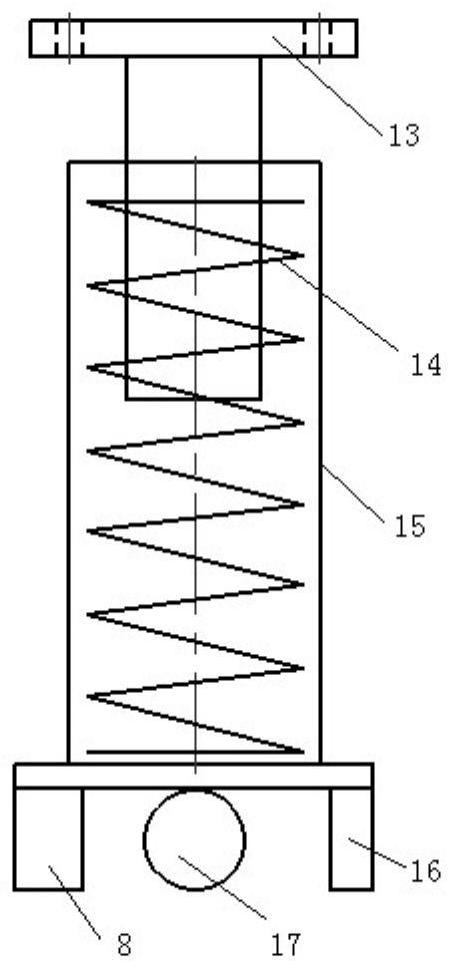

[0030] The upper connecting rod 13 of the flexible probe clamping coupling tool 7 is connected to the end of the multi-axis robot 6 by bolts; the lower sleeve 15 is connected to the upper connecting rod 13 through an elastic element 14; at the same time, the lower end is installed with a phased array ultrasonic probe through a mounting plate Module 8, rolling encoder 16, and roller 17, wherein, the phased array ultrasonic probe module 8 and the rolling encoder 16 are fixed on the mounting plate in parallel by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com