Automobile permanent magnet generator with tiny output voltage ripple

A technology for permanent magnet generators and automobiles, applied to multi-output synchronous motors, control generators, electrical components, etc., can solve problems such as large output voltage ripples, achieve output ripple reduction, good low-speed power generation performance, and promote The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical invention will be further described below in conjunction with the accompanying drawings and embodiments.

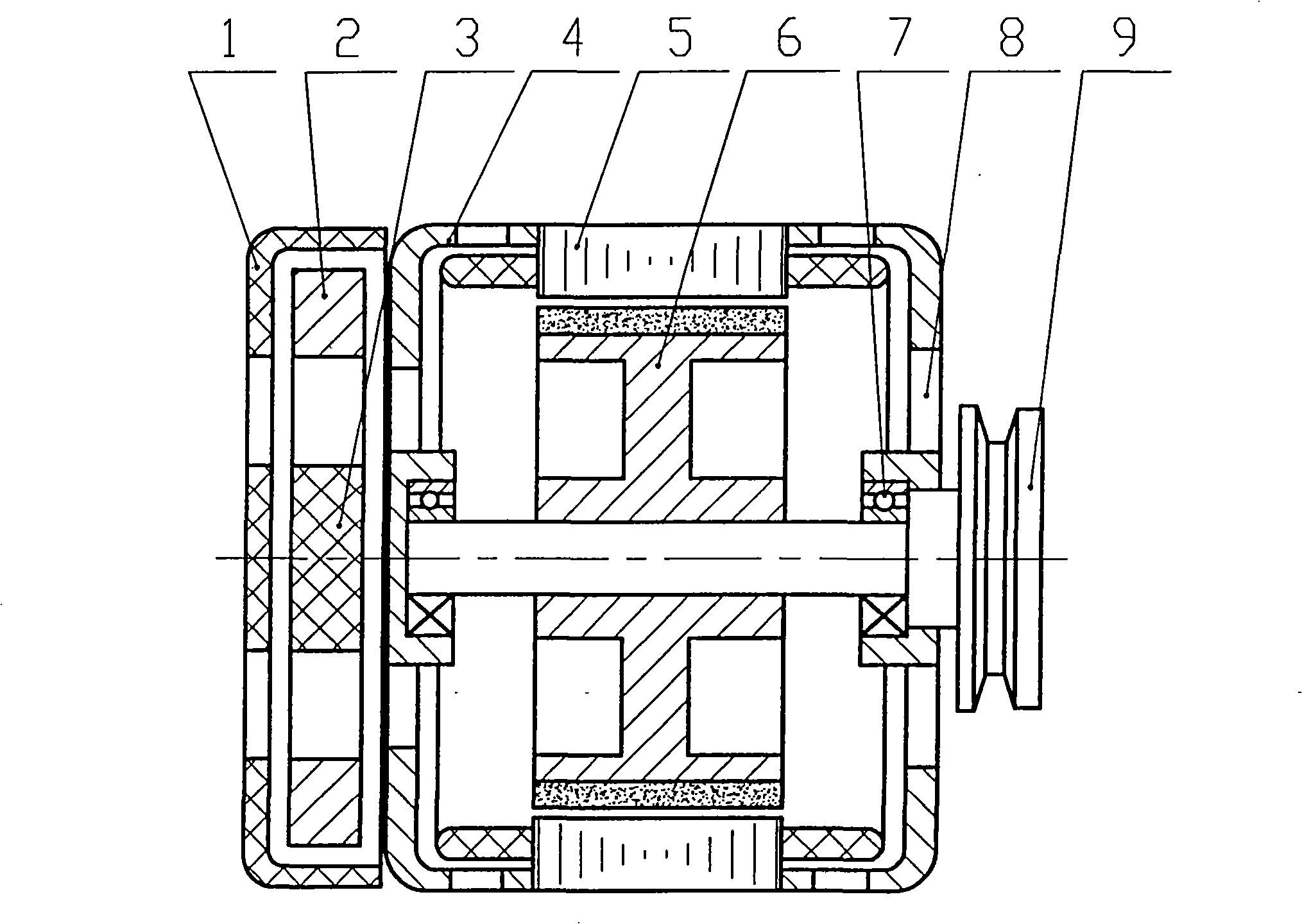

[0016] attached image 3 The automotive permanent magnet generator shown is mainly composed of a rear cover 1, a controllable rectifier 2, an electronic voltage regulator controller 3, a rear end cover 4, a stator 5, a permanent magnet rotor 6, a front cover 7, a bearing 8, and a pulley 9 When working, the belt pulley 9 drives the permanent magnet rotor 6 to rotate, and a three-phase AC voltage is induced on the winding of the stator 5. The controllable rectifier 2 adjusts the AC output of the stator 5 to a DC output, and the electronic voltage regulator controller 3 controls the controllable rectifier. The conduction angle of the thyristor on 2 makes the generator output a stable DC voltage.

[0017] attached Figure 4 is attached image 3 The electrical schematic diagram of the rectification circuit of the automobile permanent magnet generator sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com