Wide rotation speed range output permanent magnet constant speed generator system

A generator and wide speed technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc. Power control and other issues to achieve the effect of simple structure, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

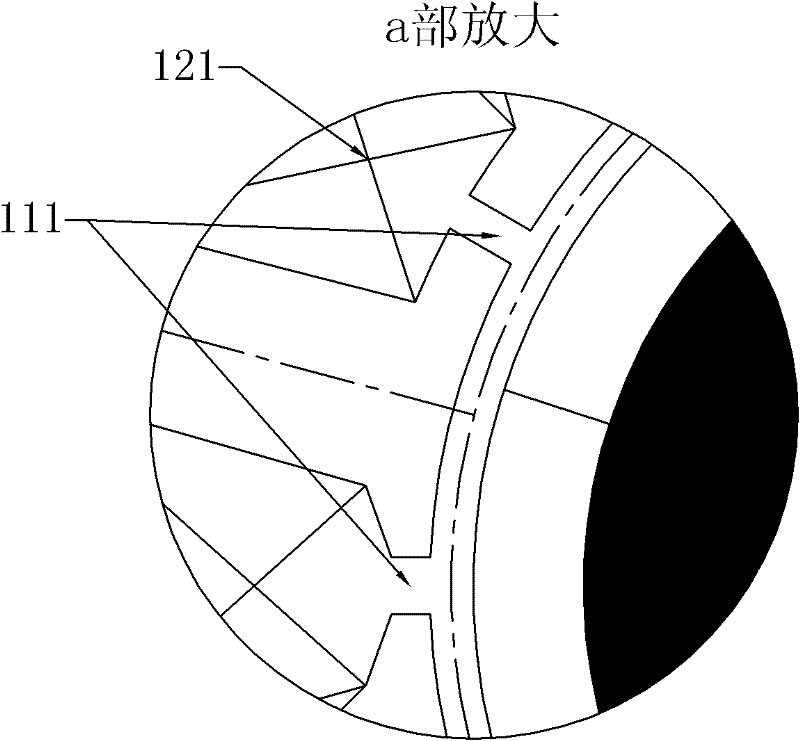

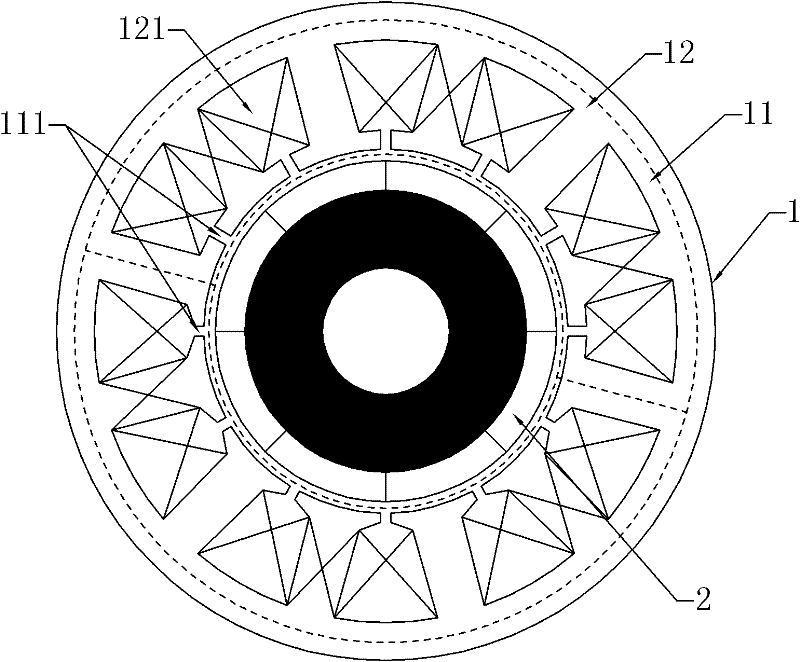

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the permanent magnet synchronous generator described in this embodiment is composed of a stator 1, a rotor 2 and an air gap, the stator 1 is composed of an armature core 11 and a winding 12, the number of slots and the number of teeth of the armature core 11 Both are 6n, and every other tooth is wound with a coil 121, wherein n is a positive integer, and n≥2; the winding 12 is a concentrated winding composed of 3n coils 121, and every adjacent 3n / j along the circumferential direction Coils 121 form a set of three-phase windings, that is, j sets of three-phase windings are formed for the 3n coils 121, wherein n is an integer multiple of j, and j≠1, each set of three in the j sets of three-phase windings The number of turns of each coil 121 in the phase windings is the same, and the number of turns of the coils 121 between the j sets of three-phase windings is different; the output e...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the slot width of the slot where the coil with multiple turns is located is 0.2 to 1.0 times the slot width of the slot where the coil with few turns is located, and the slot width of the slot where the coil with multiple turns is located The notch depth is 1.0-5.0 times of the notch depth of the slot where the coil with few turns is located. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the width of the teeth with coils is different from that of teeth without coils. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com