Regenerator for a thermal cycle engine

A technology for regenerators and engines, which is applied in the direction of regenerators, hot gas variable displacement engine devices, engine components, etc., and can solve problems such as the absence of high-efficiency regenerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

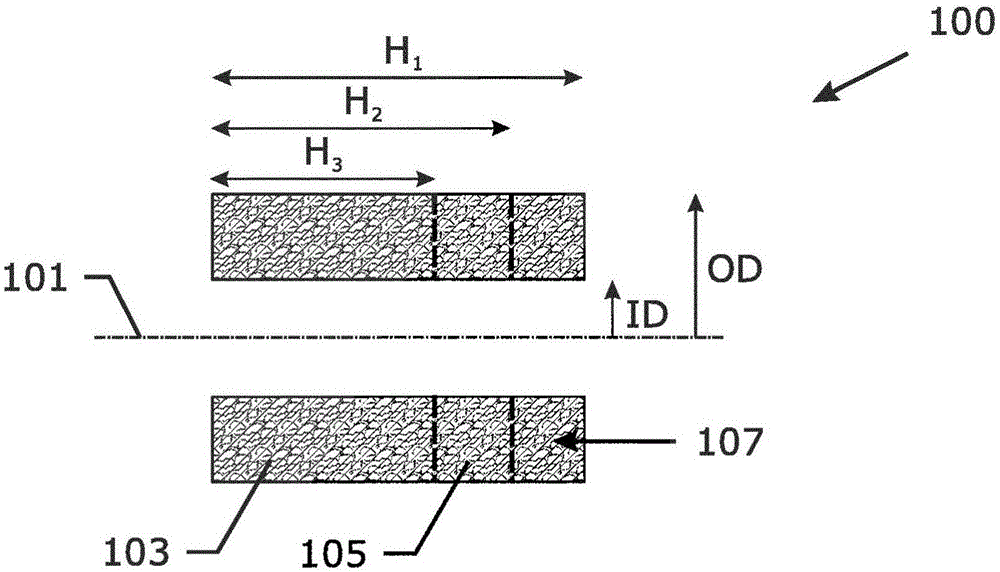

[0048] figure 1 An example 100 of a regenerator ring according to the invention is shown. The regenerator has a central axis 101 of symmetry. The regenerator is at its axial length H 1 have a constant cross-sectional shape and size. The regenerator ring has an axial length H 1 , such as 72mm. The inner diameter is ID, eg 143mm, and the outer diameter is OD, eg 221mm. The regenerator ring has three sections with different levels of porosity: a length H of eg 48 mm with a first porosity of eg 90% 3 The first segment 103; has a length H of porosity higher than the first porosity, for example 92.4% 2 -H 3 (e.g., 60mm-48mm=12mm); and a length H with a higher porosity, e.g., 94.6% 1 -H 2 (eg, 72mm-60mm=12mm) third section 107 .

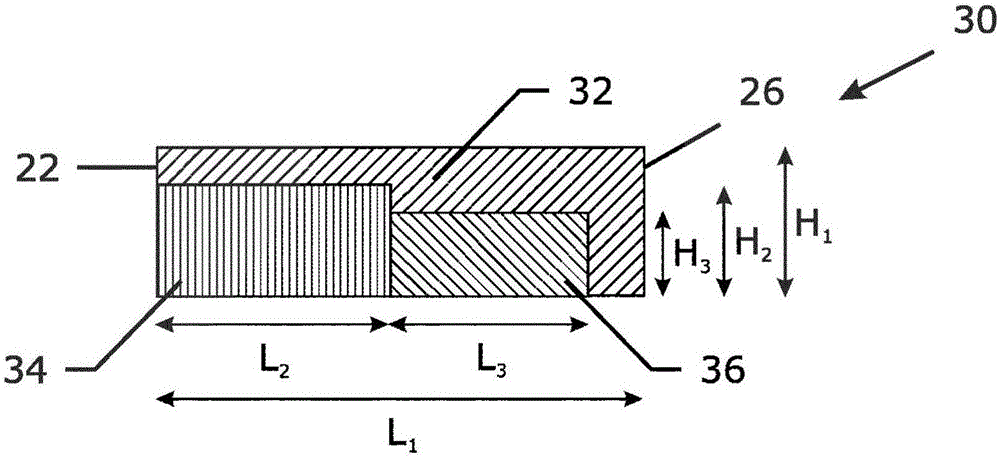

[0049] figure 2 Another example 200 of a regenerator ring according to the invention is shown. The regenerator has a central axis 201 of symmetry. The regenerator at its axial length H of eg 72mm 1 available in different cross-sectional shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com