Labeling device for textiles

A labeling and equipment technology, applied in the directions of labeling, labeling, labeling machines, etc., can solve the problems of uneven quality, unsatisfactory, laborious, etc., and achieve the effect of low mislabeling rate, preventing mislabeling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

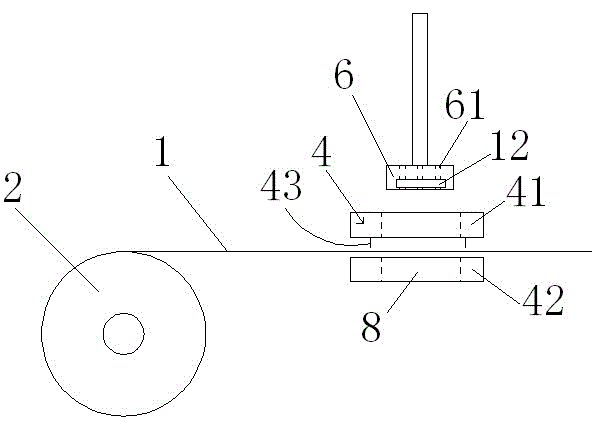

[0011] see figure 1 As shown, a labeling device for textiles includes a label material tray 2 wound with a label material tape 1, a cutting die 4, and a cylinder-driven pressure head 6. The label material tray 2 can rotate under the influence of a power device, so The cutting die 4 includes an upper die 41 and a lower die 42, the upper die 41 has a cutting edge 43, the upper die 41 and the lower die 42 have a passage 8 for the pressure head 6 to pass through, and the pressure The head 6 has a plurality of vacuum suction ports 61 distributed in a rectangular shape. When in use, the label material 1 is passed through the middle of the cutting die 4. The pressure head 6 first absorbs the label material 1, and the cutting die 4 then presses the label material. After cutting, the indenter 6 moves vertically downward to attach the label to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com