Positioning and ejection device for sock-knitting and end-stitching all-in-one machine

The technology of an ejector device and an integrated machine is applied to circular knitting machines for weft knitting with individual moving needles, knitting, and weft knitting. The problems such as head work failure can be avoided, so as to avoid the failure of hosiery knitting, accurate stop position, and improve the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

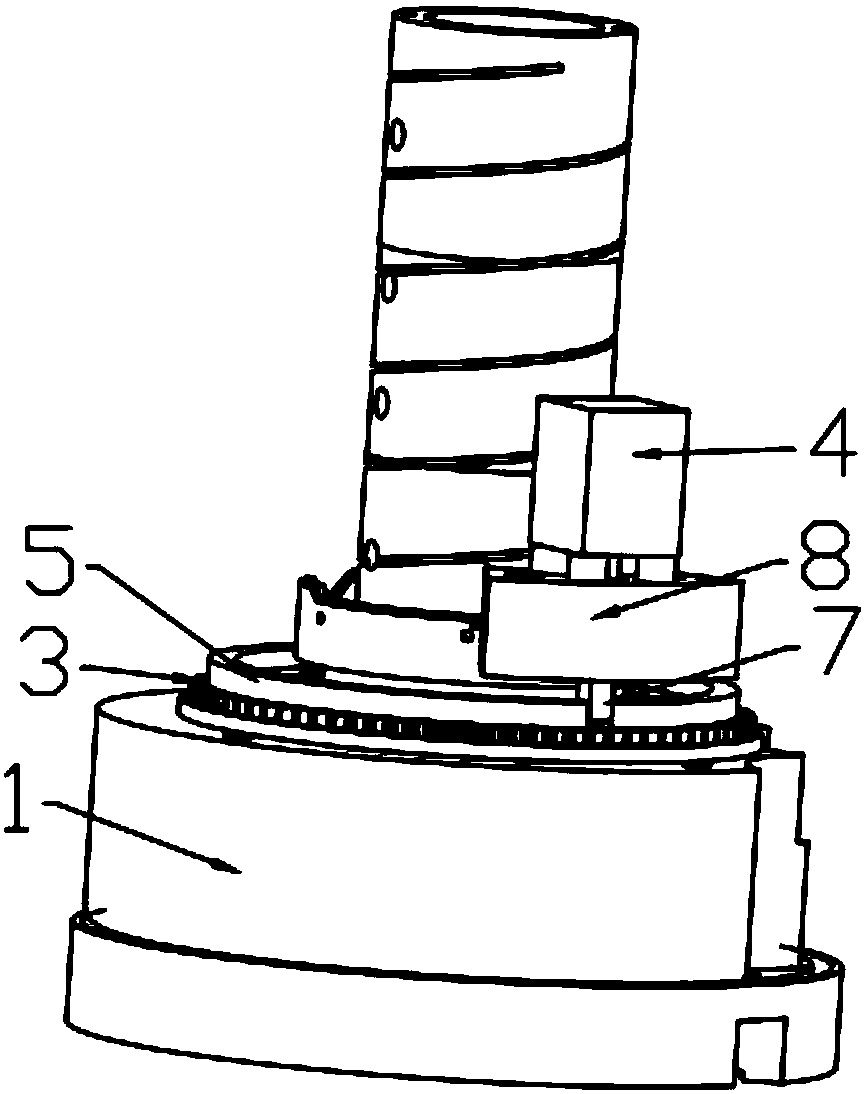

[0024] Such as figure 1 with 2 As shown, a positioning and ejecting device for a hosiery knitting head integrated machine includes a frame 1 (that is, the lower sock tube seat on the sock knitting machine), a needle cylinder core 2, and a gear 3 (that is, the lower sock tube seat on the sock knitting machine). Syringe teeth wheel), sock tube 13, positioning assembly and lifting assembly. The needle cylinder core 2 is fixed on the frame, and the needle cylinder core 2 is arranged coaxially with the knitting needle cylinder on the sock knitting machine. The gear 3 is supported on the frame 1 . Gear 3 is driven by a motor. The gear 3 is used to drive the knitting cylinder on the hosiery machine to rotate.

[0025] Such as figure 1 , 2 As shown in and 3, the positioning assembly includes a positioning cylinder 4, a positioning ring 5, a fixed plate 6, a limiting block 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com