Passive control type wind power generation system capable of automatically tracking maximum wind energy

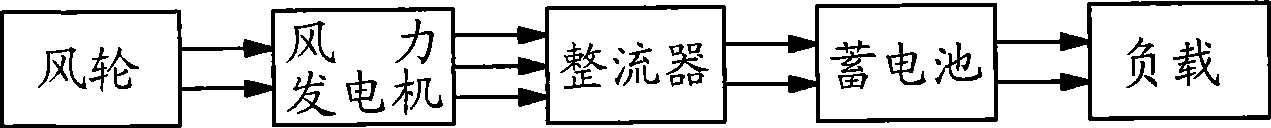

A technology for wind power generation systems and maximum wind energy, applied in control systems, control generators, collectors, etc., can solve the problems of not taking into account the maximum wind energy capture at the same time, low technical difficulty, simple control, etc., to achieve simple structure, high efficiency, The effect of strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

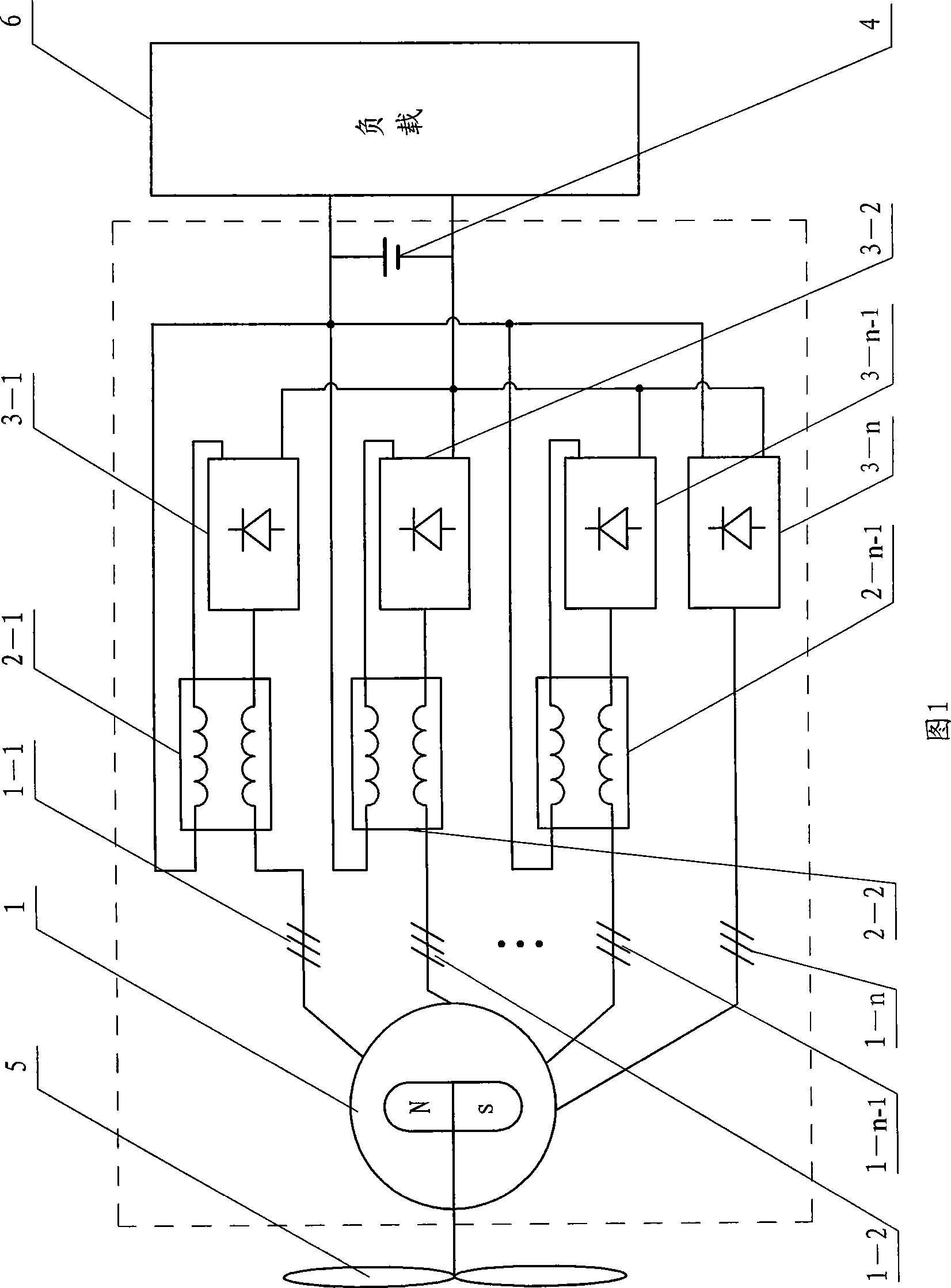

[0014] Specific Embodiment 1: The present embodiment will be described below in conjunction with FIG. 1. This embodiment includes a permanent magnet generator 1, n-1 reactors (2-1, 2-2...2-n-1), and n rectifiers (3-1, 3-2...3-n-1 and 3-n) and DC power supply 4, permanent magnet generator 1 has n sets of windings (1-1, 1-2...1-n-1 and 1—n),

[0015] The first winding 1-1 is connected to one end of the AC winding of the first reactor 2-1, and the other end of the AC winding of the first reactor 2-1 is connected to the input end of the first rectifier 3-1, and the first rectifier 3 The positive output end of -1 is connected to one end of the DC winding of the first reactor 2-1, the other end of the DC winding of the first reactor 2-1 is connected to the positive pole of the DC power supply 4, and the negative pole of the first rectifier 3-1 The output terminal is connected with the negative pole of the DC power supply 4,

[0016] The second winding 1-2 is connected to one end o...

specific Embodiment approach 2

[0021] Specific implementation mode two: the following combination Figure 4 and Figure 5 This embodiment is described. The difference between this embodiment and Embodiment 1 is that the impedance values of the first reactor 2-1 to the n-1th reactor 2-n-1 decrease by 20% to 80% sequentially, and other components and The connection mode is the same as that in Embodiment 1.

[0022] n reactors (2-1, 2-2...2-n) are adjustable reactors, such as Figure 4 As shown, the core of the reactor is in the shape of "Tian", and the core columns on both sides of each reactor are wound with DC windings Nc1, Nc2, Nc3 and Nc4, and the coils of Nc1 and Nc2 are wound on one side of the core column. On the contrary, the coils of Nc3 and Nc4 wound on the other side of the stem are opposite to each other, and the two output terminals of Nc1, Nc2, Nc3 and Nc4 connected in series are respectively connected to a corresponding rectifier (3-1, 3-2 ...or 3—n) positive output end and load 6 positive...

specific Embodiment approach 3

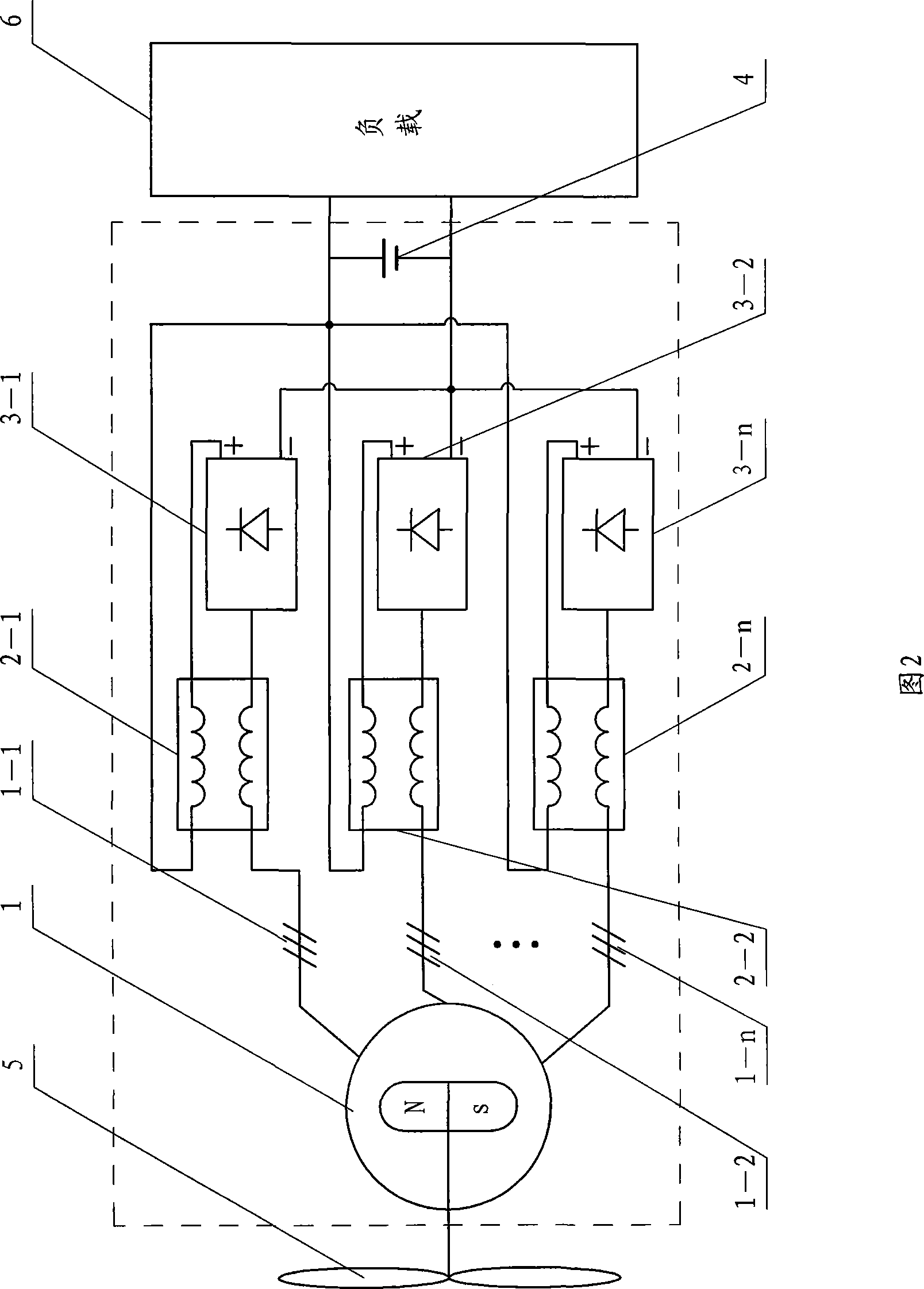

[0026] Specific embodiment three: below in conjunction with Fig. 2, Image 6 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes the nth reactor 2-n,

[0027] The n-th winding 1-n is connected to one end of the AC winding of the n-th reactor 2-n, and the other end of the AC winding of the n-th reactor 2-n is connected to the input end of the n-th rectifier 3-n, and the n-th rectifier 3 The positive output end of —n is connected to one end of the DC winding of the nth reactor 2—n, the other end of the DC winding of the nth reactor 2—n is connected to the positive pole of the DC power supply 4, and the negative pole of the nth rectifier 3—n The output end is connected with the negative pole of the DC power supply 4 . Other composition and connection methods are the same as those in Embodiment 1.

[0028] like Image 6Shown is the output characteristic of the power generation system, and the curve L-out is the ideal state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com