Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about "Regenerators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal transfer internal combustion engine

A thermal transfer internal combustion engine with an air transfer cylinder located between a pair of power cylinders. The transfer cylinder has an intake valve and two transfer valves alternately feeding the two power cylinders. The power cylinders each contain a mono valve used for both intake and exhaust. Counter-flow manifolds connect the mono valves of the power cylinders to the transfer valves of the transfer cylinder. A regenerator with catalytic converter properties is located in each counter-flow manifold. The regenerator is heated by exhaust gases exiting the power cylinders, prior to exiting the engine through exhaust dump valves. Uncompressed intake air is pushed from the transfer cylinder through the regenerator where it is heated and delivered to the power cylinder for conventional processing. The heat recovery system provides high compression temperatures at low compression ratios, reducing engine fuel consumption.

Owner:WAIT IRVING S

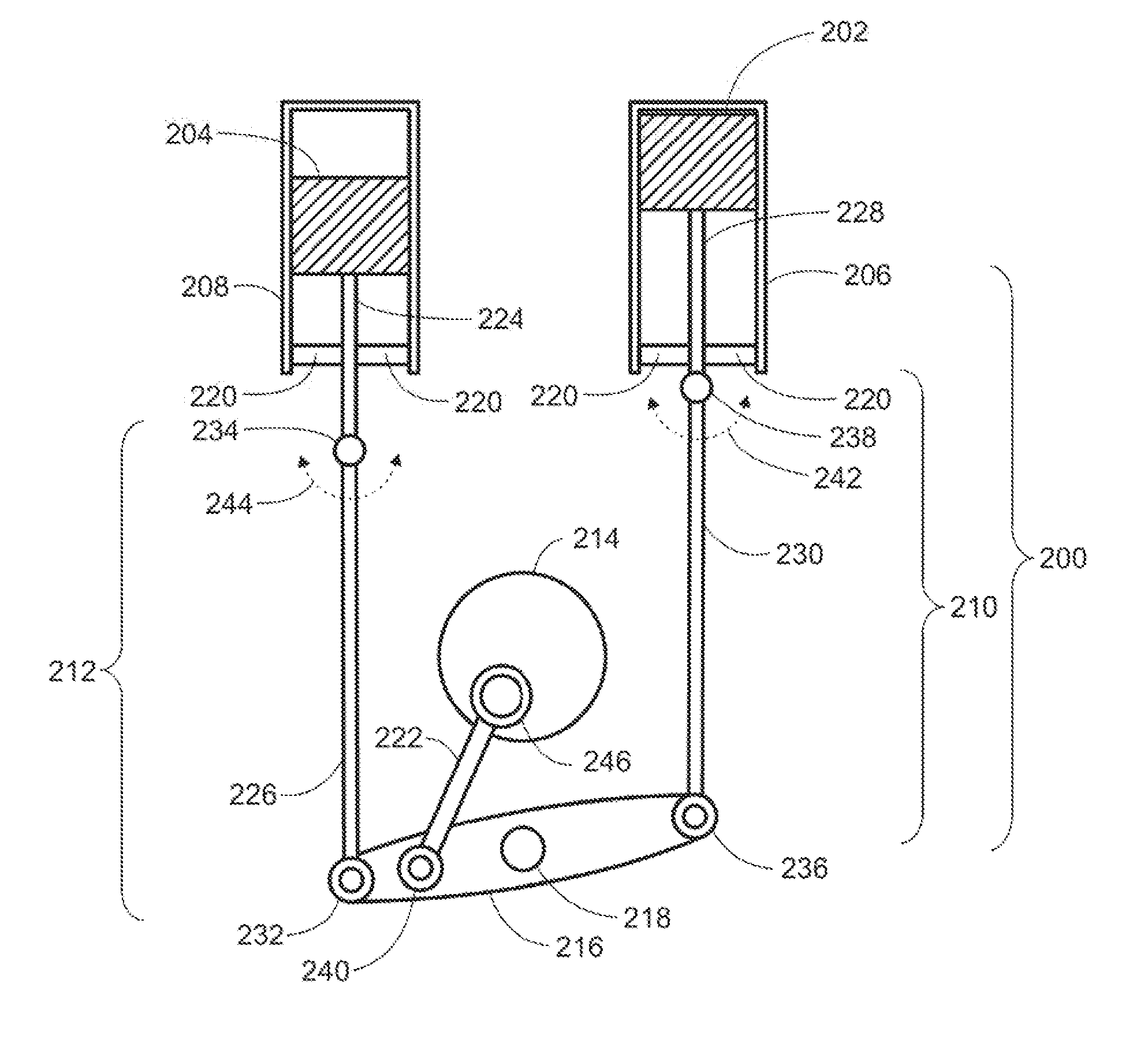

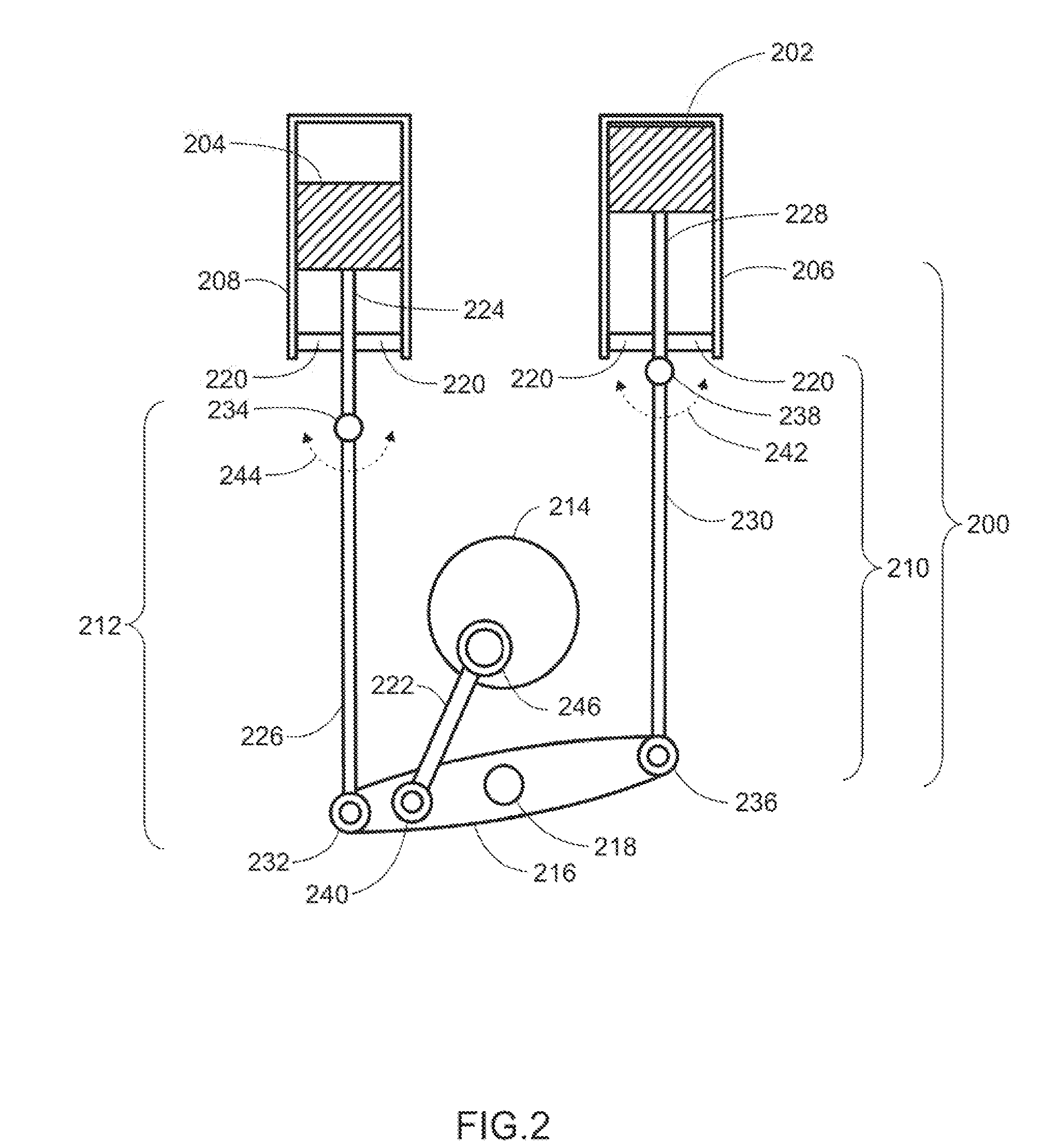

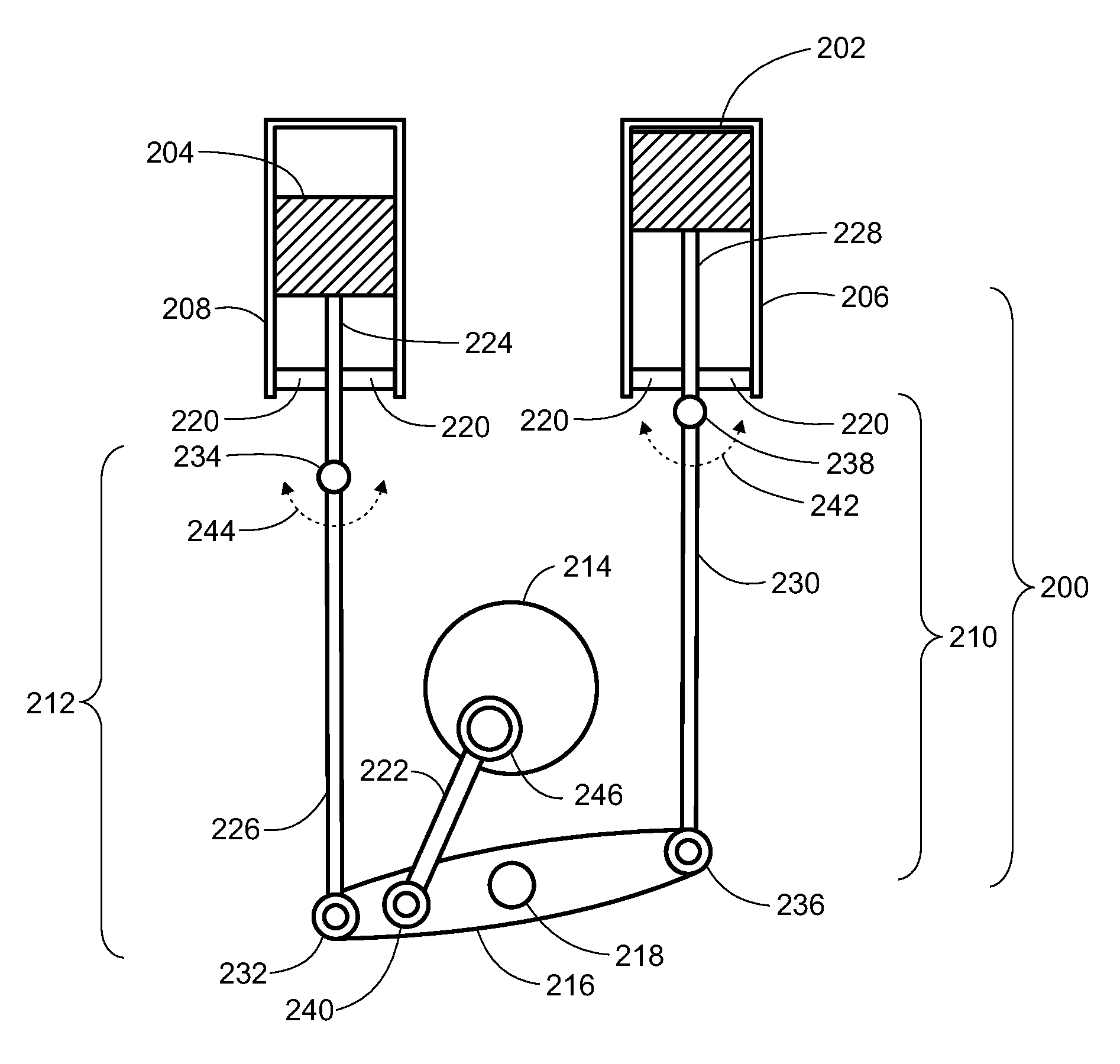

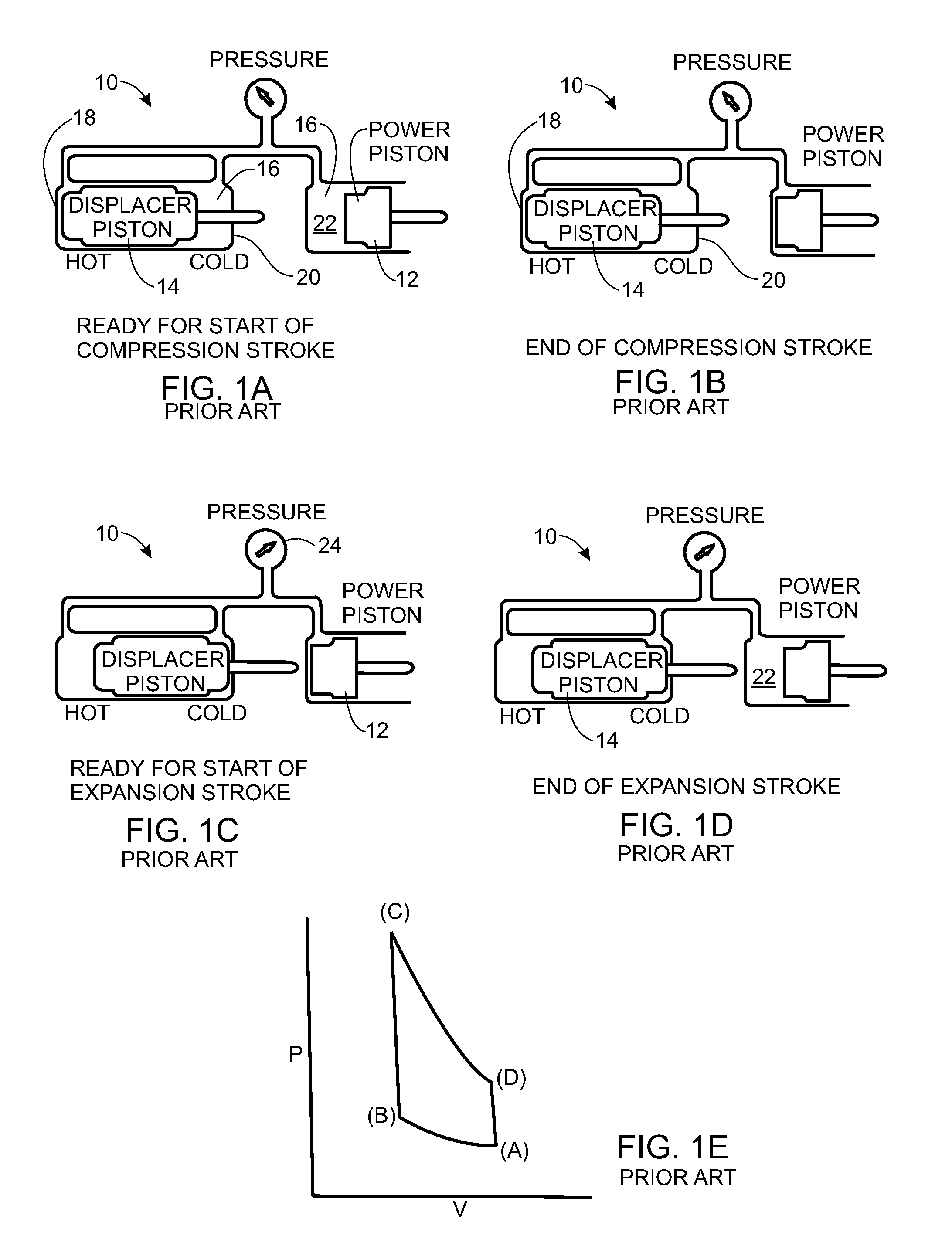

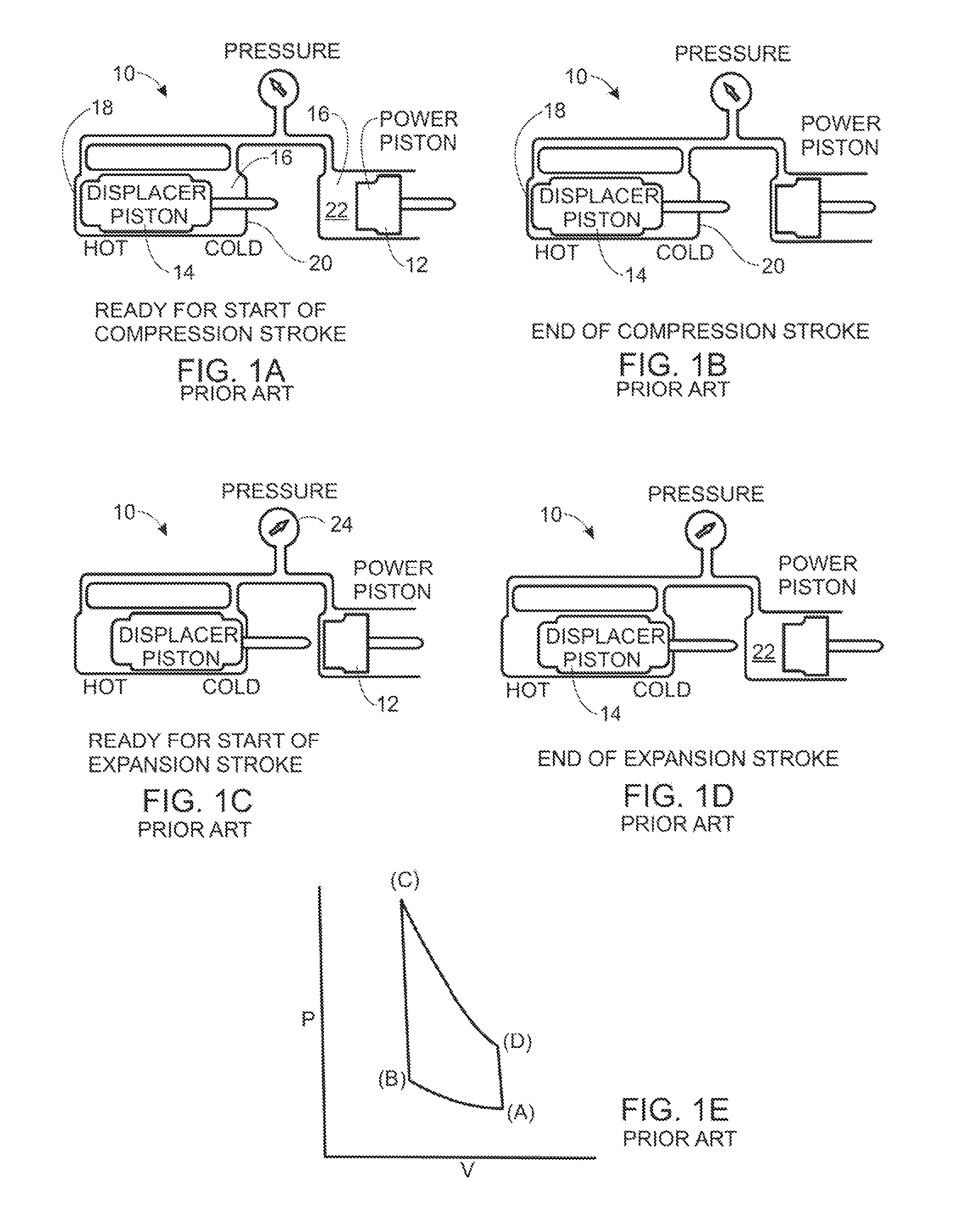

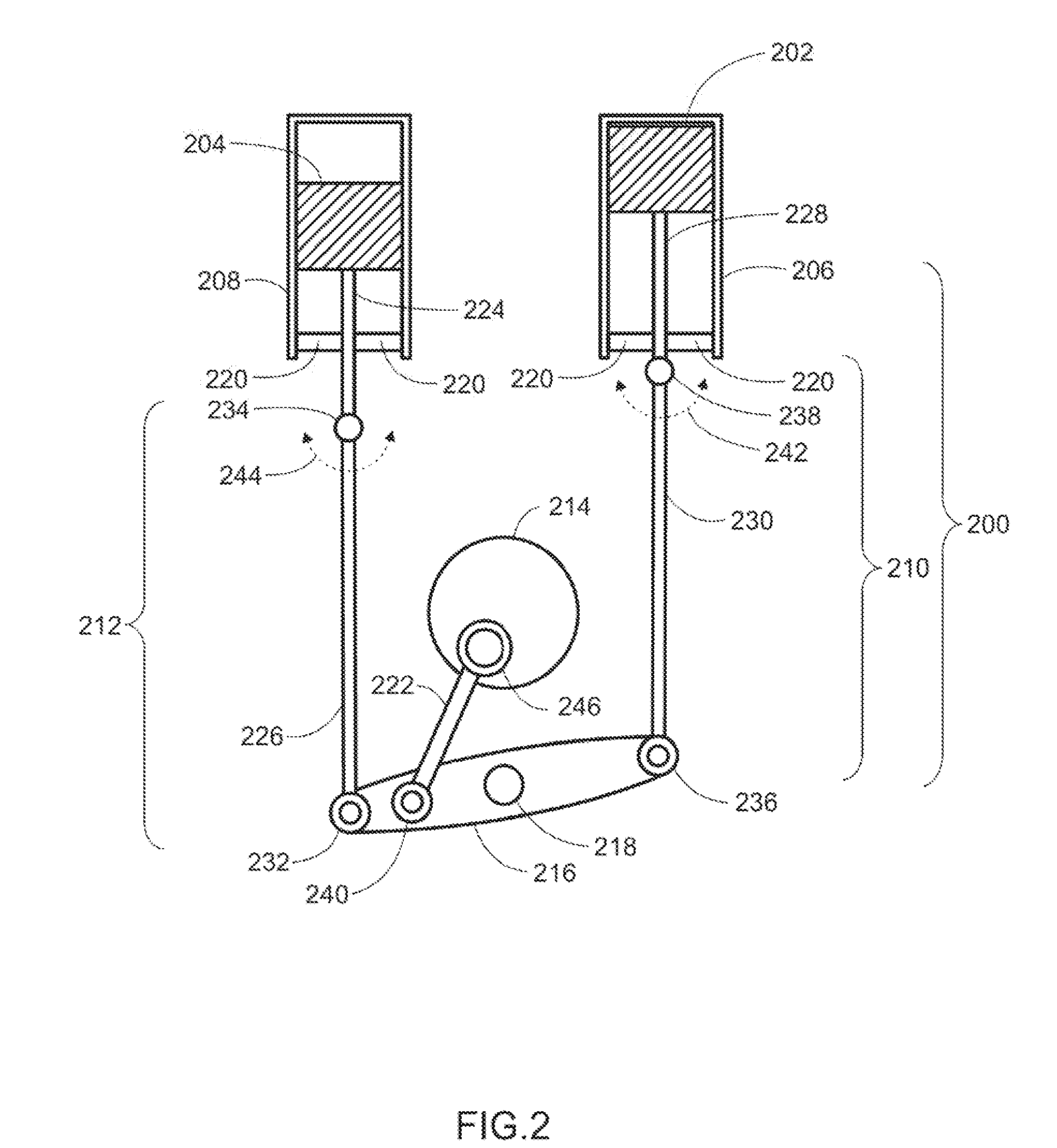

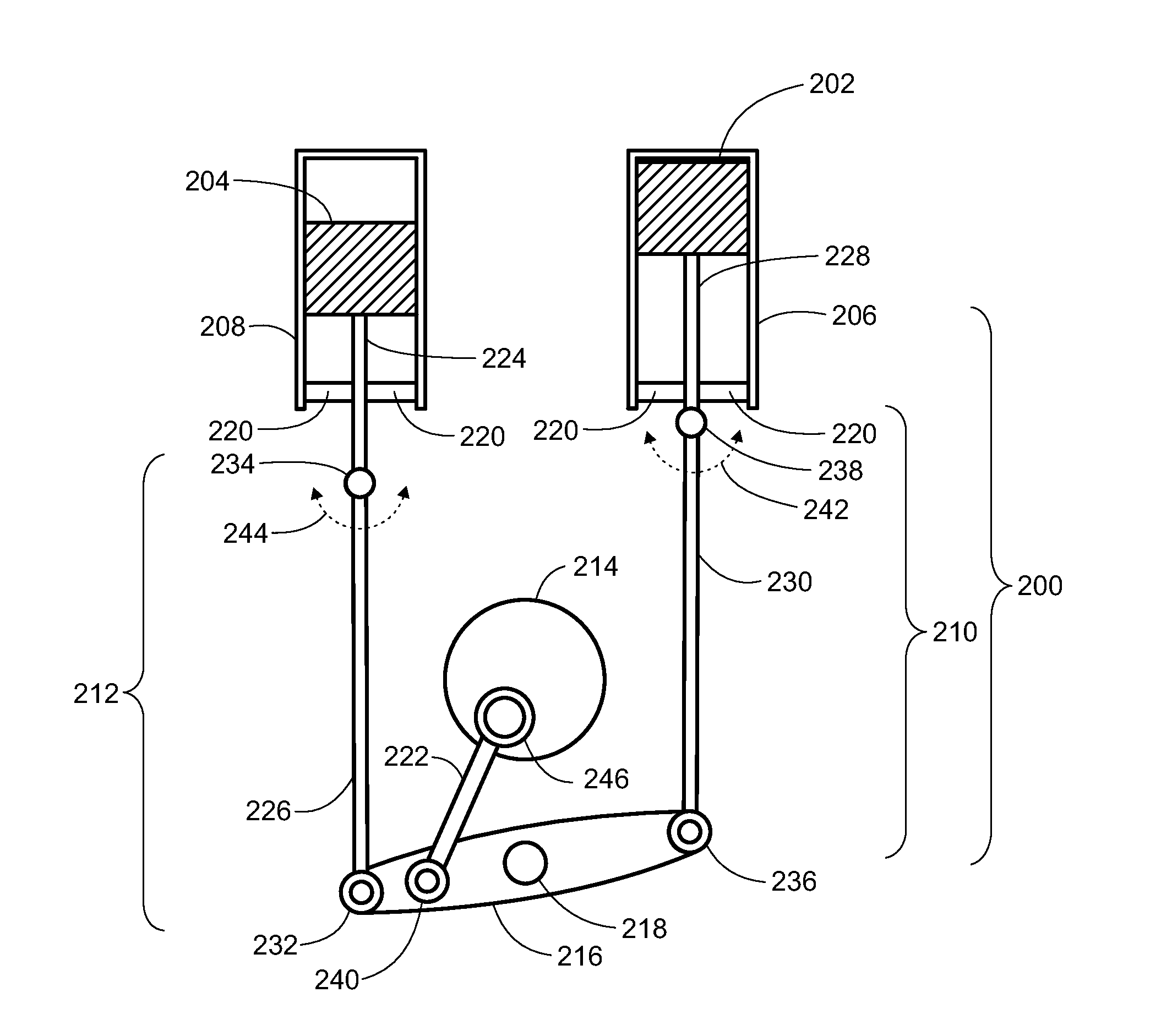

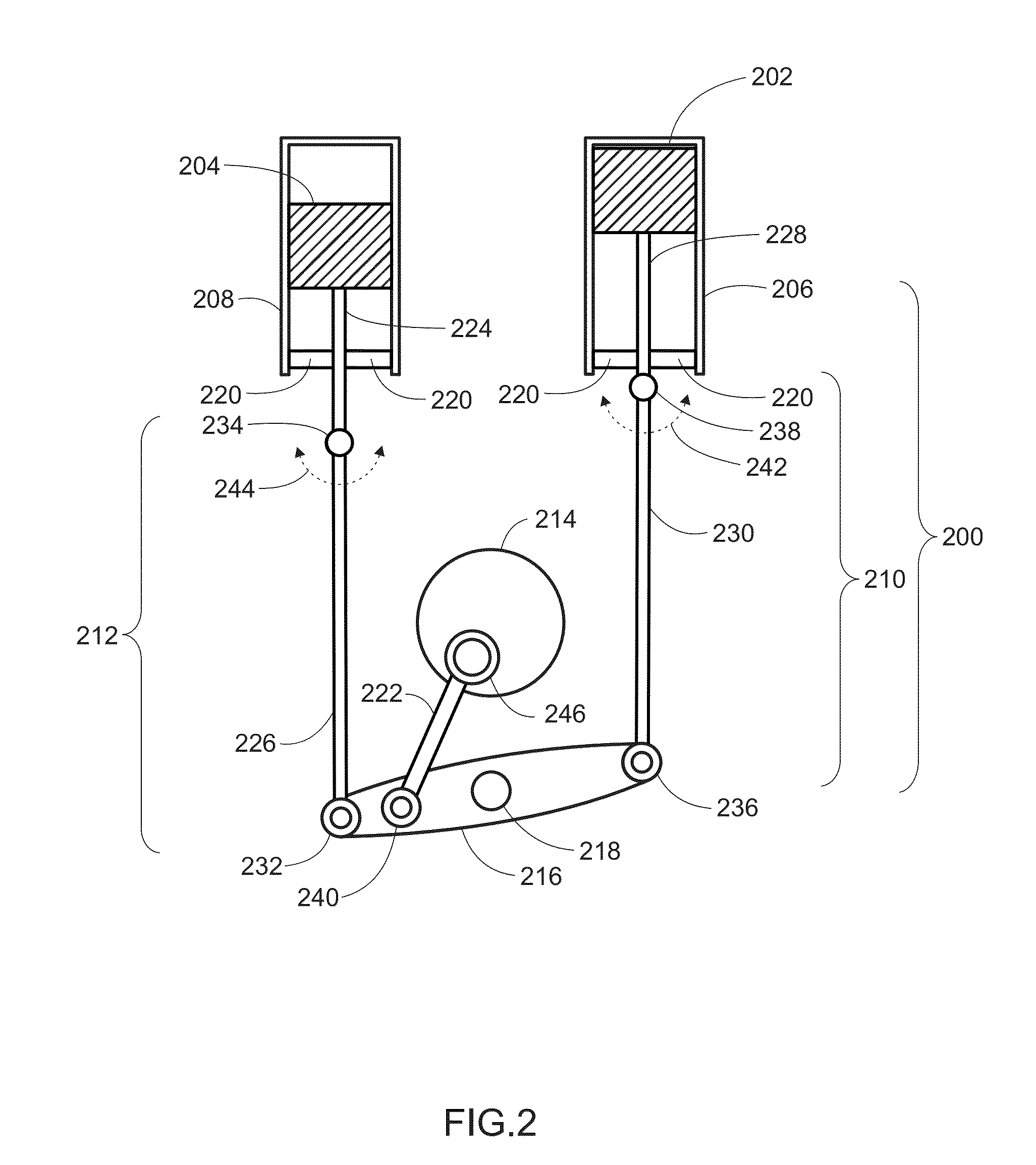

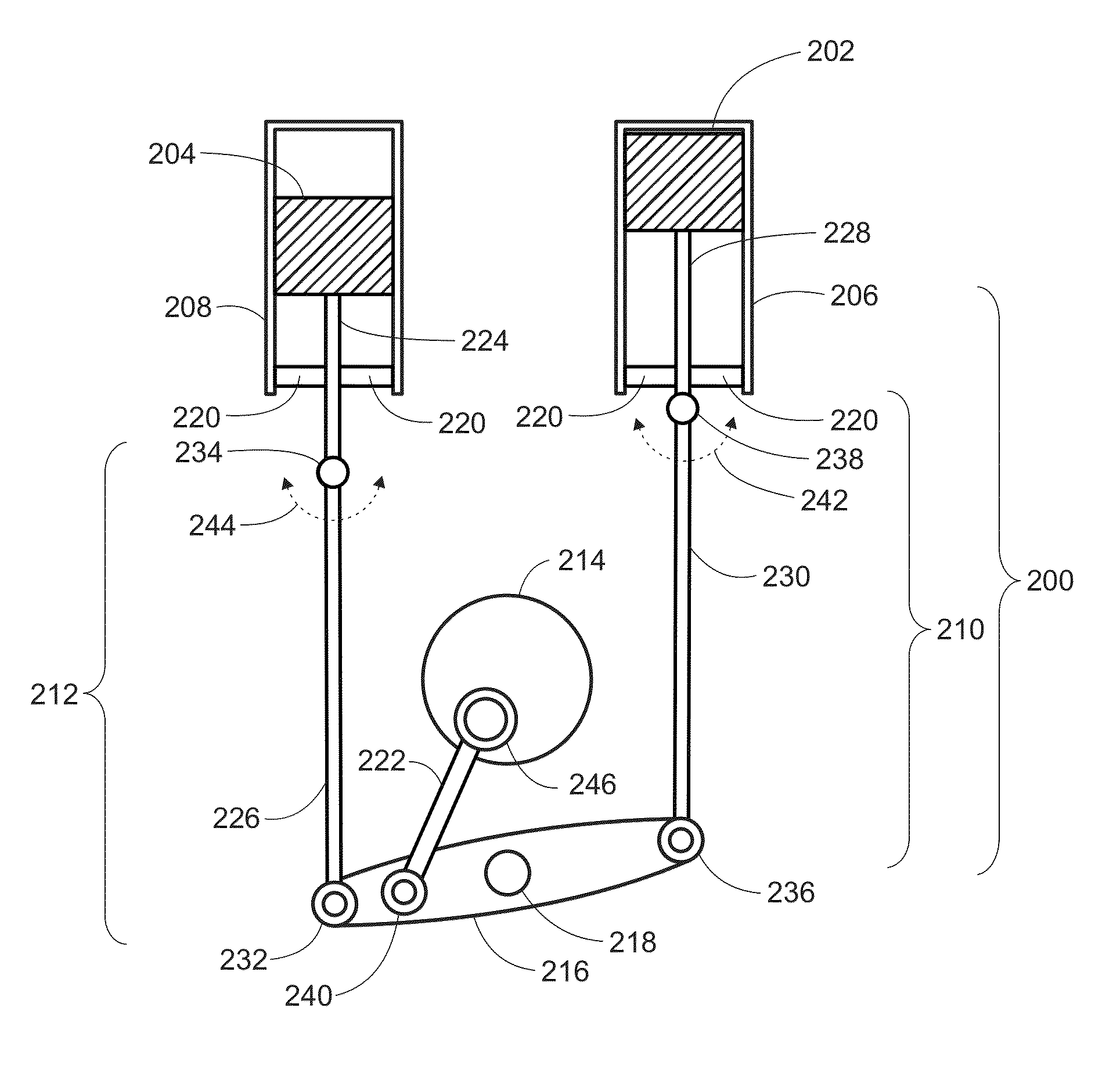

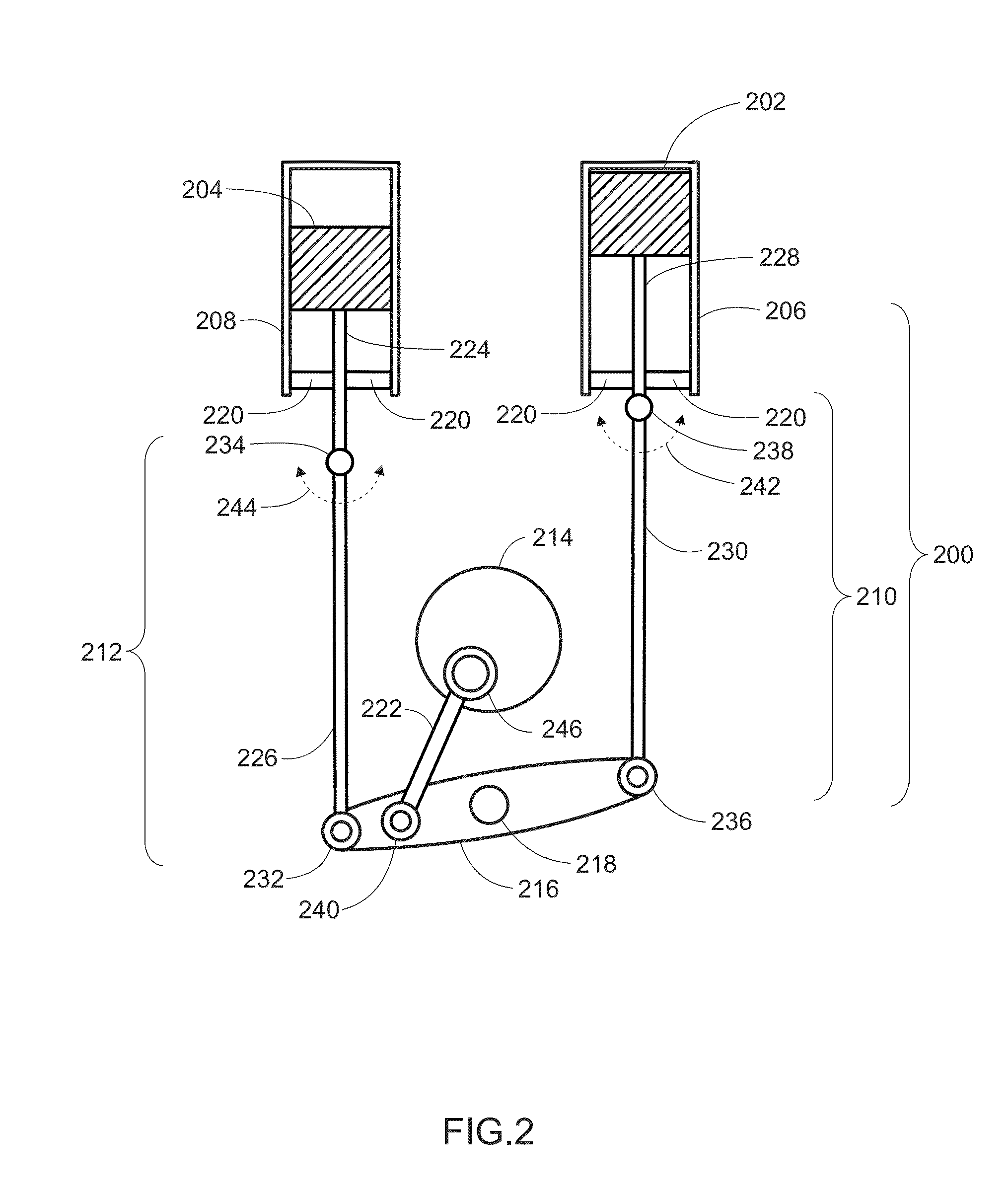

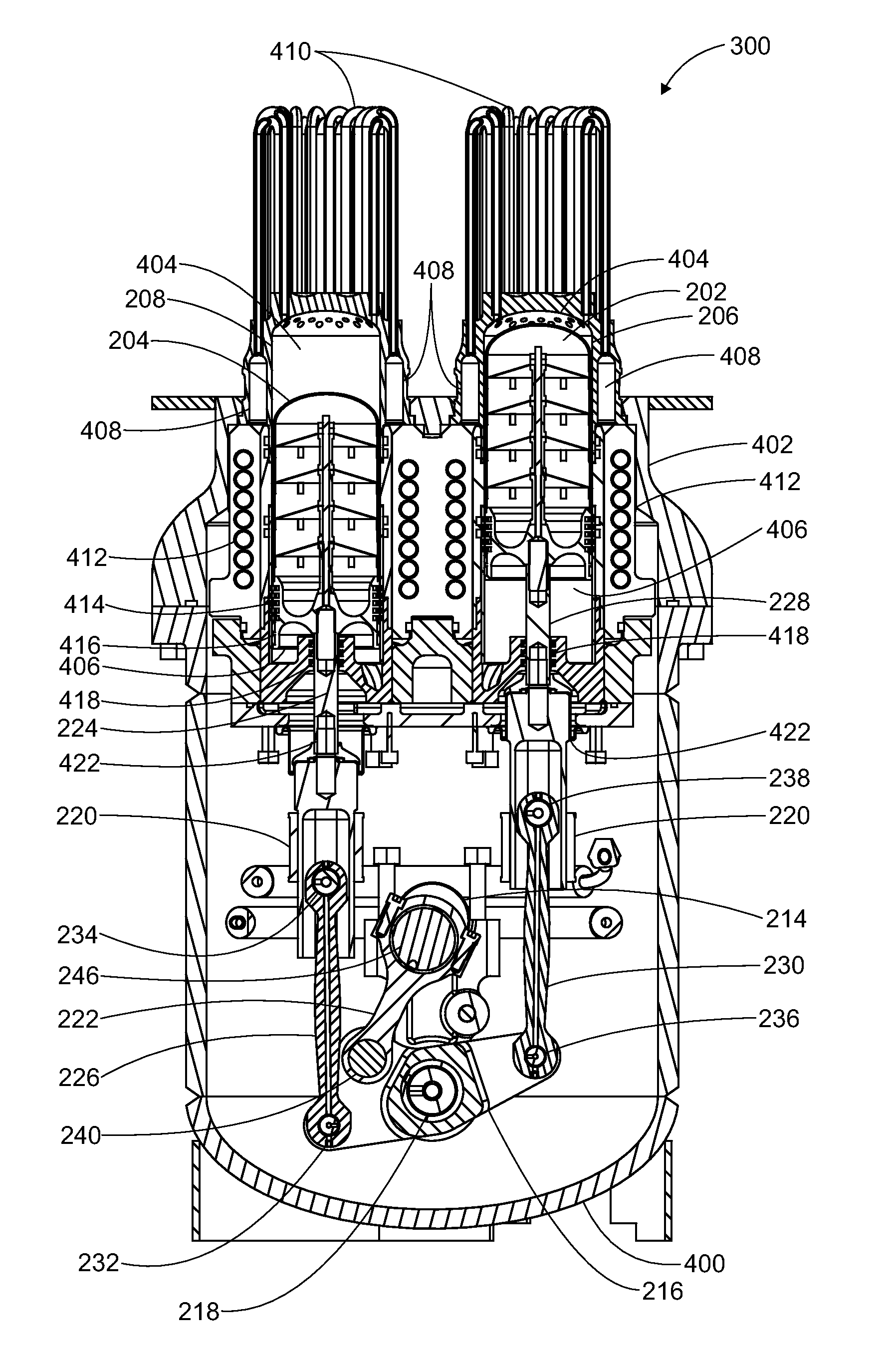

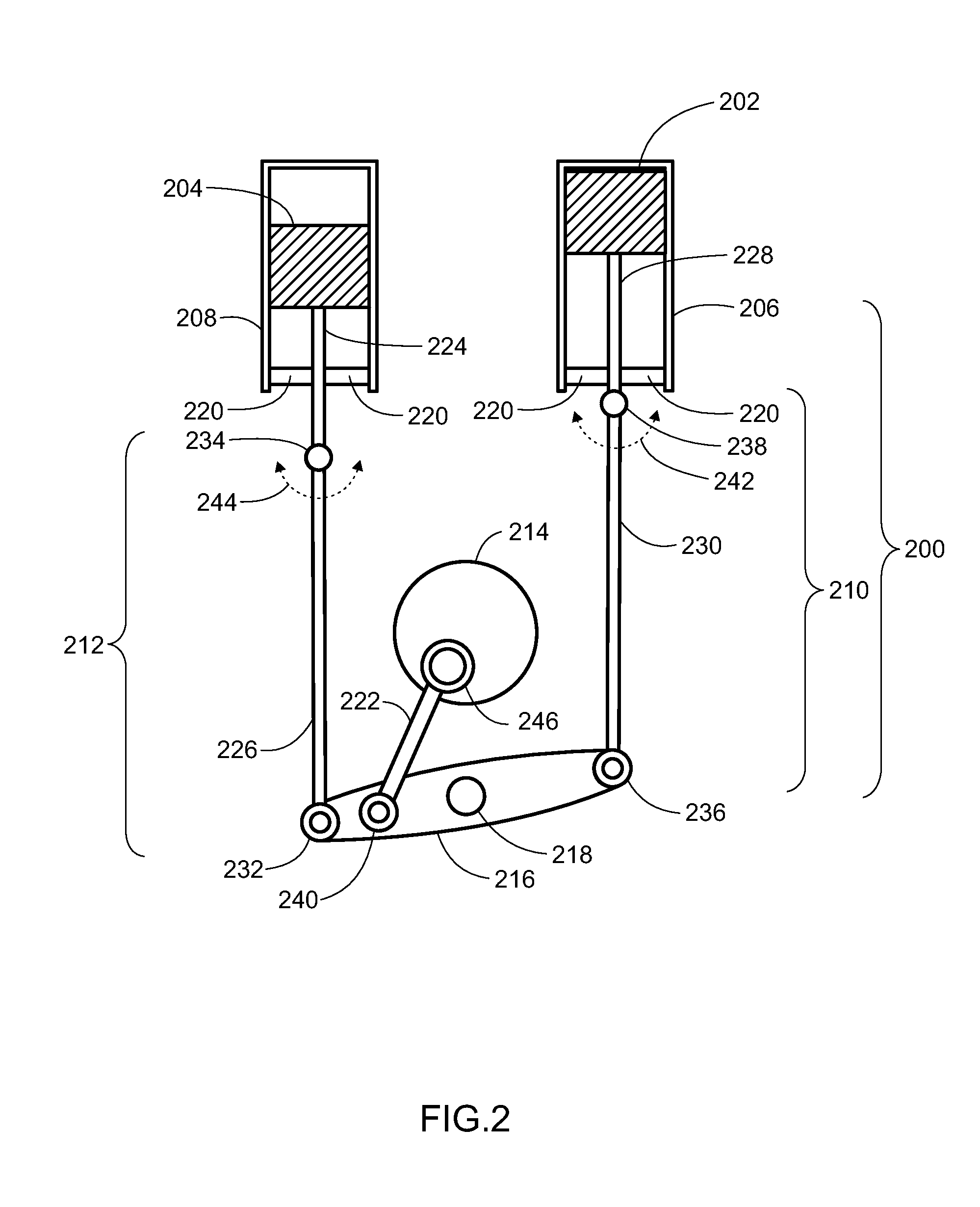

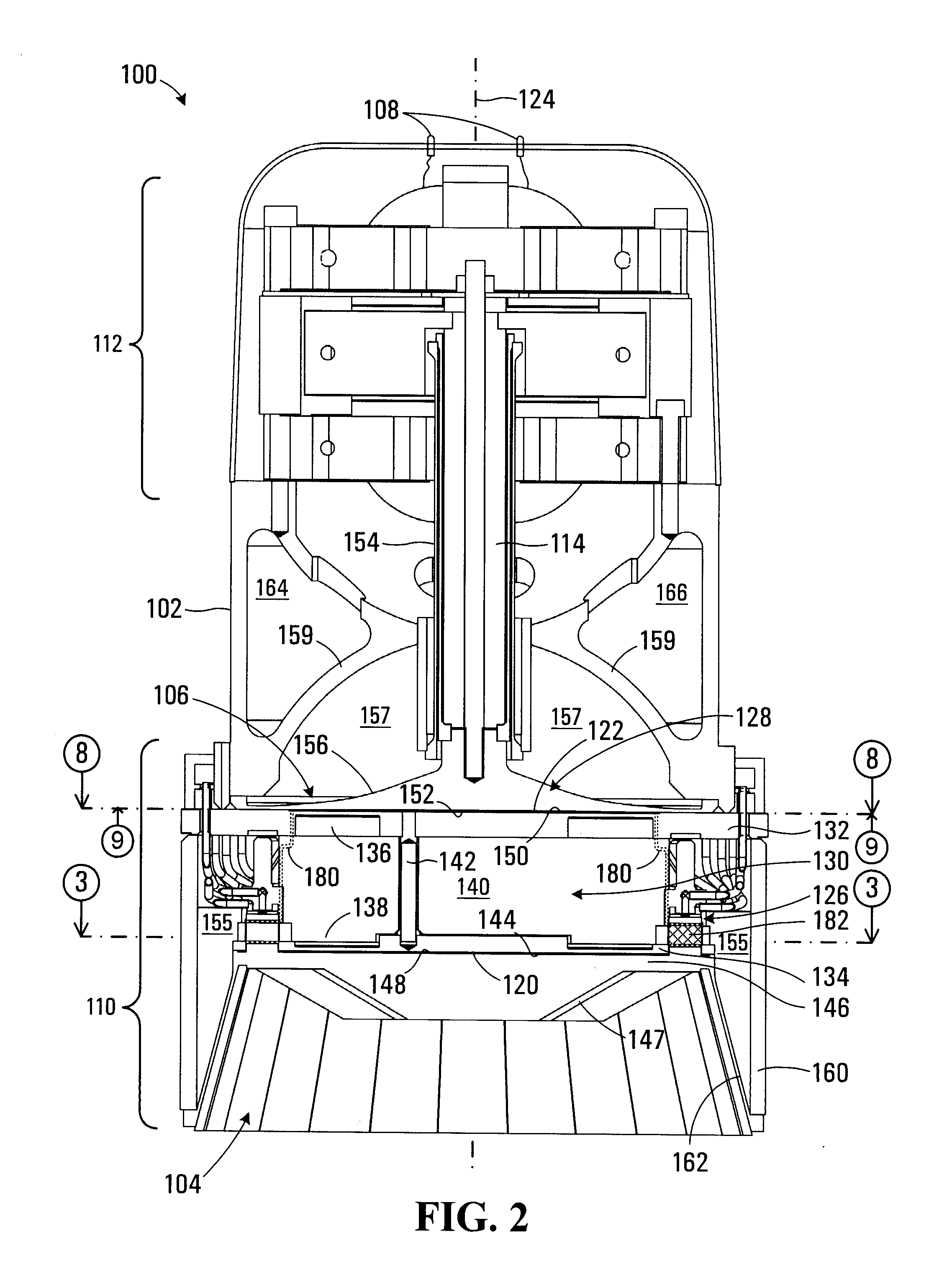

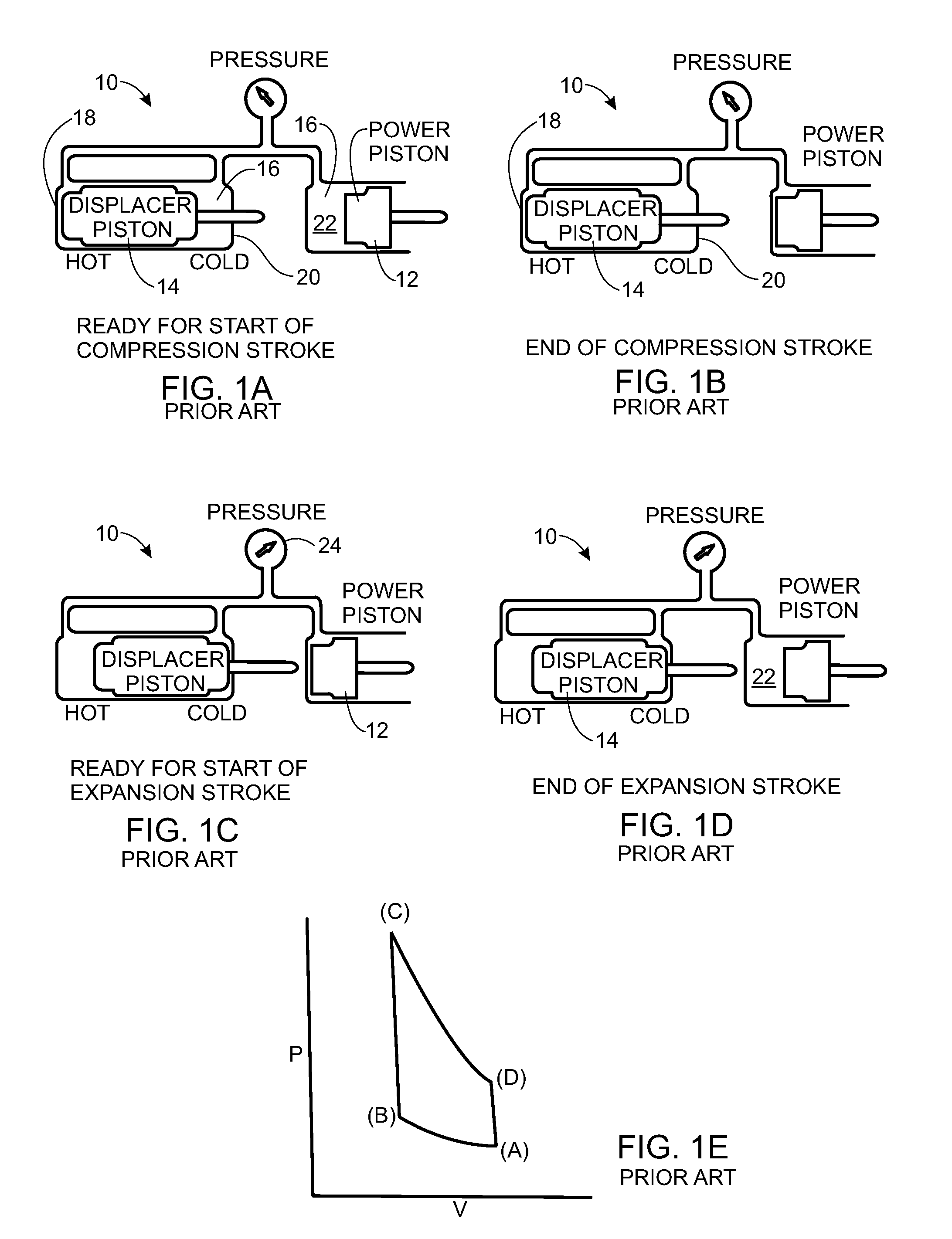

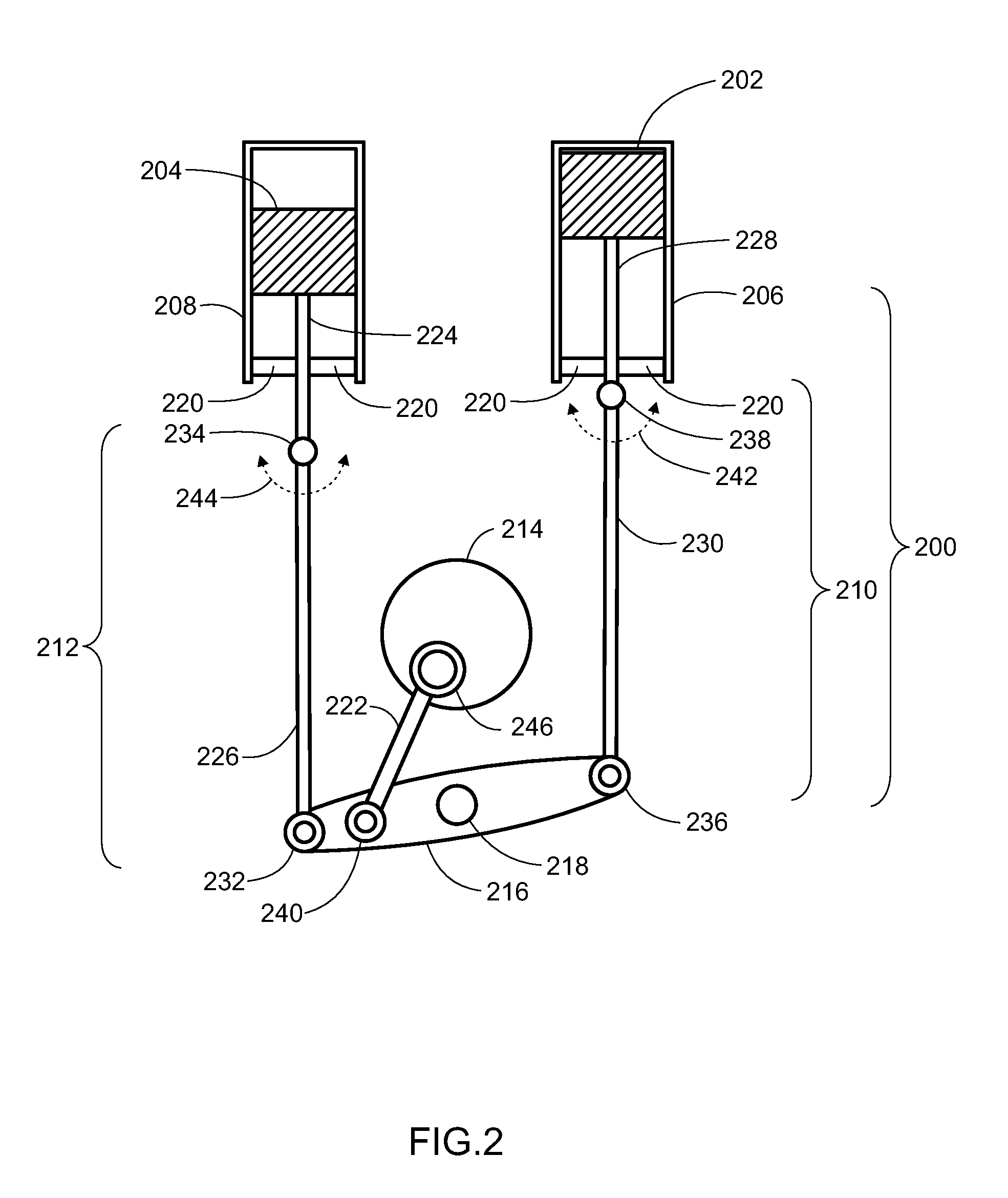

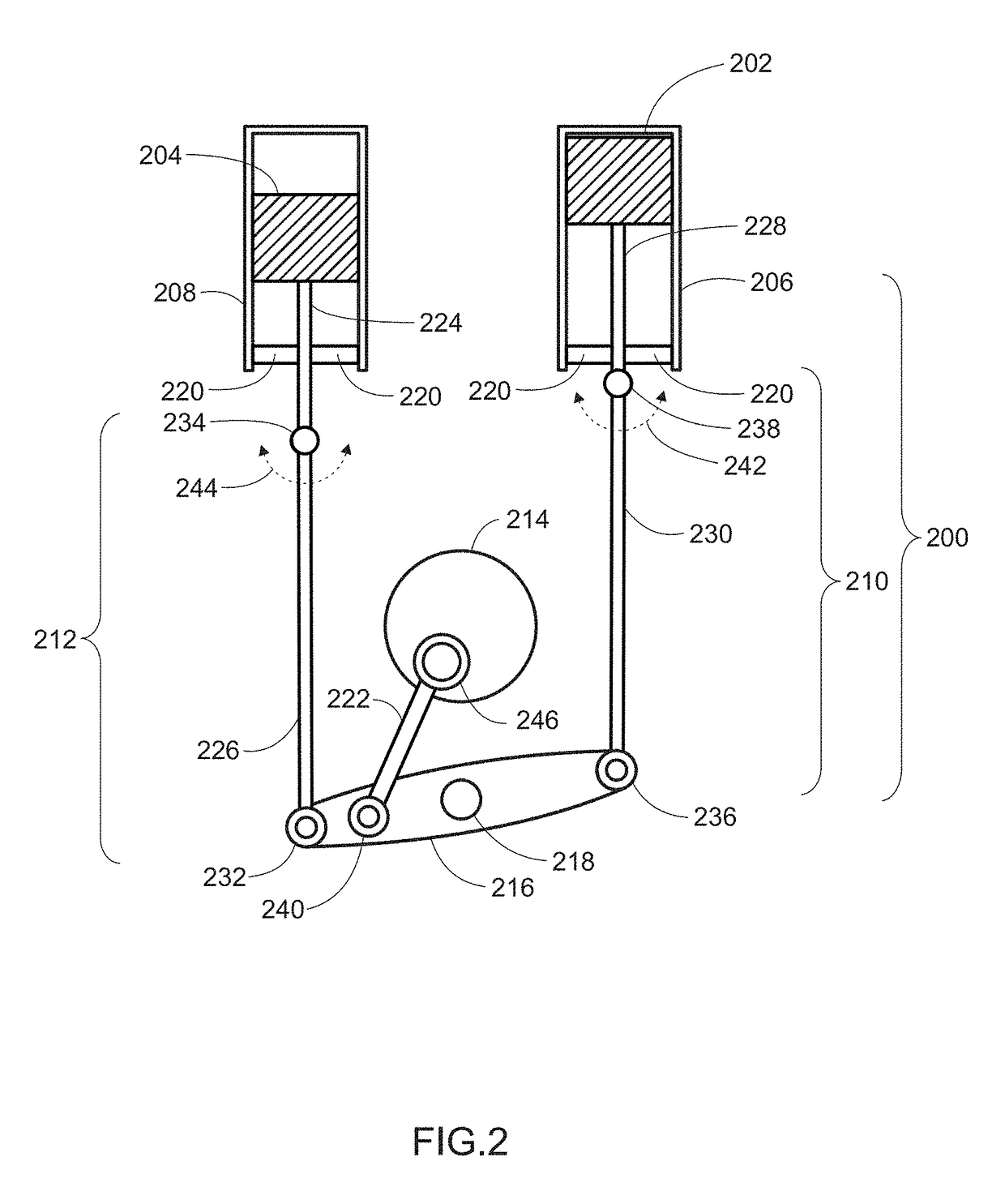

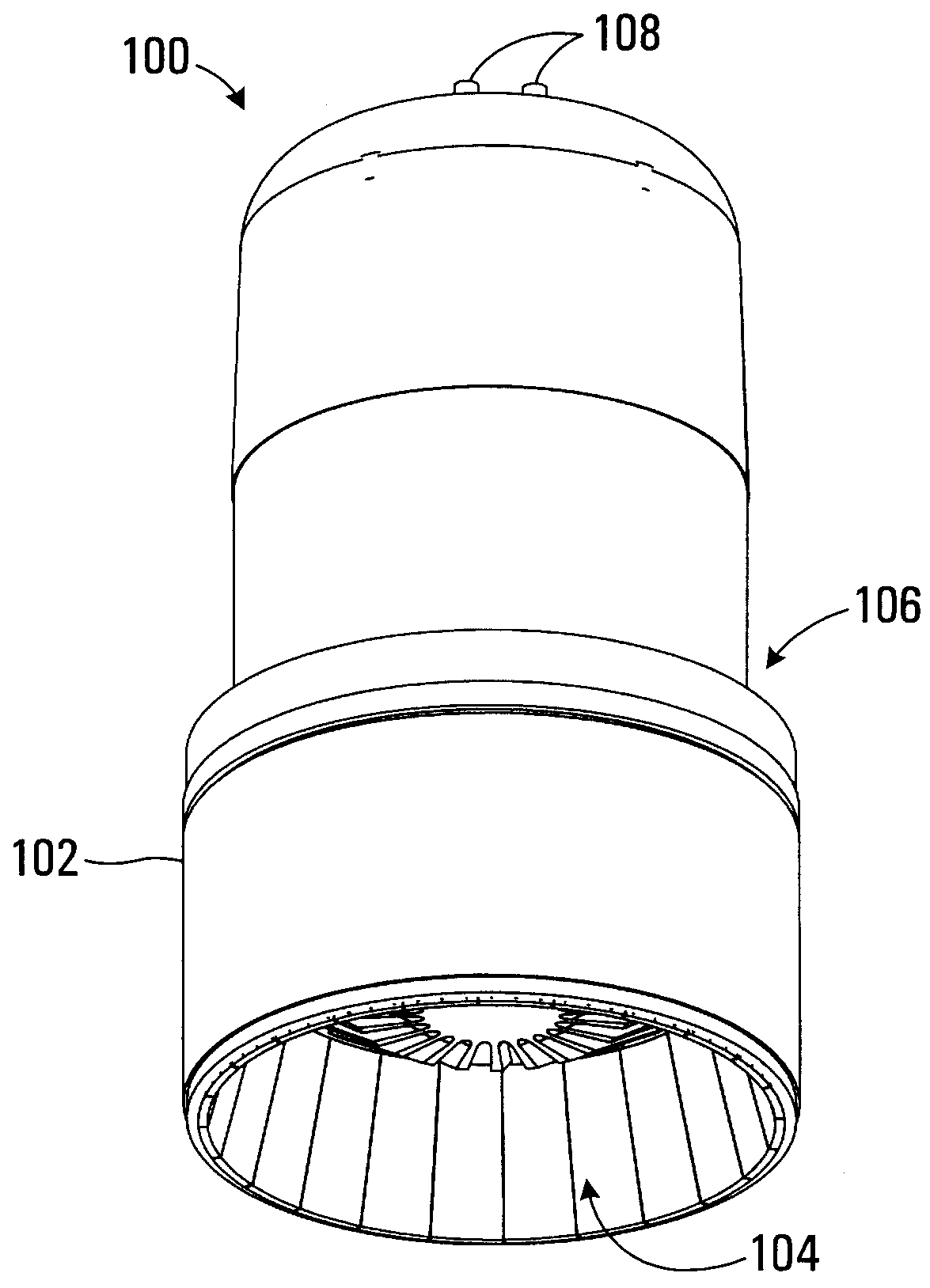

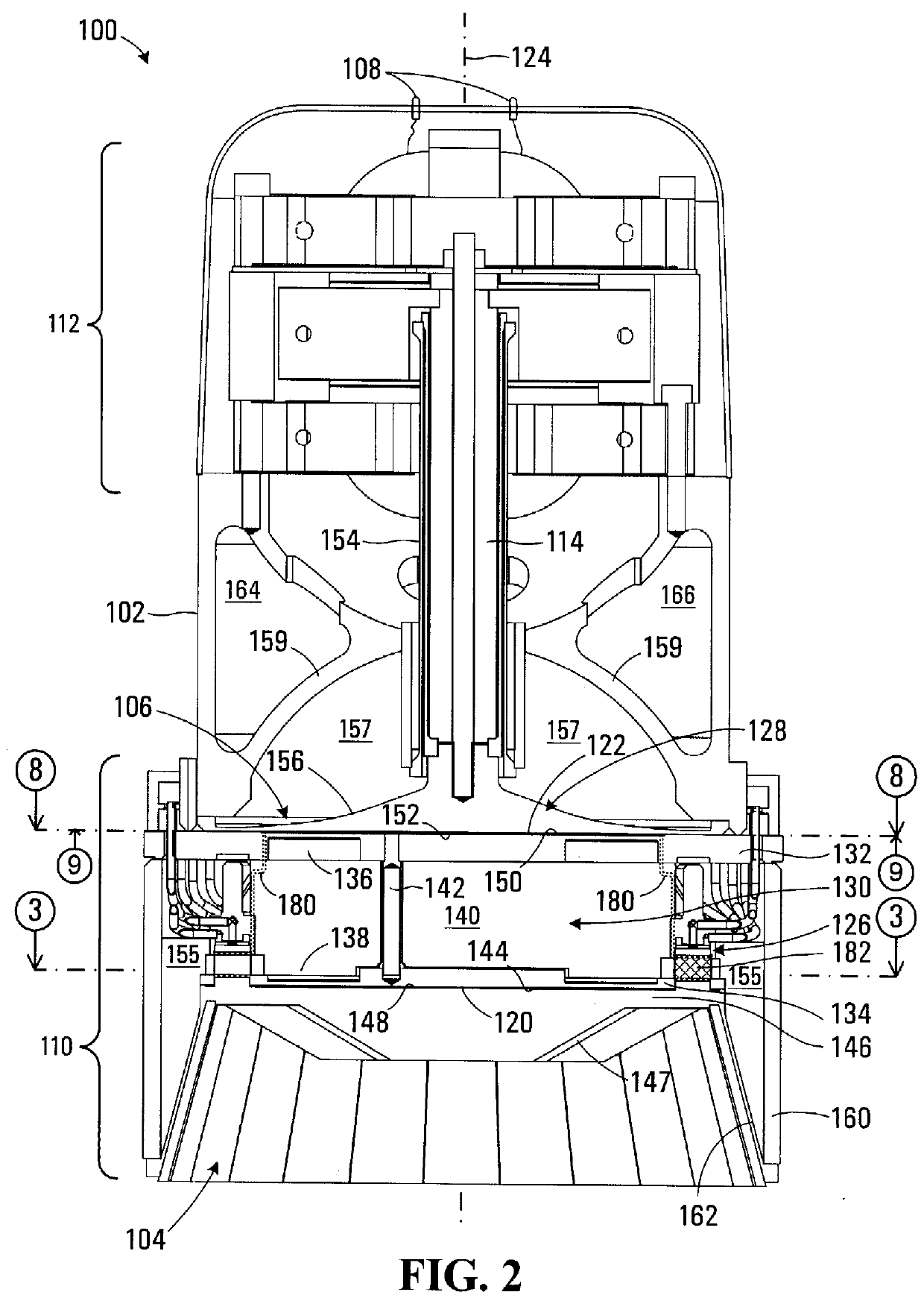

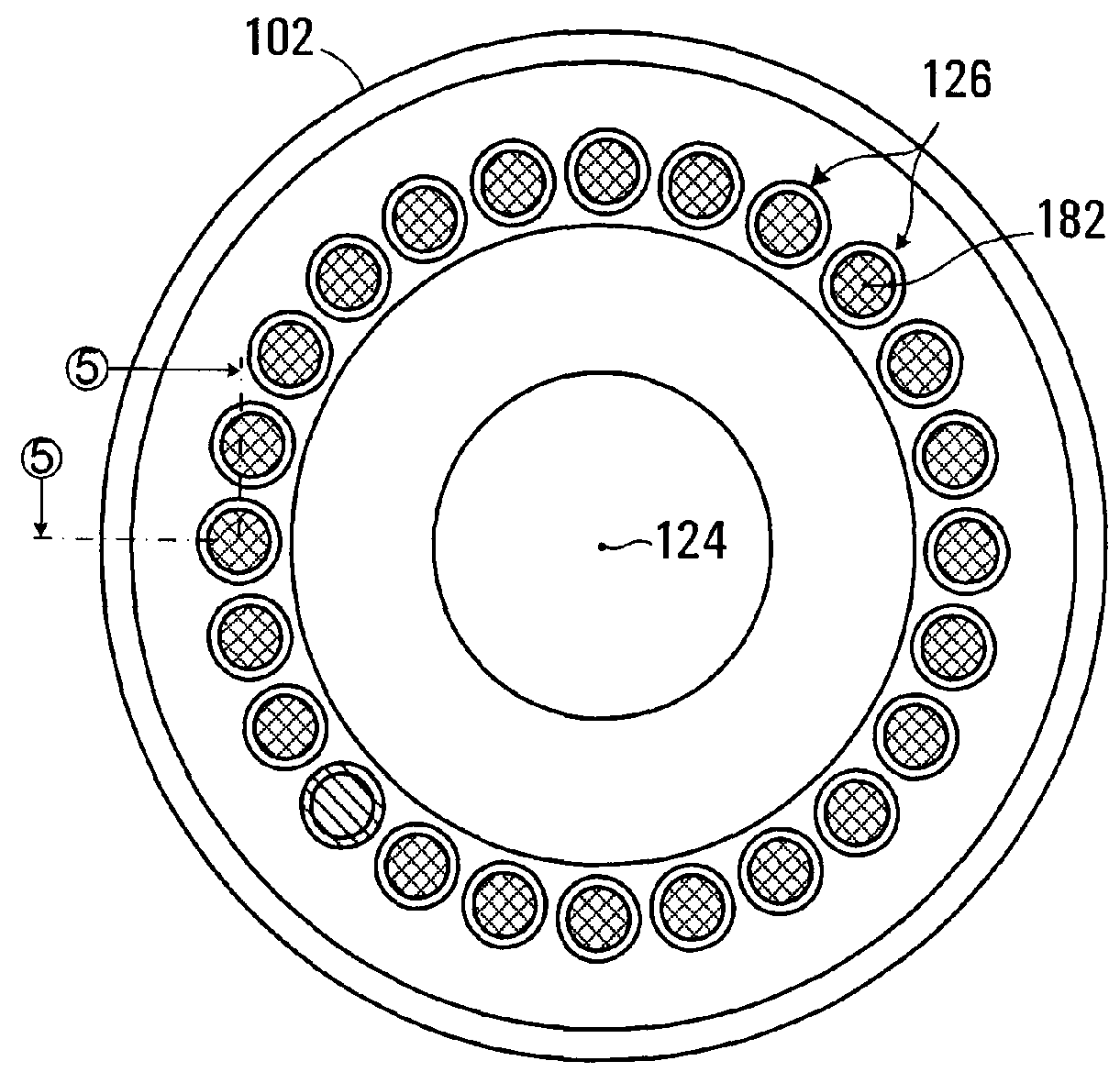

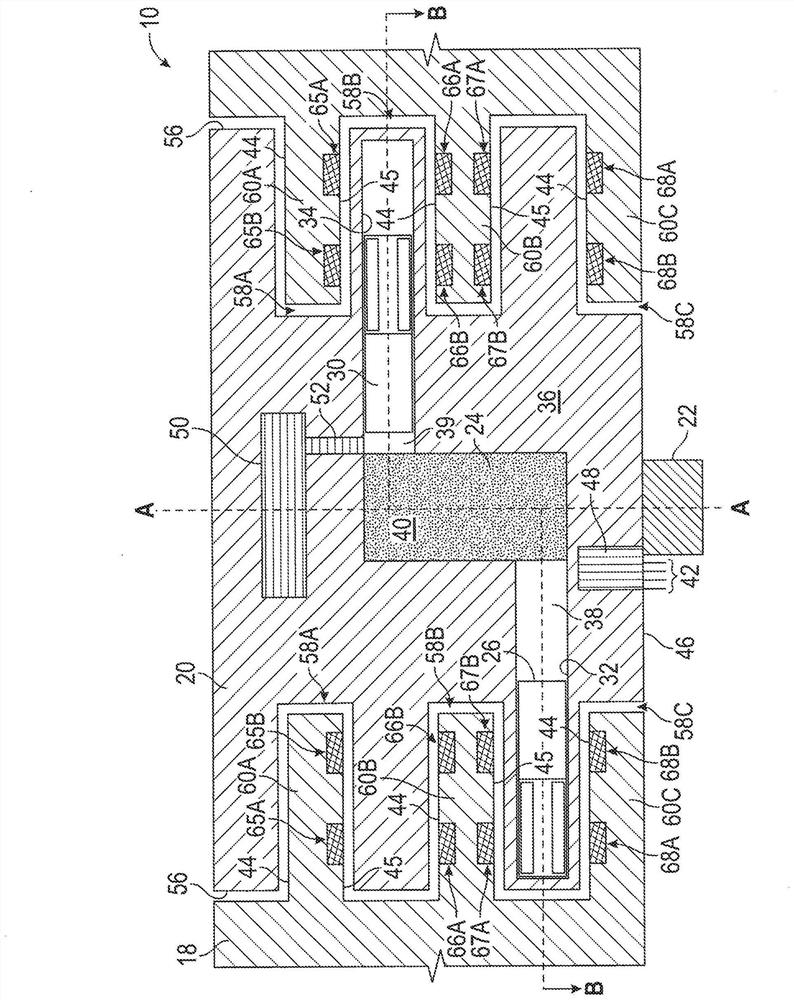

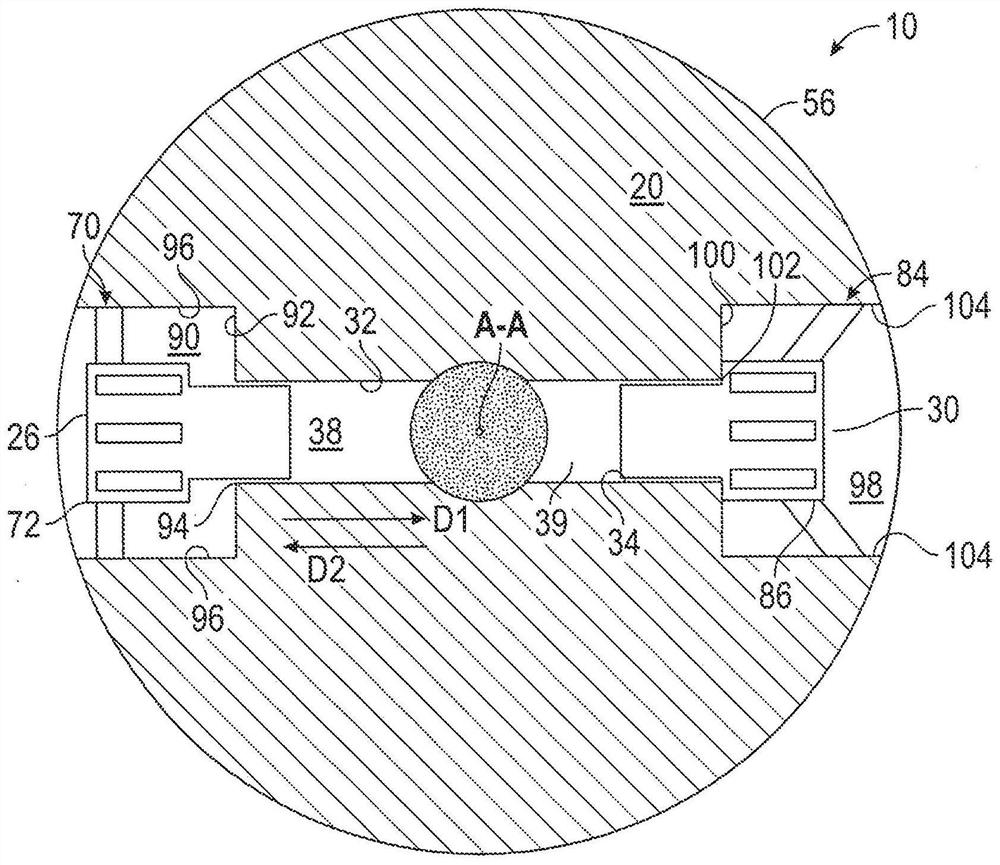

Stirling cycle machine

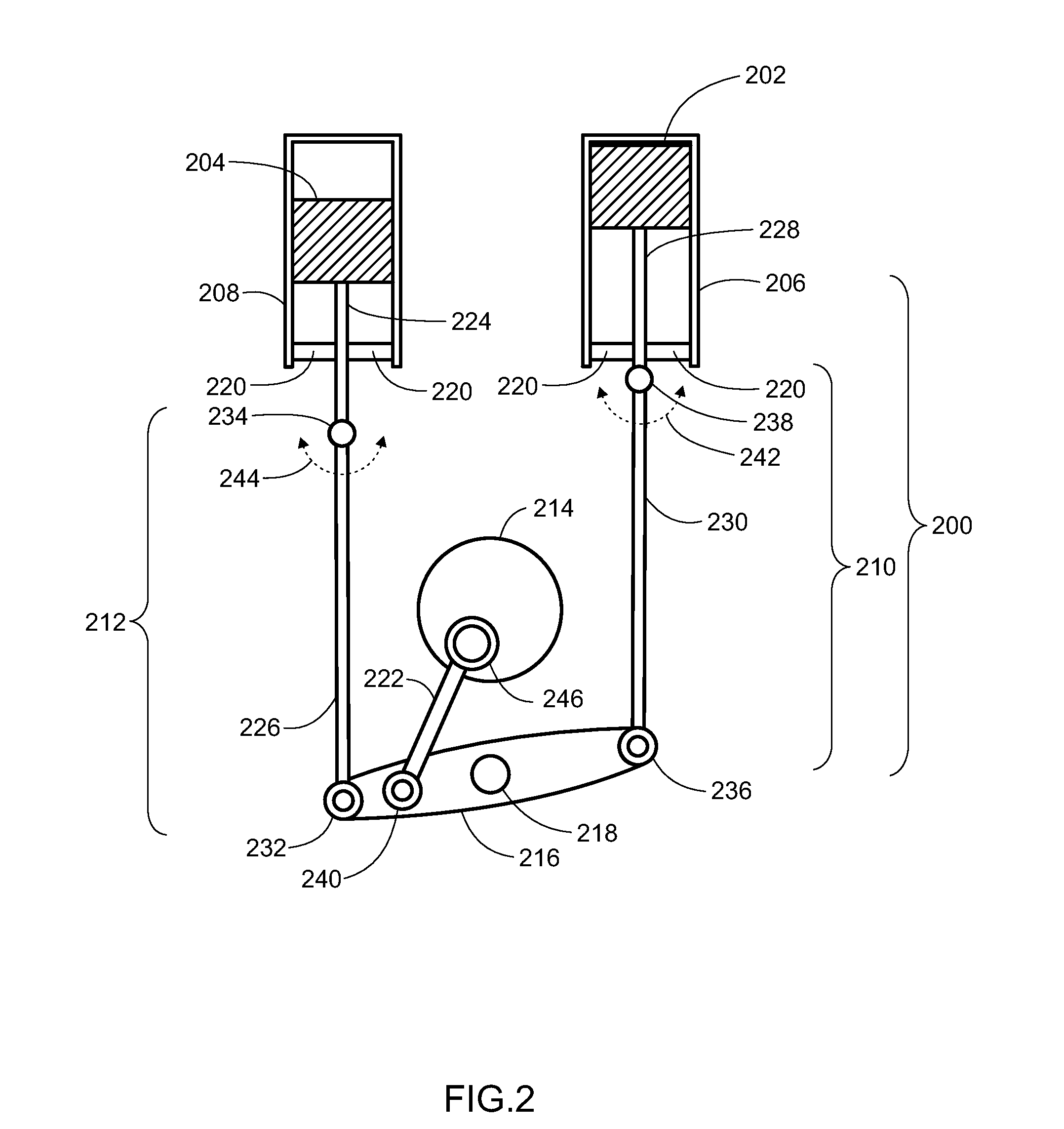

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

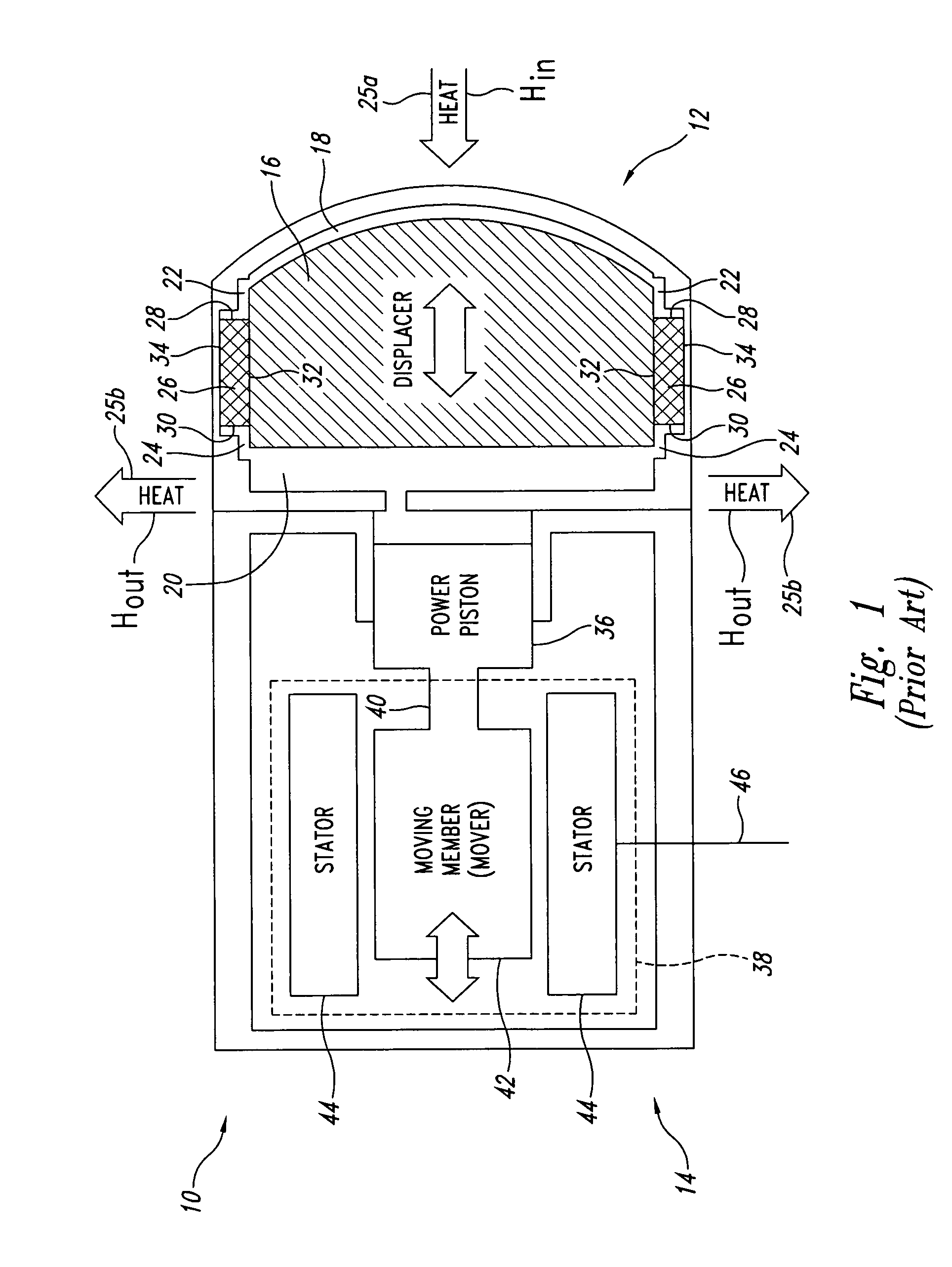

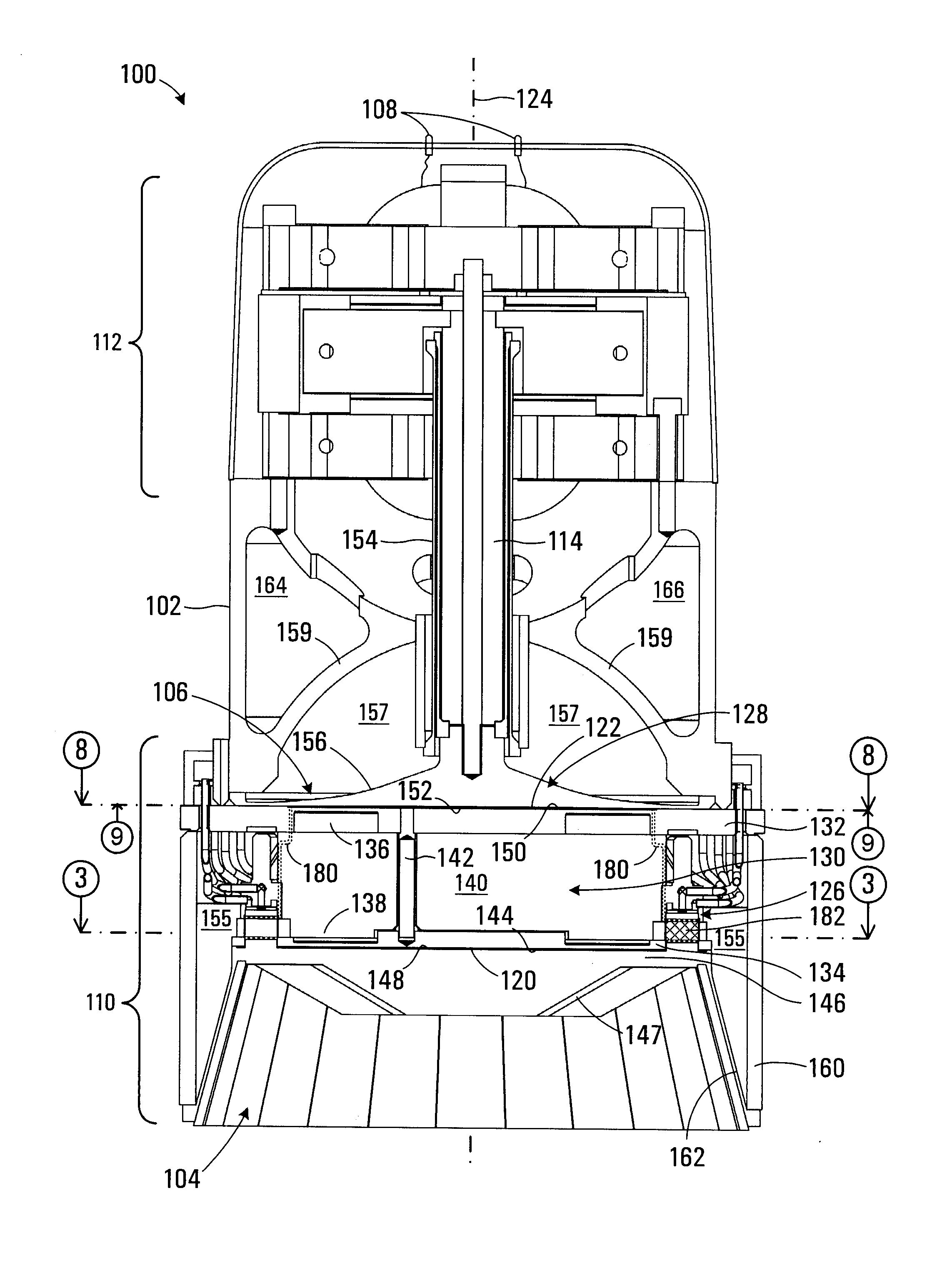

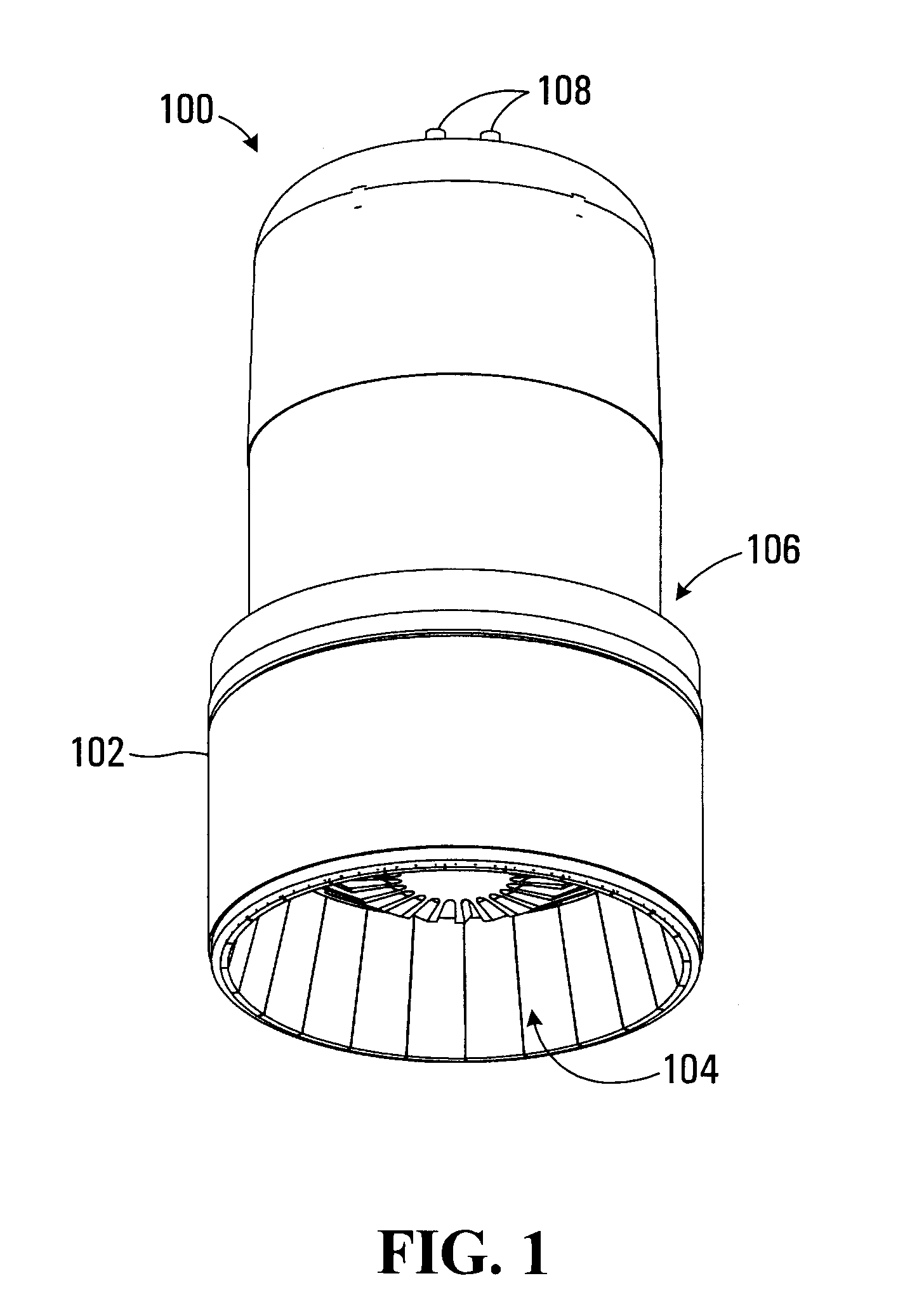

Stirling cycle machine

An external combustion engine is disclosed. The external combustion engine containing a working fluid and including a burner element for heating the working fluid of the engine, at least one heater head defining a working space containing the working fluid, at least one piston cylinder containing a piston for compressing the working fluid, a cooler for cooling the working fluid, a crankcase. The crankcase includes a crankshaft for producing an engine output, a rocking beam rotating about a rocker pivot for driving the crankshaft, a piston rod connected to the piston, a rocking beam driven by the piston rod, and a connecting rod connected at a first end to the rocking beam and at a second end to a crankshaft to convert rotary motion of the rocking beam to rotary motion of the crankshaft. The external combustion engine also includes an airlock space separating the crankcase and the working space for maintaining a pressure differential between the crankcase housing and the working space housing and an airlock pressure regulator connected between the crankcase and one of the airlock space and working space.

Owner:DEKA PROD LLP

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

Annular Venturi Burner for Stirling Engine

An annular venturi burner assembly and Stirling engine. The annular venturi burner injects fuel into combustion air flowing axial through an port with an annular cross section. The fuel enters the annular cross-section from the outside diameter. The flow of air through the annular section creates suction that draws the fuel through the ports. An venturi bushing directs the flow of fuel to provides improved and more uniform mixing of fuel and air.

Owner:DEKA PROD LLP

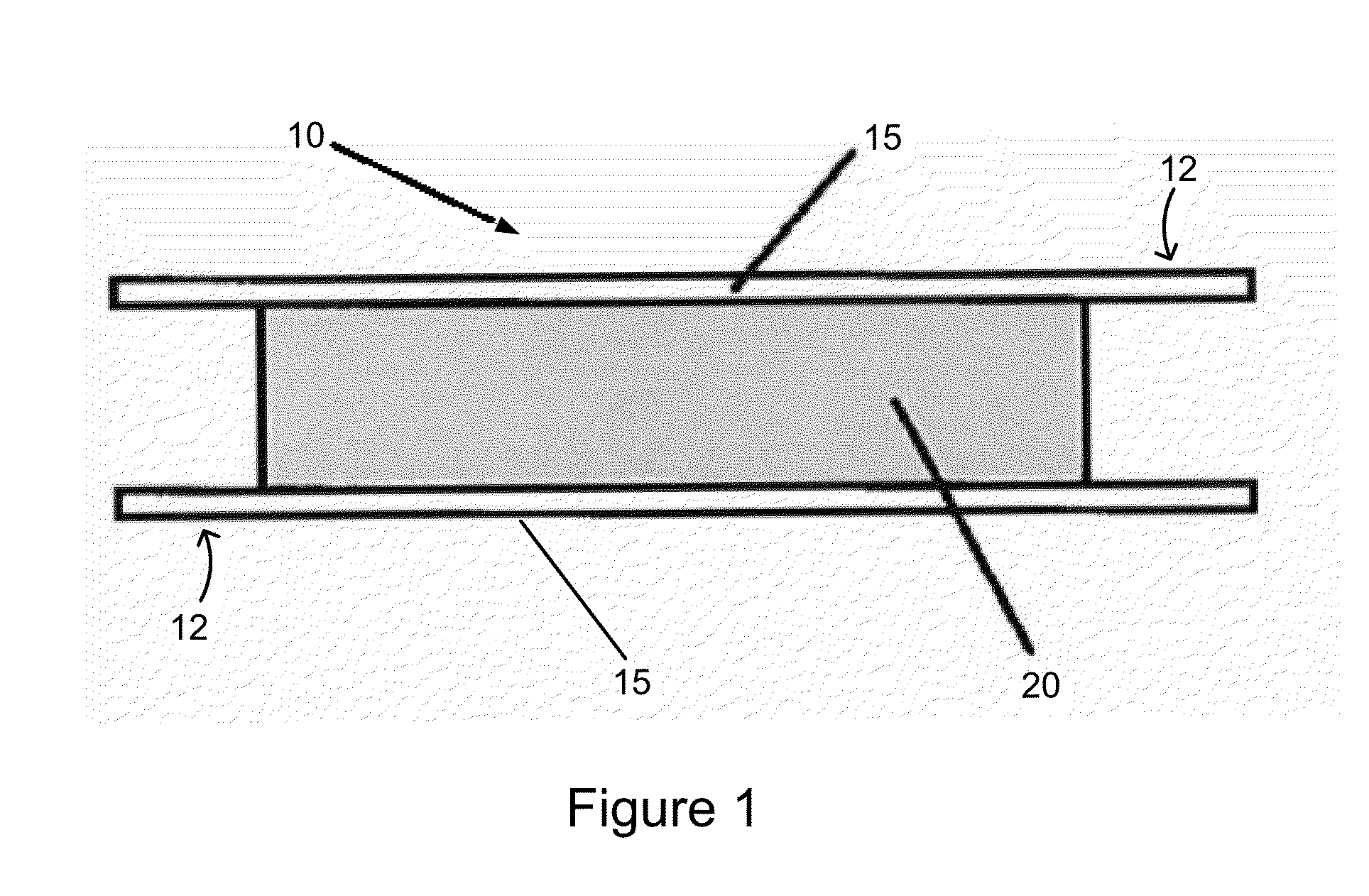

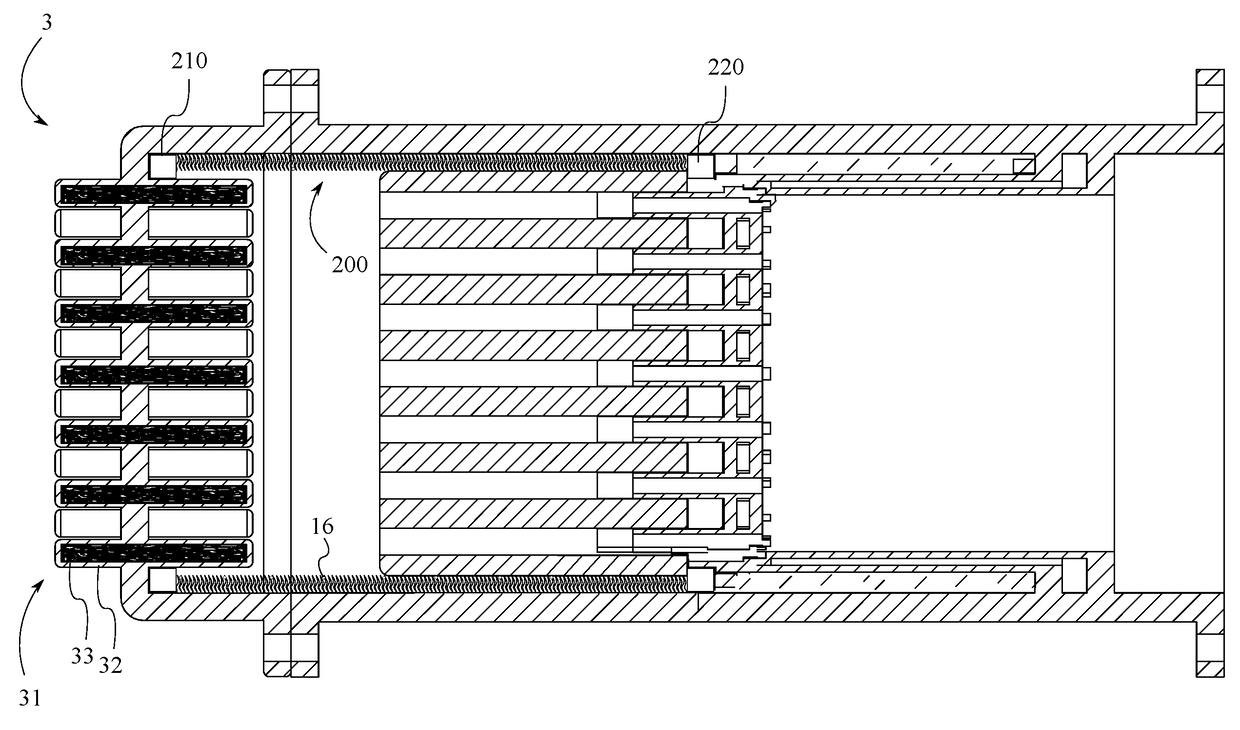

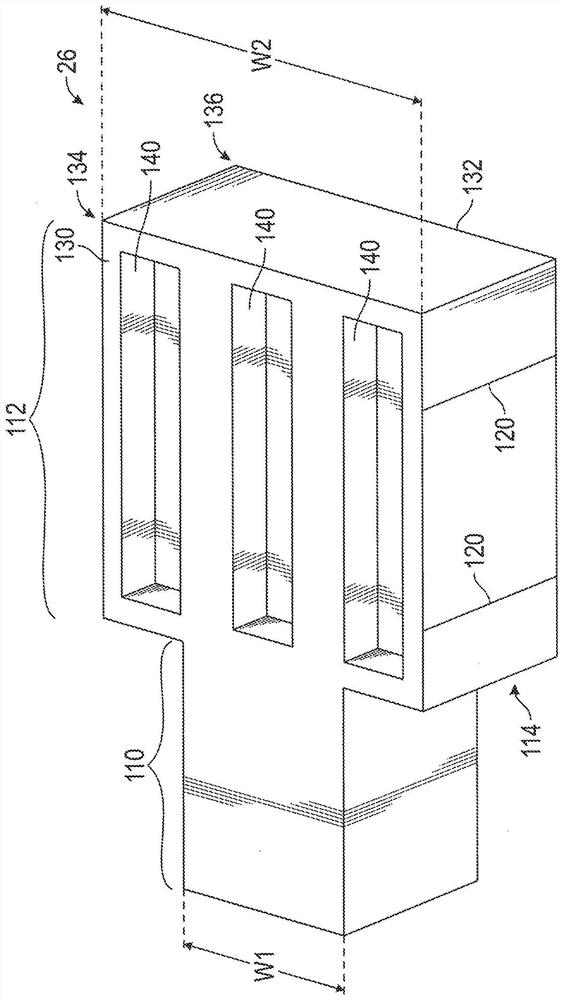

Channelized stratified heat exchangers system and method

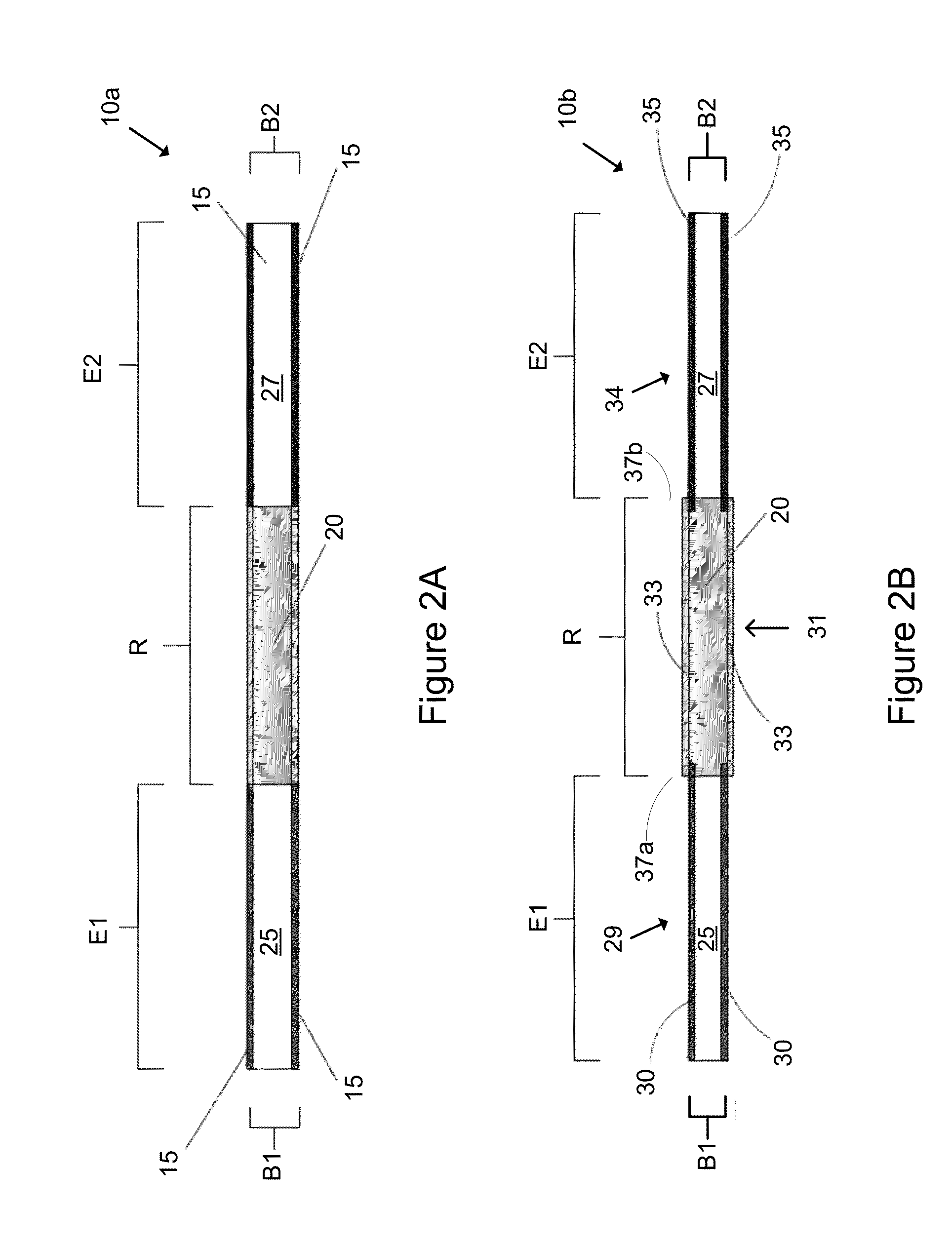

InactiveUS20060179834A1Avoid short travelClosed-cycle gas positive displacement engine plantRegeneratorsWorking fluidStructural geometry

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:RICOR GENERATION

Stirling Cycle Machine

ActiveUS20140182282A1Heat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

Owner:NEW POWER CONCEPTS

Stirling Cycle Machine

ActiveUS20150040751A1Heat exchanger casingsStationary tubular conduit assembliesPressure differenceMechanical engineering

A rod seal assembly. The rod seal assembly includes a housing between two spaces configured to receive a reciprocating rod, the reciprocating rod disposed within a first space and a second space, a floating bushing configured to move axially and radially within the housing and disposed coaxially around the reciprocating rod, a rod seal configured to seal the outside diameter of the reciprocating rod relative to an inside surface of the floating bushing, and at least one stationary bushing fixed within the housing that may form a seal with the floating bushing to the axial flow of fluid in the presence of a pressure difference between the two spaces.

Owner:NEW POWER CONCEPTS

Linear Cross-Head Bearing for Stirling Engine

ActiveUS20150184614A1Heat exchanger casingsStationary tubular conduit assembliesLinear motionCombustor

An external combustion engine including a burner element, a heater head, a piston cylinder containing a piston, a cooler and a crankcase. The crankcase includes a crankshaft, a piston rod connected to the piston, a drive mechanism for converting the linear motion of the piston rod to rotary motion of the crankshaft and a linear cross-head bearing that is connected rigidly to the piston rod at one end and to the drive mechanism at the other end. Also the external combustion engine includes a piston clearance seal and a piston rod seal unit that has floating rod seals. The piston includes a inner dome to reduce axial heat transfer via radiation and convection.

Owner:NEW POWER CONCEPTS

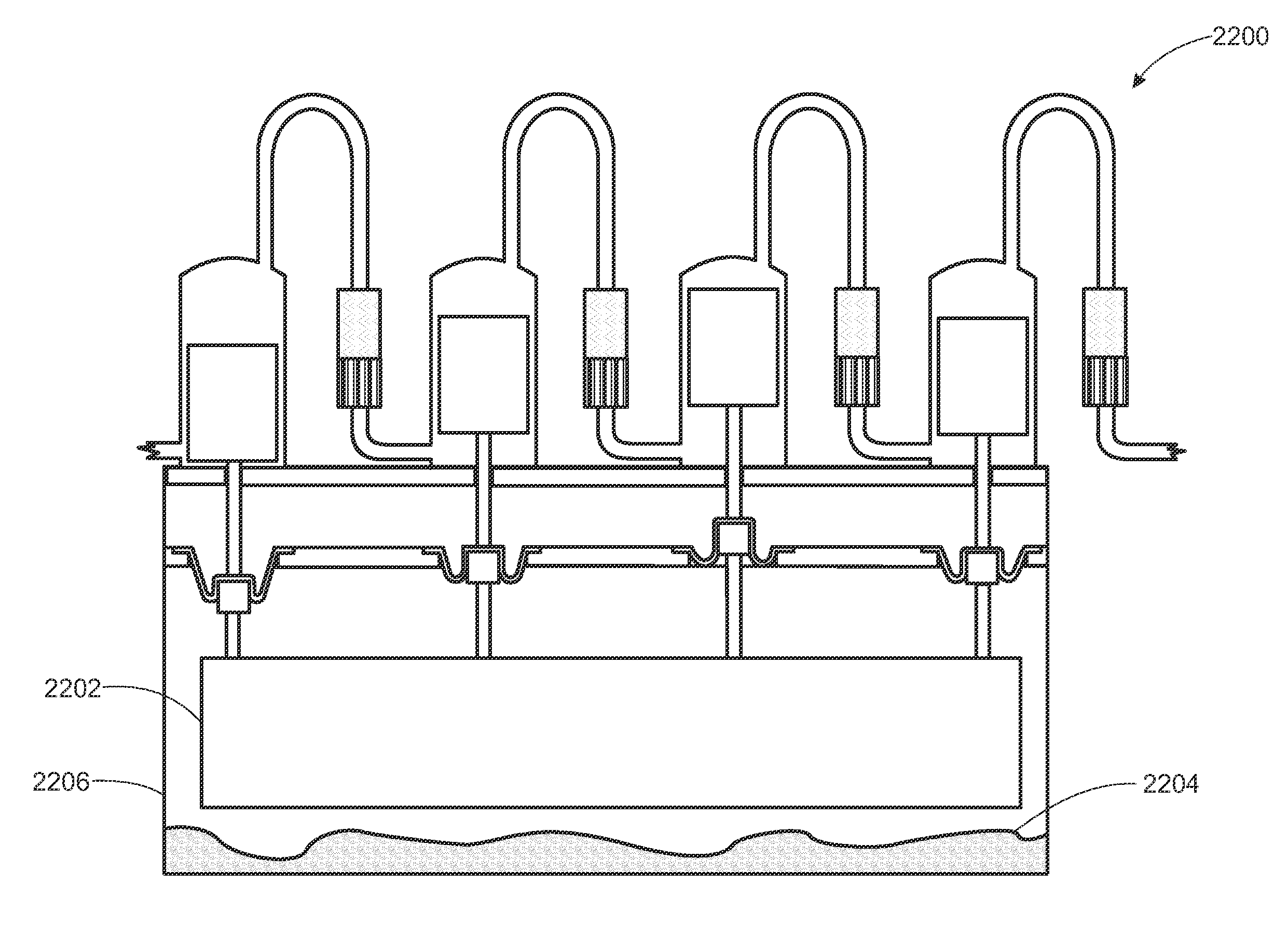

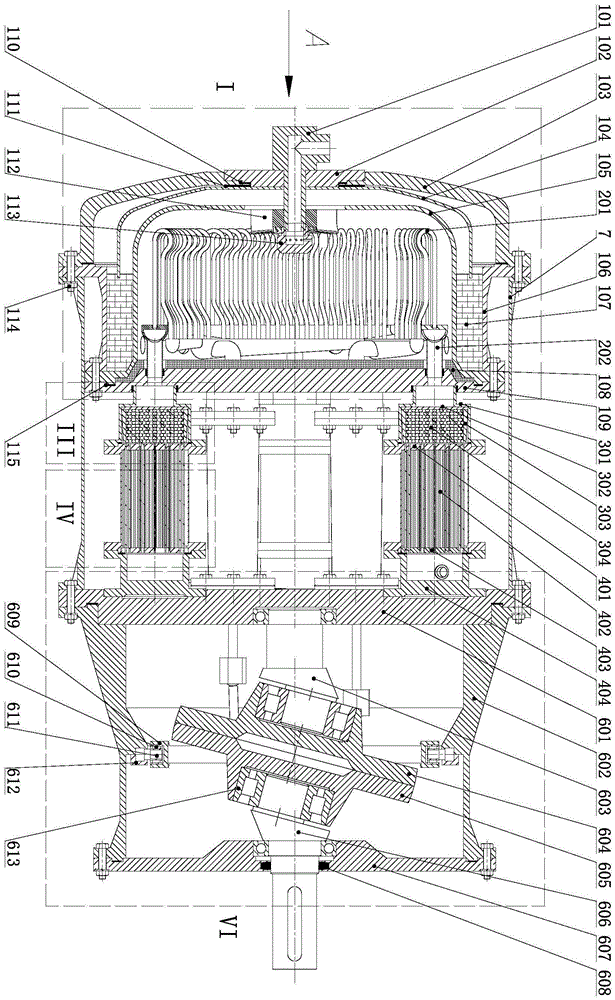

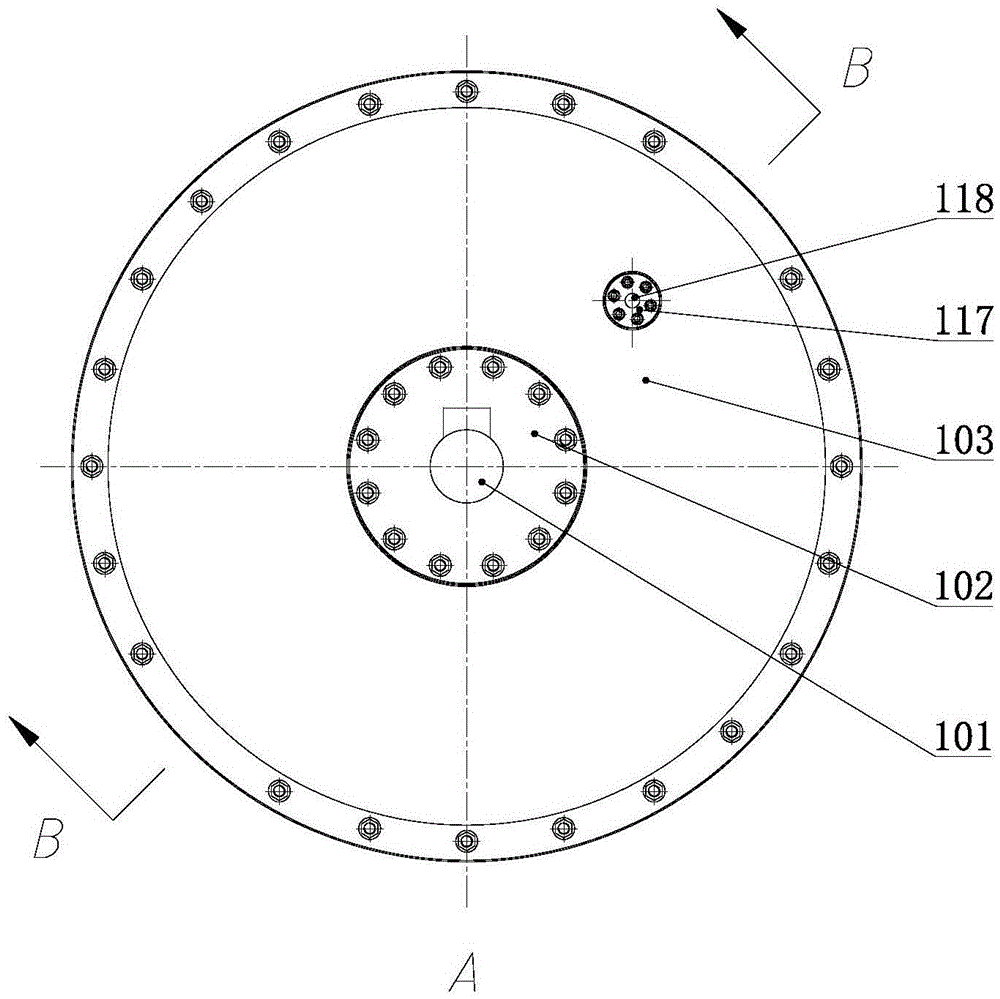

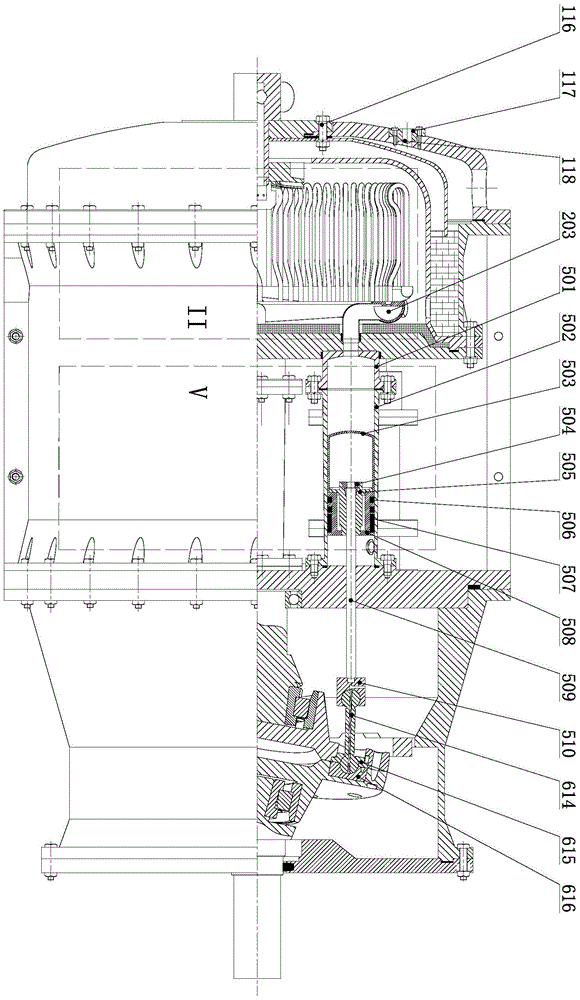

Gas axial transmission alpha type four-cylinder double-acting stirling engine

InactiveCN105626304AExtend your lifeHigh working reliabilityCombustion technology mitigationHeater tubesLow noiseCombustion

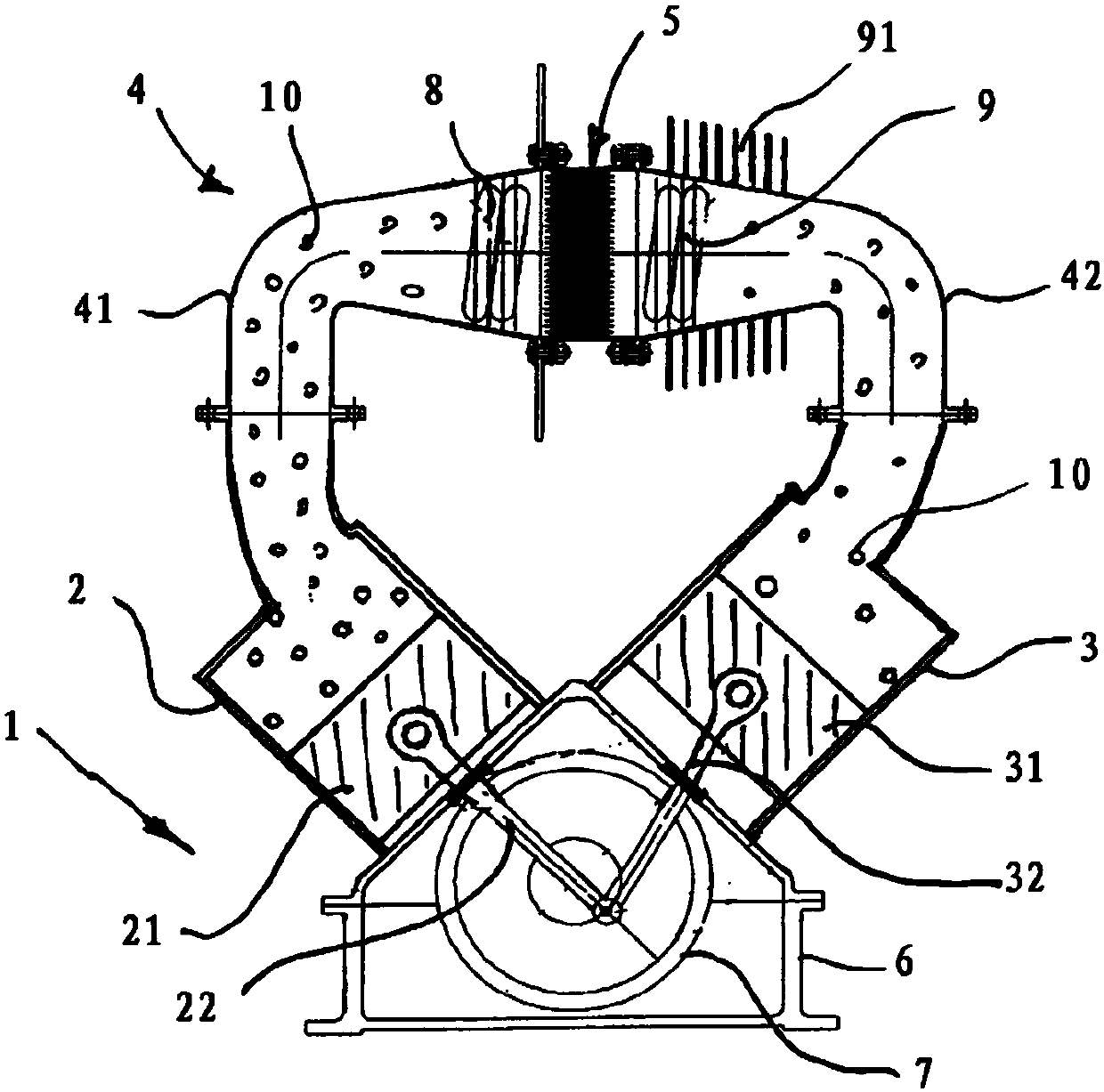

The invention discloses a gas axial transmission alpha type four-cylinder double-acting stirling engine which comprises a combustion device; a heating device is arranged indie the combustion device; an air cylinder top of a working medium circulating device is connected with the heating device; an air cylinder at one end of the working medium circulating device is connected with the corresponding cooling device; the heating device and the cooling devices are connected through heat regenerators to form a closed working medium circulating loop; a transmission device is connected with a piston rod of the working medium circulating device through a connecting rod; the transmission device and the combustion device are connected by a split casing to form a whole; by taking ammonia or helium as a working medium and adopting a positive sterling cycle, the working medium absorbs heat from the combustion device, stores energy through the heat regenerators and discharges heat to the cooling devices, thereby forming a complete working medium circulating loop; and a transmission mechanism outputs shaft work to the outside. The gas axial transmission alpha type four-cylinder double-acting stirling engine disclosed by the invention has the advantages of cleanness, high efficiency and low noise; and in addition, the service life of a sealing element of the engine can be longer.

Owner:XI AN JIAOTONG UNIV

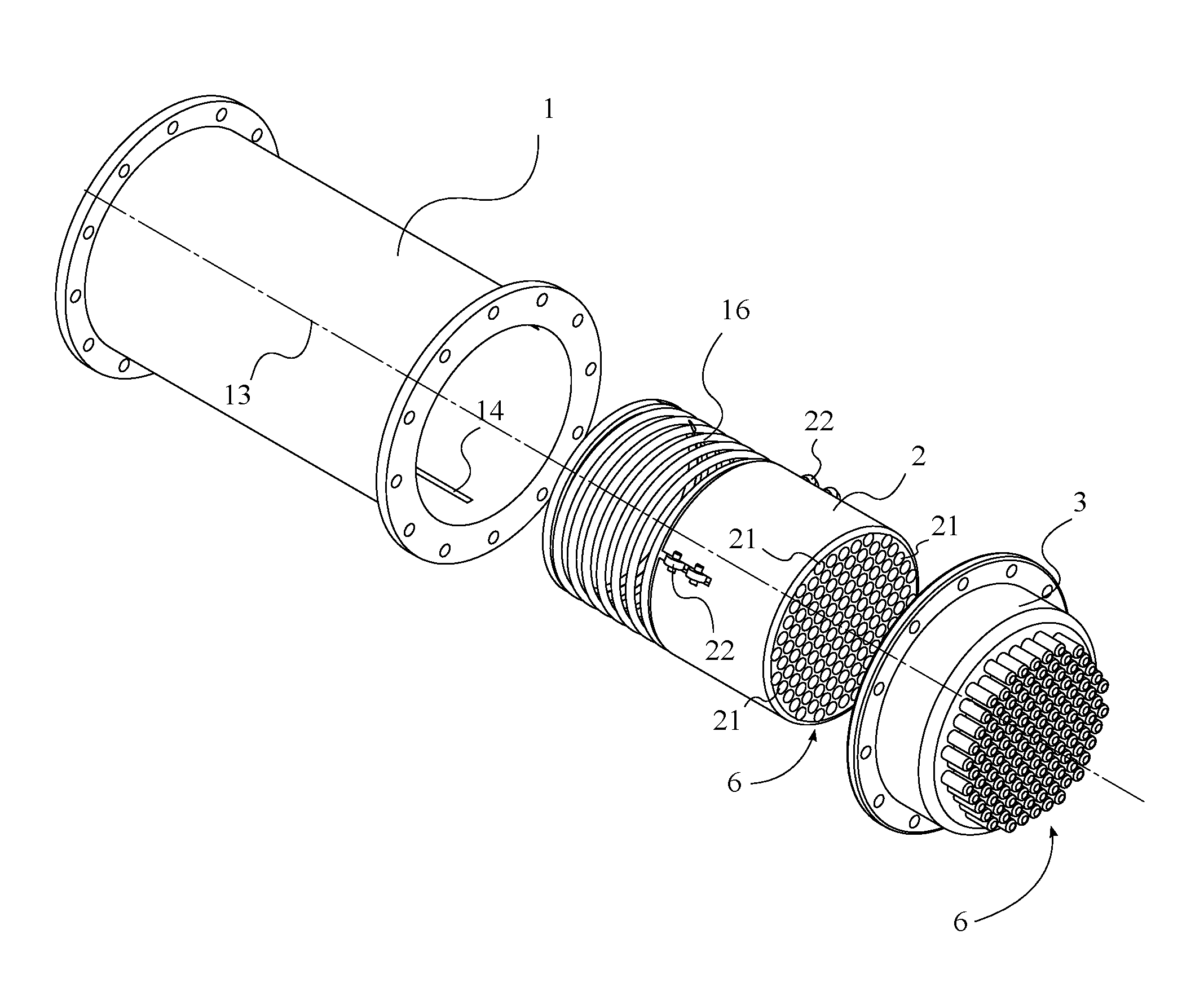

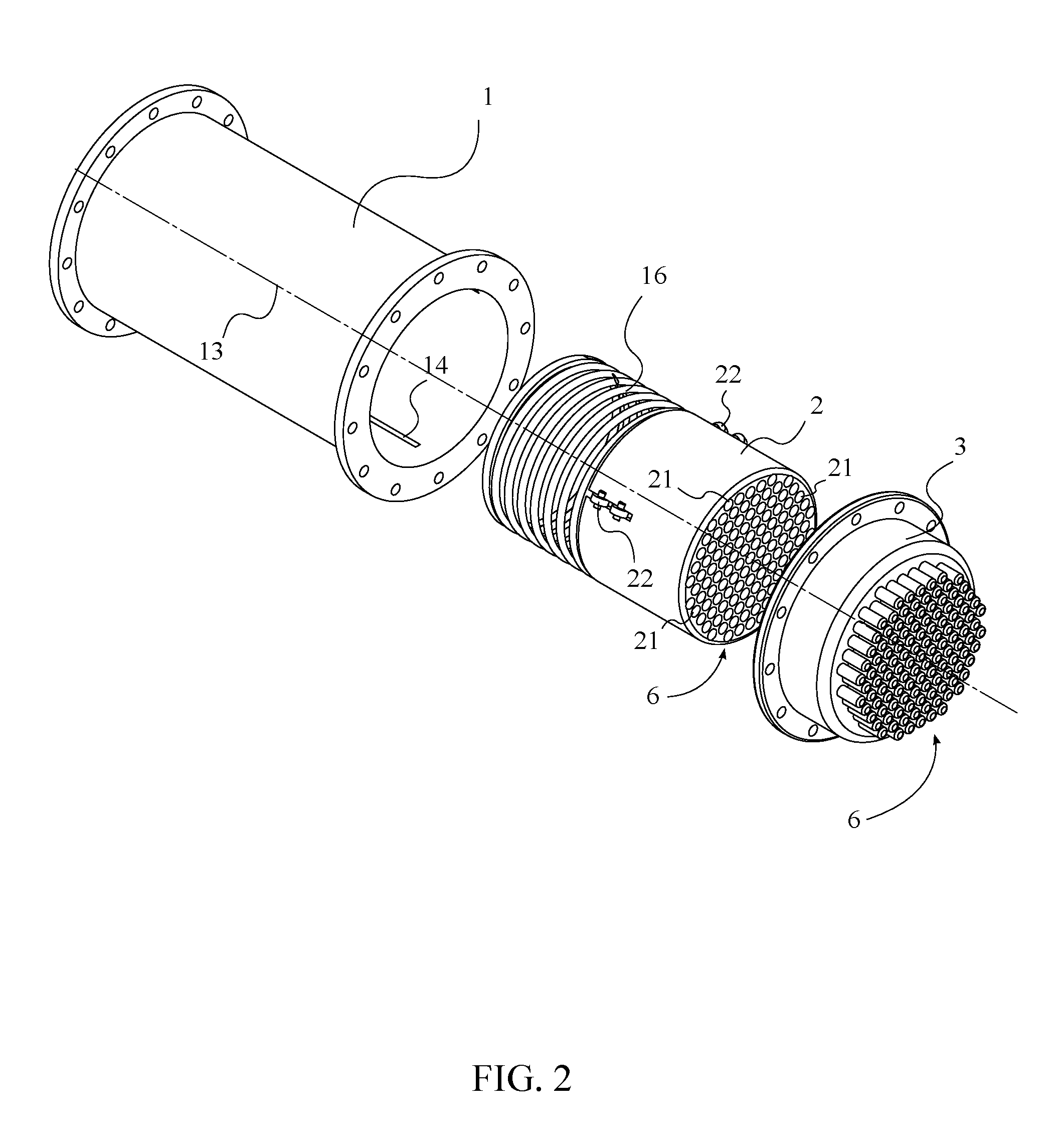

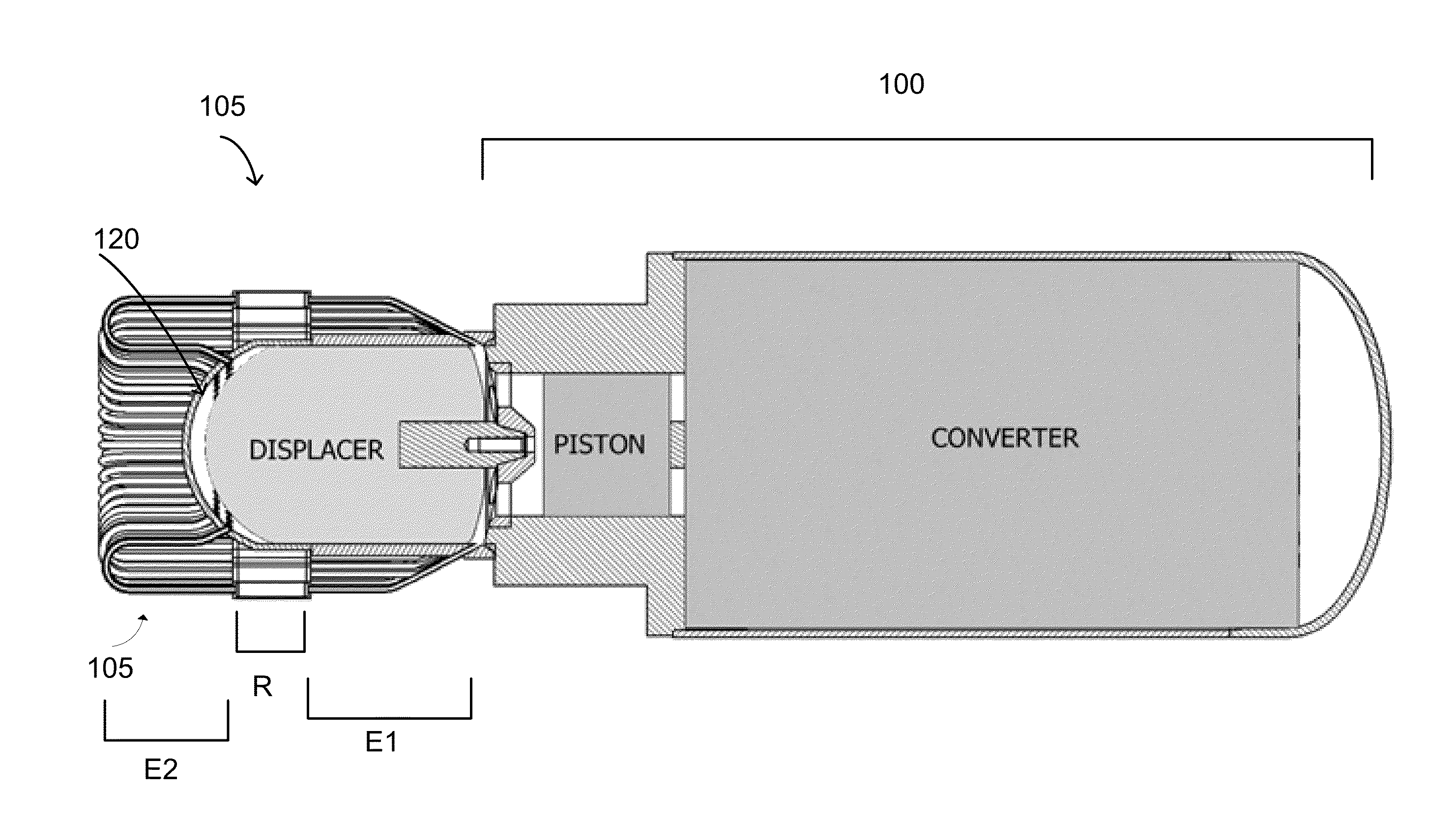

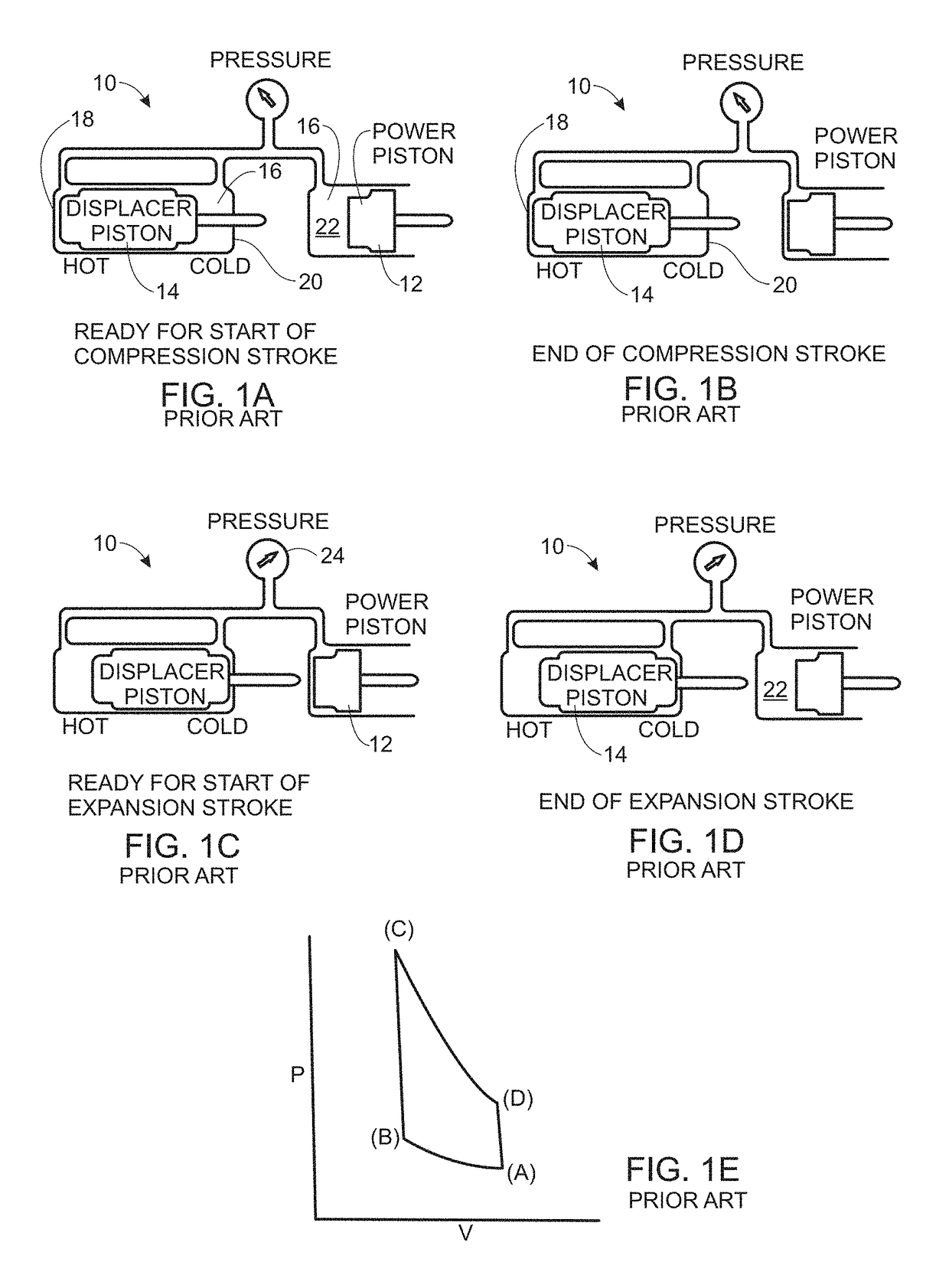

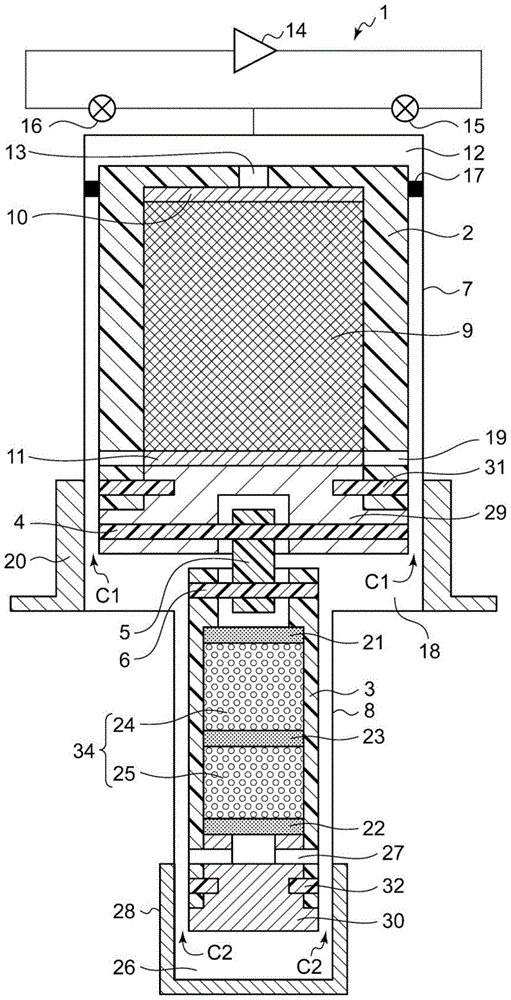

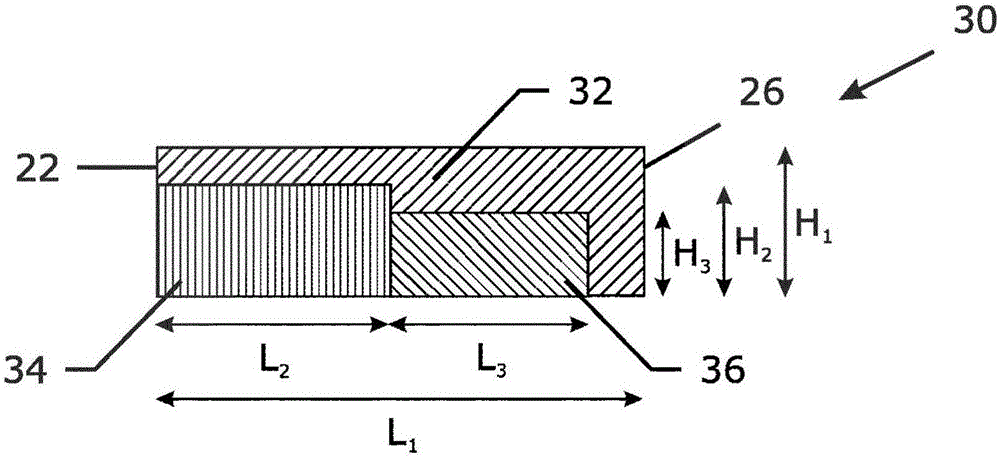

Stirling cycle transducer apparatus

ActiveUS20130239564A1Speed up heat exchangeReduce lossesClosed-cycle gas positive displacement engine plantRegeneratorsTransducerProcess engineering

A communication passage in a Stirling cycle transducer includes a cylindrical shaped thermal regenerator providing flow paths aligned with a regenerator cylindrical axis for providing periodic gas flow between first and second interfaces of the regenerator. A first heat exchanger conveys gas between a periphery of the heat exchanger and the first interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the gas and an external environment in a direction aligned with the regenerator cylindrical axis. A second heat exchanger conveys gas between a periphery of the heat exchanger and the second interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the external environment and the gas in a direction aligned with the regenerator cylindrical axis.

Owner:ETALIM

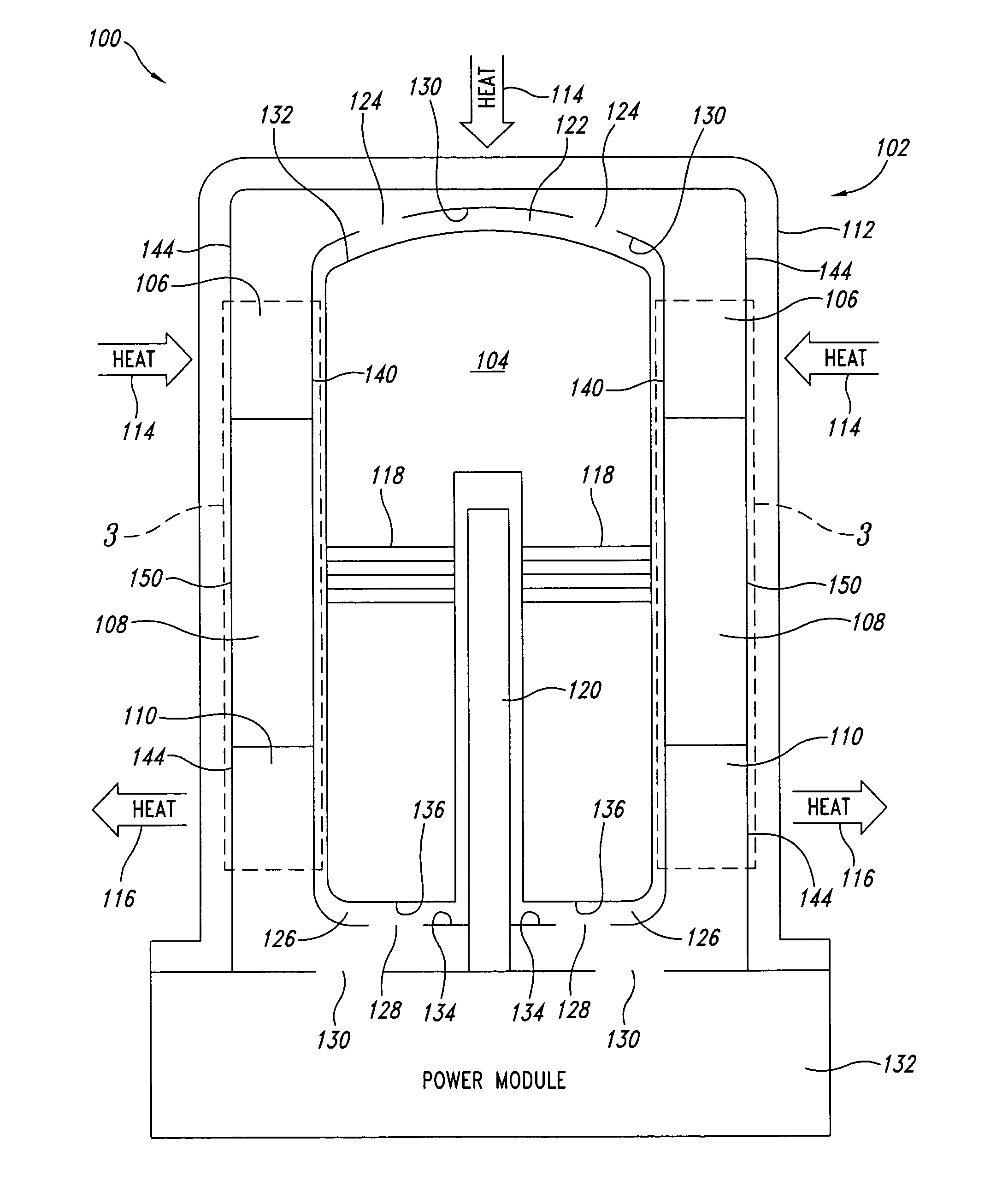

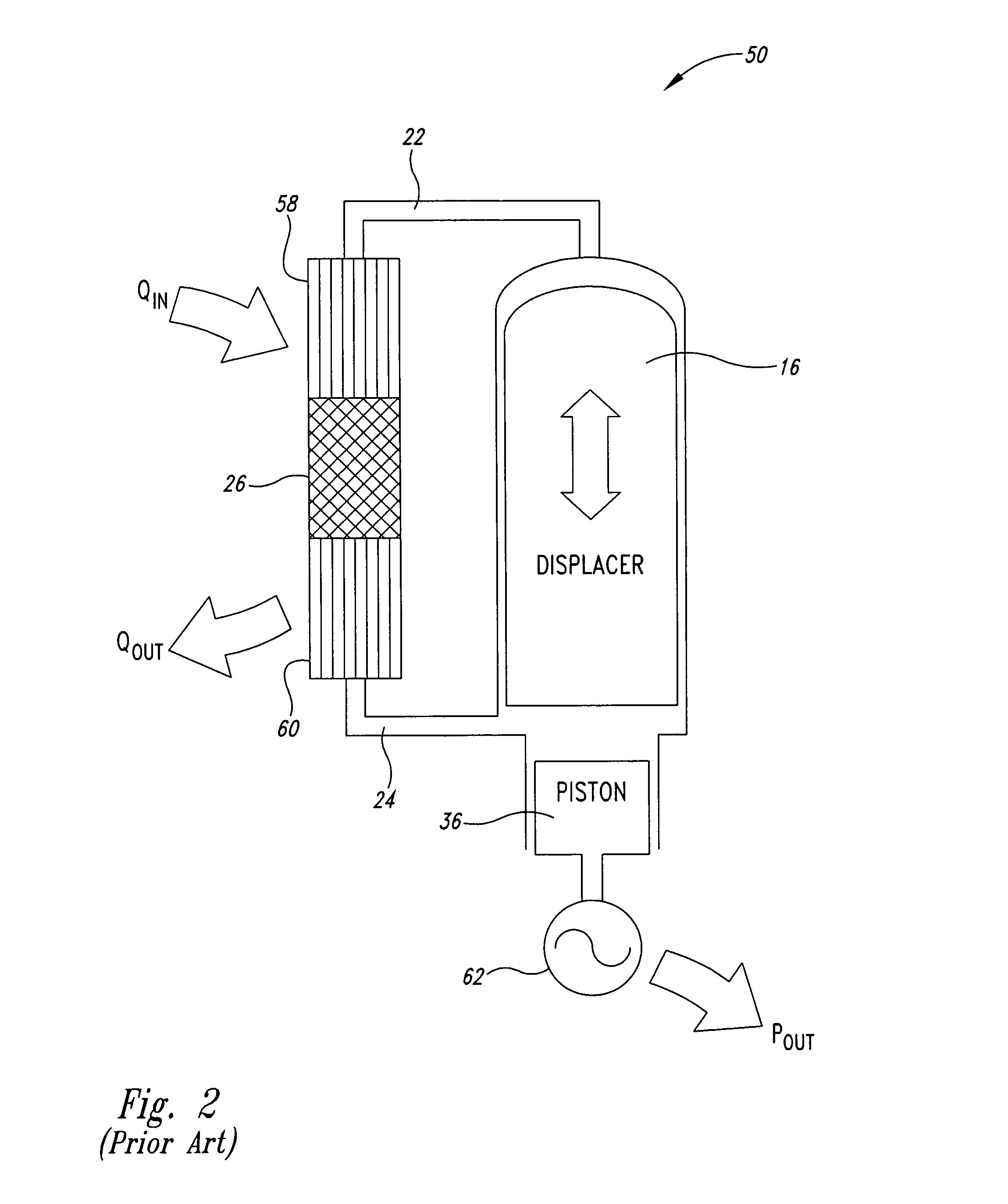

Stirling Engine with Regenerator Internal to the Displacer Piston and Integral Geometry for Heat Transfer and Fluid Flow

A Stirling engine with internal regenerator and integral geometry for heat transfer and fluid flow has a displacer piston with a plurality of cavities traversing through the displacer piston and arranged in a specific cross sectional geometry. A heater head has heater fin protrusions that are arranged in the specific geometry, and a cooling bridge has cooler fin protrusions that are in the specific geometry. The displacer piston alternates between the heater head and the cooling bridge, with the cavities of the piston alternately enveloping the heater protrusions and the cooling protrusions, providing more efficient heat transfer to and from the working fluid. Each cavity in the displacer also contains a regenerator core, further improving heat transfer efficiency. The heater fin protrusions may also contain thermally conductive cores. A bellows assembly may also be used to seal the displacer piston from the heater head in order to reduce unswept volume.

Owner:HOLSAPPLE ALAN CARL

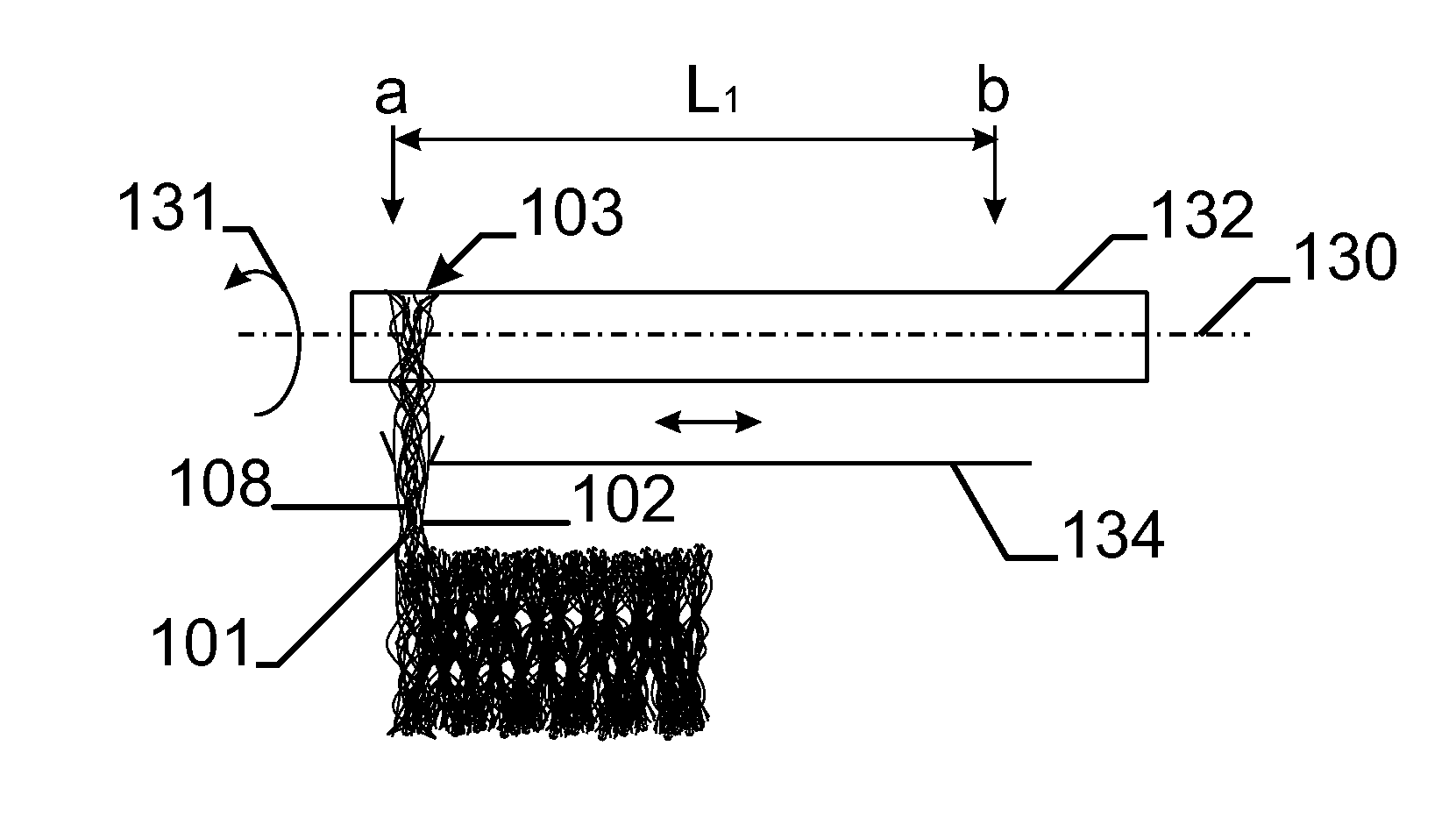

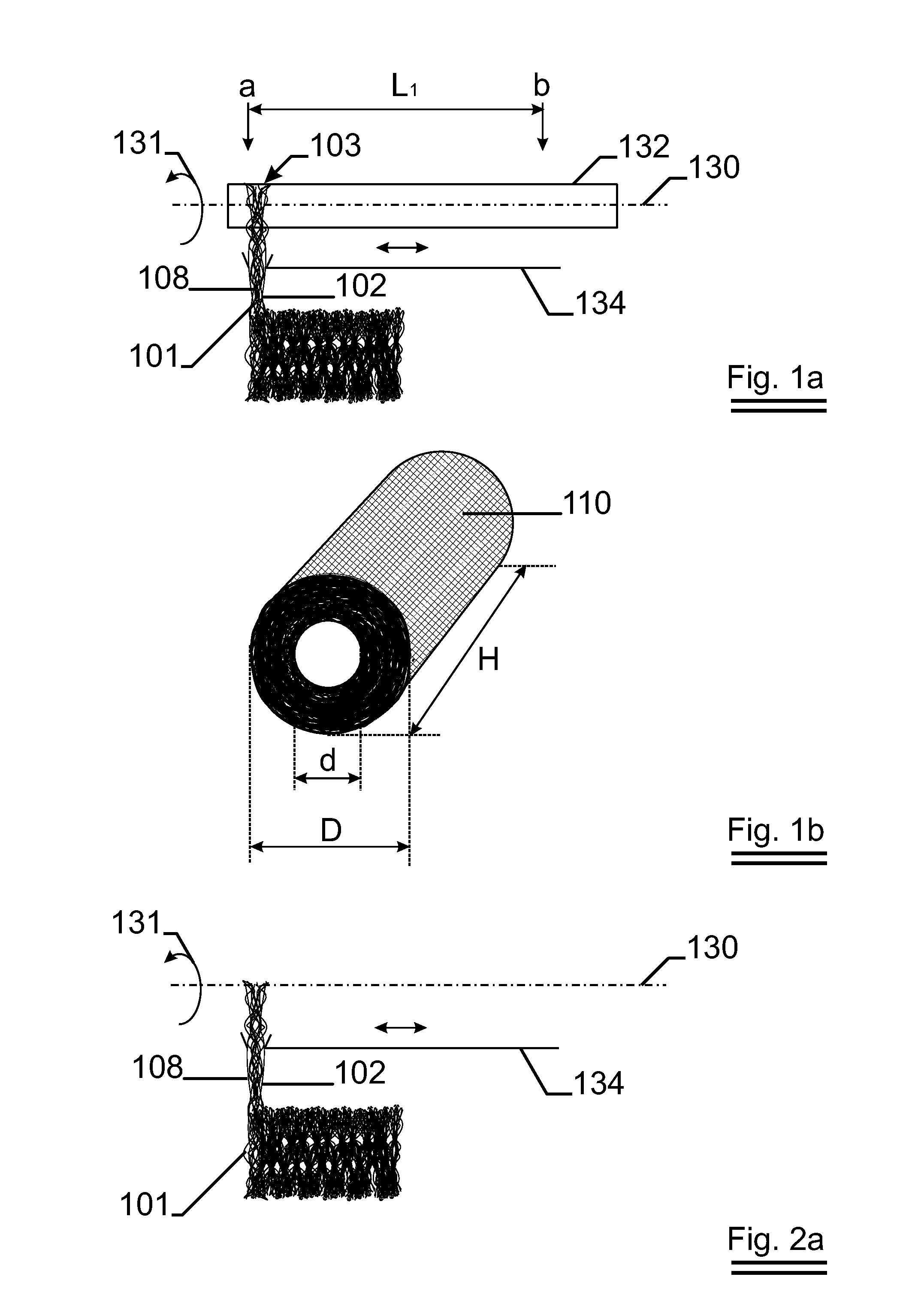

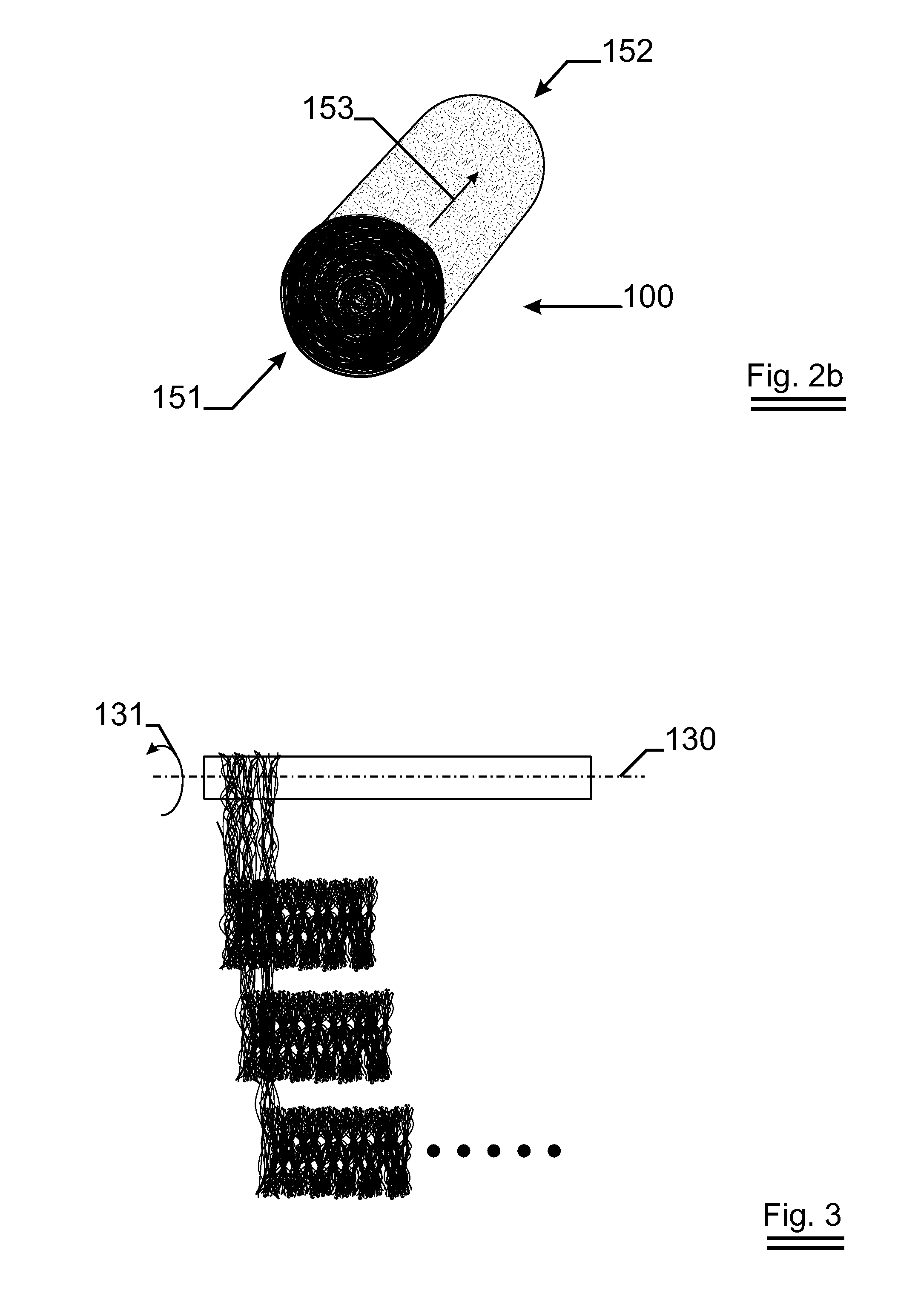

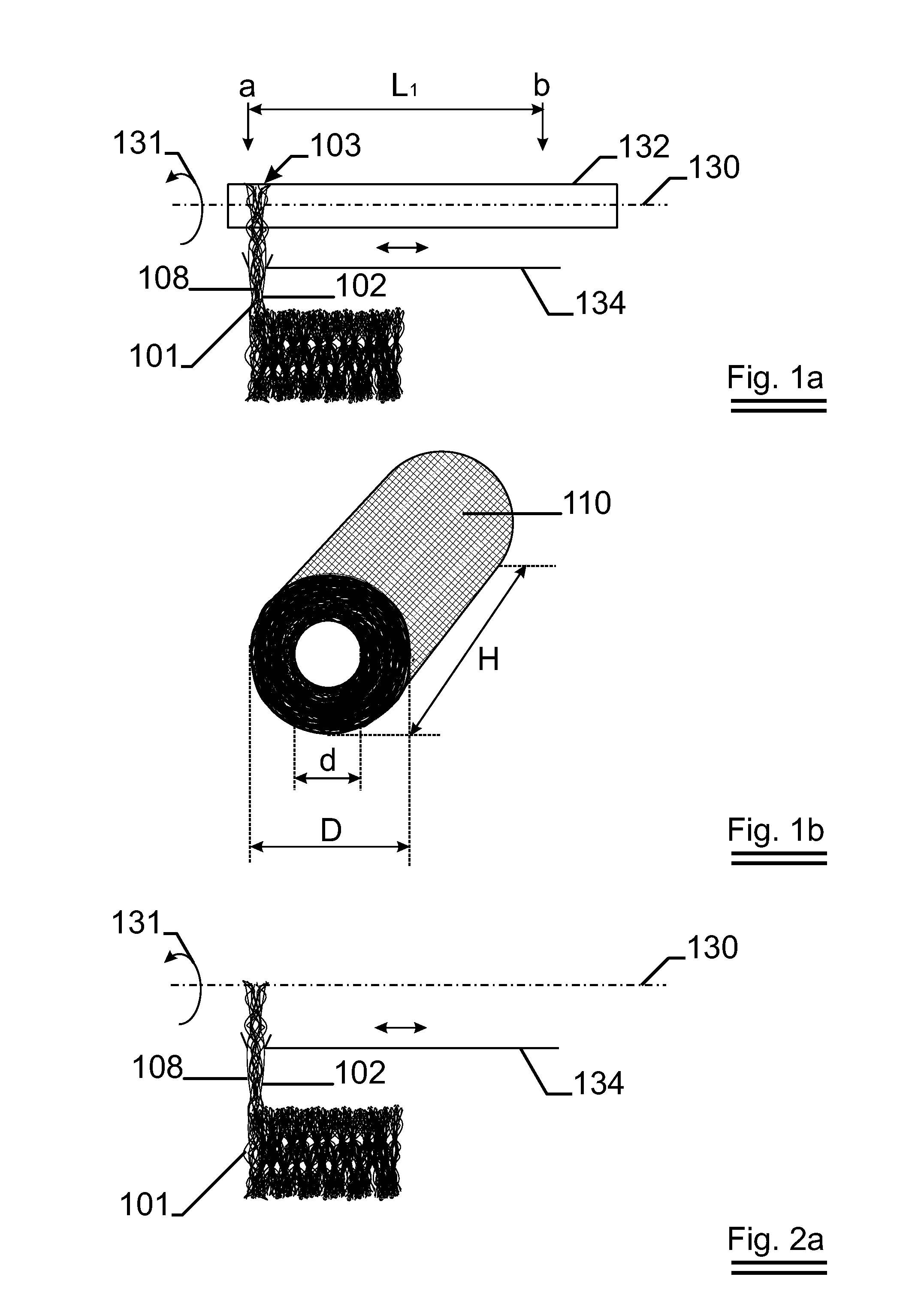

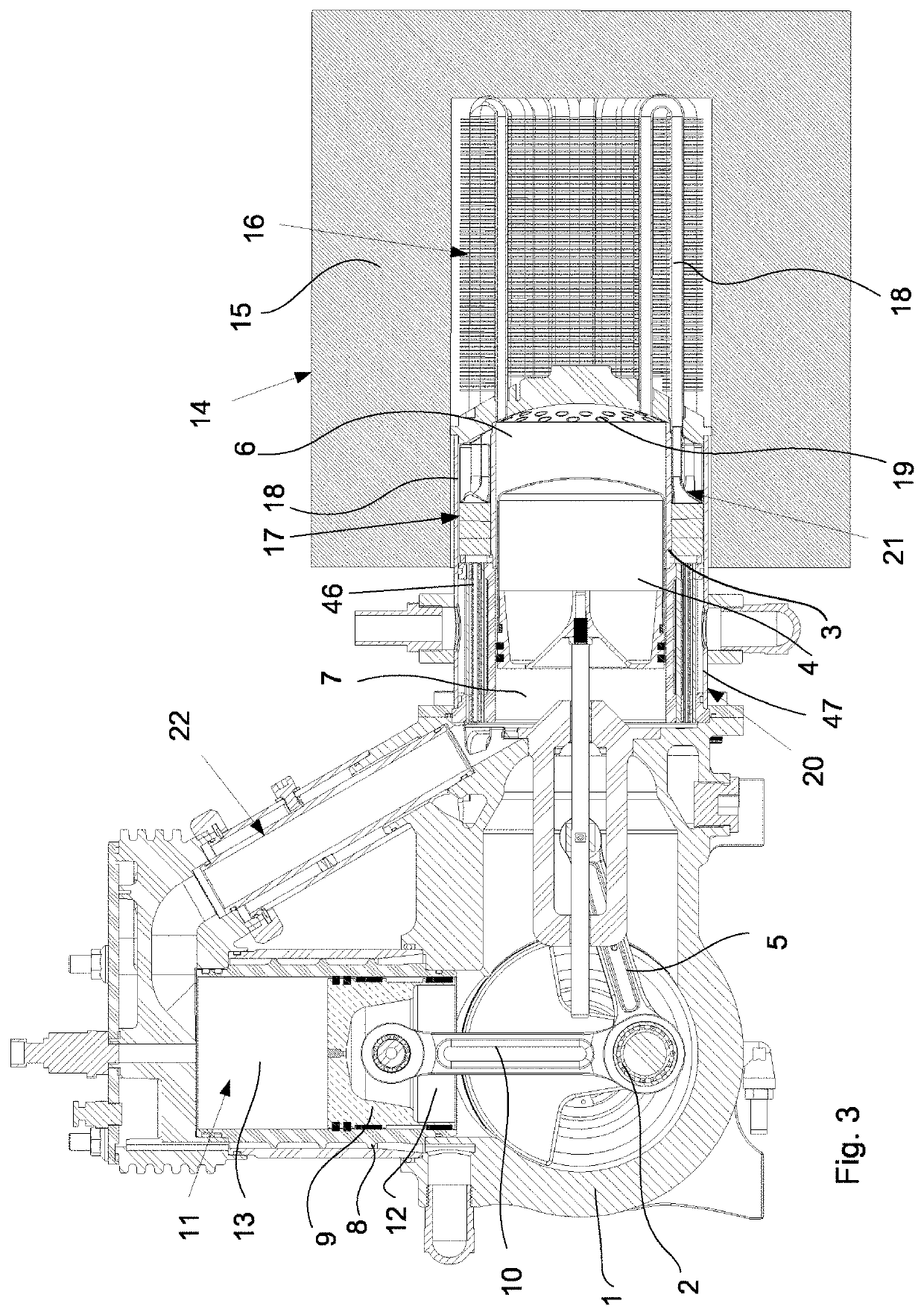

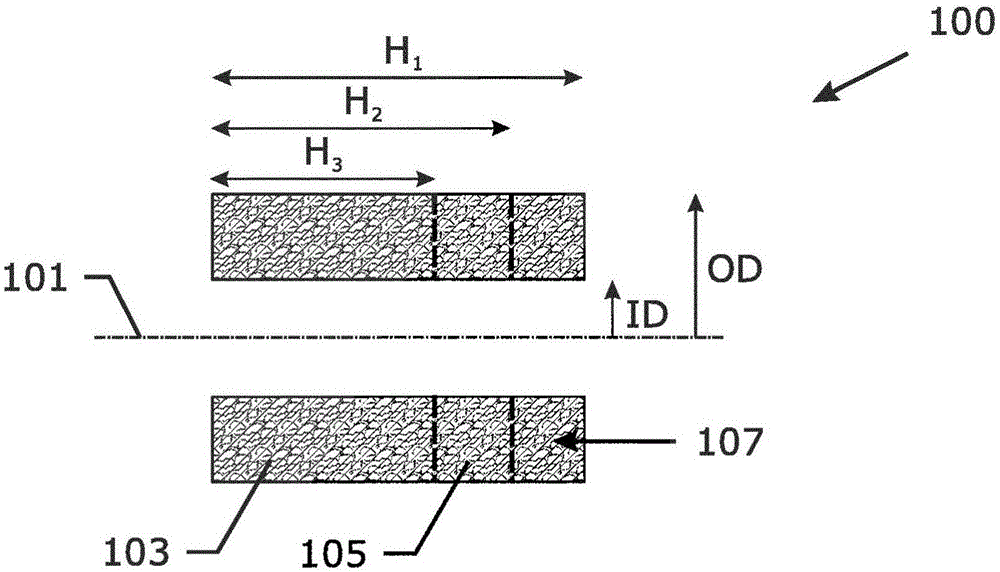

Regenerator for a thermal cycle engine

InactiveUS20110315341A1Avoiding preferential airflowHigh porosityCombustion processMetal-working apparatusCombustionFiber bundle

A regenerator (100), for a thermal cycle engine with external combustion, according to the invention comprises a network of metal fibers wherein a majority of the fibers at least partially encircles the axis of the regenerator. The fibers were part of a fiber bundle which is coiled and sintered thereby obtaining the regenerator.

Owner:NV BEKAERT SA

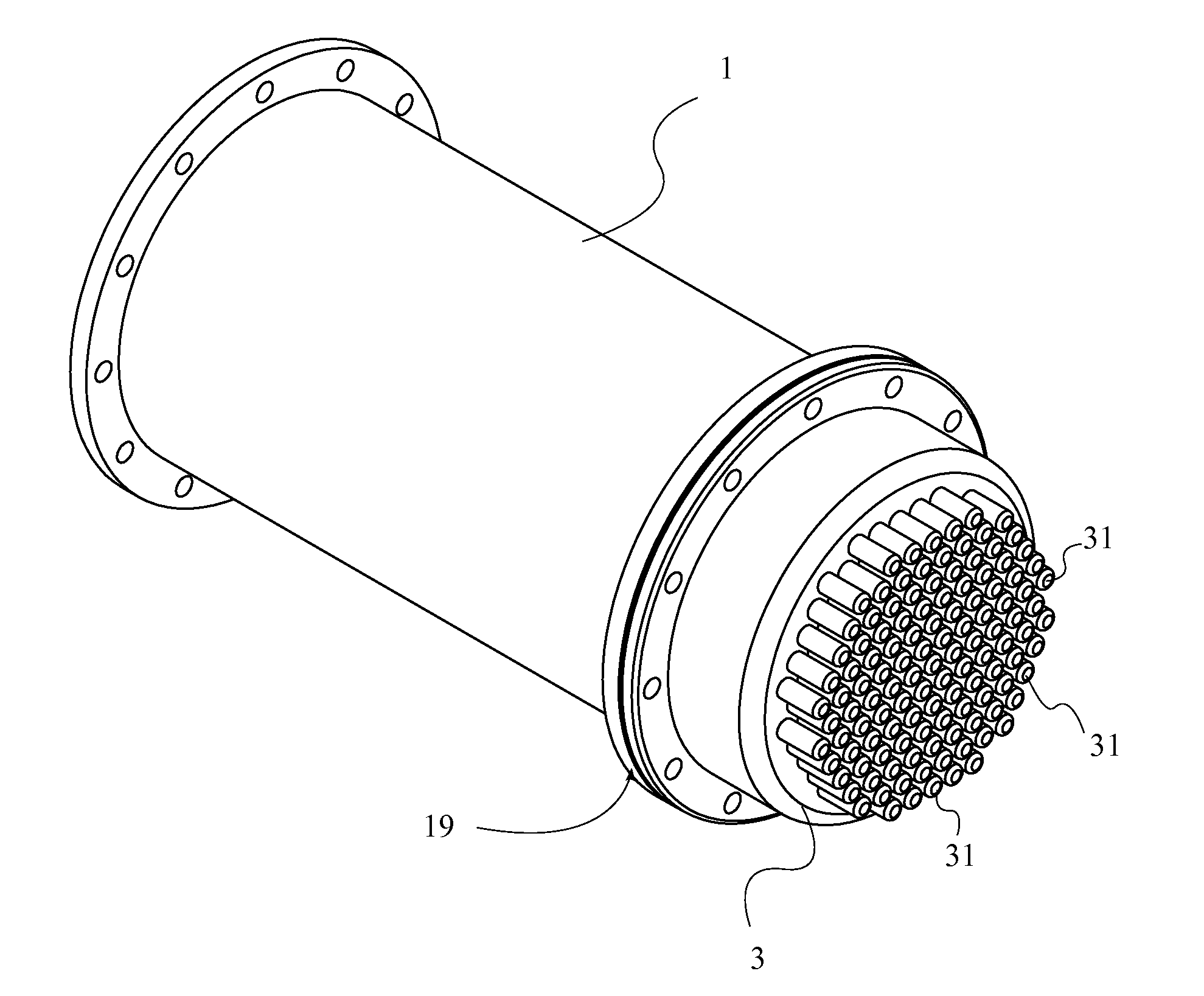

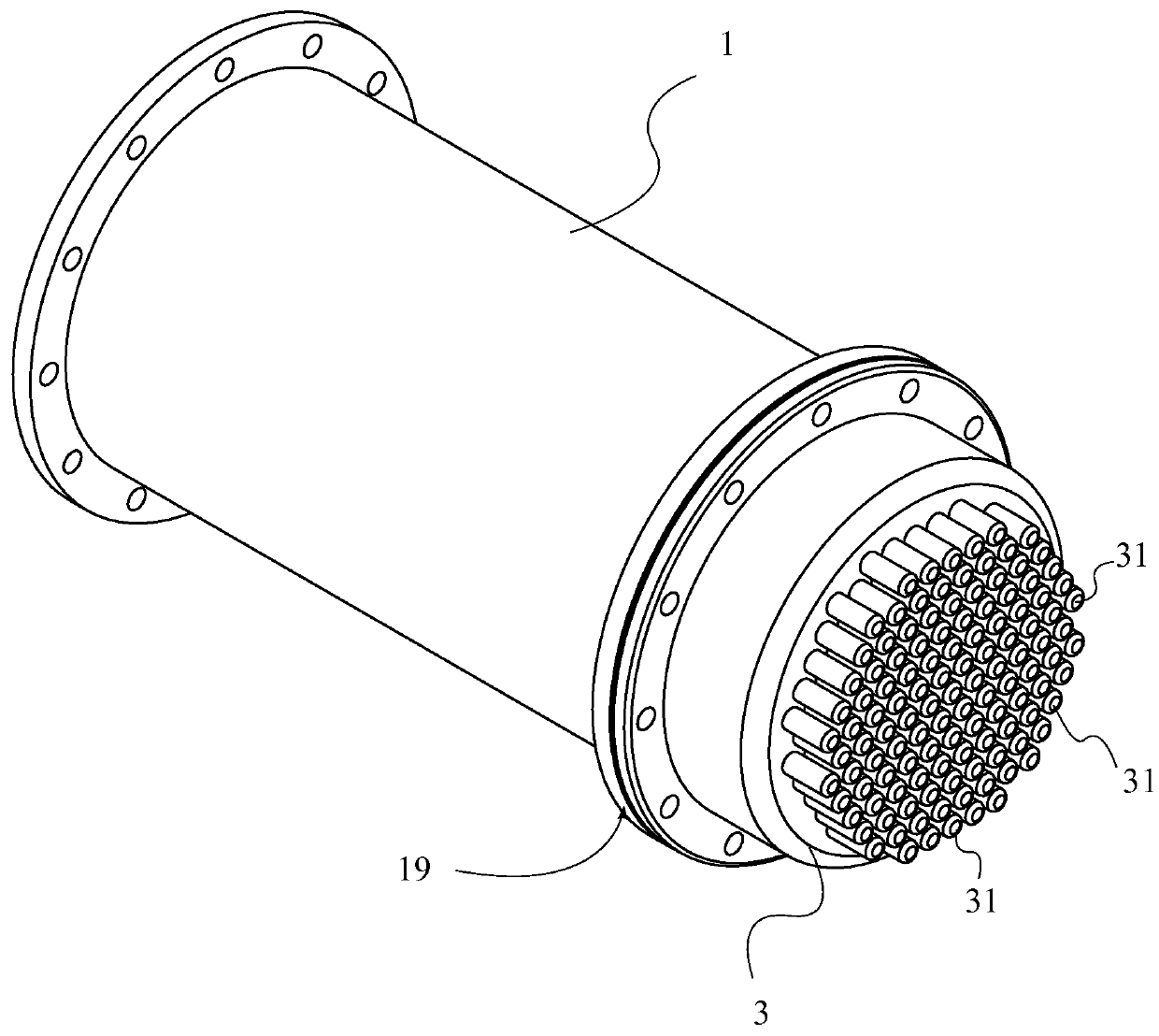

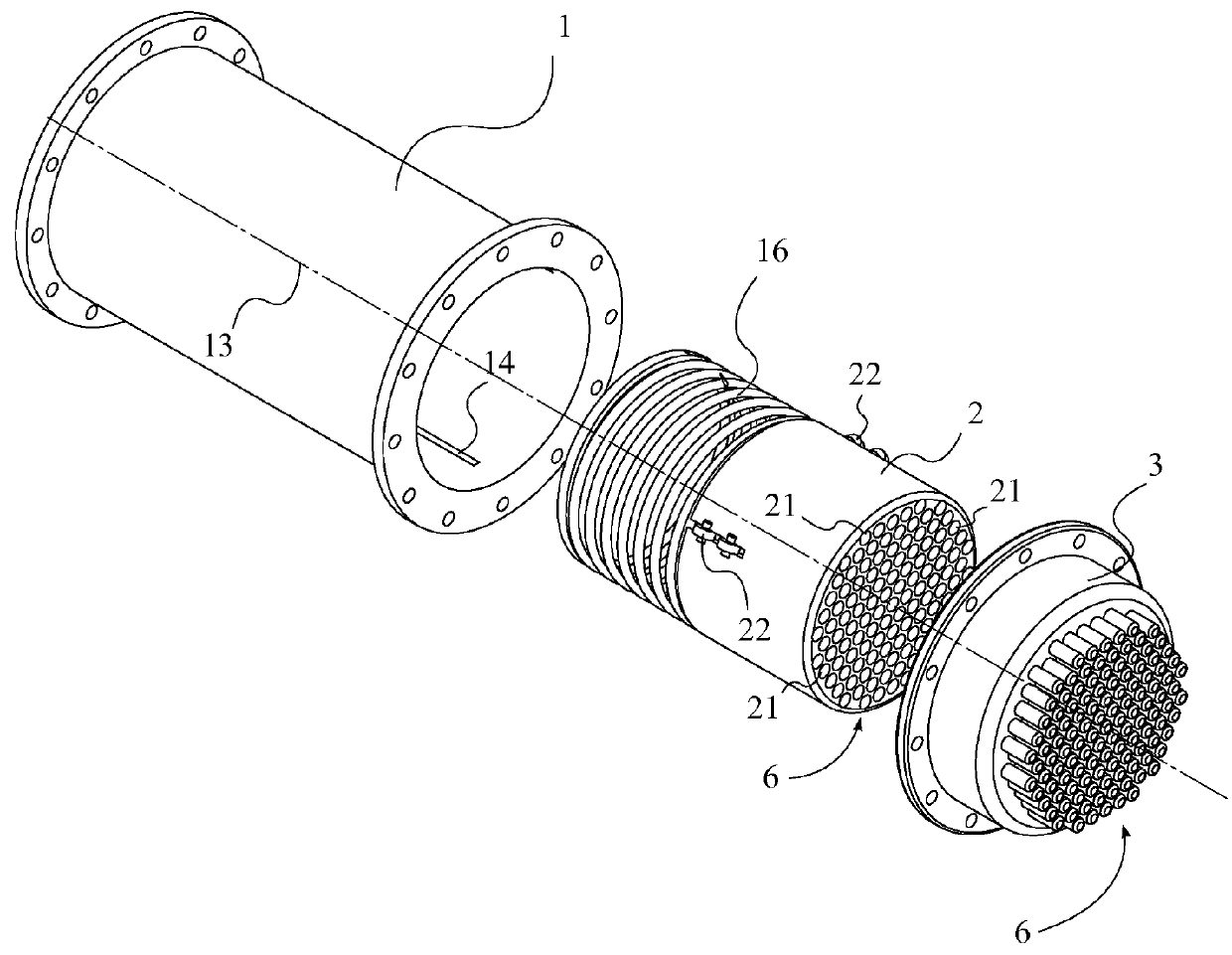

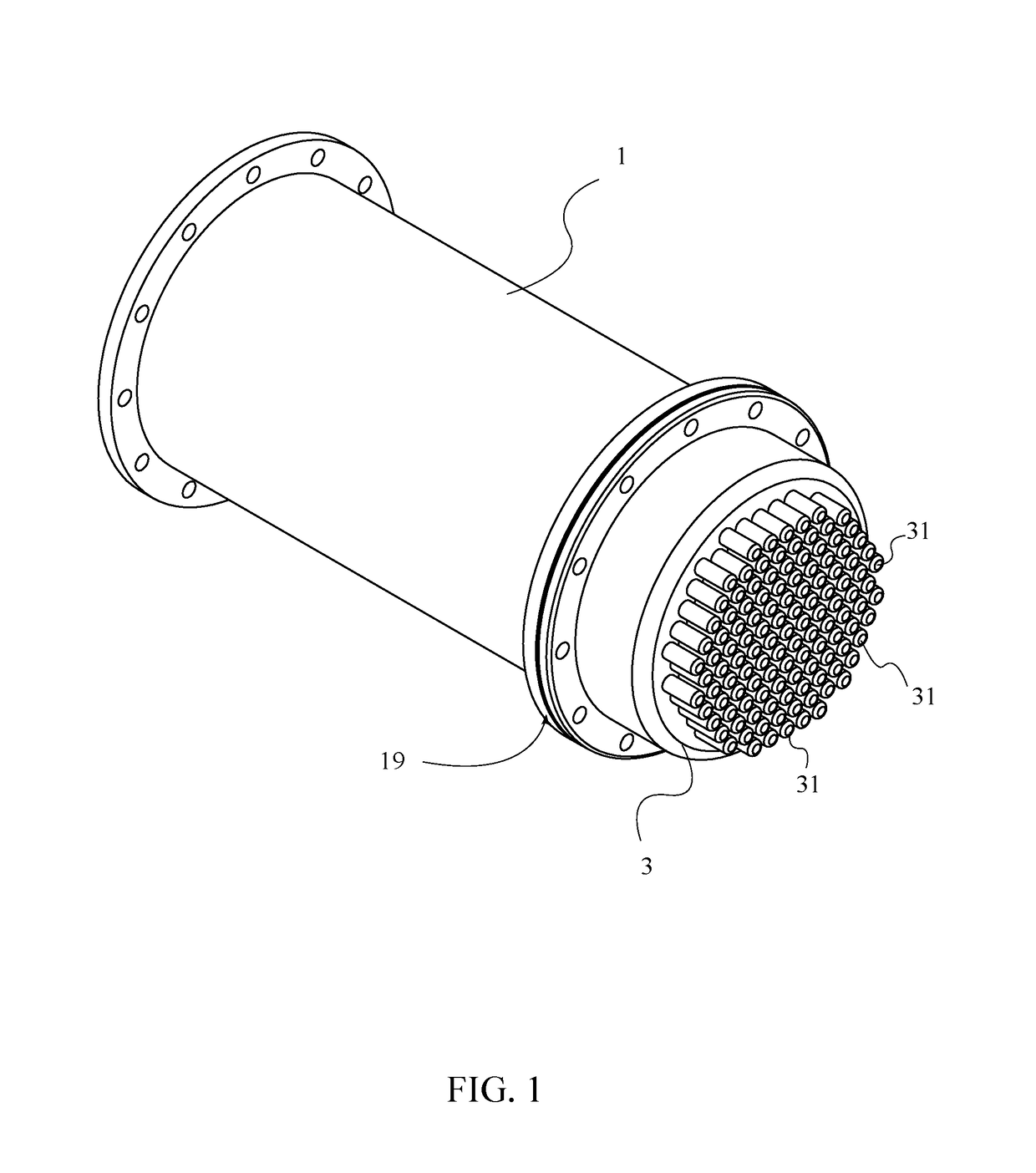

Tubular Heat Exchange

In one embodiment, the invention relates to a heat exchanger suitable for use with a thermodynamic cycle-based machine such as an engine, an energy conversion machine, a cooling machine or other suitable systems and machines. The heat exchanger can include one or more tubes arranged to form a heat exchanger. In one embodiment, a unitary tube is used. The heat exchanger can include a canister that includes a regenerator material. The canister can be in thermal communication with a working material and a containment vessel having a containment chamber in one embodiment.

Owner:QNERGY

Stirling Engine with Regenerator Internal to the Displacer Piston and Integral Geometry for Heat Transfer and Fluid Flow

ActiveUS20140026553A1Stirling type enginesClosed-cycle gas positive displacement engine plantWorking fluidEngineering

A Stirling engine with internal regenerator and integral geometry for heat transfer and fluid flow has a displacer piston with a plurality of cavities that traverse through the displacer piston and are arranged in a specific cross sectional geometry. A heater head has heater fin protrusions that are also arranged in the specific cross sectional geometry, and a cooling bridge has cooler fin protrusions that are also arranged in the specific cross sectional geometry. The displacer piston alternates between the heater head and the cooling bridge, with the cavities of the piston alternately enveloping the heater protrusions and the cooling protrusions, providing more efficient heat transfer to and from the working fluid. Each cavity in the displacer also contains a regenerator core, further improving heat transfer efficiency.

Owner:HOLSAPPLE ALAN CARL

Stirling engine with regenerator internal to the displacer piston and integral geometry for heat transfer and fluid flow

A Stirling engine with internal regenerator and integral geometry for heat transfer and fluid flow has a displacer piston with a plurality of cavities that traverse through the displacer piston and are arranged in a specific cross sectional geometry. A heater head has heater fin protrusions that are also arranged in the specific cross sectional geometry, and a cooling bridge has cooler fin protrusions that are also arranged in the specific cross sectional geometry. The displacer piston alternates between the heater head and the cooling bridge, with the cavities of the piston alternately enveloping the heater protrusions and the cooling protrusions, providing more efficient heat transfer to and from the working fluid. Each cavity in the displacer also contains a regenerator core, further improving heat transfer efficiency.

Owner:HOLSAPPLE ALAN CARL

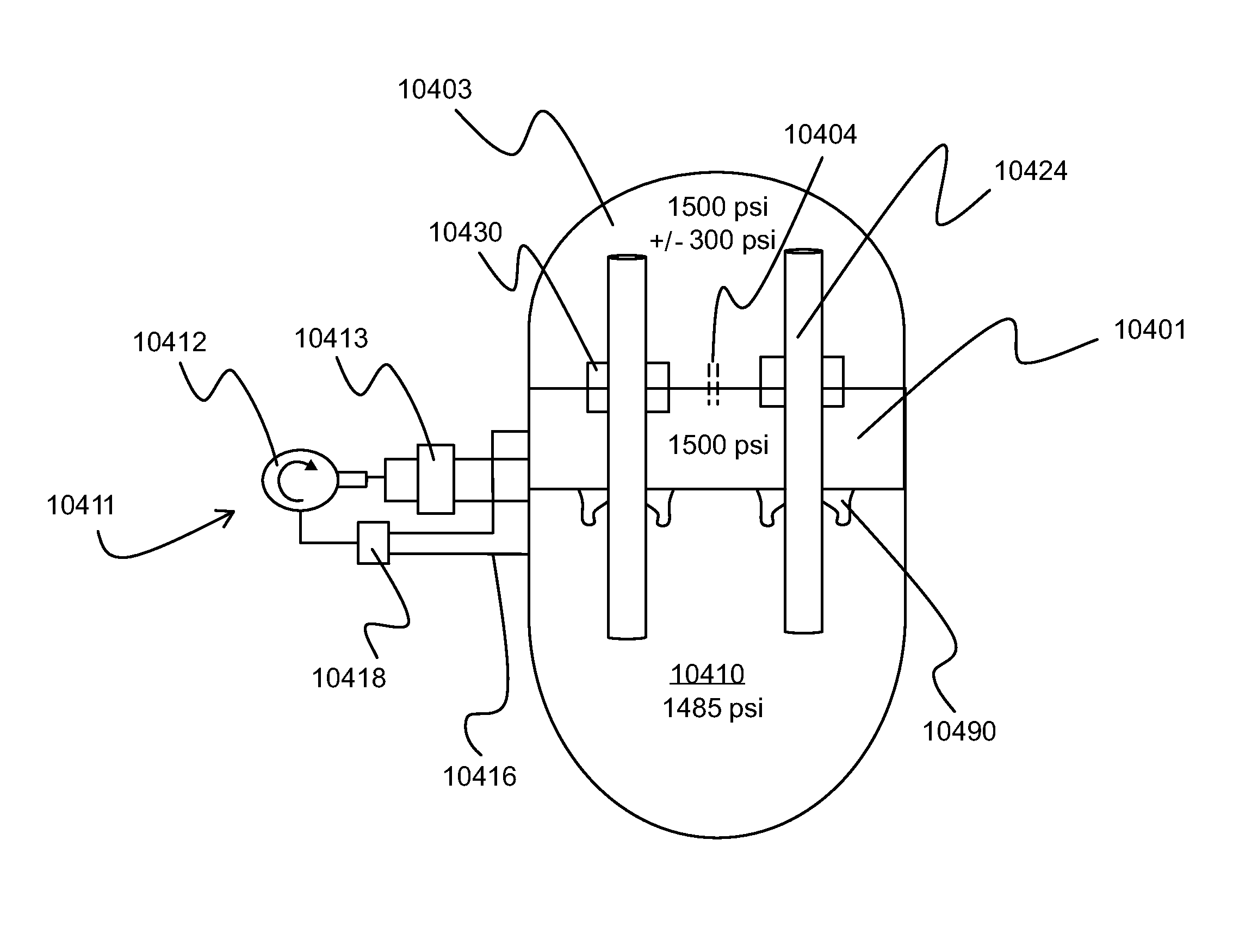

Stirling cycle machine with airlock pressure regulator and burner controls

An external combustion engine is disclosed. The external combustion engine includes a working fluid and a burner element, at least one heater head defining a working space, at least one piston cylinder containing a piston, a cooler, a crankcase including a crankshaft for producing an engine output, a rocking beam, a piston rod connected to the piston, a rocking beam driven by the piston rod, and a connecting rod connected at a first end to the rocking beam and at a second end to a crankshaft to convert rotary motion of the rocking beam to rotary motion of the crankshaft. The external combustion engine also includes an airlock space separating the crankcase and the working space for maintaining a pressure differential between the crankcase housing and the working space housing and an airlock pressure regulator connected between the crankcase and one of the airlock space and working space.

Owner:DEKA PROD LLP

Stirling engine with regenerator internal to the displacer piston and integral geometry for heat transfer and fluid flow

A Stirling engine with internal regenerator and integral geometry for heat transfer and fluid flow has a displacer piston with a plurality of cavities traversing through the displacer piston and arranged in a specific cross sectional geometry. A heater head has heater fin protrusions that are arranged in the specific geometry, and a cooling bridge has cooler fin protrusions that are in the specific geometry. The displacer piston alternates between the heater head and the cooling bridge, with the cavities of the piston alternately enveloping the heater protrusions and the cooling protrusions, providing more efficient heat transfer to and from the working fluid. Each cavity in the displacer also contains a regenerator core, further improving heat transfer efficiency. The heater fin protrusions may also contain thermally conductive cores. A bellows assembly may also be used to seal the displacer piston from the heater head in order to reduce unswept volume.

Owner:HOLSAPPLE ALAN CARL

Stirling cycle machine

A rod seal assembly. The rod seal assembly includes a housing between two spaces configured to receive a reciprocating rod, the reciprocating rod disposed within a first space and a second space, a floating bushing configured to move axially and radially within the housing and disposed coaxially around the reciprocating rod, a rod seal configured to seal the outside diameter of the reciprocating rod relative to an inside surface of the floating bushing, and at least one stationary bushing fixed within the housing that may form a seal with the floating bushing to the axial flow of fluid in the presence of a pressure difference between the two spaces.

Owner:NEW POWER CONCEPTS

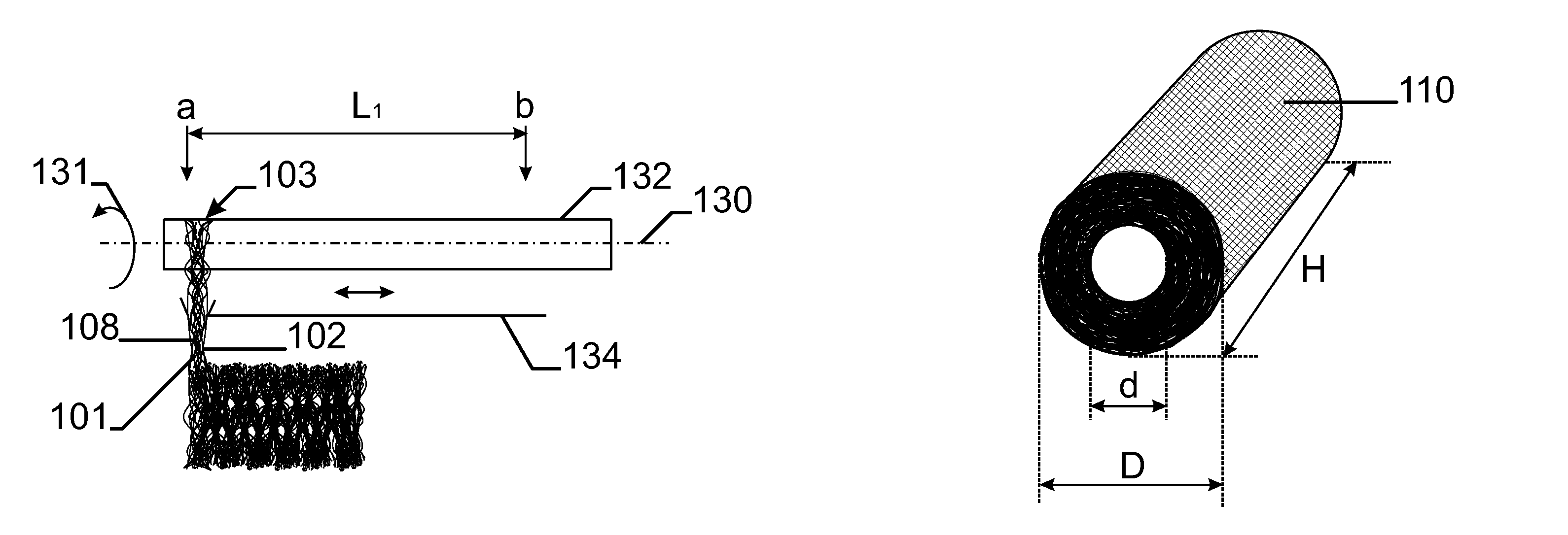

Regenerator for a thermal cycle engine

InactiveUS8782890B2High porosityImprove breathabilityCombustion processRegenerative heat exchangersCombustionFiber bundle

A regenerator (100), for a thermal cycle engine with external combustion, according to the invention comprises a network of metal fibers wherein a majority of the fibers at least partially encircles the axis of the regenerator. The fibers were part of a fiber bundle which is coiled and sintered thereby obtaining the regenerator.

Owner:NV BEKAERT SA

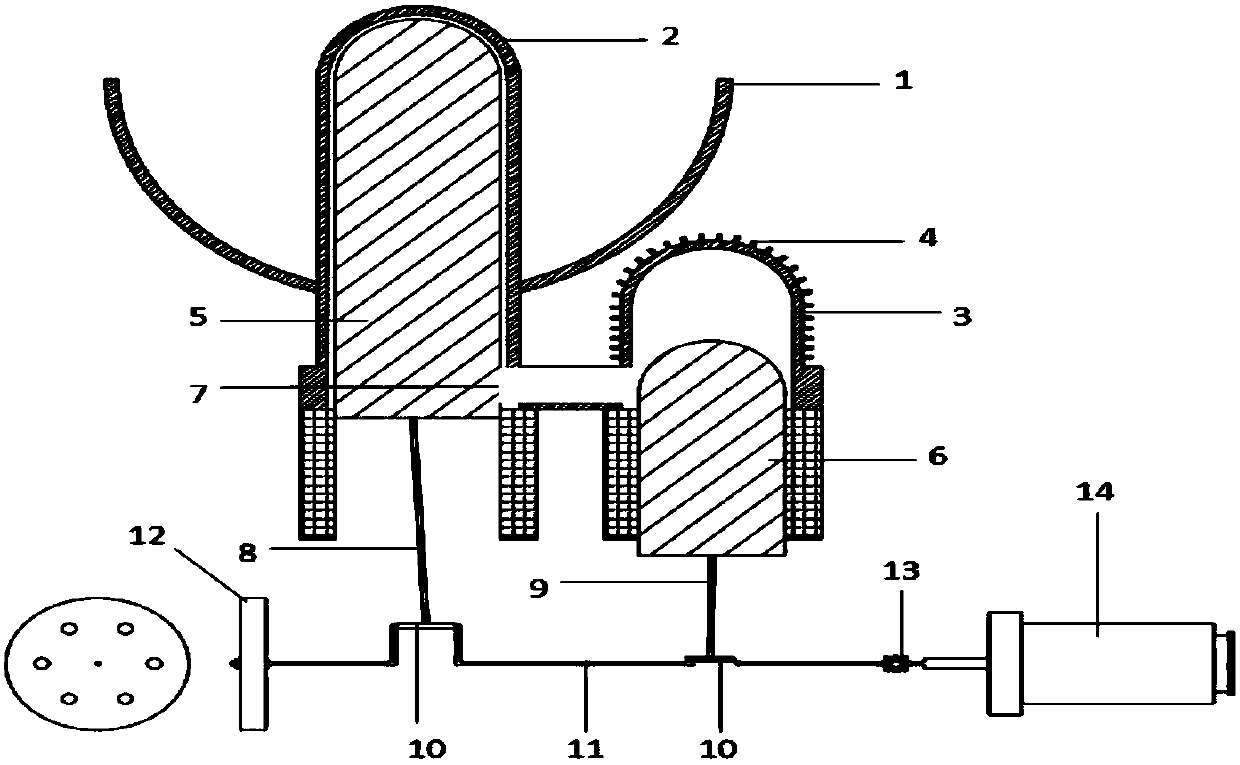

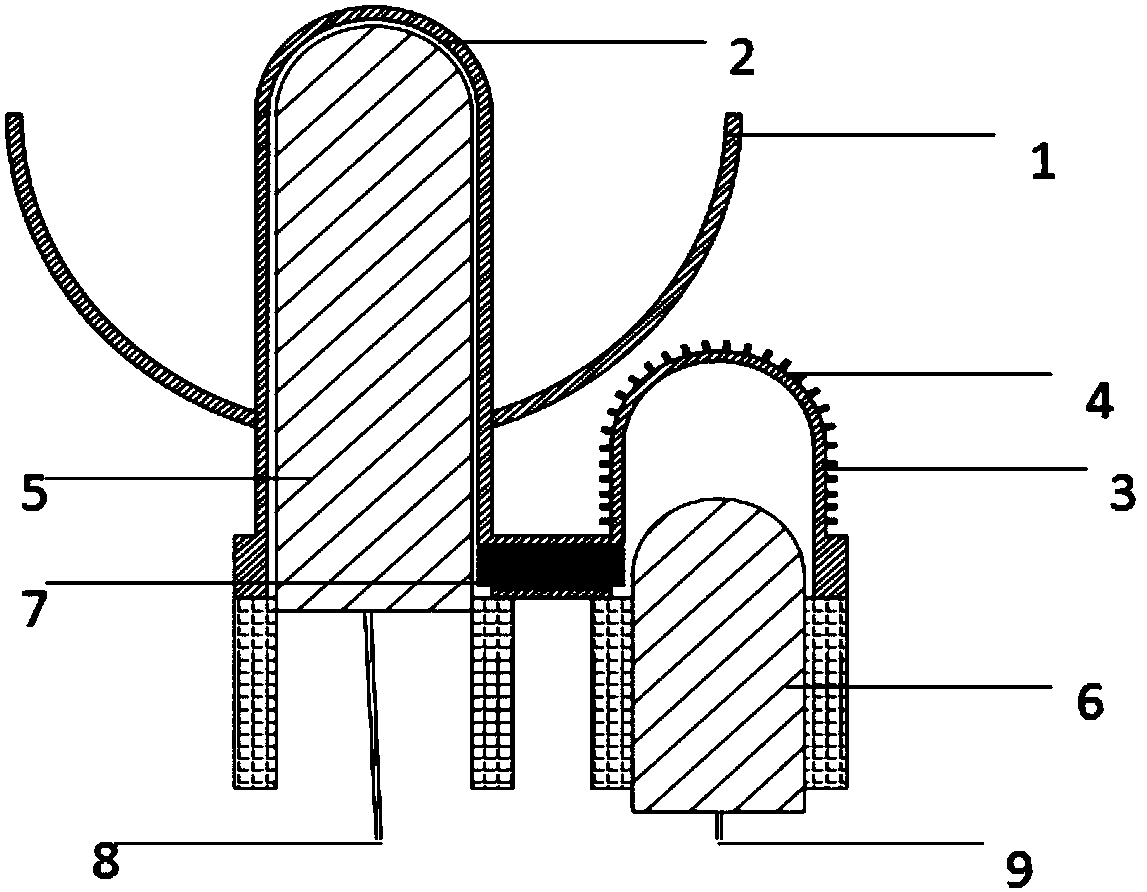

Stirling generator with labyrinth corridor heat regenerator

PendingCN107701328AImprove power generation efficiencyReduce production energy consumptionFrom solar energyRegeneratorsEngineeringSolar power

The invention discloses a Stirling generator with a labyrinth corridor heat regenerator, and belongs to the technical field of solar power generation. The generator is based on a Stirling cycle, a solar thermal effect power generation manner is utilized, other materials are completely replaced, production energy consumption is reduced, and pollution is reduced. The labyrinth corridor heat regenerator is adopted, and the heat regenerator is located in a channel used for connecting a cold cylinder with a hot cylinder; when the hot cylinder exhausts air to the cold cylinder, the air radiates heatto the heat regenerator, and when cold air flows back to the hot cylinder from the cold cylinder, the cold air absorbs heat from the heat regenerator; heat exchange is enhanced by increasing the heatexchange distance, the labyrinth corridor cannot relate to a flow separation problem, and therefore the flow losses caused by boundary layer separation cannot occur. A fluid flows in the labyrinth corridor channel, the heat exchange distance is lengthened, double-faced heat exchange of a heat absorbing plate is achieved for enhancing heat exchange, and it is guaranteed that the generator has highpower generation efficiency. The Stirling generator with the labyrinth corridor heat regenerator can also cooperate with various power storage devices for use, and therefore electric power is stored.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

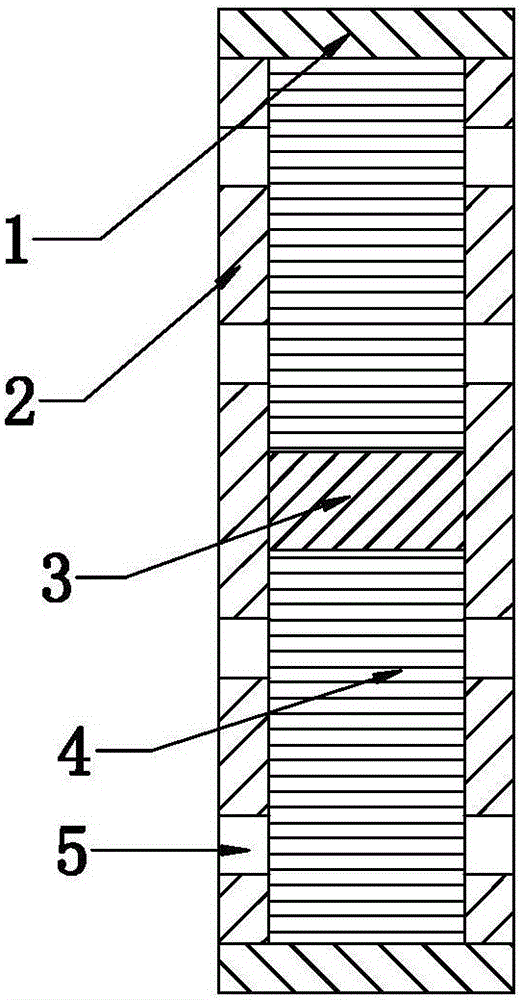

Scroll plate type heat regenerator of Stirling engine

InactiveCN105804888ASmall flow resistanceSimple structural designRegeneratorsHot gas positive displacement engine plantsStirling engineEngineering

The invention discloses heat regenerators of Stirling engines and particularly relates to a scroll plate type heat regenerator of a Stirling engine. The scroll plate type heat regenerator of the Stirling engine comprises a pipe shell and two end covers which are installed on the two side faces of the pipe shell. A scroll plate which is sealed through the end covers and formed by winding a heat exchange coiled material is arranged in the pipe shell. Through holes are formed in the two end covers correspondingly. By the adoption of the structure, through the arrangement of the scroll plate installed in the pipe shell and the end covers located on the two side faces of the pipe shell and provided with the through holes, working media can successfully penetrate into gaps of the scroll plate from the through hole in one side and flow out of the through hole in the other side, and thus the flow resistance is greatly reduced; and in addition, through the simple structural design of the scroll plate type heat regenerator, the manufacturing cost is greatly reduced.

Owner:JIANGSU YUANZHIYI ELECTRIC

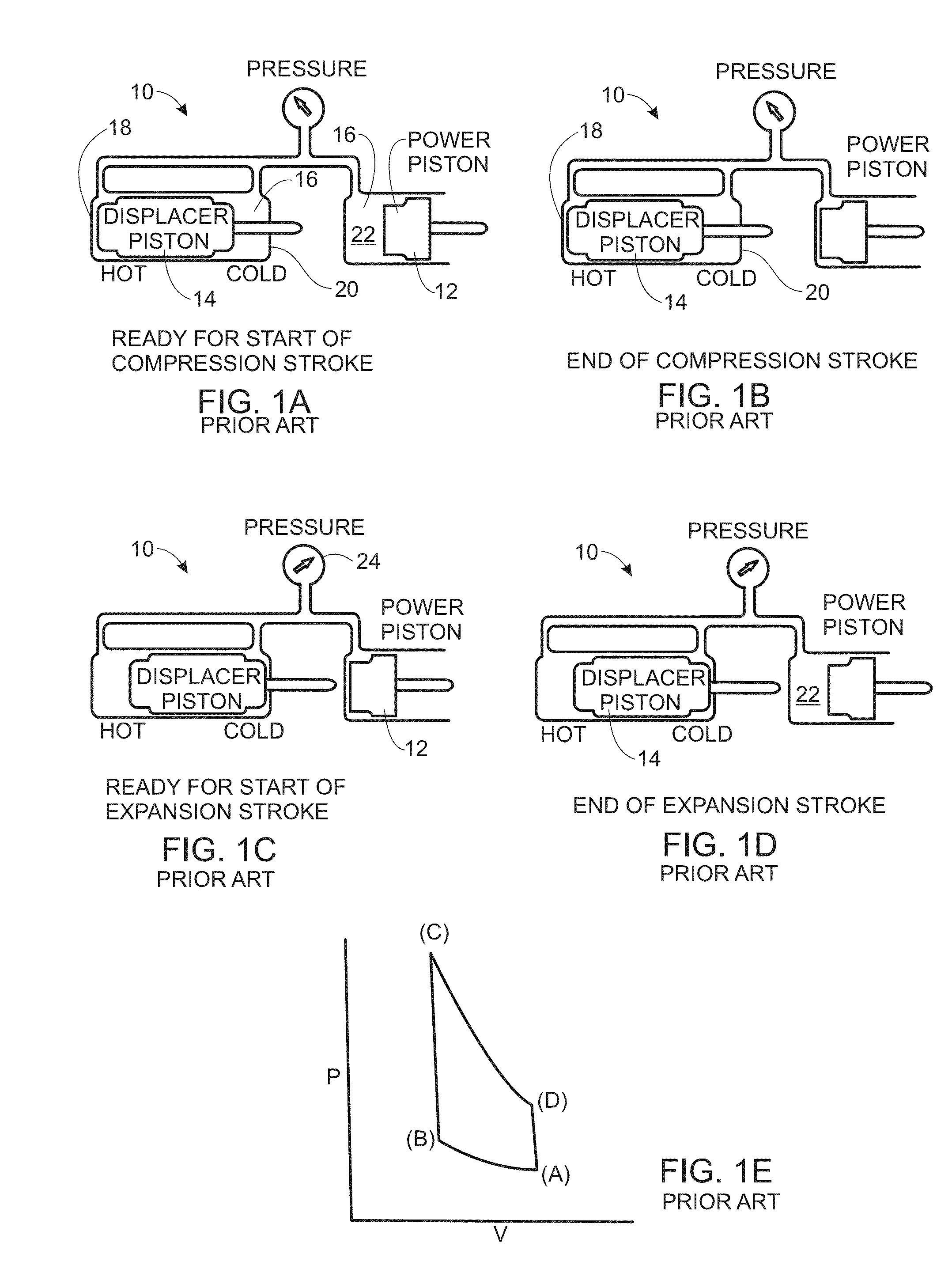

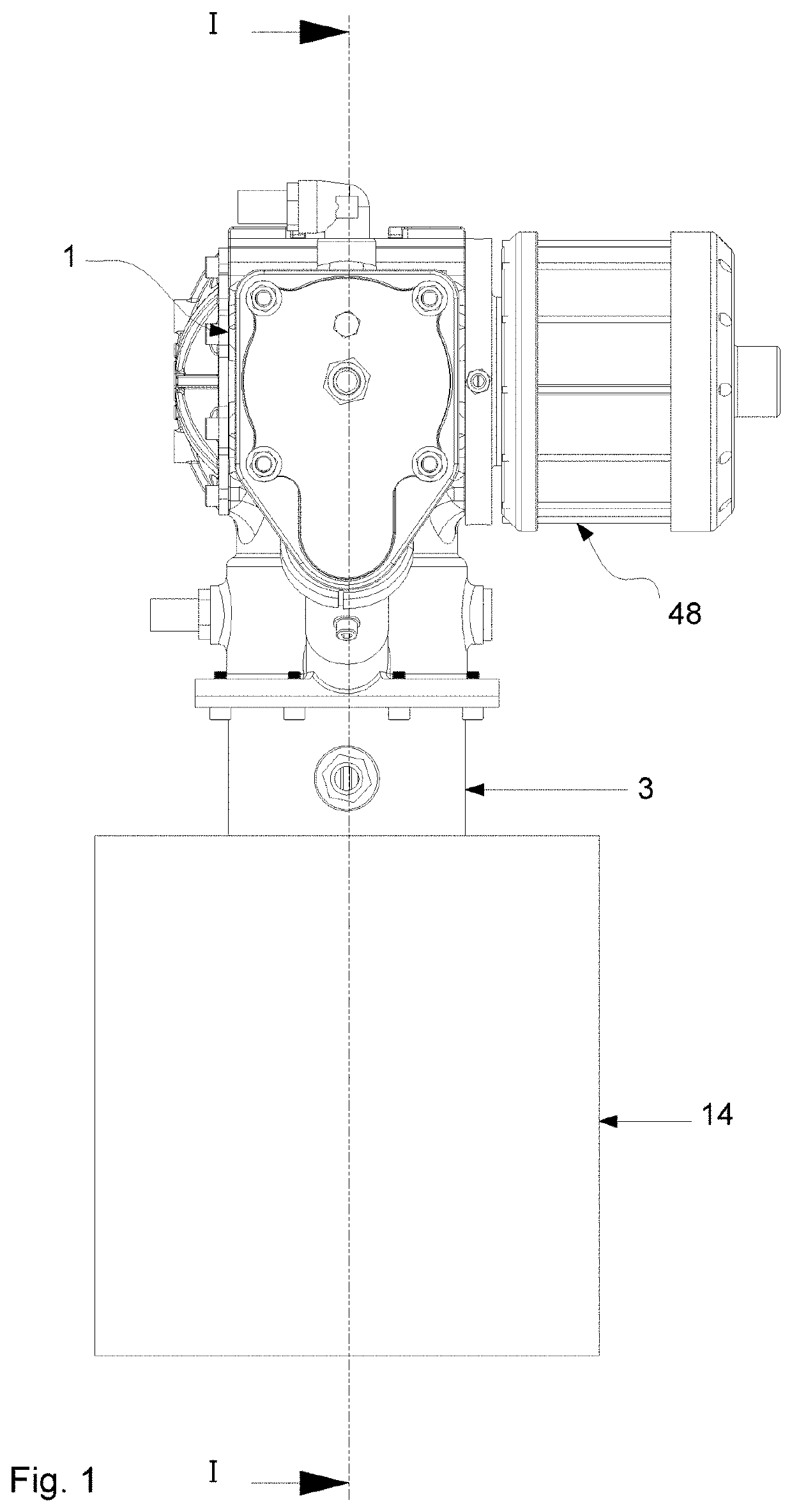

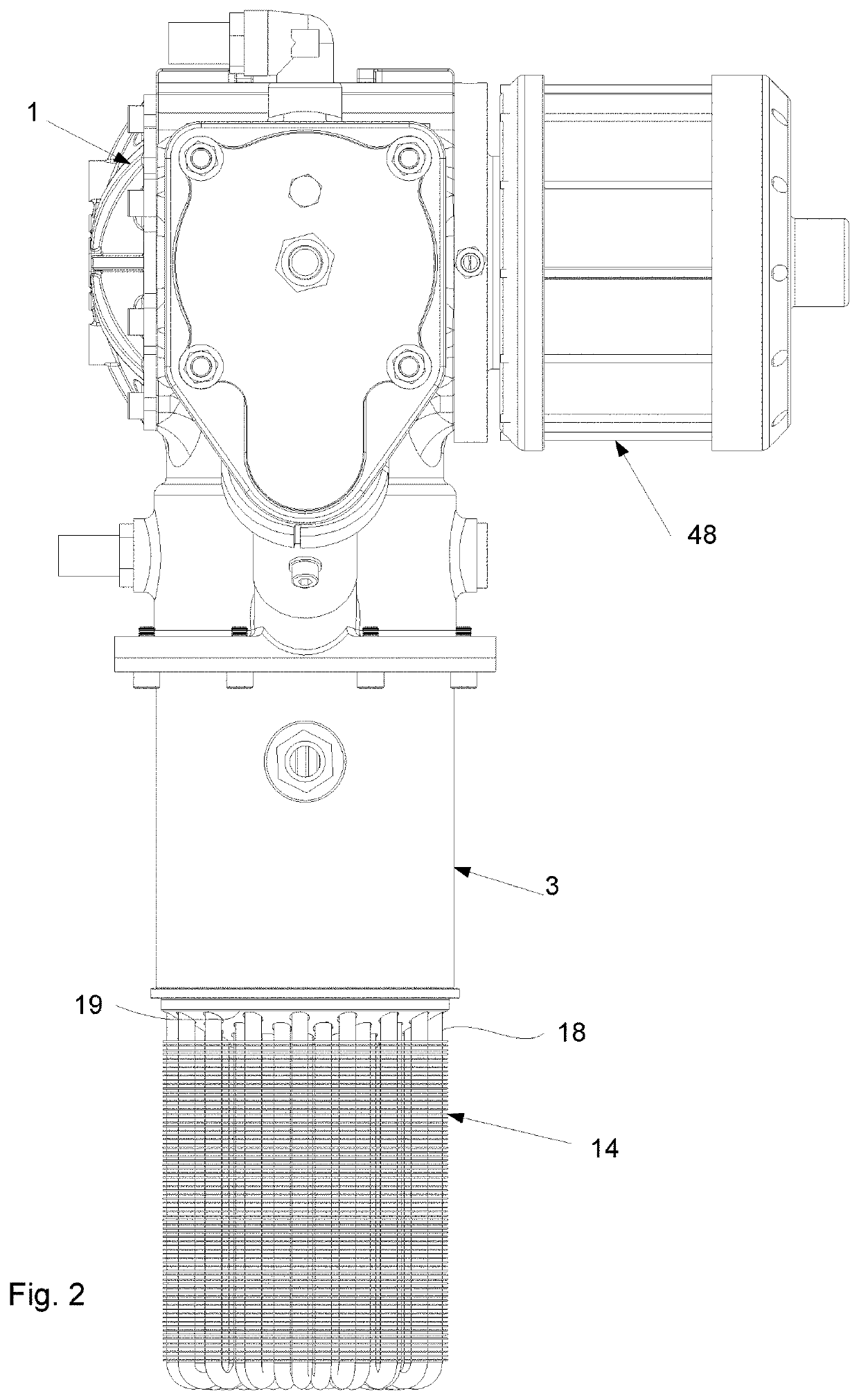

Stirling engine

ActiveUS20210054808A1Guaranteed heat exchange effectHigh fatigue strengthRegeneratorsHot gas positive displacement engine plantsCrankCooling chamber

A Stirling engine comprising:a crank case (1) with a crank shaft (2) arranged therein,a displacer cylinder (3) with a reciprocatingly arranged displacer piston (4) therein, said displacer piston (4) being connected to said crank shaft (2) via a connecting rod (5) extending through a first end of said displacer cylinder (3), and wherein the displacer cylinder (3) defines a hot chamber (6) and a cool chamber (7) separated by the displacer piston (4),a working cylinder (8) defining a working cylinder chamber (11) with a reciprocatingly arranged working piston (9) therein, said working piston (9) being connected to said crank shaft (2) via a connecting rod (10) extending through a first end of the working cylinder (8),a heater device (14), arranged at a second end of said displacer cylinder (3) opposite to said first end and configured to heat a working gas which is present in the hot chamber (6) of the displacer cylinder (3) and in fluid communication with the working cylinder chamber (11) through a working gas channel which comprisesa first heat exchanger (16) extending from a head (19) of the displacer cylinder (3) into the heater device (14), anda second heat exchanger (17) formed by a regenerator arranged outside the heater device (14). The regenerator (17) comprises a regenerator element (17) formed by metal foam that has an open porosity.

Owner:MASTON

Regenerator for a thermal cycle engine

InactiveUS20170002767A1Improve propertiesEasy to operateRegenerative heat exchangersRegeneratorsThermal cycleMechanical engineering

The regenerator has a central axis. The regenerator has a multitude of web layers wound around the central axis. The web layers are formed by two or more metal fiber or metal wire having webs wound around the central axis. When observed from the central axis to the outside of the regenerator, at least one web layer of a web of a first width is followed by a web layer of a web of a width larger than the web of a first width.

Owner:NV BEKAERT SA

Thermal acoustic passage for a stirling cycle transducer apparatus

ActiveUS9382874B2Speed up heat exchangeReduce lossesClosed-cycle gas positive displacement engine plantRegeneratorsThermoacousticsTransducer

A communication passage in a Stirling cycle transducer includes a cylindrical shaped thermal regenerator providing flow paths aligned with a regenerator cylindrical axis for providing periodic gas flow between first and second interfaces of the regenerator. A first heat exchanger conveys gas between a periphery of the heat exchanger and the first interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the gas and an external environment in a direction aligned with the regenerator cylindrical axis. A second heat exchanger conveys gas between a periphery of the heat exchanger and the second interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the external environment and the gas in a direction aligned with the regenerator cylindrical axis.

Owner:ETALIM

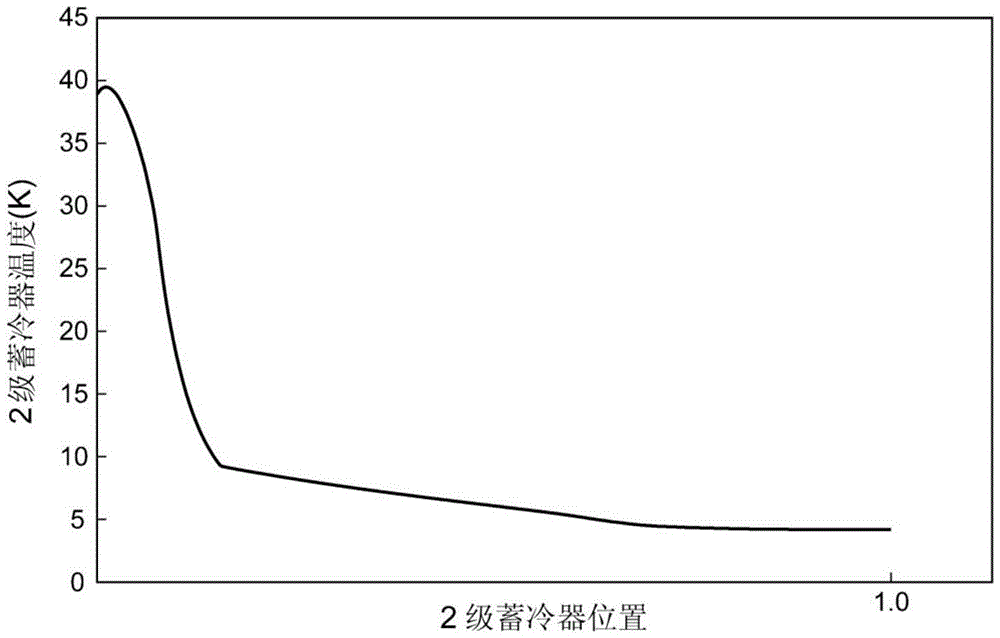

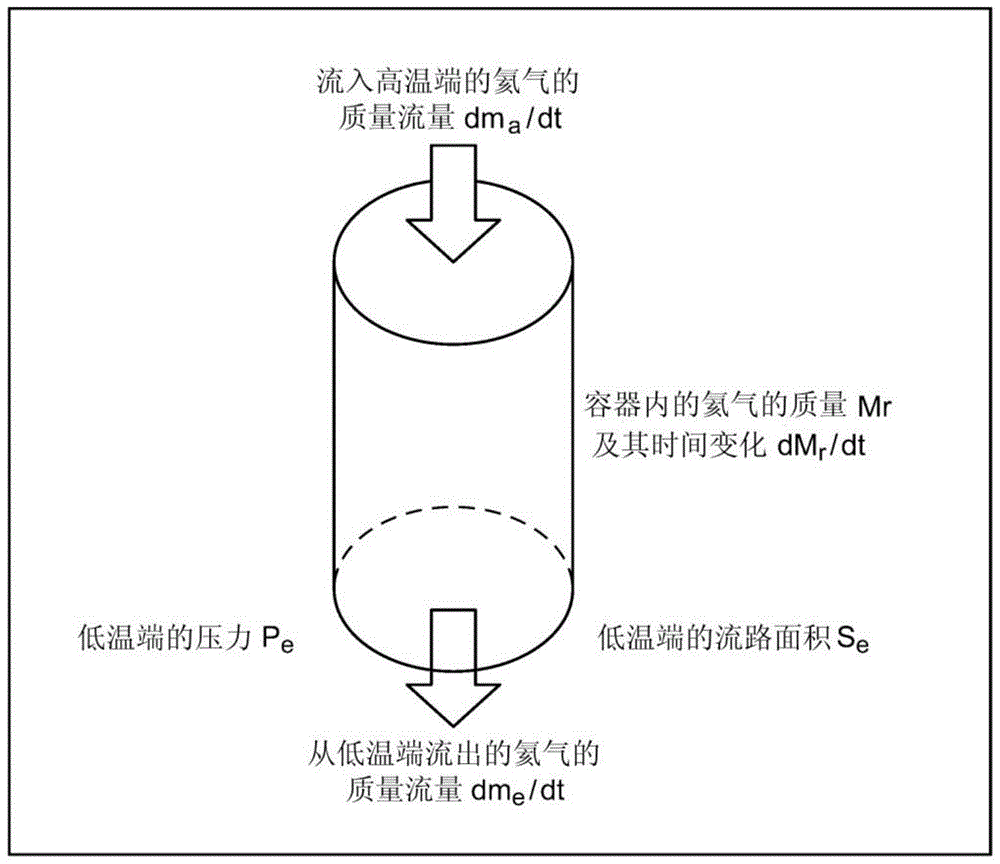

Regenerator and Regenerator Refrigerator

ActiveCN104819592BGuaranteed cooling effectCurb usageStirling type enginesCompression machinesRefrigerator carCool storage

Owner:SUMITOMO HEAVY IND LTD

Rotary machines with magnetically actuated pistons

ActiveCN109026430BReciprocating/oscillating/vibrating magnetic circuit partsDynamo-electric brakes/clutchesRotational axisMagnetic tension force

Owner:THE BOEING CO

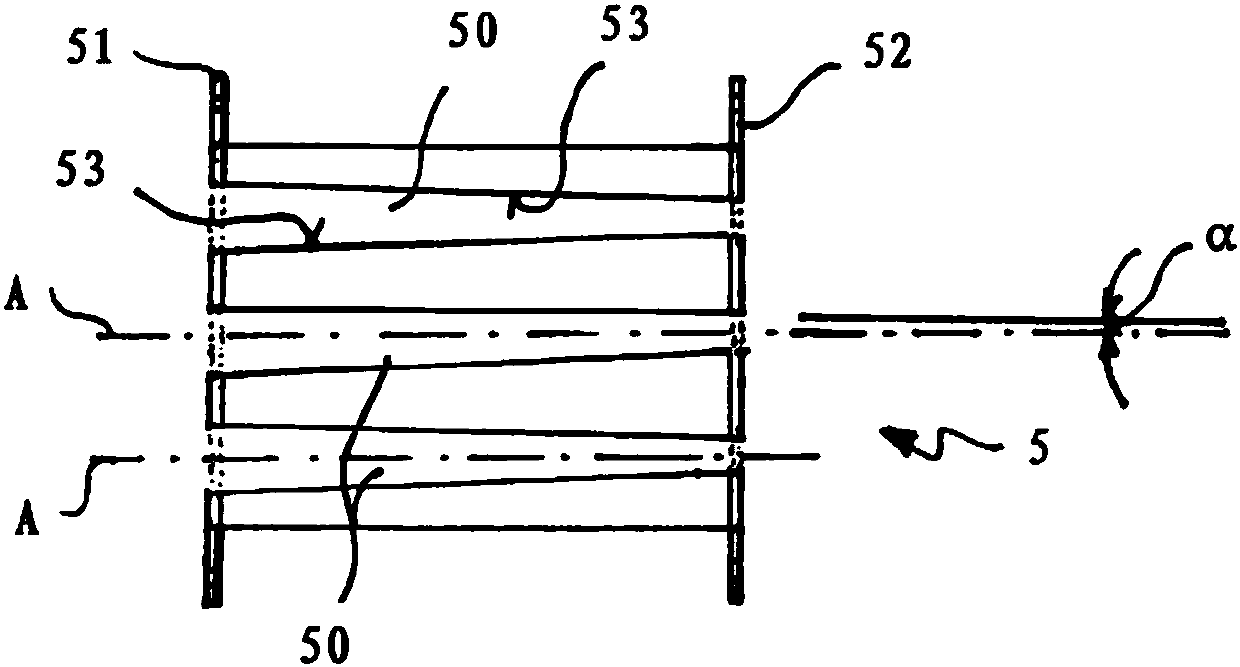

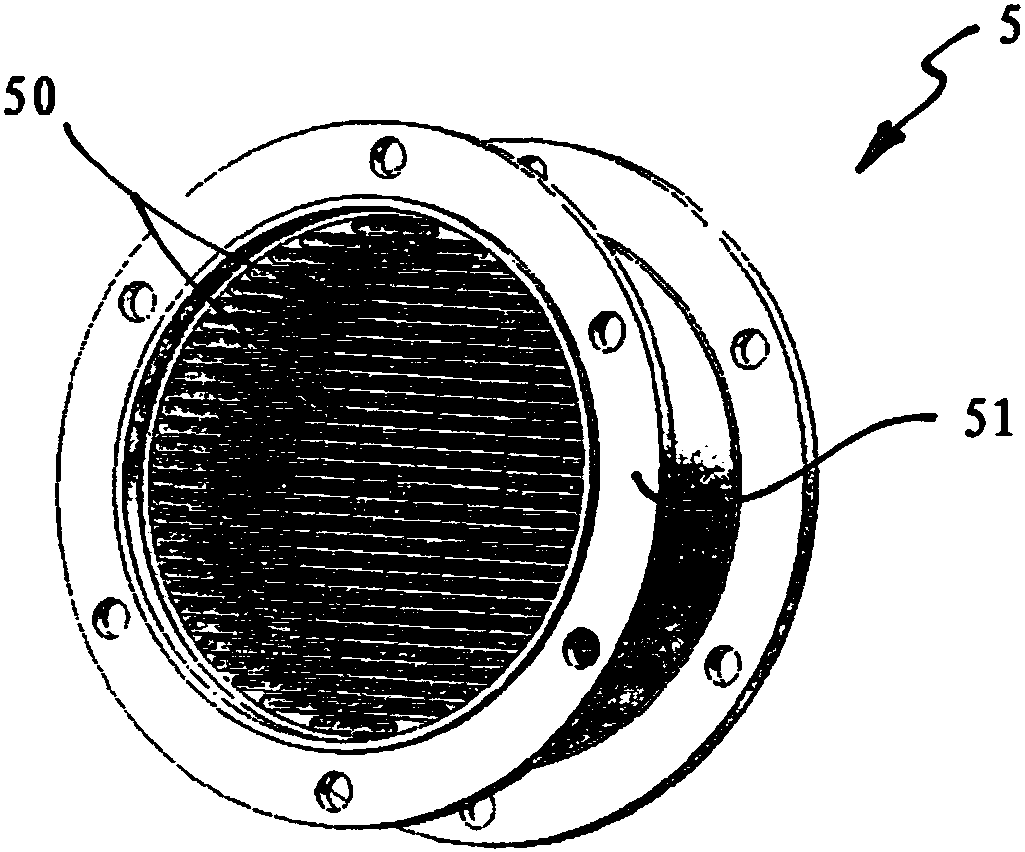

Regenerators for external combustion heat engines

The invention describes a regenerator (5) for an external combustion heat engine, in particular a Stirling engine, which is adapted to be mounted on a flow from the hot side of the engine to the cold side of the engine and from In the passage of the working fluid that flows sideways to the hot side of the engine. When the working fluid passes through the regenerator (5) on the way from the hot side to the cold side of the engine, the regenerator (5) can receive and temporarily store the heat stored by the working fluid, and when the working fluid passes through the regenerator (5) from the cold side of the engine Passing the regenerator (5) on the way to the hot side, the regenerator (5) is able to release the heat again to the working fluid. The regenerator (5) includes at least one through channel (50), and the through channel (50) is tapered from the hot side port to the cold side port of the through channel (50) along the extending direction of its axis, so that along the through channel (50) ) The flowing working fluid (10) is maintained at a substantially constant pressure.

Owner:ECOTECH ENGINES

Regenerator for a thermal cycle engine

InactiveCN106068378AIncrease the cross-sectional areaBig spaceRegenerative heat exchangersRegeneratorsEngineeringMetal fibers

The regenerator has a central axis. The regenerator comprises a multitude of web layers wound around the central axis. The web layers are formed by two or more metal fiber or metal wire comprising webs wound around the central axis. When observed from the central axis to the outside of the regenerator, at least one web layer of a web of a first width is followed by a web layer of a web of a width larger than the web of a first width.

Owner:NV BEKAERT SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com