Stirling engine

a technology of rotating engine and rotating shaft, which is applied in the direction of engine components, hot gas positive displacement engine plants, machines/engines, etc., to achieve the effects of low pressure drop, high thermal stability and fatigue strength, and efficient heat exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

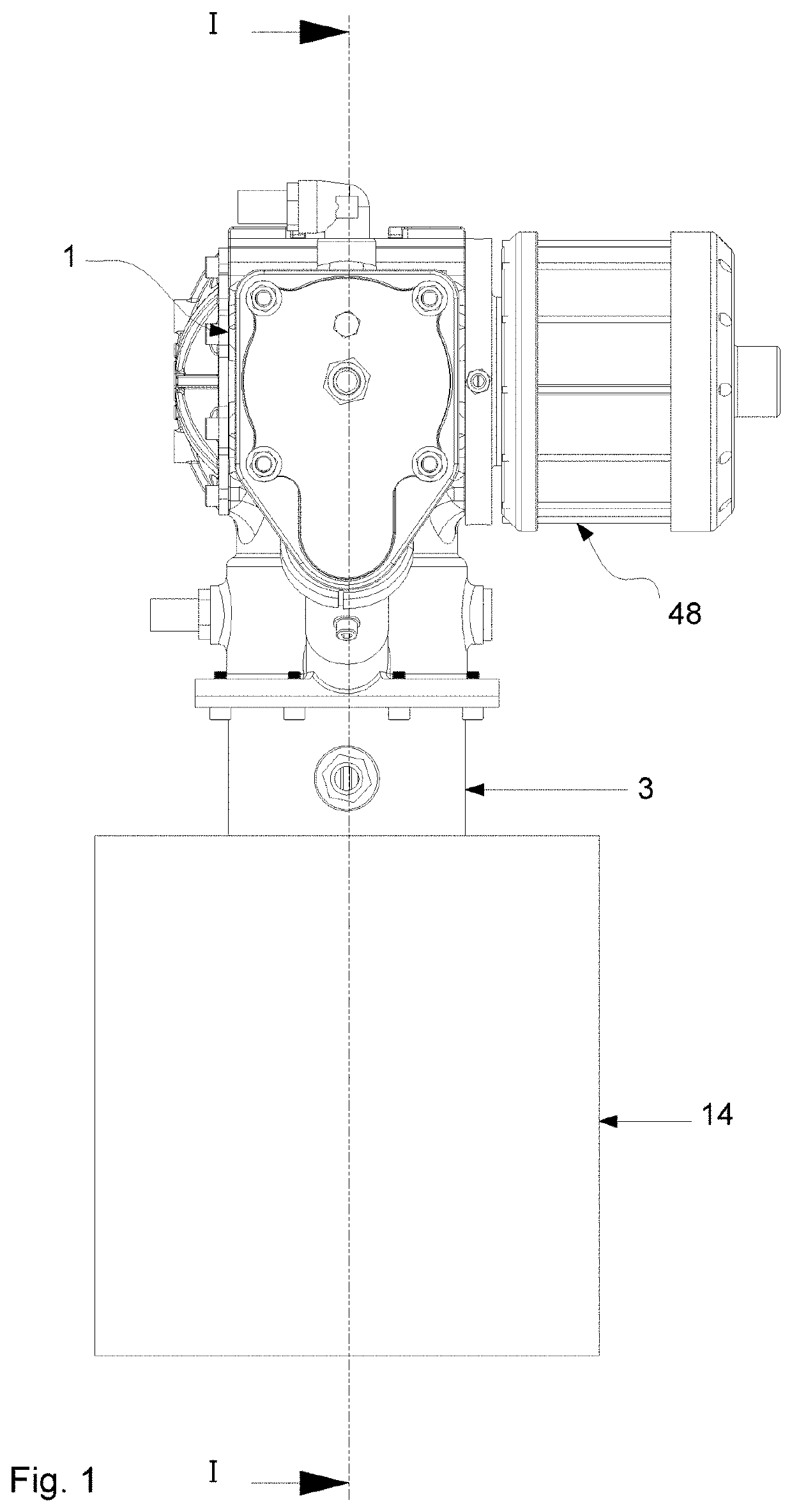

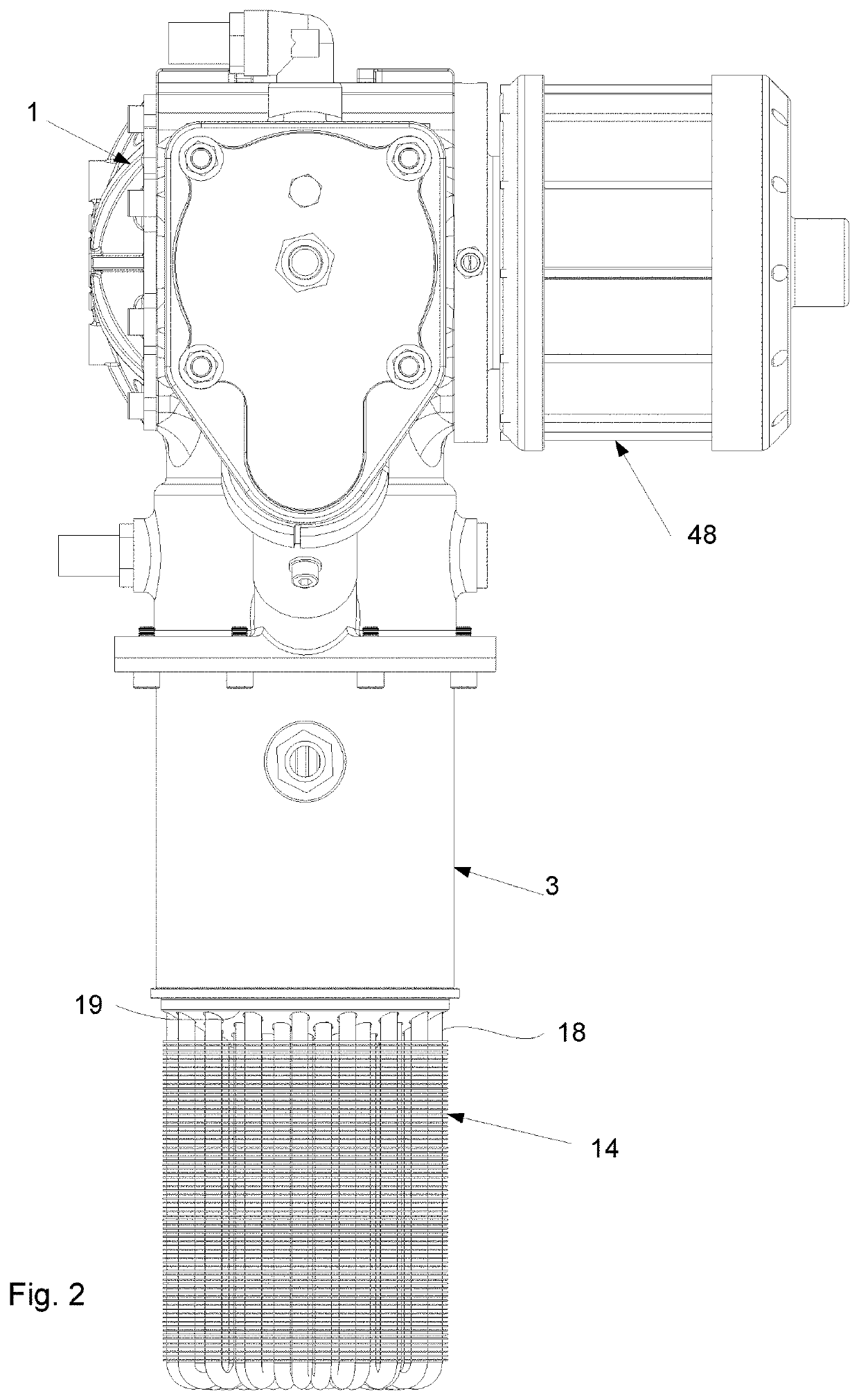

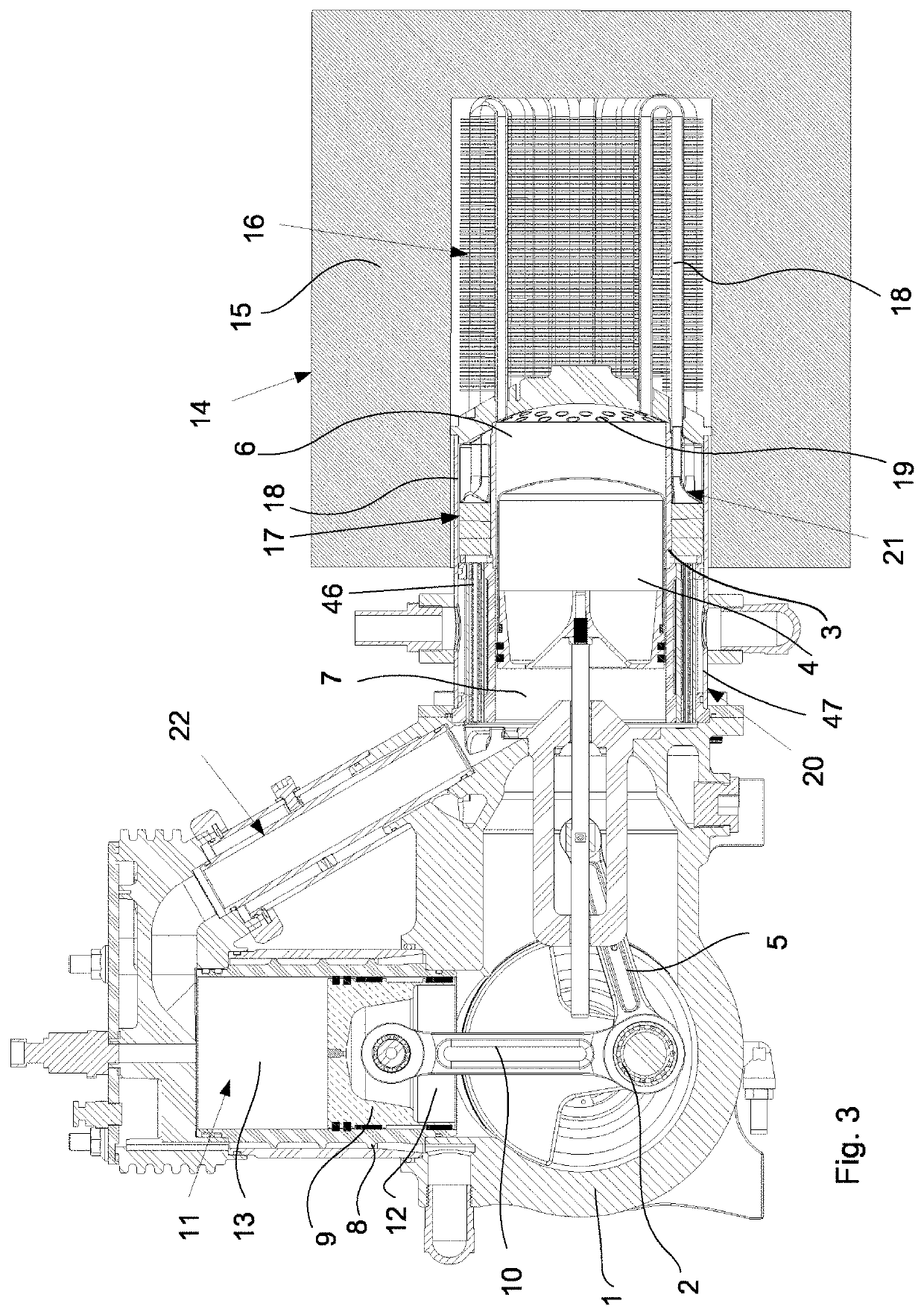

[0033]FIGS. 1-3 show an example of a Stirling engine according to the present disclosure. The Stirling engine shown is of gamma type and comprises a crank case 1 with a crank shaft 2 arranged therein, and a displacer cylinder 3 with a reciprocatingly arranged displacer piston 4 therein. The displacer piston 4 is connected to the crank shaft 2 via a connecting rod 5 extending through a first end of said displacer cylinder 3. During operation of the Stirling engine, the displacer cylinder 3 defines a hot chamber 6 and a cool chamber 7 separated by the displacer piston 4.

[0034]The Stirling engine further comprises a working cylinder 8 with a reciprocatingly arranged working piston 9 therein, said working piston 9 being connected to the crank shaft 2 via a connecting rod 10 extending through a first end of the working cylinder 8. A working cylinder chamber 11 defined by the working cylinder 8 is divided by the working piston 9 into a first part 12, through which said connecting rod 10 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com