Seat mortising machine propulsion operation saw blade direction speed harmonization component

A technology of tenon and groove machine and saw blade, which is applied in the field of tenon and groove machine, can solve the problems of low processing precision, high processing efficiency and low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

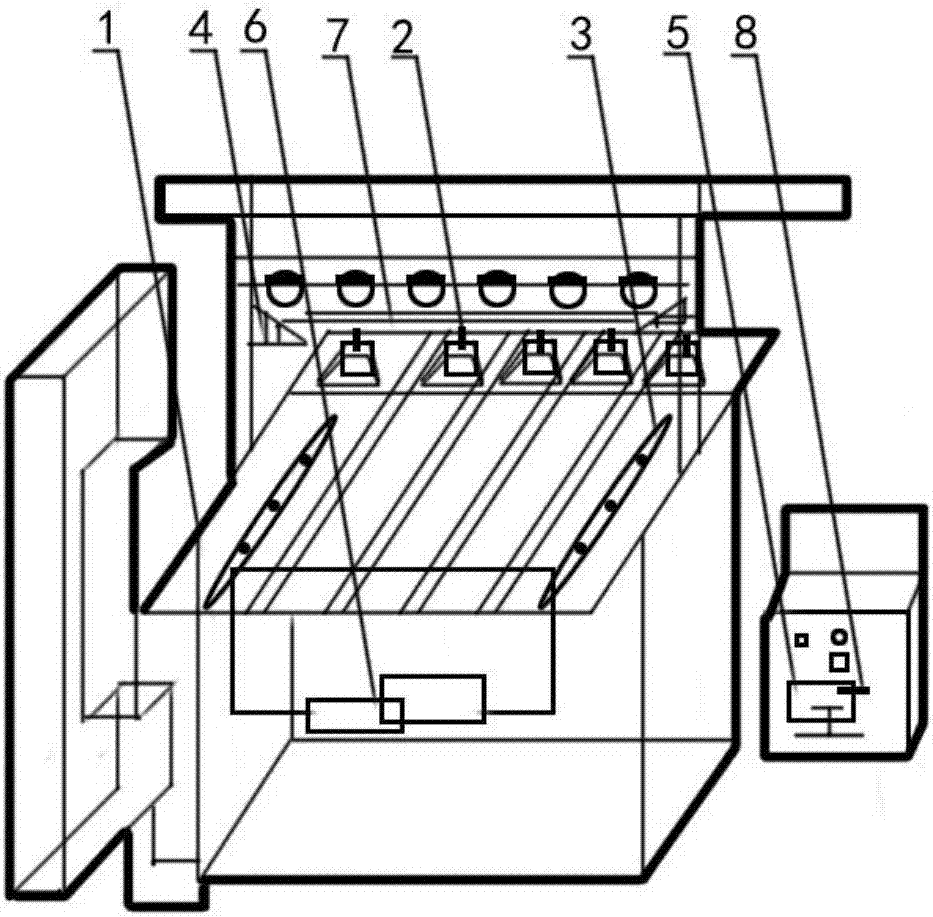

[0016] Embodiment 1: as attached figure 1 shown. The tenon and groove machine propulsion operation saw blade direction speed coordination component includes a body (1), on which an information sensing module (2), a level sensing module (3), an orientation sensing module (4), and a management module are set (5), during operation, the information sensing module (2) is respectively arranged on both sides of the saw blade, the horizontal sensing module (3) senses the horizontal direction of the saw blade, the azimuth sensing module (4) senses the position of the saw blade, and the management module (5) Process aggregated information.

[0017] The tenon and groove machine advances and operates the saw blade direction speed coordination component. A parallel counting module (6) is installed on the horizontal sensing module (3) to record the parallel position between the saw blades during the operation process of the fuselage or in a static state, including The maximum and minimum ...

Embodiment 2

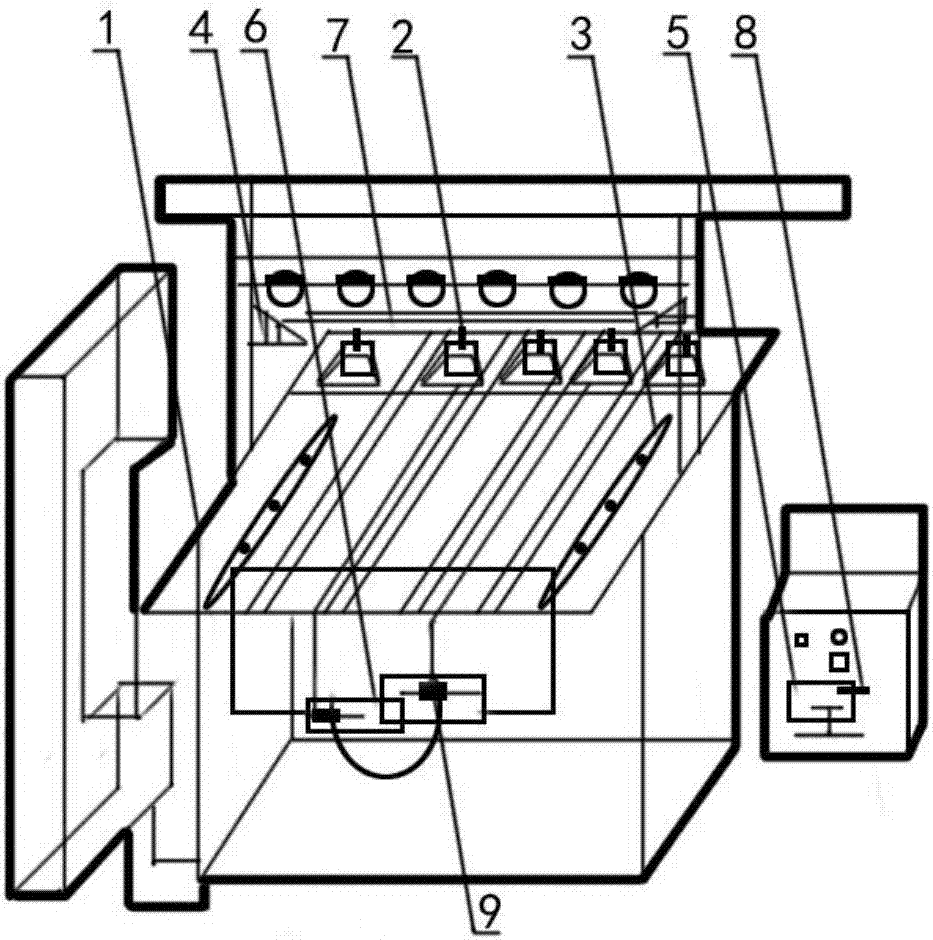

[0021] Embodiment 2: as attached figure 2 shown. The difference from Embodiment 1 is that a power-up module (9) is added to the parallel counting module (6). When the number of saw blades in parallel positions is less than two, the power-up module (9) is activated and adjusted nearby. The relative saw blade position or its travel speed.

Embodiment 3

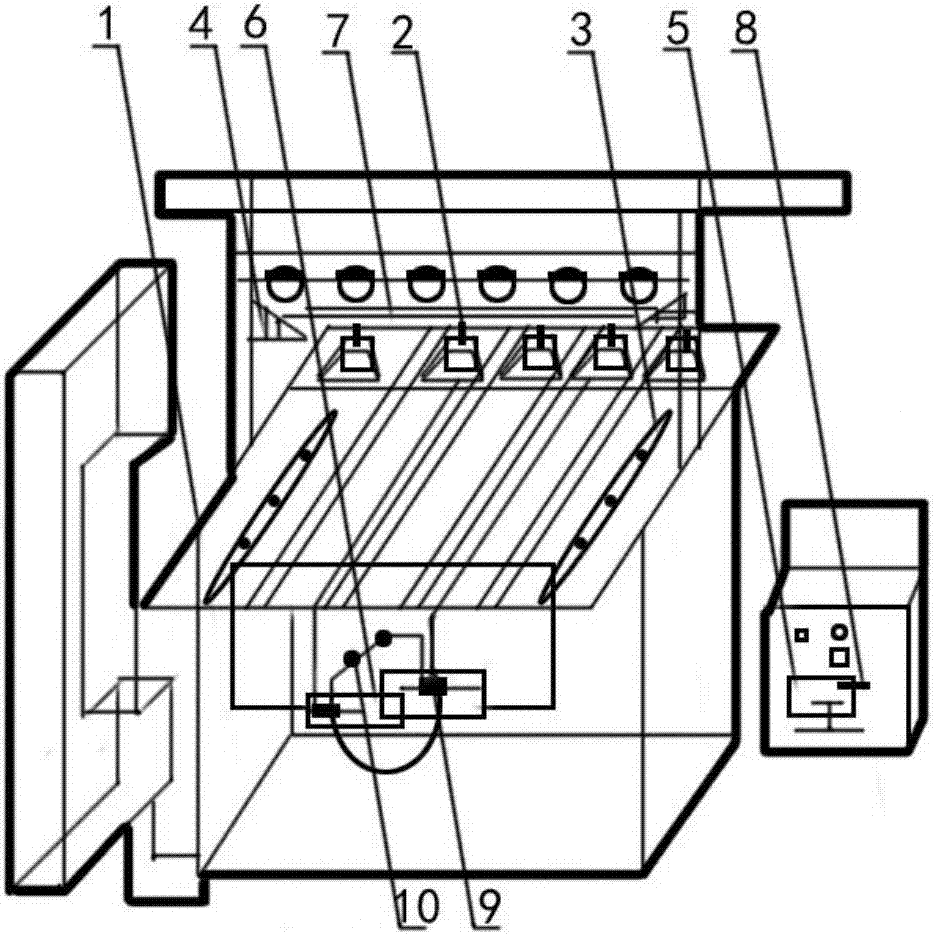

[0022] Embodiment 3: as attached image 3 shown. The difference from Embodiments 1 and 2 is that an amplitude adjustment module (10) is added to the power pulling module (9). According to the different positions of the saw blade, an appropriate power amplitude is selected to adjust the position of the saw blade or the pulling speed .

[0023] The above-mentioned tongue and groove machine advances and operates the speed coordination component of the saw blade direction. By sensing the parallel positions and specific heights of different saw blades, the speed of the saw blades is adjusted, and each saw blade is pulled to a suitable position to avoid affecting the operation effect and make the machine run smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com