Pressure filter pressure filtration operation double-hole-deviation filtrate control apparatus

A control device and filter press technology, which are applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve problems such as poor operation effect and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

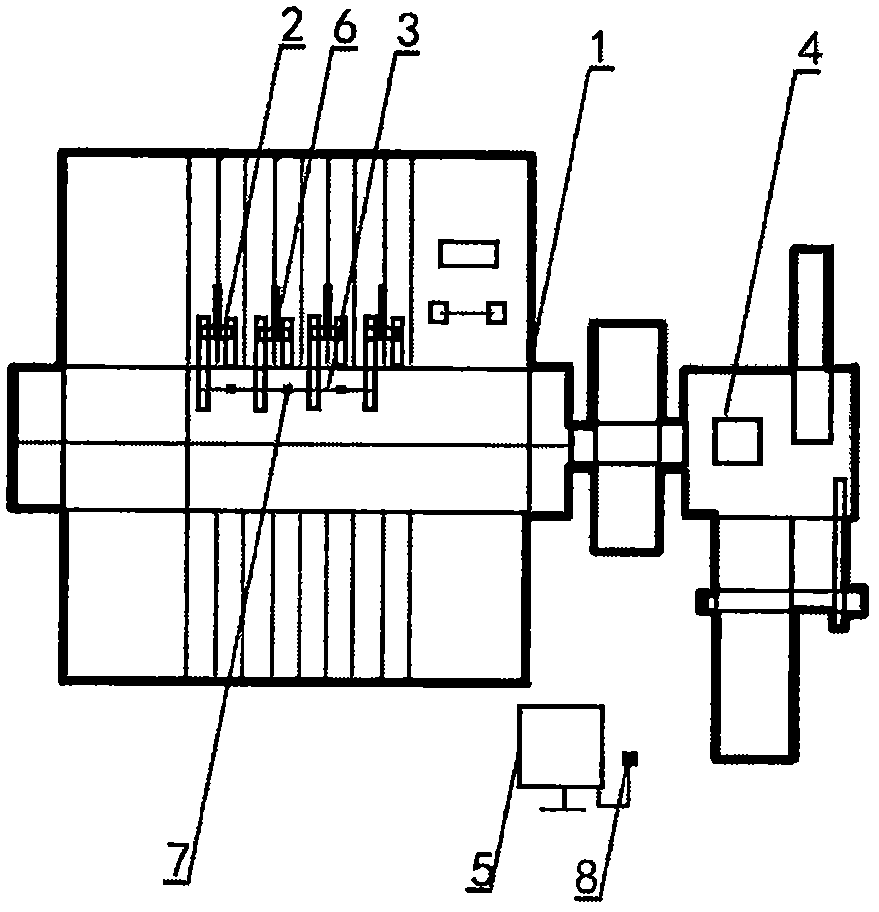

[0012] Embodiment: as shown in the accompanying drawing. A dual-hole deviation filtrate control device for filter press operation, including a body (1), on which a hole cloth fastening module (2), an edge sensing module (3), a filtrate indication module (4), The management module (5), during operation, the pore cloth fastening module (2) fastens the pore cloth on the cylinder wall, the edge sensing module (3) sets the filter plate to sense the position of the filter hole, and the filtrate indication module (4) indicates Filtrate turbidity, the management module (5) processes comprehensive information.

[0013] The dual-hole deviation filtrate control device for the filter press operation of the filter press is provided with a displacement sensing module (6) on the hole cloth fastening module (2) to sense the movement of a specific position of the hole cloth.

[0014] The dual-hole deviation filtrate control device for the filter press operation of the filter press is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com