Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about "Synchronous generators with multiple outputs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

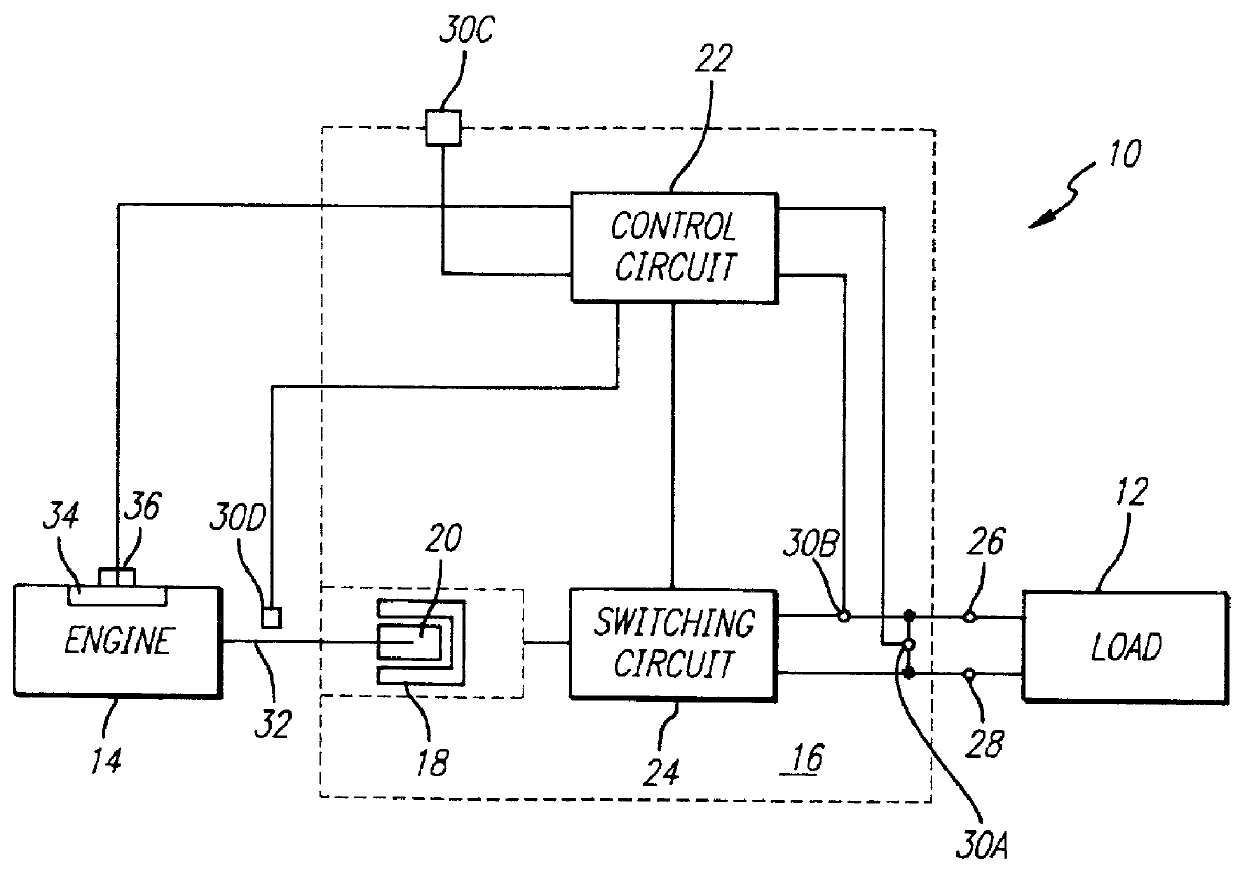

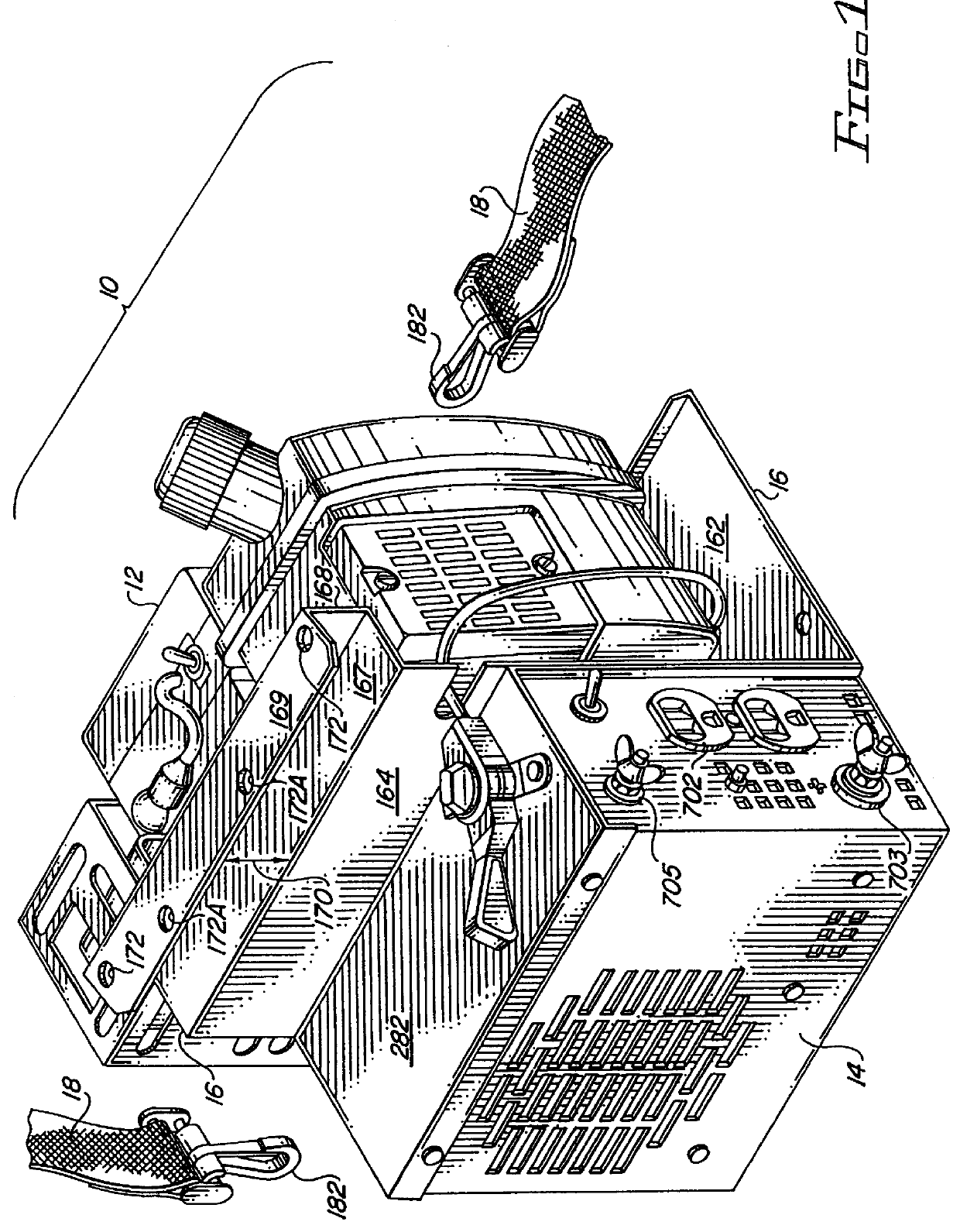

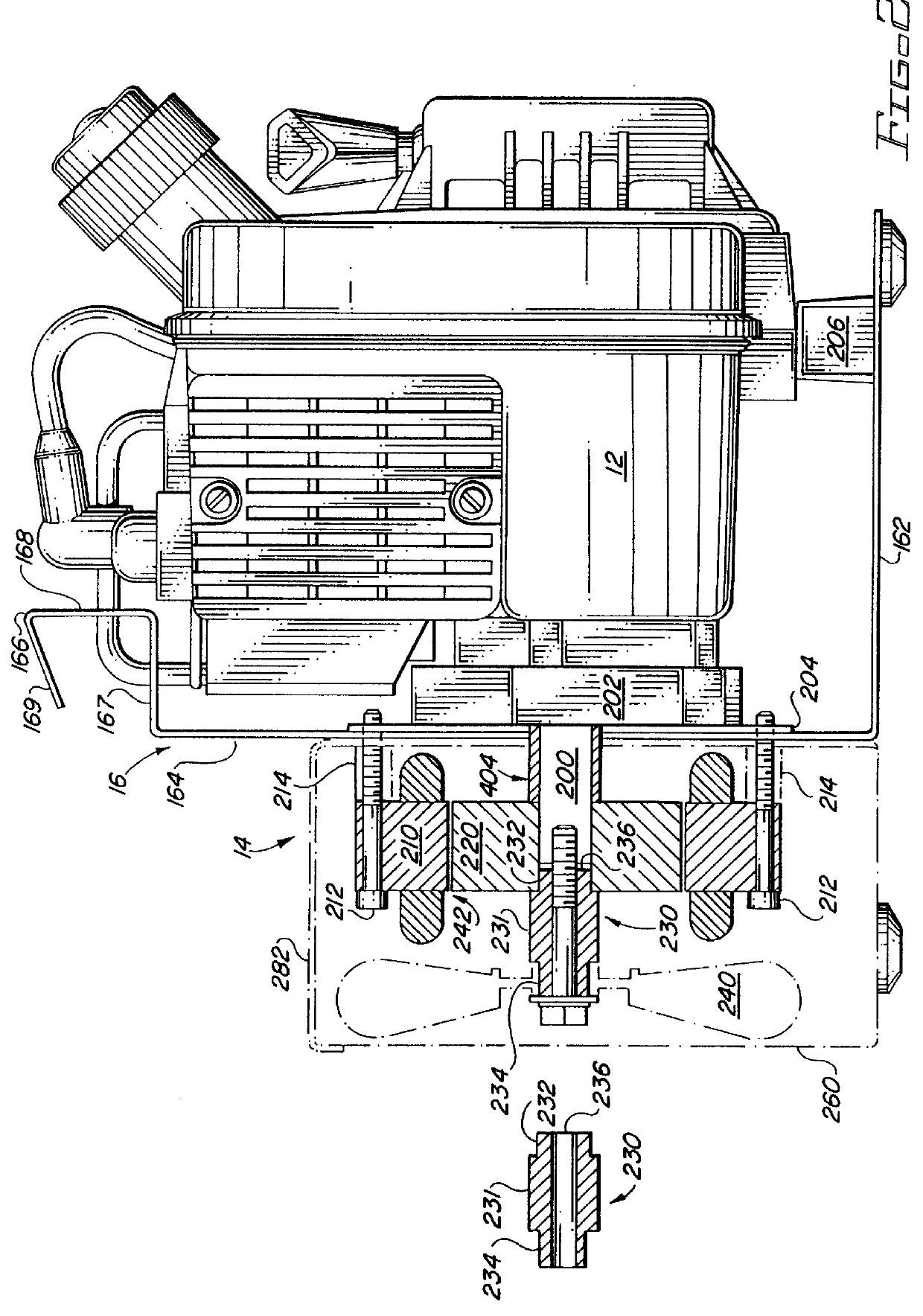

Load demand throttle control for portable generator and other applications

The throttle of an engine in an engine driven generator system operating subject to a wide and rapidly variable load, as in supplying current to a welder, is operated such that control signals are sent to a throttle actuator for adjusting the engine throttle position in response to load changes. The throttle actuator may be a solenoid pulling against a spring in accordance with the average current through the solenoid coil. In this embodiment, the processor causes pulse width modulated signals to be applied across the solenoid coil with throttle position changes being reflected in changes to the width of the pulses, such changes in the pulse width being delayed for at least the predetermined time since the last preceding adjustment to the throttle. Alternatively, the throttle actuator may be a stepper motor which is stepped by throttle position change signals from a processor which monitors engine speed and generator load to determine whether the throttle should be adjusted and, if so, in which direction and to what extent for optimum response.

Owner:PRAMAC AMERICA

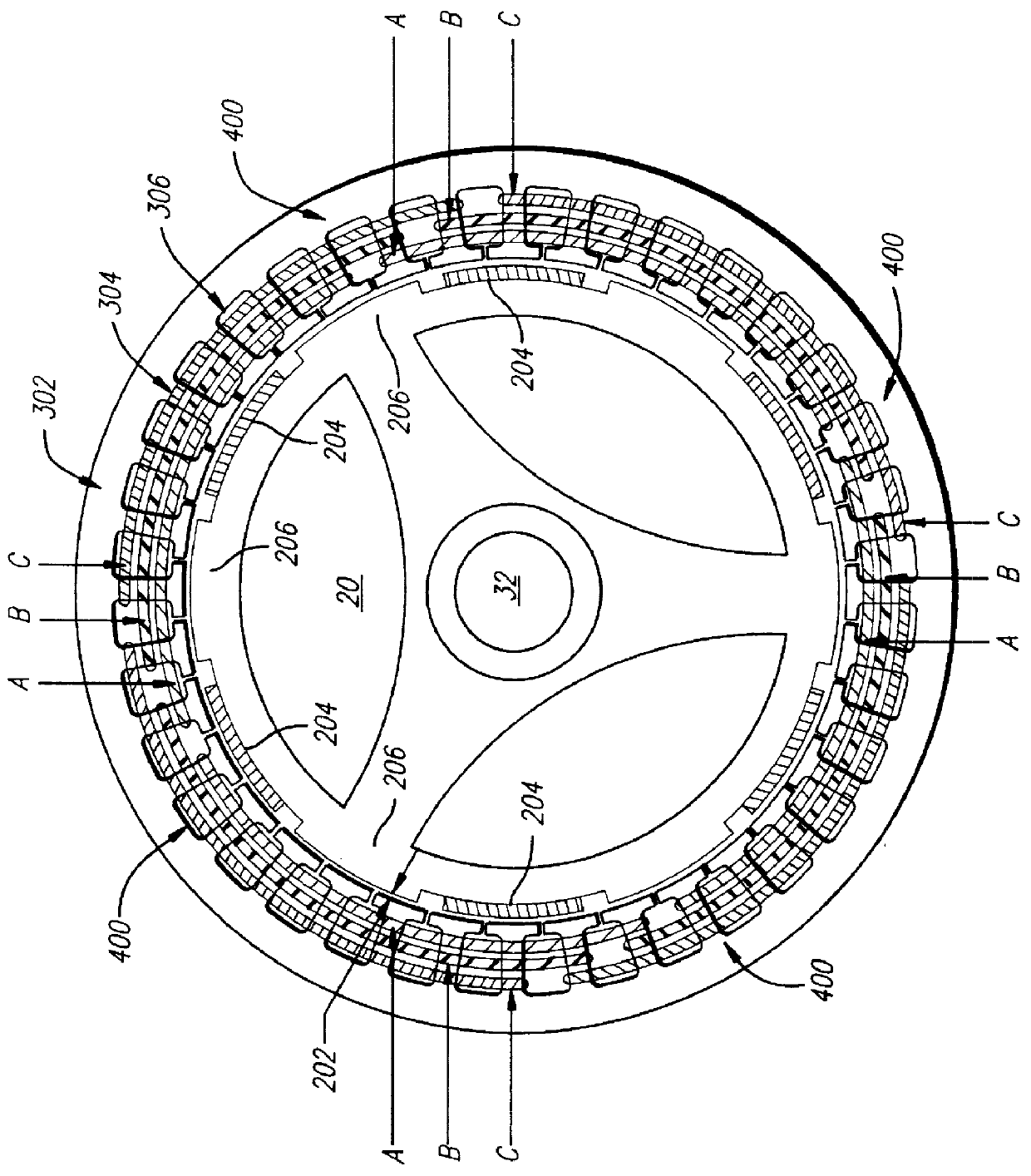

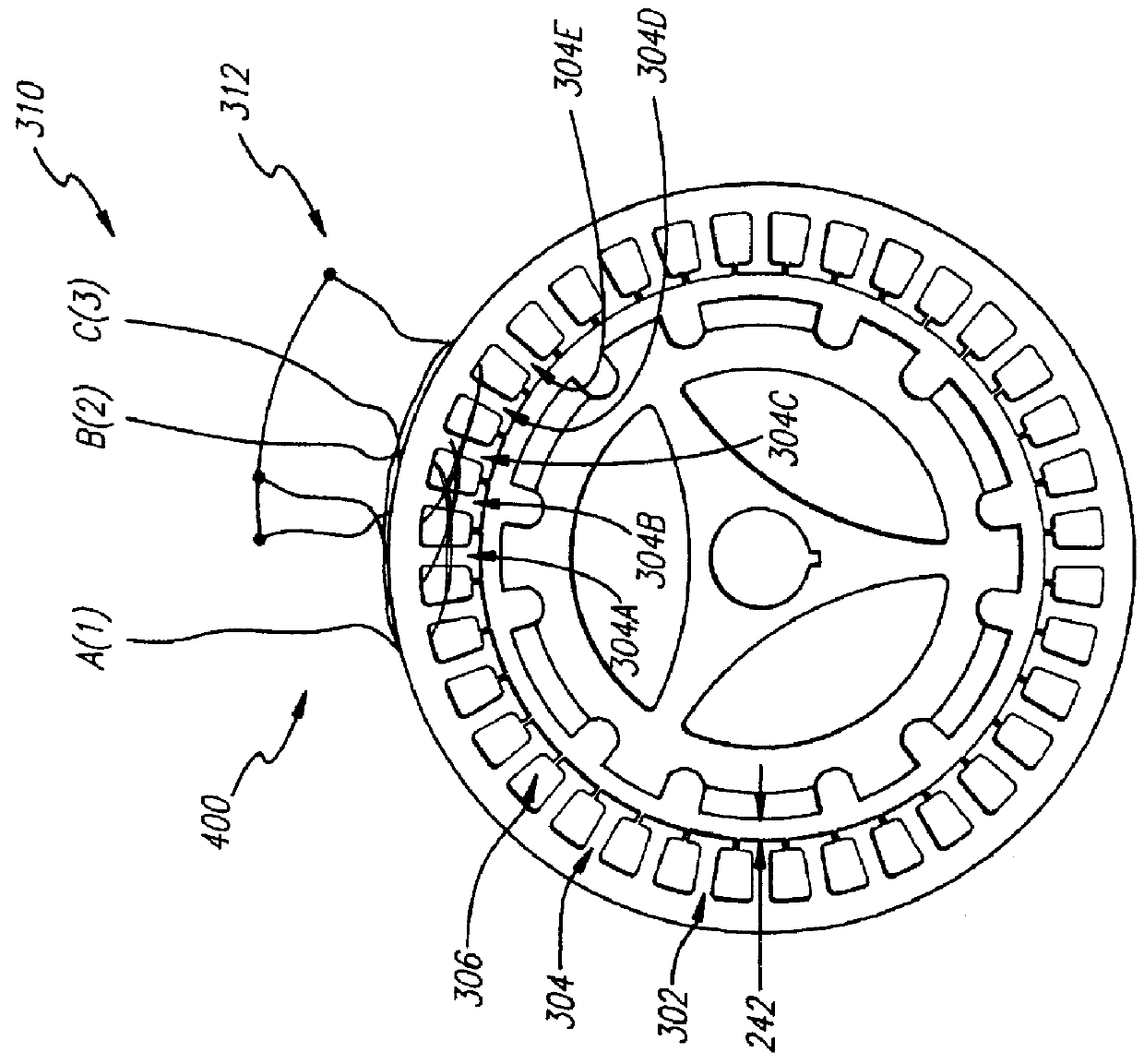

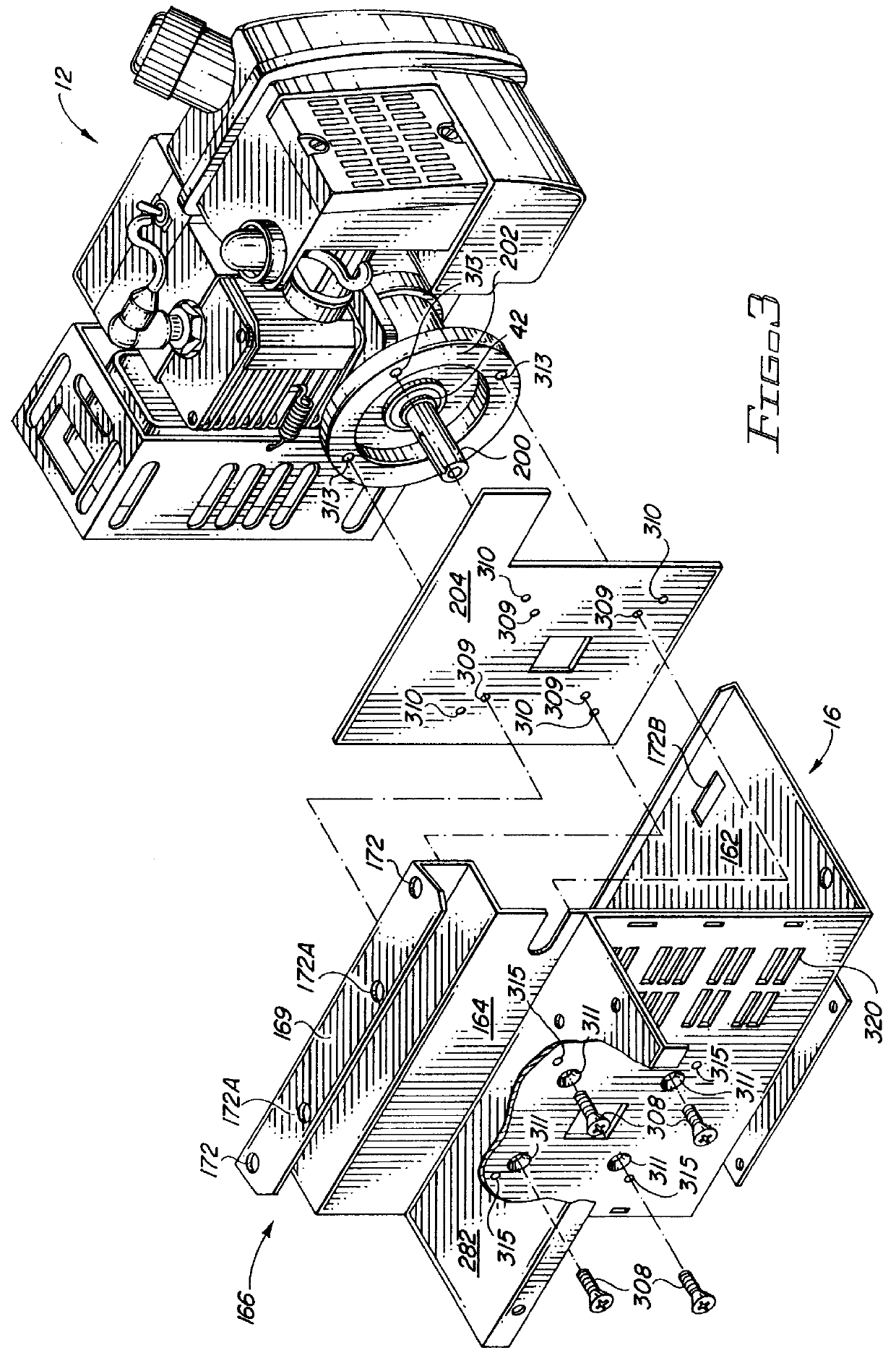

Light weight rotor and stator with multiple coil windings in thermal contact

A lightweight engine-driven generator set including a stator having at least first and second windings (preferably three-phase) and a rotor having a soft magnetic core and a plurality of high energy product permanent magnets, separated by consequence poles, disposed proximate the stator such that relative motion of the rotor and stator causes magnetic flux from the rotor to interact with and induce current in the stator windings. The first winding includes a predetermined number of turns corresponding to a first predetermined voltage output; and the second winding includes a predetermined number of turns corresponding to a second predetermined voltage output, the respective windings being grouped together as a unit and wound about the core such that the respective winding coils are wound in continuous close thermal contact with each other. The first winding generates a relatively high voltage, low amperage signal, and the second winding generates a relatively low voltage, high amperage signal; and a switch provides for selection of the desired output. Preferably the rotor is a hollow cylinder mounted on the engine shaft for rotation about the stator and such that the proper gap distance between rotor and stator is maintained during rotation of the rotor without bearings external to the engine. The low voltage, high amperage winding (or winding group) may be tapped to provide a selectable voltage output. Suitable rectifiers and inverters may be provided to effect selective DC and AC output signals.

Owner:COLEMAN POWERMATE

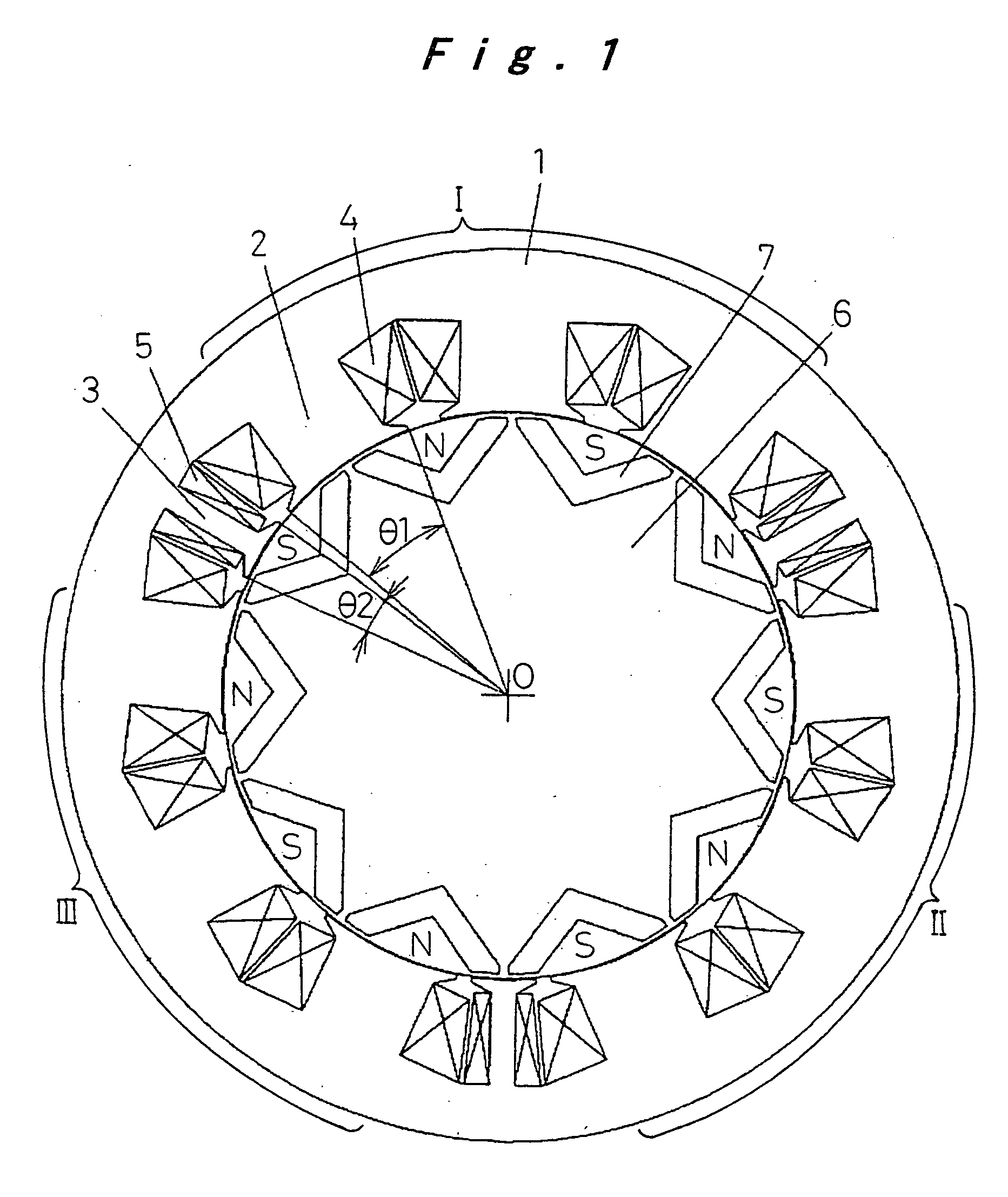

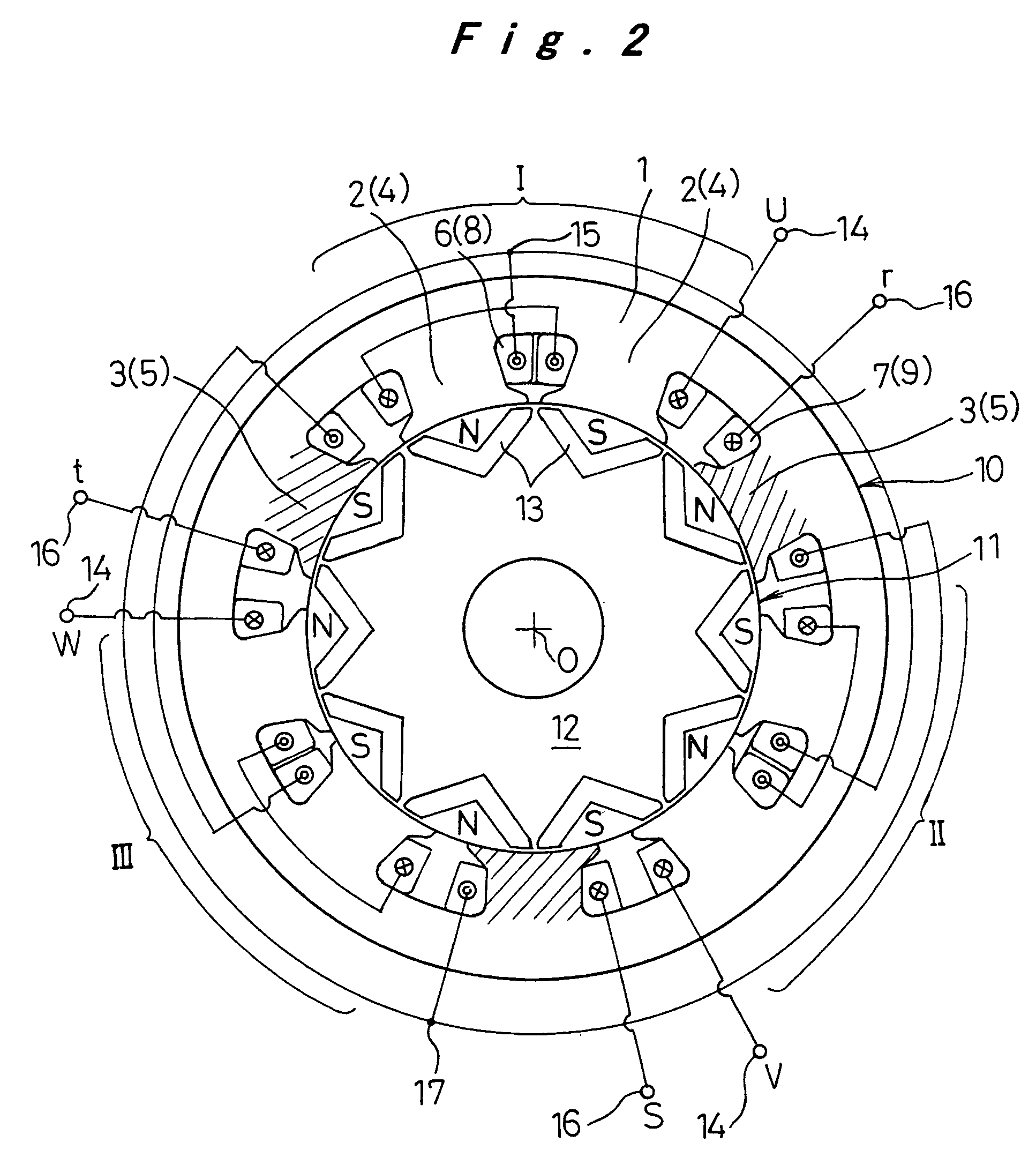

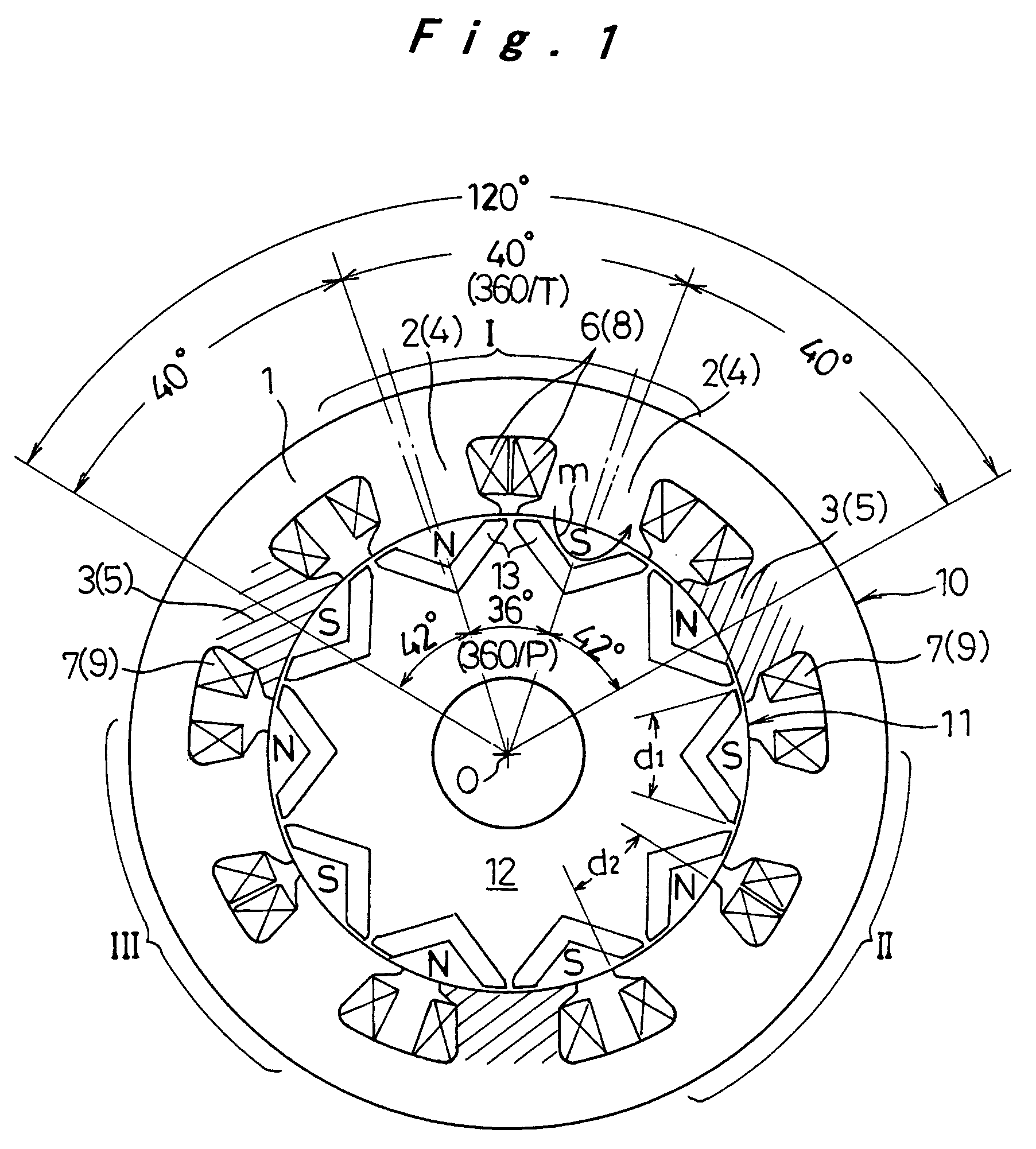

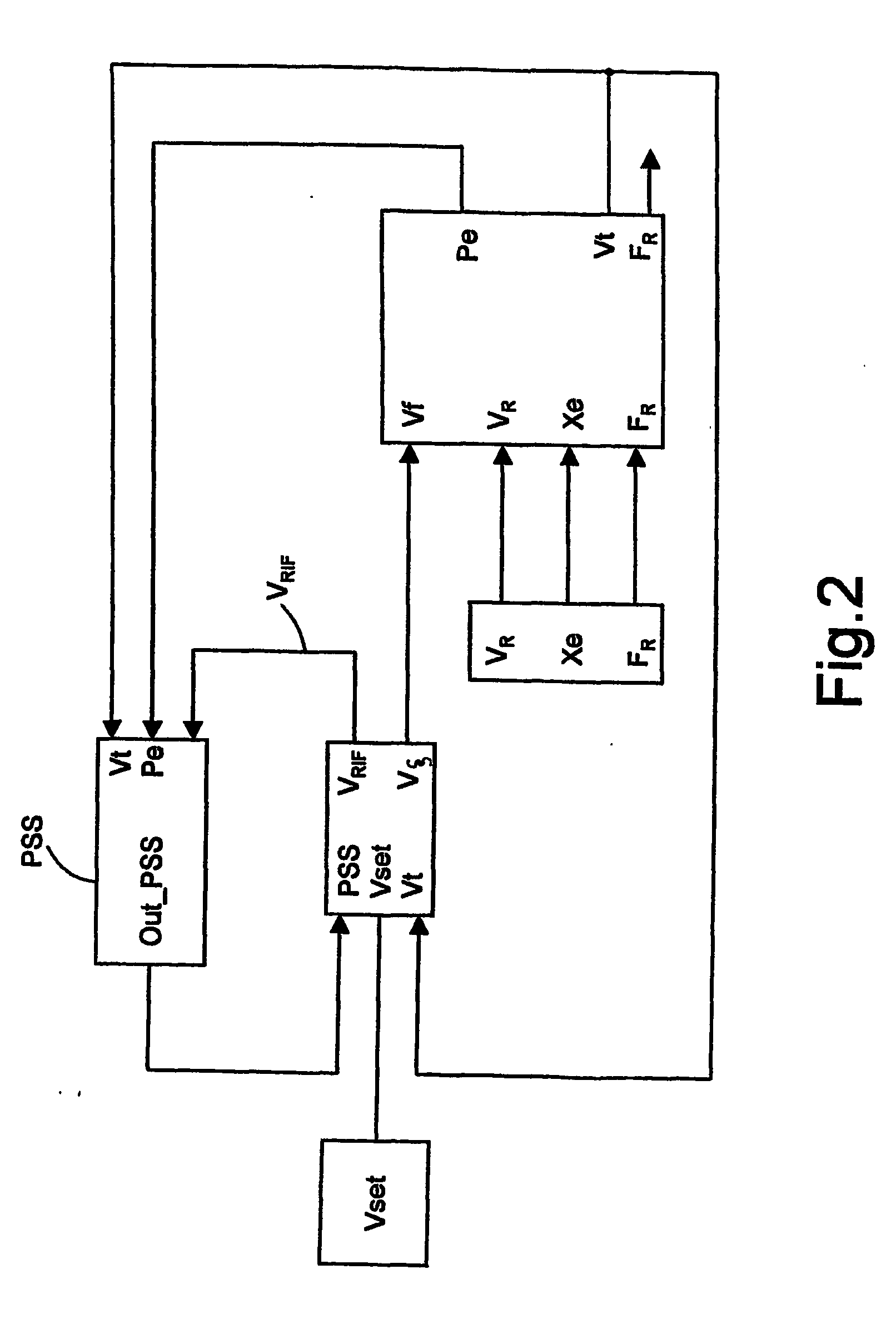

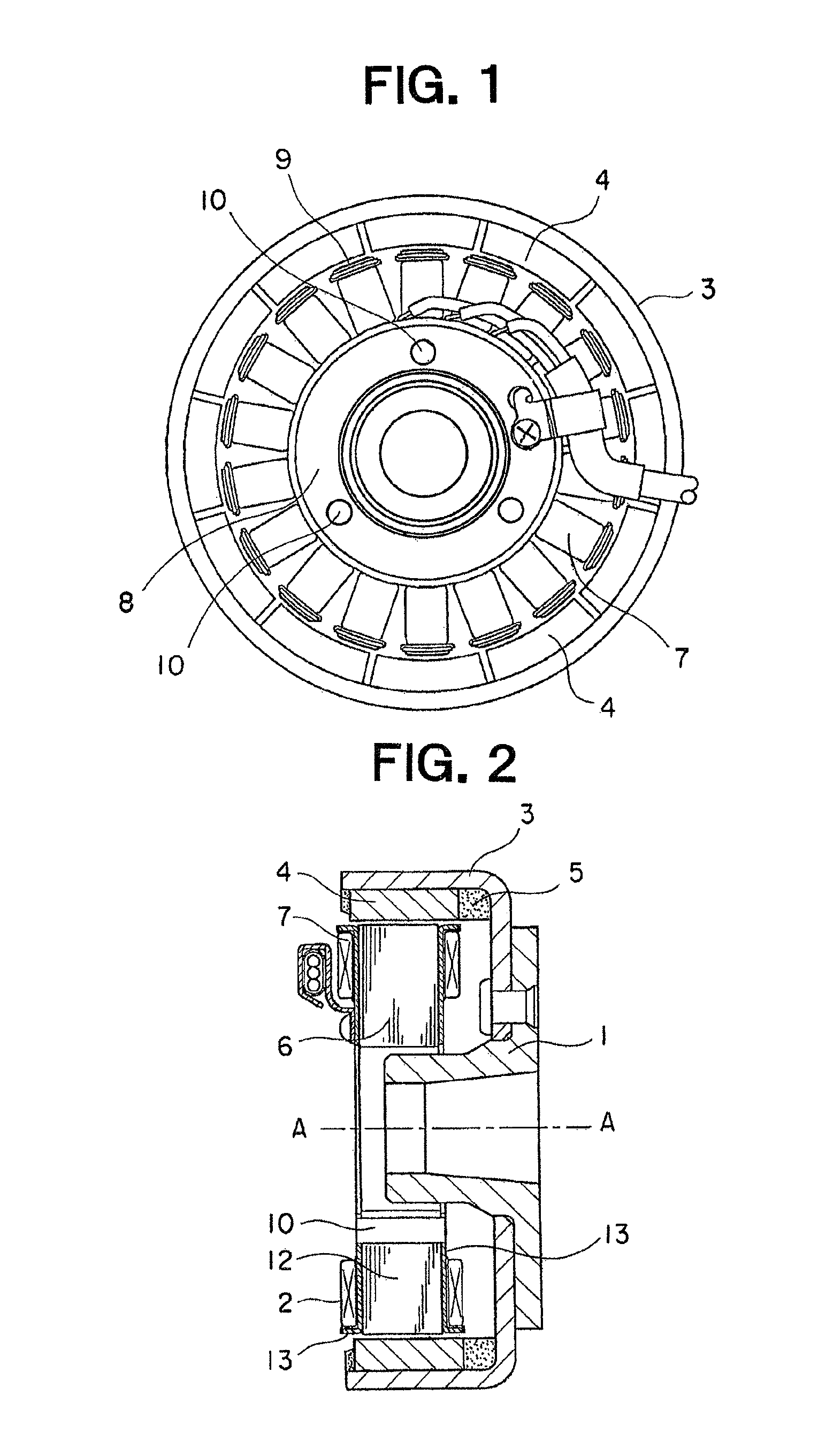

Motor generator

InactiveUS20050029890A1Good utilization of interior spaceLow costMagnetic circuitAsynchronous induction motorsCounter-electromotive forceConductor Coil

A permanent magnet embedded type concentrated winding motor generator, wherein of the mechanically and electrically independent first and second winding groups (4, 5), the plurality of first teeth (2) wound with the first winding groups (4) are divided into three groups (I, II, III) for example, and the winding directions of the windings of adjacent first teeth (2) within the same group (I, II, III) are opposite. Furthermore, one second tooth (3) wound with a second winding group (5) with a different winding specification from the first winding groups (4) is provided between each of the groups (I, II, III). Accordingly, the relative sizes of the generated voltages in the first winding groups (4) and the second winding groups (5) differ each other, allowing the realization of a compact and low cost construction capable of charging two different electric potentials from a single unit, which also enables a reduction in distortion of the waveform of the counter electromotive force, a reduction in iron loss, and an improvement in the efficiency of the motor, and enables the efficient charging of power sources with two different electric potentials.

Owner:PANASONIC CORP

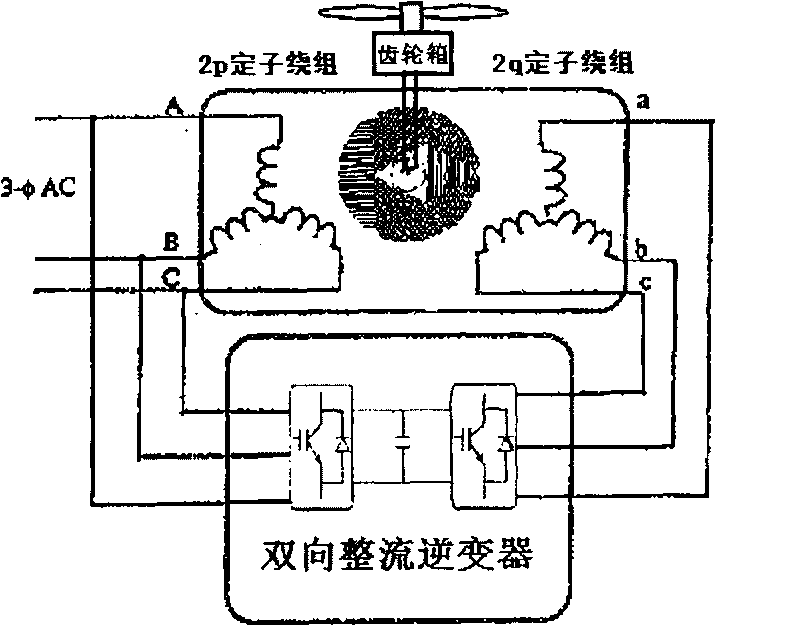

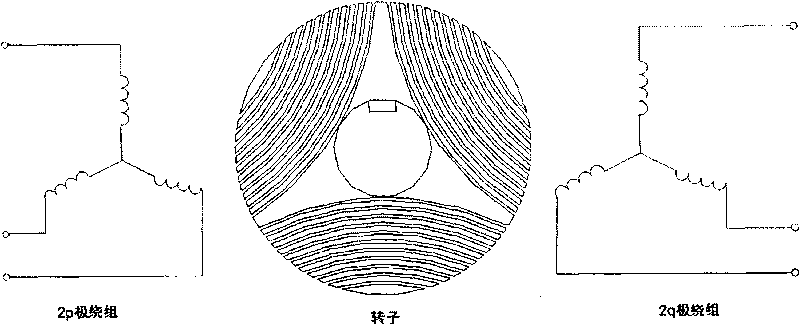

Megawatt grade brushless slip ring double-fed wind generator/motor and control method thereof

InactiveCN101764491AImprove adaptabilitySimple structureElectronic commutation motor controlVector control systemsPower gridWind power system

The invention discloses a megawatt grade brushless double-fed wind generator / motor, comprising a stator, a rotor and a bidirectional rectifying inverter, wherein the stator is provided with two sets of individual sinusoidal distributed windings, the numbers of poles of the individual distributed windings are respectively 2p and 2q, the 2p stator winding is used as a main power winding and is directly connected with an electric net, the 2q stator winding is used as a power control winding and is connected with the electric net or an external circuit by the bidirectional rectifying inverter. The megawatt grade brushless double-fed wind generator / motor has excellent suitability, and not only can be designed as a direct-driving wind generating system, but also can be designed as a wind generating system with a one-grade or multi-grade accelerating gearbox. The wind generator / motor has simple structure, thereby greatly improving the reliability and greatly reducing the cost of operation and maintenance.

Owner:徐隆亚 +1

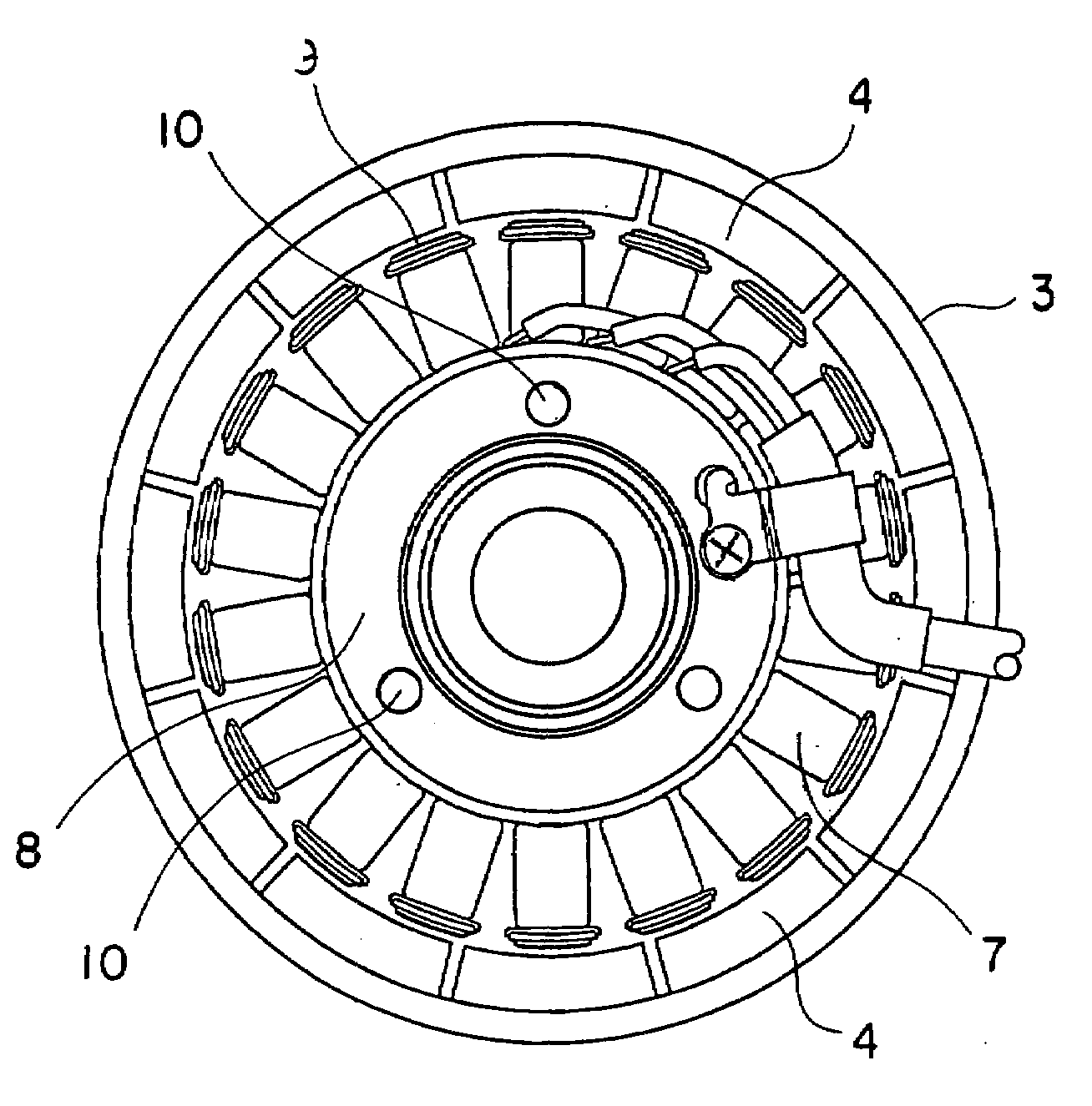

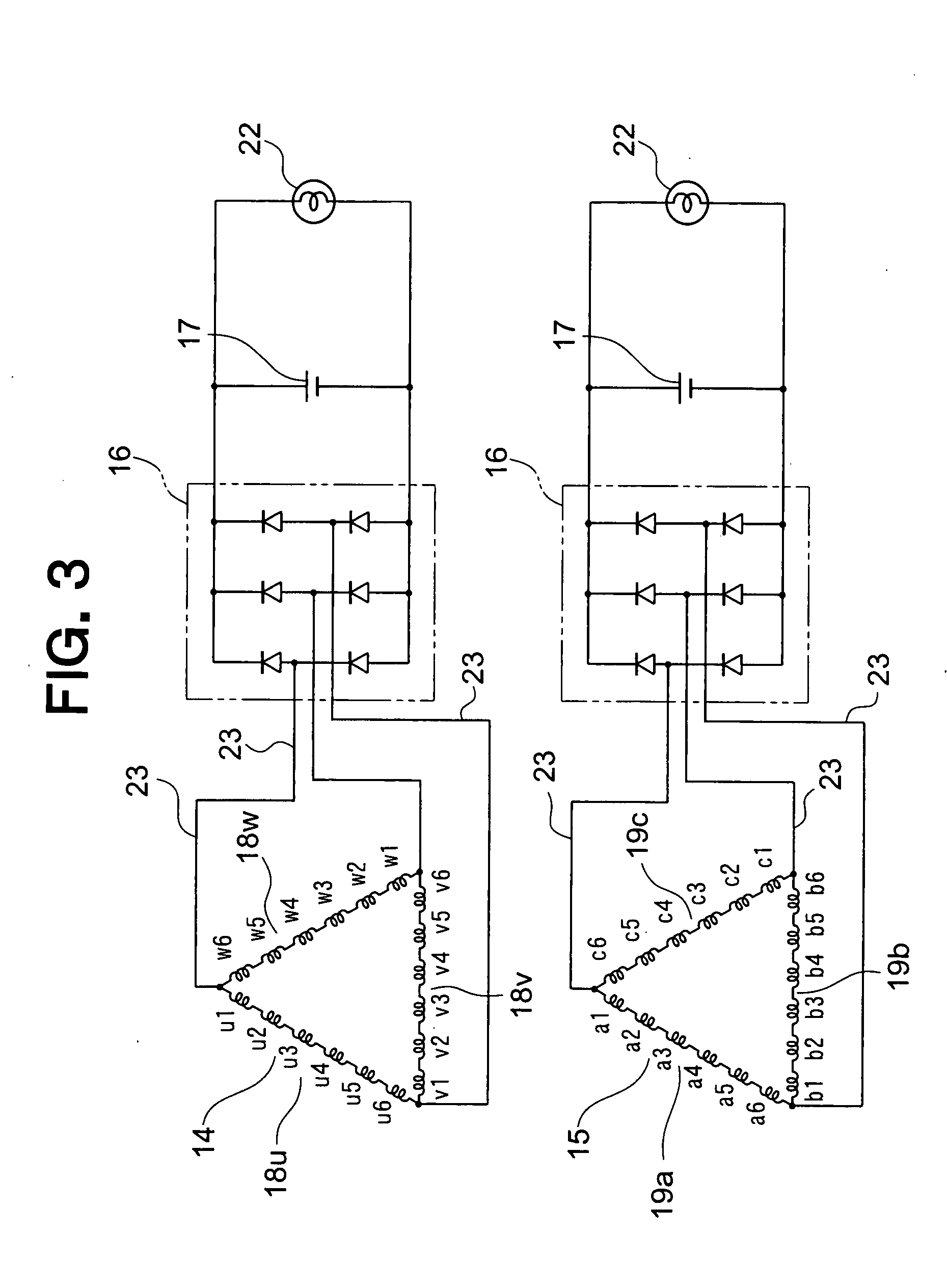

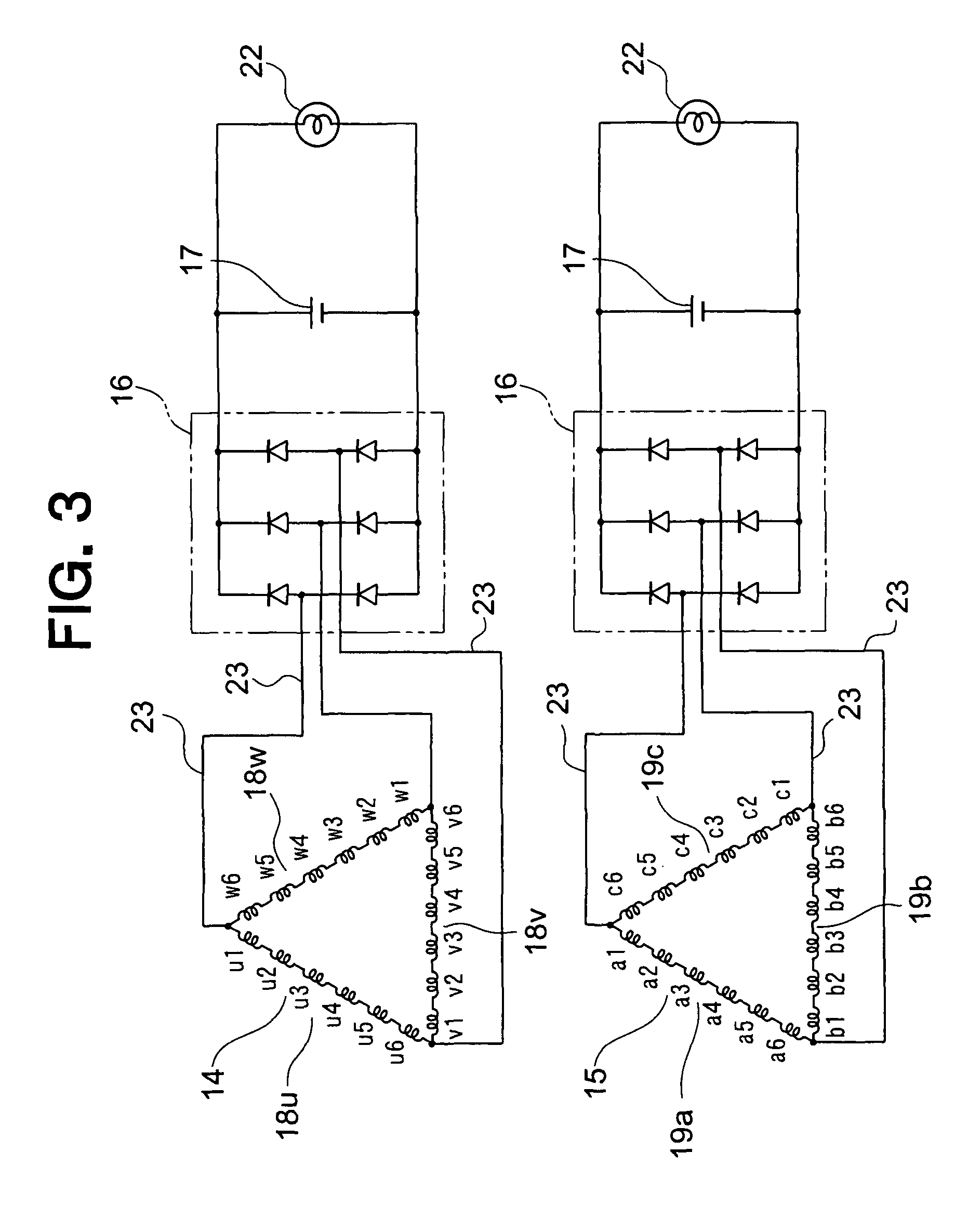

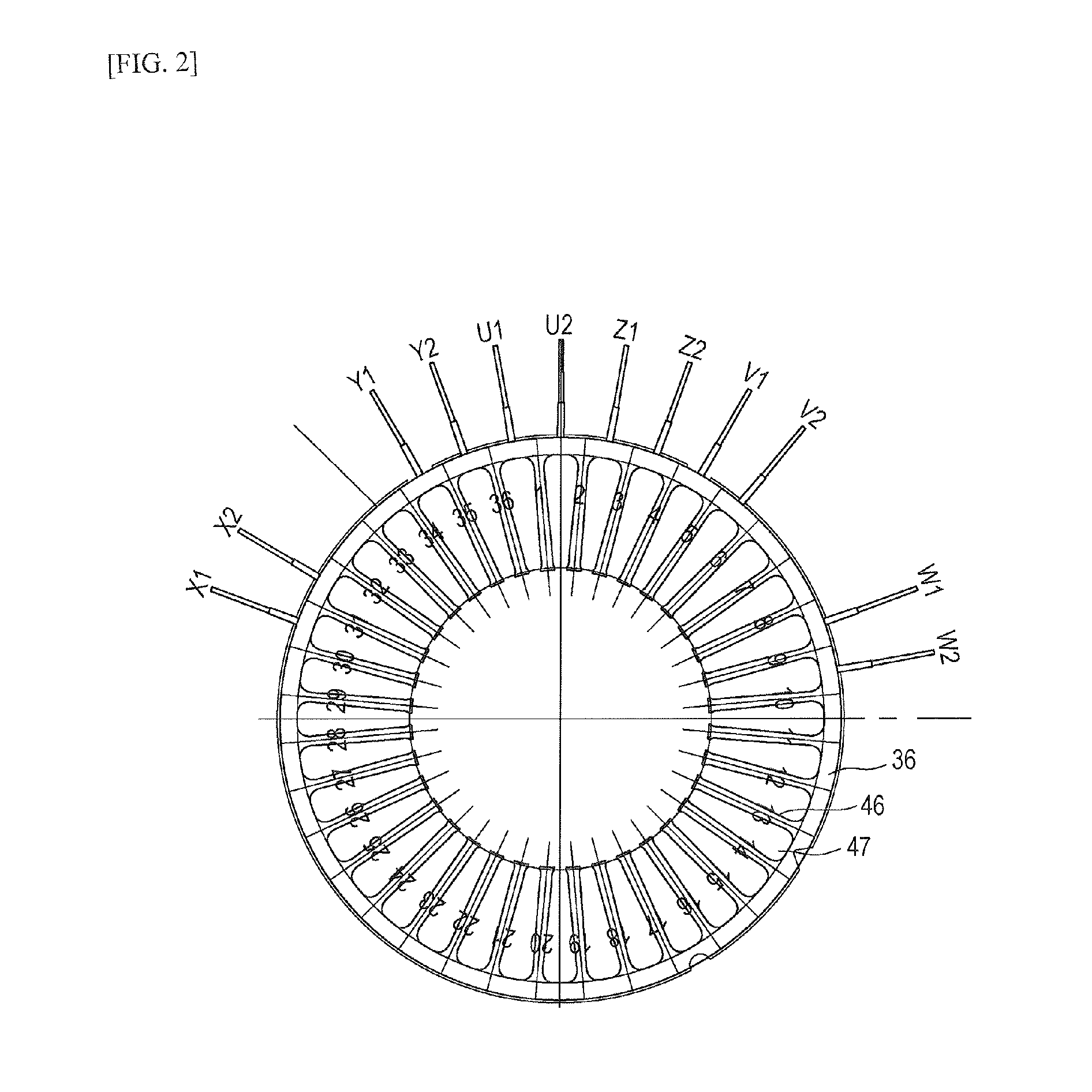

Three-phase rotating electrical machine

InactiveUS20080185933A1Small sizeLight weightSynchronous generatorsMagnetic circuitElectrical conductorElectric machine

A magneto generator can be made small in size and light in weight, and improved in power generation efficiency. The magneto generator includes an iron core having an iron core main body and a plurality of teeth (9) radially extending from the iron core main body, and an armature having a first three-phase winding (14) and a second three-phase winding (15) comprising winding portions (18u, 18v, 18w, 19a, 19b and 19c) of individual phases wound around the stator core. The individual first and second three-phase windings (14, 15) have the winding portions (18u, 18v, 18w, 19a, 19b and 19c) constructed by concentratedly winding conductors around the individual teeth (9), respectively, while skipping every predetermined number of teeth (9), and are wound in a state divided into an inner layer side and an outer layer side, respectively.

Owner:MITSUBISHI ELECTRIC CORP

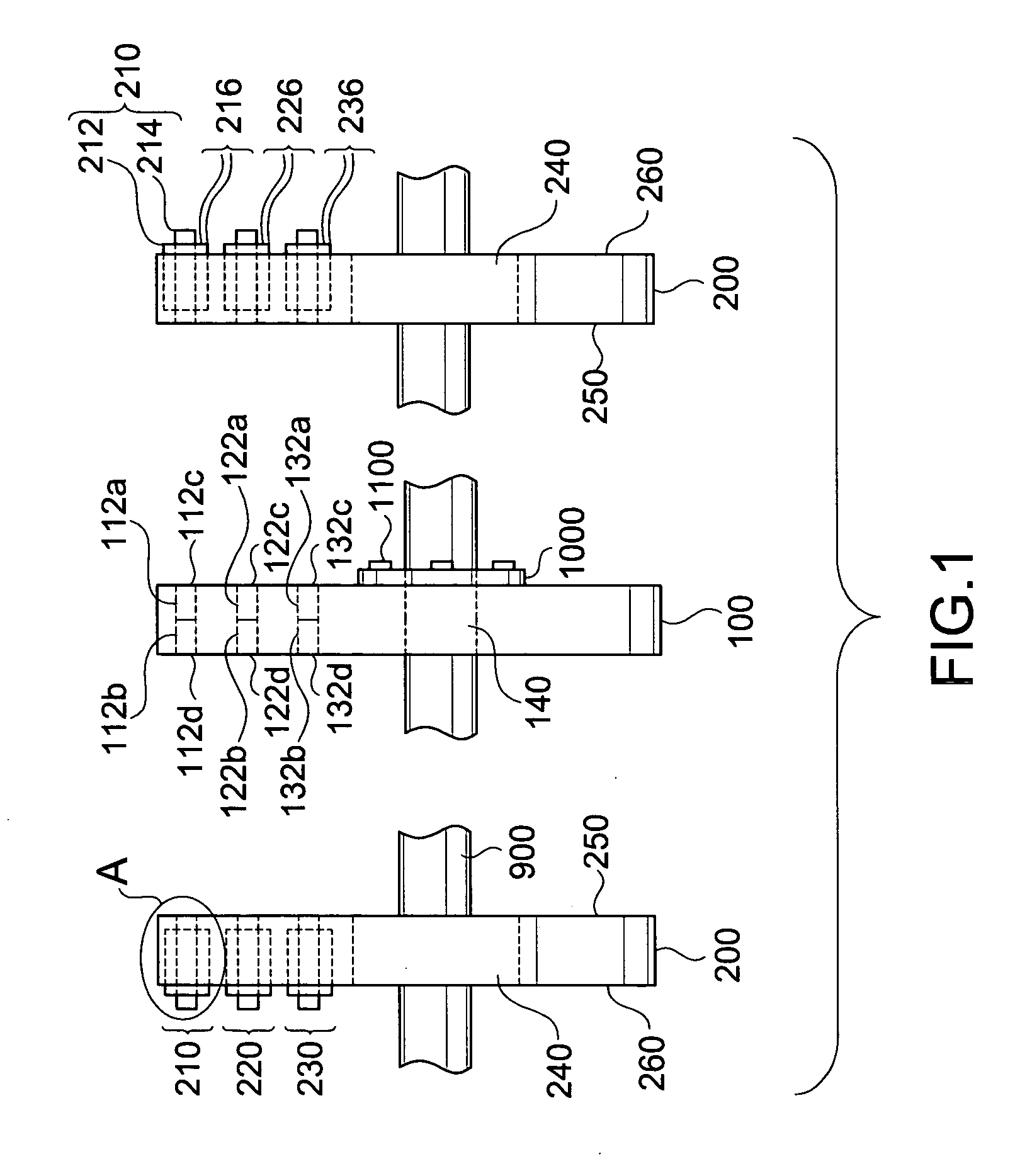

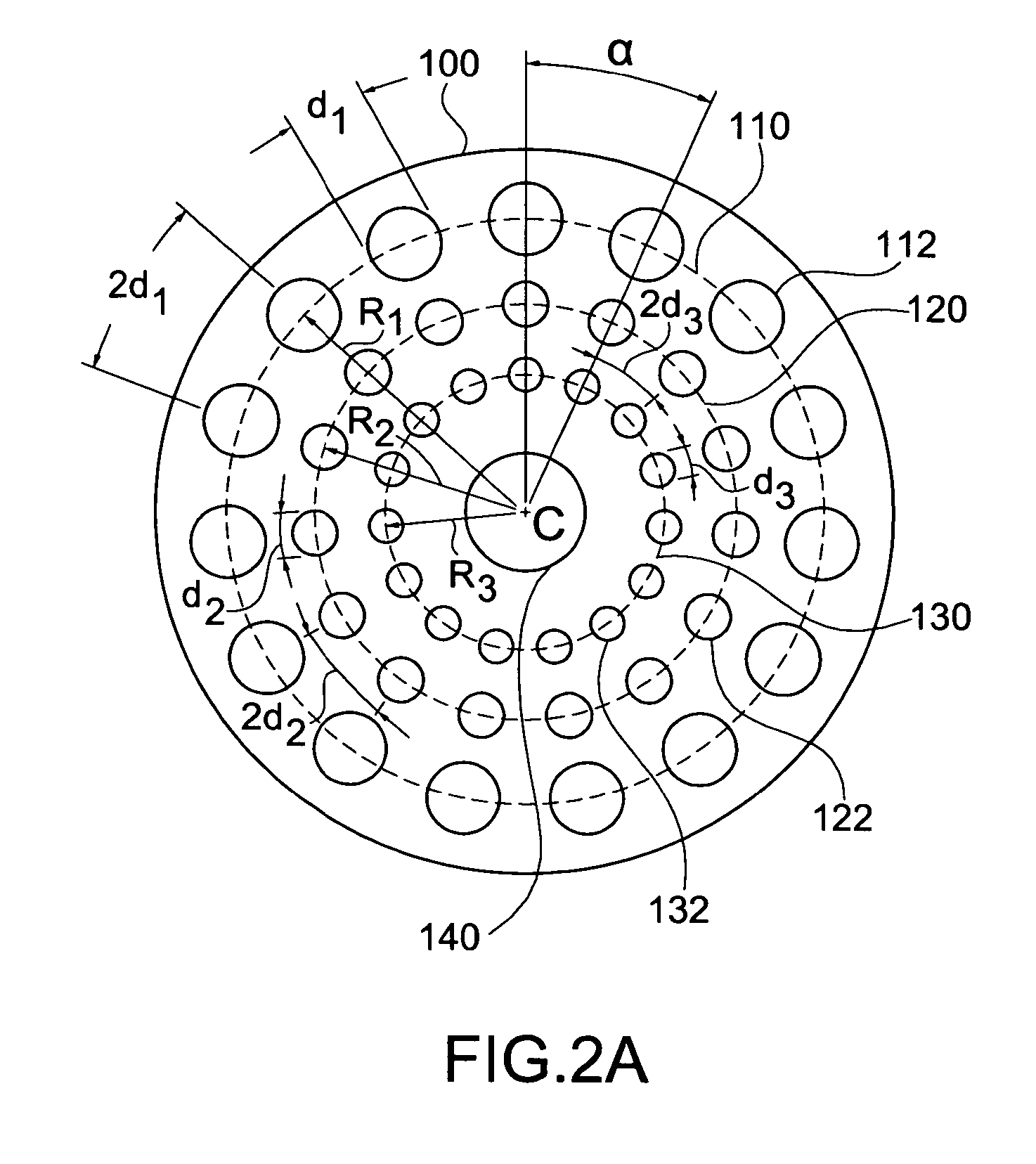

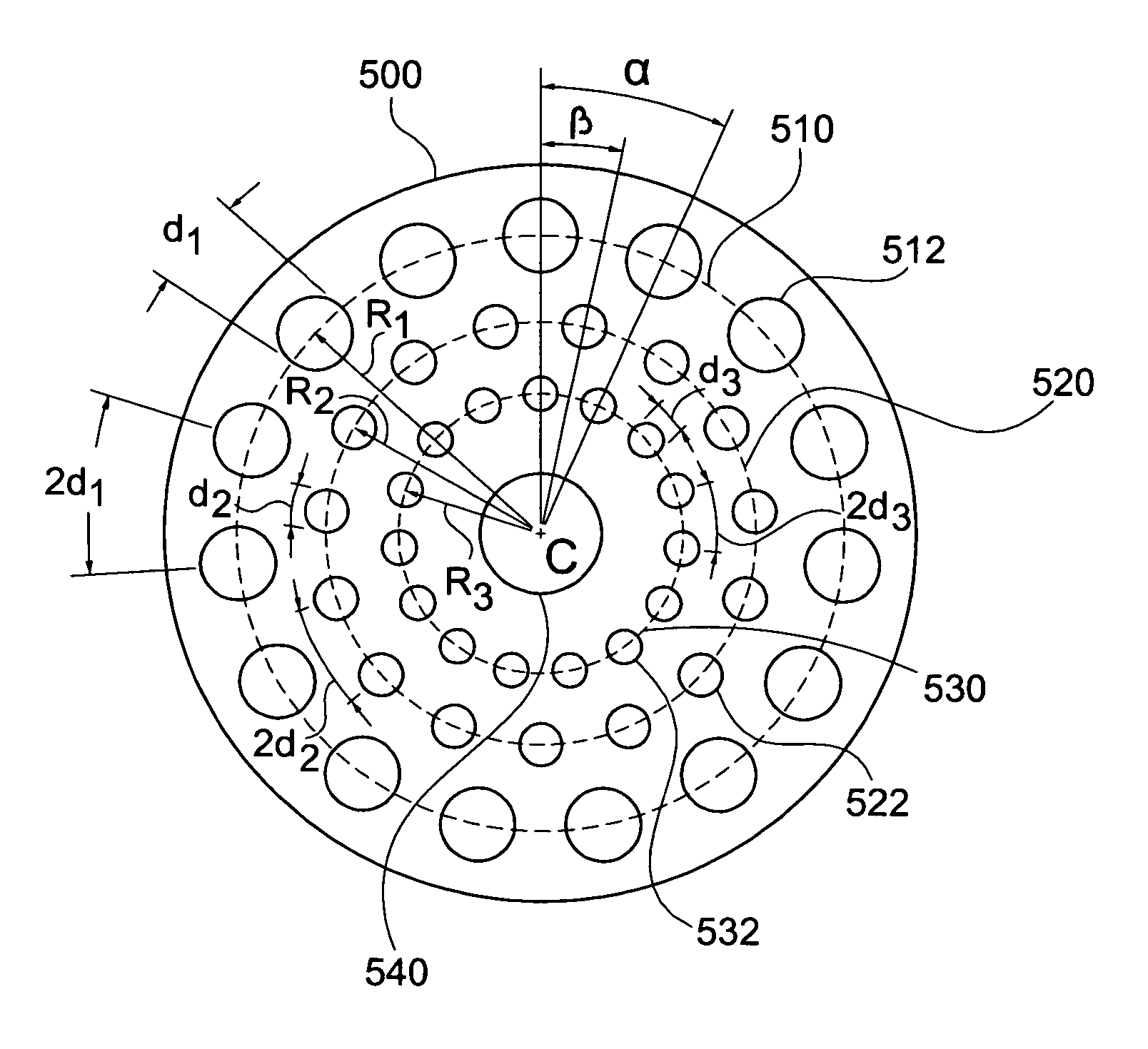

Multivariable generator and method of using the same

InactiveUS20060226725A1Extended service lifeLow heat generationSynchronous generatorsMagnetic circuit rotating partsMagnetic sourceGenerators (Apparatus)

A generator device for generating electrical energy includes a rotor having a first set of even-numbered of magnetic sources distributed along a first radius of the rotor, and a first pair of stators, each having a first set of odd-numbered coil members distributed along a first radius of the stator, the stators disposed adjacent to opposing side portions of the rotor, wherein each coil member includes a core portion having an amorphous structure. In addition, a generator device for generating electrical energy includes interchangeable rotor and stator pairs to provide variable voltage / current / frequency outputs.

Owner:CAMEL CLUB

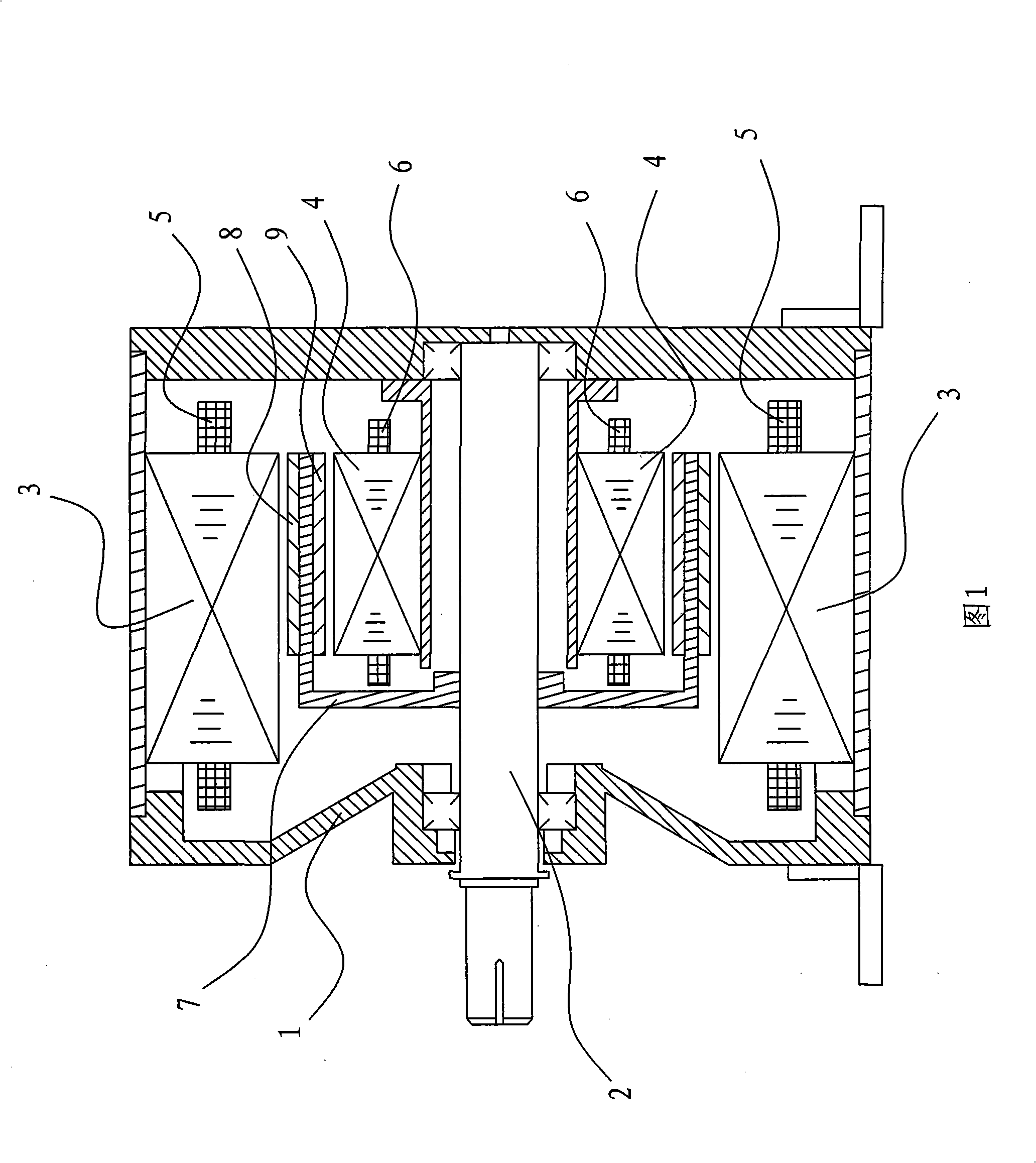

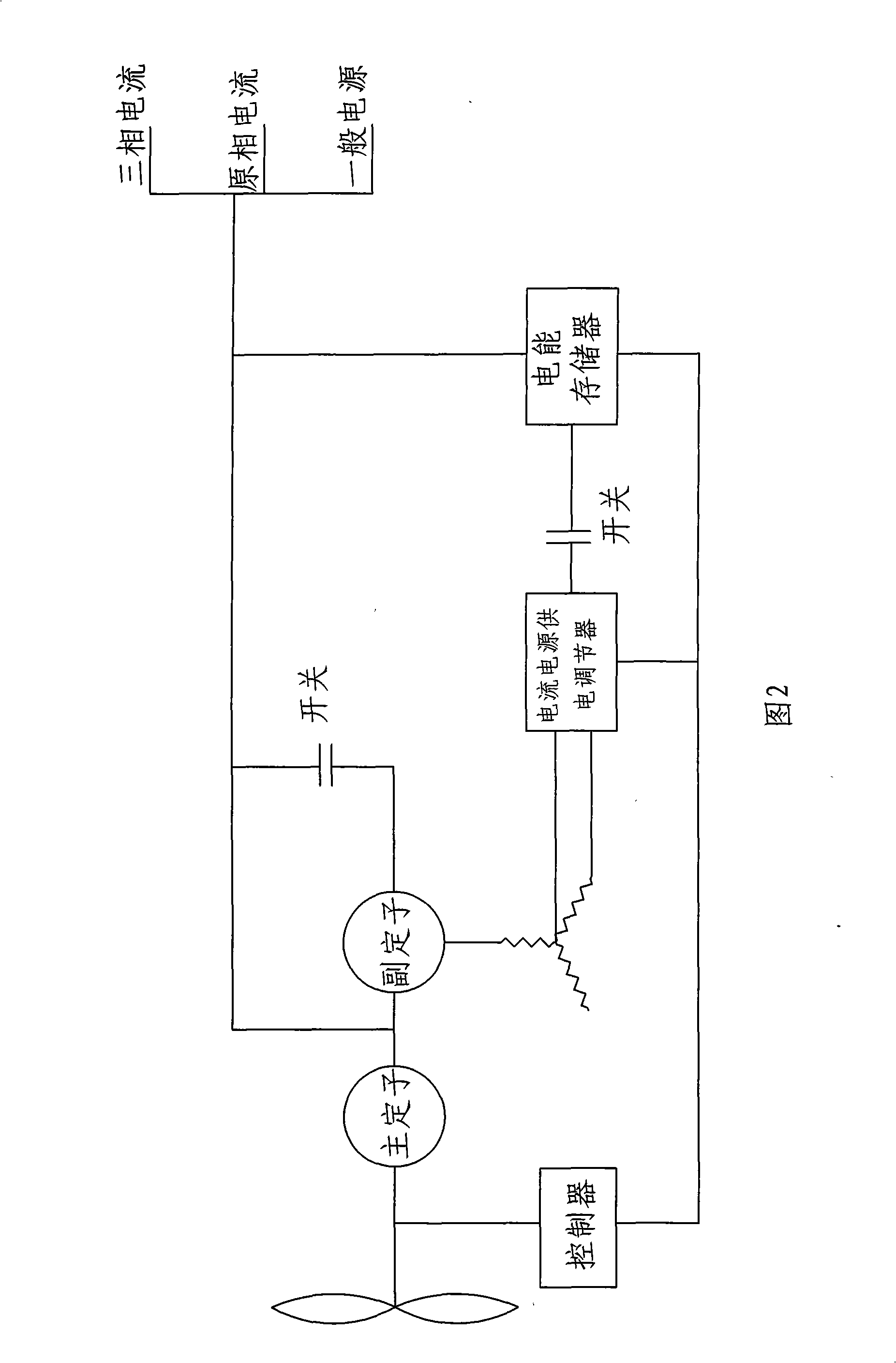

Miniature direct-drive permanent magnet synchronous aerogenerator and its small-sized wind power generation system

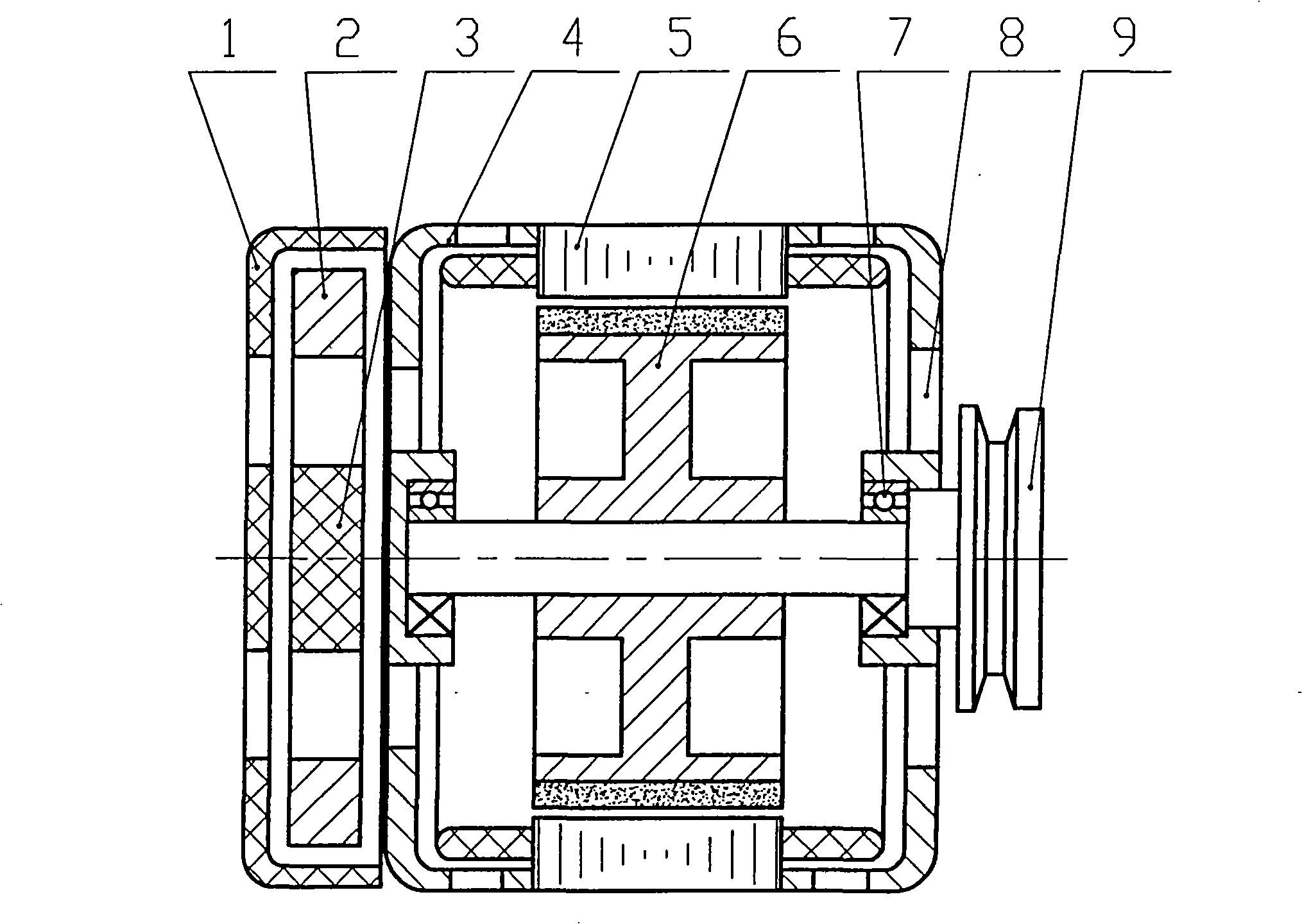

InactiveCN101404433AImprove work efficiencyReduce volumeMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a small-sized direct-drive permanent magnetism synchronous aerogenerator and a generating system thereof. The aerogenerator comprises a shell which is supported with a rotating shaft by a bearing; a main stator and an auxiliary stator are fixed in the shell, and the main stator is sheathed on the circumstance of the auxiliary stator; a main stator winding and an auxiliary stator winding are arranged respectively on the main stator and the auxiliary stator, and a rotor which is connected with the rotating shaft is arranged between the main stator and the auxiliary stator; an outer permanent magnet and an inner permanent magnet which are corresponding to the positions of the main stator and the auxiliary stator are respectively arranged on the rotor; one group of winding in the auxiliary stator winding is connected with a direct current power supplying regulation control end. The generating system also comprises an electrical energy memorizer, a direct current power supplying adjustor, a controller and the like, the aerogenerator can adopt a method of power regulation and energy compensation to keep the stability of the wind energy generating system, thus leading the working efficiency of the whole generating system to be effectively improved.

Owner:鹤山市信利带钢有限公司

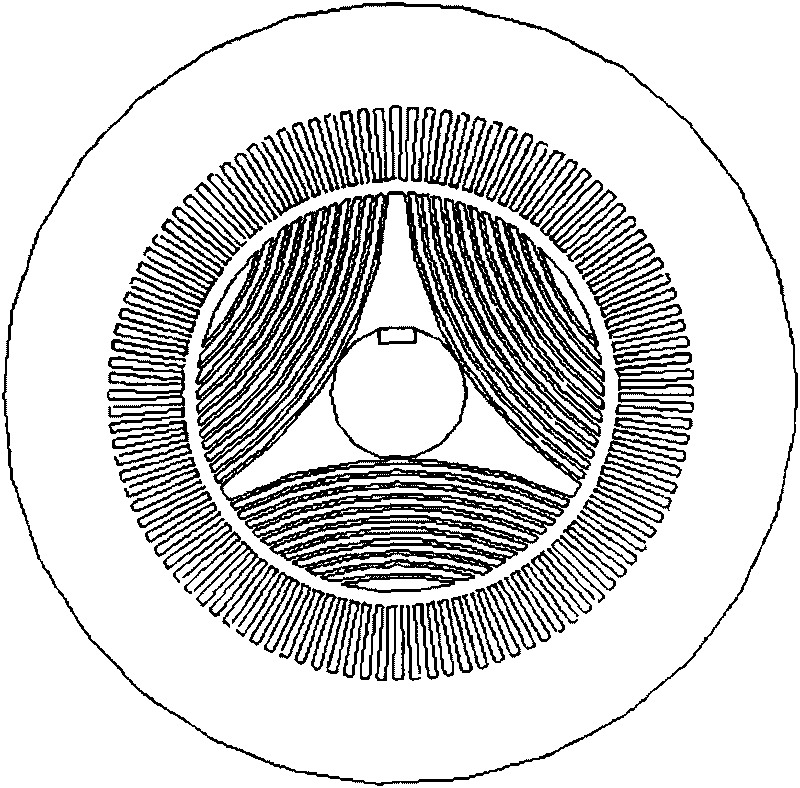

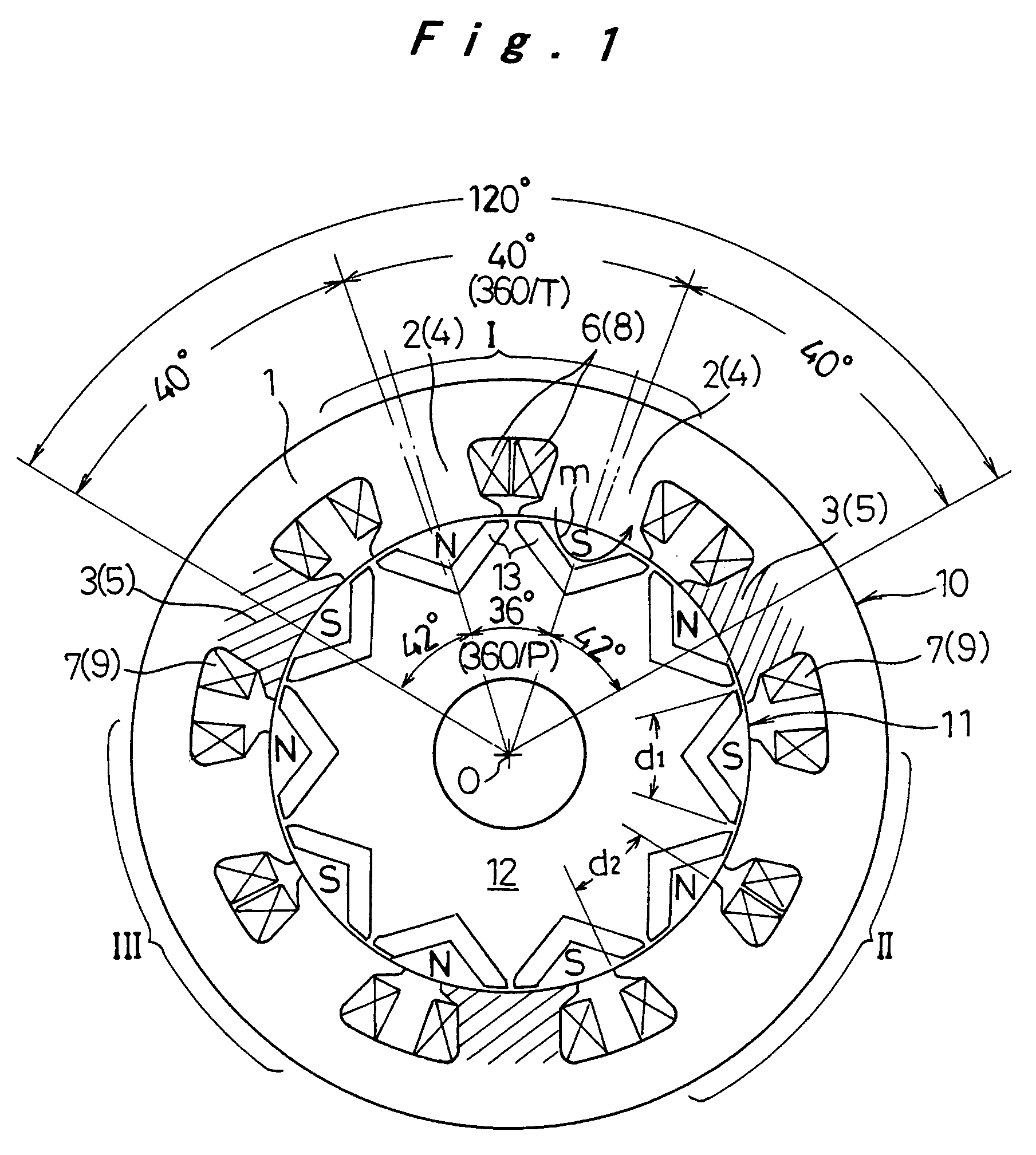

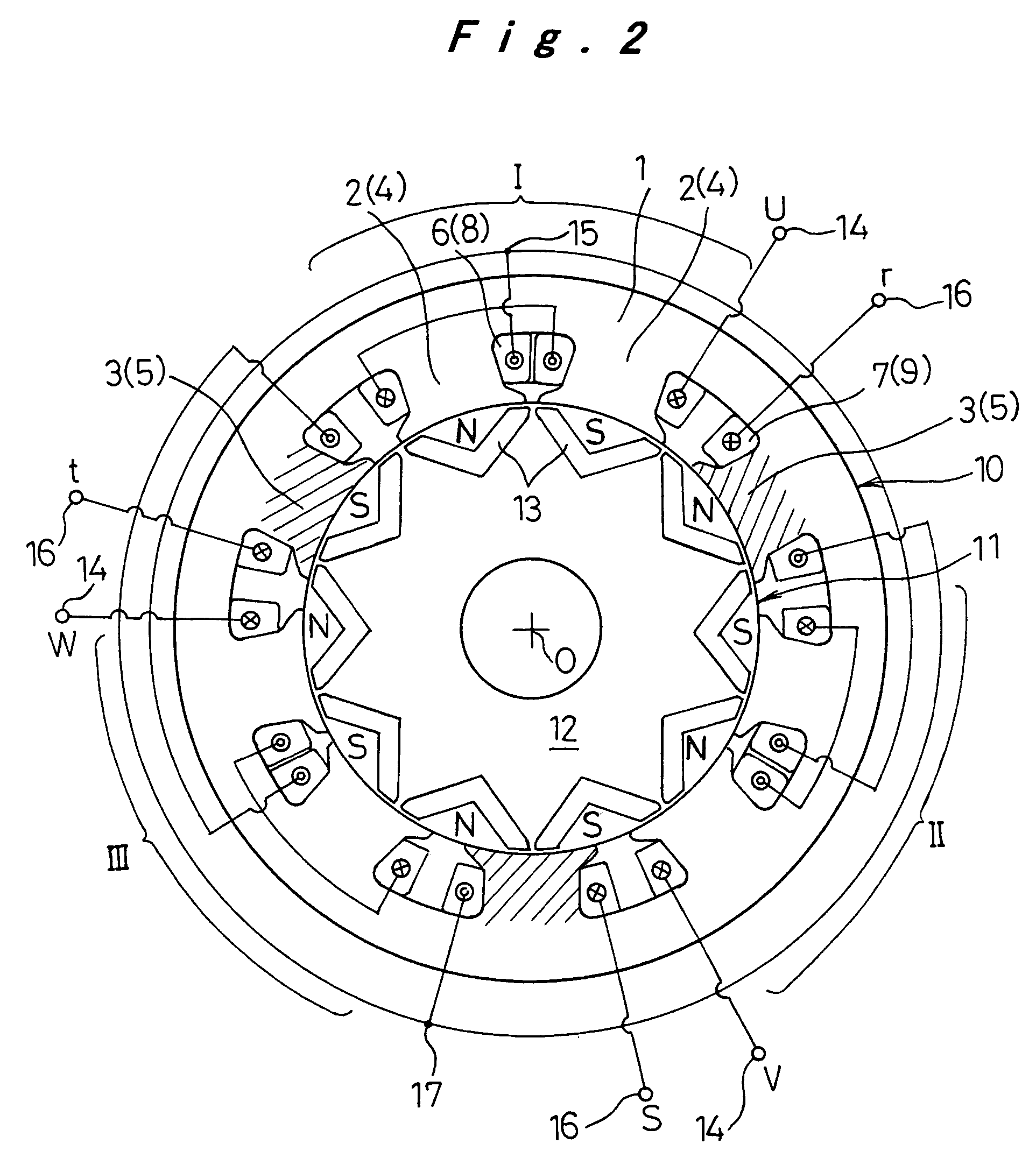

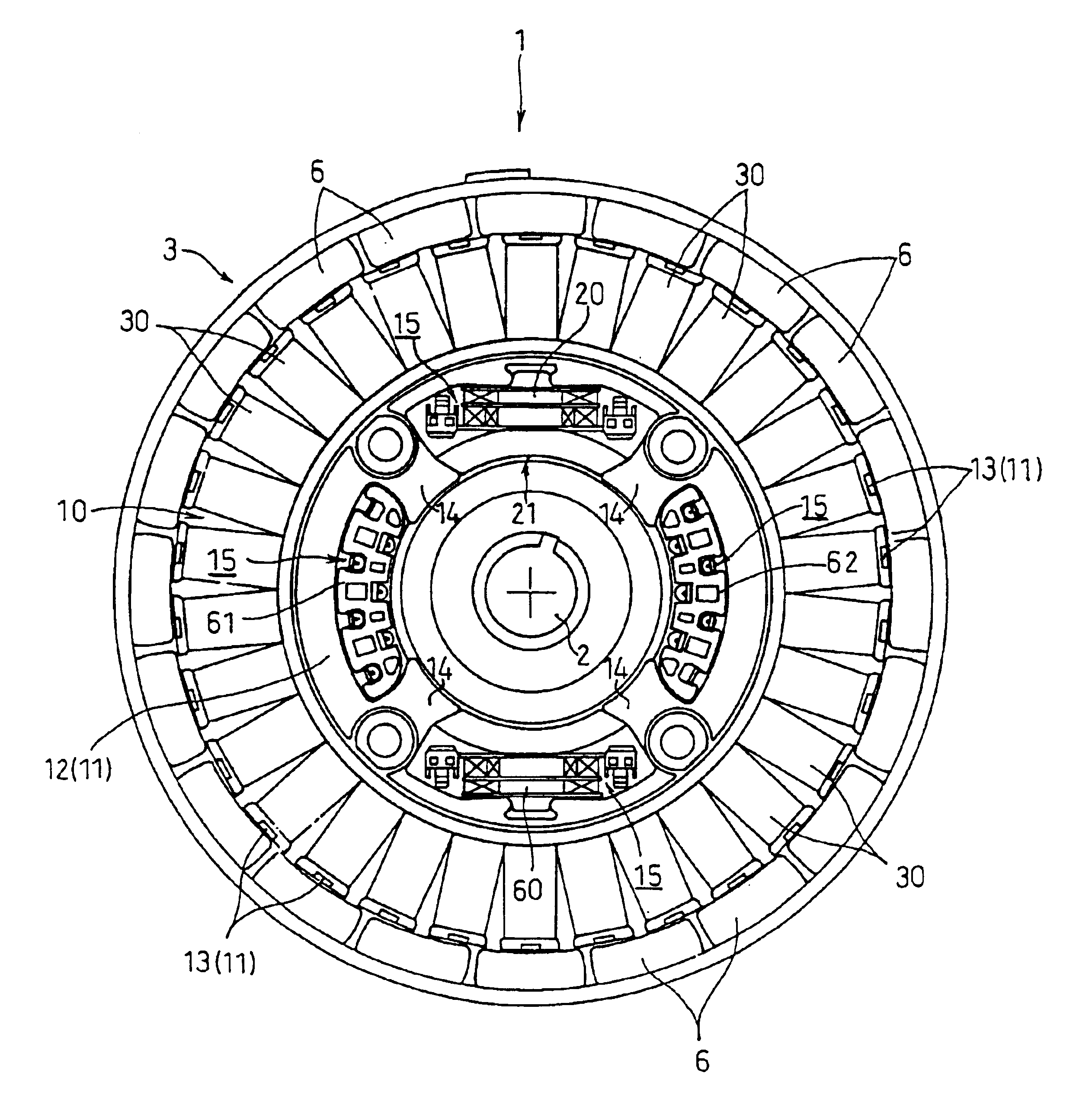

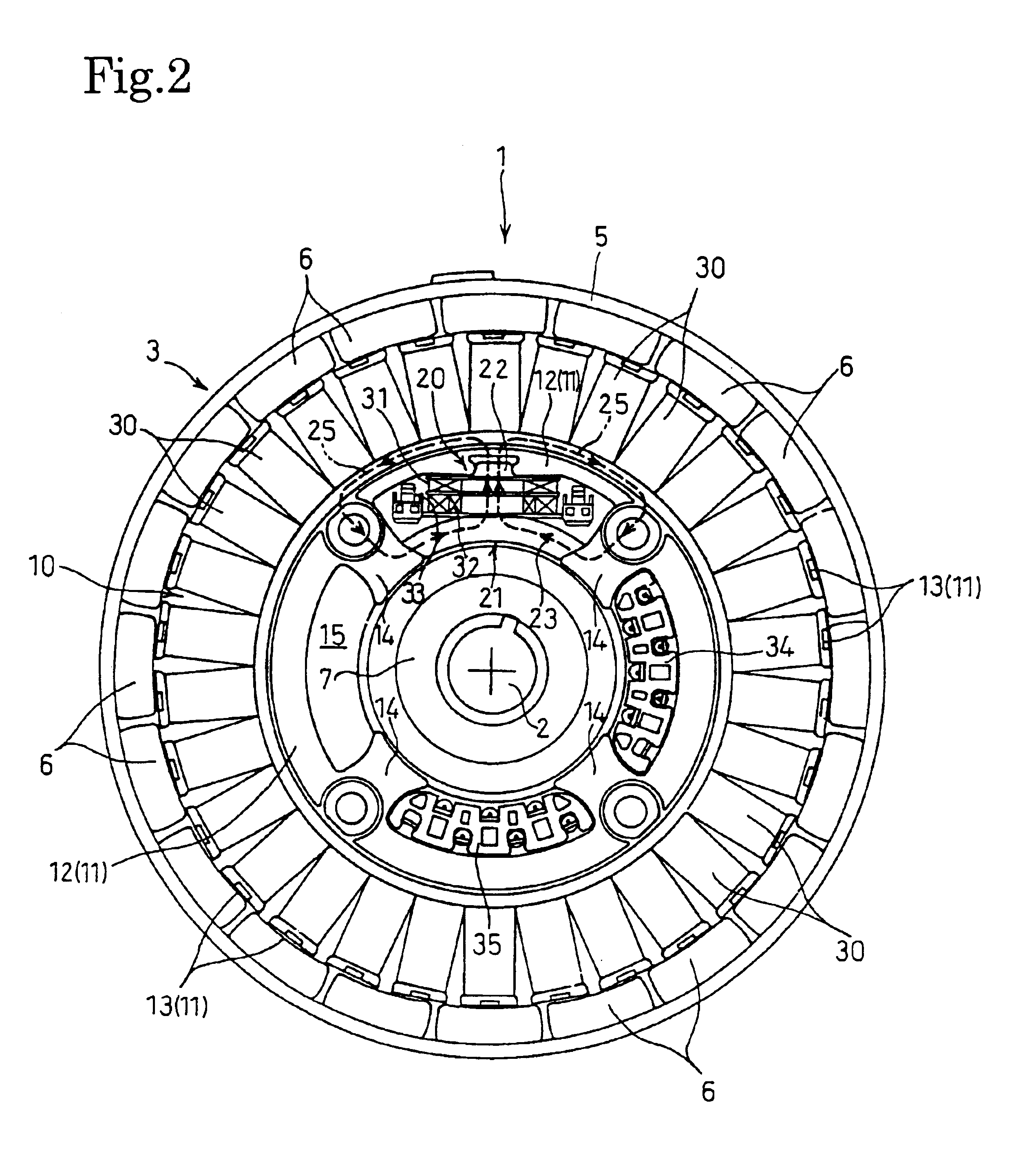

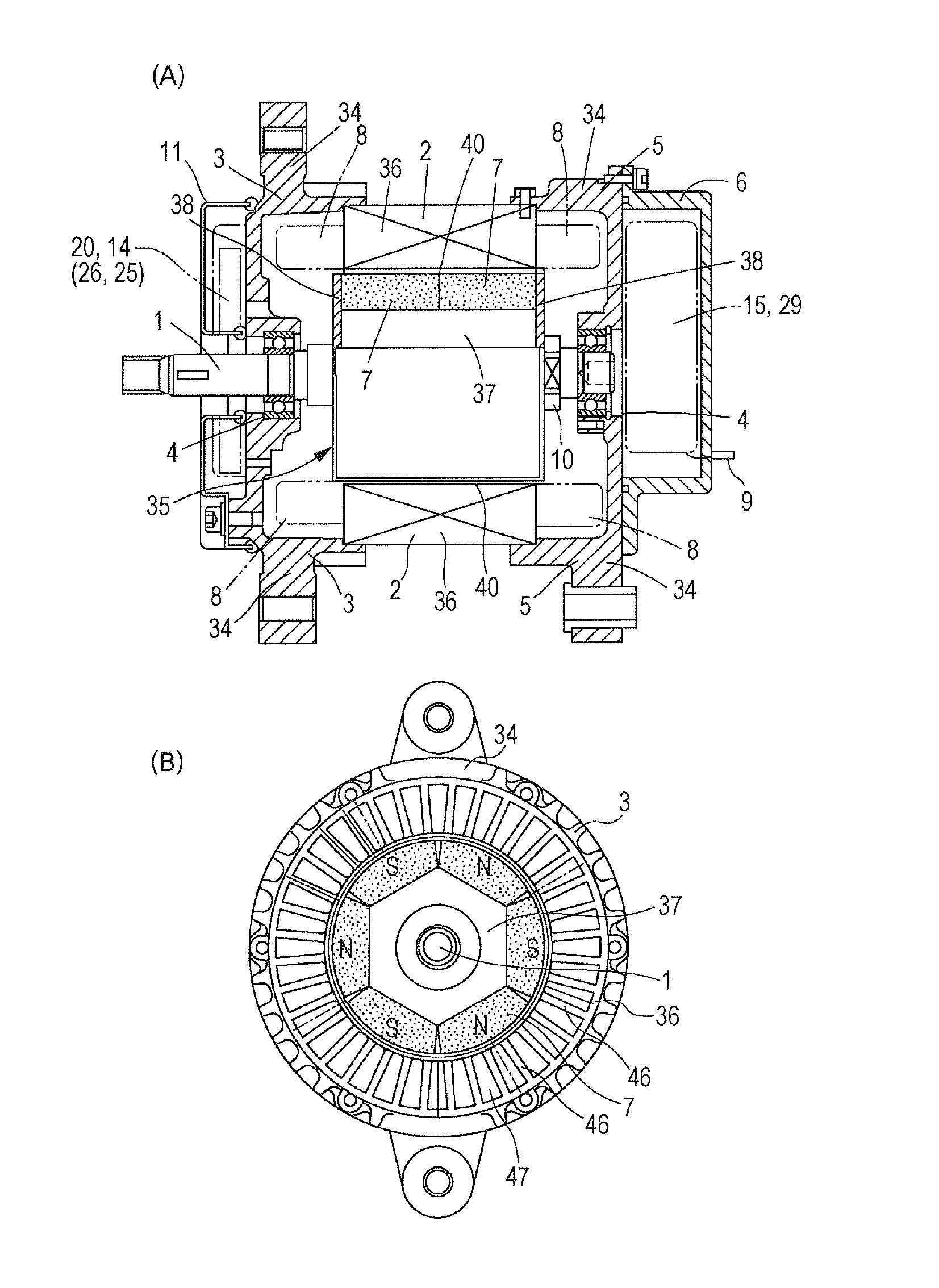

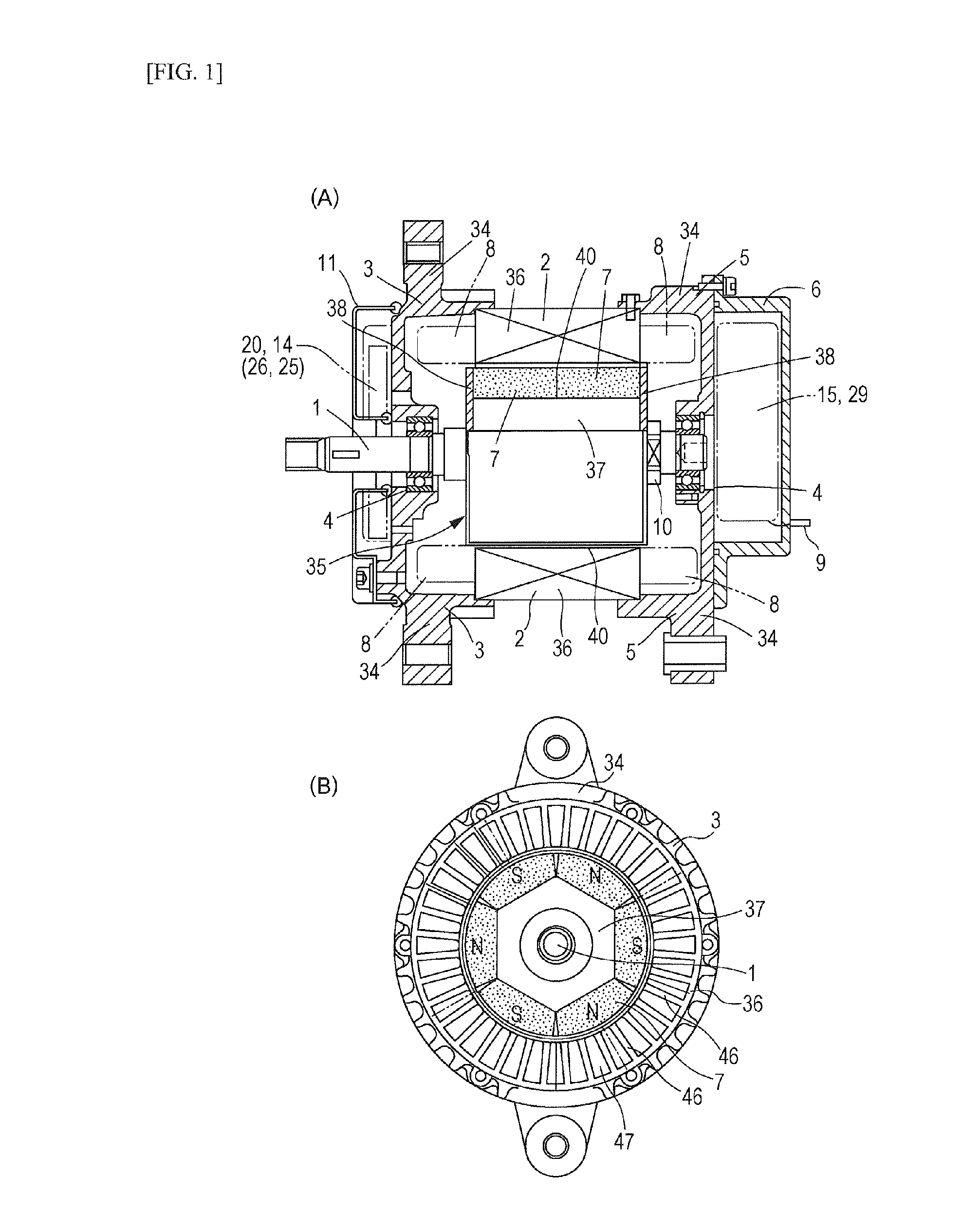

Motor generator

ActiveUS20050046304A1Low costReduced space required for installationMachines/enginesVehicular energy storageElectric power distributionConductor Coil

A motor generator is provided with a stator having a winding around each of a plurality of stator teeth, and a rotor having a plurality of permanent magnets by the number larger than that of the stator teeth, arranged in the circumferential direction at equal intervals. The stator teeth are formed of a first stator teeth section including a plurality of stator teeth groups I, II, and III each including the adjacent stator teeth around which a winding to which the same phase voltage is applied is wound and in which winding directions of the stator teeth are opposite to each other, and a second stator teeth section including a stator teeth having a winding wound therearound and being placed among stator teeth groups of different phases such that electric power is independently input and output with respect to the first and second winding sections. This makes it possible to reduce the space and the cost while inputting / outputting the electric power through different channels and allowing arbitrary design of the electric power distribution.

Owner:PANASONIC CORP

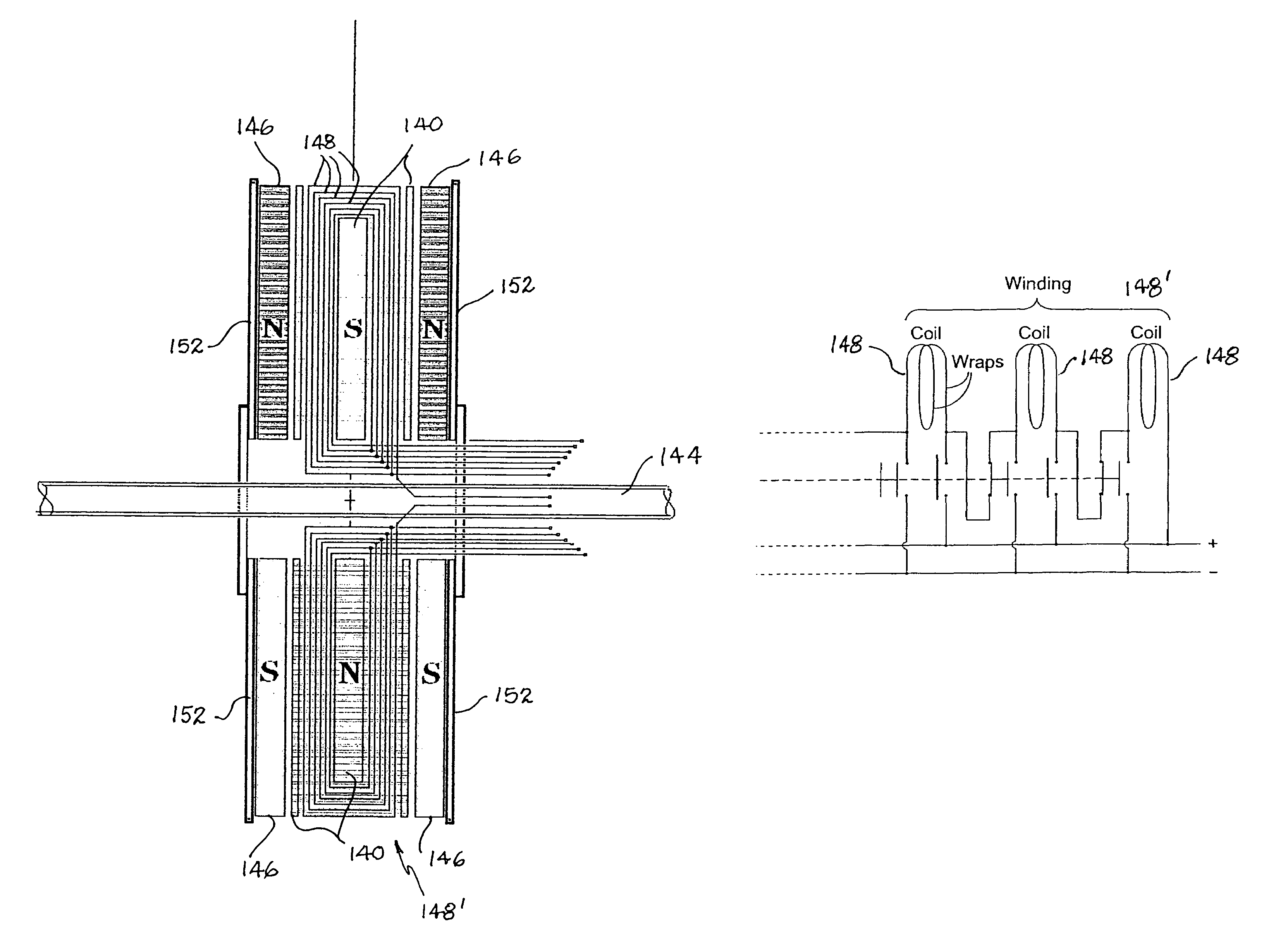

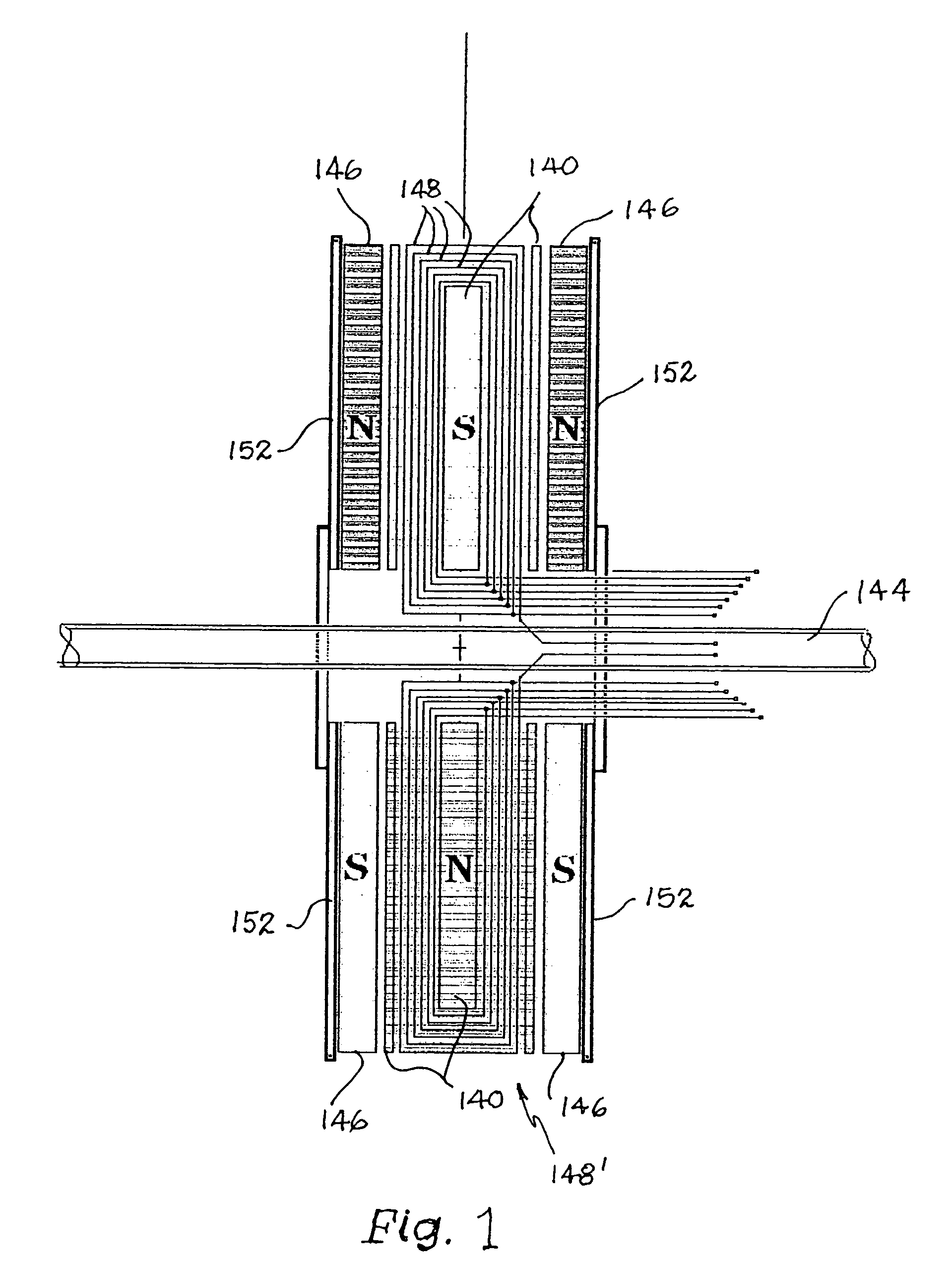

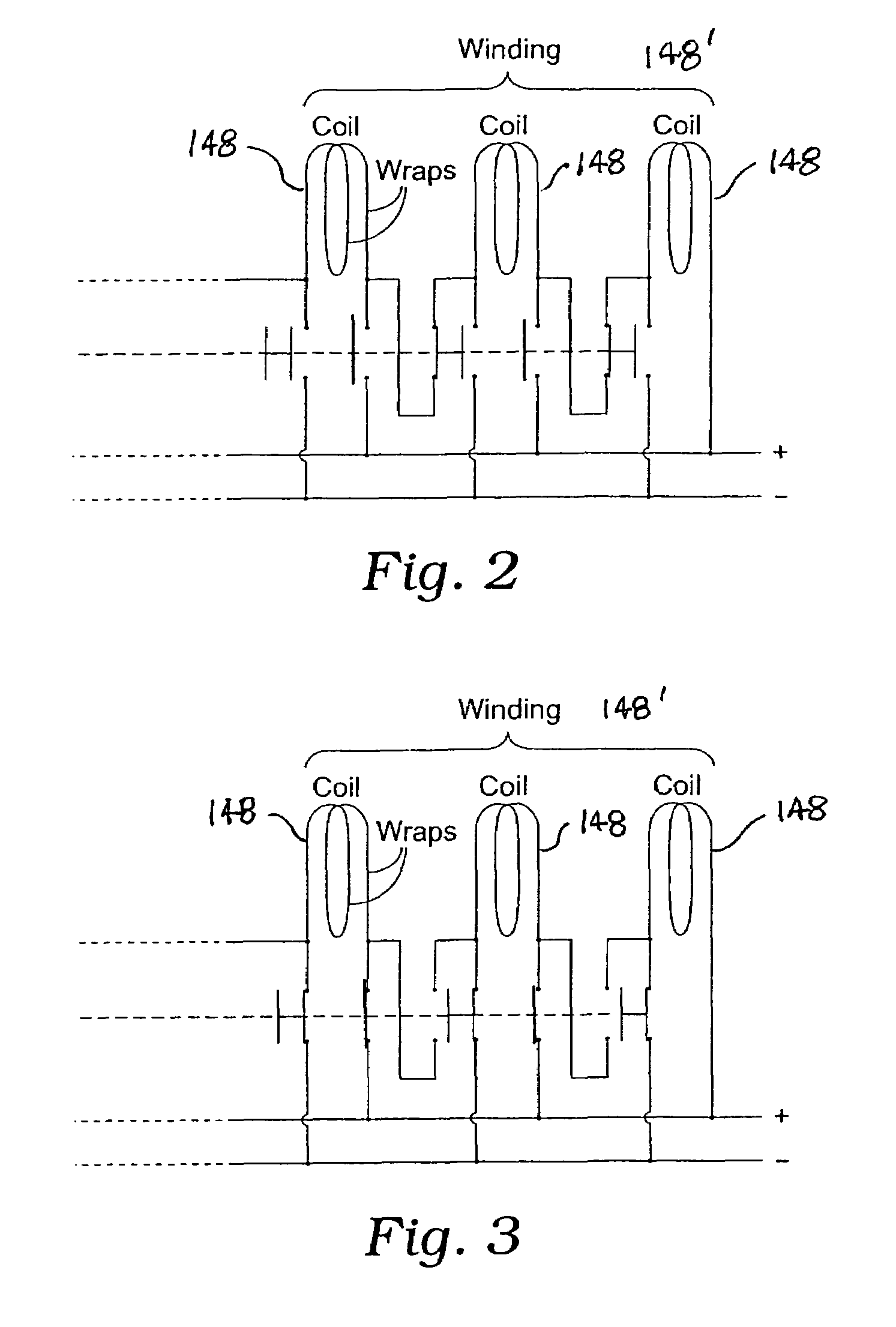

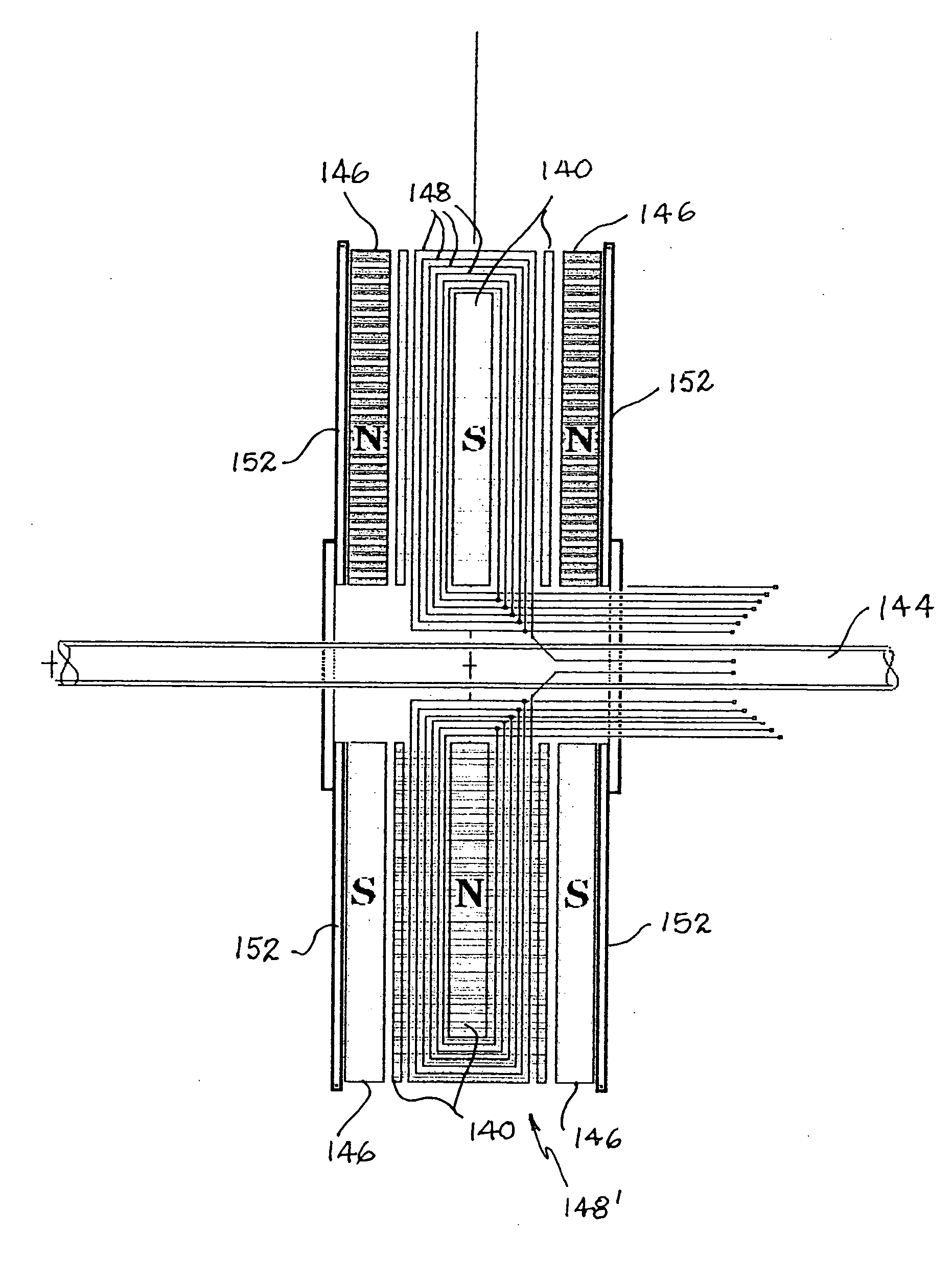

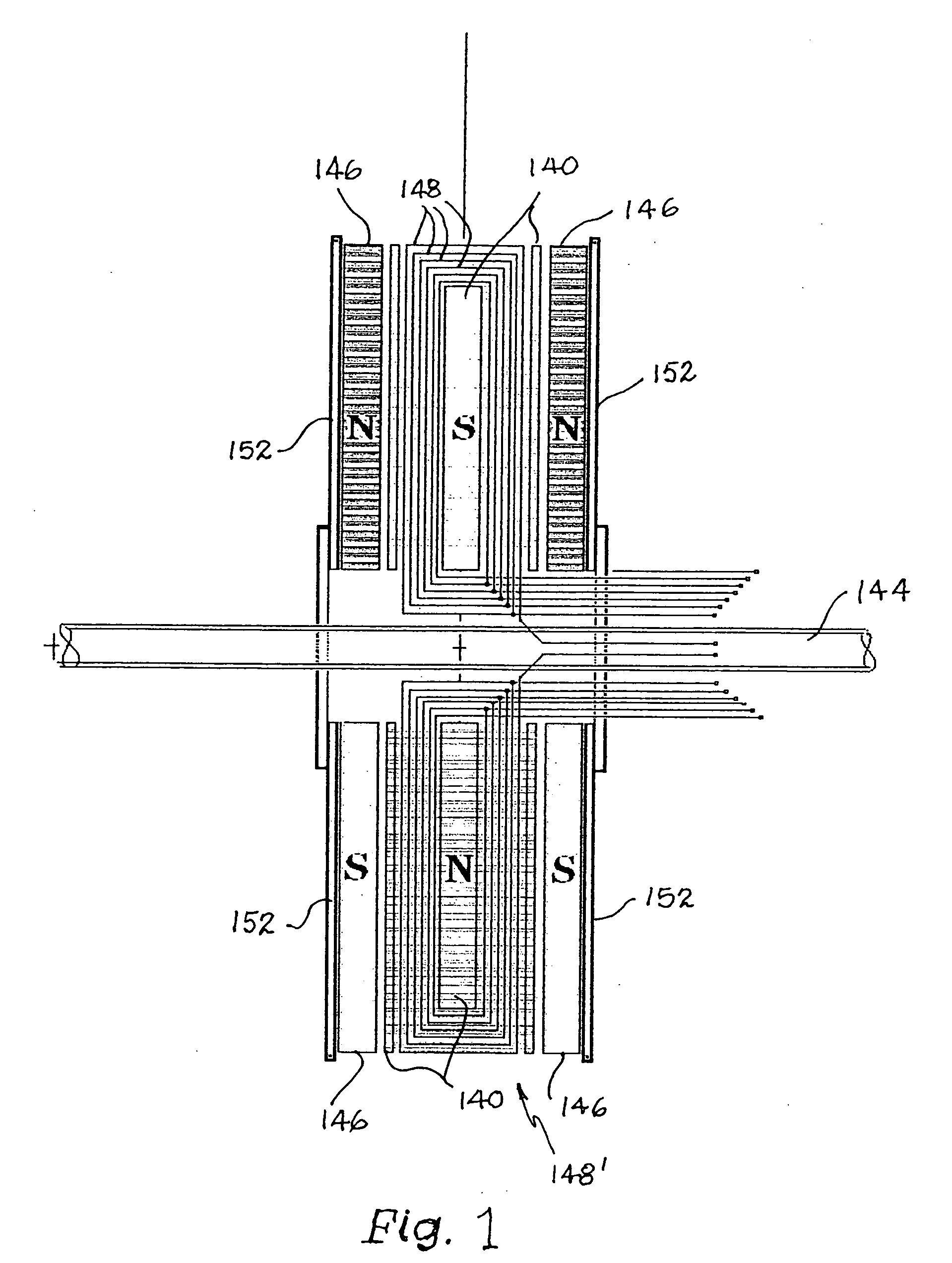

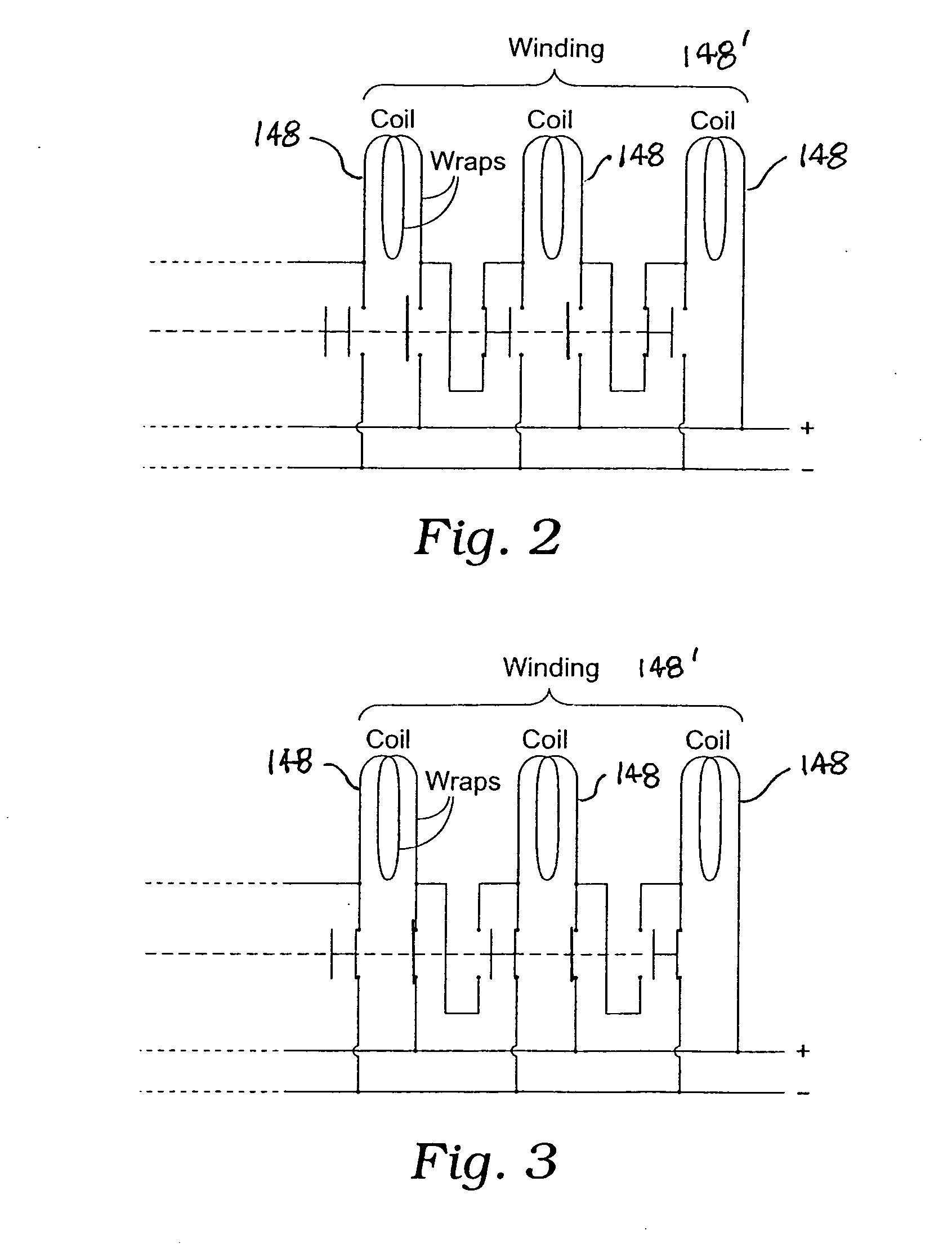

Monopole field electric motor-generator with switchable coil configuration

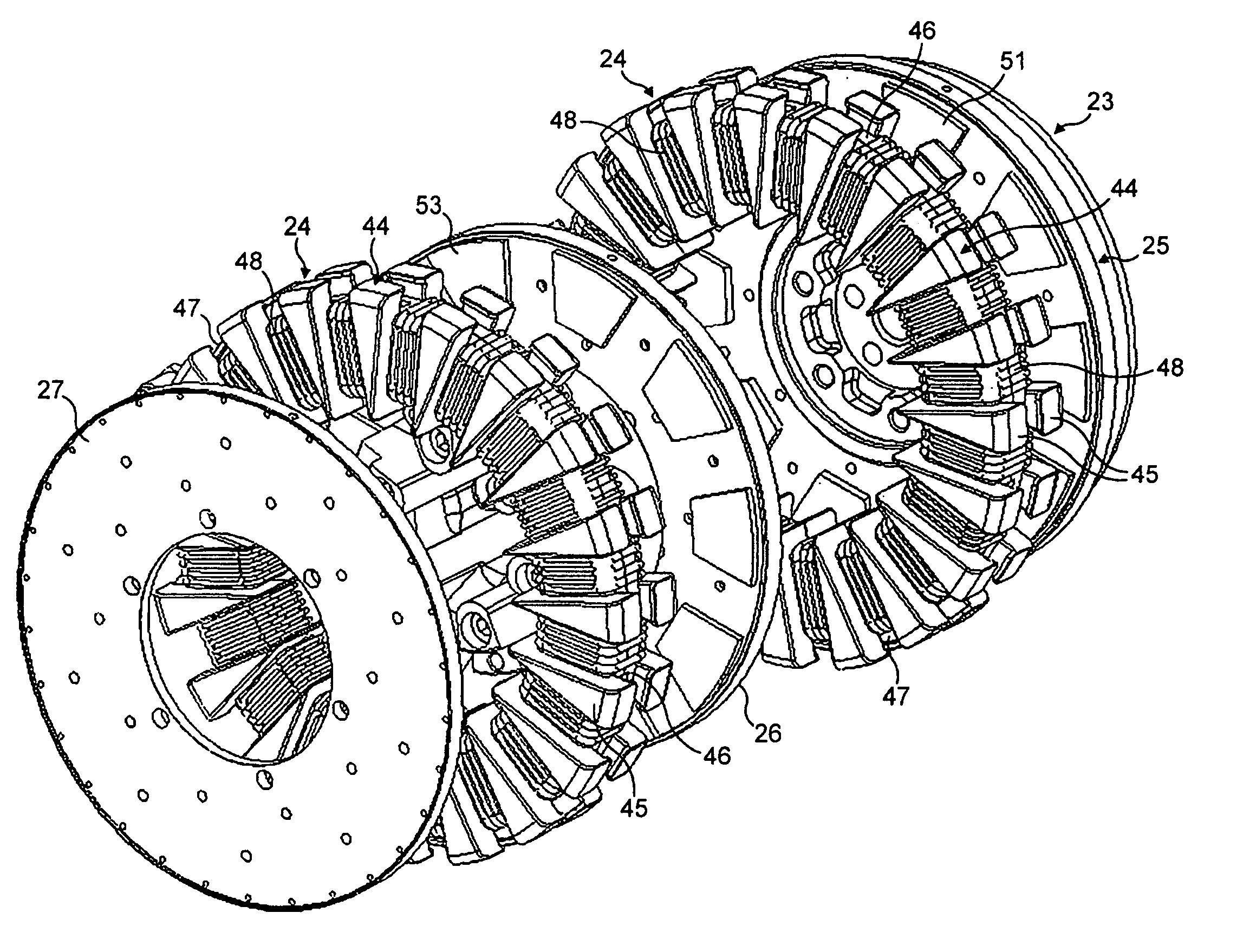

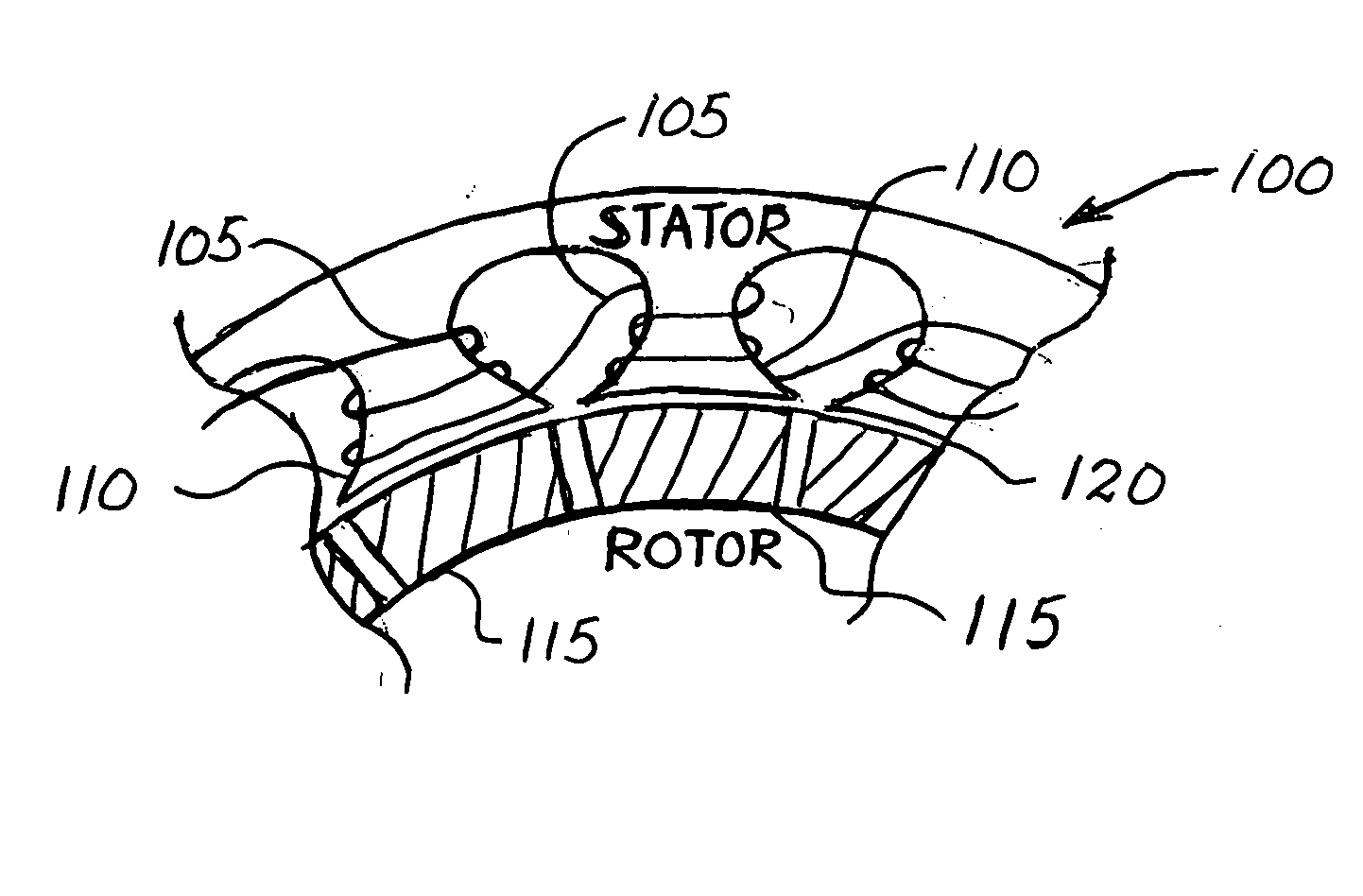

ActiveUS7348703B2Easy output controlAsynchronous induction motorsMechanical energy handlingElectricityEngineering

A pair of stators produce a magnetic field within a space between them a ferromagnetic toroidal rotor is rotationally mounted within the magnetic field. A plurality of windings are wound radially on the rotor and each winding provides a plurality of coils. Each of coils is interconnected through a switch, the switch configured for placing each of the coils within each winding alternatively in one of an electrical series connection, an electrical parallel connection, and an electrically isolated connection, so that when operated as a generator, a selected output voltage and current are produced by rotor rotation and when operated as a motor a selected output speed and torque are produced.

Owner:CLEARWATER HLDG +1

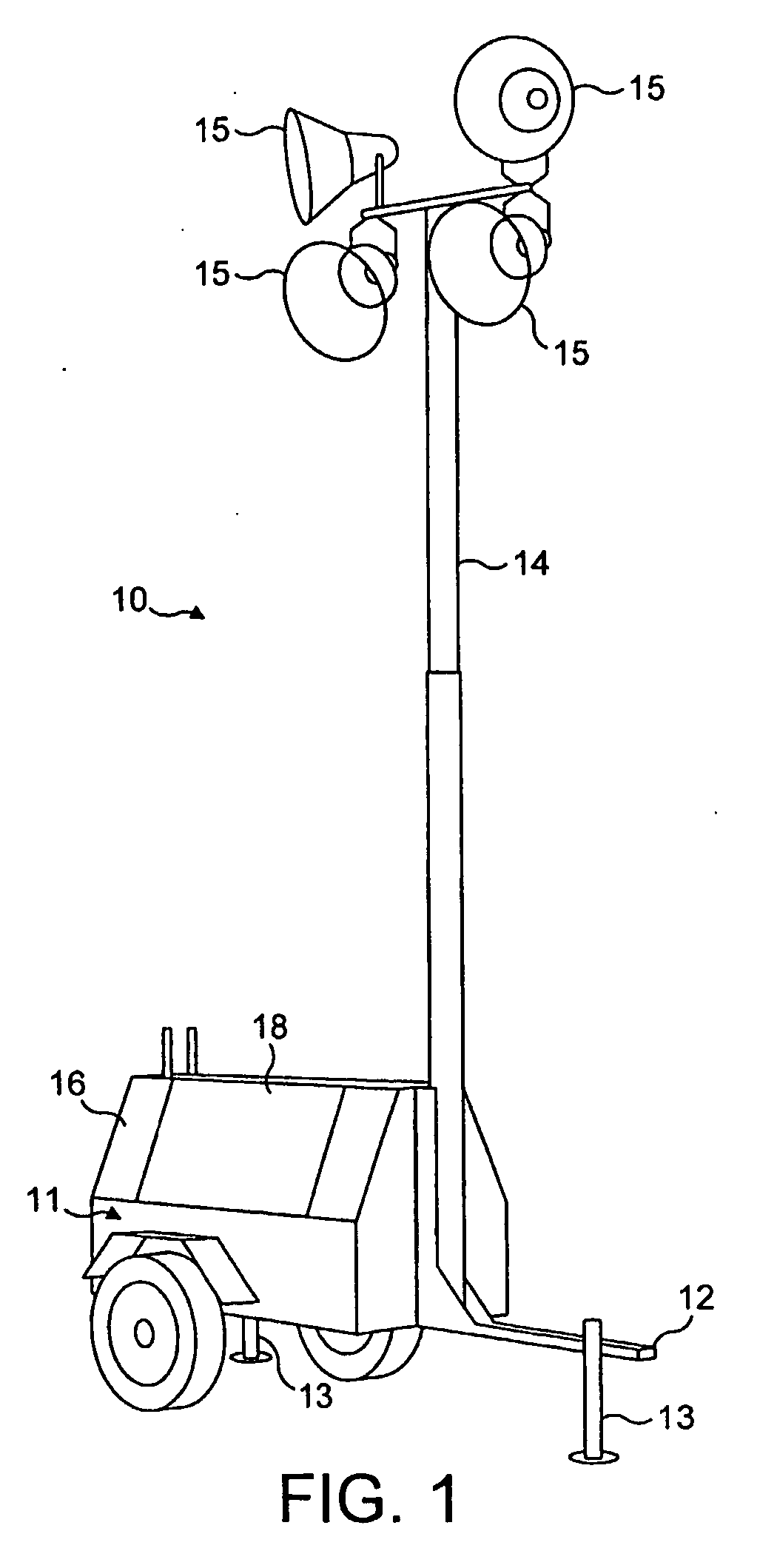

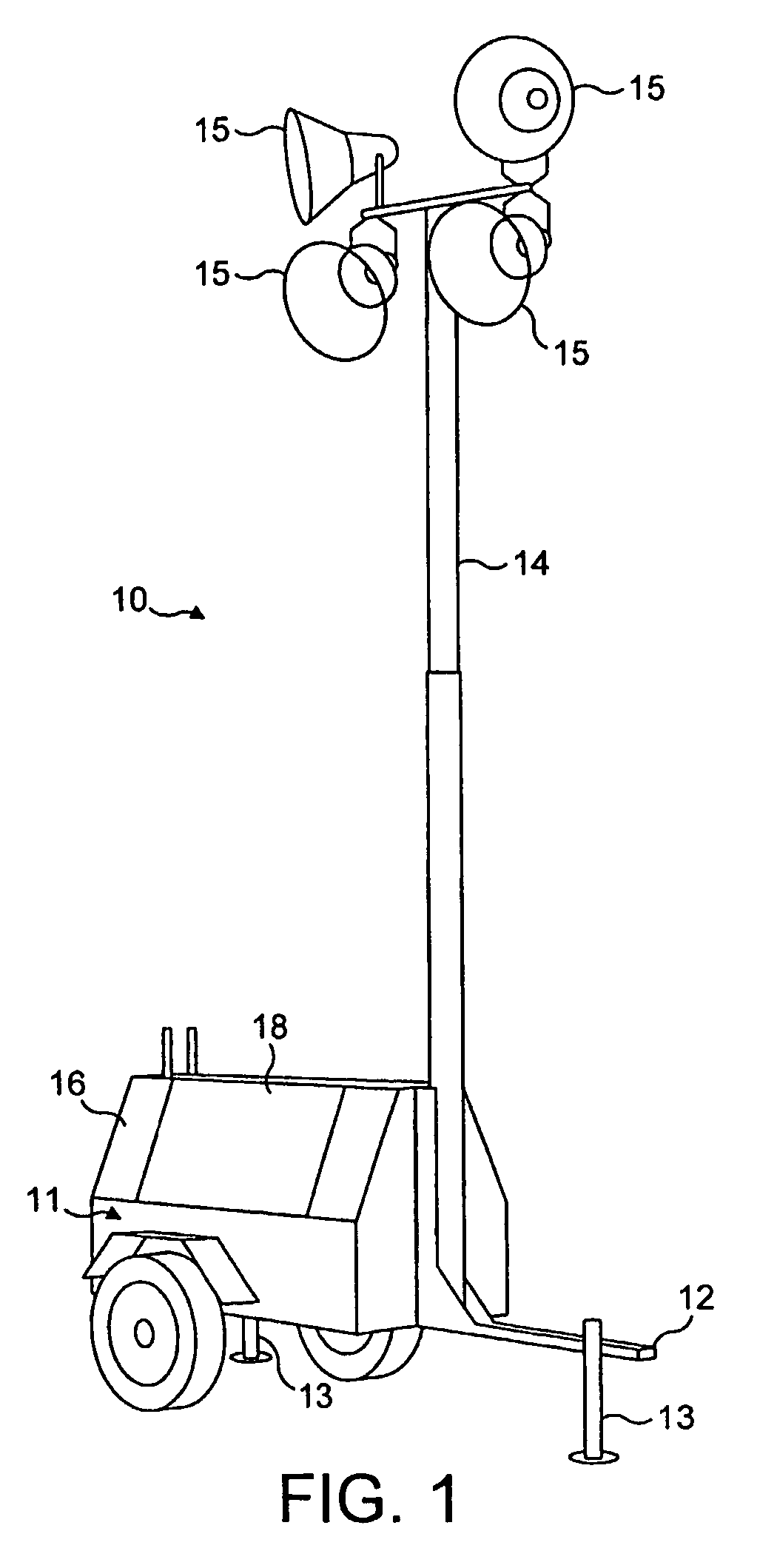

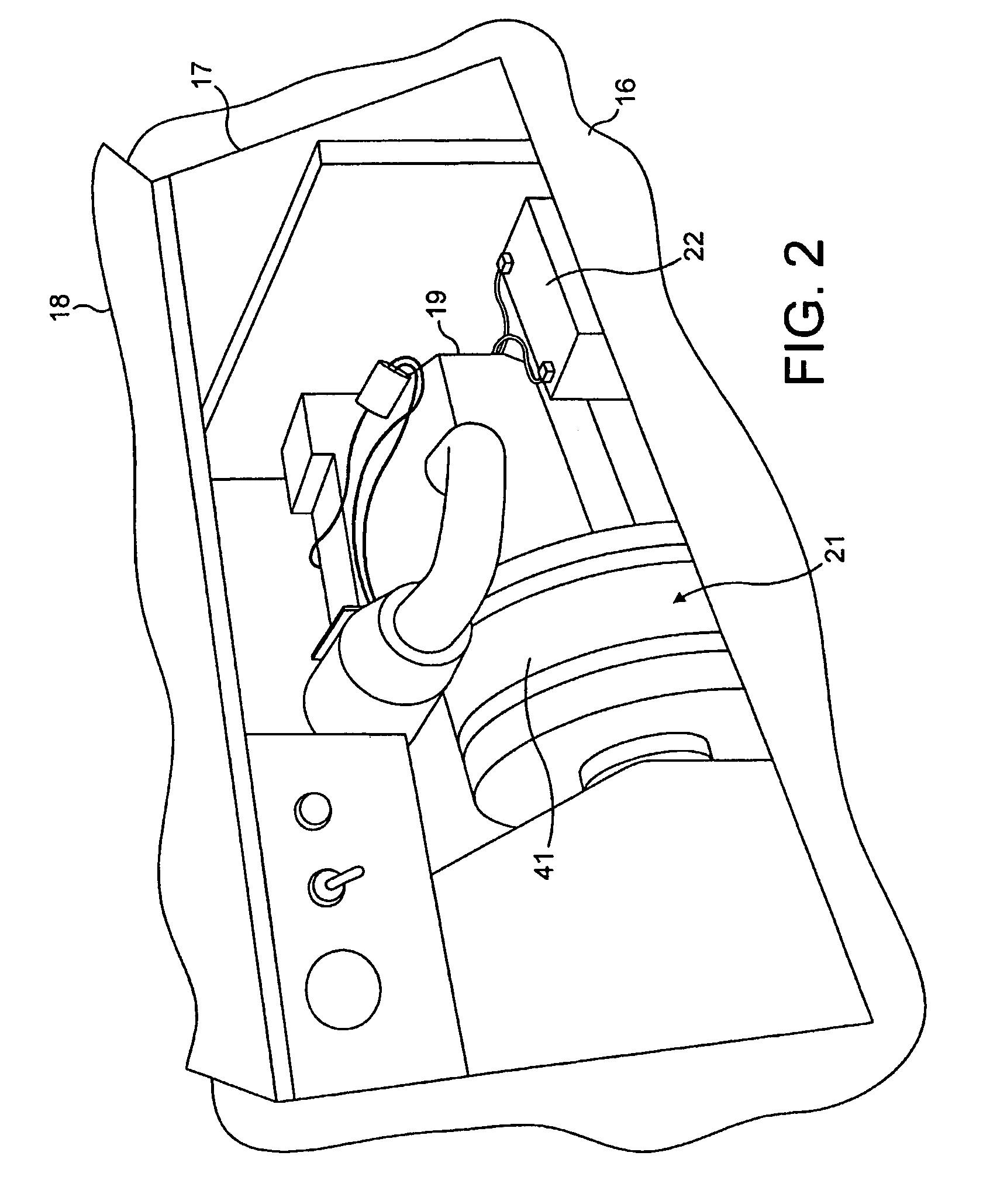

Alternator assembly

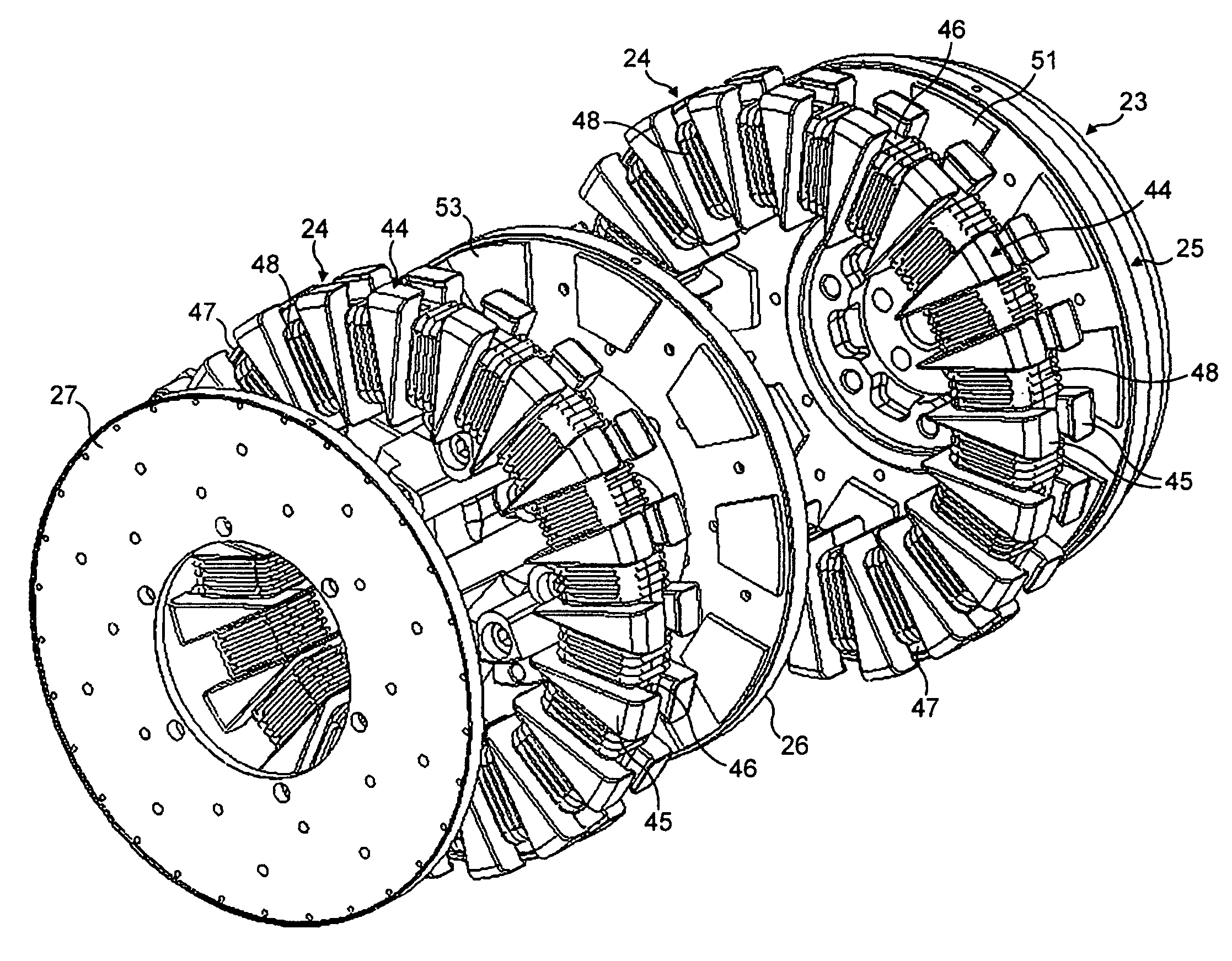

ActiveUS20070040465A1Magnetic circuit rotating partsMagnetic circuit stationary partsAlternatorInternal resistance

The stator (24) of a permanent magnet axial flux alternator comprises two annular stator components which are each wound with a respective two phase winding arrangement (48). Each of the two phase winding arrangements (48) is wound so that there is no mutual inductance between the windings of each phase. Each phase of the two phase winding arrangements (48) wound on the two stator components has a high internal impedance and is for energising a respective high intensity lamp of a light tower.

Owner:CUMMINS GENERATOR TECH LTD

Motor generator

ActiveUS7288868B2Low costReduced space required for installationMachines/enginesWind energy generationElectric power distributionConductor Coil

A motor generator is provided with a stator having a winding around each of a plurality of stator teeth, and a rotor having a plurality of permanent magnets by the number larger than that of the stator teeth, arranged in the circumferential direction at equal intervals. The stator teeth are formed of a first stator teeth section including a plurality of stator teeth groups I, II, and III each including the adjacent stator teeth around which a winding to which the same phase voltage is applied is wound and in which winding directions of the stator teeth are opposite to each other, and a second stator teeth section including a stator teeth having a winding wound therearound and being placed among stator teeth groups of different phases such that electric power is independently input and output with respect to the first and second winding sections. This makes it possible to reduce the space and the cost while inputting / outputting the electric power through different channels and allowing arbitrary design of the electric power distribution.

Owner:PANASONIC CORP

Monopole field electric motor-generator with switchable coil configuration

ActiveUS20060038460A1Easy output controlAsynchronous induction motorsMechanical energy handlingElectricityConductor Coil

A pair of stators produce a magnetic field within a space between them. a ferromagnetic toroidal rotor is rotationally mounted within the magnetic field. A plurality of windings are wound radially on the rotor and each winding provides a plurality of coils. Each of coils is interconnected through a switch, the switch configured for placing each of the coils within each winding alternatively in one of an electrical series connection, an electrical parallel connection, and an electrically isolated connection, so that when operated as a generator, a selected output voltage and current are produced by rotor rotation and when operated as a motor a selected output speed and torque are produced.

Owner:CLEARWATER HLDG +1

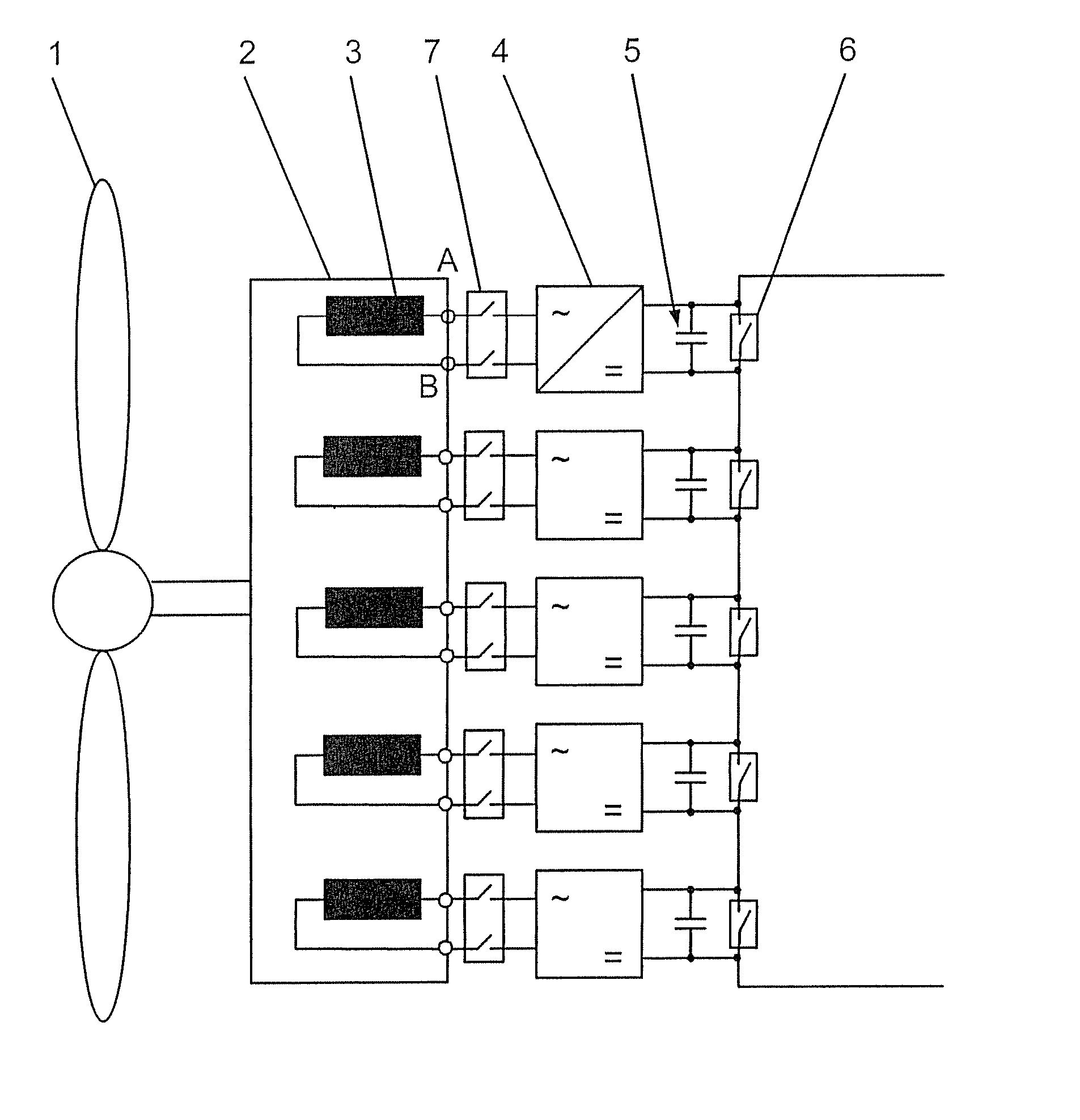

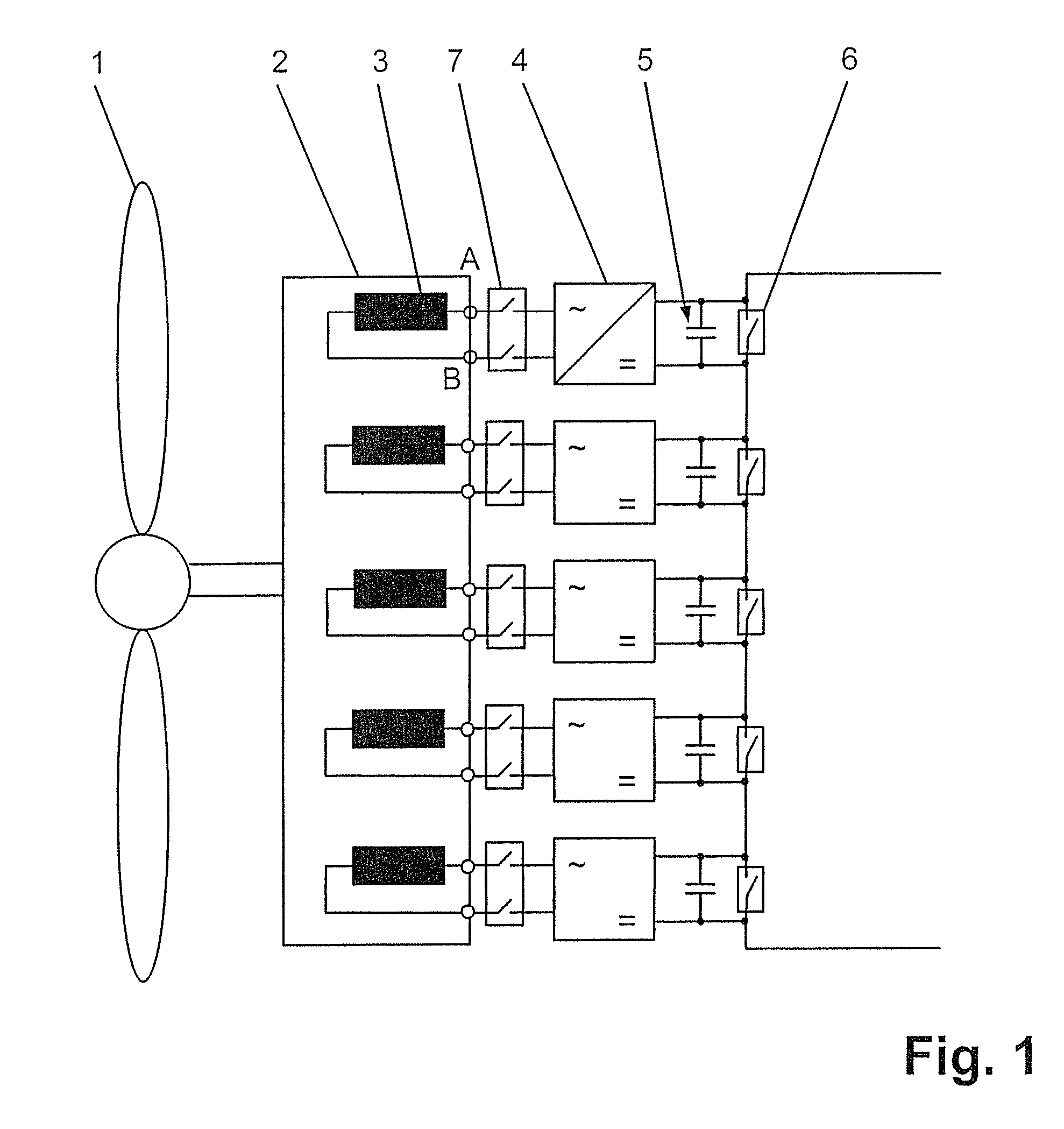

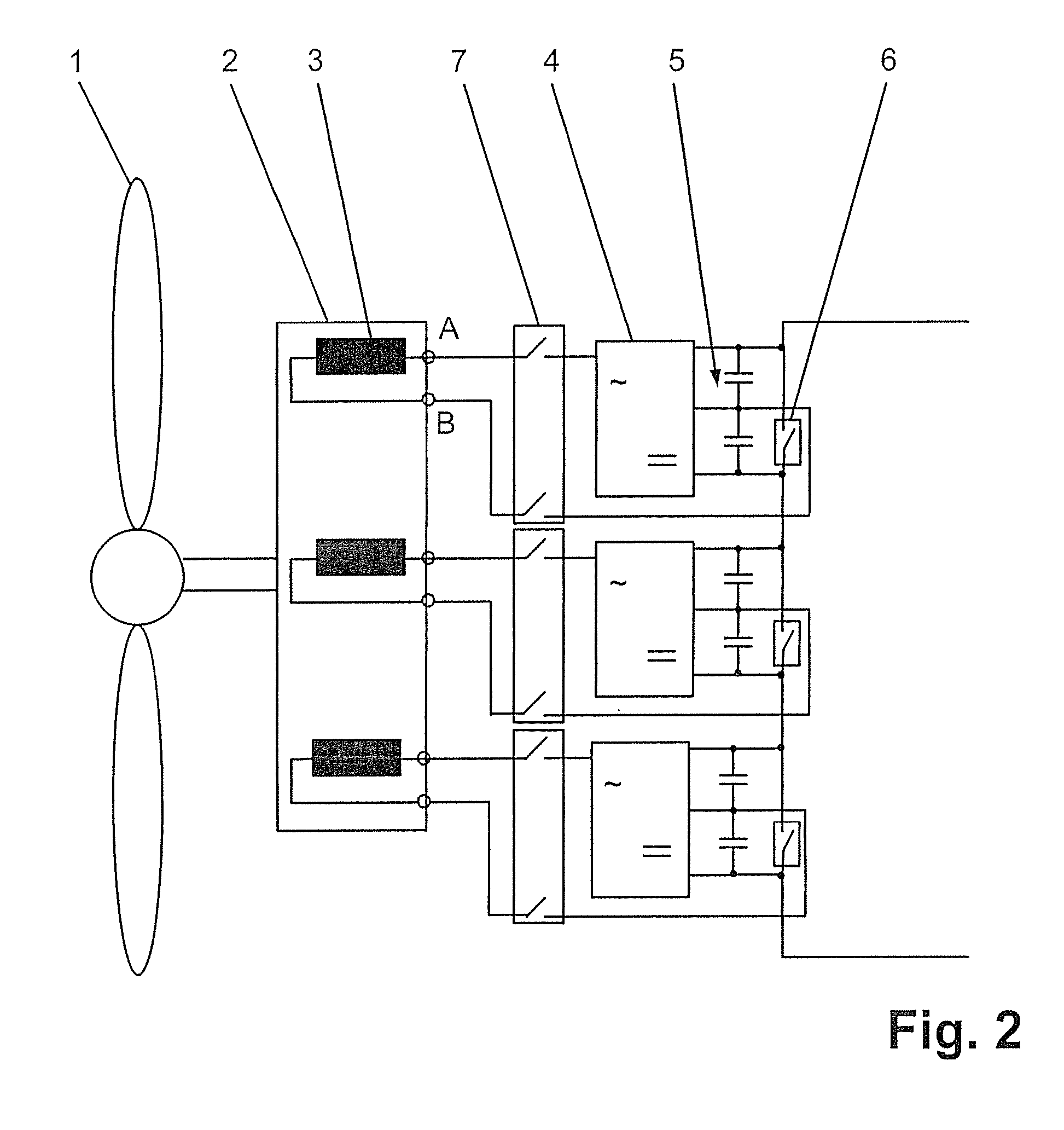

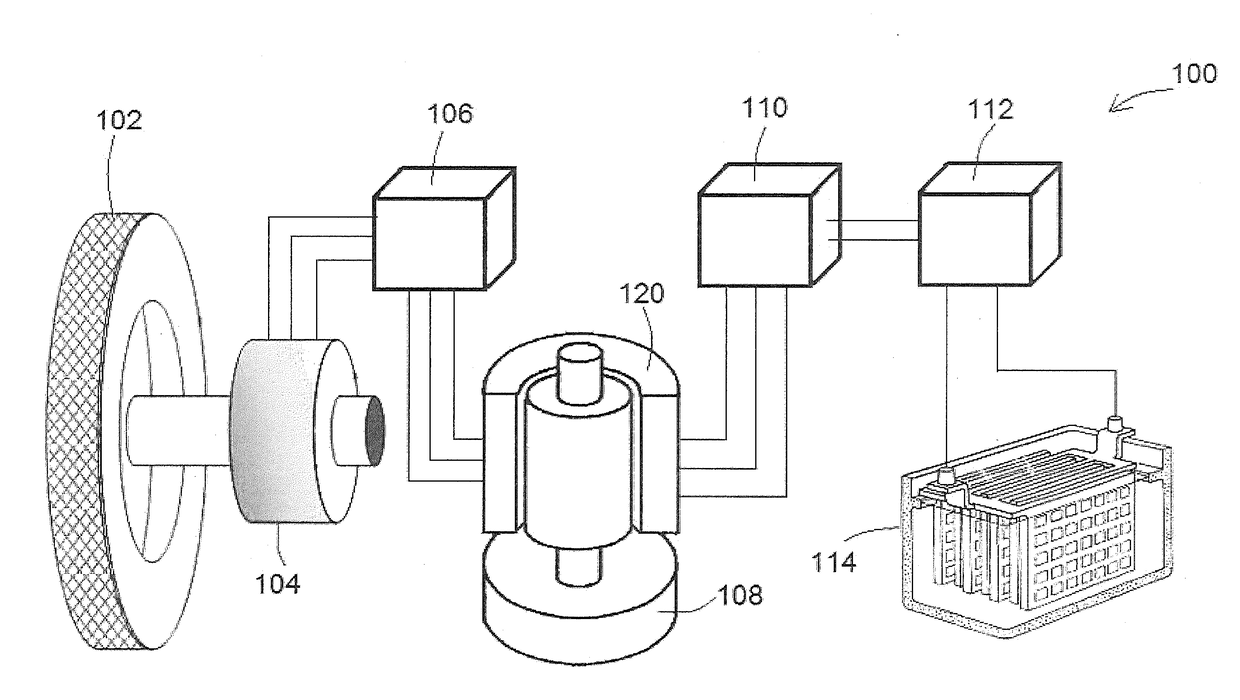

Energy system for producing DC voltage using rectifiers and energy storage circuits

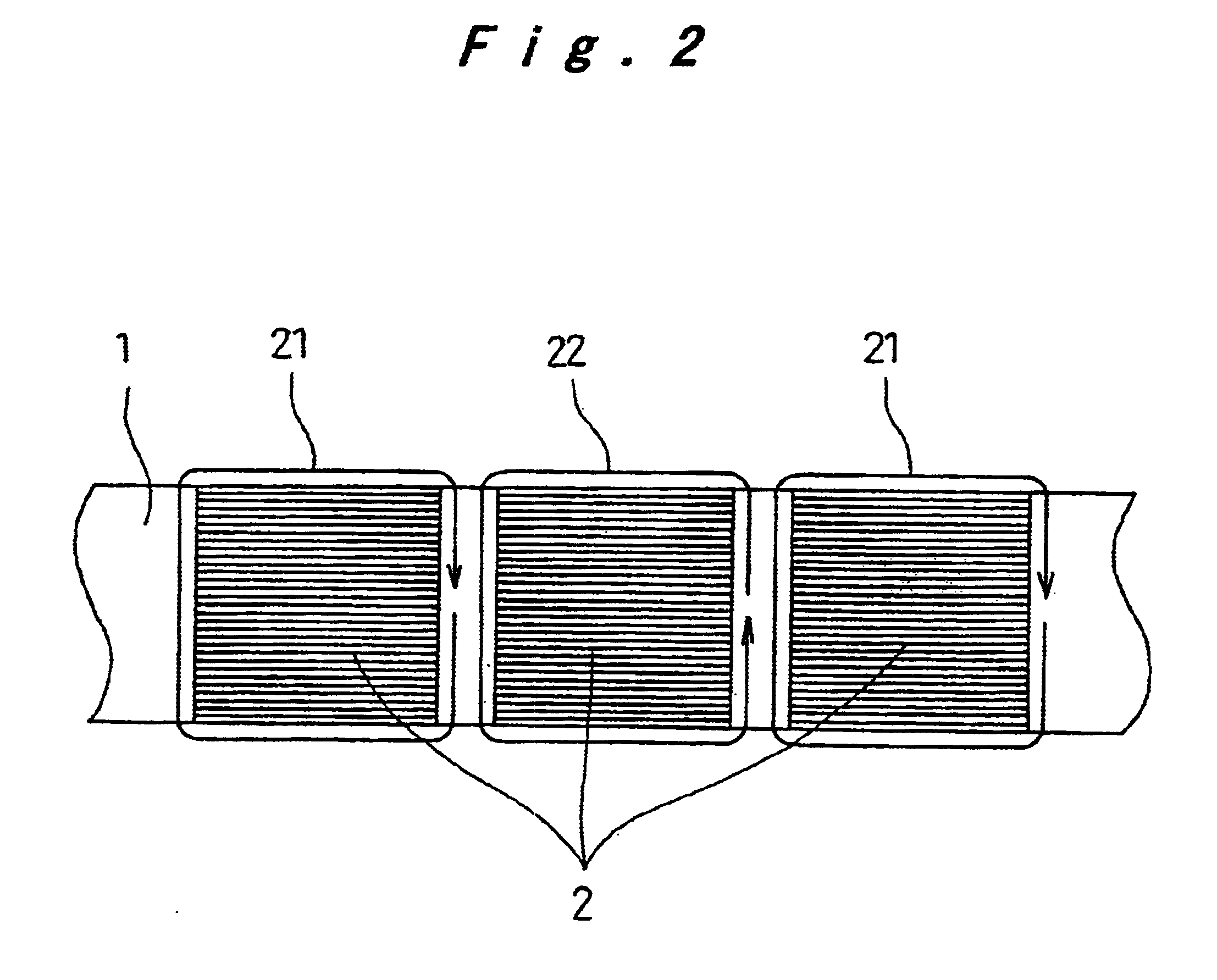

ActiveUS8212371B2Simple designSynchronous generatorsWind energy with electric storageTransformerEngineering

An energy system is specified, which comprises a wind power turbine or water power turbine, which is connected to a generator, with the generator having at least two stator windings. In order to achieve a simple and robust design without a transformer, each stator winding has an associated rectifier unit, and each stator winding is connected to the AC voltage side of the associated rectifier unit. Furthermore, each rectifier unit has a respective associated energy storage circuit, and each rectifier unit is connected in parallel on the DC voltage side to the associated energy storage circuit, with the energy storage circuits being connected to one another in series.

Owner:ABB (SCHWEIZ) AG

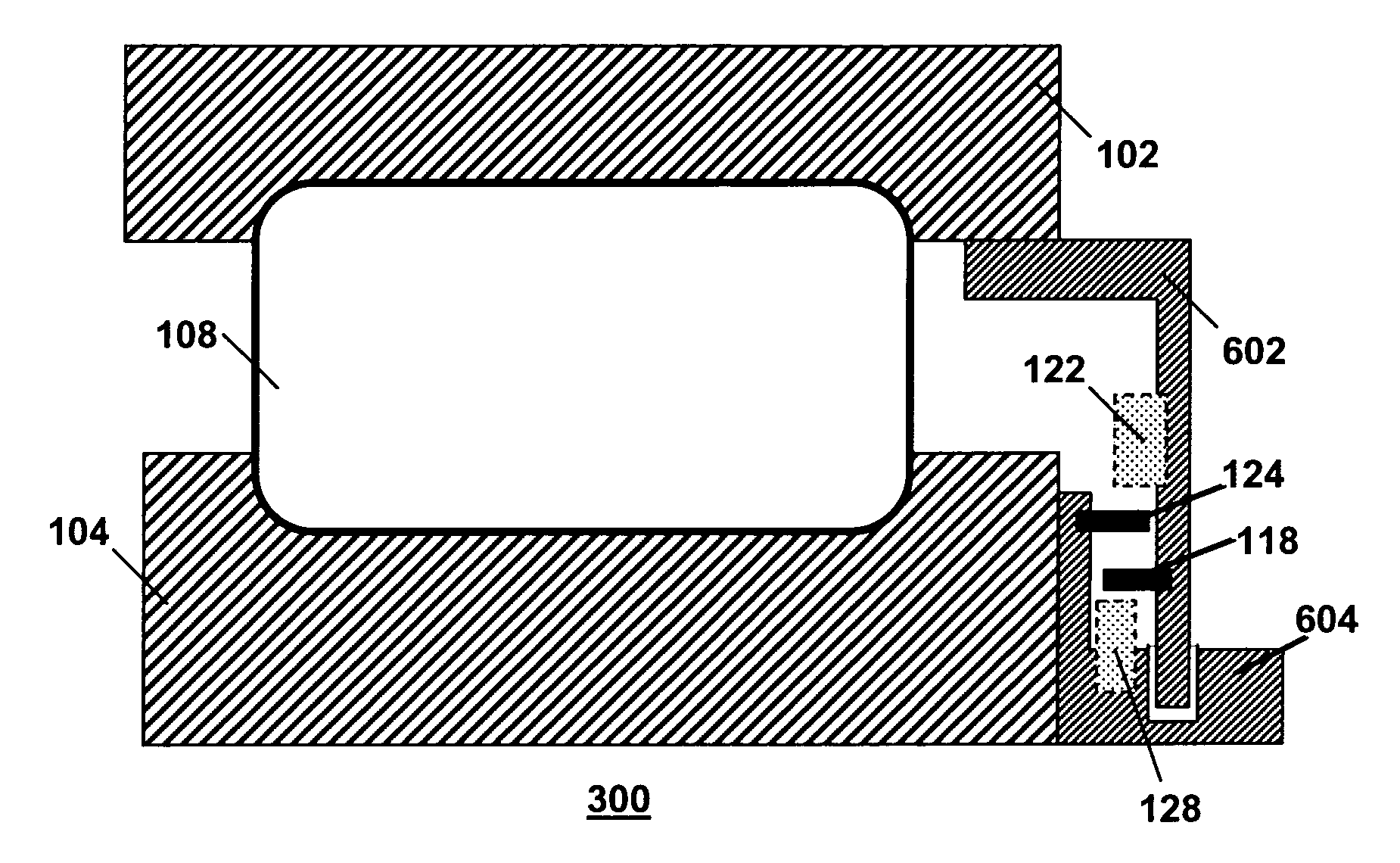

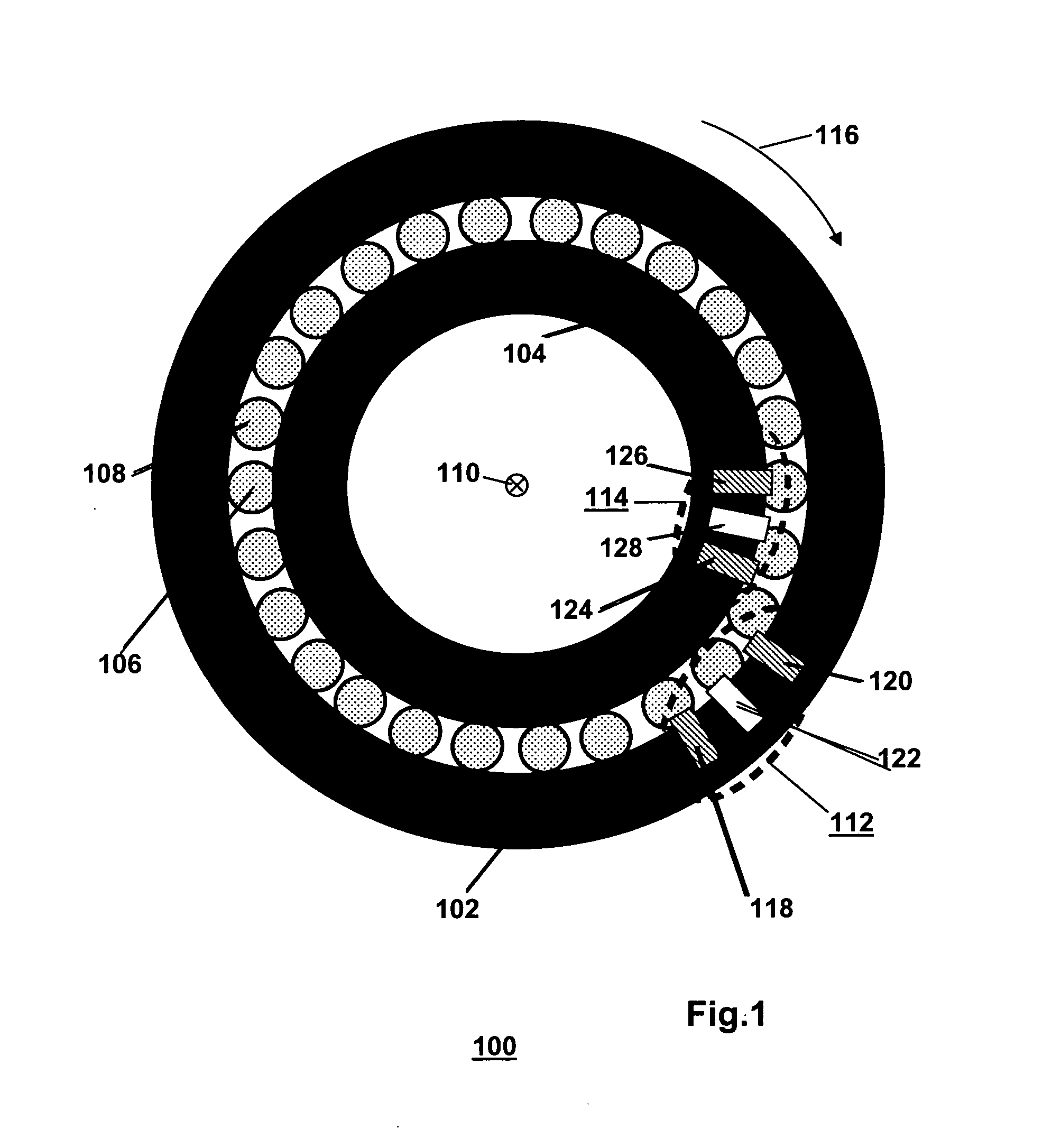

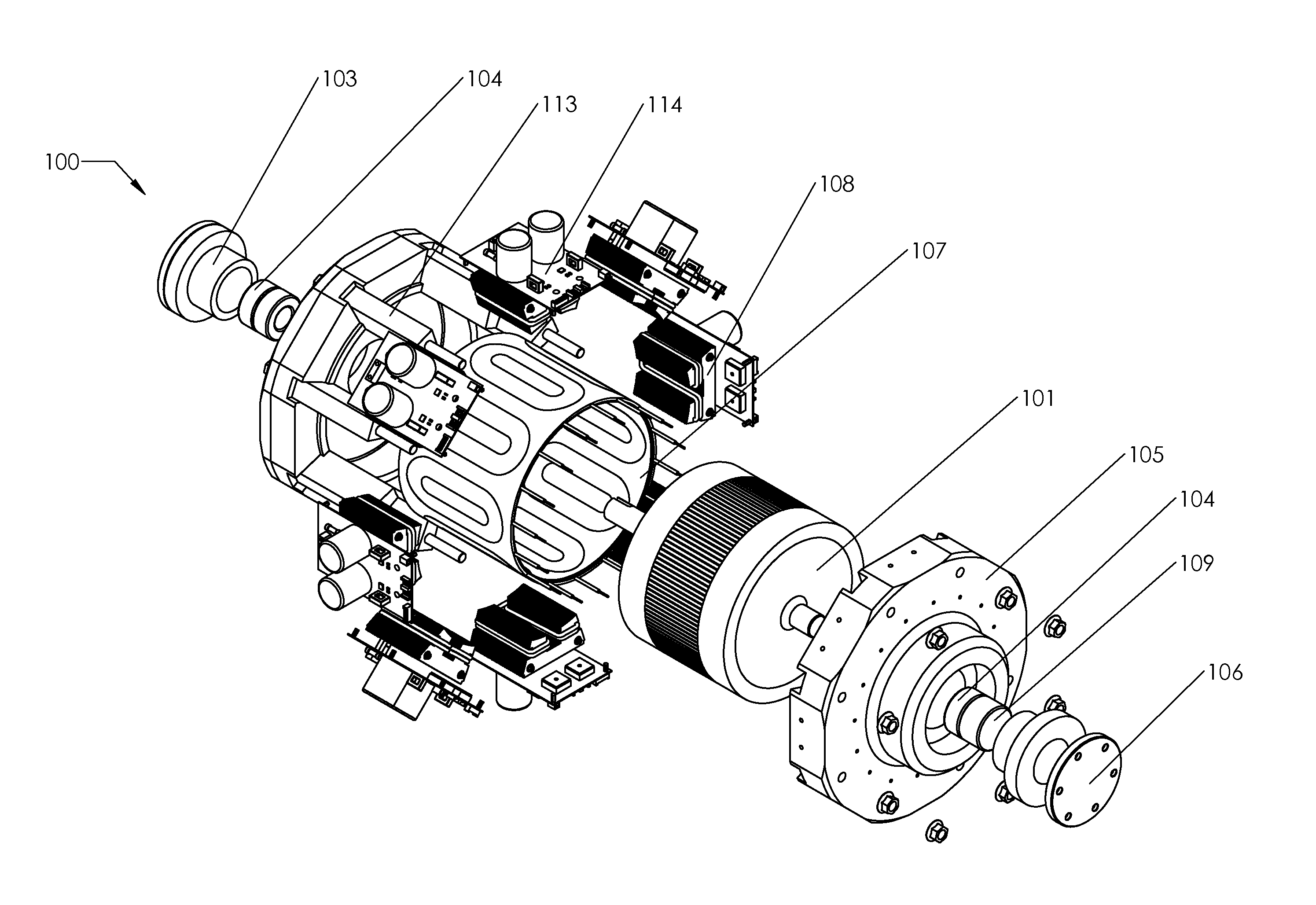

Power generator integrated with bearing

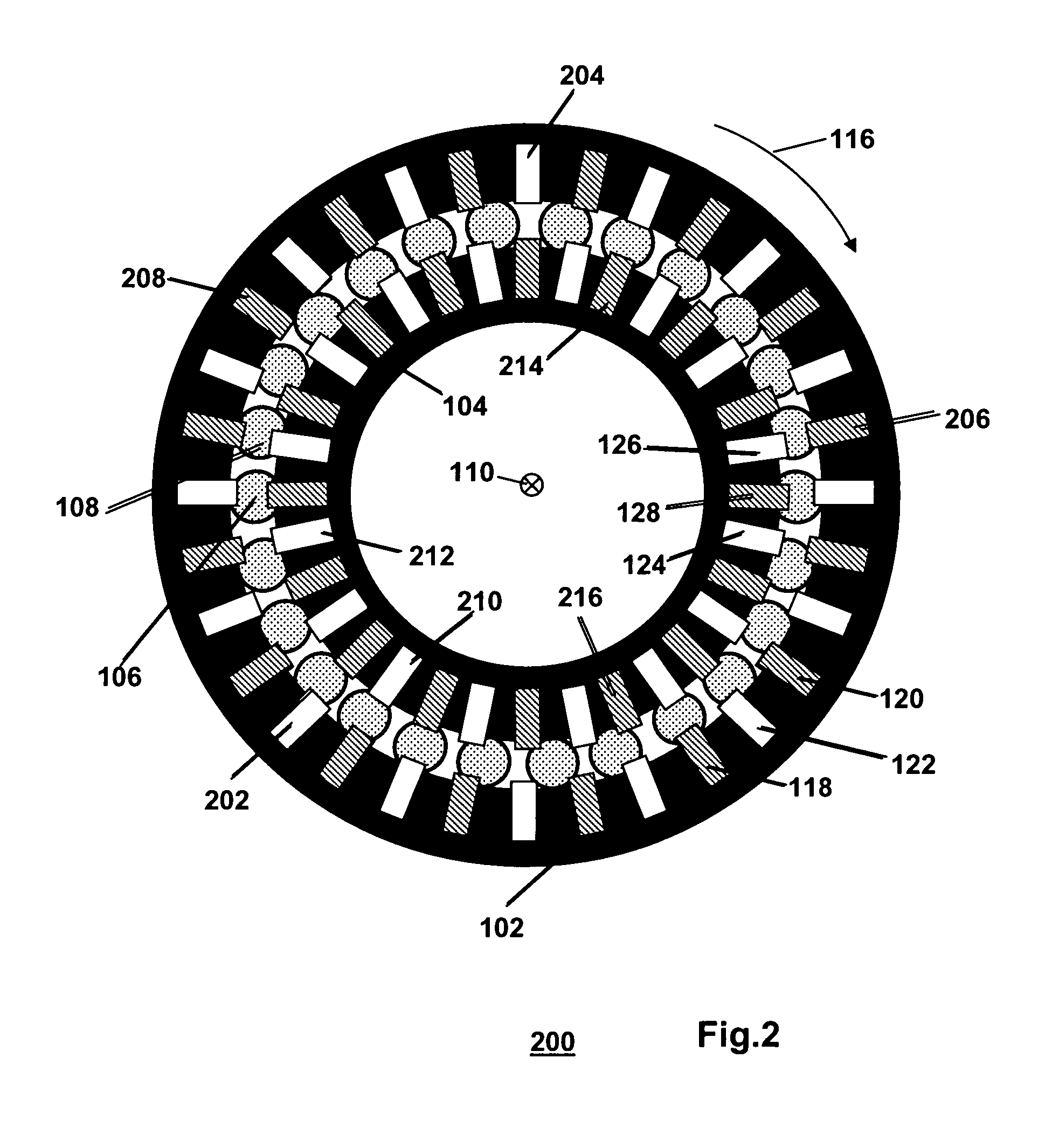

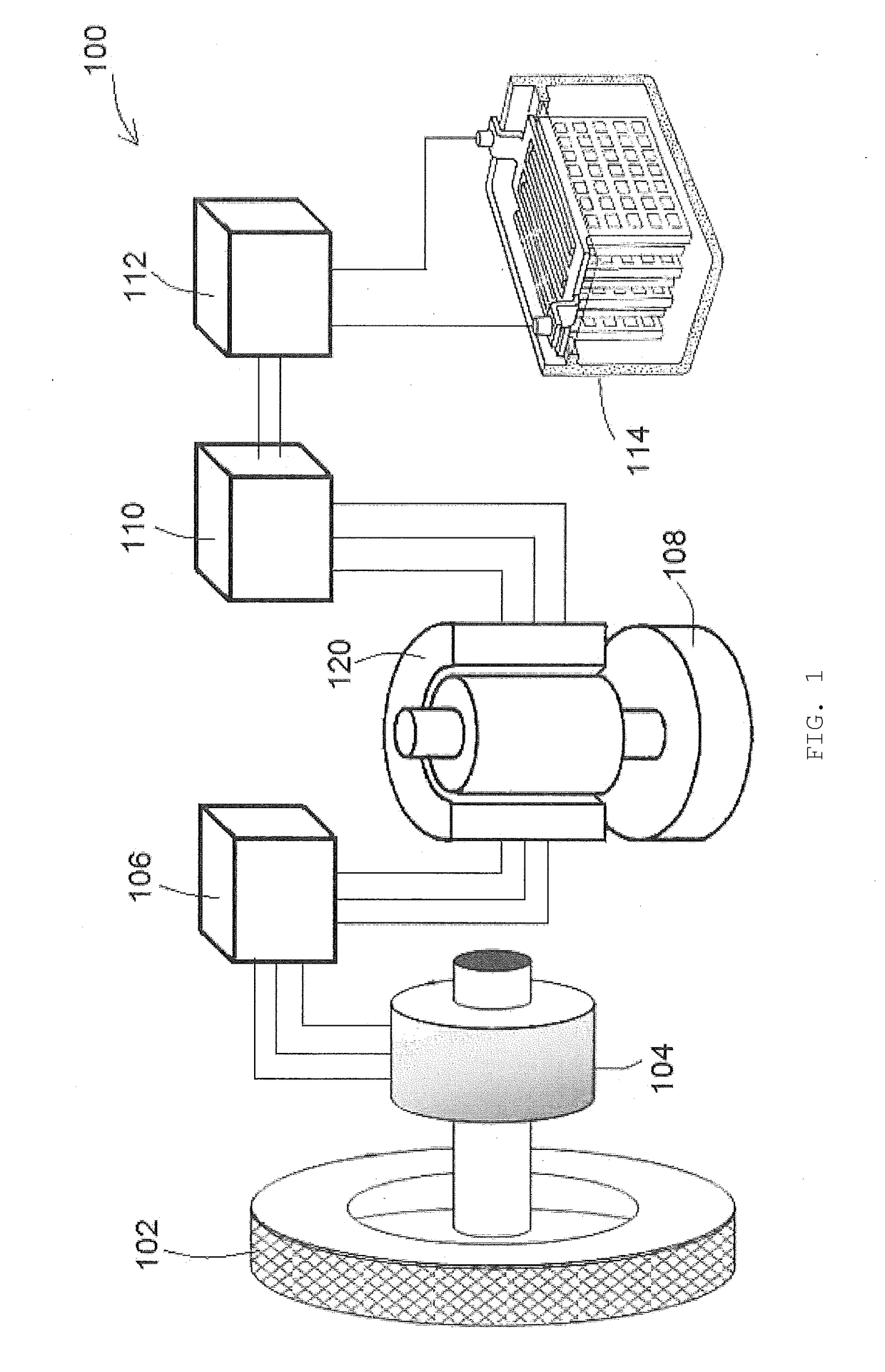

InactiveUS20140055010A1Increase rate of changeSimple configurationAssociation with control/drive circuitsRoller bearingsEngineeringFixed position

A bearing has a first ring (102) and a second ring (104) configured for coaxial rotation with respect to each other, and a generator for generating electric power in operational use of the bearing. The generator has a first arrangement (112) mounted in a fixed position with respect to the first ring, and a second arrangement (114) mounted in a fixed position with respect to the second ring. Each of the first arrangement and the second arrangement comprises one or more coils (122, 128) and one or more magnets (118, 120, 124, 126) arranged in a circumferential direction (116) of the rings. The generator is therefore configured to supply power to circuitry mounted so as to be stationary with a ring.

Owner:AB SKF

Automobile permanent magnet generator with tiny output voltage ripple

InactiveCN101325357ASmall output voltage rippleGood varietyElectric generator controlSynchronous generators with multiple outputsPermanent magnet rotorVoltage pulse

A car permanent magnet generator is mainly composed of a rear cover, a three-phase bridge type controlled rectifier, an electronic voltage regulating controller, a rear end cover, a stator, a permanent magnet rotor, a bearing, a front end cover, a belt wheel, wherein the belt wheel drives the permanent magnet rotor to rotate, to cause the stator winding to induce out the three-phase alternating current, then is set as the DC output through the three-phase bridge type controlled rectifier. The electronic voltage regulating controller controls the angle of current flow of the thyristor, to cause the generator to output the stable DC voltage, characterized in that, the stator is arranged with two sets of three-phase windings, one is in the 'Y'-connection, and the other is in the 'triangle'-connection, which constitute two three-phase controlled bridge type rectifying circuits with the three-phase bridge type controlled rectifier, wherein the two rectifying circuits are in the parallel output. Due to the voltage phase difference 30 of the two windings, the output voltage pulses every 30 degrees, so the more the pulse times of the rectifying output voltage in a period is, the smaller the ripple of the output voltage of the car permanent magnet generator is.

Owner:陈国弟

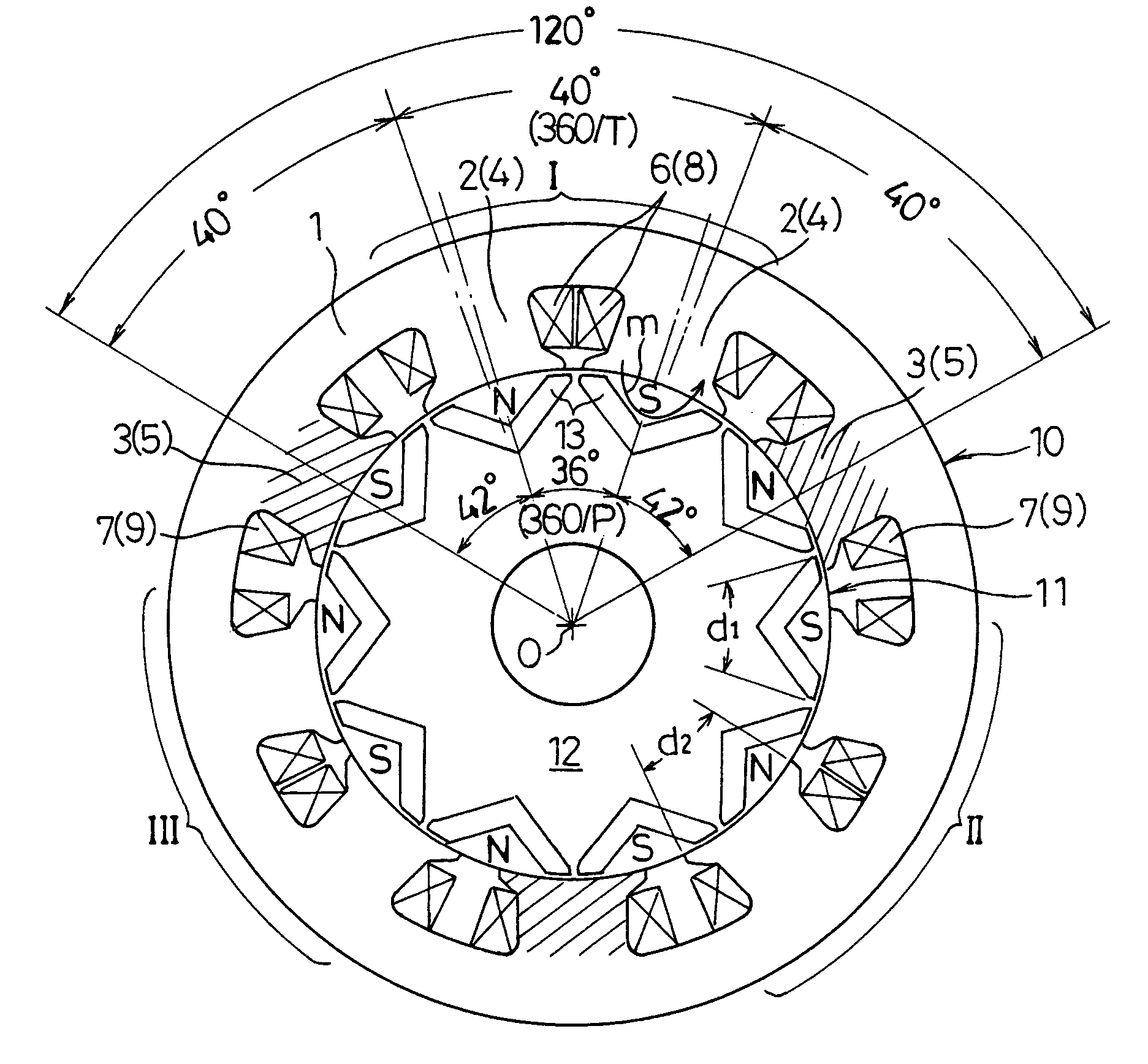

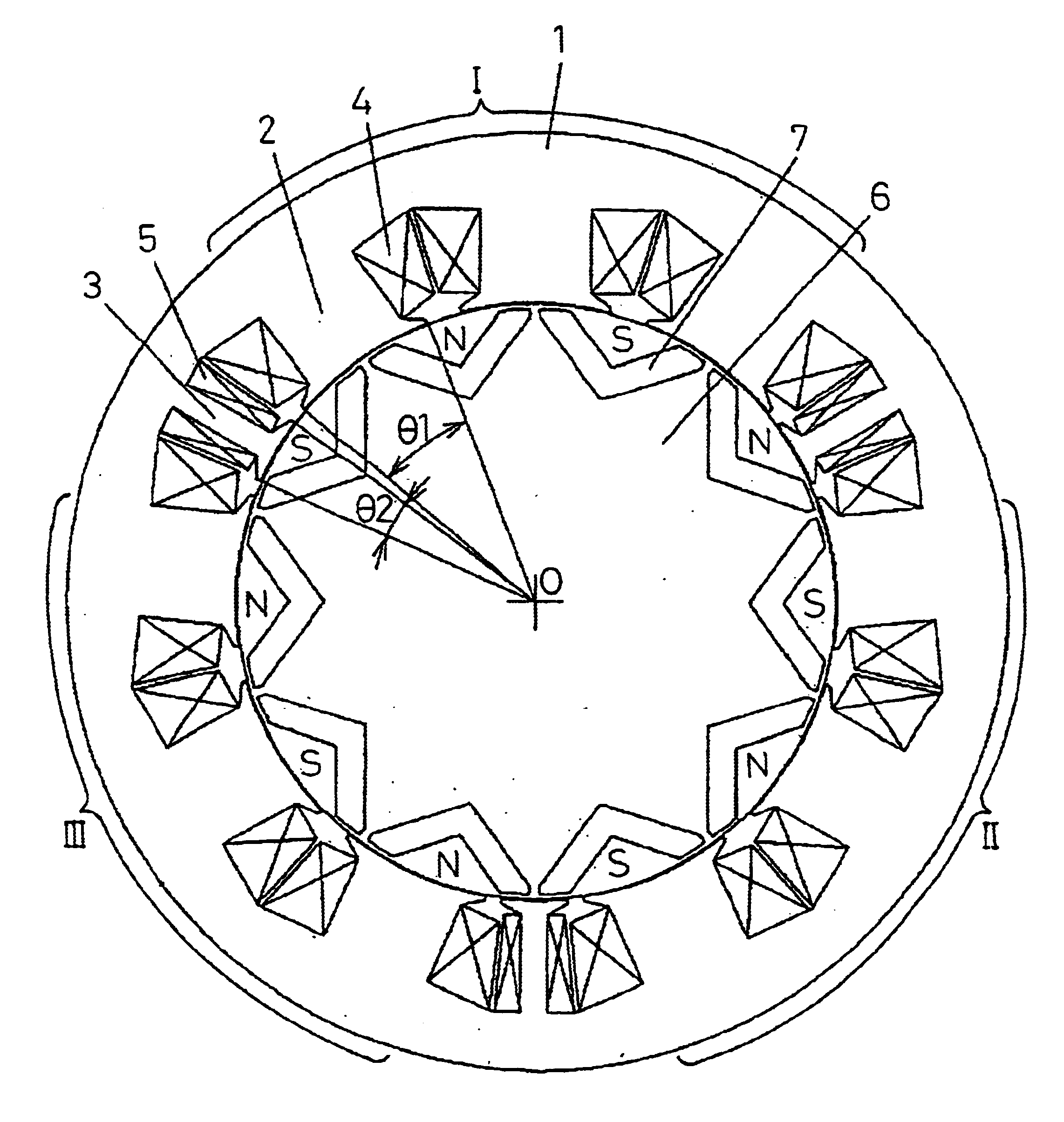

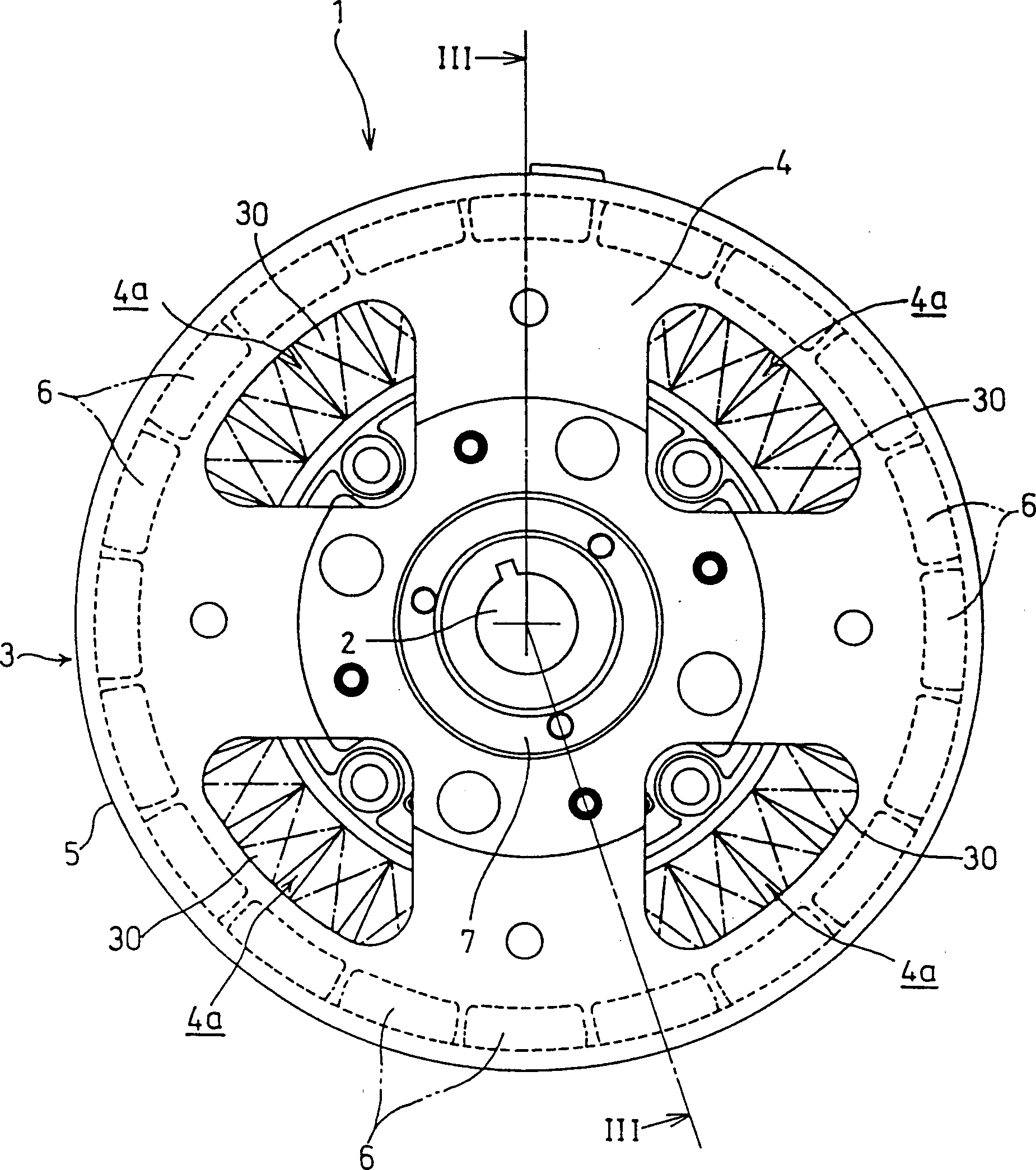

Motor generator

InactiveUS6909216B2Good utilization of interior spaceLow costMagnetic circuitAsynchronous induction motorsEngineeringCounter-electromotive force

A permanent magnet embedded type concentrated winding motor generator, wherein of the mechanically and electrically independent first and second winding groups (4, 5), the plurality of first teeth (2) wound with the first winding groups (4) are divided into three groups (I, II, III) for example, and the winding directions of the windings of adjacent first teeth (2) within the same group (I, II, III) are opposite. Furthermore, one second tooth (3) wound with a second winding group (5) with a different winding specification from the first winding groups (4) is provided between each of the groups (I, II, III). Accordingly, the relative sizes of the generated voltages in the first winding groups (4) and the second winding groups (5) differ each other, allowing the realization of a compact and low cost construction capable of charging two different electric potentials from a single unit, which also enables a reduction in distortion of the waveform of the counter electromotive force, a reduction in iron loss, and an improvement in the efficiency of the motor, and enables the efficient charging of power sources with two different electric potentials.

Owner:PANASONIC CORP

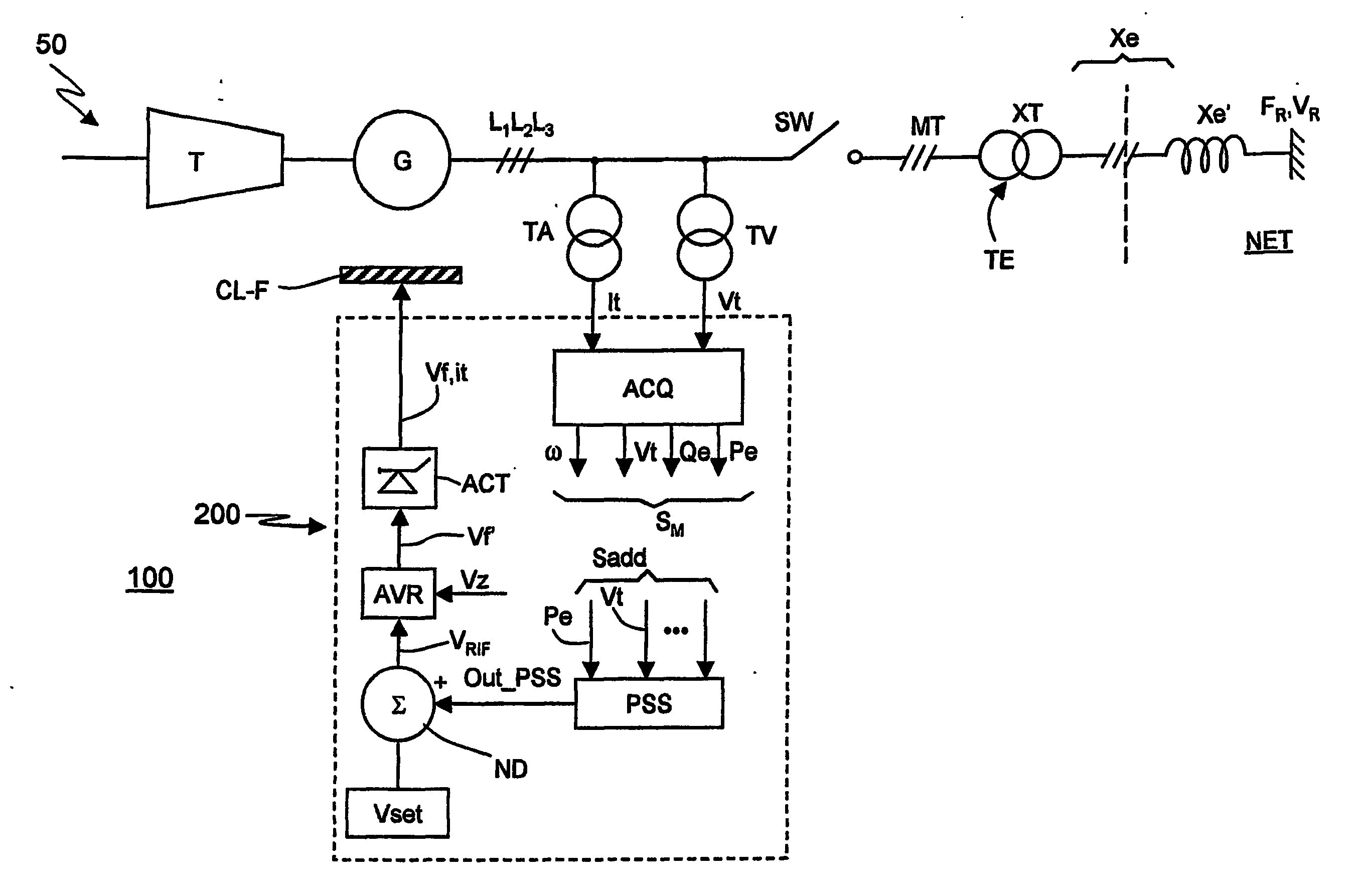

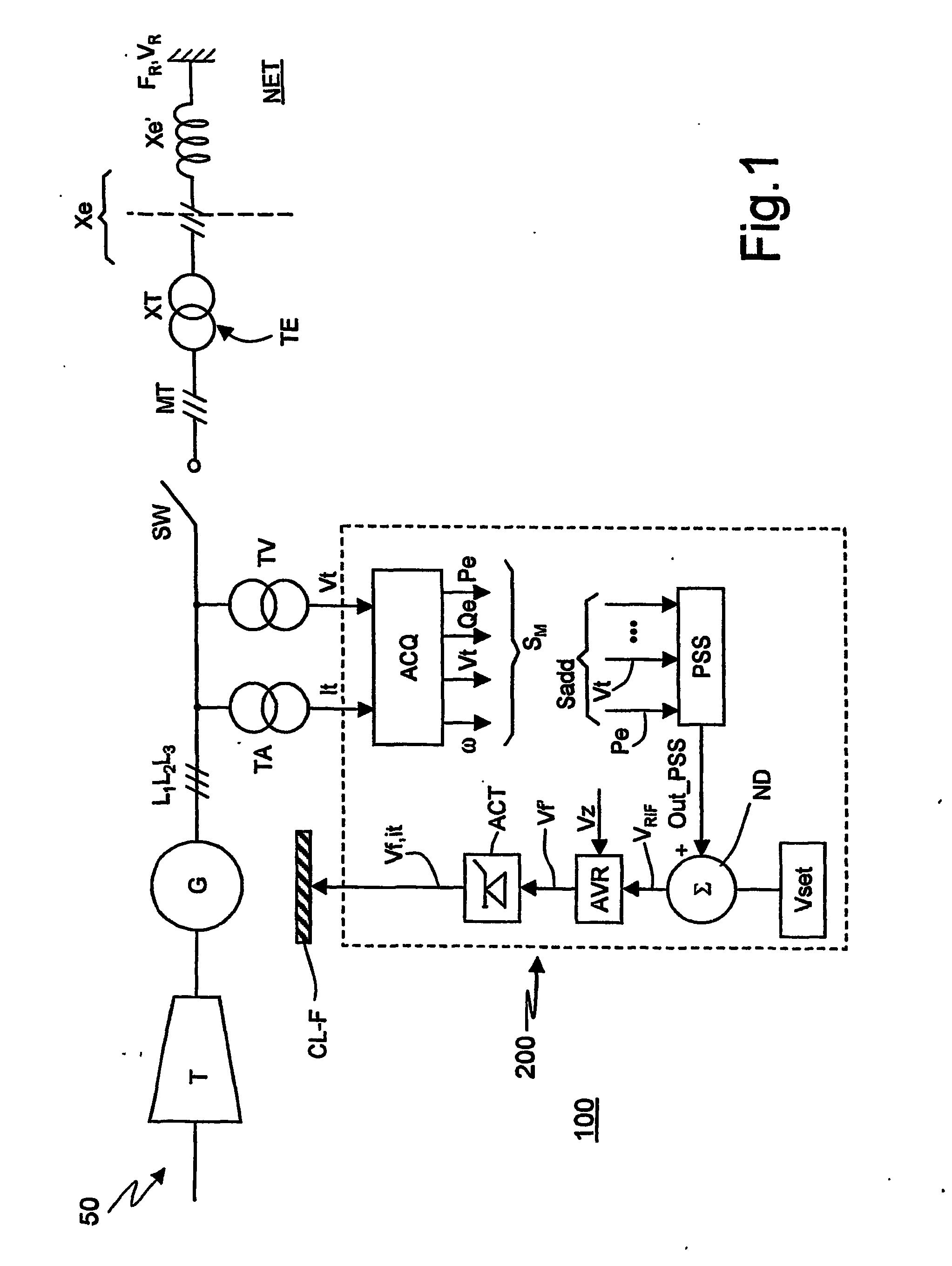

Compensator device for stabilising the power of alternators in electrical power generating plants

InactiveUS20070120424A1Dc network circuit arrangementsEmergency protective circuit arrangementsElectricityAlternator

Compensator device, for the stabilisation of electromechanical oscillations destined to provide a reference signal to a voltage regulator device of a synchronous alternator for the delivery of electrical power to a distribution network, said device including: first processing means to receive electrical measurement signals representing operative parameters characteristics of said synchronous alternator and / or to generate an electrical signal to be controlled; and a first electrical signal corresponding to a sliding surface of a control of the “sliding modes” type, second processing means of the first signal to generate the reference signal so that it has a first order “sliding modes” profile.

Owner:ANSALDO ENERGIA SPA

Magneto generator with multiple sets of three-phase windings

InactiveUS8519590B2Small sizeLight weightSynchronous generatorsMagnetic circuitElectrical conductorEngineering

A magneto generator can be made small in size and light in weight, and improved in power generation efficiency. The magneto generator includes an iron core having an iron core main body and a plurality of teeth (9) radially extending from the iron core main body, and an armature having a first three-phase winding (14) and a second three-phase winding (15) comprising winding portions (18u, 18v, 18w, 19a, 19b and 19c) of individual phases wound around the stator core. The individual first and second three-phase windings (14, 15) have the winding portions (18u, 18v, 18w, 19a, 19b and 19c) constructed by concentratedly winding conductors around the individual teeth (9), respectively, while skipping every predetermined number of teeth (9), and are wound in a state divided into an inner layer side and an outer layer side, respectively.

Owner:MITSUBISHI ELECTRIC CORP

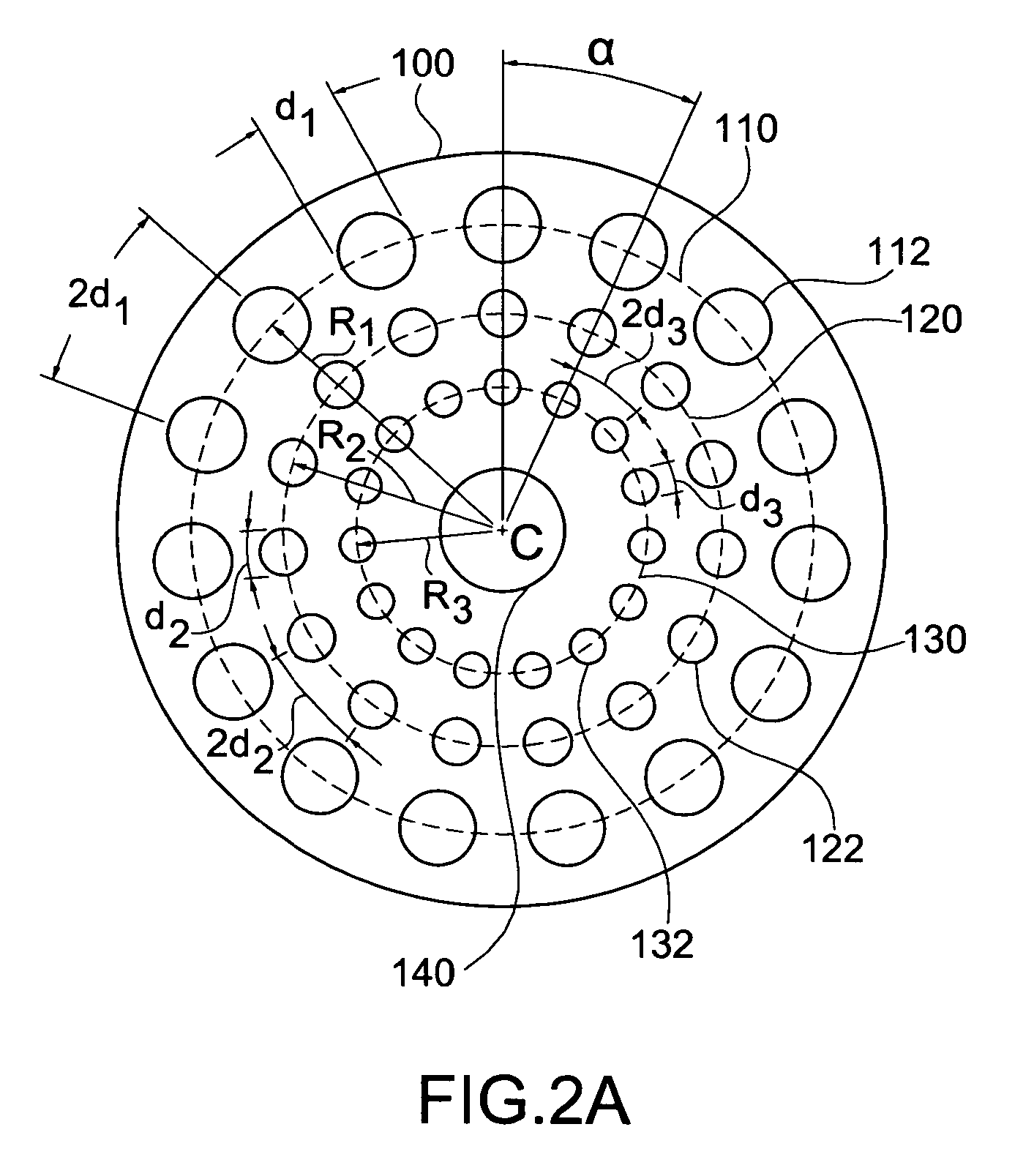

Multivariable generator and method of using the same

InactiveUS7808142B2Extended service lifeLow heat generationSynchronous generatorsMagnetic circuit rotating partsMagnetic sourceEngineering

A generator device for generating electrical energy includes a rotor having a first set of even-numbered of magnetic sources distributed along a first radius of the rotor, and a first pair of stators, each having a first set of odd-numbered coil members distributed along a first radius of the stator, the stators disposed adjacent to opposing side portions of the rotor, wherein each coil member includes a core portion having an amorphous structure. In addition, a generator device for generating electrical energy includes interchangeable rotor and stator pairs to provide variable voltage / current / frequency outputs.

Owner:CAMEL CLUB

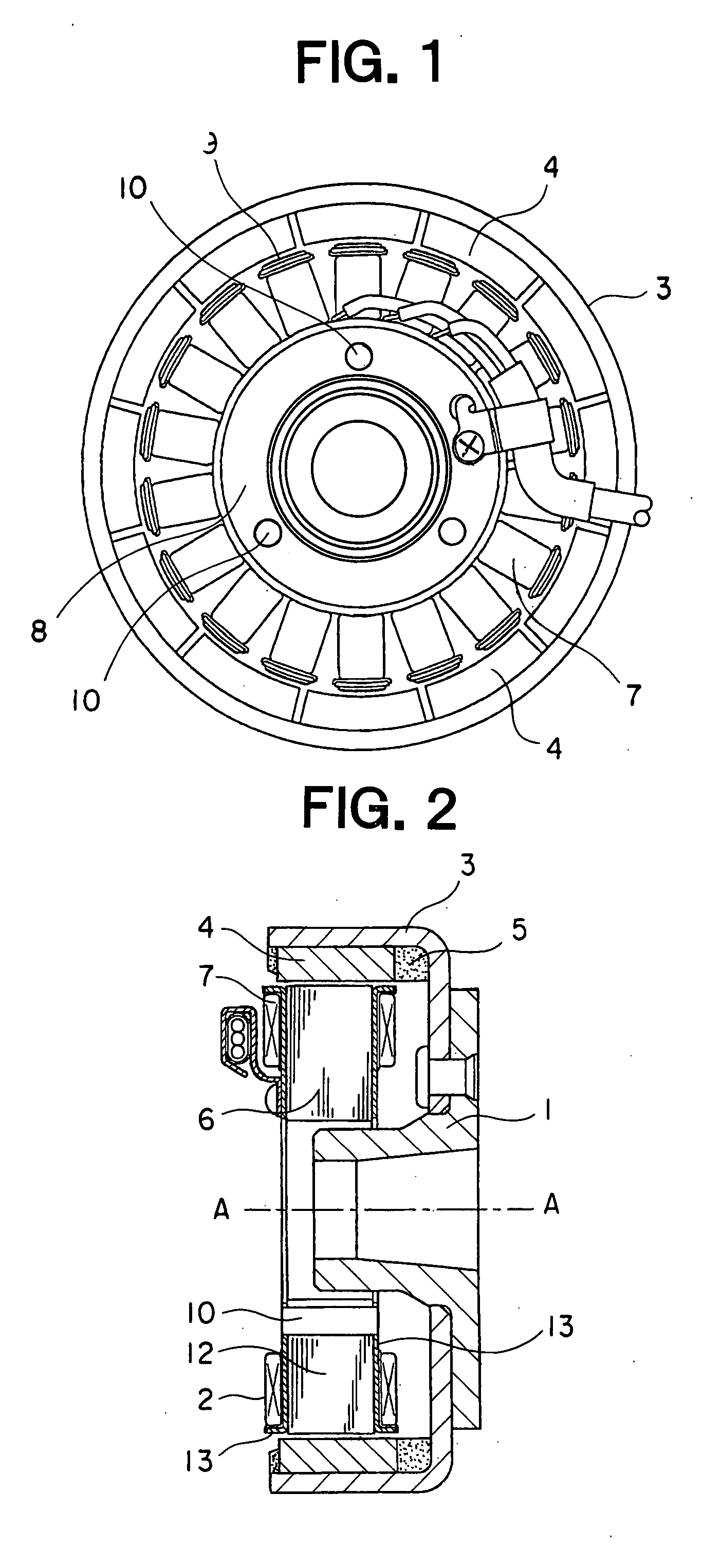

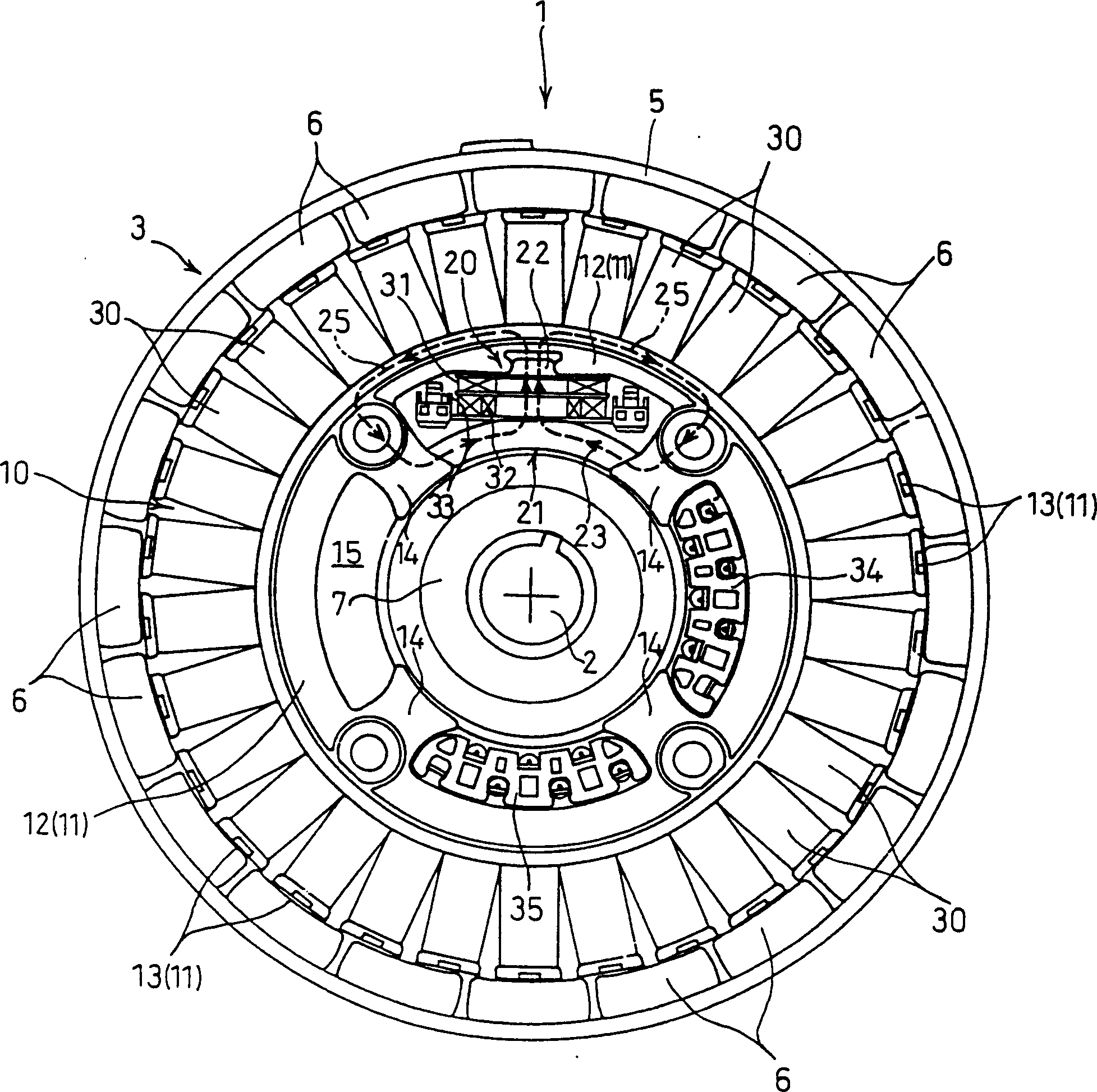

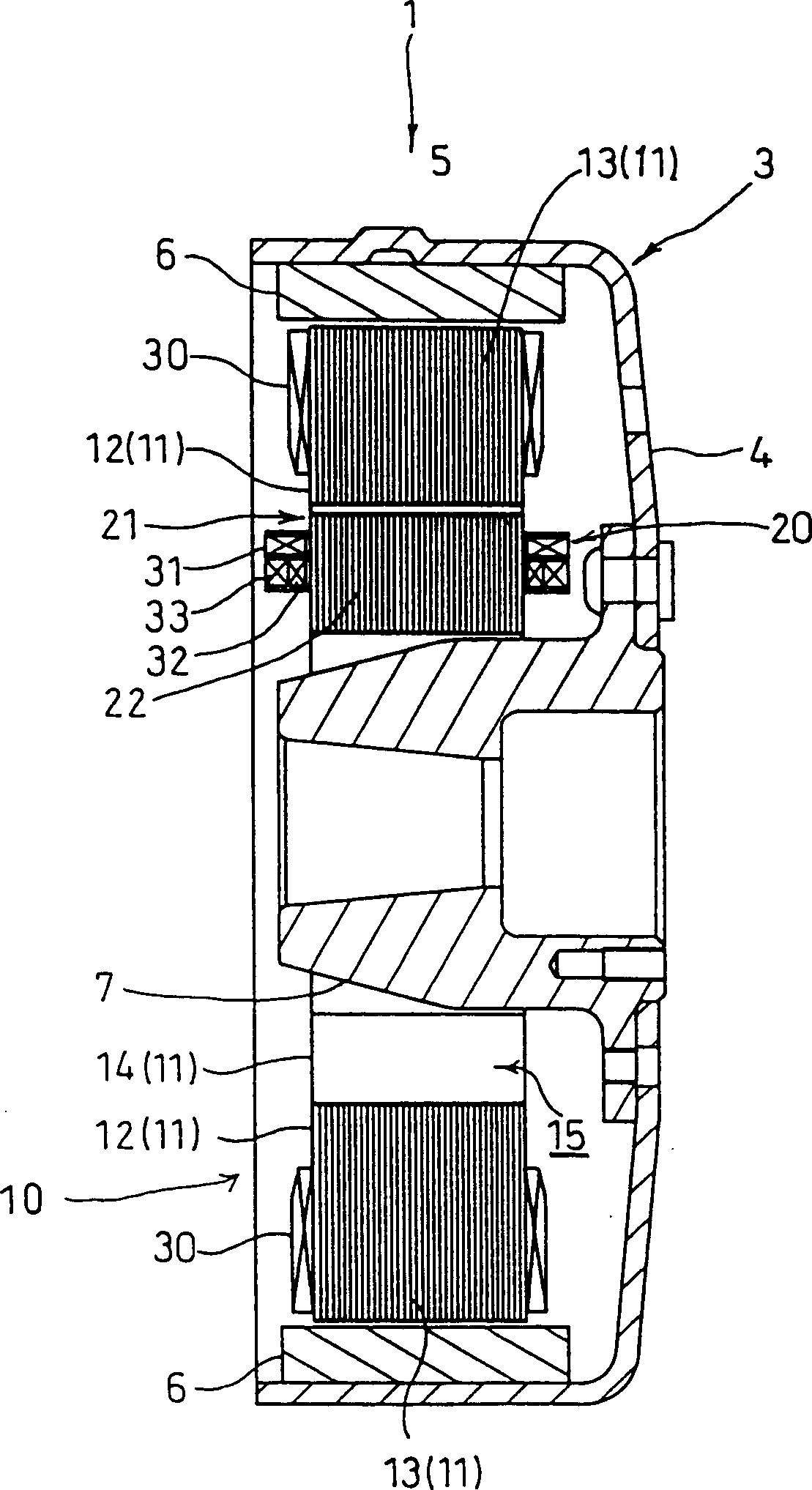

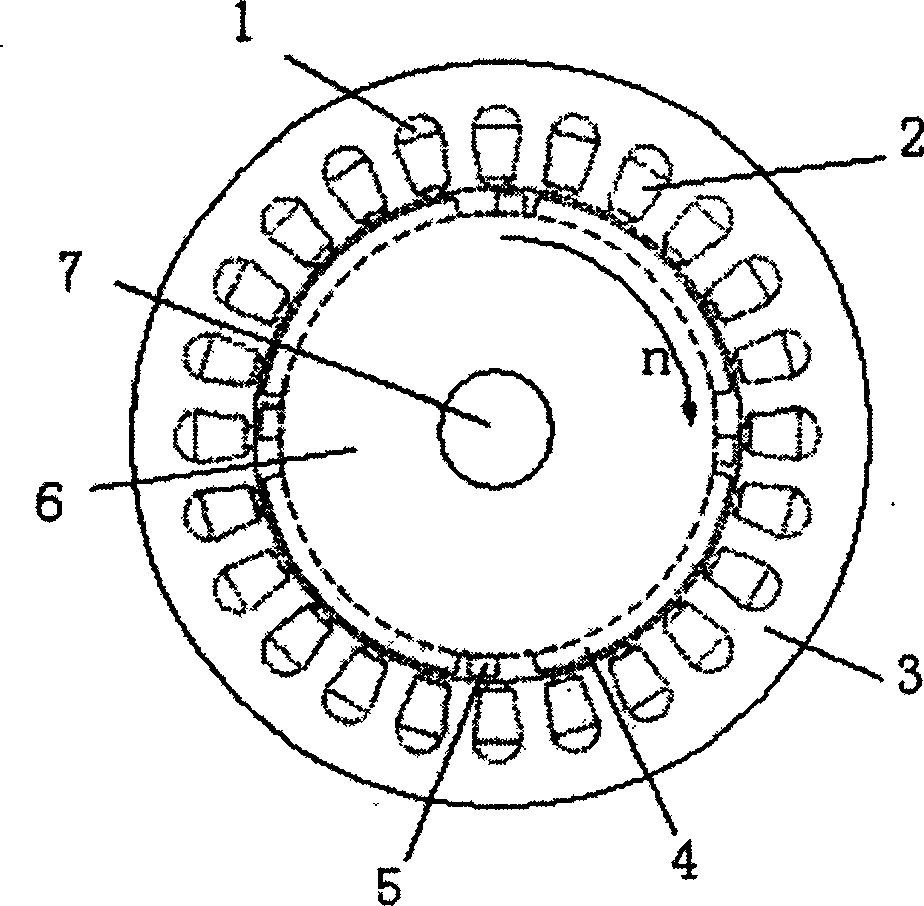

Multipolar magnetogenerator

InactiveUS6844650B2Sufficient performanceImprove space efficiencySynchronous generatorsWindingsTransformerEngineering

A multipolar magnetogenerator, which is operable under sufficient performance of its capability, permitting simultaneous extraction of various voltage outputs and is excellent in spatial efficiency, includes a magnet rotor (3) as an outer rotor and a multipolar stator (10) opposed to the radially inner surface of the magnet rotor (3) to permit extraction of an output of generated power from output windings (30) wound around the stator core 10. A transformer core (21) has a primary winding (31) and secondary windings (32, 33) wound therearound and is located adjacent the radially inner circumferential surface of the stator (10), which is remote from the magnet rotor (3), and the output windings (30) are connected to the primary wiring (32) such that transformed outputs are extracted from the secondary windings (32, 33).

Owner:HONDA MOTOR CO LTD

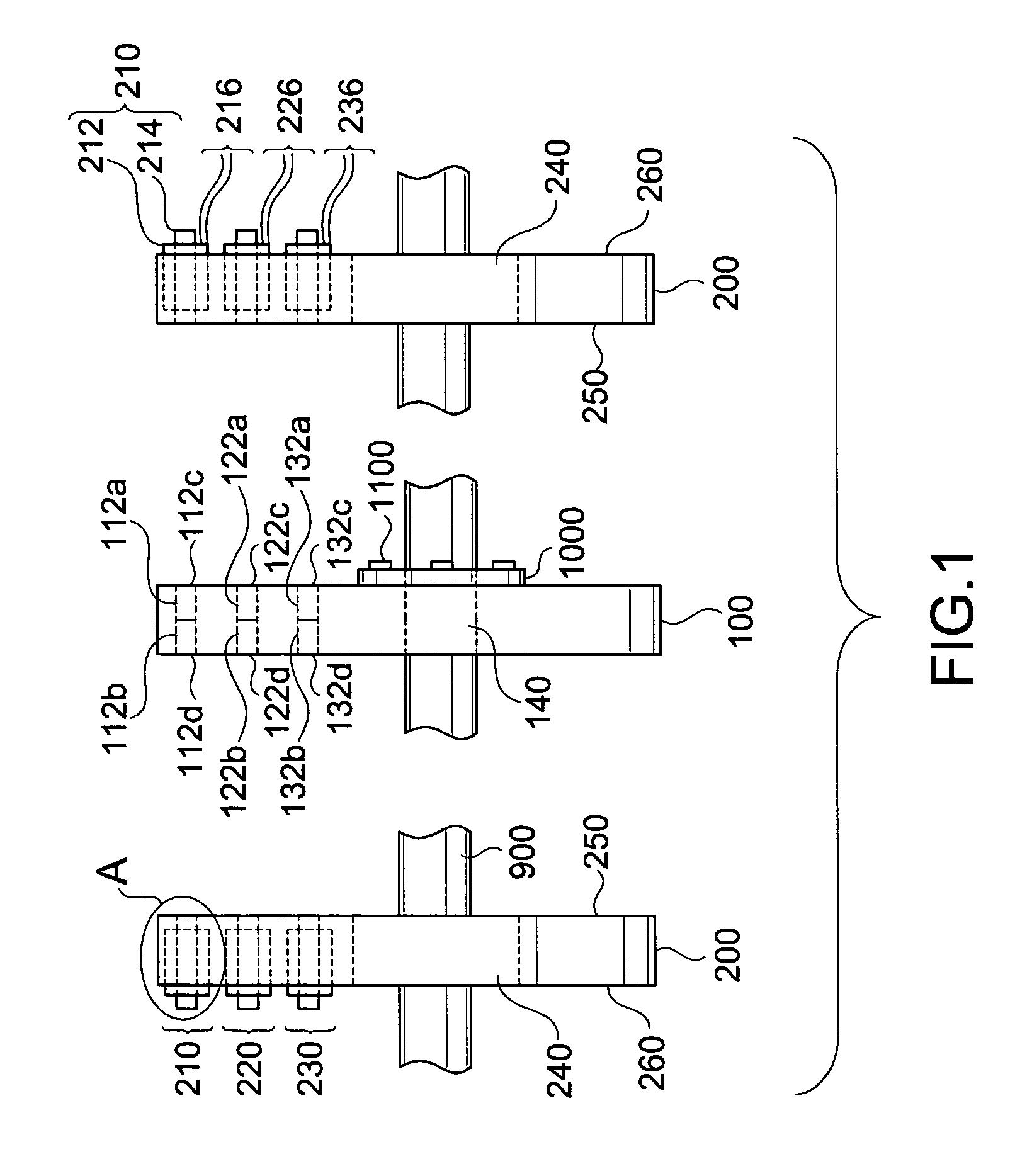

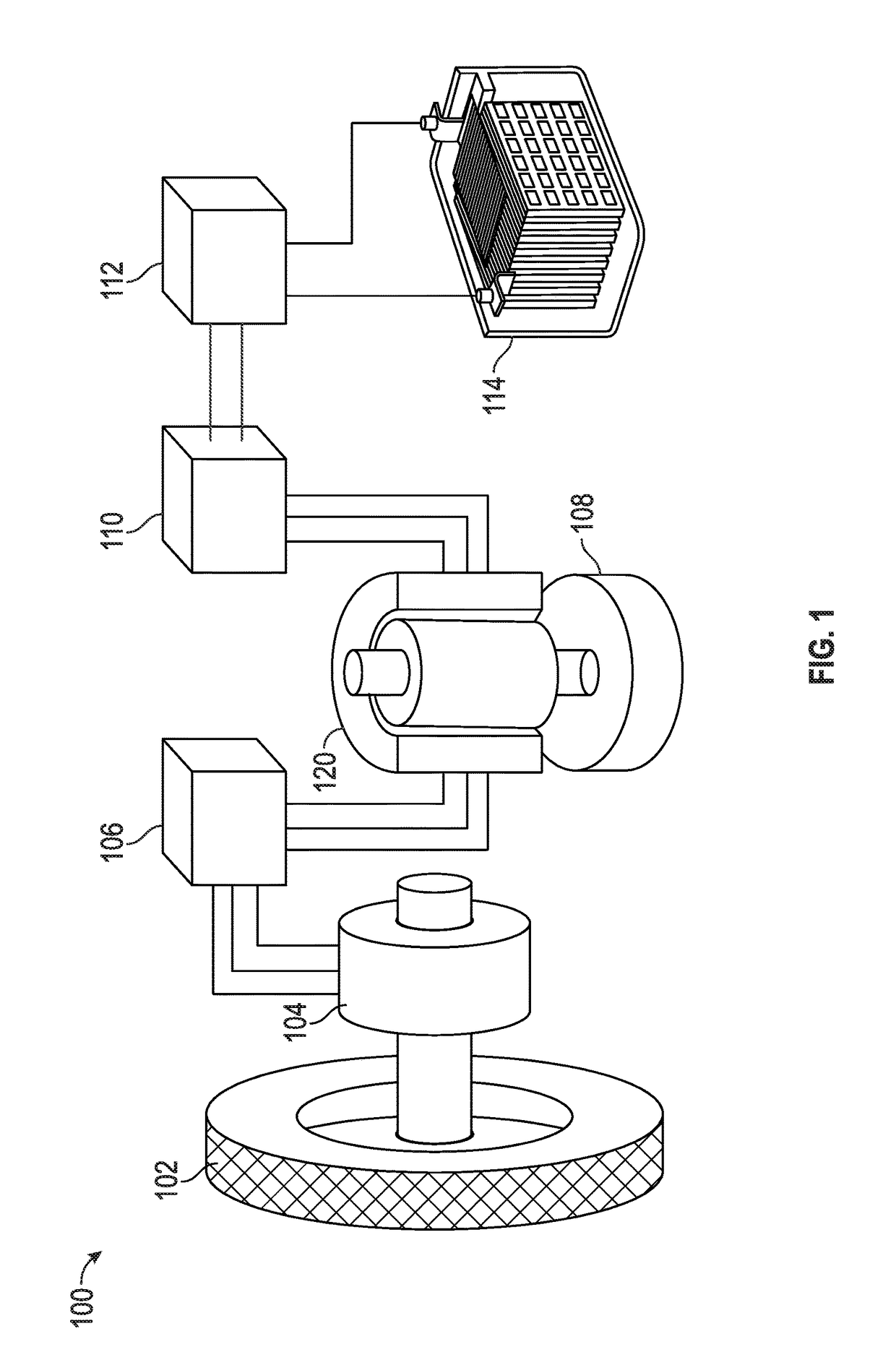

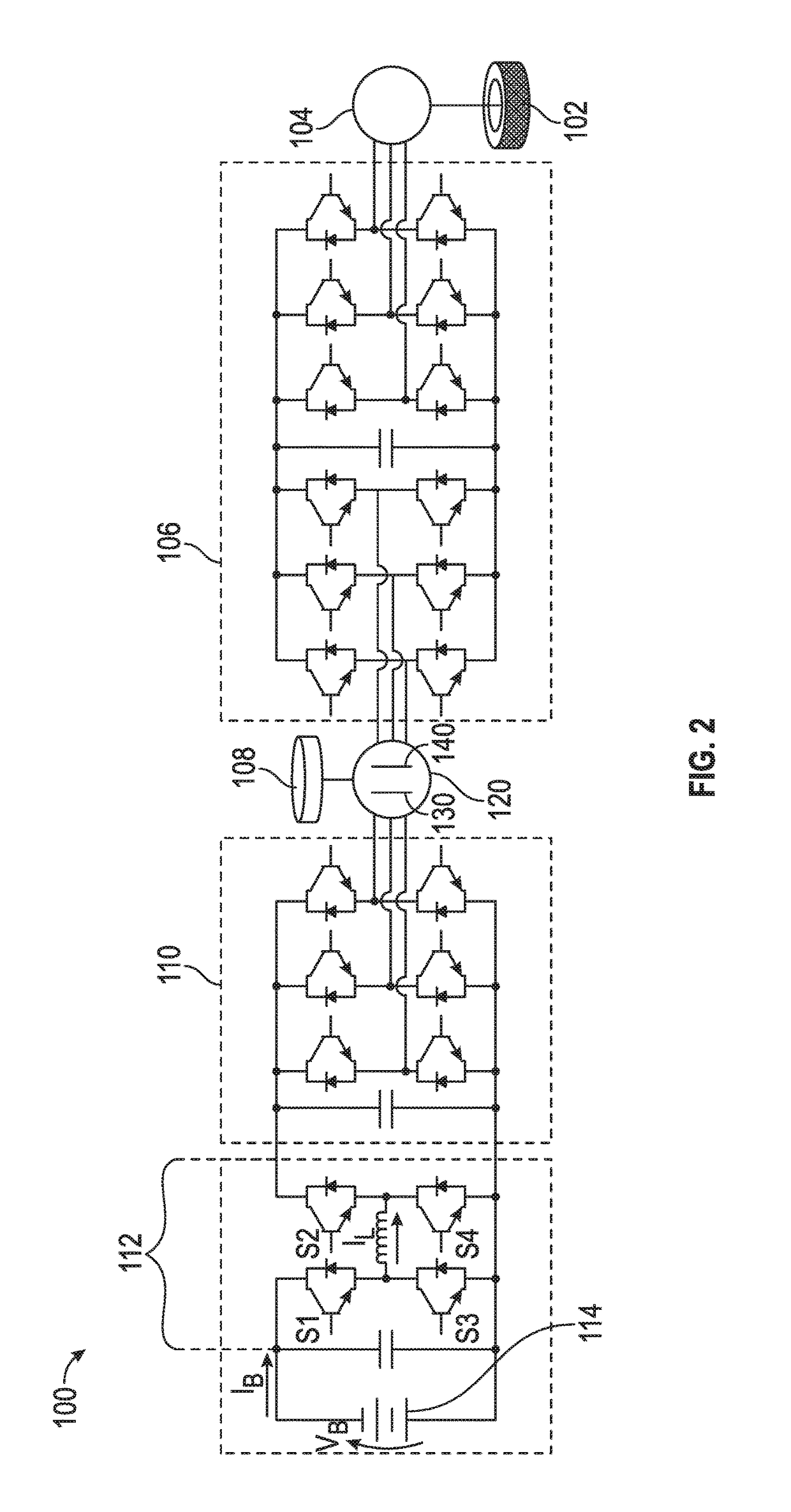

Motor-generator with multiple stator windings

ActiveUS20170163114A1AC/AC convertorsPlural diverse prime-mover propulsion mountingConductor CoilDynamo

A motor-generator includes a stator disposed along a centerline including a stator pole, a first stator winding and a second stator winding, wherein the first stator winding is wound on the stator pole and the second stator winding is wound on the stator pole, and at least one rotor axially disposed from the stator along the centerline.

Owner:HAMILTON SUNDSTRAND CORP

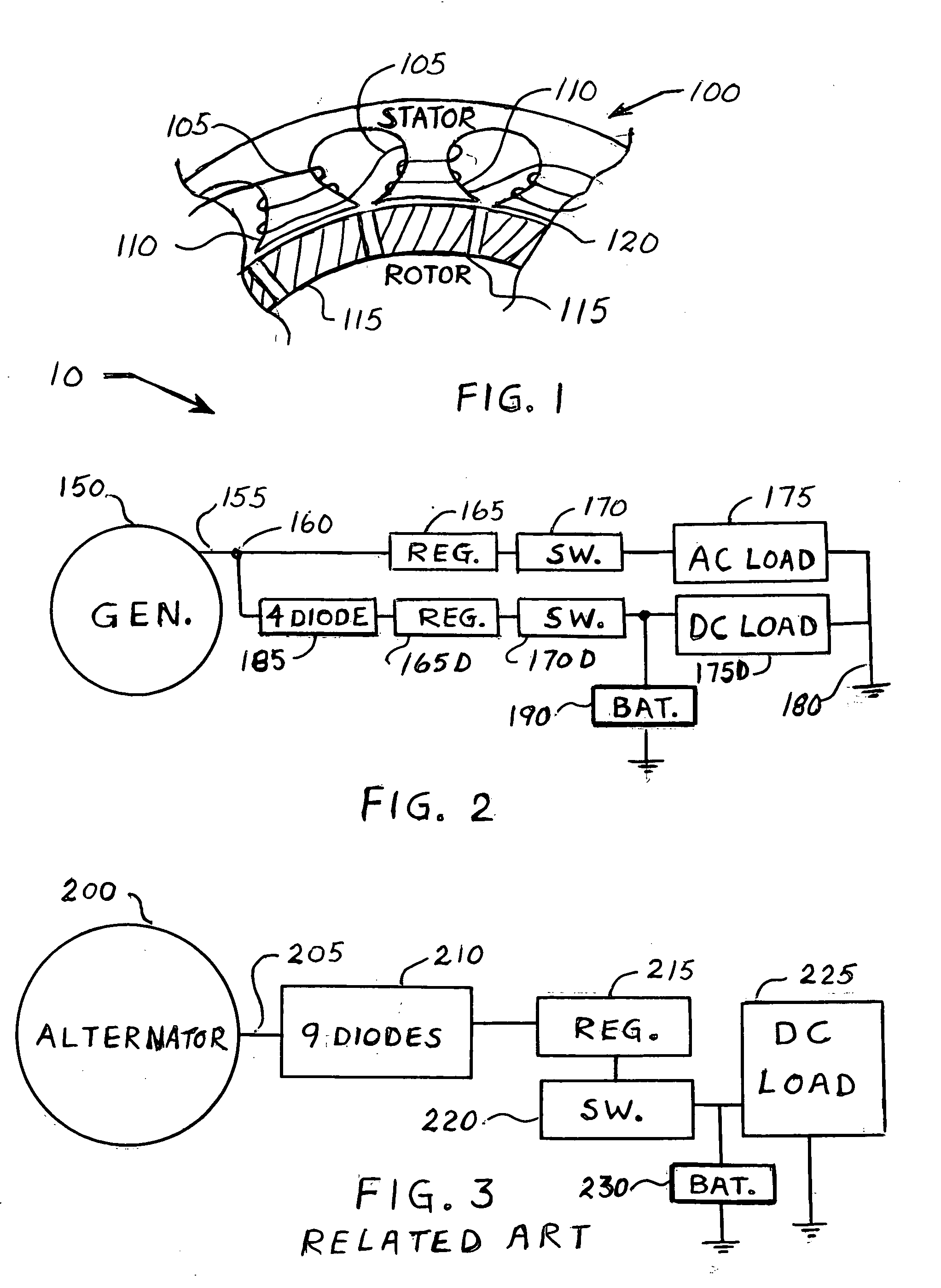

Generator with output options and low loss windings

InactiveUS20050127771A1Reliable and simpler and small and less-costlySimplify the generatorSynchronous generatorsWindingsElectricityElectrical resistance and conductance

A more fuel efficient automotive generator, then present alternators, because of its better magnetic utilization of its series connected copper windings on its salient stator poles. It also has output options for resistive loads as well as for direct current devises with both options designed for lower cost, smaller physical size, greater electrical efficiency and lower diode losses.

Owner:GERFAST STEN R

Alternator assembly

The stator (24) of a permanent magnet axial flux alternator comprises two annular stator components which are each wound with a respective two phase winding arrangement (48). Each of the two phase winding arrangements (48) is wound so that there is no mutual inductance between the windings of each phase. Each phase of the two phase winding arrangements (48) wound on the two stator components has a high internal impedance and is for energising a respective high intensity lamp of a light tower.

Owner:CUMMINS GENERATOR TECH LTD

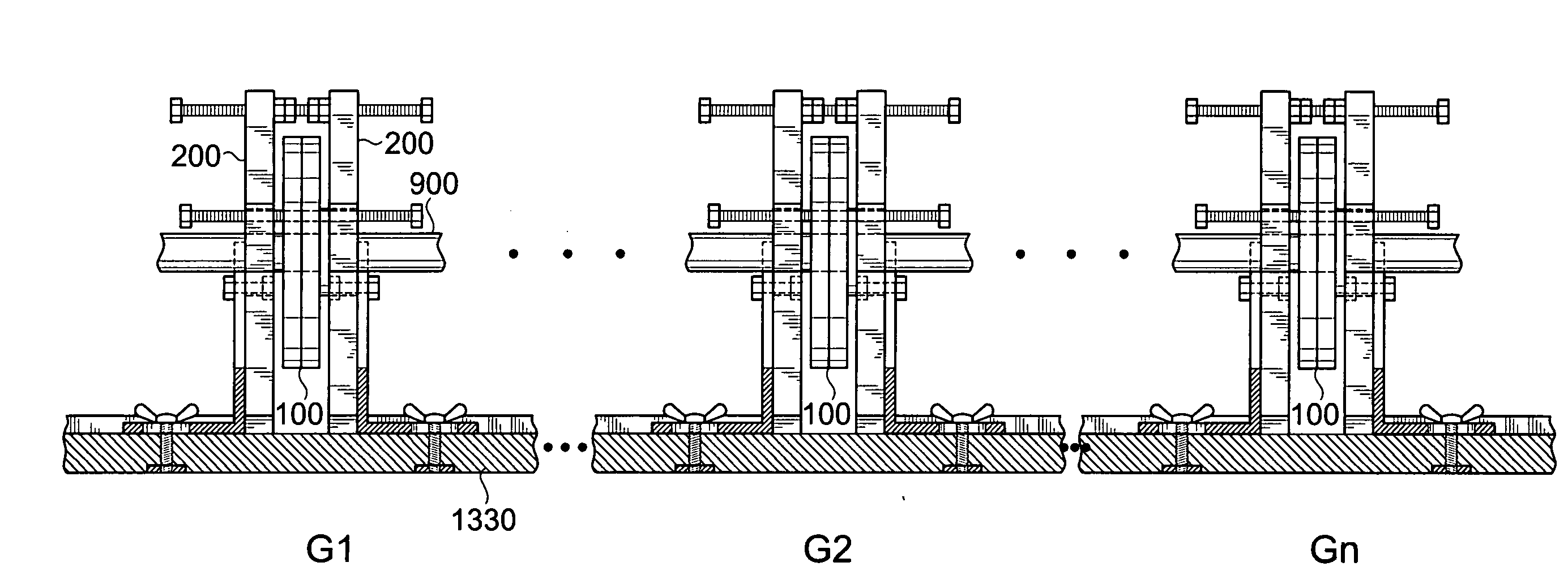

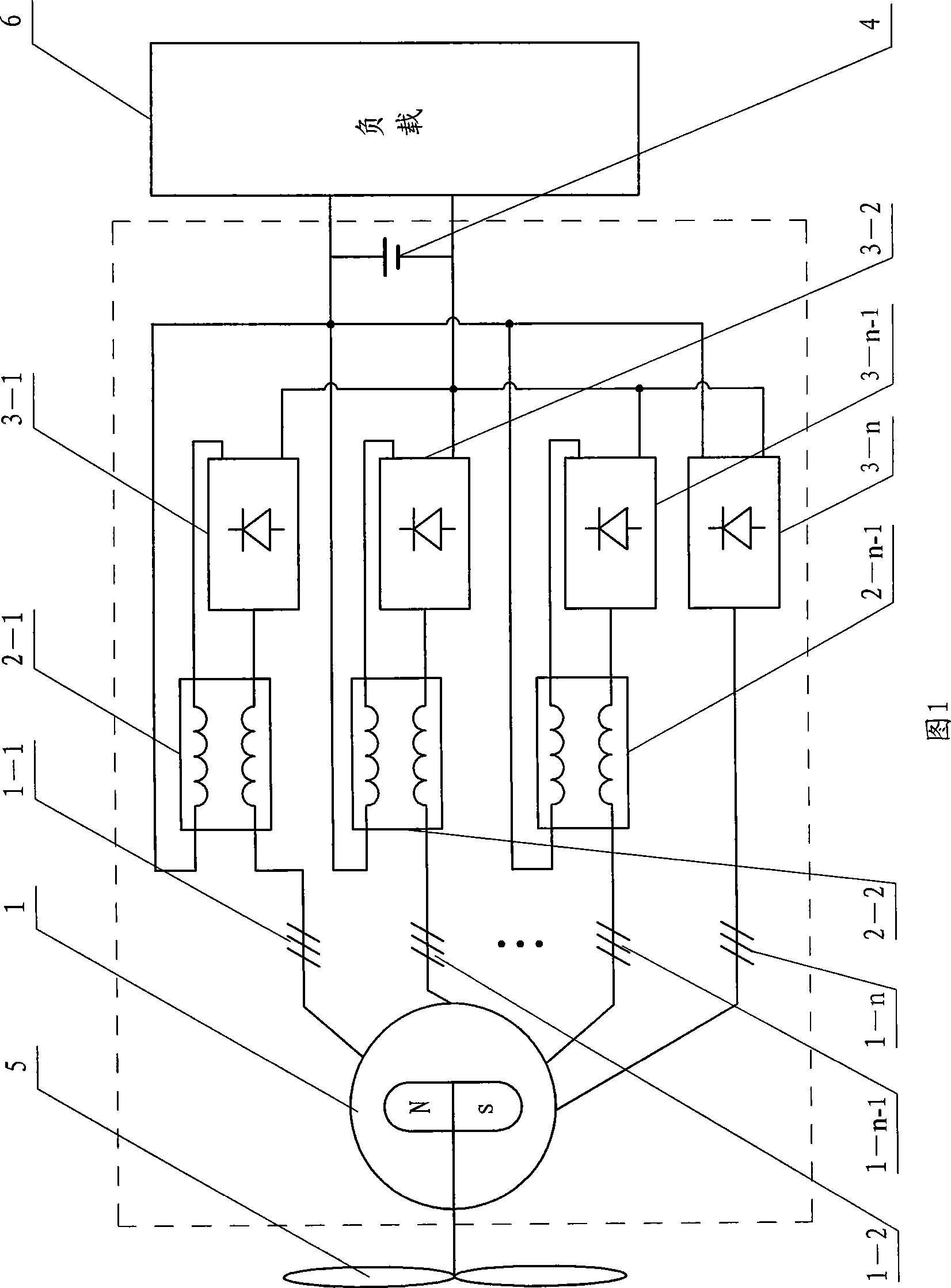

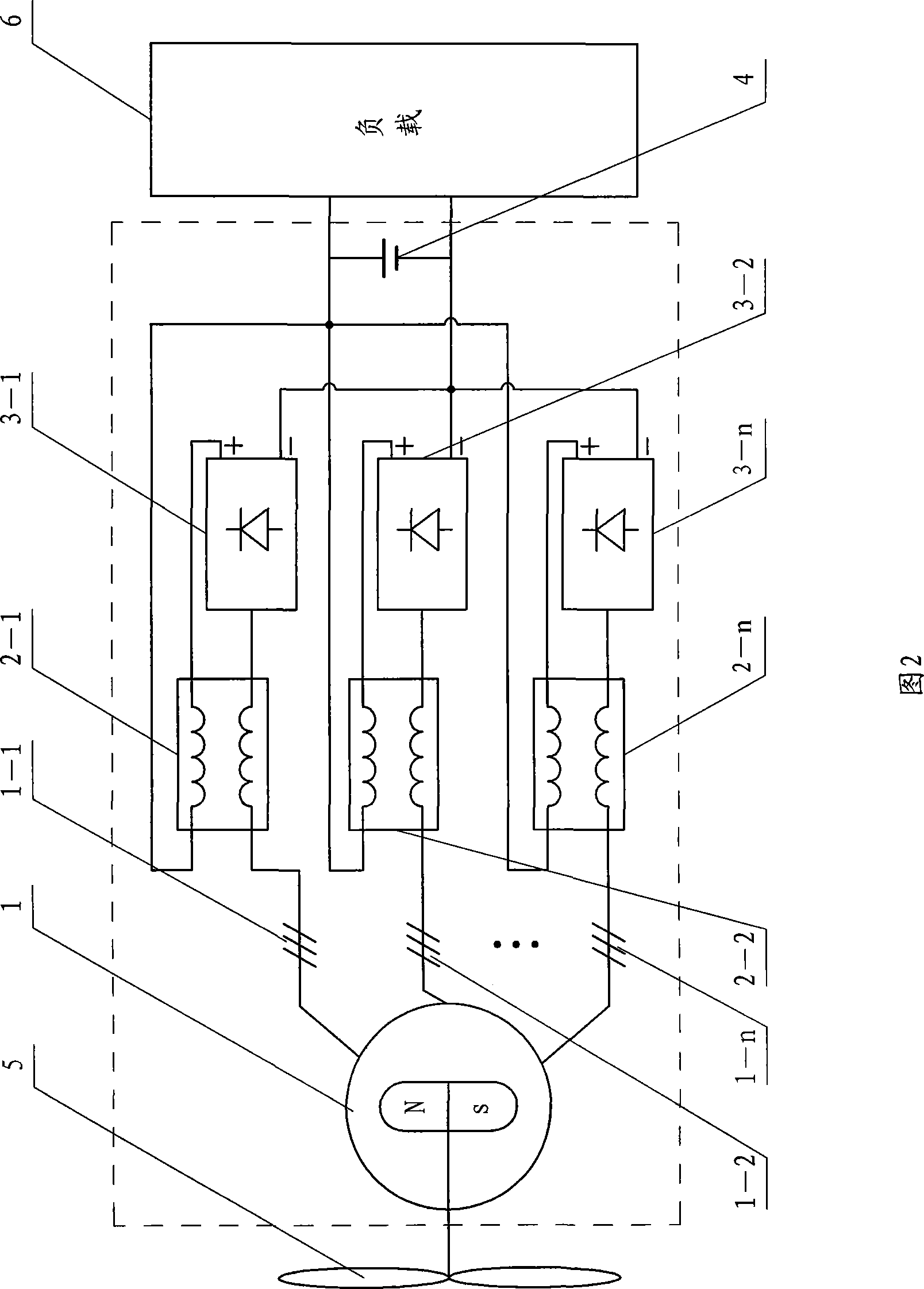

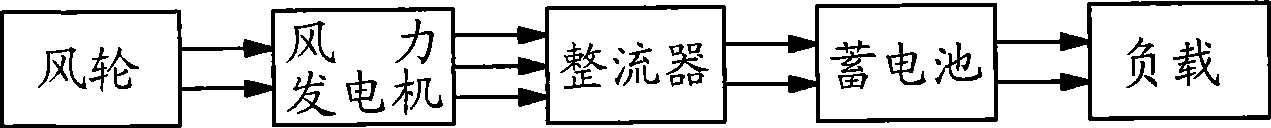

Passive control type wind power generation system capable of automatically tracking maximum wind energy

InactiveCN101378201ARealize automatic tracking controlSimple structureBatteries circuit arrangementsElectric powerEngineeringWind power system

A passive control-typed maximum wind energy automatic tracking wind power generating system belongs to the field of motors. The object of the invention is to solve the main problems existing in the out-of-grid type wind power generating system that the maximum wind capture, the maximum power control and the advantages of simple control, small technical difficulty, low cost and high reliability can not be realized simultaneously. The wind power generating system comprises a permanent magnet generator, n-1 reactors, n rectifiers and a DC power, wherein, the permanent magnet generator is provided with n sets of winding; the first n-1 sets of winding are respectively connected with the AC winding of the n-1 reactors in series, and then respectively and correspondingly connected with the n-1 rectifiers; the nth set of winding is directly connected with the nth rectifier; the DC winding of the n-1 reactors are respectively connected at the anode output terminal of the first n-1 rectifiers in series; and the n rectifiers are connected at the two ends of DC power after connecting in parallel. The wind power generating system has simple structure, low cost, high efficiency, strong overload capacity and high reliability, and can achieve the maximum wind energy automatic tracking control of the wind power generating system.

Owner:HARBIN INST OF TECH

Multipole magneto

InactiveCN1453921AHigh outputSynchronous generatorsMagnetic circuit shape/form/constructionConductor CoilMagneto

A multi-pole type magneto generator that can be operated while fully exerting its power generating capacity, can take out various voltage outputs, and is excellent in space efficiency. The multi-pole magneto generator comprises: a magnetic rotor (3), as an outer rotor; and a multi-pole stator (10), which is opposed to the radially inner surface of the magnetic rotor (3), for 10) The wound output winding (30) takes out the power generation output. The transformer core (21) has the primary winding (31) and the secondary winding (32, 33) wound thereon, and is arranged adjacent to the radially inner peripheral surface of the stator (10) away from the magnetic rotor (3), and outputs The winding (30) is connected to the primary winding (32) to take a transformed output from the secondary windings (32, 33).

Owner:HONDA MOTOR CO LTD

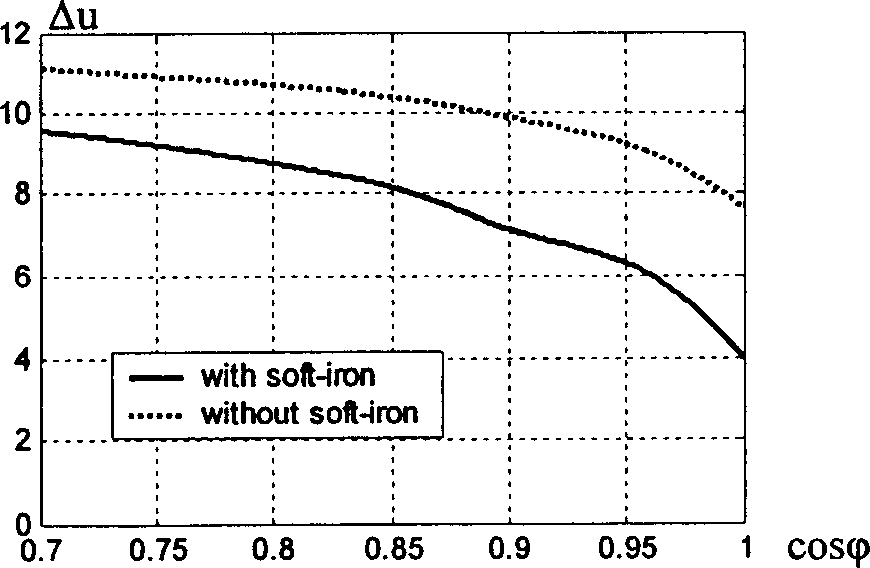

A.C./d.c permanent-magnet synchronous generator

InactiveCN1835354AImprove efficiencyImprove stabilitySynchronous machine detailsMagnetic circuit rotating partsElectricitySoft magnet

The stator of AC / DC permanent magnet generator includes three sets of winding in three phases. One set of winding is in use for providing AC power. Being in difference of 30 degrees of electrical angle each other, the other two sets of winding are connected to rectifier for supplying power for DC load. Rotor of generator is in surface recombination pole type structure. Magnetic pole is composed of permanent magnetic material of Rb-Fe-B and a soft magnetic material. Glass tape without woof is wrapped and fixed on rotor. A pole of permanent magnetism occupies 144 degrees of electrical angle. Being located at back pole tip on surface of magnetic pole, soft magnet occupies 9 degrees. The disclosed AC / DC permanent magnet synchronous generator possesses higher efficiency and better external characteristic.

Owner:SHANDONG UNIV

Permanent-magnet ac power generator

ActiveUS20160043601A1Reduce trafficReduce voltageMagnetic circuit rotating partsSynchronous generators with multiple outputsMagnetic polesEngineering

The present invention relates to a plurality windings of U phase corresponding to one magnetic pole including first and second windings wound in a short pitch winding manner. The winding starts of the first and second windings are shifted by at least one tooth. The windings are wound so that a winding angle occupied by the windings inter-slot angle from the winding start of the first winding to the winding end of the second winding corresponds to a pole angle. The windings in the V phase are disposed in the same relationship as in the U phase at the position delayed by an electric angle of 120 degrees with respect to the U phase, and those in the W phase are disposed at the position delayed by an additional 120 degrees. The outputs of the windings are then each rectified, subsequently joined together and used by adding currents.

Owner:KAWAMURA MEGUMI

System and method for a programmable electric converter

ActiveUS20140265988A1Association with control/drive circuitsMotor/generator/converter stoppersRegenerative brakeAbsorbed energy

An electric converter is provided which uses independently controlled field coils to impress a temporary magnetic field on a rotor movable relative to one or more armatures. In some embodiments, the rotor of the programmable electric converter is rotatable with the axis of rotation being on a horizontal or vertical axis. In various embodiments, the electric converter disclosed herein may be adapted for use as a continuous power solution to provide power for a limited period of time in the event of a power outage by absorbing energy and storing it mechanically in the rotor. In some embodiments, the electric converter may be utilized as a generator. In some embodiments, both AC and DC could be simultaneously produced, where AC is generated in one armature coil and DC in another coil. In some embodiments, the programmable electric converter can operate as an AC to AC converter, AC to DC converter, DC to AC converter, or DC to DC converter. In some embodiments, the electro-magnetic converter may be utilized to provide electro-magnetic propulsion to provide precise acceleration profiles and capture regenerative braking energy.

Owner:ACME PROD DEV

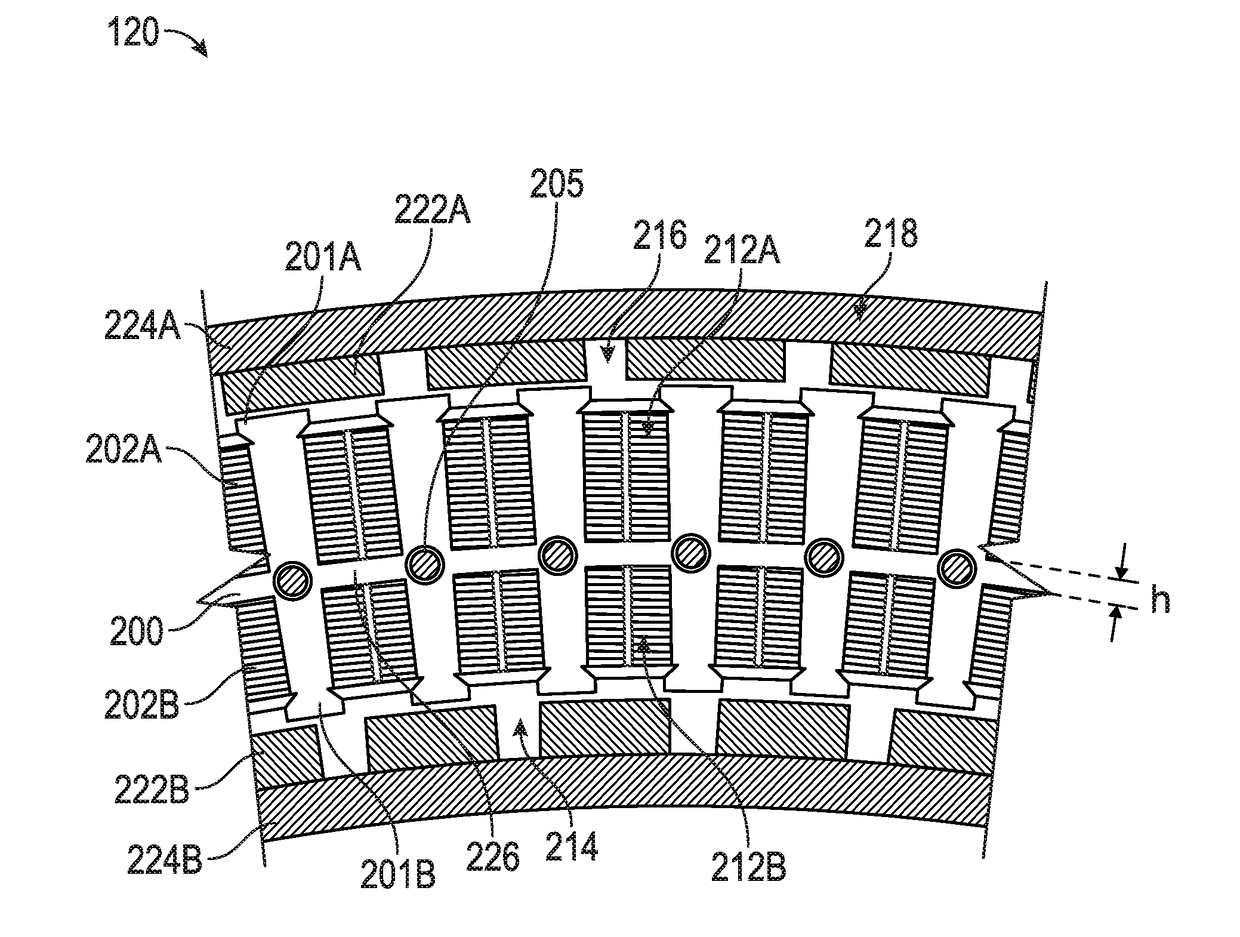

Motor-generator with radial-flux double-sided stator

ActiveUS20180034353A1Magnetic circuit rotating partsMagnetic circuit stationary partsConductor CoilDynamo

A motor-generator includes a double-sided stator having a first stator pole wound with a first stator winding of a first channel and a second stator pole wound with a second stator winding of a second channel. The first stator pole and the second stator pole are axially aligned with respect to a centerline of the motor-generator and radially offset between a radially inner side and a radially outer side of the double-sided stator. The motor-generator also includes at least one rotor radially disposed from the double-sided stator with respect to the centerline of the motor-generator.

Owner:HAMILTON SUNDSTRAND CORP

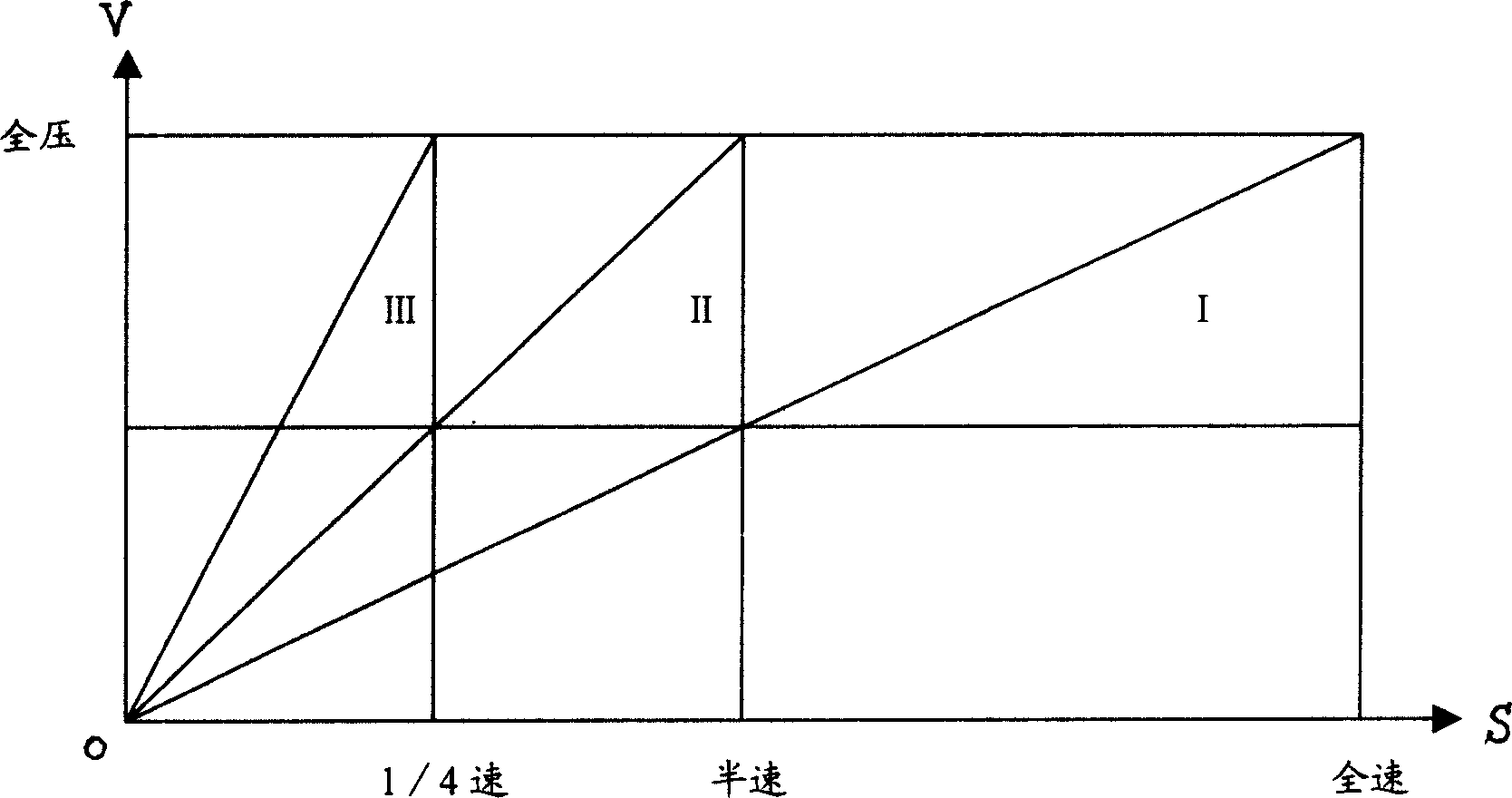

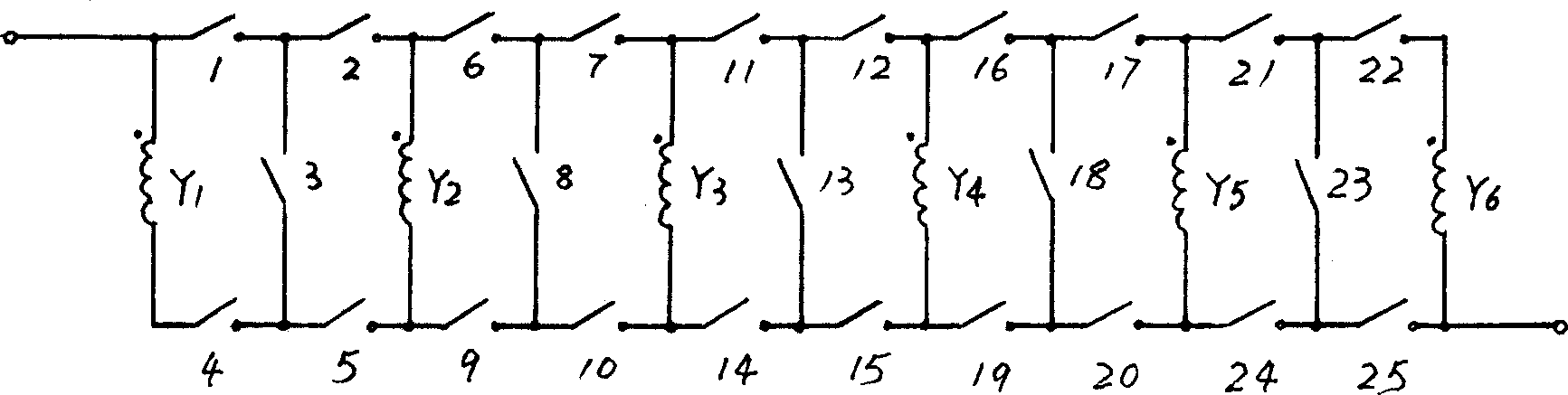

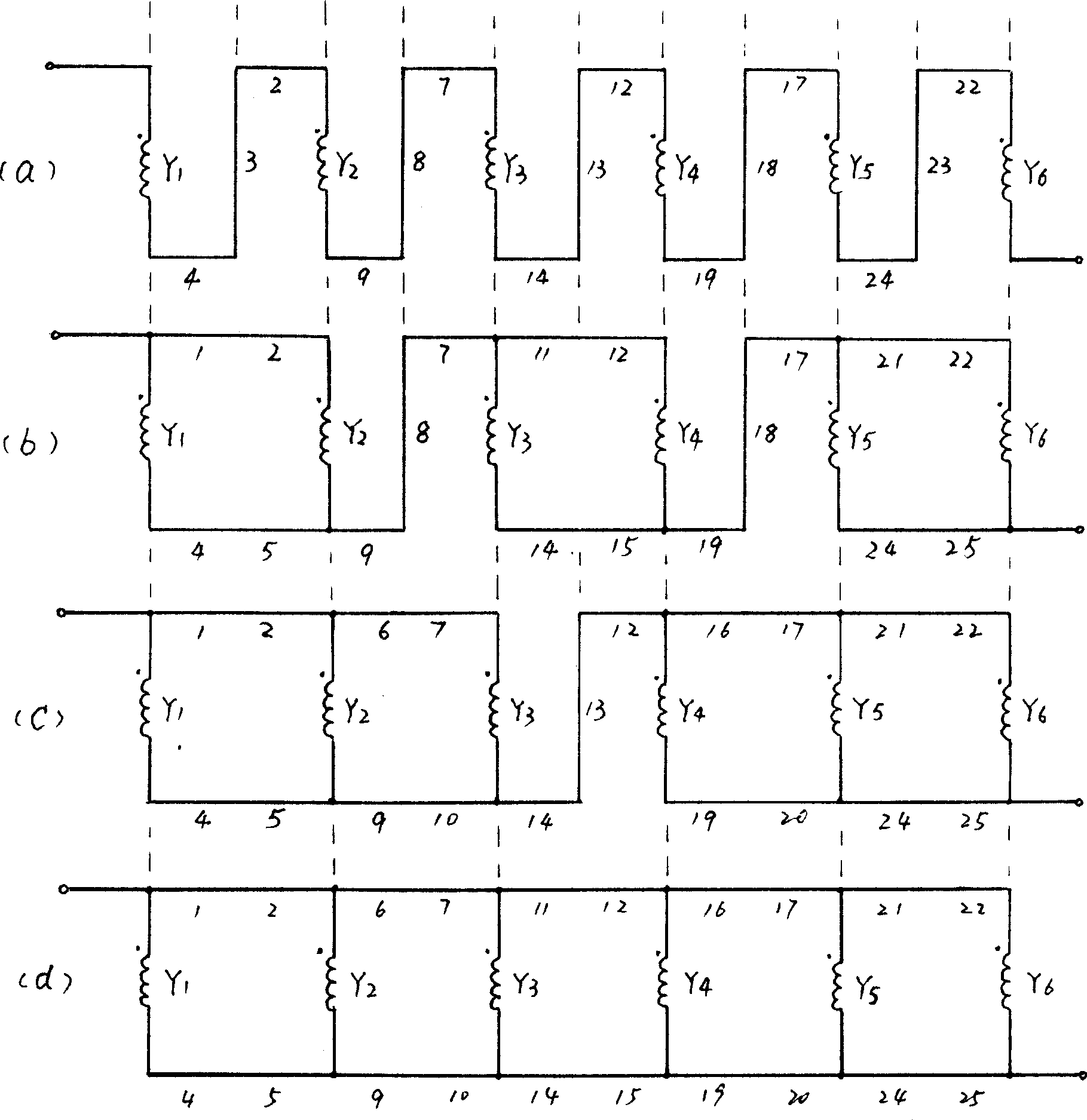

Point-divided full-voltage generation technology adapted to large range changes of rotating speed

InactiveCN1523733AImprove voltage utilizationMeet the needs of useSynchronous generatorsSynchronous generators with multiple outputsLow voltageUsability

This invention discloses a separated across-the-line generation technology suitable for large scale rotation variance aiming at solving the problem of narrow effective zone of the present generator output voltage and low voltage usability by separating the coil elements of a stator winding or sub-elements of the coil element into even parts in the same structures, each leading out independent connector groups, and between two adjacent parts, switch arrays of realizing their serial or parallel connection and same current direction of the same kind ends are designed. A generator output voltage corresponds a very large rotation effective zone in certain fluctuation sphere to increase the voltage usability.

Owner:原泽

Popular searches

Ac-dc conversion Arc welding apparatus Engine controllers Electric motor starters Generator control by field variation Windings conductor shape/form/construction Engine components Synchronous machines with stationary armatures and rotating magnets Association for rectification Power conversion systems

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com