Joint cross section overload preventing device for cold pressure welding lap joint operation

A technology of cold-pressed welding and cross-section, applied in the field of cold-pressed welding, can solve problems such as poor operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

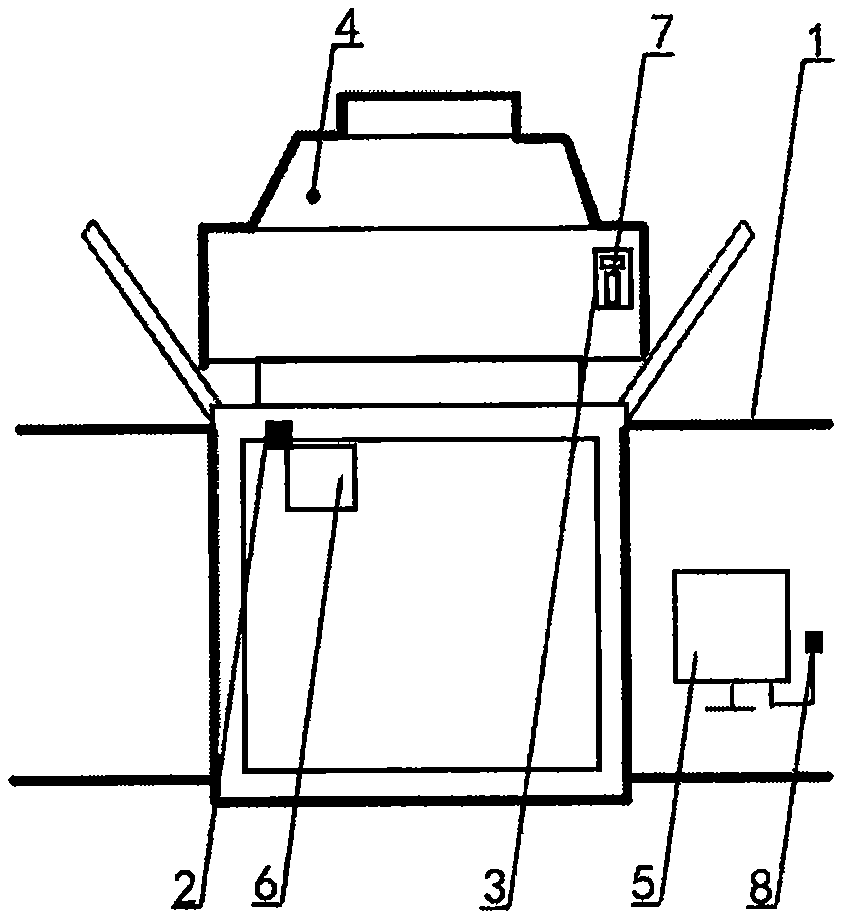

[0012] Embodiment: as shown in the accompanying drawing. The device for preventing overloading of the connection section of the cold-press welding tower includes a body (1), on which a pressure sensing module (2), a thickness sensing module (3), a remote communication module (4), and a management module ( 5), during operation, the pressure sensing module (2) is set on the connection surface to sense the pressure, the thickness sensing module (3) senses the thickness of the tower connection, and the sensed information is transmitted to the management module ( 5) Processing.

[0013] The overload prevention device for the connection section of the cold-press welding tower is provided with a display module (6) on the pressure sensing module (2) to display the pressure situation of the connection section of the induction fuselage in real time.

[0014] The overload prevention device for the connection section of the cold-press welding tower welding operation is provided with a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com