Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Avoid affecting the operation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

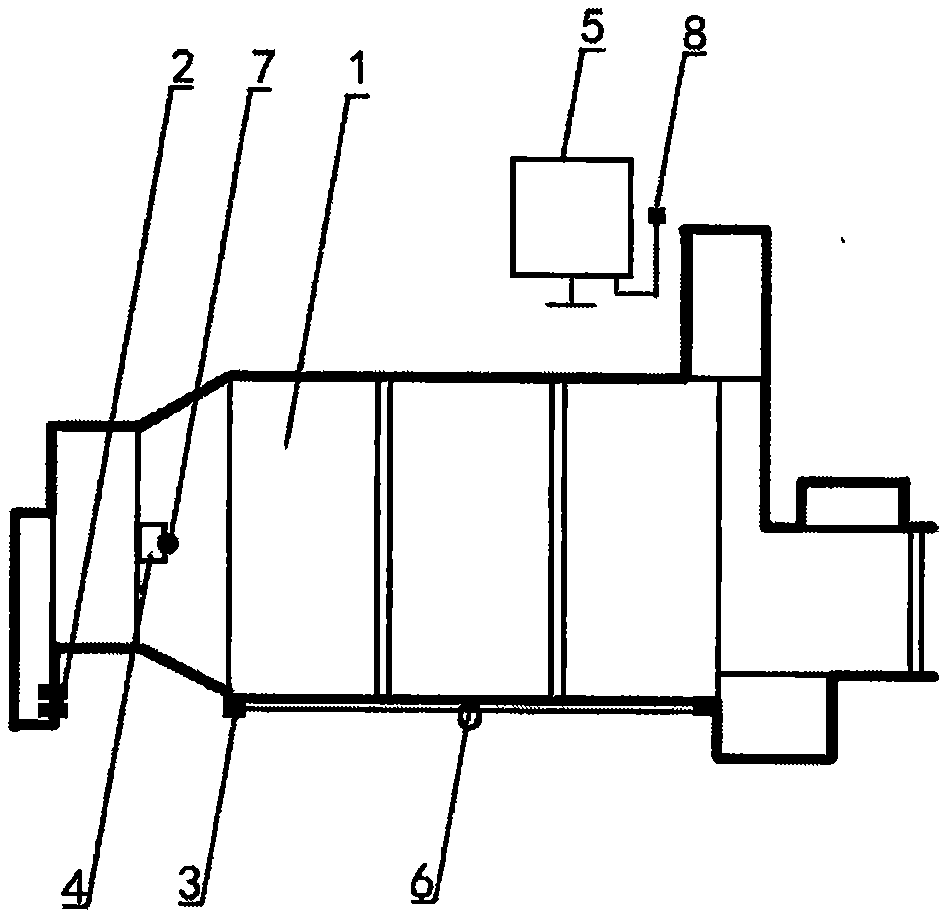

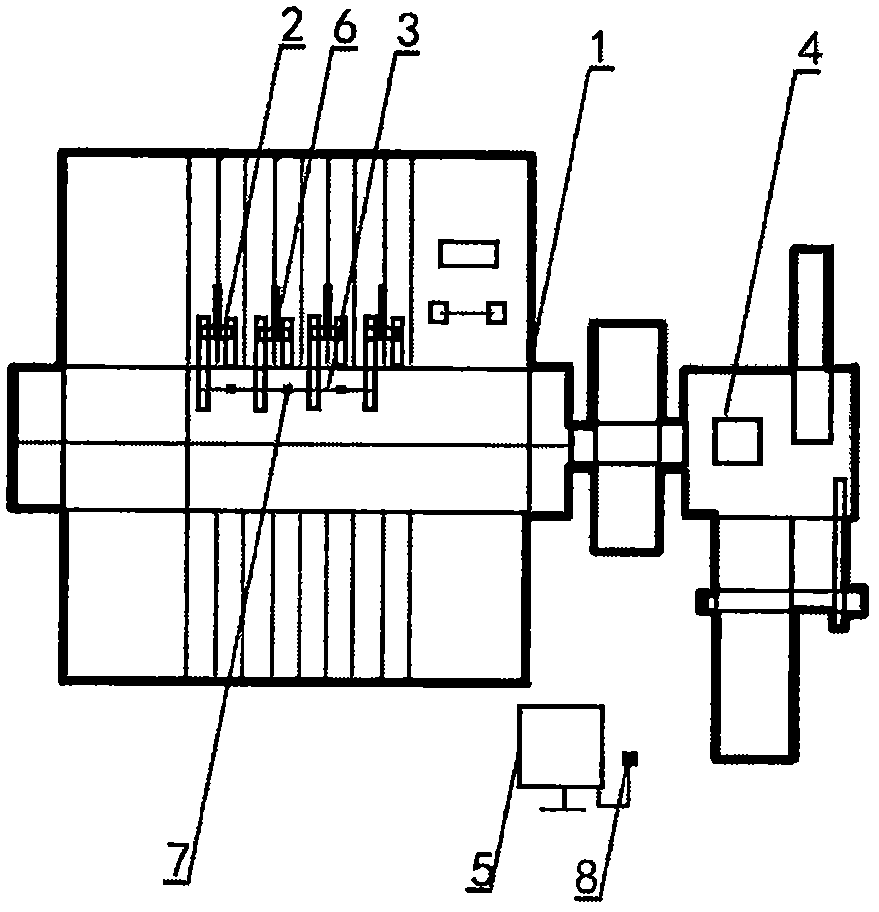

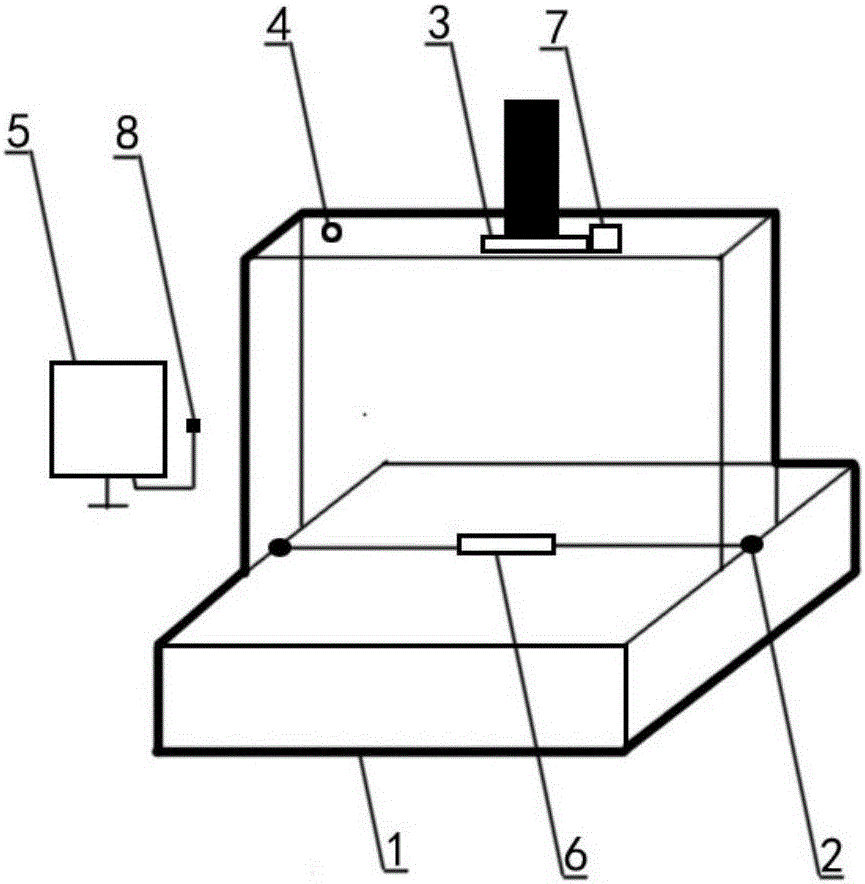

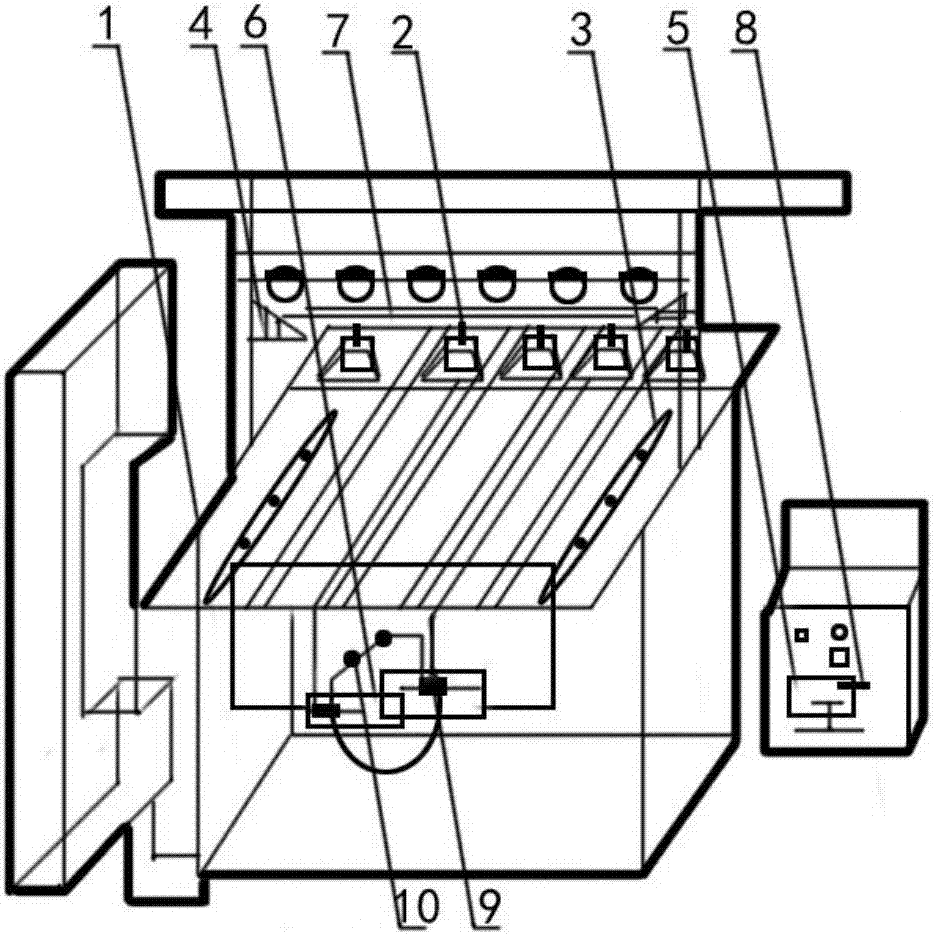

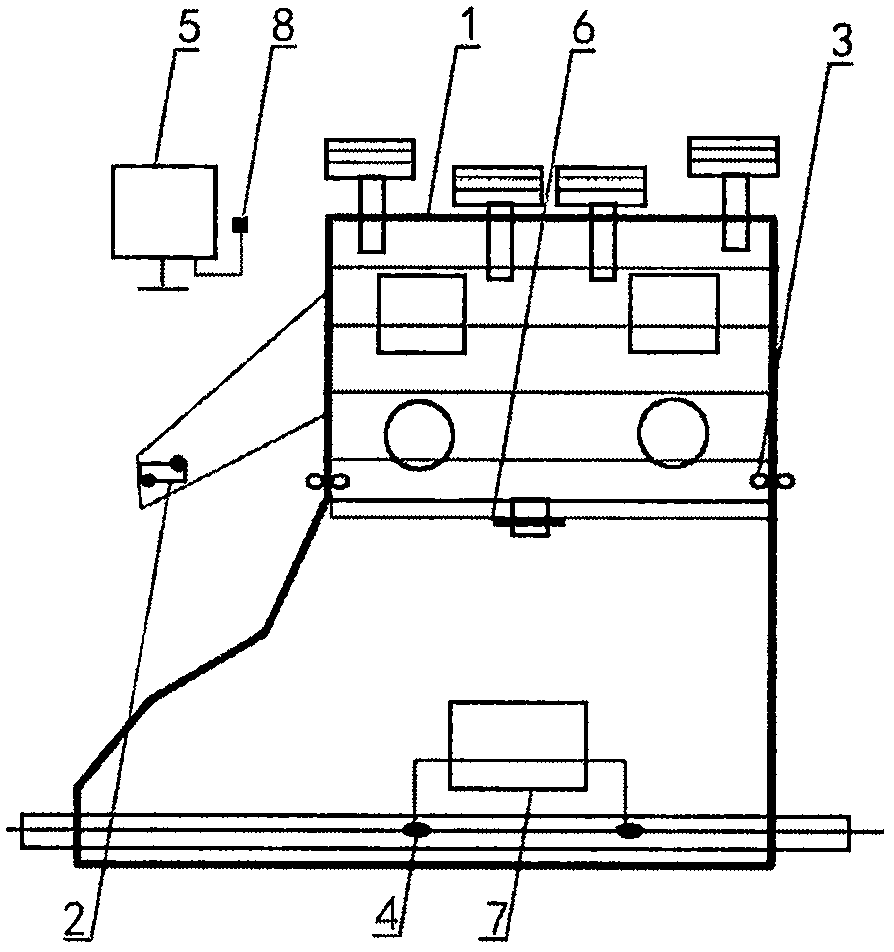

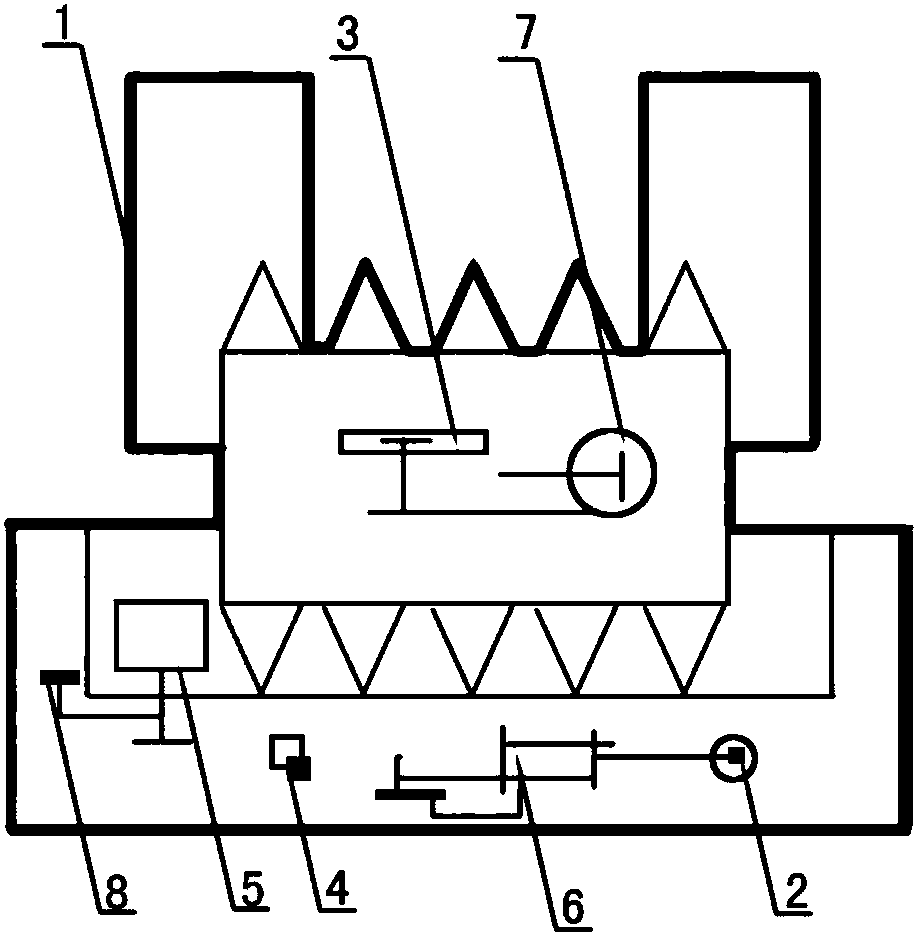

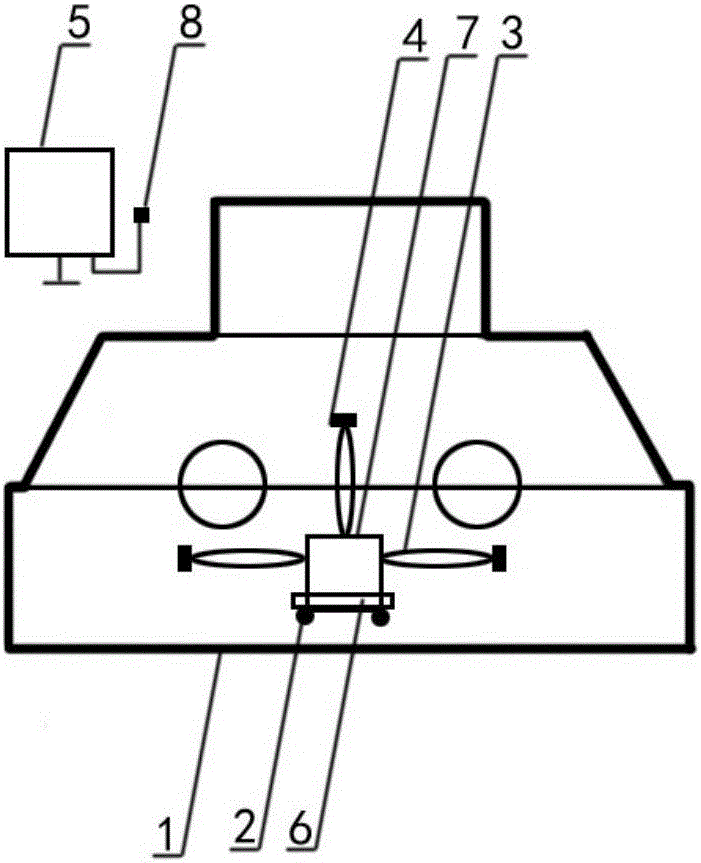

Dual-axle-center coordination assembly for installation of liner plate of high-efficiency ball mill

A high-efficiency ball mill liner installed dual-axis coordination assembly, comprising a body (1), on which a fastening sensing module (2), an information sensing module (3), an axis sensing module (4), The management module (5), when running, the fastening sensing module (2) is set on the bolt to sense the fastening condition, the information sensing module (3) is set at both ends of the grinding cylinder, and the shaft center sensing module (4) senses the double Shaft axis, the management module (5) processes comprehensive information; a displacement sensing module (6) is set on the information sensing module (3) to sense the movement of both ends of the grinding cylinder; information receiving is set on the axis sensing module (4) The module (7) receives the position of the axis of the two shafts and the displacement of the grinding cylinder; the prompt module (8) is set on the management module (5); by controlling the position of the cylinder and the condition of the axis, it avoids affecting the operation effect.

Owner:XINCHANG COUNTY YULIN STREET YUQUAN MACHINERY FACTORY

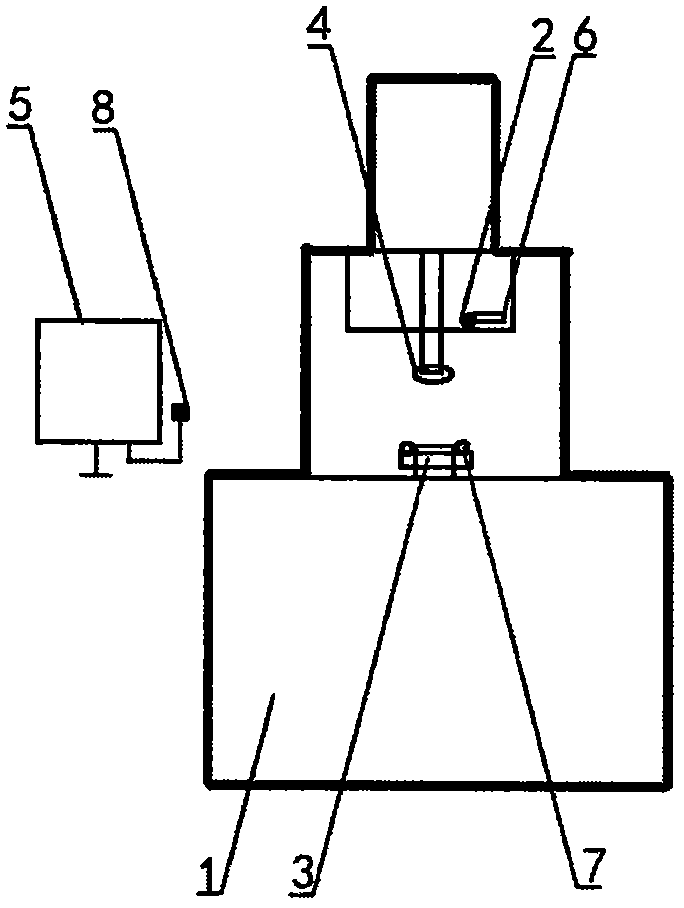

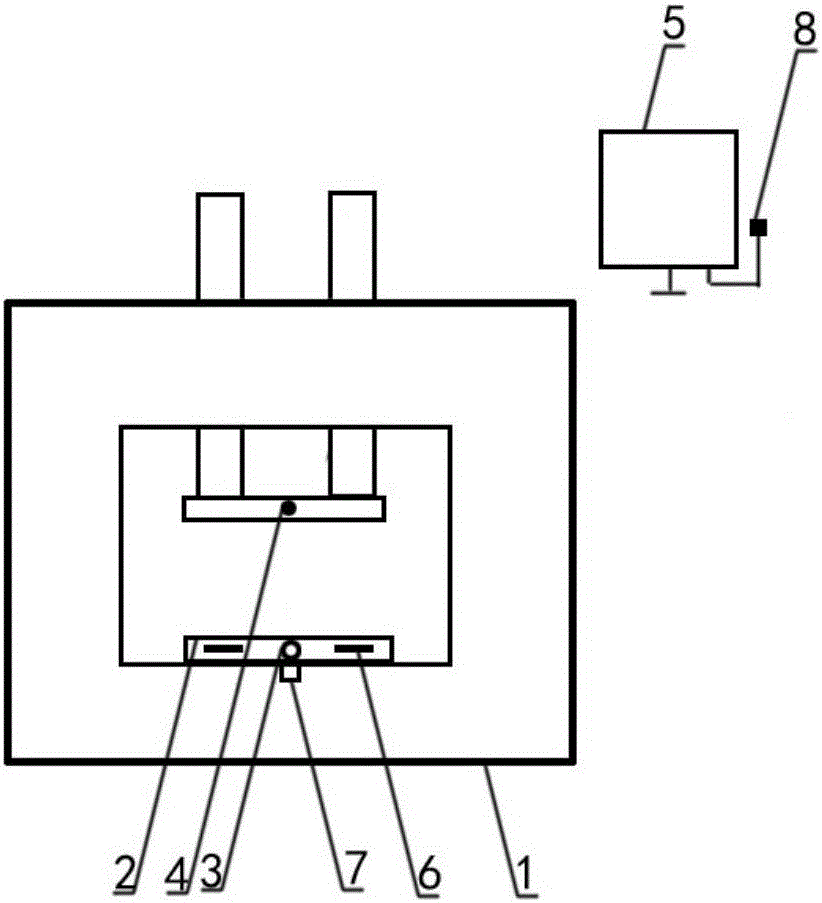

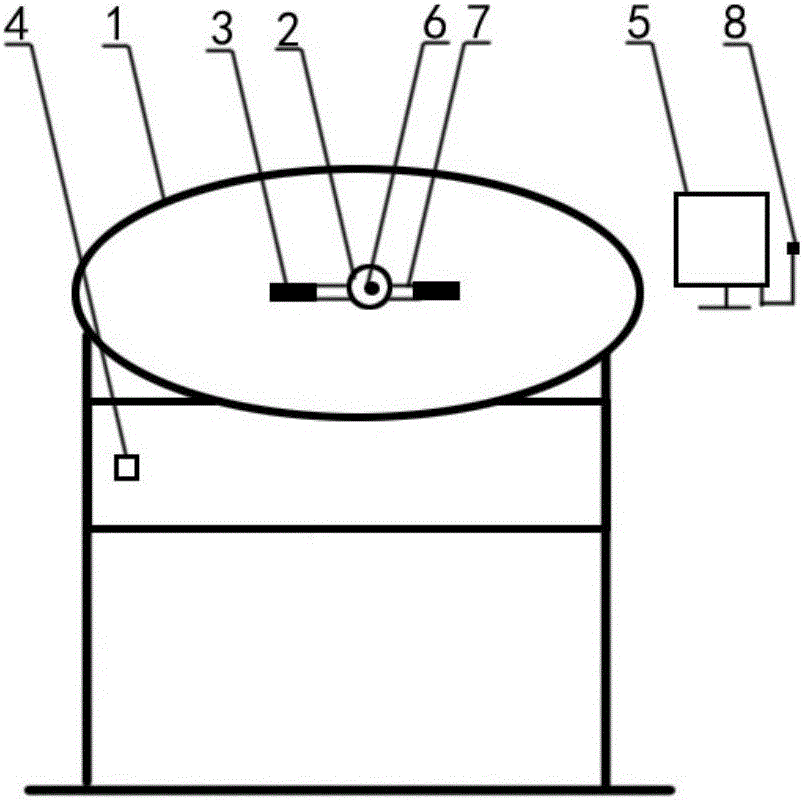

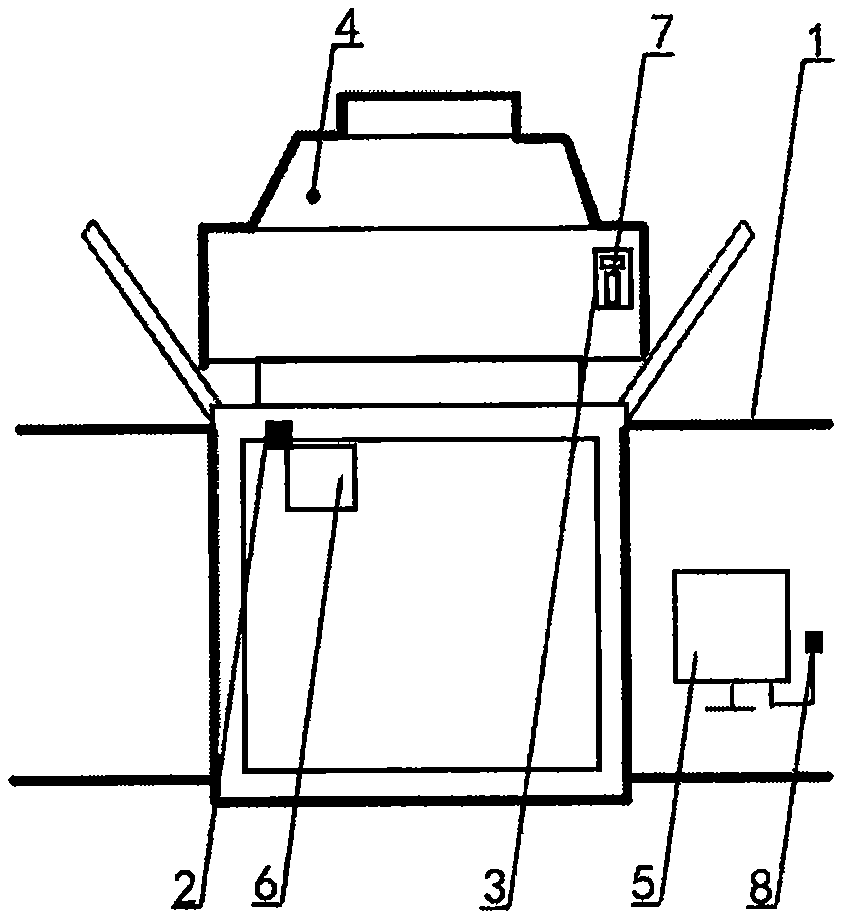

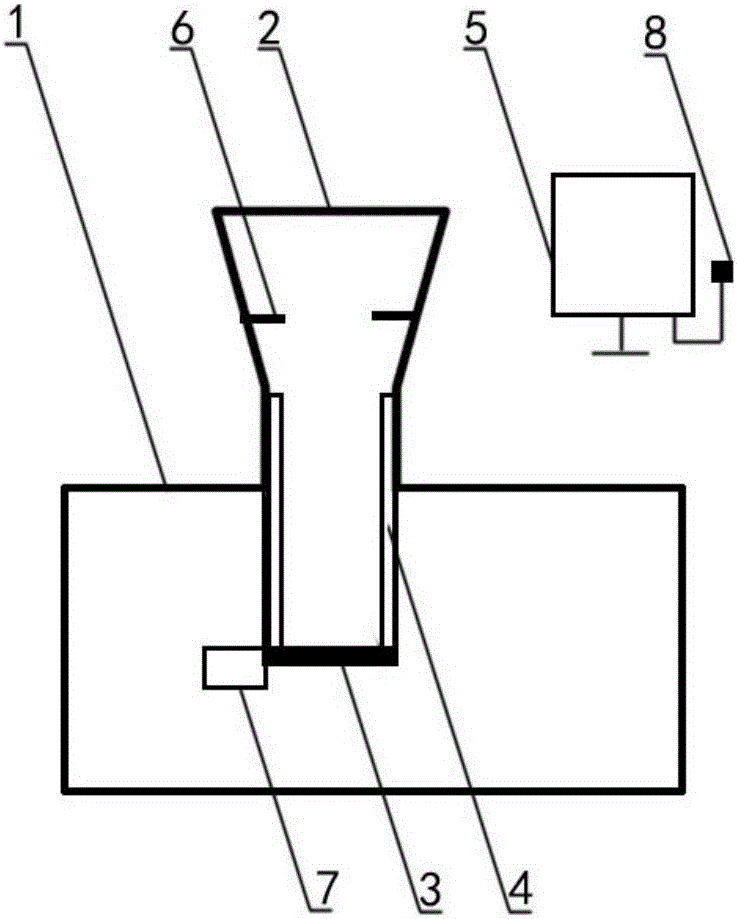

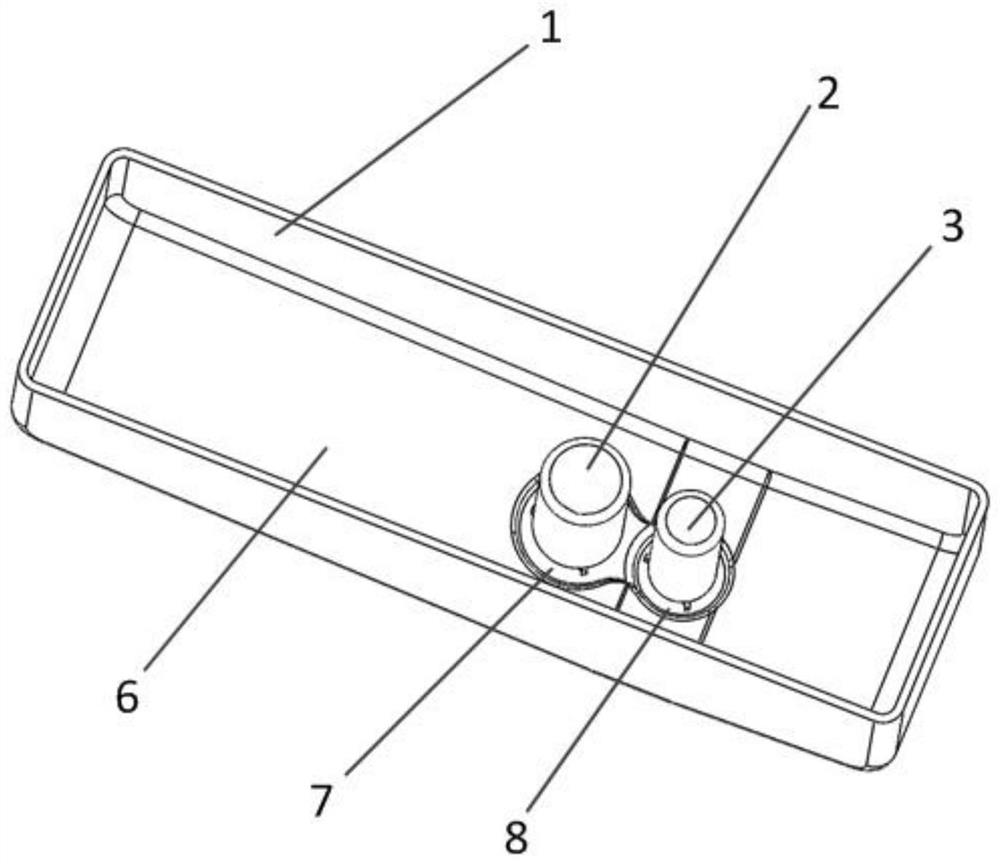

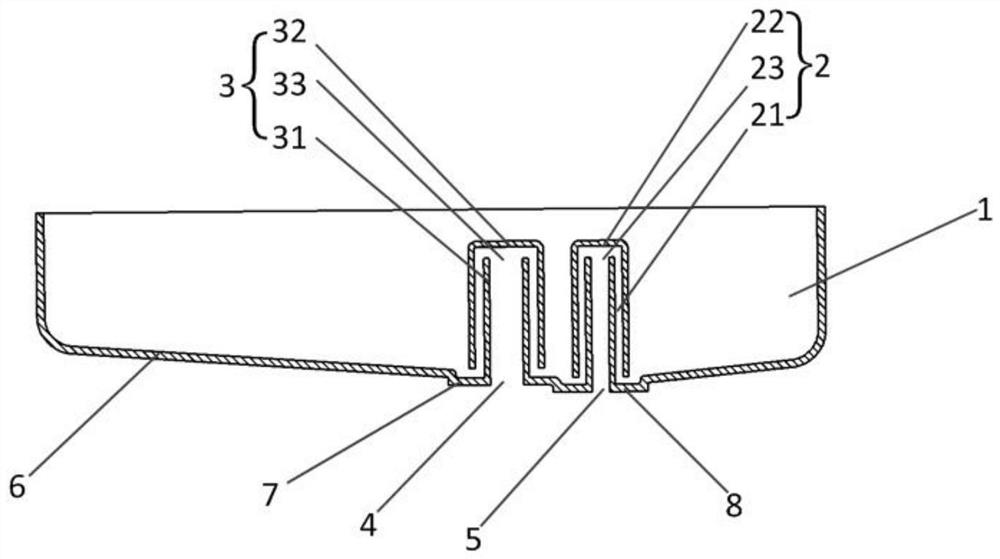

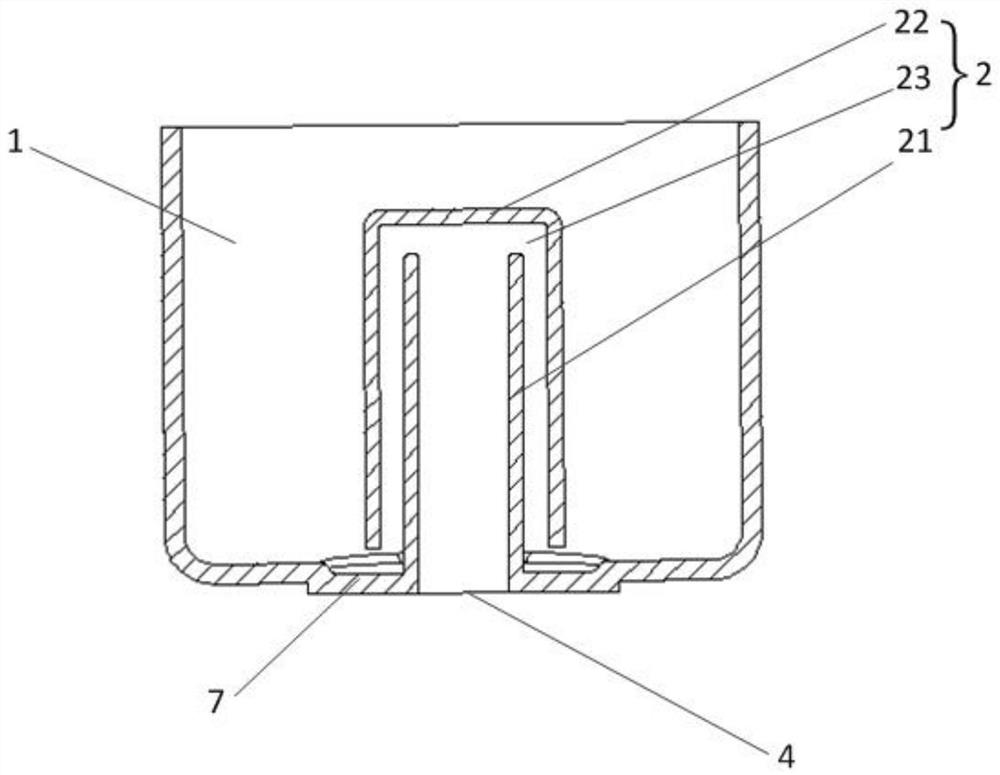

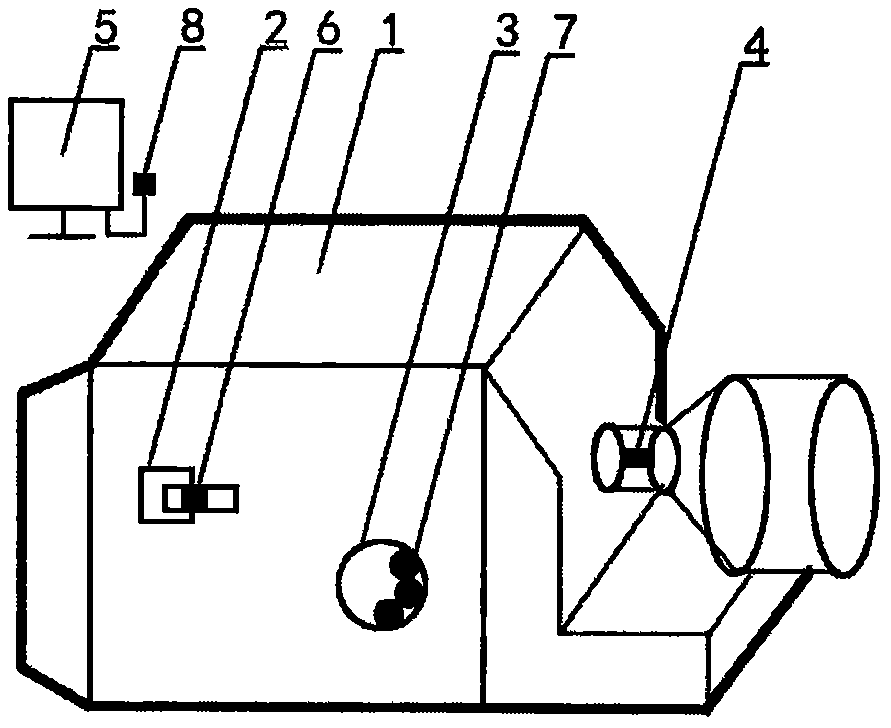

Four-column hydraulic press die center positioning and fixing auxiliary module

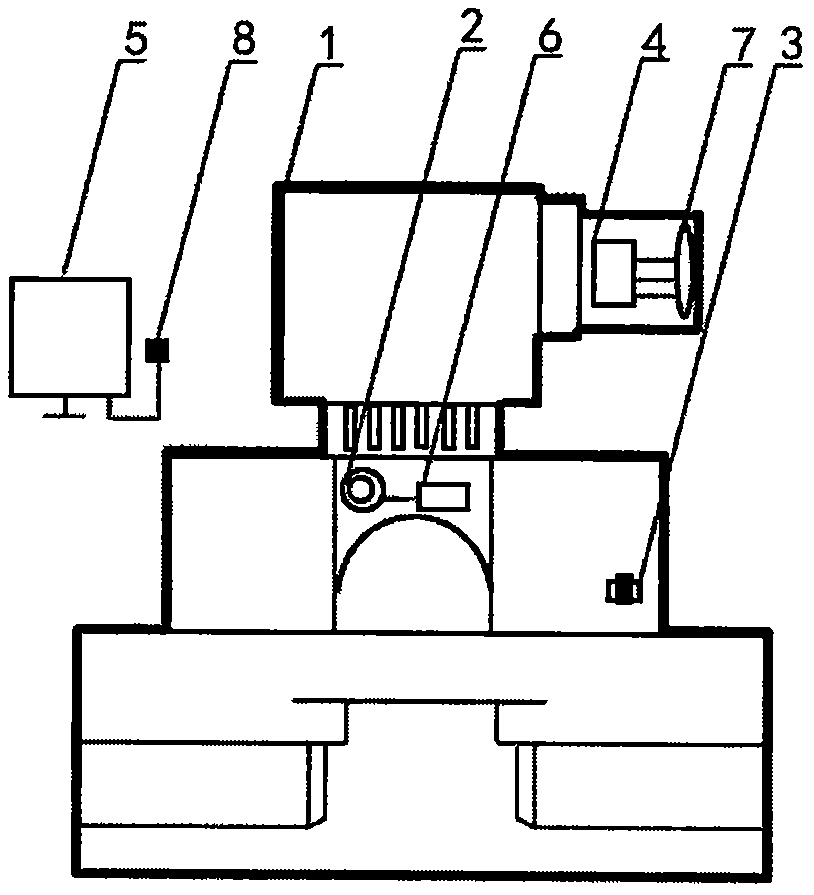

A four-column hydraulic press die center positioning and fixing auxiliary module comprises a machine body (1). A center sensing module (2), a boundary reference module (3), a ring sensing module (4) and a management module (5) are arranged on the machine body (1). During operation, the center sensing module (2) senses the center point of an upper die and the center point of a lower die; the boundary reference module (3) is arranged on the outer side of the lower die; the ring sensing module (4) is arranged on an outer layer of the upper die; and the management module (5) processes summarized information. A clearance sensing module (6) is arranged on the center sensing module (2) and senses the clearance condition around the dies. A position marking module (7) is arranged on the boundary reference module (3) and indicates and marks the sensed position of an outer layer of the lower die. A prompt module (8) is arranged on the management module (5) and sends out a prompt when it is sensedthat the centers and single layers of the dies are aligned abnormally. The operation effect is prevented from being affected by controlling the positions of the centers and the boundaries of the upper die and the lower die.

Owner:XINCHANG COUNTY JINGLING TOWN KANGLIU ELECTRONICS COMPONENT FACTORY

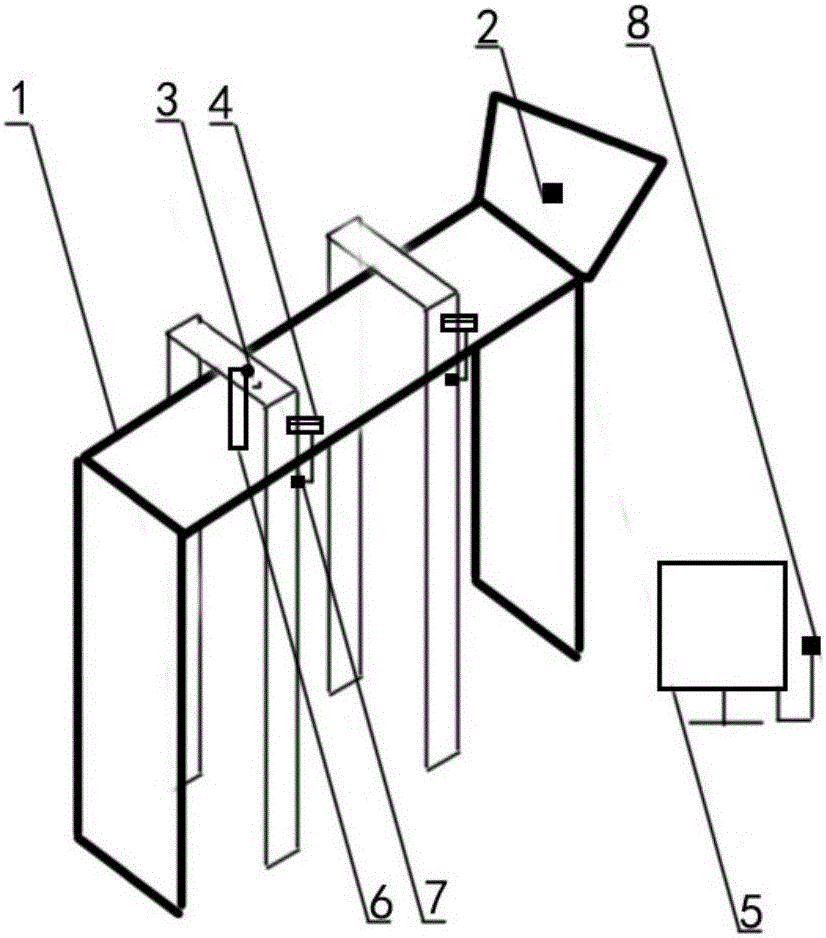

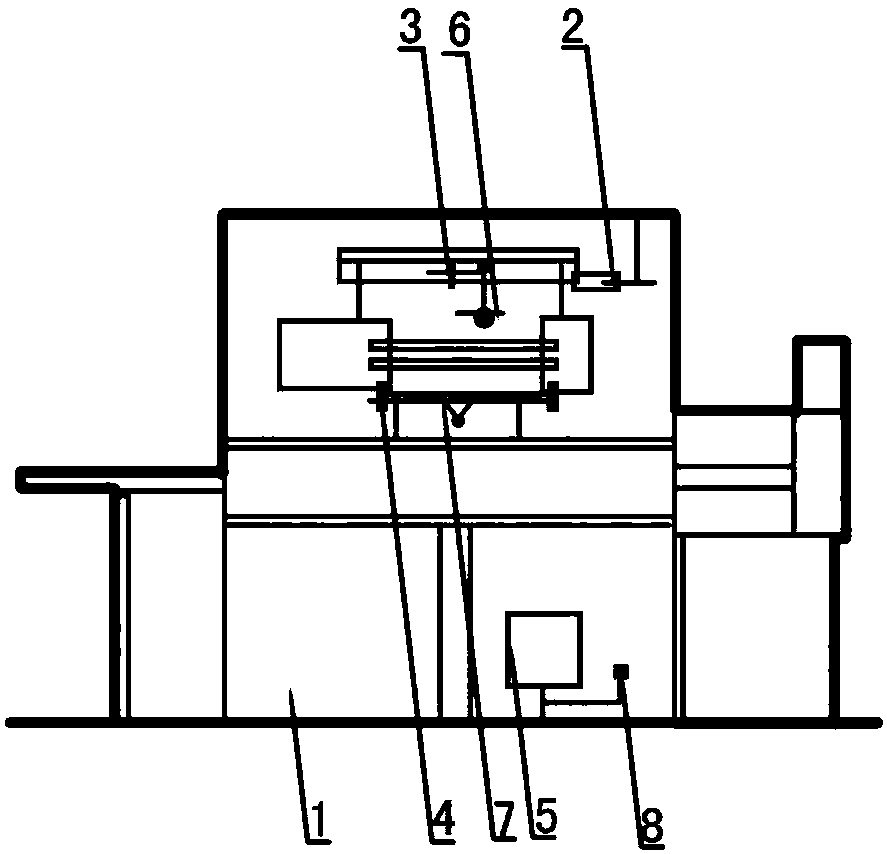

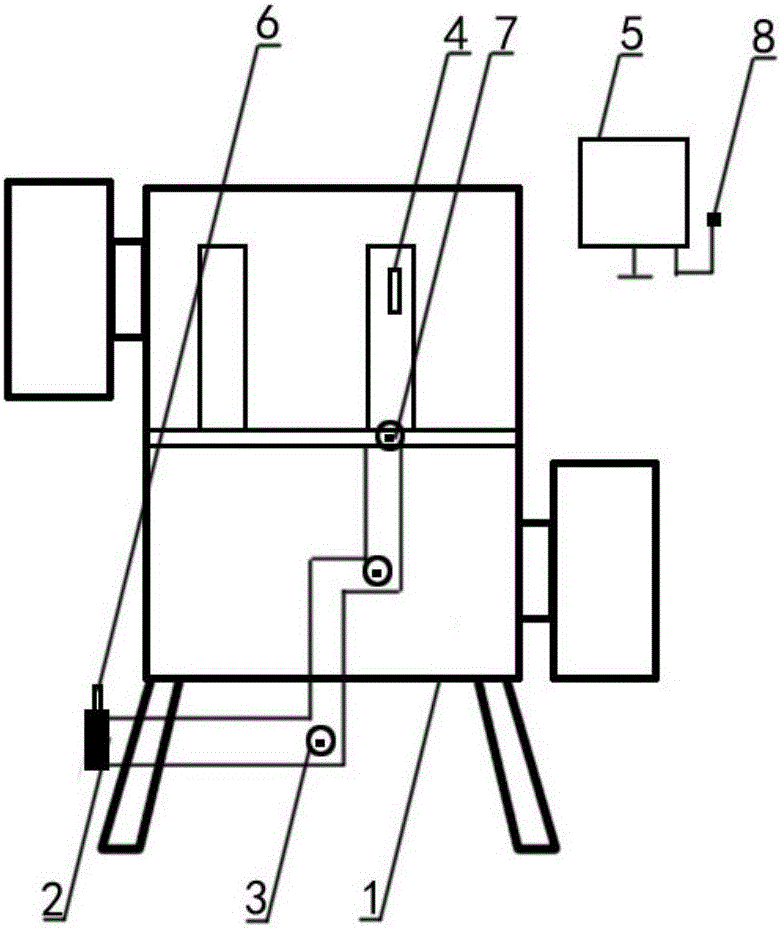

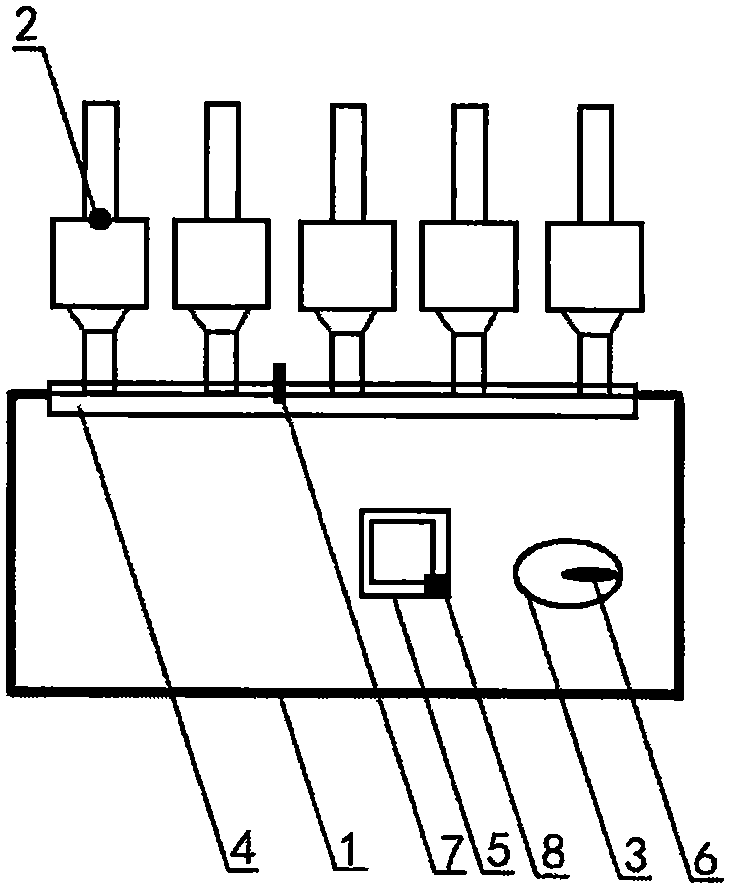

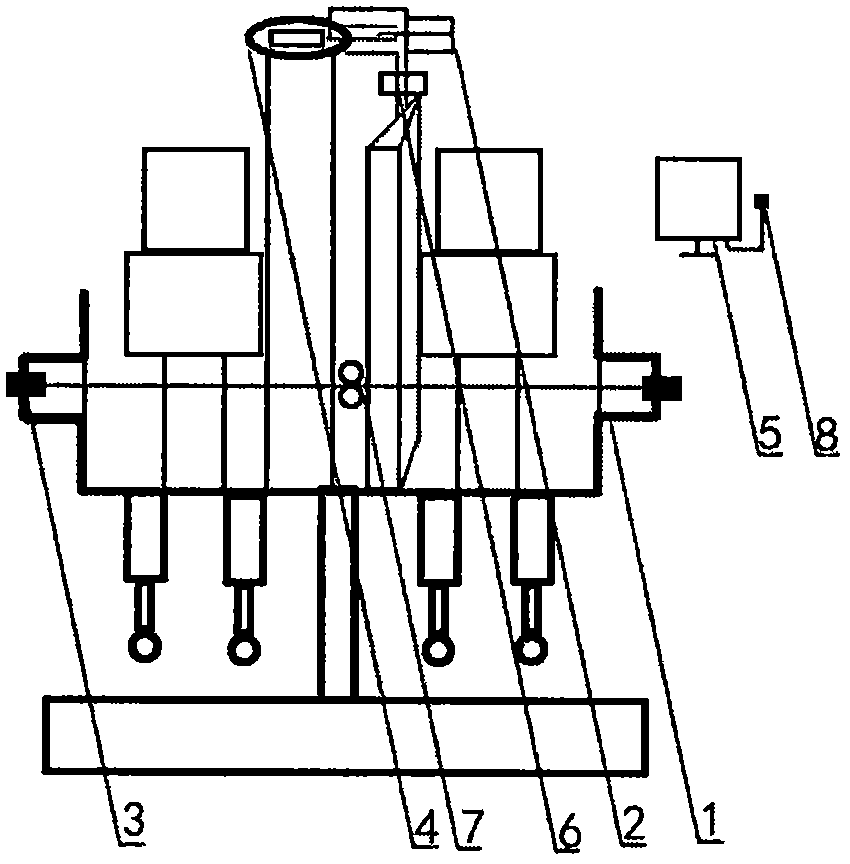

Steel tube straightening machine guiding working roll axial auxiliary device

The invention discloses a steel tube straightening machine guiding working roll axial auxiliary device which comprises a machine body (1), wherein a direction sensing module (2), a pressure sensing module (3), an axial adjustment module (4) and a management module (5) are arranged on the machine body (1); when the steel tube straightening machine guiding working roll axial auxiliary device is under operation, the direction sensing module (2) senses the position placement condition of a material; the pressure sensing module (3) senses the axial stress condition; the axial adjustment module (4) adjusts the position of a guide roll; the management module (5) deals with the comprehensive information; a setting module (6) is arranged on the pressure sensing module (3) to set a proper numerical range of pressure stressed on a guide shaft; a fixed point auxiliary module (7) is arranged on the axial adjustment module (4) to assist in fixing the guide shaft at a proper position; a prompt module (8) is arranged on the management module (5) to give out prompt when pressure or abnormal position of the guide shaft is sensed; the position of the guide roll is set according to different materials to prevent excessive pressure from affecting the operation effect.

Owner:HUAINAN YILIU MACHINERY TECH CO LTD

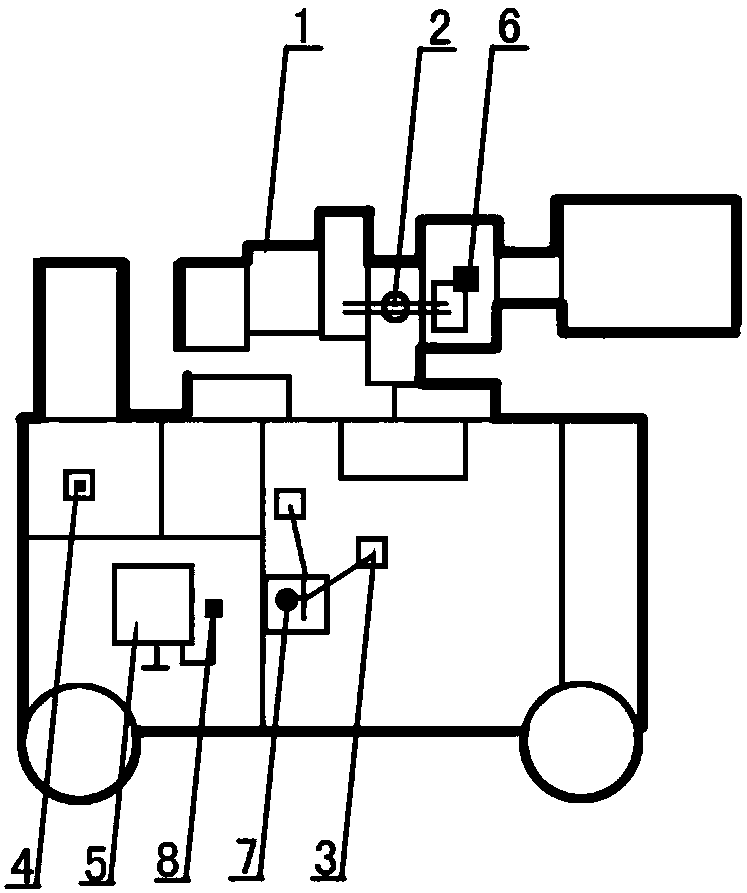

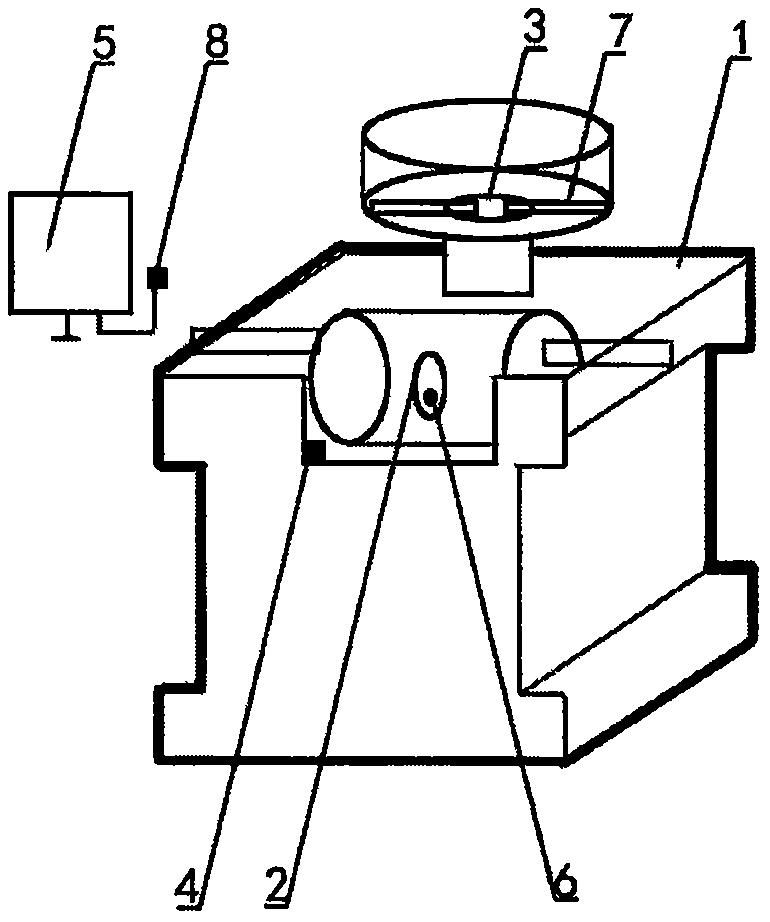

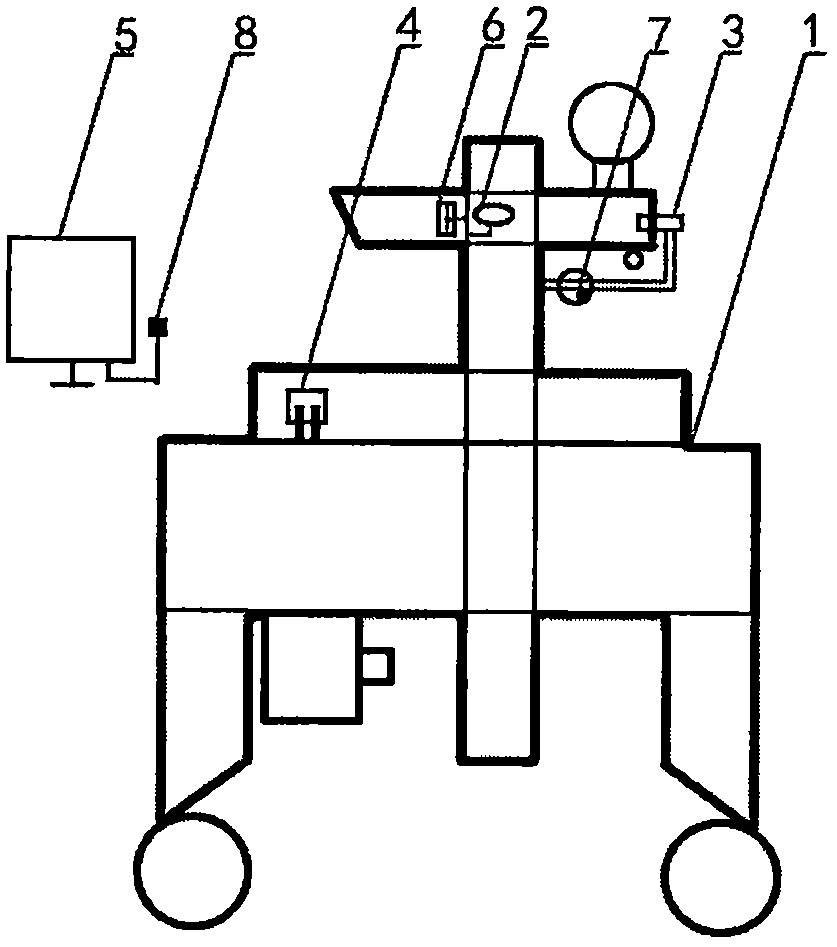

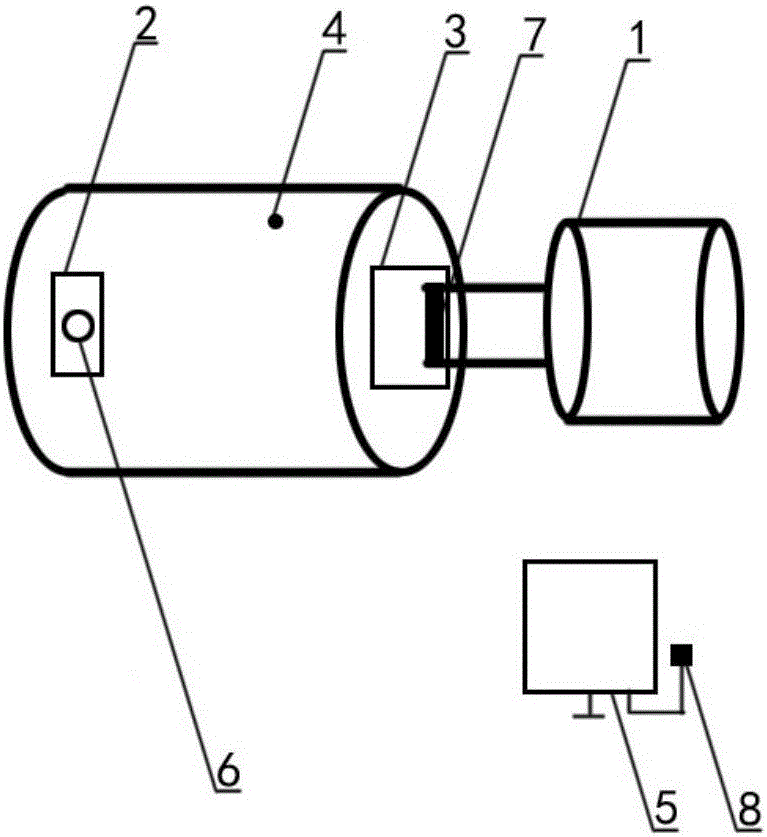

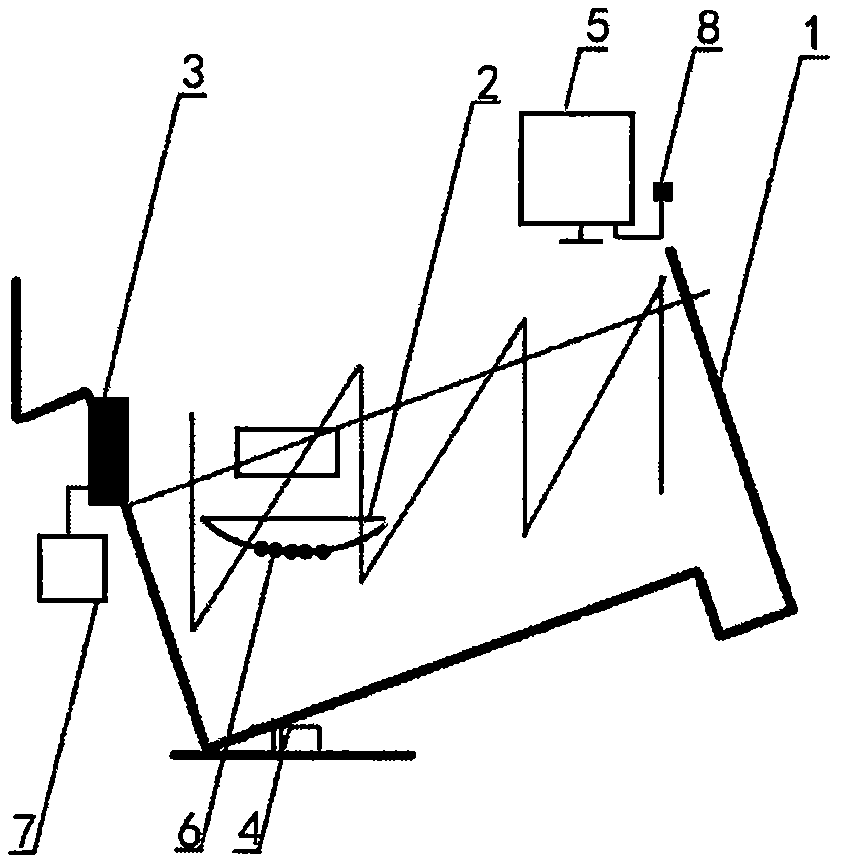

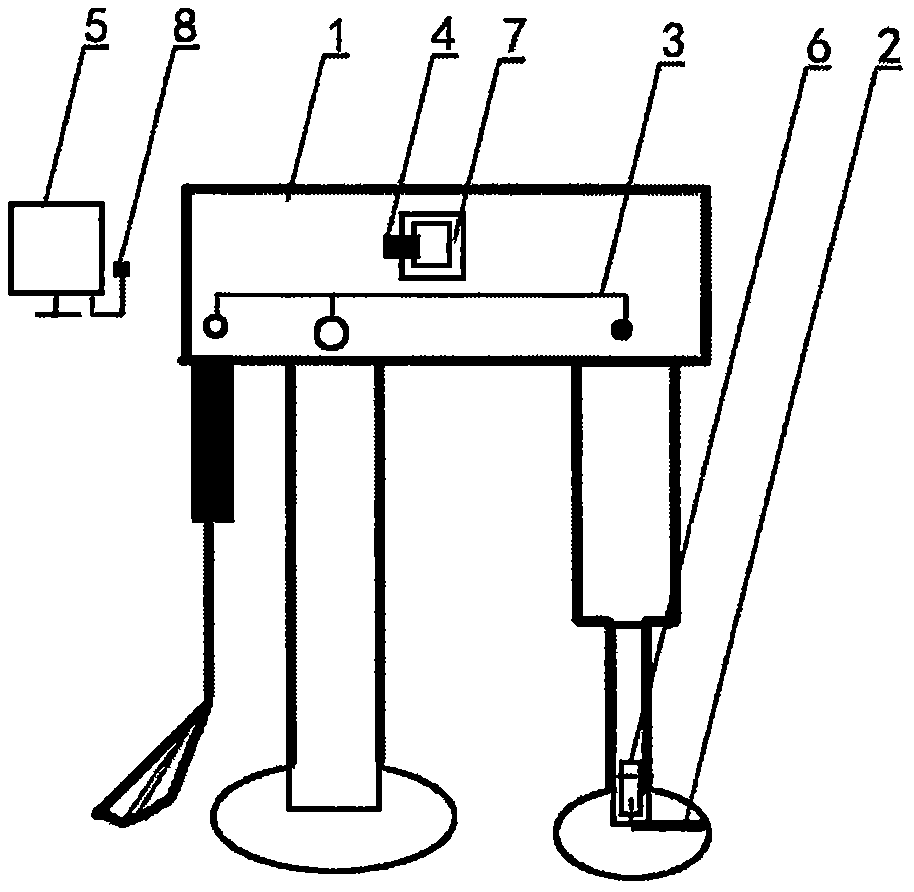

Screw-rolling machine main axle tilt speed synchronous controller

InactiveCN108052025AAvoid affecting the operation effectEasy to operateScrew-threads articlesProgramme control in sequence/logic controllersSynchronous controlComputer module

The invention provides a screw-rolling machine main axle tilt speed synchronous controller. The screw-rolling machine main axle tilt speed synchronous controller includes a body (1), wherein an anglesensing module (2), a synchronous coordination module (3), a remote communication module (4) and a management module (5) are arranged on the body (1); during the operating process, the angle sensing module (2) is arranged on a main axle part; the synchronous coordination module (3) is arranged on a rolling wheel; the remote communication module (4) transmits the sensed information to the management module (5) to process; a tilt setting module (6) is arranged on the angle sensing module (2) for setting the reasonable angle value range for deviation of the main axle; a speed sensing module (7) is arranged on the synchronous coordination module (3) for sensing the speed value changing situation when the main axle is operating; a prompt module (8) is arranged on the management module (5); andby controlling the tilt degree of the main axle to be synchronous with the rolling wheel, the screw-rolling machine main axle tilt speed synchronous controller can avoid influencing the operating effect so as to guarantee smooth operation.

Owner:XINCHANG KANGHONG MACHINERY TECH

Pressure filter pressure filtration operation double-hole-deviation filtrate control apparatus

A dual-hole deviation filtrate control device for filter press operation, including a body (1), on which a hole cloth fastening module (2), an edge sensing module (3), a filtrate indication module (4), The management module (5), during operation, the pore cloth fastening module (2) fastens the pore cloth on the cylinder wall, the edge sensing module (3) sets the filter plate to sense the position of the filter hole, and the filtrate indication module (4) indicates Filtrate turbidity, the management module (5) processes comprehensive information; a displacement sensing module (6) is set on the hole cloth fastening module (2) to sense the movement of a specific position of the hole cloth; The auxiliary module (7) assists in dismantling the induction module on the filter plate in real time; the prompt module (8) is set on the management module (5); and the operation effect is avoided by controlling the alignment of the filter plate and filter paper double holes.

Owner:求才军

Excursion-preventing calibration device for pressing operation die of oil press

The invention relates to an excursion-preventing calibration device for a pressing operation die of an oil press. The excursion-preventing calibration device comprises a device body (1), the device body (1) is provided with a zone setting module (2), an information induction module (3), an information generation module (4) and a management module (5); during running, the die placement zone scope is set by the zone setting module (2), the information induction module (3) is arranged in the center of the device body (1), the information generation module (4) is arranged on the die and induces the contact condition between the information generation module (4) and the device body (1), and the management module (5) is used for processing summarized information; a position hinting module (6) is arranged on the zone setting module (2) and used for hinting the scope of the reasonable die placement zone; an electric infrared heat release sensing module (7) is arranged on the information induction module (3) and used for sensing the movement scope of people within specific time; a prompt module (8) is arranged on the management module (5); and influences, caused by excursion of the die, on the running effect are prevented by calibrating the position of the die on the device body.

Owner:ANHUI YILIU ELECTRONICS SCI & TECH

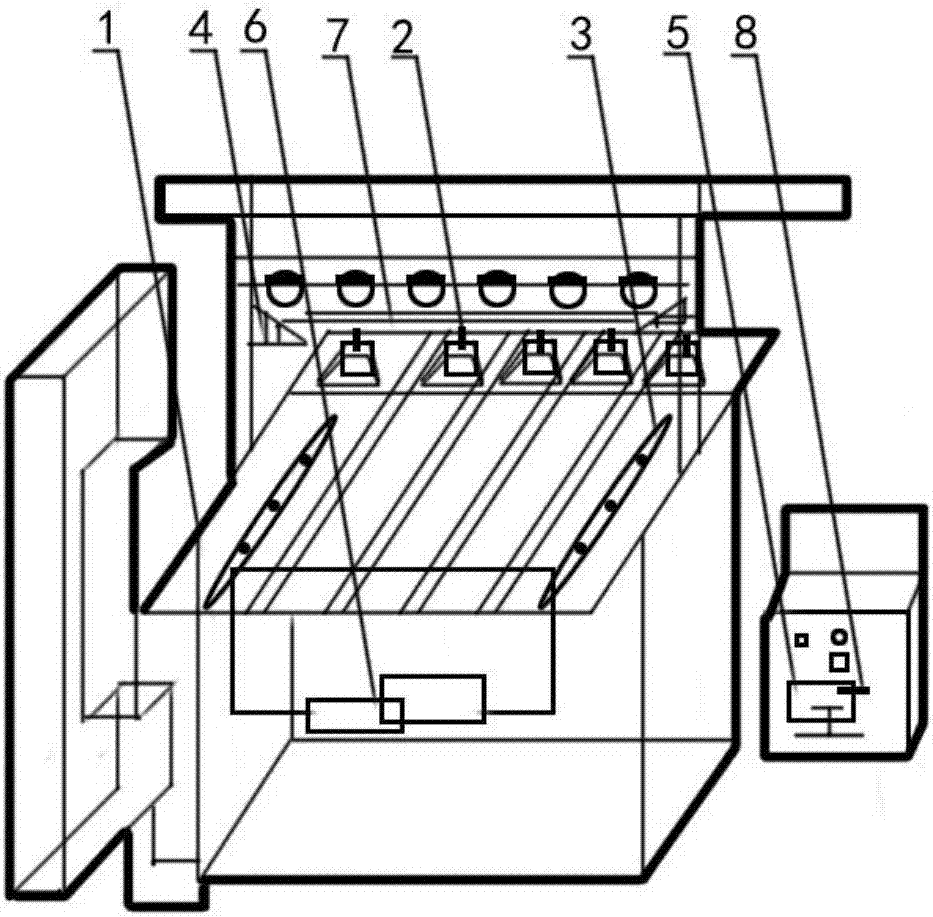

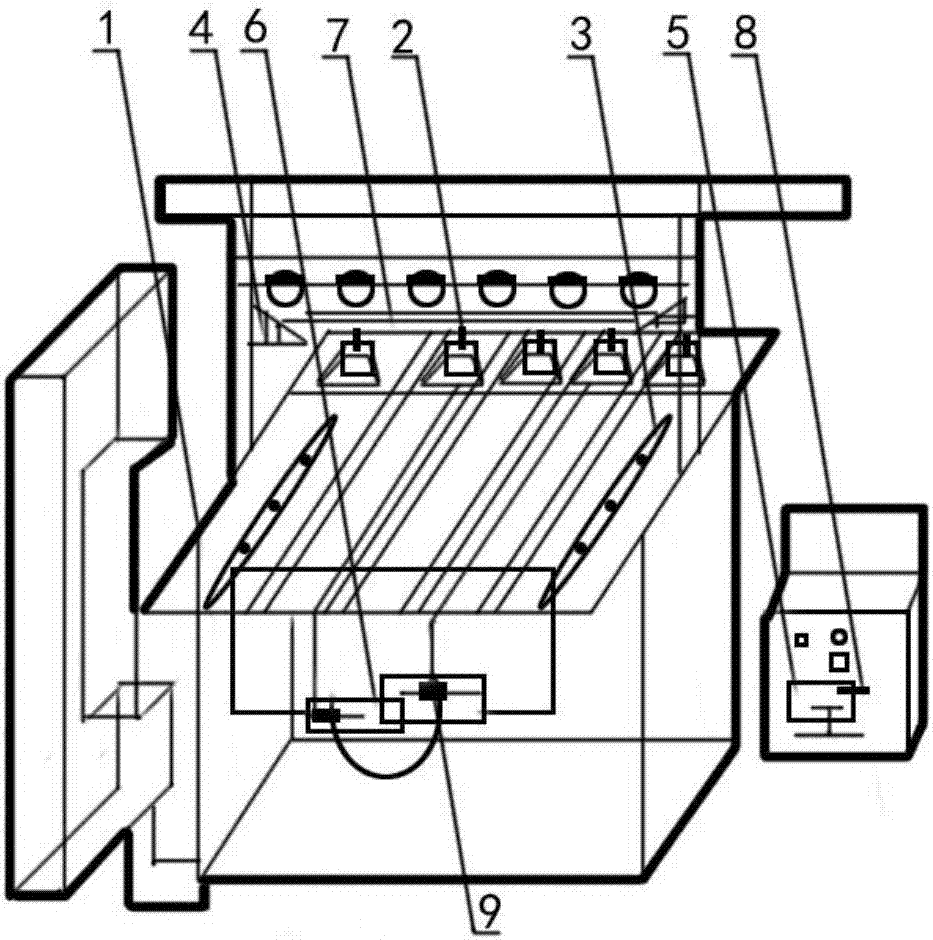

Sliding seat stroke adjusting and micro-moving auxiliary assembly for operating of screen printing machine

InactiveCN107901589AAvoid affecting the operation effectEasy to operateScreen printersEngineeringRunning time

The micro-movement auxiliary assembly for the stroke adjustment of the sliding seat in the operation of the screen printing machine includes a body (1), on which a fixed-point reference module (2), a displacement sensing module (3), a contact sensing module (4), and a management module are set (5), during operation, the fixed-point reference module (2) is set at the initial position of the sliding seat, the displacement sensing module (3) is set on the sliding seat part, the contact sensing module (4) is set on the pedal part, and the management module ( 5) Process comprehensive information; set an azimuth sensing module (6) on the displacement sensing module (3), and sense the sliding seat movement in up, down, left, and right directions in real time; set an information receiving module (7) on the contact sensing module (4), when When the displacement is abnormal, check whether the contact of the pedal parts is normal; set a prompt module (8) on the management module (5); and control the travel distance and direction of the sliding seat of the fuselage to avoid affecting the operation effect and make the operation smooth.

Owner:XINCHANG XINCHENG IND DESIGN CO LTD

Wood leftover recycling method

InactiveCN103722598AHas a softening effectPrevent rotWood treatment detailsWood impregnation detailsRoot causePulp and paper industry

The invention discloses a wood leftover recycling method which makes wood leftovers into an integral wood by the following steps to recycle the leftovers: 1, washing the leftovers clean by clear water; 2, placing the leftovers into crystal soda solution to soak; 3, washing the leftovers clean with the clear water and continuously soaking the leftovers in the clear water; 4, placing the leftovers into the crystal soda solution to soak again; 5, air-drying the leftovers; 6, placing the leftovers into the crystal soda solution to soak for the third time, boiling the crystal soda solution and continuously soaking and boiling the leftovers in the boiling crystal soda solution; 7, placing the leftovers in glue to soak to enable the surfaces of the leftovers to sufficiently adsorb the glue; 8, pressing the leftovers together to form the utilizable integral wood. Compared with the prior art, the wood leftover recycling method can sufficiently utilize the wood leftovers, implements processing recycling of the wood leftovers, is beneficial to ecological protection of valuable or rare woods, meets the market requirements and eliminates the root cause of illegal logging of logs.

Owner:XIANYOU COUNTY JINZHONG MUSICAL INSTR CO LTD

Positioning operation zone gap control module for cam slicer

InactiveCN107844063AAvoid affecting the operation effectControl using feedbackProgramme control in sequence/logic controllersMagnetic tension forceTouch Senses

A cam divider positioning operation area clearance control module, comprising a body (1), on which a contact sensing module (2), a measurement module (3), a magnetic force module (4), and a management module (5) are arranged , during operation, the contact sensing module (2) is set on the positioning work area to sense the gap between the parts, the measuring module (3) measures the gap distance, the magnetic force module (4) is set on the eccentric sleeve, and the management module (5) handles the comprehensive information; set the information receiving module (6) on the contact sensing module (2) to receive the contact condition of the parts and the value of the gap distance; set the amplitude setting module (7) on the magnetic force module (3), adjust the magnetic force according to the gap distance to drive Displacement of the eccentric sleeve; a prompt module (8) is set on the management module (5), and when an abnormality is sensed for a long time in contact with a part, a prompt is issued; by eliminating the gap in the positioning operation area, it is avoided to affect the operation effect.

Owner:XINCHANG XINCHENG IND DESIGN CO LTD

Storage fluid control module for glue outputting work of glue dispensing equipment

InactiveCN105772348AAvoid affecting the operation effectLiquid surface applicatorsCoatingsFluid controlPressure sense

The invention discloses a storage fluid control module for the glue outputting work of glue dispensing equipment. The storage fluid control module comprises a machine body (1), and a pressure sensing module (2), a valve switching sensing module (3), a remote communication module (4) and a management module (5) are arranged on the machine body (1); in the operation process, the pressure sensing module (2) senses the pressure of an air cylinder of the machine body (1) and the pressure of the air, the valve switching sensing module (3) controls the opening-closing state of a valve, and the sensed information is transmitted to the management module (5) for being processed through the remote communication module (4); the pressure sensing module (2) is provided with a pressure adjustment module (6) for adjusting the numerical value of the pressure according to the glue outputting condition; the valve switching sensing module (3) is provided with a time limiting module (7) for limiting the shortest opening time and the longest opening time of the valve; the management module (5) is provided with a reminding module (8). The glue outputting uniformity is controlled by controlling the fluid pressure and the opening time of the valve, and the operation effect is prevented from being influenced.

Owner:ANHUI HAICHENG DECHANG ELECTRONICS TECH

Workpiece mounting gravity center deviation control assembly of welding positioner

InactiveCN105880911AAvoid affecting the operation effectWelding/cutting auxillary devicesAuxillary welding devicesMarine engineeringPressure sense

A workpiece mounting gravity center deviation control assembly of a welding positioner comprises a body (1), wherein a center hinting module (2), a pressure sensing module (3), a running sensing module (4) and a management module (5) are arranged on the body (1); during running, the running sensing module (4) senses the running state of the body; the center hinting module (2) hints the center position of operation; the pressure sensing module (3) senses the condition of pressure applied to the center position; sensed information is processed by the management module (5); a contact sensing module (6) is arranged on the center hinting module (2) and senses the condition of the orientation of a part which is in contact with the center position; a balance sensing module (7) is arranged on the pressure sensing module (3); and a prompting module (8) is arranged on the management module (5), and prompts when sensing that the stress of the center is unbalanced or the position is abnormal. By controlling the conditions of orientations of the center and the gravity center of a workpiece, running efficiency is prevented from being affected.

Owner:淮南市鸿裕工业产品设计有限公司

Seat mortising machine propulsion operation saw blade direction speed harmonization component

InactiveCN106903754AAvoid affecting the operation effectGuaranteed uptimeDovetailed workCircular sawsHarmonizationEngineering

The invention provides a seat mortising machine propulsion operation saw blade direction speed harmonization component. The seat mortising machine propulsion operation saw blade direction speed harmonization component comprises a machine body (1), wherein information sensing modules (2), horizontal sensing modules (3), direction sensing modules (4) and a management module (5), wherein the information sensing modules (2) are respectively arranged at the two sides of a saw blade during operation; the horizontal sensing modules (3) are used for sensing the horizontal direction of the saw blades; the direction sensing modules (4) are used for sensing the positions of the saw blades; the management module (5) is used for processing integrated information; parallel counting modules (6) are arranged on the horizontal sensing modules (3) and are used for recording the condition of parallel positions between the saw blades; height sensing modules (7) are arranged on the direction sensing modules (4); and a reminding module (8) is arranged on the management module (5). The seat mortising machine propulsion operation saw blade direction speed harmonization component has the beneficial effects that the speed of the saw blades is adjusted by sensing the parallel positions and specific height conditions of different saw blades, so that each saw blade is pulled to an appropriate position, thereby preventing an operation effect from being affected and enabling the operation of the machine body to be smooth.

Owner:NINGXIA BAICHEN IND PROD DESIGN CO LTD

Water supply interruption and backflow prevention device for reverse-washing filter

InactiveCN105797470AAvoid affecting the operation effectFiltration separationWater flowBackflow prevention device

A water supply interruption and backflow prevention device for a reverse-washing filter comprises a machine body (1).A feed water inlet module (2), flowing water limiting modules (3), a temperature sensing module (4) and a management module (5) are arranged on the machine body (1).In the operation process, a water flow flows out of the feed water inlet module (2), the flowing water limiting modules (3) are arranged on the positions where the water flow turns or backflow is prone to occur, the temperature sensing module (4) senses the water flow temperature condition, and sensed information is treated with the management module (5); a pressure sensing module (6) is arranged on the feed water inlet module (2) to sense the pressure value condition when the water flow flows out; a flow rate sensing module (7) is arranged on each flowing water limiting module (3), and the flow rate sensing modules (7) sense water flow rate conditions of all points where the flow rate sensing modules (7) are arranged; a prompt module (8) is arranged on the management module (5).The running effect is prevented from being affected by controlling backflow of the water flow in a pipeline and maintaining a certain water flow rate in real time.

Owner:ANQING FENGBANG IND PROD DESIGN

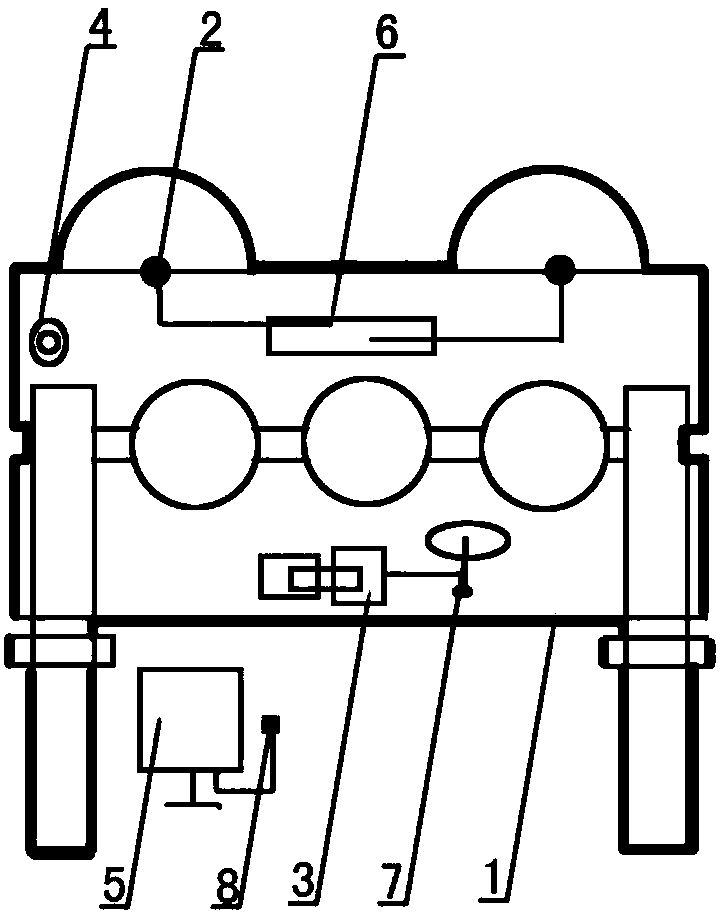

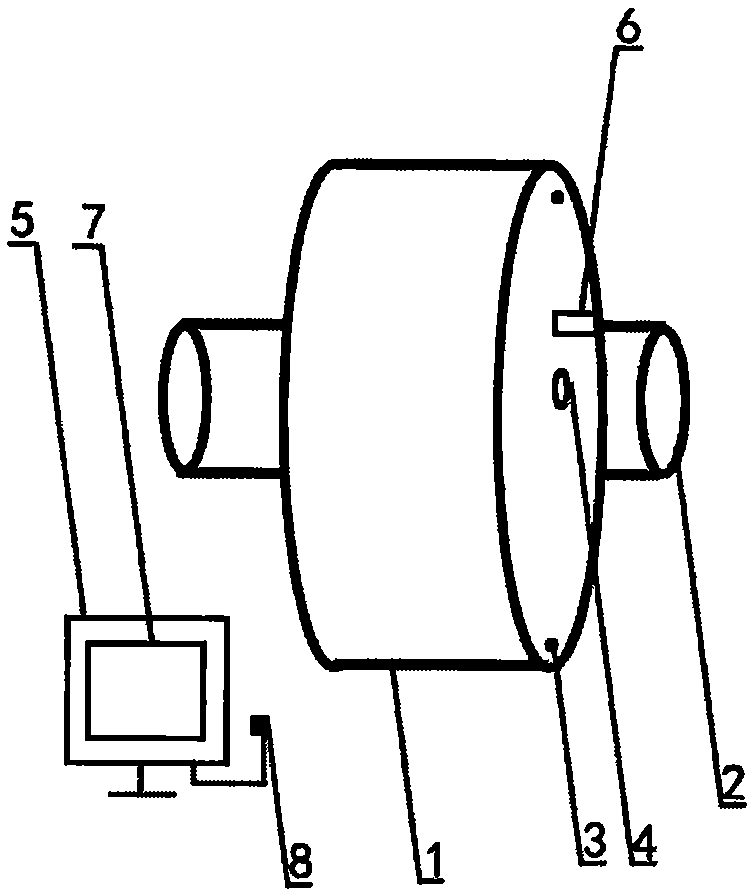

Double-disc size-coordinated control device for bench grinder

InactiveCN108032220ASmall sizeAvoid affecting the operation effectGrinding feed controlEngineeringBench grinder

The invention relates to a double-disc size-coordinated control device for a bench grinder. The device comprises a machine body (1), and an infrared sensing module (2), a numerical value reference module (3), a remote communication module (4) and a management module (5) are arranged on the machine body (1). In running, the infrared sensing module (2) is arranged on flange plates and senses the size condition of the flange plates, the numerical value reference module (3) is arranged on a grinding wheel, and the remote communication module (4) transmits sensed information to the management module (5) for processing; a double-disc comparison module (6) is arranged on the infrared sensing module (2), and whether or not the sizes of the two flange plates are identical is compared; a diameter setting module (7) is arranged on the numerical value reference module (3), and the reasonable numerical value range of the size of the grinding wheel is set according to the sizes of the flange plates;a prompt module (8) is arranged on the management module (5); by controlling the sizes of the flange plates and the grinding wheel to be reasonable, the running effect is prevented from being influenced, and operation is conducted successfully.

Owner:ZHEJIANG HAIHONG IND PROD DESIGN CO LTD

Box sealing machine nail clamping operation stroke deficiency movable adjusting module

InactiveCN107934065AAvoid affecting the operation effectWrapper twisting/gatheringLower limitOperating speed

The activity adjustment module of the case sealing machine clamping nail operation stroke is insufficient, including a body (1), and a speed sensing module (2), a displacement sensing module (3), a front buckle adjustment module (4), and a management module are arranged on the body (1) (5), during operation, the speed sensing module (2) senses the speed value of the fuselage, the displacement sensing module (3) senses the nail clip stroke, the front buckle adjustment module (4) adjusts the position of the front buckle, and the management module (5) processes comprehensive information Set the lower limit setting module (6) on the speed sensing module (2) to set the minimum value of the operating speed of the fuselage; set the information receiving module (7) on the displacement sensing module (3) to receive the sensed speed, Displacement value; a prompt module (8) is set on the management module (5), and when an abnormality in the speed or displacement is sensed, a prompt is issued; by controlling the stroke and the operating speed, the operation effect is avoided.

Owner:石秋芹

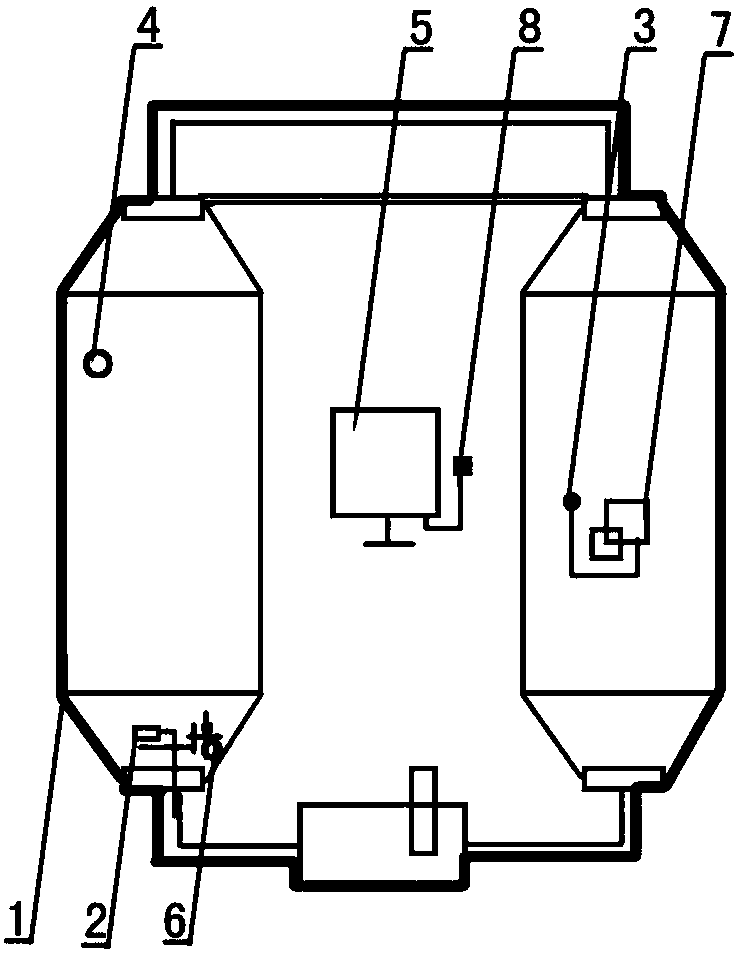

Weakening control device for silencing maintenance of adsorption drier

InactiveCN108014596AAvoid affecting the operation effectGas treatmentDispersed particle separationEngineeringDecibel

A weakening control device for silencing maintenance of an adsorption drier comprises a device body (1), wherein an exhaust test module (2), a decibel sensing module (3), a remote communication module(4) and a management module (5) are arranged on the device body (1); during operation, the exhaust test module (2) is arranged on a channel, the decibel sensing module (3) is arranged on a drier bodyto sense the noise condition, and the remote communication module (4) transmits sensed information to the management module (5) for management; a blockage sensing module (6) is arranged on the exhaust test module (2) and used for sensing whether the channel is blocked; an upper limit setting module (7) is arranged on the decibel sensing module (3) and used for setting the maximum reasonable valueof noise produced by the drier body; a prompt module (8) is arranged on the management module (5). Influence on the operation effect is avoided and parts of the drier body are maintained by controlling exhaust pressure of the drier body.

Owner:XINCHANG YULIN STREET DONGCHEN MACHINERY FACTORY

Motor stirring operation load control module for film evaporator

InactiveCN105749571AAvoid affecting the operation effectTransportation and packagingEvaporator accessoriesMarine engineeringComputer module

The invention discloses a motor stirring operation load control module for a film evaporator, which comprises a machine body (1), wherein an operation sensing module (2), a material capacity sensing module (3), a remote communication module (4) and a management module (5) are arranged on the machine body (1); during operation, the operation sensing module (2) is used for sensing the motor stirring operation situation; the material capacity sensing module (3) is used for sensing the material capacity situation; sensed information is transmitted to the management module (5) for processing through the remote communication module (4); a steering sensing module (6) for sensing the stirring direction of a motor is arranged on the operation sensing module (2); a setting module (7) for setting an appropriate material capacity range in motor stirring operation is arranged on the material capacity sensing module (3); a reminding module (8) is arranged on the management module (5). As an appropriate capacity is controlled for a loaded material, the situation that the operation effect is affected by motor stirring abnormity can be avoided.

Owner:ANQING JINHAI IND PROD DESIGN

Joint cross section overload preventing device for cold pressure welding lap joint operation

InactiveCN107627022AAvoid affecting the operation effectNon-electric welding apparatusLap jointTemperature sense

The invention provides a joint cross section overload preventing device for cold pressure welding lap joint operation. The joint cross section overload preventing device comprises a machine body (1),wherein a pressure sensing module (2), a thickness sensing module (3), a remote communication module (4) and a management module (5) are arranged on the machine body (1); during running, the pressuresensing module (2) is arranged on a joint cross section and senses the pressure condition of the joint cross section, the thickness sensing module (3) senses lap joint thickness, and sensed information is transmitted to the management module (5) through the remote communication module (4) to be processed; a display module (6) is arranged on the pressure sensing module (2) and displays and senses the pressure condition of the joint cross section of the machine body in real time; a temperature sensing module (7) is arranged on the thickness sensing module (3) and senses the temperature variationof a workpiece in the running process; and a prompt module (8) is arranged on the management module (5) and sends out a prompt when too-large temperature variation or too-large pressure variation issensed. By controlling the operation load condition of the joint cross section, the running effect is prevented from being affected by overload.

Owner:XINCHANG COUNTY CHENGTAN TOWN BONA MACHINERY PLANT

Magnetic powder clutch gland shaft concentricity auxiliary module

InactiveCN107228138AAvoid affecting the operation effectFluid clutchesMagnetic powderRotational axis

Owner:XINCHANG CHENGTAN TOWN KANGCHENG MACHINERY FITTINGS FACTORY

Hoisting overturn double-plate perpendicular auxiliary assembly of straightening machine

The invention provides a hoisting overturn double-plate perpendicularity auxiliary assembly of a straightening machine. The hoisting overturn double-plate perpendicular auxiliary assembly comprises amachine body (1). A hoisting indication module (2), information sensing modules (3), an information receiving module (4) and a management module (5) are arranged on the machine body (1). During operation, the hoisting indication module (2) indicates the hoisting operation state of the machine body. The information sensing modules (3) are arranged on the two sides of the machine body. The information receiving module (4) is arranged on a rail. The management module (5) is used for processing comprehensive information. A perpendicularity induction module (6) is arranged on the information sensing modules (3) and is used for sensing the orientation conditions of the machine body and the rail. The information receiving module (4) is provided with a range restriction module (7) used for settingthe range of a reasonable area of the machine body operating above the rail. The management module (5) is provided with a prompt module (8). The prompt module (8) is used for giving a prompt when sensing that the hoisting overturn operation orientation of the machine body is abnormal. The hoisting overturn double-plate perpendicularity auxiliary assembly prevents the influence on the operation effect by controlling the operation orientation of the machine body.

Owner:董长明

Raw material sundry hardware screening device for feeding work of film blowing machine

InactiveCN105833988AAvoid affecting the operation effectMagnetic separationMetal impuritiesEngineering

The hardware screening device for raw materials and sundries in the feeding operation of the film blowing machine includes a body (1), on which a feeding storage frame (2), an induction switch (3), a magnetic module (4), and a management module are set. (5), during operation, the raw material is placed in the feeding storage frame (2), the induction switch (3) controls its switch state, the magnetic absorption module (4) screens the metal debris in the raw material, and the management module (5) according to the specific situation Process comprehensive information; set a stirring vibration module (6) on the feed storage frame (2) to vibrate and stir the raw materials, so that the metal debris in it is fully screened; set a timing module (7) on the sensor switch (3), according to the vibration Stirring operation is used to set the closing time of the switch; a prompt module (8) is set on the management module (5), and when it is sensed that the metal debris in the debris has not been screened in time, a prompt is issued; the raw material is vibrated and stirred to screen the metal debris to avoid affecting the operation effect.

Owner:安徽科信伟德机电产品设计有限公司

Collating machine gripper spring hanging pillar movable sleeve contact control module

InactiveCN107628454AAvoid affecting the operation effectArticle feedersSheet bindingPull forceEngineering

The invention discloses a collating machine gripper spring hanging pillar movable sleeve contact control module which comprises a machine body (1). Tension induction modules (2), an operation induction module (3), a touch induction module (4) and a management module (5) are arranged on the machine body (1). During operation, the tension induction modules (2) induct the part tension value, the operation induction module (3) inducts the operation condition of the machine body, the touch induction module (4) inducts the touch condition of a movable sleeve, and the management module (5) processescomprehensive information. A replacement indicating module (6) is arranged on the operation induction module (3), and the time for part replacement is indicated according to the operation condition. An infrared measuring module (7) is arranged on the touch induction module (4) to measure the lengths of the movable sleeve in all directions. A prompting module (8) is arranged on the management module (5) and is used for conducting prompting when contact or tension is inducted to be abnormal. Due to the fact that the tension and contact condition among parts is inducted, the machine body is prevented from being damaged, and the operation effect is prevented from being affected.

Owner:XINCHANG HONGYU IND PROD DESIGN

Overflow weir regulating device based on settling zone of high weir spiral classifier

InactiveCN107866330AAvoid affecting the operation effectWet separationInformation processingComputer module

The high weir type spiral classifier is based on the overflow weir adjustment device in the sedimentation area, including a body (1), on which is set a fine particle sieve module (2), a height adjustment module (3), and a height indication module (4) , the management module (5), during operation, the particle fine screening module (2) sieves the materials that have completed the operation, the height adjustment module (3) adjusts the height of the overflow weir, the height indication module (4) indicates the original height of the sedimentation area, and the management module (5) Process comprehensive information; install a vibration module (6) on the particle fine sieve module (2), and vibrate to assist in screening material particles; set an amplitude setting module (7) on the height adjustment module (3), adjust according to the material particles Increase or decrease the range of height; a prompt module (8) is set on the management module (5), and when abnormal particle size or height is sensed, a prompt is issued; by controlling the height of the overflow weir, it is avoided to affect the operation effect.

Owner:XINCHANG COUNTY DONGMING TOWNSHIP DECHUANG MACHINERY PLANT

Liquid feeding device and clothes treatment equipment

PendingCN112831993ASpeed up emissionsNot easy to cleanOther washing machinesTextiles and paperSiphonProcess engineering

The invention belongs to the technical field of liquid feeding, and aims to solve the problems that residual liquid is not easy to clean and feeding is insufficient due to the fact that relatively more liquid is left after feeding of an existing liquid feeding device is completed. Therefore, the invention provides a liquid feeding device and clothes treatment equipment. The liquid feeding device comprises a feeding box, a first siphon mechanism and a second siphon mechanism; a first liquid outlet and a second liquid outlet are formed in the bottom of the feeding box; the first siphon mechanism is arranged in the feeding box and enables the interior of the feeding box to communicate with the first liquid outlet; the second siphon mechanism is arranged in the feeding box and enables the interior of the feeding box to communicate with the second liquid outlet; the inner bottom wall of the feeding box is arranged in a non-planar mode; and the arrangement position of the first liquid outlet is higher than that of the second liquid outlet. The amount of residual liquid in the feeding device after siphoning can be reduced, the situation that the feeding device is not easy to clean due to excessive residual liquid is avoided, and meanwhile the preset liquid is fed as much as possible.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Uniform adjusting device for stress in overturning of milling drum of milling machine

InactiveCN108035227AEven by forceAvoid affecting the operation effectRoads maintainenceTransmissionStress sensingEngineering

The invention discloses a uniform adjusting device for the stress in overturning of a milling drum of a milling machine. The uniform adjusting device comprises a machine body (1), wherein the machinebody (1) is provided with an overturning sensing module (2), a stress sensing module (3), a remote communication module (4) and a management module (5); in operation, the overturning sensing module (2) is arranged at the middle position of the machine body; the stress sensing module (3) is arranged on the milling surface; the remote communication module (4) transmits sensed information to the management module (5) for processing; a grounding indication module (6) for sensing the condition of the position contacting with the ground when in overturning operation of the machine body; the stress sensing module (3) is provided with a stress buffering module (7) for buffering the pressure on parts when sensing overlarge stress; the management module (5) is provided with a prompting module (8). The uniform adjusting device disclosed by the invention has the beneficial effects that by reasonable overturning control and balanced stress, the influence on the operation effect is avoided, so thatthe operation is smooth.

Owner:XINCHANG COUNTY JINGLING TOWN LINGKANG MACHINERY FACTORY

Movable chassis plane impurity screening device of chain crusher

The invention discloses a movable chassis plane impurity screening device of a chain crusher. The device comprises a machine body (1); a bottom wheel moving module (2), a dust sucking module (3), a contact induction module (4) and a management module (5) are arranged on the machine body (1); when the device is operated, the bottom wheel moving module (2) drives the machine body to move on a chassis, the dust sucking module (3) removes dust on the chassis, the contact induction module (4) induces the contact condition between the machine body and impurities on the chassis, and the management module (5) processes general information; a path setting module (6) is arranged on the bottom wheel moving module (2) for setting moving path and area of the machine body; an impurity storage module (7) is arranged on the dust sucking module (3) for absorbing and storing the dust and the impurities on the chassis; and a prompt module (8) is arranged on the management module (5). The device removes the dust and screens the impurities on the plane of the chassis to prevent influence on the operation effect.

Owner:ANHUI HAICHENG DECHANG ELECTRONICS TECH

Material-mixing-based operation coordination device for horizontal mixer

InactiveCN107837753AAvoid affecting the operation effectTransportation and packagingMixer accessoriesLiquid ratioProcess engineering

The invention provides a material-mixing-based operation coordination device for a horizontal mixer. The material-mixing-based operation coordination device comprises a body (1), wherein a mixing degree sensing module (2), an operation sensing module (3), a liquid spray adjustment module (4) and a management module (5) are arranged on the body (1). During operation of the device, the mixing degreesensing module (2) senses the solid-liquid ratio of a material; the operation sensing module (3) senses the operation program of the body; the liquid spray adjustment module (4) adjusts the amplitudeof liquid spraying operation; the management module (5) processes comprehensive information; a time setting module (6) is arranged on the mixing degree sensing module (2) and used for setting operation time according to the mixing degree of the material; an operation indicating module (7) is mounted on the operation sensing module (3) and used for indicating the current operation state of the body; and a prompting module (8) is mounted on the management module (5). According to the invention, the operation programs of the body are coordinated according to the mixing degree of the material soas to avoid influence on operation effect.

Owner:XINCHANG DONGMING BAOYU MACHINERY FACTORY

Auxiliary assembly for rolled cap rotating rolled head of hand-held cap screwing machine

InactiveCN107934871AAvoid affecting the operation effectCapsThreaded caps applicationSetting timeEngineering

An auxiliary assembly for capping and rotating rolling head of a hand-held capping machine, comprising a body (1), on which a workpiece feeding module (2), a rotation adjustment module (3), and a test feedback module (4) are arranged , the management module (5), during operation, the workpiece feeding module (2) continuously drives the workpiece to move, the rotation adjustment module (3) adjusts the rotation of the operating handle, the test feedback module (4) feedbacks the operation effect of the workpiece, and the management module (5) processes Comprehensive information; a timing module (6) is set on the workpiece feeding module (2) to set the time for the workpiece to stay in the fuselage; a pressure sensing module (7) is set on the rotation adjustment module (3) to sense its impact on the workpiece The change value of the applied pressure; the prompt module (8) is set on the management module (5), and when the force on the workpiece is sensed or the feedback effect is abnormal, a prompt is issued; the tightness of the capping head is controlled to avoid affecting the operation effect.

Owner:董幼兰

Fixed-point adjusting device for reference part of dispersion diameter of disperser

InactiveCN107837751AAvoid affecting the operation effectTransportation and packagingMixer accessoriesReal time displayComputer science

The invention provides a fixed-point adjusting device for the reference part of the dispersion diameter of a disperser. The fixed-point adjusting device comprises a body (1), wherein the body (1) is provided with a reference setting module (2), a fixed point reference module (3), a measurement module (4) and a management module (5). During operation of the fixed-point adjusting device, the reference setting module (2) sets the unit length of the dispersion diameter; the fixed point reference module (3) uses each point as a fixed point for reference; the measurement module (4) measures height in each direction; and the management module (5) processes general information; a deviation setting module (6) is arranged on the reference setting module (2) and is used for setting the length deviation ranges of other components according to a unit diameter; a display module (7) is mounted on the measurement module (4) and displays the length values of other parts measured in real time; and a prompting module (8) is installed on the management module (5) and issues a prompt when abnormality in the length of the body is sensed. The fixed-point adjusting device can control the length of other parts according to diameter length, so influence on operation effect can be avoided.

Owner:XINCHANG DONGMING BAOYU MACHINERY FACTORY

Exhaust and mould-closing control device for abnormal material intake of hollow extrusion blower

The control device for abnormal exhaust and mold closing of hollow extrusion blowing machine includes a body (1), on which a gas sensing module (2), a noise sensing module (3), a pressure sensing module (4), a management Module (5), during operation, the gas sensing module (2) senses the gas content, the noise sensing module (3) senses the decibel value inside the fuselage, the pressure sensing module (4) senses the force value, and the management module (5) processes the comprehensive Information; a timing module (6) is set on the gas sensing module (2) to set the change of gas within a certain period of time in the fuselage; a display module (7) is set on the pressure sensing module (4) to display the sensed pressure in real time Numerical value; a prompting module (8) is set on the management module (5); the prompting module (8) sends prompts in the form of sound or LED display; by controlling the exhaust and mold closing conditions, it is avoided to affect the operation effect.

Owner:XINCHANG CHENGTAN DADONG MACHINERY FACTORY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com