Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167results about "Input signal generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

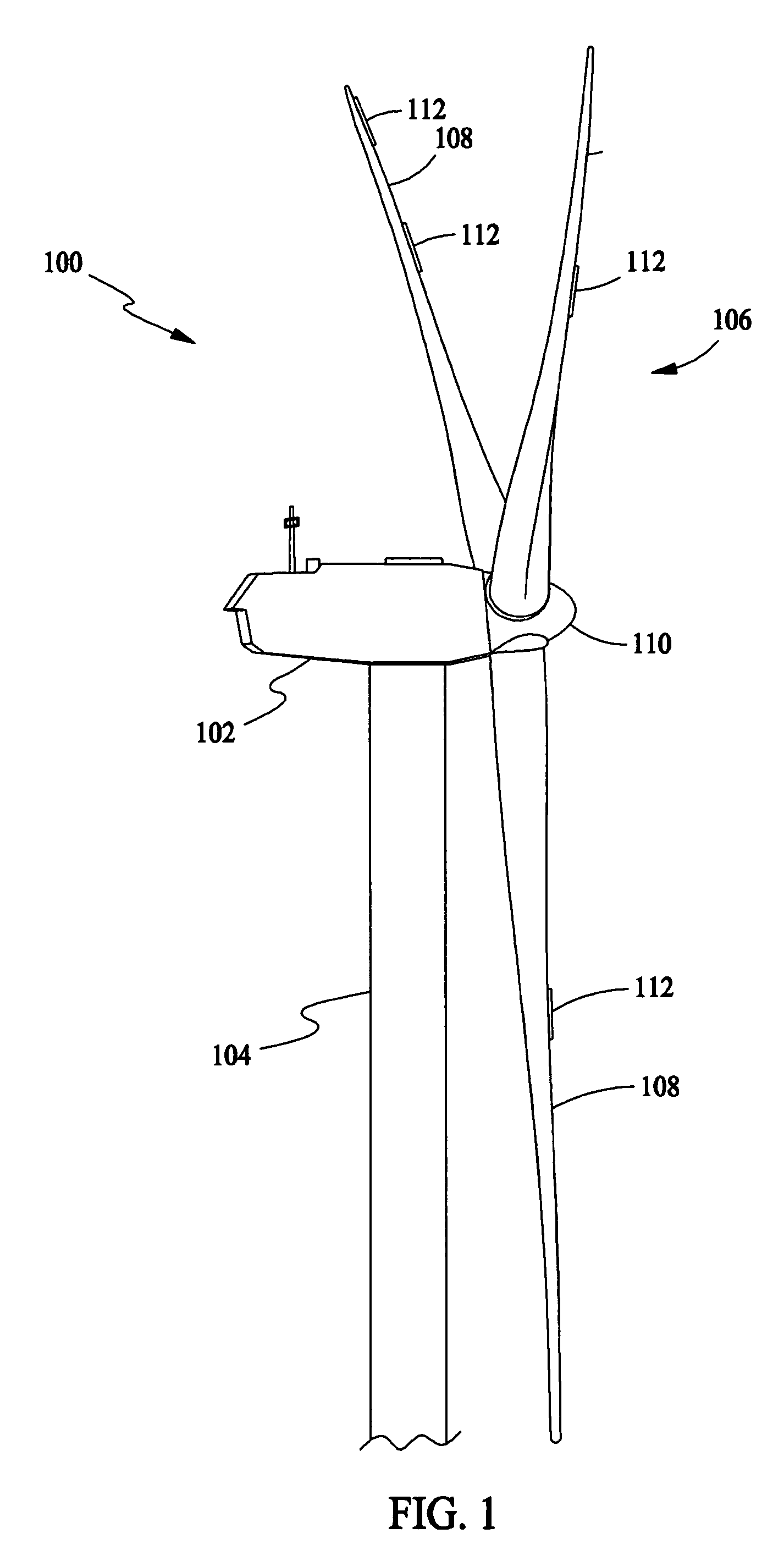

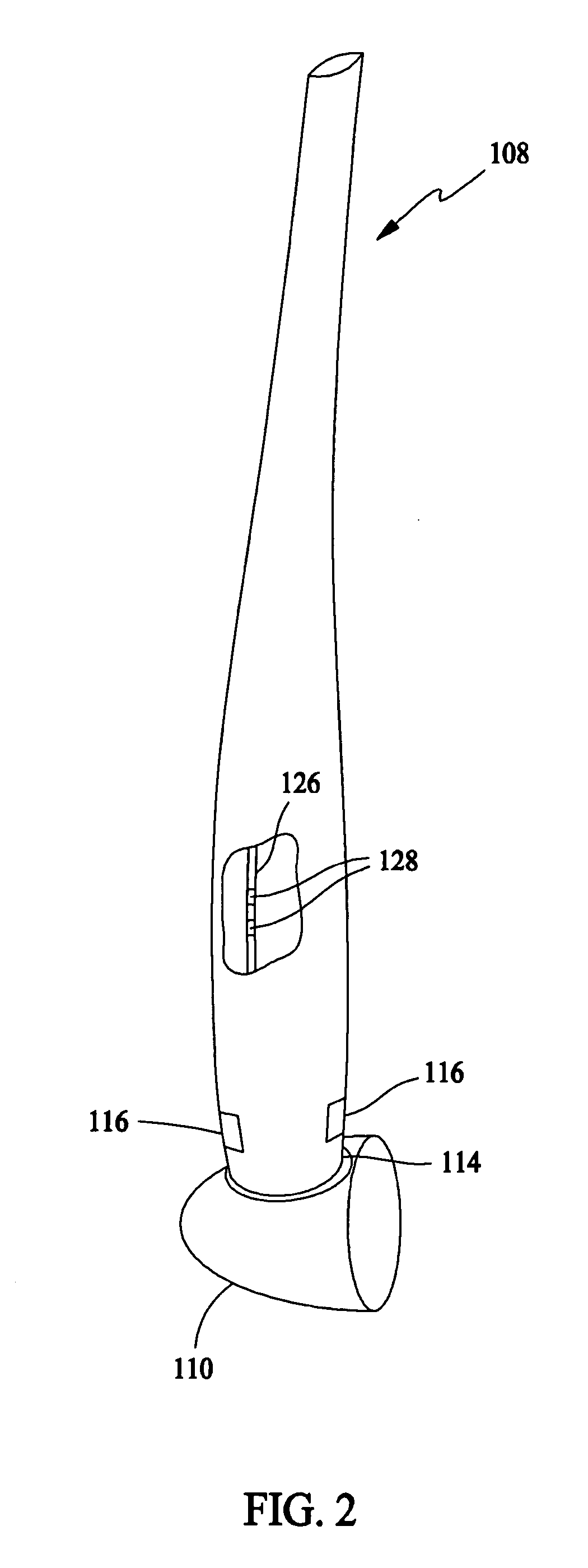

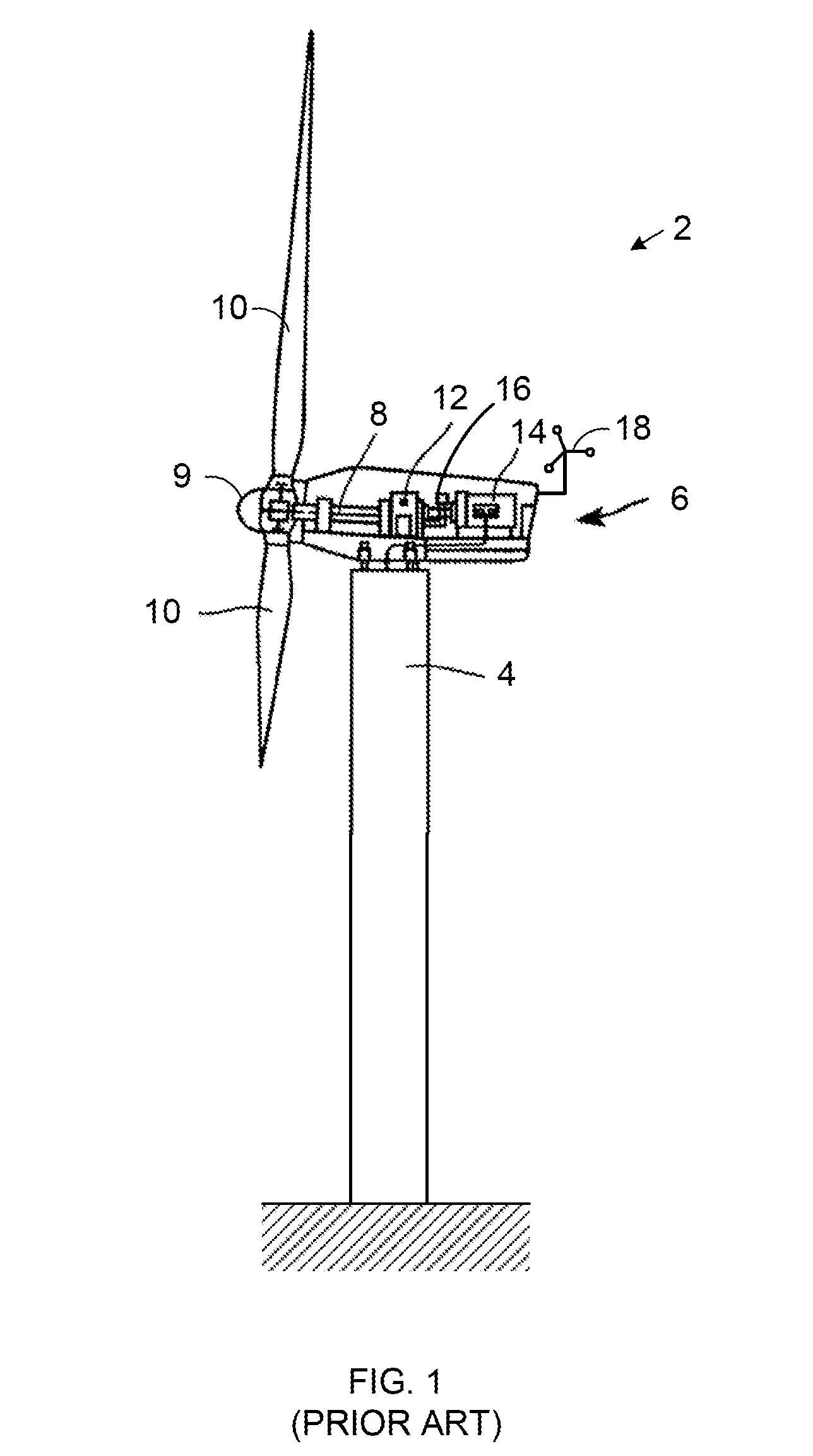

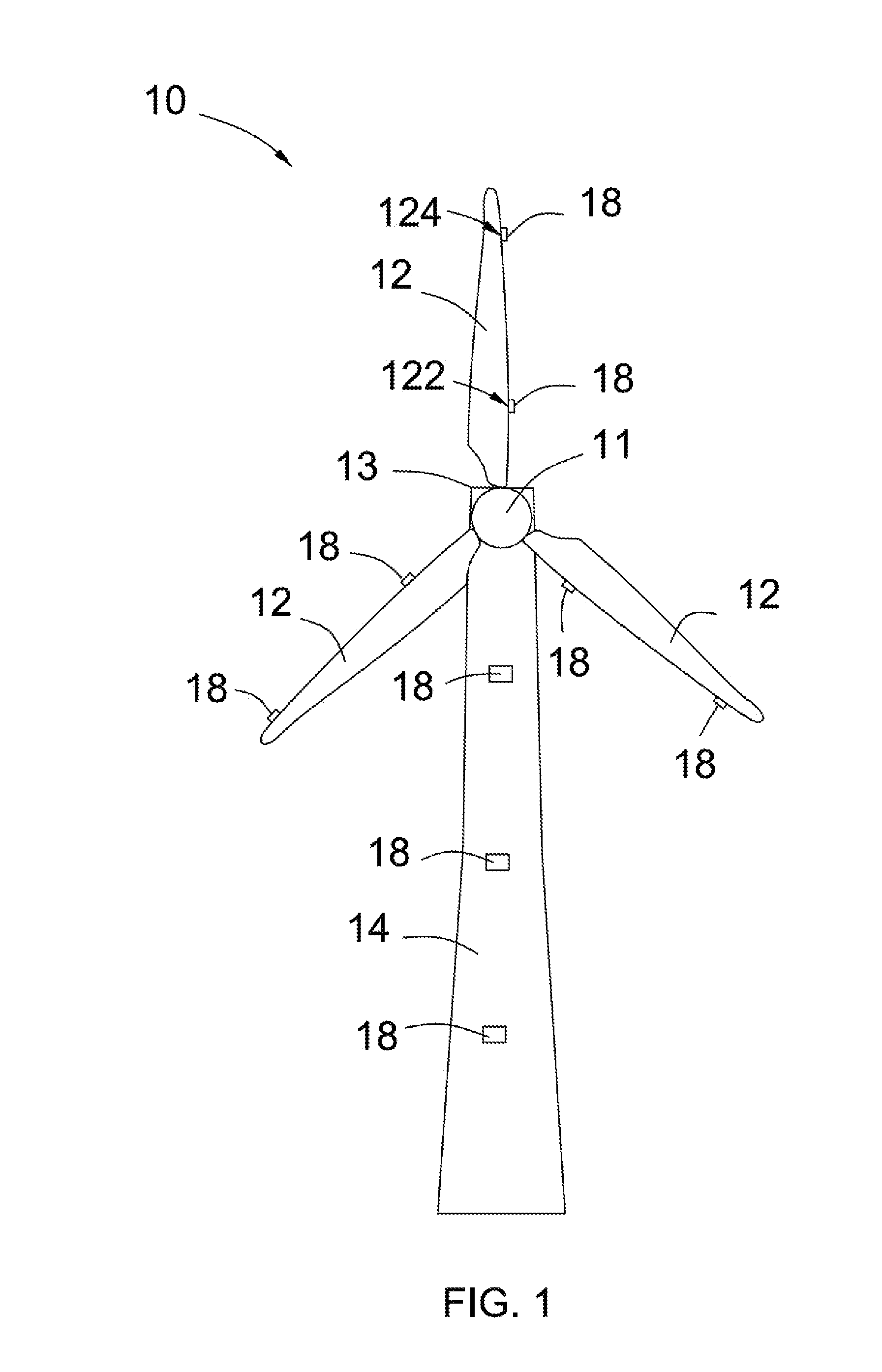

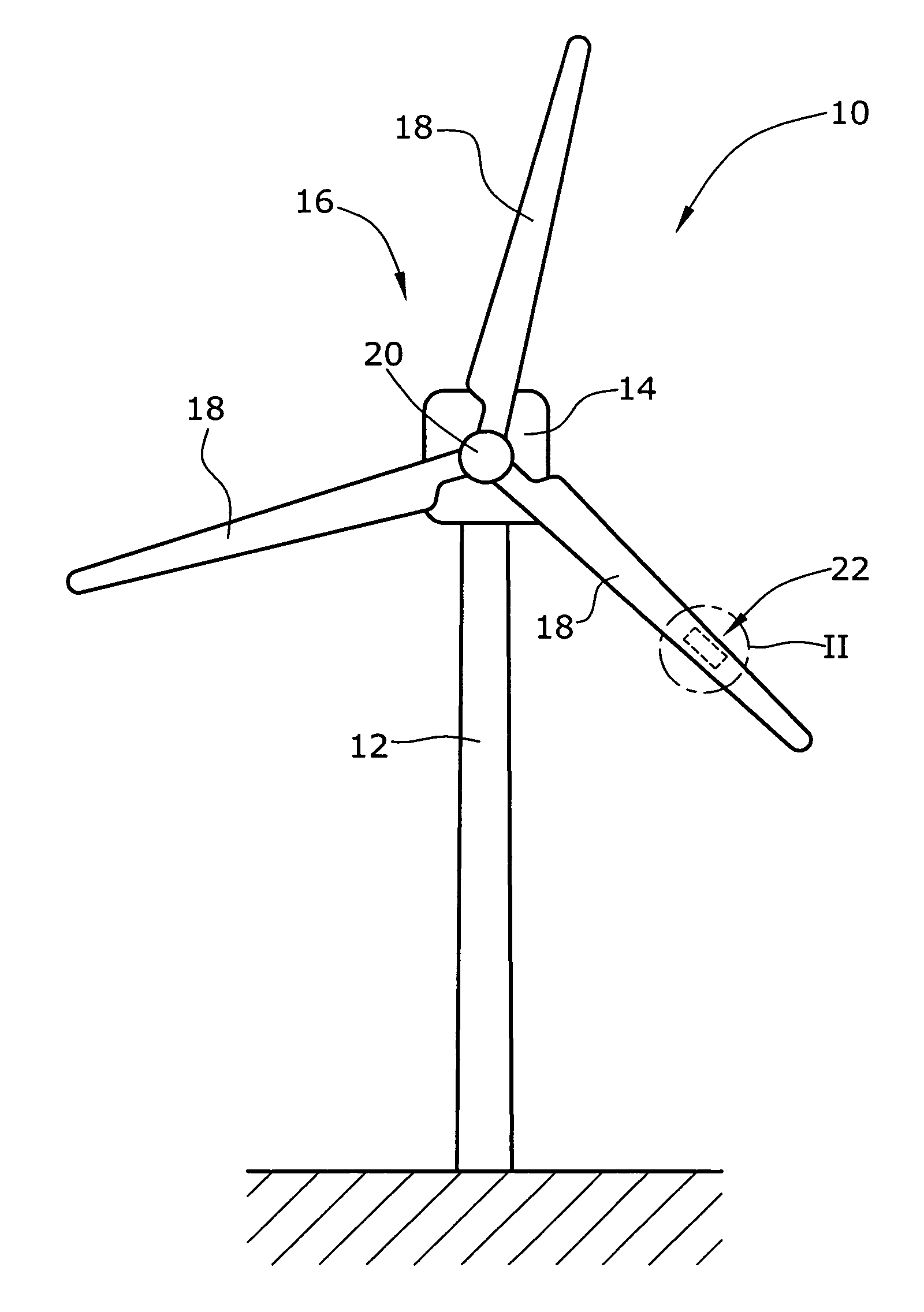

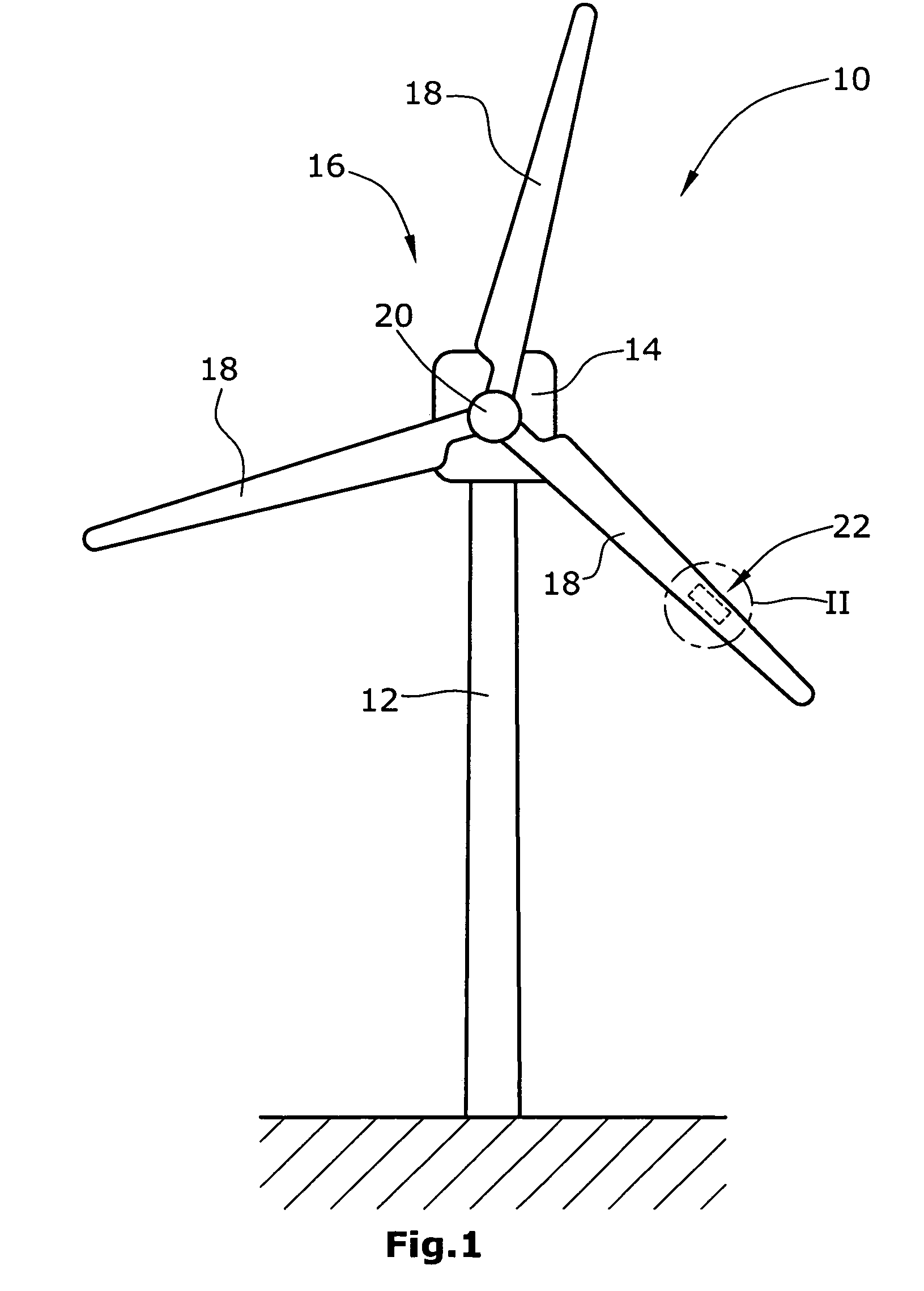

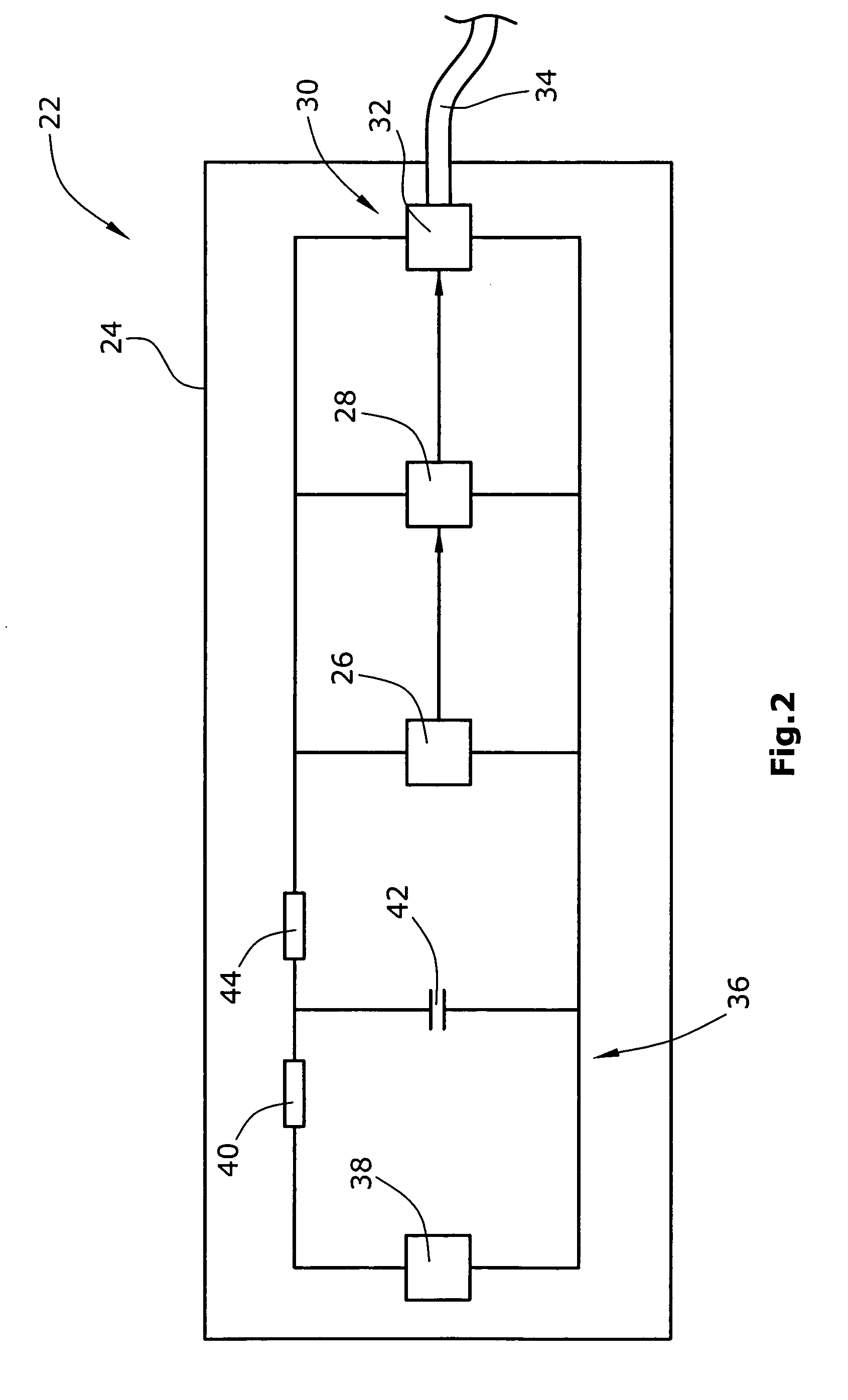

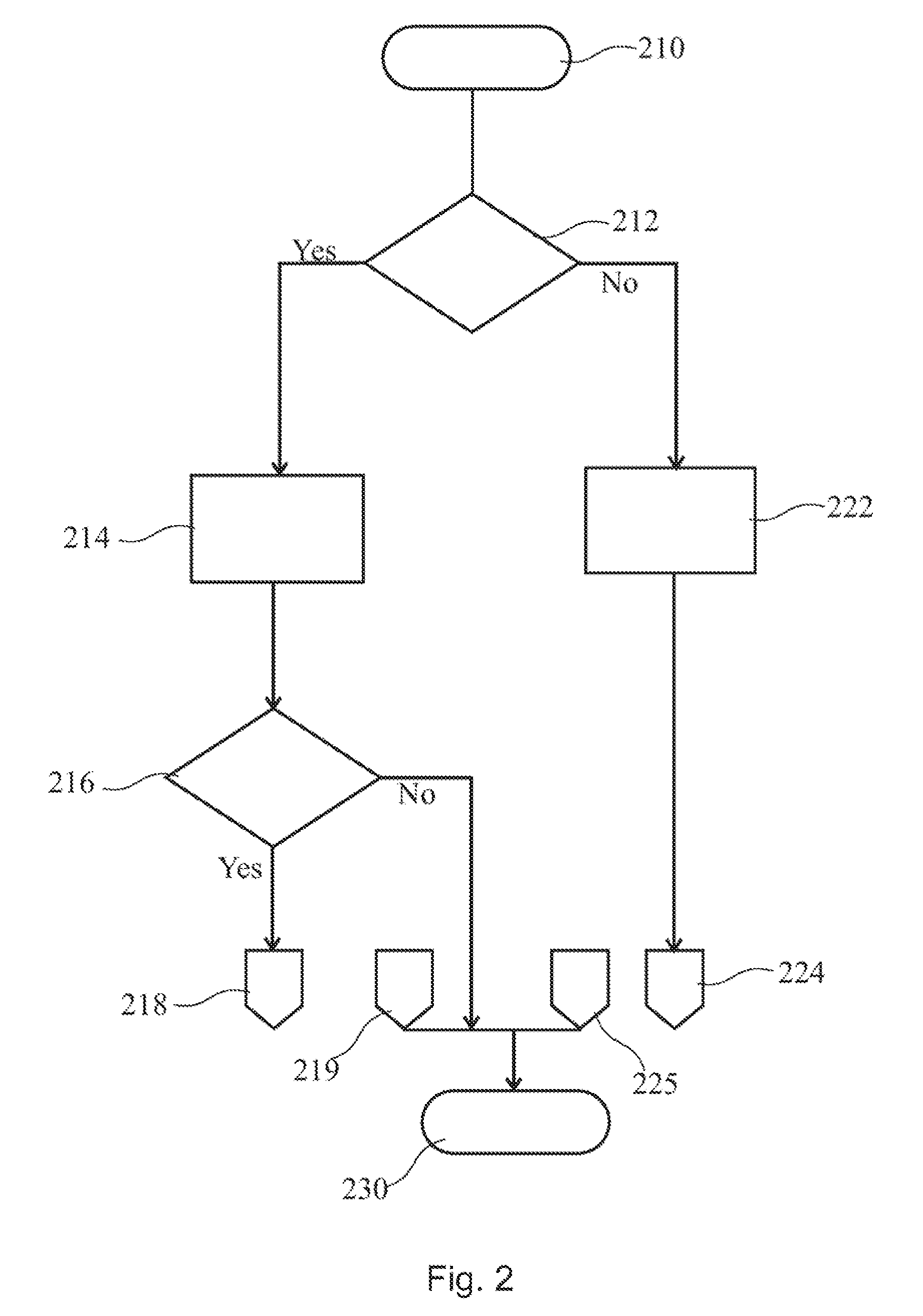

Methods and apparatus for rotor blade ice detection

ActiveUS20050276696A1Reduced lifting capabilityDiminished aerodynamic rotor blade performancePropellersWind motor controlIcing conditionsEngineering

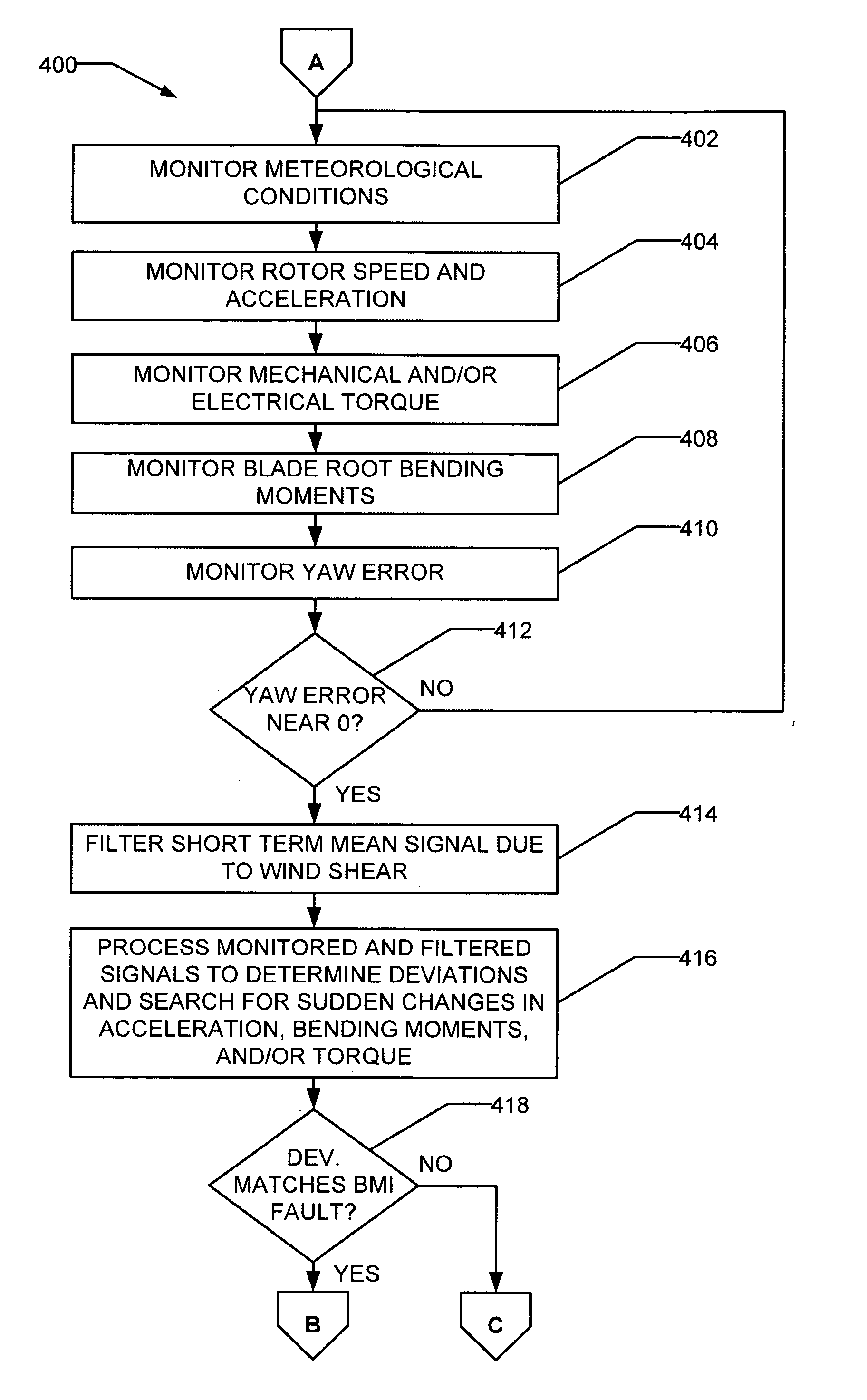

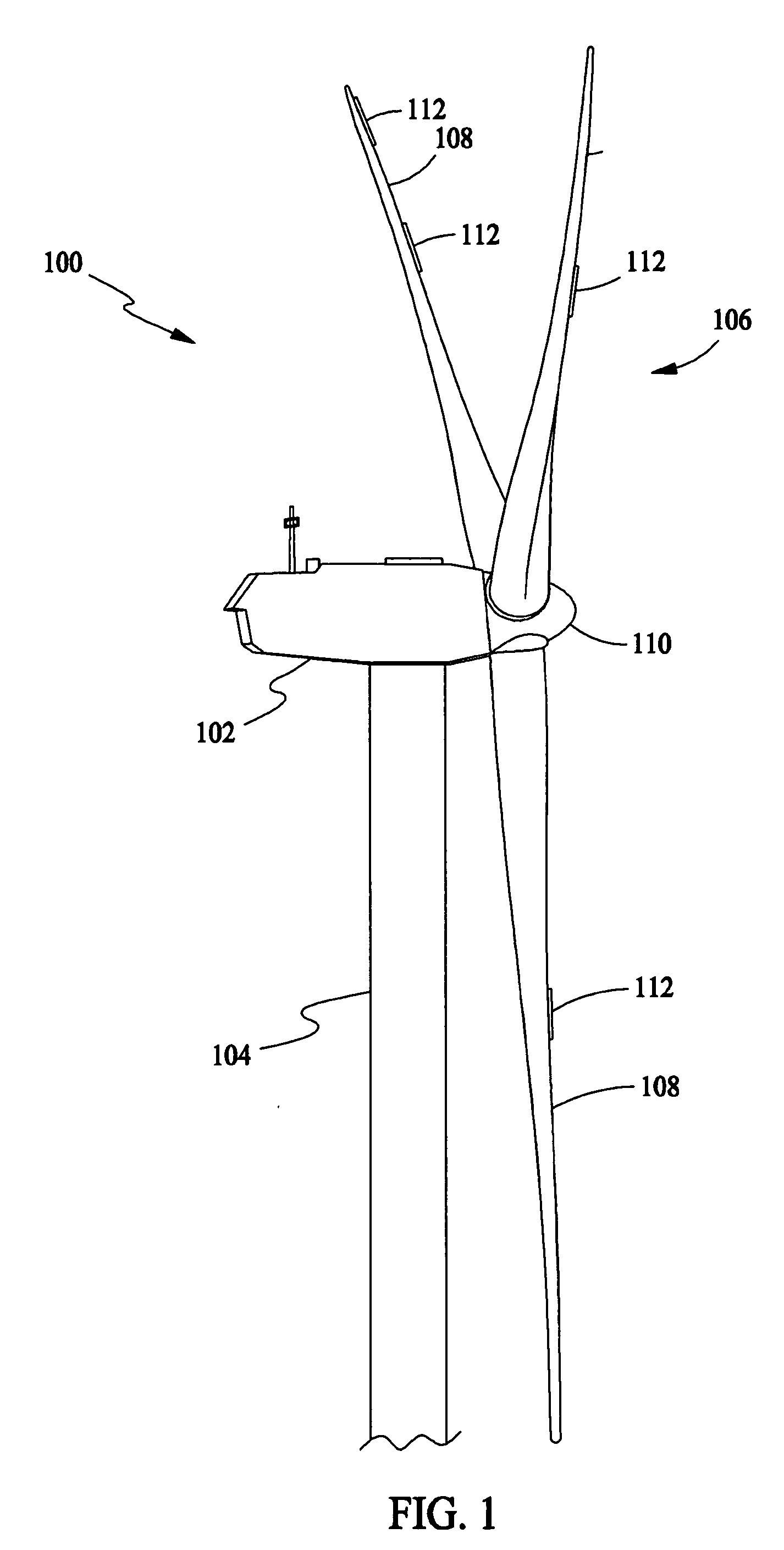

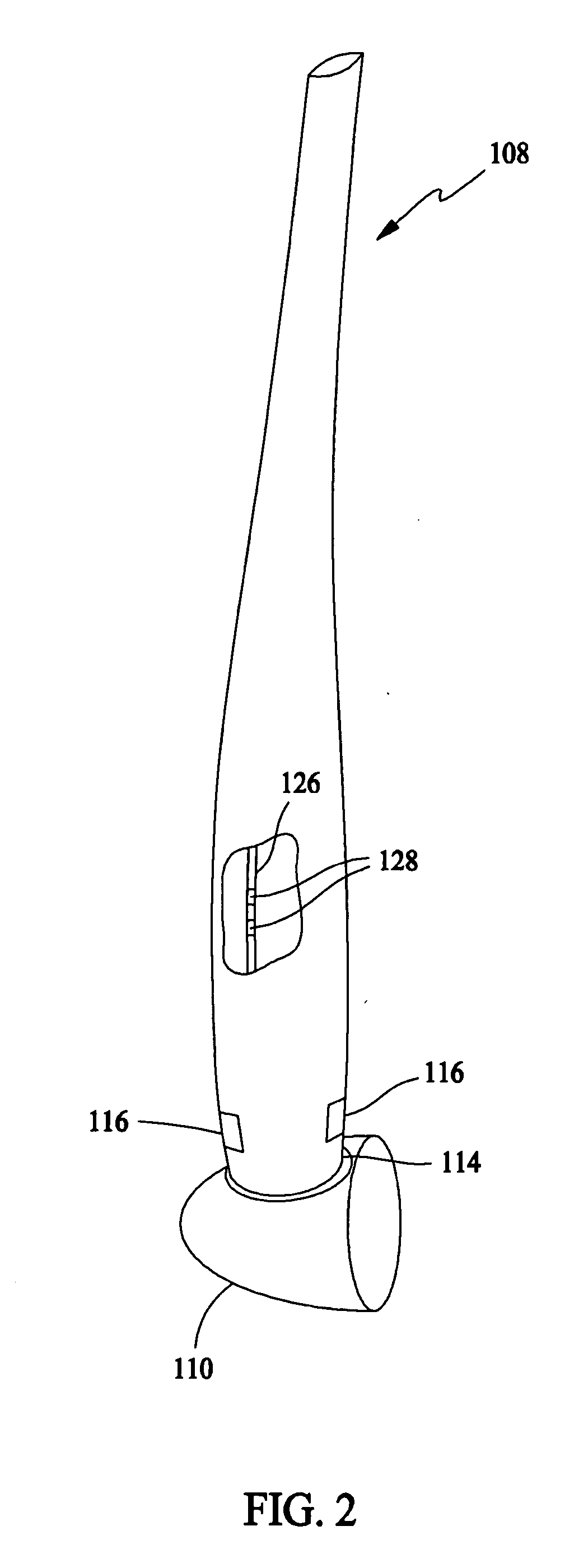

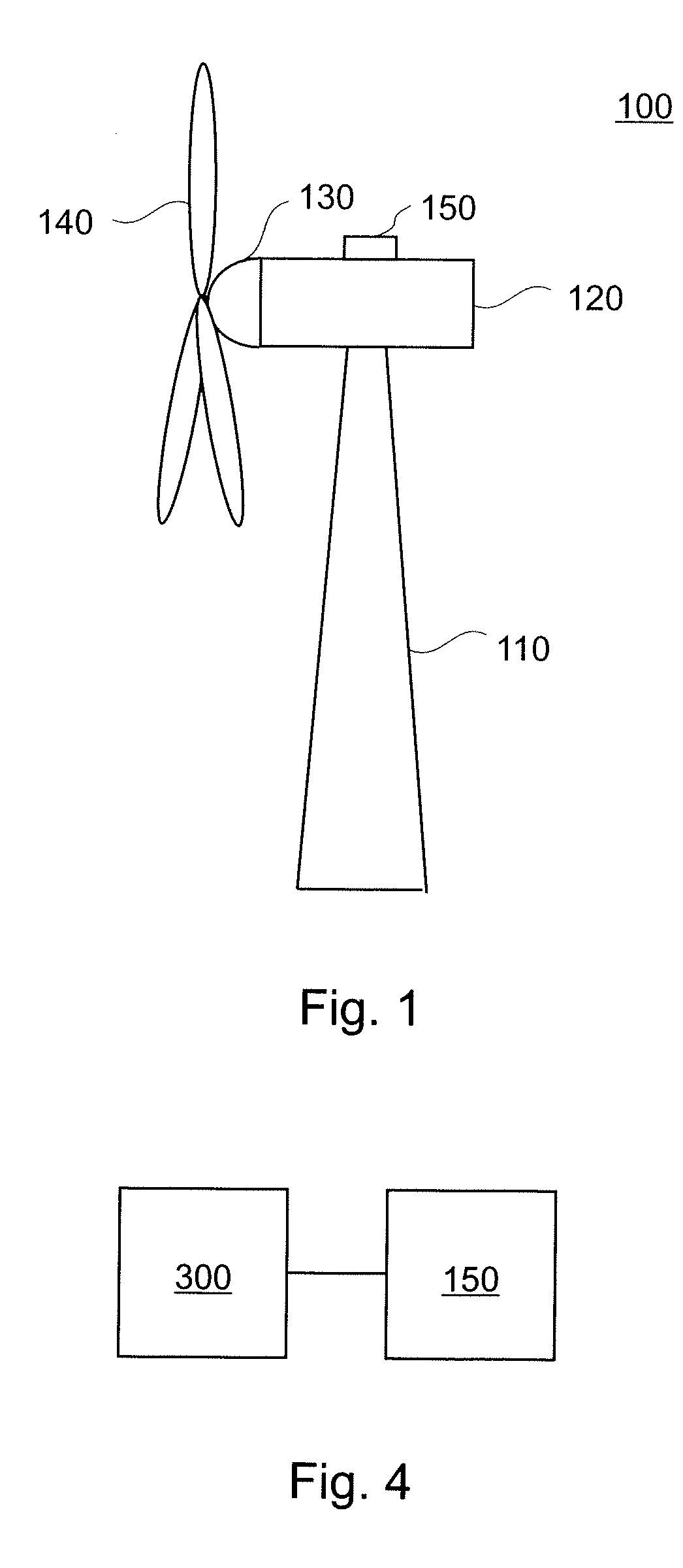

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for rotor blade ice detection

ActiveUS7086834B2Lower performance requirementsPropellersWind motor controlIcing conditionsEngineering

A method for detecting ice on a wind turbine having a rotor and one or more rotor blades each having blade roots includes monitoring meteorological conditions relating to icing conditions and monitoring one or more physical characteristics of the wind turbine in operation that vary in accordance with at least one of the mass of the one or more rotor blades or a mass imbalance between the rotor blades. The method also includes using the one or more monitored physical characteristics to determine whether a blade mass anomaly exists, determining whether the monitored meteorological conditions are consistent with blade icing; and signaling an icing-related blade mass anomaly when a blade mass anomaly is determined to exist and the monitored meteorological conditions are determined to be consistent with icing.

Owner:GENERAL ELECTRIC CO

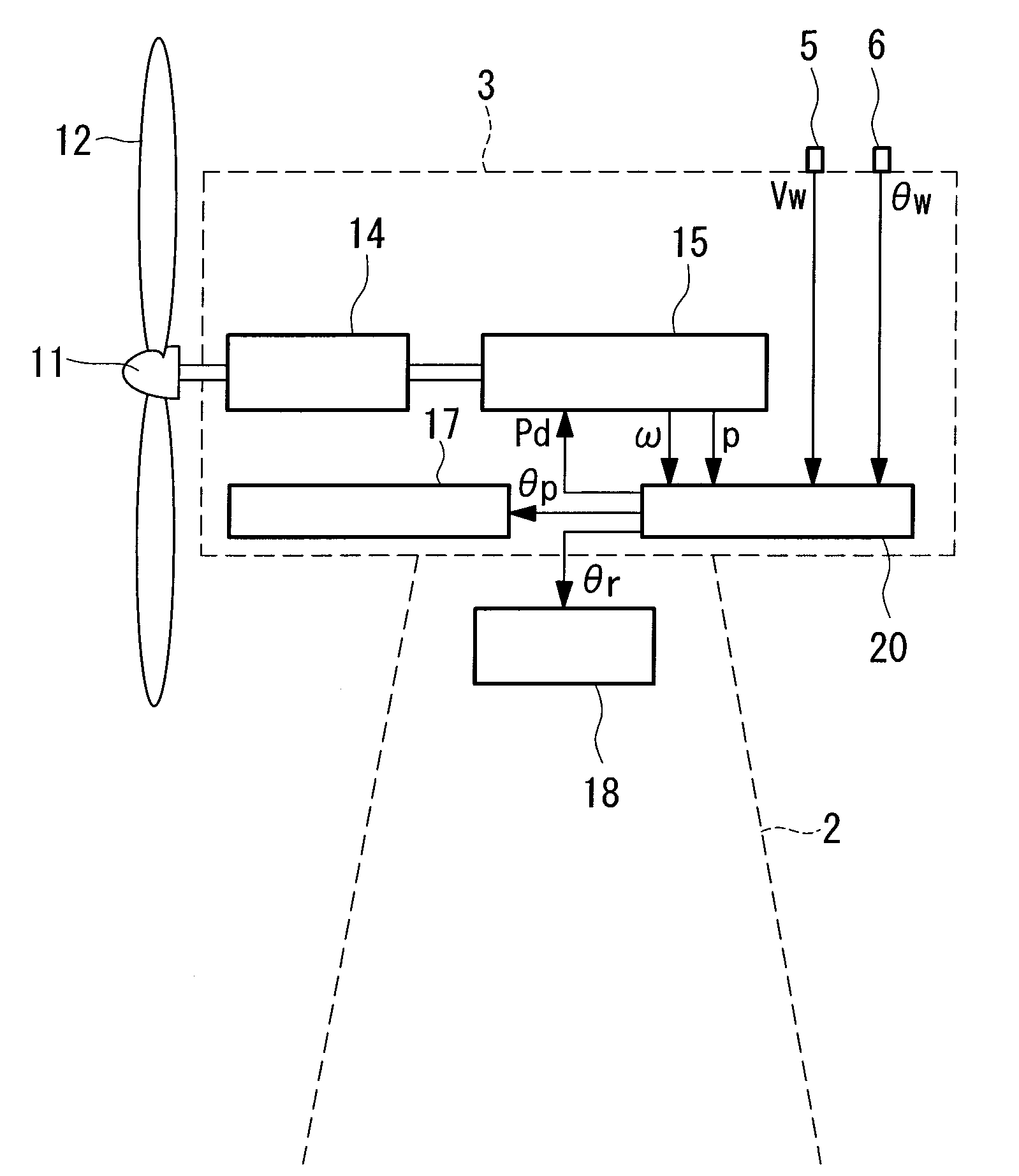

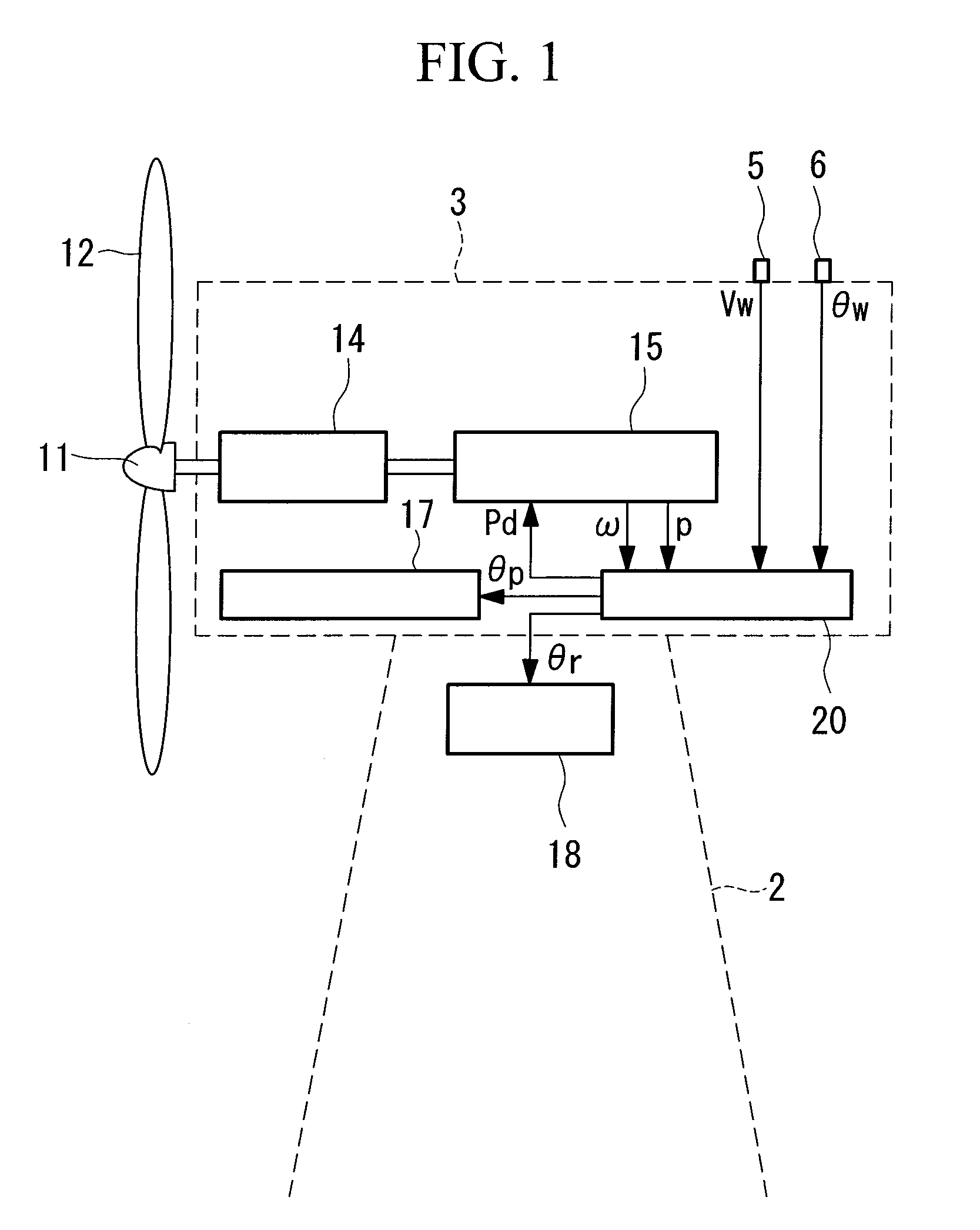

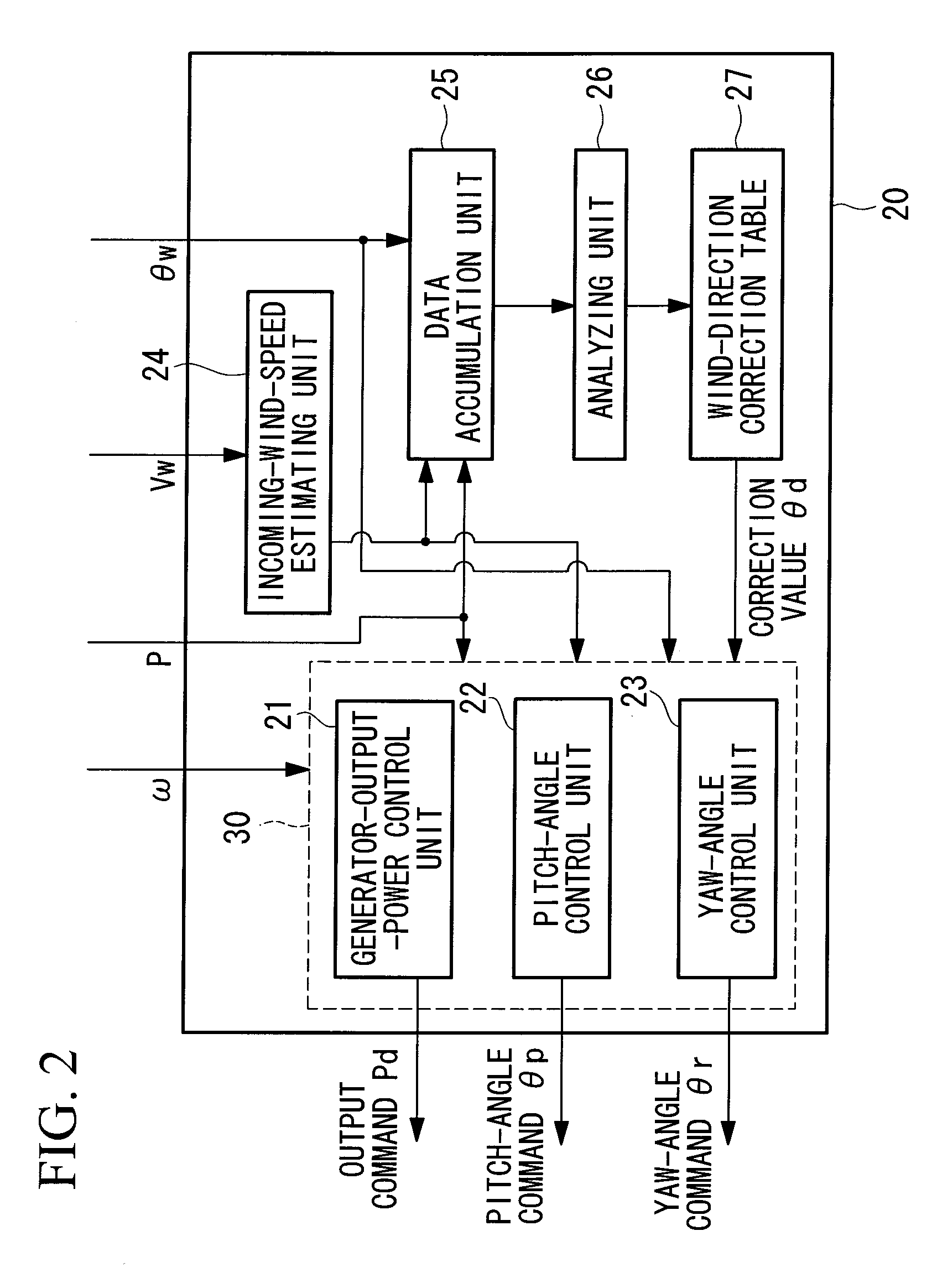

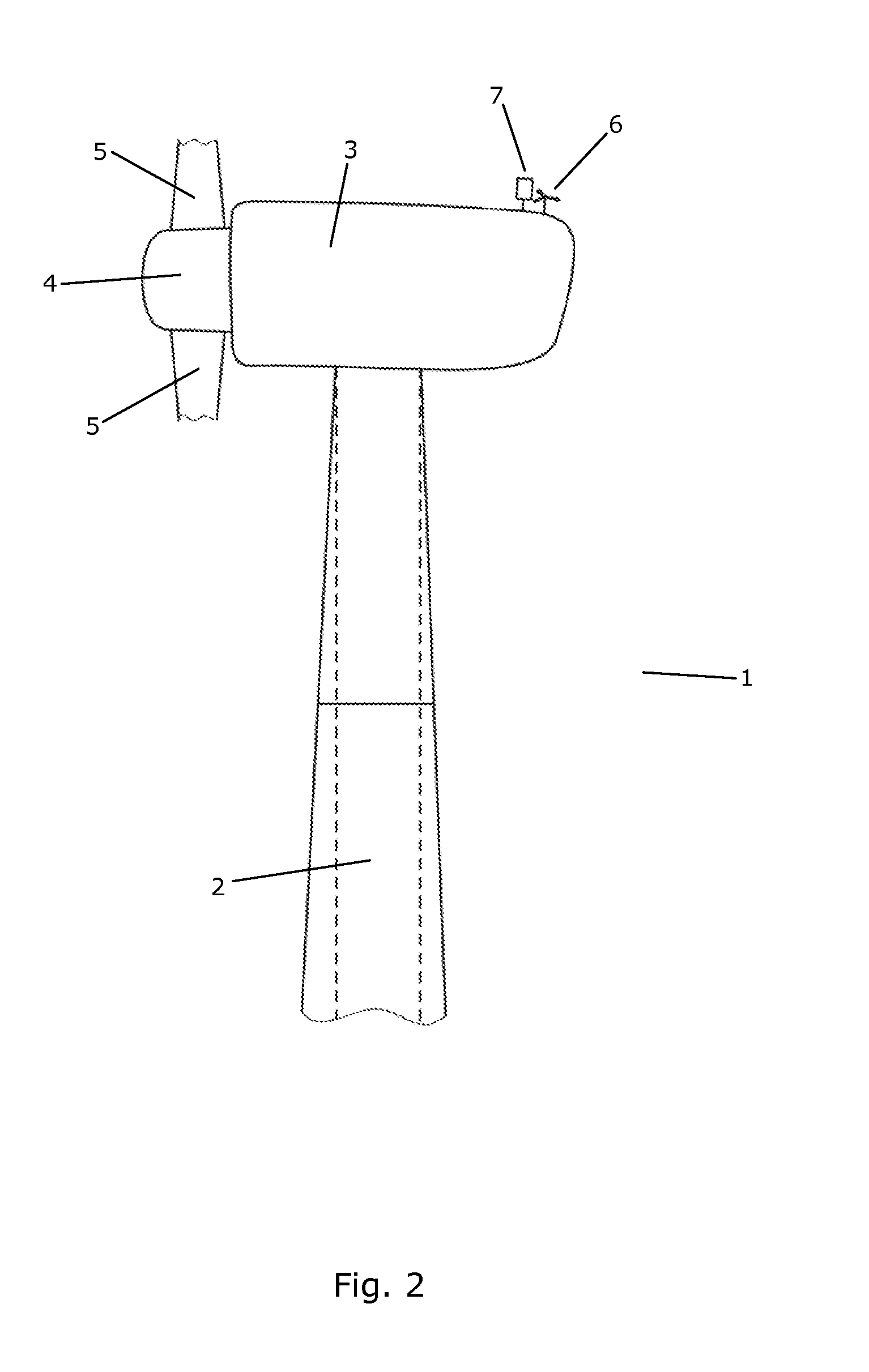

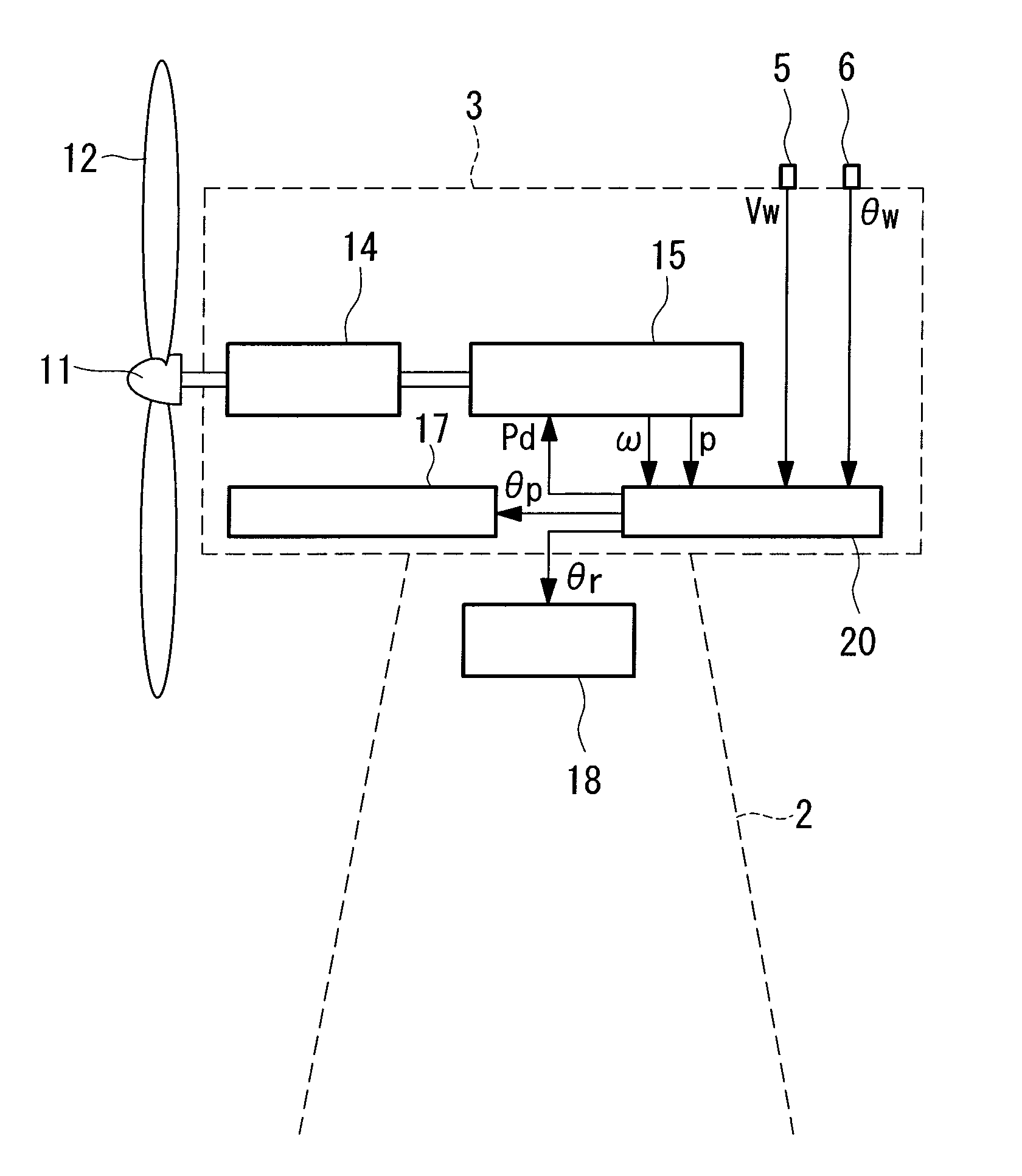

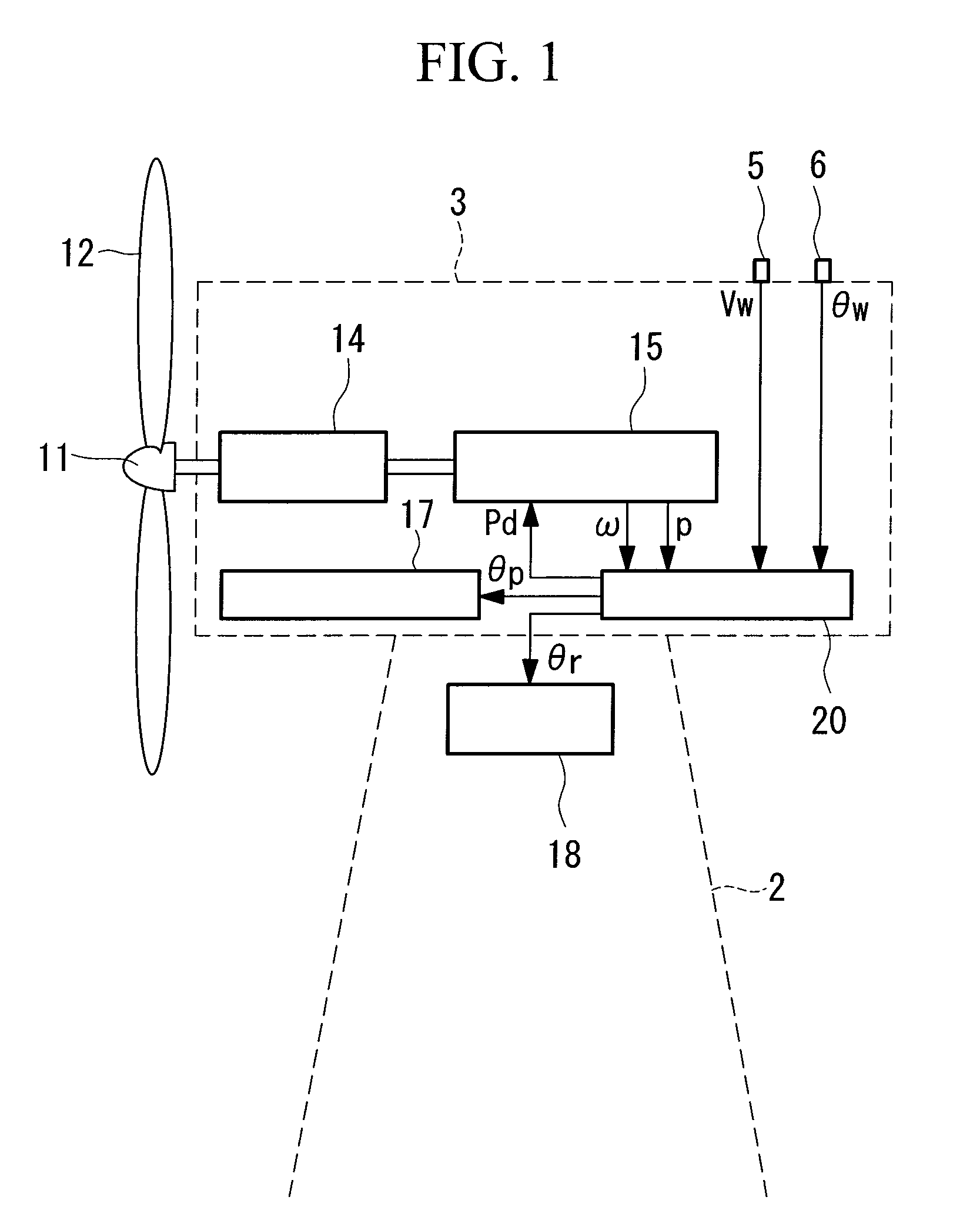

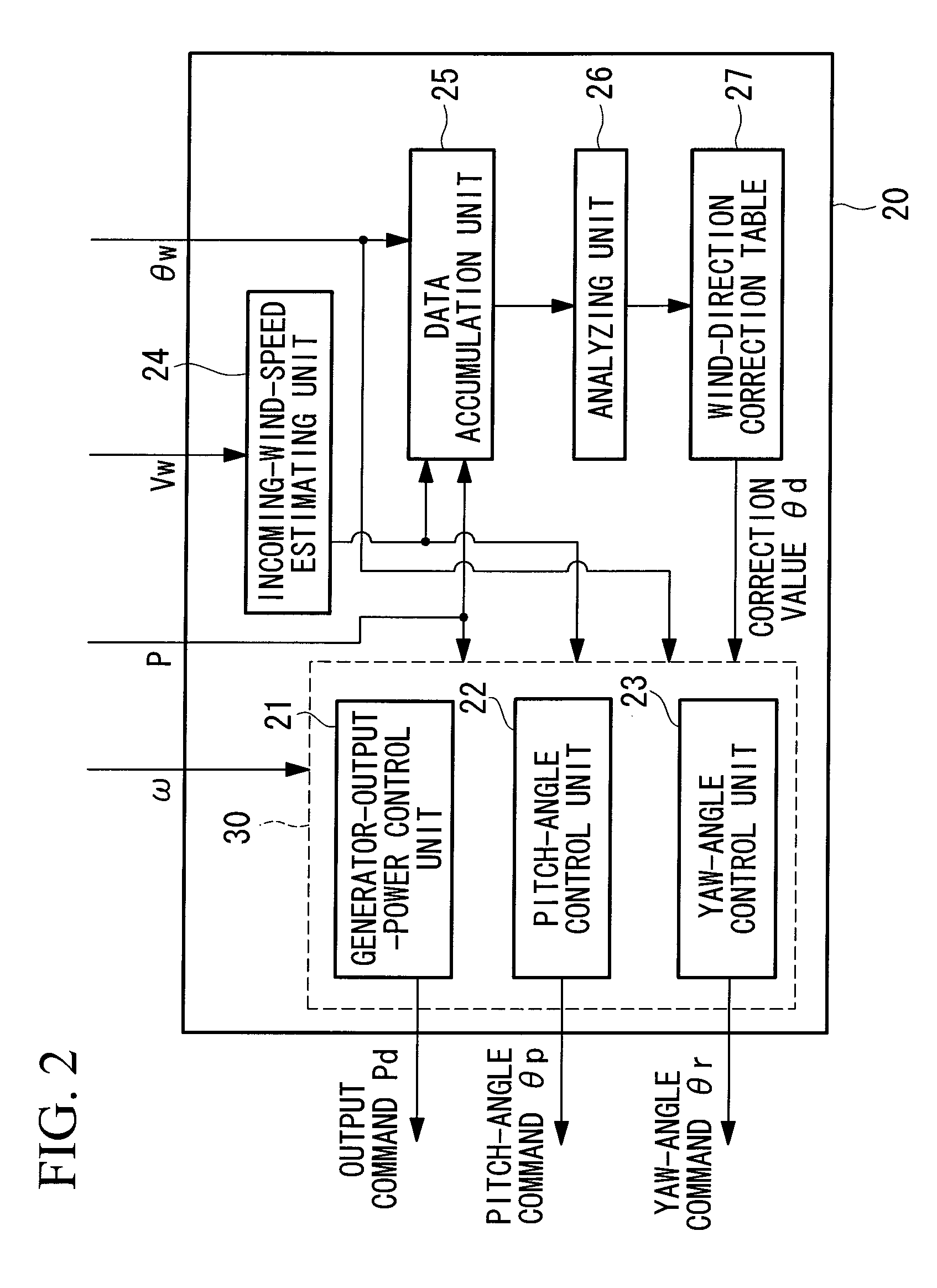

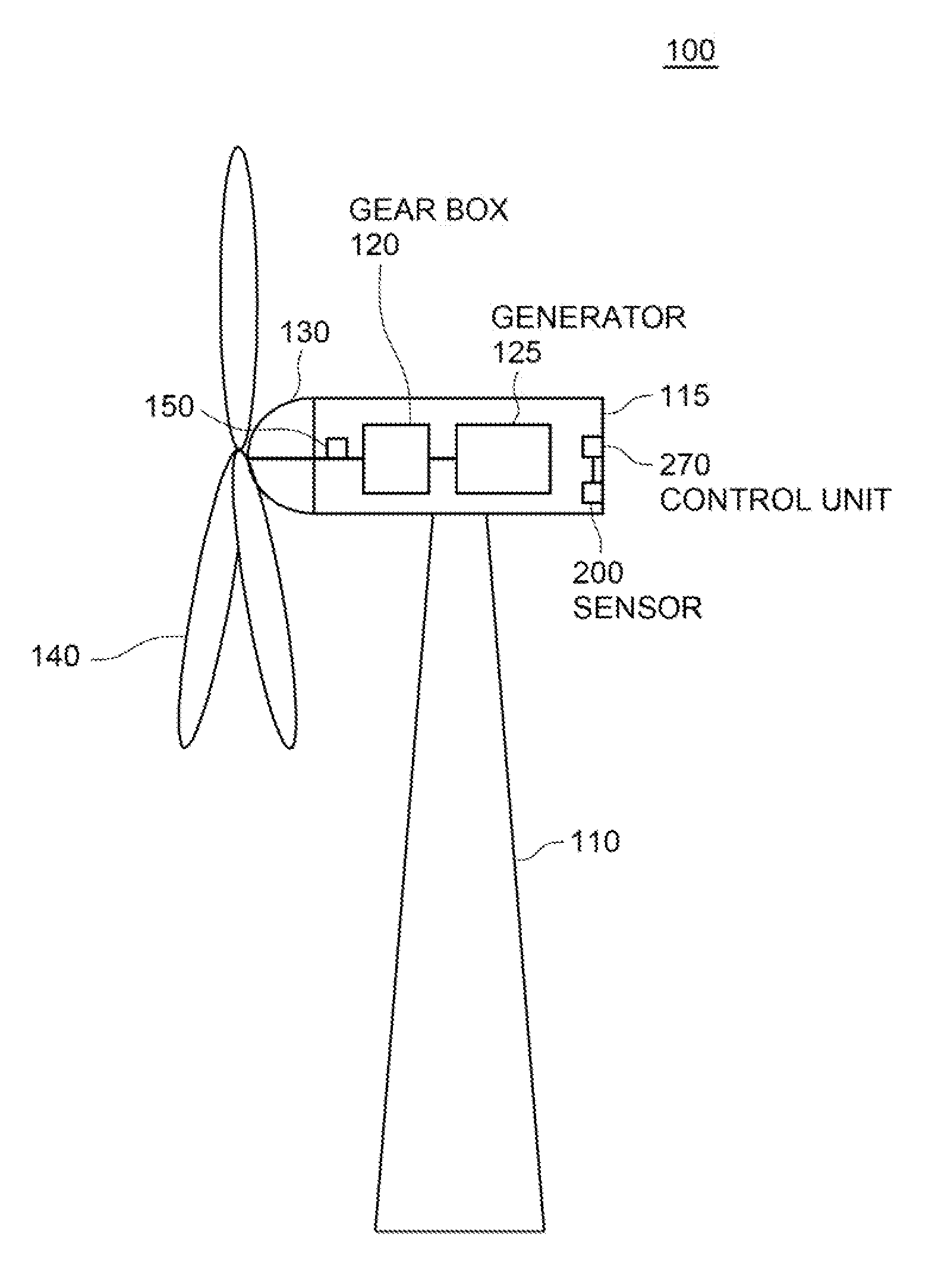

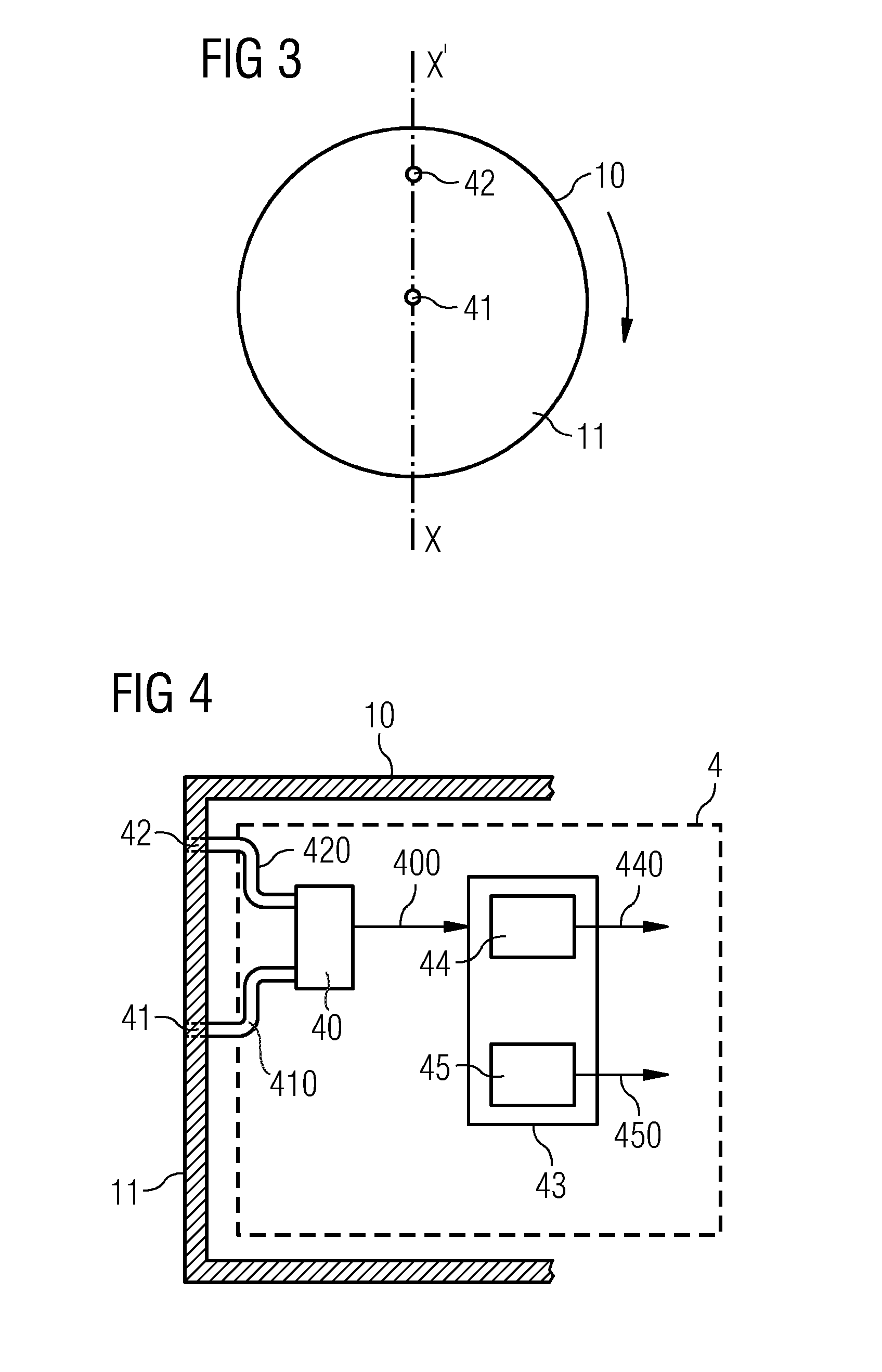

Wind turbine generator, wind turbine generator system, and power generation control method of wind turbine generator

ActiveUS20100066087A1Accurate wind directionIncrease costElectric motor controlWind motor controlNacellePeak value

To provide a wind turbine generator, a wind turbine generator system, and a power-generation control method of a wind turbine generator that are capable of improving the power-generation capability and reducing the fatigue load on the windmill. A data accumulation unit 25 sequentially accumulates data sets of a generated output power P during operation of the wind turbine generator, an incoming wind speed Ws estimated on the basis of a wind speed measured at the anemometer, and a wind direction deviation, which is the difference between a wind direction θw measured at the anemoscope and the orientation of the nacelle; statistical analysis of the data accumulated is carried out by an analyzing unit 26; a distribution curve corresponding to the wind direction deviation of the generated output power at each incoming wind speed is determined; the wind direction deviation corresponding to the peak of the distribution curve is set as a correction value θd of the anemoscope; the correction value of the anemoscope for each incoming wind speed is stored in the wind-direction correction table 27; the wind direction Vw measured at the anemoscope is corrected with the correction value θd of the anemoscope for each incoming wind speed Ws; and power-generation control is carried out using the corrected wind direction as a control parameter.

Owner:MITSUBISHI HEAVY IND LTD

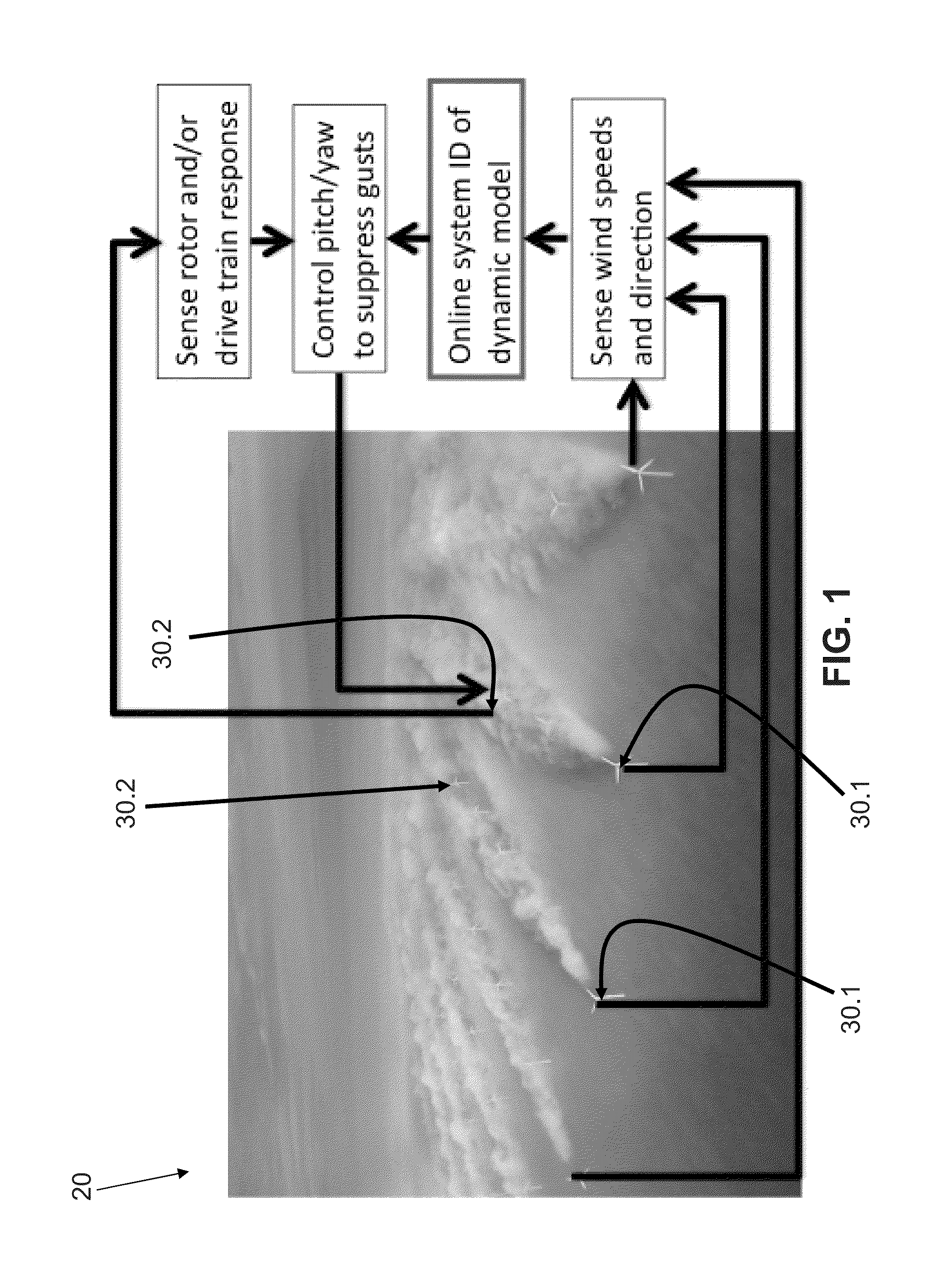

Load shape control of wind turbines

Methods and apparatus for control and monitoring of wind turbines. Various embodiments pertain to the operational analysis of vibratory modes of the blades of the wind turbine. This real time analysis of blade modal response can be used as feedback in a control system to change the yaw angle of the hub and nacelle to capture higher power from the wind stream, change the pitch on one or more blades to reduce uneven blade loading, to identify damage to a blade, and further to identify the accumulation of ice on a blade.

Owner:PURDUE RES FOUND INC

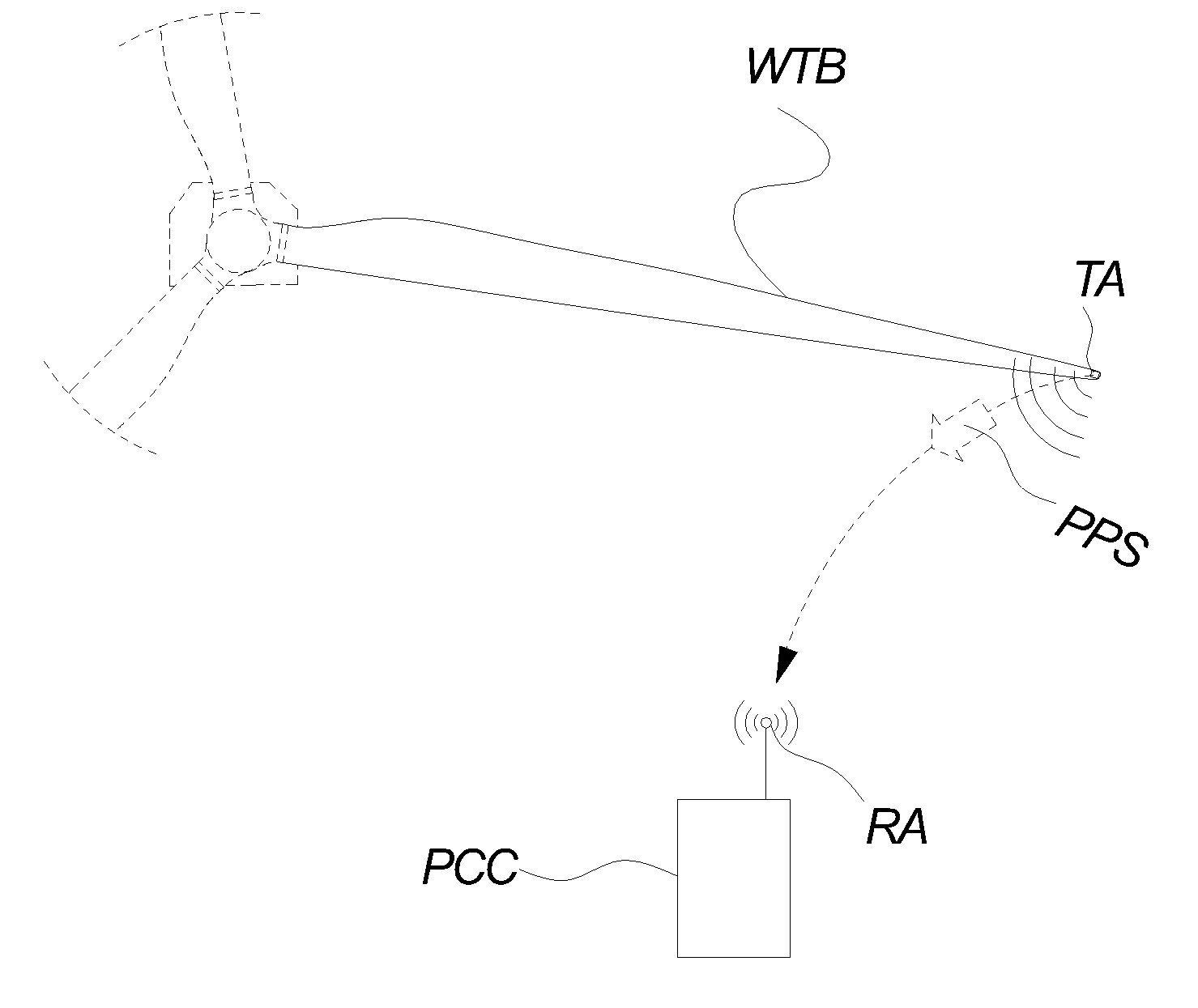

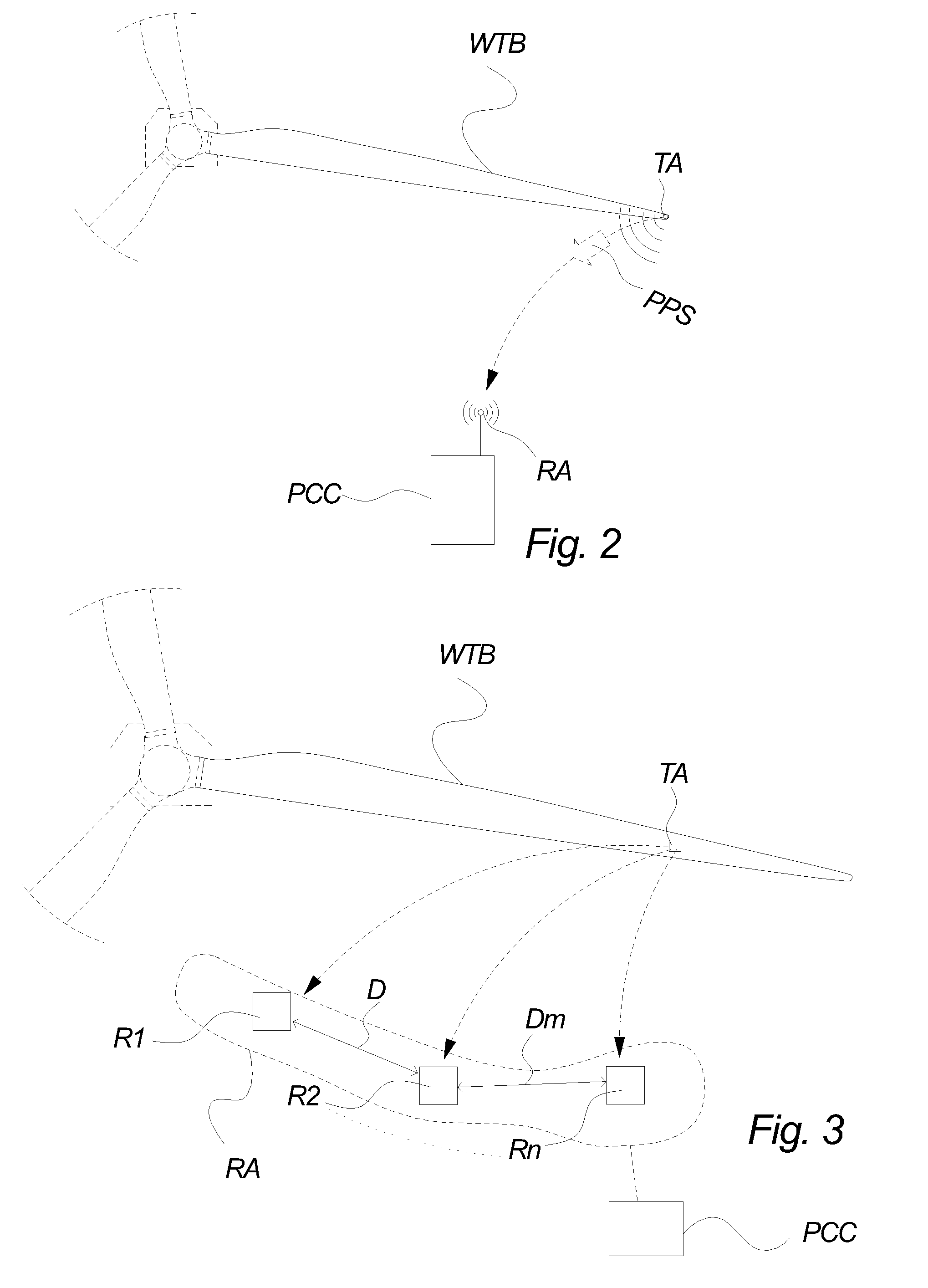

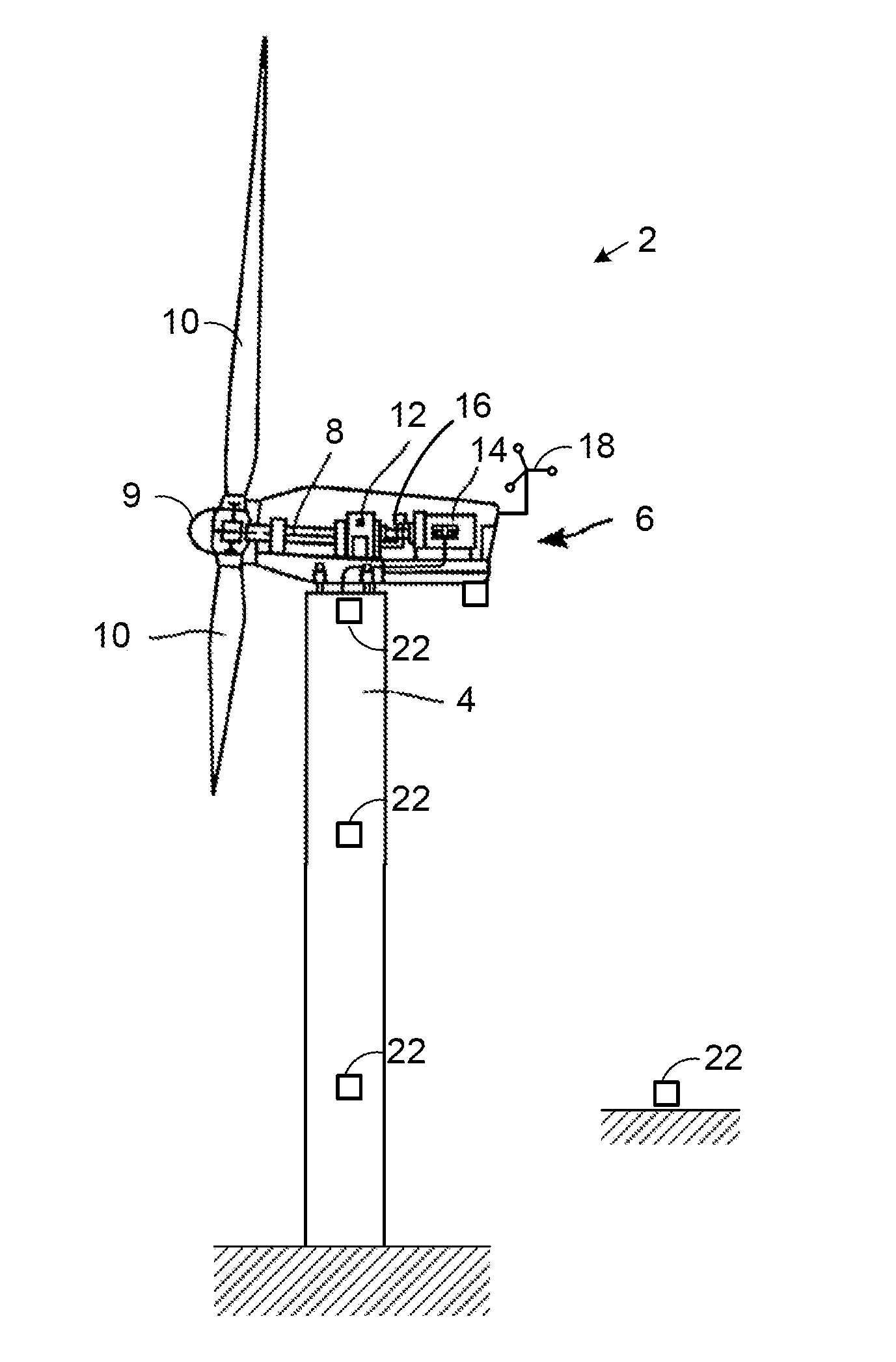

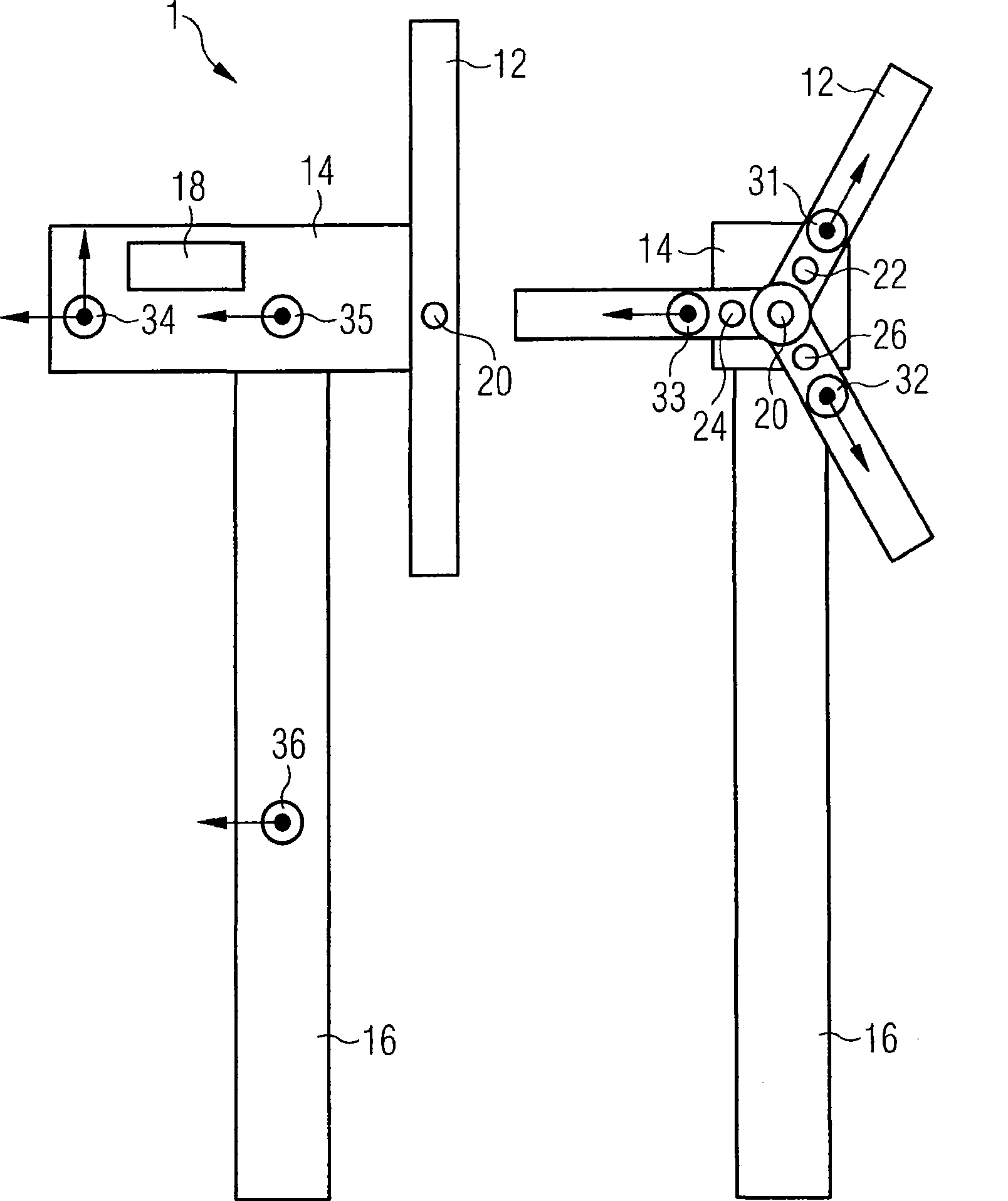

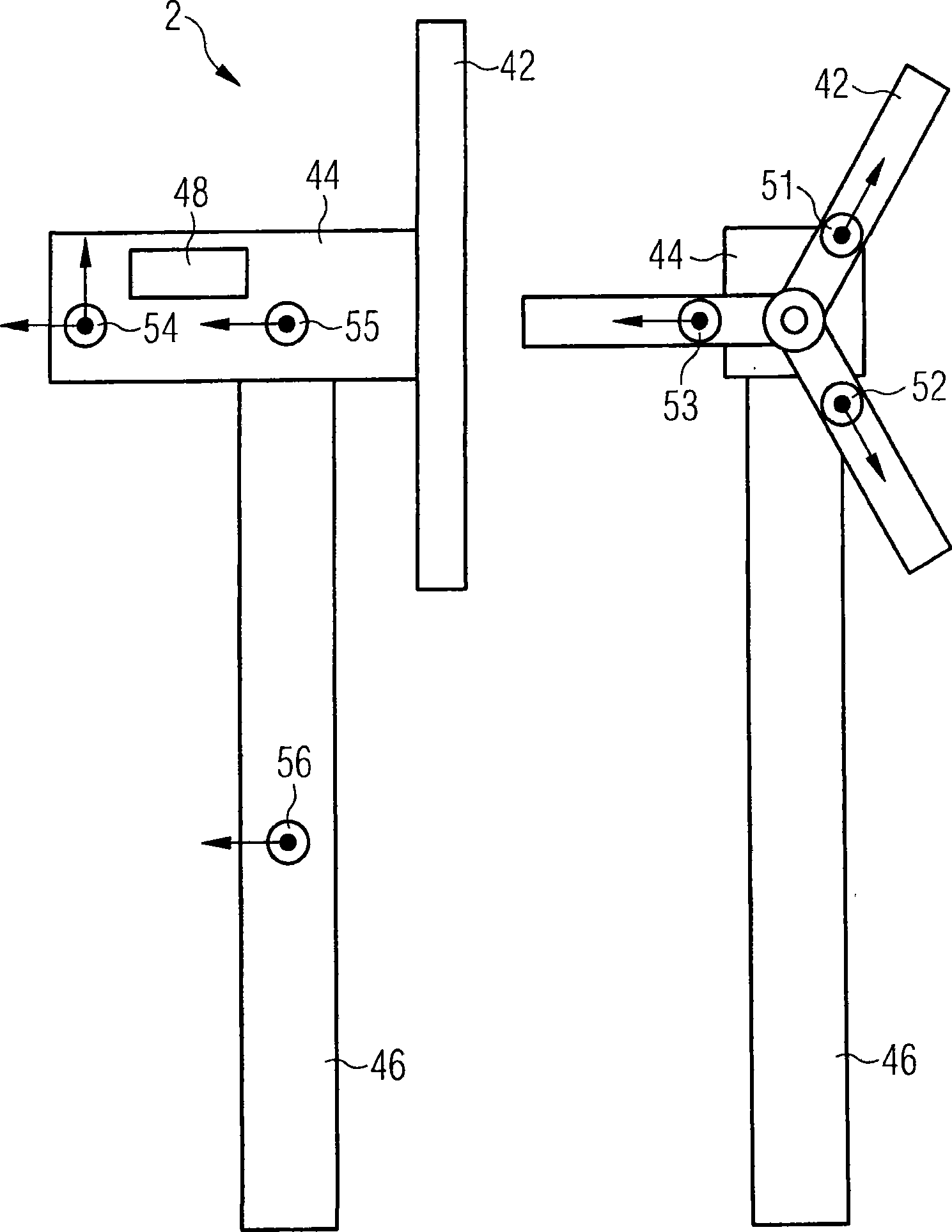

Wind Turbine Blade Position Determination System

InactiveUS20100021298A1Low costEasy to replacePropellersWind motor controlWireless transmissionTurbine blade

A system for determining the position of at least a part of a wind turbine blade by wireless transmission of a signal includes a transmitter arrangement attached to a wind turbine blade, a receiving arrangement, and at least one position calculation computer, wherein the signal is wirelessly transmitted from the at least one transmitter arrangement to the receiving arrangement, and wherein the position calculation computer calculates position indicative data on the basis of the signal received by the receiving arrangement and wherein the position indicative data indicates a position of at least a part of the wind turbine blade.

Owner:VESTAS WIND SYST AS

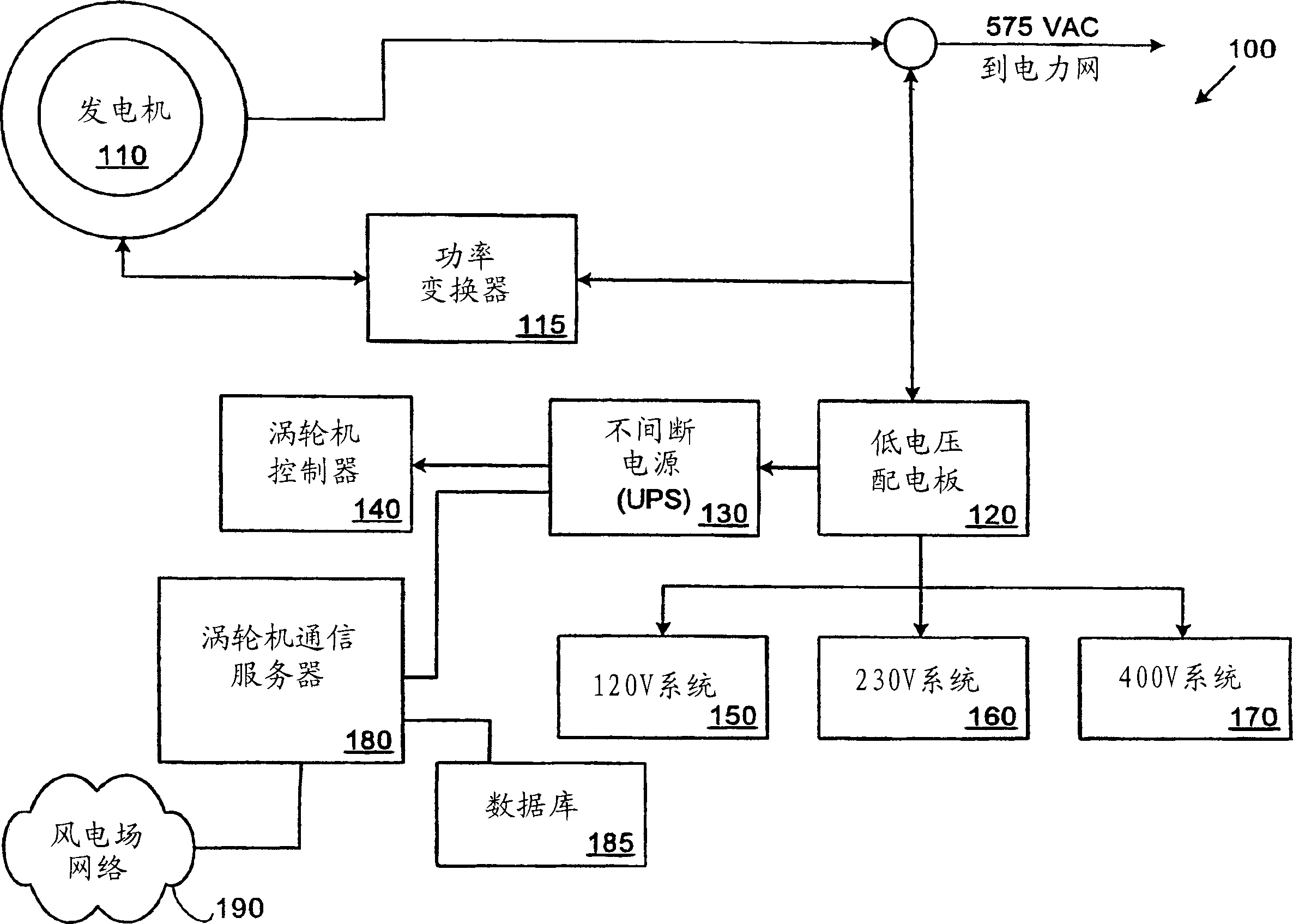

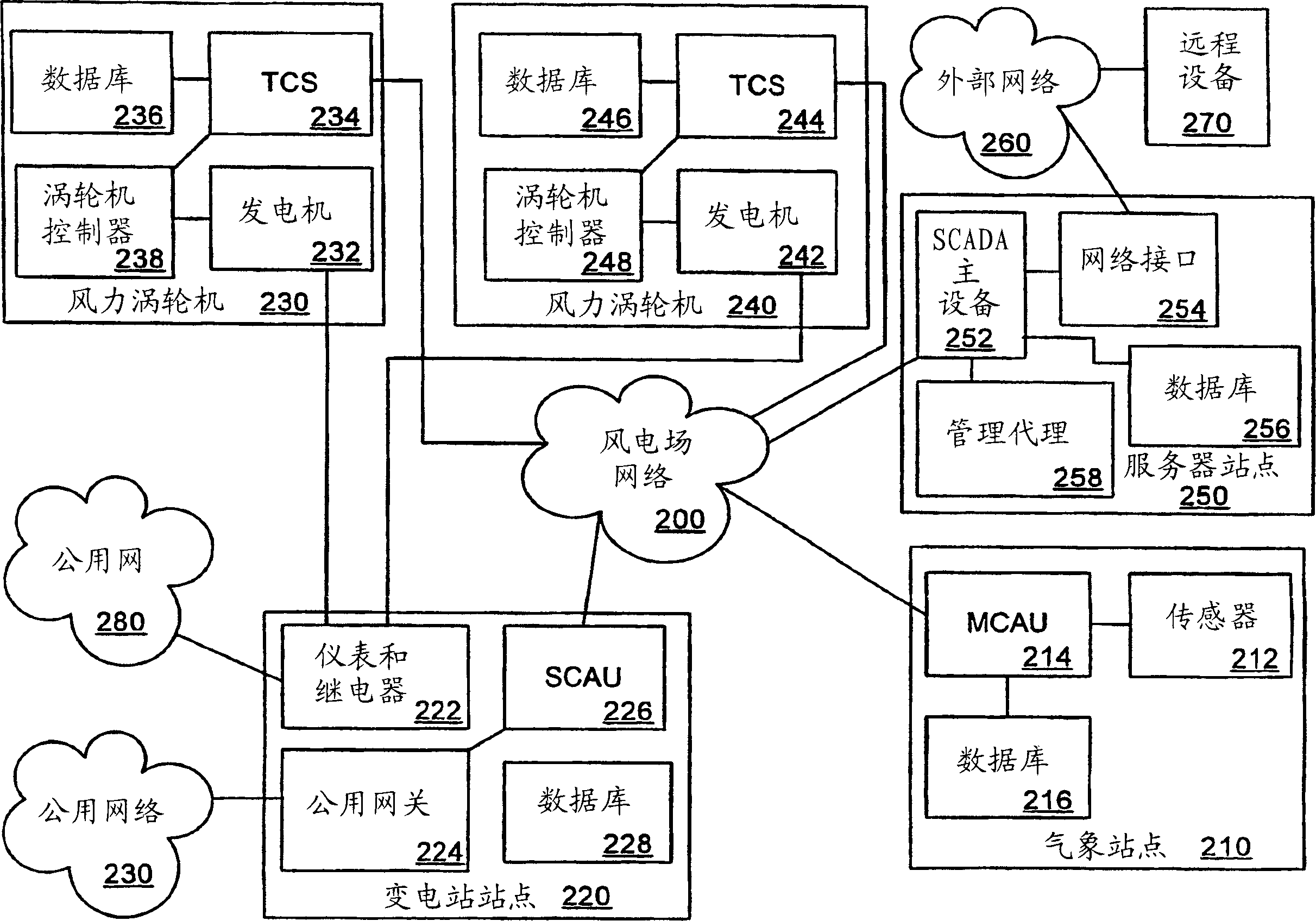

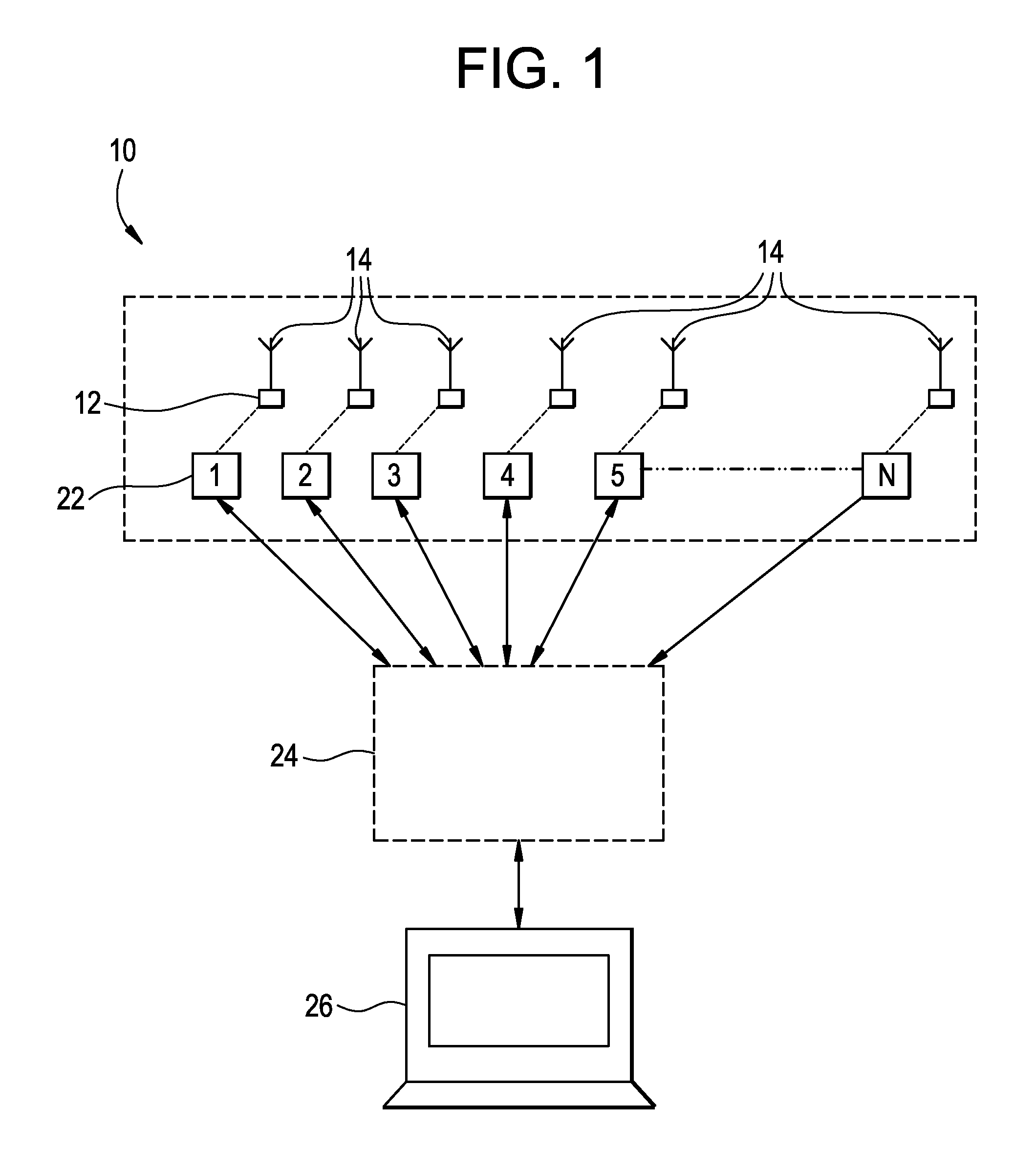

Wind turbine system control

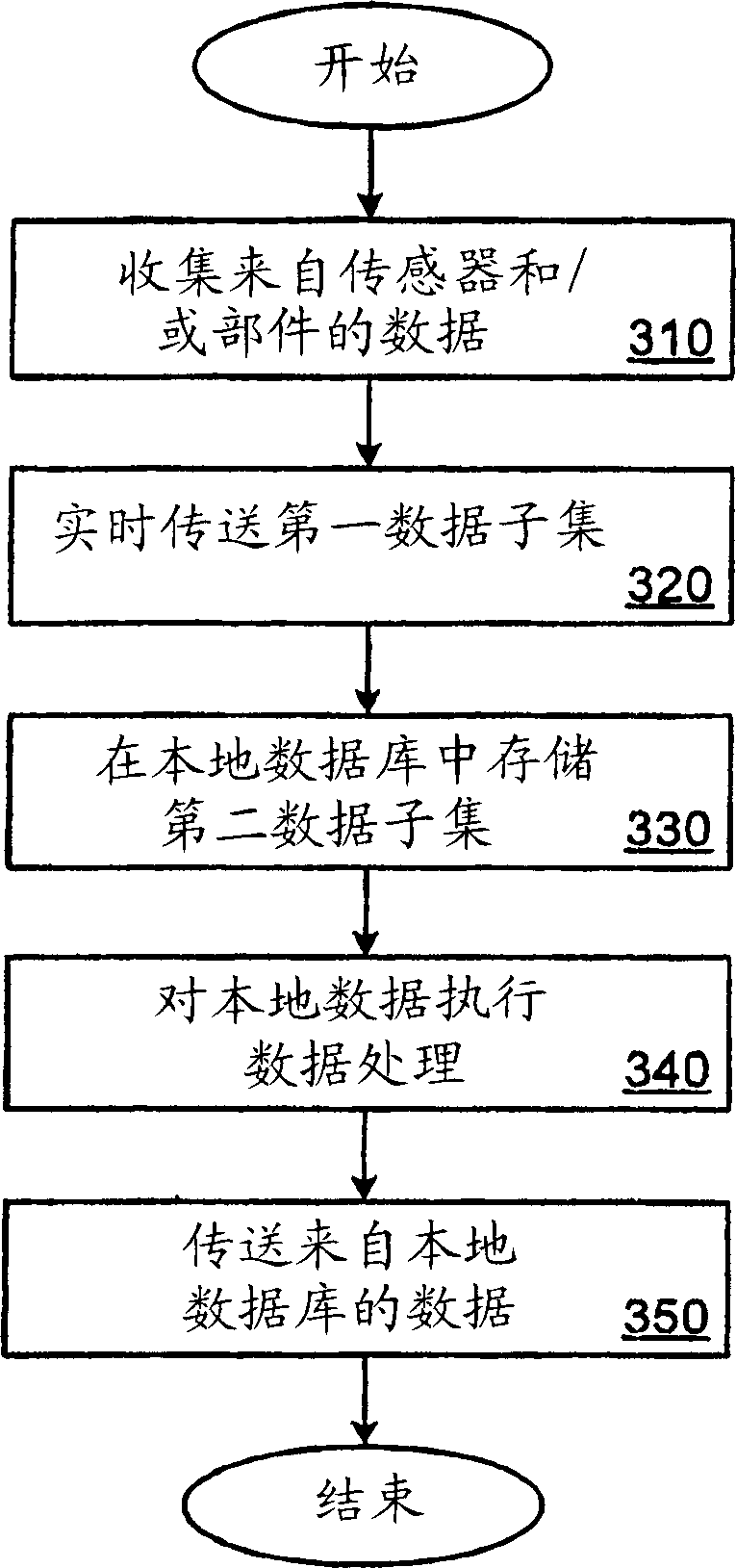

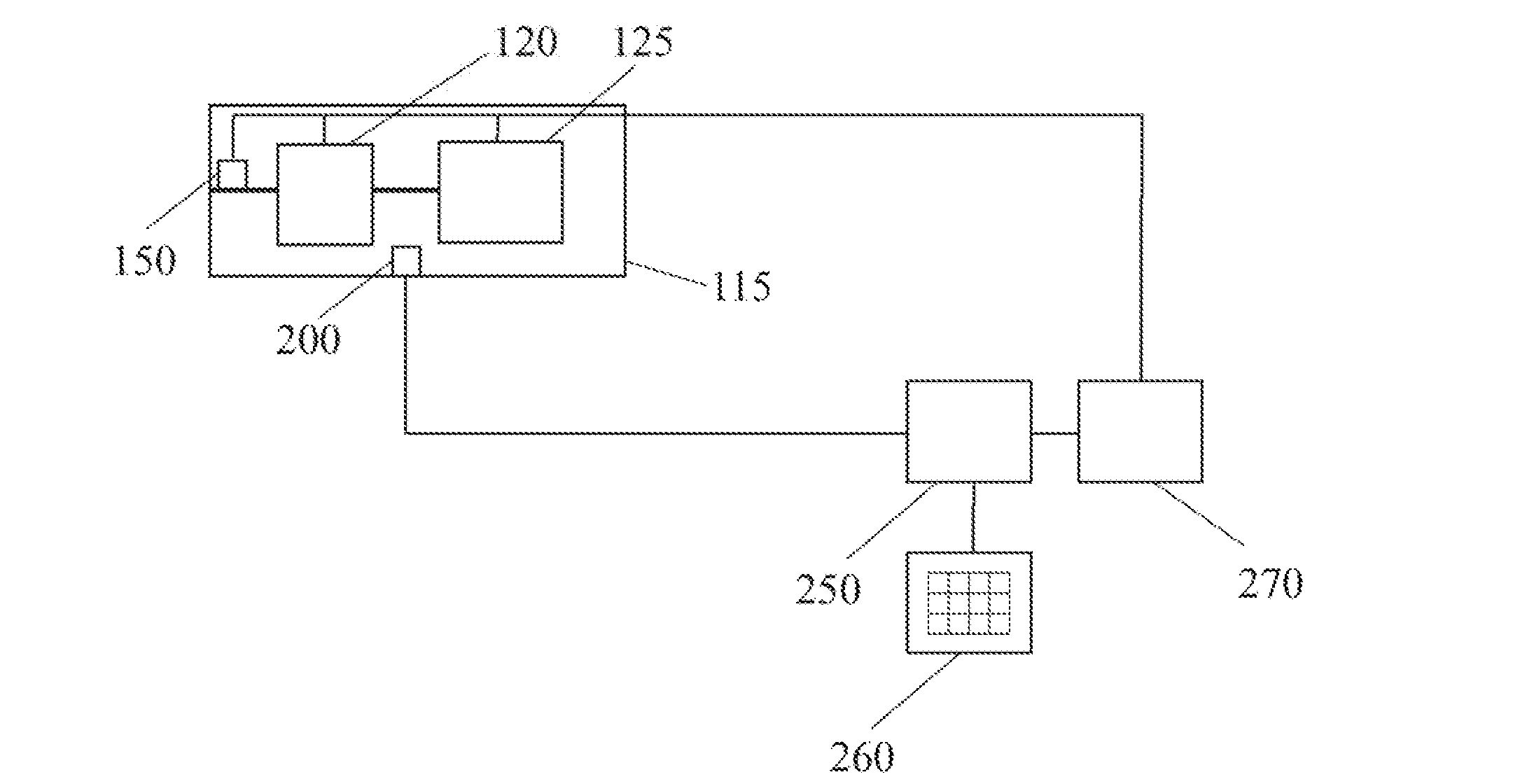

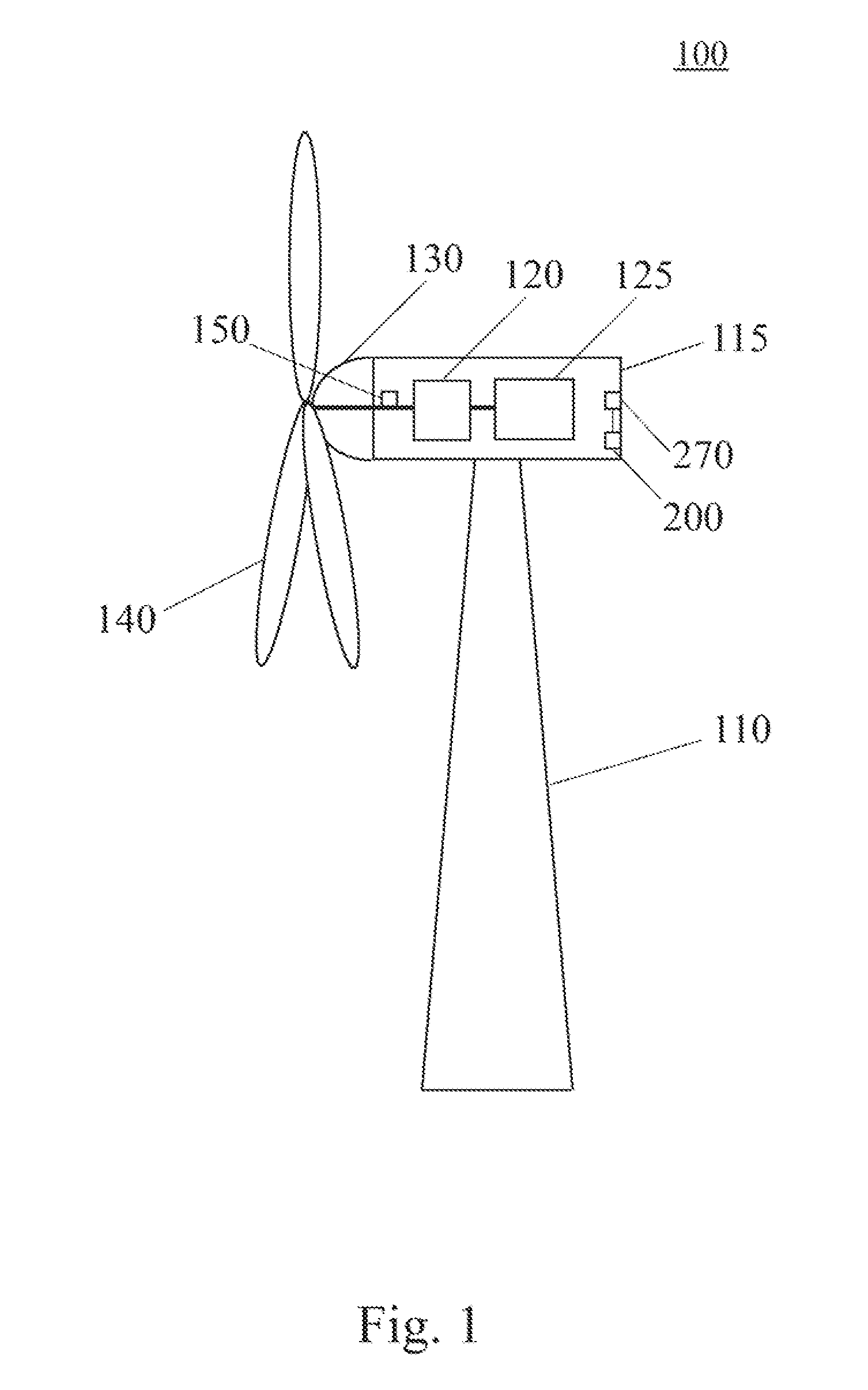

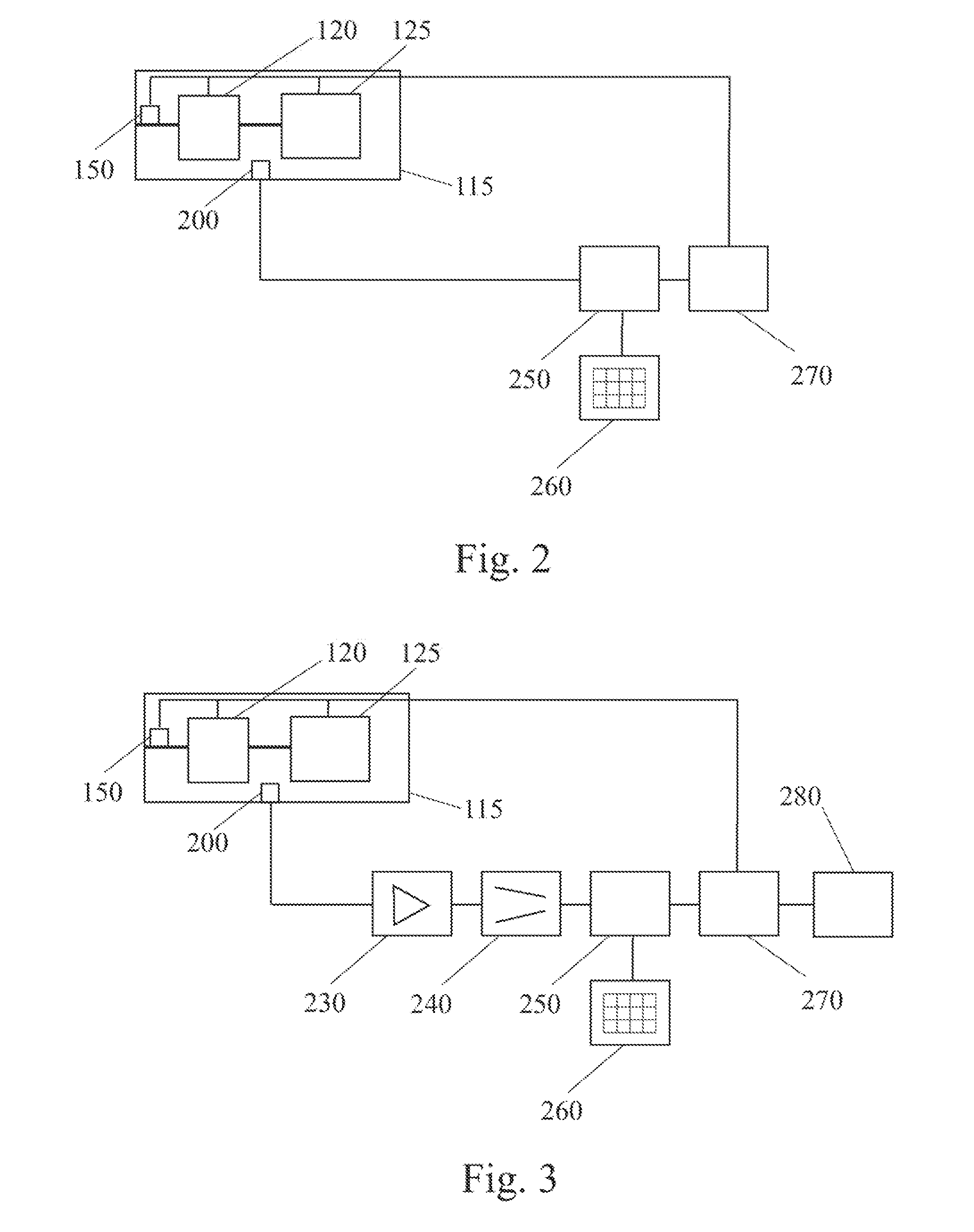

Wind turbine generator wind farm systems to collect data for use for wind farm control. A combination master-slave supervisory command and data acquisition (SCADA) architecture together with distributed databases local to the data producing device within a wind farm provide functionality for real-time monitoring and control as well as secondary data processing and / or remote user access. The architecture facilitates approximately real-time monitoring and control of devices in the wind farm both locally and remotely while also facilitating reliable archiving of operational data of individual wind turbines as well as totalized wind farm data.

Owner:GENERAL ELECTRIC CO

Tonal emission control for wind turbines

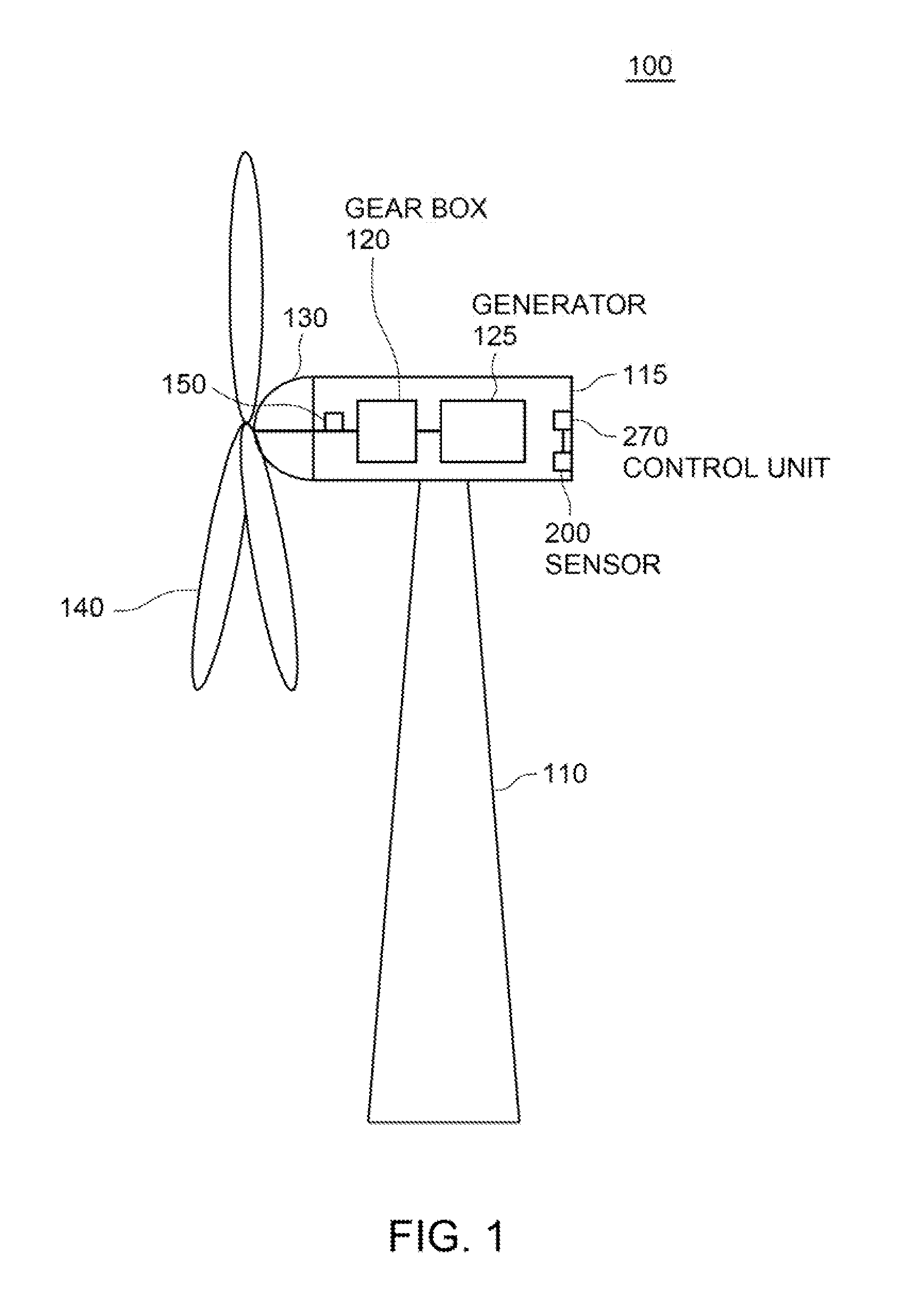

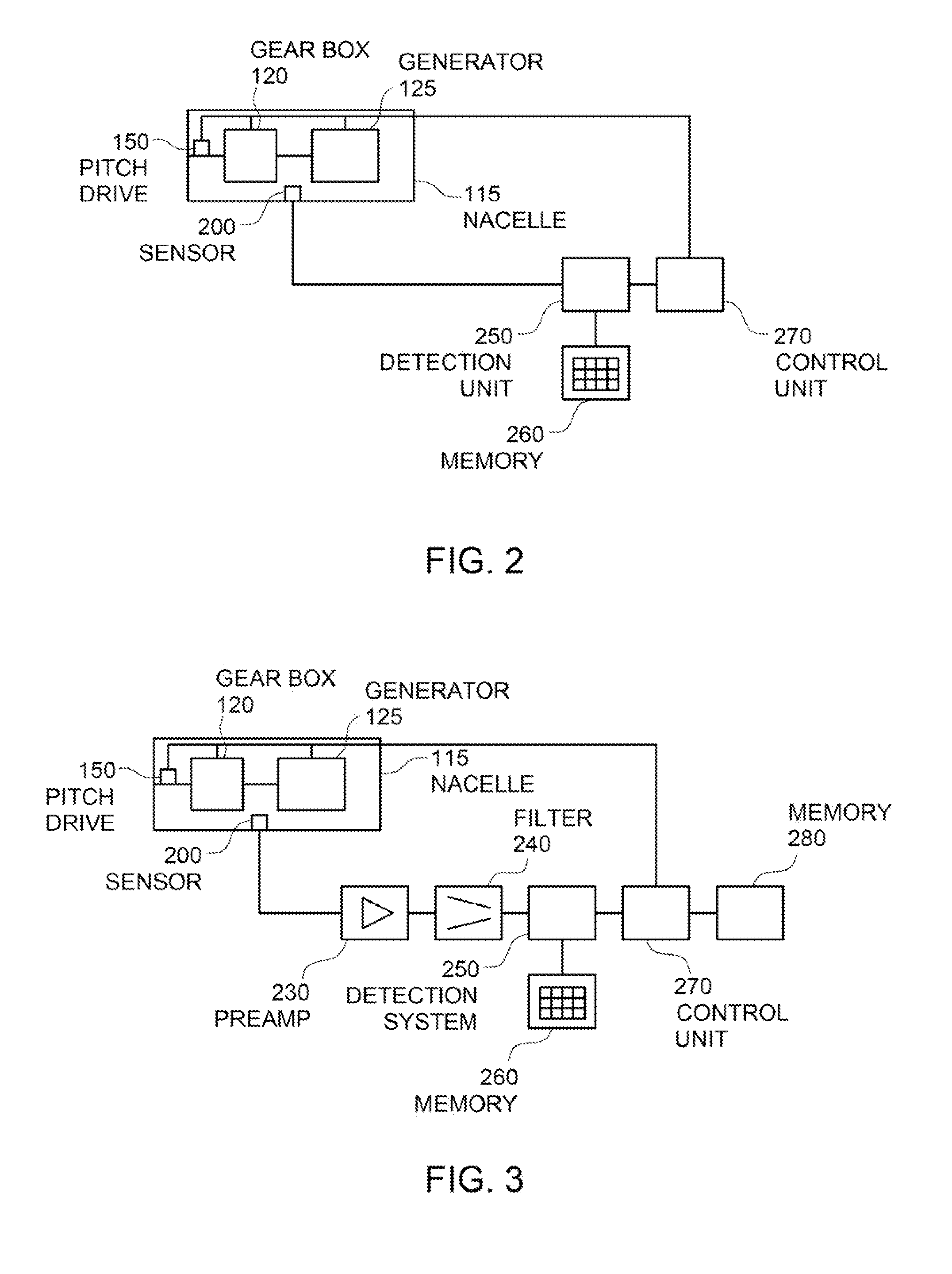

ActiveUS20080164091A1Effective avoidanceTonal emissionPropellersWind motor controlAmplitude controlNoise reduction

A system for the noise reduction of wind turbines comprises at least one acoustic sensor provided at the wind turbine, a detection unit and a control unit, wherein said detection unit is adapted to detect tonal components in a signal of said sensor, and wherein said control unit is adapted to control wind turbine operating parameters in dependence of an amplitude of a tonal component.

Owner:GENERAL ELECTRIC CO

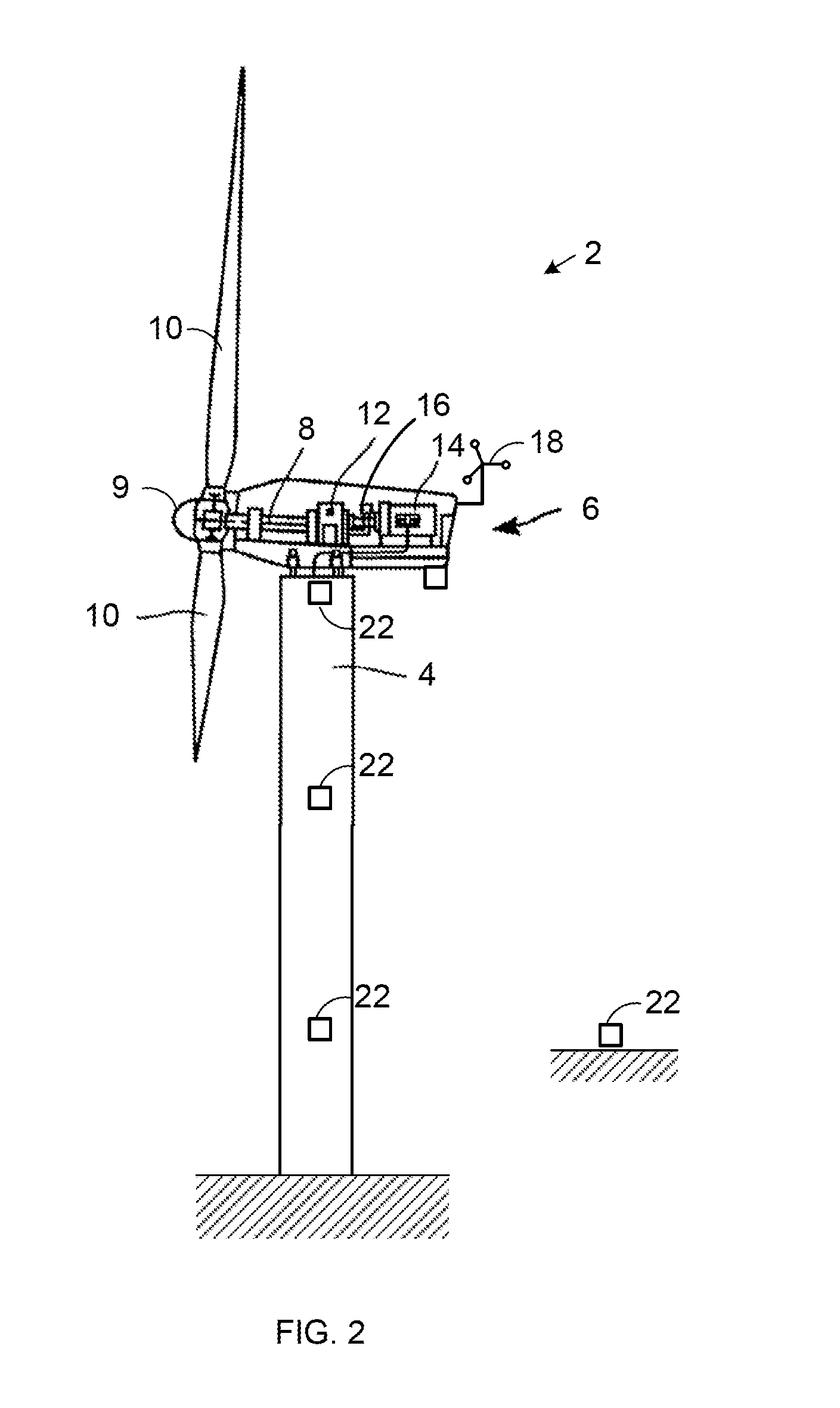

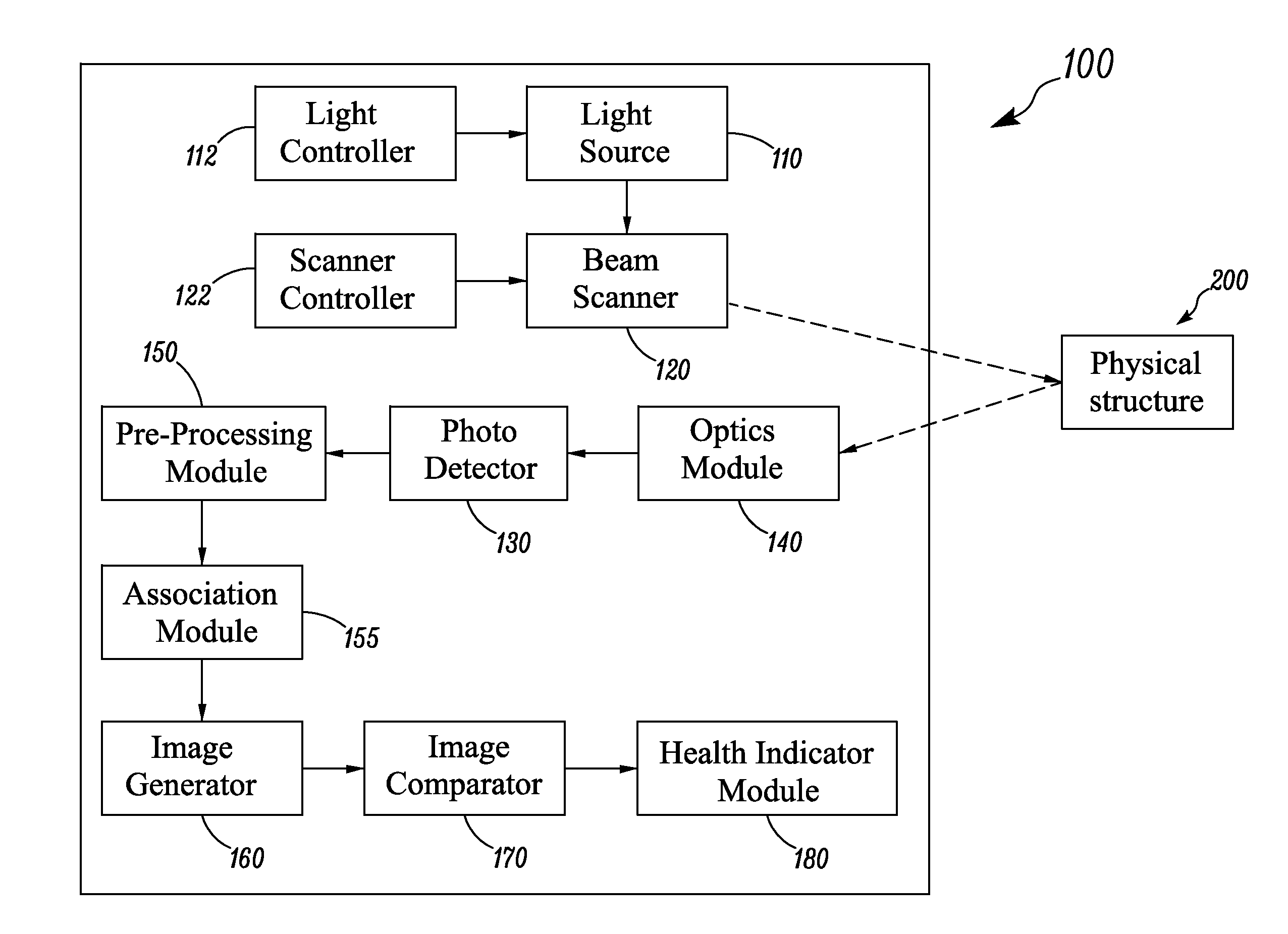

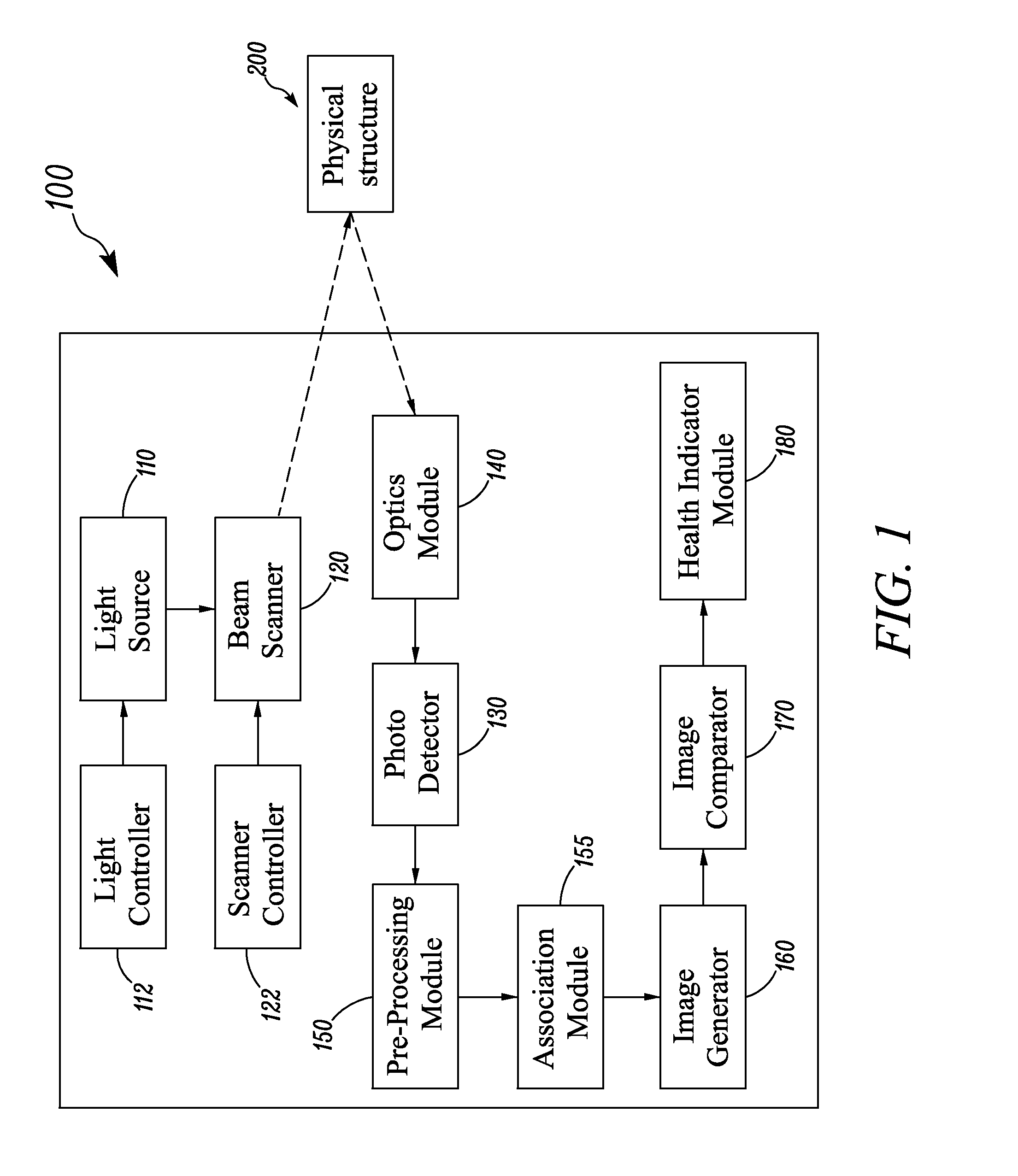

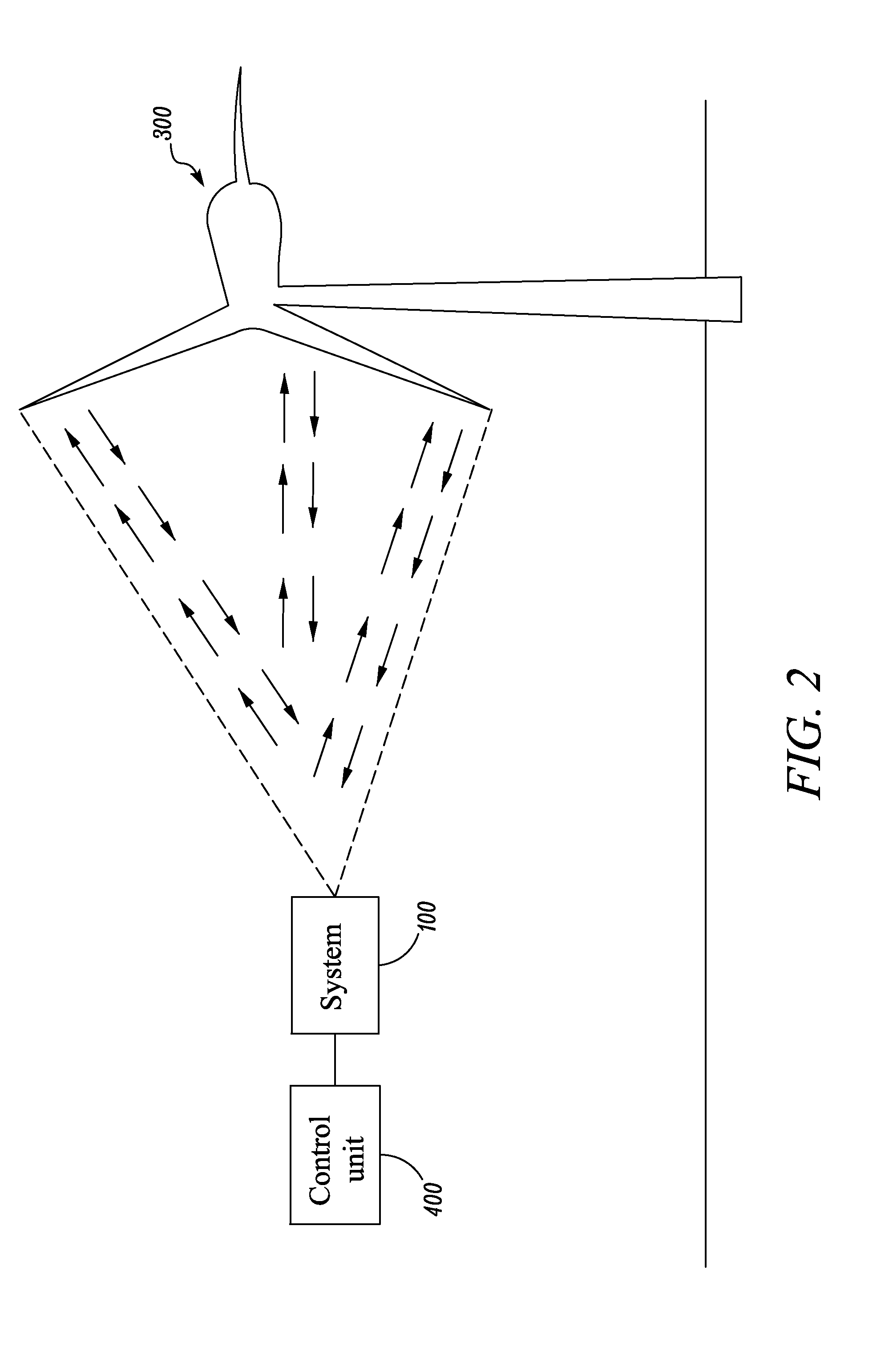

System and method for monitoring and controlling physical structures

A system for controlling a wind turbine is disclosed. A system includes a light source and a beam scanner to scan the light pulses over the wind turbine. The system further receives backscattered light pulses and subsequently, provides a signal corresponding to the light pulses. The system adjusts a threshold of the signal based on a normalized value of a detected peak value of the signal. The system associates a time of flight with each of the received backscattered light pulse. The system generates an image of the wind turbine based on the time of flight associated with the light pulses and subsequently, compares the generated image with at least one known image of the wind turbine. The system generates a health profile of the wind turbine based on the comparison and subsequently, change one or more parameters of the wind turbine based on the health profile.

Owner:GENERAL ELECTRIC CO

Control System and a Method for Controlling a Wind Turbine

ActiveUS20110148112A1Increased energy productionReliable measurementSafety arrangmentsWind motor controlControl systemEngineering

A control system for controlling operation of a wind turbine, a wind turbine having such a control system and a method for controlling a wind turbine are disclosed. The control system comprises a first sensor device and a second sensor device, each being arranged for measuring the same control parameter used for controlling operation of the wind turbine. The first sensor device has a first set of operating failure conditions, and the second sensor device has a second set of operating failure conditions. The first set of operating failure conditions comprises at least one operating failure condition which does not form part of the second set of operating failure conditions. The system further comprises a third sensor device for detecting an operating failure condition of the first sensor device and / or of the second sensor device. The control system is adapted to select between controlling operation of the wind turbine on the basis of control parameters measured by the first sensor device or on the basis of control parameters measured by the second sensor device, based on measurements performed by means of the third sensor device. Thereby a redundant system for measuring the control parameter is obtained, allowing reliable measurements of the control parameter, even under conditions where the first sensor device fails.

Owner:VESTAS WIND SYST AS

Wind turbine generator, wind turbine generator system, and power generation control method of wind turbine generator

ActiveUS7952215B2Reduce fatigue loadIncreasing costElectric motor controlWind motor controlNacelleStatistical analysis

To provide a wind turbine generator, a wind turbine generator system, and a power-generation control method of a wind turbine generator that are capable of improving the power-generation capability and reducing the fatigue load on the windmill. A data accumulation unit 25 sequentially accumulates data sets of a generated output power P during operation of the wind turbine generator, an incoming wind speed Ws estimated on the basis of a wind speed measured at the anemometer, and a wind direction deviation, which is the difference between a wind direction θw measured at the anemoscope and the orientation of the nacelle; statistical analysis of the data accumulated is carried out by an analyzing unit 26; a distribution curve corresponding to the wind direction deviation of the generated output power at each incoming wind speed is determined; the wind direction deviation corresponding to the peak of the distribution curve is set as a correction value θd of the anemoscope; the correction value of the anemoscope for each incoming wind speed is stored in the wind-direction correction table 27; the wind direction Vw measured at the anemoscope is corrected with the correction value θd of the anemoscope for each incoming wind speed Ws; and power-generation control is carried out using the corrected wind direction as a control parameter.

Owner:MITSUBISHI HEAVY IND LTD

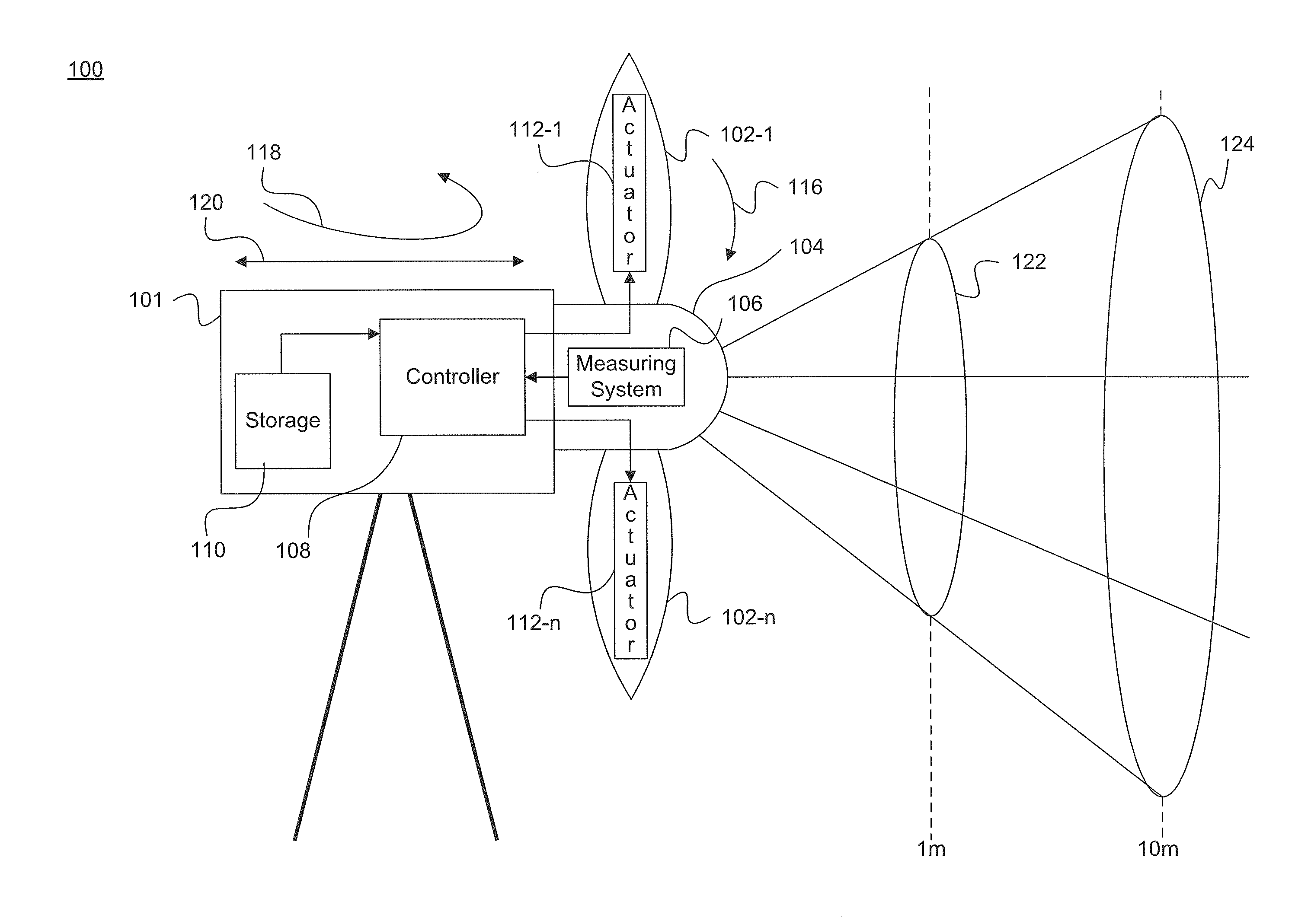

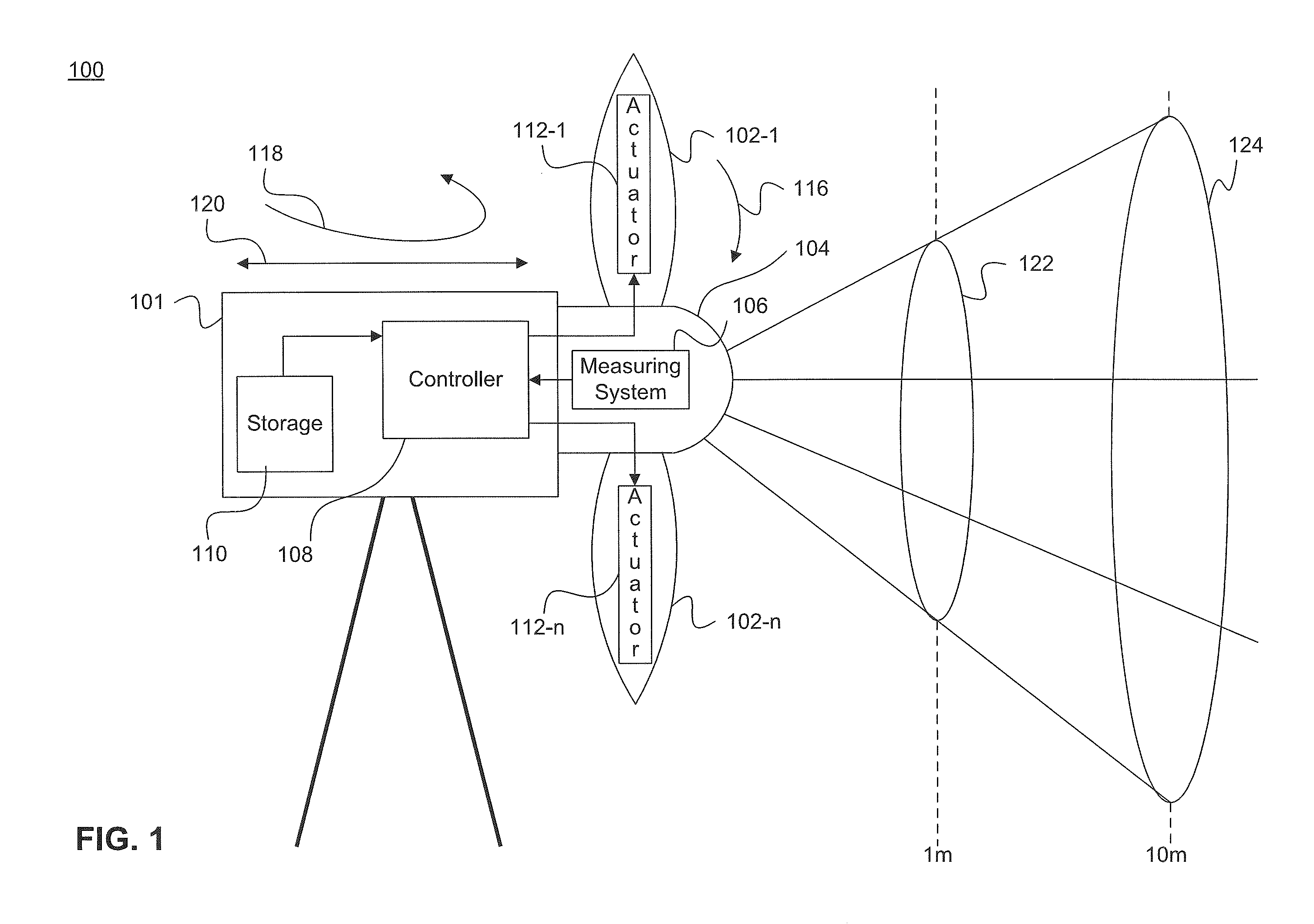

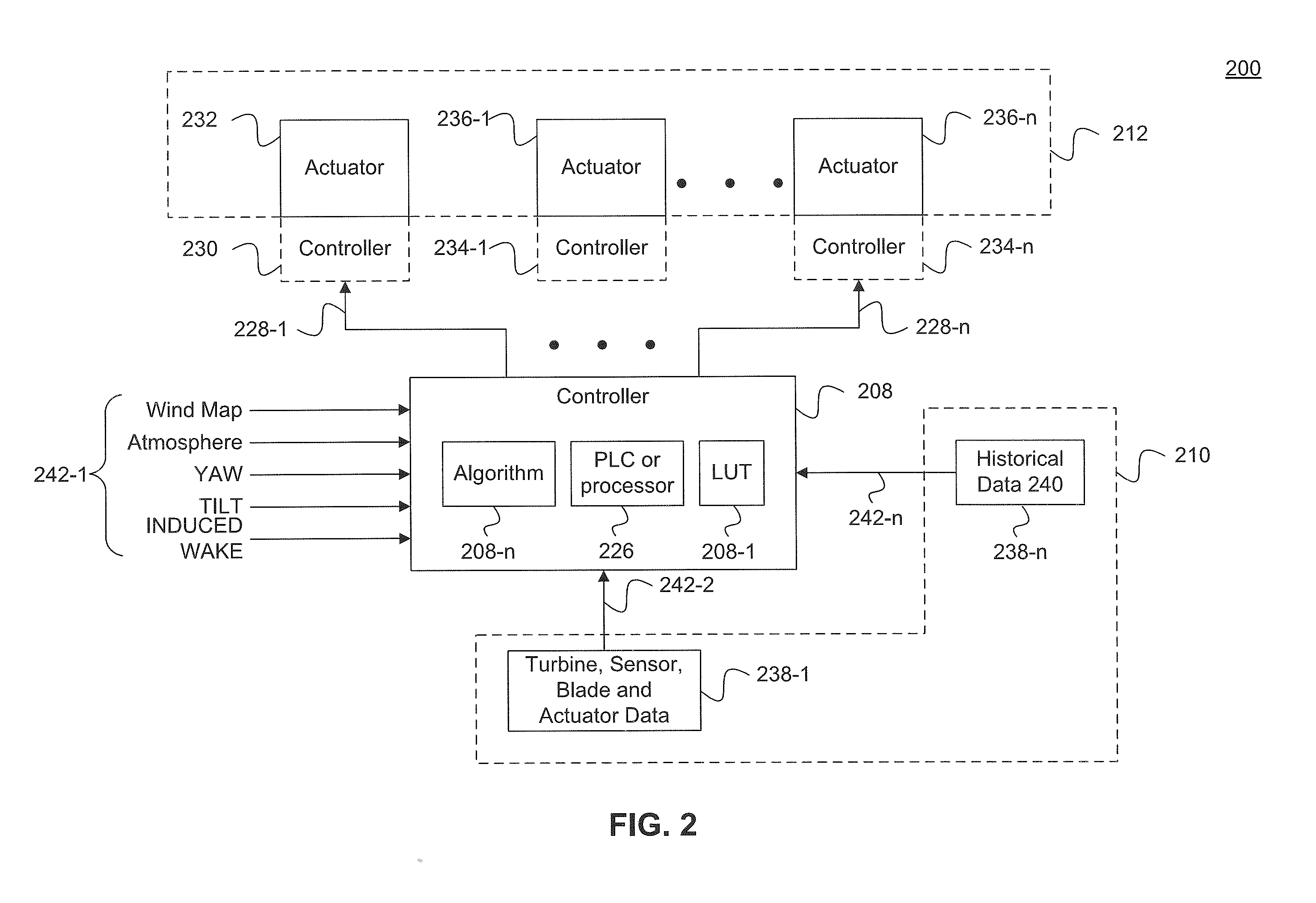

Independent blade pitch control

InactiveUS20120051907A1Efficiently and effectively configure and orientIncrease generationPropellersWind motor controlControl signalEngineering

A system and method are provided to increase efficiency of turbines in wind farms. A sensor is configured to generate a wind map of an inflow of wind. A controller is configured to generate a control signal based the wind map. A pitch adjustment device configured to adjust pitch of a blade of the turbine based on the control signal.

Owner:BLUESCOUT TECH INC

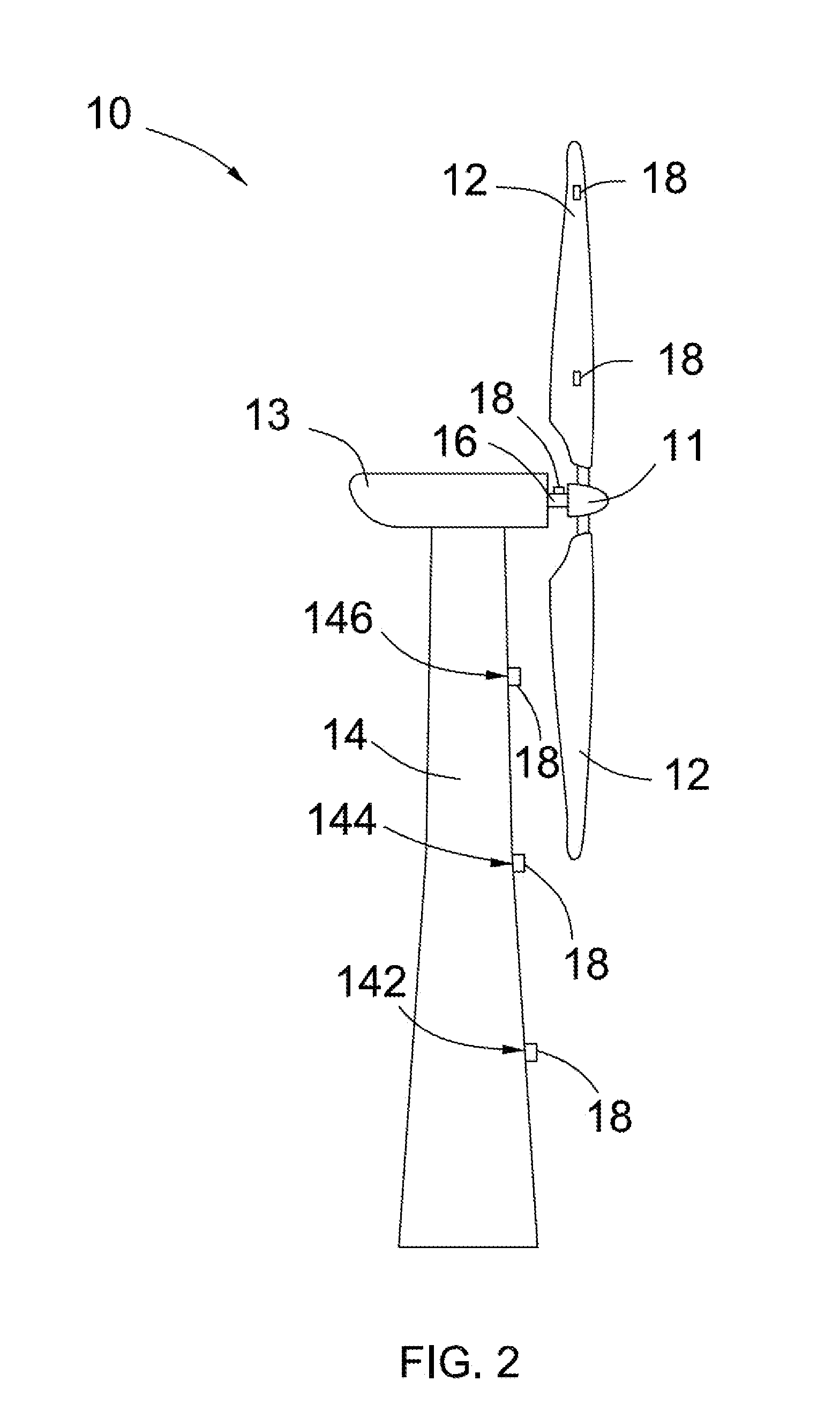

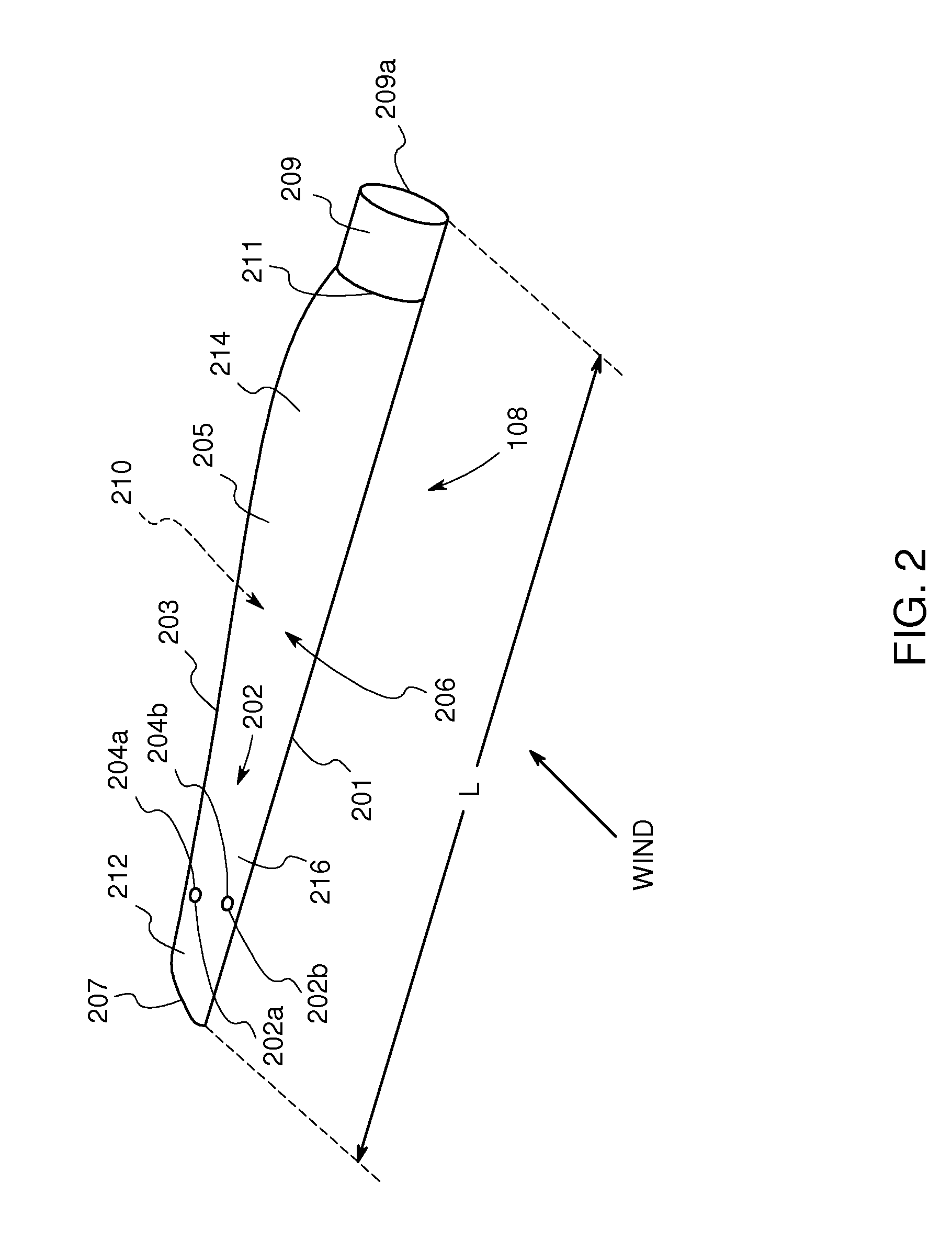

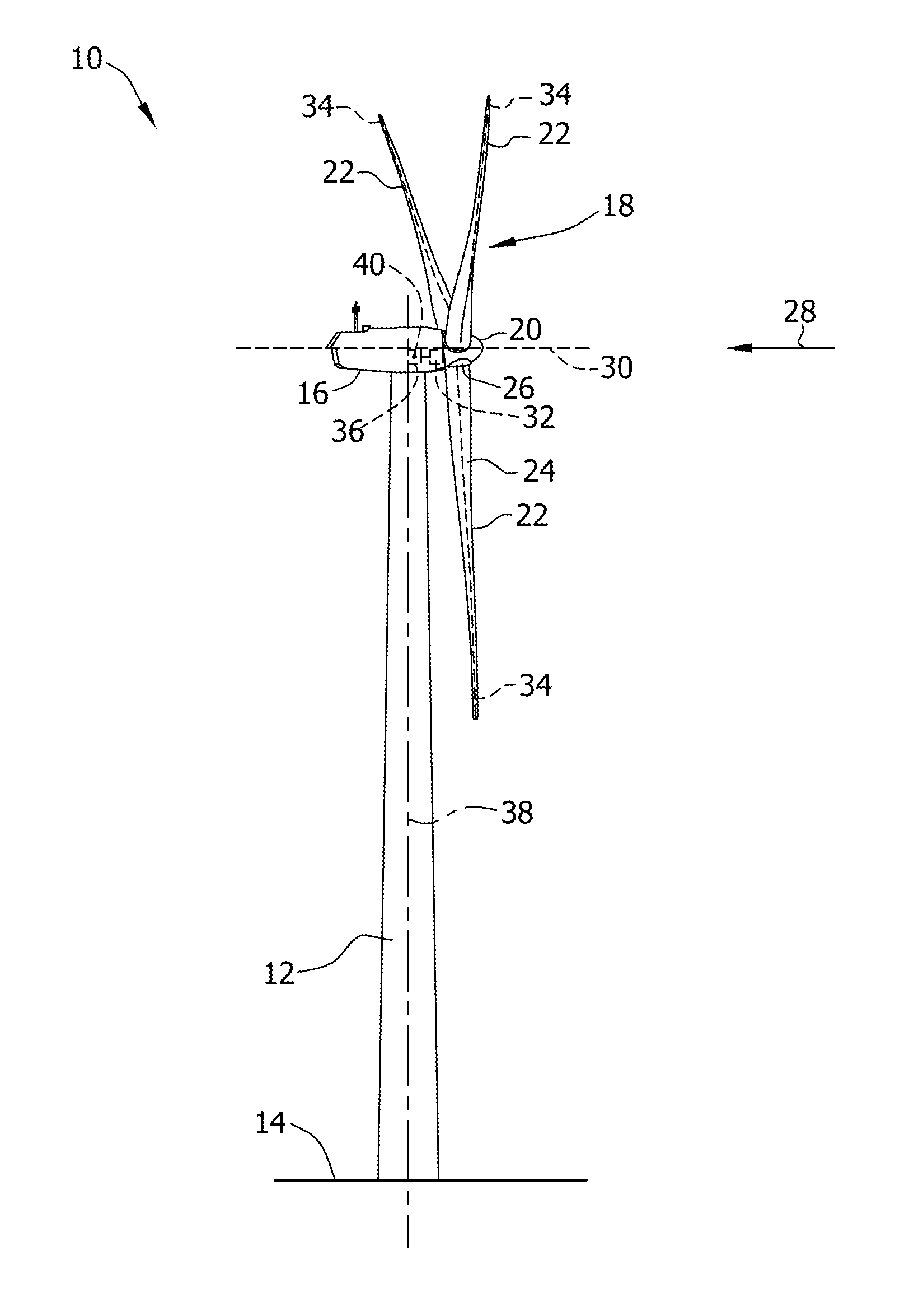

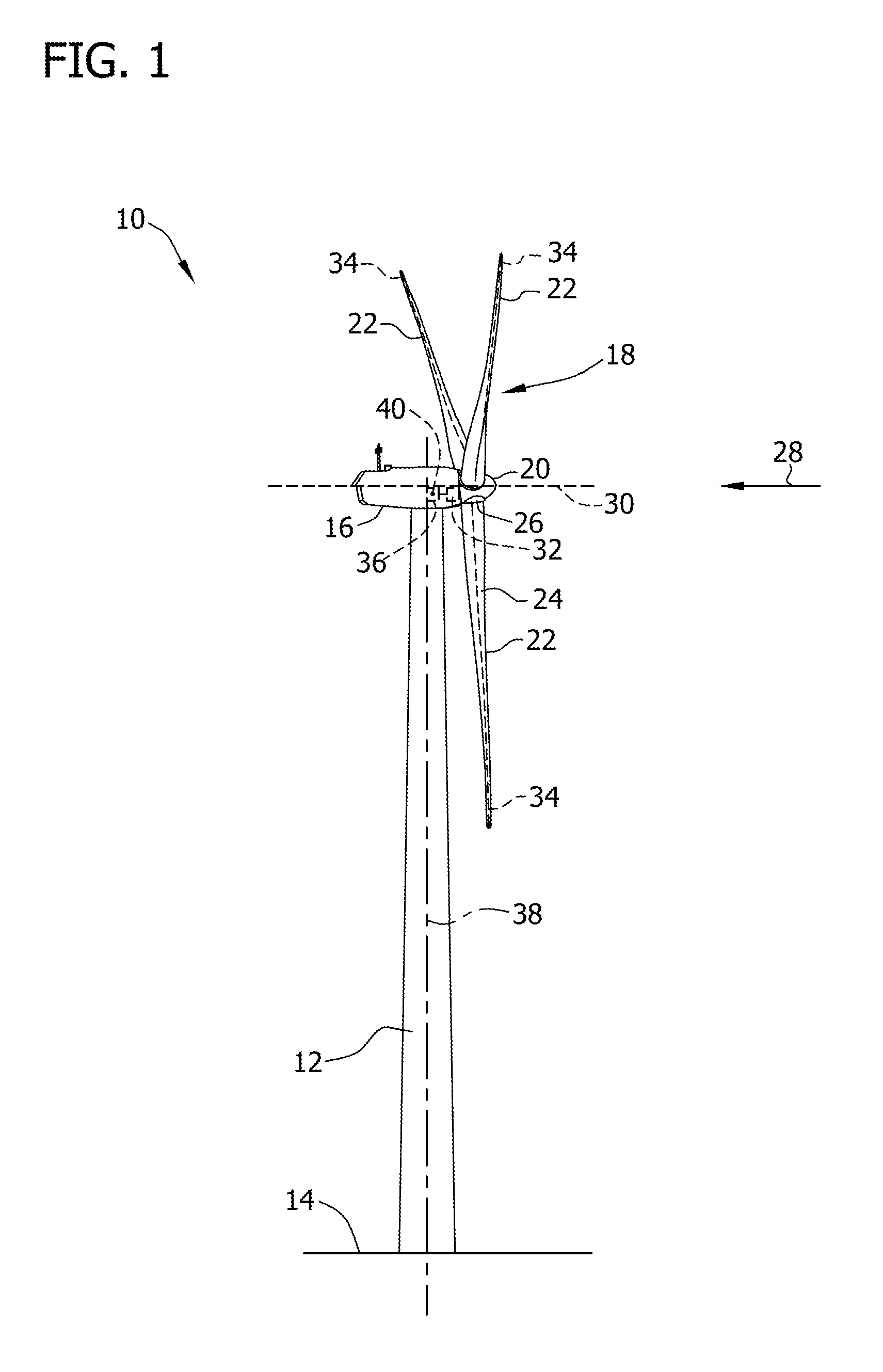

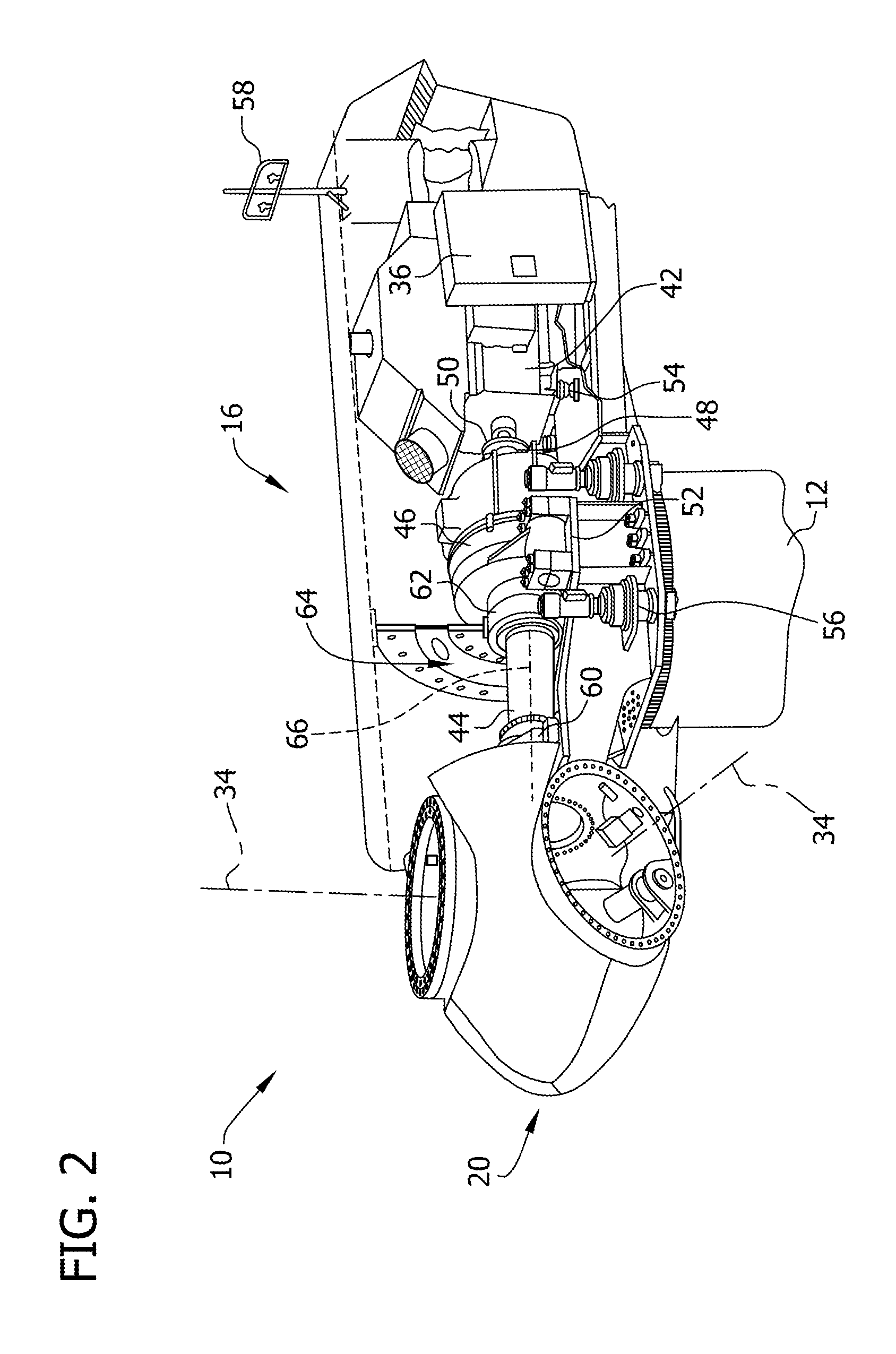

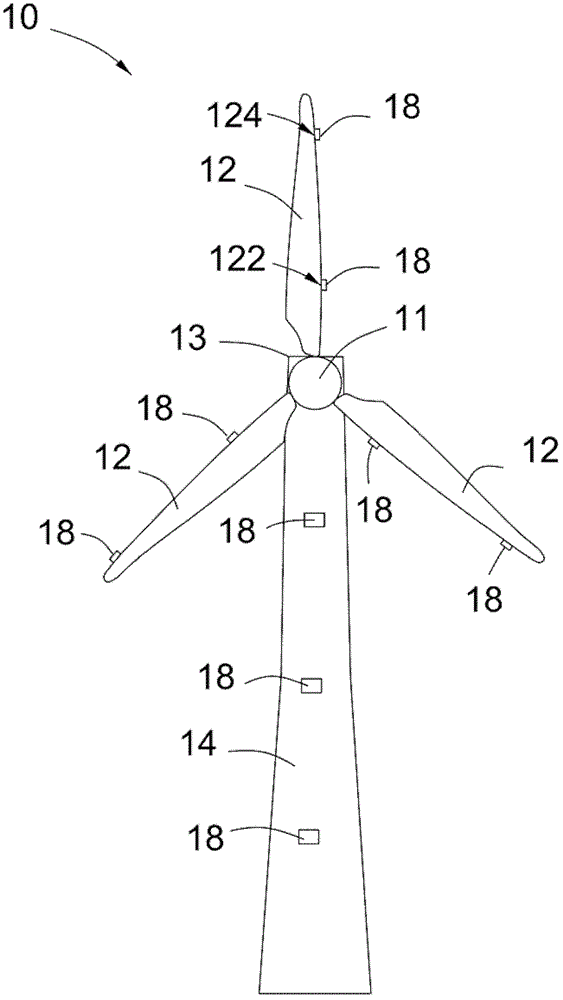

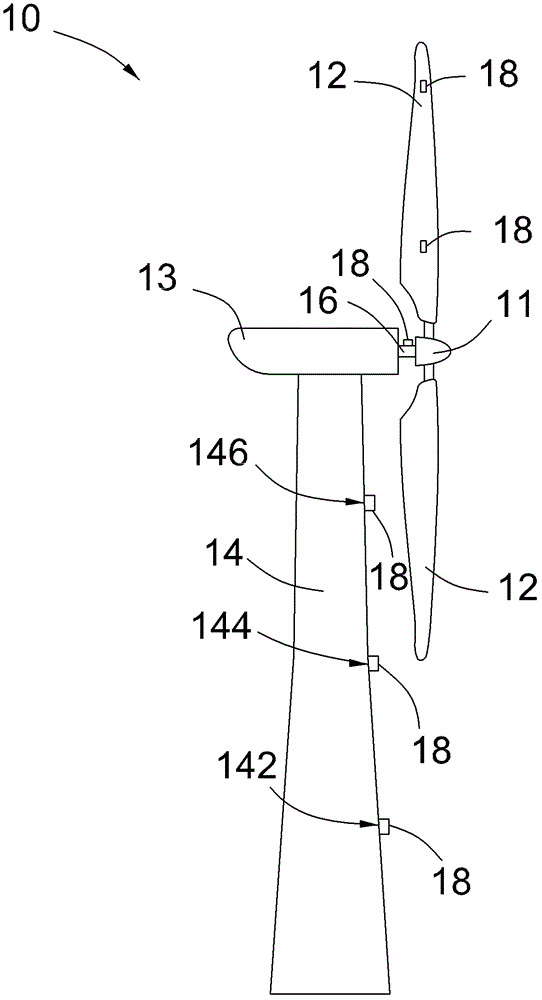

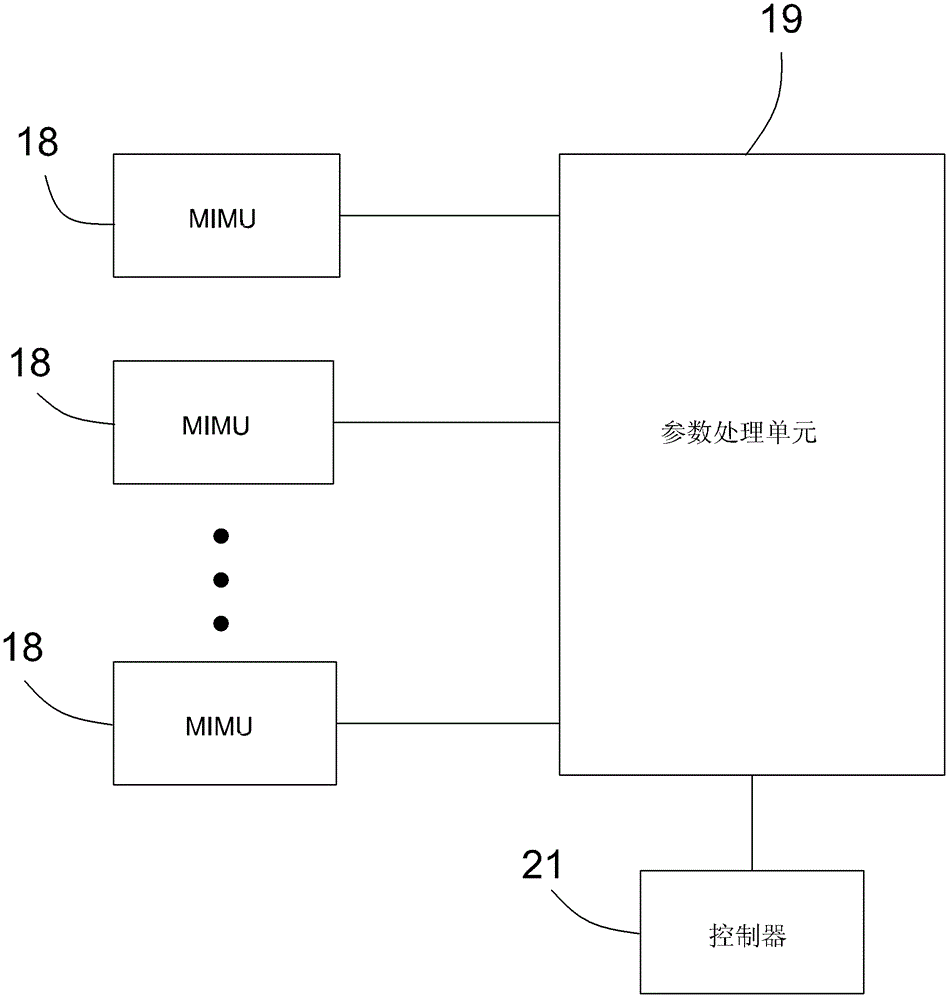

Wind turbine and method for determining parameters of wind turbine

A method for determining parameters of a wind turbine is disclosed. The method may generally include receiving signals from at least one Micro Inertial Measurement Unit (MIMU) mounted on or within a component of the wind turbine and determining at least one parameter of the wind turbine based on the signals received from the at least one MIMU.

Owner:GENERAL ELECTRIC CO

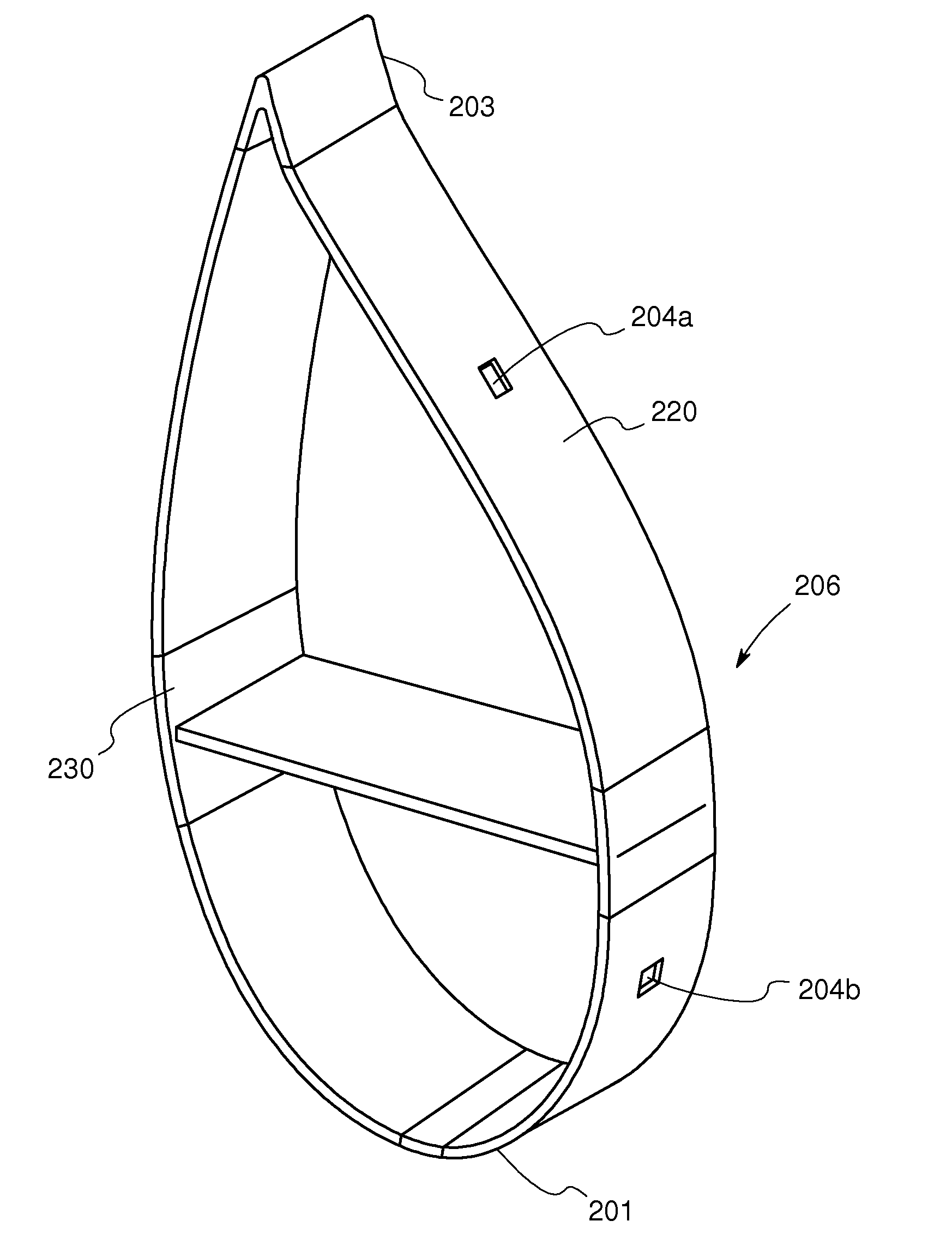

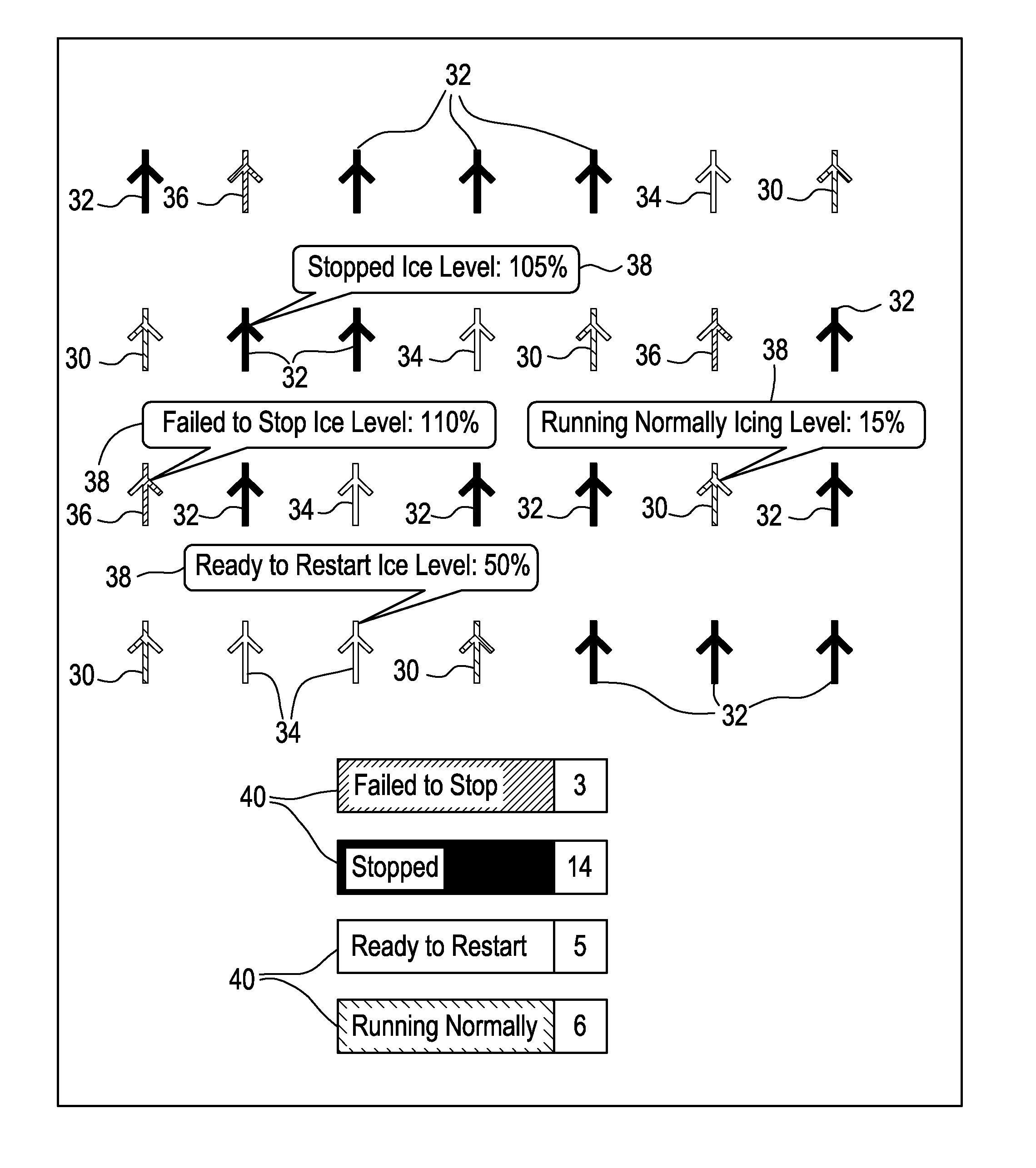

Wind turbine blade with foreign matter detection devices

A wind turbine includes a wind turbine blade and a foreign matter detection device disposed on the wind turbine blade for detecting an accumulation of foreign matter on the wind turbine blade. The detection device automatically sends an indication when a threshold level of foreign matter accumulation is detected. A wind farm control system can display a color coded live plot of all wind turbines in a wind farm system, with a indication of foreign matter accumulation for each turbine.

Owner:GENERAL ELECTRIC CO

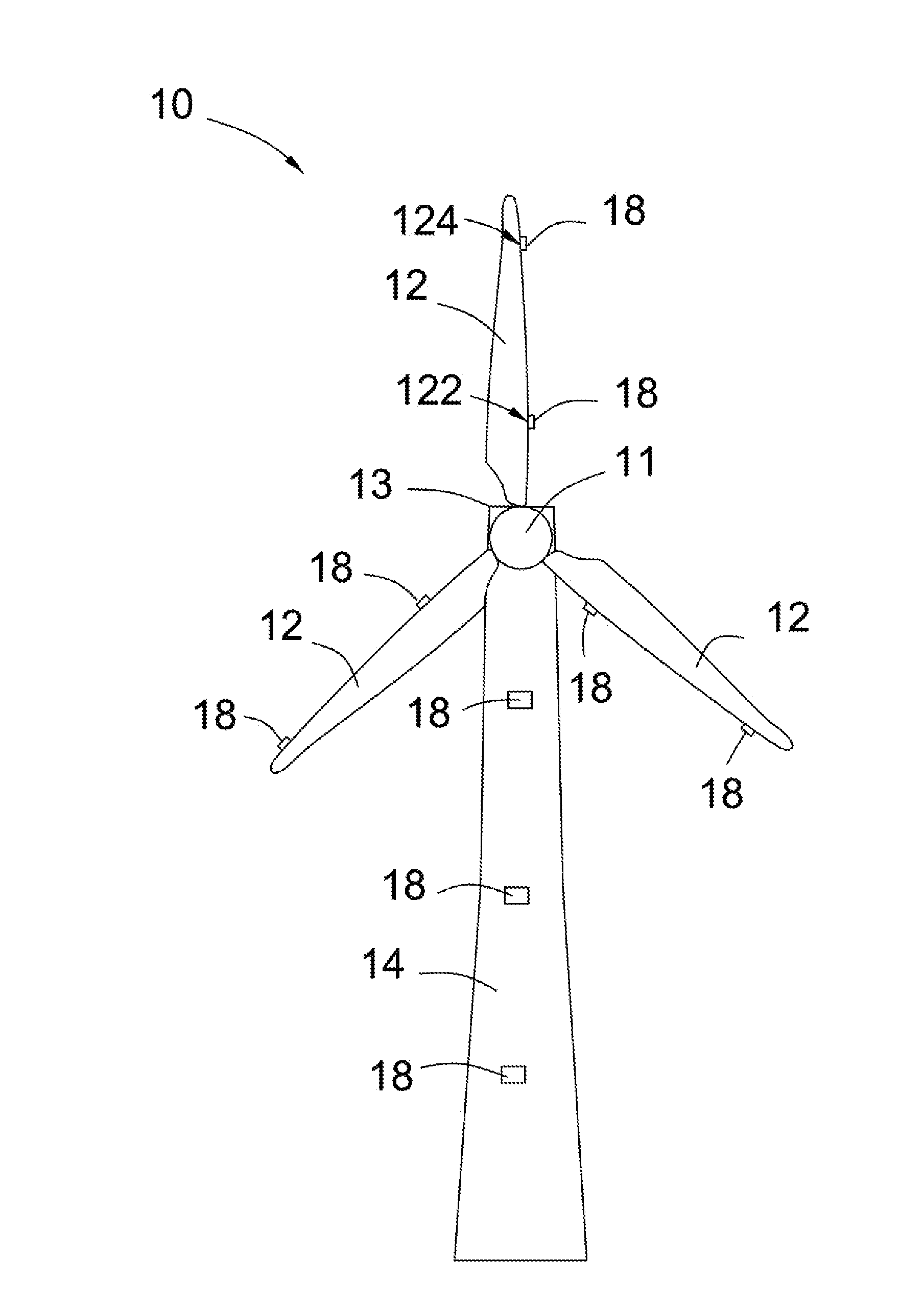

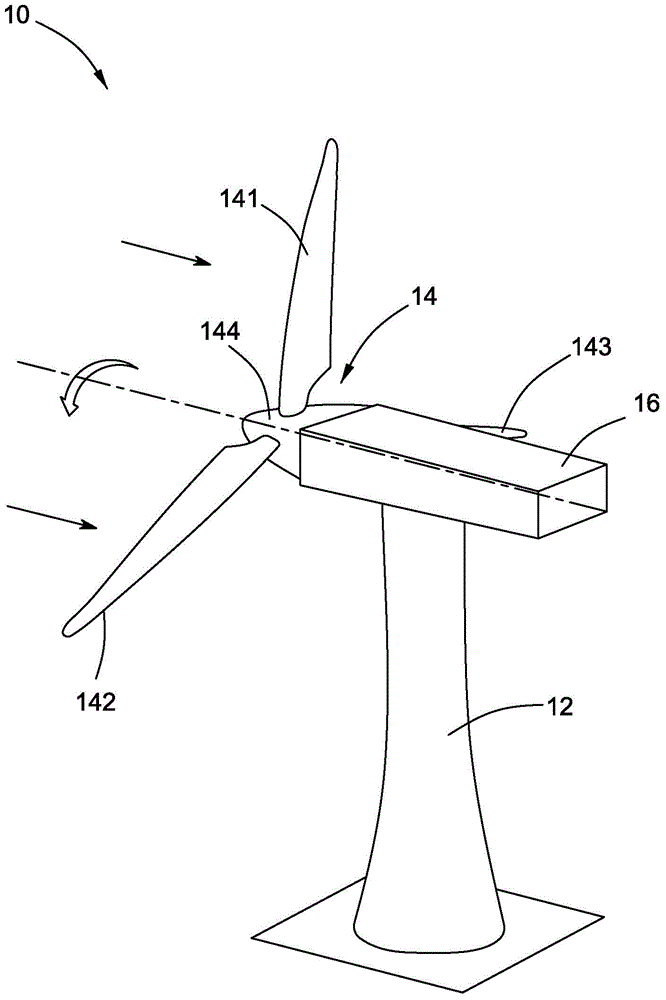

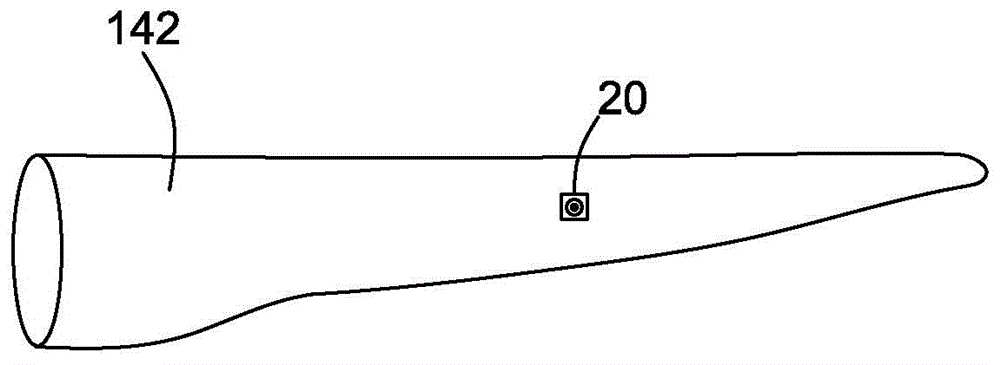

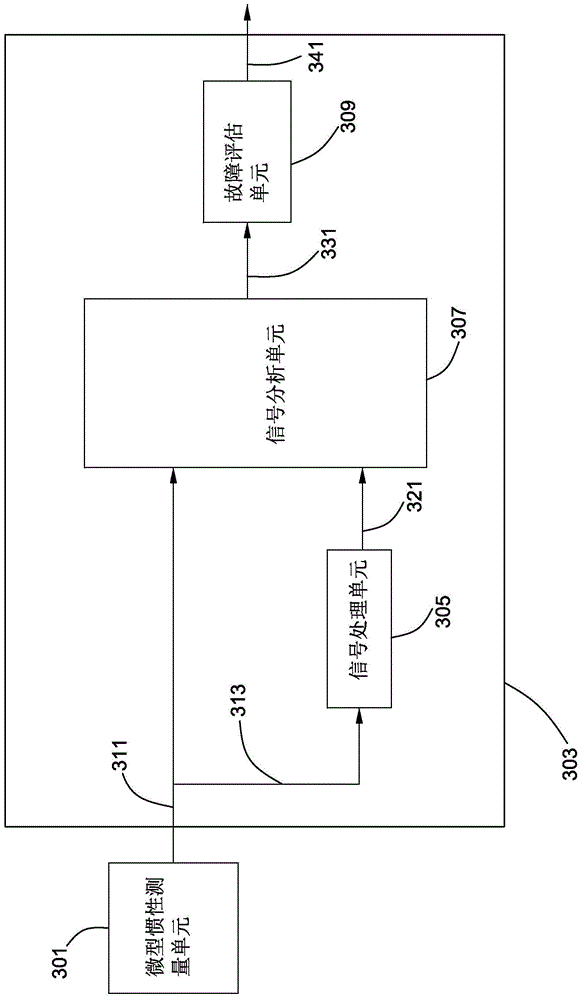

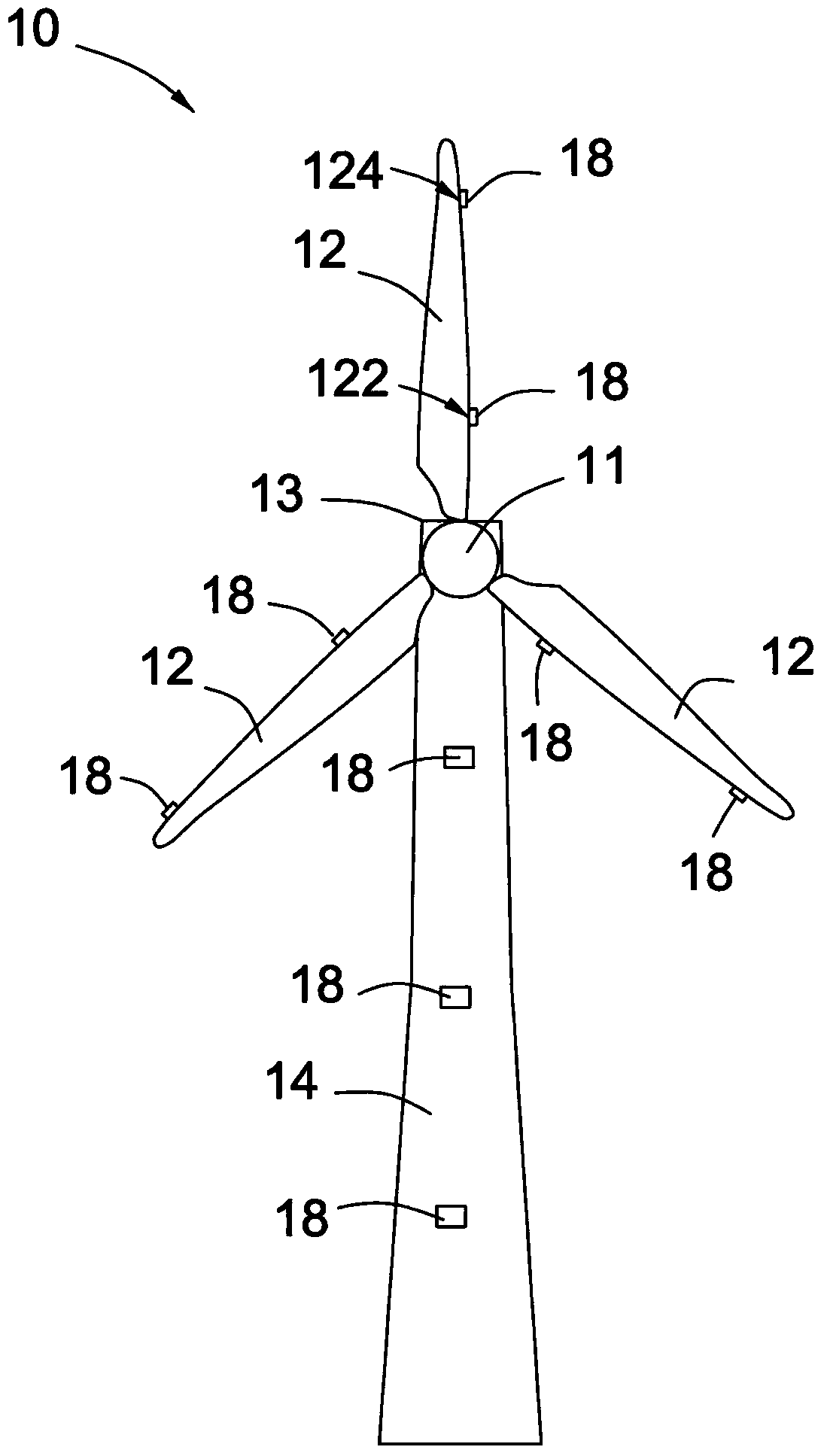

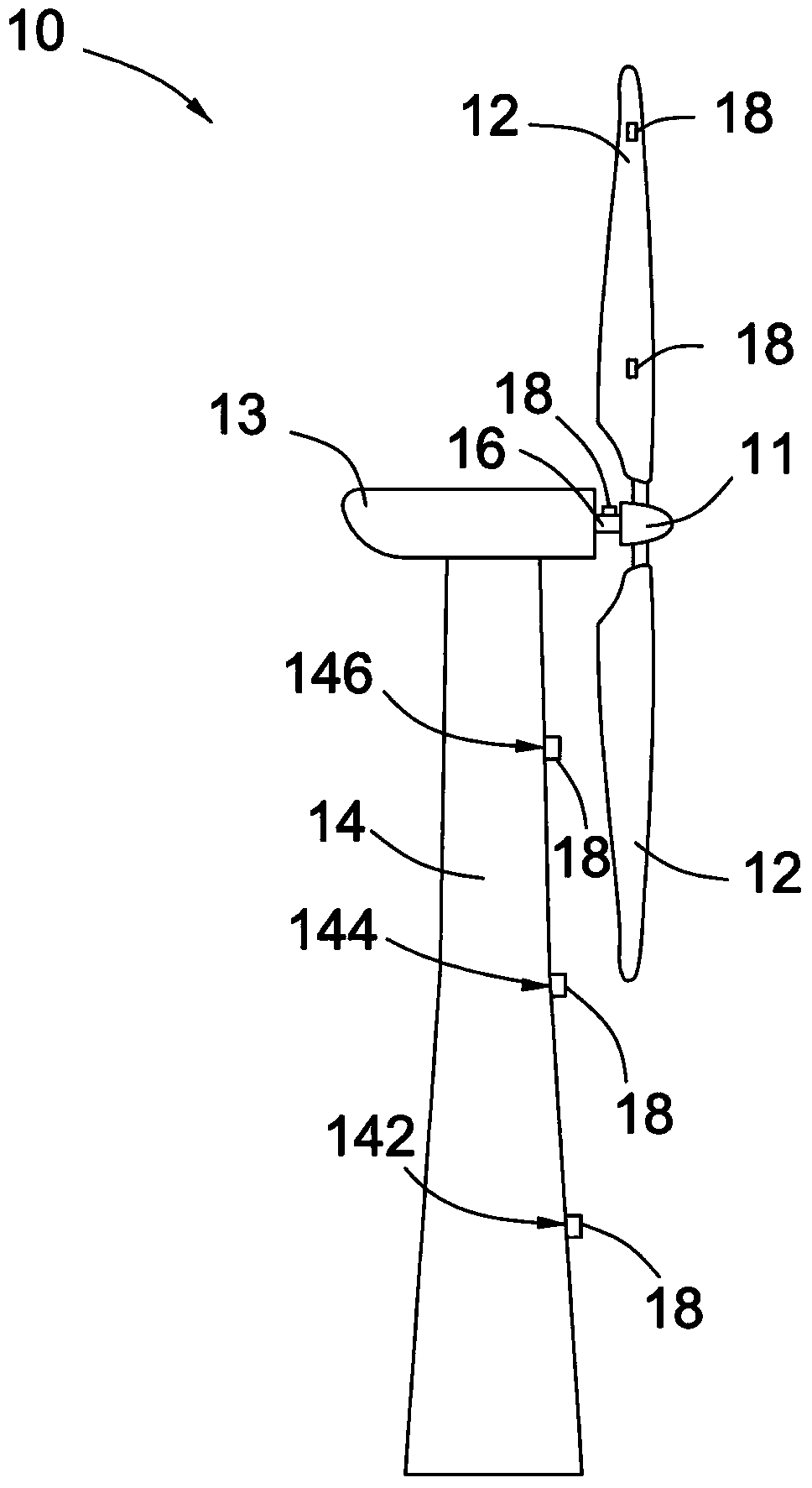

Wind turbine and method for evaluating health status of blades thereon

ActiveCN104595112ASimple structureReduce complexityMachine part testingGas-turbine engine testingTurbine bladeMonitoring system

The present invention relates to a wind turbine (10), which includes a plurality of blades (141, 142, 143), a micro inertial measurement unit (20), and a monitoring system (303). The micro inertial measurement unit (20) is installed on each blade (141, 142, 143), and is configured to sense a plurality of detection parameter signals at corresponding installation positions. The monitoring system (303) is configured to monitor an operating state of the plurality of blades (141, 142, 143), and the monitoring system (303) includes a signal processing unit (305), a signal analyzing unit (307), and a fault evaluating unit (309). The signal processing unit (305) obtains a processing parameter signal through calculation based on the plurality of detection parameter signals (313). The signal analyzing unit (307) analyzes each analysis parameter signal to obtain a fault estimation signal. The analysis parameter signal is selected from the plurality of detection parameter signals (313) and the processing parameter signal, and each fault estimation signal is used to estimate whether a corresponding blade works in a fault state. The fault evaluating unit (309) is configured to evaluate, based on a plurality of fault estimation signals, whether a corresponding blade fails or a probability that the corresponding blade fails. The present invention further discloses a method (1000) for evaluating a health state of a wind turbine blade (10).

Owner:GENERAL ELECTRIC CO

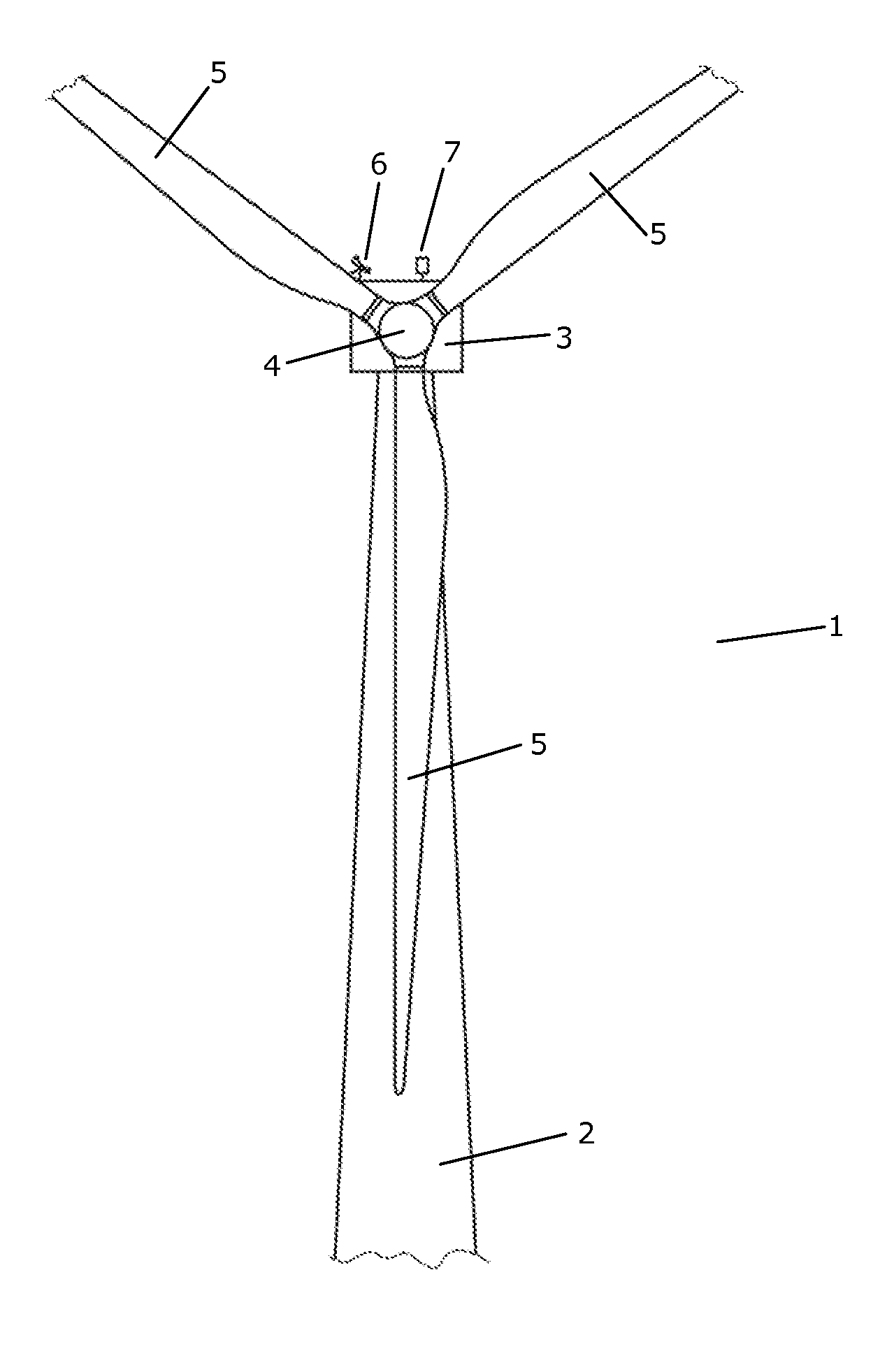

Rotor for a wind energy turbine

ActiveUS7348683B2PropellersPiezoelectric/electrostriction/magnetostriction machinesMechanical energyEngineering

A the rotor for a wind energy turbine includes a hub and at least one rotor blade connected to the hub. The rotor also includes comprises at least one sensor for sensing at least one physical value of the rotor, e.g. mechanical stress, and a power supply for supplying electrical power to the at least one sensor. The power supply includes an electromechanical converter for converting mechanical energy from vibrations of the rotor when subjected to wind loads, e.g. during operation of the wind energy turbine, into electrical energy for supplying to the at least one sensor.

Owner:GE INFRASTRUCTURE TECH INT LLC

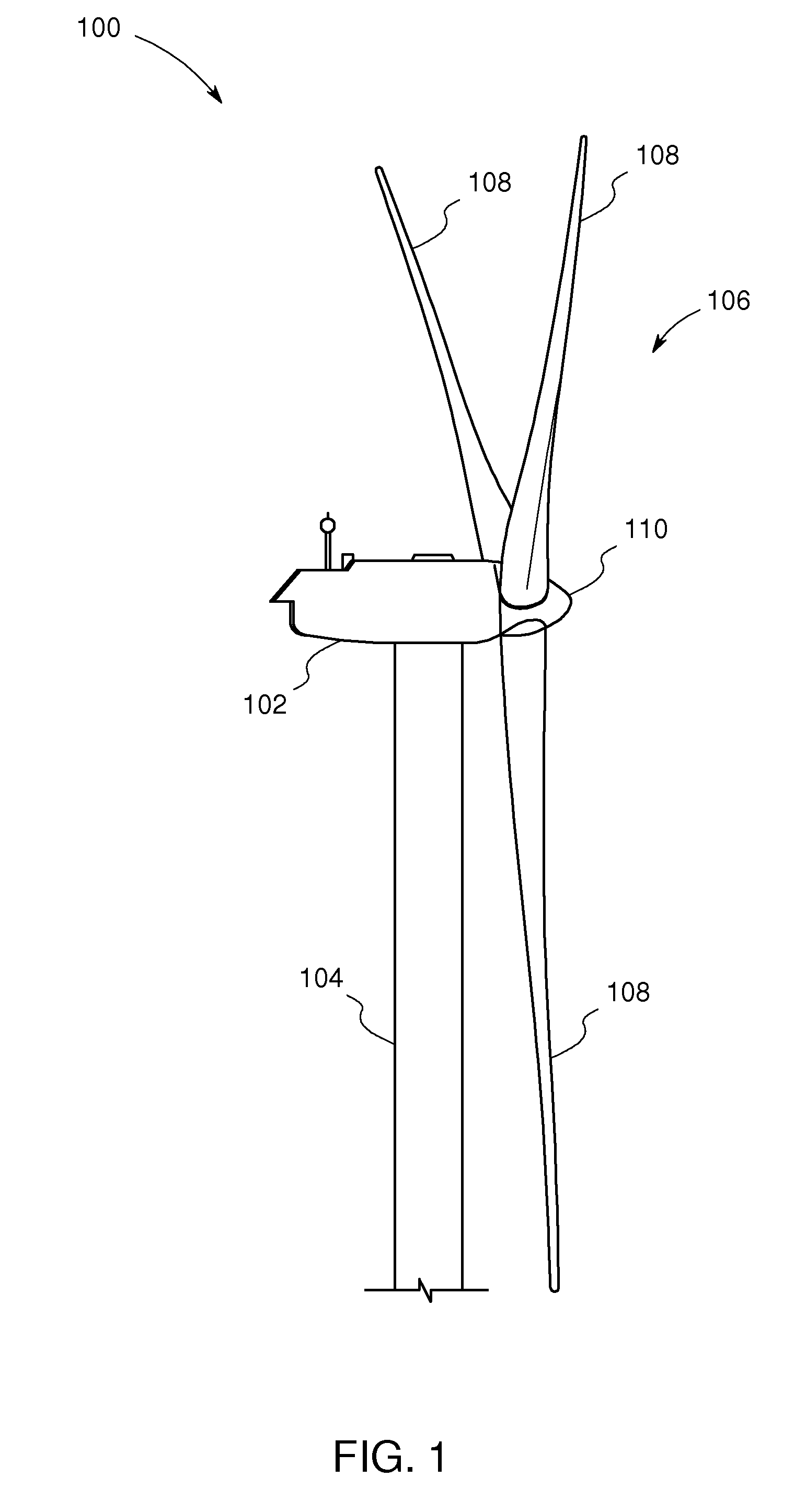

Ice detection based on anemometry

ActiveUS7487673B2Reduce impactTesting/calibration apparatusWind motor controlIcing conditionsEngineering

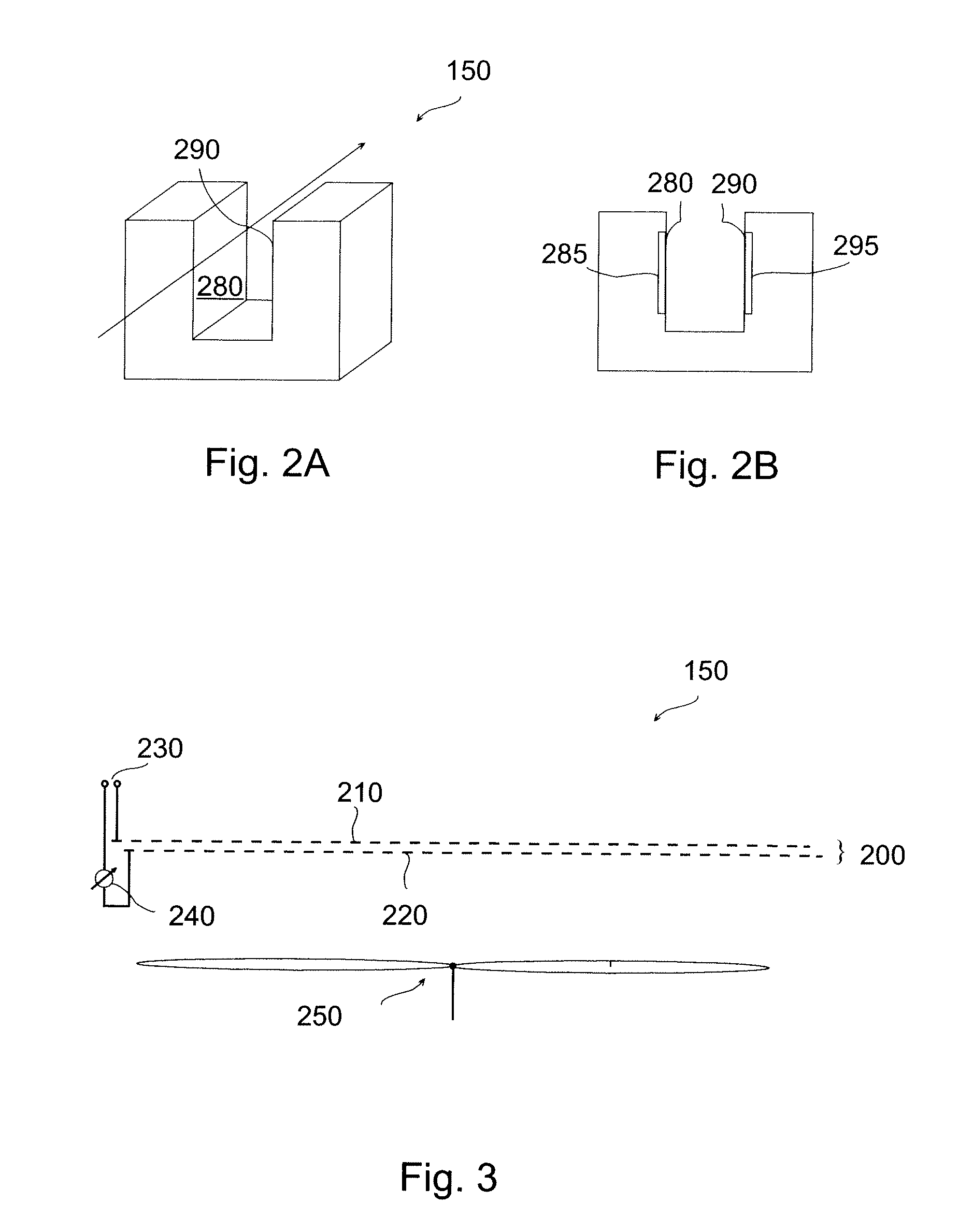

A method for ice detection for a wind turbine is provided. The method includes providing an ice condition threshold parameter adapted for distinguishing a condition during which icing may occur and a condition during which icing may not occur, measuring a wind velocity with a first anemometer, wherein the first anemometer being of a first type, measuring a wind velocity with a second anemometer, wherein the second anemometer being of a second type, and wherein the second type is different from the first type, evaluating, for a condition during which icing may occur, a deviation of the wind velocity measured with the first anemometer and the wind velocity measured with the second anemometer, and determine whether the deviation exceeds a limit value based on a calibration conducted under a condition during which icing may not occur.

Owner:GENERAL ELECTRIC CO

Ice detection based on anemometry

ActiveUS20080141768A1Reduce impactTesting/calibration apparatusWind motor controlIcing conditionsEngineering

A method for ice detection for a wind turbine is provided. The method includes providing an ice condition threshold parameter adapted for distinguishing a condition during which icing may occur and a condition during which icing may not occur, measuring a wind velocity with a first anemometer, wherein the first anemometer being of a first type, measuring a wind velocity with a second anemometer, wherein the second anemometer being of a second type, and wherein the second type is different from the first type, evaluating, for a condition during which icing may occur, a deviation of the wind velocity measured with the first anemometer and the wind velocity measured with the second anemometer, and determine whether the deviation exceeds a limit value based on a calibration conducted under a condition during which icing may not occur.

Owner:GENERAL ELECTRIC CO

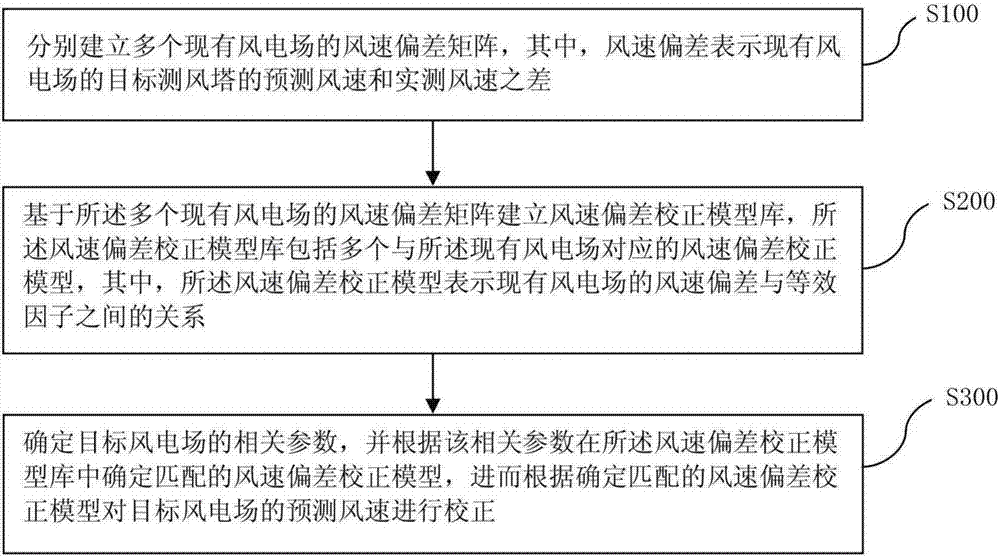

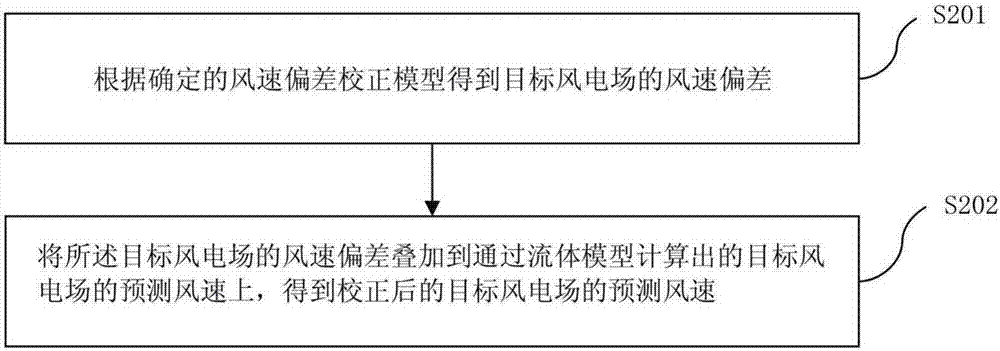

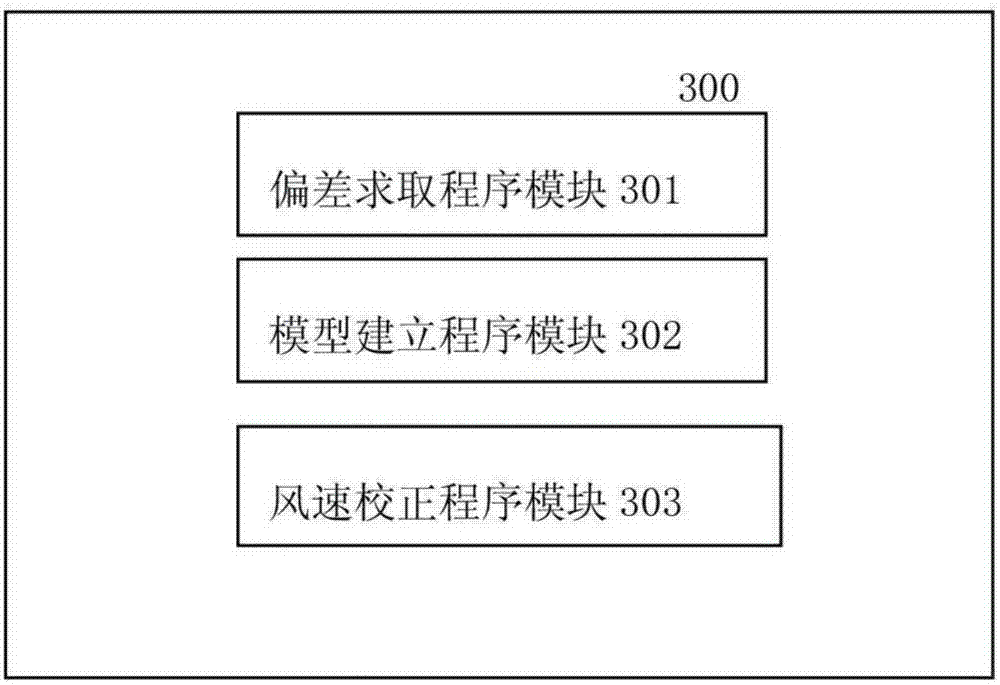

Wind farm predicted wind speed correction method and wind farm predicted wind speed correction device

The invention provides a wind farm predicted wind speed correction method and a wind farm predicted wind speed correction device. The wind farm predicted wind speed correction method comprises steps that a plurality of conventional wind farm wind speed deviation matrixes are established, and wind speed deviations represent differences between the predicted wind speeds of the target wind measuring masts of the conventional wind farms and actual measured wind speeds; based on the plurality of conventional wind farm wind speed deviation matrixes, a wind speed deviation correction model database is established, and comprises a plurality of wind speed deviation correction models corresponding to the conventional wind farms, and the wind speed deviation correction models represent relations between the wind speed deviations of the conventional wind farms and equivalent factors; related parameters of a target wind farm are determined, and according to the related parameters, the matched wind speed deviation correction model is determined in the wind speed deviation correction model database, and then the predicted wind speed of the target wind farm is corrected according to the determined wind speed deviation correction model. Errors generated during the calculation of the wind speeds of the wind farms by using conventional fluid models are effectively remedied.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Wind power generator with windproof function

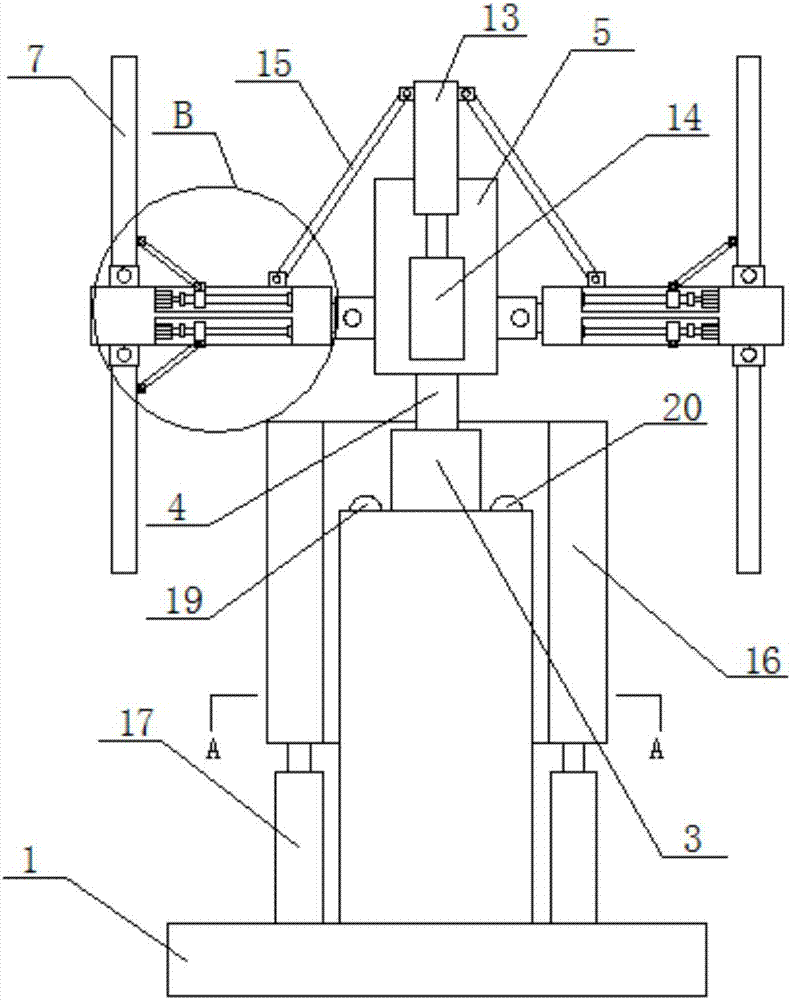

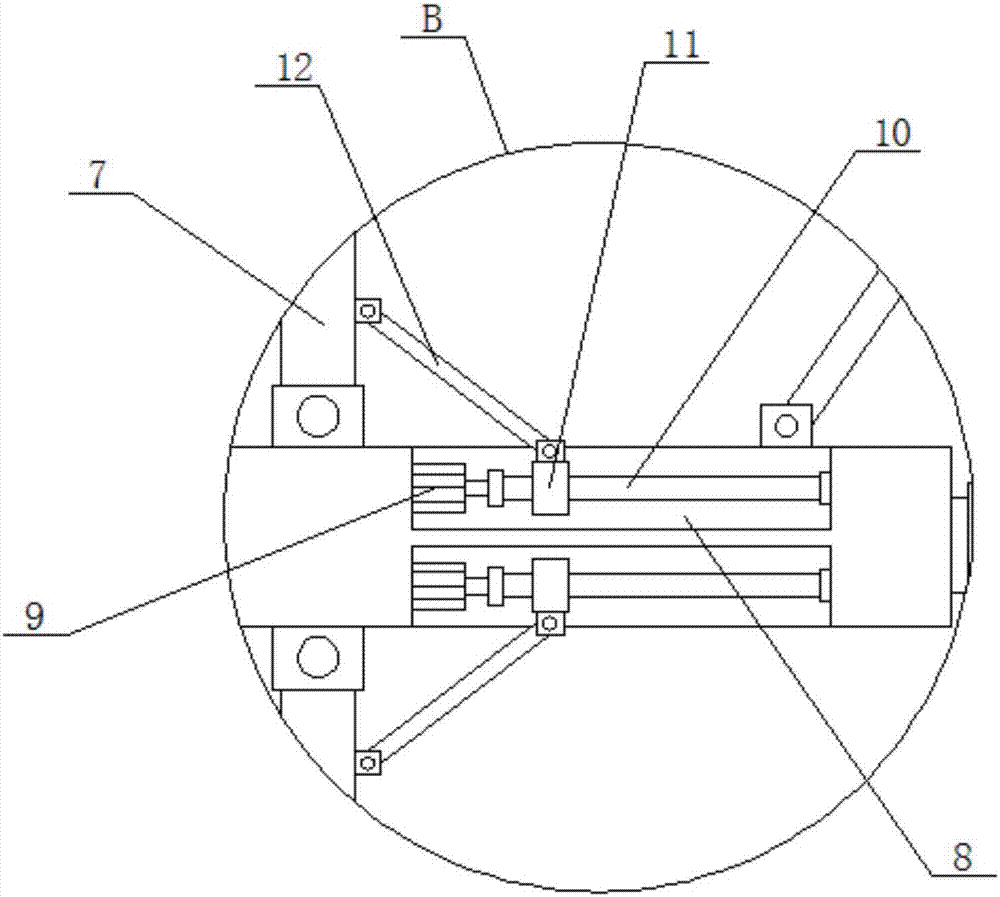

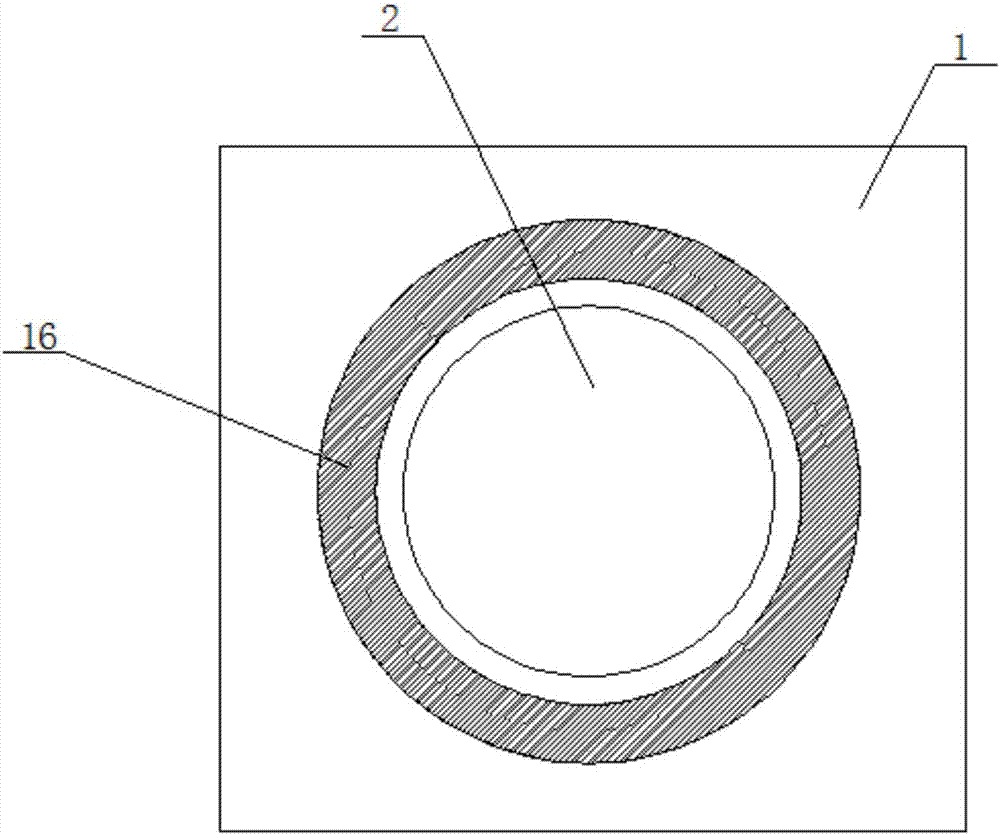

InactiveCN107191322AWith windproof functionExquisite structureWind motor with solar radiationWind motor controlDrive shaftEngineering

The invention relates to a wind power generator with a windproof function. The wind power generator comprises a seabed anchor, a connecting pile, a base, a floater, a tower barrel, a generator unit, a drive mechanism, a first fixing mechanism and a second fixing mechanism. The first fixing mechanism comprises a support rod, a push rod, a first rack, a second rack and a circular gear. The second fixing mechanism comprises a force sensor, a winch and a pull rope. The drive mechanism comprises blades, a flange plate and a transmission shaft. According to the wind power generator with the windproof function, under the normal situation, the tower barrel of the wind power generator is fixed into the base, and when the sea level is extremely elevated under the conditions of rainstorm, tsunami and the like, the tower barrel can float on the sea surface under the action of the floater. In addition, the wind power generator is further provided with an anti-collision mechanism, and during ship collisions, the wind power generator and the ships can all be protected.

Owner:国网山东省电力公司庆云县供电公司

Tonal emission control for wind turbines

ActiveUS8021110B2Reduction of tonal noise emissionReduce noisePropellersPump componentsNoise reductionTurbine

A system for the noise reduction of wind turbines comprises at least one acoustic sensor provided at the wind turbine, a detection unit and a control unit, wherein said detection unit is adapted to detect tonal components in a signal of said sensor, and wherein said control unit is adapted to control wind turbine operating parameters in dependence of an amplitude of a tonal component.

Owner:GENERAL ELECTRIC CO

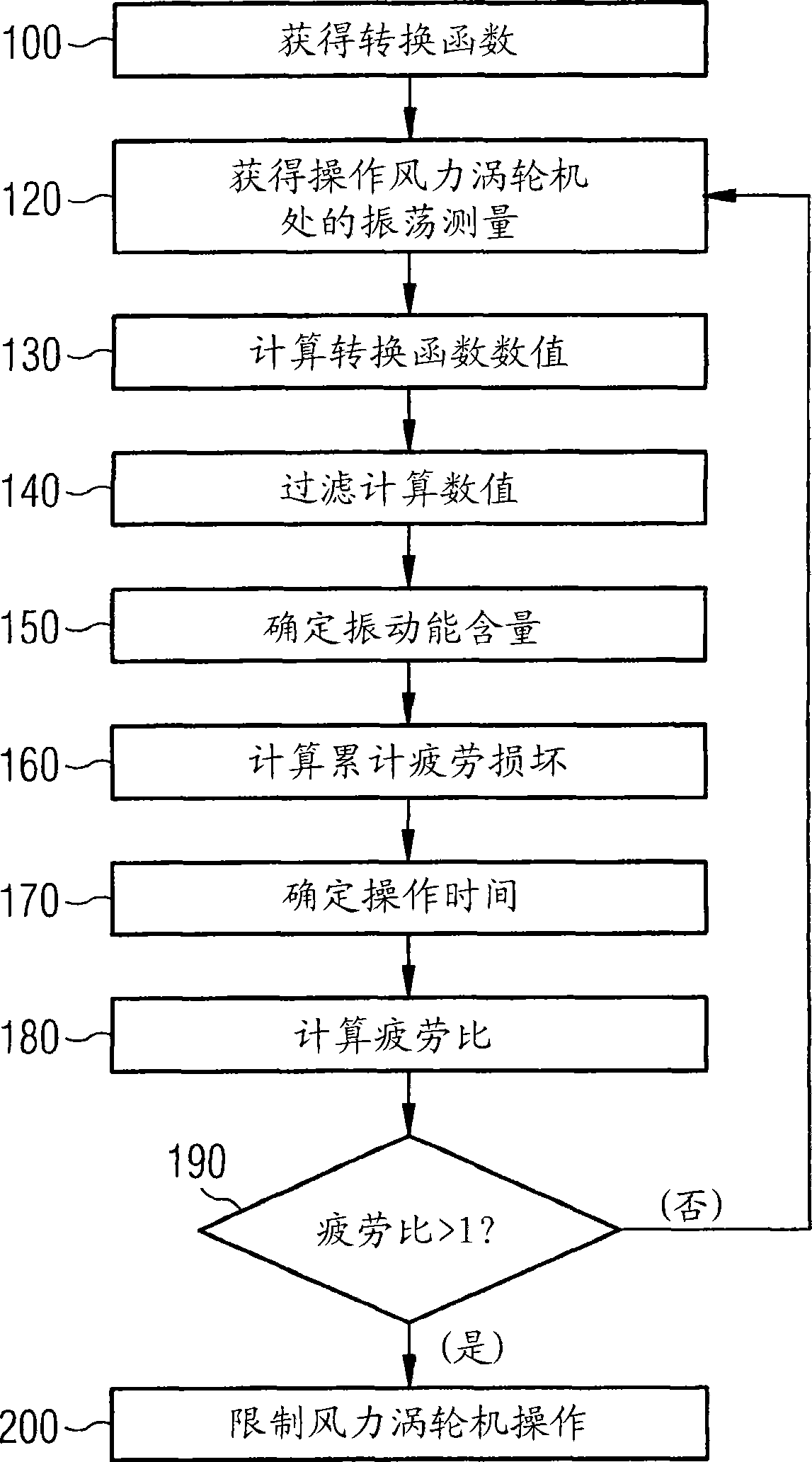

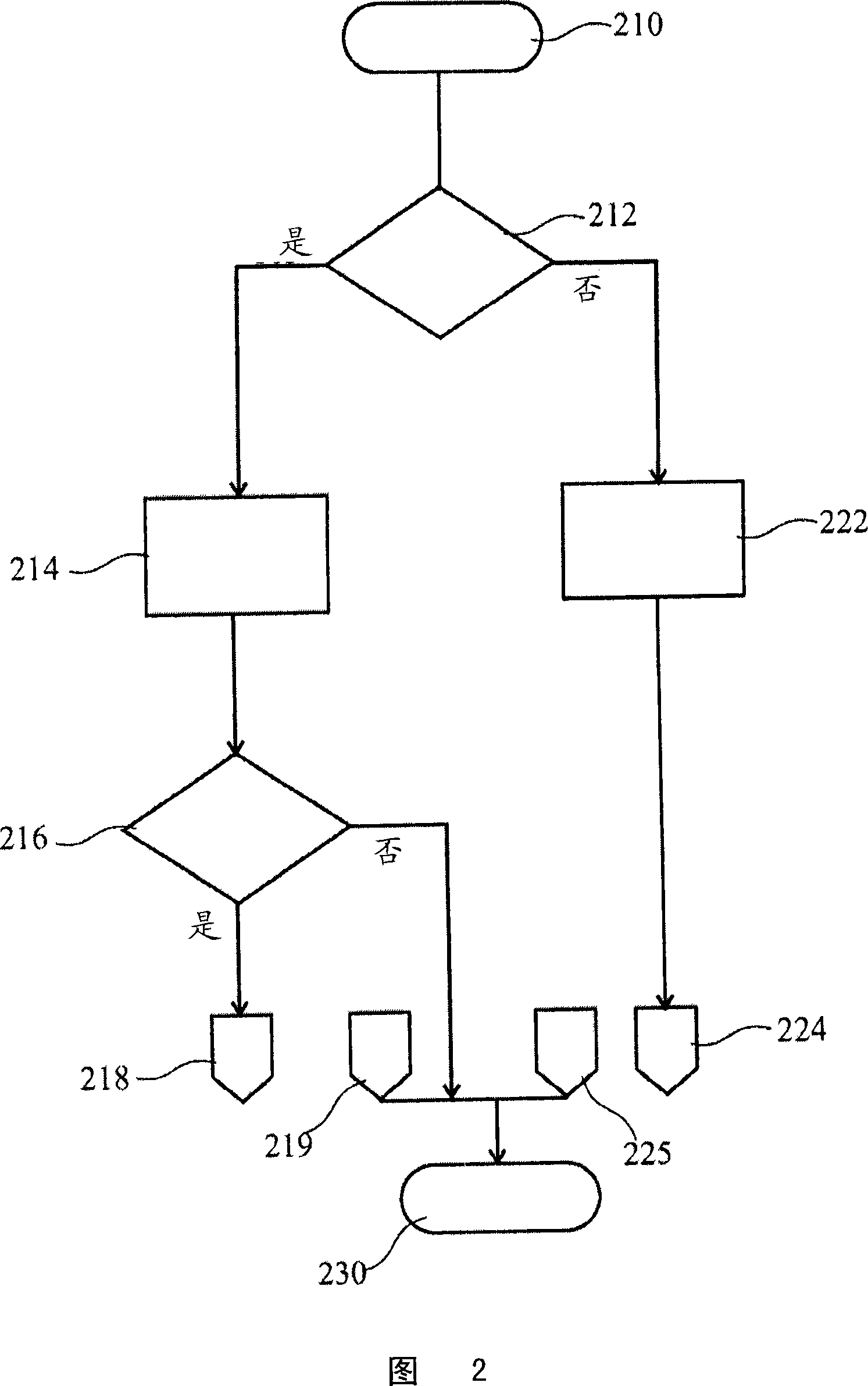

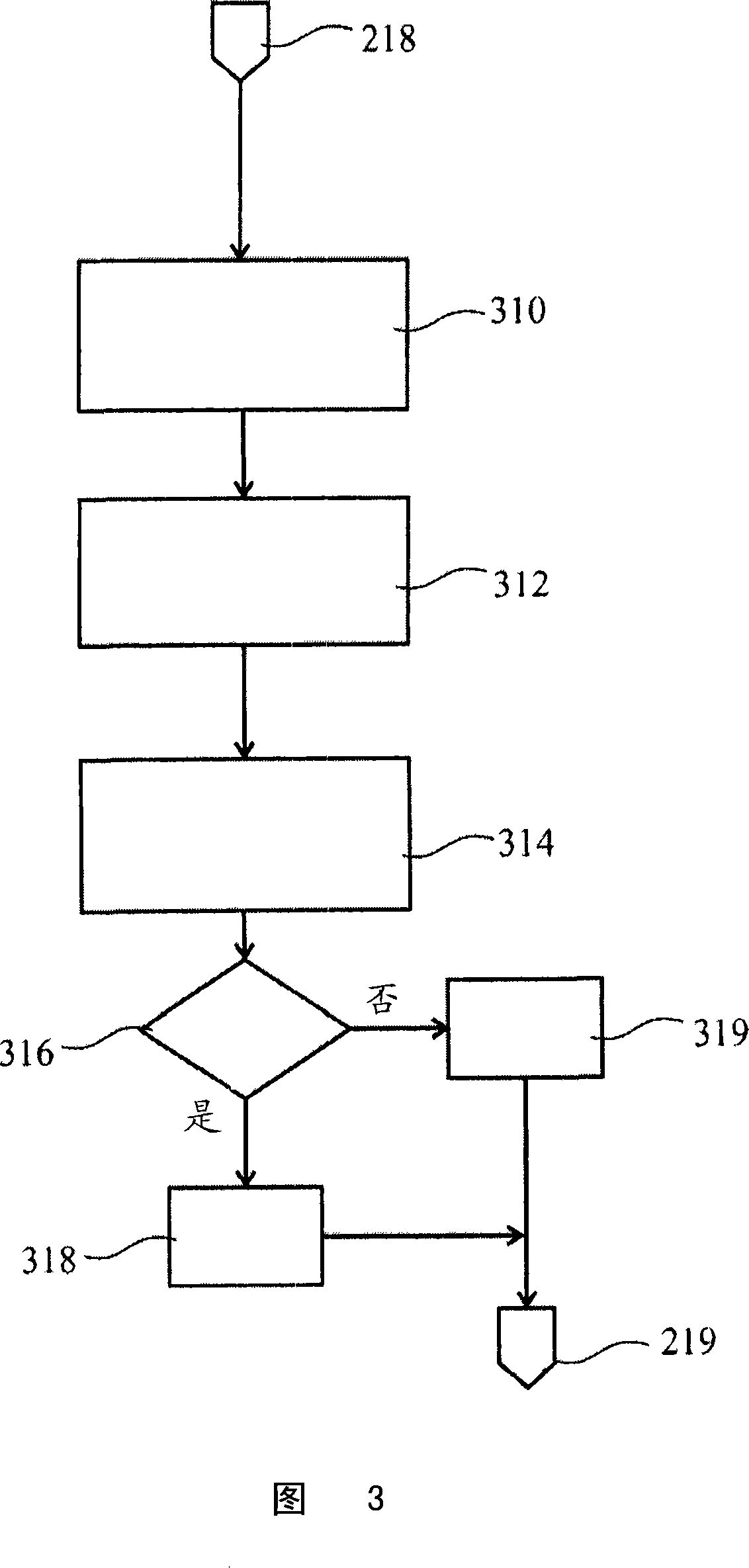

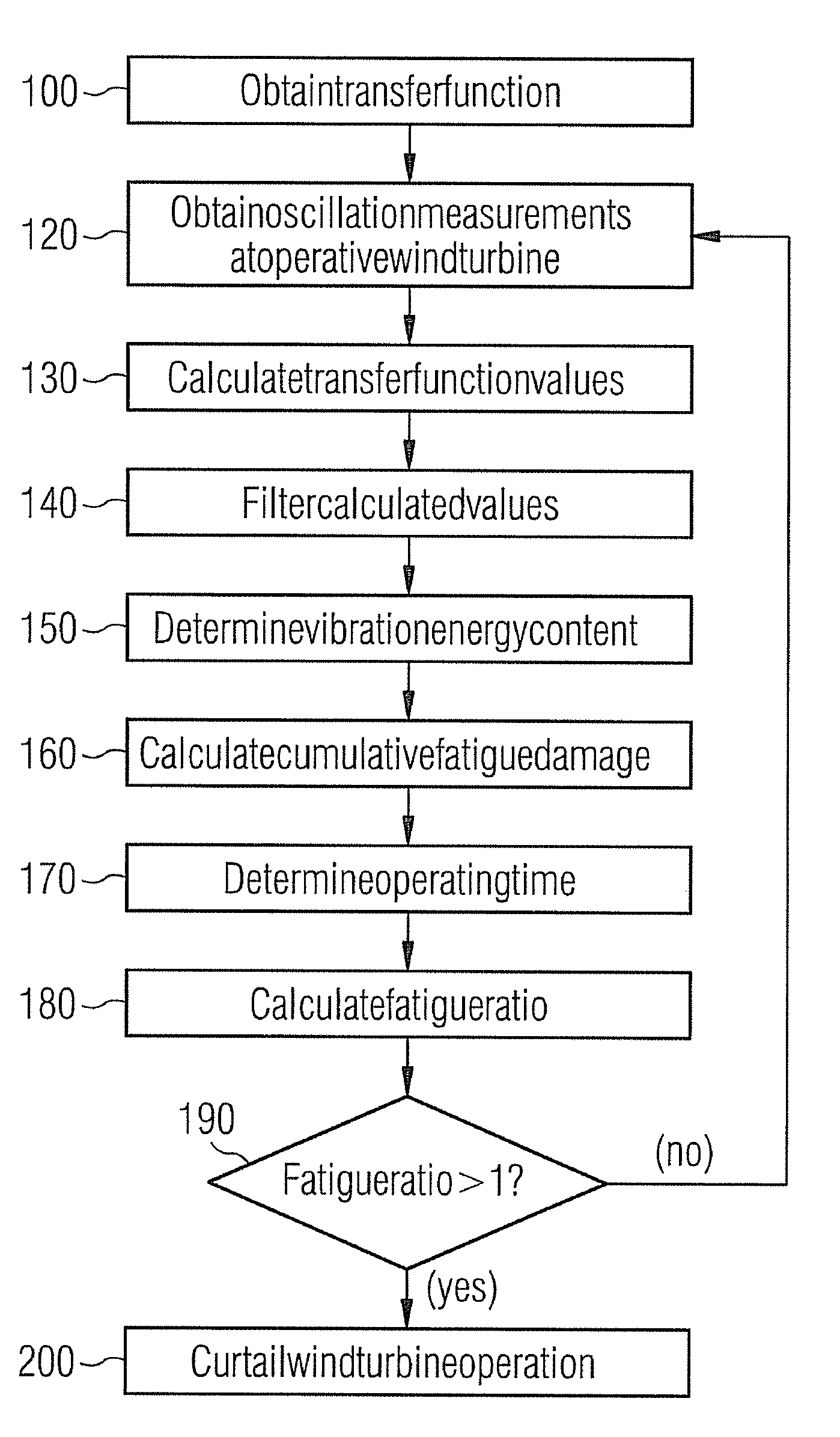

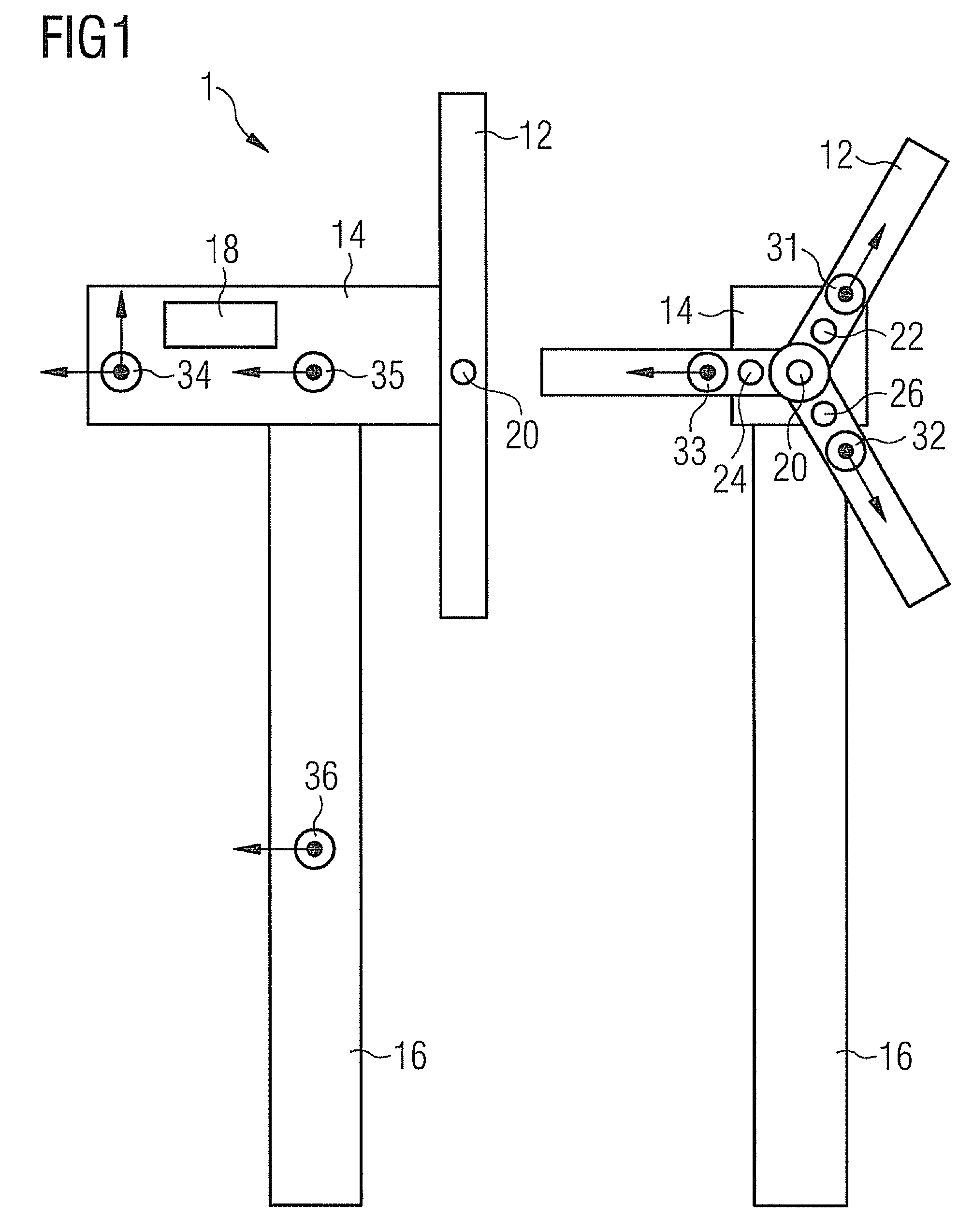

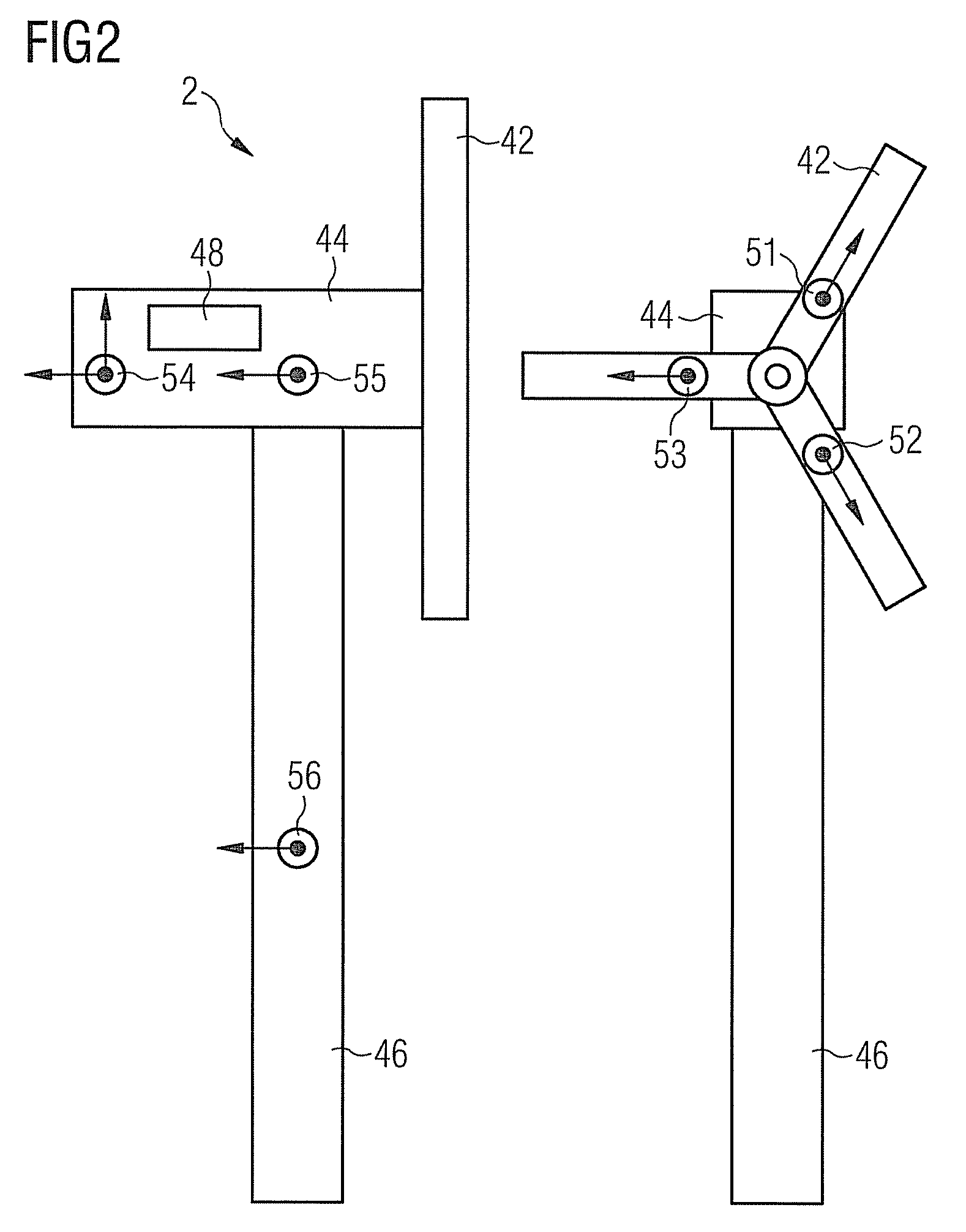

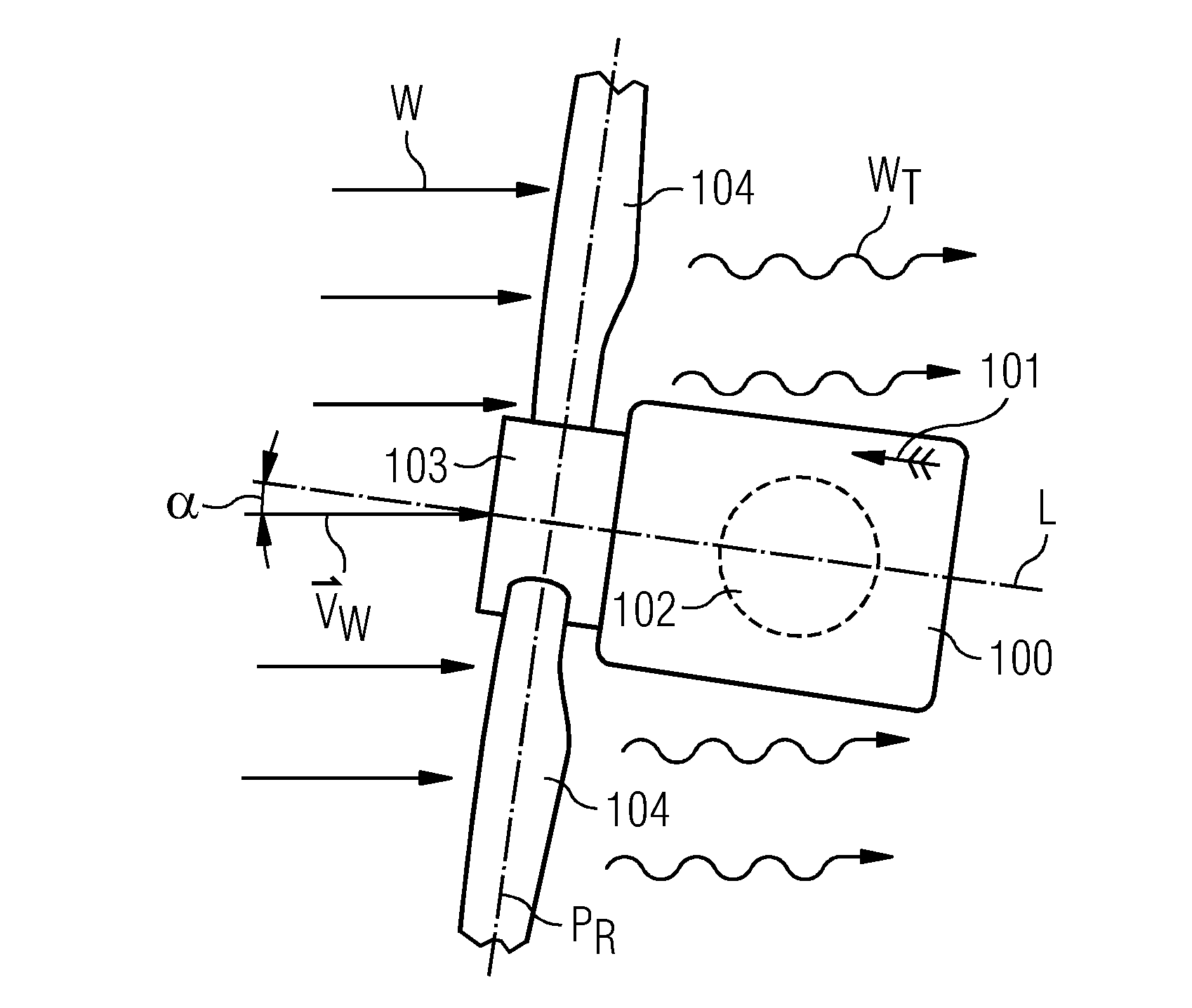

Method for determining fatigue load of a wind turbine and for fatigue load control, and wind turbines therefor

The invention relates to a method of determining and controllign fatigue load of a wind turbine, and a wind turbine. The method of determining fatigue load of at least one operative wind turbine, comprising: providing a transfer function that associates an obtained at least one measurement value of a first sensor to an obtained at least one measurement value of a second sensor the at least one measurement value of the first sensor and the at least one measurement value of the second sensor being obtained by use of a reference wind turbine at which the first sensor and the second sensor are located; obtaining at least one measurement value of a third sensor, wherein the third sensor is located at the at least one operative wind turbine, and wherein the third sensor corresponds in type and position to the first sensor at the reference wind turbine; calculating at least one transfer function value corresponding to the obtained at least one measurement value of the third sensor by use of the provided transfer function; calculating the fatigue load of the at least one operative wind turbine based on the calculated transfer function value.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

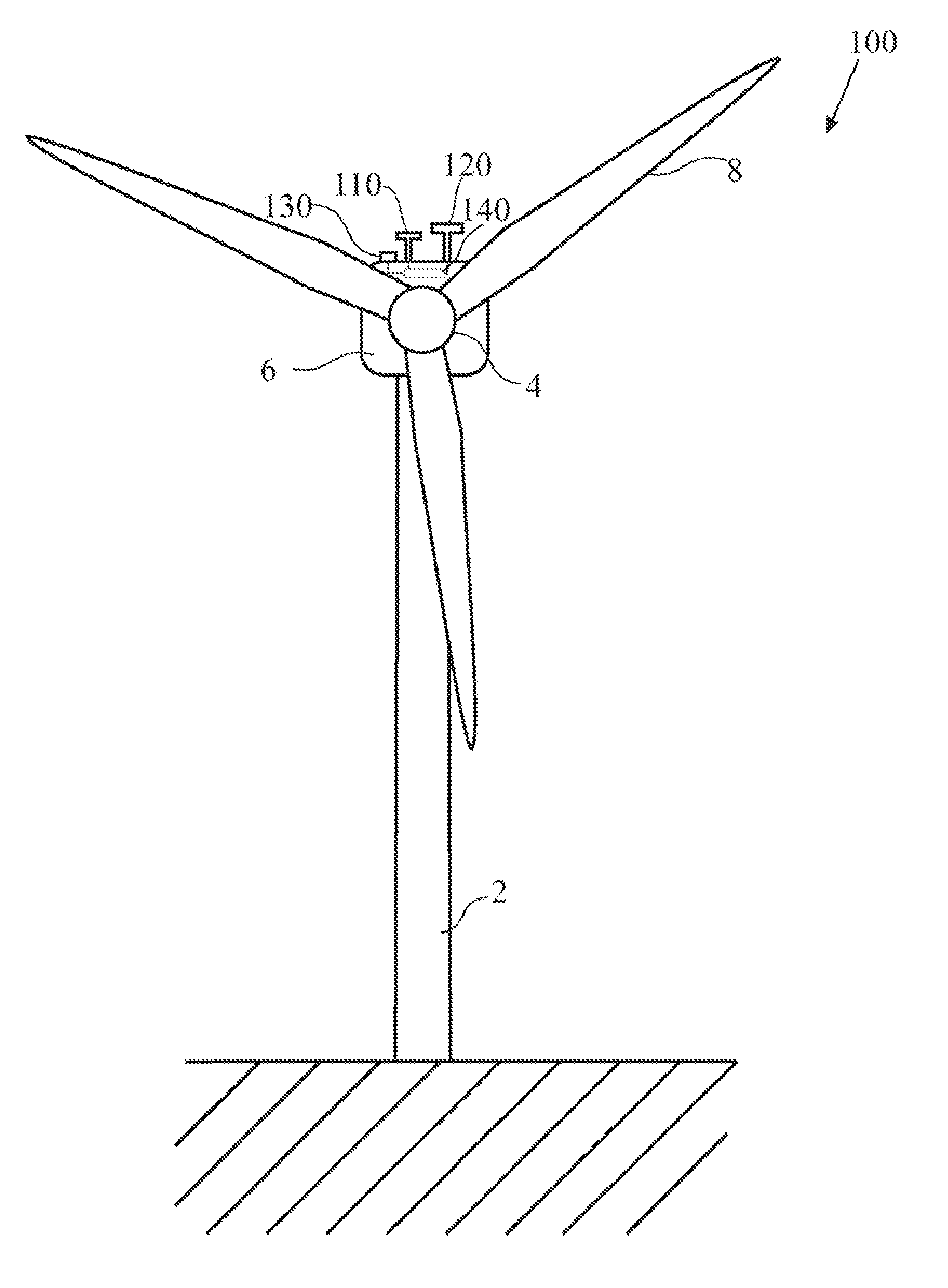

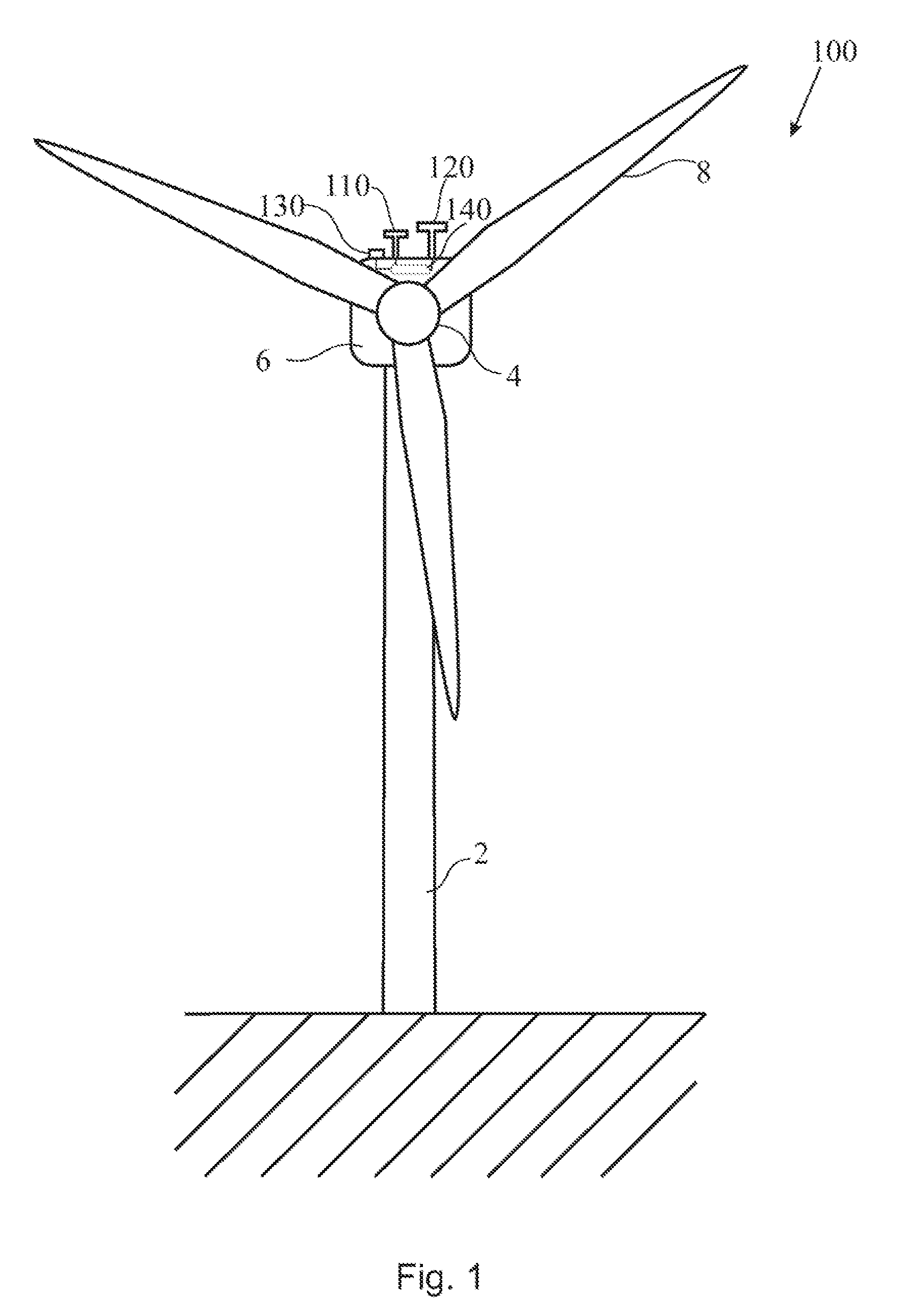

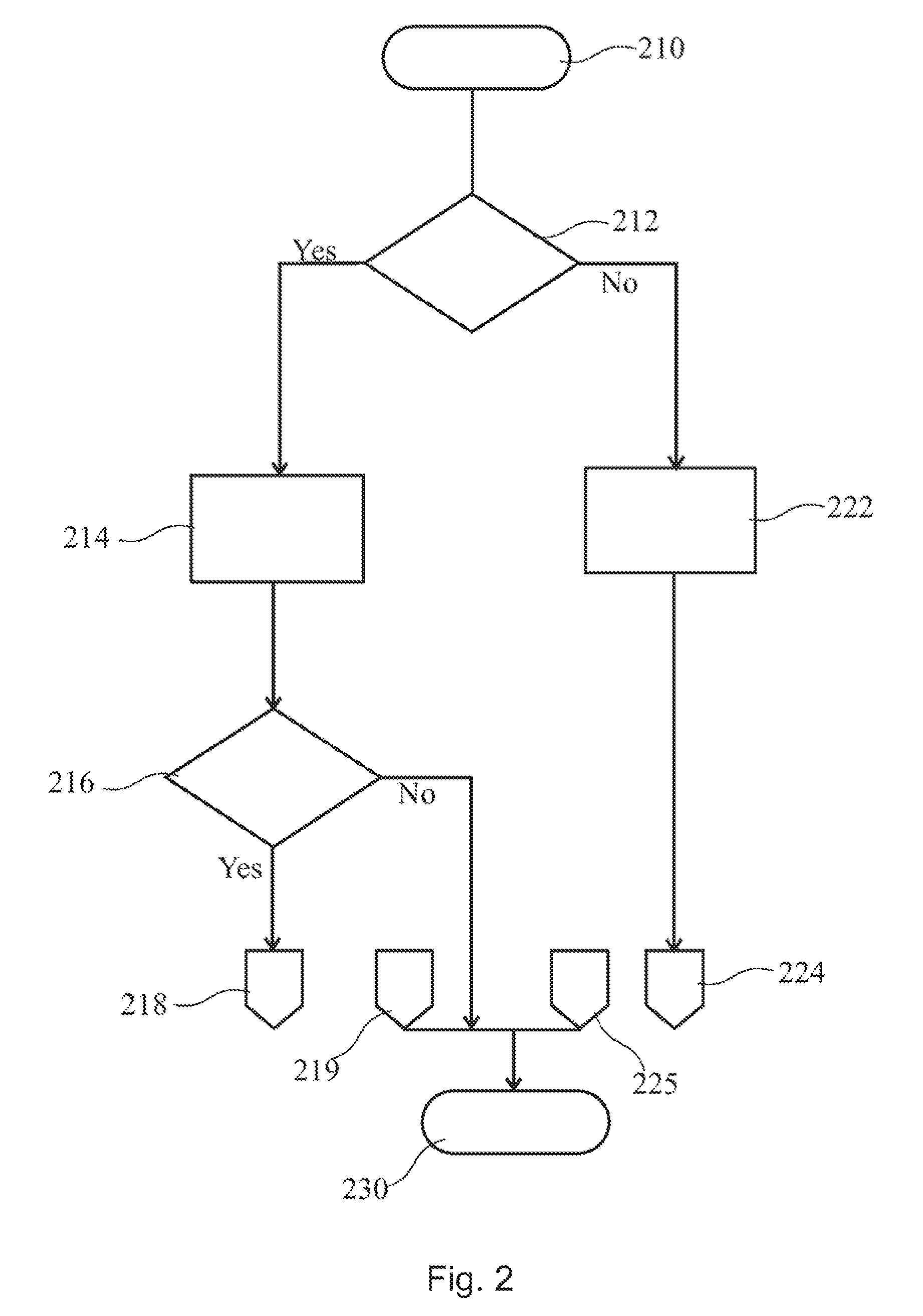

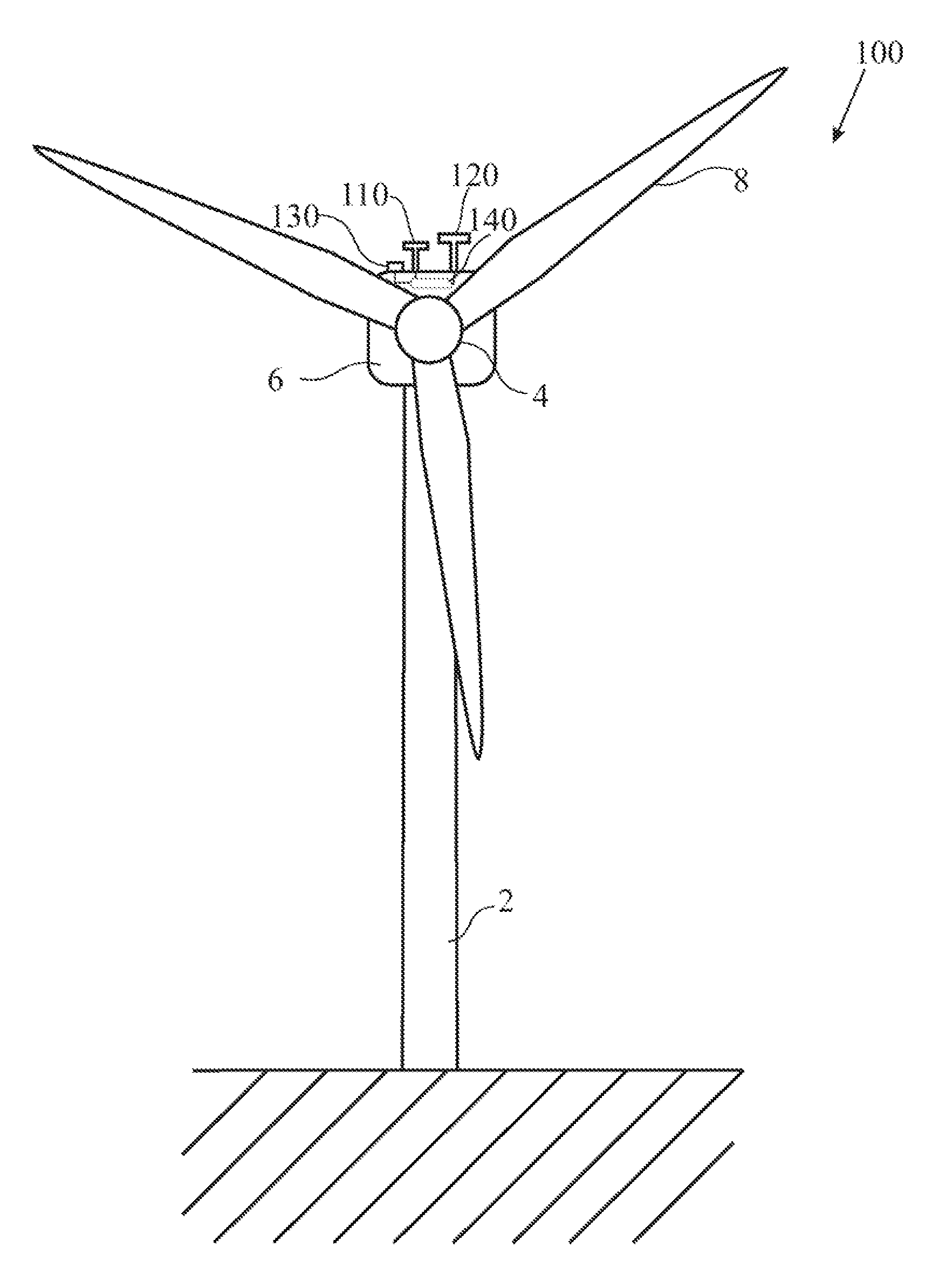

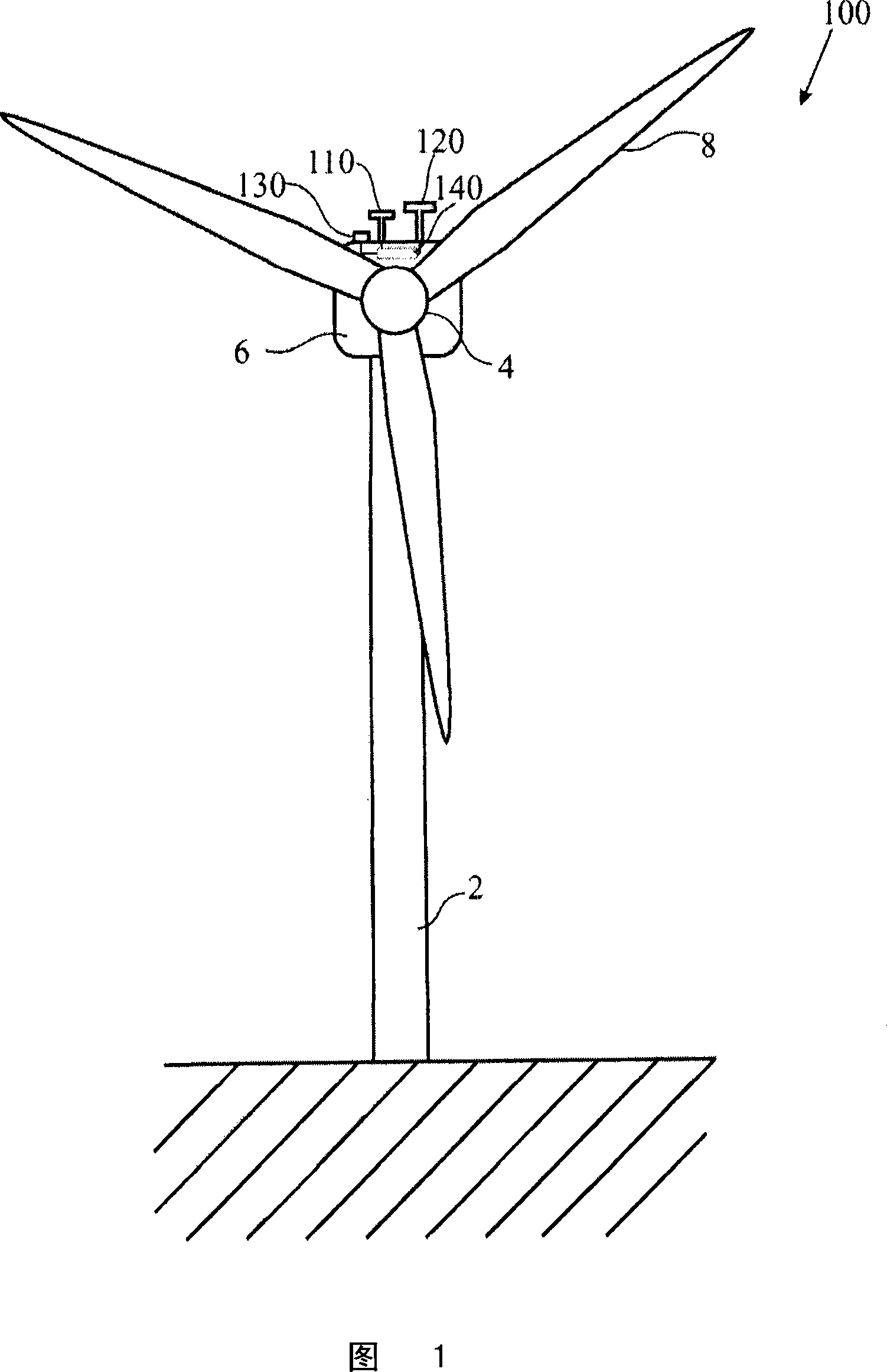

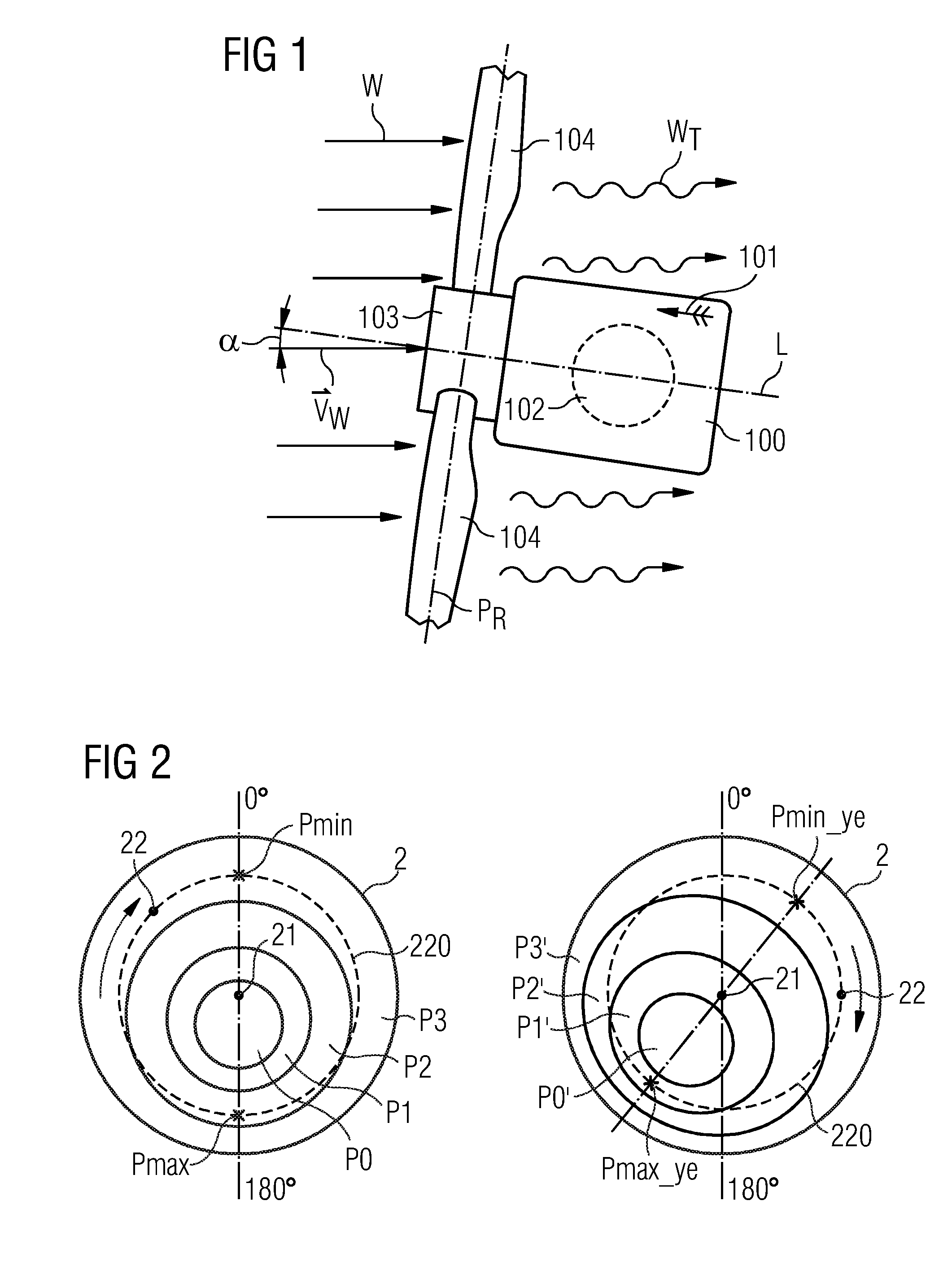

Ice detection based on anemometry

The present invention provides a method for ice detection for a wind turbine. The method includes providing an ice condition threshold parameter adapted for distinguishing a condition during which icing may occur and a condition during which icing may not occur, measuring a wind velocity with a first anemometer (110), wherein the first anemometer being of a first type, measuring a wind velocity with a second anemometer (120), wherein the second anemometer being of a second type, and wherein the second type is different from the first type, evaluating, for a condition during which icing may occur, a deviation of the wind velocity measured with the first anemometer and the wind velocity measured with the second anemometer, and determine whether the deviation exceeds a limit value based on acalibration conducted under a condition during which icing may not occur.

Owner:GENERAL ELECTRIC RENOVABLES ESPANA SL

Method for determining fatigue load of a wind turbine and for fatigue load control, and wind turbines therefor

InactiveUS8033788B2Reduce the amount requiredImprove robustnessPropellersWind motor controlFatigue loadingTurbine

A method of determining fatigue load of at least one operative wind turbine, comprising: providing a transfer function that associates an obtained at least one measurement value of a first sensor to an obtained at least one measurement value of a second sensor the at least one measurement value of the first sensor and the at least one measurement value of the second sensor being obtained by use of a reference wind turbine at which the first sensor and the second sensor are located; obtaining at least one measurement value of a third sensor, wherein the third sensor is located at the at least one operative wind turbine, and wherein the third sensor corresponds in type and position to the first sensor at the reference wind turbine; calculating at least one transfer function value corresponding to the obtained at least one measurement value of the third sensor by use of the provided transfer function; calculating the fatigue load of the at least one operative wind turbine based on the calculated transfer function value.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Wind turbine measurement system

A measurement system is provided for a wind turbine having a plurality of rotor blades mounted to a spinner at the front of a nacelle and arranged to rotate in a rotor plane. The measurement system includes a measuring device for determining a pressure at a number of pressure measurement points. The pressure measurement points are arranged in front of the rotor plane, an analysis module for generating a control signal on the basis of the pressure measurements, and output means for issuing the control signal to a controller of the wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Wind turbine and method for determining parameters of wind turbine

Owner:GENERAL ELECTRIC CO

Method for controlling a wind turbine, and wind turbine arrangement

The present disclosure relates to a method for controlling a wind turbine, the wind turbine including at least one movable portion which is movable during operation of the wind turbine and at least one movable portion device including at least one of a movable portion transmitter or a movable portion receiver, the movable portion transmitter or the movable portion receiver being disposed at the least one movable portion; the method including: at least one of sending to or receiving from at least three reference points at least one signal by at least one of the movable portion transmitter or movable portion receiver; and determining at least one operational parameter of the wind turbine depending on at least one characteristic of the at least one received signal. Further the present disclosure relates to a wind turbine arrangement and a system for controlling a wind turbine, comprising a controller of the wind turbine and a movable portion.

Owner:GENERAL ELECTRIC CO

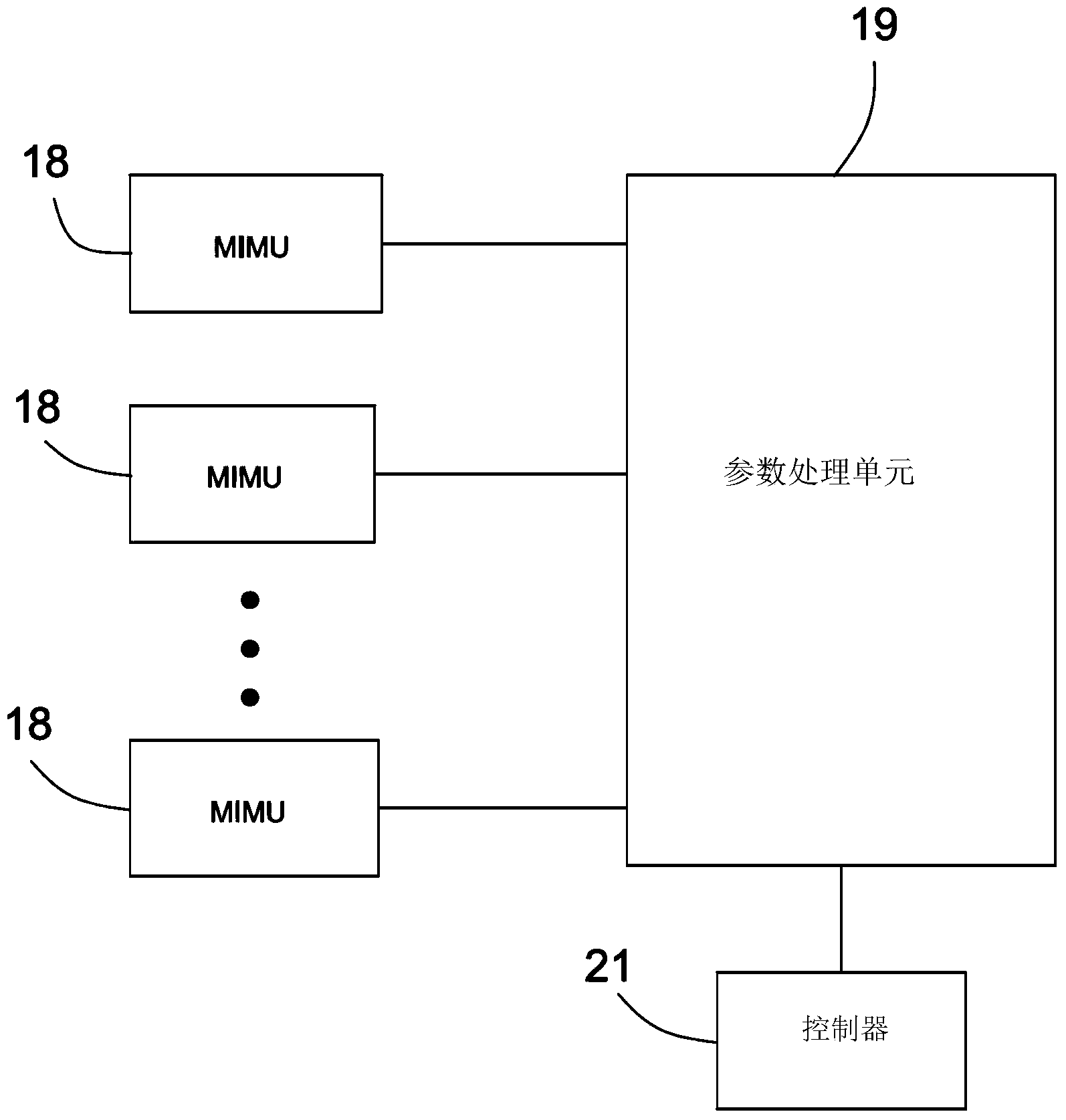

Wind turbine and method for monitoring parameter thereof

InactiveCN102797634AEasy to controlSimple monitoring systemWind motor controlMachines/enginesEngineeringInertial measurement unit

The invention relates to a wind turbine and a method for monitoring a parameter thereof. The wind turbine comprises a blade, a miniature inertial measurement unit mounted on the blade and a parameter processing unit, wherein the miniature inertial measurement unit is used for sensing a parameter signal at a corresponding mounting position, and the parameter processing unit is used for receiving the parameter signal sensed by the miniature inertial measurement unit and calculating a corresponding parameter.

Owner:GENERAL ELECTRIC CO

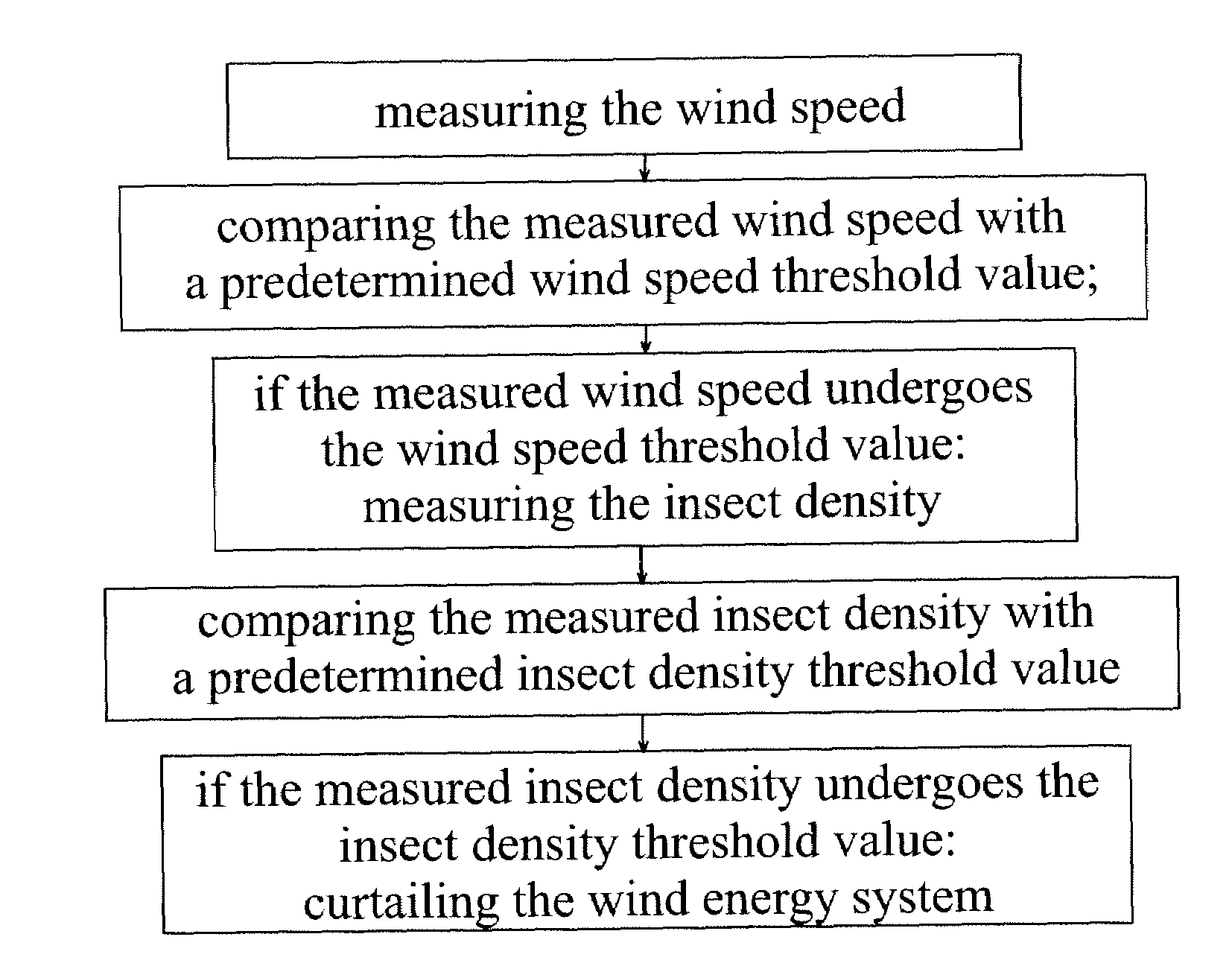

Wind energy system having an insect sensor

The invention relates to wind energy systems. A wind energy system is provided having an insect sensor. The insect sensor is adapted for measuring the insect density in the air. Further, a method for operating a wind energy system taking into account the insect density in the air is provided. The wind energy system is curtailed during times with a high insect density. Hence, in periods following times with a high insect density, the wind energy system can be operated without the aero-dynamical performance of the rotor blades being spoiled by smashed insects.

Owner:GENERAL ELECTRIC CO

System and method for wind friction monitoring

A monitoring system for at least one wind turbine includes at least one sensor disposed at the at least one wind turbine to detect wind friction at the at least one wind turbine. At least one controller is connected to the at least one wind turbine, and a monitor server is connected to the controller to change an operational status of the at least one wind turbine based on wind friction data received from the at least one sensor. A method of operation of at least one wind turbine includes continuously measuring data relative to wind friction at the at least one wind turbine via at least one sensor located thereat. The data is continuously compared to a predetermined wind friction threshold. A trend in the comparisons is evaluated, and the operational status of the wind turbine is changed via a monitor server based on a result of the comparison.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com