Lift support type release paper fit device

A lamination device and release paper technology, applied in lamination devices, lamination auxiliary operations, lamination, etc., can solve problems such as large differences in batches, inability to locate, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

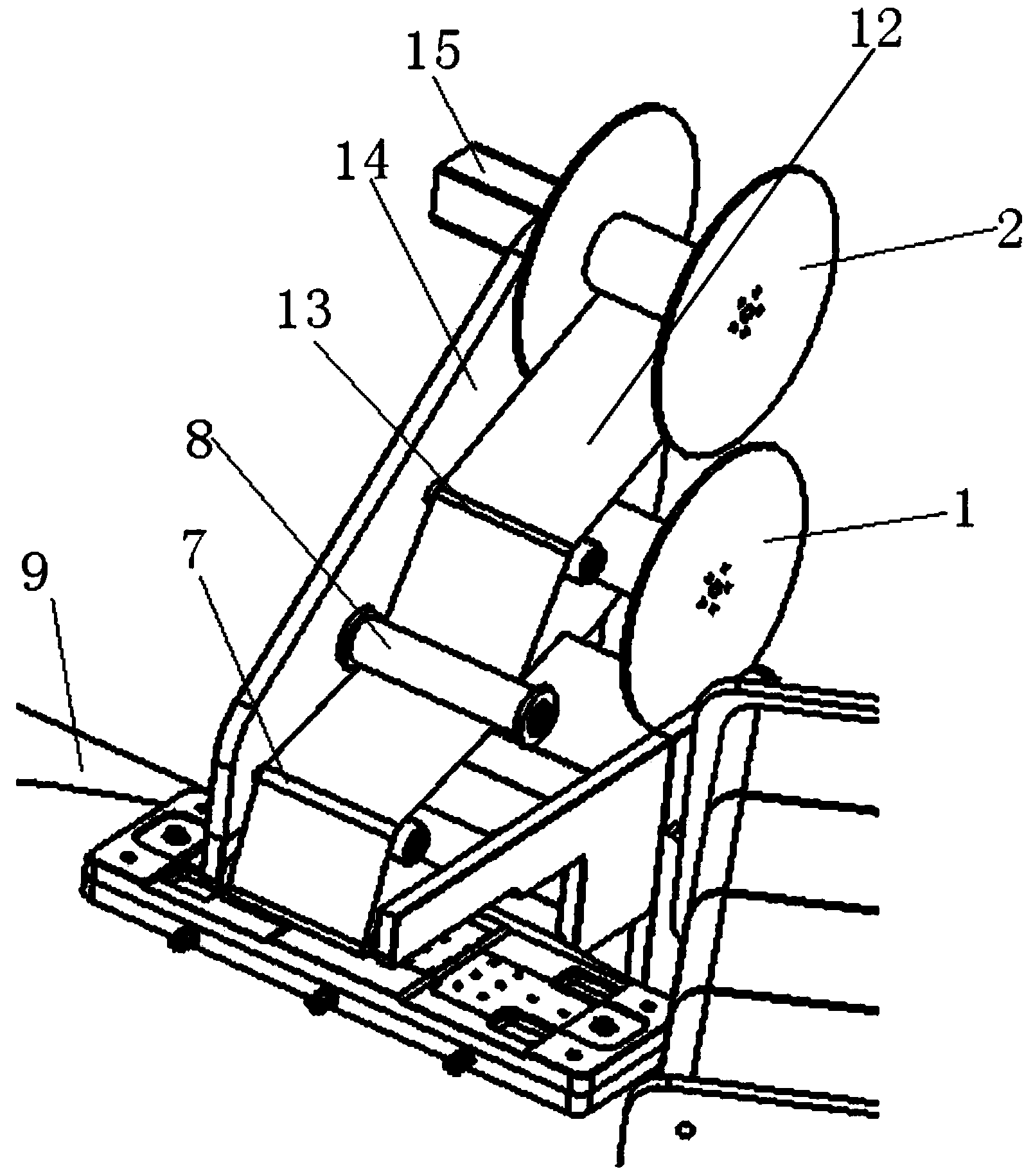

[0021] Such as Figure 1-2 As shown, a bracket lifting type release paper bonding device is characterized in that: it includes: a discharge roller 1, a receiving roller 2 and a separation roller 3, and the discharging roller 1 is located below the receiving roller 2 , the discharge roller 1 and the receiving roller 2 are located on the table 9, the separation roller 3 is located under the table 9, and the front of the discharge roller 1 is provided with a device for peeling off the lower layer of the release paper 12 Separating the guide roller group 4, the release paper 12 passes through the first guide roller 5, the second guide roller 6, the third guide roller 7, the fourth guide roller 8 and the fifth guide roller after passing through the separation guide roller group 4. After the roller 13, the upper layer of the release paper 12 enters the receiving roller 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com