Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Accurate stop position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

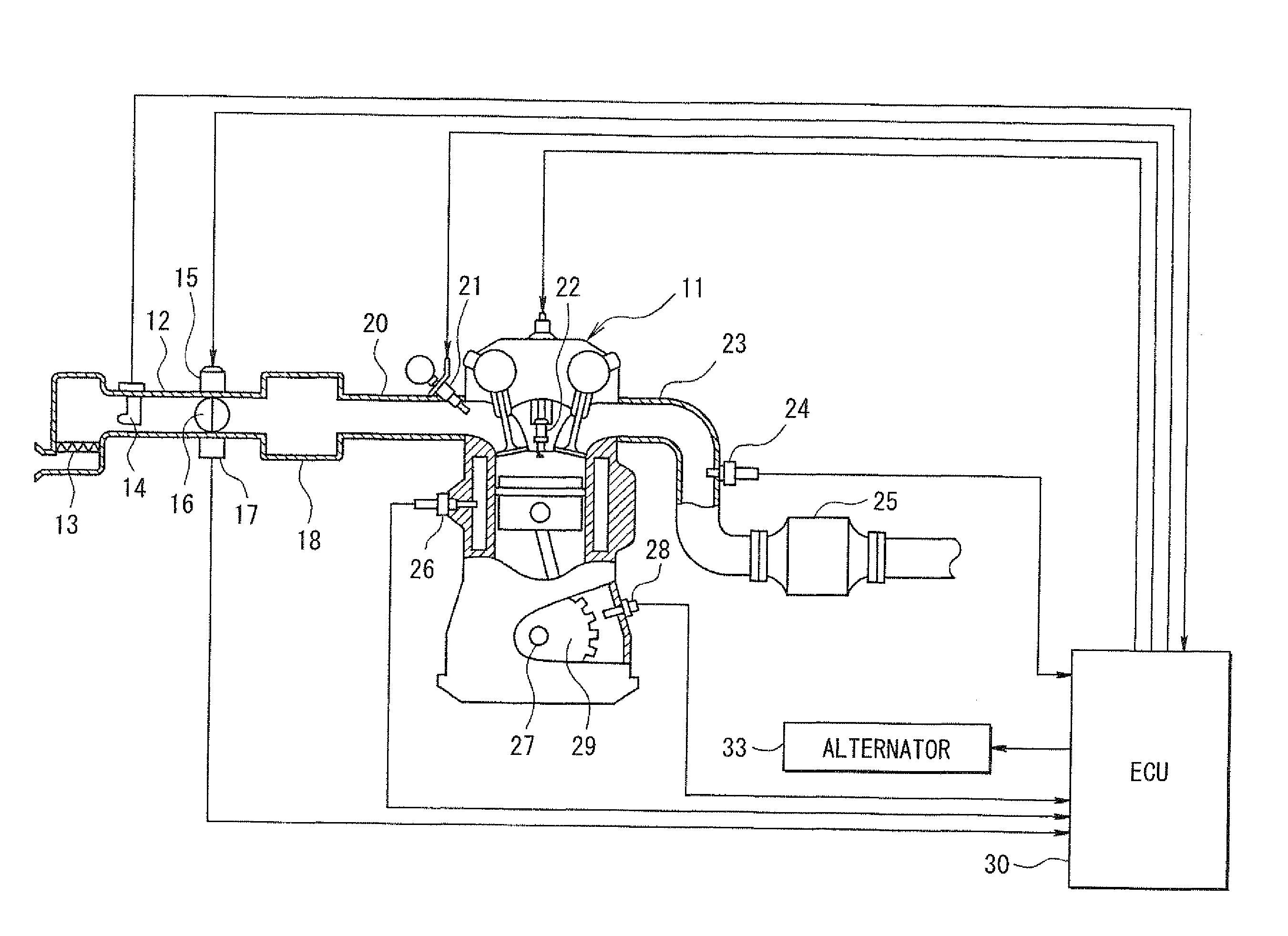

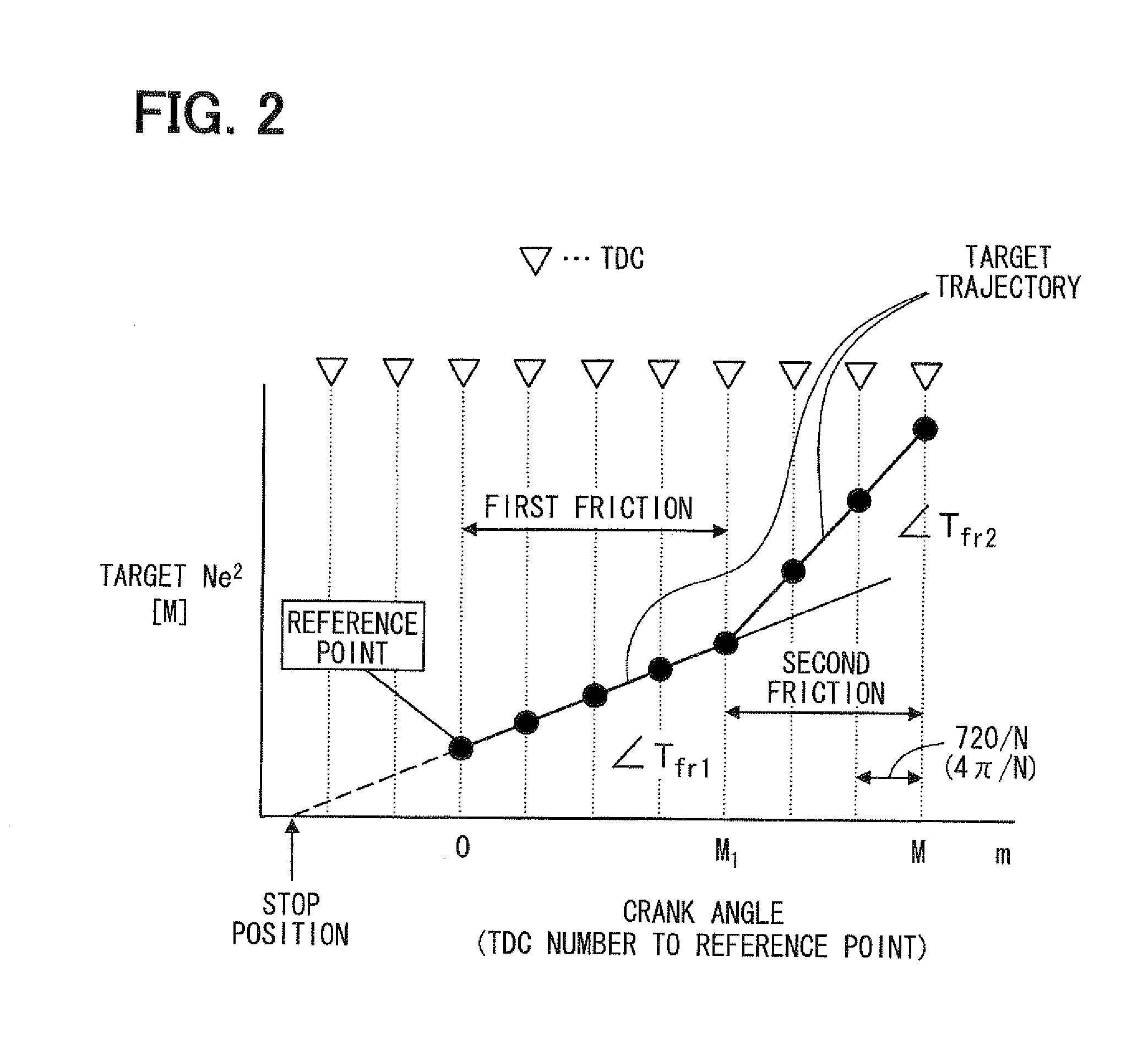

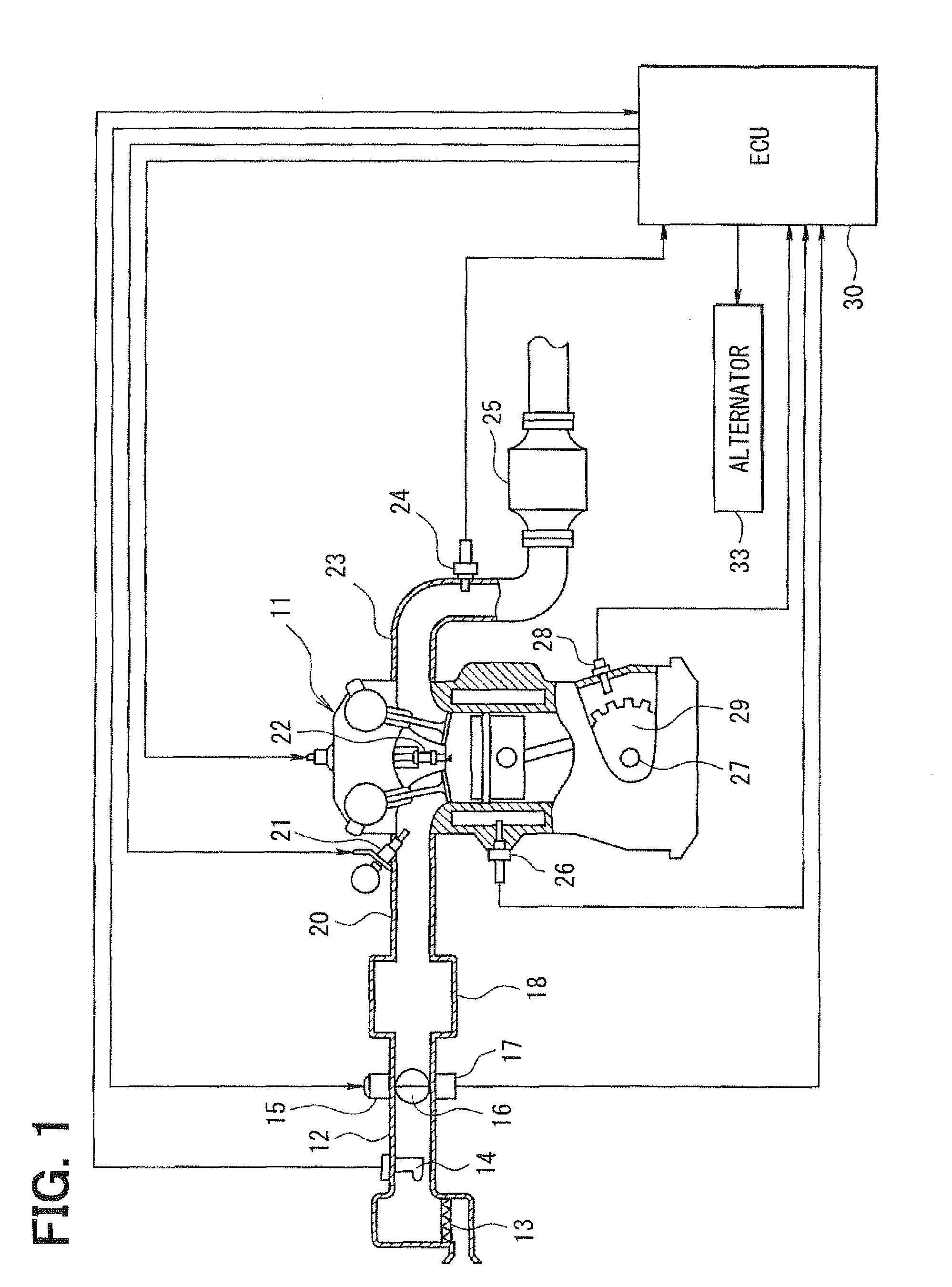

Engine stop control device

ActiveUS20100204908A1Reduce variationImprove restarting performanceHybrid vehiclesAnalogue computers for vehiclesAlternatorControl theory

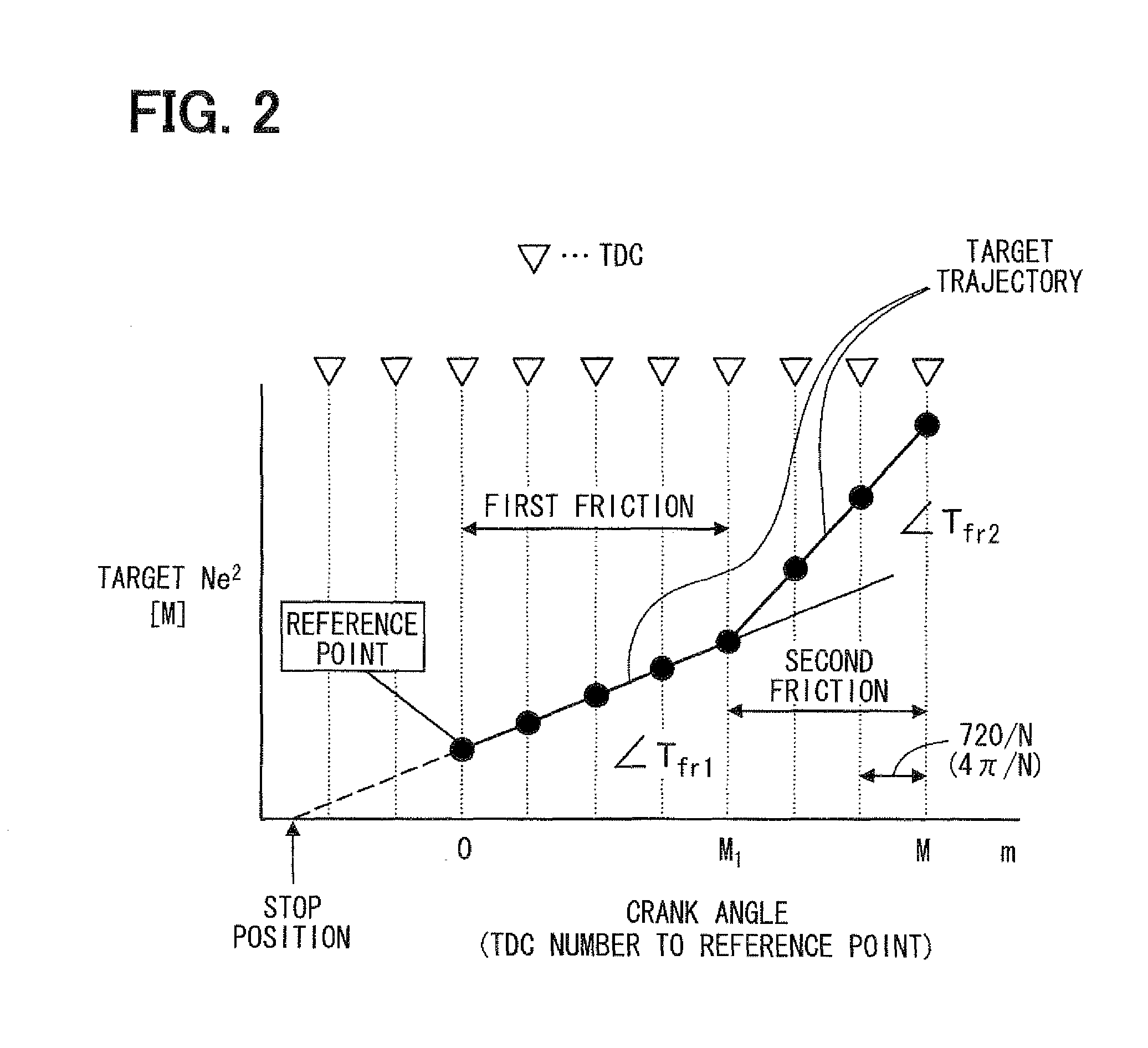

Target rotation speed at a reference point set at TDC slightly preceding a target stop position of engine rotation is set. A target trajectory of an engine rotation behavior extending since an engine rotation stop behavior starts until the target rotation speed at the reference point is reached is calculated based on the target rotation speed at the reference point and an engine friction. Torque of an alternator is controlled to conform the engine rotation behavior to the target trajectory during the engine rotation stop behavior. Generation of the torque of the alternator stops at a position preceding the reference point by a predetermined crank angle. Therefore, the torque of the alternator is controlled such that an energy deviation between the target trajectory and the engine rotation behavior becomes zero at the position preceding the reference point by the predetermined crank angle.

Owner:DENSO CORP

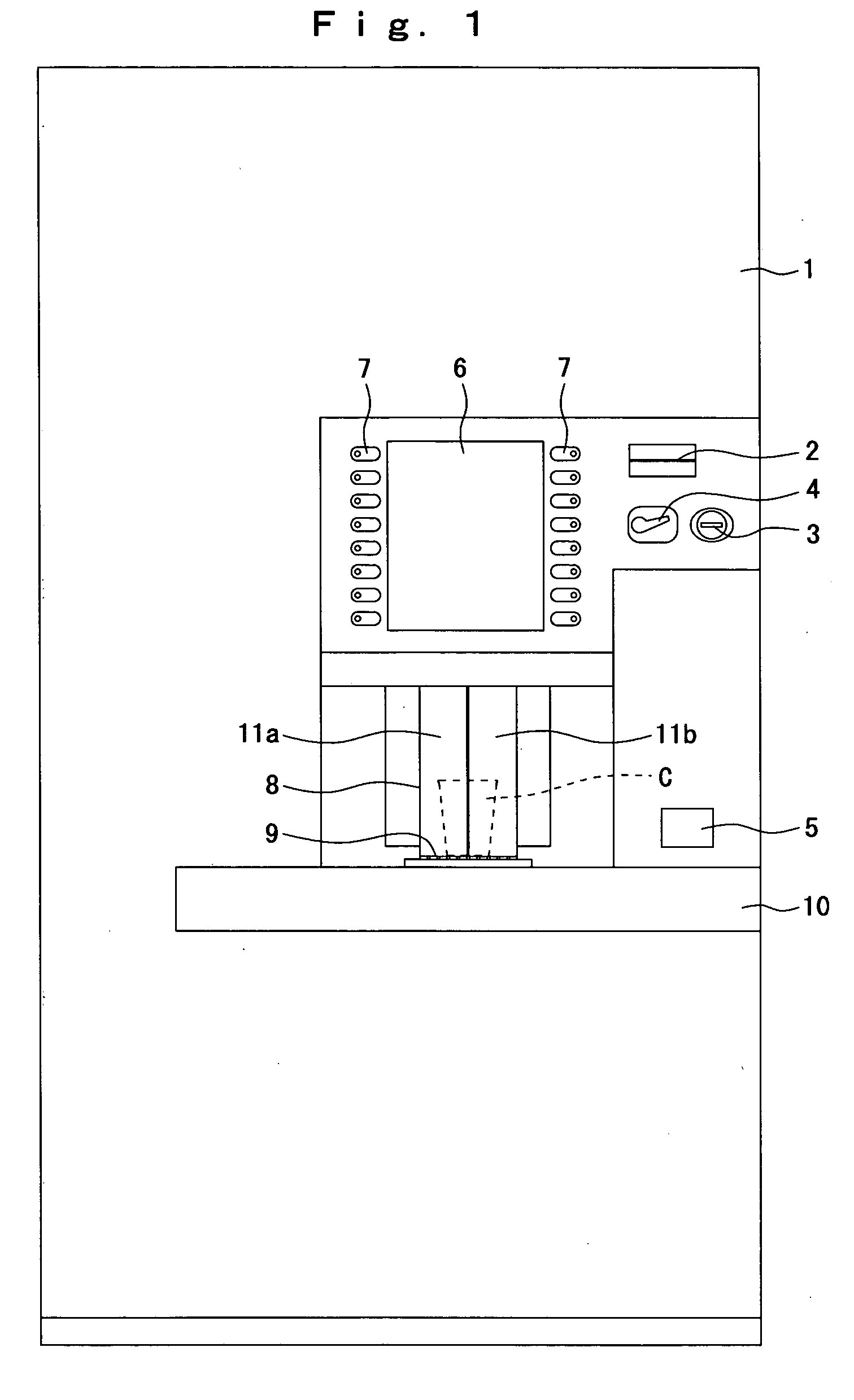

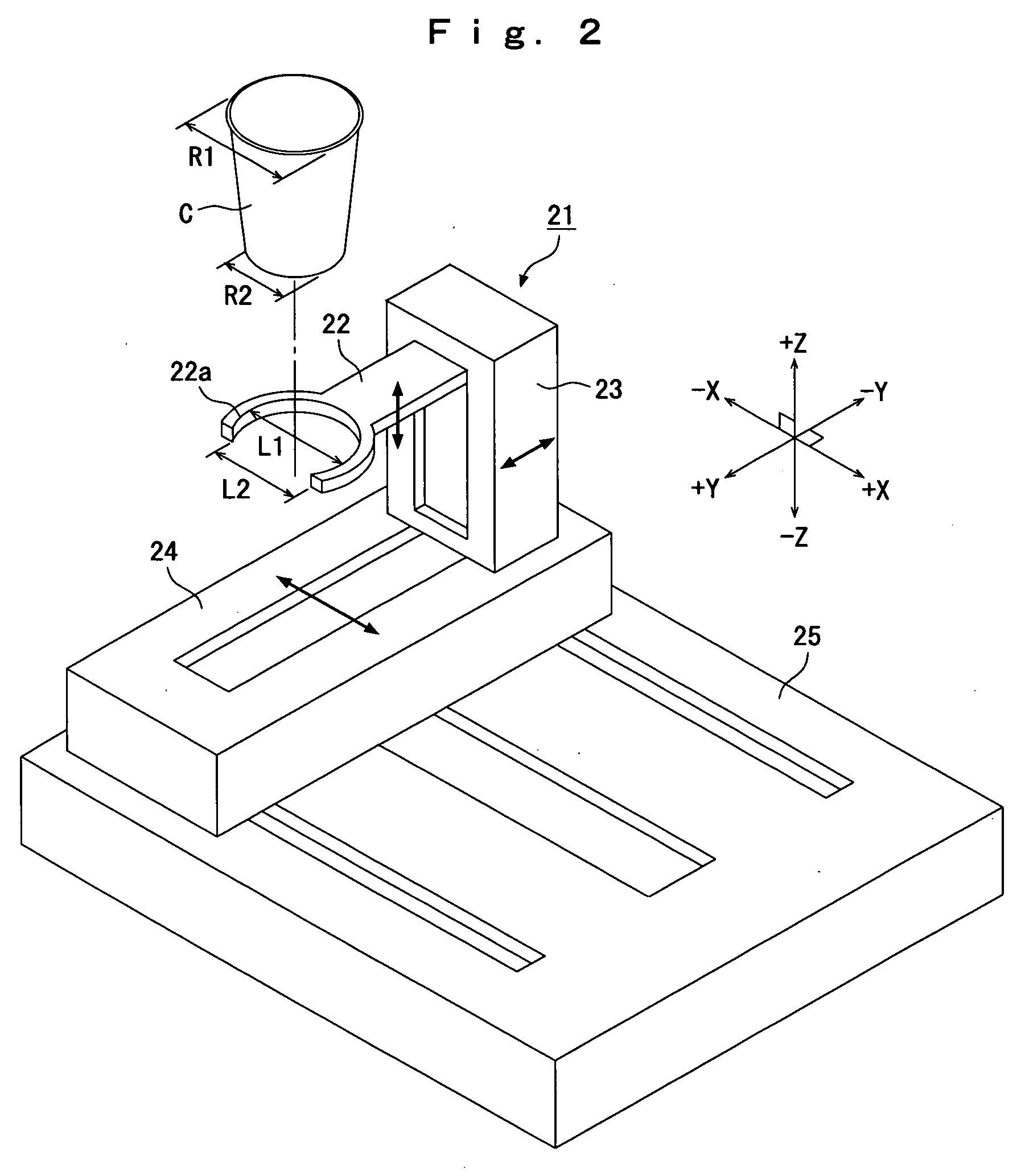

Beverage dispenser

InactiveUS20060131323A1Effective correctionAccurate stop positionCoin-freed apparatus detailsApparatus for dispensing fluids/granular materialsControl theoryEncoder

A beverage dispenser can replace a X-Y coordinate of a predetermined cup stop position with a corrected X-Y coordinate by operating an X-axis motor and a Y-axis motor of a cup mover so that an actual cup stop position become consistent with a predetermined cup stop position and deciding the corrected X-Y coordinate based on position signals obtained from an X-axis encoder and a Y-axis encoder according to the operation.

Owner:SANDEN CORP

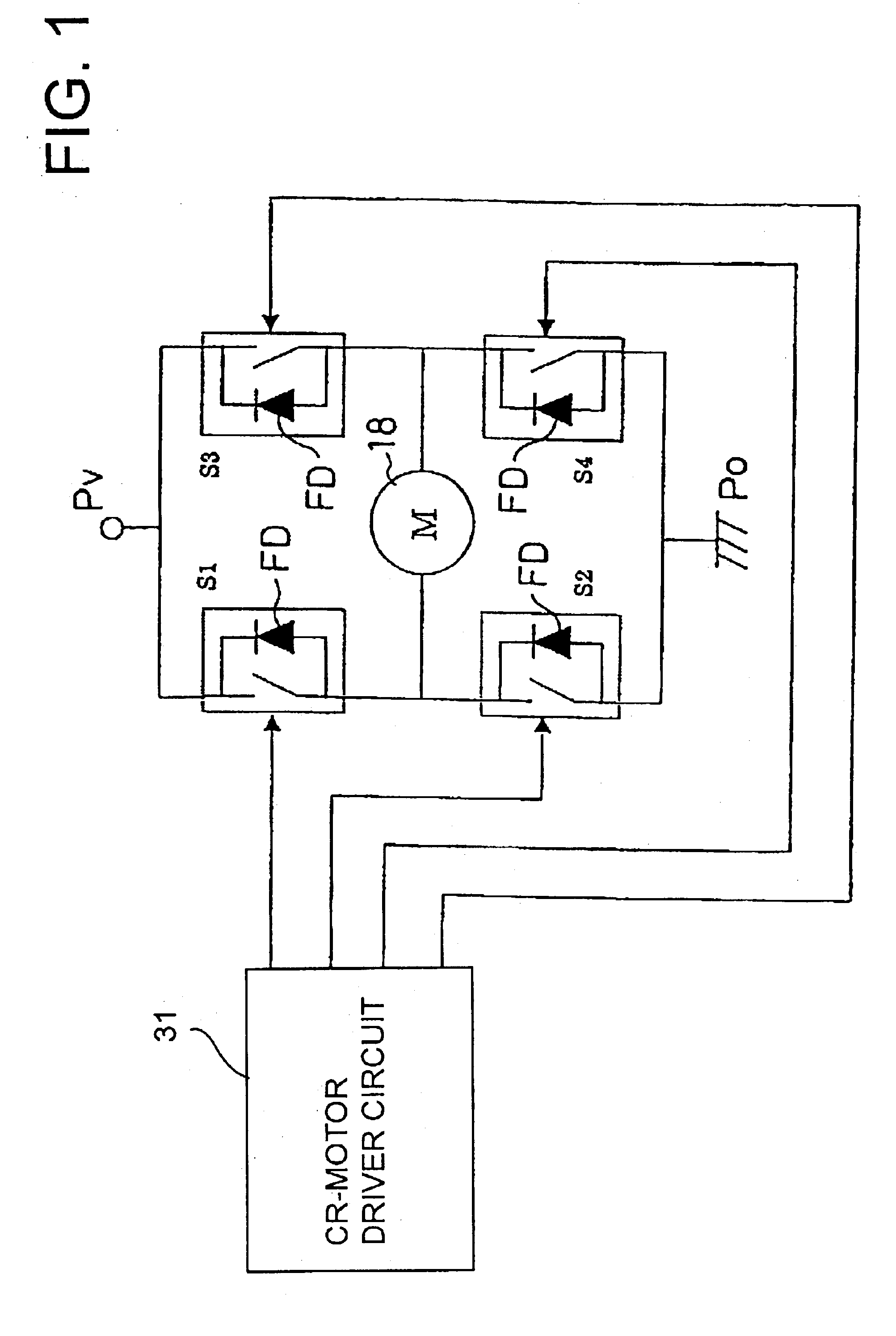

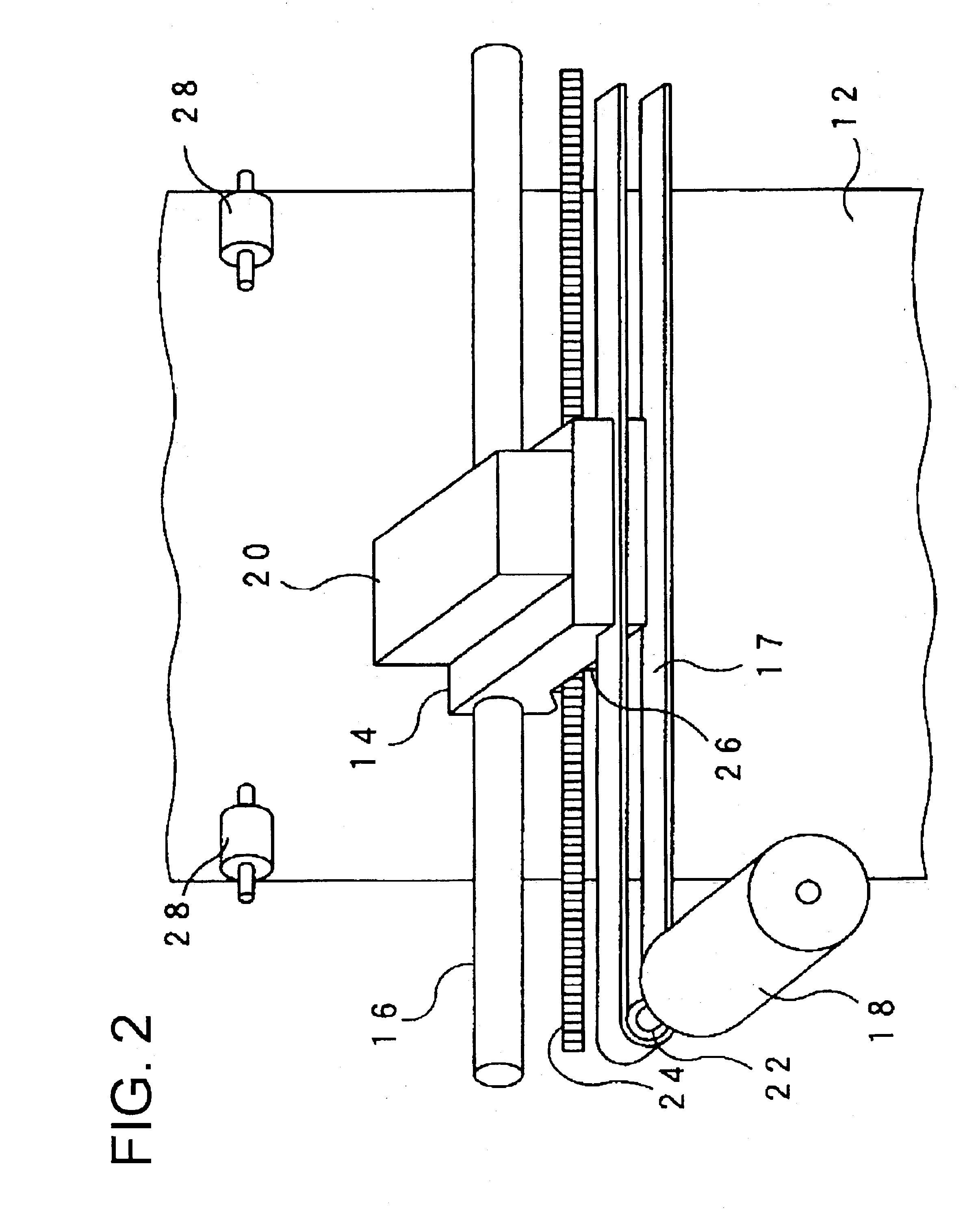

Apparatus for controlling deceleration of DC motor

ActiveUS6930458B2Easy to understandShort timeAC motor controlDC motor speed/torque controlRegenerative brakeMotor drive

An apparatus for controlling deceleration of a DC motor which is driven in a forward operating direction with a forward-drive electric current applied thereto by a forward driving device, wherein the forward motor driving device applies the forward-drive electric current in the form of pulses to the DC motor during its deceleration, and wherein a plugging-braking device operable while the motor is subjected to a regenerative brake or operated in a non-braked state is operated to apply a reverse-drive electric current in the form of pulses to the motor, to apply a plugging brake to the motor, such that at least one pulse of the reverse-drive electric current follows every predetermined number of pulses of the forward-drive electric current. The plugging-braking device may be replaced by a dynamic braking device operable to short-circuit the motor to apply a dynamic brake to the motor, with at least one pulse of a dynamic-brake current following every predetermined number of pulses of the forward-drive electric current.

Owner:BROTHER KOGYO KK

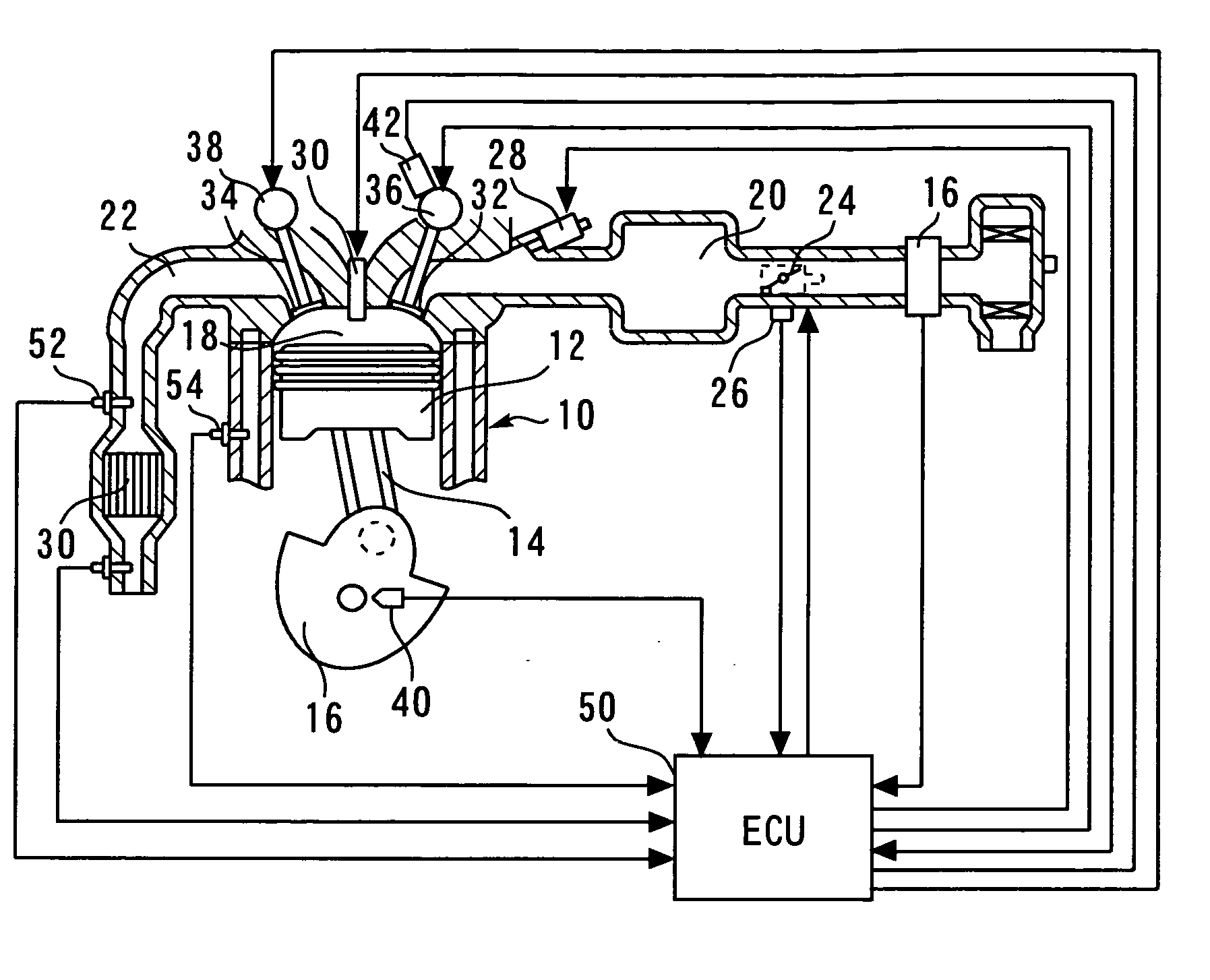

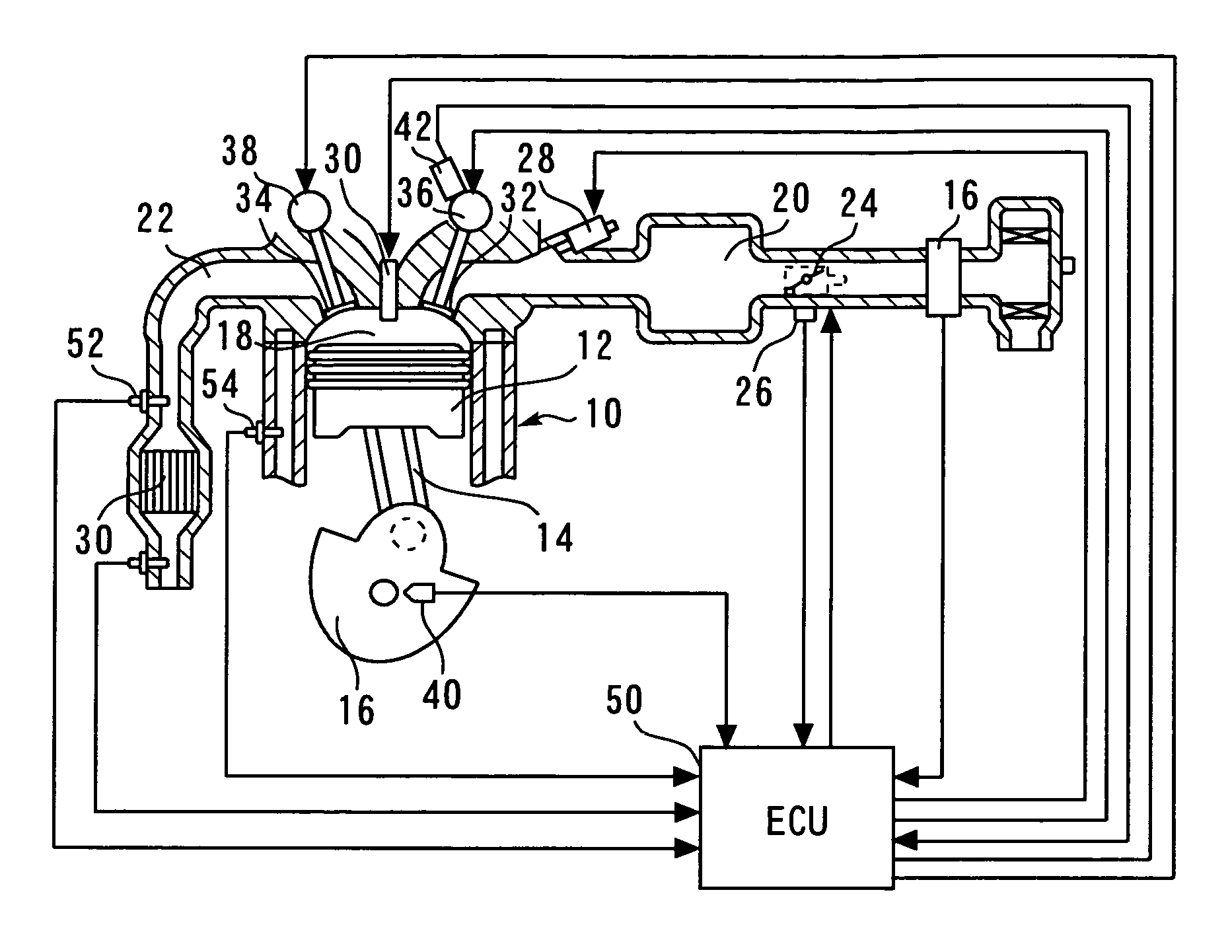

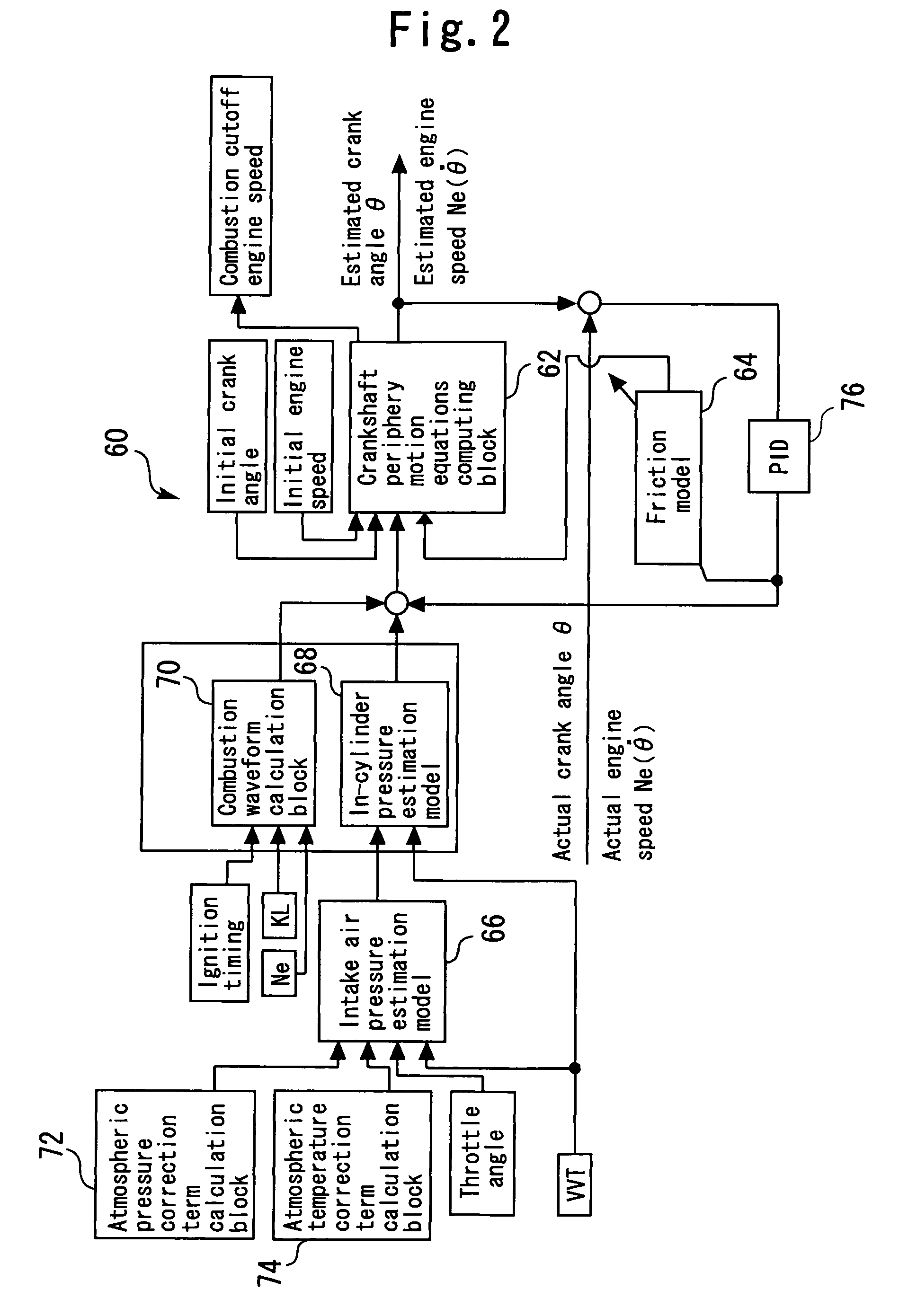

Stop Position Control Apparatus for Internal Combustion Engine

InactiveUS20090248282A1Accurate stop positionAccurate estimateAnalogue computers for vehiclesElectrical controlAtmospheric temperatureEngineering

An engine model is configured so as to include a crankshaft periphery motion equations computing block, a friction model, an intake air pressure estimation model, an in-cylinder pressure estimation model, a combustion waveform calculation block, an atmospheric pressure correction term calculation block, and an atmospheric temperature correction term calculation block. While combustion is cut off, the friction model is learned and updated using estimated relating to the crank stop position calculated by the engine model and measured data relating to the crank stop position.

Owner:TOYOTA JIDOSHA KK

Engine stop control device

ActiveUS8676478B2Precise rotationAccurately controlling an engine rotation stop positionHybrid vehiclesAnalogue computers for vehiclesAlternatorControl theory

Target rotation speed at a reference point set at TDC slightly preceding a target stop position of engine rotation is set. A target trajectory of an engine rotation behavior extending since an engine rotation stop behavior starts until the target rotation speed at the reference point is reached is calculated based on the target rotation speed at the reference point and an engine friction. Torque of an alternator is controlled to conform the engine rotation behavior to the target trajectory during the engine rotation stop behavior. Generation of the torque of the alternator stops at a position preceding the reference point by a predetermined crank angle. Therefore, the torque of the alternator is controlled such that an energy deviation between the target trajectory and the engine rotation behavior becomes zero at the position preceding the reference point by the predetermined crank angle.

Owner:DENSO CORP

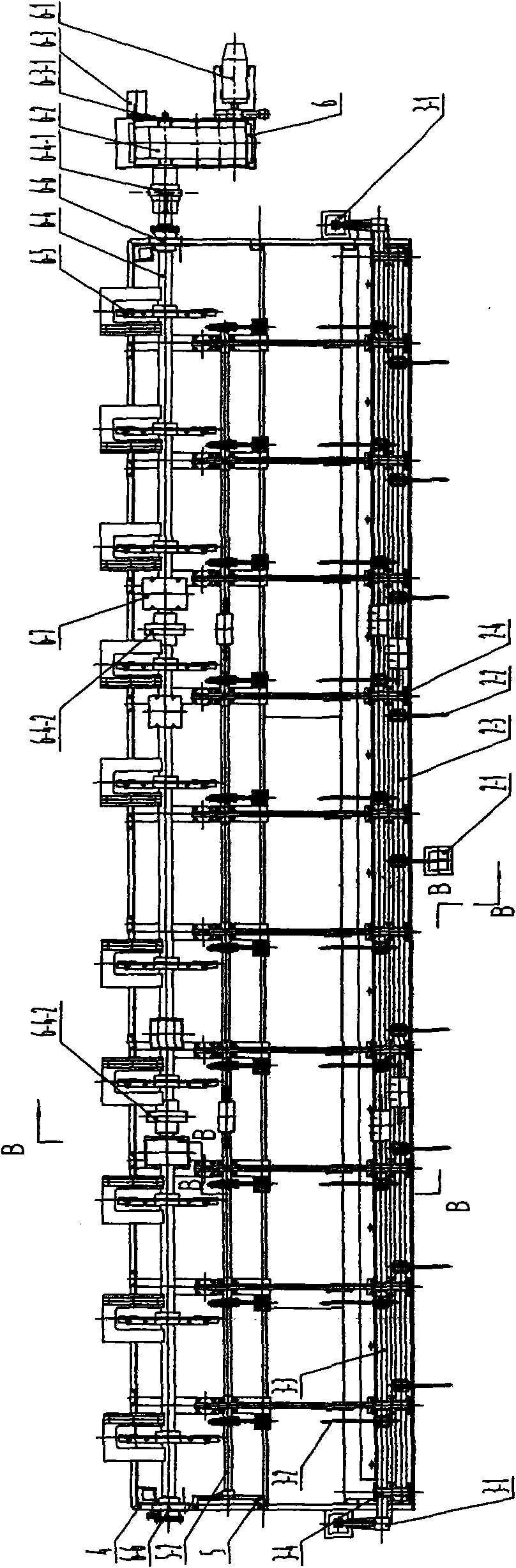

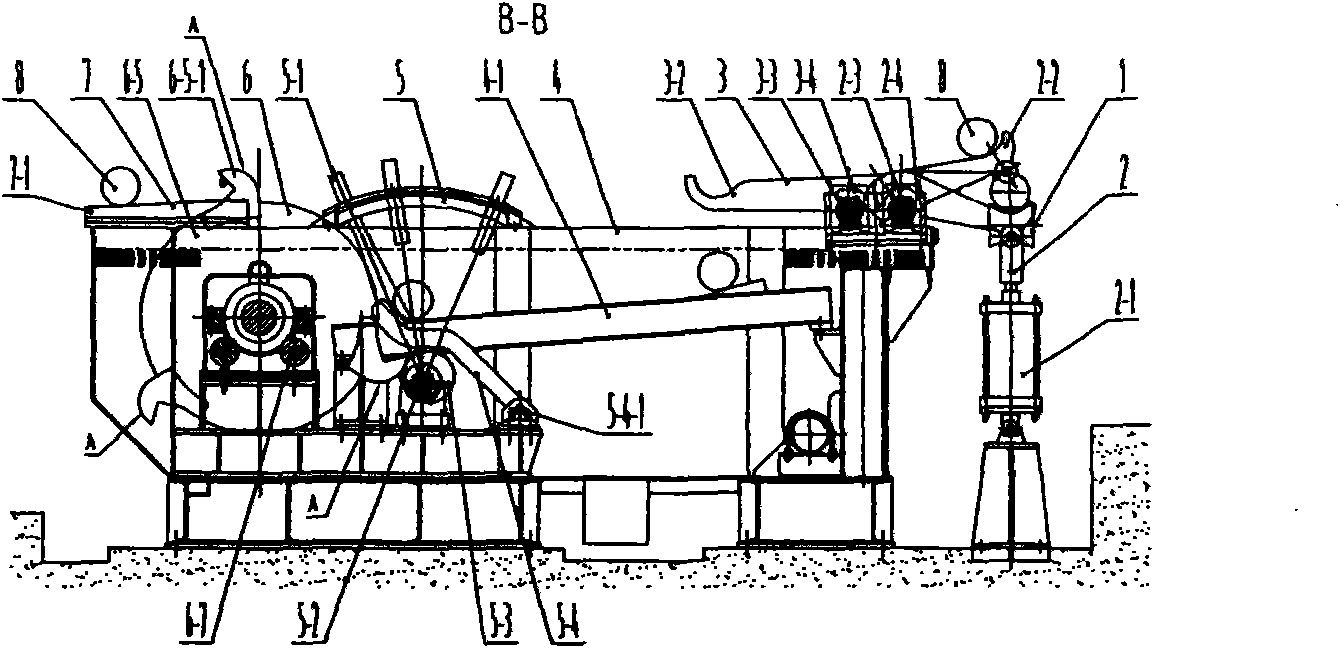

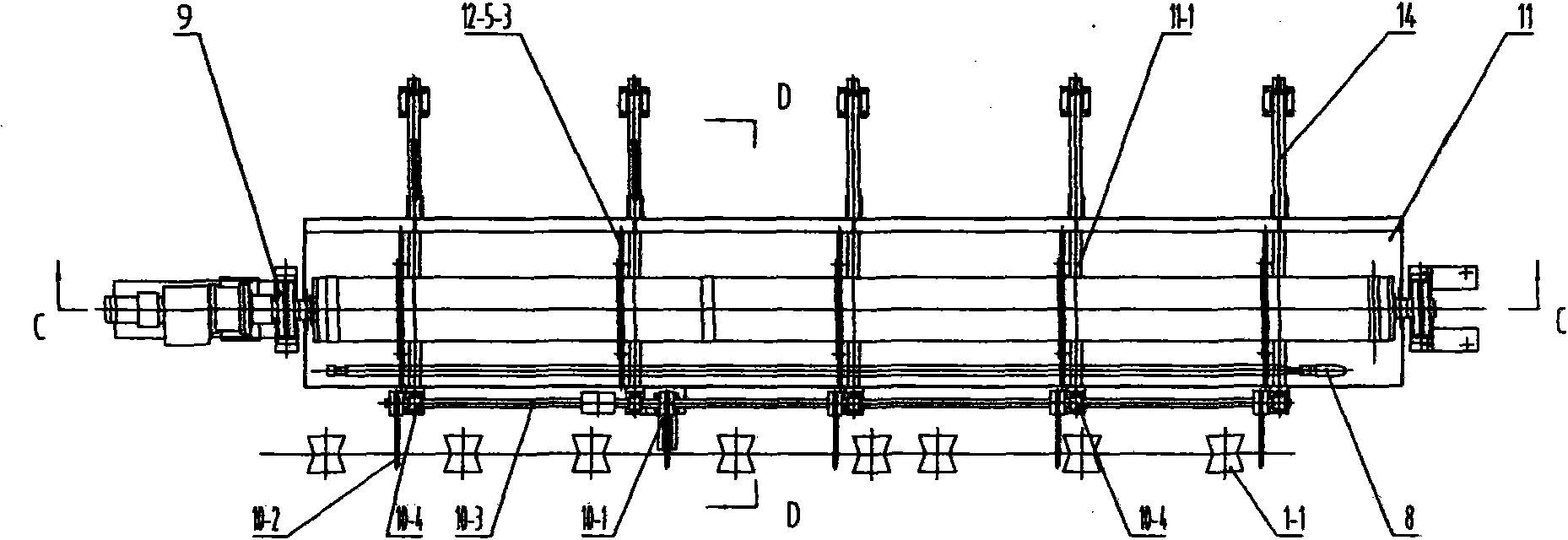

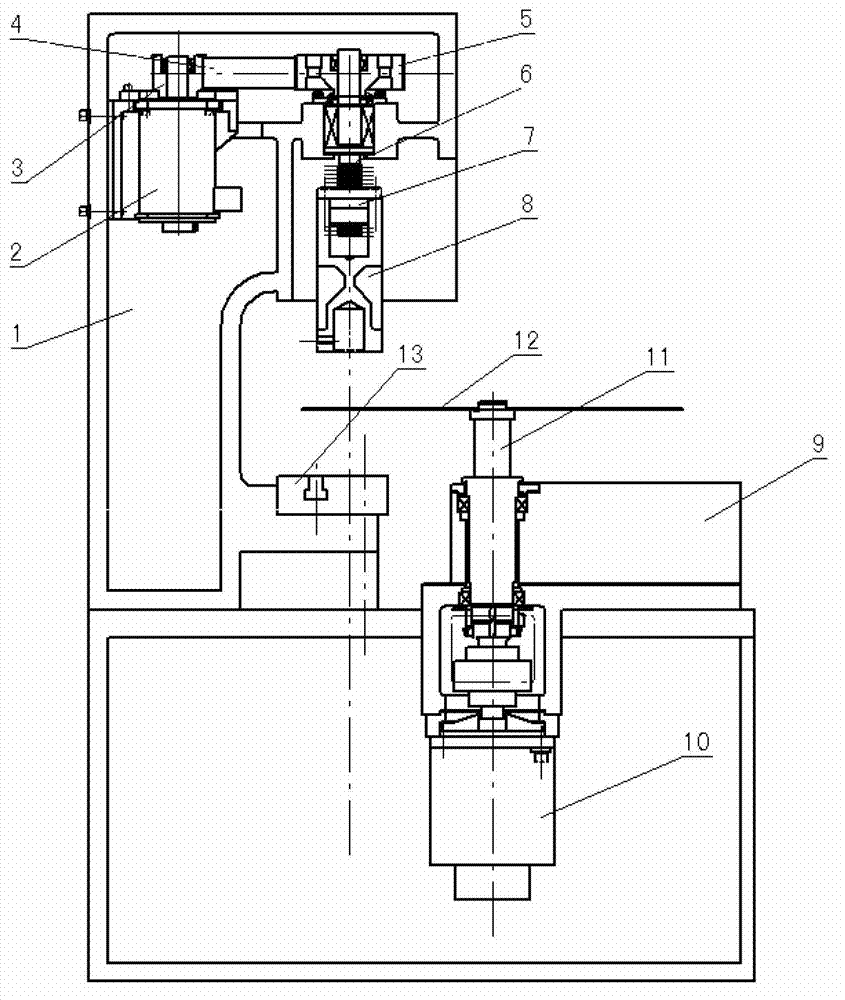

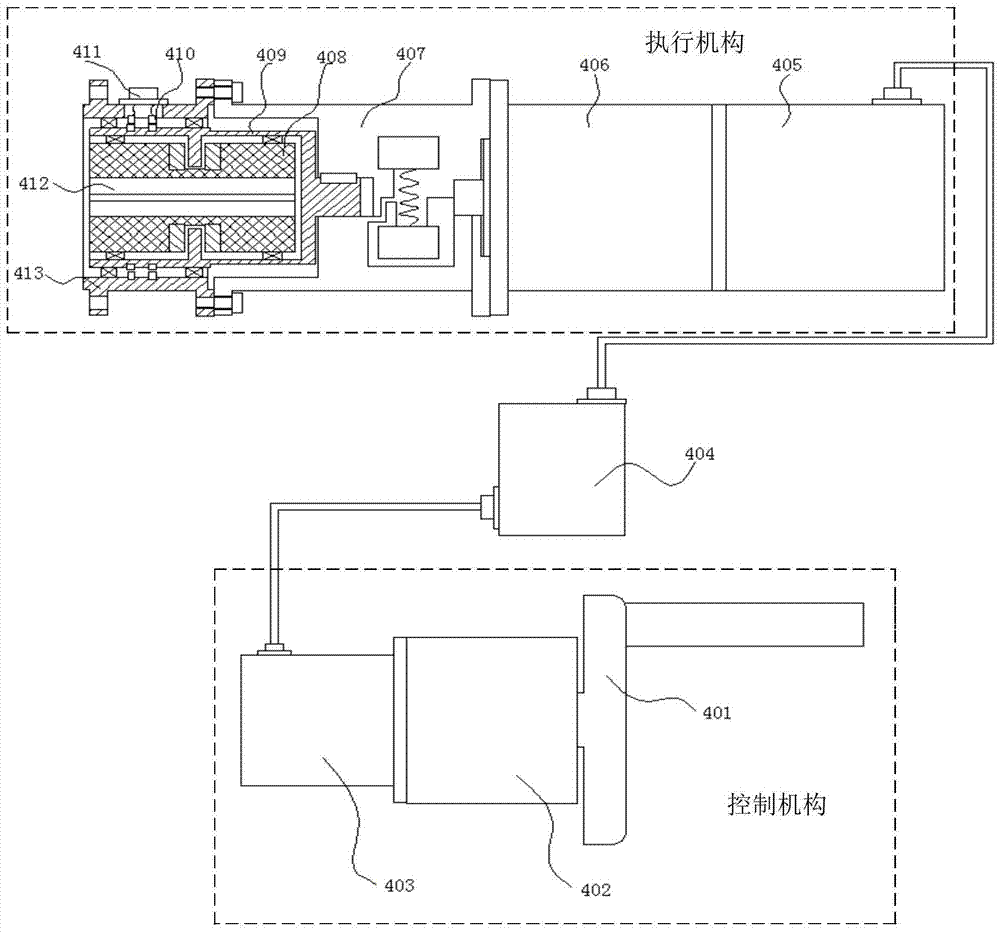

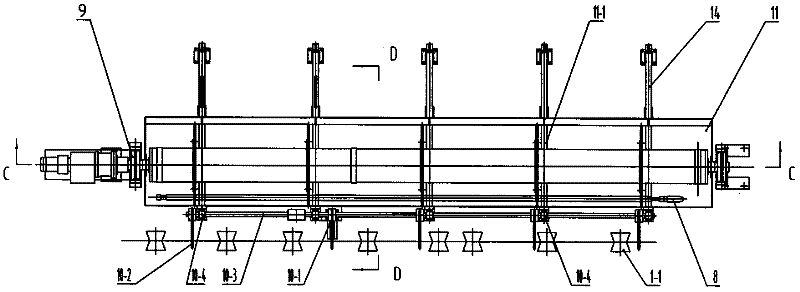

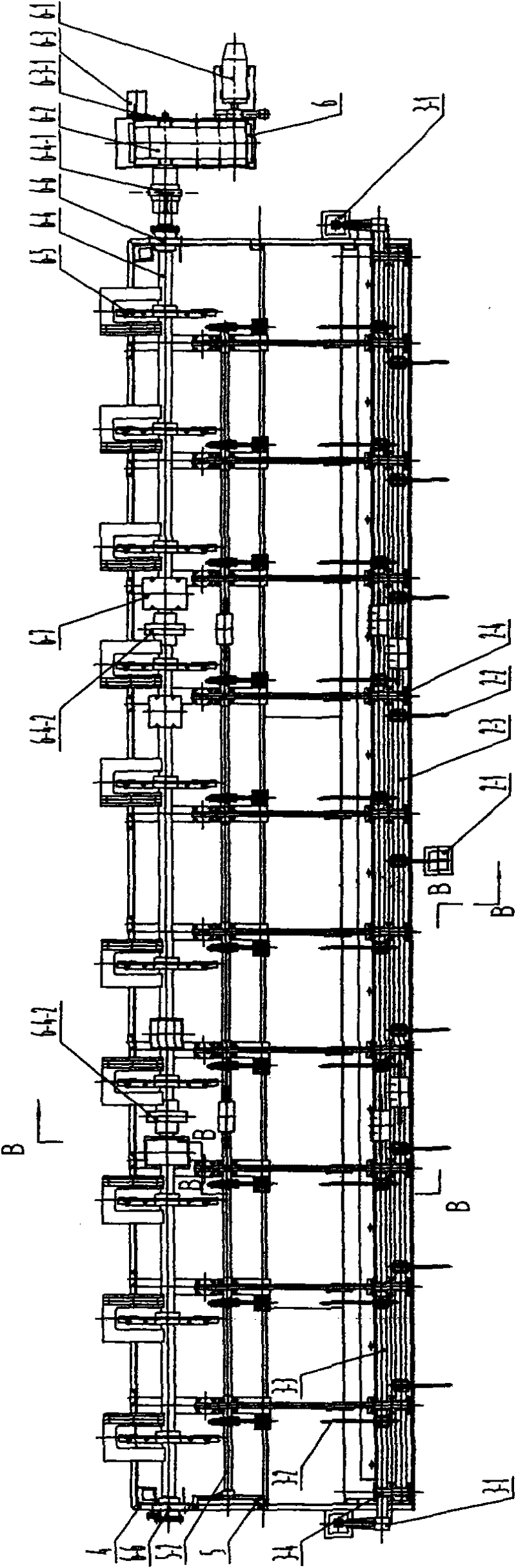

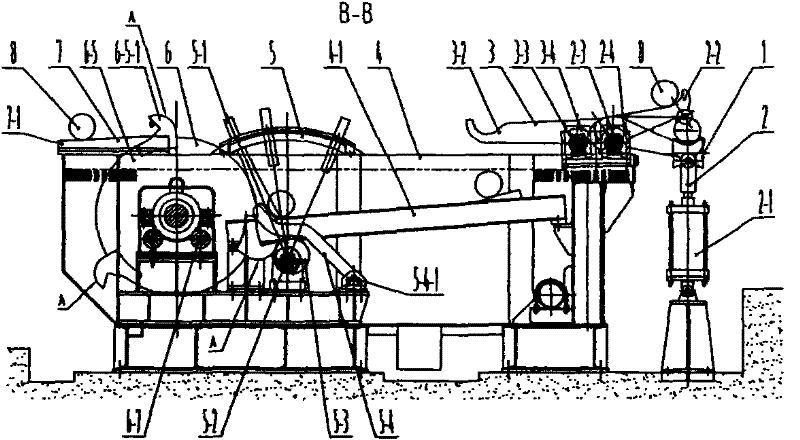

Cooling tank device of hot-rolling perforation machine set

InactiveCN101791628AGuaranteed uptimeReduce widthMandrelsMetal rolling arrangementsHydraulic cylinderCooling effect

The invention discloses a cooling tank device of a hot-rolling perforation machine set, relating to hot-rolling perforation machine set equipment. The invention solves the problems that the existing cooling tank device has large occupied area, large cooling water requirement amount, poor cooling effect and inaccurate mandril control so as to affect normal production operation. The invention is characterized in that in-bound equipment is an in-bound device 10 which is composed of a hydraulic cylinder 10-1, five material toggling grooves 10-2, a rotary shaft 10-3 and five bearing pedestals 10-4; the bottom of a cooling trough 4 is welded with five semicircular mandril slideways 4-2; a rotary device utilizes a support frame arranged outside the cooling trough and a rotary drum device 9 arranged right above the cooling trough 4; and a control mechanism is a controller 11 consisting of a profile modelling disk 11-1 and an approach switch 11-2.

Owner:TAIYUAN HEAVY IND

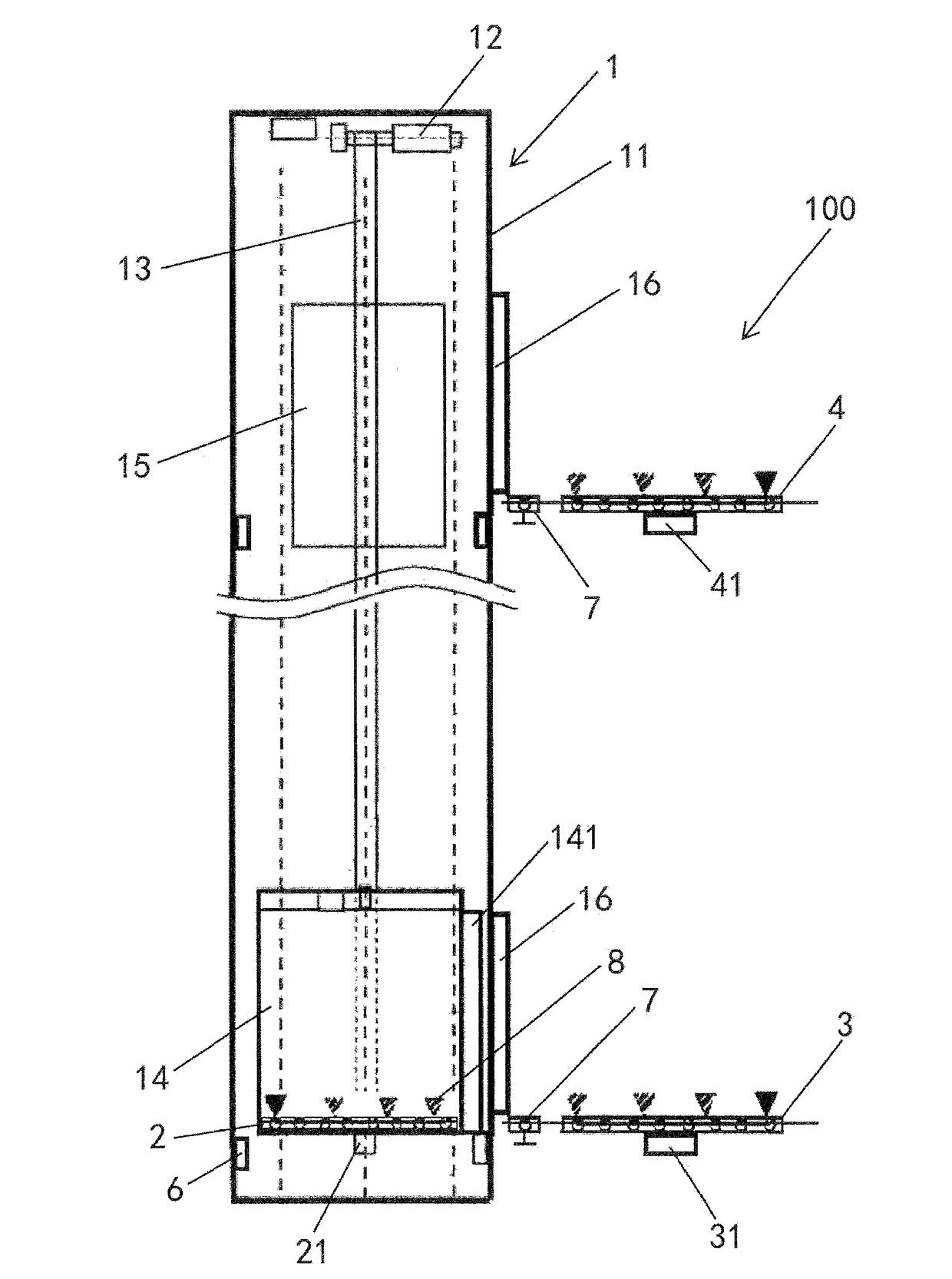

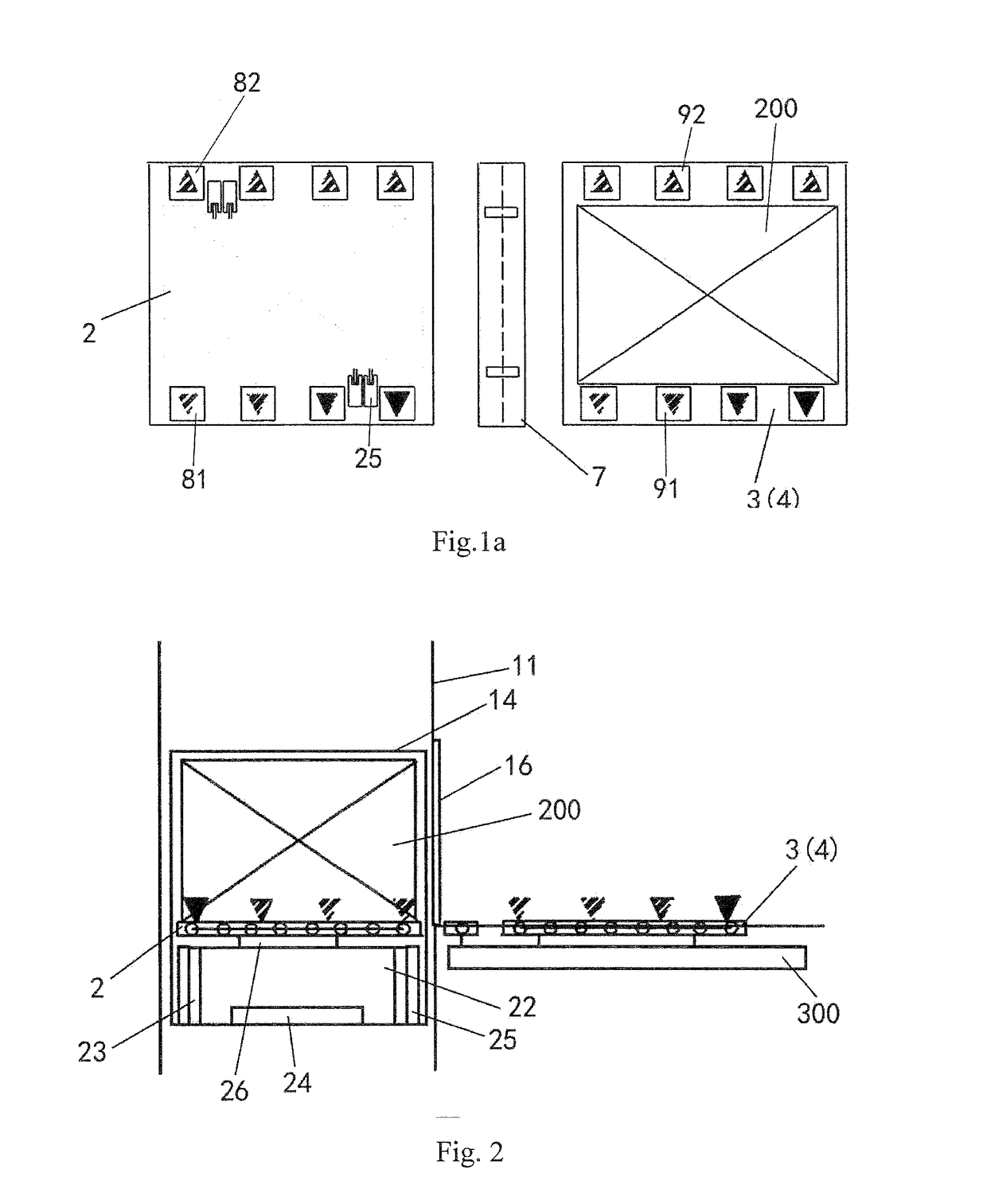

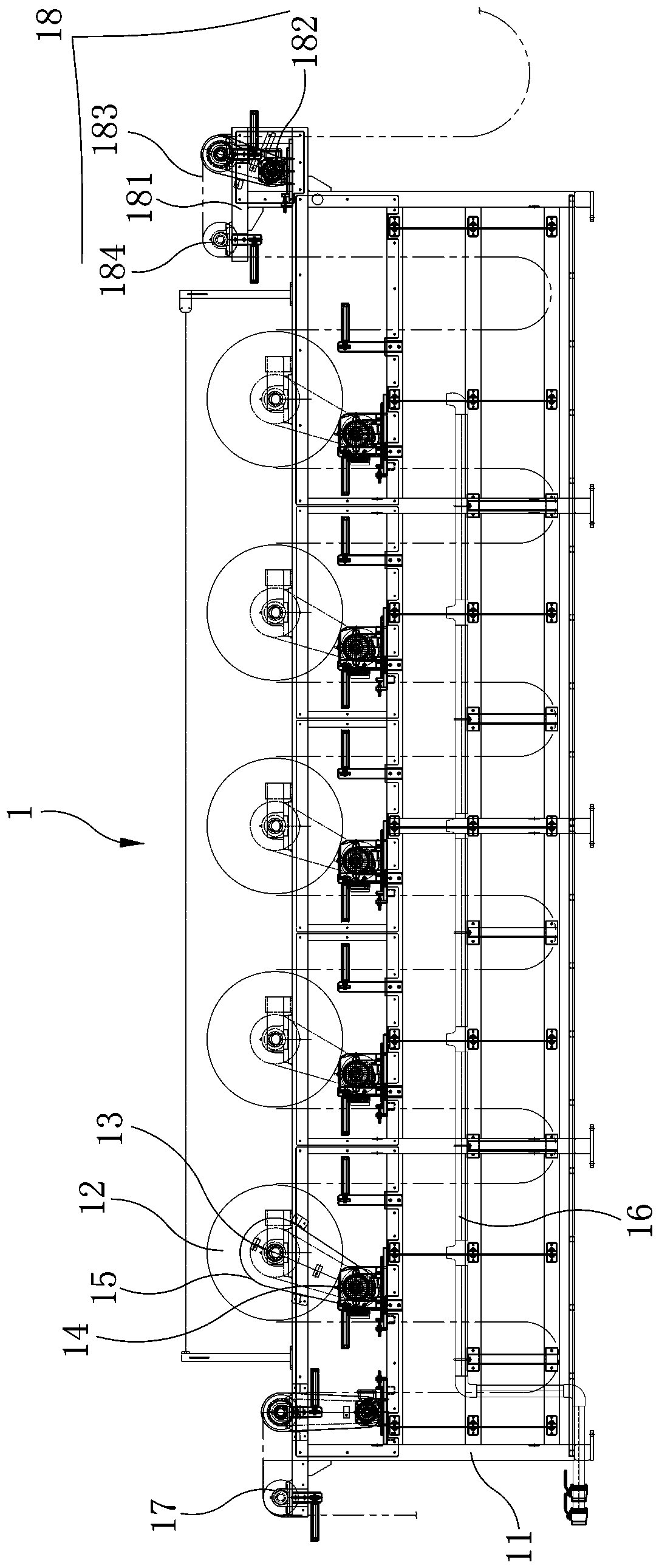

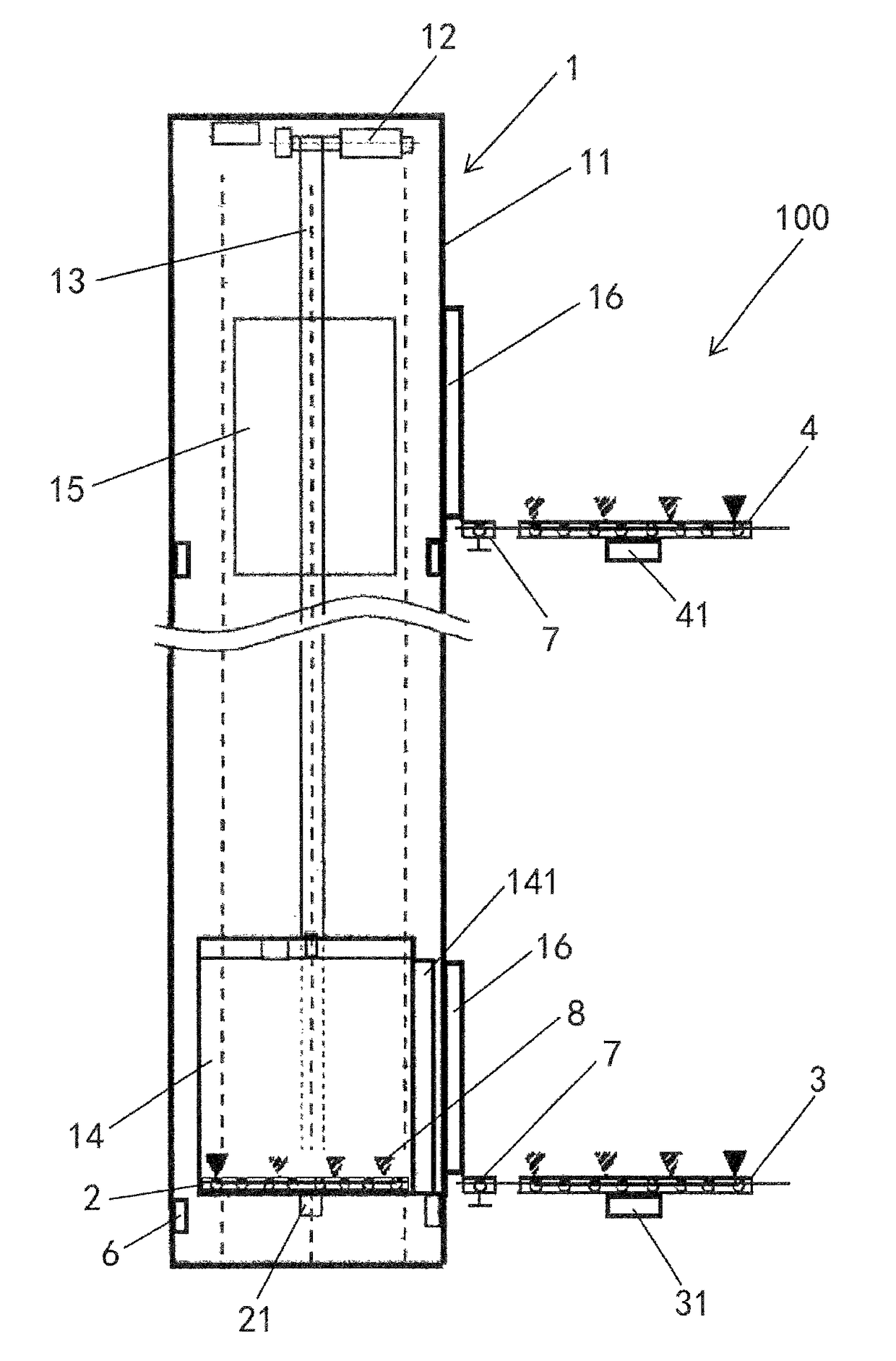

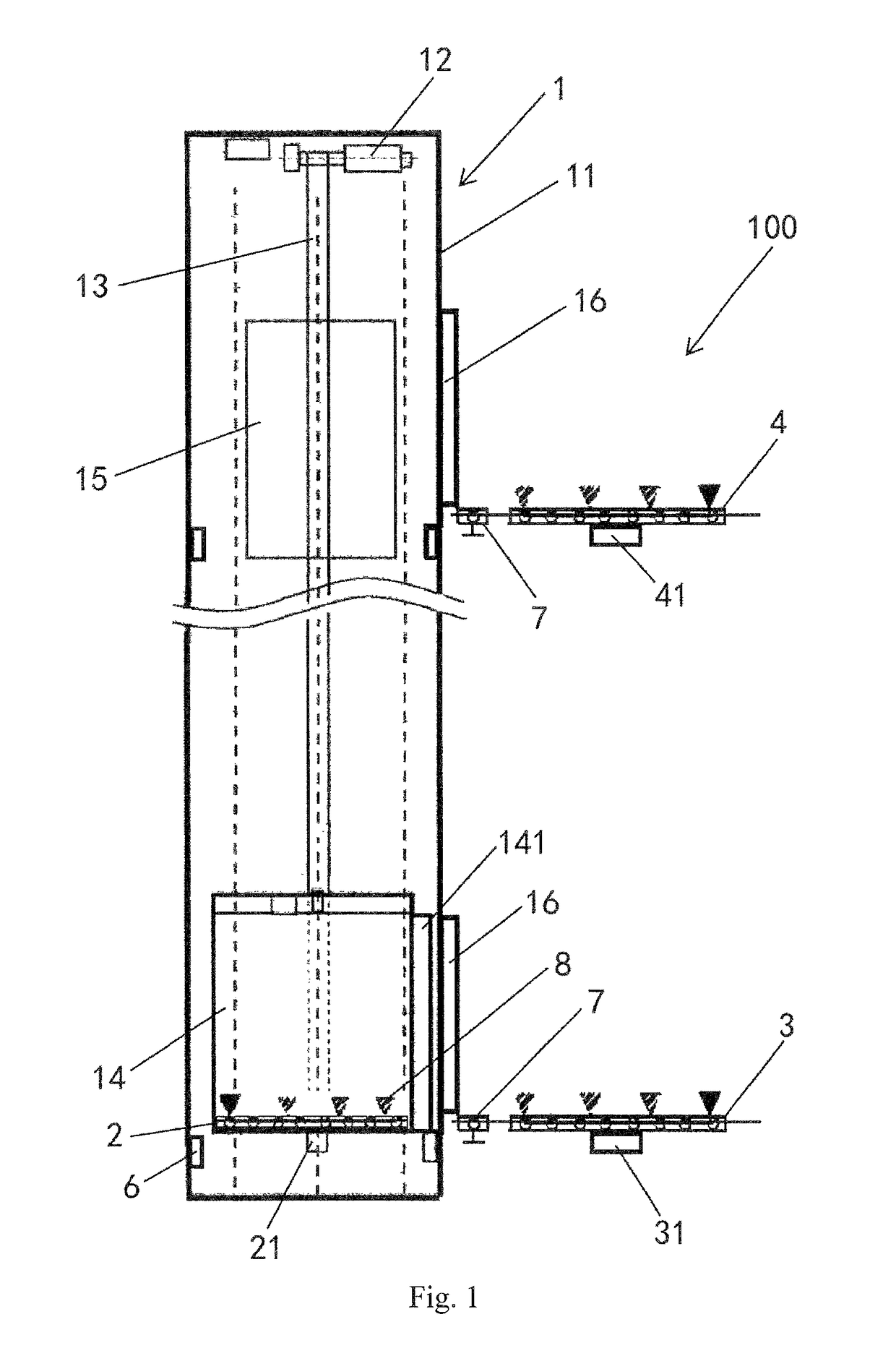

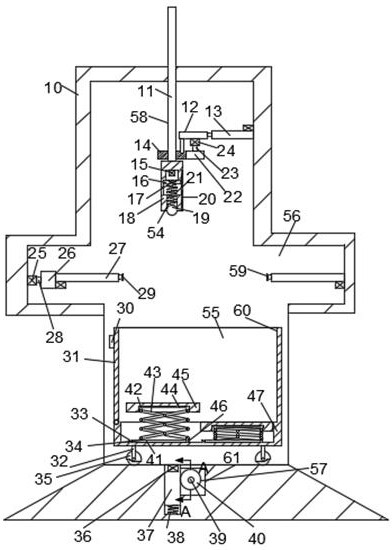

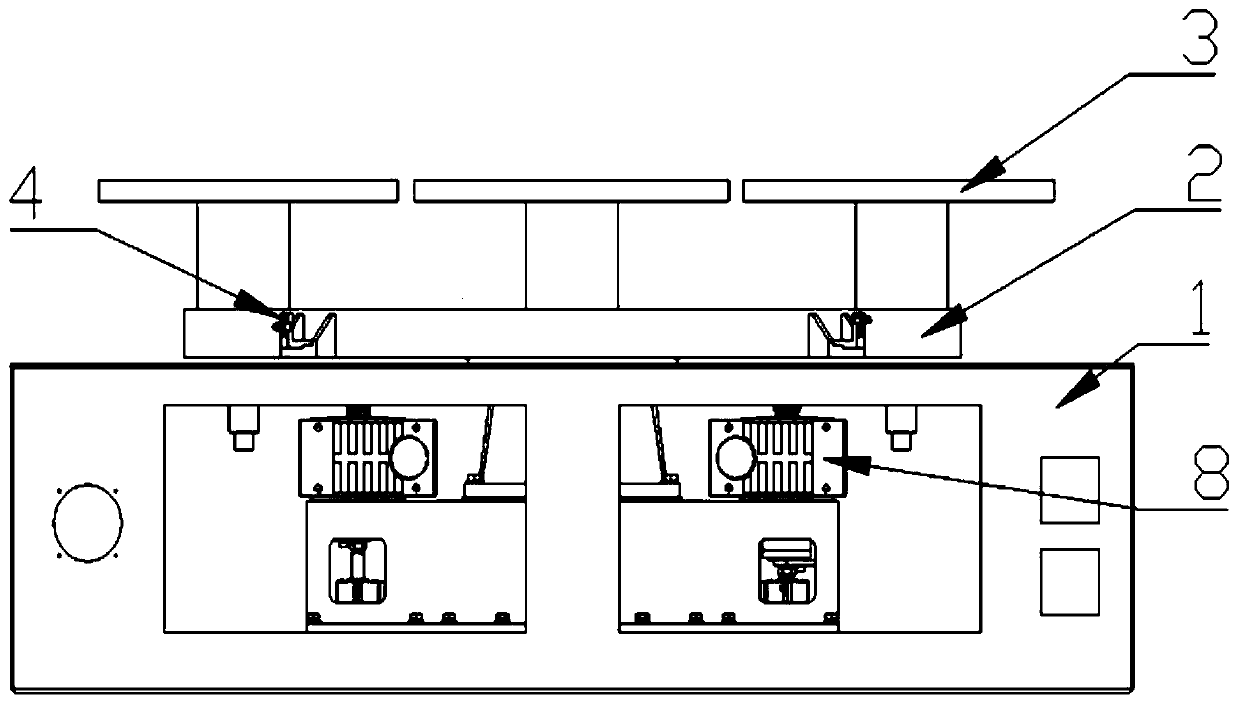

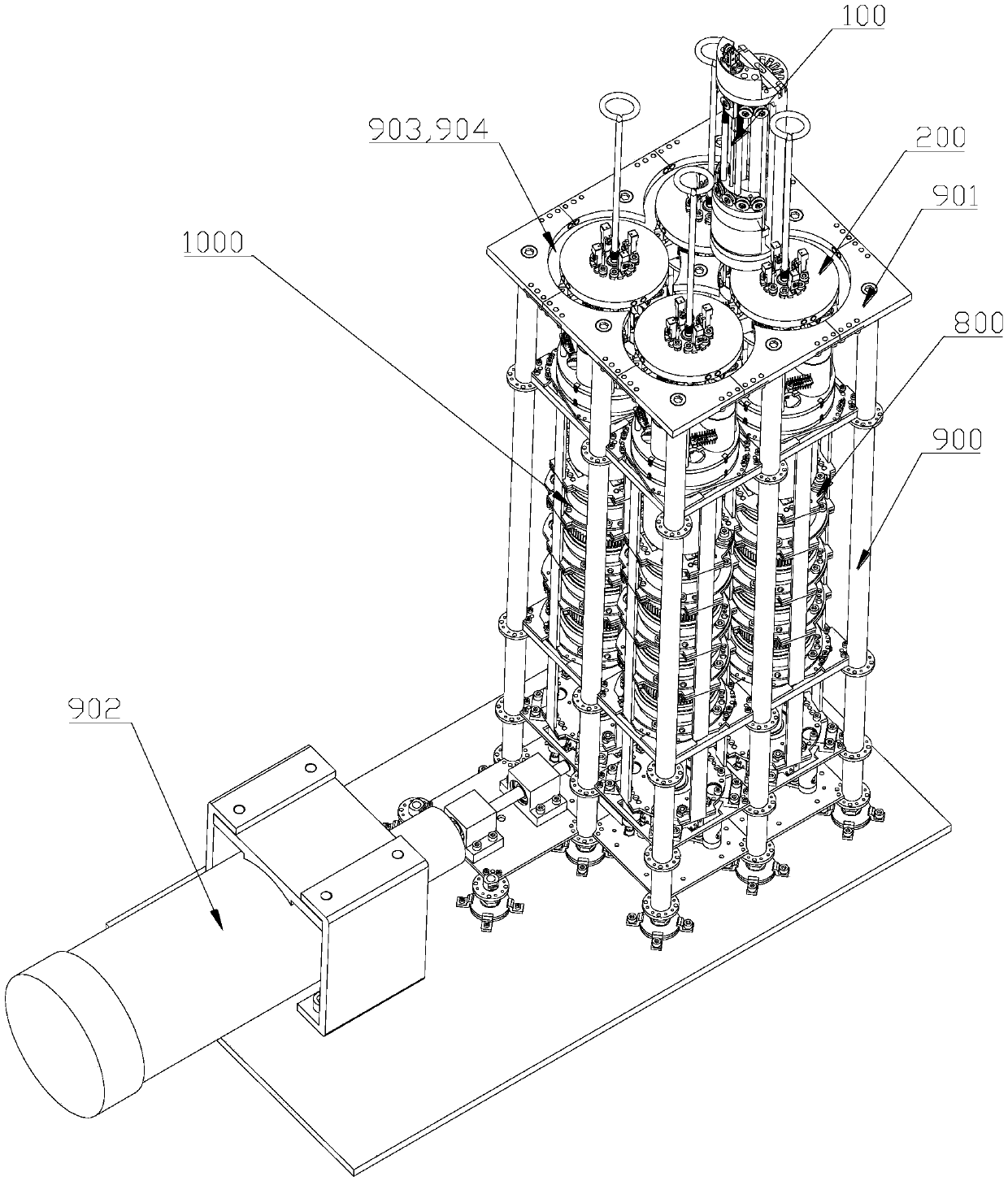

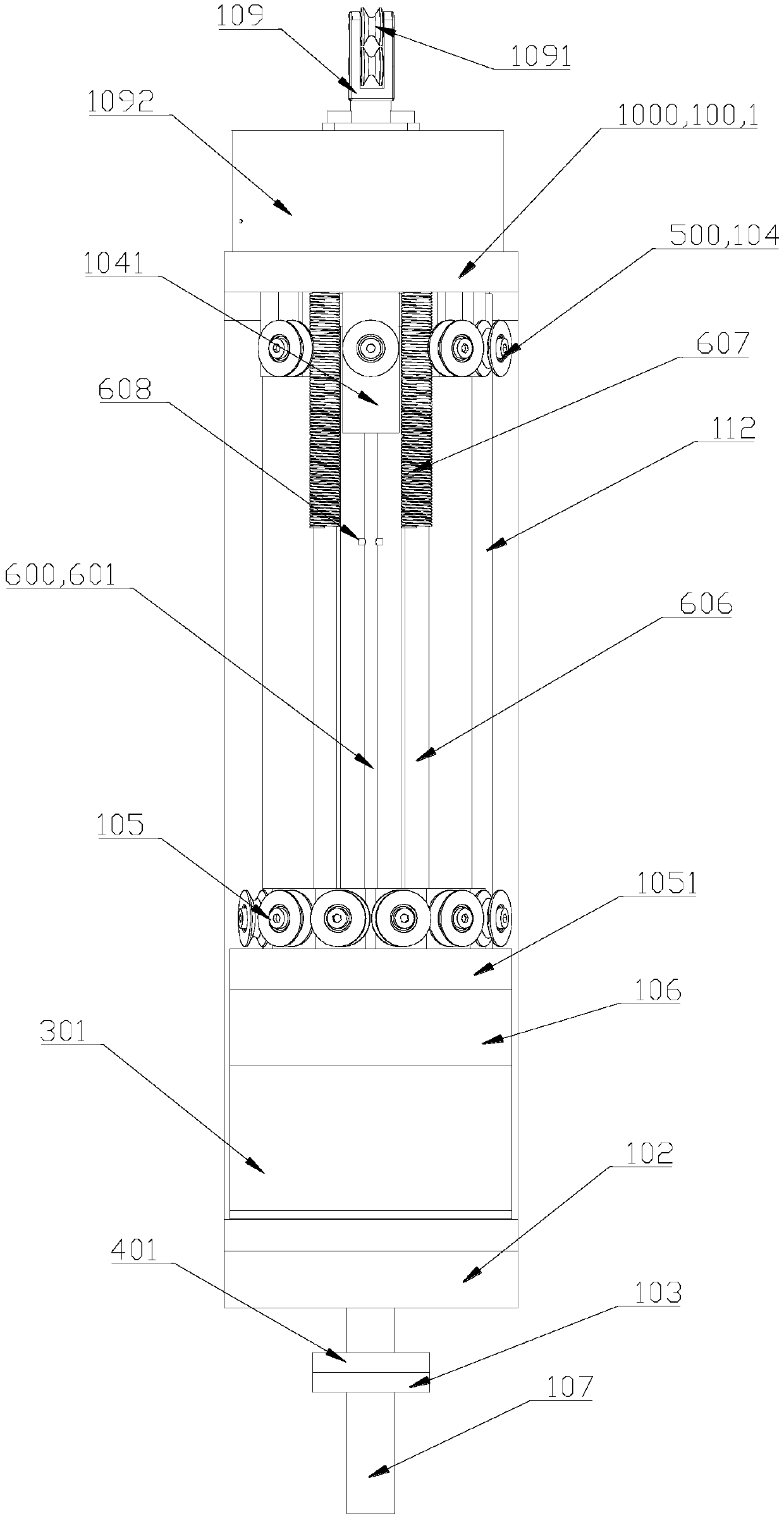

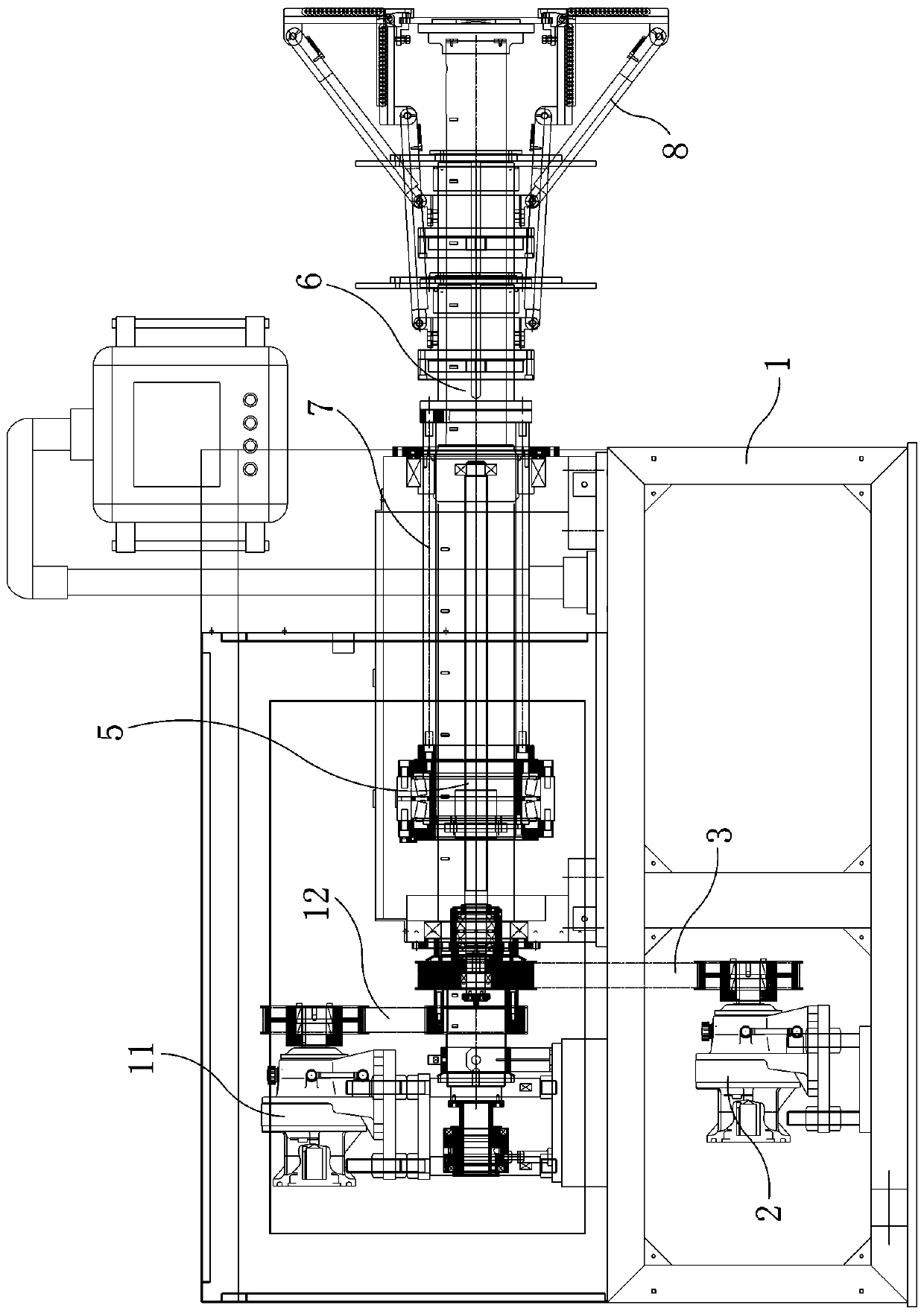

System For Loading And Unloading Cassette and Method For Loading And Unloading Cassette

ActiveUS20170144844A1Smooth unloadingPrecise alignmentConveyorsSemiconductor/solid-state device manufacturingMagnetic tapeEngineering

The embodiment of the present disclosure discloses a system and a method for loading and unloading a cassette. The system for loading and unloading the cassette comprises: a lifting device configured to vertically ascend and descend between a first height and a second height; a first conveying device mounted in the lifting device and configured to move the cassette in a horizontal direction; a second conveying device mounted at the first height and configured to move the cassette in a horizontal direction; a third conveying device mounted at the second height and configured to move the cassette in the horizontal direction; a plurality of first position sensors configured to detect a position of the lifting device; and a control device configured to control ascending and descending of the lifting device, and adjust a further rising or falling of the first conveying device in the lifting device based on an initial stop position of the lifting device detected by the first position sensor such that the first conveying device is aligned with the second conveying device at the first height, or is aligned with the third conveying device at the second height. The conveying device of the lifting device and the conveying device on the platform are capable to accurately align with each other so as to achieve the smooth loading and unloading of the cassette.

Owner:BOE TECH GRP CO LTD +1

Stop position control apparatus for internal combustion engine

InactiveUS7809493B2Accurate stop positionAccurate estimateAnalogue computers for vehiclesElectrical controlCrankEngineering

An engine model is configured so as to include a crankshaft periphery motion equations computing block, a friction model, an intake air pressure estimation model, an in-cylinder pressure estimation model, a combustion waveform calculation block, an atmospheric pressure correction term calculation block, and an atmospheric temperature correction term calculation block. While combustion is cut off, the friction model is learned and updated using estimated relating to the crank stop position calculated by the engine model and measured data relating to the crank stop position.

Owner:TOYOTA JIDOSHA KK

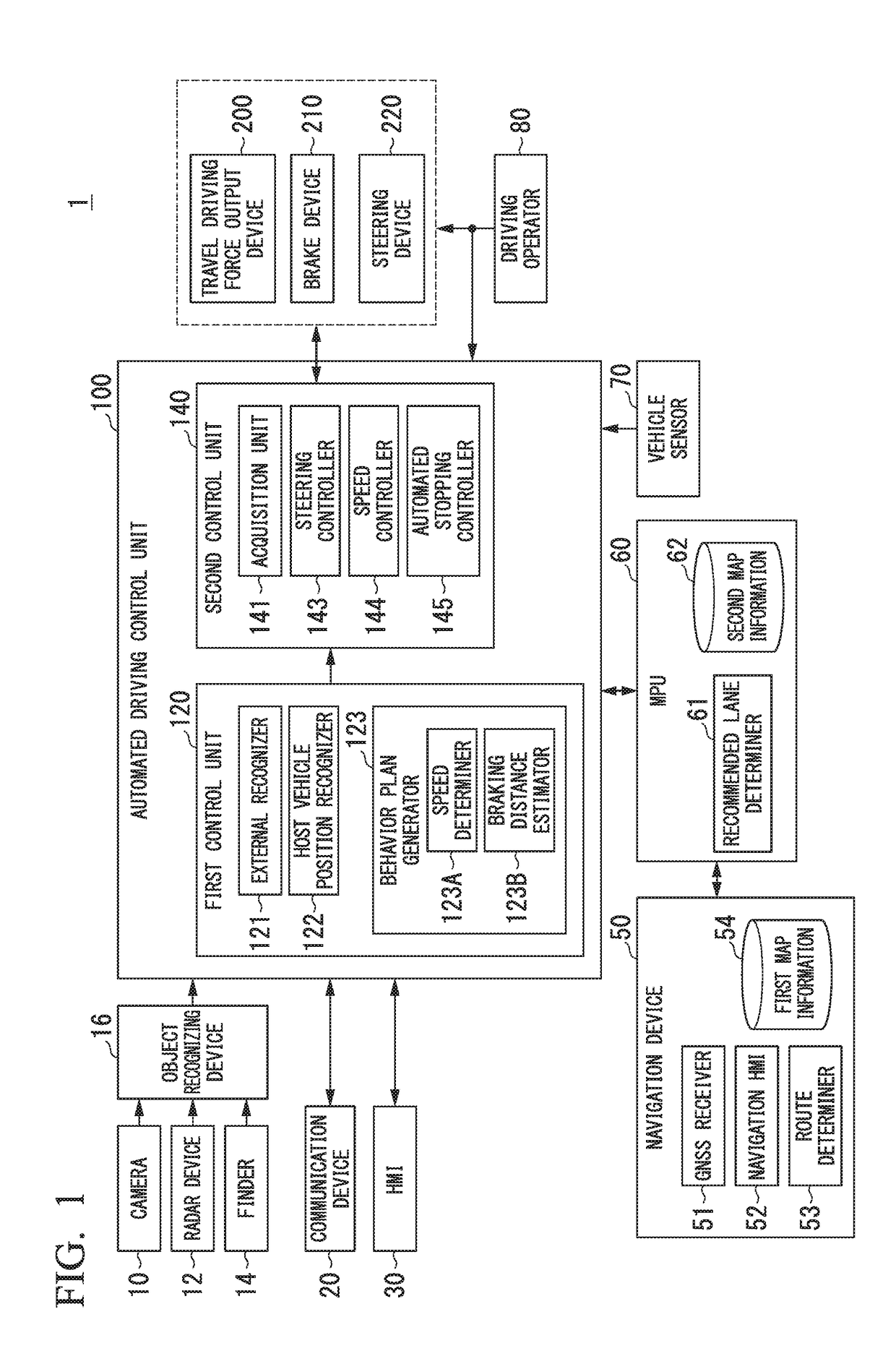

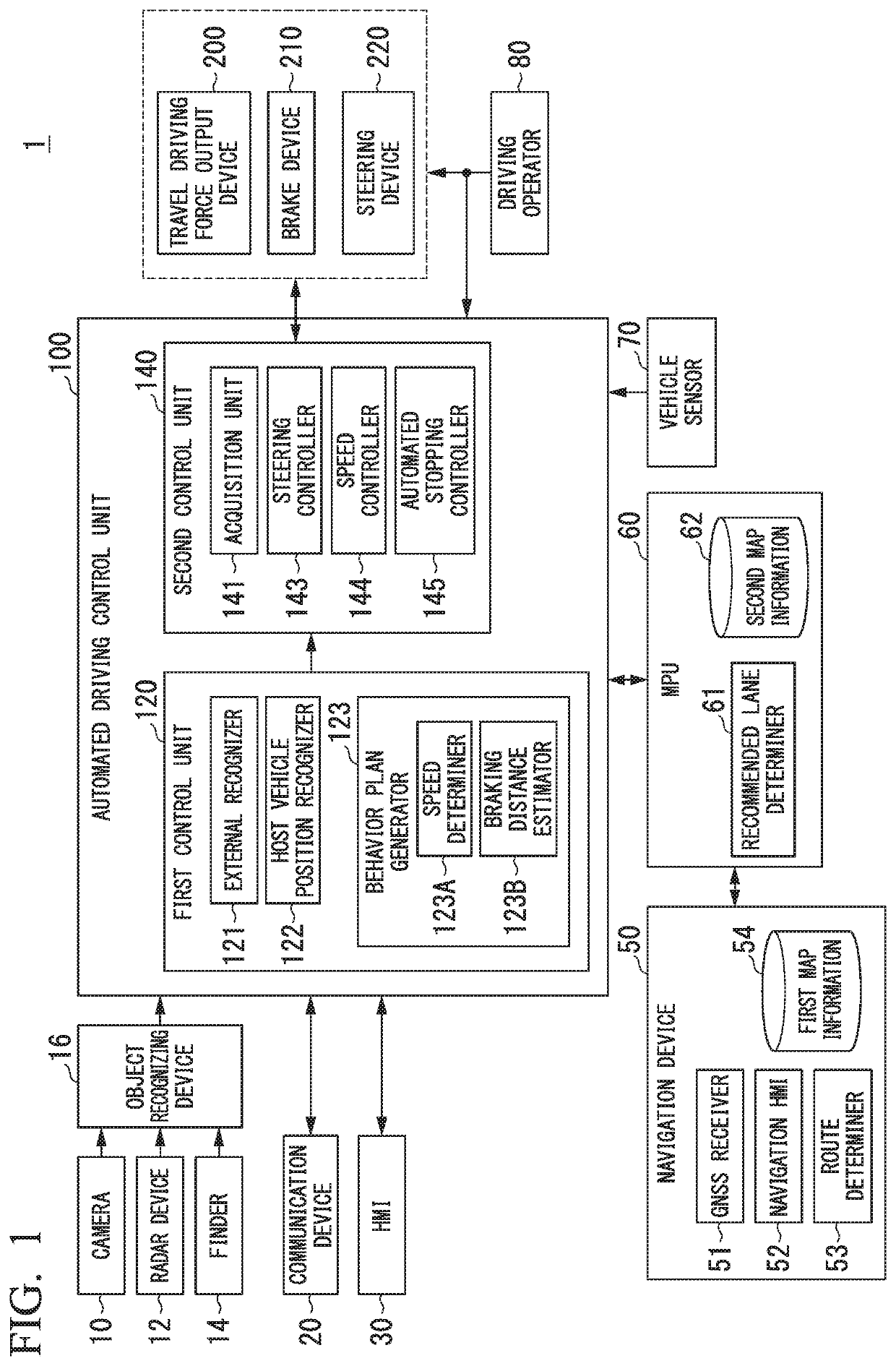

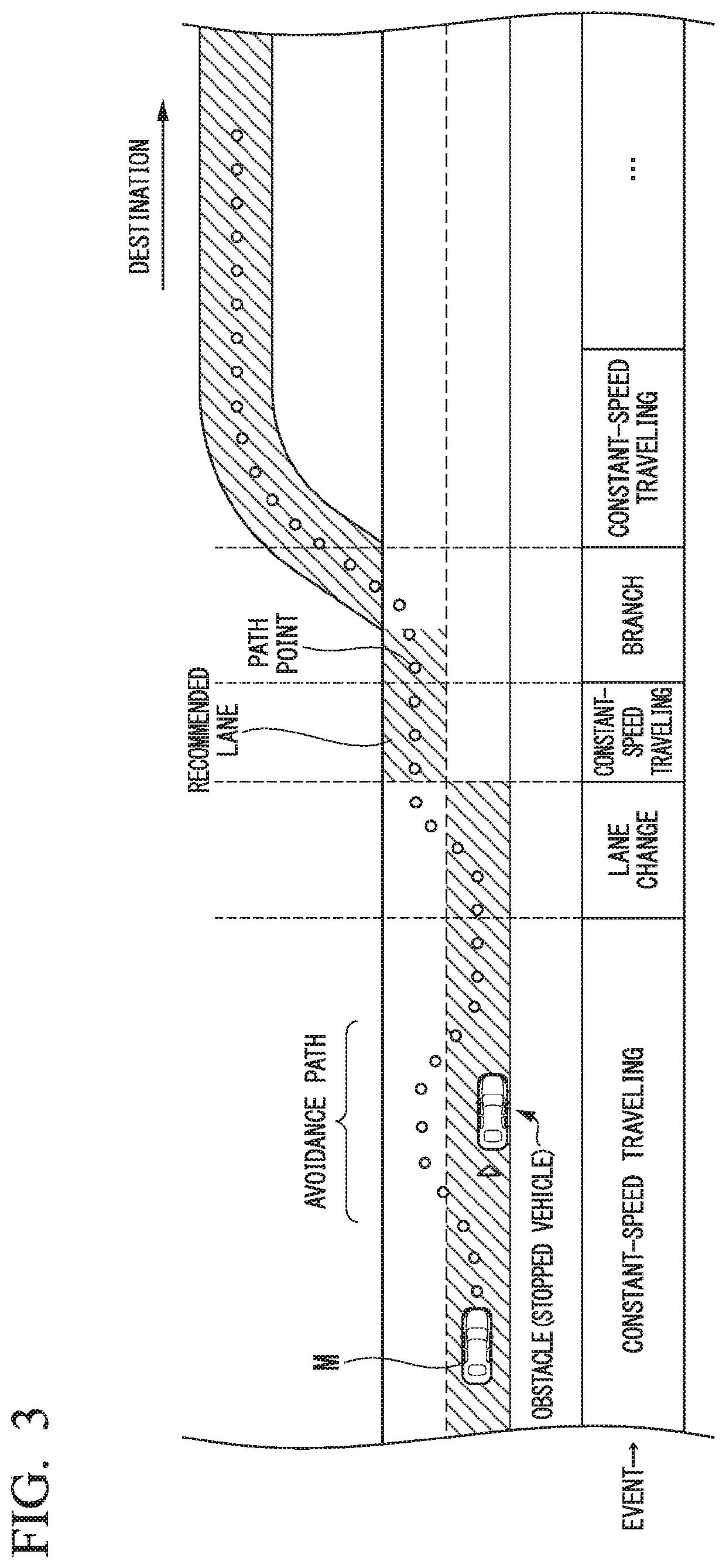

Vehicle controller, vehicle control method, and storage medium

ActiveUS20180345969A1Smoothly decelerateAccurate stop positionAnti-collision systemsImage captureEngineering

A vehicle controller includes: a recognizer (121,122) configured to recognize a distance to a stop position as a first distance on the basis of an image captured by an imaging unit that images the front of a vehicle; and a braking distance estimator (123B) configured to estimate a braking distance to the stop position on the basis of the first distance recognized by the recognizer at a predetermined time point and a second distance acquired on the basis of a speed of the vehicle and to adjust a degree of reflection of the second distance in the braking distance on the basis of the first distance recognized by the recognizer after the predetermined time point.

Owner:HONDA MOTOR CO LTD

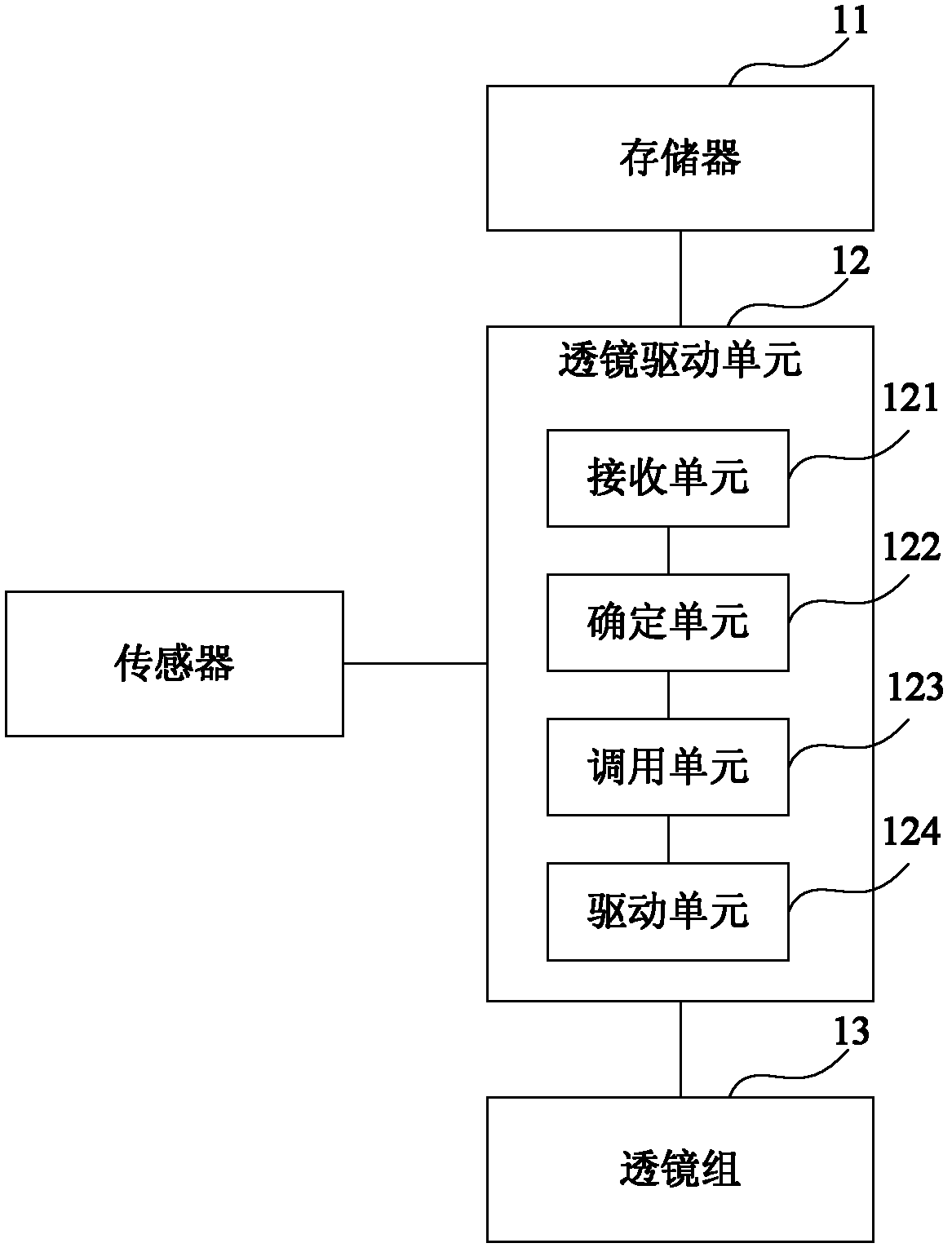

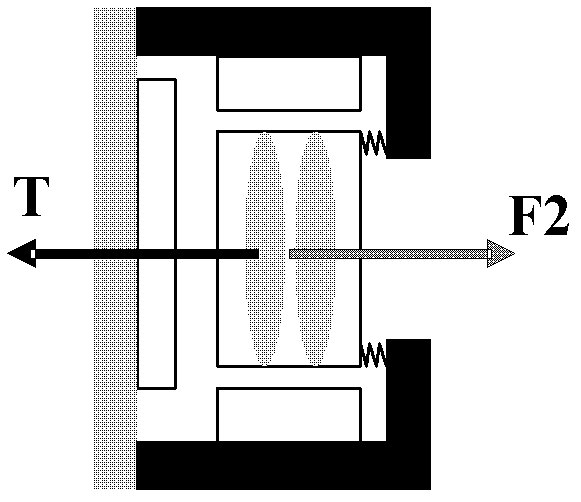

Camera module, electronic device containing camera module and automatic focusing method

InactiveCN103185948AReduce consumptionAccurate stop positionProjector focusing arrangementCamera focusing arrangementComputer moduleCamera module

The invention provides a camera module, an electronic device containing the camera module and an automatic focusing method. The camera module conducts automatic focusing controlling according to received direction information of the camera module, and the camera module comprises a storer, a lens driving unit and a lens group. The storer is used for storing focusing driving information of different directions of the camera module, according to sensed direction of the camera module by a sensor, the lens driving unit calls focusing driving information, corresponding to the direction, stored in the storer, according to the focusing driving information, the lens driving unit drives the lens group to conduct automatic focusing, and according to driving of the lens driving unit, the lens group conducts automatic focusing. The camera module is more accurate in recording of the automatic focusing beginning position and stopping position or the presetting position, improves responding time, and simultaneously reduces power source consumption.

Owner:SONY ERICSSON MOBILE COMM AB

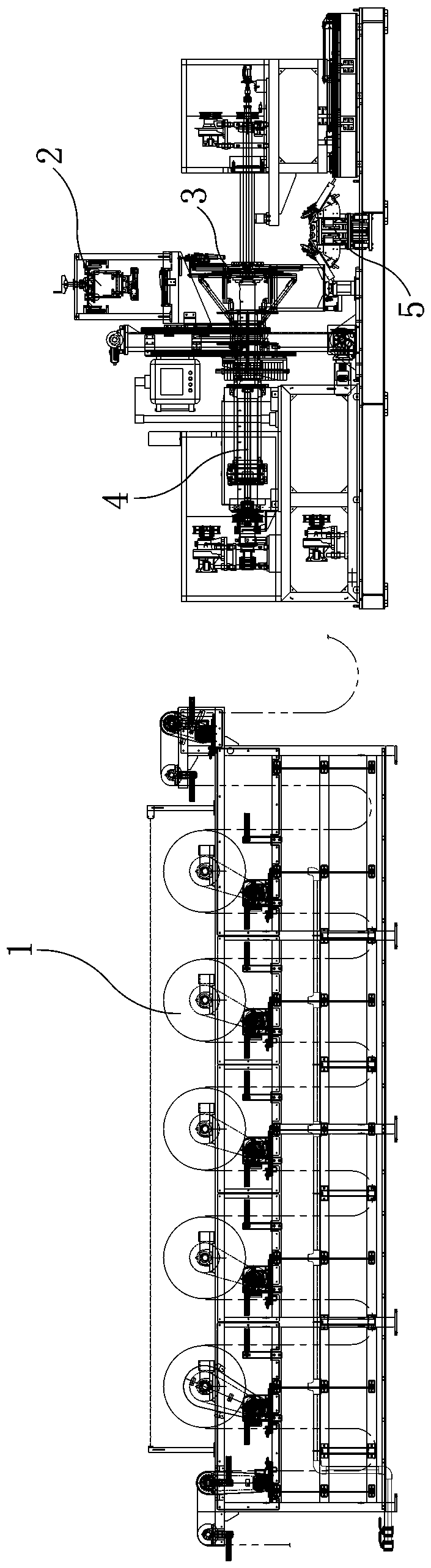

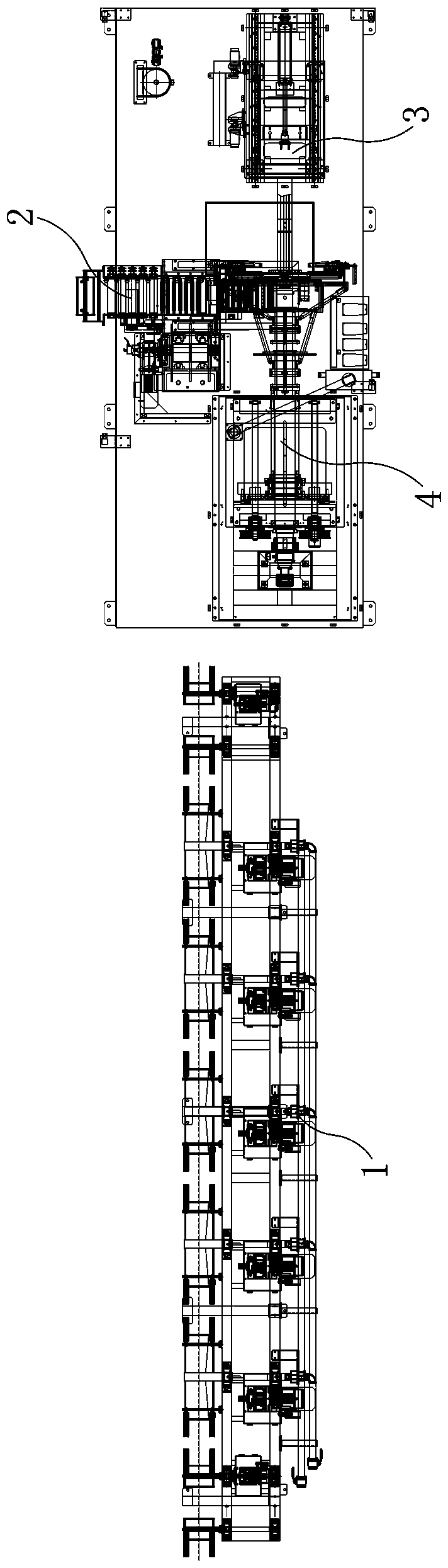

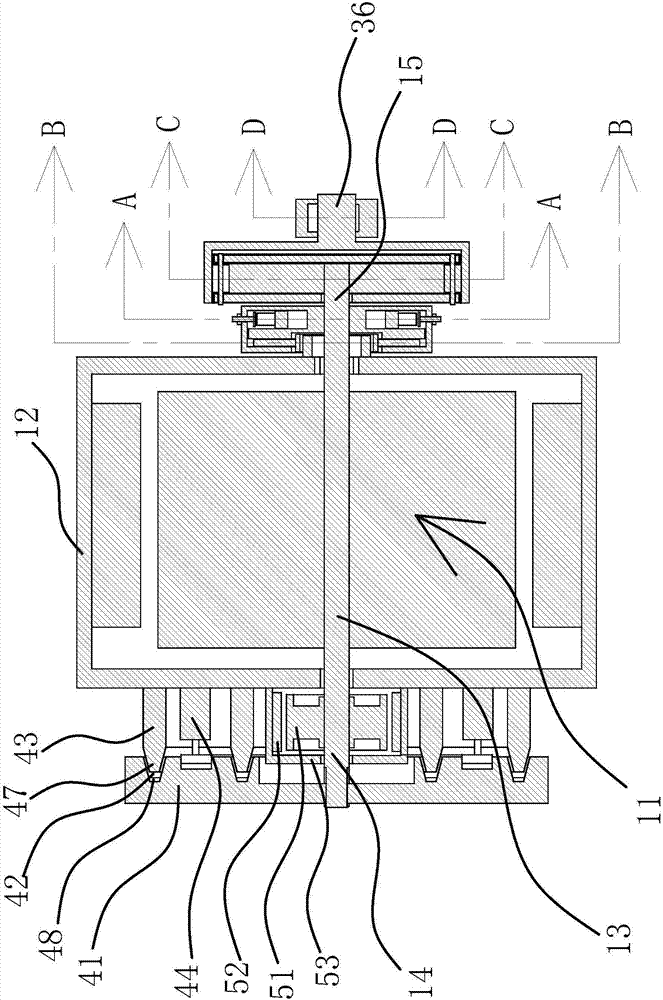

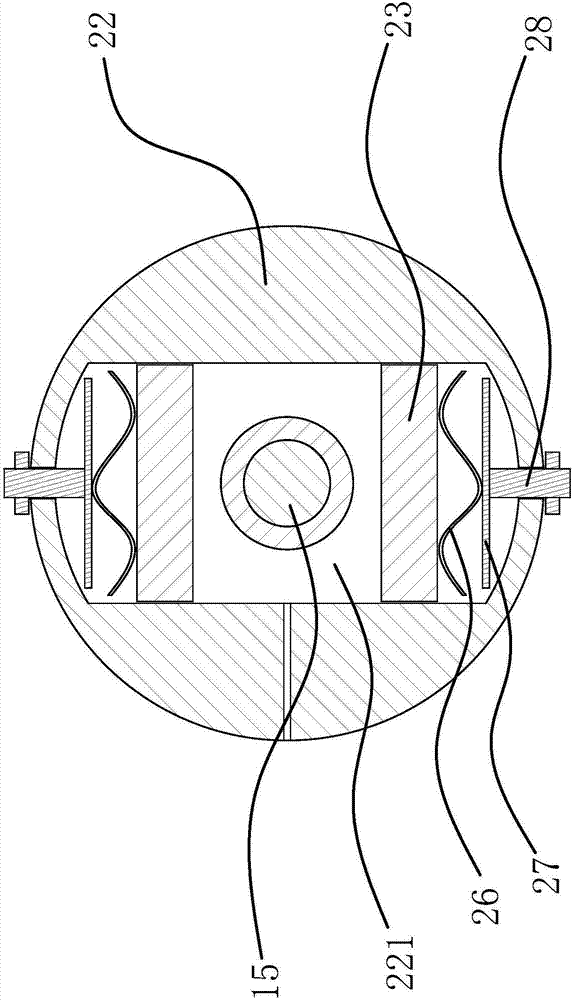

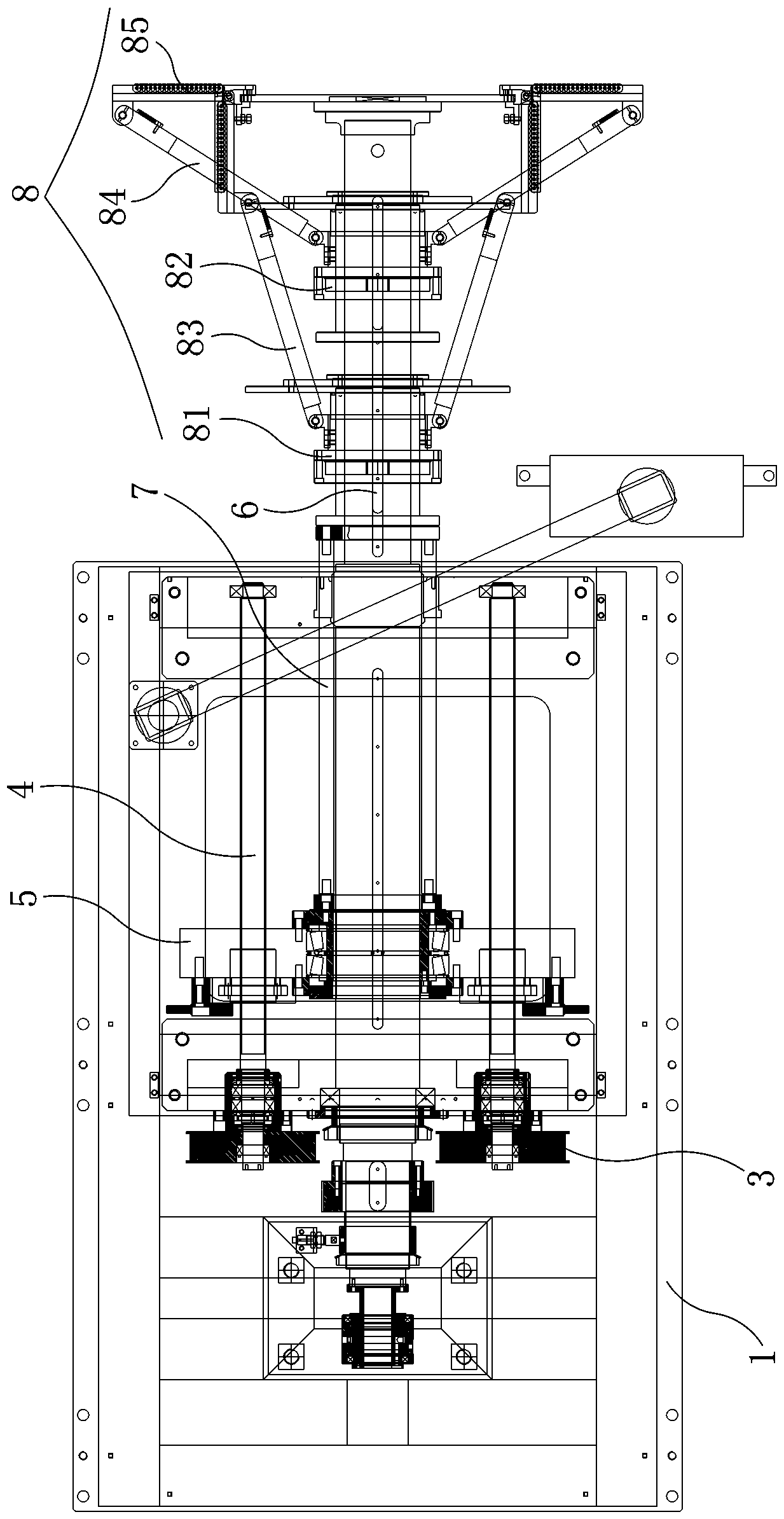

Production assembly line for bead filler

The invention discloses a production assembly line for a bead filler. The production assembly line for the bead filler comprises a cooling storage device, a supply device, a bead filler forming drum,a bead filler bonding device, and a bead filler rolling device, wherein the supply device is installed at a discharge end of the cooling storage device; the bead filler forming drum and the bead filler bonding device are oppositely arranged, and the combined surface of the bead filler forming drum and the bead filler bonding device is a discharge end of the supply device; and the bead filler rolling device is installed below the bead filler bonding device. According to the production assembly line for the bead filler, the cooling storage device realizes low-temperature cooling shaping for thebead filler; the supply device realizes automatic supply for the bead filler to the bead filler forming drum, supply is carried out in the manner of suction of a vacuum suction disc, and feeding is controlled through a cylinder; the power of the bead filler forming drum, the bead filler bonding device and the bead filler rolling device is driven by a servo motor, a high deformation speed and an accurate stopping position are achieved; and a rolling mechanism is used for exhaust, compaction, and shaping and rolling after a steel wire ring is compounded with the bead filler, so that effective bonding for the bead filler and the steel wire ring is guaranteed.

Owner:XIAMEN HAOSHENG MECHANICAL & ELECTRICAL ENG CO LTD

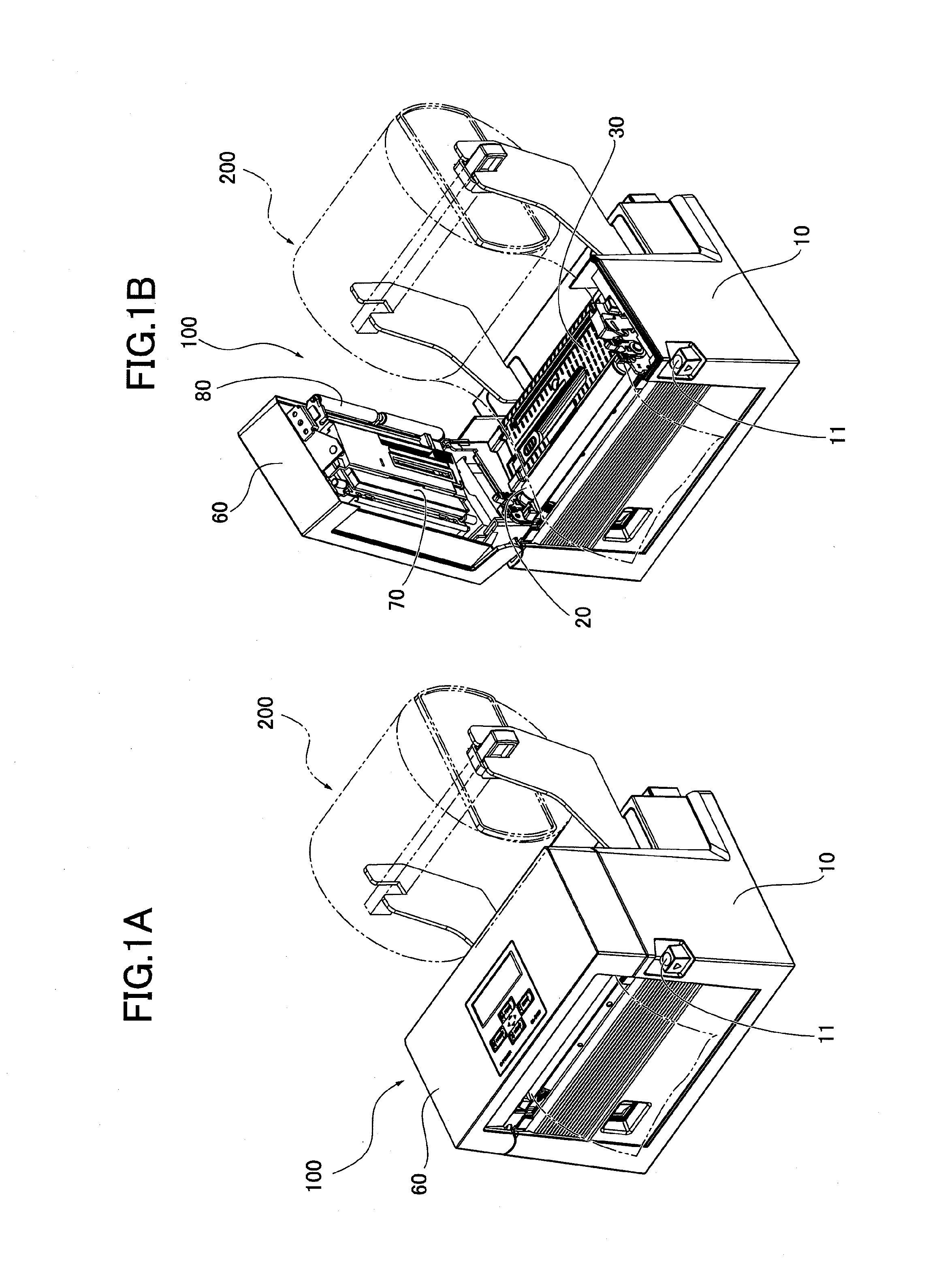

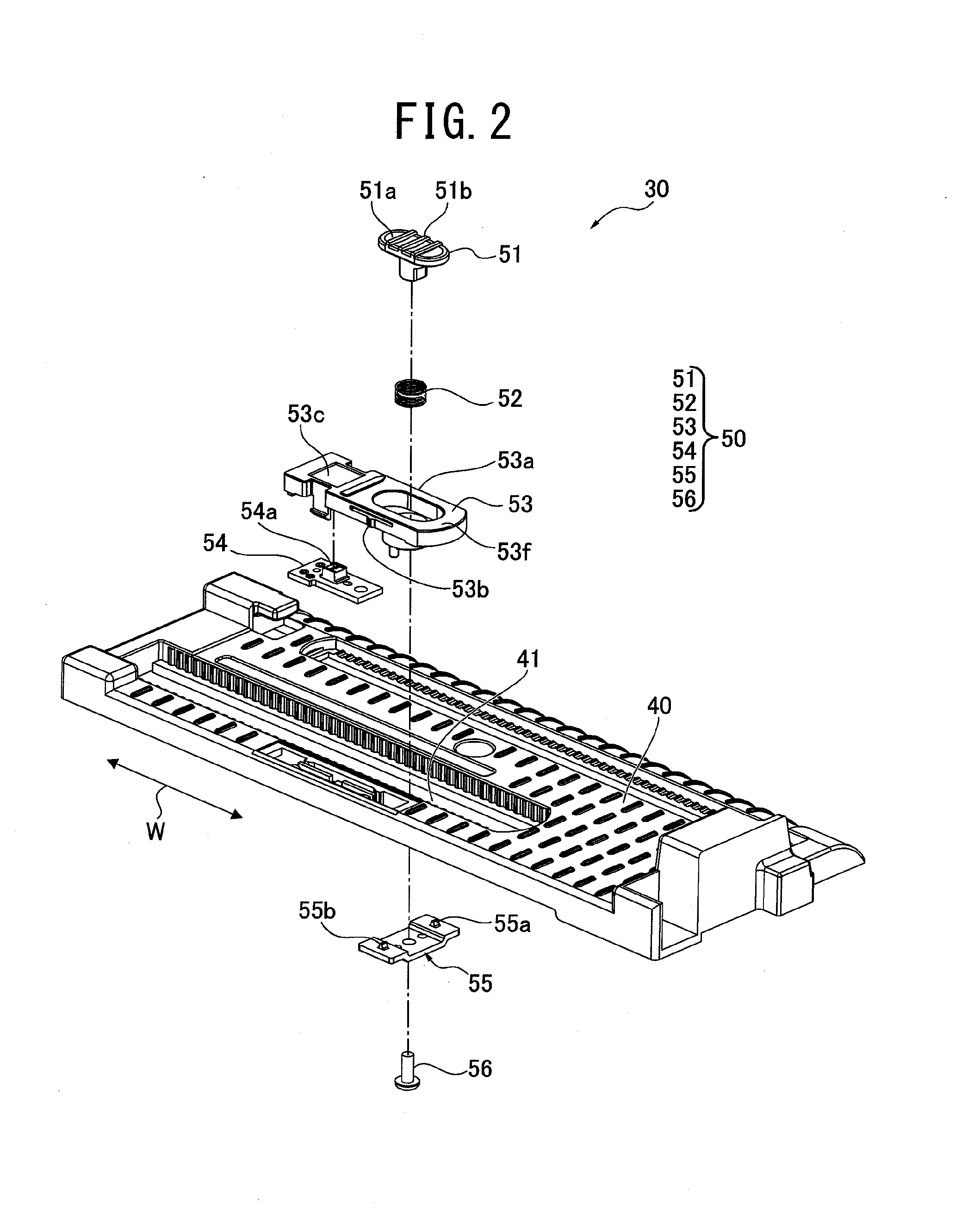

Paper detecting device and printer including the same

ActiveUS20120188547A1Smooth movementEasy to operateTransmissivity measurementsOther printing apparatusPulp and paper industry

Owner:CITIZEN SYST JAPAN +1

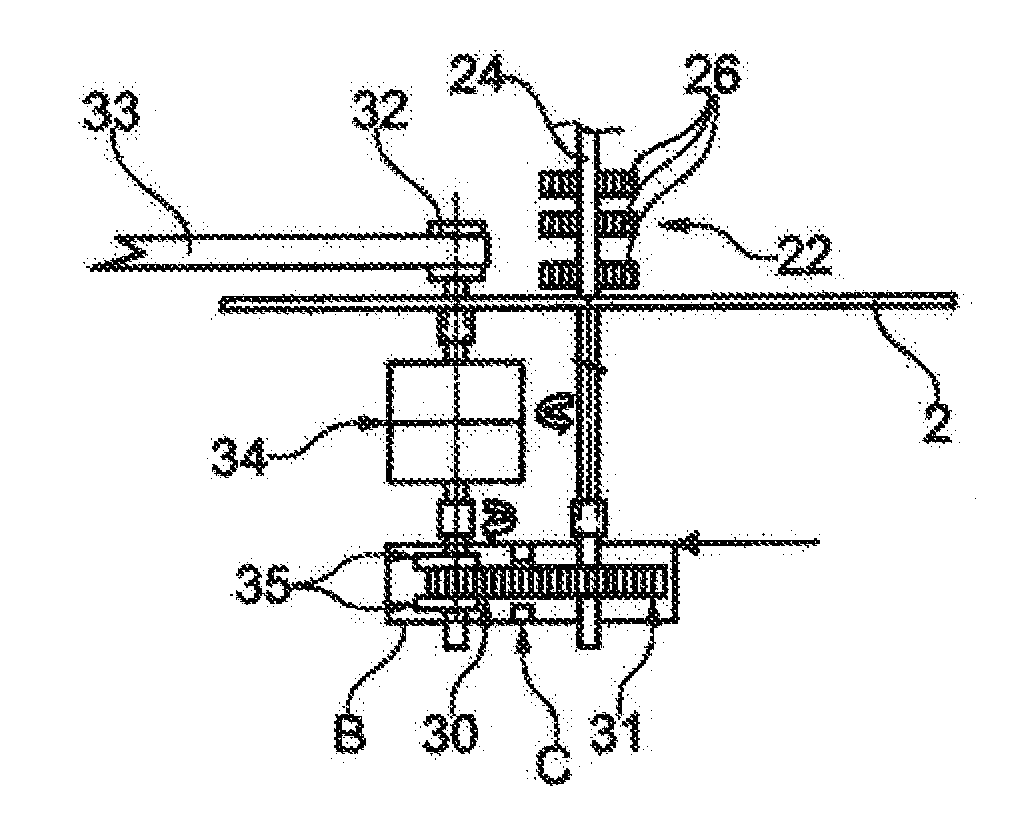

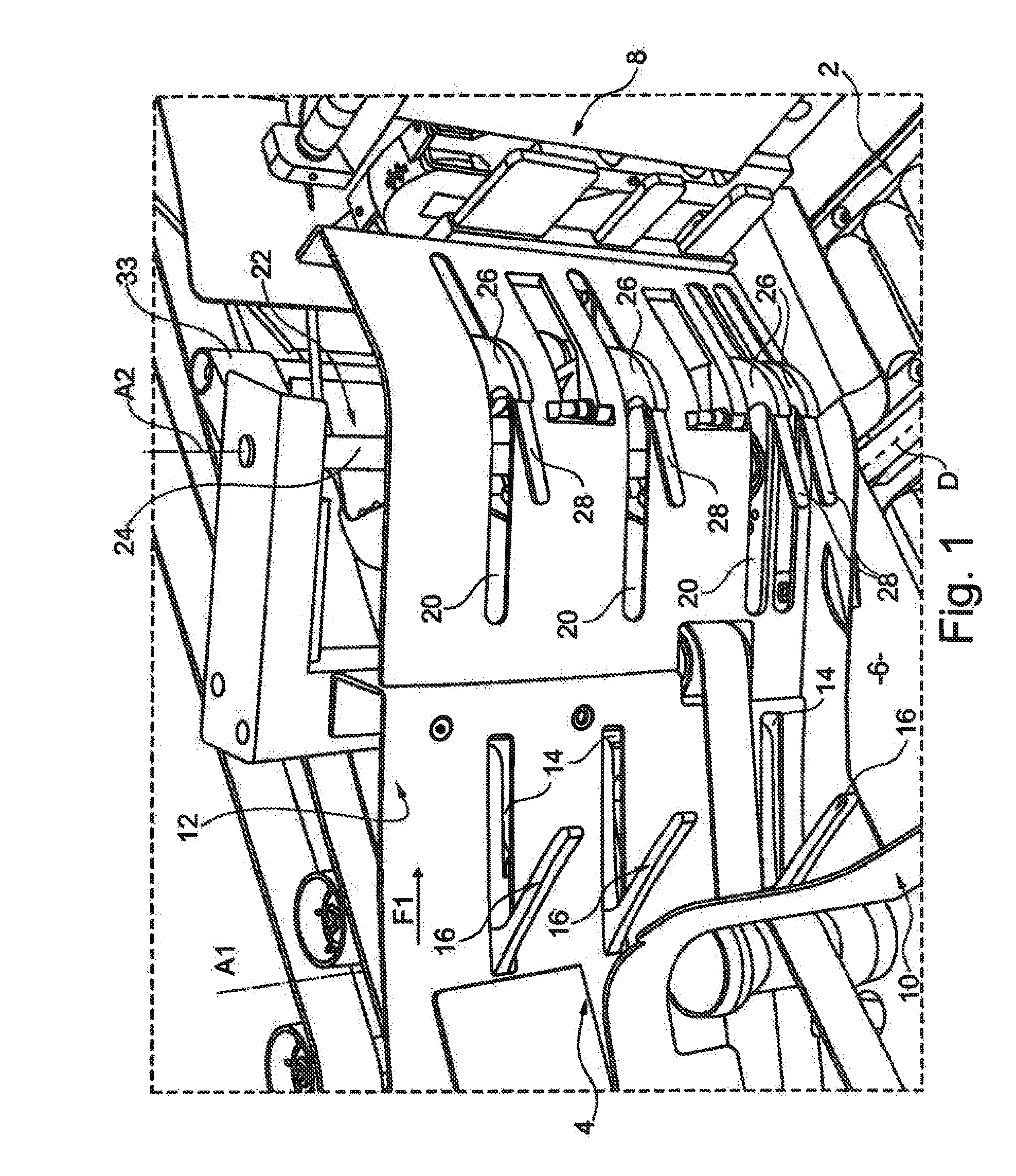

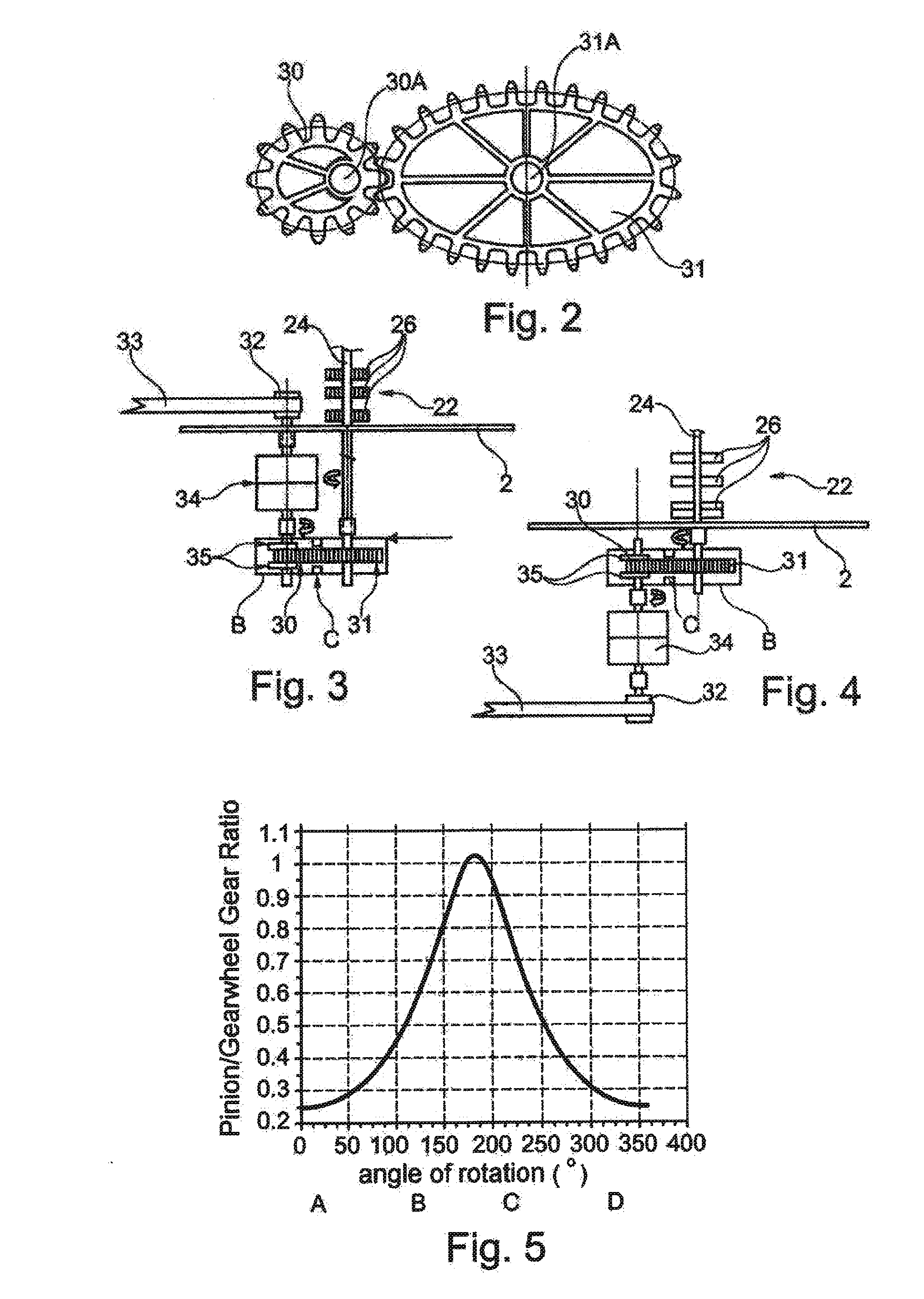

A Mechanical Transmission For a Mail Stacker Unit With a Clutch Brake and Elliptical Gearing

InactiveUS20160281827A1Limit number of and complexityEasy to adjustGearingFunction indicatorsActuatorStacker

A mail stacker unit in a postal sorting machine includes a stacking actuator (22) driven in stop-start rotation for the purpose of stacking mailpieces on edge in a storage receptacle. The actuator is coupled in rotation to a clutch brake (34) driven at constant speed, and elliptical gearing (30, 31) is also provided between the clutch brake and said stacking actuator.

Owner:SOLYSTIC

System for loading and unloading cassette and method for loading and unloading cassette

ActiveUS9919878B2Accurate stop positionSmooth loading and unloadingConveyorsSemiconductor/solid-state device manufacturingEngineeringPosition sensor

The embodiment of the present disclosure relates to a system and a method for loading and unloading a cassette. The system comprises: a lifting device vertically moving between a first height and a second height; a first conveying device in the lifting device to move the cassette horizontally; a second conveying device to move the cassette in horizontally; a third conveying device to move the cassette horizontally, a plurality of first position sensors to detect a position of the lifting device; and a control device to control vertical movements of the lifting device, and adjust further movements of the first conveying device in the lifting device based on an initial stop position of the lifting device such that the first conveying device is aligned with the second conveying device at the first height, or is aligned with the third conveying device at the second height.

Owner:BOE TECH GRP CO LTD +1

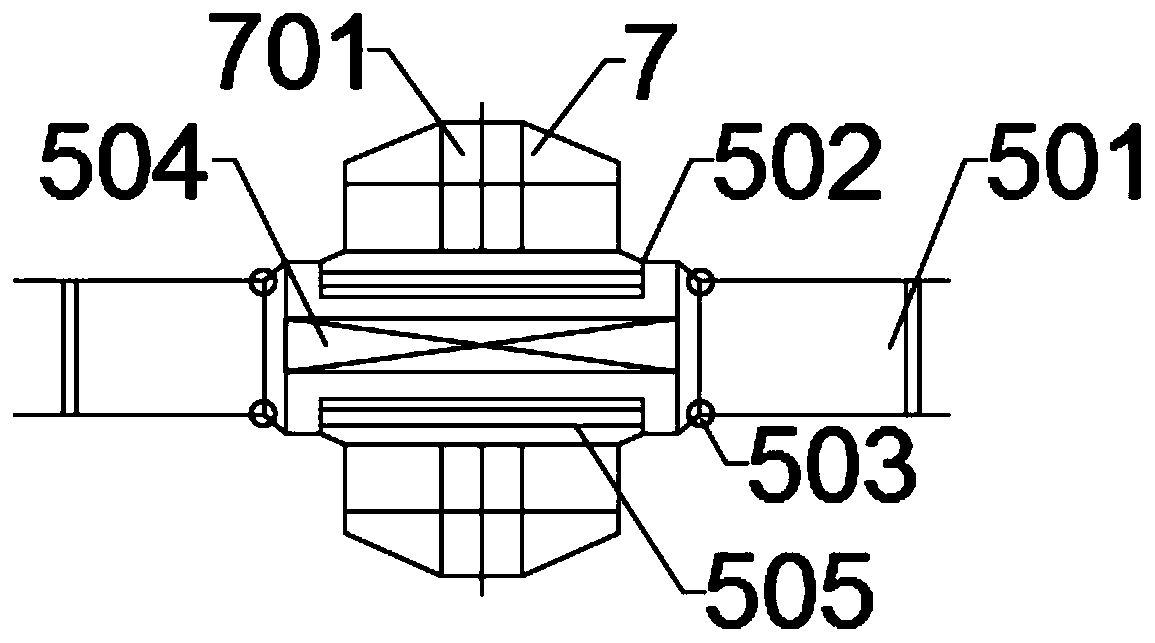

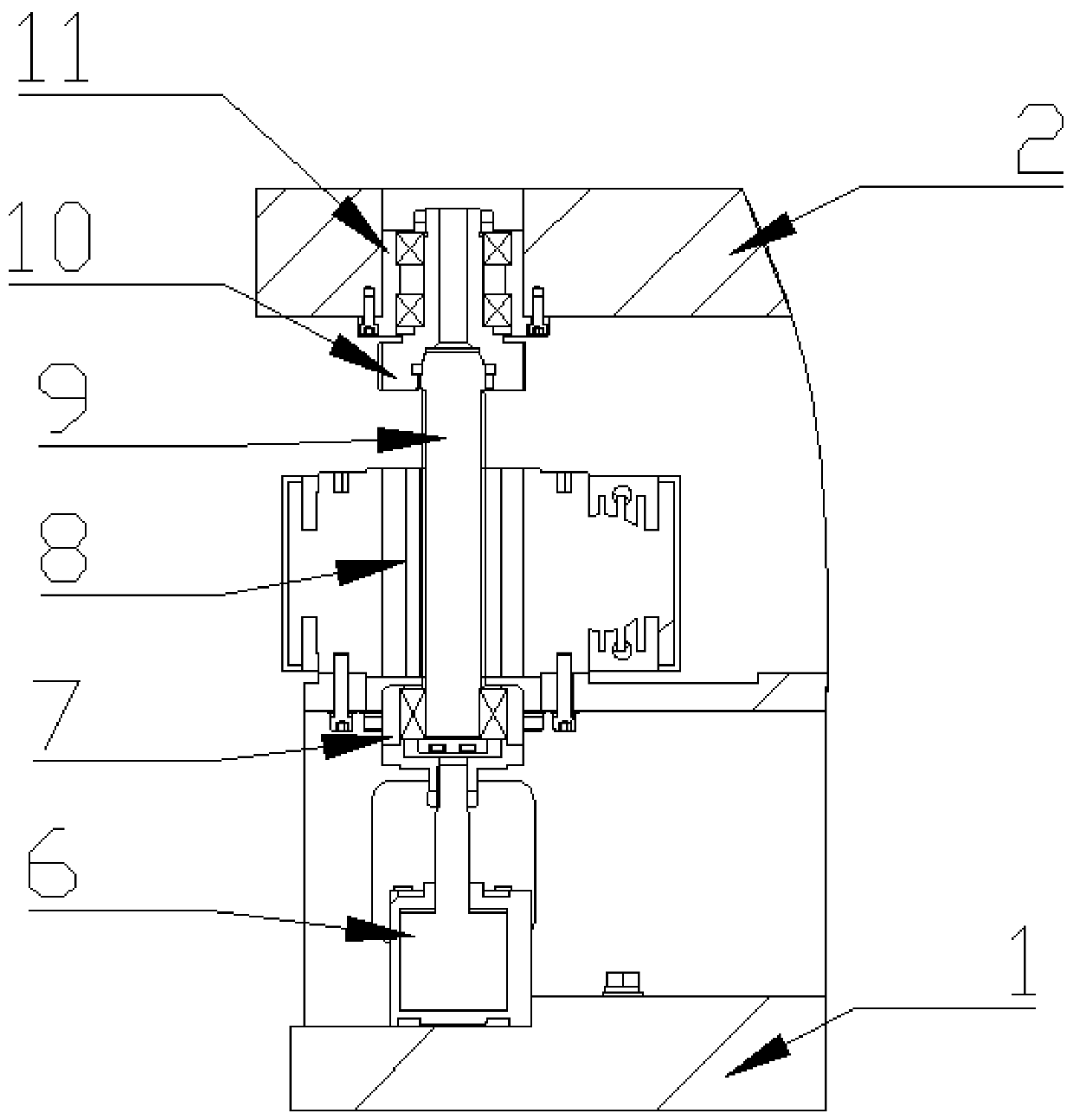

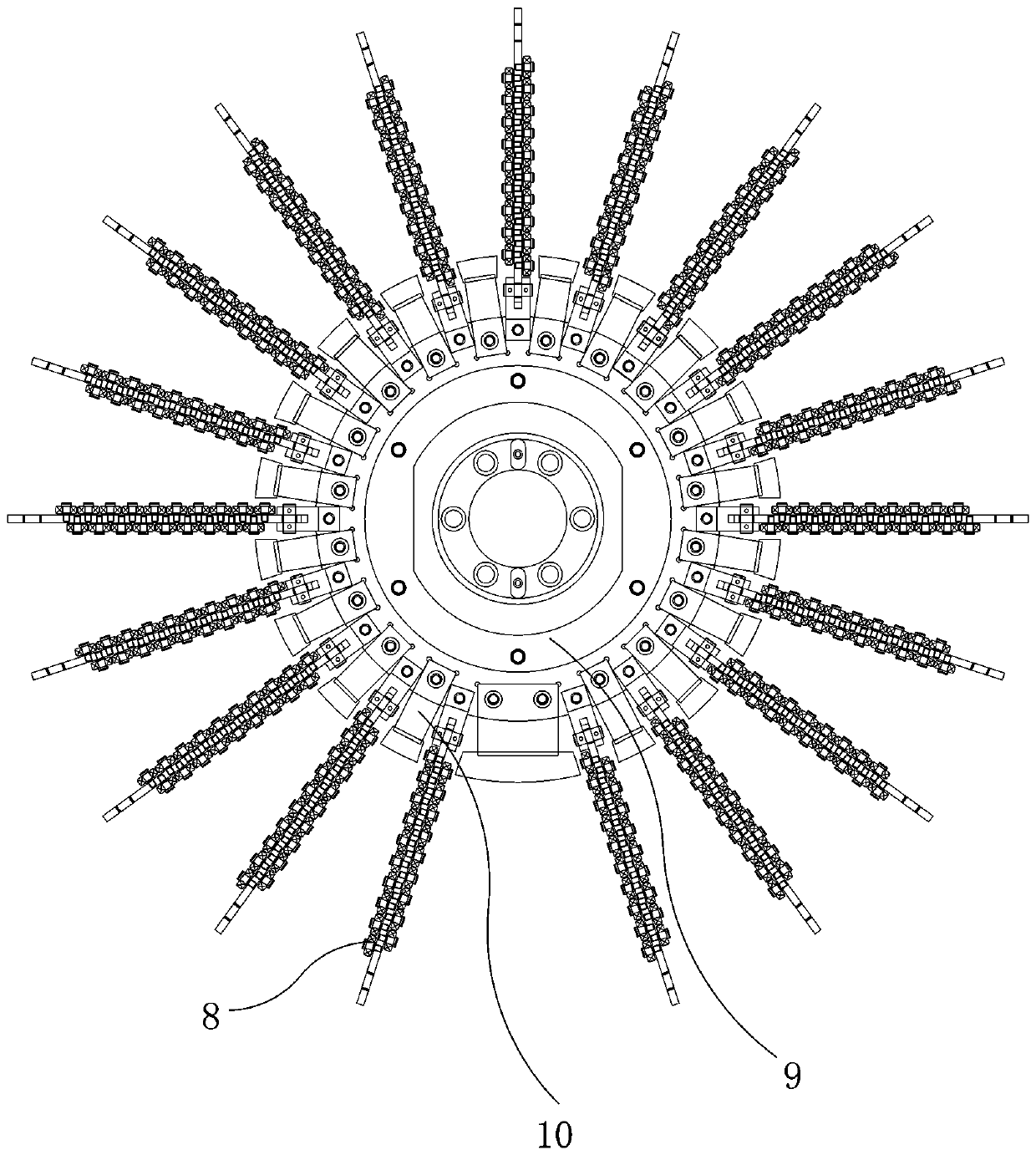

Hosiery body locating and ejecting device with movable sinker cover for integrated hosiery knitting machine

ActiveCN107805875AAccurate stop positionAvoid Seam FailureTextile/flexible product manufactureCircular knitting machinesEngineeringMechanical engineering

The invention discloses a hosiery body locating and ejecting device with a movable sinker cover for an integrated knitting machine. The precision requirement for the displacement of a cover piece is high, and the thickness requirements of different parts of hosiery are different. When existing hosiery knitting and end sewing integrated machines are used for transferring the hosiery, the problem that kitting needles are inaccurately aligned with transfer sheets easily occurs. The device comprises a rack, a needle cylinder core, a gear, a hosiery containing cylinder, a locating mechanism, a lifting mechanism, a support plate, the sinker cover, a connecting rod, a cover piece adjusting mechanism and a mechanism for adjusting a left eyebrow-shaped piece and a right eyebrow-shaped piece; the locating mechanism comprises a locating air cylinder, a locating ring, a fixing disc and a limiting block; the lifting mechanism includes an optical axis, a lifting air cylinder, an air cylinder supportbase and a lifting sliding block. By means of the device, the situation that end sewing fails since a needle head is misaligned in the process of transferring the hosiery by the hosiery knitting andend sewing integrated machine can be avoided, the displacement angle of the sinker cover can be controlled, the tightness degrees of the different parts of the hosiery can be controlled, and the quality of the hosiery is improved.

Owner:浙江专博纺织机械有限公司

Positioning and ejection device for sock-knitting and end-stitching all-in-one machine

PendingCN107805876AAccurate stop positionAvoid Seam FailureCircular knitting machinesSOCKSOptical axis

The invention discloses a positioning and ejection device for a sock-knitting and end-stitching all-in-one machine. When an existing sock-knitting and end-stitching all-in-one machine transfers socks,the problem of inaccurate position alignment of knitting needles and transfer sheets easily exists. The positioning and ejection device comprises a gear, a sock containing cylinder, a positioning component, a lifting component and a rack. The positioning component comprises a positioning air cylinder, a positioning ring, a fixing disk and a limit block. The fixing ring is fixed to the top surfaceof the gear, a limit groove is formed in the top surface of the positioning ring, and the fixing disk is located over the positioning ring and fixed to the rack. The positioning air cylinder is fixedto the top surface of the fixing disk, the limit block is fixed to the outer end of a piston rod of the positioning air cylinder, and the limit block is located above the positioning ring. The lifting component comprises an optical axle, a lifting air cylinder, an air cylinder supporting base and a lifting sliding block. The positioning and ejection device can avoid end-stitching failure caused by needle head dislocation in the sock transferring process of the sock-knitting and end-stitching all-in-one machine.

Owner:XINCHANG ZHENXING TEXTILE MACHINERY CO LTD

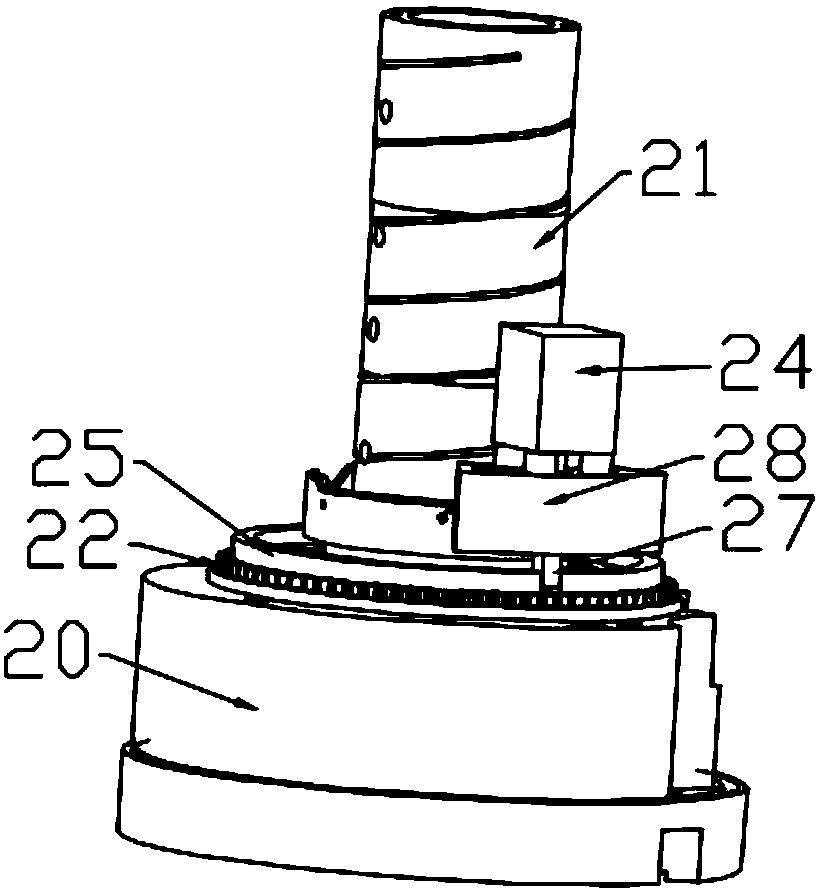

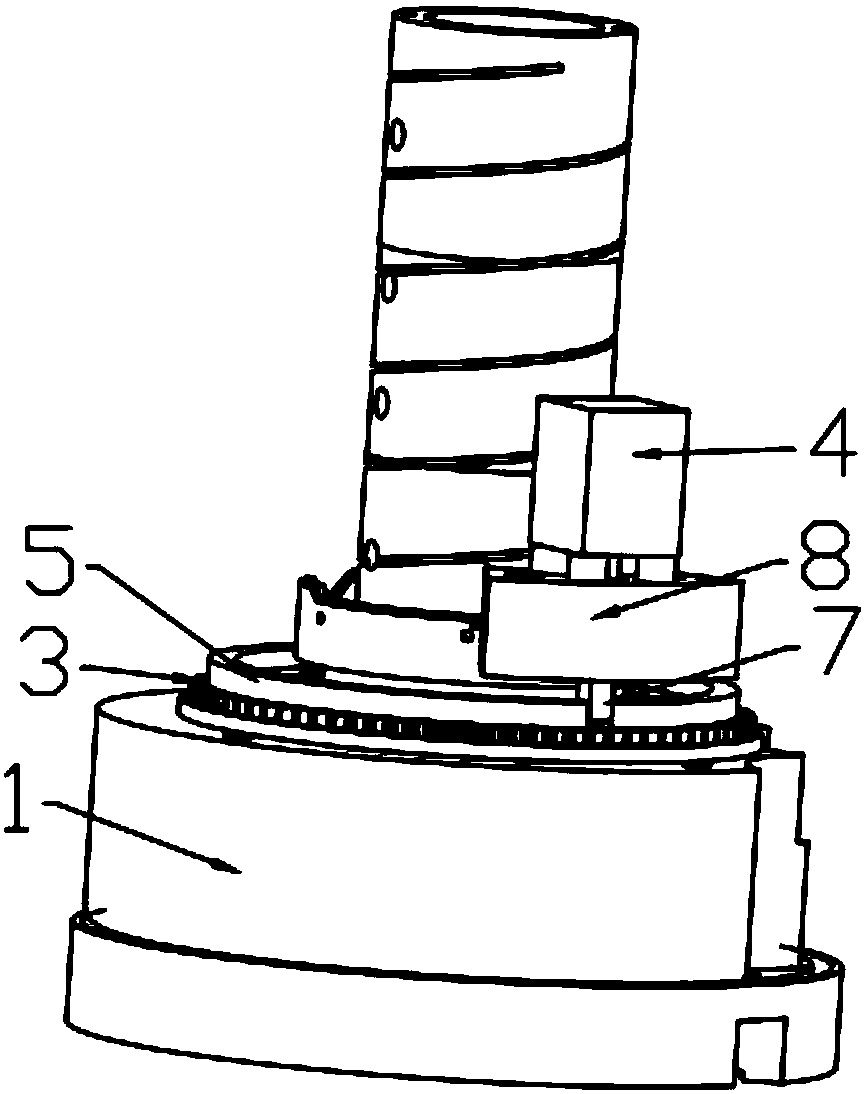

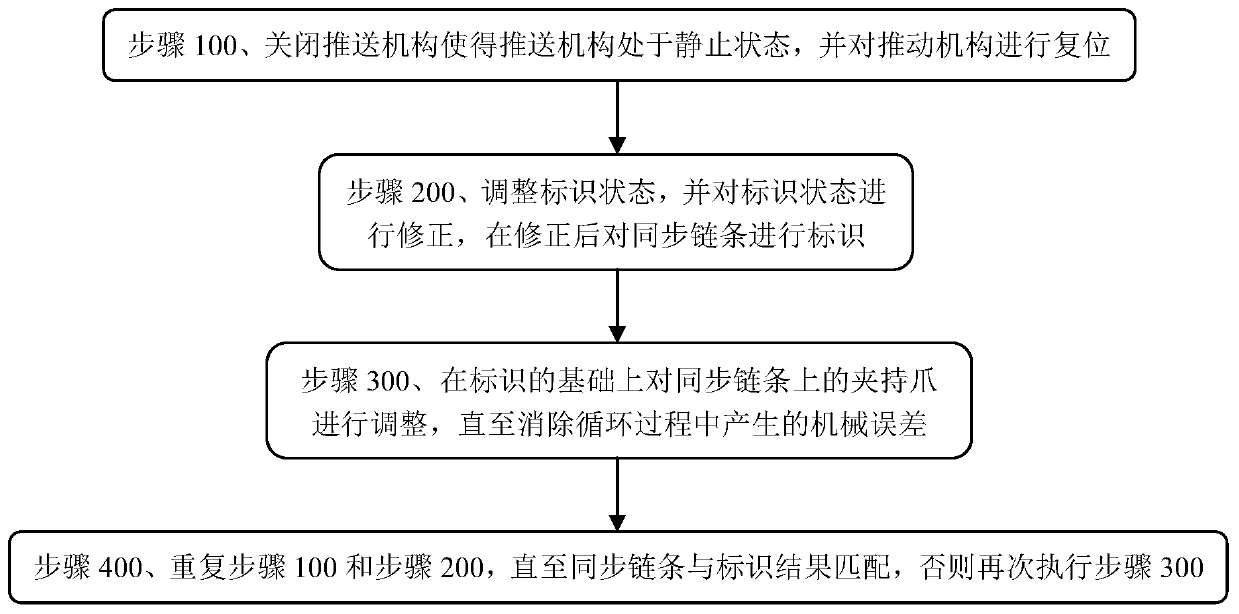

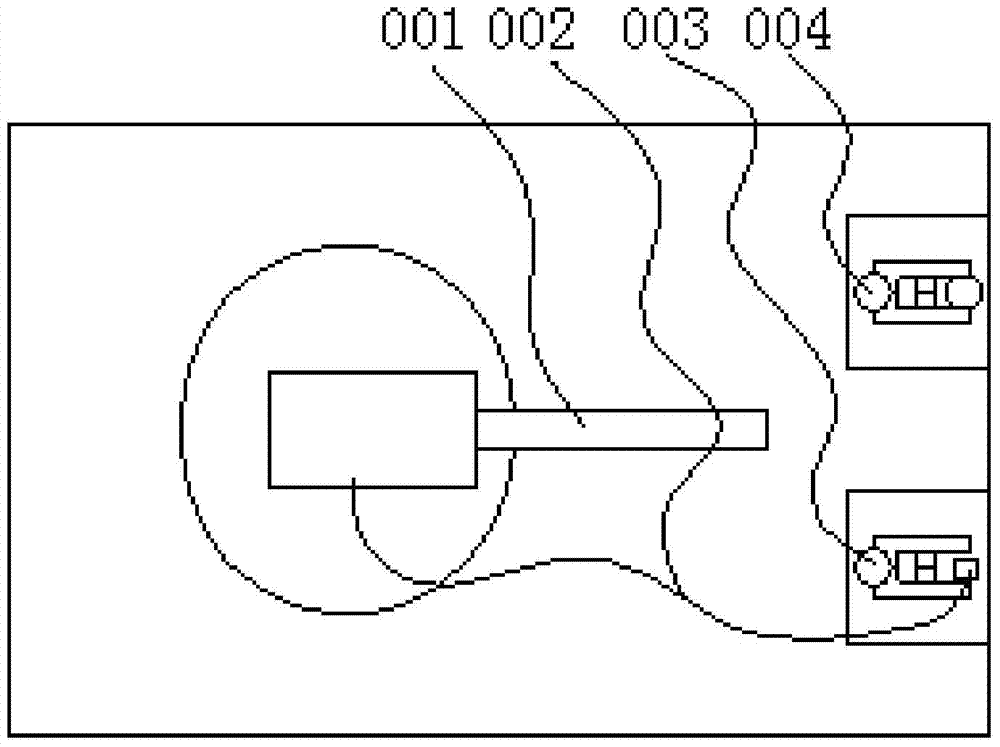

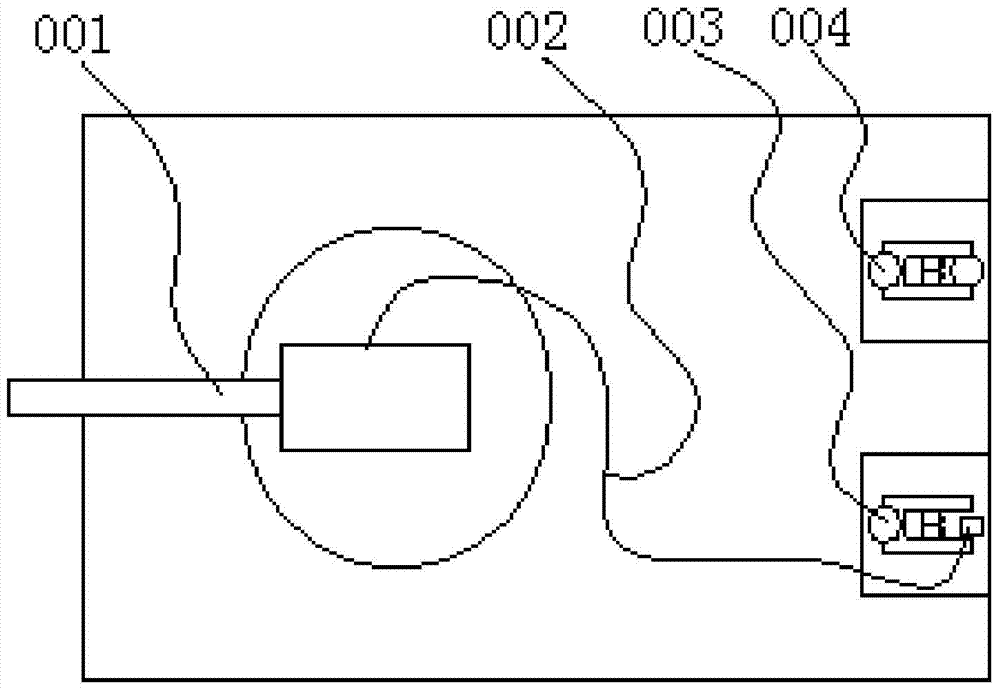

Zero correction device and method for covering pushing

InactiveCN110666943AEliminate errorsError versus Accuracy EliminationAuxillary shaping apparatusControl engineeringControl theory

The embodiment of the invention discloses a zero correction method for covering pushing. The method comprises the following steps that step 100, a pushing mechanism is closed to be in a static state,and the pushing mechanism is reset; step 200, the identification state is adjusted, the identification state is corrected, and after correction, a synchronous chain is identified; step 300, clamping jaws on the synchronous chain are adjusted on the basis of identification until mechanical error generated in the circulation process is eliminated; and step 400, the step 100 and the step 200 are repeatedly carried out until the synchronous chain is matched with the identification result, otherwise, the step 300 is executed again. The invention further discloses a zero correction device. Accordingto the method and the device, the pushing mechanism is subjected to synchronous correction by establishing a reference plane, so that the position of a stopping station of covering control is more accurate, and the mechanical error generated in the running process is eliminated; and furthermore, the correction precision is ensured through a plurality of methods, and the correction result can be checked out, so that the correction precision is further improved.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

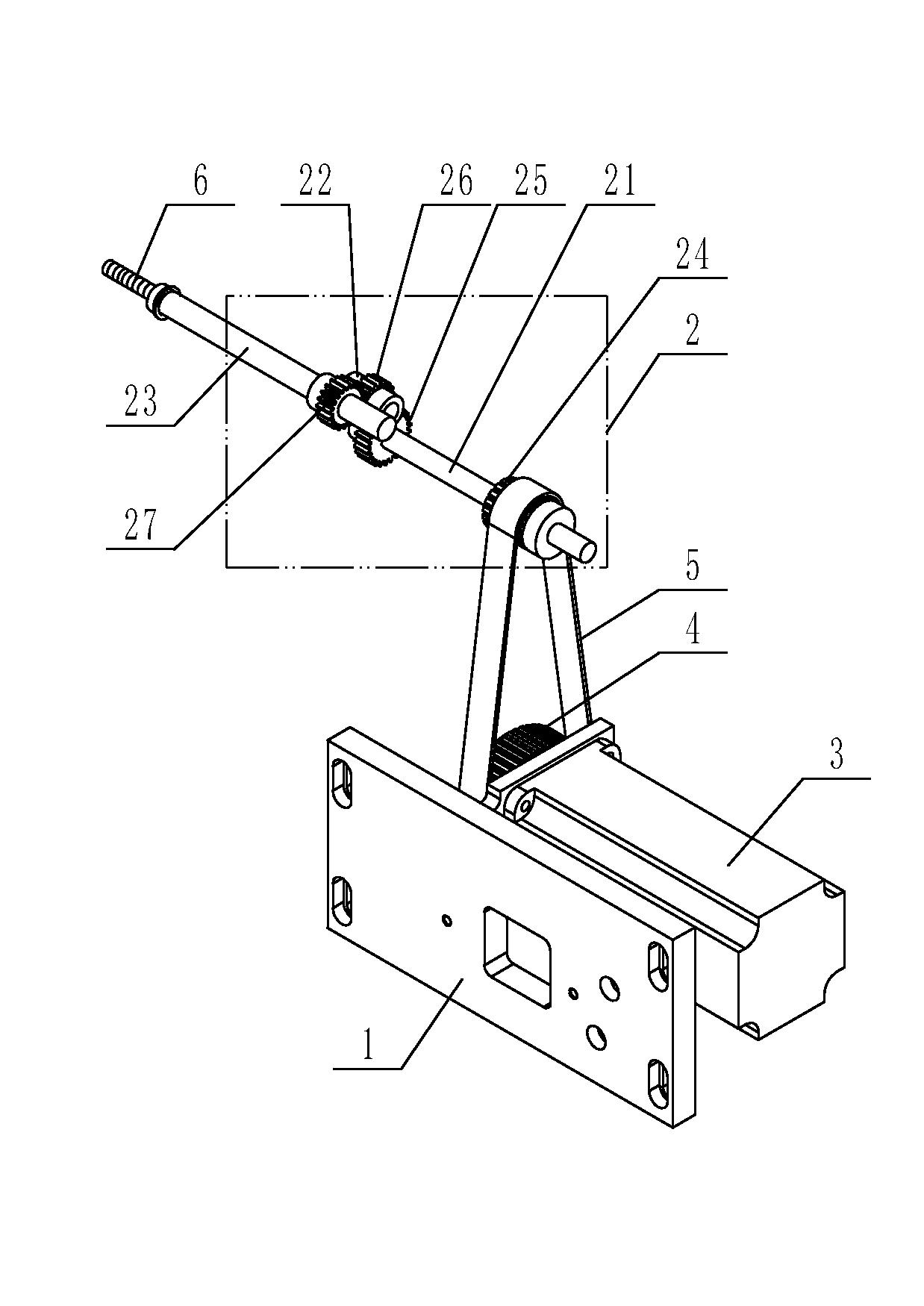

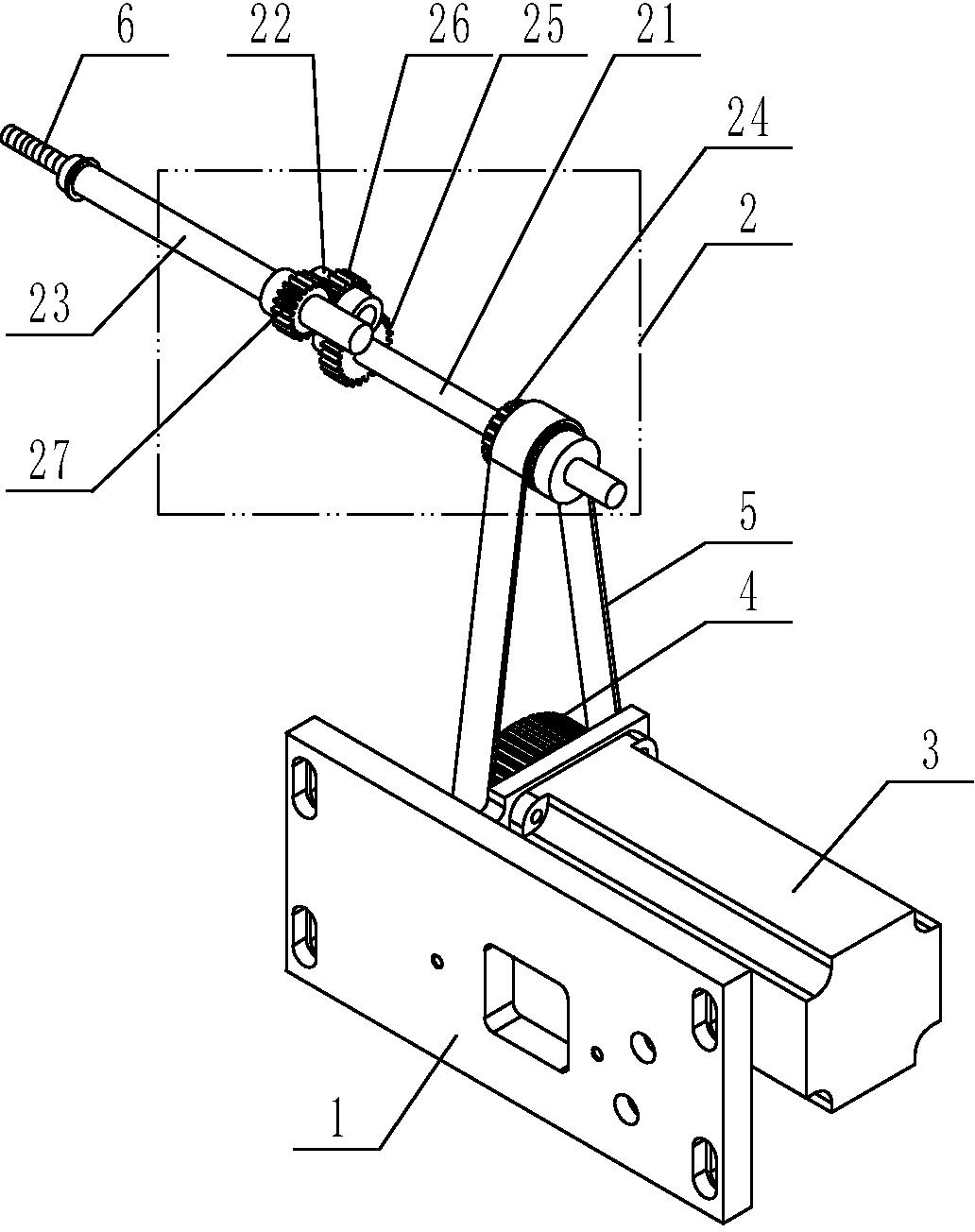

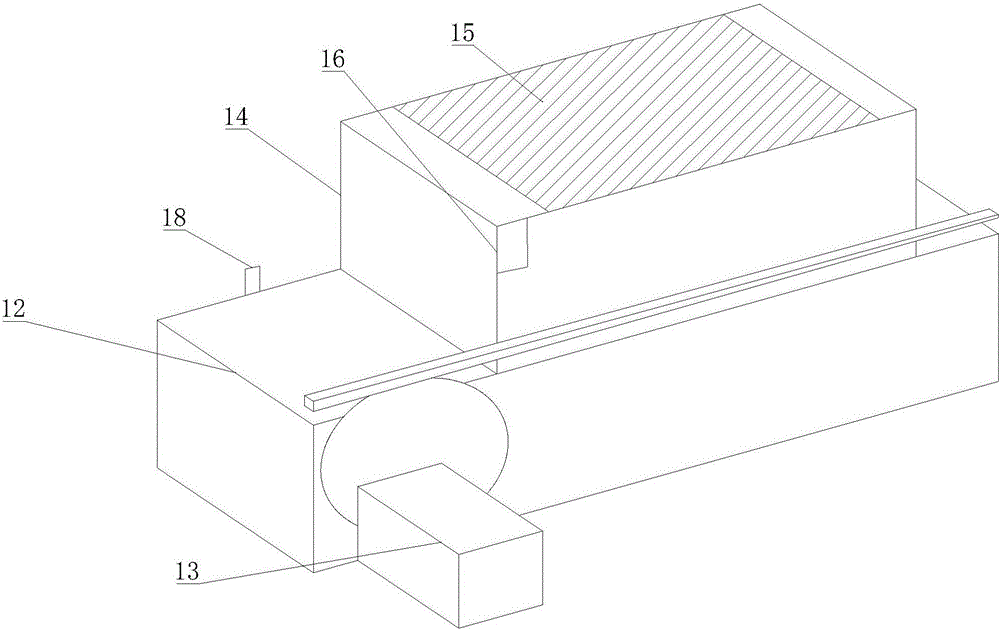

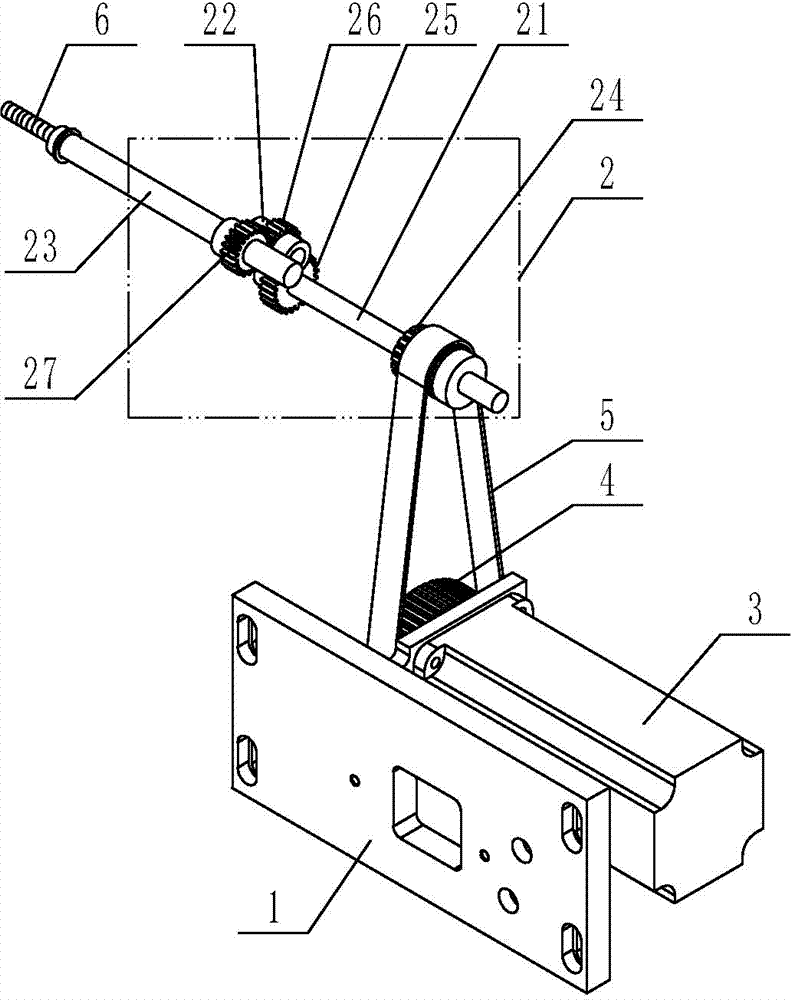

Tapping device for automatic lathe

InactiveCN102189301AExpand the scope of processing applicationsNot in placeThread cutting machinesOther manufacturing equipments/toolsServomotorPulley

The invention relates to a tapping device for an automatic lathe, comprising a rack, wherein the rack is provided with a servo motor and a speed regulating device, the output shaft of the servo motor is provided with a servo belt pulley, the speed regulating device comprises an input shaft and an output shaft, one end of the input shaft is provided with a driven belt pulley, the other end of the input shaft is provided with an input gear, the output shaft is provided with an output gear, the input gear and the output gear are meshed, the driven belt pulley is connected with the servo belt pulley by virtue of a belt, and the output shaft of the speed regulating device is provided with a tapping head. The tapping device provided by the invention is applicable to the automatic lathe, the stopping position of the tapping head can be accurately determined, the problem that tapping is uncompleted can be effectively solved, the tapping accuracy is greatly improved, the processing applicationrange of the automatic lathe is widened, and the processing efficiency is improved.

Owner:张家港名阳精密机械制造有限公司

Mold steel plate strength detection device

ActiveCN114047065AAccurate stop positionGuaranteed comparabilityMaterial strength using tensile/compressive forcesInvestigating material hardnessMachineElectromagnet

The invention discloses a mold steel plate strength detection device. The detection device comprises a machine shell and a storage frame, wherein an electronic display screen is arranged in the machine shell, a functional cavity is formed in the machine shell, a tightening cavity is formed in the storage frame, a detection cavity is formed in a detection shell, a fixing cavity is formed in a lower end wall of the functional cavity, and a detection mechanism, a conveying mechanism and a fixing mechanism are arranged in the machine shell. By means of a pressure monitor arranged in the detection mechanism, the condition of the storage frame can be automatically judged, then stopping of the storage frame is controlled by controlling stopping and starting of an electromagnet, the stopping position of the storage frame is more accurate, and at the moment, a hydraulic rod can accurately grab the center of a steel plate when grabbing the steel plate; the air cylinder can be aligned when adjusting the detection shell to the central position of the steel plate, so all the positions for detecting the strength of the steel plate are fixed, detected data are comparable, whether the strength of the steel plate is in a reasonable range or not can be detected, manual participation is reduced, and working efficiency is improved.

Owner:如皋市宏茂铸钢有限公司

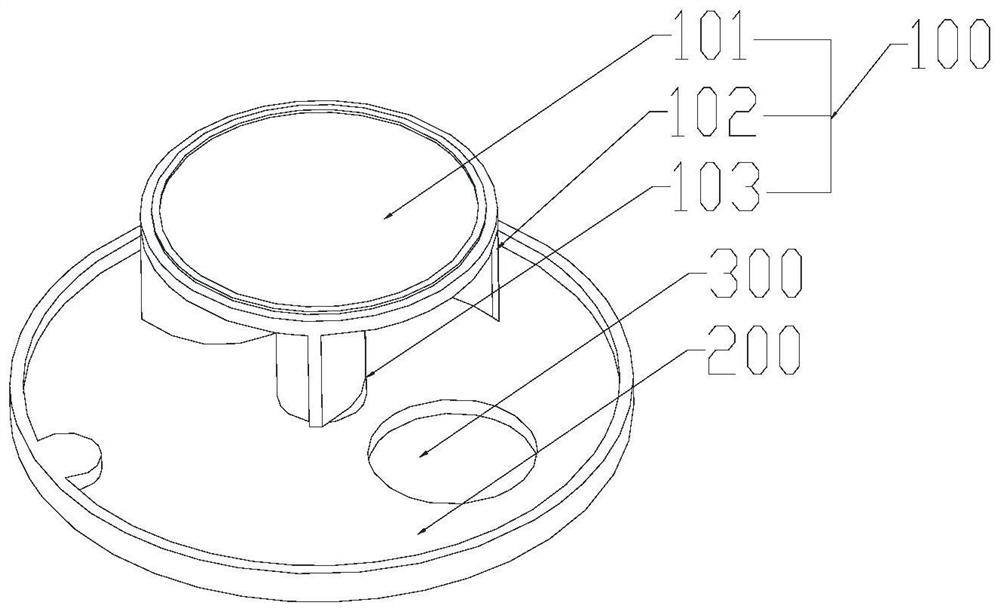

Water diversion valve, water diversion device and dish-washing machine

PendingCN112244730ADivide water to achieveAccurate stop positionTableware washing/rinsing machine detailsWater diversionMechanical engineering

The invention provides a water diversion valve, a water diversion device and a dish-washing machine, and relates to the technical field of kitchen related equipment. The water diversion valve comprises a water diversion valve shell and a water diversion assembly; the water diversion assembly is rotationally arranged in the water diversion valve shell, a driving part is arranged on the water diversion assembly, and the driving part drives the water diversion assembly to rotate; a magnetic attraction assembly is arranged at the corresponding position of the water diversion assembly and the waterdiversion valve shell so as to achieve stalling of the water diversion assembly. According to the water diversion valve, the water diversion assembly is driven by the driving part to rotate, when thewater diversion assembly needs to stop rotating, the magnetic attraction assembly can stop the water diversion assembly at the designated position, water diversion of the water diversion assembly isachieved, and the position of the water diversion assembly does not need to be checked; the magnetic attraction assembly corresponding to the stalling position of the specified water diversion assembly is directly generated to generate magnetic force, so that the control logic is simpler and more reliable, and the stopping position of the water diversion assembly is more accurate.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Continuous type station positioning device for multi-station polishing machine

ActiveCN110039427AAccurate stop positionWill not deformGrinding machinesGrinding work supportsEngineeringContinuous type

The invention discloses a continuous type station positioning device for a multi-station polishing machine. The continuous type station positioning device comprises a box body, a rotary platform, station units, and is equipped with stroke collision blocks, a multi-union stroke switch, a positioning gas cylinder, a lifting movable base, a reduction motor, a spline shaft, a gear shaft and a bearingbase, wherein the multi-union stroke switch is mounted on the box body; number of the stroke collision blocks is same with that of the station units; the stroke collision blocks are uniformly distributed and mounted on different height positions of the rotary platform, and are horizontally aligned to different induction points of the multi-union stroke switch; when the stroke collision blocks arealigned to the multi-union stroke switch, the corresponding station units are positioned in front of the machine; a piston rod the positioning gas cylinder is concentric with the output shaft of the reduction motor; the piston rod of the positioning gas cylinder is fixedly connected to the lifting movable base; the spline shaft passes through the reduction motor; the lower end of the spline shaftis mounted in the lifting movable base through a bearing; the gear shaft is mounted in the bearing base through a bearing; and when the stroke collision blocks are aligned to the multi-union stroke switch, the gear shaft is aligned to the spline shaft. The continuous type station positioning device has the advantages of being reliable in induction, precise in positioning, simple in structure, andthe like.

Owner:宇晶机器(长沙)有限公司

Punching machine

InactiveCN106270134AHigh precisionAccurate stop positionPerforating toolsMetal-working feeding devicesEngineeringPiston rod

The invention discloses a punching machine. The punching machine comprises a punching device and a conveying structure which is located under a punching knife of the punching device. The punching device comprises a rack, an oil cylinder, the punching knife and an oil cylinder control device, wherein the oil cylinder is arranged on the rack in an inverted manner, and the punching knife is mounted on the end face of a piston rod of the oil cylinder. The conveying structure comprises a workbench, a conveying device and a locating device, wherein the workbench is located under the punching knife, and the locating device is located on the workbench. The locating device comprises a first photoelectric sensor and a locating control device, wherein the first photoelectric sensor is located on the upper end face of the workbench. A panel is conveyed onto the workbench through the conveying device. According to the punching machine, a second photoelectric sensor detects the moving distance of a moving device, and precision of the moving distance of the moving device is enhanced; and rotating speed of a servo motor is constant, the first photoelectric sensor senses passing of the panel, and the position where the panel is stopped is accurate.

Owner:TONGCHENG YUNCHENG PLATEMAKING

Vehicle controller, vehicle control method, and storage medium

ActiveUS10913457B2Accurate stop positionStop preciseAnti-collision systemsControl engineeringControl theory

A vehicle controller includes: a recognizer (121,122) configured to recognize a distance to a stop position as a first distance on the basis of an image captured by an imaging unit that images the front of a vehicle; and a braking distance estimator (123B) configured to estimate a braking distance to the stop position on the basis of the first distance recognized by the recognizer at a predetermined time point and a second distance acquired on the basis of a speed of the vehicle and to adjust a degree of reflection of the second distance in the braking distance on the basis of the first distance recognized by the recognizer after the predetermined time point.

Owner:HONDA MOTOR CO LTD

Operation method of three-dimensional automatic weaving device

The invention belongs to the field of operation methods of weaving devices, and relates to an operation method of a three-dimensional automatic weaving device. The three-dimensional automatic weavingdevice comprises a plurality of yarn storage devices and a plurality of weaving stations. The weaving stations are distributed in arrays. Each weaving station comprises a body section and a clip section, wherein the clip section is arranged on the body section and can rotate relative to the axis of the body section, the clip section is provided with a plurality of clips for clamping the corresponding yarn storage devices, and the yarn storage devices are arranged around the weaving station and opposite to the clips. The three-dimensional automatic weaving device controls the clip sections to extend at least one clip to clamp the opposite yarn storage devices. The clip sections rotate to drive the yarn storage devices to circumferentially rotate by a certain angle and then stop, the clips retreat, the three-dimensional automatic weaving device controls the clip sections according to a weaving program to sequentially repeat the process, and yarn is interwoven to obtain a three-dimensional braided fabric. The yarn storage devices are clamped by the clips of the clip sections and driven to rotate relative to the body sections, and the yarn is interwoven to obtain the three-dimensionalbraided fabric.

Owner:CHINESE TEXTILE ACAD

Elevator traction machine

ActiveCN107089578AAvoid damageGuaranteed accuracyElevatorsBuilding liftsReduction driveElectric machinery

The invention provides an elevator traction machine and belongs to the technical field of motors. The technical problem that an existing elevator traction machine is poor in safety is solved. The elevator traction machine comprises a motor. The motor is provided with a machine shell and a rotating shaft. A speed reducer and a brake are arranged between the machine shell and the rotating shaft. The rotating shaft stretches out of the control end and the output end of the machine shell. The output end is provided with a passive safety device. The passive safety device comprises a first brake disc fixed to the machine shell and a speed limiting box fixed to the rotating shaft. A plurality of sliding cavities are evenly formed in the speed limiting box. Each sliding cavity is internally provided with a balance weight valve element capable of sliding. The machine shell is further provided with guide cavities in one-to-one correspondence with the sliding cavities. The sliding cavities communicate with the corresponding guide cavities. Valve posts are in sliding connection with the interiors of the guide cavities and connected with brake pads. The guide cavities and the sliding cavities are filled with hydraulic oil. The elevator traction machine has the advantage of being good in safety performance.

Owner:HUBEI UNIV OF SCI & TECH

Electric spiral slot puncher

The invention discloses an electric spiral slot puncher which comprises a body. A slider is arranged on the body. A servo motor is mounted at the top of the body. A small synchronous pulley is disposed on an output shaft of the servo motor and drives a large synchronous pulley through transmission of a synchronous belt. A screw is disposed on the large synchronous pulley and rotates in a screw nut. The screw nut is fixed on the slider. An indexing device is disposed below the body and comprises an indexing servo motor and a vertical centering head which is in drive connection with the indexing servo motor. A core lamination is disposed at the upper end of the centering head. A bench facing to a punch is disposed below the core lamination. The electric spiral slot puncher is compact in structure, high in flexibility, high in intelligence and smooth in operation. The position, speed and acceleration of the punch slider can be controlled, so that slotting noise is low, the service life of a punching die can be prolonged, impact and vibration of the puncher are reduced, and stop position of the punch slider is more accurate.

Owner:WUHU ELECTROTECHN MACHINERY

Tire apex turning device

The invention discloses a tire apex turning device. The tire apex turning device comprises a cooling storage device, a supplying device, an apex molding drum, an apex laminating device and an apex rolling device; the supplying device is installed at the discharging end of the cooling storage device; the apex molding drum is opposite to the apex laminating device, in addition, the combination surfaces of the apex molding drum and the apex laminating device serve as the discharging end of the supplying device; and the apex rolling device is installed below the apex laminating device. According to the tire apex turning device, low-temperature cooling and shape setting of apex are achieved through the cooling storage device; through the supplying device, the apex is automatically supplied to the apex molding drum, supplying is conducted in the mode that the apex is sucked by vacuum suction cups, and feeding is controlled by an air cylinder; the apex molding drum, the apex laminating deviceand the apex rolling device are driven by a servo motor, the deforming speed is high, and the stopping position is precise; and a rolling mechanism is used for air exhausting, compacting and shape setting rolling after a steel wire ring and the apex are composited, and it is ensured that the apex and the steel wire ring are effectively laminated.

Owner:XIAMEN HAOSHENG MECHANICAL & ELECTRICAL ENG CO LTD

A manual remote control drive device

ActiveCN104898766BFlexible layoutAccurate stop positionMechanical energy handlingManual control with single controlling memberElectromagnetic clutchRemote control

The invention provides a manual remote control driving device, which uses a hand-operated power generation device and a driving motor in cooperation, so that the manual end and the driving end can be flexibly arranged and moved arbitrarily; a bidirectional backstop is installed at the output end of the driving motor to realize At the same time of pure manual remote control drive, it can realize accurate positioning and stop and avoid the load from dragging the handle in reverse, which will hurt the operator; an electromagnetic clutch is installed at the output end of the drive motor to realize pure manual remote control drive, and at the same time realize the electric / manual conversion function and transmission chain Protective function. Compared with the prior art, the manual remote control driving device provided by the present invention has simple structure, flexible layout, safety, reliability, good adaptability and easy maintenance.

Owner:CHINA NORTH VEHICLE RES INST

Cooling tank device of hot-rolling perforation machine set

InactiveCN101791628BGuaranteed uptimeReduce widthMandrelsMetal rolling arrangementsHydraulic cylinderCooling effect

The invention discloses a cooling tank device of a hot-rolling perforation machine set, relating to hot-rolling perforation machine set equipment. The invention solves the problems that the existing cooling tank device has large occupied area, large cooling water requirement amount, poor cooling effect and inaccurate mandril control so as to affect normal production operation. The invention is characterized in that in-bound equipment is an in-bound device (10) which is composed of a hydraulic cylinder (10-1), five material toggling grooves (10-2), a rotary shaft (10-3) and five bearing pedestals (10-4); the bottom of a cooling trough (4) is welded with five semicircular mandril slideways (4-2); a rotary device utilizes a support frame arranged outside the cooling trough and a rotary drum device (9) arranged right above the cooling trough (4); and a control mechanism is a controller 11 consisting of a profile modelling disk (11-1) and an approach switch (11-2).

Owner:TAIYUAN HEAVY IND

Tapping device for automatic lathe

InactiveCN102189301BExpand the scope of processing applicationsNot in placeThread cutting machinesOther manufacturing equipments/toolsGear wheelEngineering

The invention relates to a tapping device for an automatic lathe, comprising a rack, wherein the rack is provided with a servo motor and a speed regulating device, the output shaft of the servo motor is provided with a servo belt pulley, the speed regulating device comprises an input shaft and an output shaft, one end of the input shaft is provided with a driven belt pulley, the other end of the input shaft is provided with an input gear, the output shaft is provided with an output gear, the input gear and the output gear are meshed, the driven belt pulley is connected with the servo belt pulley by virtue of a belt, and the output shaft of the speed regulating device is provided with a tapping head. The tapping device provided by the invention is applicable to the automatic lathe, the stopping position of the tapping head can be accurately determined, the problem that tapping is uncompleted can be effectively solved, the tapping accuracy is greatly improved, the processing applicationrange of the automatic lathe is widened, and the processing efficiency is improved.

Owner:张家港名阳精密机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com