Collating machine gripper spring hanging pillar movable sleeve contact control module

A technology of control module and contact sensing module, which is applied in the directions of printing, object supply, pile separation, etc., can solve the problems of airframe parts affecting the running effect and large contact tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

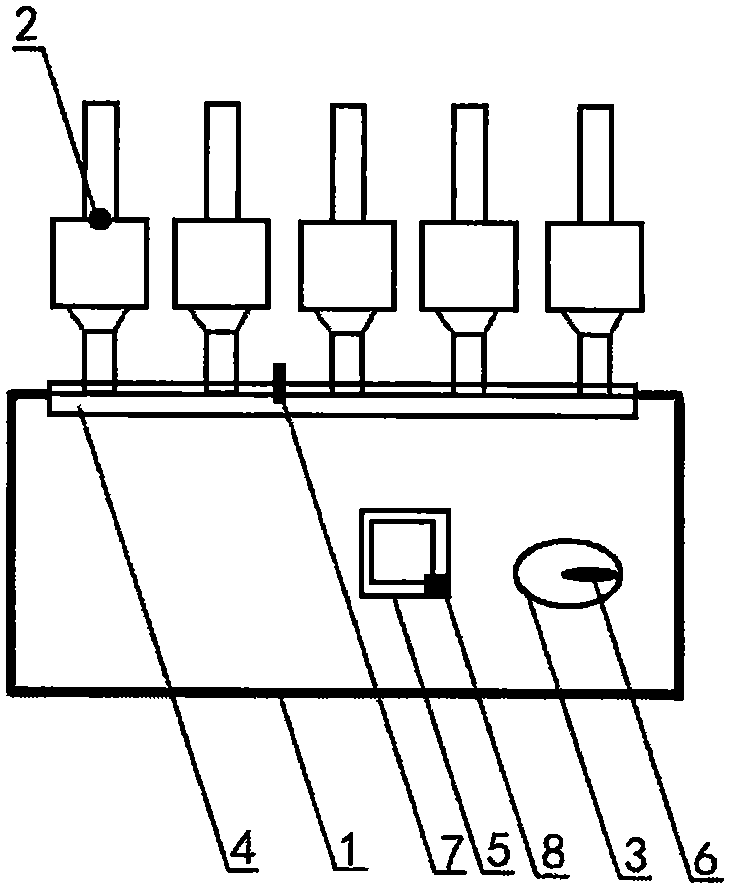

[0012] Embodiment: as shown in the accompanying drawing. The contact control module of the collating machine teeth hanging spring column movable sleeve includes a body (1), on which a tension sensing module (2), an operation sensing module (3), a contact sensing module (4), a management Module (5), when running, the tension sensing module (2) senses the tension value of the component, the operation sensing module (3) senses the operation of the fuselage, the contact sensing module (4) senses the contact condition of the movable sleeve, and the management module (5) handles the comprehensive information.

[0013] The collating machine teeth hanging spring column movable sleeve contacts the control module, and the replacement indicating module (6) is set on the operation sensing module (3), indicating the time to replace parts according to the operation situation.

[0014] Collating machine teeth hanging spring column movable cover contact control module, an infrared measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com