Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about "Vehicle endless-track testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

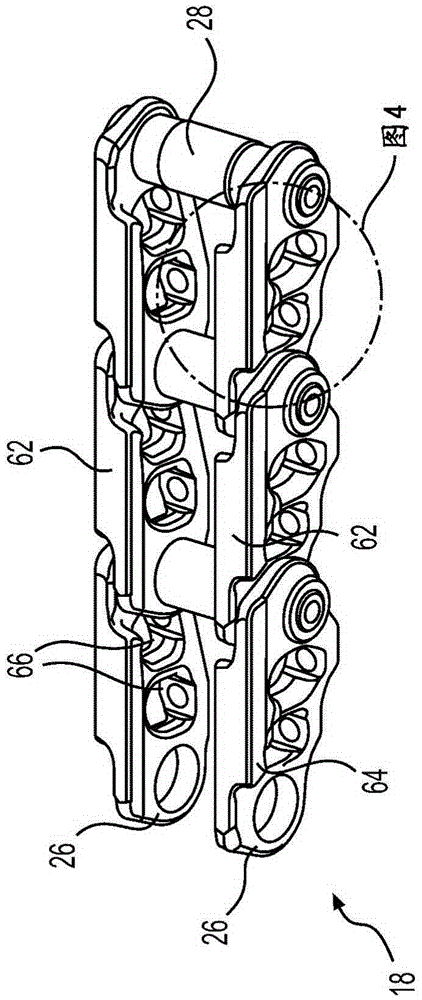

Track assembly having a wear monitoring system

ActiveCN105584546ARegistering/indicating working of vehiclesVehicle endless-track testingMonitoring systemSprocket

A track assembly having a wear monitoring system is disclosed. The track assembly may have a chain assembly including a plurality of track links, a traction assembly including track shoes secured to the plurality of track links, a drive sprocket, an idler assembly including an idler and a mount, and a roller assembly including a plurality of rollers and a roller frame. The wear monitoring system may have a wear sensor configured to generate a signal indicative of a current position of a first component of the track assembly, and a controller in communication with the at least one wear sensor, the controller being configured to determine an amount of wear experienced by the track assembly based on the signal. The first component may be configured such that wear of at least a second component causes the first component to move to the current position from a previous position.

Owner:CATERPILLAR INC

Caterpillar track ground pressure simulation test device

InactiveCN103743579AReduced external driving resistanceImprove traction performanceVehicle endless-track testingApparatus for force/torque/work measurementBogieControl theory

The invention discloses a caterpillar track ground pressure simulation test device, which belongs to the field of the ground pressure test. The caterpillar track ground pressure simulation test device comprises a bed frame, a tensile force loading device, bogie wheel loading devices and a caterpillar track, wherein the bed frame is a fixed saddle piece and is firmly connected with the ground, the lower surface of the bed frame is provided with the tensile force loading device and a plurality of independent bogie wheel loading devices in parallel, the tensile force loading device is connected with the caterpillar track, and the lower end of each bogie wheel loading device is contacted with the caterpillar track. The caterpillar track ground pressure simulation test device is a static test device for simulating the ground pressure distribution of a rubber caterpillar track or a steel caterpillar track in different structures and under different terrains through a caterpillar track tension device and the bogie wheel loading devices, the distribution rule of the caterpillar track ground pressure can be disclosed, and the design of a caterpillar track chassis structure can be instructed.

Owner:NO 63908 TROOPS PLA

Tire pressure sensor mounting system

The present invention features a tire pressure sensor mounting system to mount a tire pressure sensor on a wheel rim directly. The system comprises a singular mounting piece with a rim strap and at least two side straps to securing a tire pressure sensor. The side straps are disposed along the rim strap with extension direction perpendicular to the rim strap. Both the rim strap and side straps have lock means to securely lock the tire rim and tire pressure sensor respectively.

Owner:BROWN HOWARD

Automated diagnostics for crawler transmission hydraulic circuits

ActiveUS20090043442A1Analogue computers for trafficMachine gearing/transmission testingDisplay deviceHydraulic circuit

A diagnostic system and method for diagnosing problems in a hydrostatic transmission of a vehicle including a transmission control unit that has a monitor and pressure sensors and at least one temperature sensor connectable between diagnostic hose ports coupled to the transmission and inputs on the transmission control unit. A symptom or problem area is selected on the monitor; and a test sequence is initiated by command input on the monitor. The transmission control unit performs calculations based upon input data from the pressure sensors to determine a hydraulic problem, and provides directions for adjustments or replacing parts on the hydrostatic transmission. The monitor may provide instructions to relocate existing sensor connections for the test sequence selected.

Owner:DEERE & CO

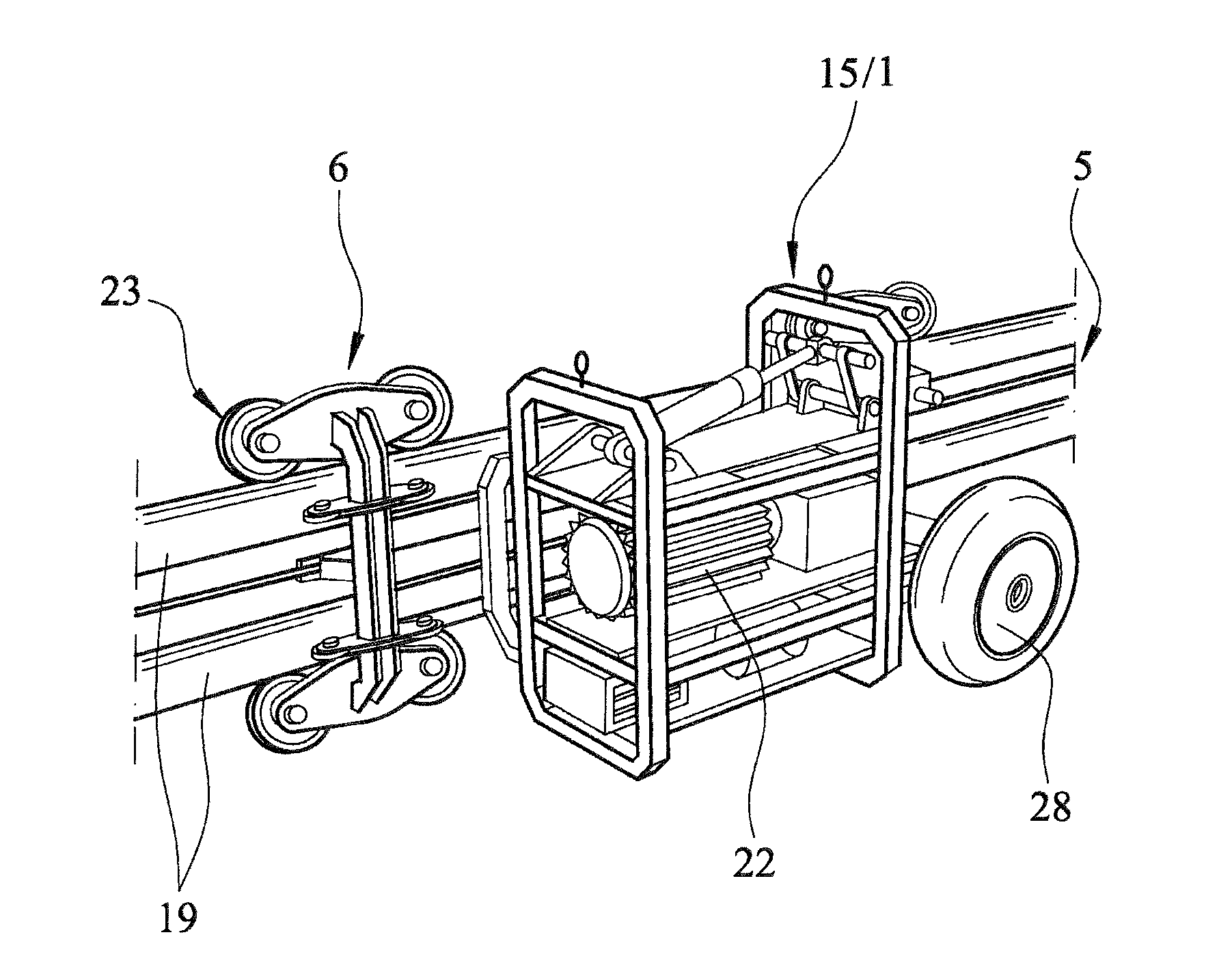

Flatbottomed crawler belt travelling charger

InactiveCN1603775AOvercome the defect that it is not convenient to take forcePrevent stuck phenomenonVehicle endless-track testingEngineeringChain drive

This invention relates to a flat crawler moving load apparatus, which comprises the following: upper rack, two pins, level beam, carrying idler, drive chain, slave chain and assisted apparatus. Their connections are the following: the two pins are separately connected with upper rack and two level beams; to fix at least four carrying idler on the level idler; there located with carrying idler main chain wheel on both ends of carrying idler; the random two carrying idler forms a chain drive through main chain wheel and main chain; the four carrying idlers can form three group of main drive chain; each carrying idler group and assisted apparatus form a sub-drive though slave chain.

Owner:天津鼎盛工程机械有限公司

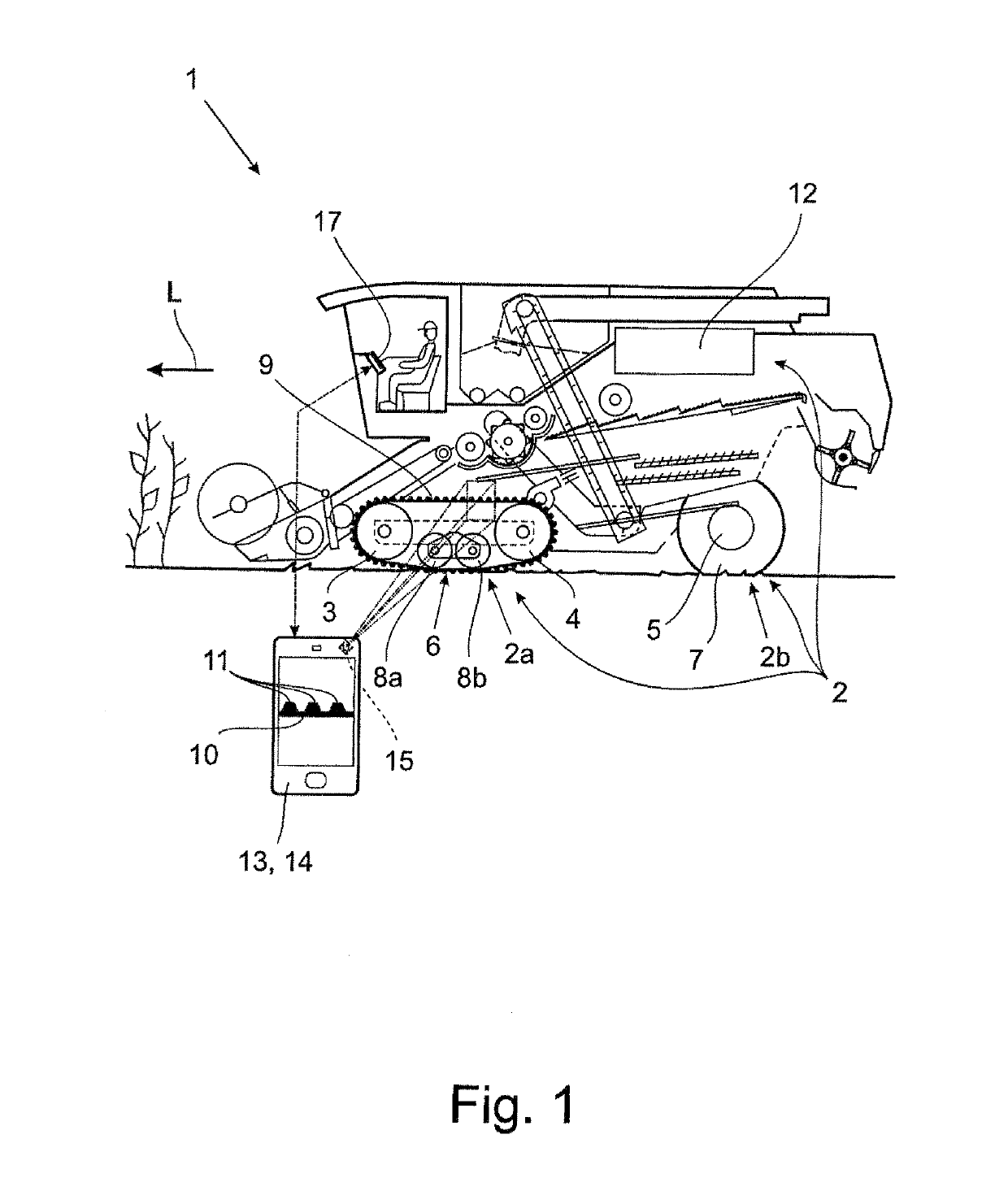

Tracked vehicle

ActiveUS20190139211A1Easy to compareAccurately ascertainedImage enhancementImage analysisDrive wheelEngineering

A tracked vehicle, in particular an agricultural tracked vehicle, has a crawler track assembly including at least one track-laying unit. The track-laying unit has at least two ground drive wheels and a track belt guided over the ground drive wheels. An evaluation device is provided, which is configured for carrying out a determination of the state of wear of at least one track belt of the crawler track assembly with the aid of an image-based comparison of at least two components of the tracked vehicle, at least one of which is a component of the track belt.

Owner:CLAAS INDTECHN

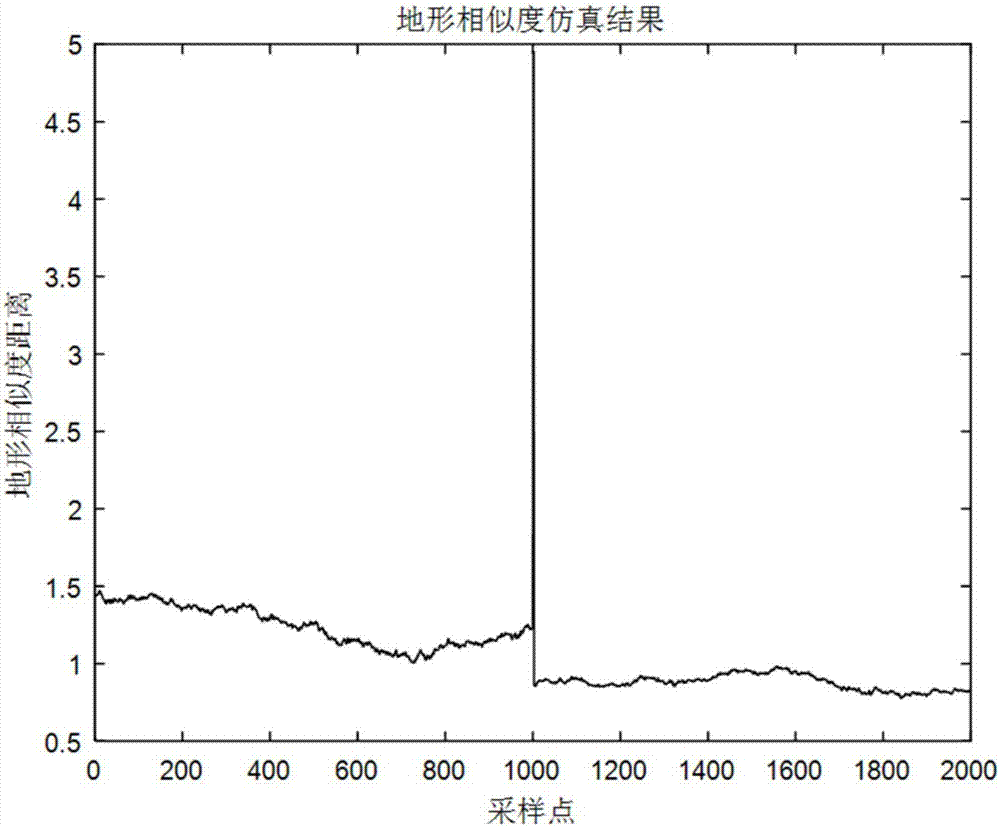

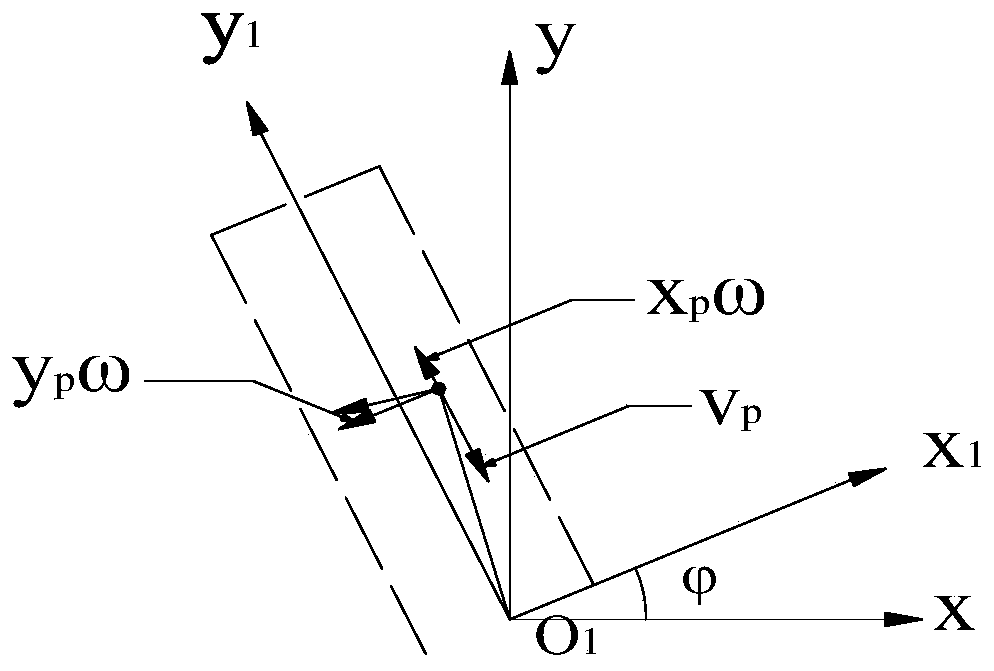

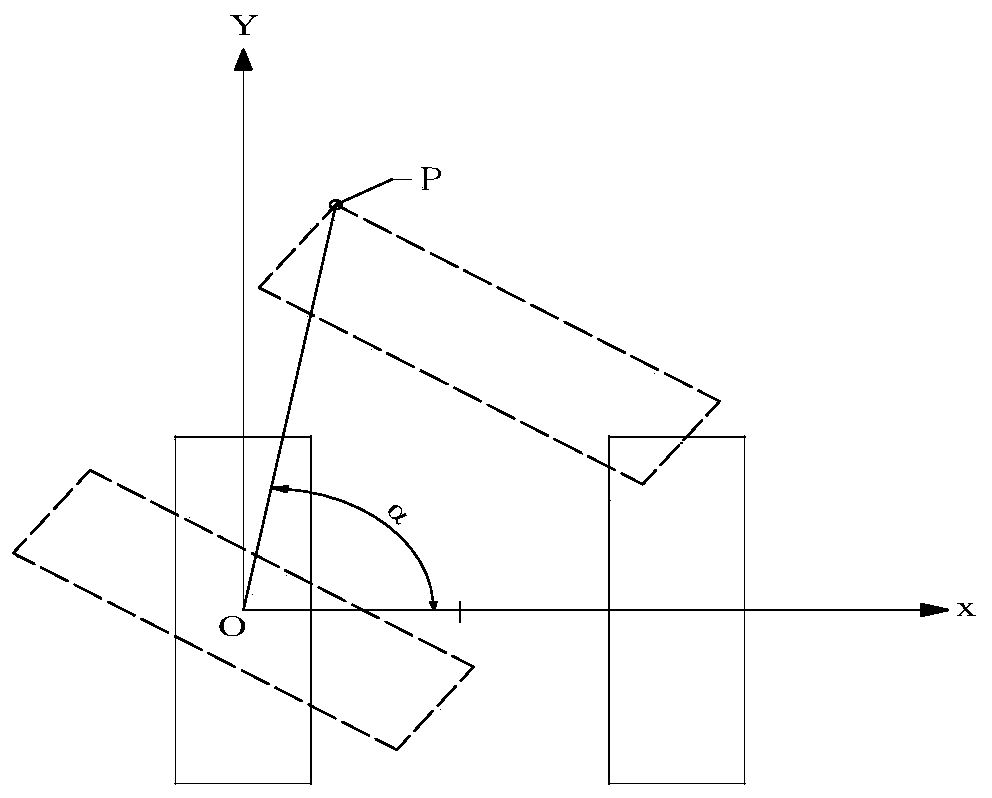

Tracked robot slide parameter detection method

ActiveCN107991110AGuaranteed stabilityGuaranteed accuracyVehicle endless-track testingTerrainProcess noise

The invention discloses a tracked robot slide parameter detection method. According to the method, by introducing an optimal estimation theory and a terrain detection algorithm, the estimation value of slide parameters of a robot can be obtained. The detection method includes the steps of conducting initialization, collecting data of sensors, conducting terrain detection, adjusting a process noisevariance of a slide system, detecting the state, updating the state and outputting an estimation value of a slide coefficient. In the process of predicting the state, a colorless conversion mode is introduced to ensure the accuracy of state prediction under a strong nonlinear condition; since the terrain detection is introduced, when an obvious change happens to terrains, the process noise variance of the slide system can be adjusted according to the method. By means of the adaptive mechanism, the stability of estimation of the slide coefficient can be ensured, the convergence time is shortened at the same time, and the method is suitable for scenes with complicated terrains.

Owner:安徽大科有道信息技术有限公司

Test facility for a vehicle equipped with at least one vehicle tire

ActiveUS20140250997A1Easy constructionRoads maintainenceVehicle endless-track testingInterior spaceAcceleration Unit

A test facility for a vehicle having at least one tire includes an acceleration track; a test section; a return track; a guide defining a direction of travel; a slide configured to run on the guide and to guide the vehicle; a building defining an interior space; at least a part of the test facility being disposed in the interior space of the building; and, the test section being configured to be displaceable in at least one of a first direction transverse to the direction of travel and a second direction in the direction of travel.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Tracked vehicle

Owner:CLAAS INDTECHN

Method for observing deformation of elastic material and apparatus for capturing projection image of elastic material

InactiveUS20160282286A1Using wave/particle radiation meansVehicle endless-track testingElastomerProjection image

To observe an elastic material under a dynamically deformed state. [Solution] A method for observing deformation of an elastic material 1 including rubber or elastomer, and an apparatus for capturing a projection image of the elastic material suitably used therefor. The observing method includes: a projection image obtaining step S1 of capturing a projection image of at least a part of the elastic material 1, from a direction perpendicular to an arbitrary axis of the elastic material 1, at a plurality of capture positions P around the axis; a three-dimensional image constructing step S2 of constructing a three-dimensional image 51 of the elastic material 1 from the projection images, and a step of observing the three-dimensional image 51. The projection image obtaining step S1 comprises: a deforming step S12 of deforming the elastic material 1 in predetermined cycles; a signal output step S13 of outputting an capture signal St at a predetermined specific time point during one cycle; and a capturing step S14 of capturing the projection image of the elastic material 1 based on the capture signal St. The deforming step S12, the signal output step S13 and the capturing step S14 are performed at each of the capture positions.

Owner:SUMITOMO RUBBER IND LTD

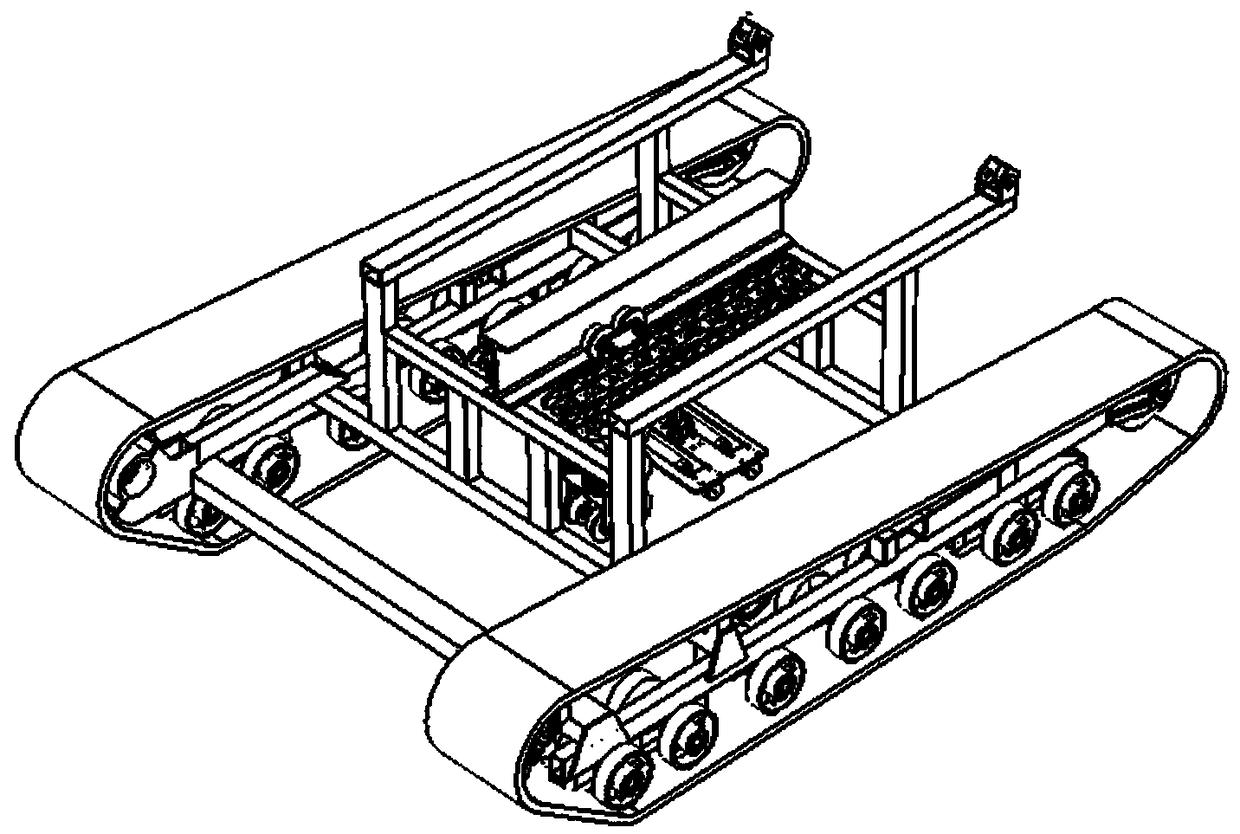

Underwater crawler-type work robot experiment system

ActiveCN107870094AVerify and optimize structural design parametersImprove underwater walking performanceVehicle endless-track testingModel sampleMarine engineering

A underwater crawler-type work robot experiment system comprises a crawler-type model sample vehicle, a simulated water bottom sediment soil groove, a simulated water bottom sediment, a sensor group,a cable, a traction device and a rack. The technical effects in the invention are characterized in that aiming at different underwater operation function requirements and a water bottom work environment, the underwater crawler-type work robot experiment system is comprehensively established so that underwater walking and passing performance and continuous work performance are effectively increased; and through traction performance experiments of a model sample vehicle which can be detached and recombined in the experiment system under different hook traction forces, a structure design parameter of a work robot is verified and optimized.

Owner:CENT SOUTH UNIV +1

Track-rail integrated transfer platform and track chassis slip detection method

ActiveCN109282993AImprove adhesionIncrease frictionVehicle endless-track testingMagnetic tapeMonorail

The invention discloses a track-rail integrated transfer platform and a track chassis slip detection method, and belongs to the safe driving field of a transfer platform. The transfer platform comprises track chassises and a monorail rail for providing a reference for the tracks. The monorail rail is provided with a magnetic tape, the magnetic tape is long-strip-shaped, and hollow circular holes are equidistantly are formed in the center of the magnetic tape; track rotation speed sensors and magnetic tape detection sensors for detecting the magnetic tape information are arranged on the track chassises. The monorail rail is a mechanical basis for the walking reference of the track chassis, and can be used as a detection element of the magnetic tape sensors of the track chassis, so that themagnetic tape sensors can acquire the slip state of the track by detecting the magnetic stripe information, and a basis is provided for the operation state of the track chassis.

Owner:HUNAN AGRICULTURAL UNIV

Hydraulic load test system for crawler type walking device

PendingCN108612687AReduce energy consumptionEasy to testMachine gearing/transmission testingServomotorsManufacturing cost reductionControl unit

The invention discloses a hydraulic load test system for a crawler type walking device. The hydraulic load test system for the crawler type walking device comprises a main control unit, an oil supplementary unit, a tensioning unit, a cooling unit and an external oil tank, wherein the main control unit is connected with the oil supplementary unit through an oil pipe; and the oil supplementary unit,the tensioning unit and the cooling unit are connected with the external oil tank through oil pipes. A proportional overflow valve in a loop is selected to control the pressure and the oil pump displacement difference of a driver load motor, and the displacement and the pressure of crawler tensioning are adjusted through the tensioning unit, so that the aims of reducing the equipment installationperiod, reducing the manufacturing cost, and improving the experiment control accuracy and the system universality are achieved.

Owner:柳州北斗星液压科技有限公司

Testing method of power loss of track traveling device

InactiveCN107782568ASolve the problem of lack of test method for power lossVehicle endless-track testingElectric machineSimulation

The invention belongs to the technical field of experiment testing methods, and particularly relates to a testing method of force flow closure power loss of a track propulsion device. According to thetesting method, a variable-frequency and variable-speed motor is utilized as a power device of a testing device, and a rotation speed and torque sensor at the front end of the testing device is utilized as a measuring device of the testing device. The testing method is mainly applied in different states of track pre-tensioning force, the power loss of the track propulsion device is tested, basisis provided for research, development and improvement of design of the power loss of the track propulsion device, and the problem that the power loss of the track propulsion device is lack of testingmethods of is solved.

Owner:CHINA NORTH VEHICLE RES INST

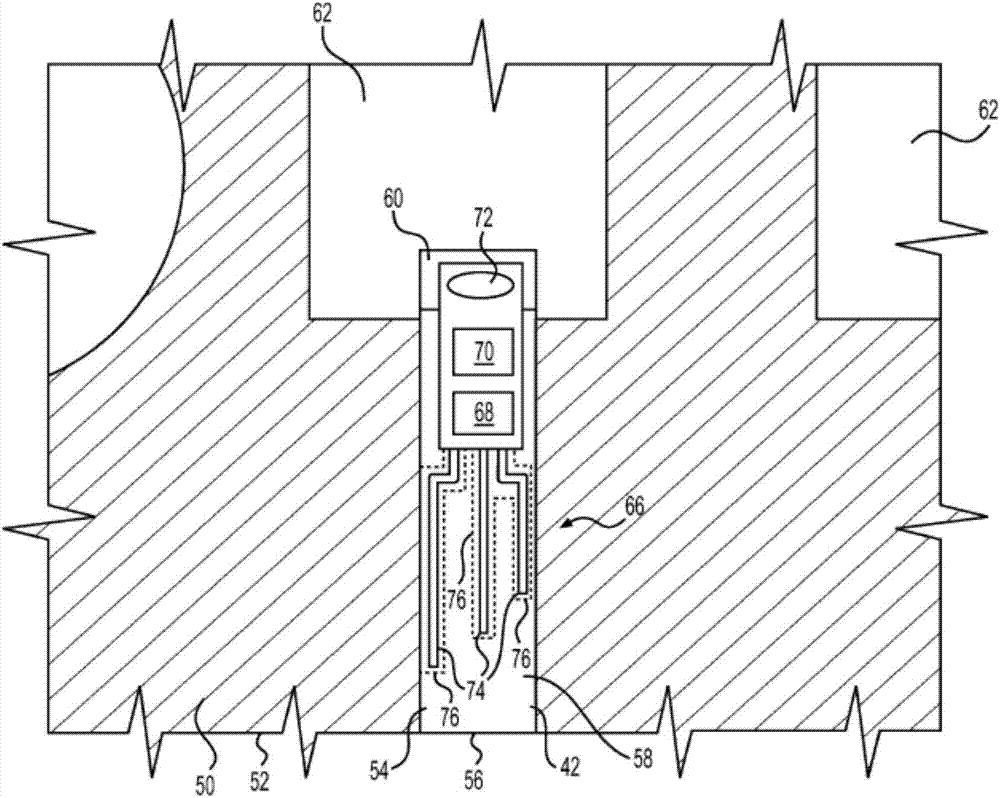

Wear sensing device having a housing

ActiveCN107041134ASoil-shifting machines/dredgersVehicle endless-track testingCommunication deviceBiomedical engineering

A wear sensing device (42) is disclosed. The wear sensing device may have a wear sensor (66). The wear sensor may have plurality of wear members (74), a communication device (72), and a processing device (68). The processing device may be configured to generate a signal indicative of wear, based on a state of the plurality of wear members. The processing device may be further configured transmit the signal with the communication device. The wear sensing device may further have a housing (56). The housing may at least partially enclose the wear sensor and include a plurality of separate slots (76). The plurality of wear members may be positioned in the plurality of separate slots.

Owner:CATERPILLAR INC

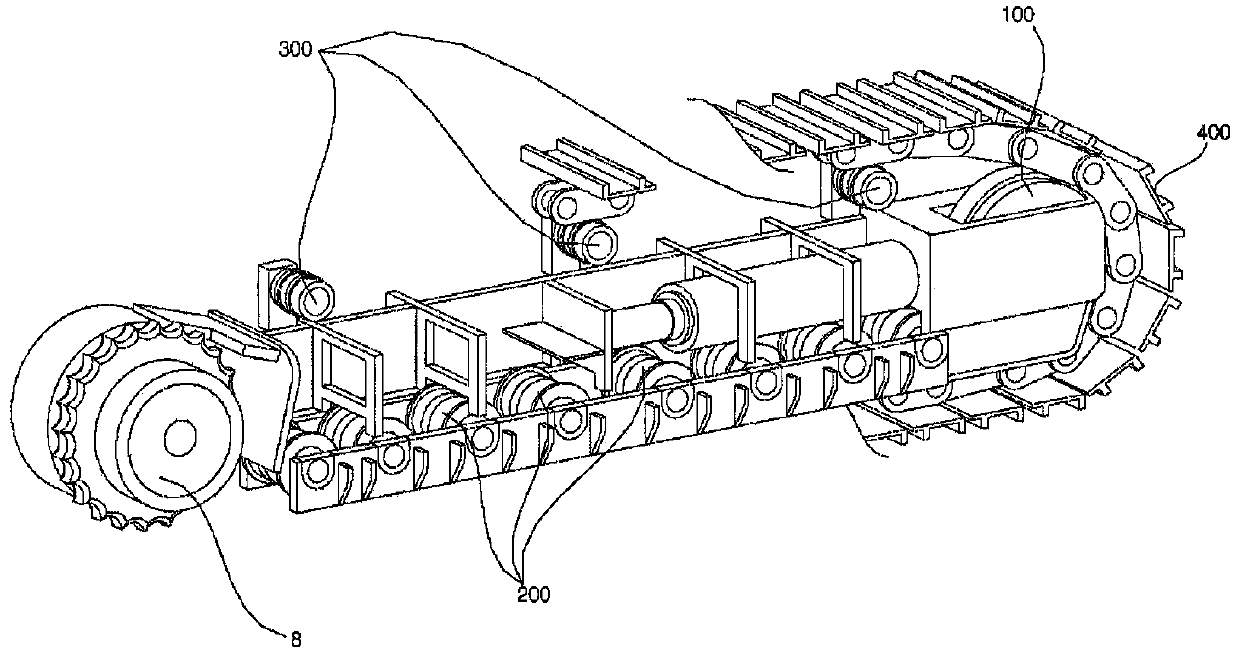

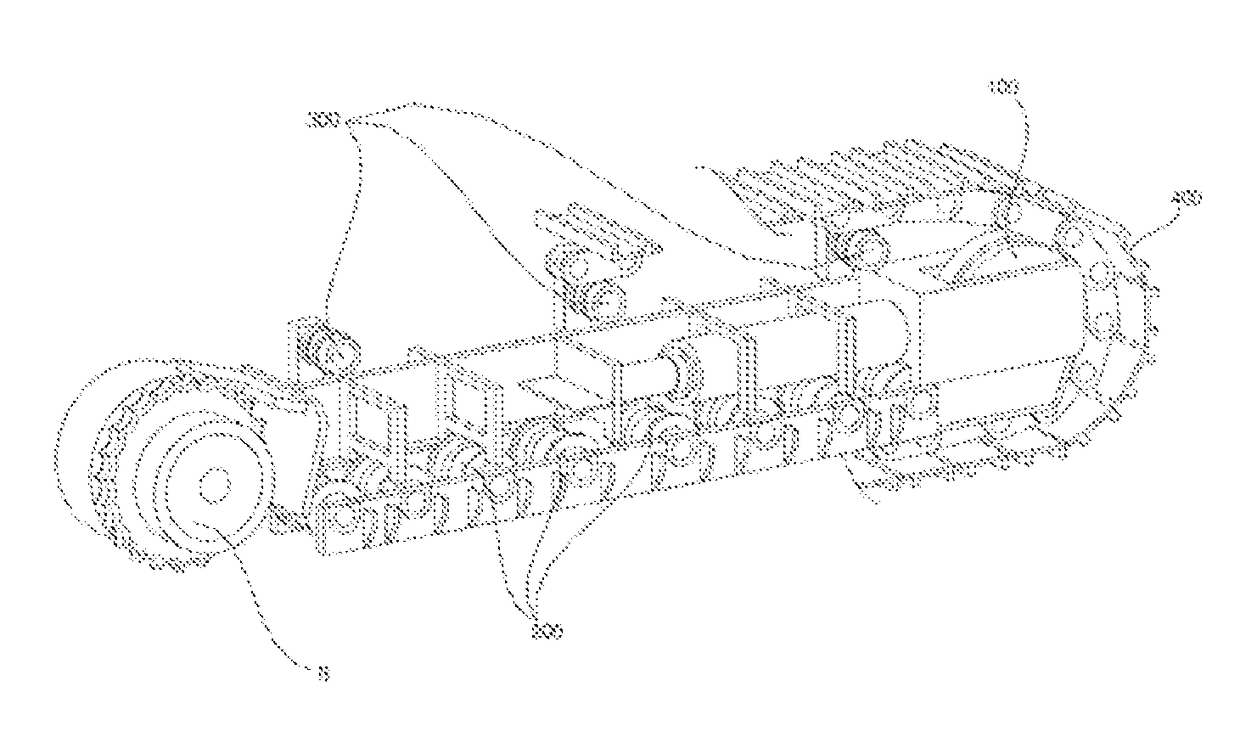

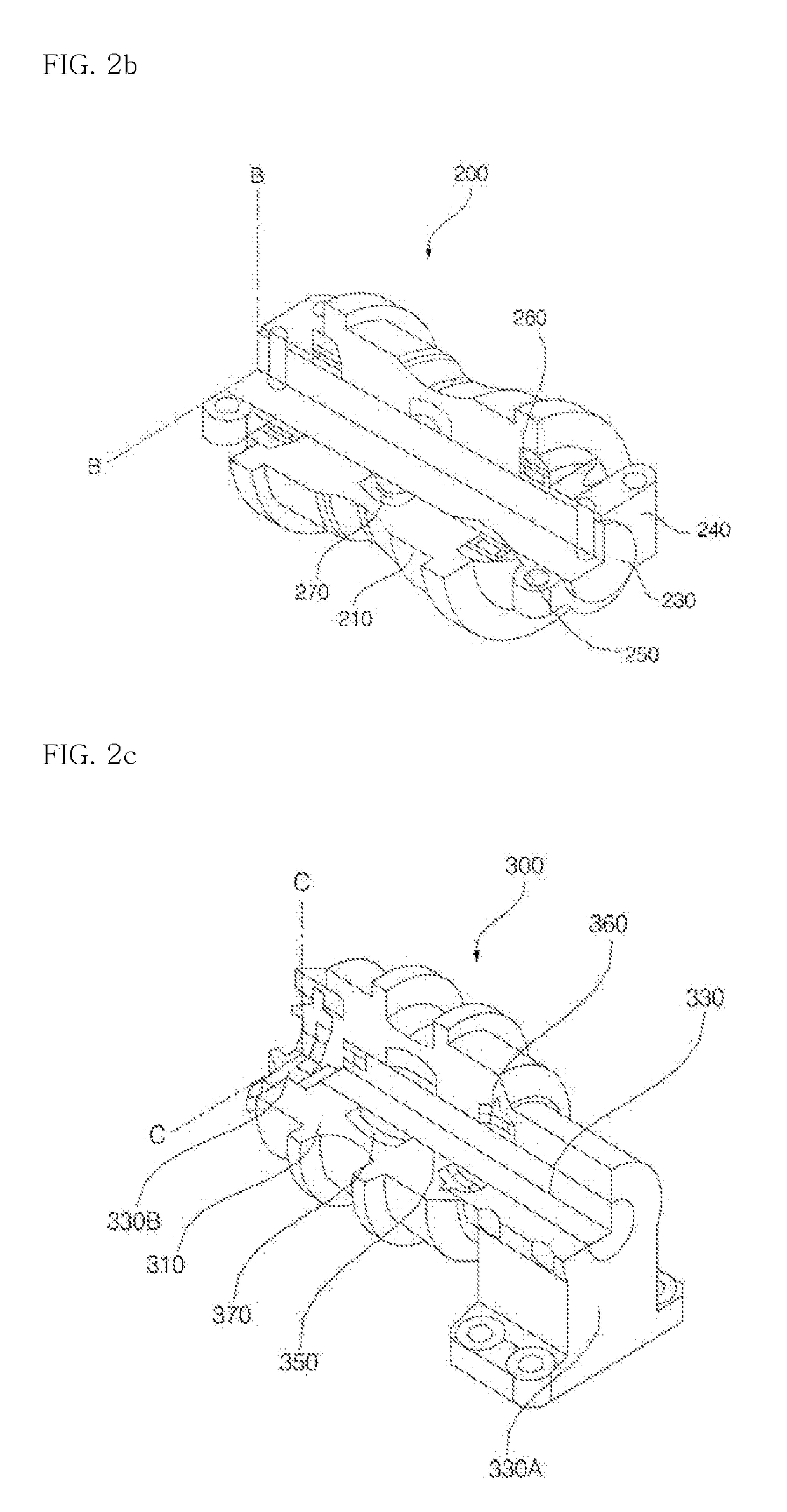

Track assembly for tracked vehicle

ActiveCN107592846AConfirm leak or notConfirm the effect of lifeAcceleration measurementTemperature measurement of flowing materialsCommunication unitEngineering

The present invention relates to a track assembly for a tracked vehicle, which, particularly, comprises: a support shaft disposed to be orthogonal to a traveling direction of a work body; a connectingcollar for connecting the support shaft to the work body while supporting both ends of the support shaft; a rotary roller fitted on the outer periphery of the support shaft and rotating while supporting the inner peripheral surface of a track; a first detection unit disposed between the support shaft and the rotary roller to measure the number of rotations of the rotary roller or the accelerationthereof; a second detection unit for measuring the temperature of a lubricant applied between the support shaft and the rotary roller; a third detection unit disposed on the rotary roller to measurea wear state of the rotary roller; and a communication unit for communicating, to the outside, a result value measured by the first detection unit or the third detection unit. Therefore, the track assembly can improve the efficiency and reliability of work.

Owner:JINSUNG T E C CO LTD

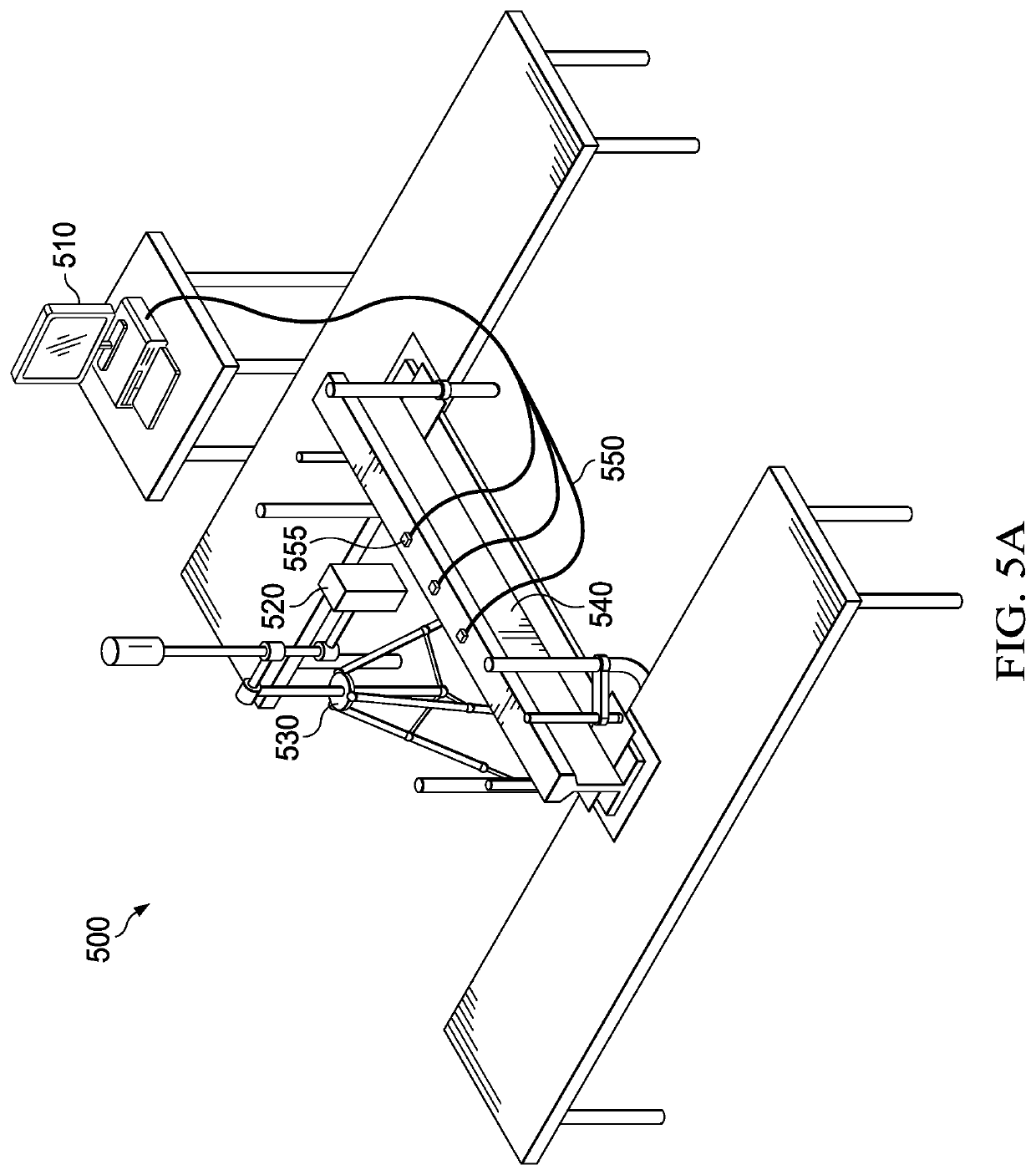

Mobile railway track defect detection

PendingUS20200271543A1Analysing solids using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementVibration amplitudeTrackway

A railway track defect detection system may include a mobile defect detection platform and a modal parameter analyzer. The platform may include an excitation mechanism (e.g., an excitation hammer or wheels that are in contact with a railway track) to apply multiple impact forces to the railway track while the platform travels along the railway track, and a laser Doppler vibrometer to capture, while the platform travels along the railway track, vibration data representing vibrations of the railway track caused by application of the multiple impact forces by the excitation mechanism. The modal parameter analyzer may be configured to detect, based on the vibration data captured by the laser Doppler vibrometer, a defect in the railway track. For example, changes in vibration amplitudes, mode shapes, damping ratios, or a natural frequency derived from the received vibration data may indicate the presence of a defect in the railway track.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

A crawler ground specific pressure simulation test device

InactiveCN103743579BReduced external driving resistanceImprove traction performanceVehicle endless-track testingApparatus for force/torque/work measurementBogieTerrain

The invention discloses a caterpillar track ground pressure simulation test device, which belongs to the field of the ground pressure test. The caterpillar track ground pressure simulation test device comprises a bed frame, a tensile force loading device, bogie wheel loading devices and a caterpillar track, wherein the bed frame is a fixed saddle piece and is firmly connected with the ground, the lower surface of the bed frame is provided with the tensile force loading device and a plurality of independent bogie wheel loading devices in parallel, the tensile force loading device is connected with the caterpillar track, and the lower end of each bogie wheel loading device is contacted with the caterpillar track. The caterpillar track ground pressure simulation test device is a static test device for simulating the ground pressure distribution of a rubber caterpillar track or a steel caterpillar track in different structures and under different terrains through a caterpillar track tension device and the bogie wheel loading devices, the distribution rule of the caterpillar track ground pressure can be disclosed, and the design of a caterpillar track chassis structure can be instructed.

Owner:NO 63908 TROOPS PLA

Device and method for the non destructive testing of tyres by tomography

ActiveCN105102966AHandling using diaphragms/collimetersVehicle endless-track testingNon destructiveClassical mechanics

Owner:CYXPLUS

Ground mechanical characteristic and parameter test bench of mountain caterpillar tractor

InactiveCN108303276AControllable test conditionsReal-time storageVehicle endless-track testingReal time analysisData acquisition

The invention discloses a ground mechanical characteristic and parameter test bench of a mountain caterpillar tractor. The test bench is composed of a mechanical system, a camera system, and a data acquisition and analysis system. The mechanical system consists of a hydraulic power console, a hydraulic cylinder, a soil tank and soil. The camera system includes an endoscope console and an industrial endoscope. The data acquisition and analysis system includes two dynamic signal test analyzers, a synchronous clock signal generator, a single-layer pressure sensor network, a multi-layer pressure sensor network and an upper computer. The ground mechanical characteristic and parameter test bench can be applied to the traction attachment testing of the mountain caterpillar tractor on the slope condition; and the real-time collection, real-time storage, real-time display, and real-time analysis of the mechanical performance index and related data of the tractor on the slope condition can be realized. Therefore, the test bench having high practicability has the great promotion and application value.

Owner:NORTHWEST A & F UNIV

Method for testing steering slip rate of tracked vehicle

ActiveCN111076951ASimple test methodVerification is feasible and effectiveVehicle endless-track testingDrive wheelMathematical model

The invention provides a method for testing the steering slip rate of a tracked vehicle. The method comprises the following steps: establishing a motion equation of any point on a track shoe in a steering process; establishing a mathematical model of single-side braking steering time T and a track slip rate i of a tracked vehicle; and calculating a slip rate i of a crawler belt by testing the single-side braking steering time T of the tracked vehicle and a rotating speed n of a driving wheel. According to the invention, the track slip rate of the tracked vehicle during steering under differentground conditions can be measured; the test process is simple, and the test efficiency is improved.

Owner:JIANGSU UNIV

Tracked vehicle steering slip rate and slip rate monitoring system and application method thereof

InactiveCN111272451ASlip rate real-time monitoringImprove accuracyVehicle steering/rolling behaviourVehicle endless-track testingControl engineeringData acquisition

The invention discloses a tracked vehicle steering slip rate and slip rate monitoring system and an application method thereof. The monitoring system comprises a data acquisition I / O board card; an industrial personal computer which communicates with the data acquisition I / O board card and is used for data acquisition and instruction output; two encoders which communicate with a left crawler belt, ta right crawler belt and the data acquisition I / O board card respectively and are used for acquiring rotating speed information of the left crawler belt and the right crawler belt; a GPS receiverwhich communicates with the industrial personal computer and is used for acquiring positioning information and advancing speed information of a vehicle; and a power supply which supplies power toa monitoring system. Monitoring and detection of the tracked vehicle steering system are achieved, the slip rate of the low-speed side of a track and the slip rate of the high-speed side of the track during vehicle steering are accurately analyzed and calculated, and the accuracy of the traveling track of the tracked vehicle is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

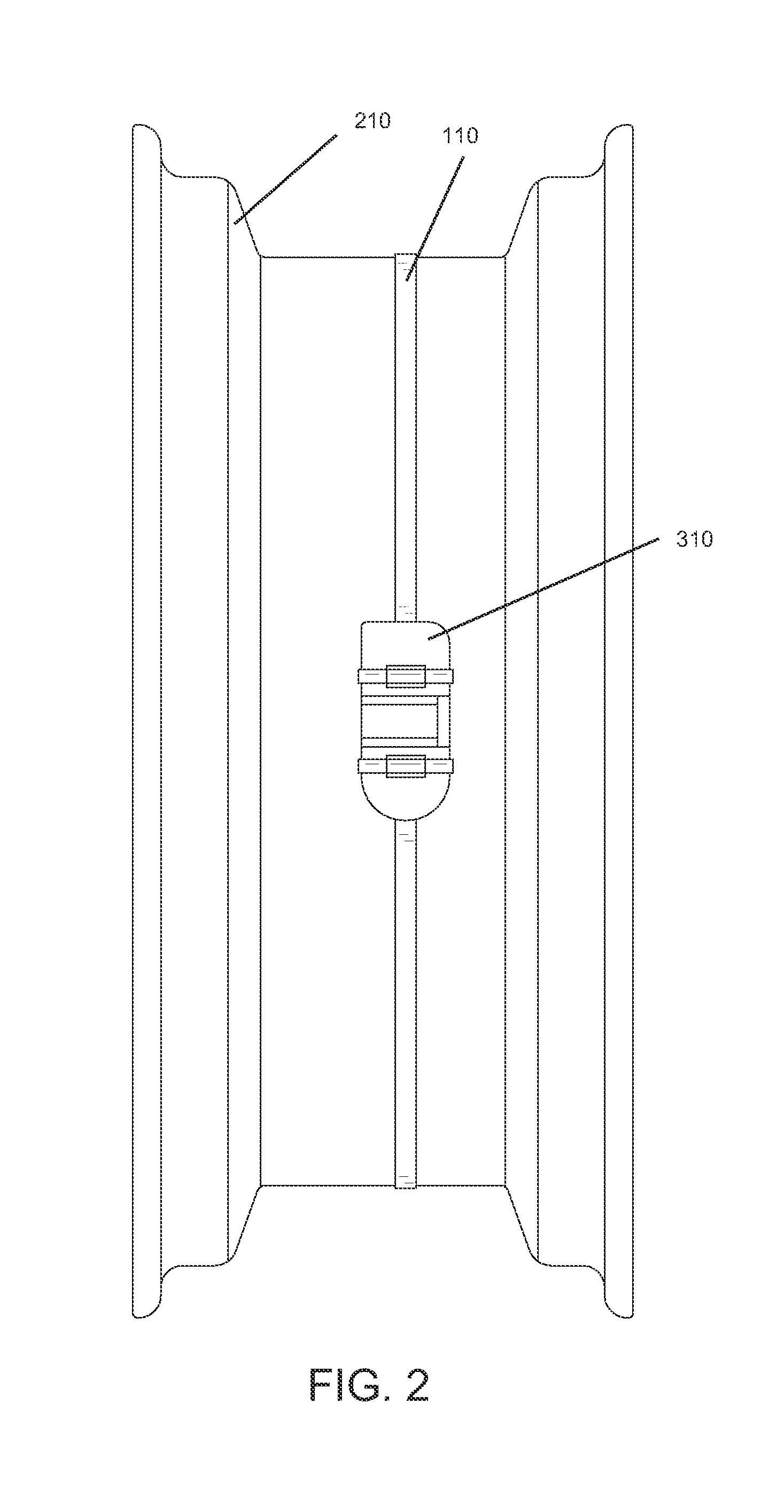

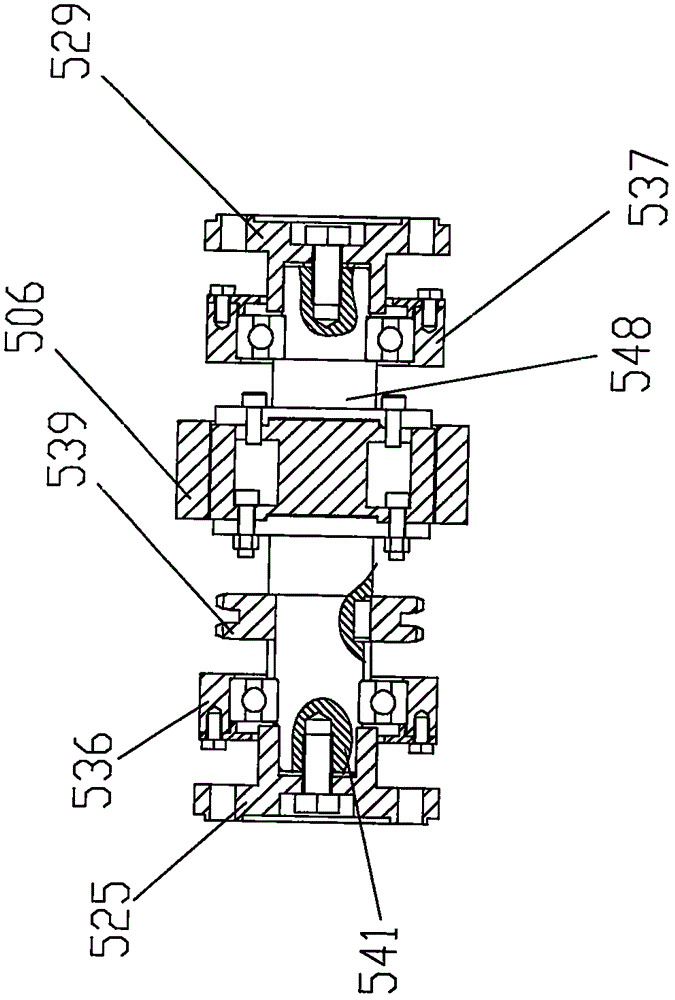

Track assembly for tracked vehicle

ActiveUS20180086398A1Check residual lifeImprove efficiencyAcceleration measurementTemperature measurement of flowing materialsCommunication unitEngineering

The present invention relates to a track assembly for a tracked vehicle, which, particularly, comprises: a support shaft disposed to be orthogonal to a traveling direction of a work body; a connecting collar for connecting the support shaft to the work body while supporting both ends of the support shaft; a rotary roller fitted on the outer periphery of the support shaft and rotating while supporting the inner peripheral surface of a track; a first detection unit disposed between the support shaft and the rotary roller to measure the number of rotations of the rotary roller or the acceleration thereof; a second detection unit for measuring the temperature of a lubricant applied between the support shaft and the rotary roller; a third detection unit disposed on the rotary roller to measure a wear state of the rotary roller; and a communication unit for communicating, to the outside, a result value measured by the first detection unit or the third detection unit. Therefore, the track assembly can improve the efficiency and reliability of work.

Owner:JINSUNG IND

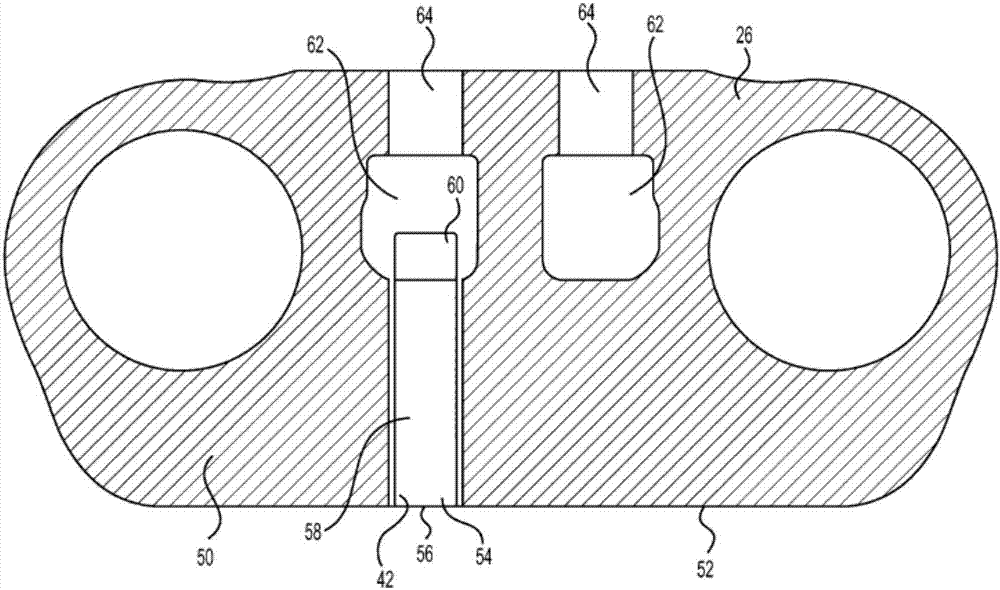

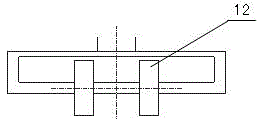

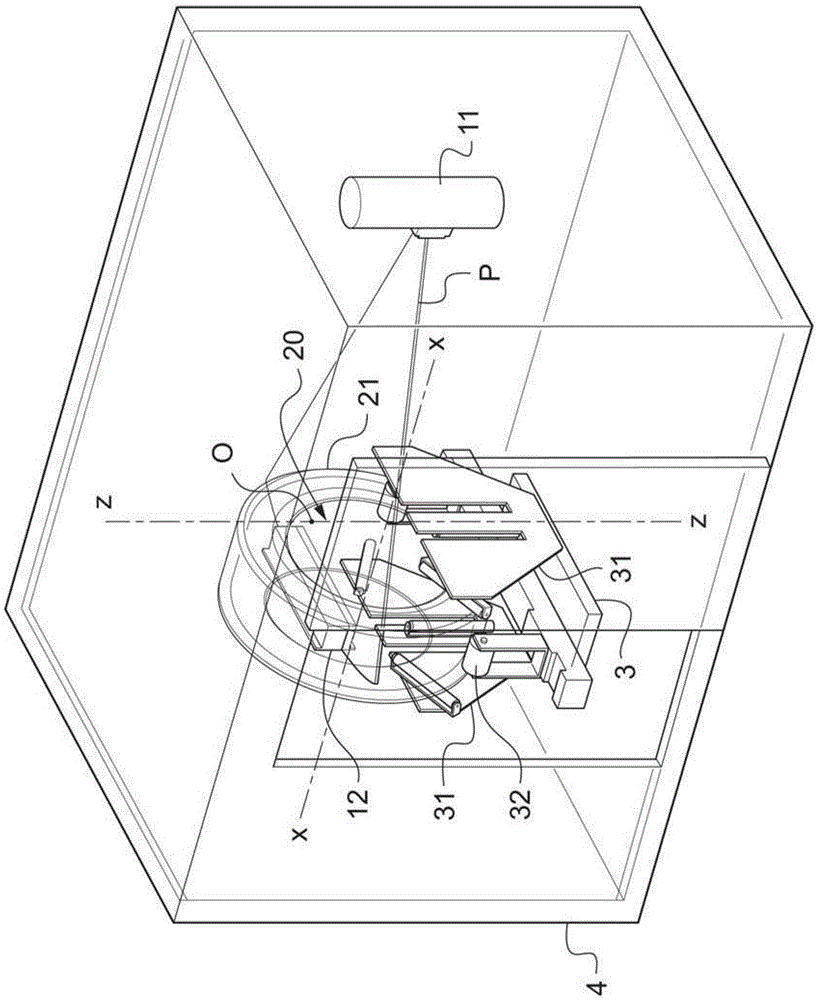

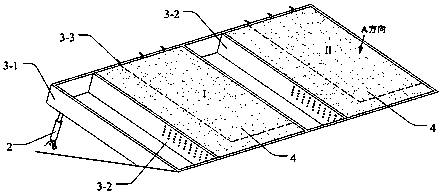

Device and method for the nondestructive testing of tires by tomography

ActiveUS9702833B2Shorten cycle timeIncrease contrastHandling using diaphragms/collimetersVehicle endless-track testingTomographyEngineering

A device for testing a tyre (2) for representing tomographical images of sections of a casing of the tyre includes a source (11) of ionizing radiation arranged outside the tyre (2) and a detector (12) for receiving the radiation. The detector (12) is situated opposite the source (11) with respect to at least one section of the casing. The axis (X-X) of the tyre runs parallel to a sectional plane (P) passing through the focus (F) of the source (11) and the detector (12). The tyre and the source-detector assembly are moved with rotational motion relative to one another about an axis of rotation (Z-Z) perpendicular to the sectional plane (P), according to a predetermined angular excursion range. The detector (12) is disposed in a central internal zone (20) of the tyre (2) during the testing cycle.

Owner:CYXPLUS

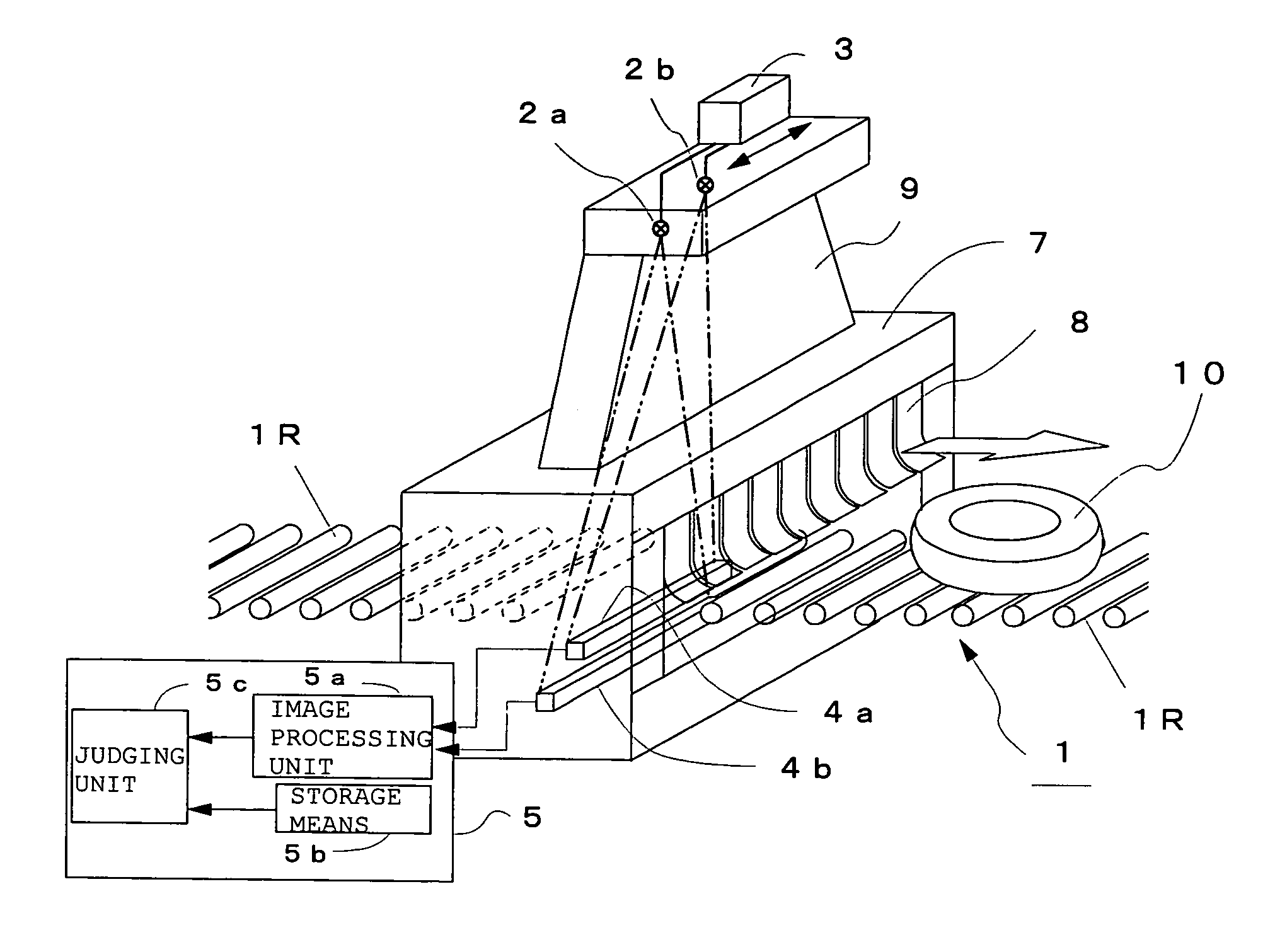

Method and device for X-ray inspection of tire

InactiveUS7076022B2Inspect the interior of the tire accuratelyInspection is accurateVehicle endless-track testingUsing wave/particle radiation meansImage InspectionLine sensor

An X-ray tire inspection apparatus comprising X-ray tubes 2a and 2b for applying an X-ray to a tire 10, installed right above the opposite ends of the tire 10 conveyed by a roll conveyor 1, and X-ray line sensors 4a and 4b arranged in the space between adjacent rolls 1R and 1R below the above roll conveyor 1 at positions corresponding to the above X-ray tubes 2a and 2b, respectively, wherein transmission X-ray images of left half and right half portions of the tire 10 are taken by the X-ray line sensors 4a and 4b and combined by tire internal image inspection means 5 to obtain a transmission X-ray composite image of the whole tire 10. Therefore, even a tire having a low aspect ratio can be internally inspected accurately and efficiently.

Owner:BRIDGESTONE CORP

Crawler tractor production-used track anti-slip performance detection device

The invention relates to the technical field of tractor detection equipment, in particular to a crawler tractor production-used track anti-slip performance detection device. The device comprises a test bench; the top of the test bench is provided with a plurality of bearing convex seats; a plurality of rows of rollers are rotarily connected between two adjacent columns of bearing convex seats; anabutting column is arranged between two adjacent rows of rollers; the right end of the abutting column is tightly welded with a rotating shaft; the right end surface of the test bench is provided witha control device; and the control device comprises a base, a sliding column and a plurality of stop blocks. According to the crawler tractor production-used track anti-slip performance detection device, through adjusting the abutting force of the stop block on the control device for the abutting column, the purpose of adjusting the force needed when the roller drives the abutting column to rotateis achieved, the pavements with different smoothness can thus be simulated, and through arranging a protection platform, the crawler tractor can be blocked by the protection platform when detected tobe out of control, and the safety of surrounding people is protected.

Owner:湖南沃工智电科技有限公司

Test track walking mechanism for vehicle ground mechanics soil tank test bench

InactiveCN105928719AOptimizing track performanceVehicle endless-track testingVehicle frameDrive shaft

The invention relates to a test track walking mechanism for a vehicle ground mechanics soil tank test bench. The test track walking mechanism comprises a vehicle frame; the front end of the middle of the vehicle frame is provided with a front bearing supporting seat; the rear end of the middle of the vehicle frame is provided with a rear bearing supporting seat; the rear bearing supporting seat is provided with a rear track driving shaft through a bearing; the front bearing supporting seat is provided with a front track driving shaft through a bearing; the outer end of the front track driving shaft is sleeved with a front connection flange; the middle of the front track driving shaft is sleeved with a track driving chain wheel; the cross section of the outer end of the rear track driving shaft is a hexagon or a square; the outer end of the rear track driving shaft is sleeved with a rear connection flange; the inner end of the rear track driving shaft and the inner end of the front track driving shaft are connected with end surfaces of a disc type torque sensor respectively; and the shell of the disc type torque sensor is connected with the frame through a torque sensor fixing plate. The test track walking mechanism for the vehicle ground mechanics soil tank test bench can measure the stressed state of the soil tank test bench, authentically simulate the actual operating states of tracks, and simulate actual height in an experiment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Control device of dynamometer system

ActiveUS10942091B2Avoid it happening againEliminate speed differencesAverage speed measurementVehicle endless-track testingSynchronous controlInertial control

A control device of a dynamometer system is provided with: a driving force observer which estimates a generated driving force of a vehicle; an electrical inertia control unit which uses the driving force to generate a front wheel basic torque command signal and a rear wheel basic torque command signal; a synchronization control unit which generates a synchronization control torque command signal with respect to the basic torque command signal and the basic torque command signal in such a way as to eliminate a speed difference; and torque command signal generating units which use the synchronization control torque command signal to adjust the basic torque command signal and the basic torque command signal. The synchronization control unit is defined in such a way that the poles of a denominator polynomial of a transfer function from the driving force to the speed difference are all negative real numbers.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Test method for testing ground pressure of tracked vehicle

InactiveCN105067285AVehicle endless-track testingApparatus for force/torque/work measurementGround pressureForce sensor

A test method for testing ground pressure of a tracked vehicle includes the following steps: A. according to the number of loading wheels at one side of a tracked vehicle which needs testing, a corresponding number of holes are dug on the ground, all the holes are arranged in a row, and distance between adjacent holes equals to that between adjacent loading wheels at one side of the tracked vehicle; B. a ground pressure sensor is placed in each hole, each ground pressure sensor is numbered, a numbering sequence is that the ground pressure sensor located at one end is numbered as Number 1, the ground pressure sensor adjacent to the Number 1 ground pressure sensor is numbered as Number 2, the next ground pressure sensor adjacent to the Number 2 ground pressure sensor is numbered as Number 3, and according to this sequence, all the ground pressure sensors are numbered. The invention aims to provide a test method for testing ground pressure of a tracked vehicle, and the method can help researchers to accurately analyze ground tractive characteristics and steering performance of the tracked vehicle.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Anti-skid performance detection equipment for track production

ActiveCN114397118AEasy to movePrevent rotationVehicle endless-track testingStructural engineeringRoad surface

The invention relates to the technical field of crawler belt production detection equipment, discloses anti-skid performance detection equipment for crawler belt production, and solves the problems that the skid degree is inconvenient to adjust, the distance between two adjacent rollers is fixed, and when the distance between two crawler belts is different, different test benches need to be replaced, so that the production efficiency is high. The device comprises an anti-skid performance supporting detection table, a plurality of first rectangular holes and a plurality of second rectangular holes are formed in the top of the anti-skid performance supporting detection table, rollers are arranged in the first rectangular holes and the second rectangular holes, and supporting movable seats are arranged at the two ends of each roller. The two ends of the roller are fixedly connected with a first fixing shaft and a second fixing shaft respectively; the distance between every two adjacent rollers can be conveniently adjusted, so that the two crawler belts can be located on the rollers, the application range is widened, the resistance borne by rotation of the rollers can be adjusted, and the use condition of the crawler tractor on road surfaces with different slippery degrees can be simulated.

Owner:常州欧爱欧履带有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com