Dual-axle-center coordination assembly for installation of liner plate of high-efficiency ball mill

A ball mill liner and dual-axis technology, which is applied in grain processing and other directions, can solve problems such as impact, poor operation effect, and abnormal axis position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

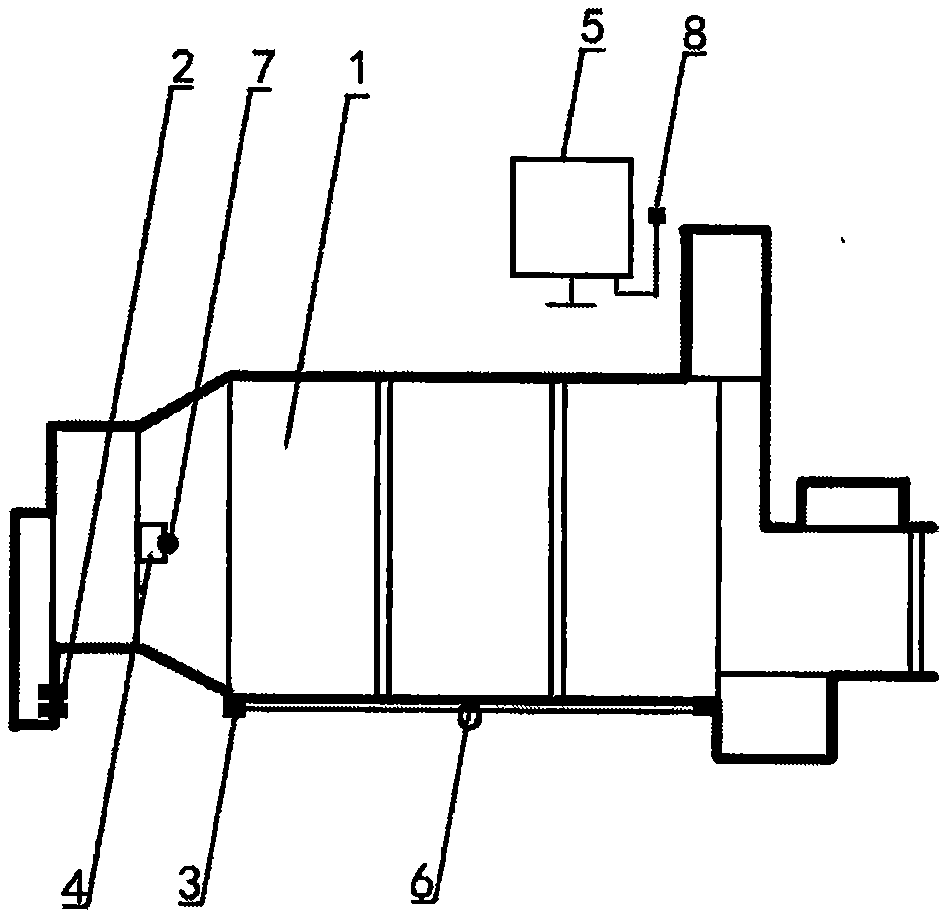

[0012] Example: as shown in the attached drawings. A high-efficiency ball mill liner installation double-axis coordination assembly, comprising a body (1), on which are provided a fastening induction module (2), an information induction module (3), an axis induction module (4), The management module (5), during operation, the tightening sensing module (2) is arranged on the bolt to sense its tightening condition, the information sensing module (3) is arranged at both ends of the grinding cylinder body, and the shaft center sensing module (4) senses the double Axis axis, the management module (5) processes the comprehensive information.

[0013] A high-efficiency ball mill liner is installed with a double-axis coordination component, and a displacement sensing module (6) is arranged on an information sensing module (3) to sense the movement of both ends of a grinding cylinder.

[0014] A high-efficiency ball mill liner is installed with a dual-axis coordination component, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com