Four-column hydraulic press die center positioning and fixing auxiliary module

A mold center and auxiliary module technology, applied in the field of four-column hydraulic presses, can solve problems such as poor operation, influence, and misalignment of mold centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

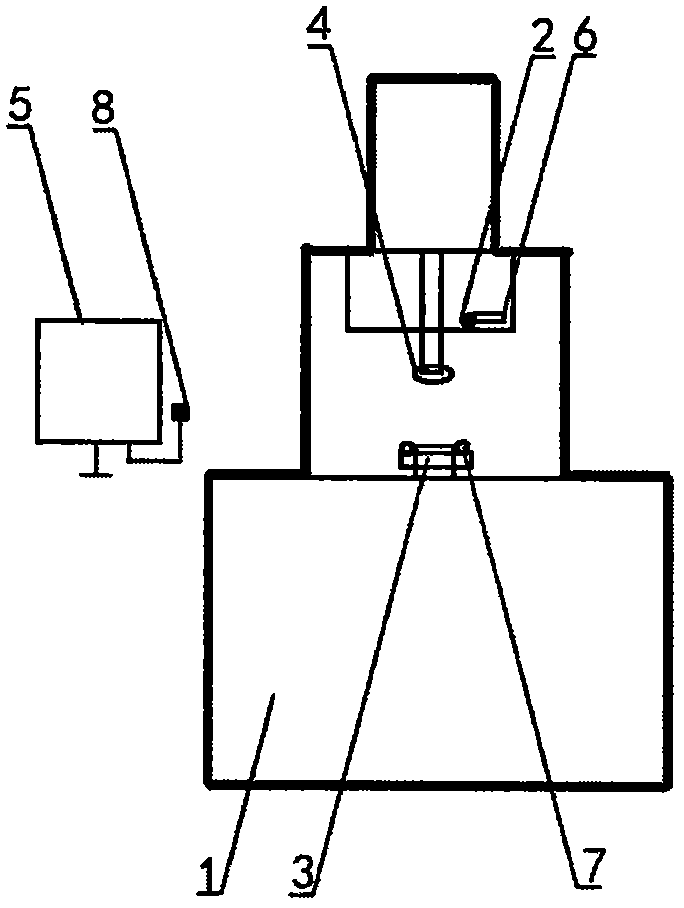

[0012] Embodiment: as shown in the accompanying drawing. The four-column hydraulic press mold center positioning and fixing auxiliary module includes a body (1), and a center sensing module (2), a boundary reference module (3), a ring sensing module (4), and a management module (5) are arranged on the body (1), During operation, the center sensing module (2) senses the center points of the upper and lower molds, the boundary reference module (3) is arranged outside the lower mold, the ring sensing module (4) is arranged on the outer layer of the upper mold, and the management module (5) processes comprehensive information.

[0013] The center positioning and fixing auxiliary module of the four-column hydraulic press mold is provided with a gap sensing module (6) on the center sensing module (2) to sense the gap distance around the mould.

[0014] The center positioning and fixing auxiliary module of the four-column hydraulic press mold is provided with a position marking modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com