Cooling tank device of hot-rolling perforation machine set

A technology of hot-rolled perforation and cooling grooves, applied in metal rolling, metal rolling, tool manufacturing, etc., can solve the problems of inaccurate control of cam switches, unintuitive adjustment of cam switches, easy twisting and deflection of claws, etc., and achieve structural Simple, small footprint, accurate stop position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

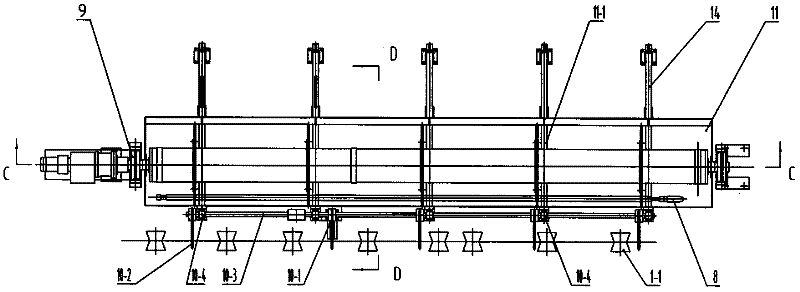

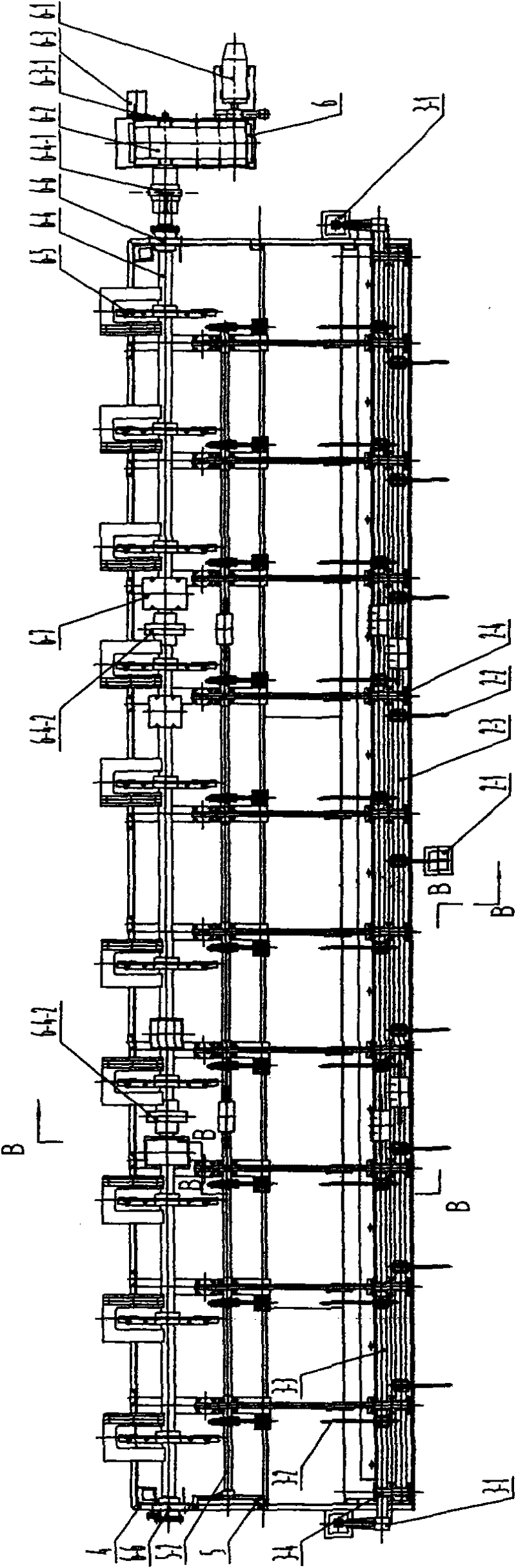

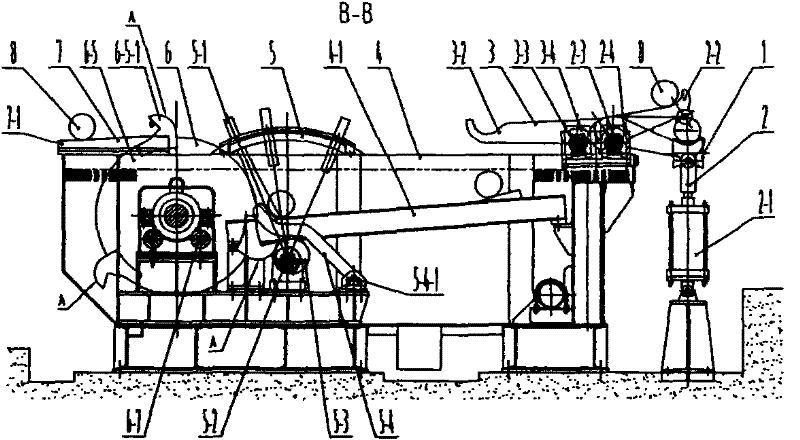

[0022] Such as image 3 , 4 , 5, 6, and 7, a cooling tank device for a hot-rolled piercing unit, including: a feed roller table 1, a dial-in device 10, a cooling tank 4, a barrel device 9, a controller 11, and a discharge table 7 . The feed roller table 1 is composed of a plurality of rollers 1-1; the dial-in device 10 is composed of a hydraulic cylinder 10-1, five dial hooks 10-2, a rotating shaft 10-3, five The bearing seat 10-4 is formed, the middle trunnion of the hydraulic cylinder 10-1 is hinged on the cooling groove 4, and the piston rod earring of the hydraulic cylinder 10-1 is hinged at the middle Z of one of the five shifting hooks 10-2, five The end of each material shifting hook 10-2 is connected on a rotating shaft 10-3, and the rotating shaft 10-3 is connected in five bearing seats 10-4 and can rotate, and the five bearing seats 10-4 are fixed in the cooling tank 4; the cooling tank 4 is a large welded metal tank body, five semicircular ejector slides 4-2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com