Hosiery body locating and ejecting device with movable sinker cover for integrated hosiery knitting machine

A technology for moving a gram cover and an ejecting device is applied to circular knitting, knitting, weft knitting and other directions for weft knitting with separate action needles. Need, unable to control the tightness of socks, etc., to achieve the effect of improving reliability and effectiveness, improving aesthetics and quality, and avoiding the failure of sock knitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the drawings.

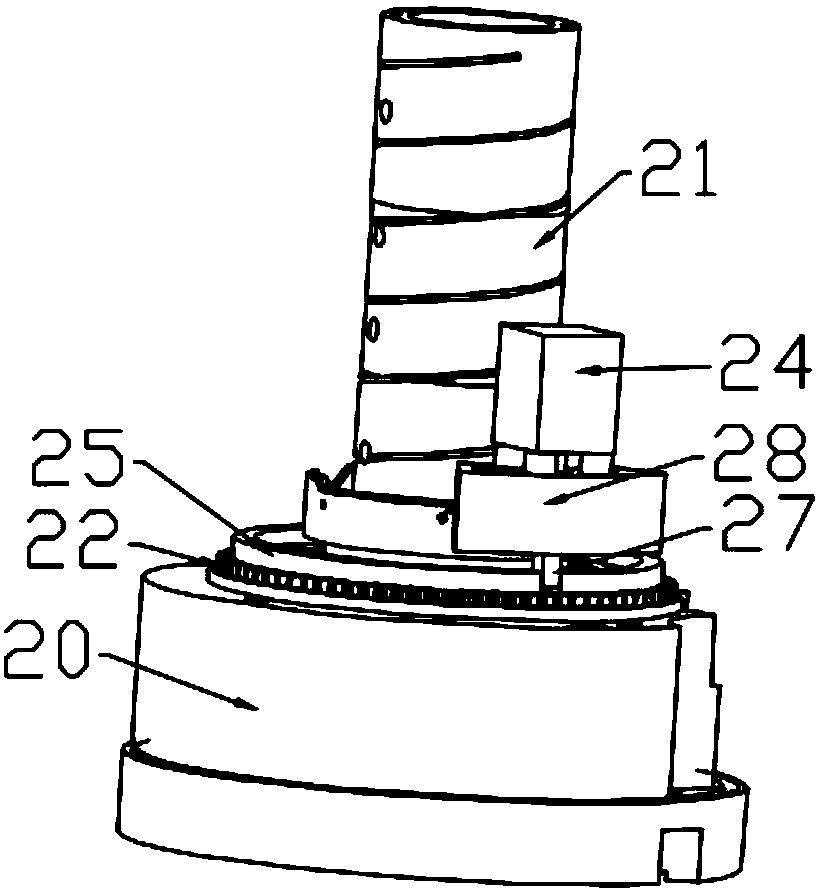

[0043] Such as figure 1 , 2 , 3 and 5, an integrated hosiery machine sock body positioning ejection device with a movable sock cover, including a frame 20, a needle cylinder core 21 (that is, the lower sock tube seat on the hosiery machine), Gear 22 (that is, the cylinder tooth wheel on the sock knitting machine), sock barrel 23, positioning mechanism I, lifting mechanism II, support plate 1, Shengke cover III, connecting rod 14, cover adjustment mechanism IV and left and right eyebrow adjustment Institution V. The support plate 1 is fixed to the frame 20. The needle cylinder core 21 is fixed on the frame, and the needle cylinder core 21 is coaxially arranged with the needle cylinder on the hosiery machine. The gear 22 is supported on the frame 20. The gear 22 is driven by a syringe motor. The gear 22 is used to drive the needle cylinder on the hosiery machine to rotate.

[0044] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com