Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

293results about "Force transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

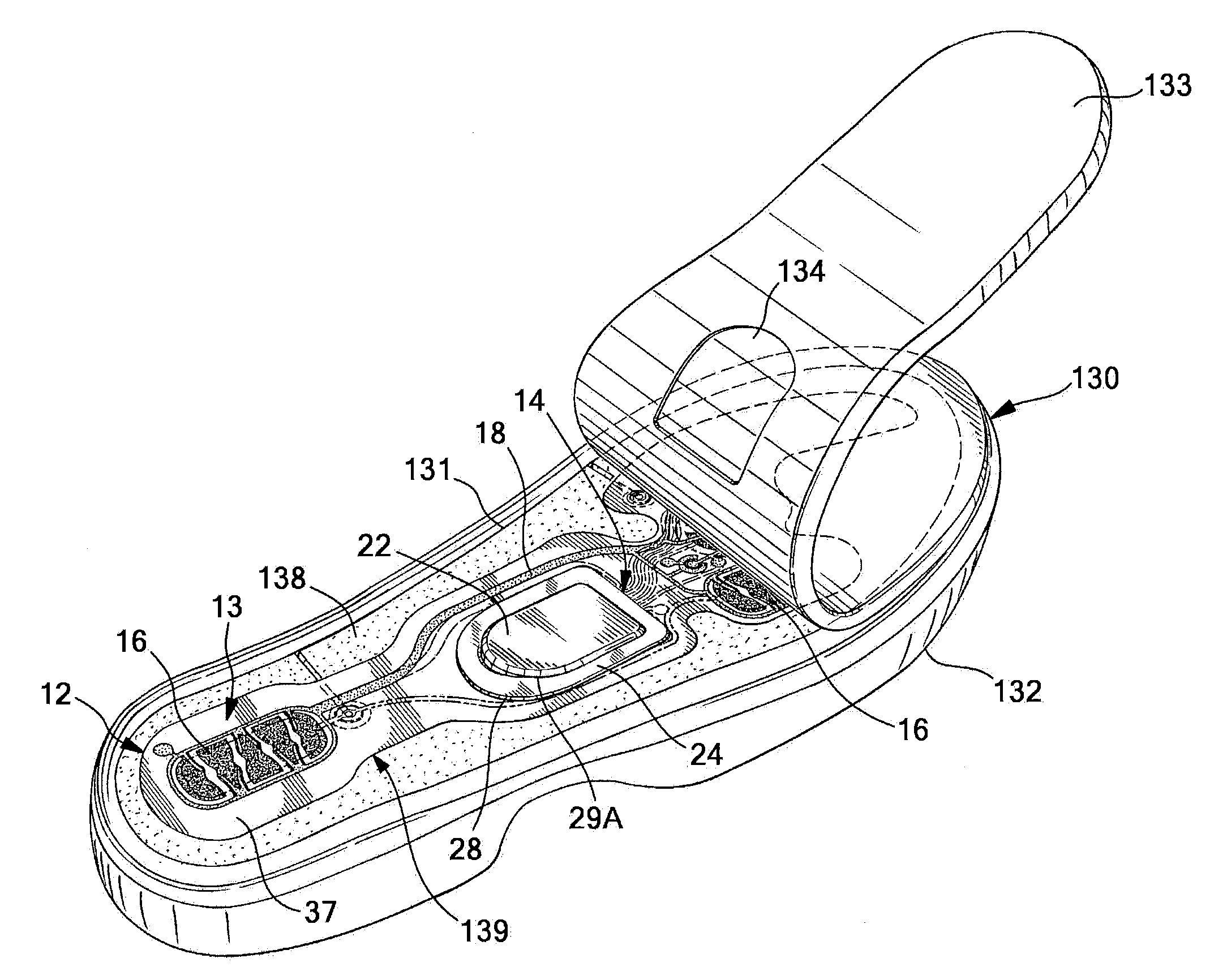

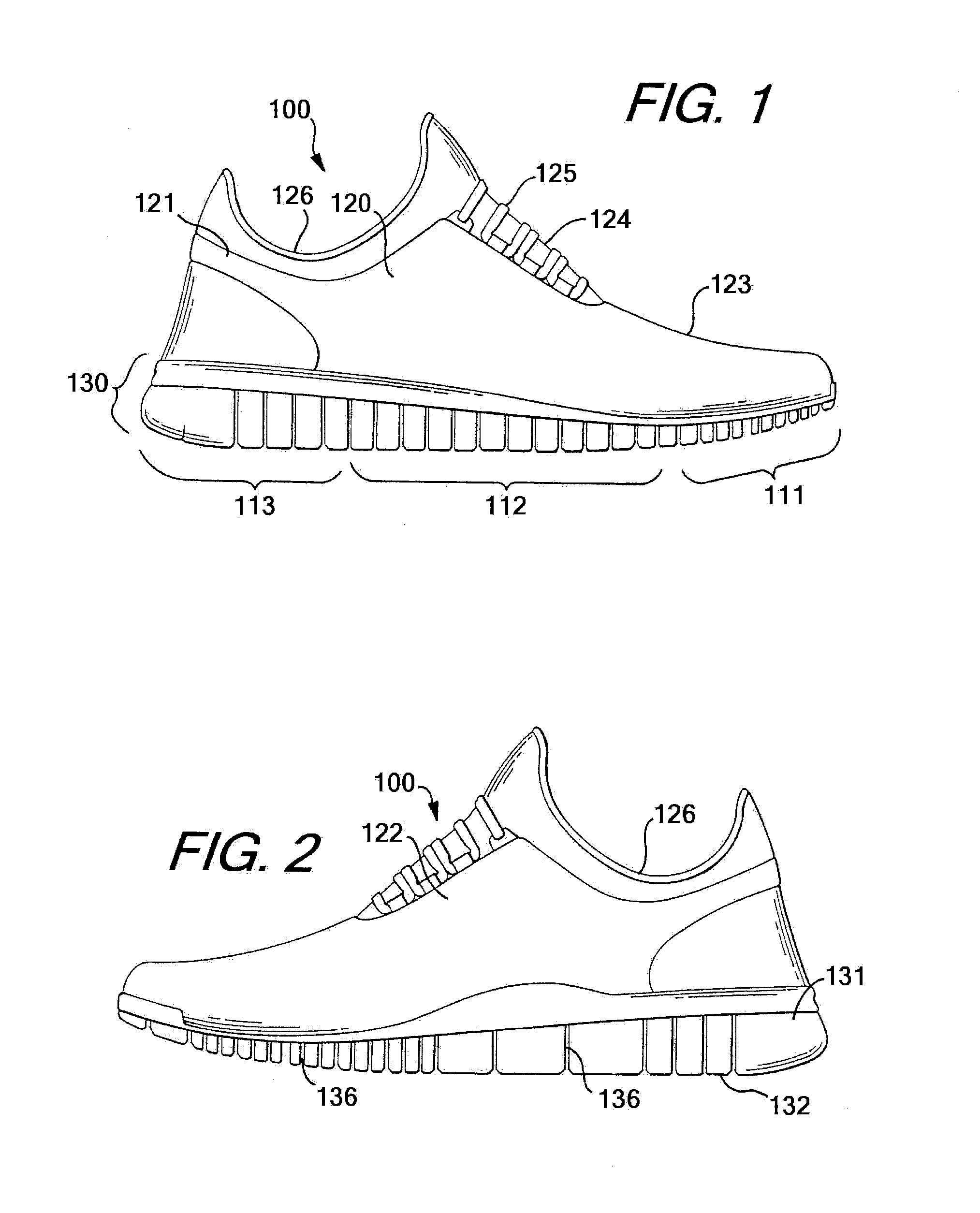

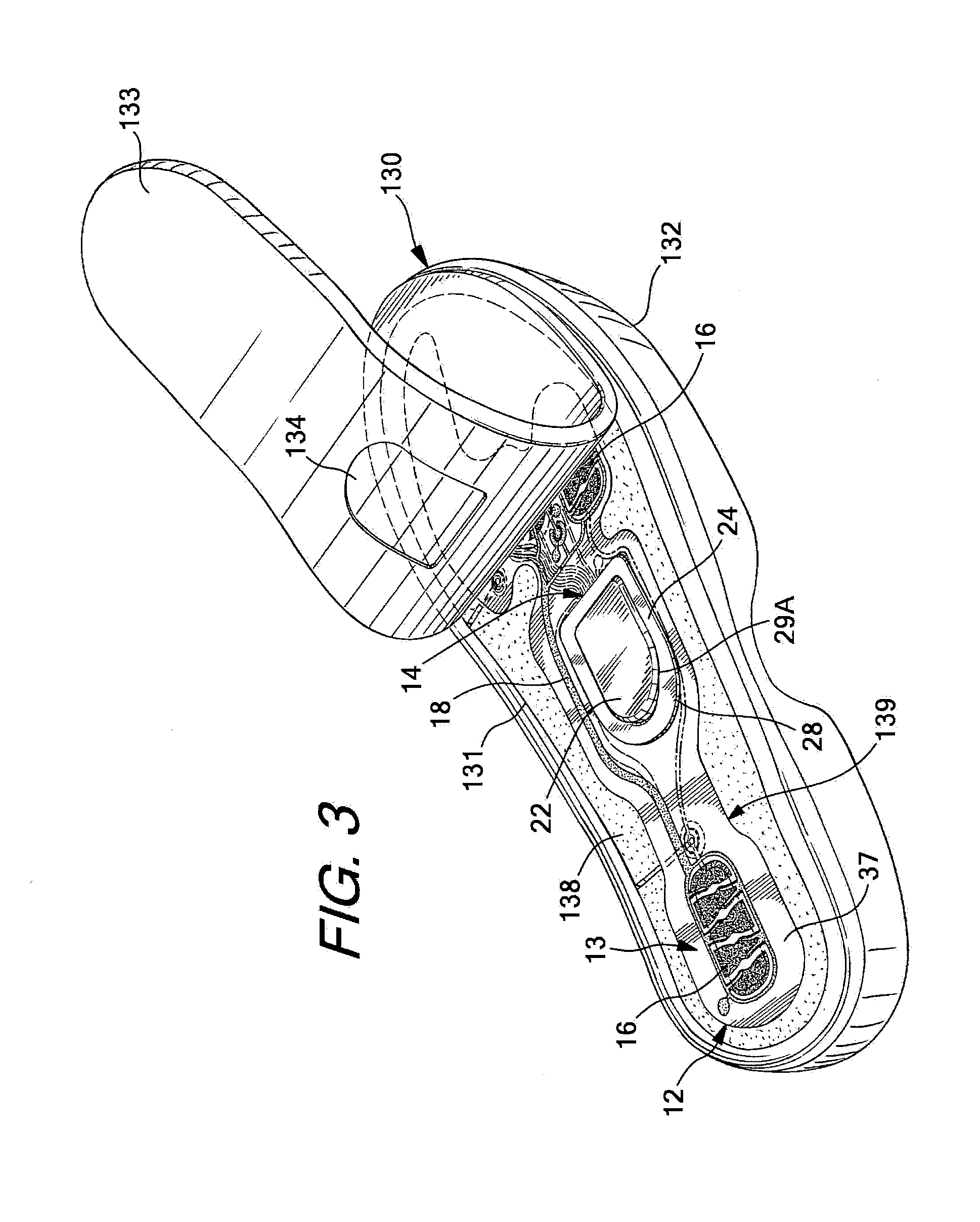

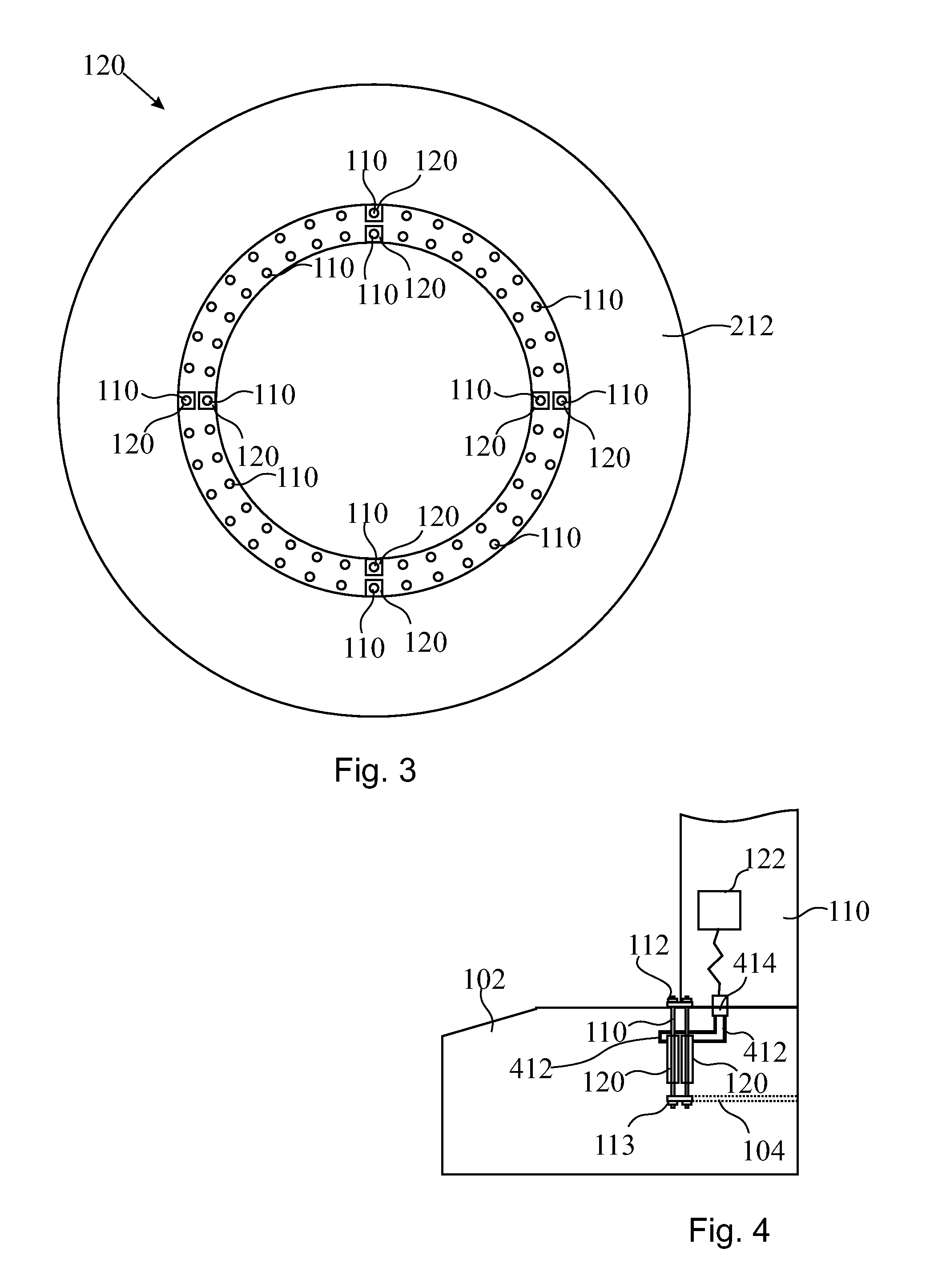

Footwear Having Sensor System

InactiveUS20130213146A1Reinforcement and wear resistance to the bend areaProvide wear resistanceSolesForce measurementEngineeringSensor system

A sensor system is adapted for use with an article of footwear and includes an insert member including a first layer and a second layer, a port connected to the insert and configured for communication with an electronic module, a plurality of force and / or pressure sensors on the insert member, and a plurality of leads connecting the sensors to the port.

Owner:NIKE INC

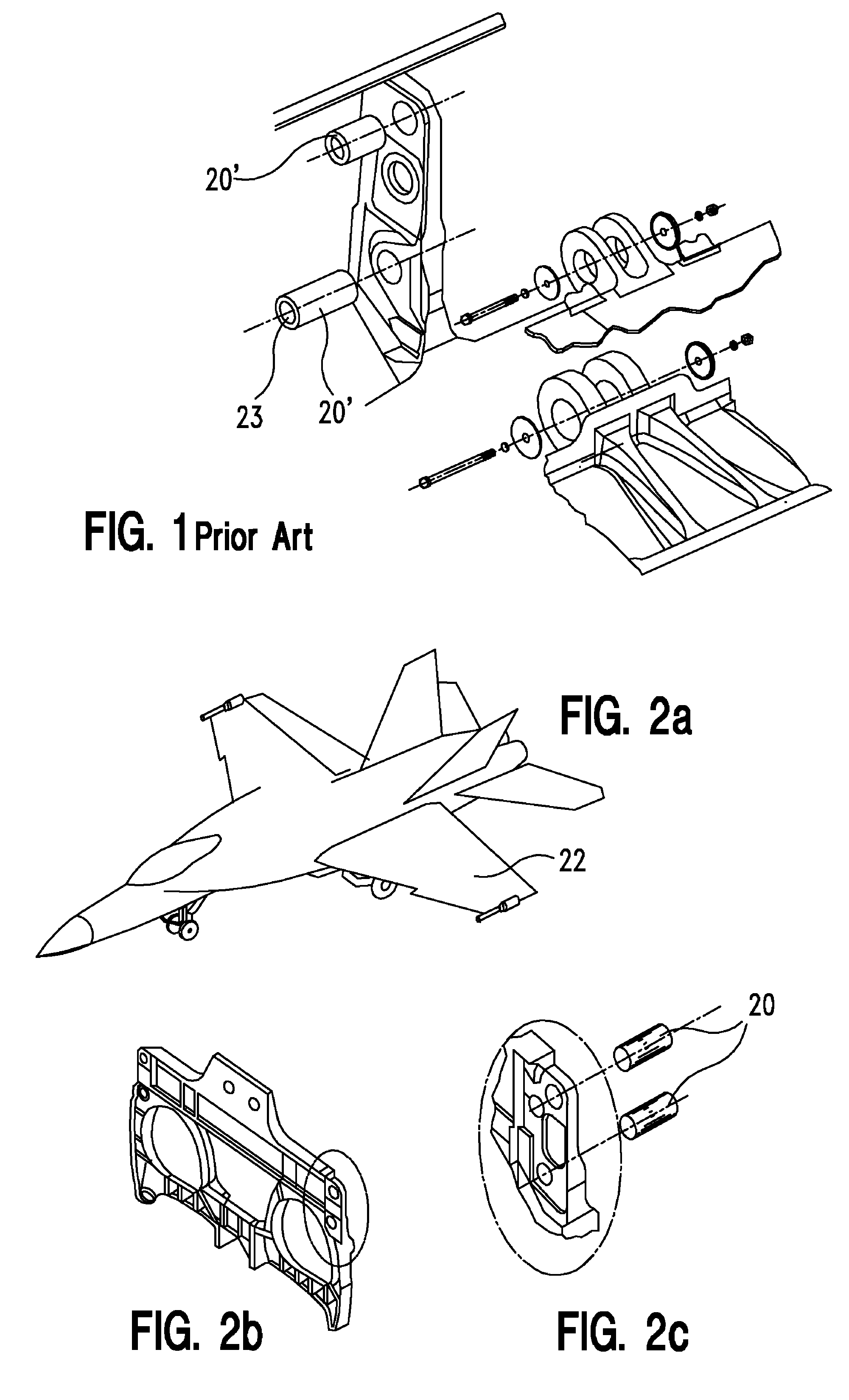

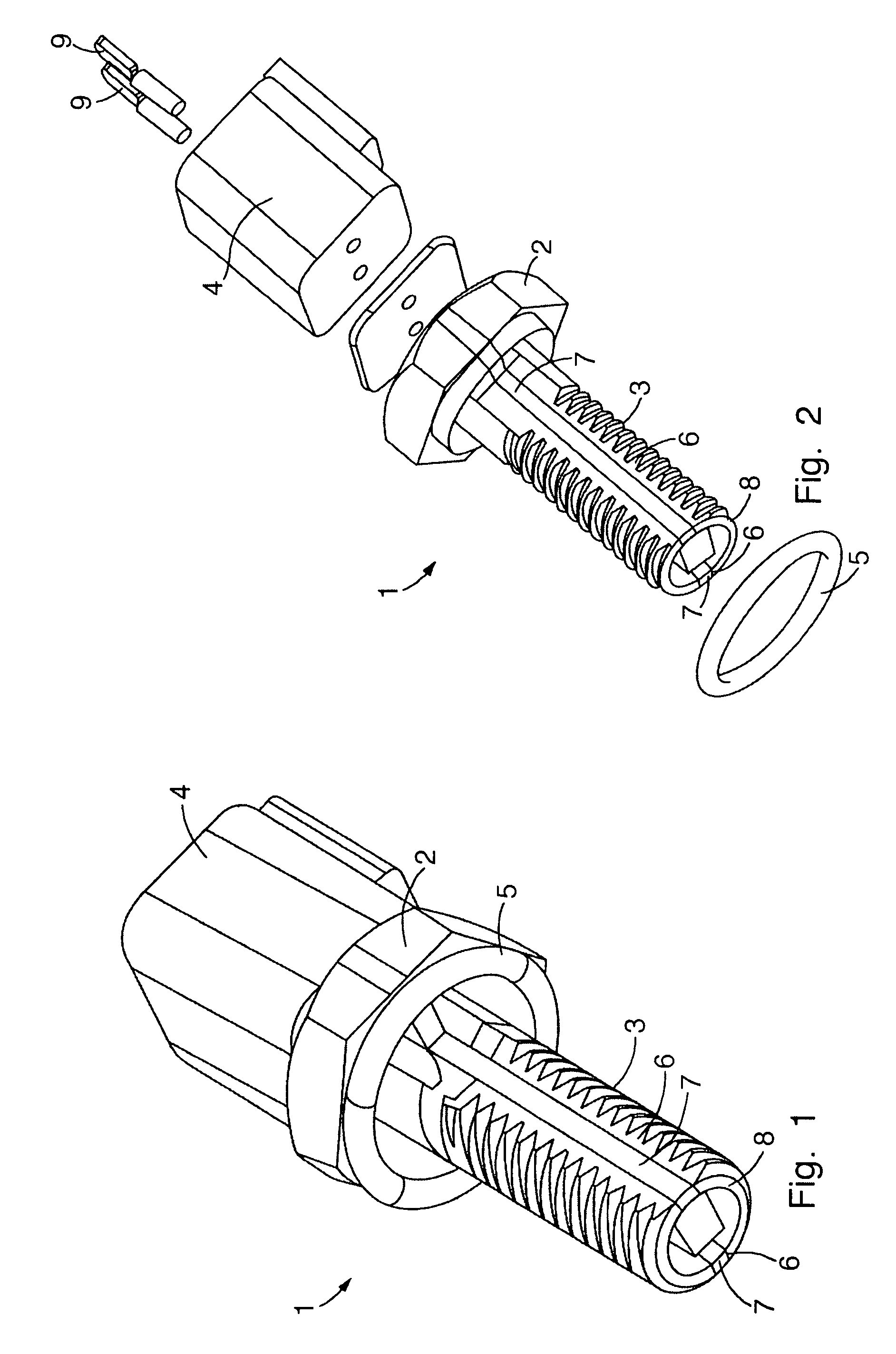

Independently calibrated wireless structural load sensor

InactiveUS8024980B2Testing/calibration apparatusMeasurement of torque/twisting force while tighteningStructural loadEngineering

A device includes a removable load element. The removable load element includes a pin portion and a housing portion. The pin portion extends from the housing portion. The pin portion includes a sensor. The housing portion includes an electronic circuit connected to the sensor.

Owner:LORD CORP

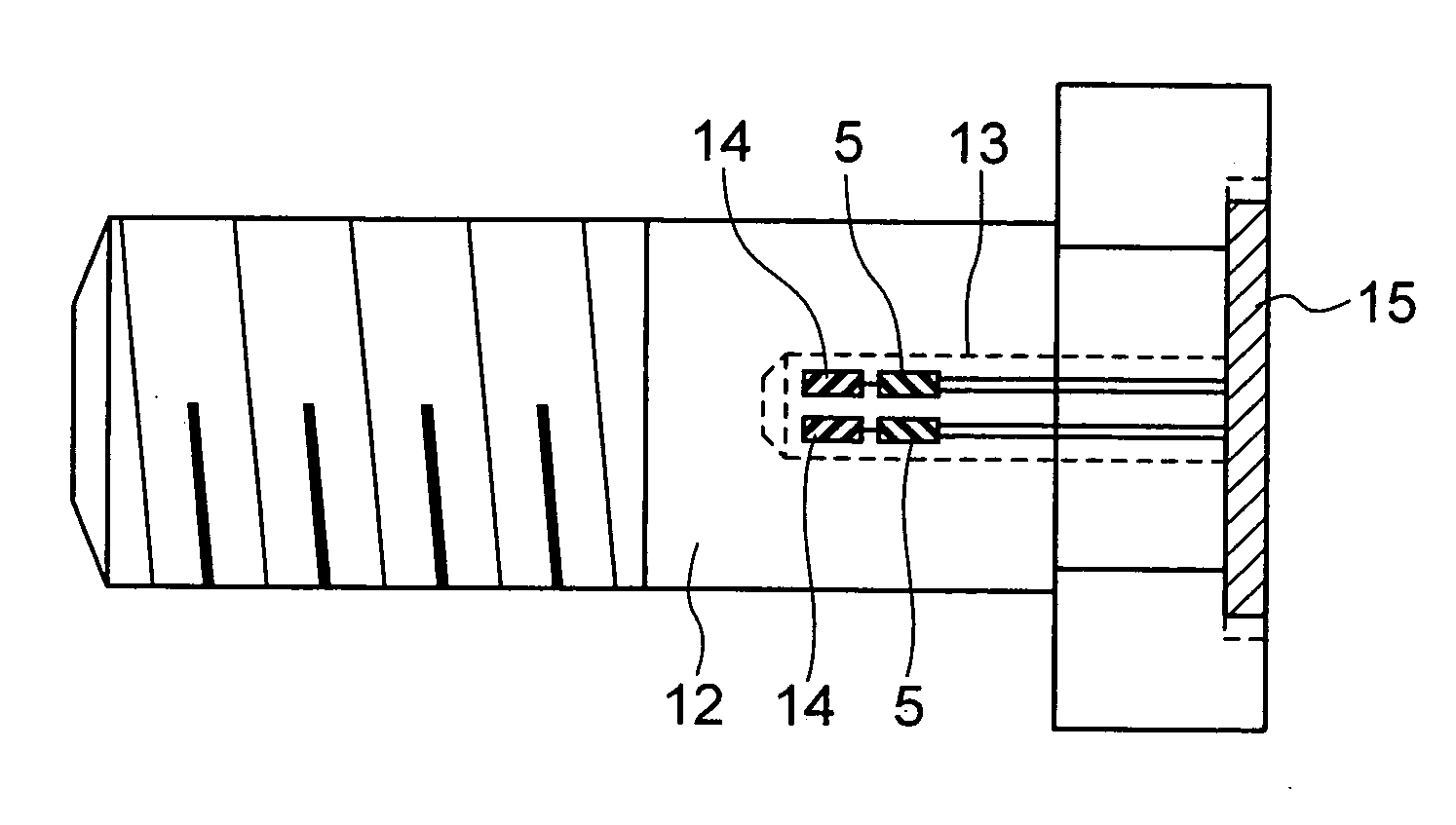

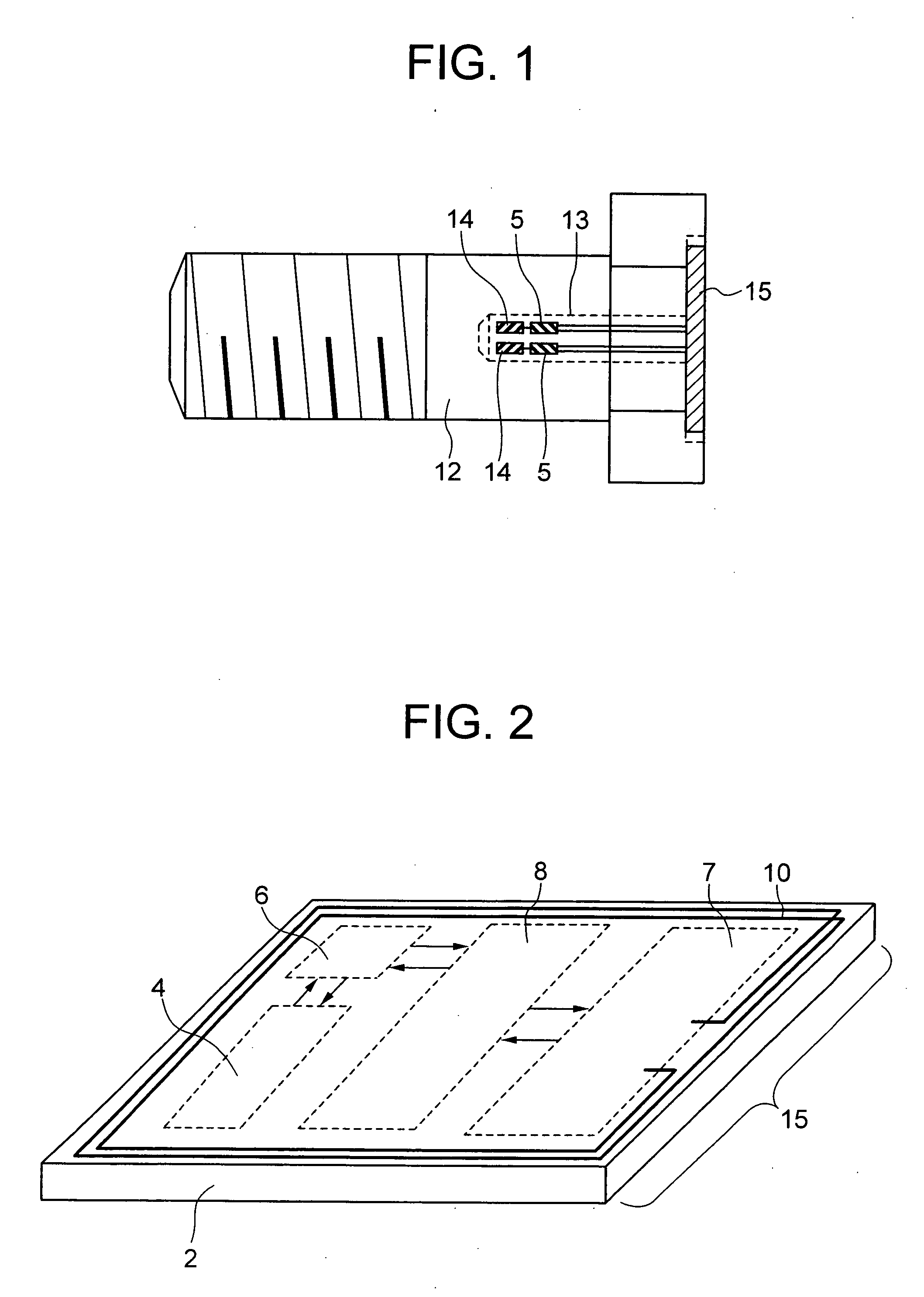

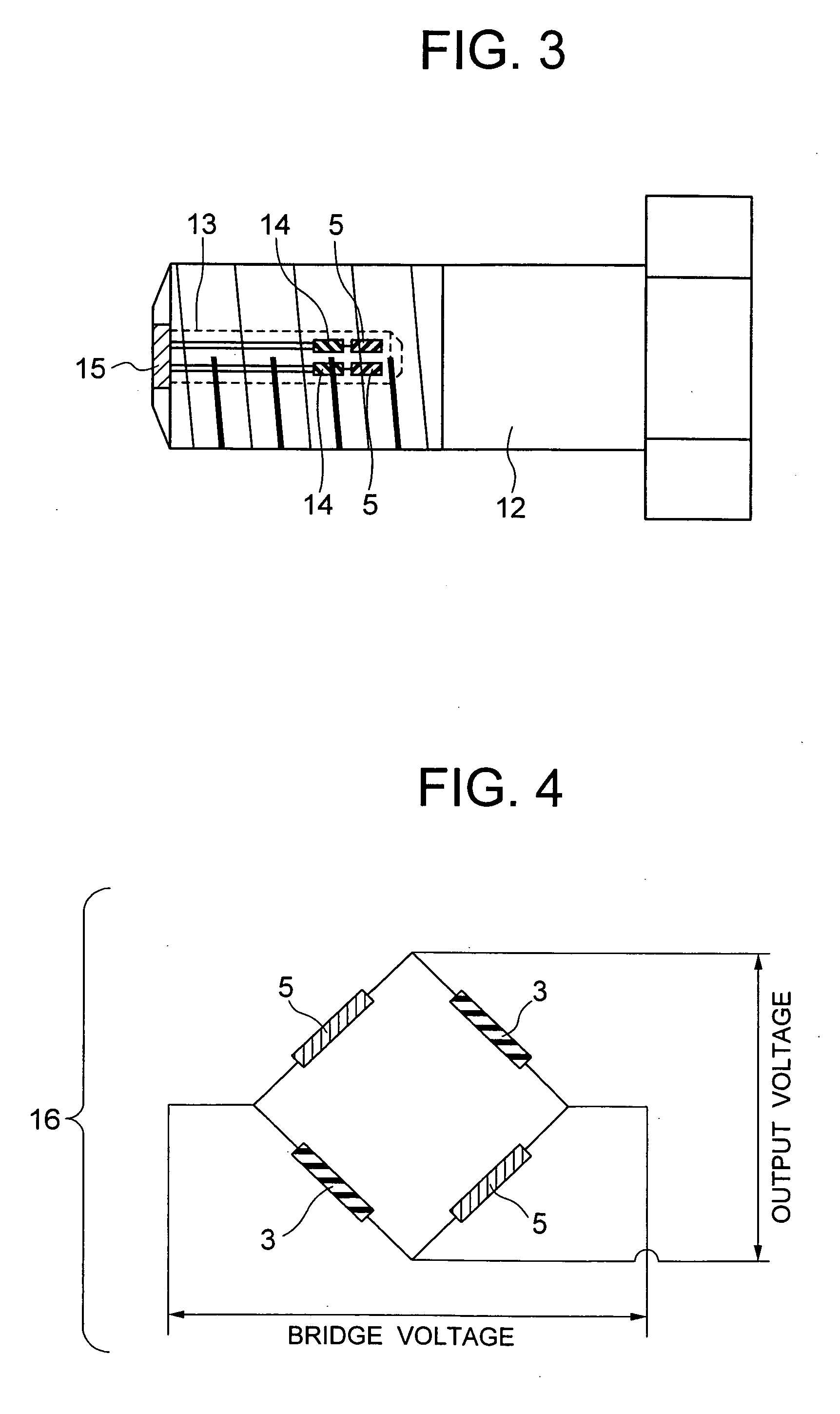

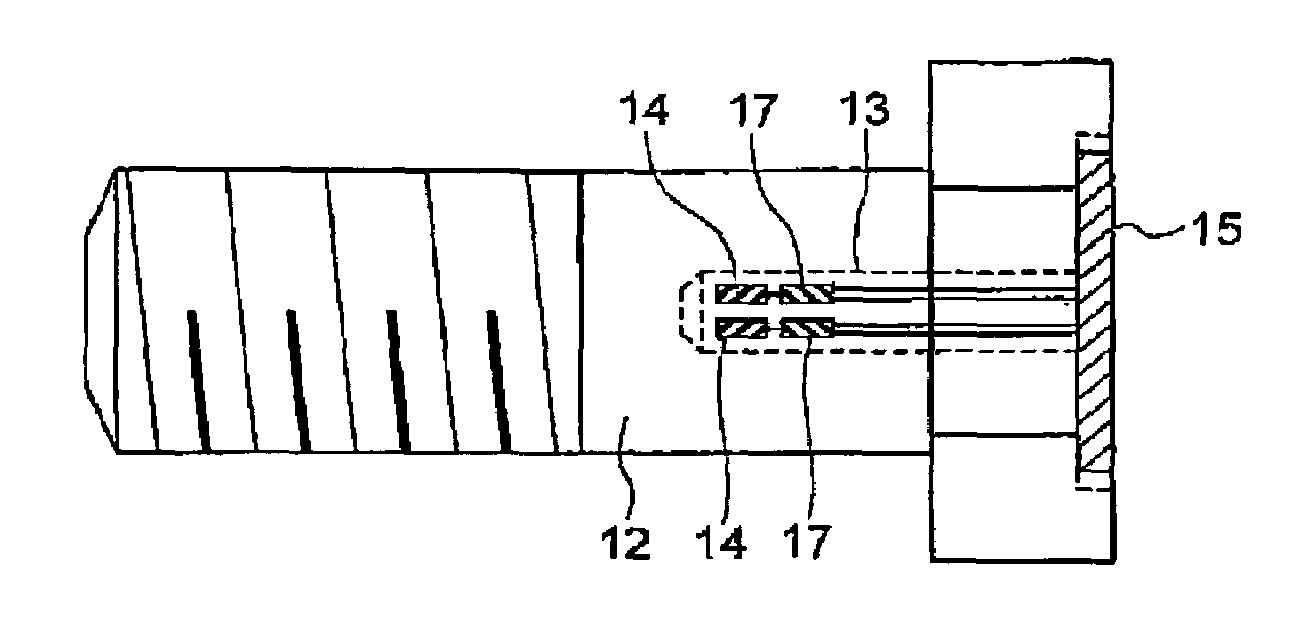

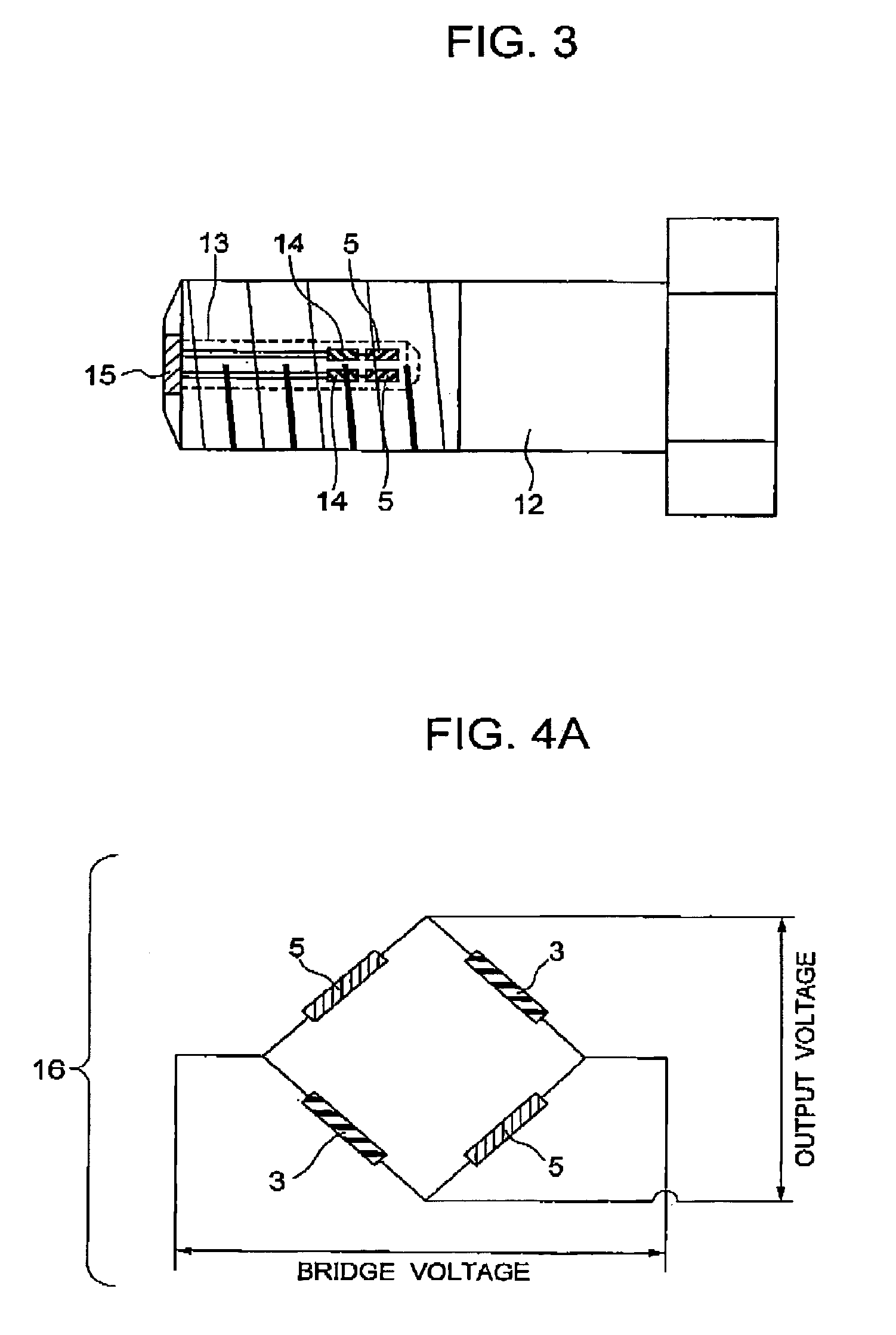

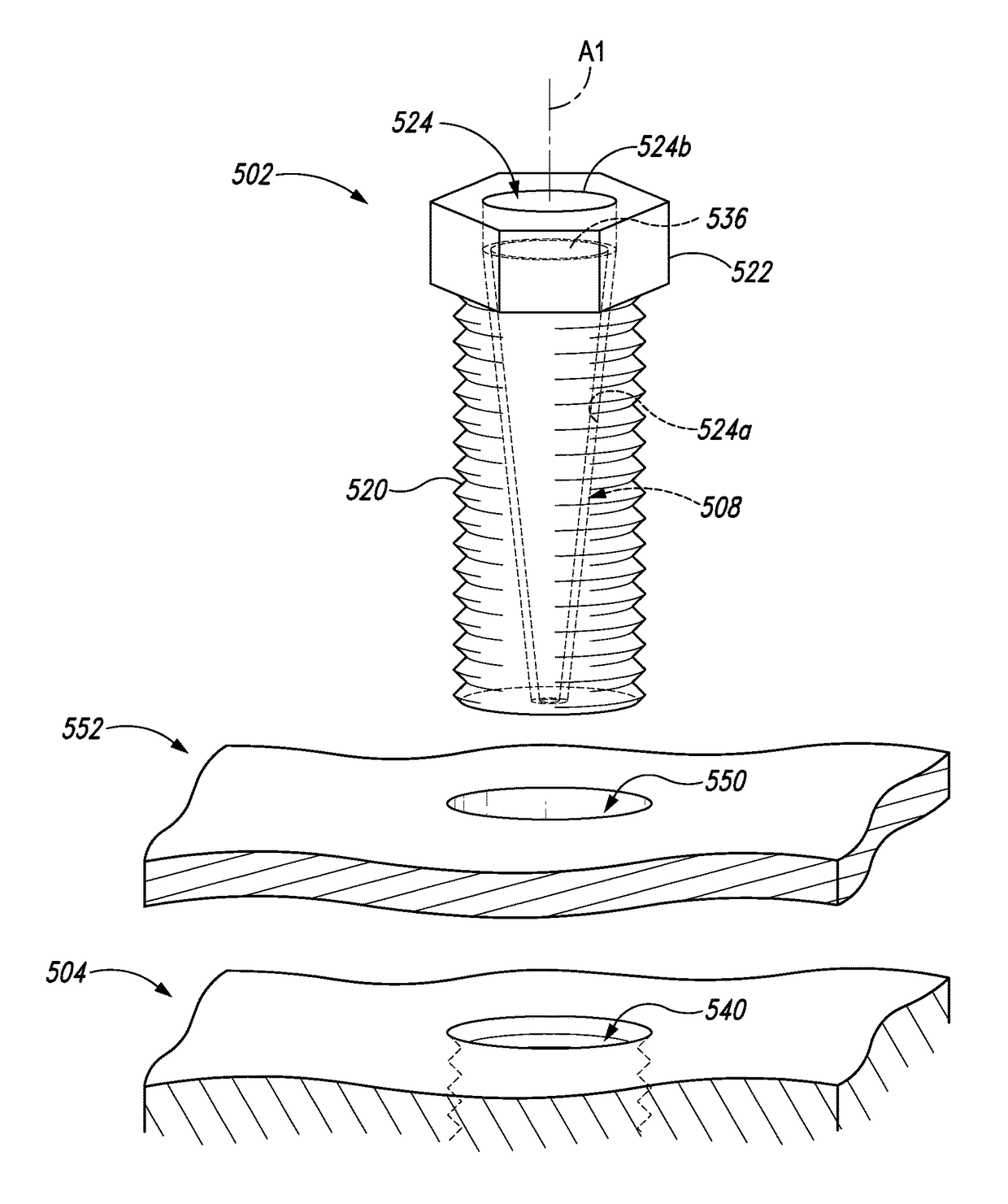

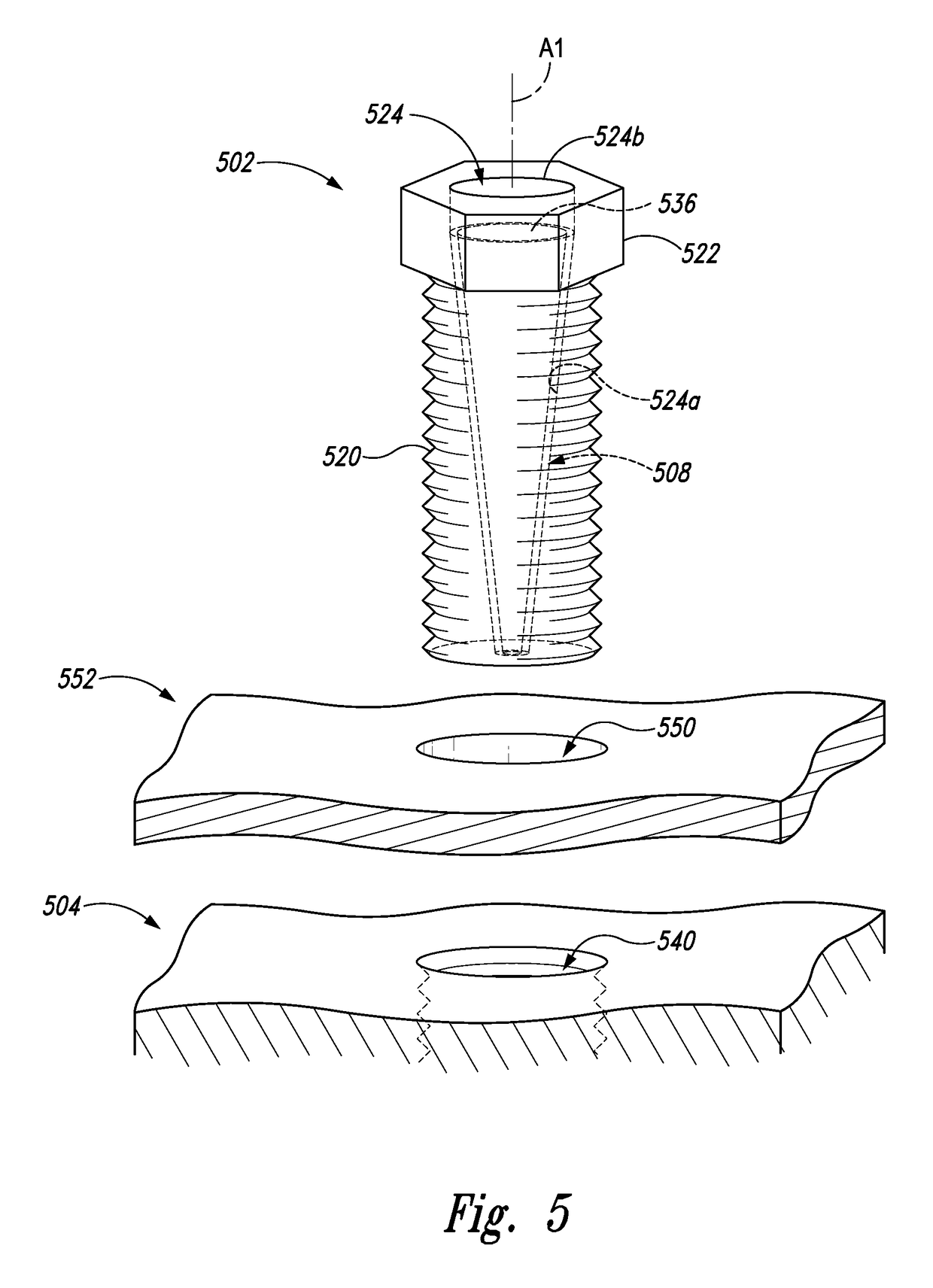

Bolt with function of measuring strain

ActiveUS20070017295A1Improve accuracyHigh precision measurementAcceleration measurement using interia forcesTesting/calibration apparatusElectrical resistance and conductanceEngineering

A bolt with a function of measuring strain, comprising a Wheatstone bridge circuit comprising a strain sensor and a dummy resistor, a translate circuit that amplifies a signal from the Wheatstone bridge circuit to convert the same into a digital signal, a transmitting circuit that transmits the digital signal outside the bolt, and a power circuit, by which electromagnetic wave energy received from outside the bolt is supplied as a power source for at least any one of the circuits.

Owner:HITACHI LTD

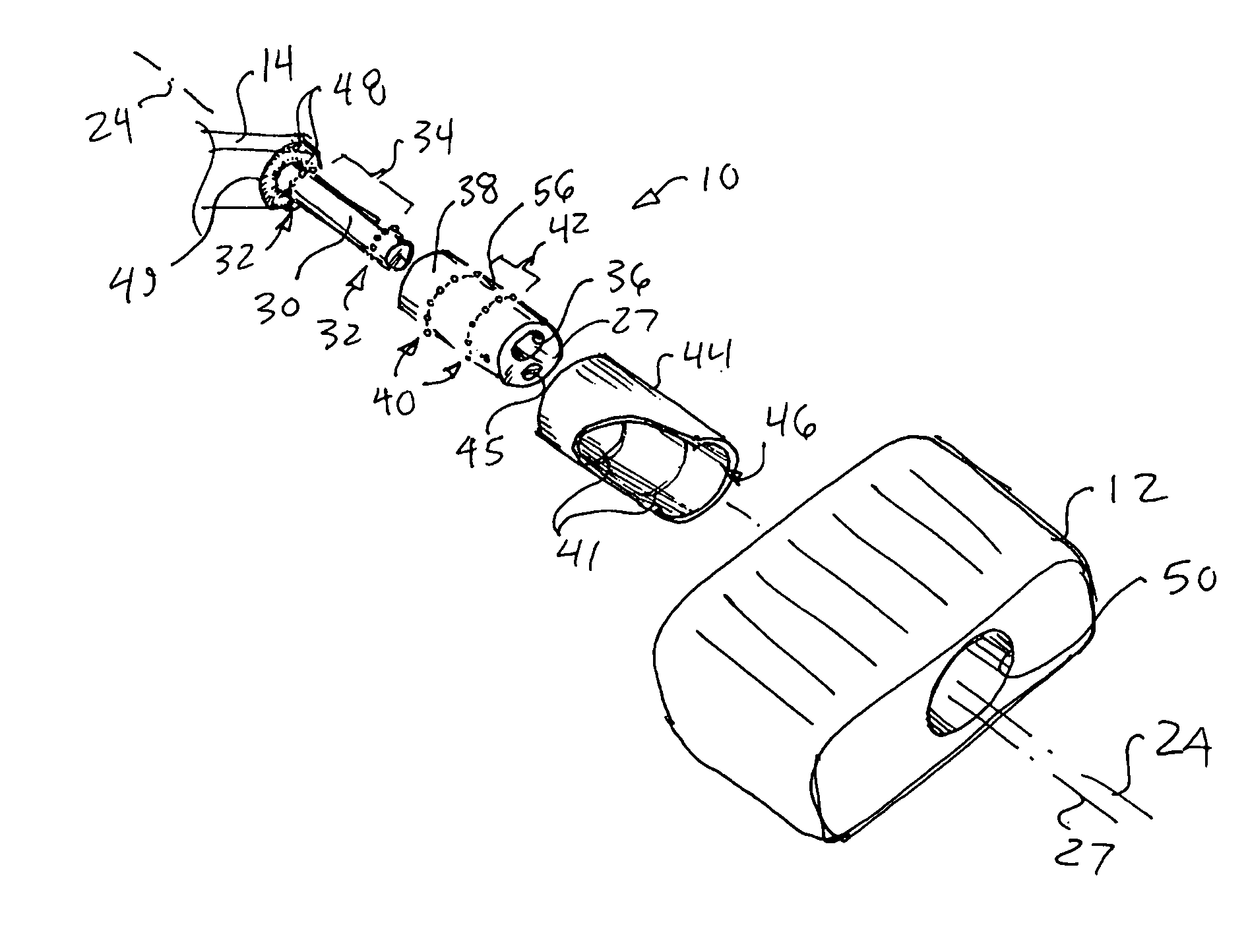

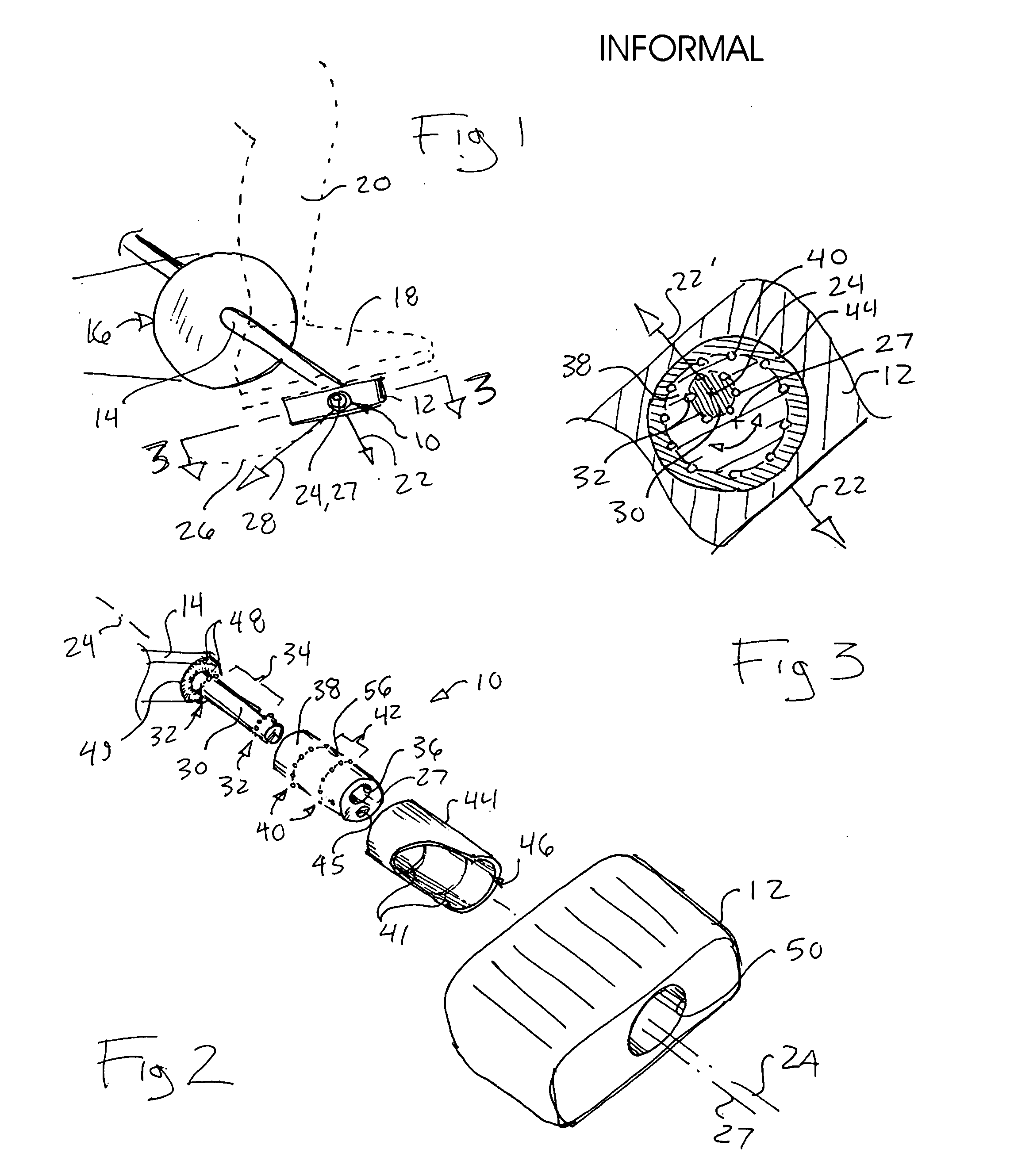

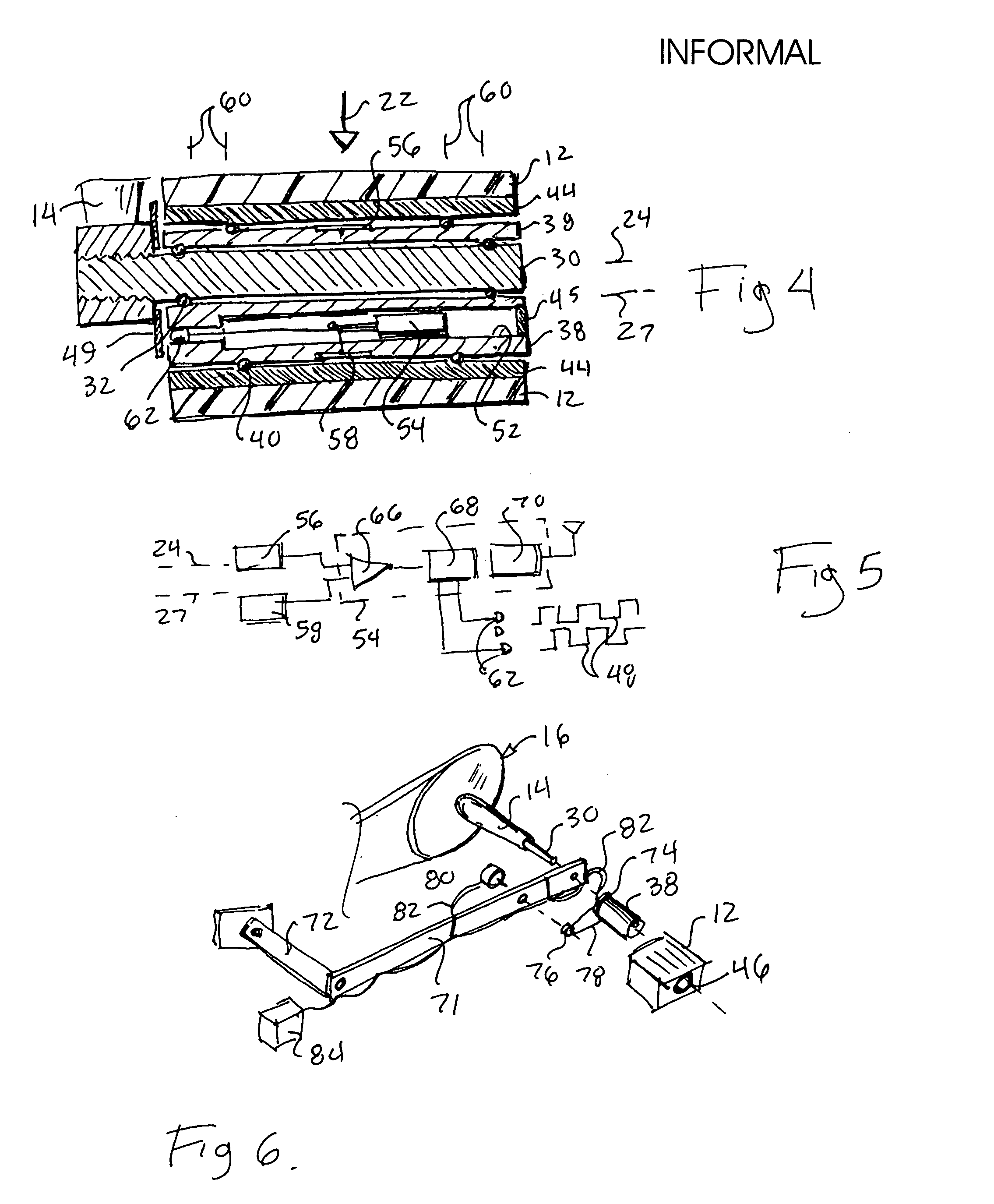

Electromechanical force-magnitude, force-angle sensor

ActiveUS20070137307A1Better user feedbackEasy to FeedbackMechanical apparatusVehicle cranksElectric forceEngineering

An electromechanical force sensor uses a rotating element that aligns with the force and may carry a force magnitude sensor simplifying and providing more accurate measurement of force-angle and force-magnitude. The ability to detect simply force-angle and force-magnitude enables a variety of training and exercise devices.

Owner:WISCONSIN ALUMNI RES FOUND

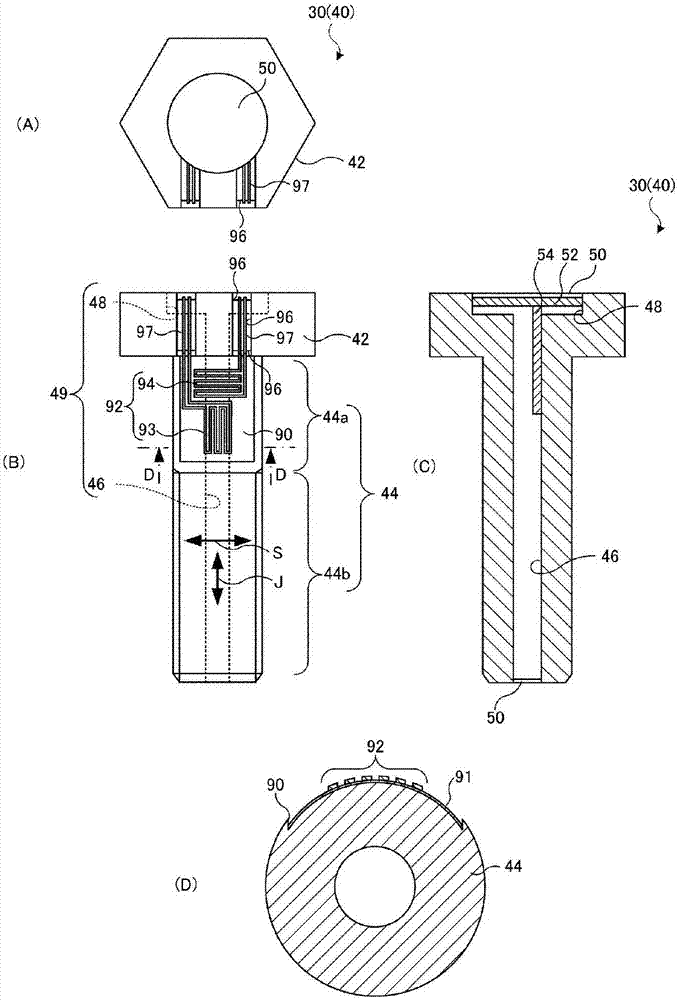

Conduction-path-equipped member, method for patterning conduction path, and method for measuring changes in member

InactiveUS20180067003A1Low costWide rangeLoad modified fastenersForce measurementEngineeringMechanical engineering

Owner:NEJILAW

Bolt with function of measuring strain

ActiveUS7293466B2Improve accuracyChange resistanceAcceleration measurement using interia forcesTesting/calibration apparatusPower circuitsStrain sensor

A bolt with a function of measuring strain, comprising a Wheatstone bridge circuit comprising a strain sensor and a dummy resistor, a translate circuit that amplifies a signal from the Wheatstone bridge circuit to convert the same into a digital signal, a transmitting circuit that transmits the digital signal outside the bolt, and a power circuit, by which electromagnetic wave energy received from outside the bolt is supplied as a power source for at least any one of the circuits.

Owner:HITACHI LTD

Method and device for testing geo-stress in deep soft rock based on flow stress restoration principle

InactiveCN102628716AConvenient researchGet goodForce measurement by measuring frquency variationsTesting machinesObservation dataSlurry

The invention discloses a method and device for testing a geo-stress of a deep soft rock. The device comprises a connecting rod; two three-direction pressure boxes are adjacently fixed on the connecting rod; the three-direction pressure box is provided with three vertical working surfaces; a direction cosine of any two working faces among the two three-direction pressure boxes is not 1; a device for measuring a normal pressure stress is mounted on each working face of the two three-direction pressure boxes; and the device is connected with a reading instrument outside a drilling hole through a data wire. A geo-stress testing method comprises the following steps of: sending the two three-direction pressure boxes to a test point after drilling; grouting the drilling hole and sealing the drilling hole after the drilling hole is entirely filled; and after slurry is solidified, substituting six pressure data measured by the two three-direction pressure boxes into a geo-stress testing principle formula after the data is stable, so as to obtain the geo-stress at the test position. With the adoption of the method, a stress value inside surrounding rocks can be directly observed, and observation data can be obtained for a long time. Therefore, the method and device provided by the invention is good for researches of coal deep rock geo-stress and the stability of a surrounding rock.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

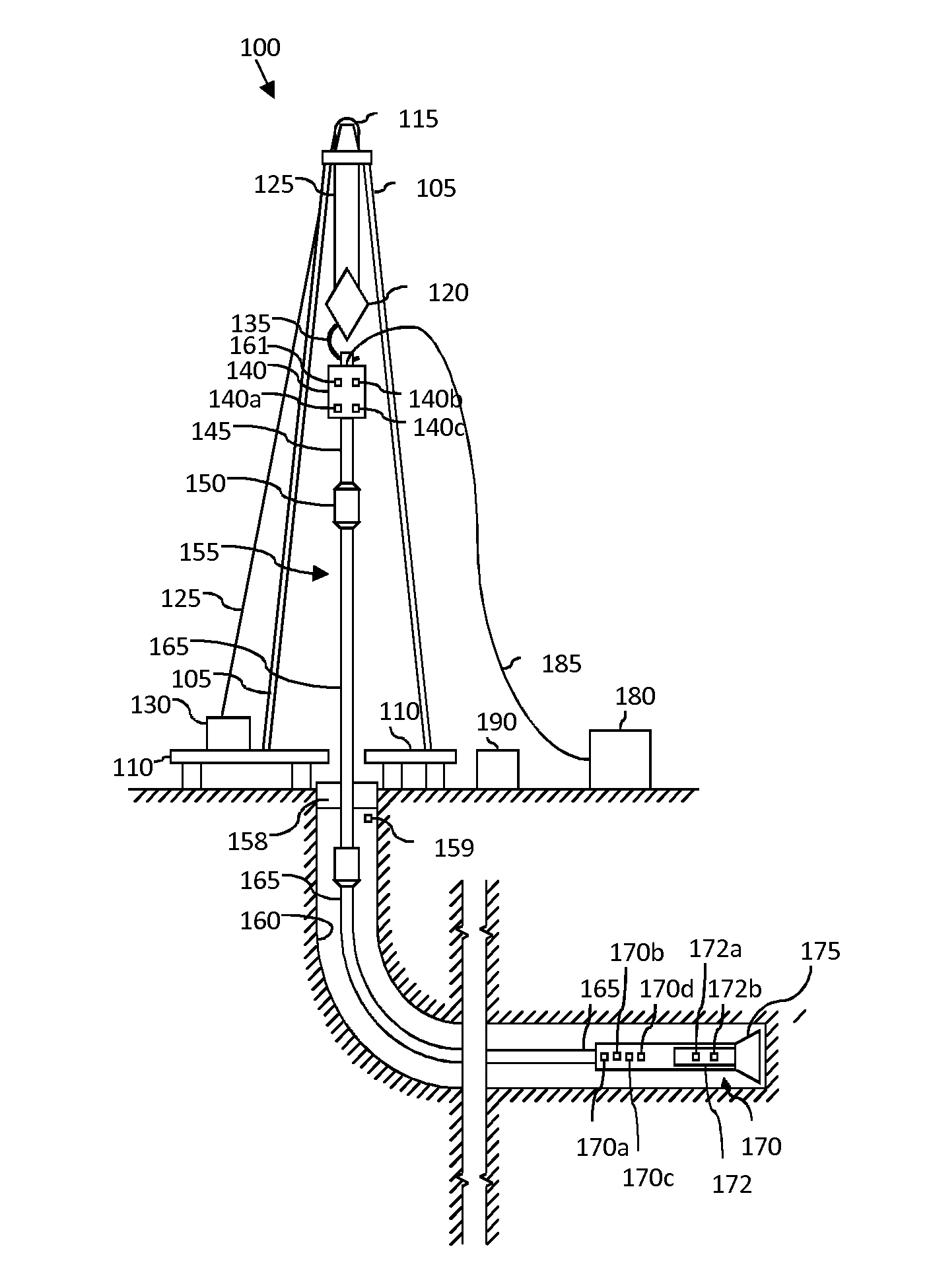

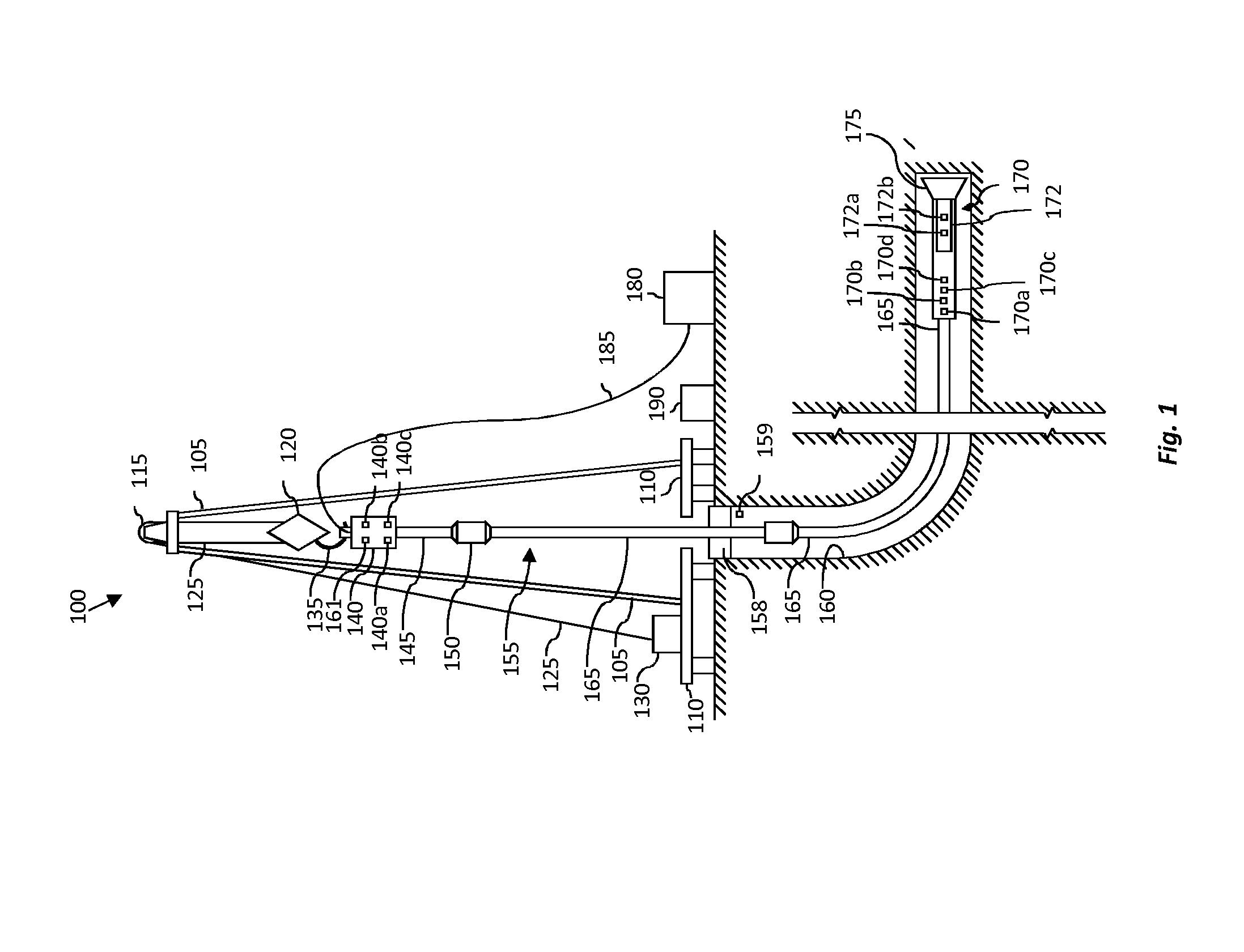

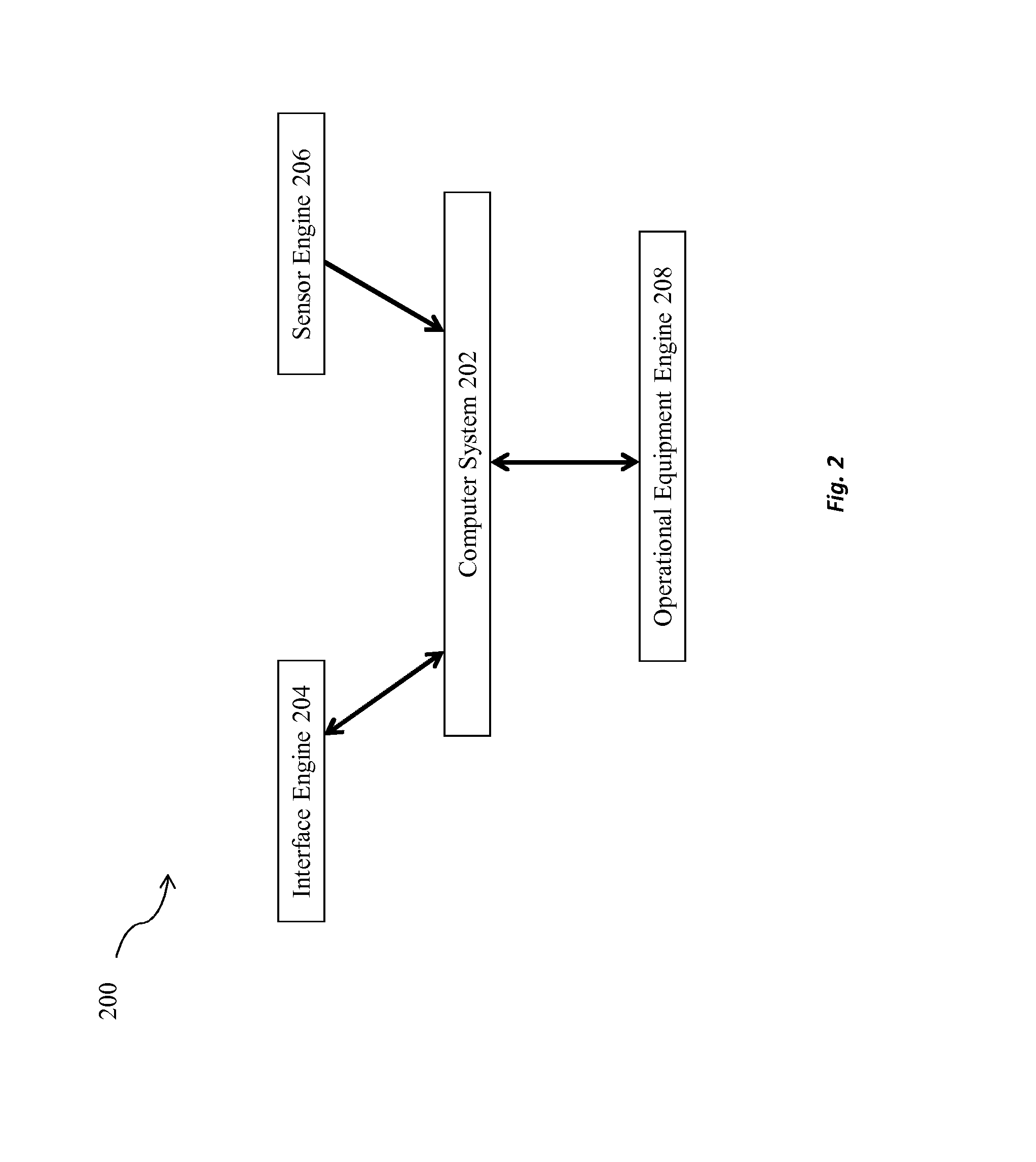

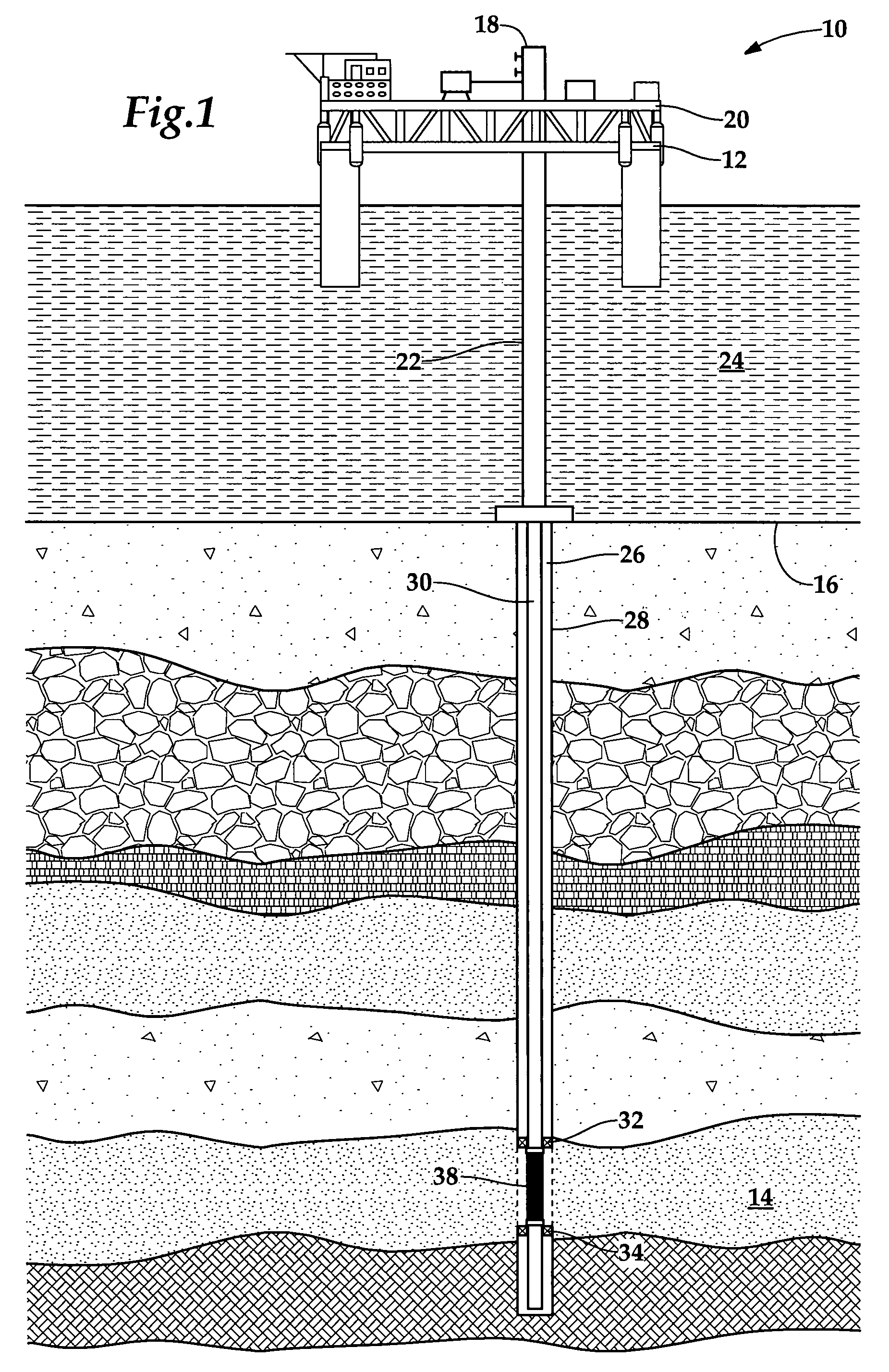

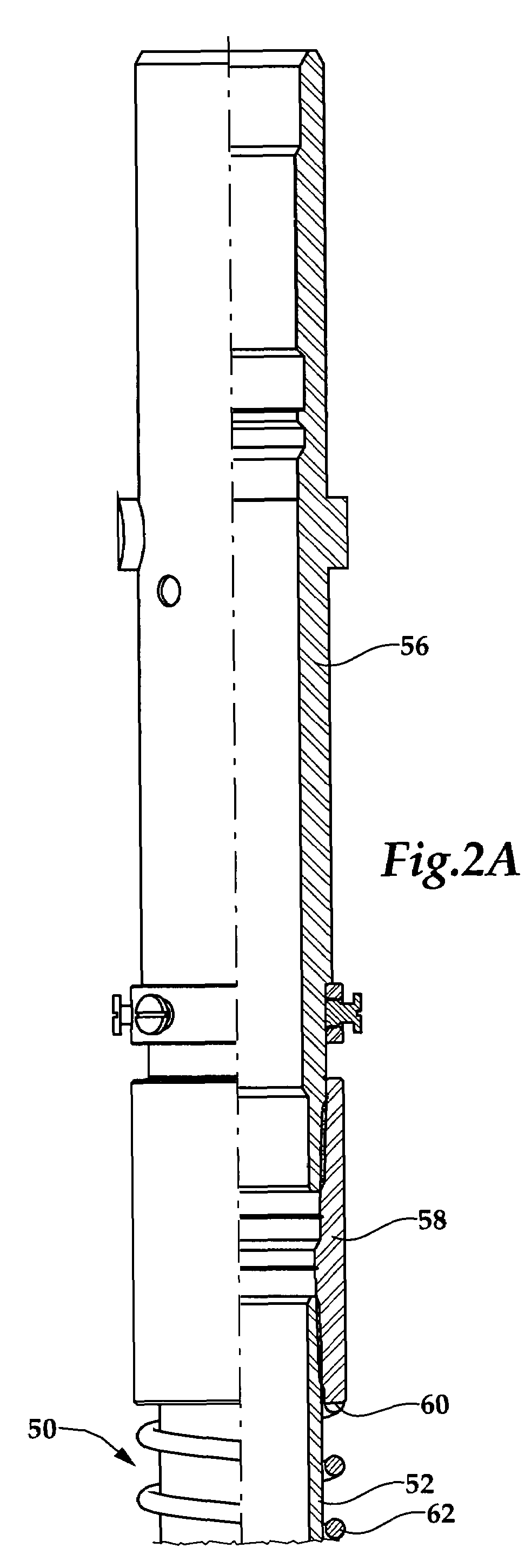

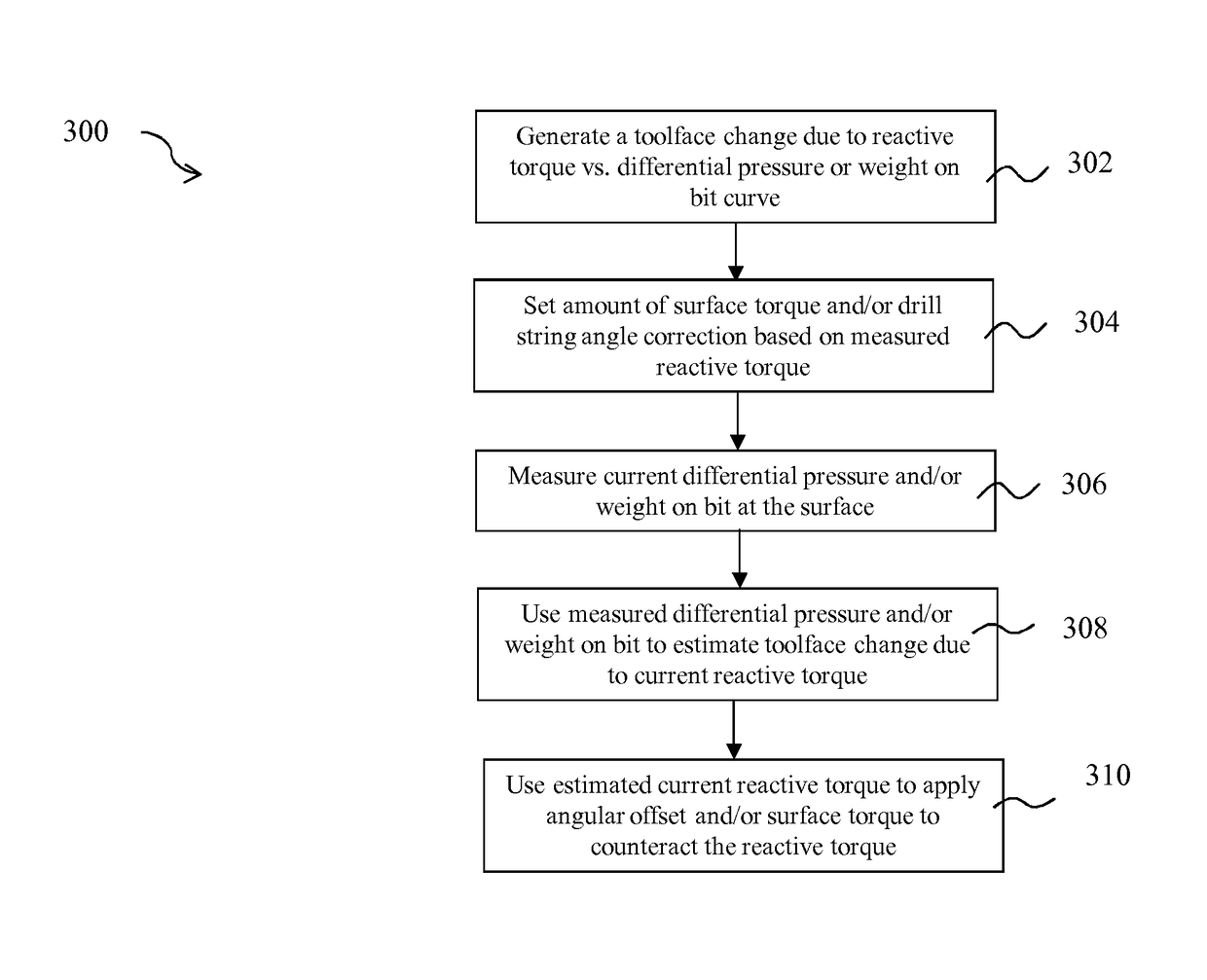

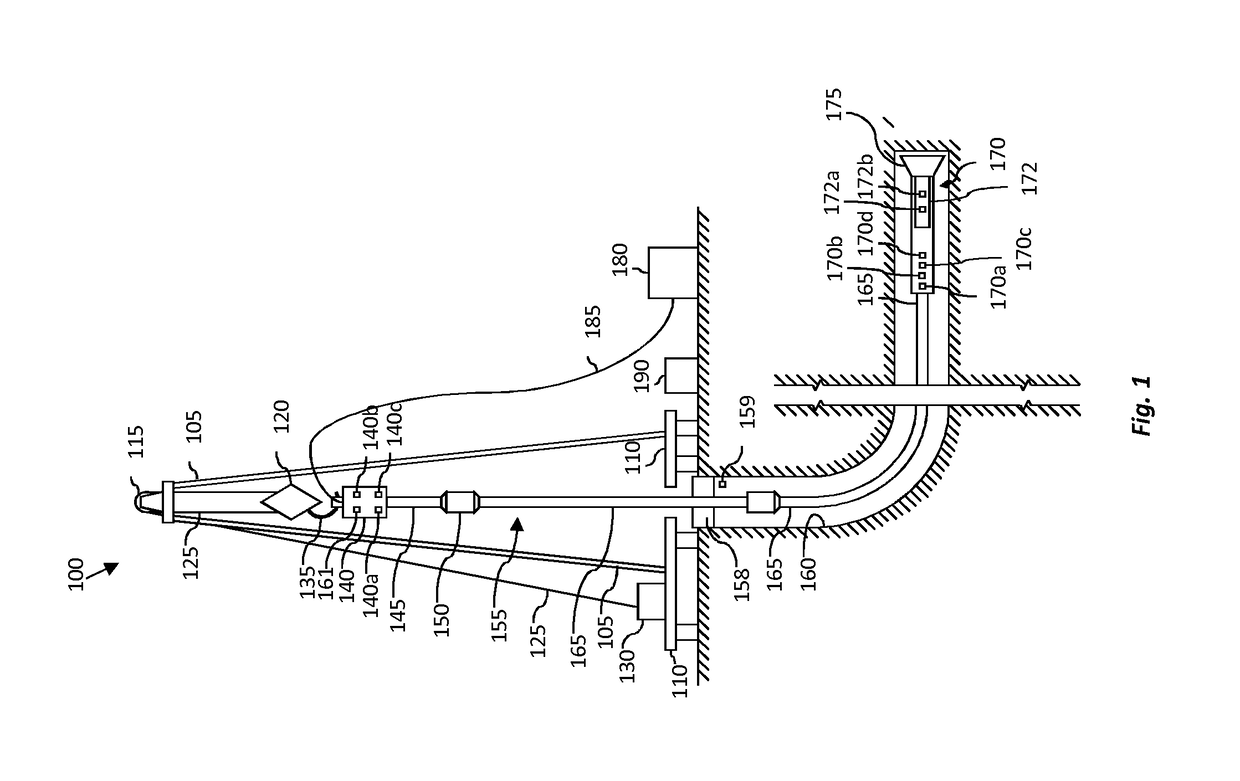

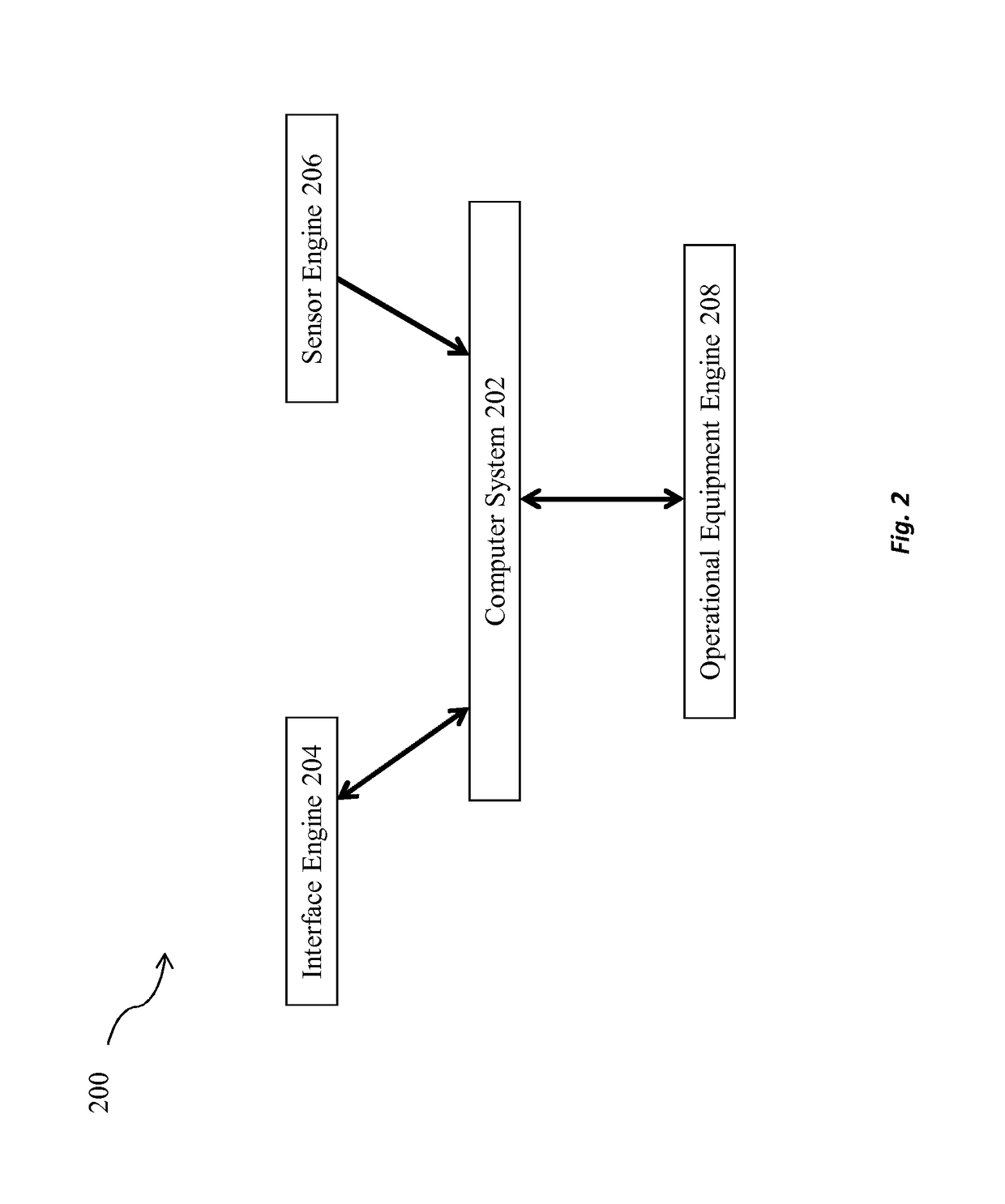

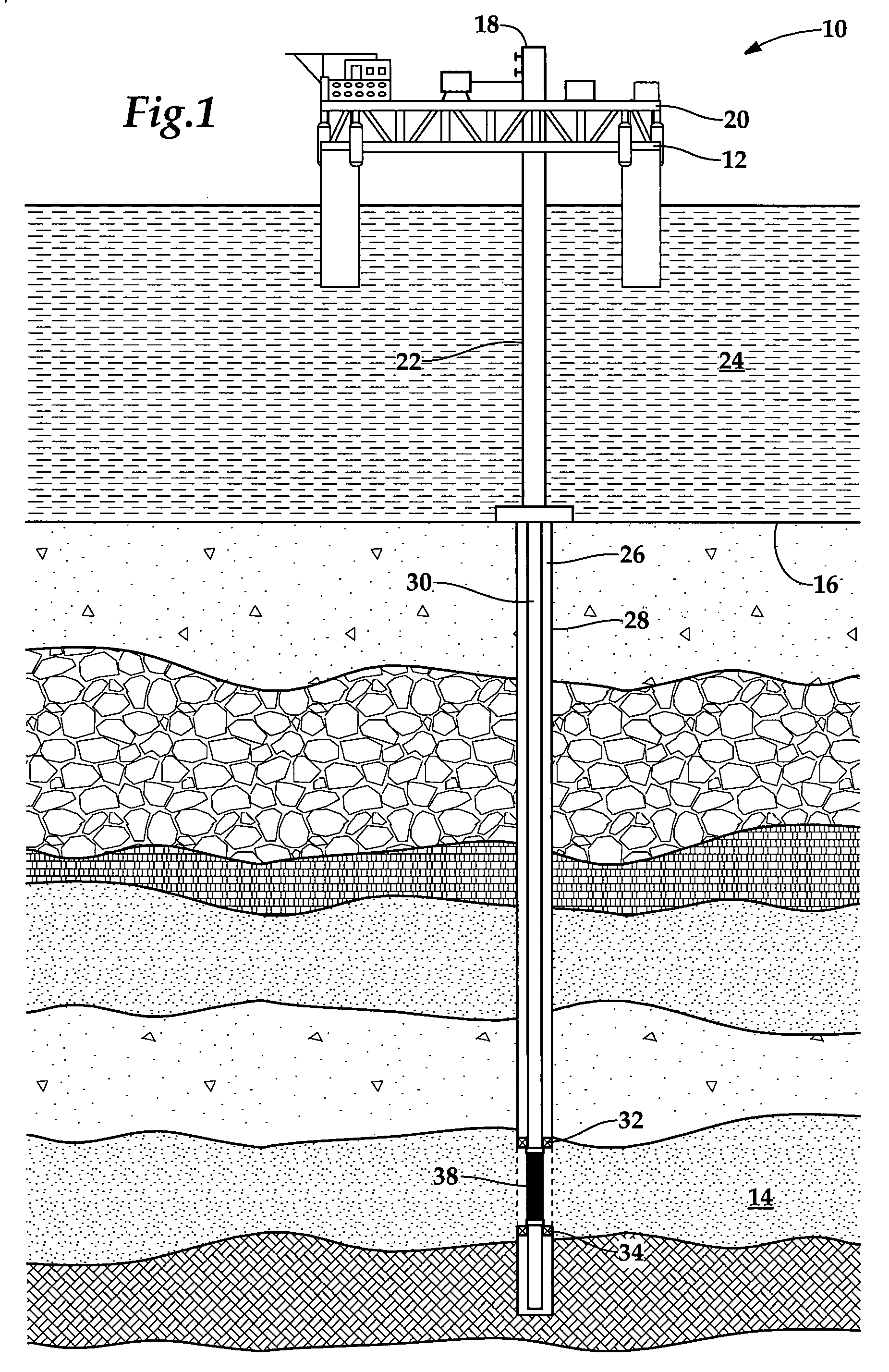

Automated control of toolface while slide drilling

Apparatuses, systems, and methods for controlling slide drilling on a drilling rig are described. The methods include detecting current differential pressure of a mud motor and / or weight on bit (WOB) at a surface of a borehole, predicting current reactive torque of the mud motor based on the current differential pressure and / or WOB, and automatically adjusting surface torque and / or angular offset of a tubular adjacent the surface to counteract the current reactive torque and to keep the mud motor at a desired toolface orientation in the borehole.

Owner:NABORS DRILLING TECH USA INC

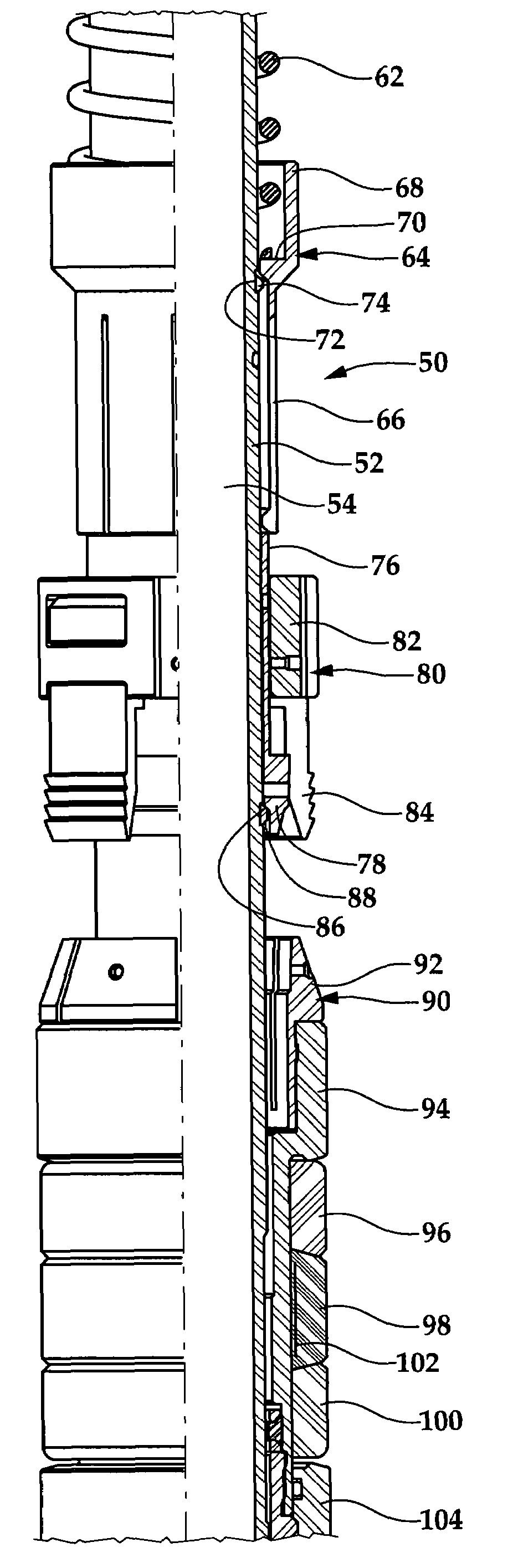

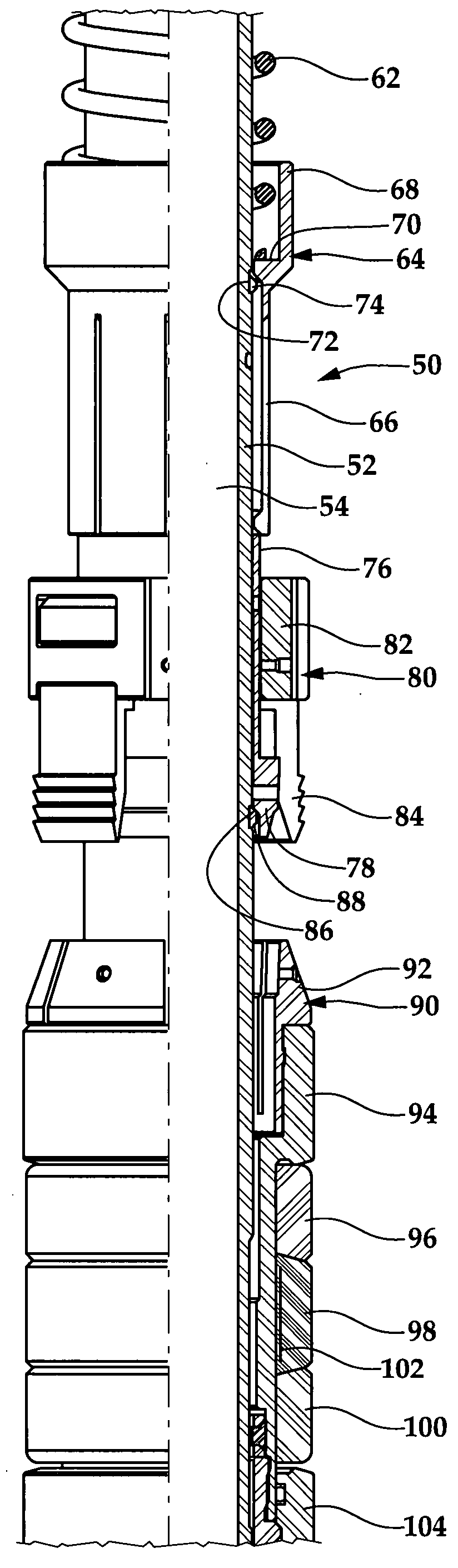

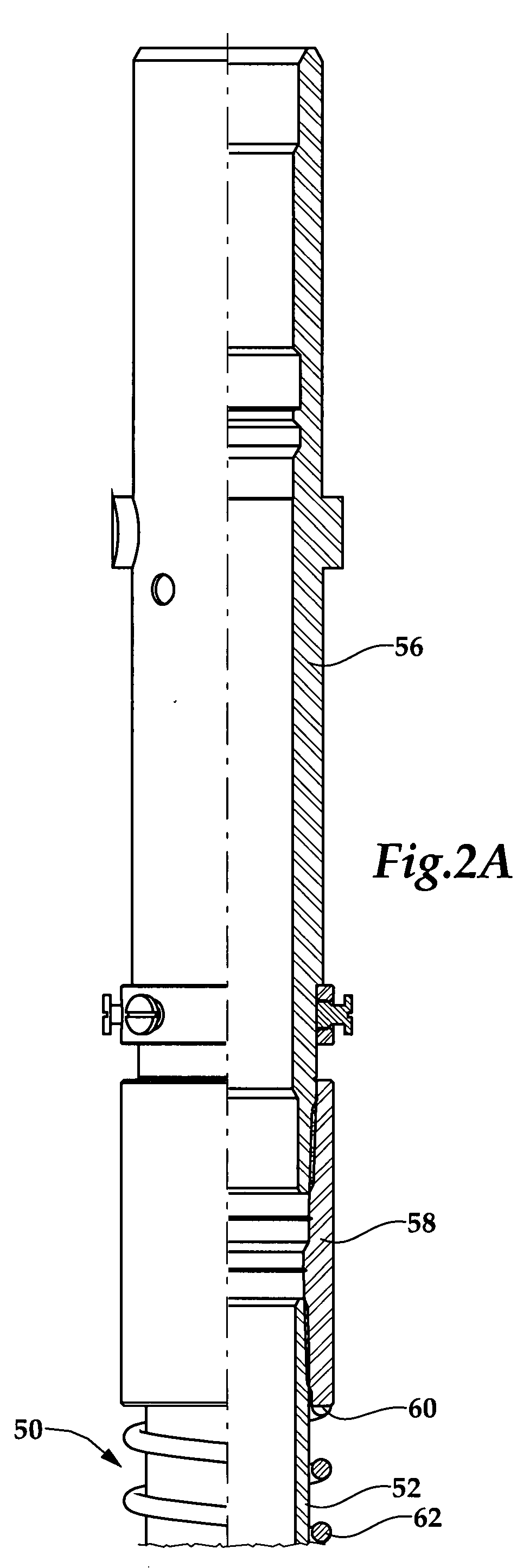

Downhole seal assembly having embedded sensors and method for use of same

A downhole seal (50) includes an elastomeric element (98) operably to provide a seal between two downhole components. A strain sensor (102) is embedded in the elastomeric element (98). The strain sensor (102) has a mechanical flexibility that is substantially matched to the mechanical flexibility of the elastomeric element (98). The strain sensor (102) is operably connected to circuitry that is operable to identify changes in a property of the strain sensor (98) indicative of the strain being experienced by the strain sensor (98), which is representative of the strain experienced by the elastomeric element (98).

Owner:HALLIBURTON ENERGY SERVICES INC

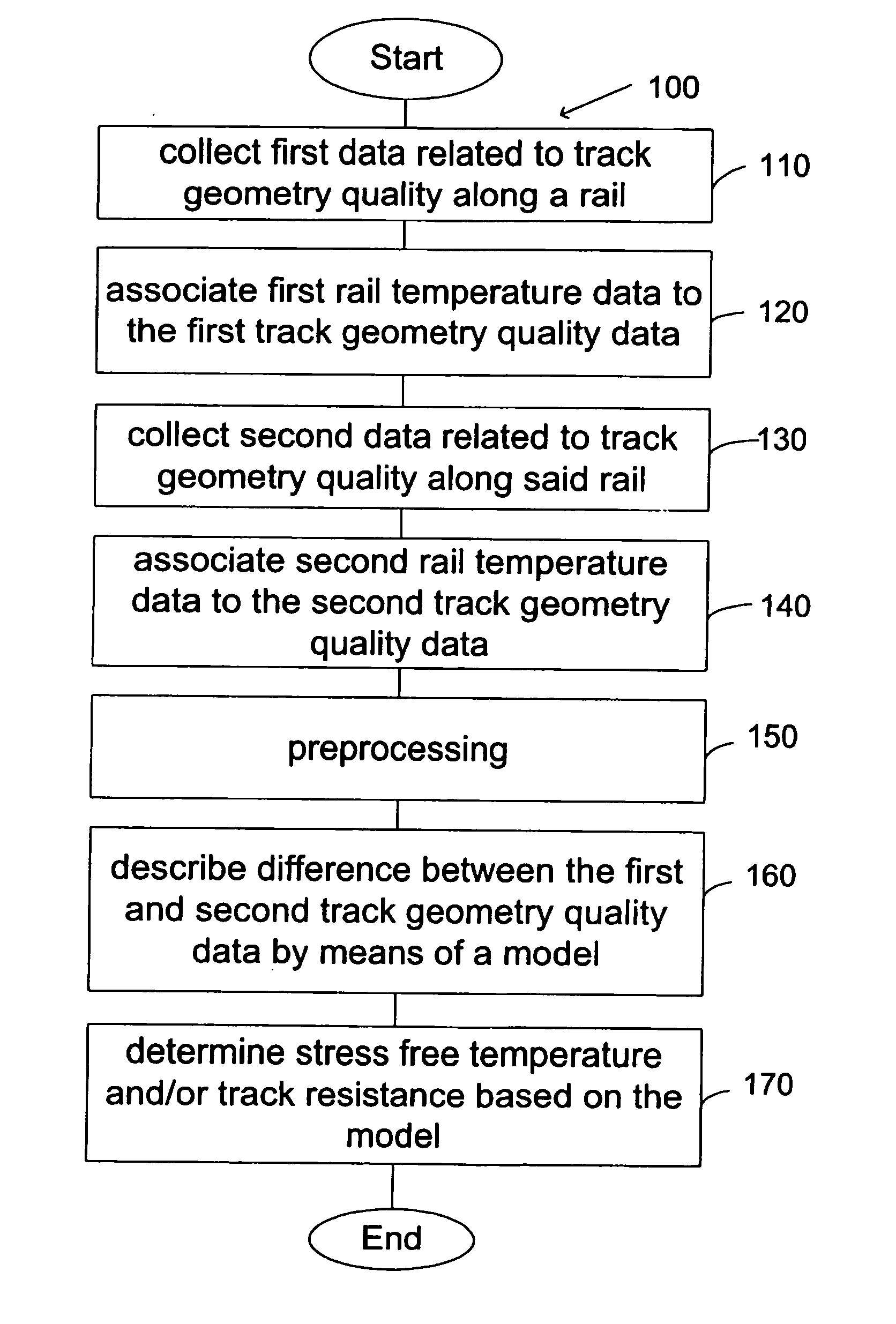

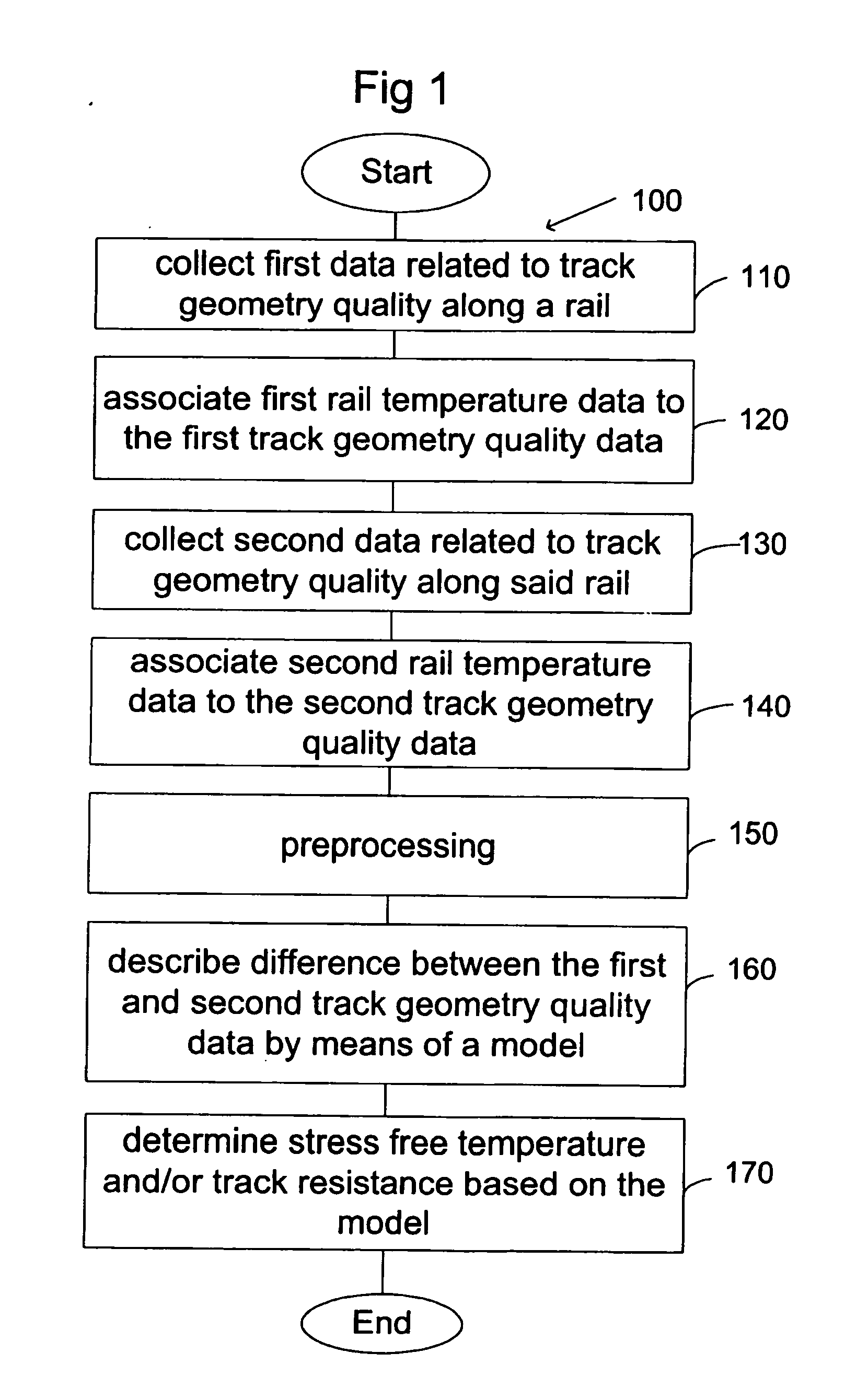

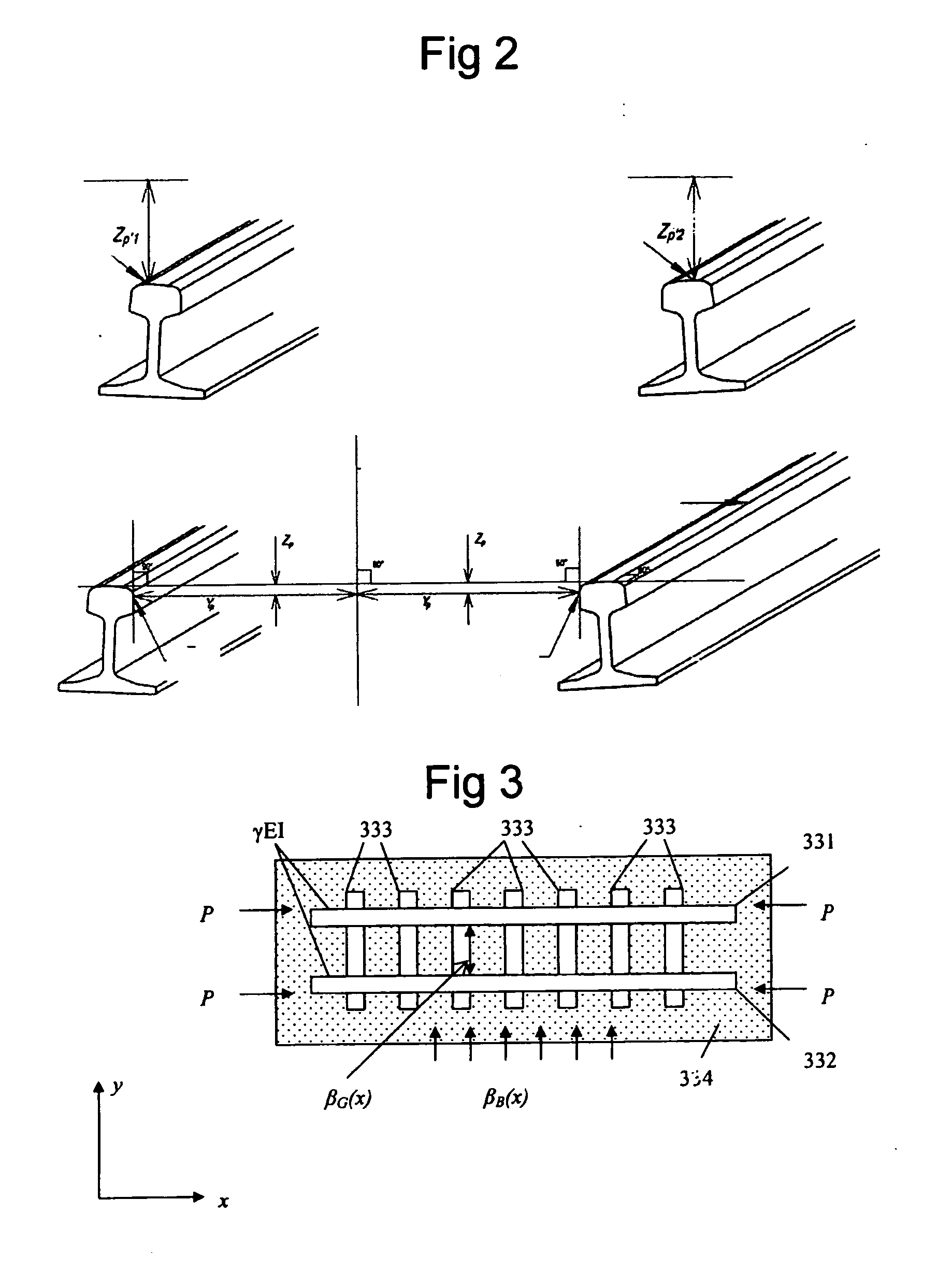

Method for determining the stress free temperature of the rail and/or the track resistance

InactiveUS20120245908A1Way of increaseComputation using non-denominational number representationMeasuring apparatusQuality dataEngineering

A method and device for determining at least a first parameter of a track. The method includes providing a first track geometry quality data associated to at least one point along a rail at a first temperature, providing a second track geometry quality data associated to at least one point at a second temperature, and describing a difference between the first and second track geometry quality data using a model. The model relates the first and second track geometry quality data with associated temperatures to stress free temperature and / or track resistance, and estimates the stress free temperature and / or track resistance in at least one point based on the model.

Owner:EBER DYNAMICS

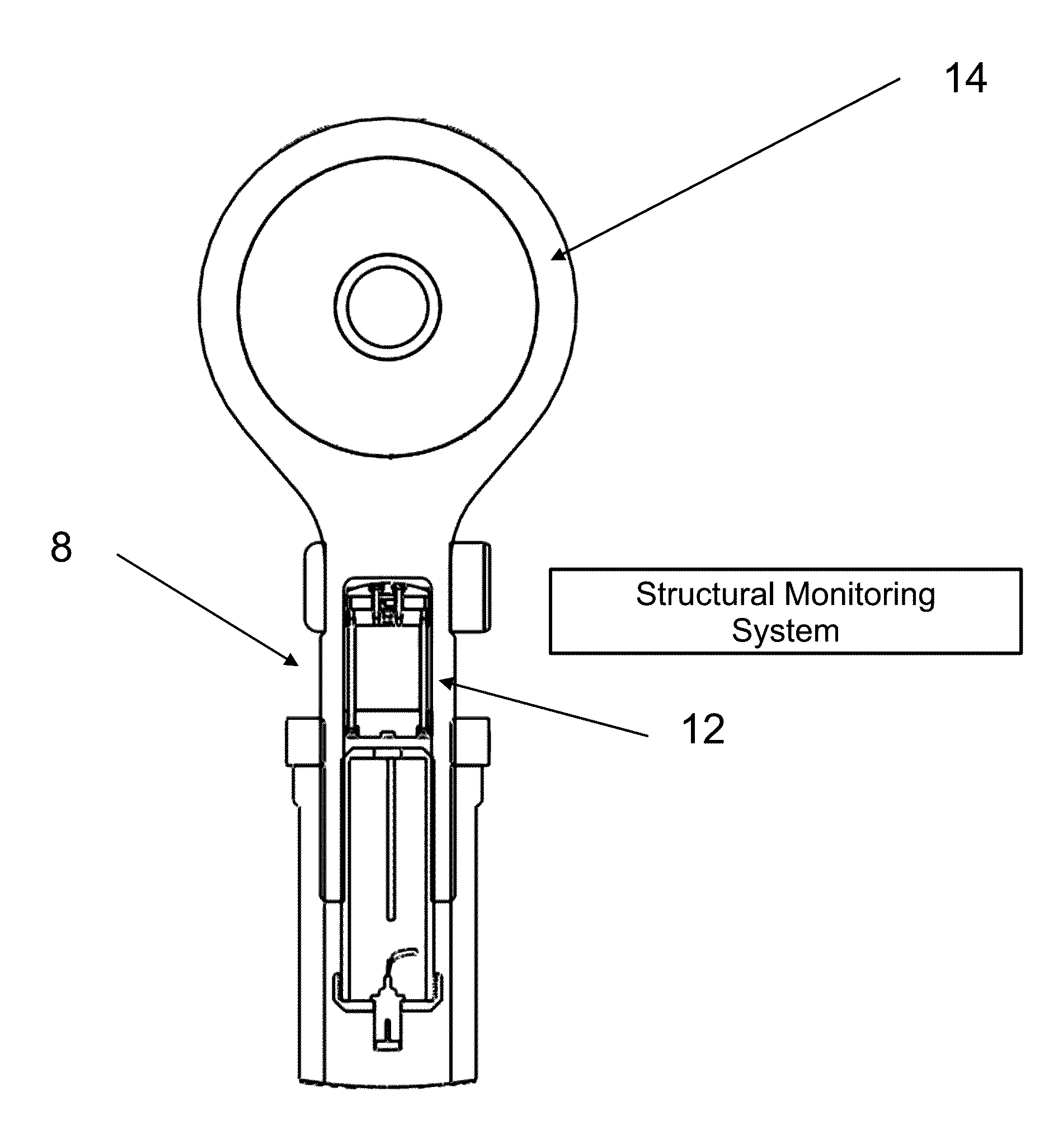

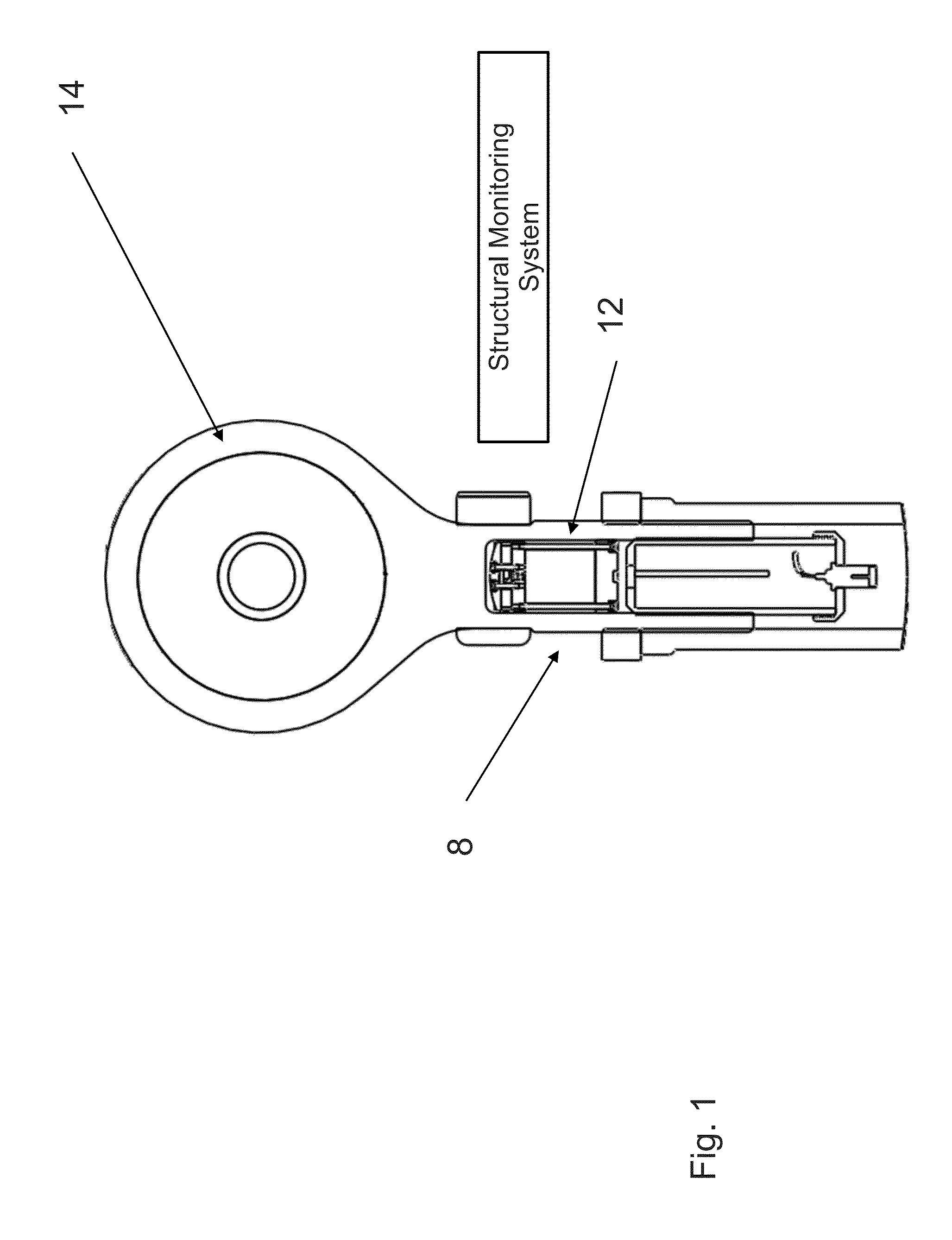

Independently Calibrated Wireless Structural Load Sensor

ActiveUS20090210173A1Testing/calibration apparatusMeasurement of torque/twisting force while tighteningStructural loadElectronic circuit

A device includes a removable load element. The removable load element includes a pin portion and a housing portion. The pin portion extends from the housing portion. The pin portion includes a sensor. The housing portion includes an electronic circuit connected to the sensor.

Owner:LORD CORP

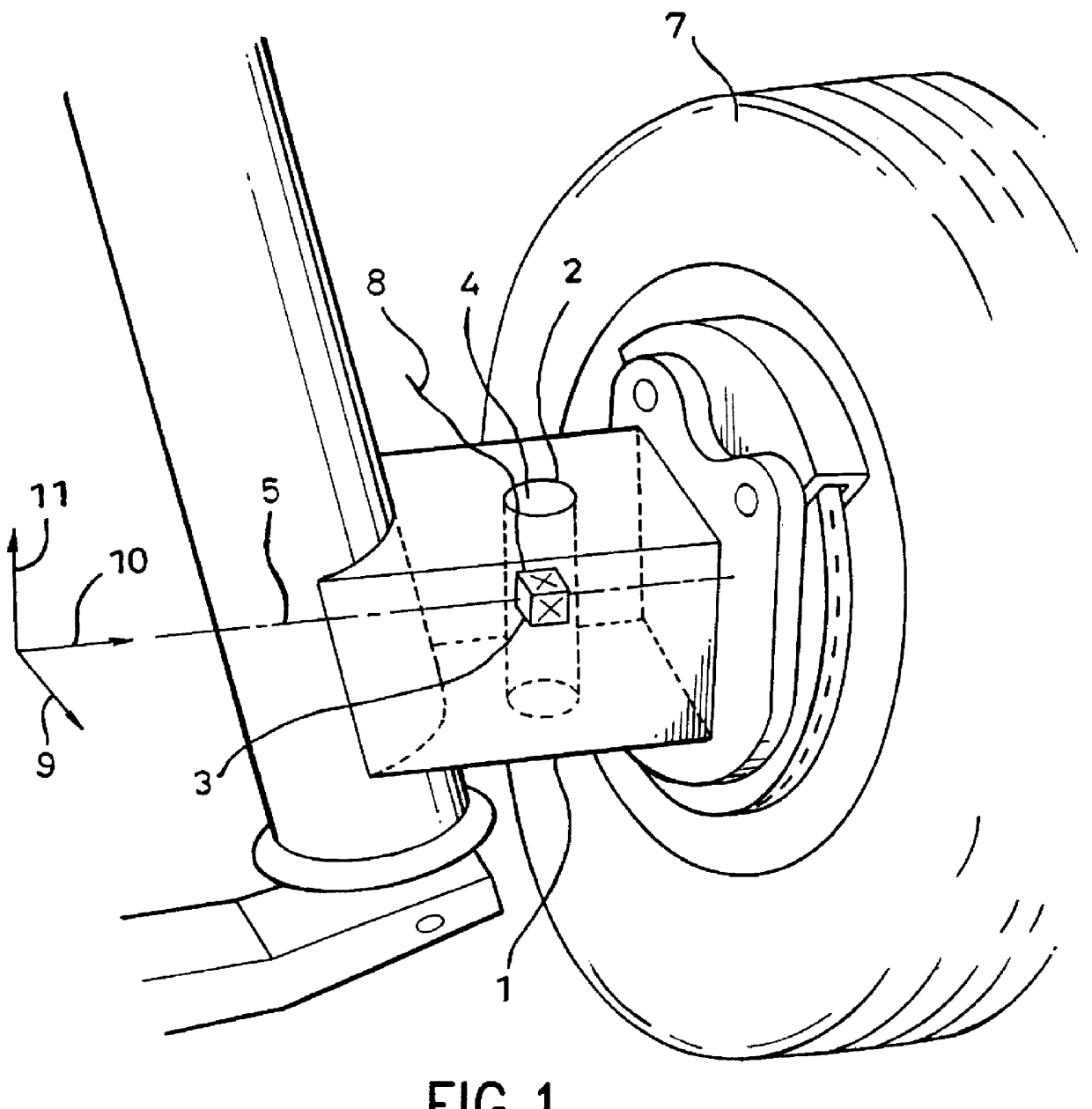

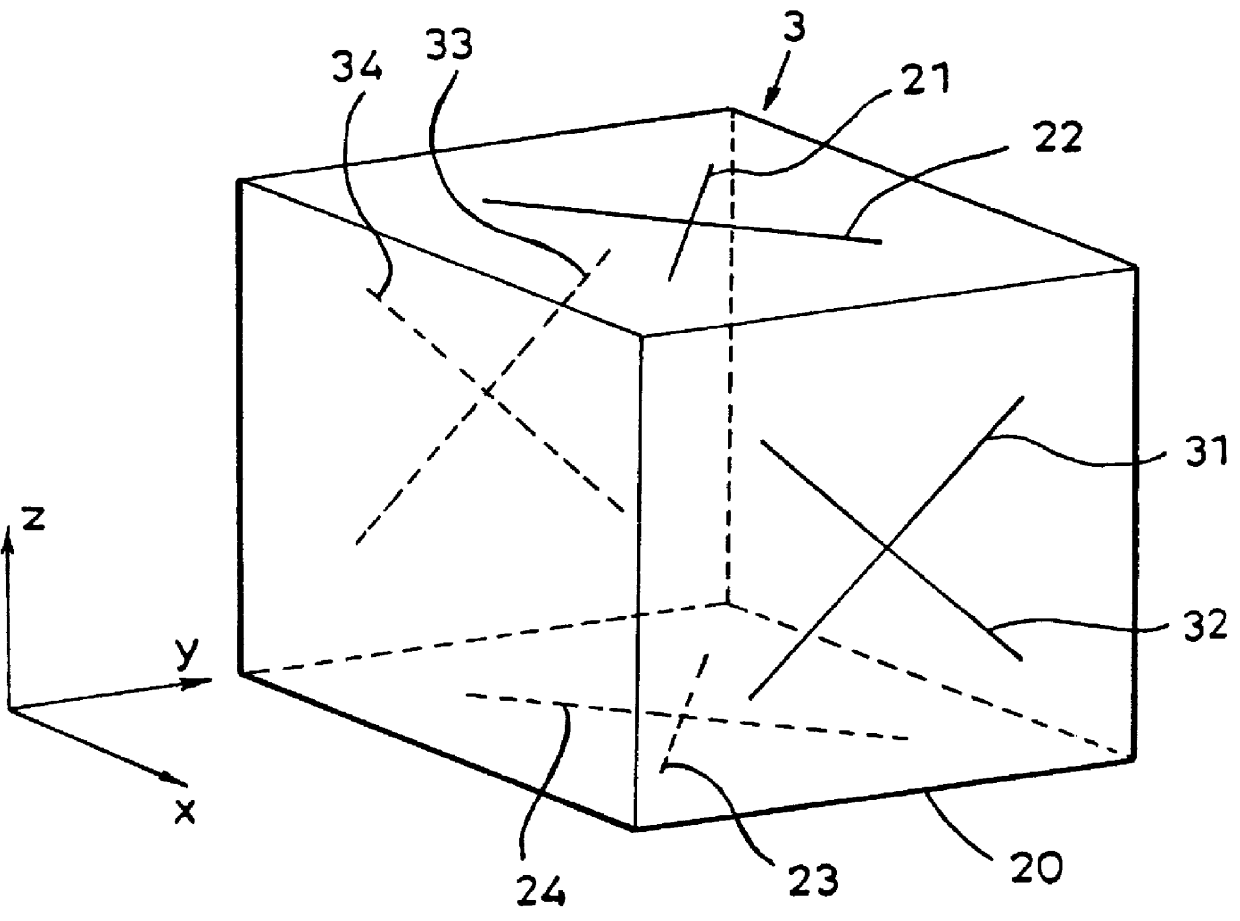

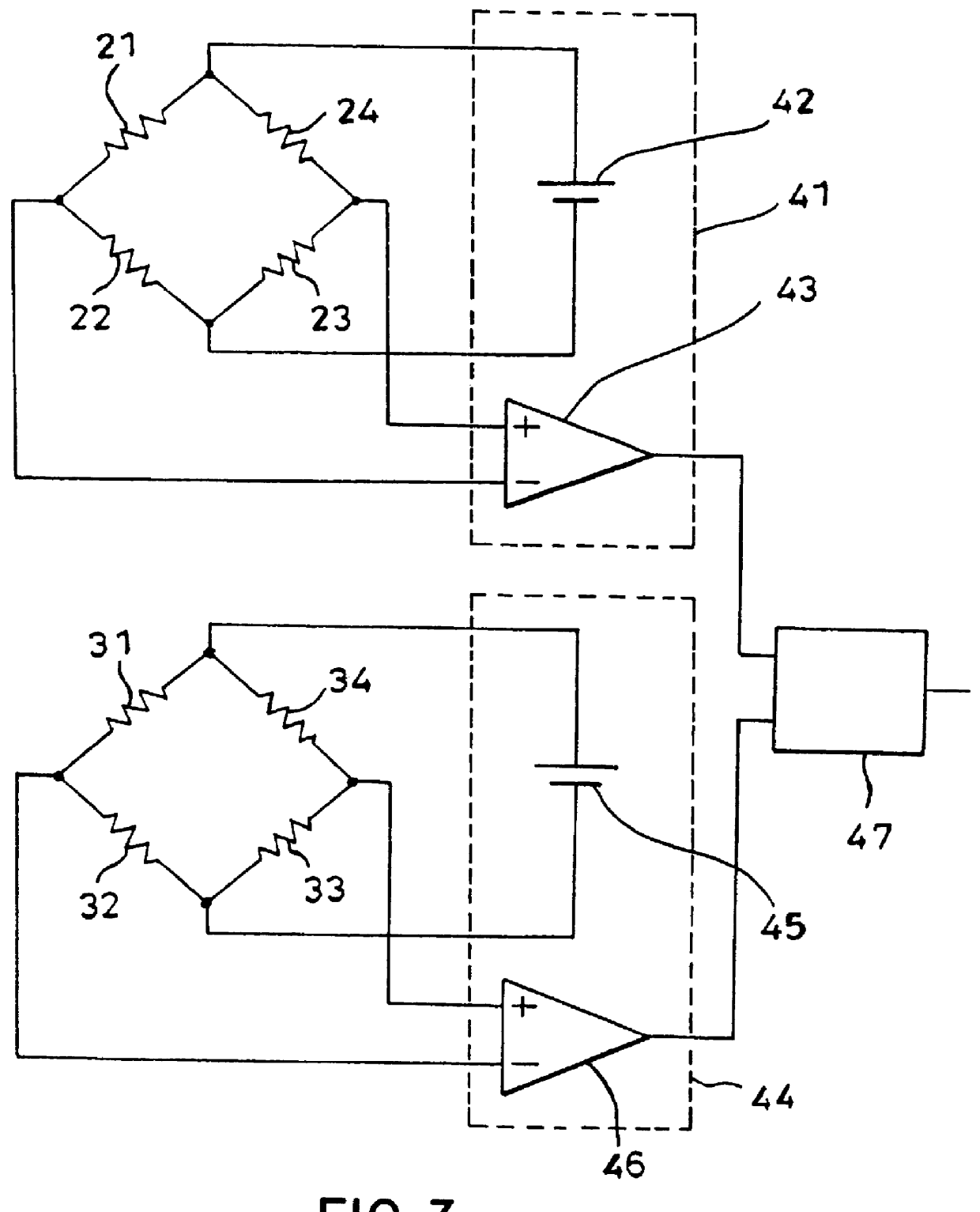

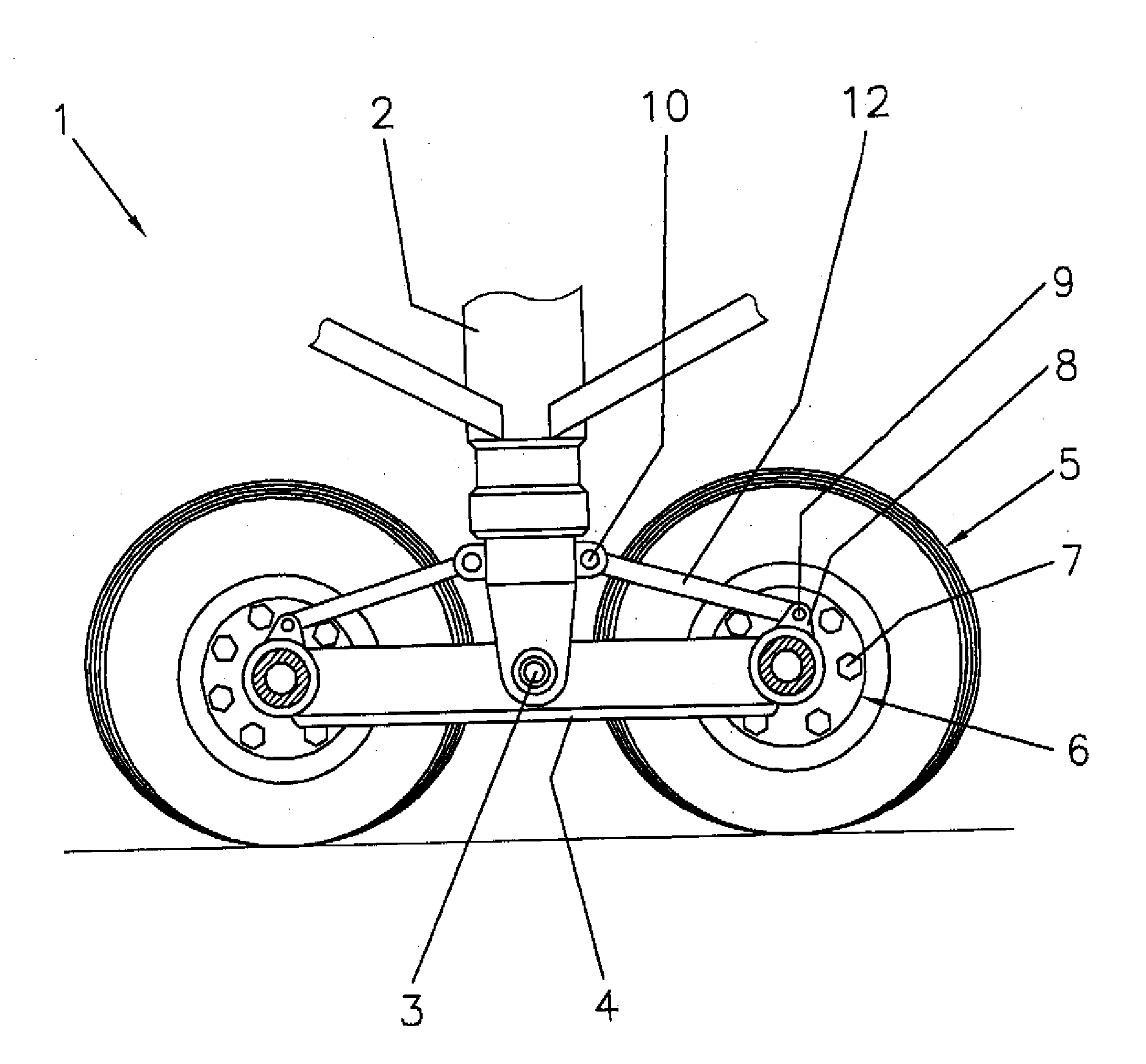

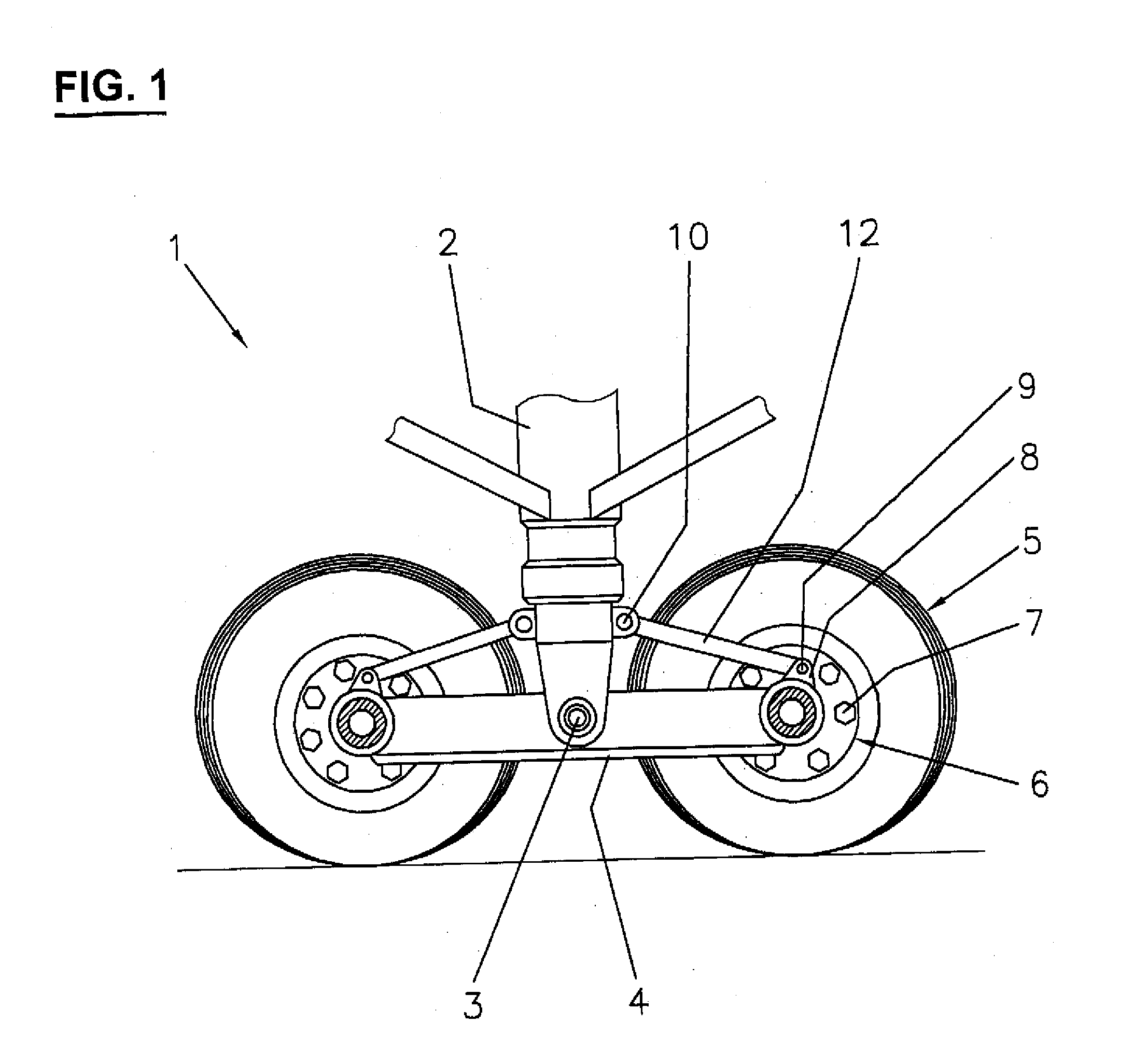

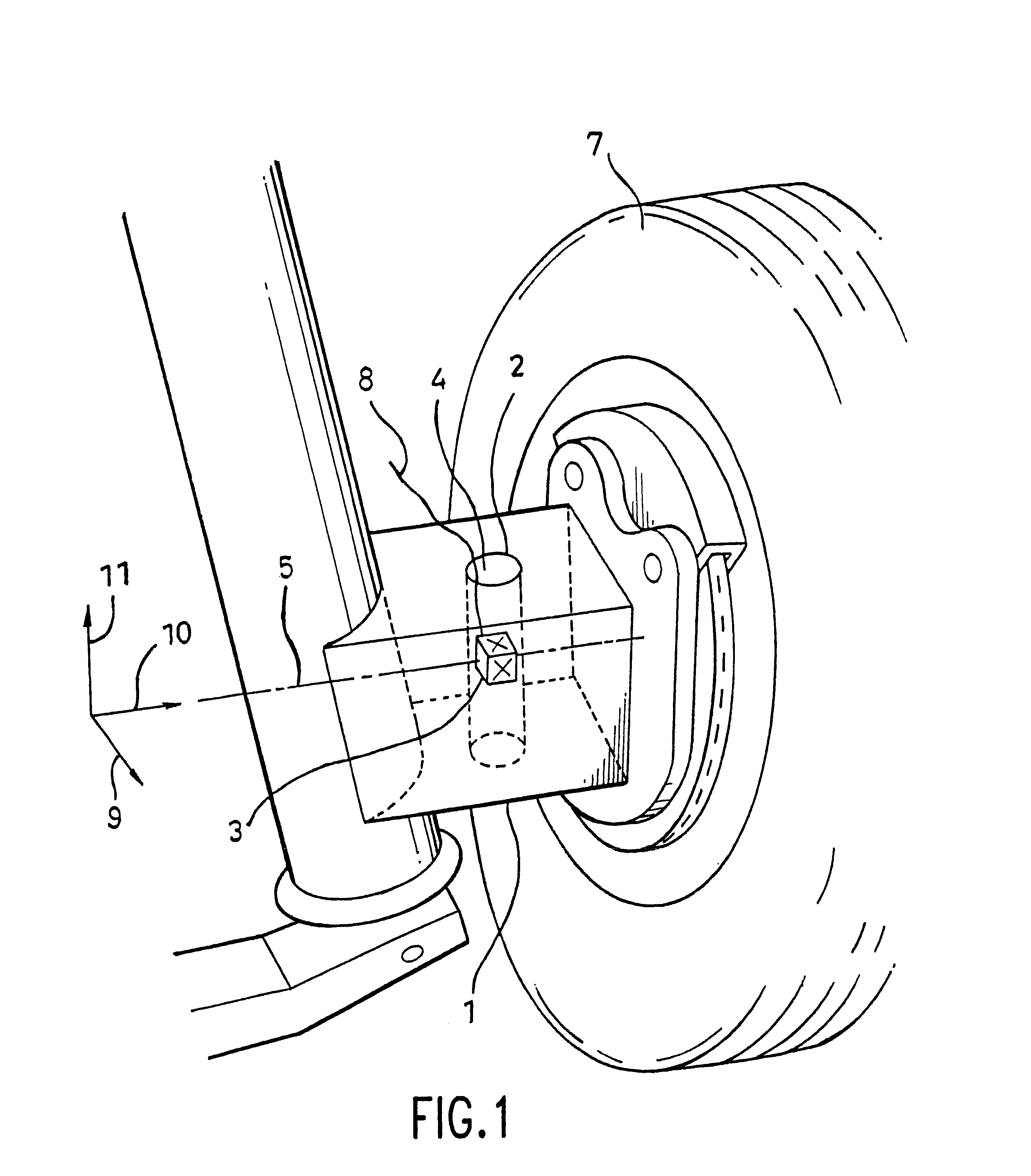

Device for measuring action force of wheel and device for measuring stress of structure

InactiveUS6032520AEasy to measureShorter braking distanceAxially engaging brakesEngine testingSignal processing circuitsTraction control system

Action force of a wheel is measured in order to measure the road surface frictional force, vertical drag, road surface friction coefficient, etc. Means for making these measurements can be constituents of an antilock brake system, traction control system, etc. These constituents may also serve as devices for measuring stresses generated in other structures. In a specific example, axle of a vehicle is formed with a hole, a stress detection sensor is installed in the hole and secured in position with the aid of a spacer element, and a detection signal from the stress detection sensor is processed in a signal processing circuit.

Owner:JAPAN ELECTRONICS IND LTD

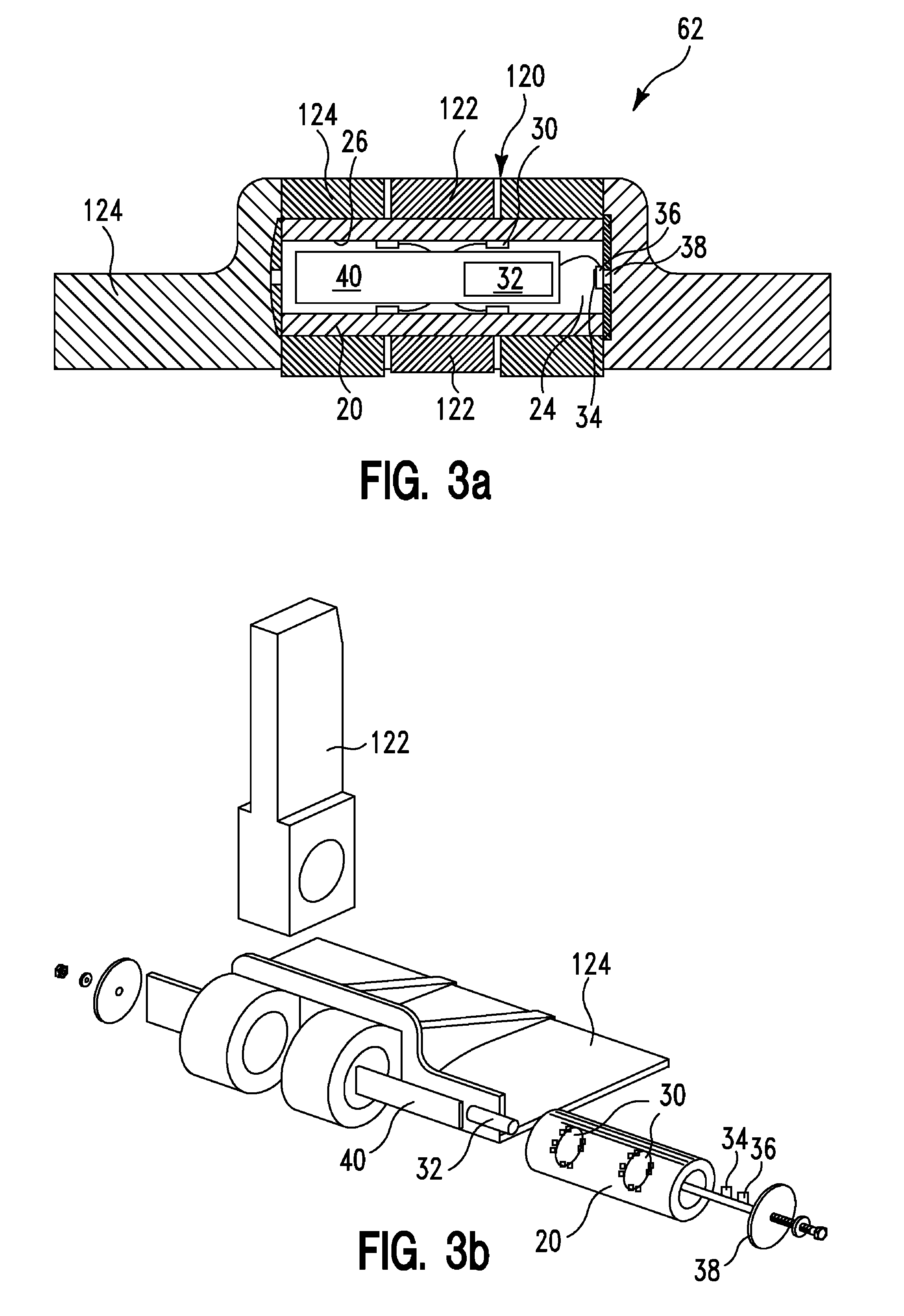

Wheel action force detector for detecting axle forces absent brake torque

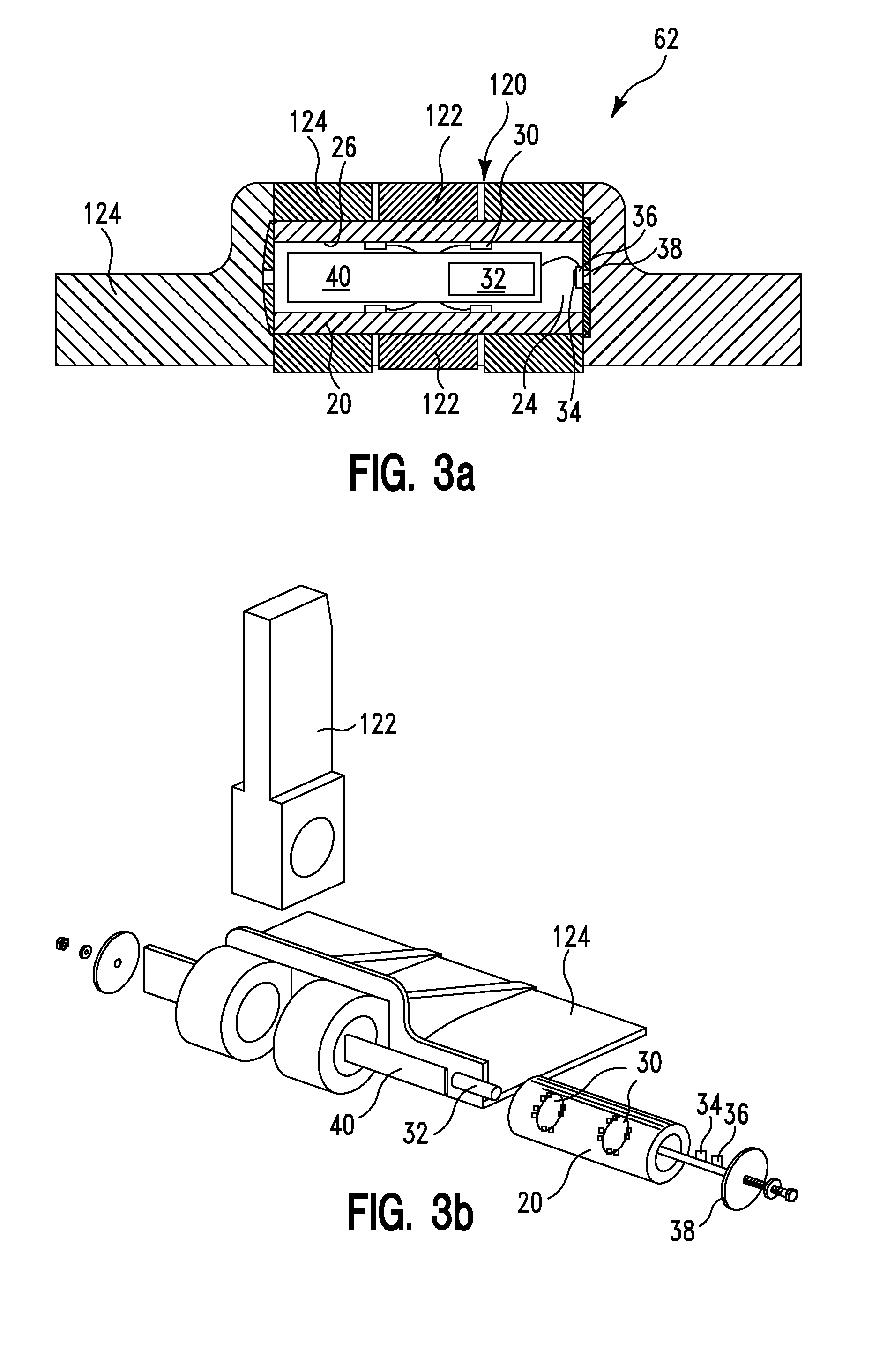

InactiveUS6138505AProtected against external environmentReduce outputAxially engaging brakesRoads maintainenceBrake torqueSignal processing circuits

Owner:MIYAZAKI NAGAO

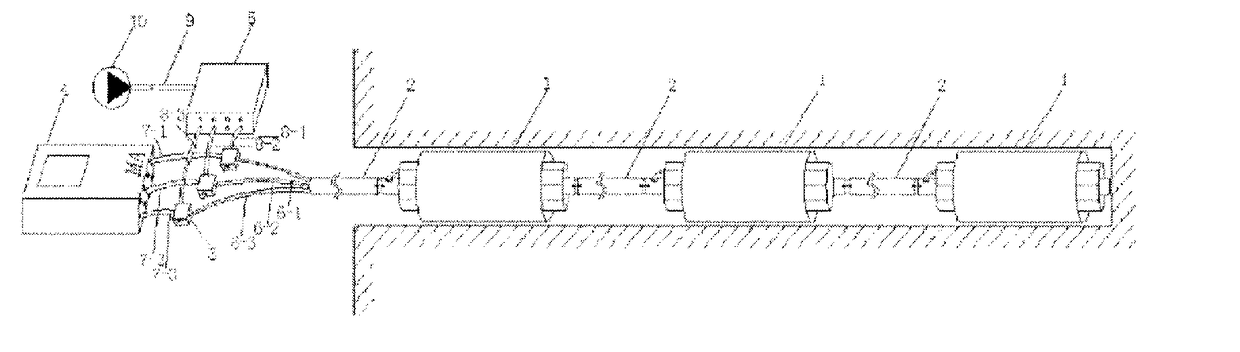

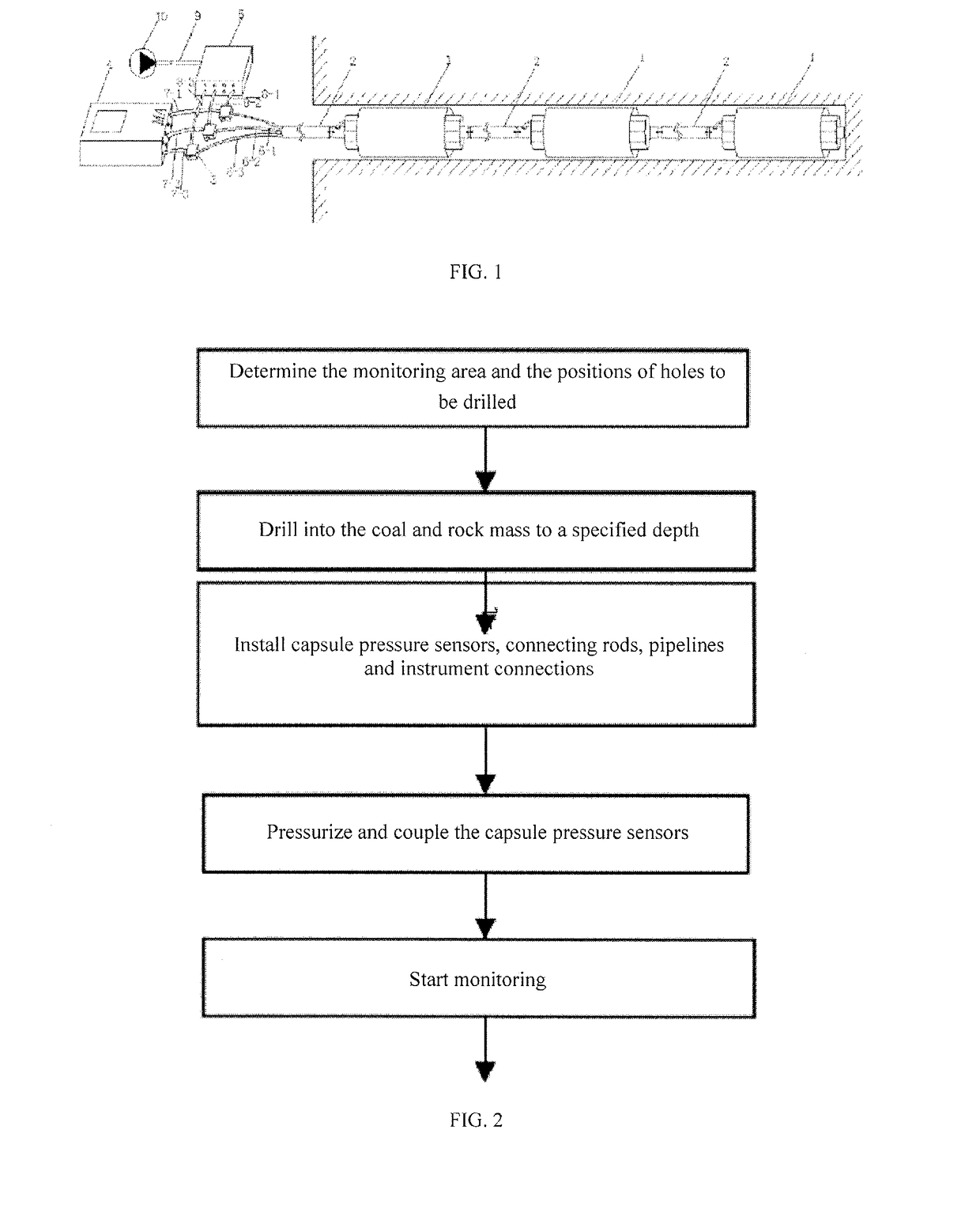

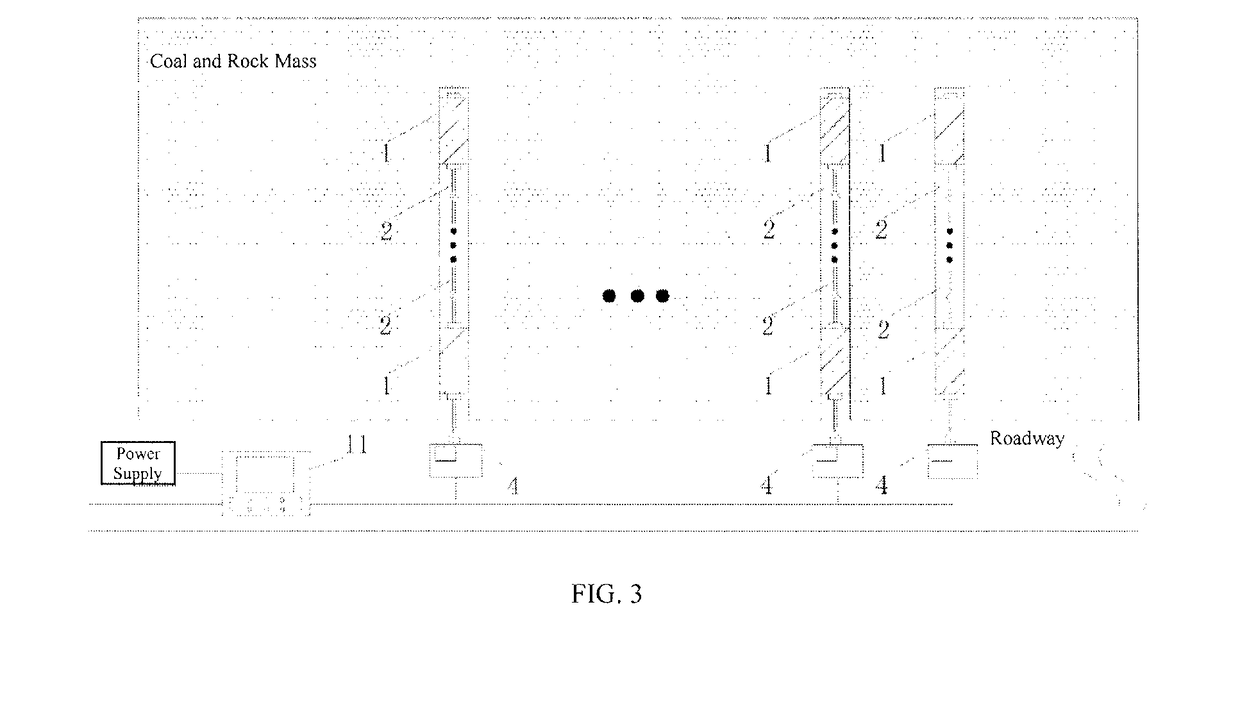

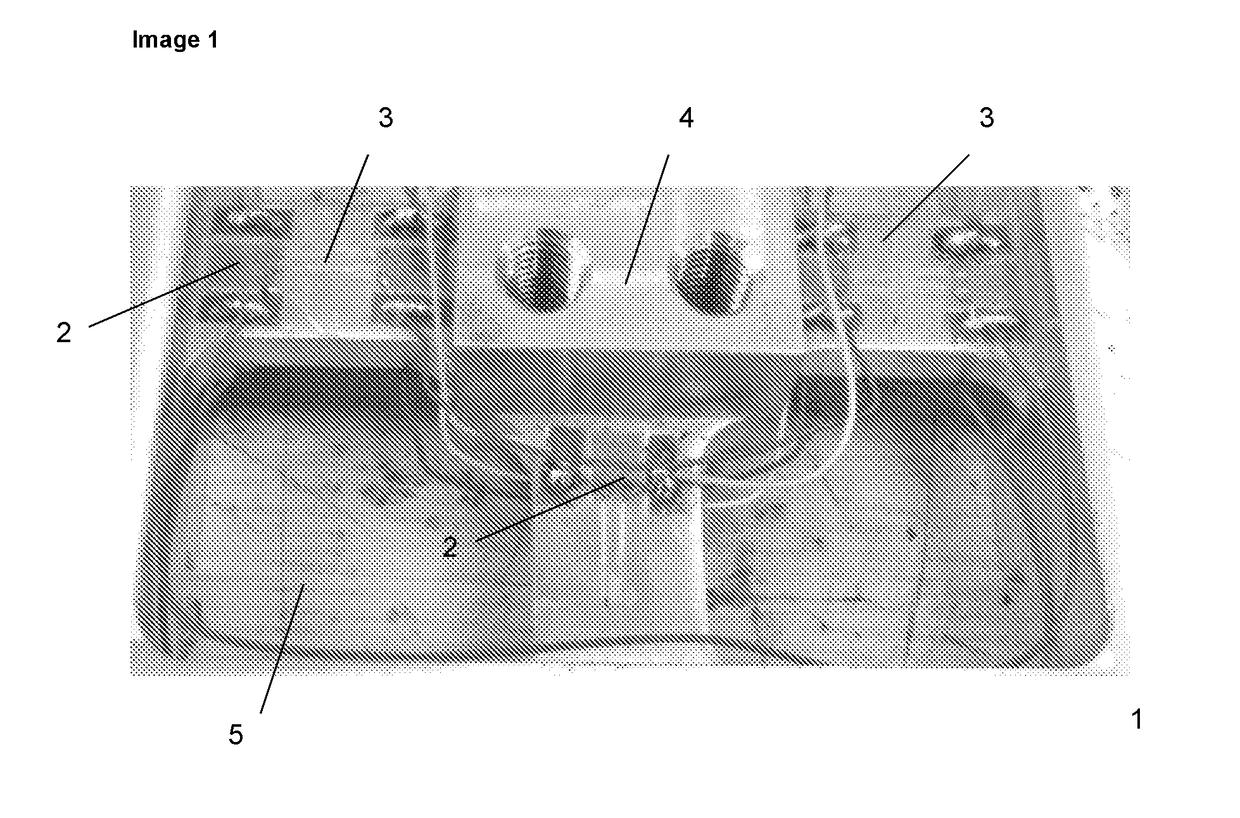

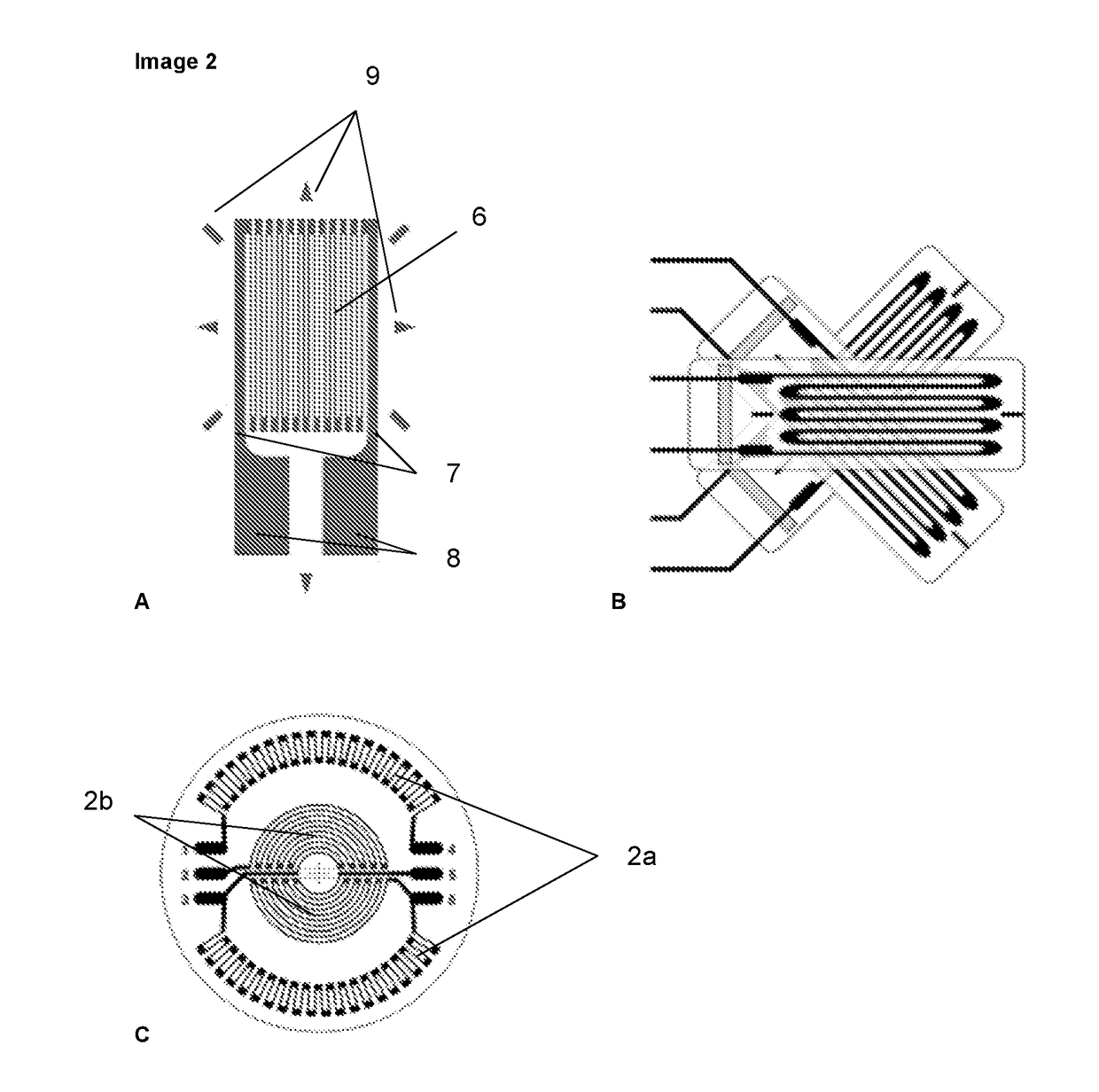

Multipoint Coal and Rock Mass Stress Real-Time Monitoring Device and Method

ActiveUS20170122822A1Improve adaptabilityImprove stabilityMining devicesTesting machinesDisaster monitoringMeasurement point

A multipoint coal and rock mass stress real-time monitoring device. The device is composed of a plurality of capsule pressure sensors (1), connection rods (2), three-way valves (3), a multichannel monitor (4), a multichannel control valve (5), first high-pressure oil pipes (6), second high-pressure oil pipes (7), third high-pressure oil pipes (8), a four high-pressure oil pipe (9), a high-pressure oil pump (10) and monitoring substations (11). The present invention also relates to a multipoint coal and rock mass stress real-time monitoring method. Oil is injected into each capsule pressure sensor (1) that is arranged in a drilled hole through the multi-channel control valve (5), so that oil pressure inside each capsule pressure sensor (1) reaches the preset pressure, and the capsule pressure sensors and the coal and rock mass are well coupled; monitoring signals are synchronously collected, converted, stored and displayed by the multichannel monitor (4) or are transferred to a remote monitoring center through the monitoring substations (11). The device and method can be used for coal and rock dynamic disaster monitoring early warning such as coal and rock mass stress monitoring, mine pressure analysis, rock burst and coal and gas rush, and the stress and changes of the stress of multiple measuring points can be measured at the same time in the multiple drilled holes of the coal and rock mass.

Owner:CHINA UNIV OF MINING & TECH

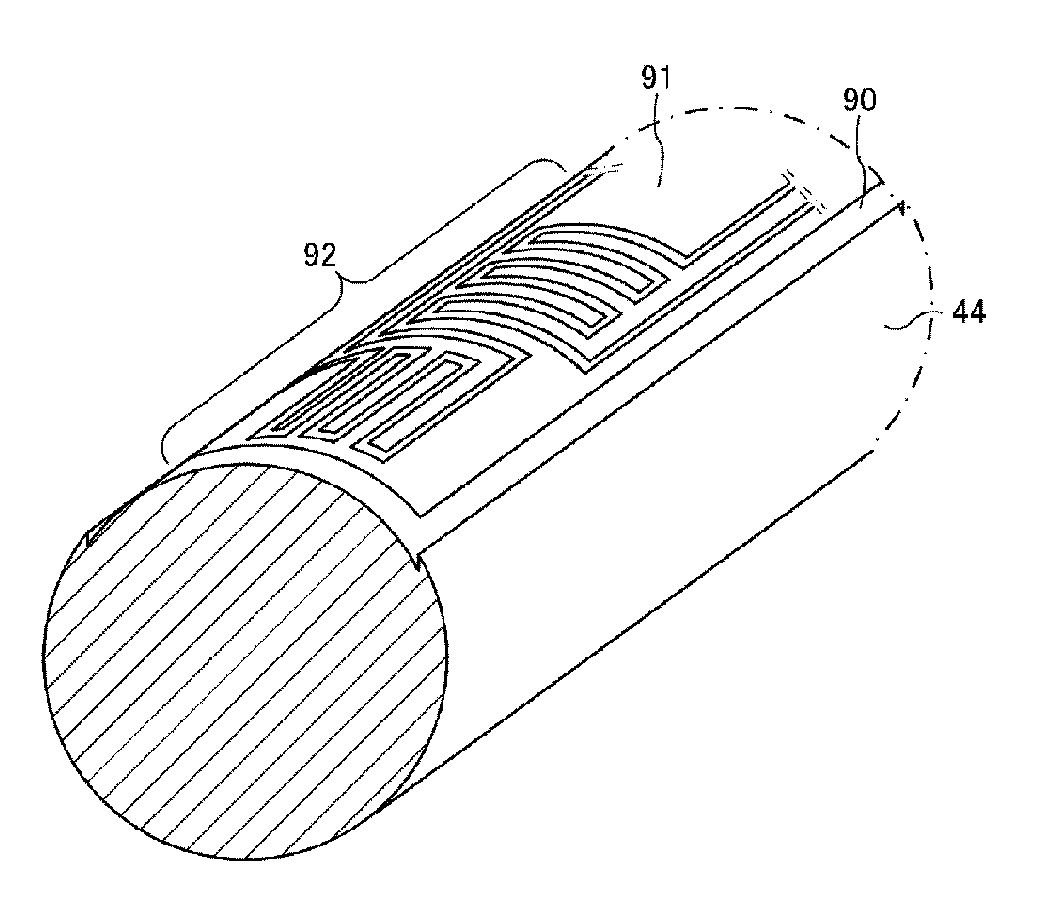

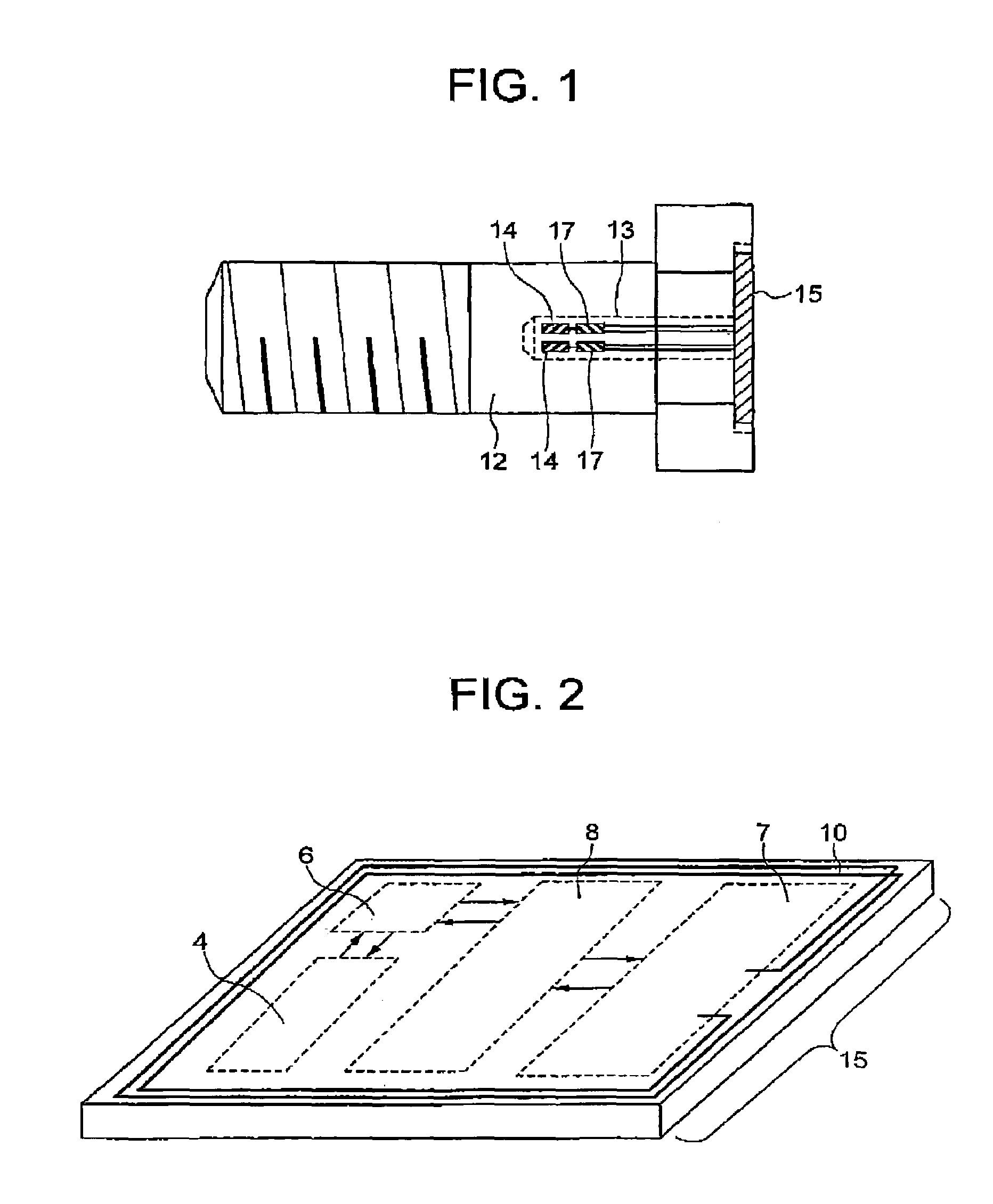

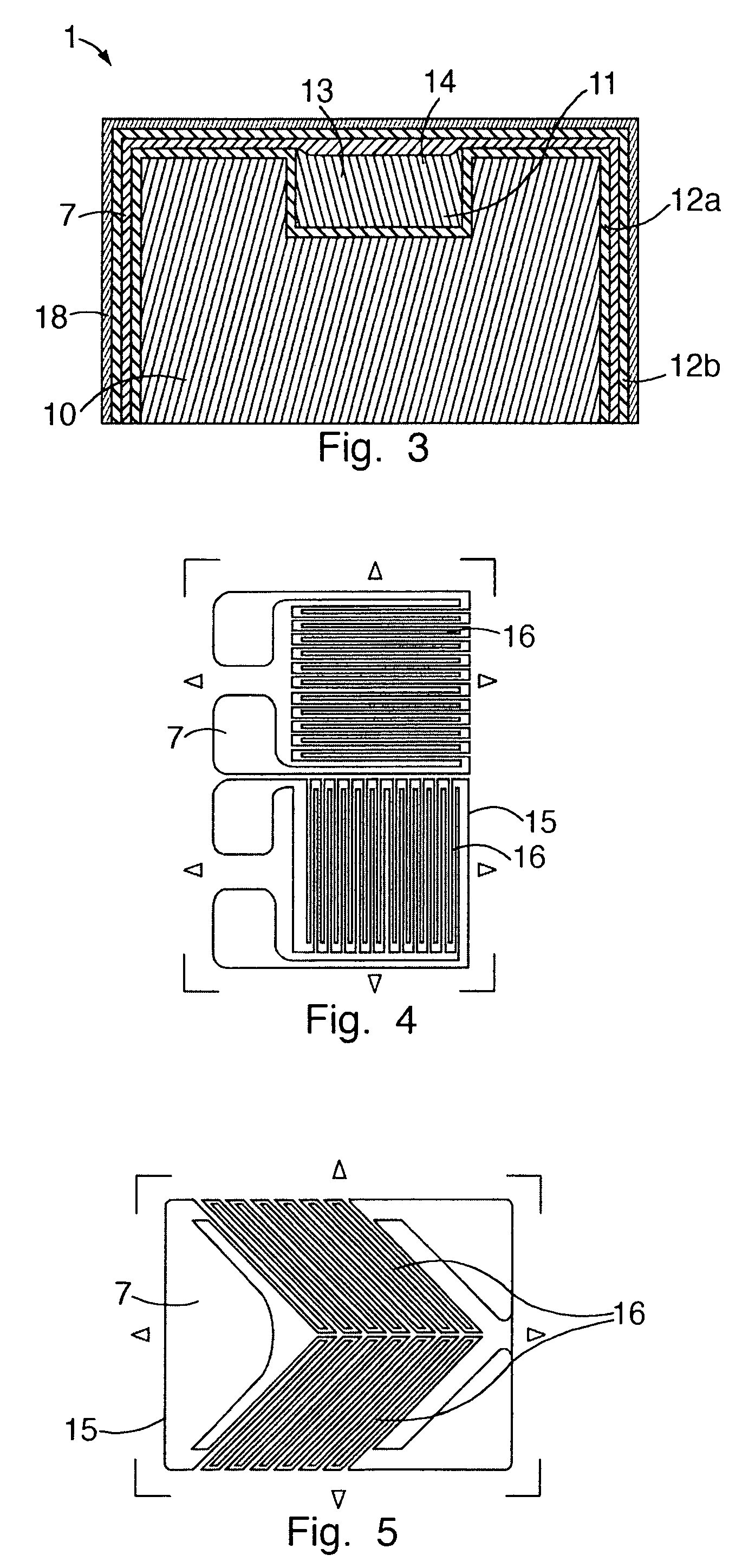

Object having a layer of conducting material forming a sensing device

ActiveUS7766547B2Precise positioningThermometer detailsMeasurement apparatus componentsConductive materialsEngineering

An object comprising a body part having an electrically insulating outer surface part, and a first layer arranged on the outer surface part. The first layer is formed by one or more electrically conducting materials and defines one or more conducting paths between a first area of the outer surface part and a second area of the outer surface part. Thereby electrical signals may be transferred between the first and second area parts. The layer further defines a sensing device, which is thereby embedded into the object. The object is provided with a threaded portion defining an outer thread. Thereby the object may easily be fitted into an opening having a mating inner thread. The object may be in the form of an ordinary bolt with a sensing device embedded in a surface part thereof.

Owner:DANFOSS PAUER SOLYUSHENS APS

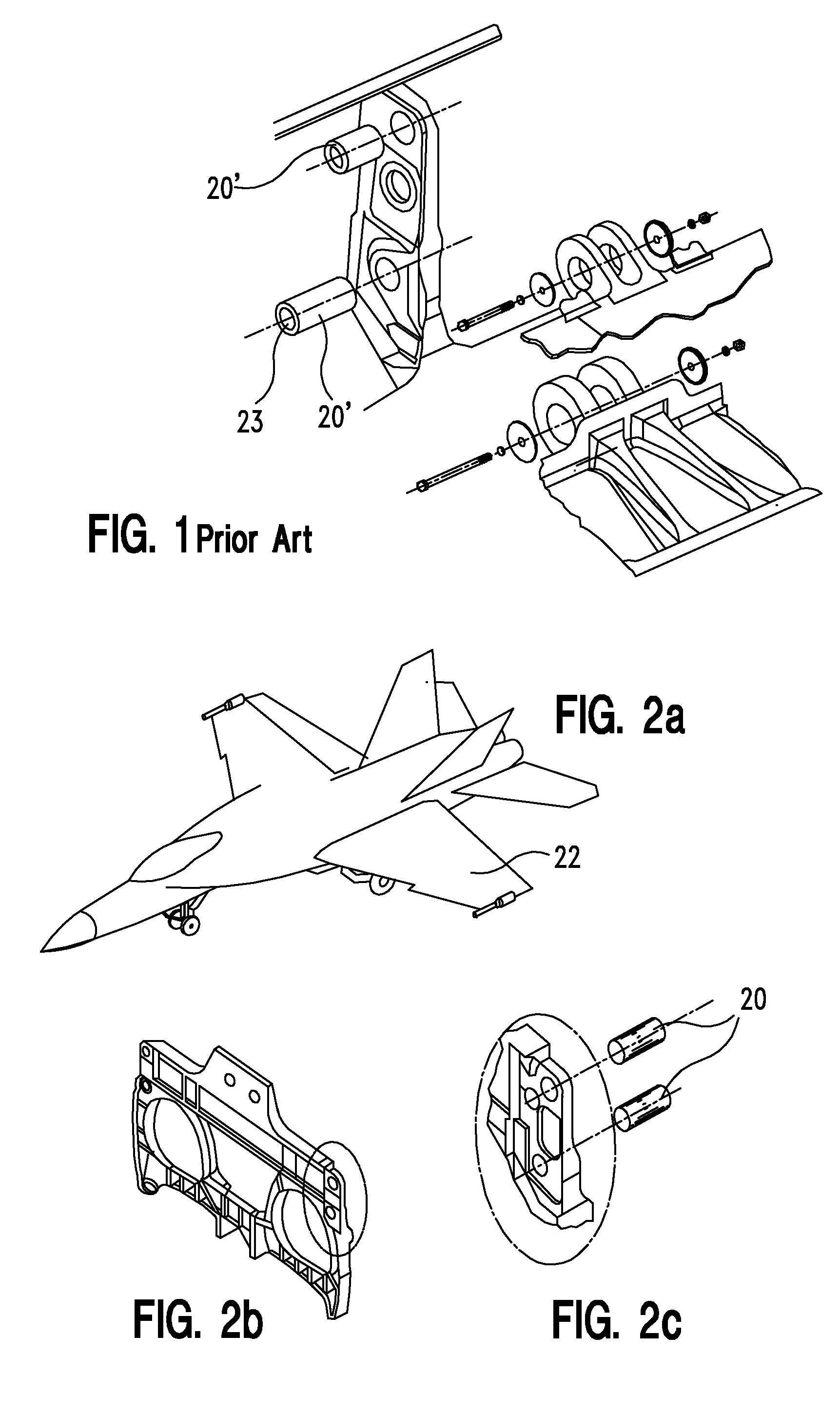

Force-sensing device for vehicle running gears

ActiveUS20070228825A1Force measurement by measuring magnetic property varationUsing electrical meansBrake torqueAircraft landing

In a measuring device for the measurement of forces in a vehicle undercarriage, more particularly of the brake torque on a vehicle undercarriage, e.g. an aircraft landing gear, a sensor is introduced into a hollow connecting element that is transversally loaded by said forces, which sensor produces a measuring signal in function of a deformation of said connecting element. Distance measuring elements which detect the distance of the inner wall of said connecting element from said sensor are used as measuring elements.

Owner:VIBRO METER

Electromechanical force-magnitude, force-angle sensor

Owner:WISCONSIN ALUMNI RES FOUND

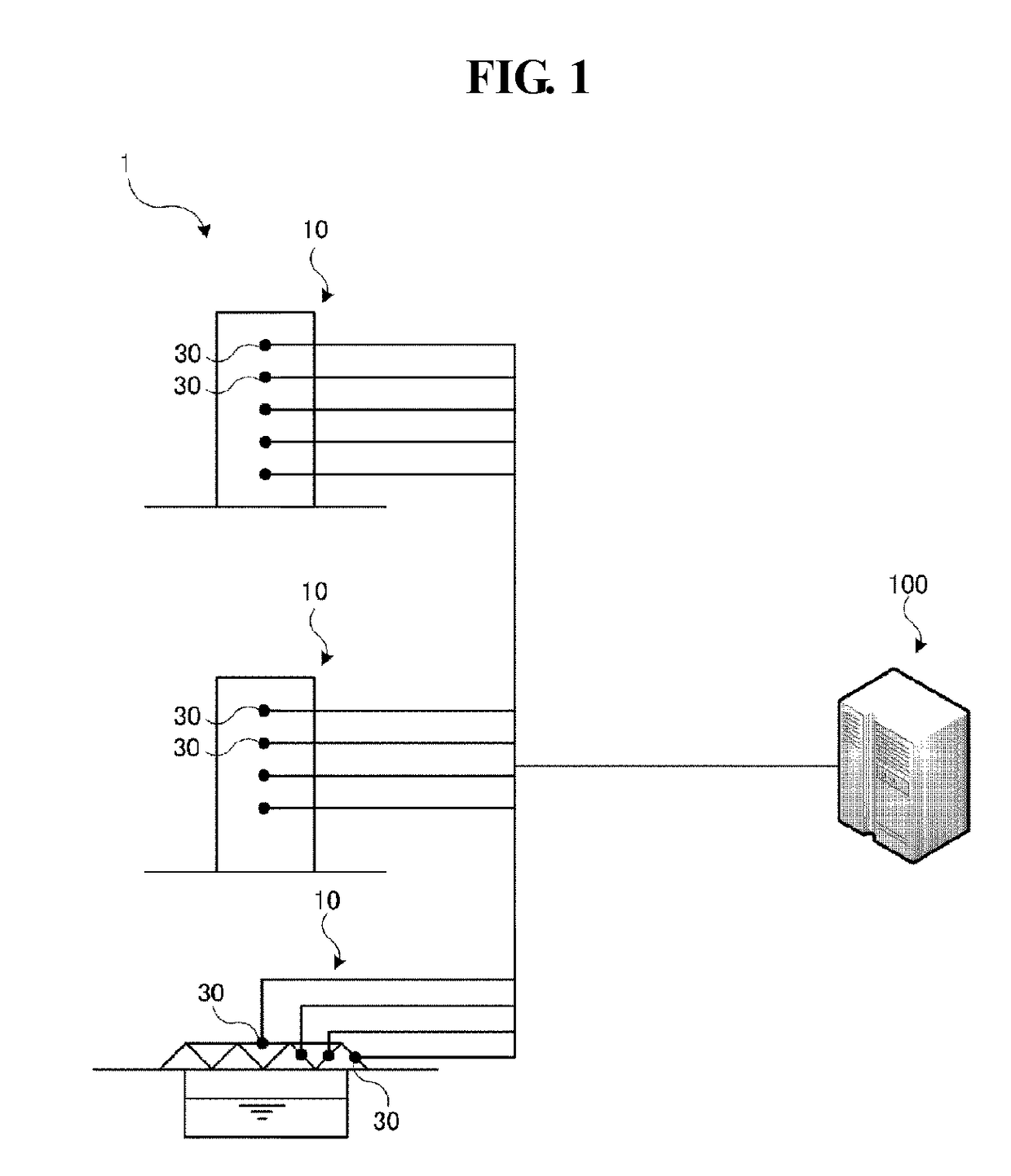

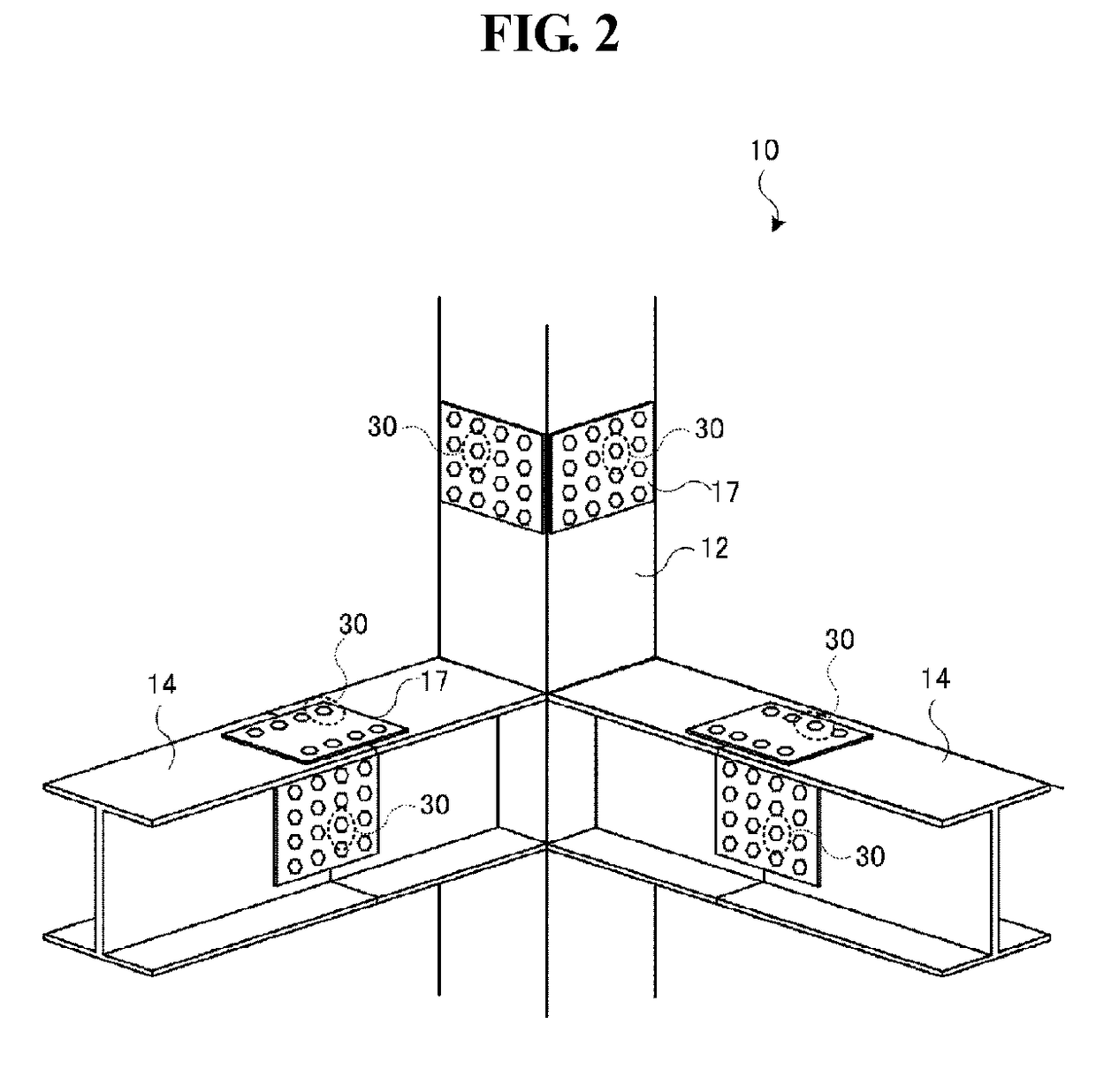

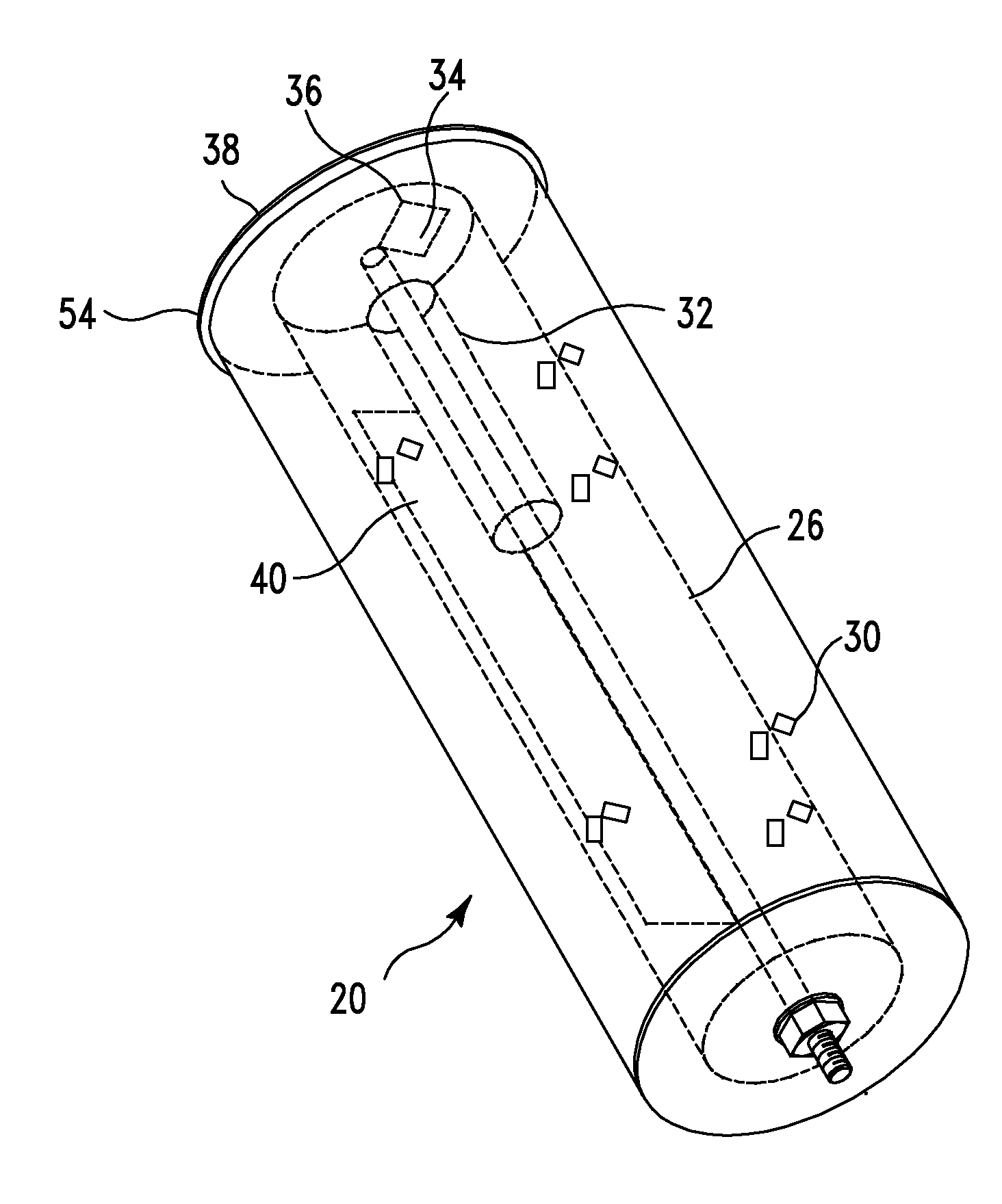

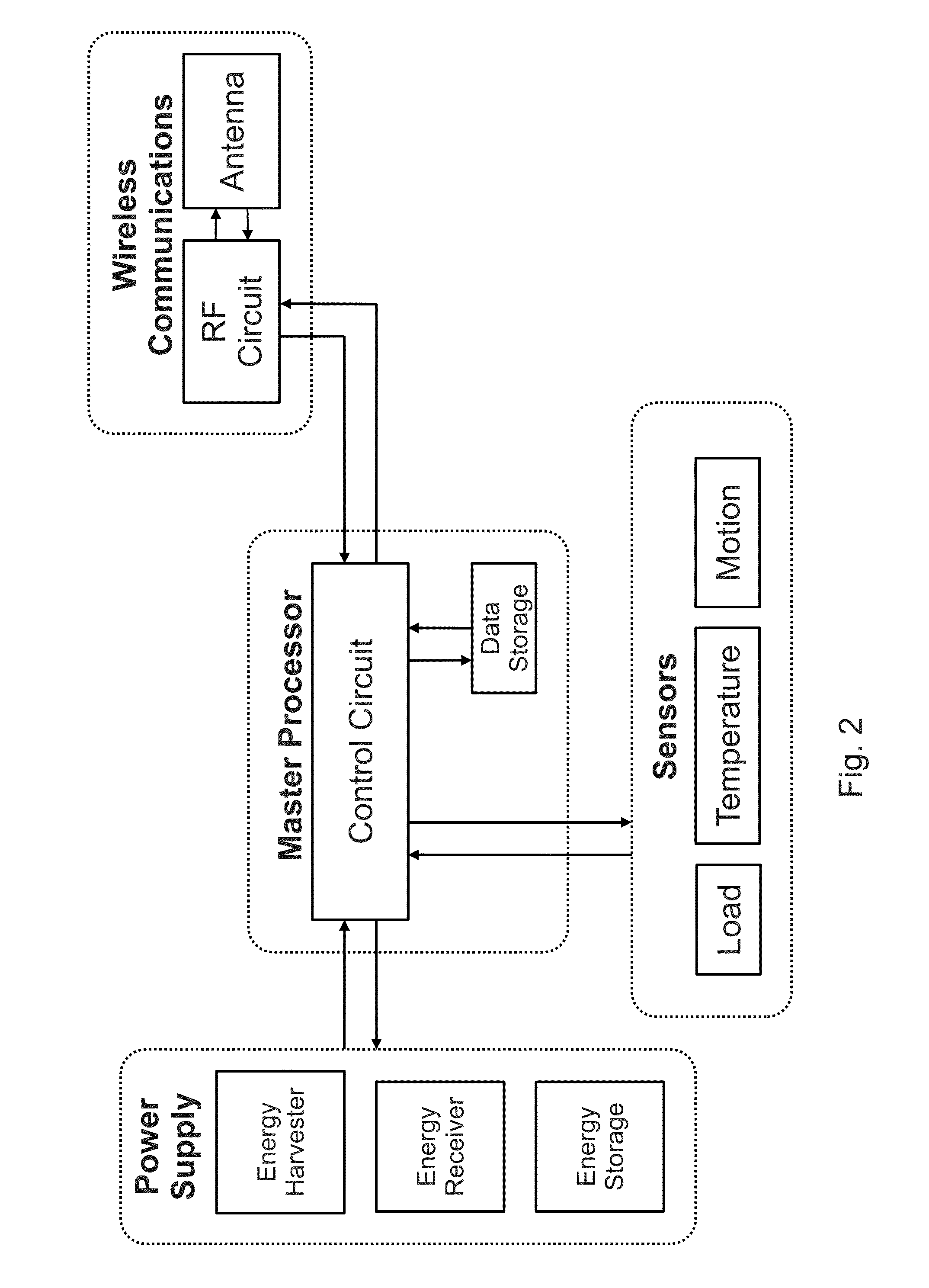

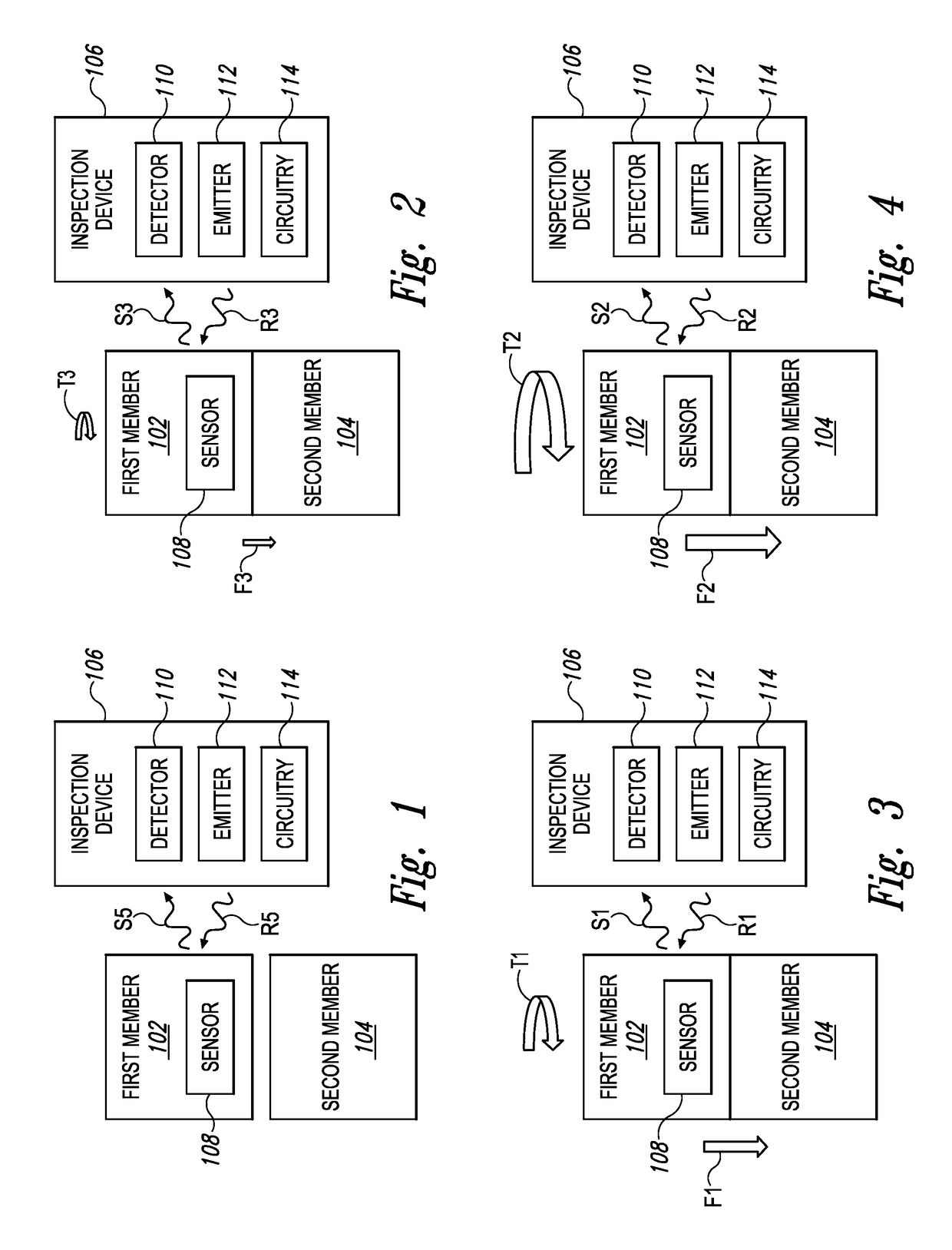

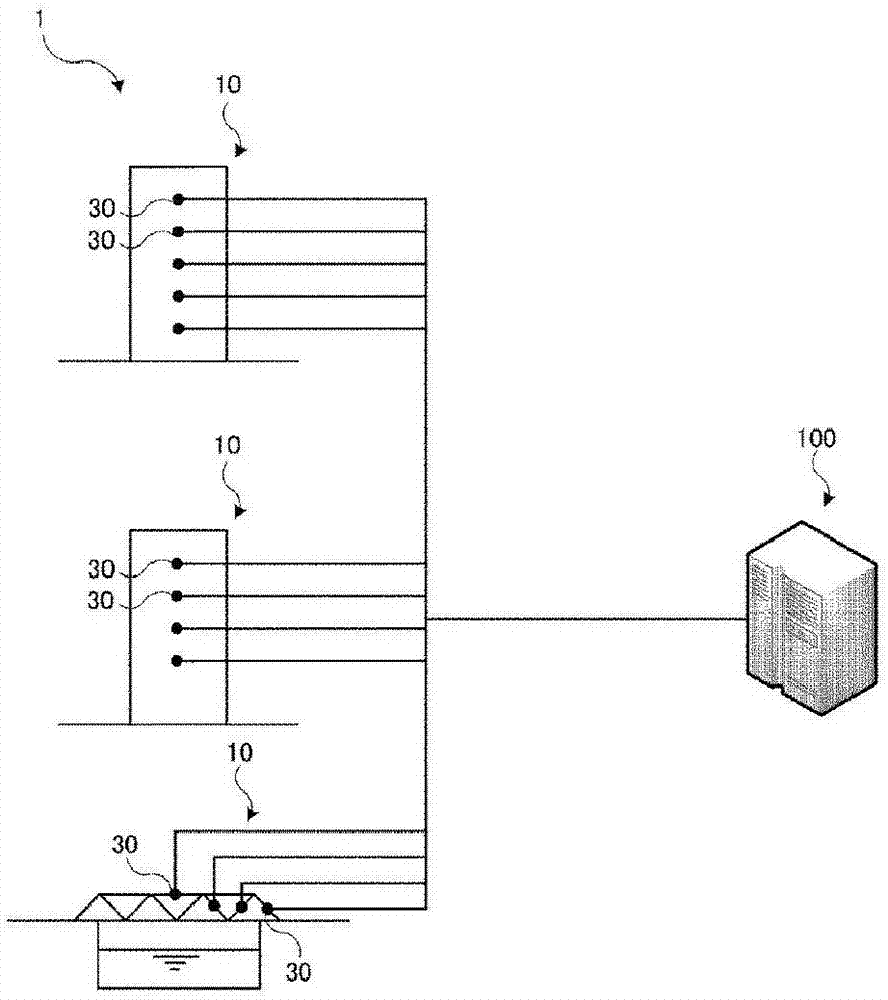

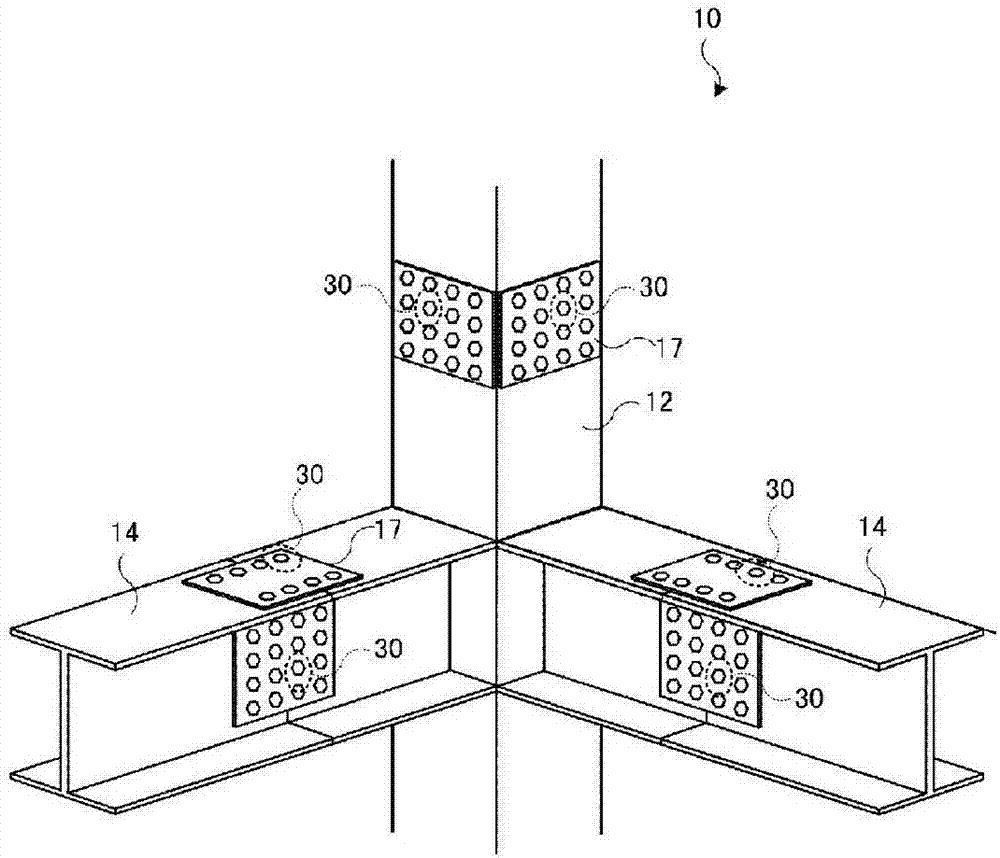

Internal structural monitoring system

An internal structural monitoring system for a structure that includes a sensor mounted within the structure to measure at least one of strain experienced by the structure and vibration experience by the structure. It includes a first system support mounted and second system support mounted in the structure, where the first system and the second system support are mounted in the structure such that the sensor is between the first system support and the second system support to hold the sensor in position so that the sensor senses at least one of strain and vibration. It includes a wireless communication unit mounted within the structure, the wireless communication unit connected to the sensor to receive data from the sensor and transmit the data to a receiver outside the structure. It includes a power supply mounted within the structure to supply necessary electrical power to the sensor and the communication unit.

Owner:KCF TECHNOLOGIES

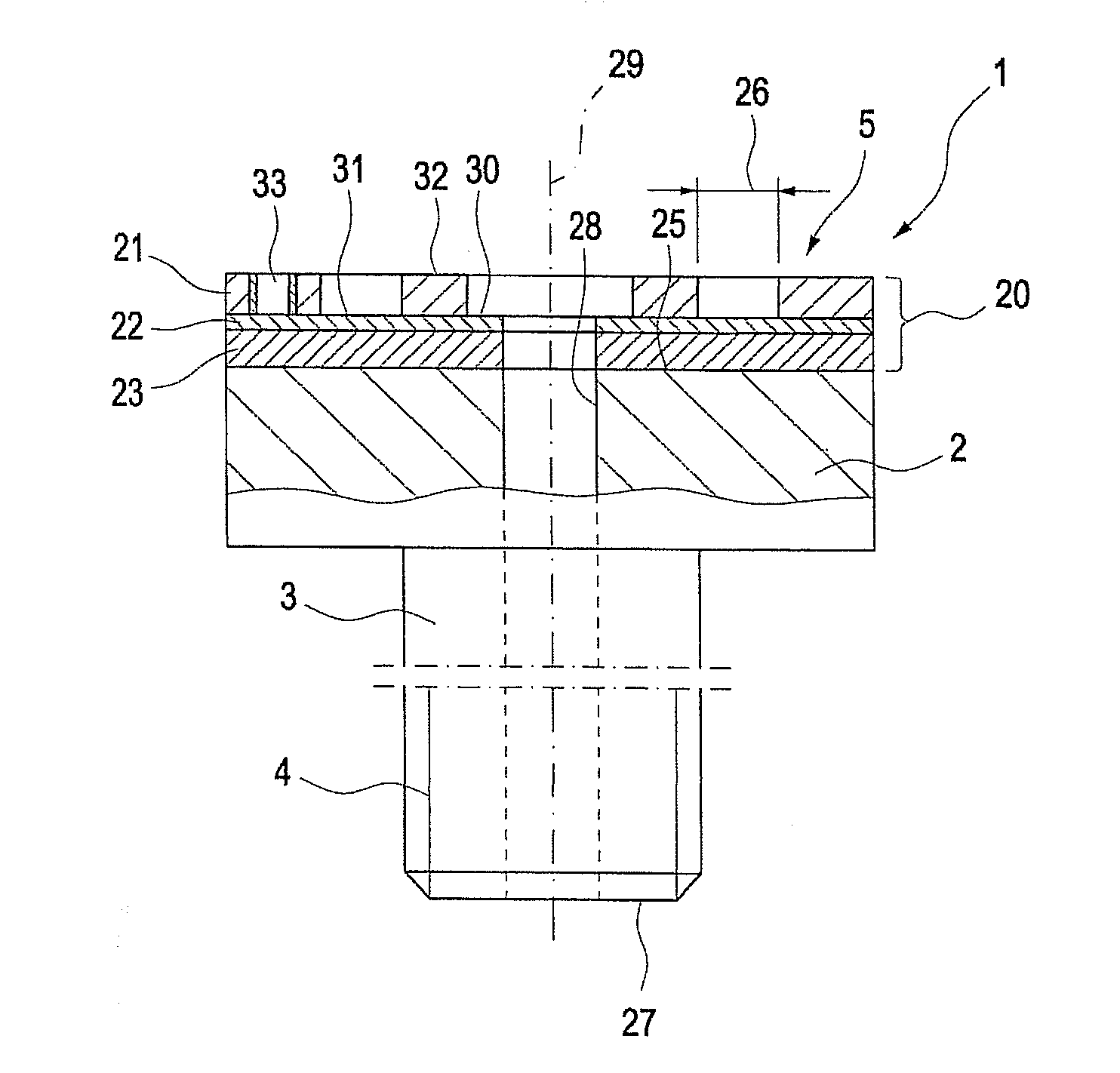

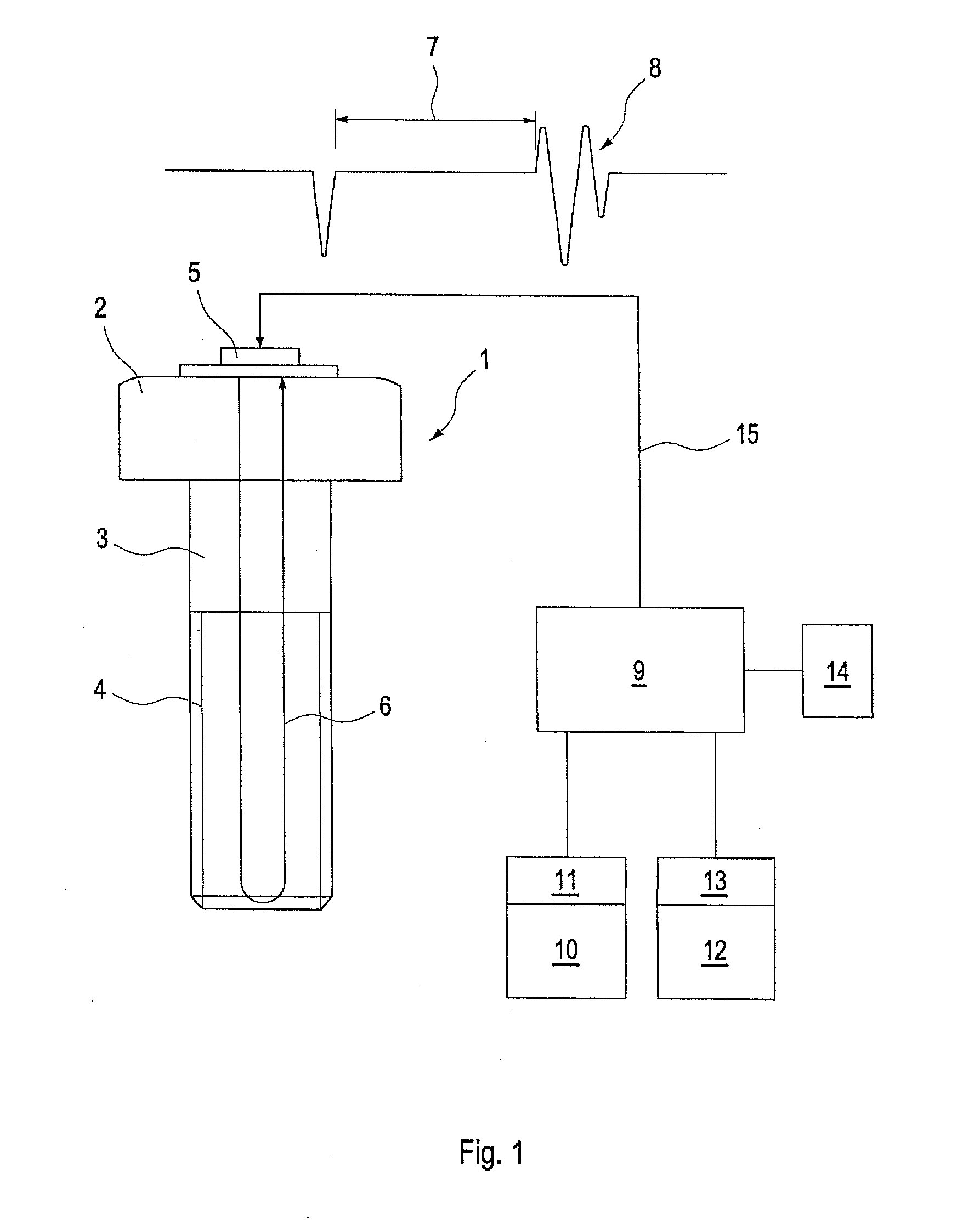

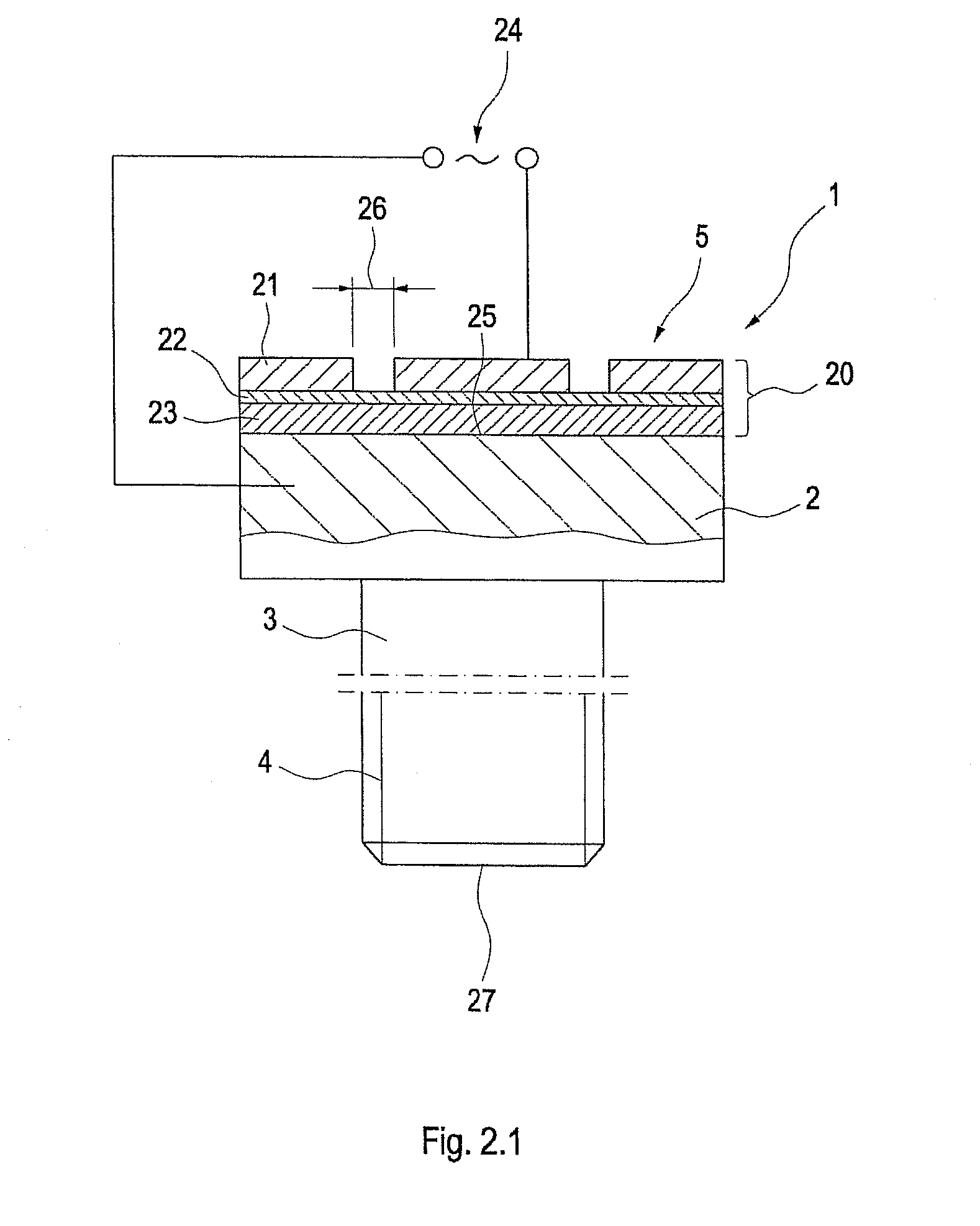

Sensor element

InactiveUS20110146412A1Avoid damageEasy to adaptPiezoelectric/electrostrictive device manufacture/assemblyAnalysing solids using sonic/ultrasonic/infrasonic wavesOptoelectronicsLaser ablation

A connection component is provided that includes an integrated ultrasound sensor, wherein the ultrasound sensor has a layer structure comprising at least two layers, with an electrode layer and at least one layer of a material having piezoelectric properties. The at least one electrode layer and the at least one layer of a material having piezoelectric properties are arranged on a freely accessible end of the connection component. Structures are formed in the electrode layer in order to produce electrodes by laser-ablated regions.

Owner:AMG INTELLIFAST

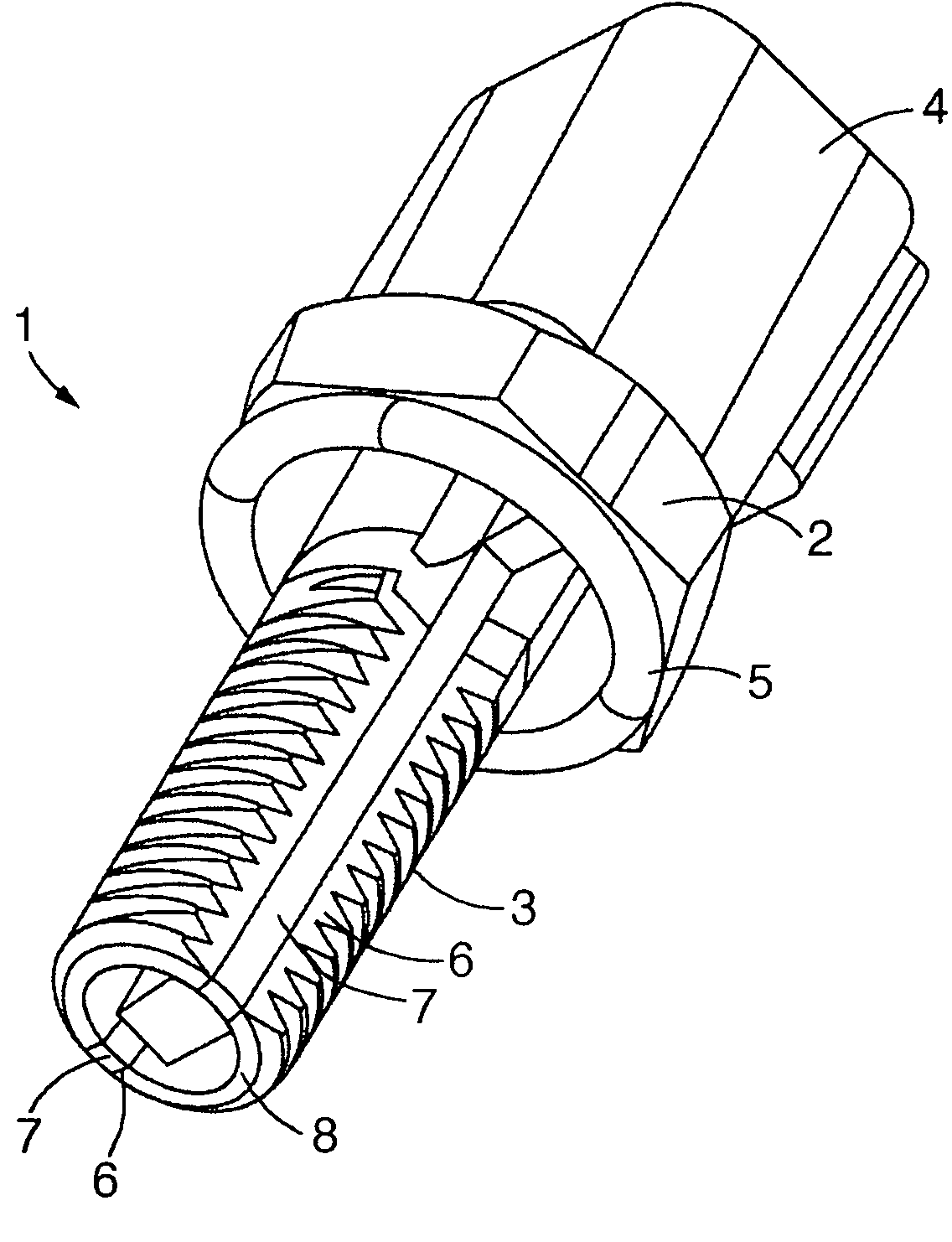

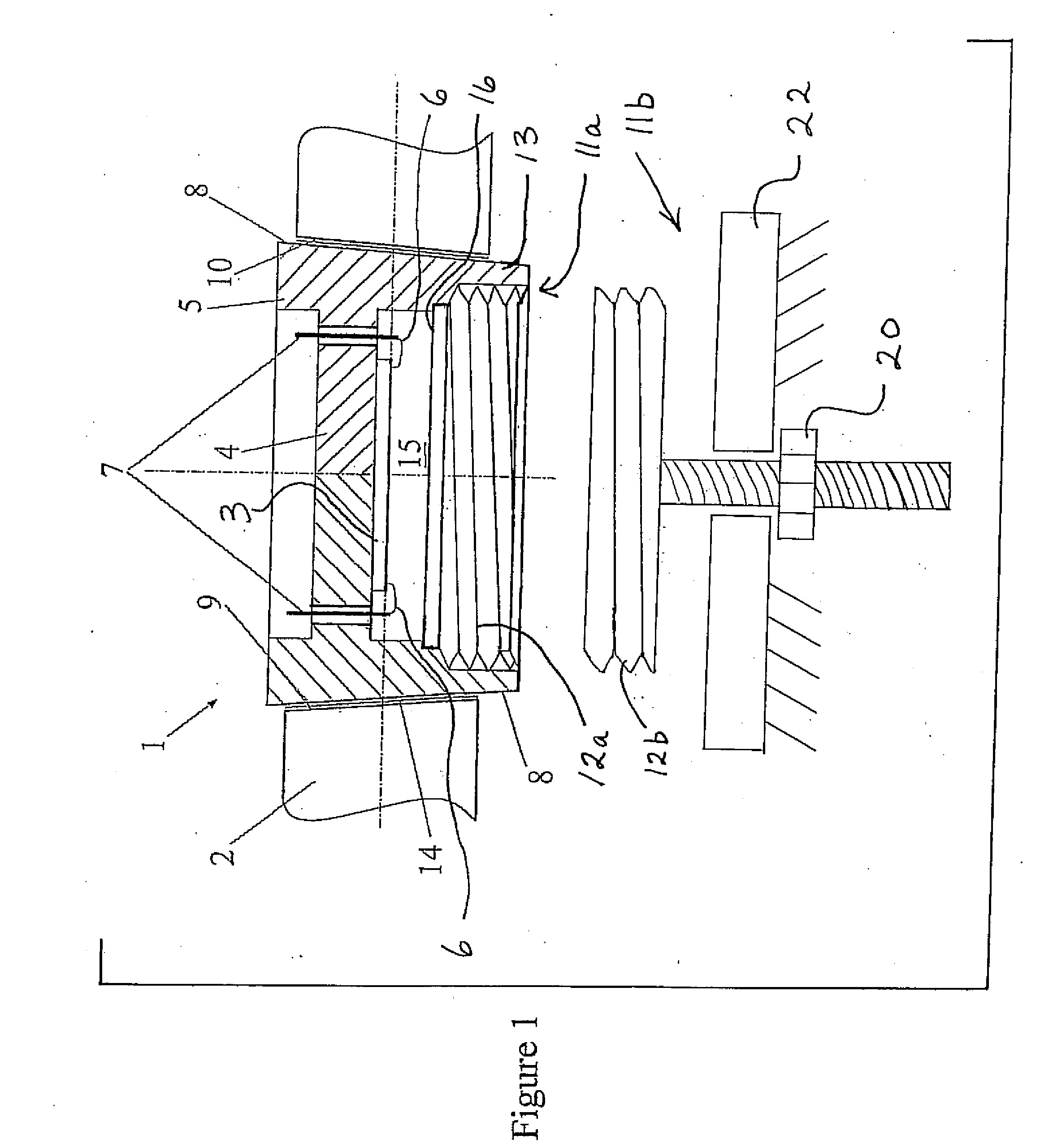

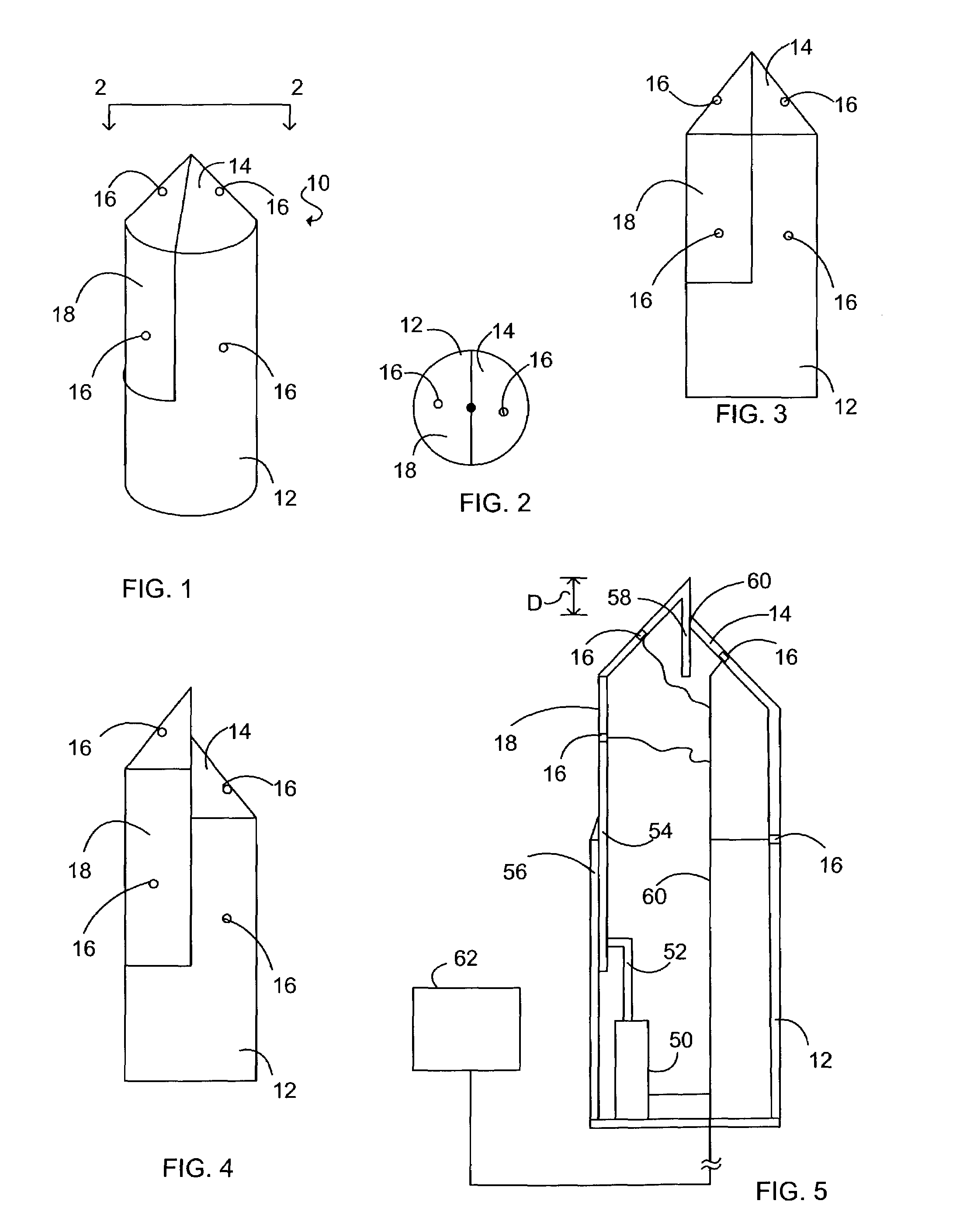

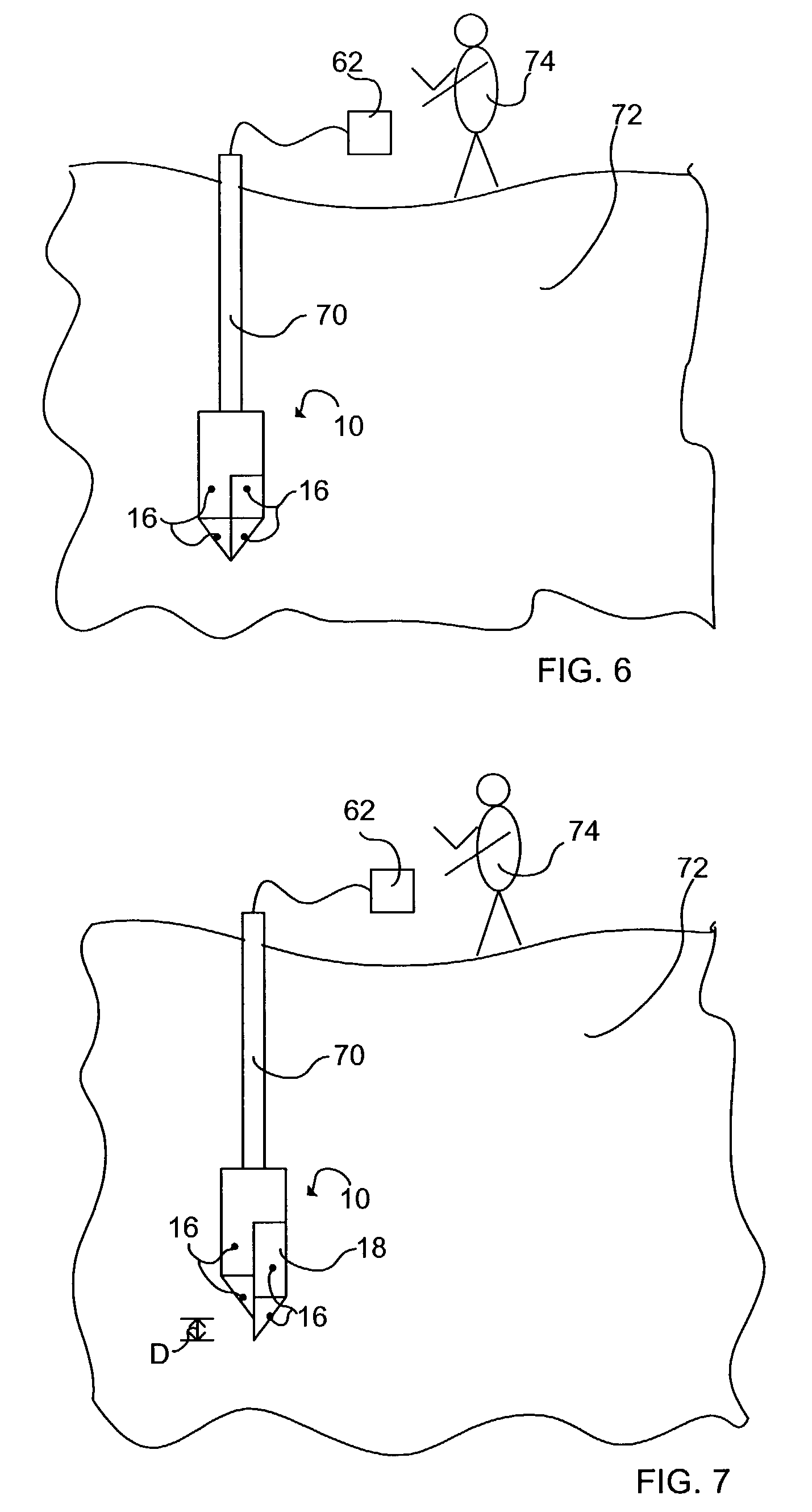

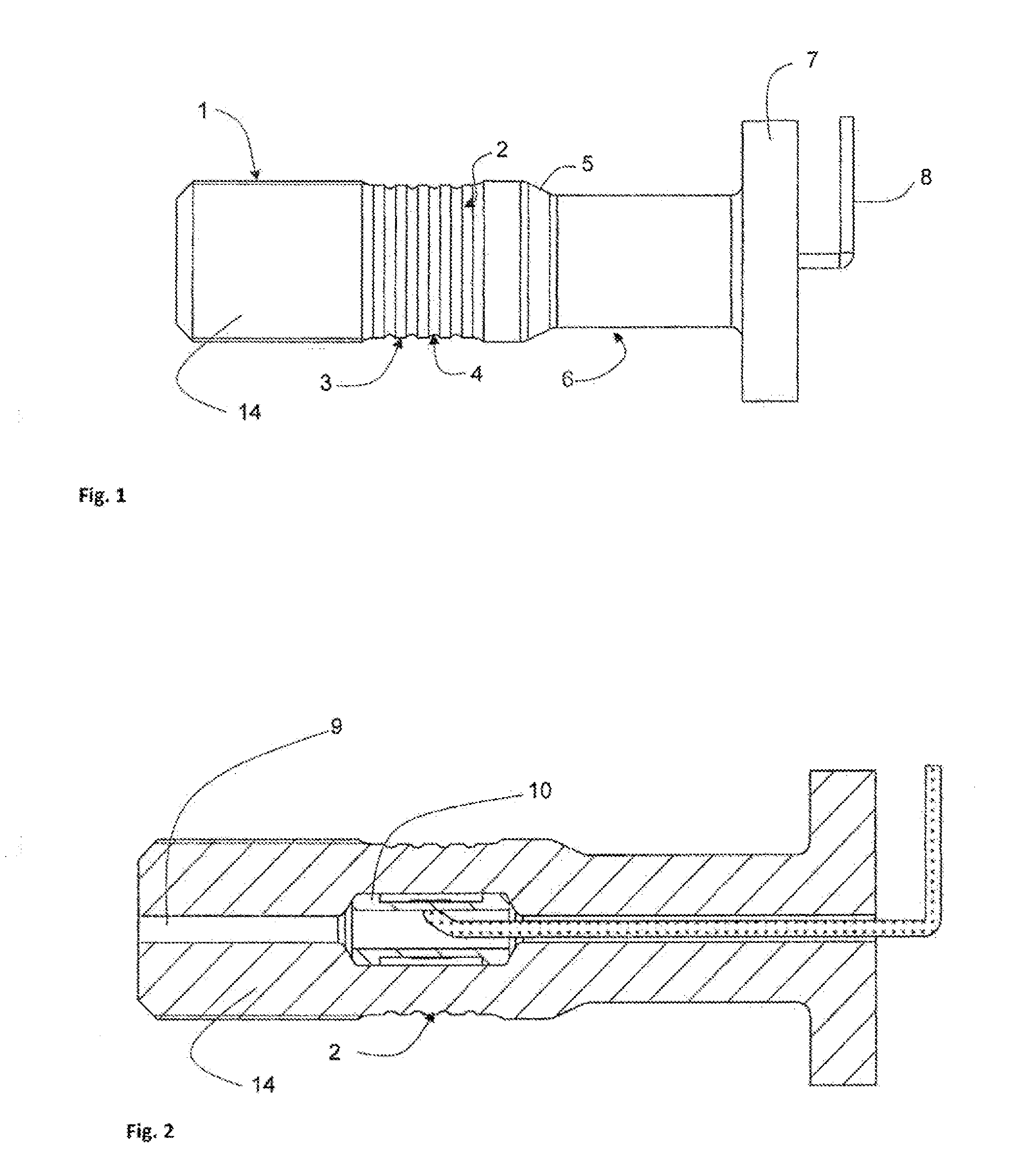

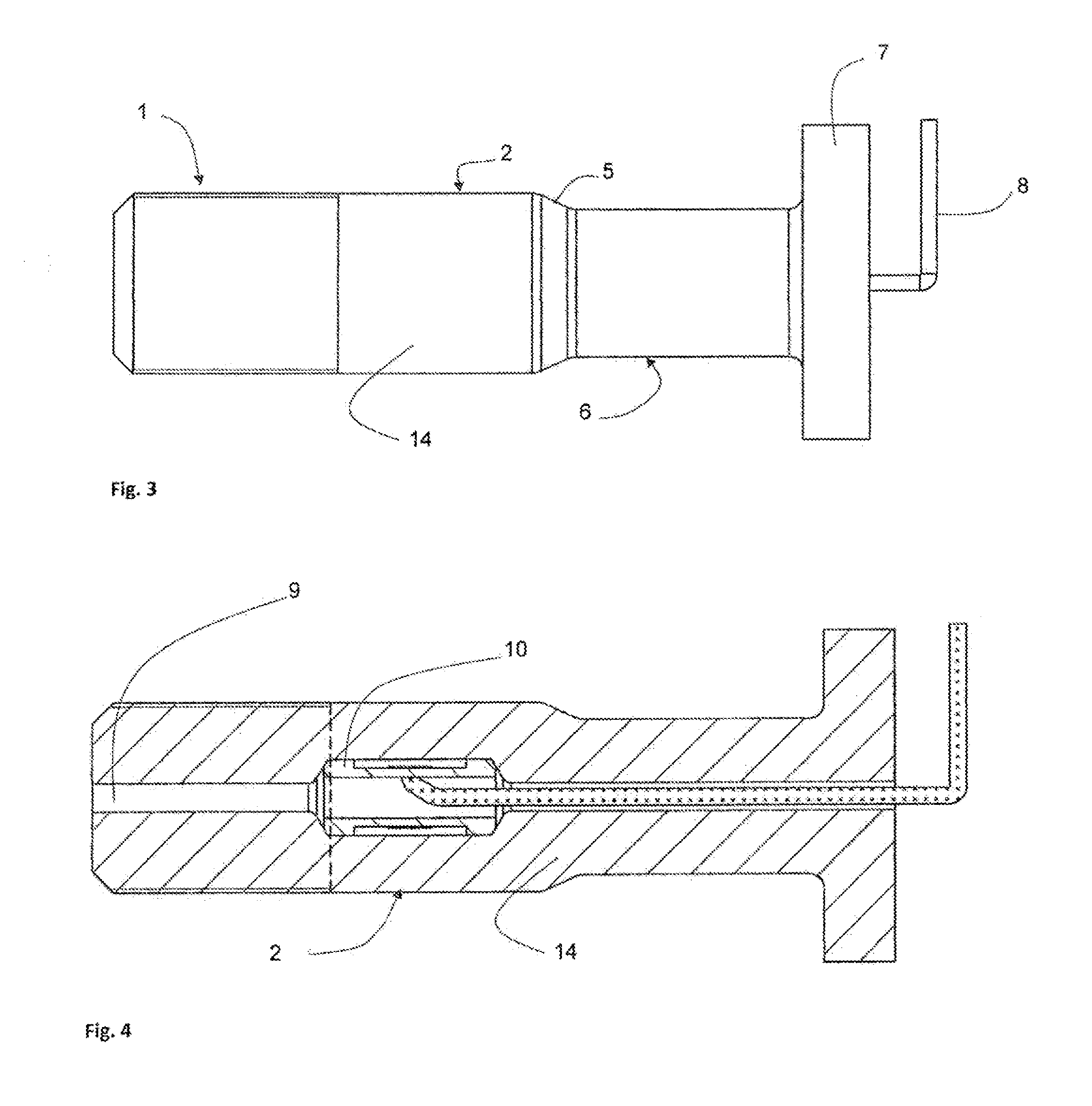

Method and apparatus for mounting a sensor

InactiveUS20090084197A1Eliminate measurement resultingPrevent accidental backingForce transducersForce measurement by elastic gauge deformationEngineeringAxial force

A sensor has a body having a tapered locking surface, and engages in a component with a mounting surface having a complementary taper to the tapered locking surface of the body. The body is positioned on the component with the tapered locking surface aligned with the mounting surface, and an axial force is applied to the body to drive the tapered locking surface into engagement with the complementary taper of the mounting surface. The body is then fixed relative to the component by swaging outwards a skirt on the body into engagement with a lower surface of the component.

Owner:TRANSENSE TECH

Automated control of toolface while slide drilling

Apparatuses, systems, and methods for controlling slide drilling on a drilling rig are described. The methods include detecting current differential pressure of a mud motor and / or weight on bit (WOB) at a surface of a borehole, predicting current reactive torque of the mud motor based on the current differential pressure and / or WOB, and automatically adjusting surface torque and / or angular offset of a tubular adjacent the surface to counteract the current reactive torque and to keep the mud motor at a desired toolface orientation in the borehole.

Owner:NABORS DRILLING TECH USA INC

Downhole seal assembly having embedded sensors and method for use of same

A downhole seal (50) includes an elastomeric element (98) operably to provide a seal between two downhole components. A strain sensor (102) is embedded in the elastomeric element (98). The strain sensor (102) has a mechanical flexibility that is substantially matched to the mechanical flexibility of the elastomeric element (98). The strain sensor (102) is operably connected to circuitry that is operable to identify changes in a property of the strain sensor (98) indicative of the strain being experienced by the strain sensor (98), which is representative of the strain experienced by the elastomeric element (98).

Owner:HALLIBURTON ENERGY SERVICES INC

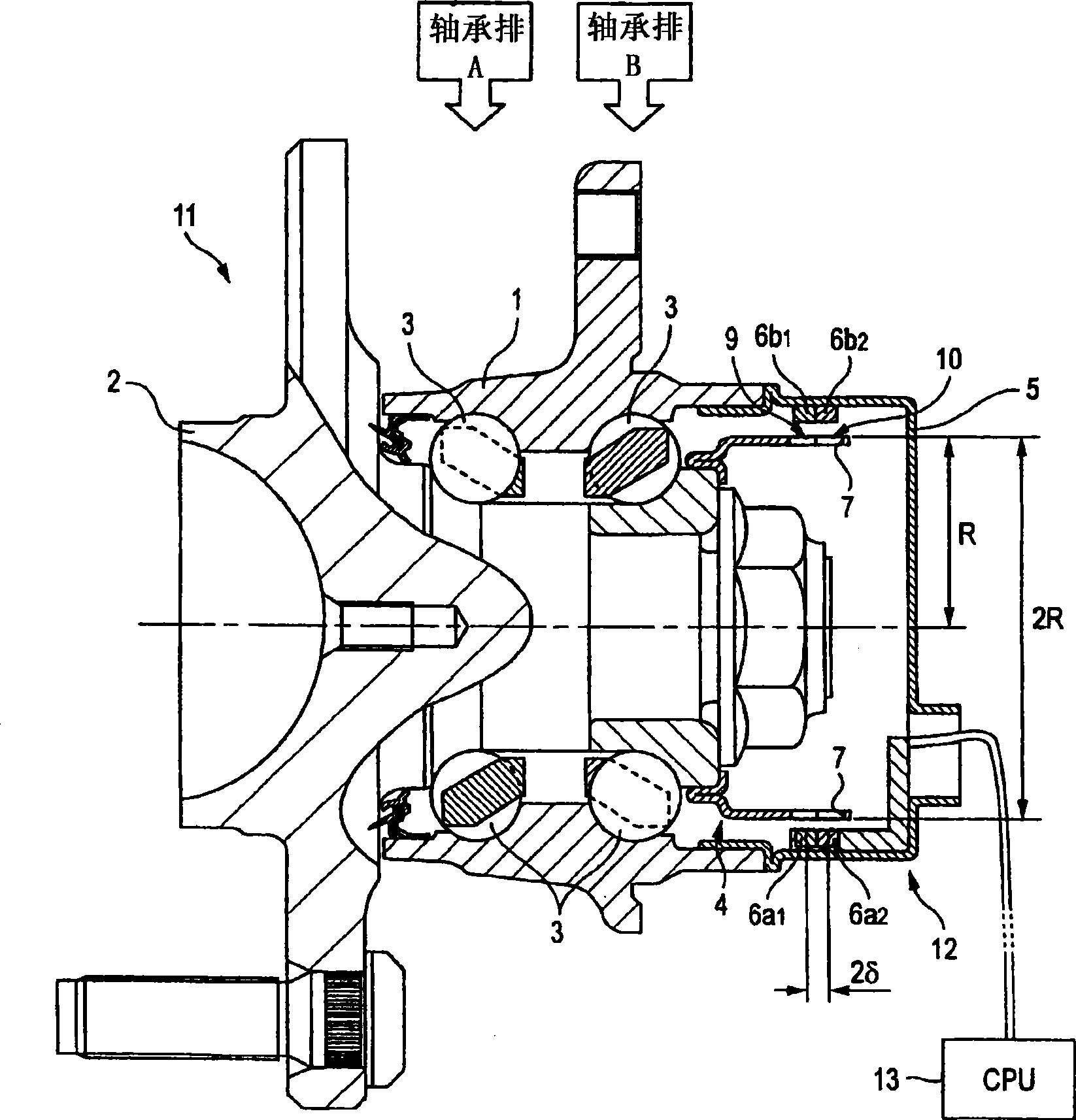

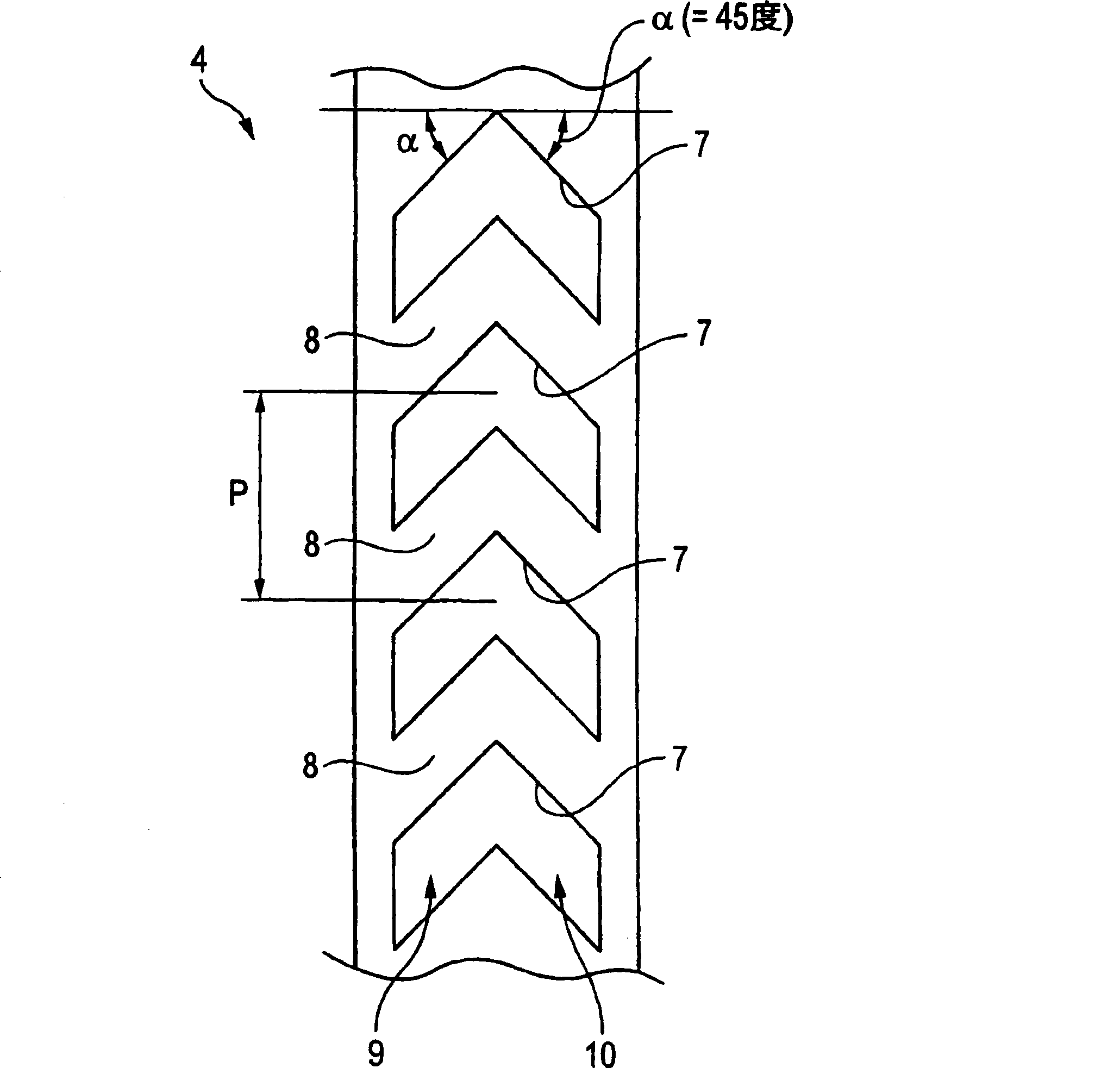

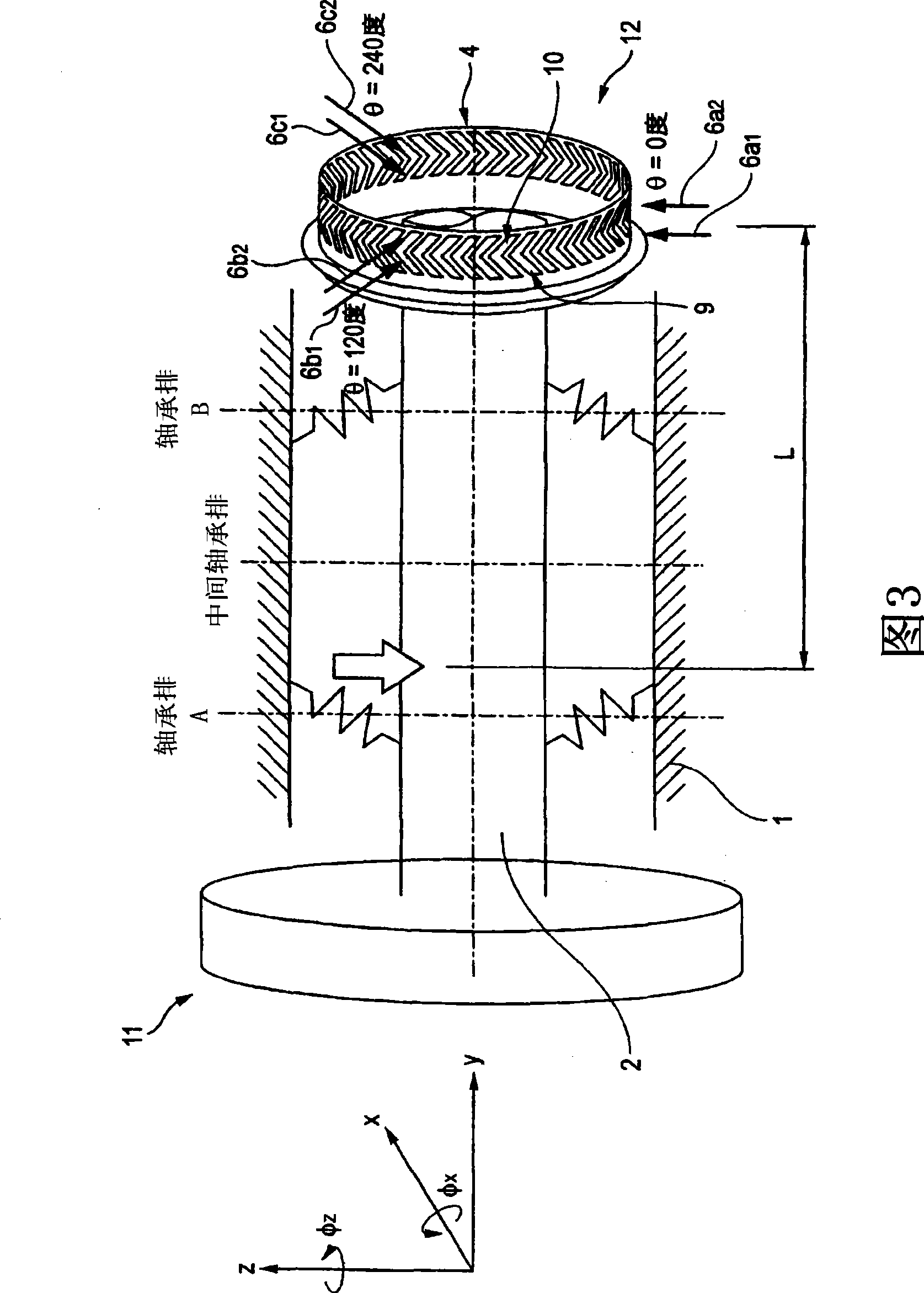

Quantity-of-state measuring device for rotary machine

InactiveCN101395456ALow costSmall sizeRolling contact bearingsBearing assemblyPhase differenceMachine

The outer circumference of an encoder (4) has its inner and outer half portions formed into first and second characteristic changing portions (9, 10), in which the directions of inclination of characteristic boundaries are different from each other. Three circumferential portions of those two characteristic changing portions (9, 10) are individually confronted by detecting units of pairs of sensors (6a1 (6b1, 6c1)) and (6a2 (6b2, 6c2)). Moreover, a not-shown functional unit is given a function to compute displacements (x, y, z) and inclinations (theta x, theta z) on the basis of the phase differences existing between the output signals of those individual sensors (6a1, 6a2, 6b1, 6b2, 6c1, 6c2).

Owner:NSK LTD

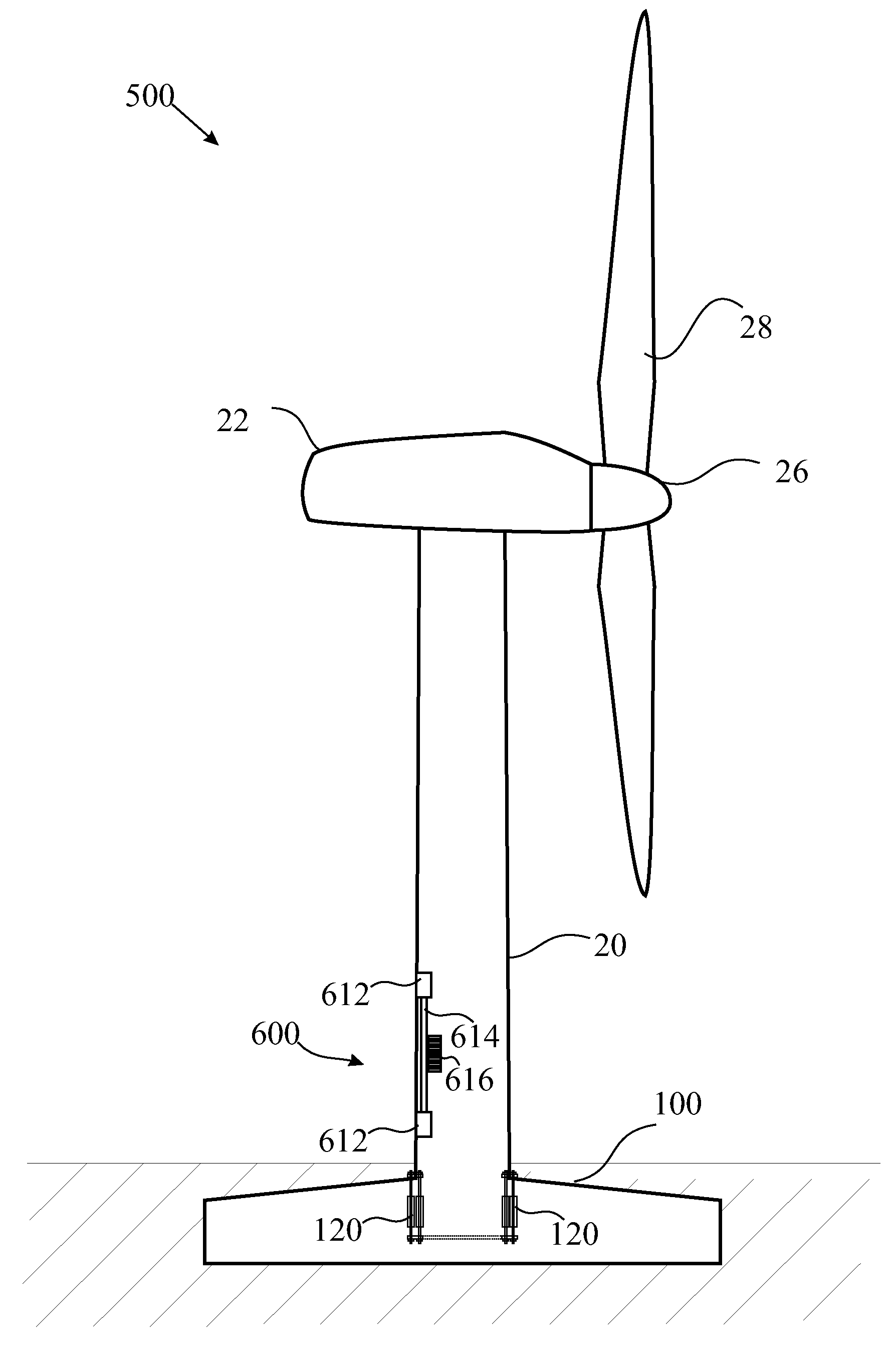

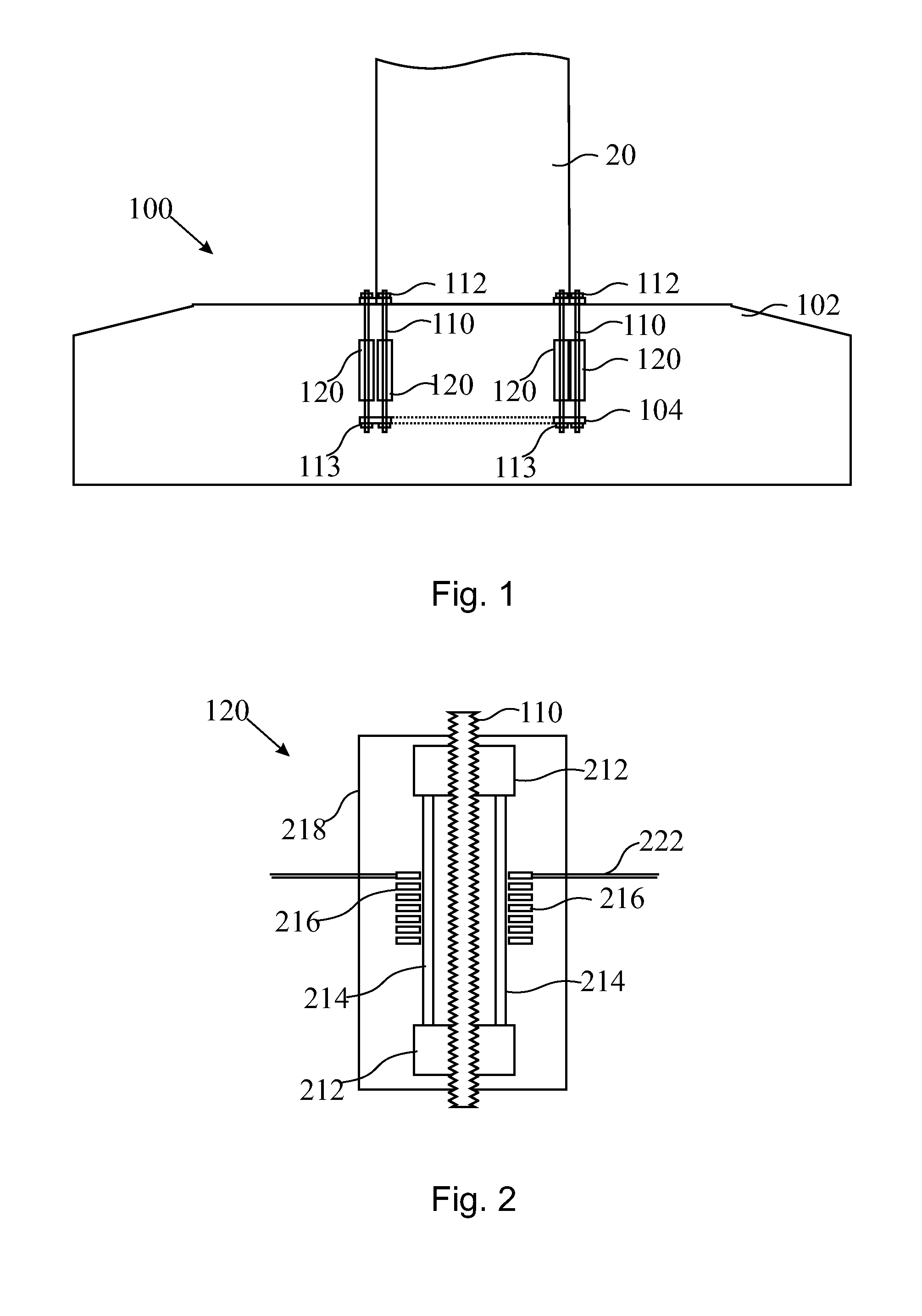

Magnetostrictive measurement of tensile stress in foundations

ActiveUS20090169380A1PropellersForce measurement by measuring magnetic property varationEngineeringAnchor bolt

A foundation for supporting a structure is provided. The foundation includes a foundation body, at least one anchor bolt connecting a lower anchor plate and the structure, a magnetostrictive load measuring sensor for measuring loads on the at least one anchor bolt, the magnetostrictive load measuring sensor being positioned within the foundation body.

Owner:GENERAL ELECTRIC CO

Witness enabled fasteners and related systems and methods

ActiveUS9677592B2Measurement of torque/twisting force while tighteningLoad modified fastenersEngineeringFastener

Owner:THE BOEING CO

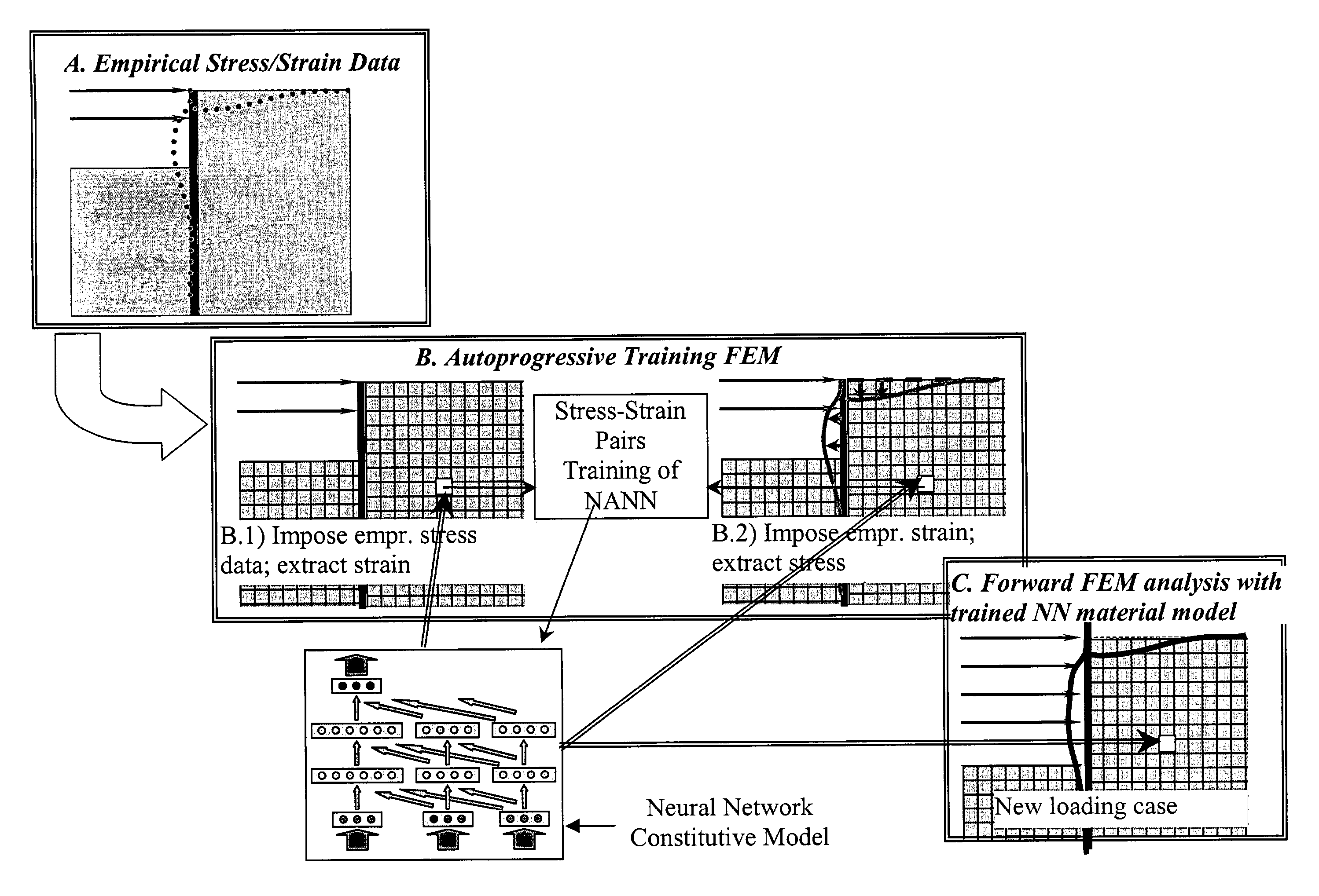

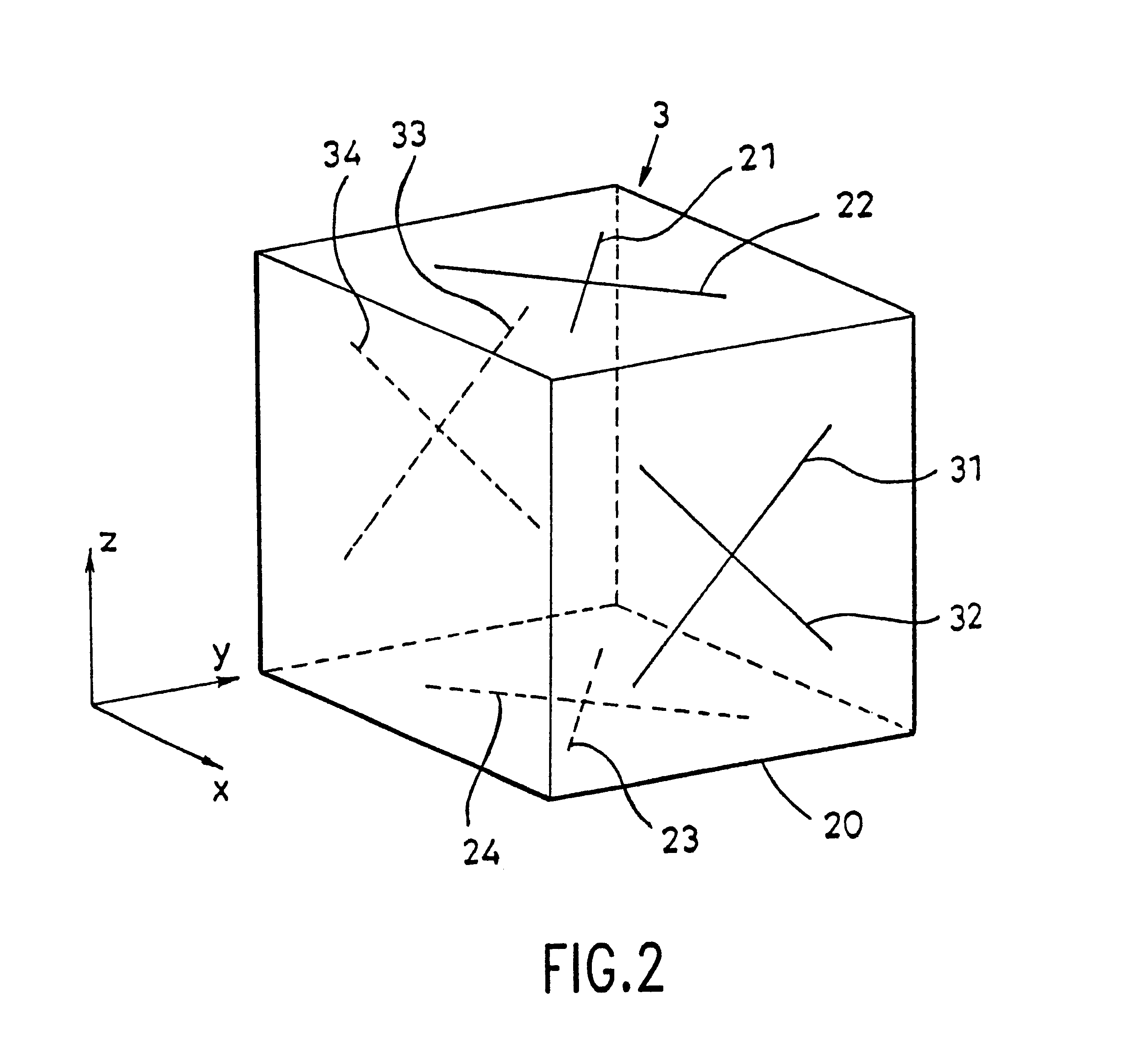

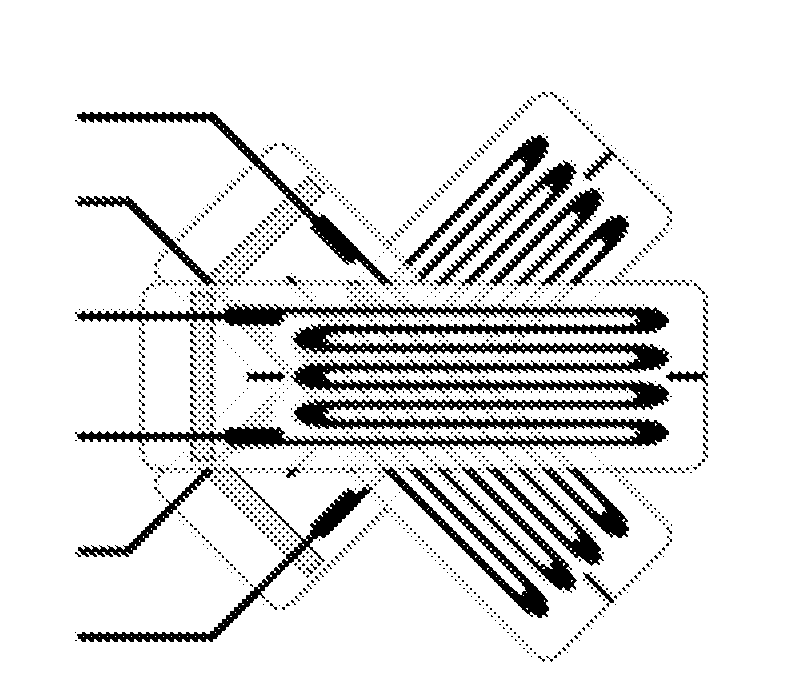

Methods and systems for modeling material behavior

InactiveUS7447614B2Force measurementComputation using non-denominational number representationLaboratory deviceComputational model

A method for modeling material behavior includes using empirical three dimensional non-uniform stress and strain data to train a self-organizing computational model such as a neural network. A laboratory device for measuring non-uniform stress and strain data from material includes an enclosure with an inclusion in it. As the enclosure is compressed, the inclusion induces a non-uniform state of stress and strain. A field testing device includes a body having a moveable section. When the body is inserted in a material and the moveable section moved, a non-uniform state of stress and strain can be characterized.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

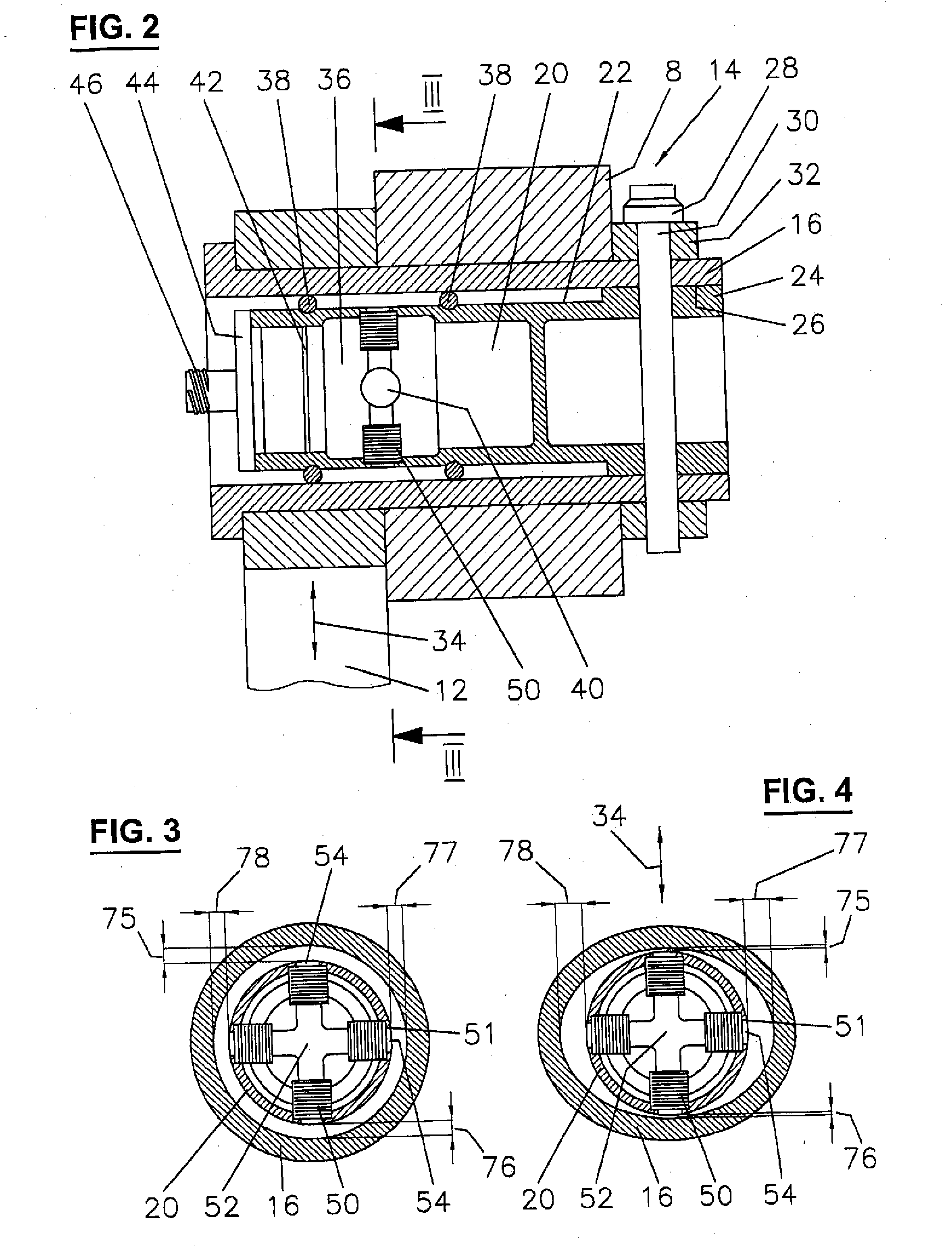

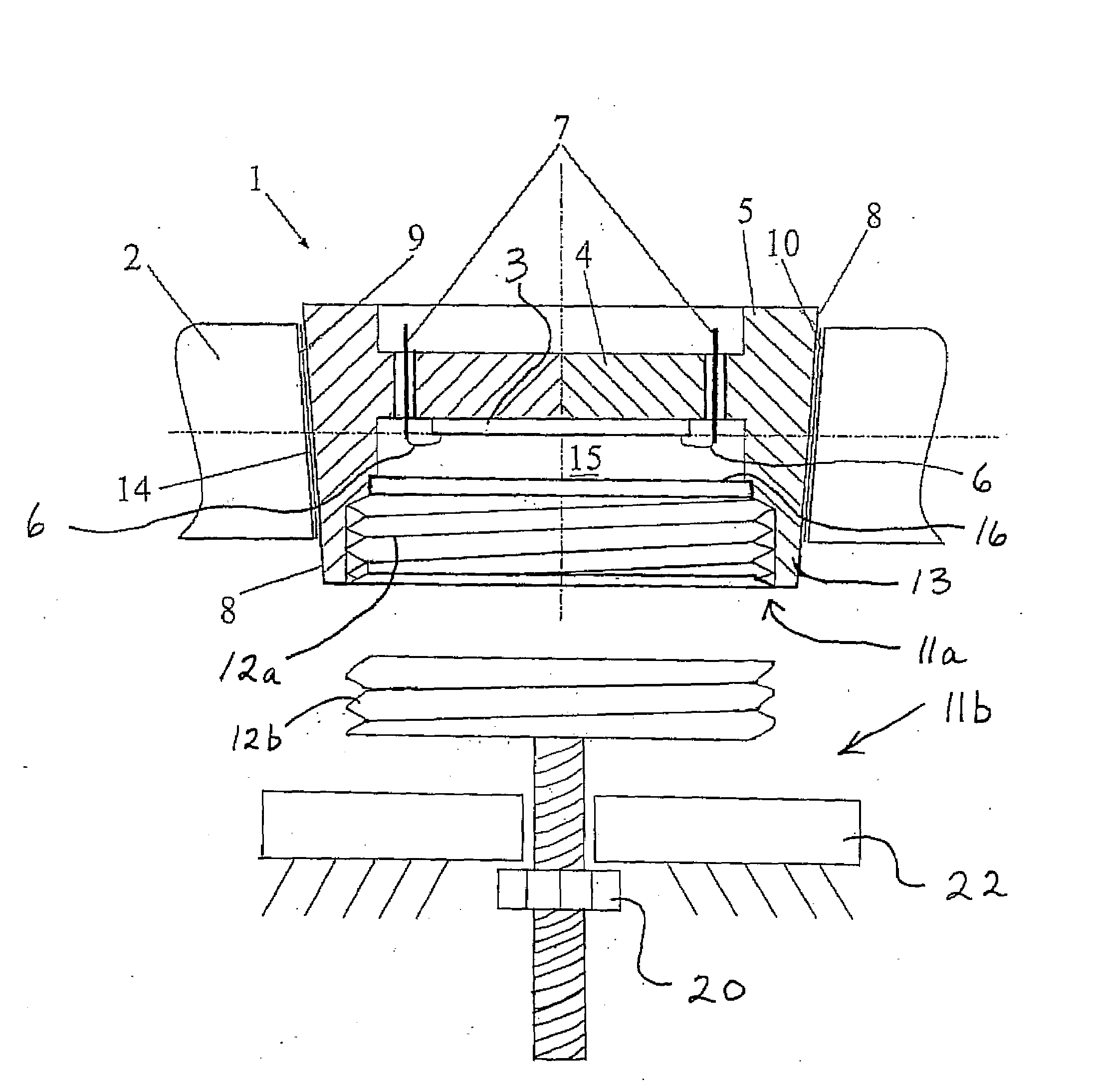

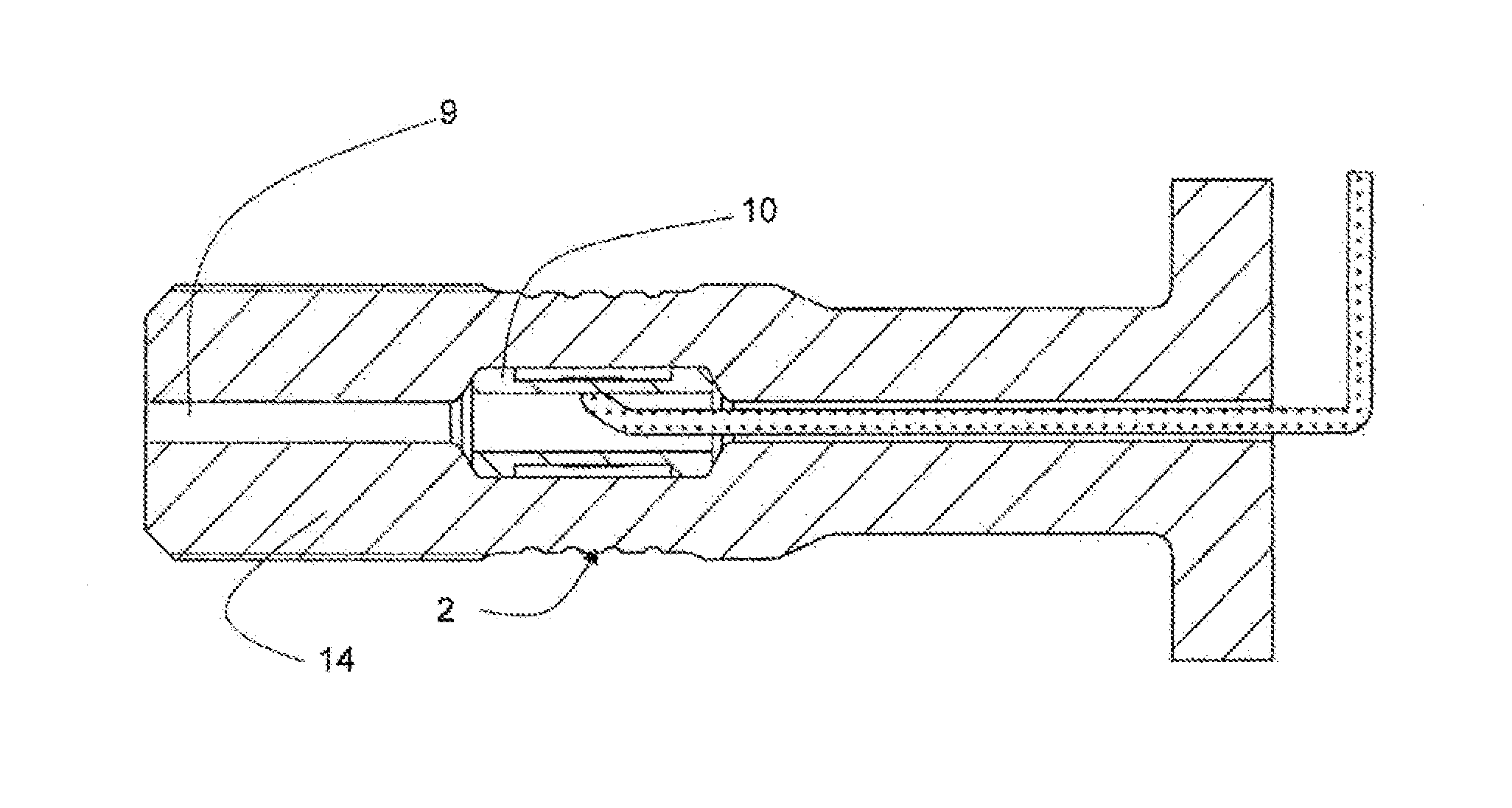

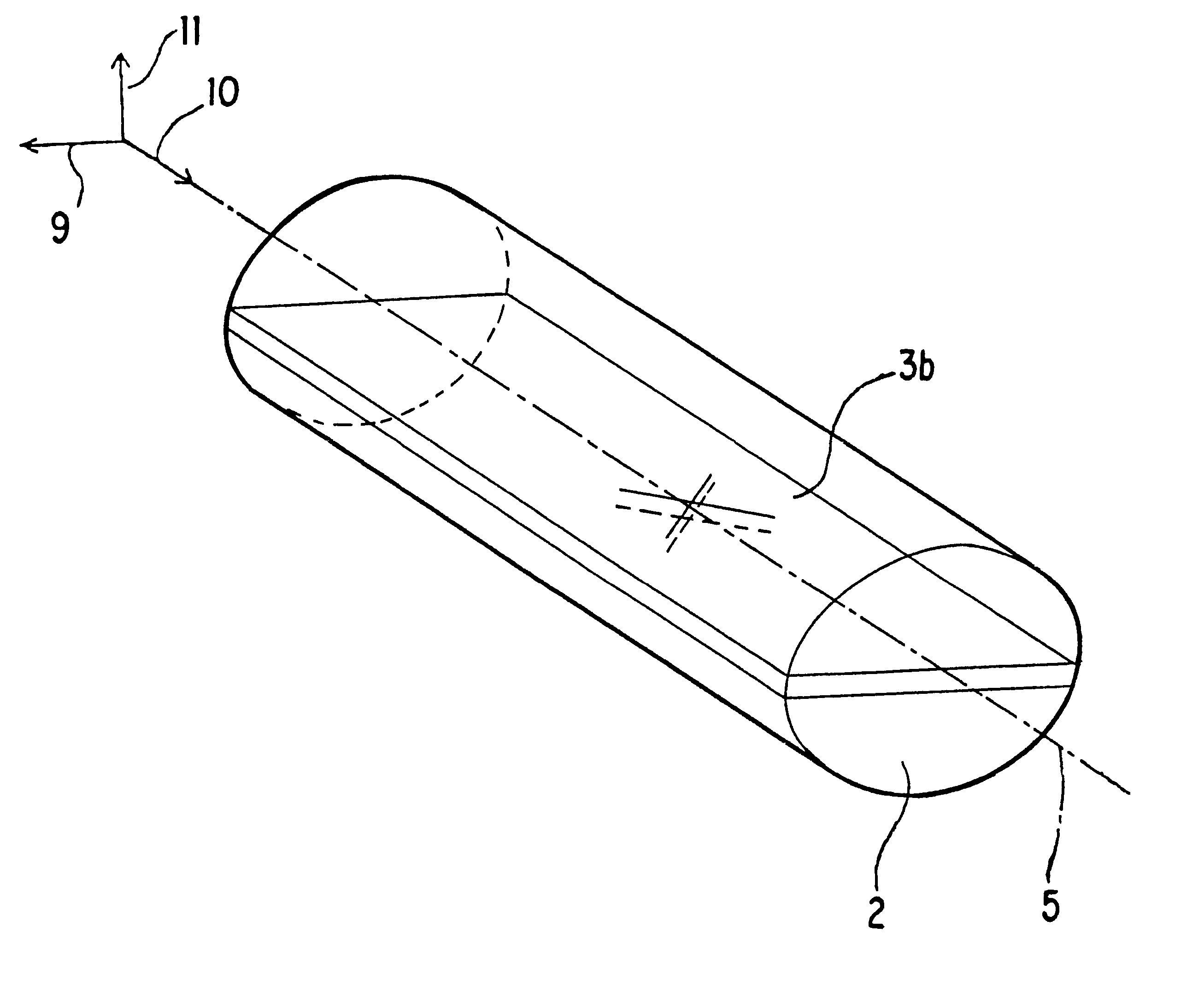

Sensor-containing connection element and manufacturing method

ActiveUS20150030408A1Low costReduce gapMeasurement apparatus componentsMeasurement of torque/twisting force while tighteningStructural engineeringMechanical engineering

A connection element consists of a longitudinally oriented support structure that is at least partially hollow and a sensor unit that is arranged in the inside of the support structure, is connected to a signal transmission device, and is non-positively connected to the support structure. The required force for the non-positive connection is produced by internal stresses after a plastic deformation of the support structure during a joining process of the support structure and the sensor unit. A method for manufacturing a connection element consisting of a support structure that is at least partially hollow and a sensor unit includes positioning the sensor unit in a region of the support structure and, using radially movable tool segments, exerting a force on the support structure in the radial direction and at the same time reducing the periphery of the support structure in the region in which the sensor unit is positioned.

Owner:GLBS PATENTVERWERTUNGSGESELLSCHAFT GBR

Device including a stress detection sensor for measuring action force of a wheel

InactiveUS6651518B1Protected against external environmentReduce outputAxially engaging brakesForce measurementSignal processing circuitsEngineering

A device for measuring action force of a wheel includes a vehicle axle upon which the wheel is mounted, the vehicle axle having a stress neutral line, and a stress detecting sensor having at least one strain gauge. The stress detecting sensor is disposed within the vehicle axle so as to detect at least one of a horizontal shear stress and a vertical sheer stress with the at least one strain gauge being one of aligned with or proximate the stress neutral line thereby permitting substantial removal of axle torque influence from an output of the stress detecting sensor. A signal processing circuit processes the output of the stress detecting sensor.

Owner:JAPAN ELECTRONICS IND LTD

Pressure sensor containing mechanically deforming elements

The invention has the objective of offering a sensor the allows for measuring the pressure force of the springs on the carbon brushes as well as the actual brush pressure on its contact surface. This is obtained by measuring between the carbon brush, and there is limited space through its holder, and the contact surface and is therefore characterized by the fact that the sensor is thinner than 4 mm, and that it is provided with a target (4) which is suspended in the sensor (1) by means of a mechanically deformable section (3), and where the sensor is fitted with one or more strain gauges (2) that is / are set up as such that it can detect the shearing of the mechanical deformable measuring section under pressure. In contrast to the existing measuring sensors, the measuring strips also connect the suspension points of the mechanically deformable elements with the sensor and / or the suspended target or measuring point through which sensitivity increases and makes the sensor useful for such applications.

Owner:MERSEN BENELUX BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com