A manual remote control drive device

A driving device, manual remote control technology, applied in mechanical control devices, manually operated control mechanisms, electromechanical devices, etc., can solve problems such as inability to complete remote control tasks, and achieve the effects of easy maintenance, flexible layout, and accurate stop position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

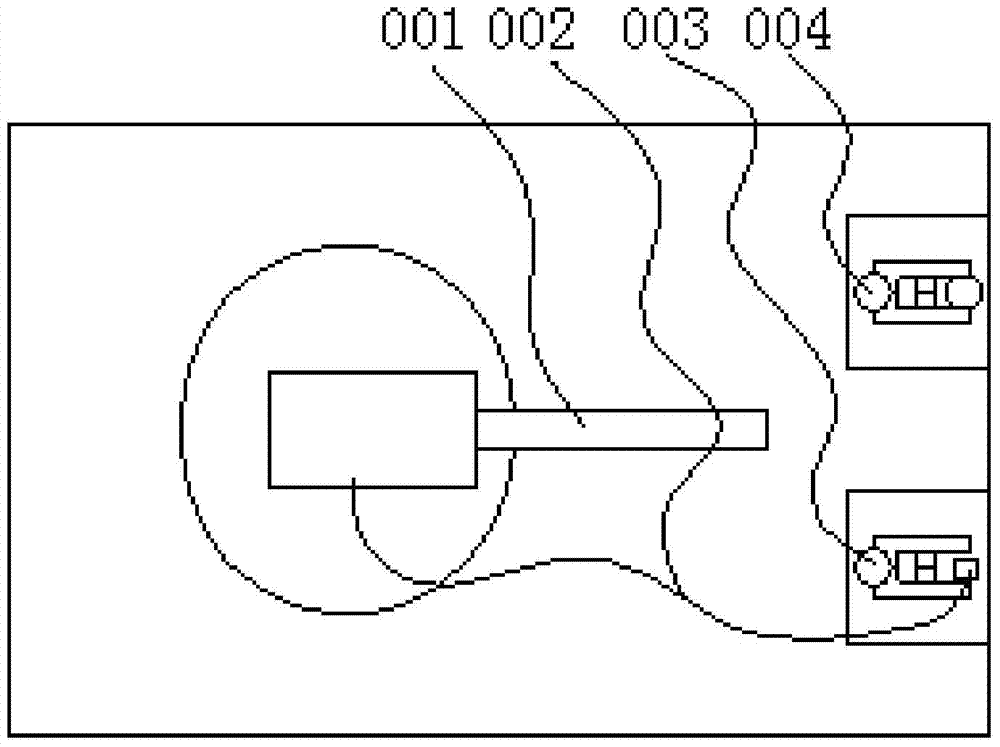

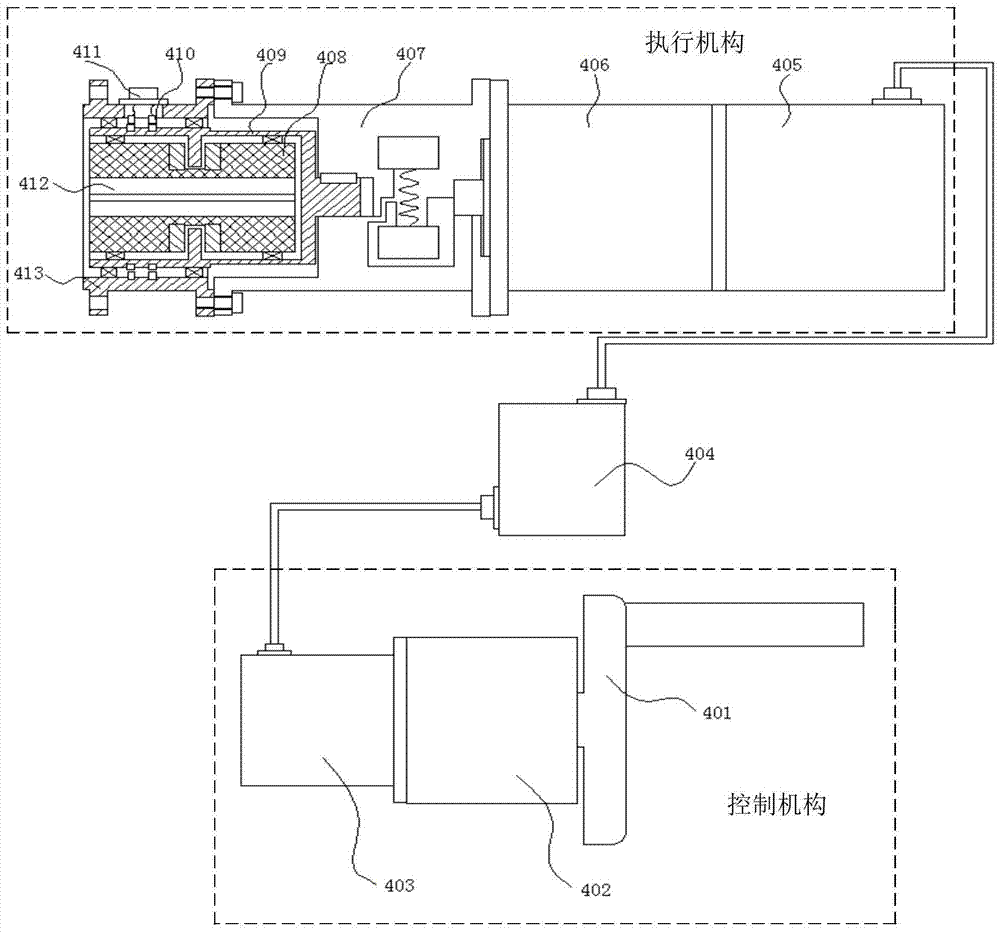

[0039] The manual remote control driving device 400 is used for tooth arc type pitching mechanism, such as Figure 4 As shown, the toothed arc type pitching mechanism includes a pitching trunnion 100, a gear box 300 and an electric drive motor 500, a toothed arc 200 is arranged between the pitching trunnion 100 and the gear box 300, and the power output hole 412 and the electric drive motor 500 are connected to the gears respectively. Box 300 is connected. Expand the gear box 300, use gears to lead out a manual interface, and connect with the power output hole 412 of the actuator of the manual remote control drive device 400. The electric and manual share a part of the transmission chain, and the cable of the electric drive motor 500 is connected to the chassis through the rotary connector 404. The power supply on the vehicle is connected, and the cable of the actuator is also connected with the driving mechanism at the co-driver's position on the chassis through the rotary co...

Embodiment 2

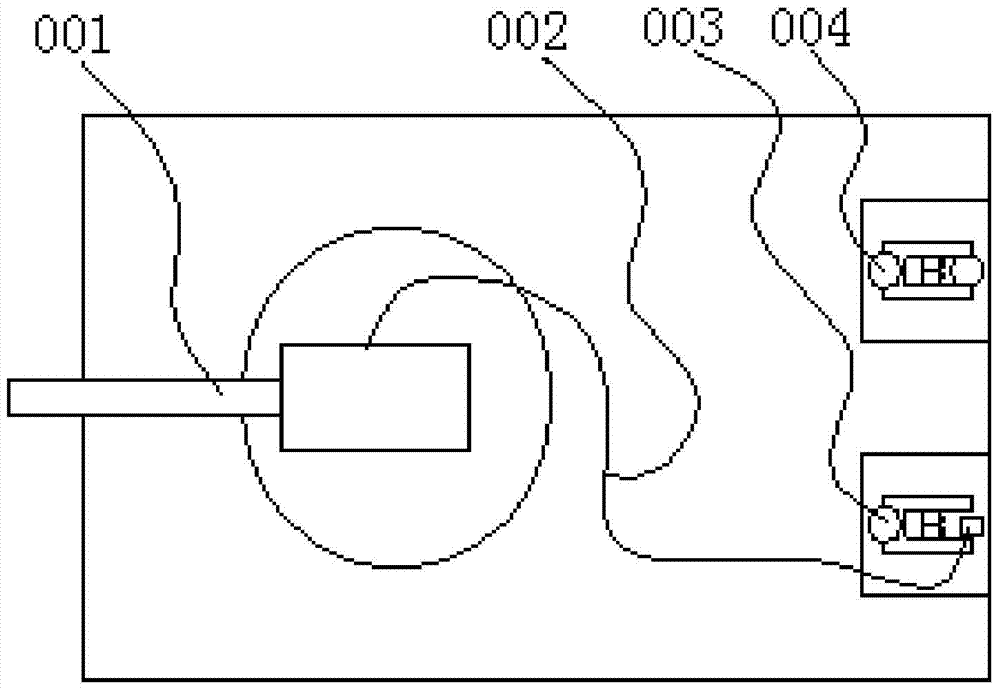

[0041] The manual remote control driving device 400 is used for the lead screw type pitching mechanism, such as Figure 5 As shown, the lead screw pitch mechanism includes a pitch trunnion 100 , a gearbox 300 and an electric drive motor 500 , the gearbox 300 is connected to the lead screw 600 , and the power output hole 412 and the electric drive motor 500 are connected to the gearbox 300 respectively. Expand the gear box 300, use gears to lead out a manual interface, and connect with the power output hole 412 of the actuator of the manual remote control drive device 400. The electric and manual share a part of the transmission chain, and the cable of the electric drive motor 500 is connected to the chassis through the rotary connector 404. The power supply on the vehicle is connected, and the cable of the actuator is also connected with the driving mechanism at the co-driver's position on the chassis through the rotary connector 404. The power of manually shaking the handle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com