A tracking control method for the main vapor pressure of a circulating fluidized bed for biomass heat and power cogeneration

A circulating fluidized bed and main steam pressure technology, applied in fluidized bed combustion equipment, combustion methods, lighting and heating equipment, etc., can solve the problems of complex application process and complex online calculation, and achieve simple online implementation and improved control Horizontal, design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

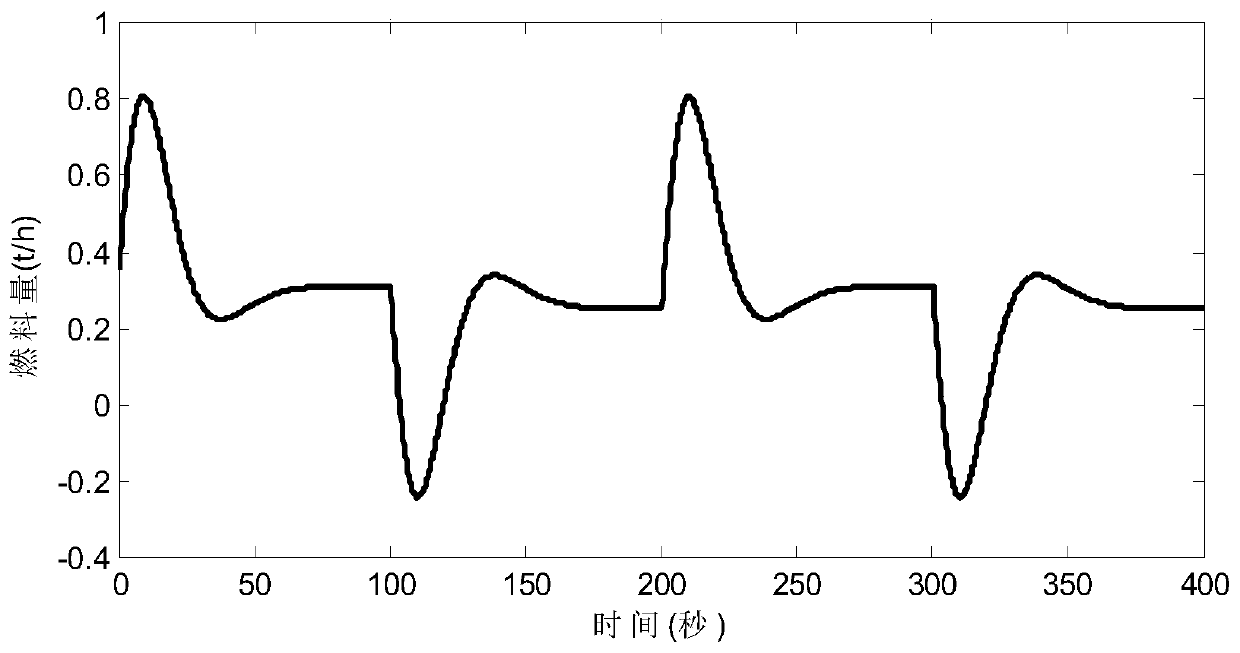

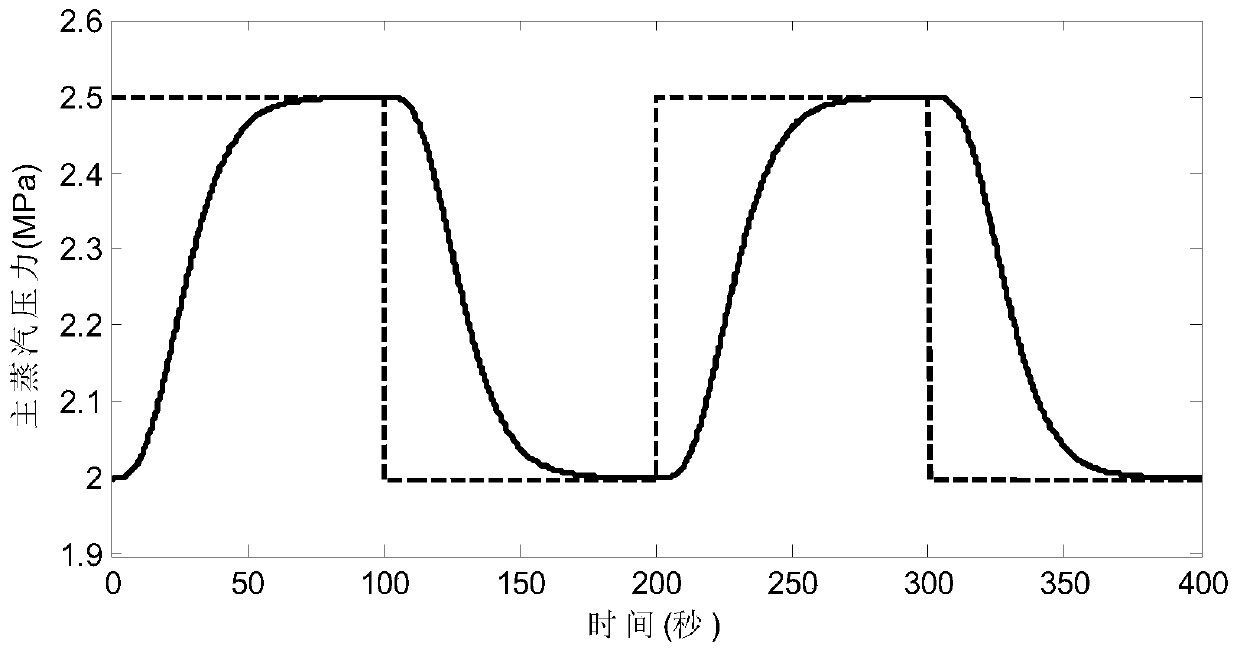

[0032] refer to figure 1 and figure 2 , a biomass heat and power cogeneration circulating fluidized bed main vapor pressure tracking control method, the method comprises the following steps:

[0033] 1) Consider the third-order differential equation of the main vapor pressure of the biomass cogeneration circulating fluidized bed and the amount of biomass fuel, see formula (1):

[0034]

[0035] Among them, t represents the time variable; P represents the main vapor pressure variable of the circulating fluidized bed, MPa; u represents the amount of biomass fuel used for combustion, t / h; "·", "··" and "···" respectively Represents the first derivative, second derivative and third derivative of the main vapor pressure; the constant G represents the steady-state gain of the main vapor pressure of the circulating fluidized bed; the constant T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com