Gas axial transmission alpha type four-cylinder double-acting stirling engine

A Stirling engine, four-cylinder double-acting technology, applied in the direction of hot gas variable capacity engine device, engine components, engine cooling, etc., can solve the problems of serious environmental pollution, large output torque, unfavorable engine life, etc. The effect of high combustion efficiency, radial force reduction, and improved energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

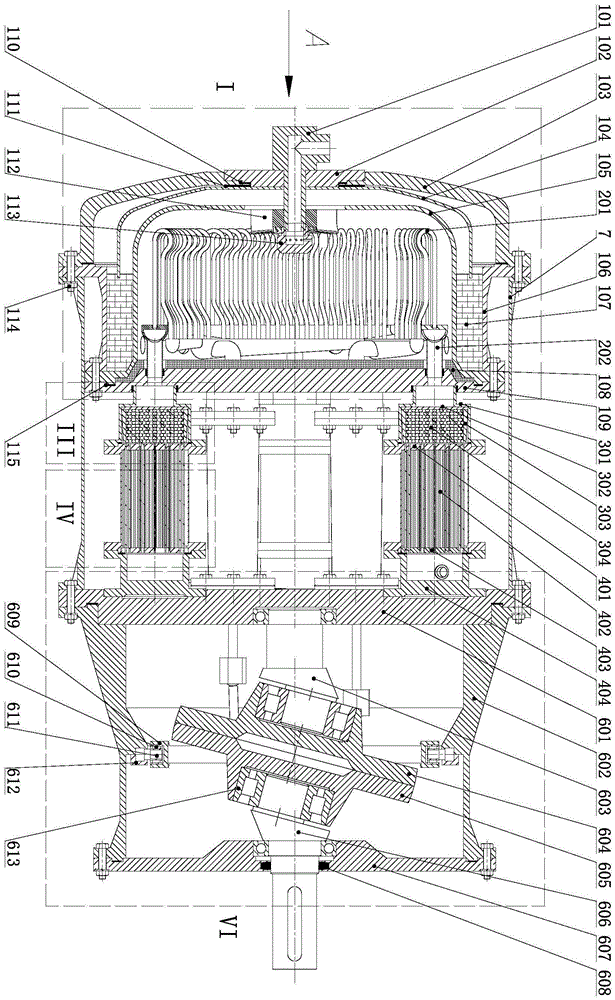

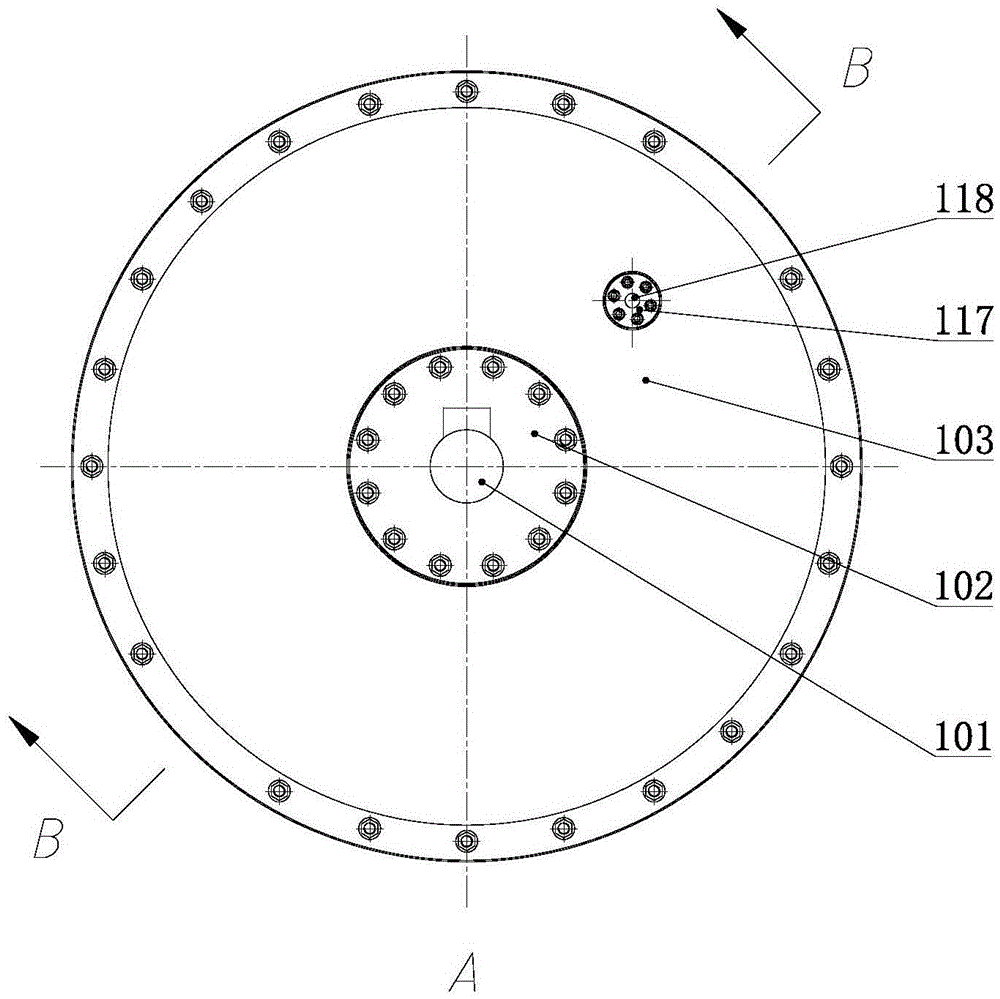

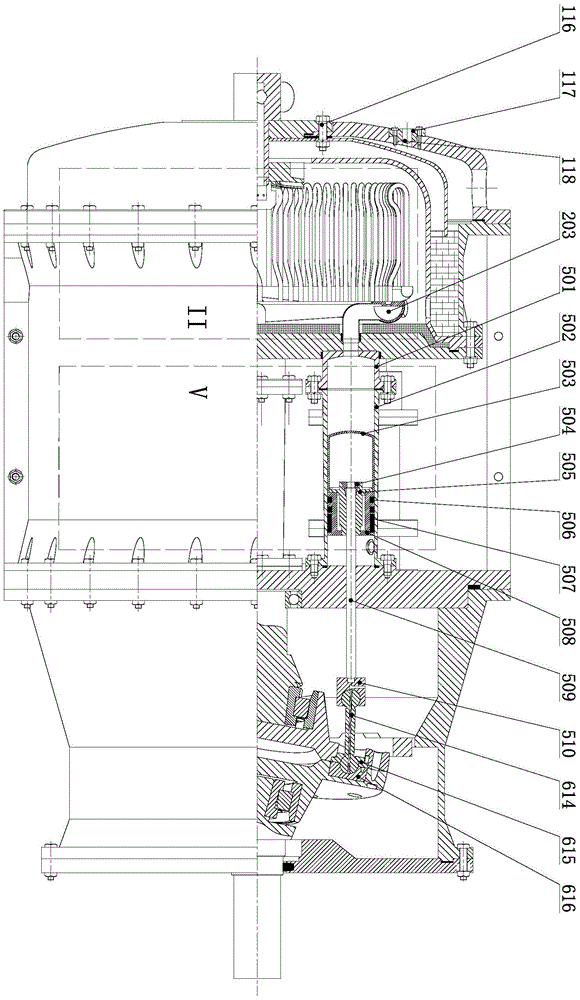

[0022] refer to figure 1 , figure 2 and image 3 , a gas-fired axial transmission α-type four-cylinder double-acting Stirling engine, including a combustion device I, a heating device II inside the combustion device I, a cylinder head 501 of a working medium circulation device V connected to the heating device II, and a cylinder 502 It is connected with the cooling device IV, the heating device II is connected with the cooling device IV via the regenerator III to form a closed working medium circulation loop, the transmission device VI is connected with the piston rod 509 of the working medium circulation device V through a connecting rod, the transmission device VI and the combustion medium The device I is connected as a whole through the split casing 7. The engine uses hydrogen or helium as the working fluid and adopts a forward Stirling cycle. The worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com