Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about "Fluidic programme control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

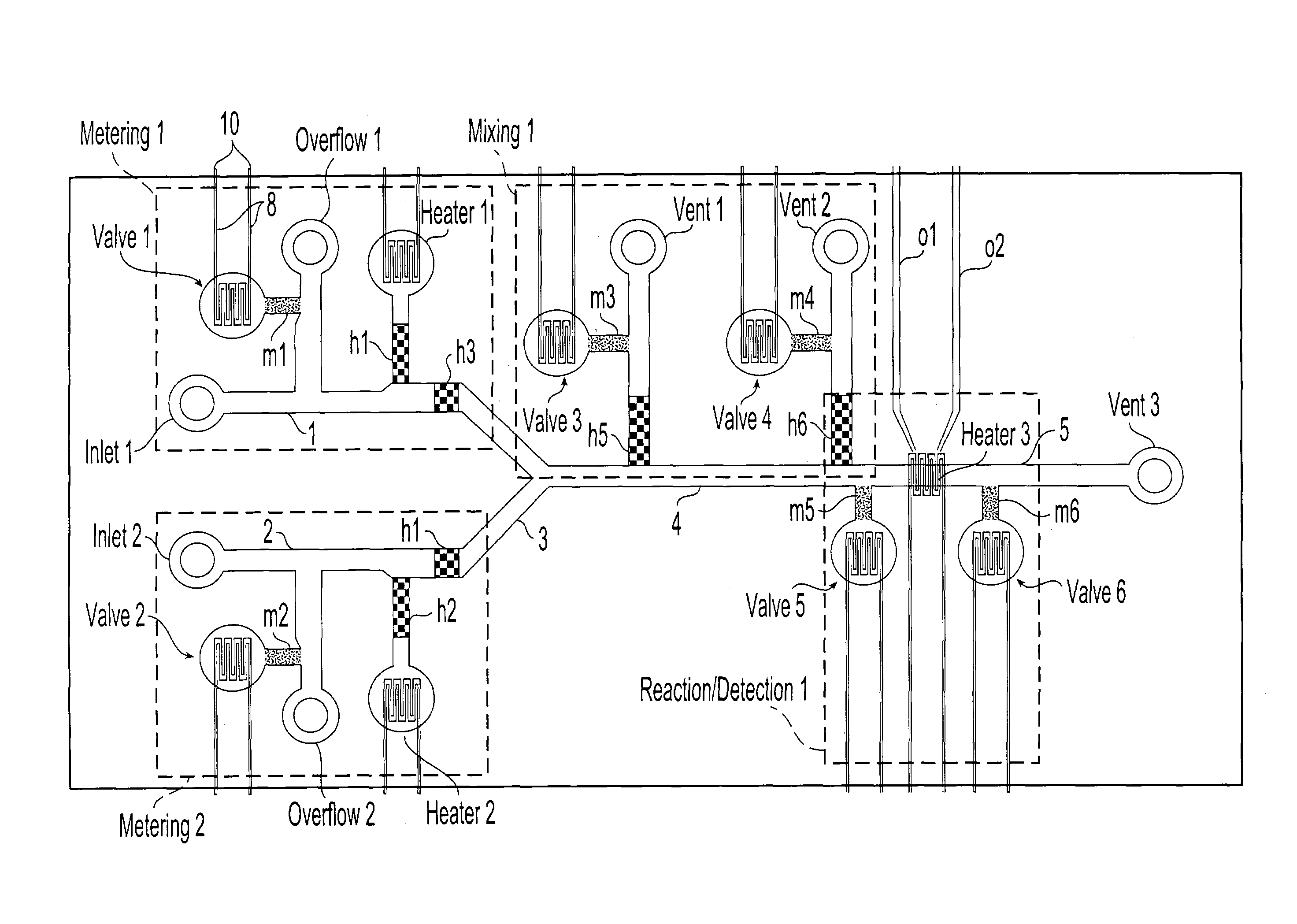

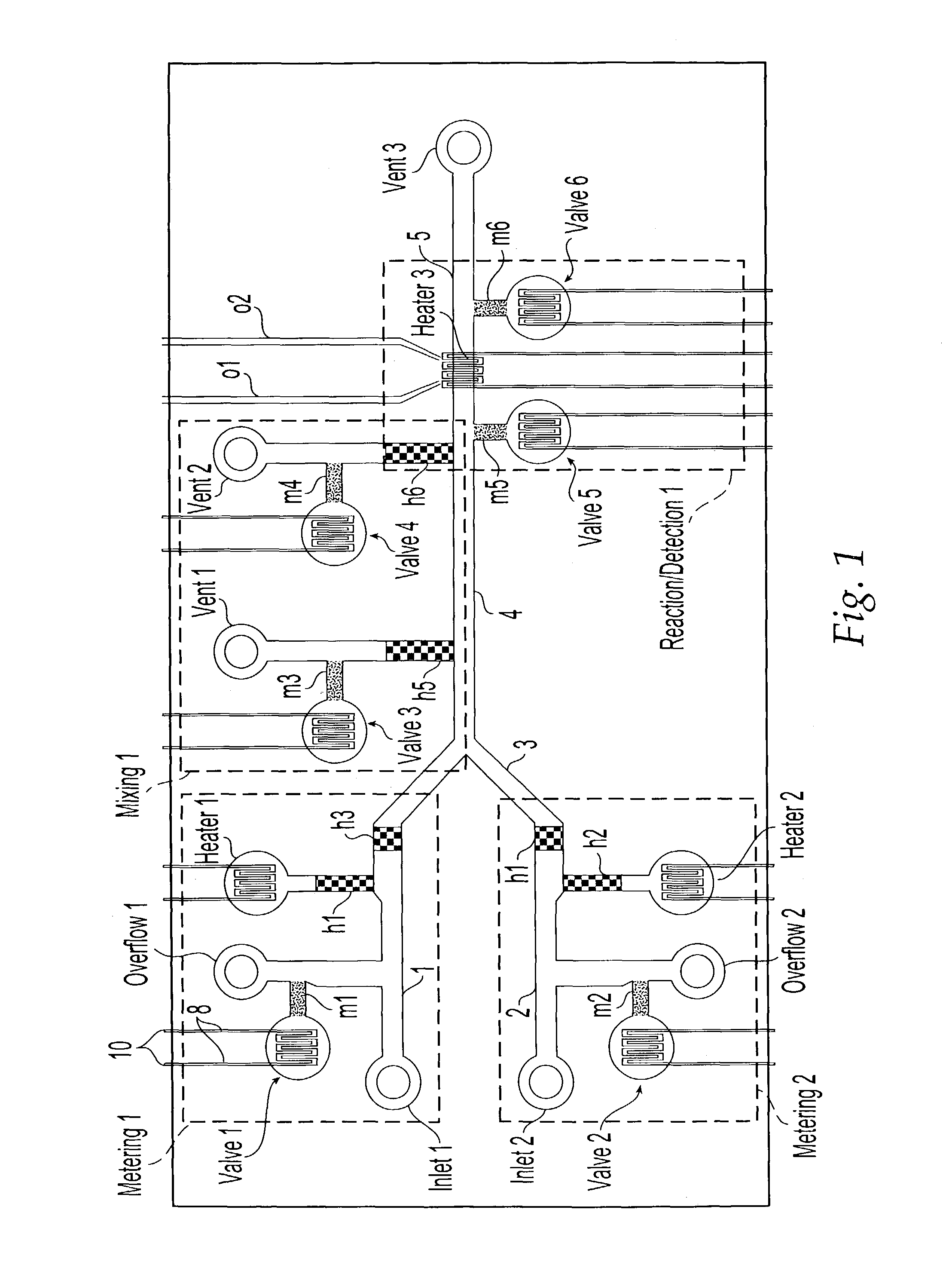

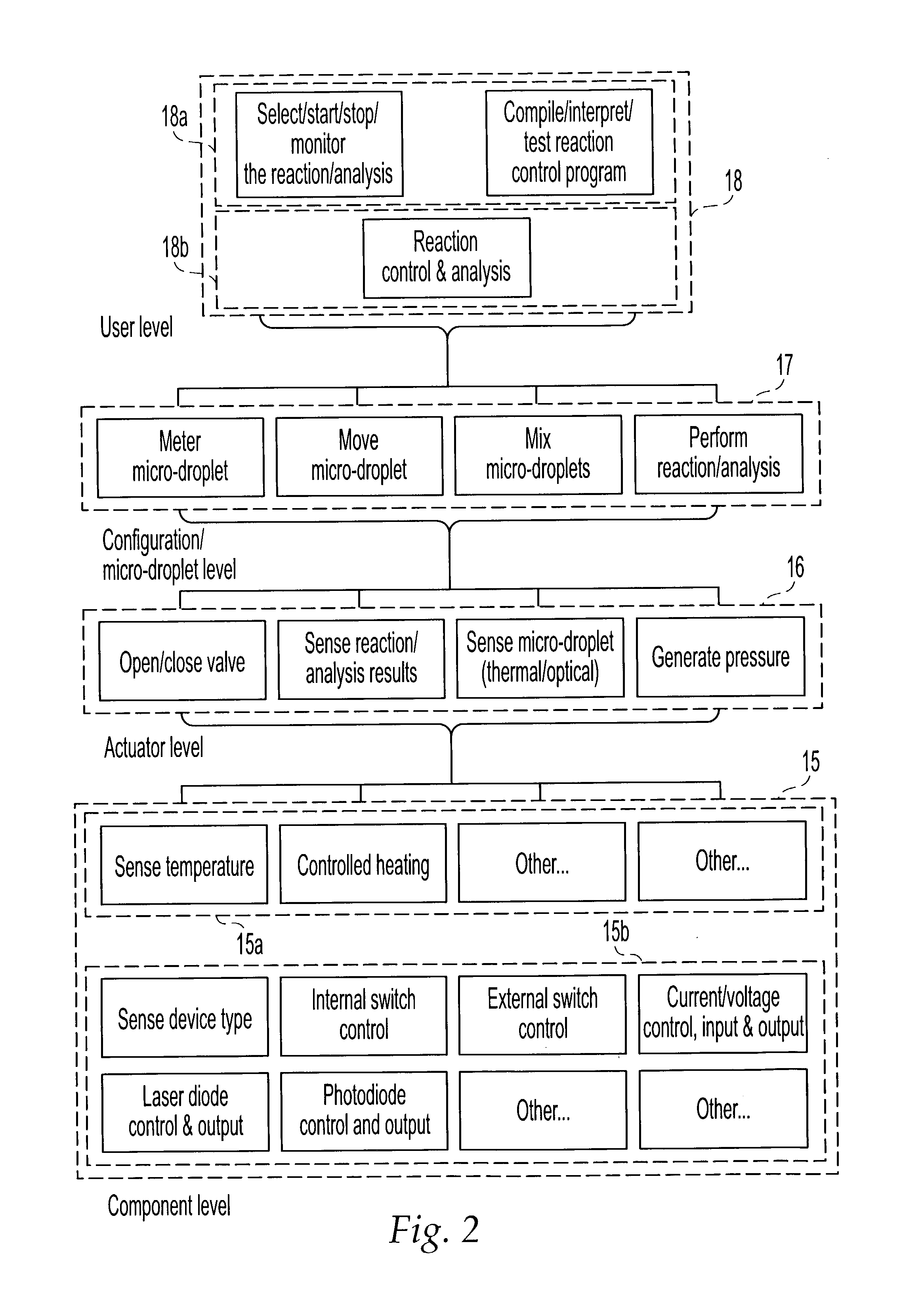

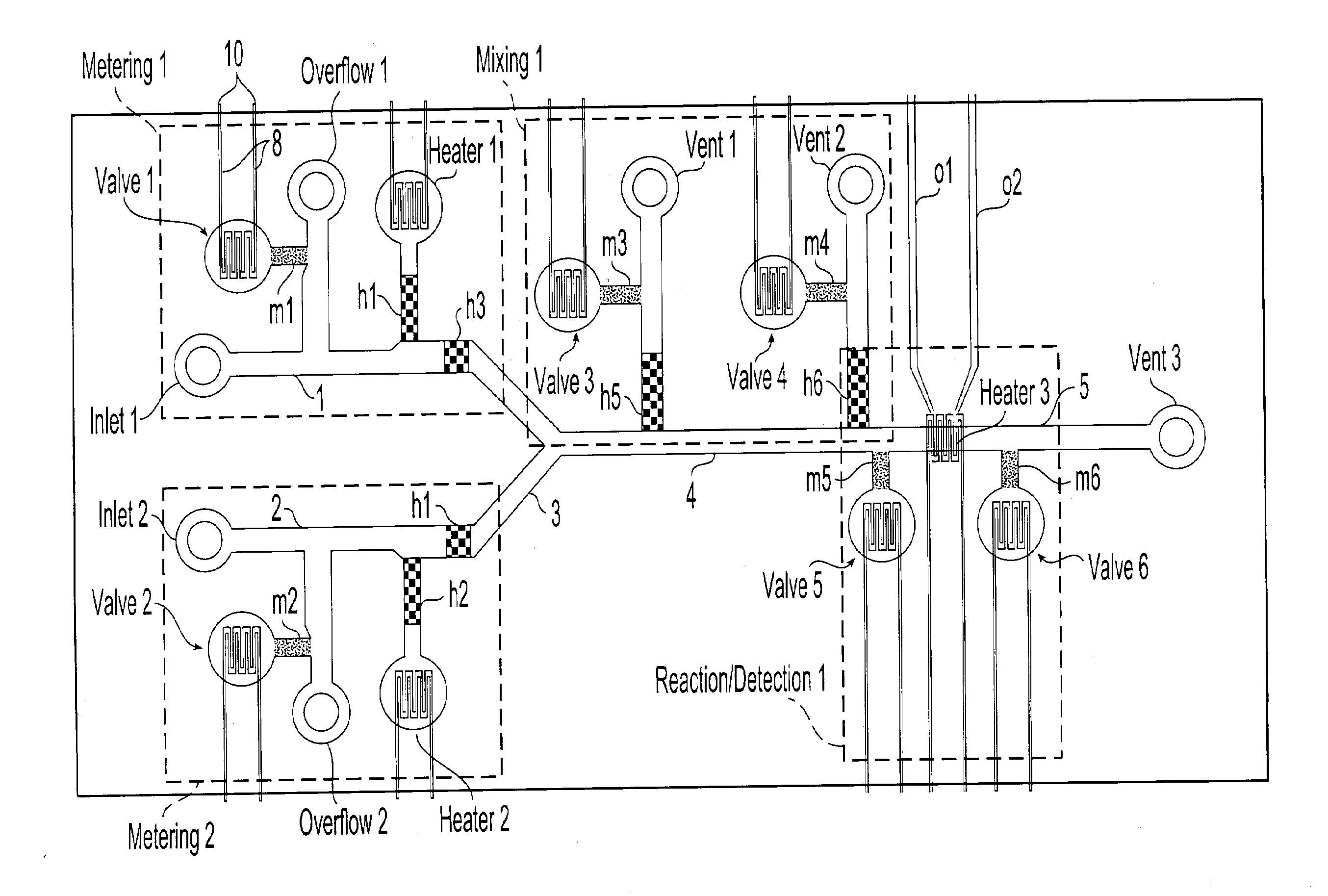

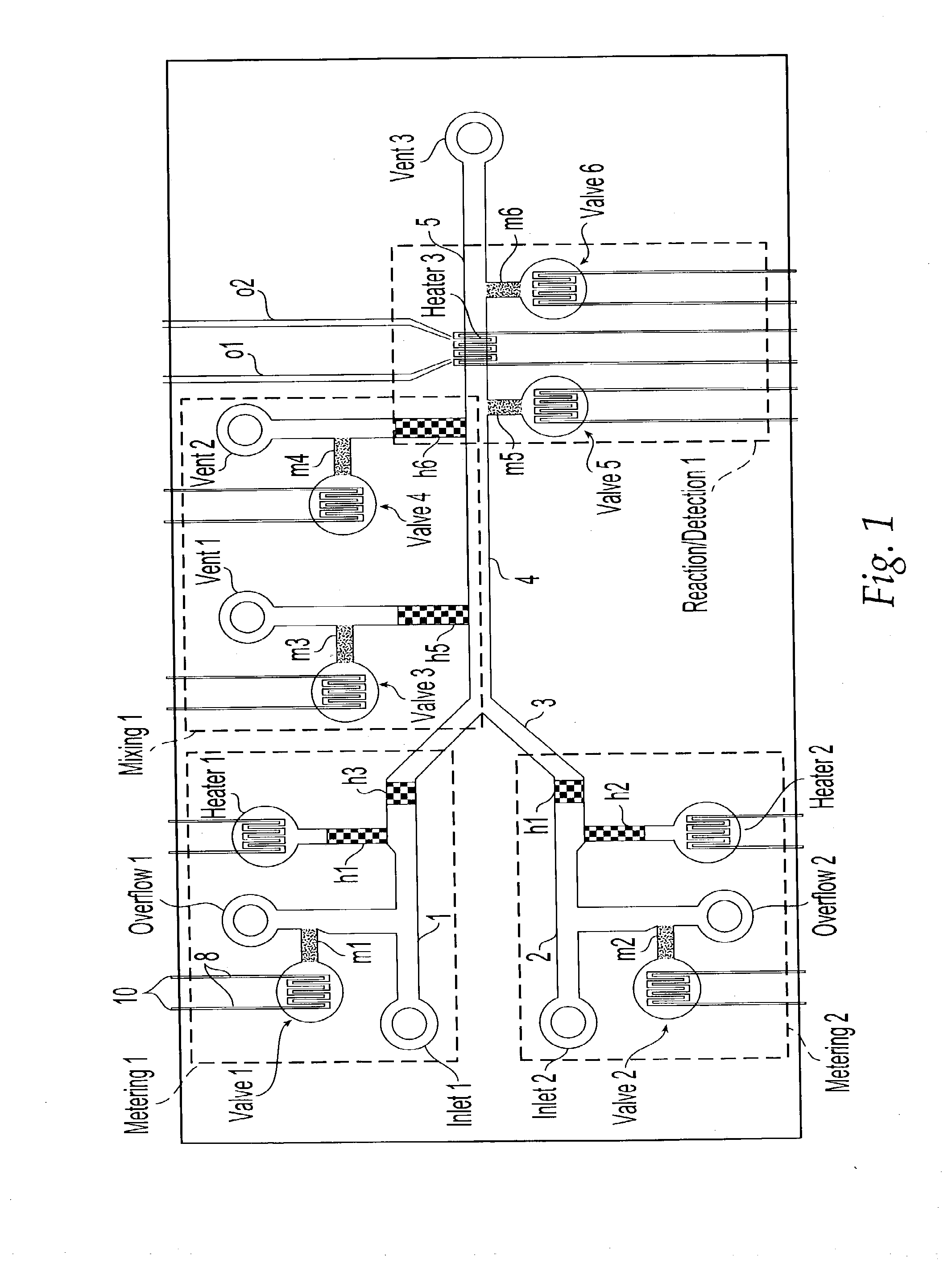

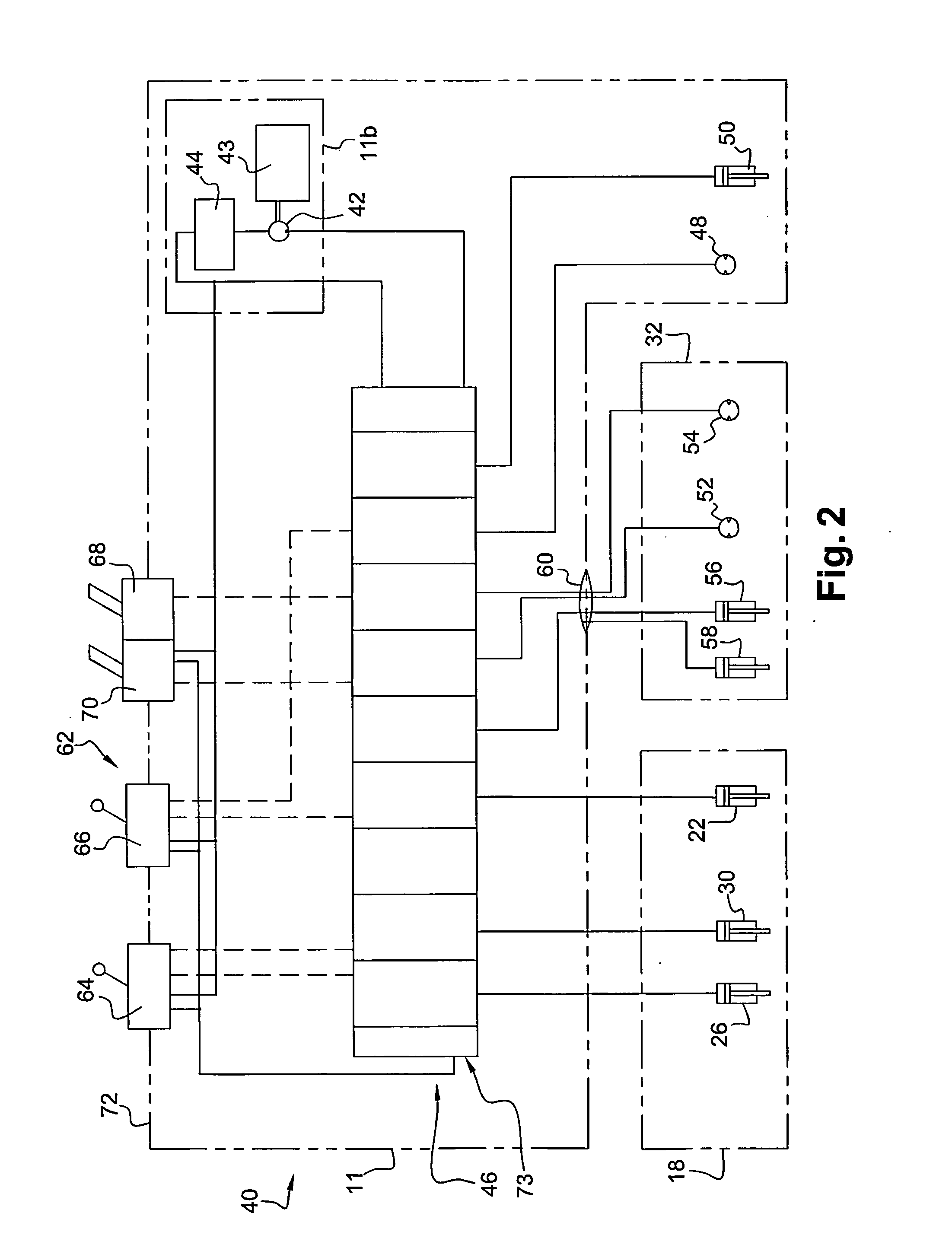

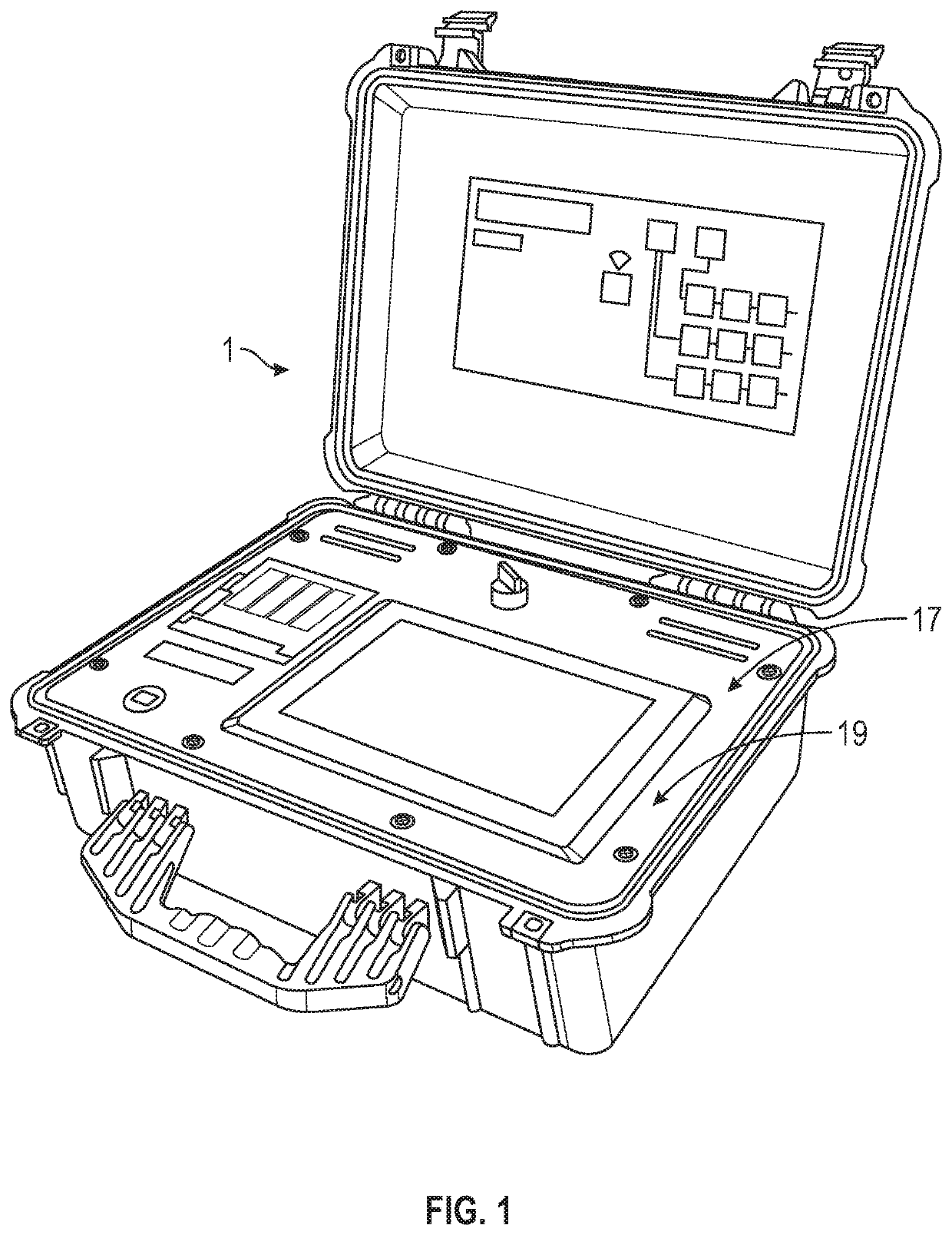

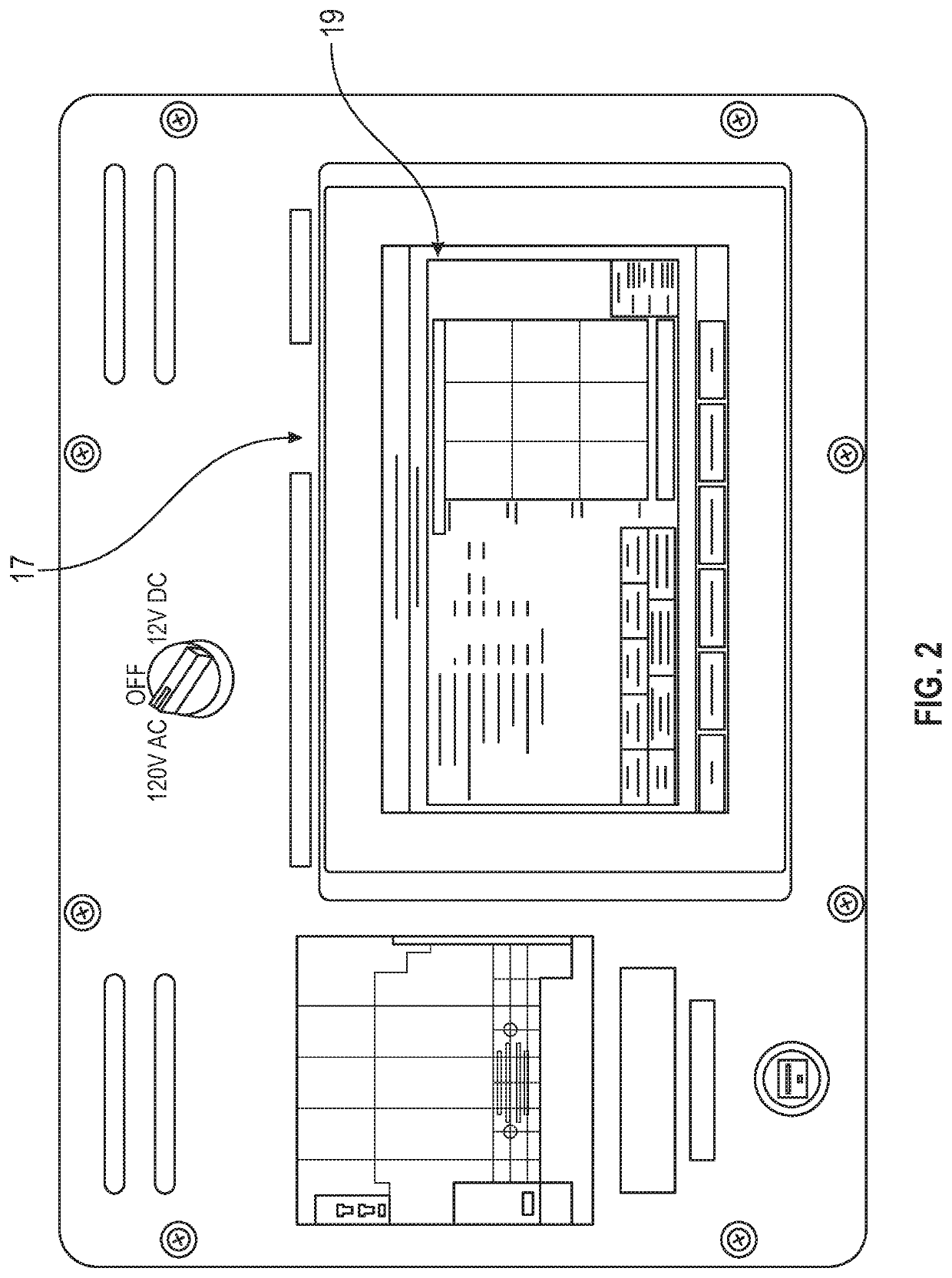

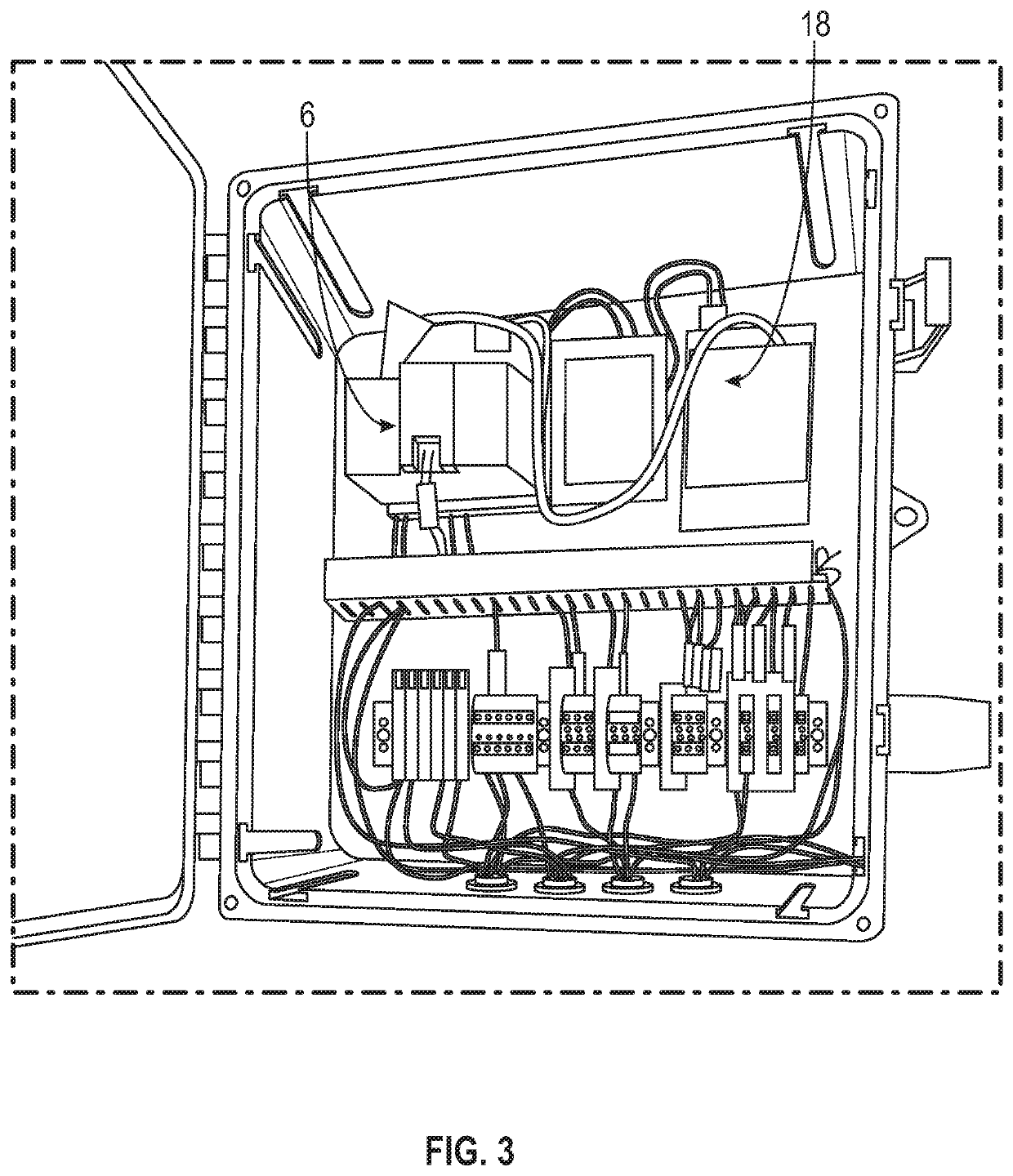

Methods and systems for control of general purpose microfluidic devices

ActiveUS8895311B1Overcome deficienciesEasy programmingHeating or cooling apparatusSamplingGeneral purposeLow voltage

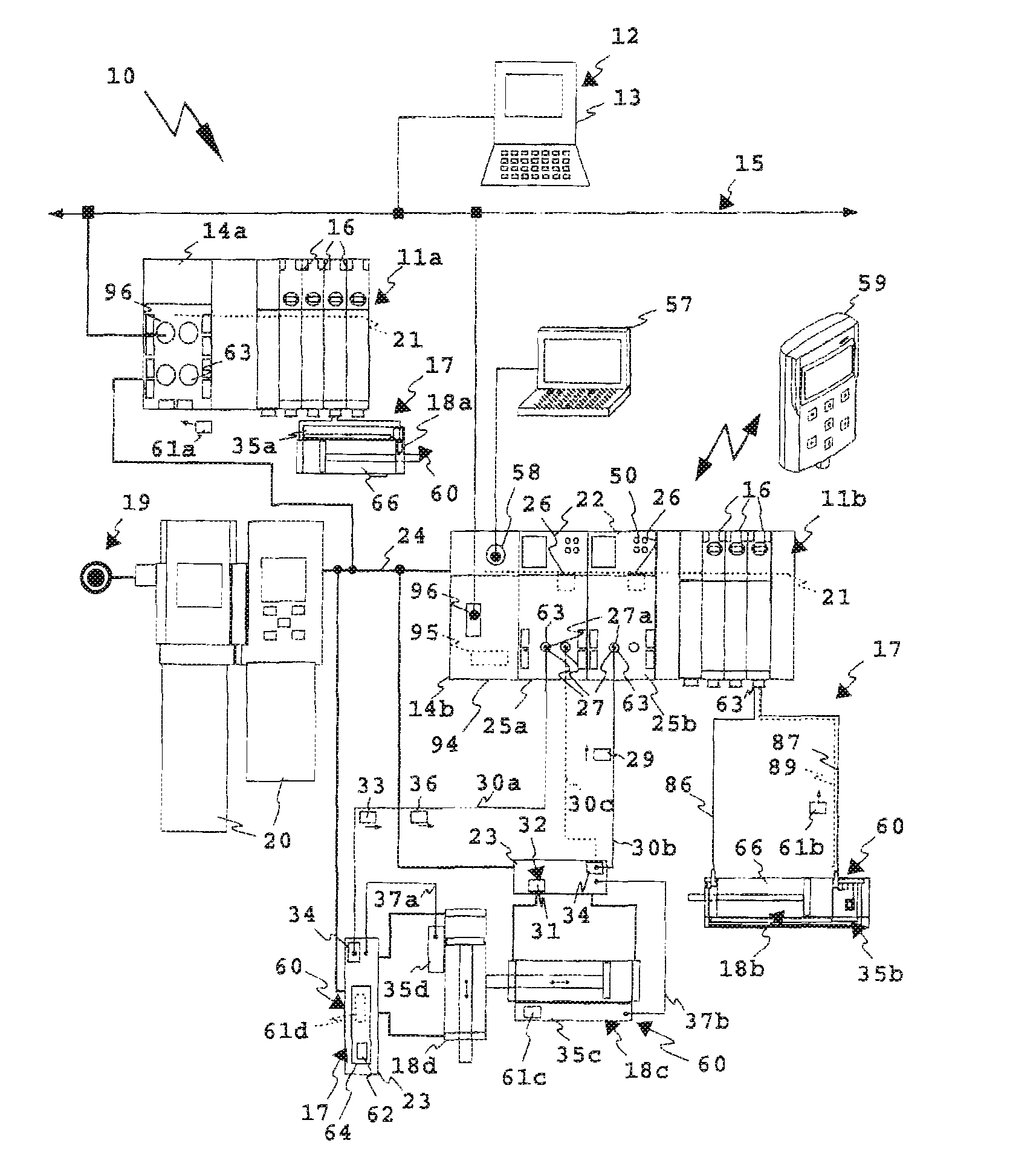

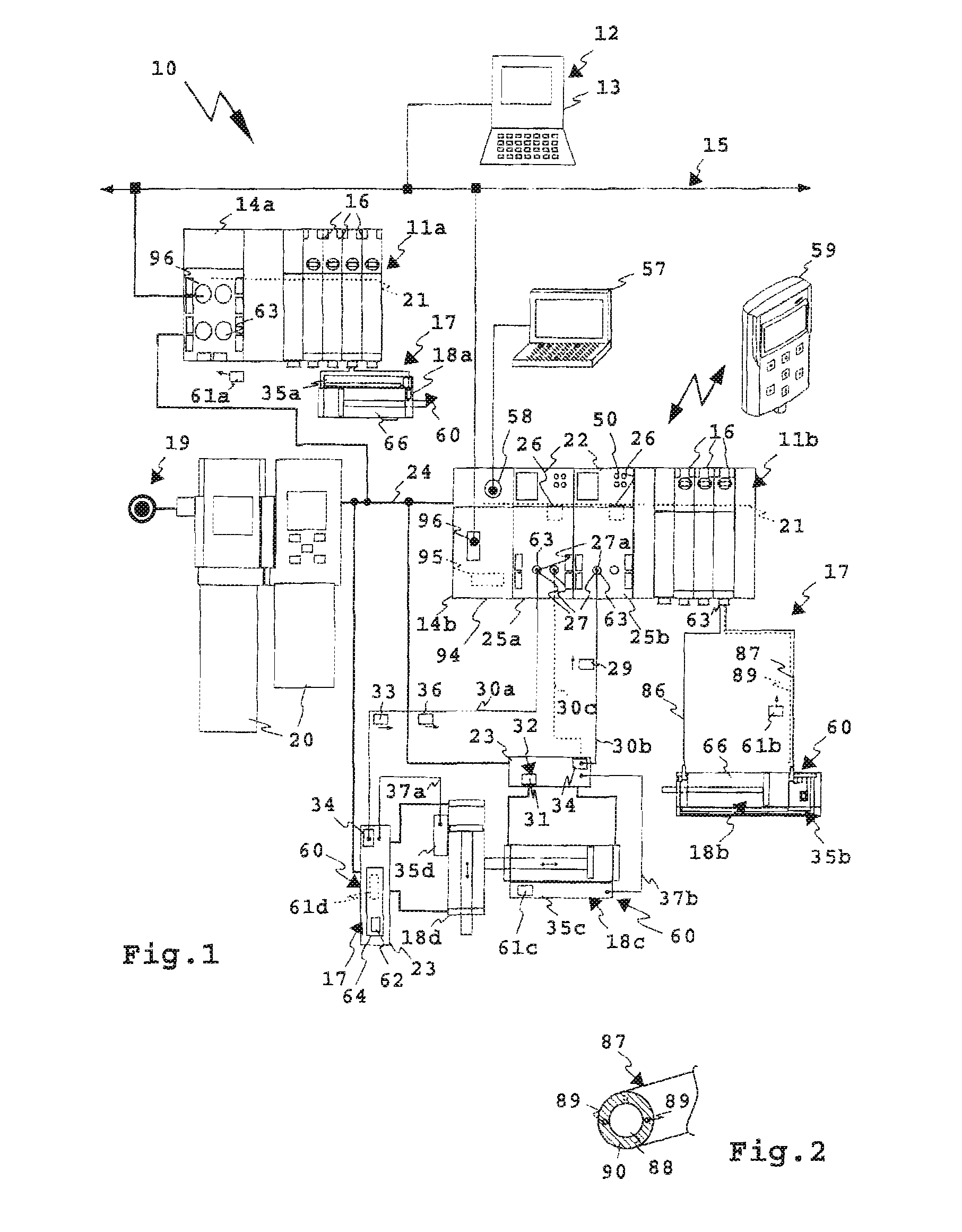

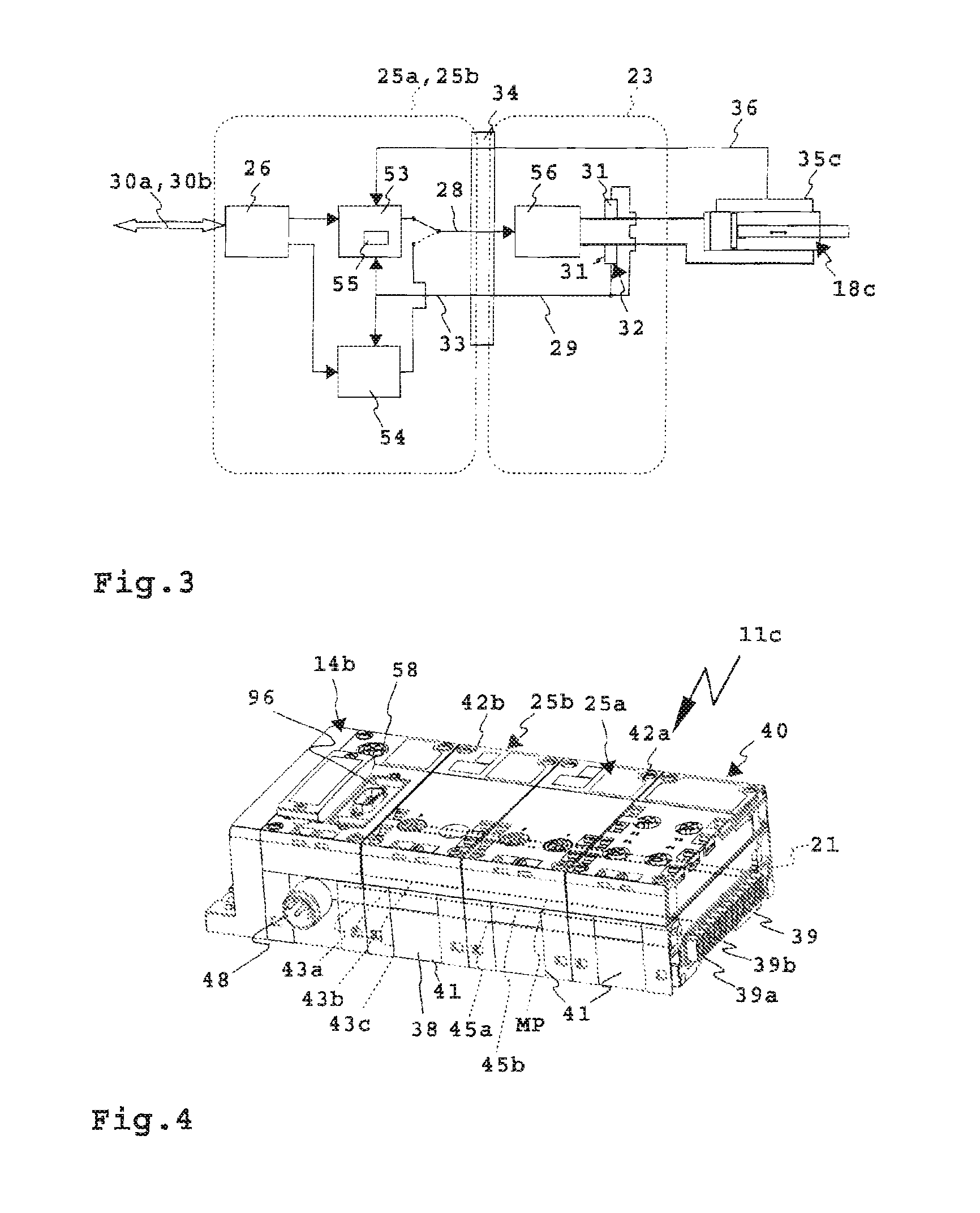

The present invention provides control methods, control systems, and control software for microfluidic devices that operate by moving discrete micro-droplets through a sequence of determined configurations. Such microfluidic devices are preferably constructed in a hierarchical and modular fashion which is reflected in the preferred structure of the provided methods and systems. In particular, the methods are structured into low-level device component control functions, middle-level actuator control functions, and high-level micro-droplet control functions. Advantageously, a microfluidic device may thereby be instructed to perform an intended reaction or analysis by invoking micro-droplet control function that perform intuitive tasks like measuring, mixing, heating, and so forth. The systems are preferably programmable and capable of accommodating microfluidic devices controlled by low voltages and constructed in standardized configurations. Advantageously, a single control system can thereby control numerous different reactions in numerous different microfluidic devices simply by loading different easily understood micro-droplet programs.

Owner:HANDYLAB

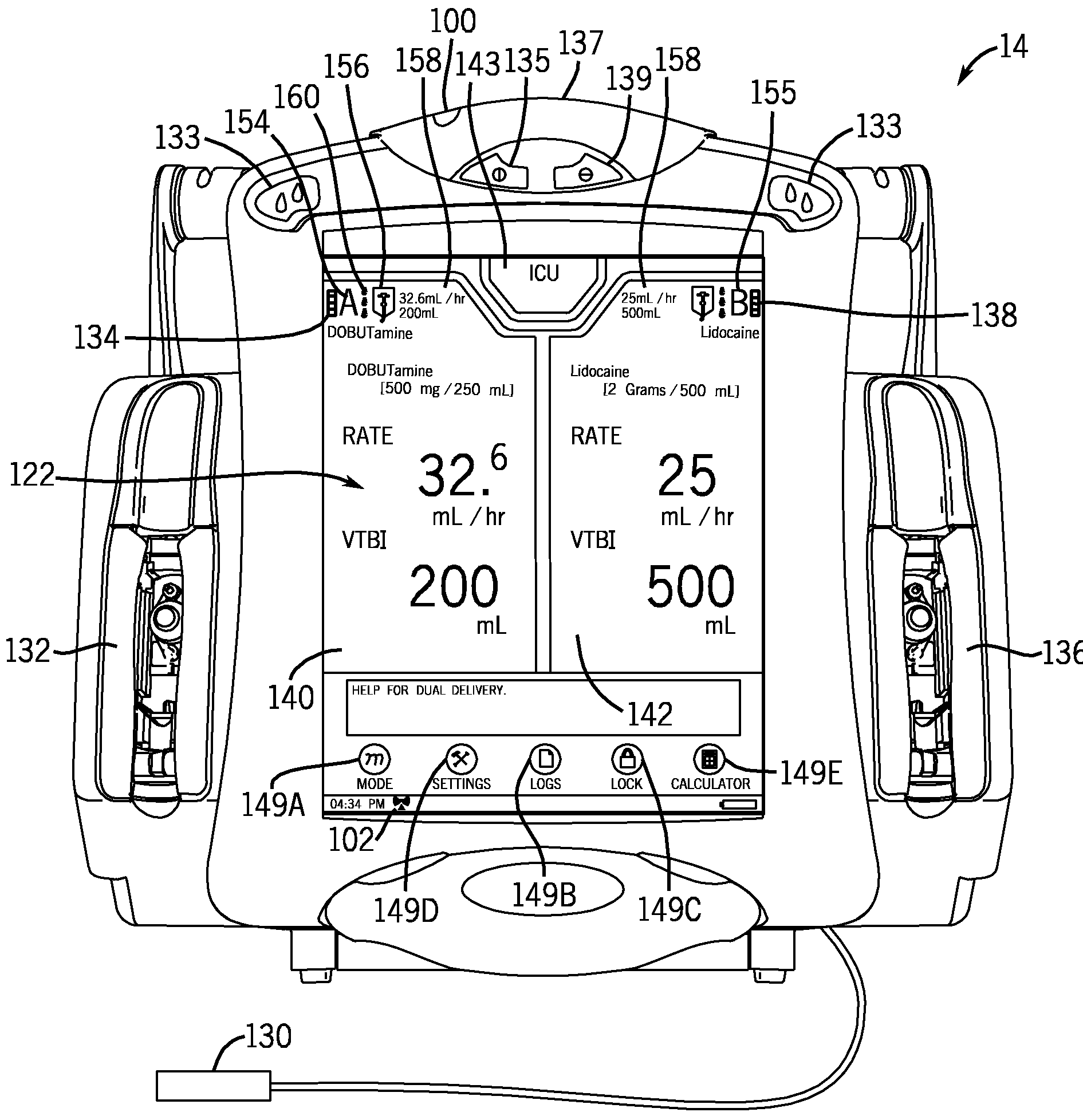

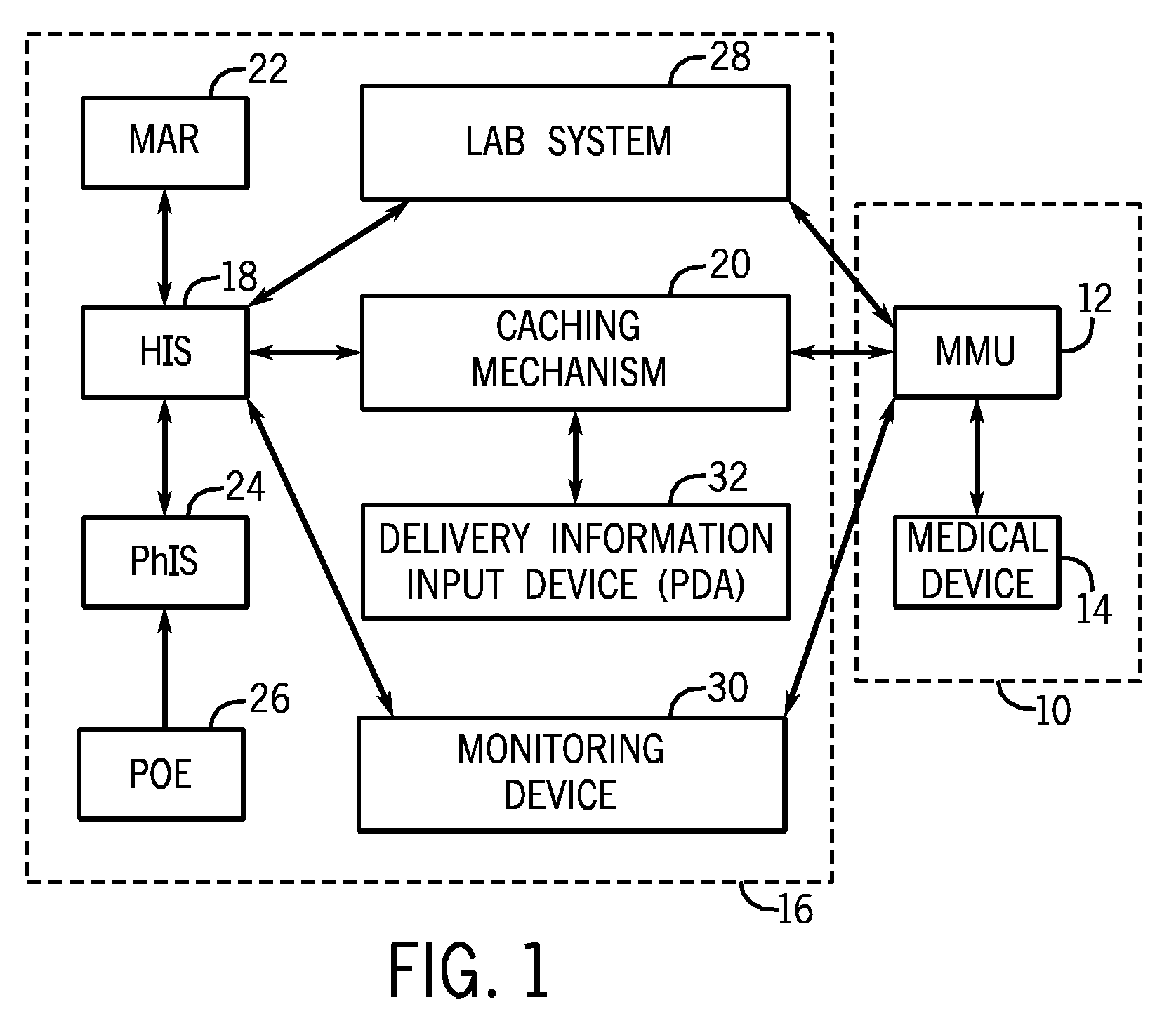

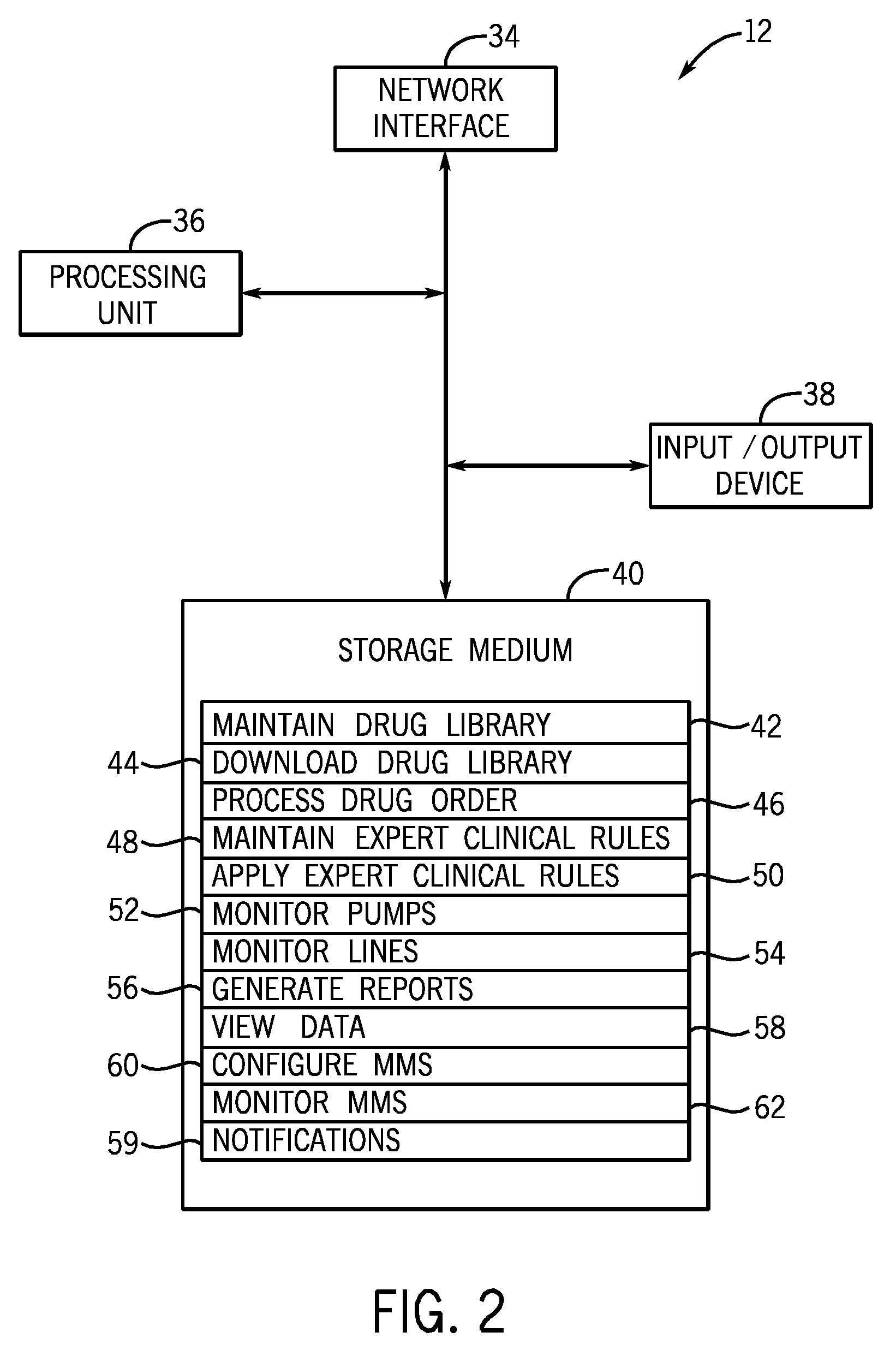

User interface improvements for medical devices

ActiveUS20090177180A1Easy to navigateMaintaining the infusion parametersDrug and medicationsSurgeryMedical deviceBiomedical engineering

A method and system is disclosed for operating a medical device with or without a cassette in place. A method is disclosed for adding additional VTBI to an ongoing infusion without stopping the infusion and with maintaining the infusion parameters. A method and system is disclosed for changing the CCA without having to interrupt or completely stop an ongoing infusion. Quick titration buttons are provided to allow improved navigation between various delivery display screens.

Owner:ICU MEDICAL INC

Methods and systems for control of general purpose microfluidic devices

InactiveUS20150142186A1Easy programmingInexpensive to buildHeating or cooling apparatusSamplingGeneral purposeControl system

The present invention provides control methods, control systems, and control software for microfluidic devices that operate by moving discrete micro-droplets through a sequence of determined configurations. Such microfluidic devices are preferably constructed in a hierarchical and modular fashion which is reflected in the preferred structure of the provided methods and systems. In particular, the methods are structured into low-level device component control functions, middle-level actuator control functions, and high-level micro-droplet control functions. Advantageously, a microfluidic device may thereby be instructed to perform an intended reaction or analysis by invoking micro-droplet control function that perform intuitive tasks like measuring, mixing, heating, and so forth. The systems are preferably programmable and capable of accommodating microfluidic devices controlled by low voltages and constructed in standardized configurations. Advantageously, a single control system can thereby control numerous different reactions in numerous different microfluidic devices simply by loading different easily understood micro-droplet programs.

Owner:HANDYLAB

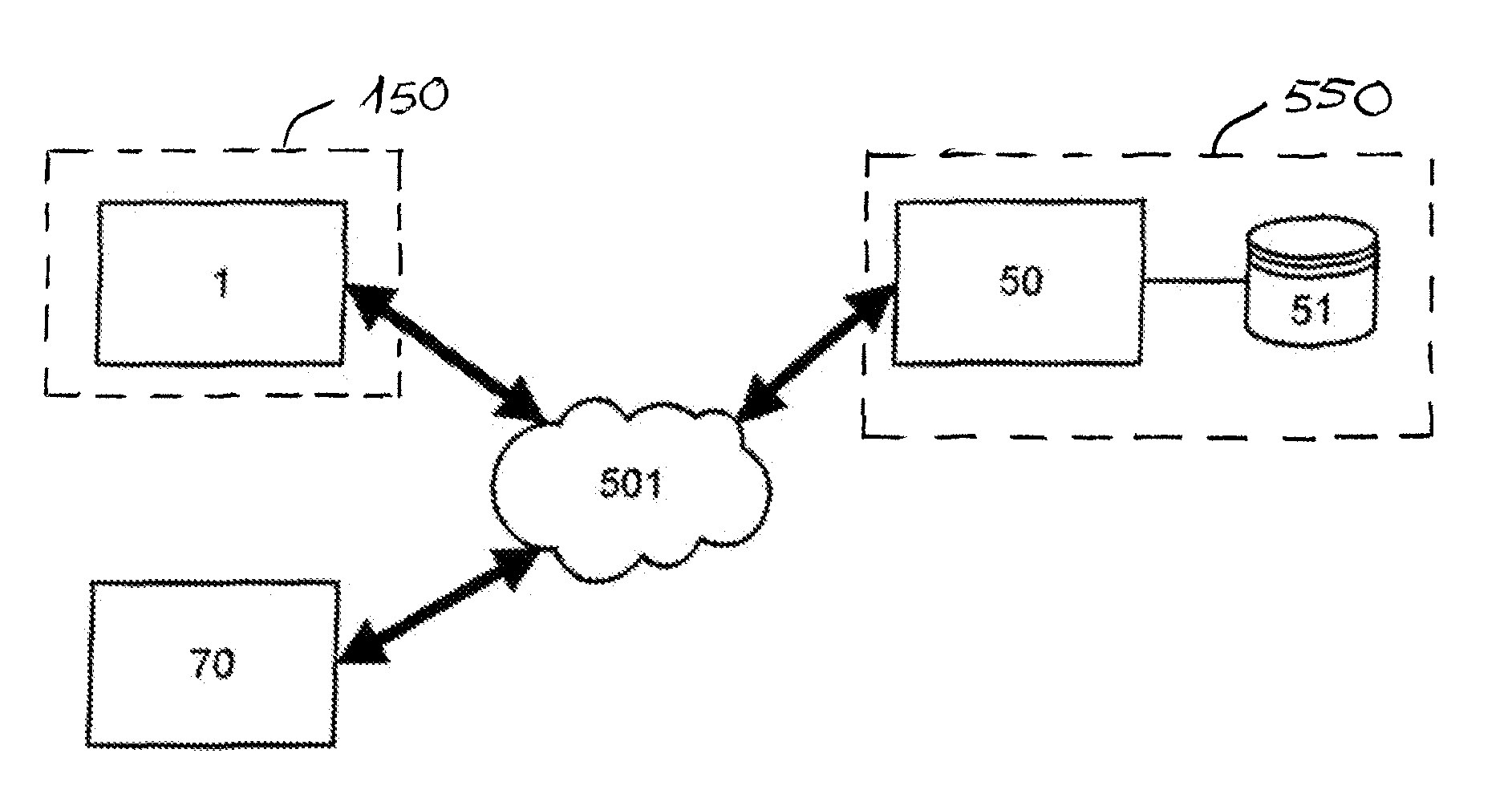

Beverage preparation machine supporting a remote service functionality

ActiveUS20120245732A1Less interactionReduce interactionCoin-freed apparatus detailsDigital computer detailsComputer science

The present invention relates to a method for remotely providing service functionalities for a beverage preparation machine (1). The beverage preparation machine (1) is adapted for preparing a beverage by receiving a capsule in a capsule extraction unit, circulating a carrier liquid, such as water in particular heated water, through said capsule in the extraction unit and by dispensing a resulting beverage. The machine is in data communication with a remote server (50) via a communication network (511, 501, 502). The machine (1) monitors (S1, S2, S3, S4) parameters related to the machine and submits (S5) the monitored parameters to the server (5). The server (5) initiates (S8, S9) a service functionality depending on the submitted parameters. The present invention further relates to a beverage preparation machine (1) adapted to support such a method and to a system (100) for remotely providing service functionalities for a beverage preparation machine (1) at a customer location (150).

Owner:SOC DES PROD NESTLE SA

Methods and systems for control of general purpose microfluidic devices

InactiveUS10571935B2Easy programmingInexpensive to buildHeating or cooling apparatusComputer controlGeneral purposeLow voltage

The present invention provides control methods, control systems, and control software for microfluidic devices that operate by moving discrete micro-droplets through a sequence of determined configurations. Such microfluidic devices are preferably constructed in a hierarchical and modular fashion which is reflected in the preferred structure of the provided methods and systems. In particular, the methods are structured into low-level device component control functions, middle-level actuator control functions, and high-level micro-droplet control functions. Advantageously, a microfluidic device may thereby be instructed to perform an intended reaction or analysis by invoking micro-droplet control function that perform intuitive tasks like measuring, mixing, heating, and so forth. The systems are preferably programmable and capable of accommodating microfluidic devices controlled by low voltages and constructed in standardized configurations. Advantageously, a single control system can thereby control numerous different reactions in numerous different microfluidic devices simply by loading different easily understood micro-droplet programs.

Owner:HANDYLAB

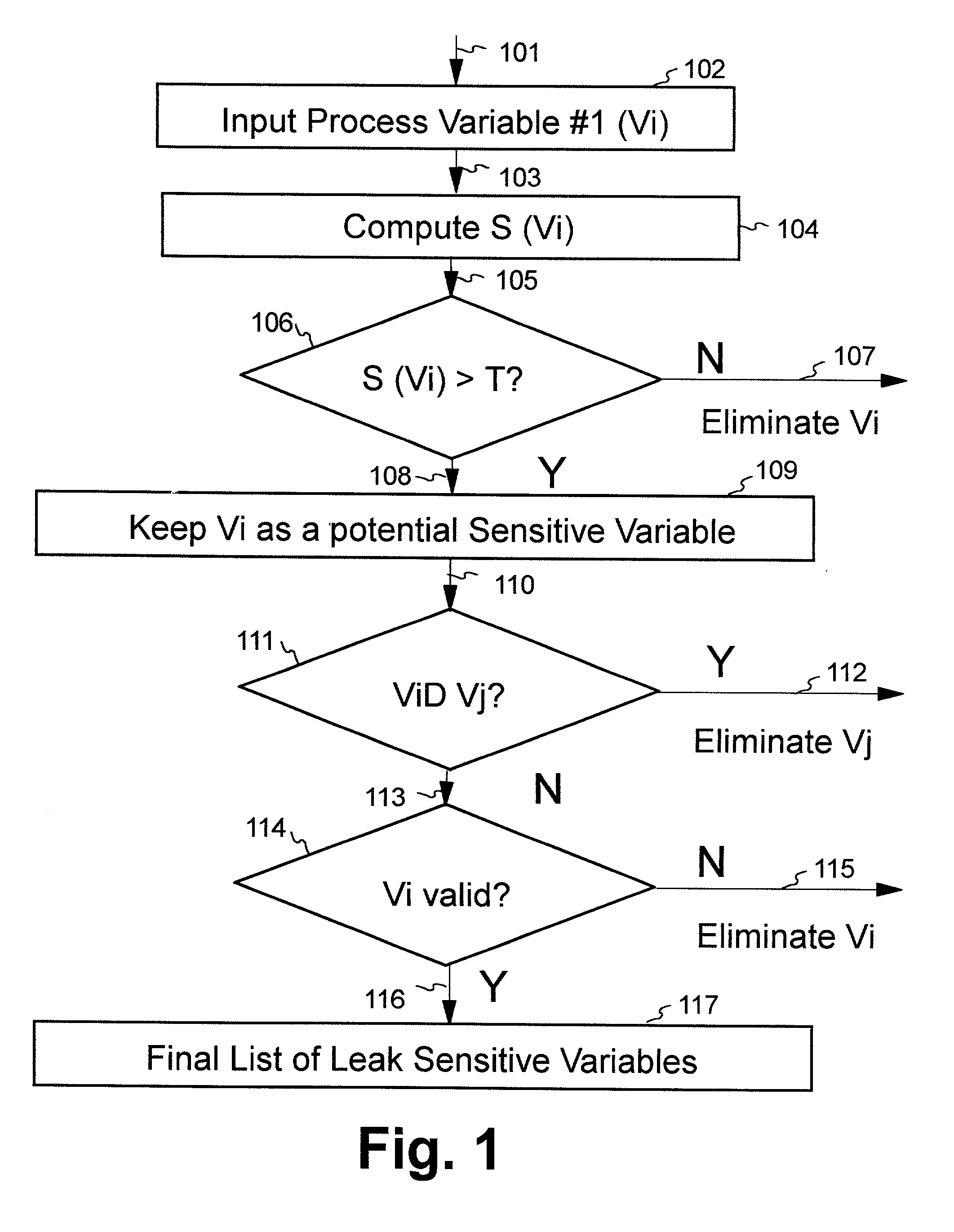

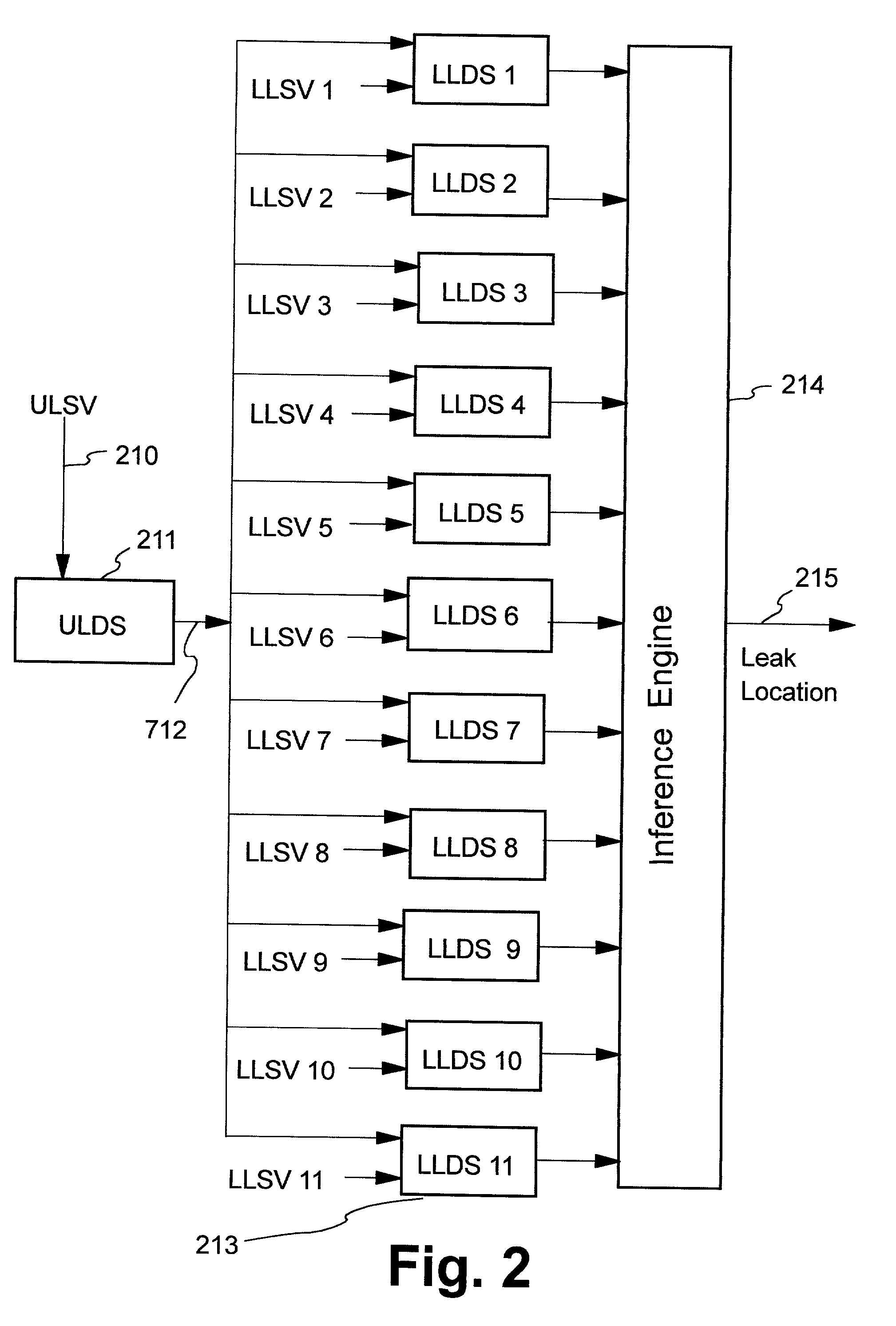

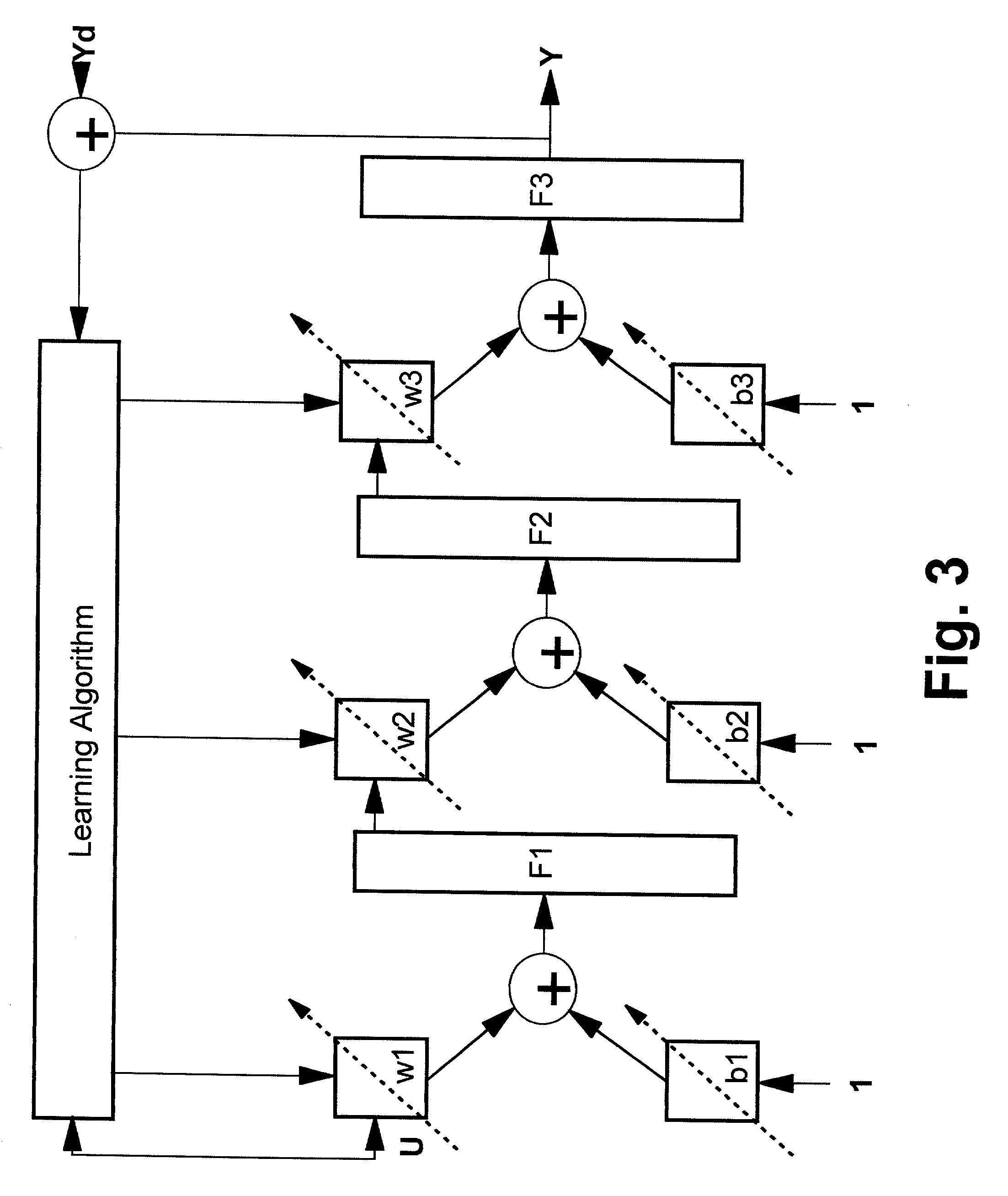

Artificial neural network and fuzzy logic based boiler tube leak detection systems

Power industry boiler tube failures are a major cause of utility forced outages in the United States, with approximately 41,000 tube failures occurring every year at a cost of $5 billion a year. Accordingly, early tube leak detection and isolation is highly desirable. Early detection allows scheduling of a repair rather than suffering a forced outage, and significantly increases the chance of preventing damage to adjacent tubes. The instant detection scheme starts with identification of boiler tube leak process variables which are divided into universal sensitive variables, local leak sensitive variables, group leak sensitive variables, and subgroup leak sensitive variables, and which may be automatically be obtained using a data driven approach and a leak sensitivity function. One embodiment uses artificial neural networks (ANN) to learn the map between appropriate leak sensitive variables and the leak behavior. The second design philosophy integrates ANNs with approximate reasoning using fuzzy logic and fuzzy sets. In the second design, ANNs are used for learning, while approximate reasoning and inference engines are used for decision making. Advantages include use of already monitored process variables, no additional hardware and / or maintenance requirements, systematic processing does not require an expert system and / or a skilled operator, and the systems are portable and can be easily tailored for use on a variety of different boilers.

Owner:TENNESSEE TECHNOLOGICAL UNIVERSITY +1

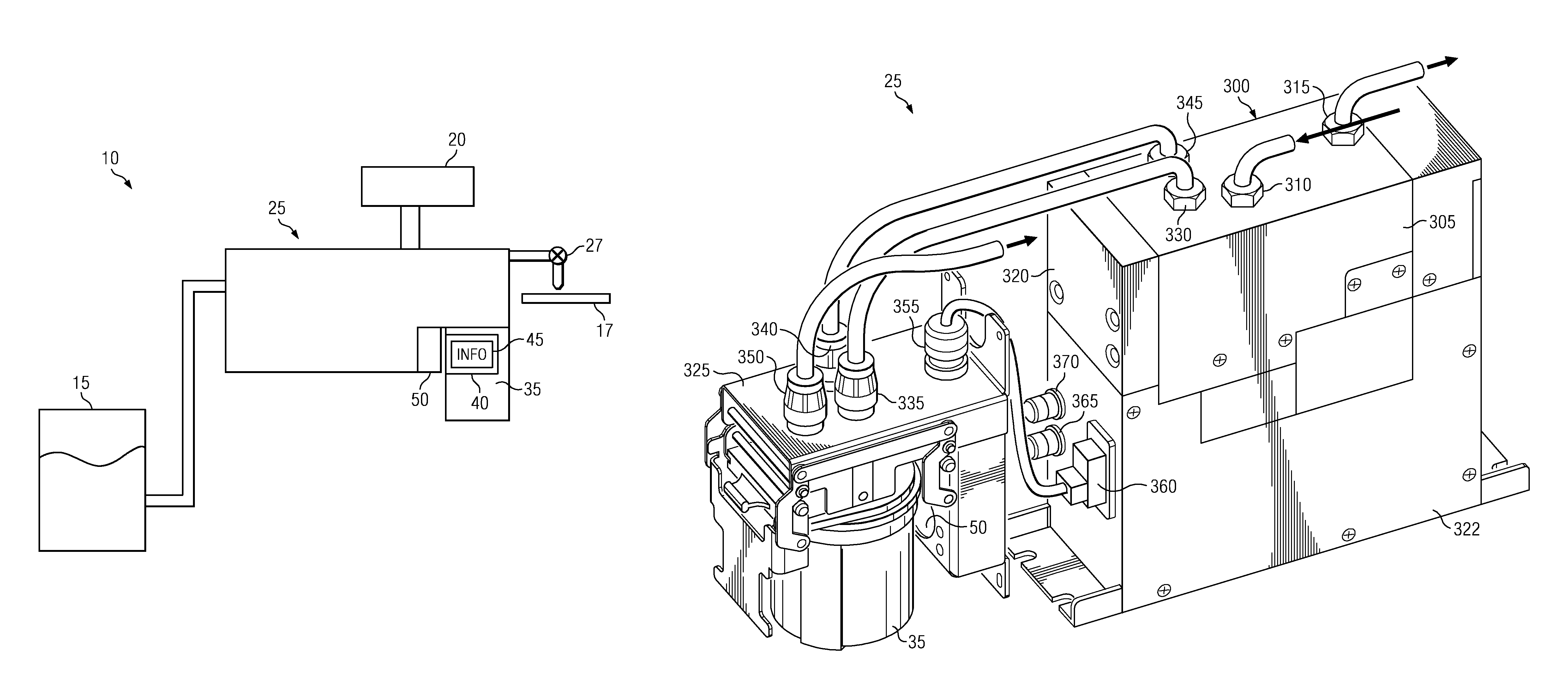

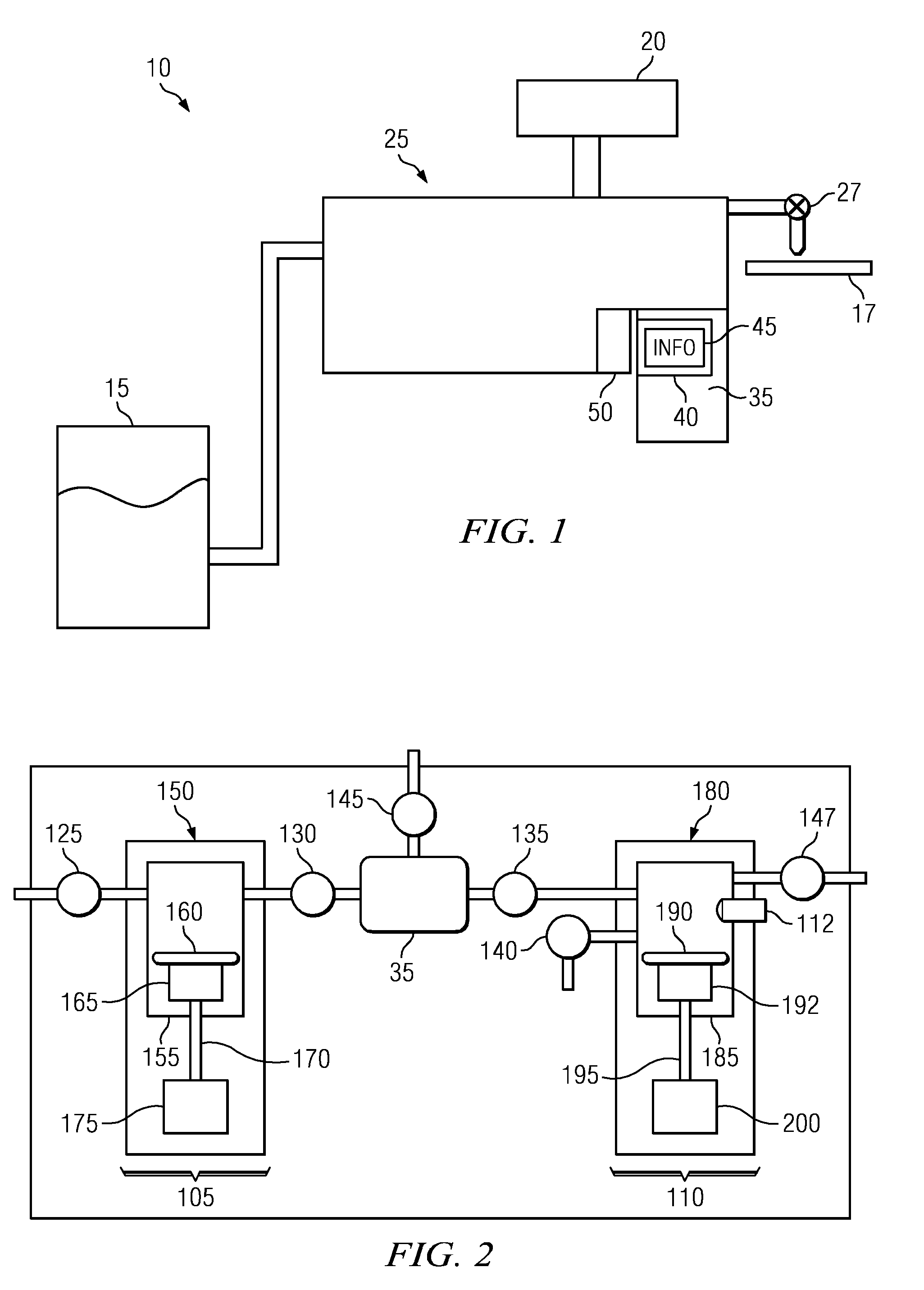

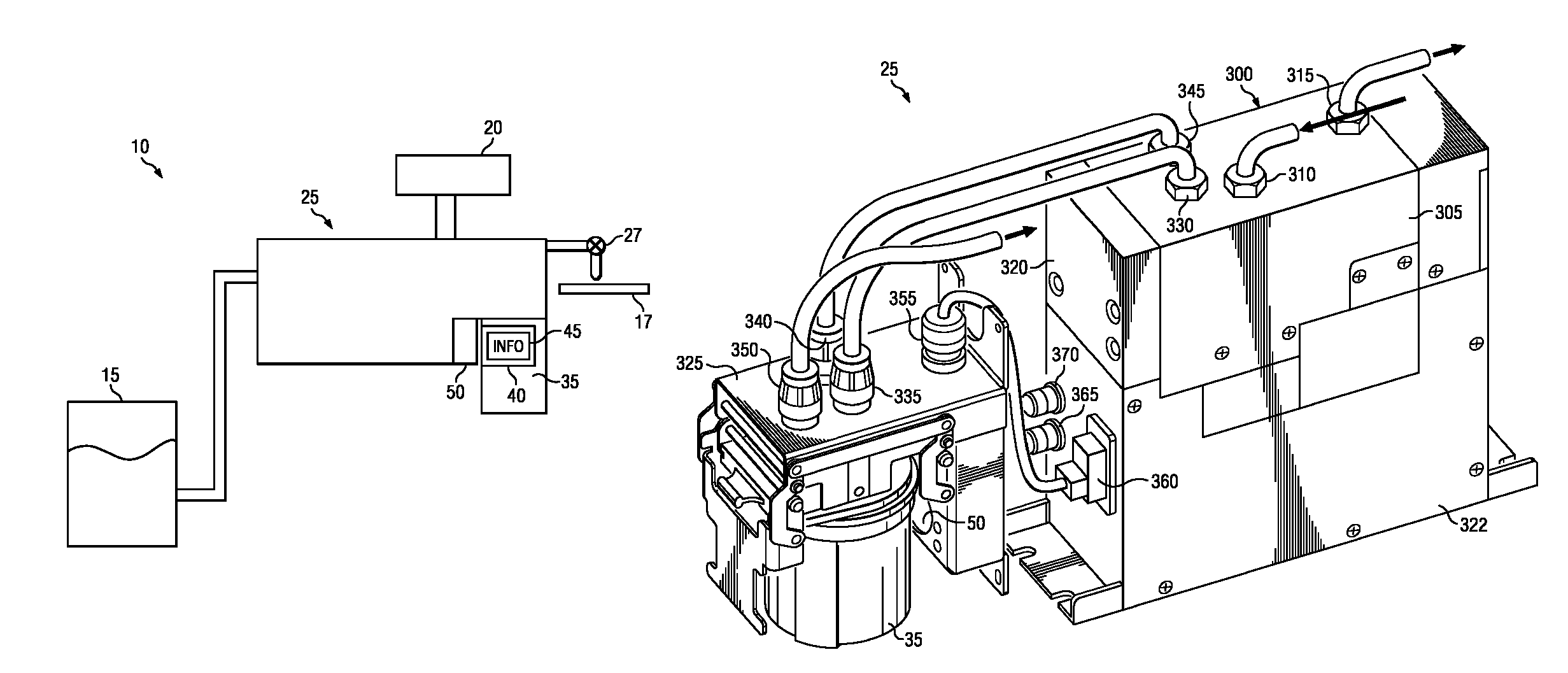

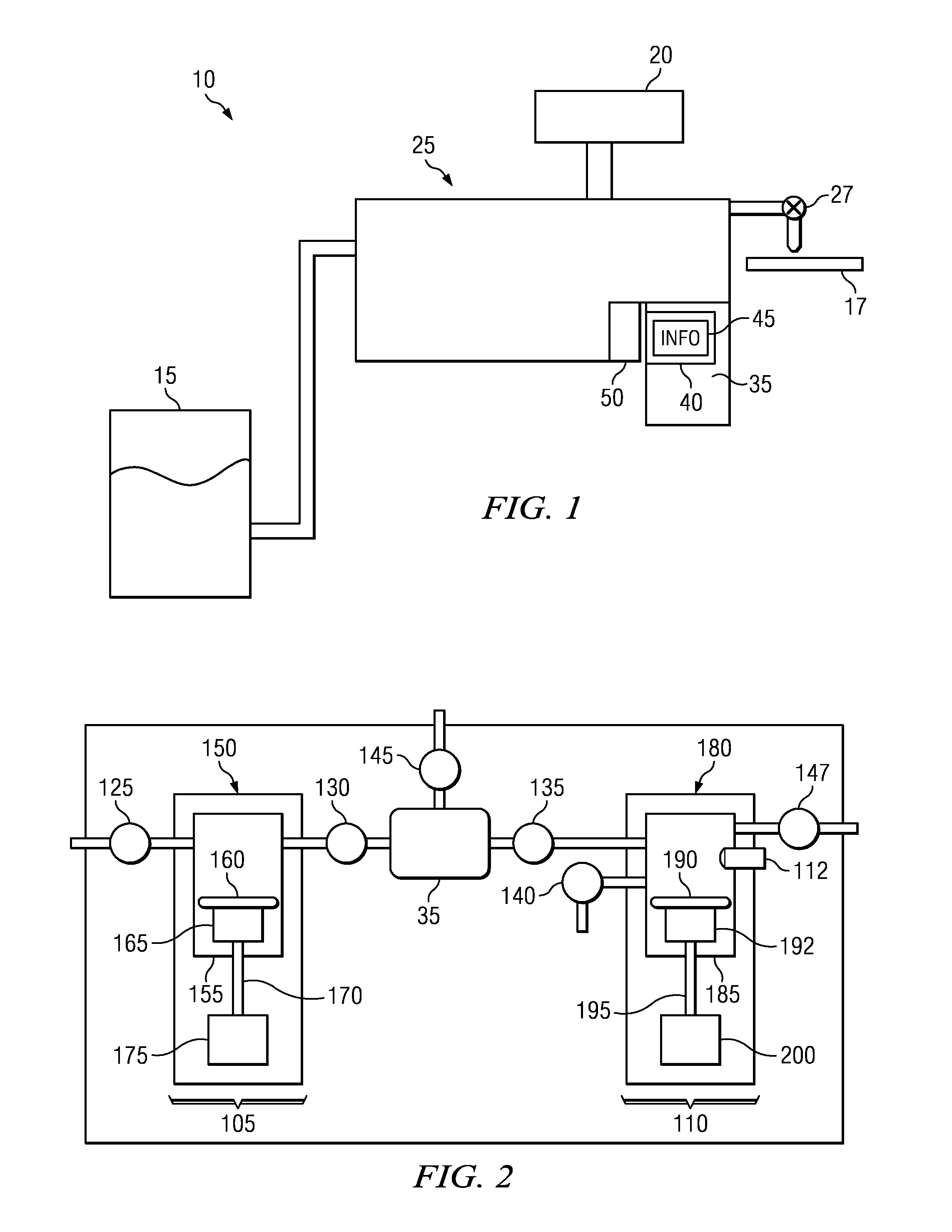

Method and system for controlling operation of a pump based on filter information in a filter information tag

The disclosure describes systems and methods relating generally to filtration. Even more particularly, this disclosure relates to controlling the operation of a pump using filter information. A removable filter can include an electronically readable tag storing filter information. The filter information can be read by a tag reader and rules applied to the filter information to determine whether or how to operate a pump.

Owner:ENTEGRIS INC

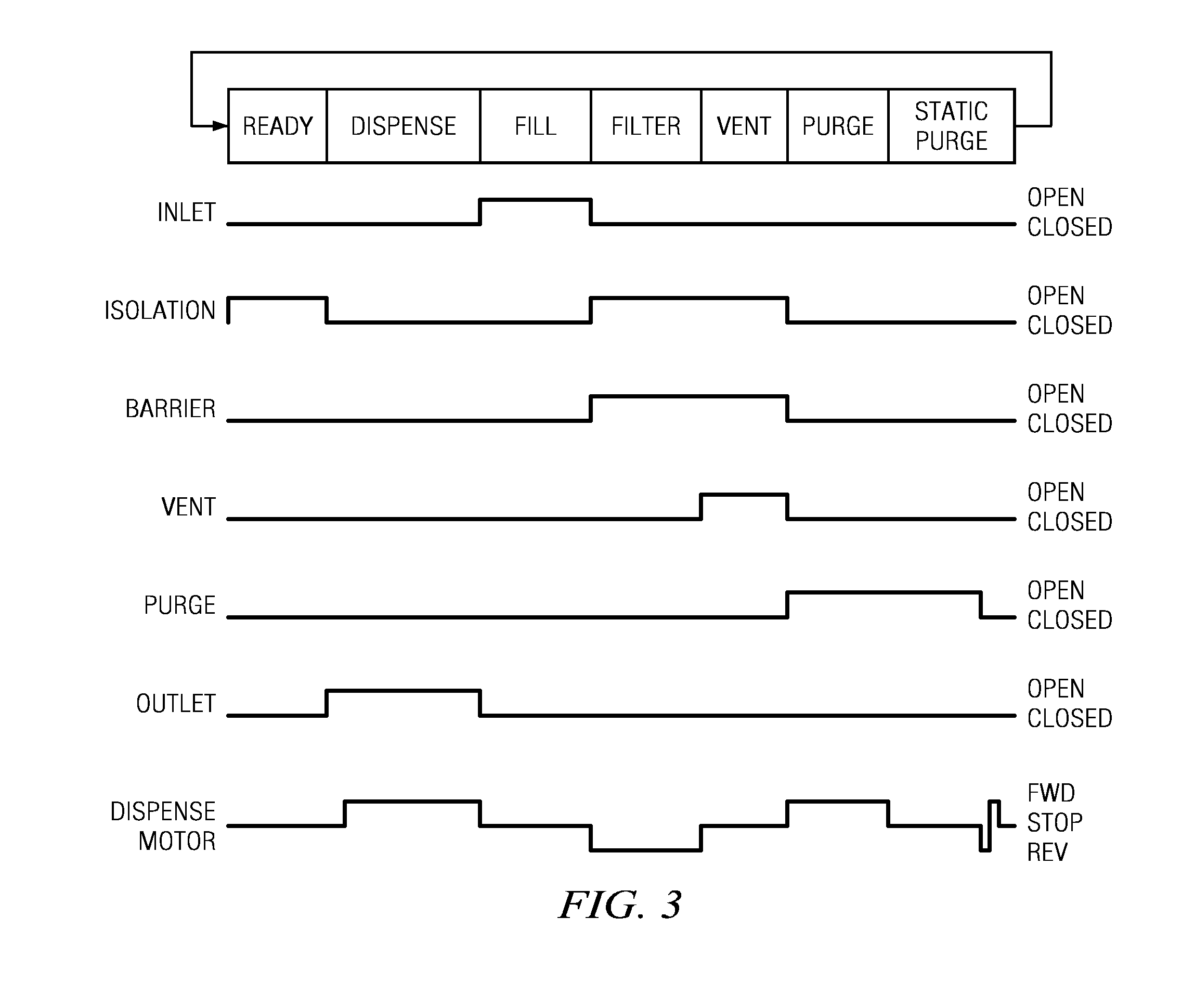

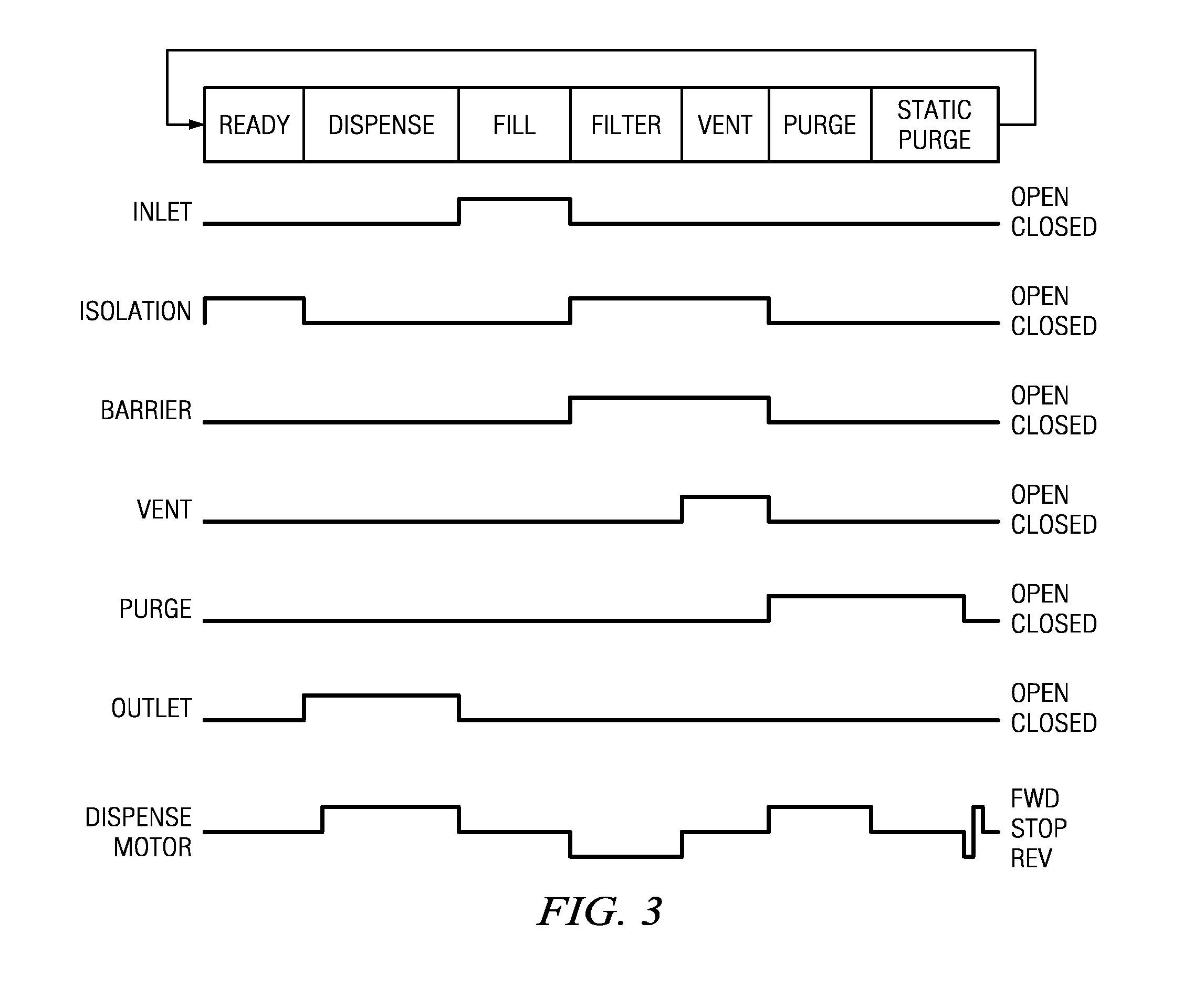

Method and system for optimizing operation of a pump

The disclosure describes systems and methods relating generally to filtration. Even more particularly, embodiments described herein relate to optimizing operating routines of a pump based on filter information and process fluid information. The filter information can be stored on an electronically readable tag on the filter.

Owner:ENTEGRIS INC

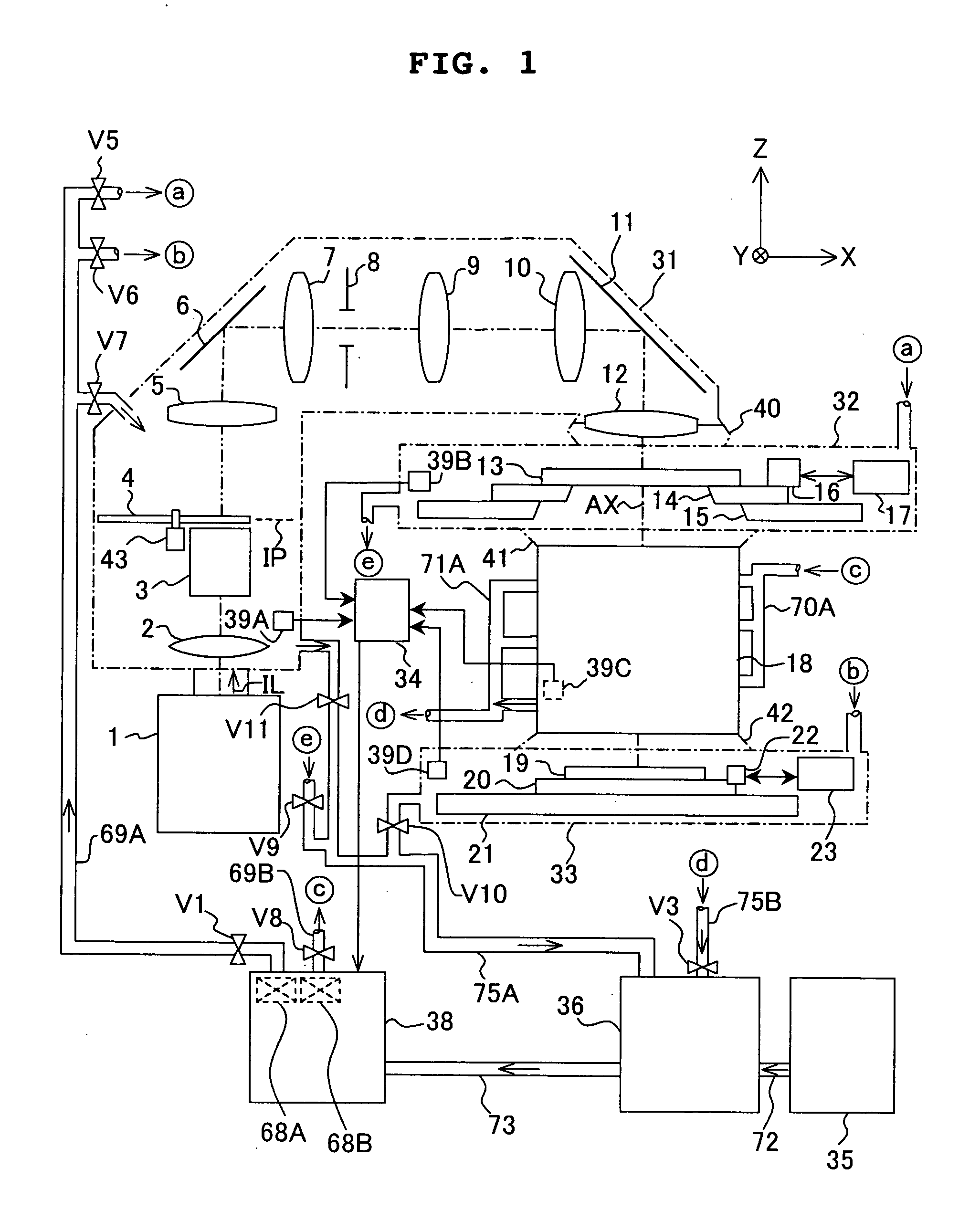

Temperature control method and apparatus and exposure method and apparatus

InactiveUS20050175497A1High temperature control accuracyImprove overlay accuracyLavatory sanitoryDisinfectionTemperature controlCompound (substance)

A temperature control technique and an exposure technique are provided with which high temperature control accuracy can be realized even when a device, which causes thermal fluctuation depending on a temperature-controlled fluid, is used. A gas recovered from a reticle chamber as the temperature control objective, and a high purity purge gas supplied from a gas supply source are mixed in a mixing section. The temperature of the mixed gas is lowered by a refrigerator. Subsequently, the humidity of the gas is measured by a temperature sensor. The gas is then supplied to the reticle chamber via a heating mechanism, a chemical filter which absorbs or generates heat depending on the humidity and a dust protective filter. The heating amount to the gas by the heating mechanism is controlled based on temperature information by a temperature sensor in the reticle chamber and humidity information by the humidity sensor.

Owner:NIKON CORP

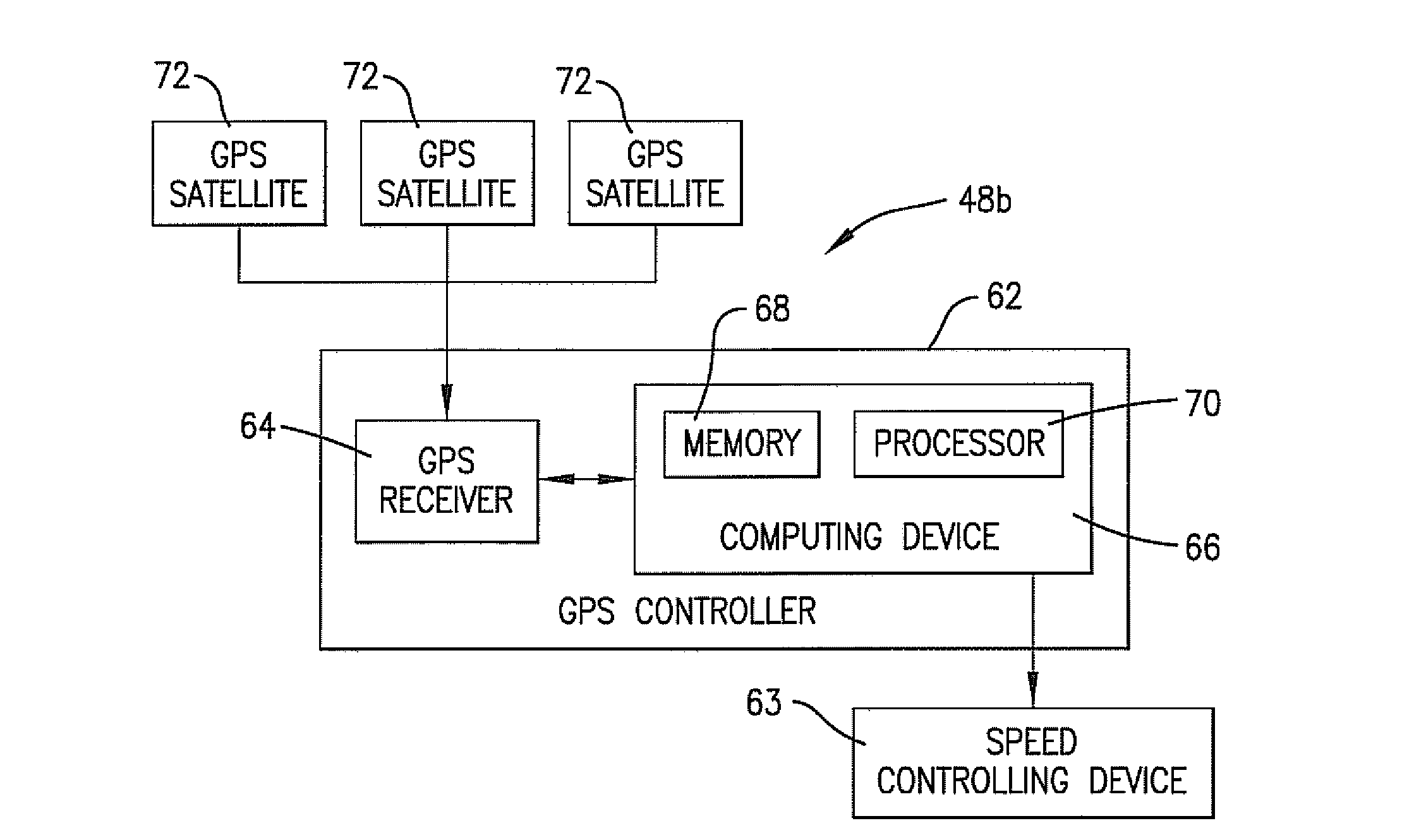

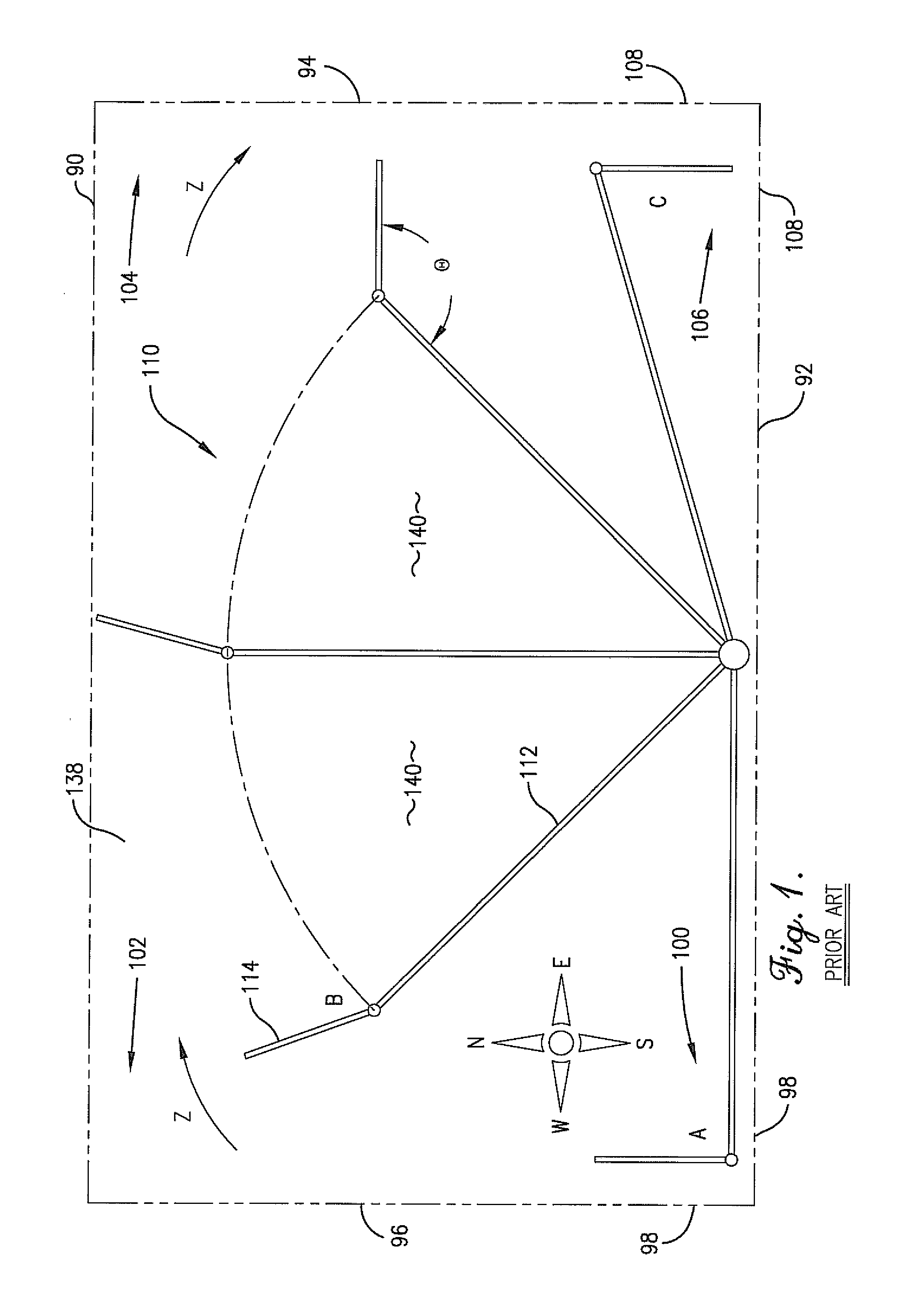

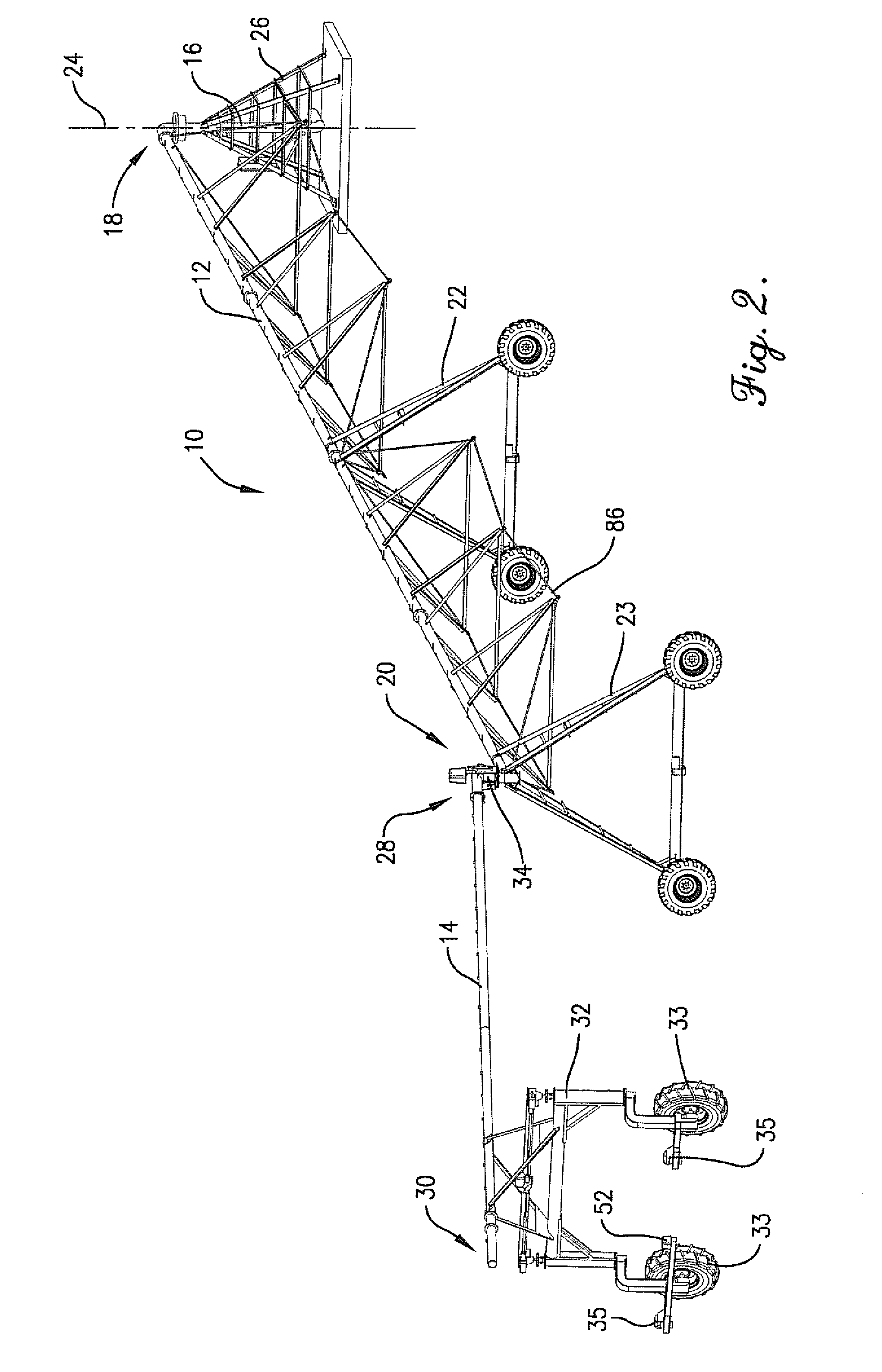

Method, apparatus, and computer program for irrigating a field space wtih a center pivot irrigation machine

ActiveUS20100274398A1Uniform coverageSelf-acting watering devicesWatering devicesControl systemTower

To allow for optimal uniform application of irrigation fluid in a field space outfitted with a center pivot irrigation machine having a main pipeline and an auxiliary or corner pipeline, the auxiliary pipeline is operable to both lead and lag the main pipeline as the main pipeline makes a progressive rotation in a single direction through the field space. In one embodiment a control system for the irrigation machine comprises a buried cable control system. In another embodiment a control system comprises a global positioning satellite control system. In a third embodiment a control system comprises at least two position sensing devices, a first device for sensing an angle of the main pipeline with respect to a center tower and a second device for sensing an angle between the main pipeline and the auxiliary pipeline, and a speed controlling device for controlling a speed of rotation of the main and auxiliary pipelines.

Owner:LINDSAY CORP

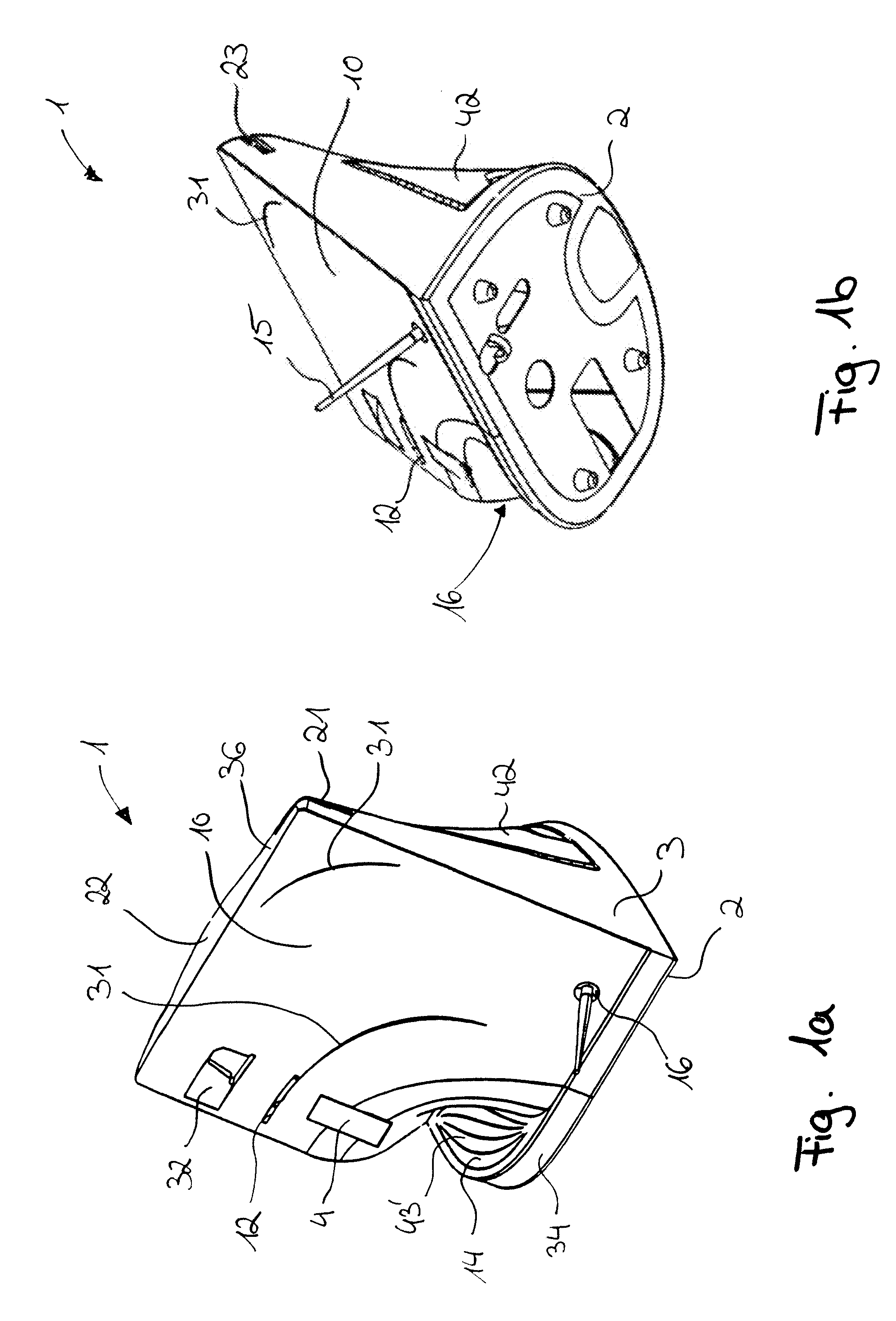

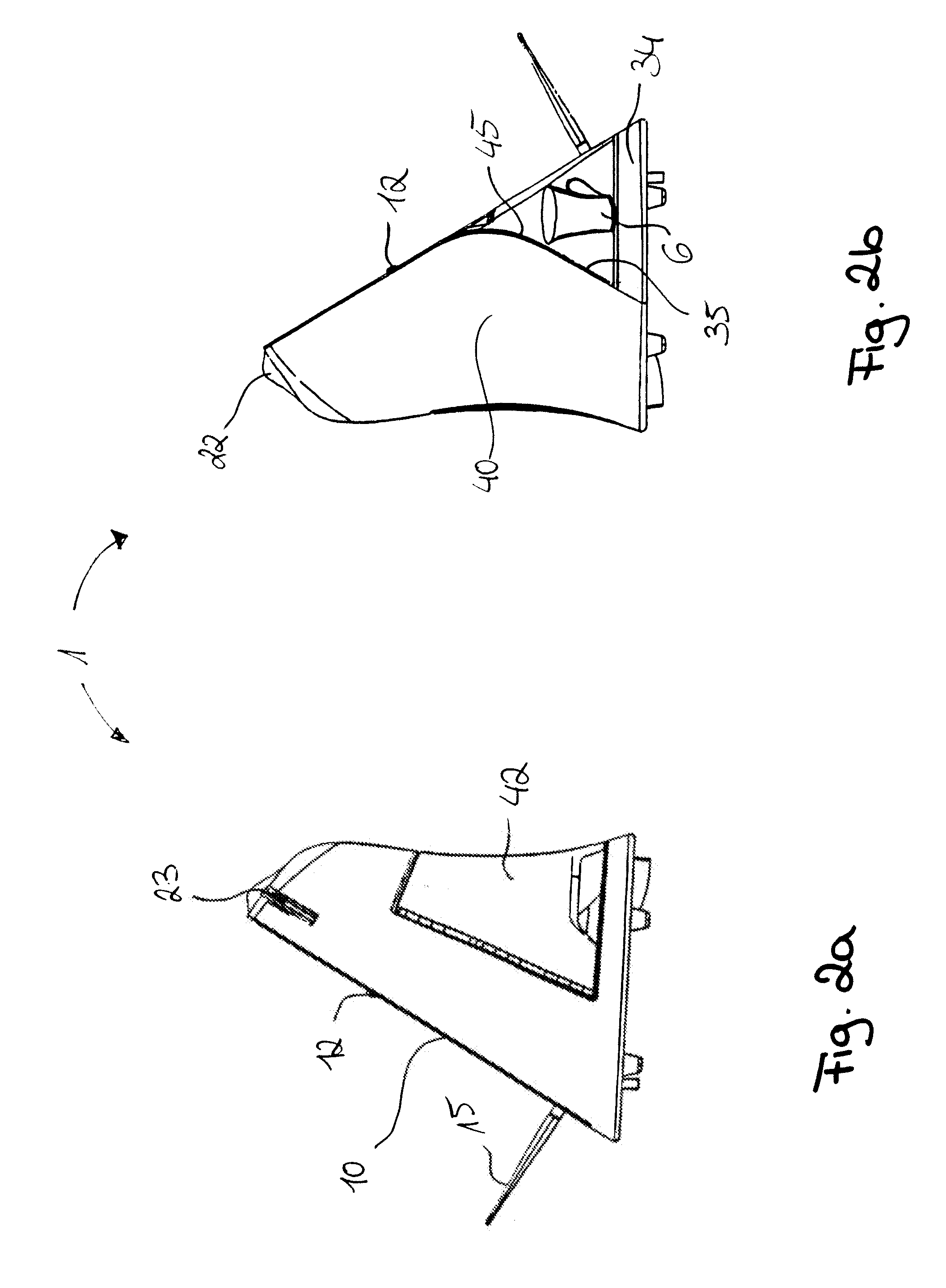

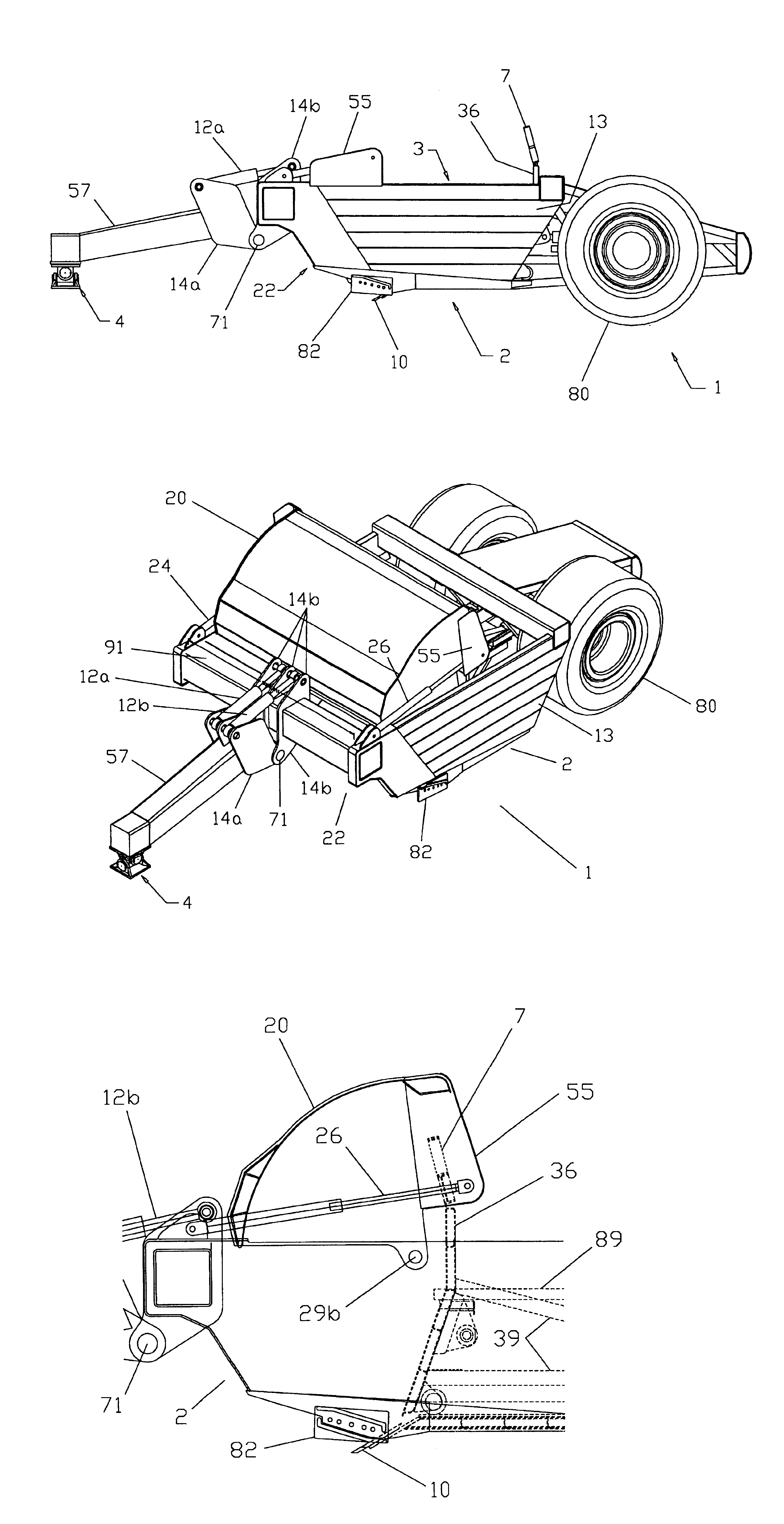

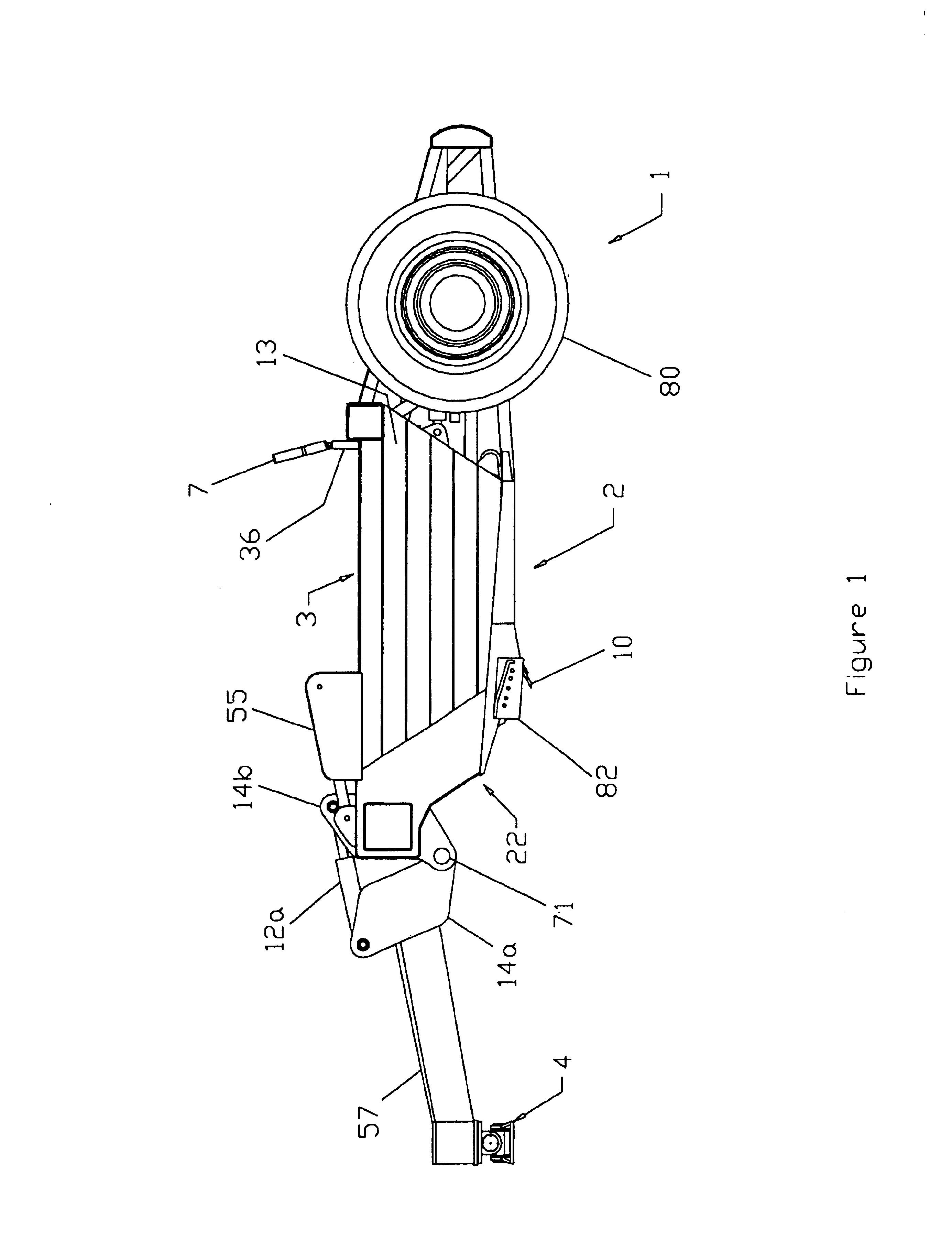

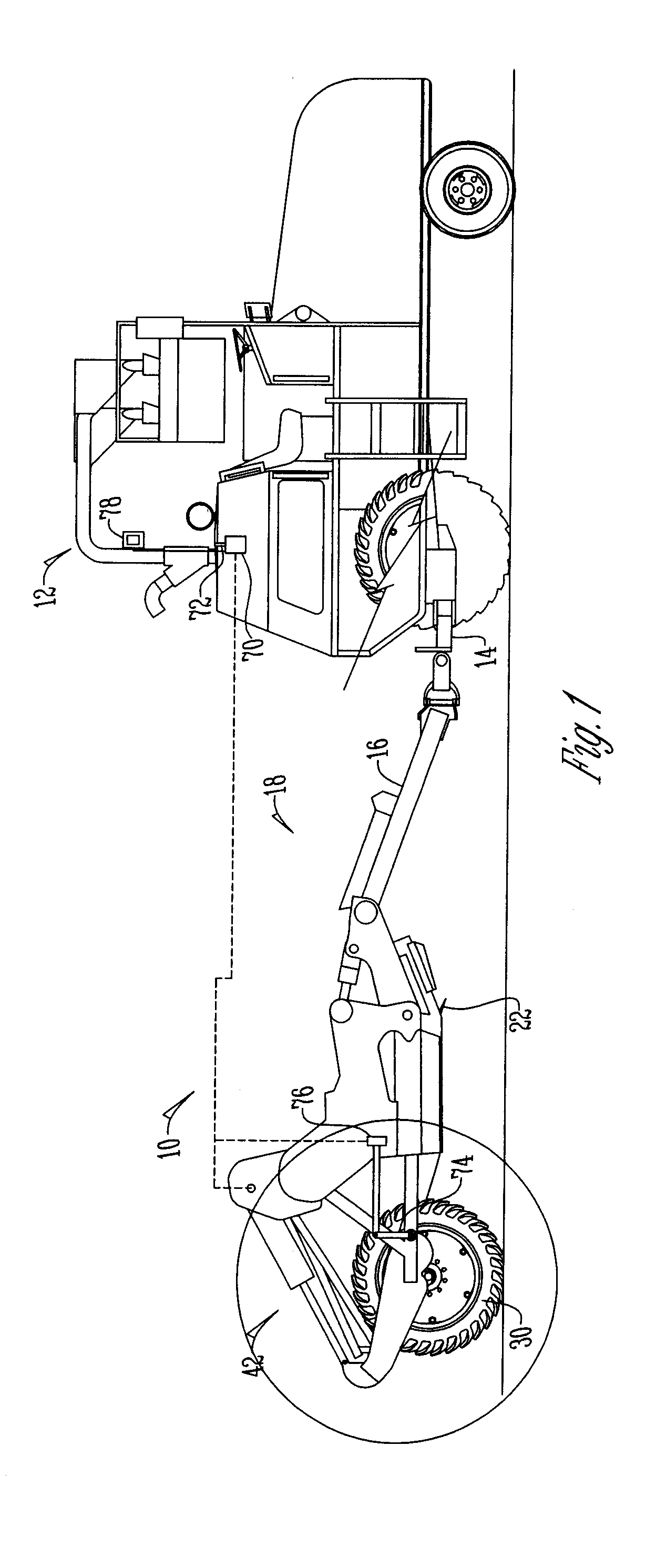

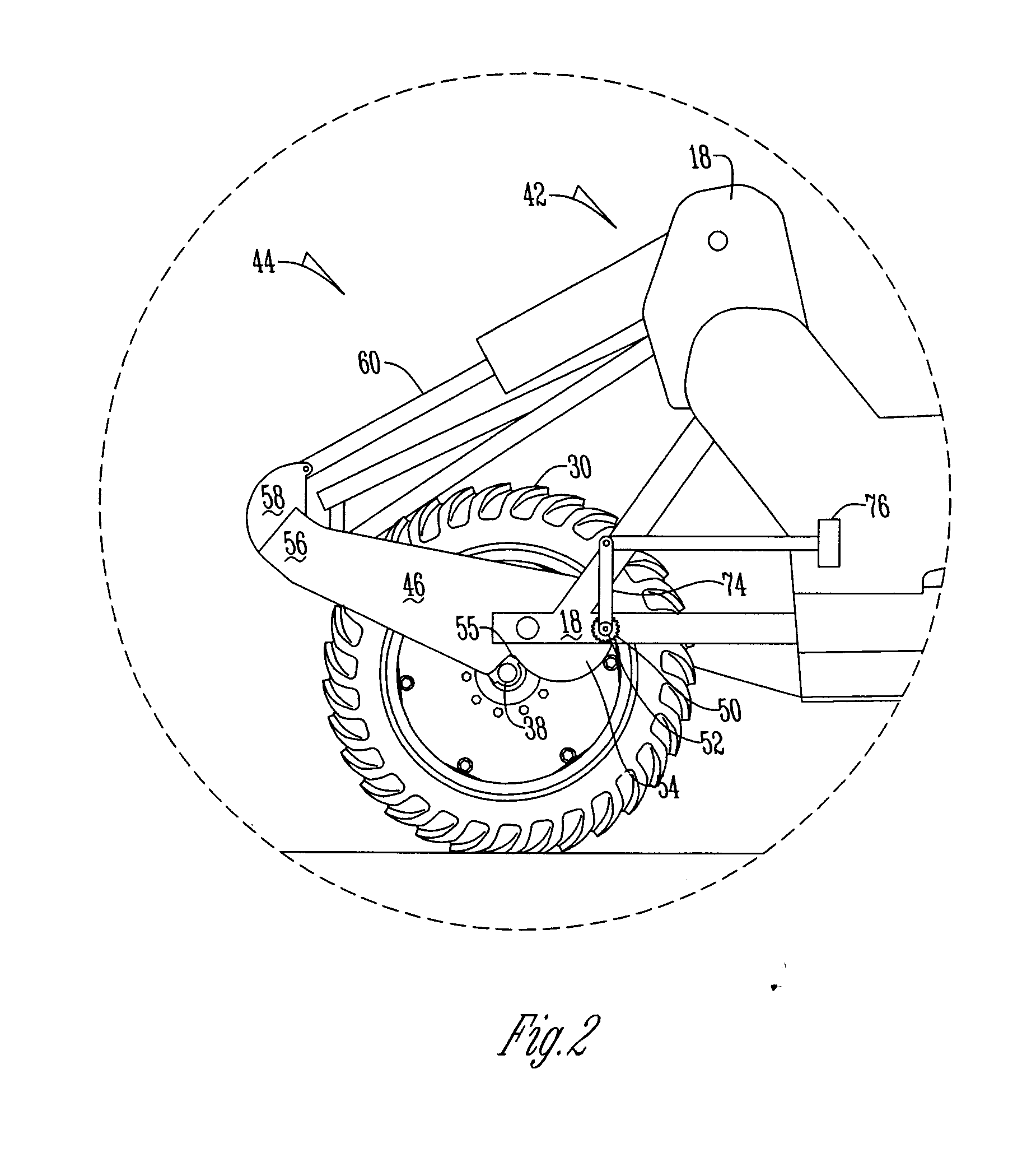

Scraping device and a system and a method for collecting materials

InactiveUS6910289B2Reduce the amount requiredPrevent fallingMining devicesComputer controlEngineering

A scraping device, a system and a method for collecting a material are provided. The scraping device may have a bowl having a first end and a second end. A lip may be positioned at the first end and may cover an opening at the first end. In an embodiment, direct mounted cylinders may be attached to the lip and may move the lip to completely cover or uncover the opening. The scraping device may have a tongue mounted to the bowl having a triangular-shaped plate mechanism that may be used to raise and to lower a cutting edge attached to the bowl. Cylinders connected to the mechanism may be retracted or extended to raise or to lower the scraping device. A load within the scraping device may be lifted by force exerted from a barrel end of a cylinder, thus utilizing a maximum potential of the cylinder.

Owner:CATERPILLAR INC

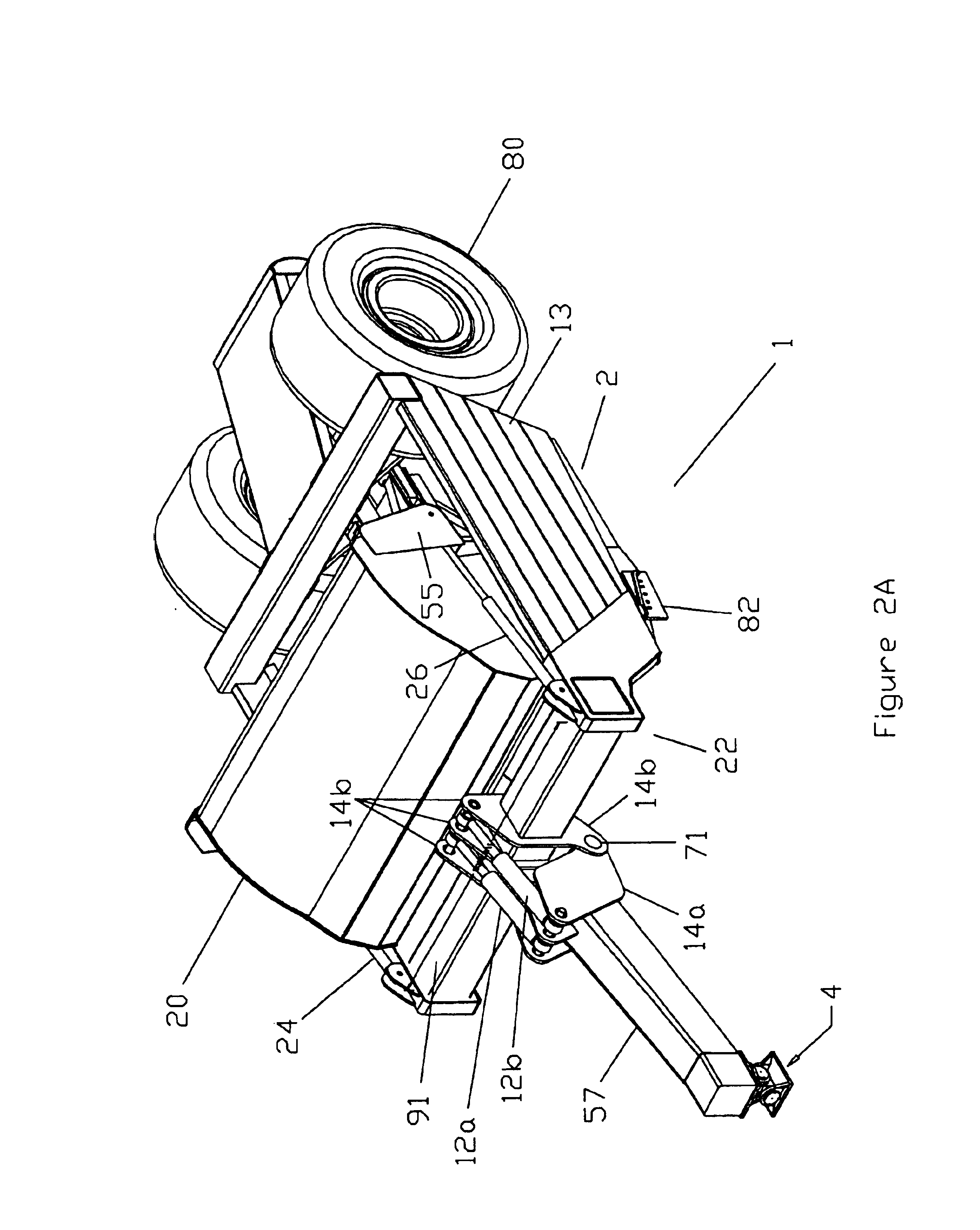

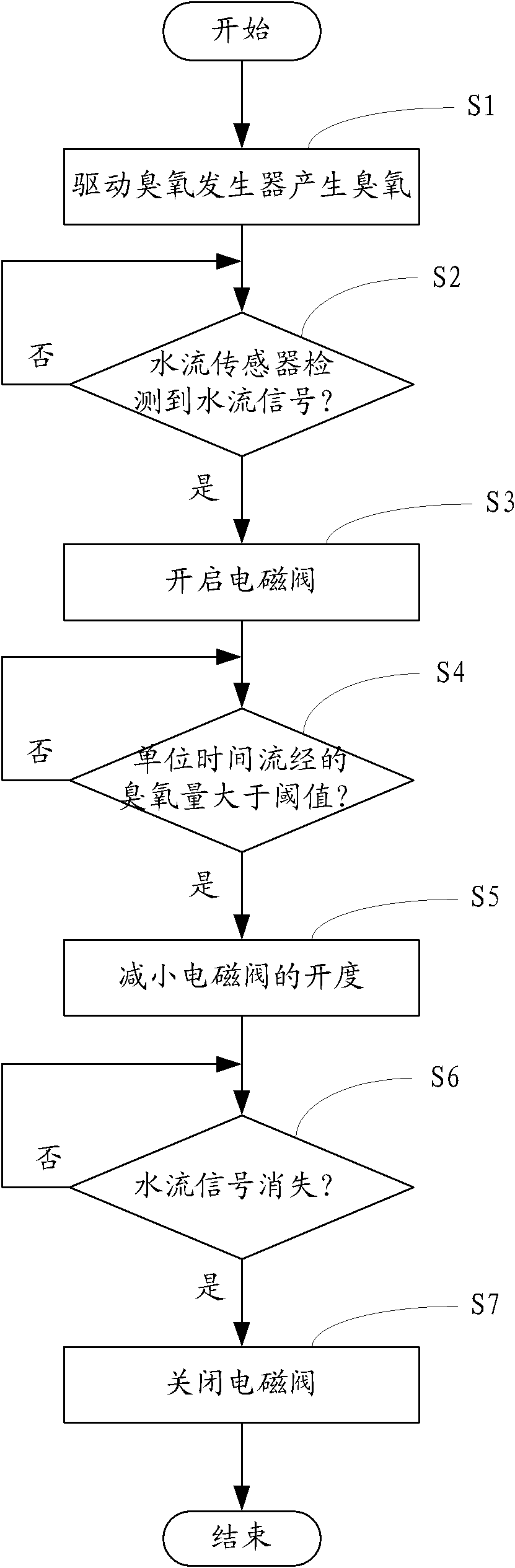

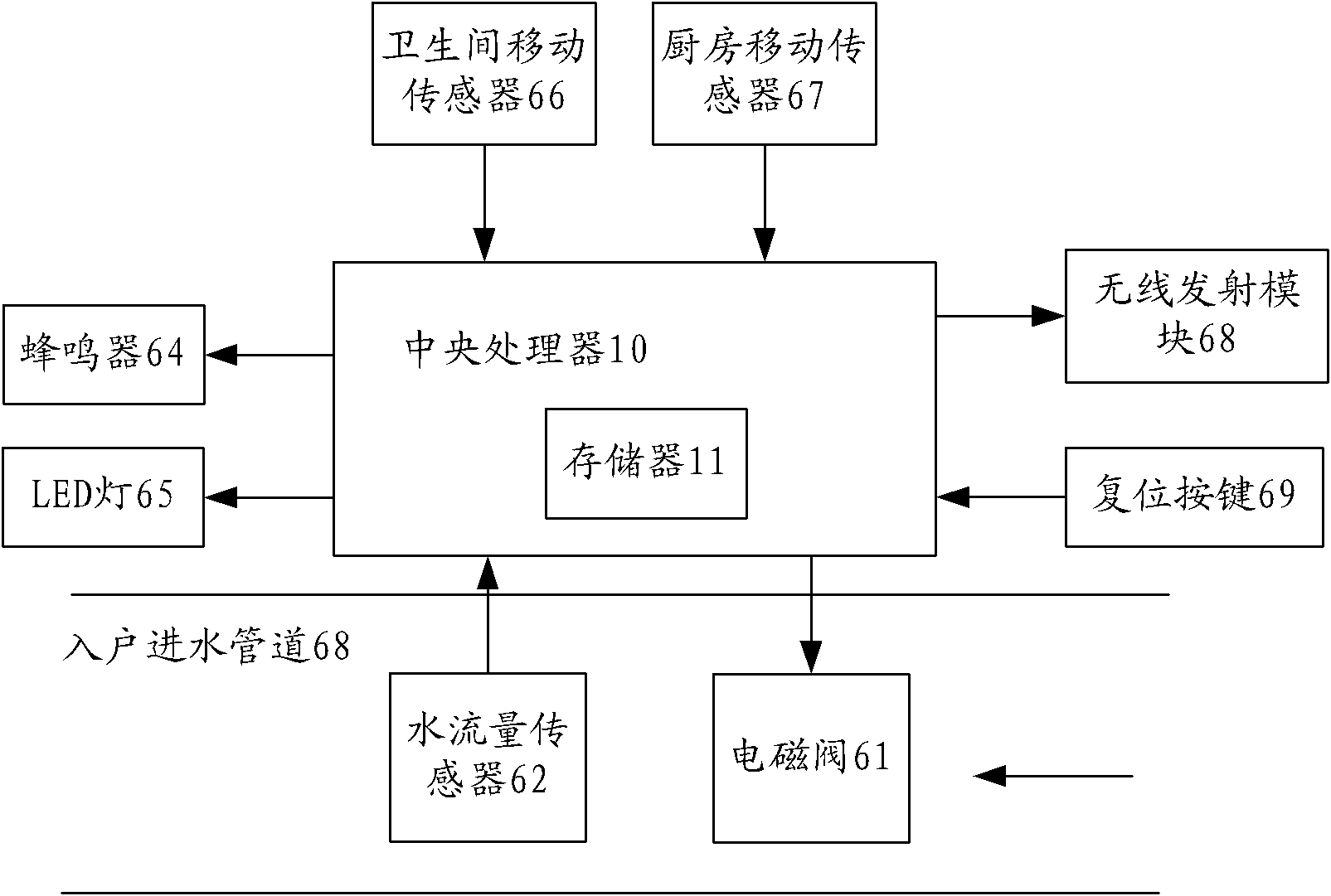

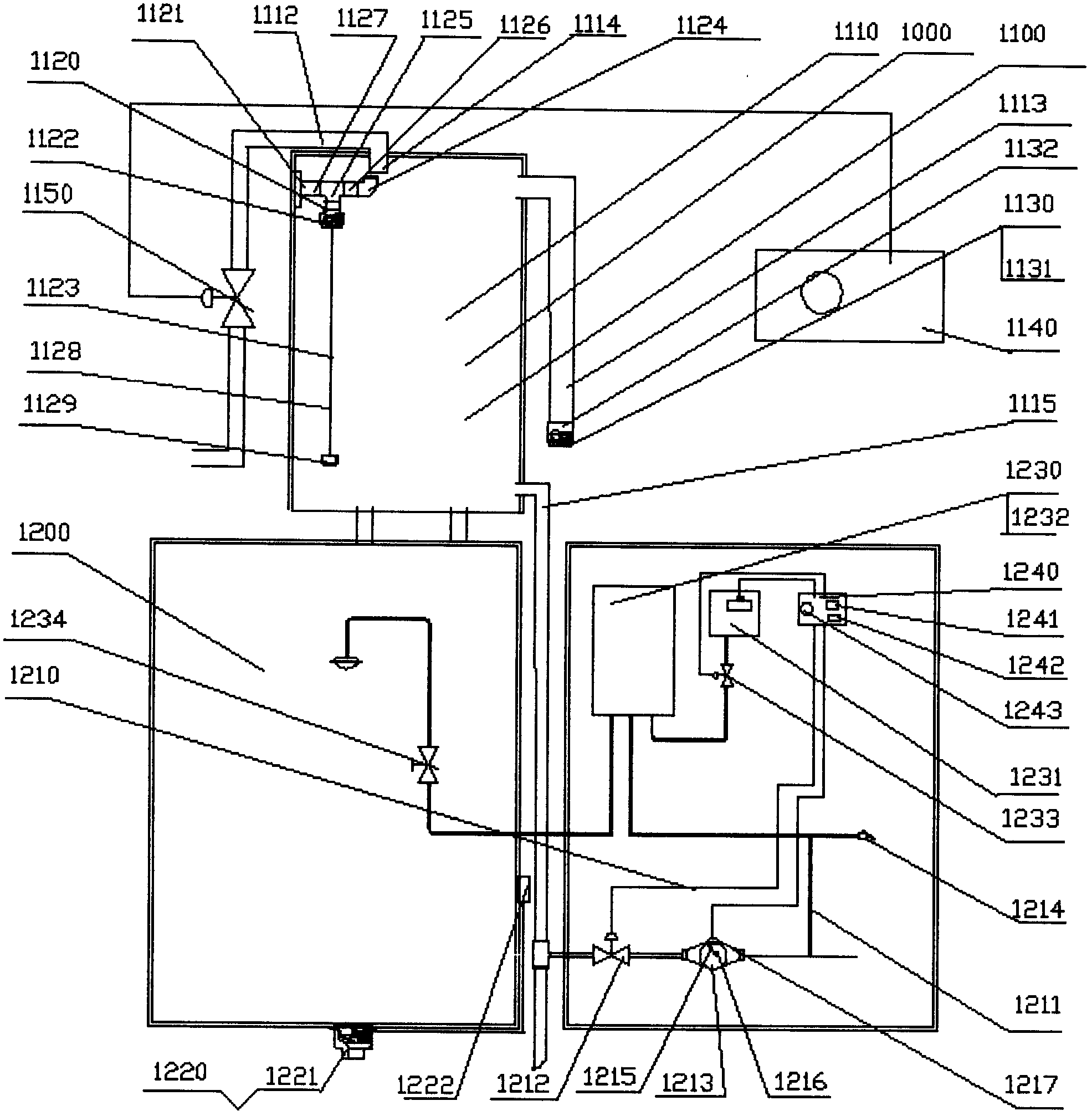

Smart home system and working method thereof

ActiveCN102122166AEnable central supplyRealize multiple supplyDisinfectionOzone preparationOzone generatorElectricity

The invention provides a smart home system and a working method thereof, wherein the system comprises a controller, a plurality of air supply outlets and solenoid valves; the controller is used for controlling work state of an ozone generator, each air supply outlet is connected with an air vent of the ozone generator through a pipeline, the solenoid valves are used for controlling the opening and the closing of the air supply outlets, and the controller is electrically connected with each solenoid valve and controls the start and the stop of each solenoid valve. The method comprises the following steps that: the controller drives the ozone generator to generate ozone, a central processing unit controls the solenoid valves to open after receiving an externally input signal of opening the solenoid valves, an open angle of each solenoid valve is reduced when an air flow sensor detects that the quantity of the ozone flowing through an air inlet within unit time is more than a flow rate threshold, and the central processing unit controls the solenoid valves to be closed after receiving a signal of closing the solenoid valves. With the system and the method provided by the invention, ozone water can be provided, and the risk of using the ozone at home is reduced simultaneously, the system is convenient to operate and control, and a health protection smart home system is implemented.

Owner:江洪

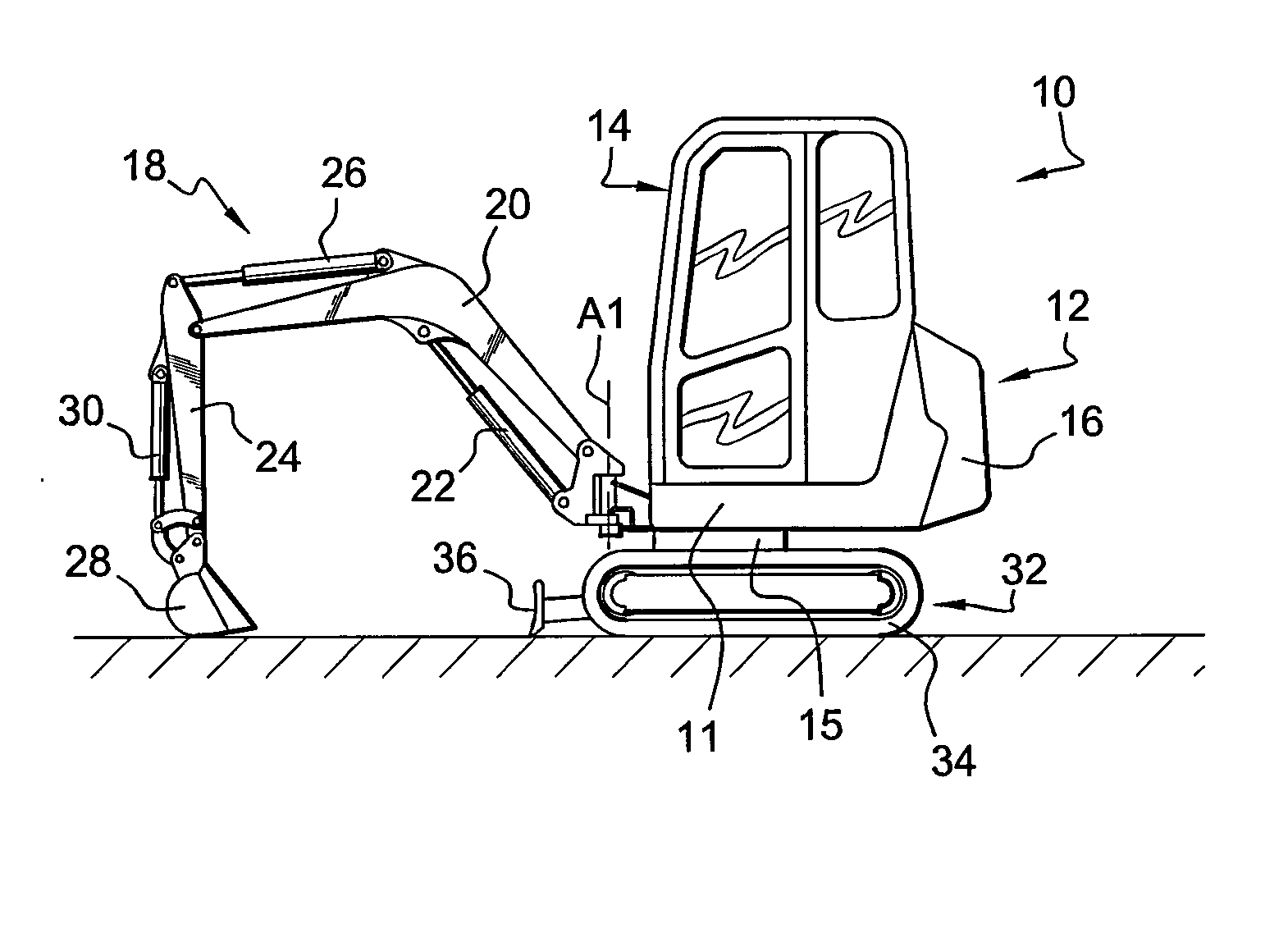

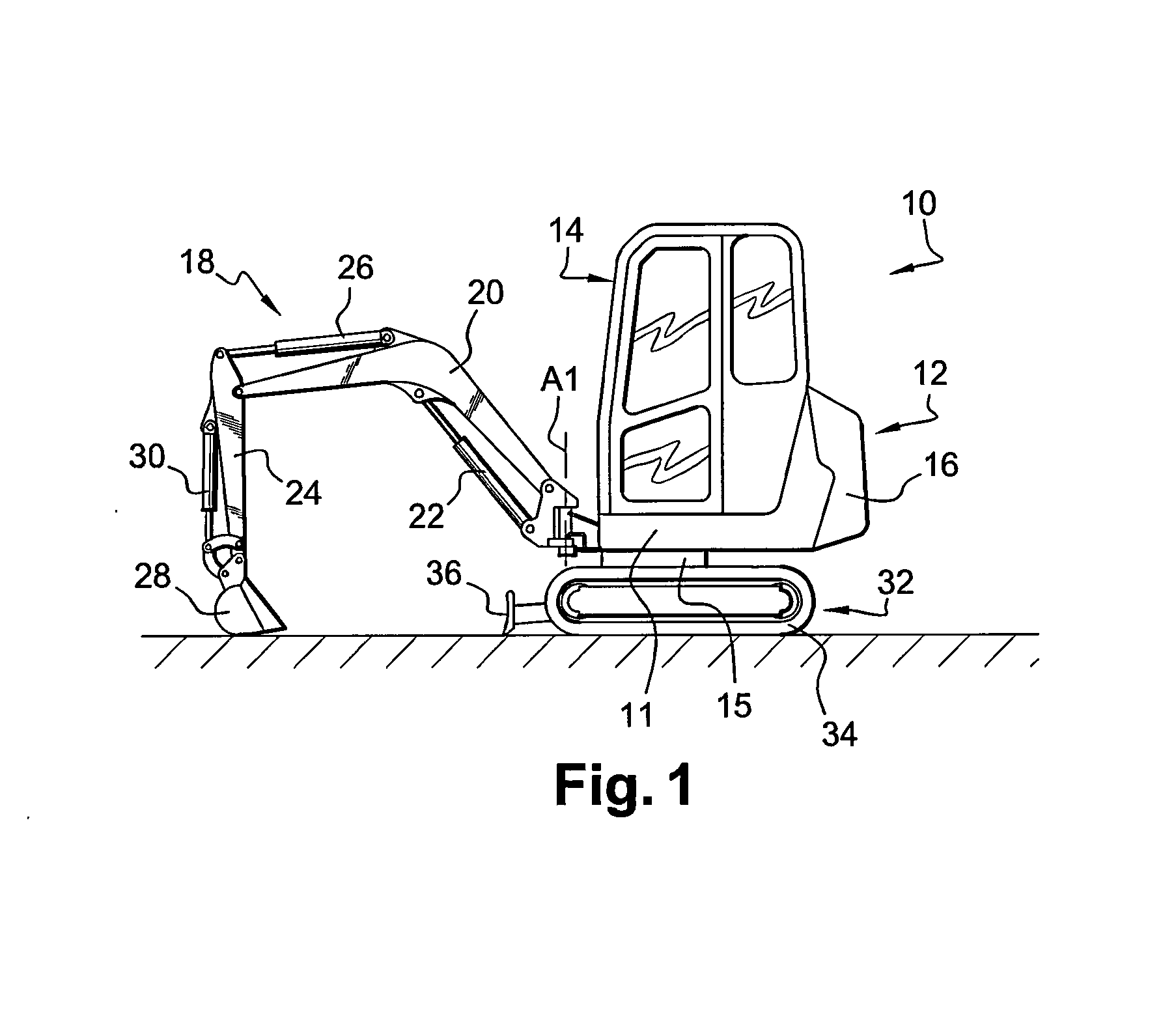

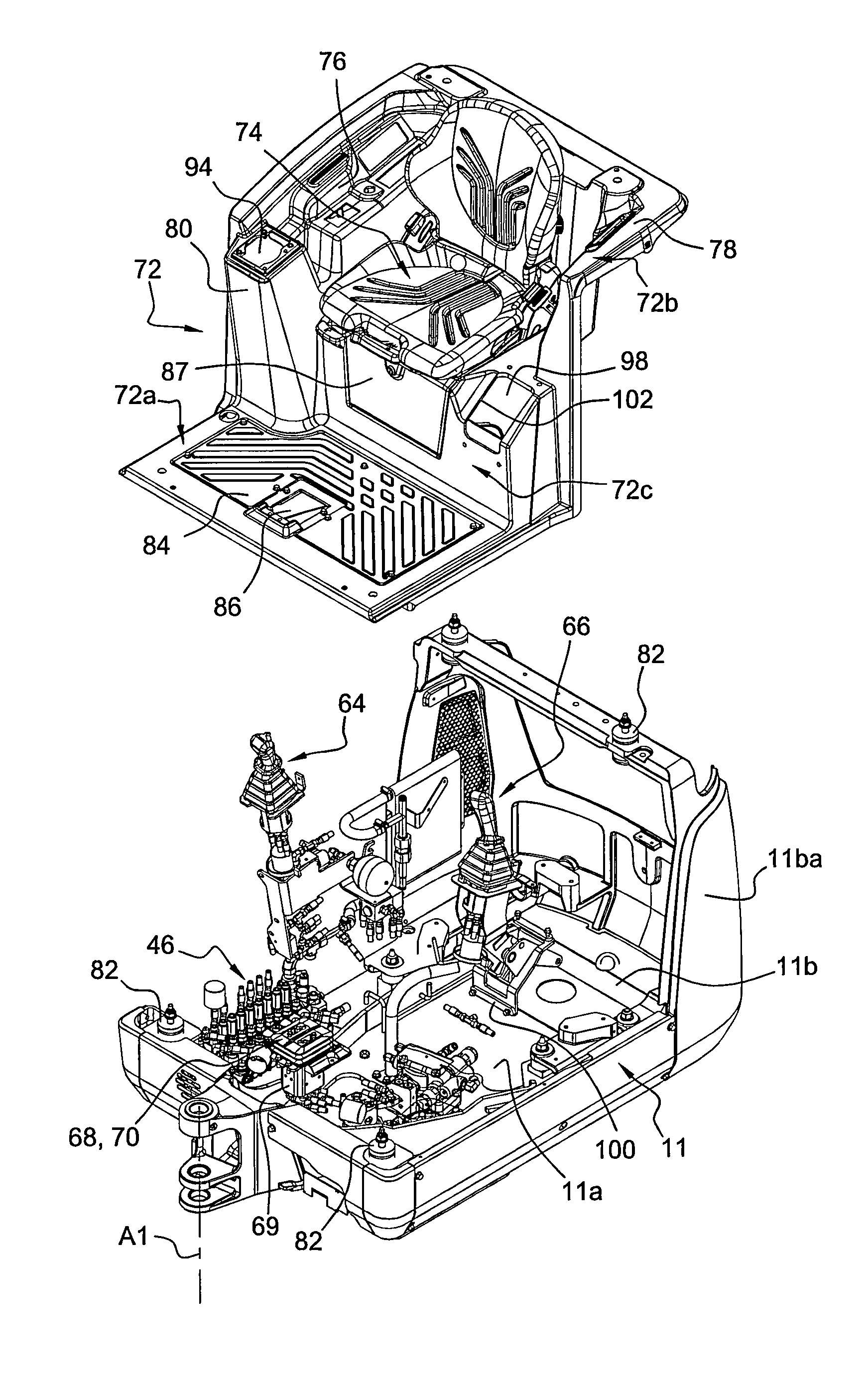

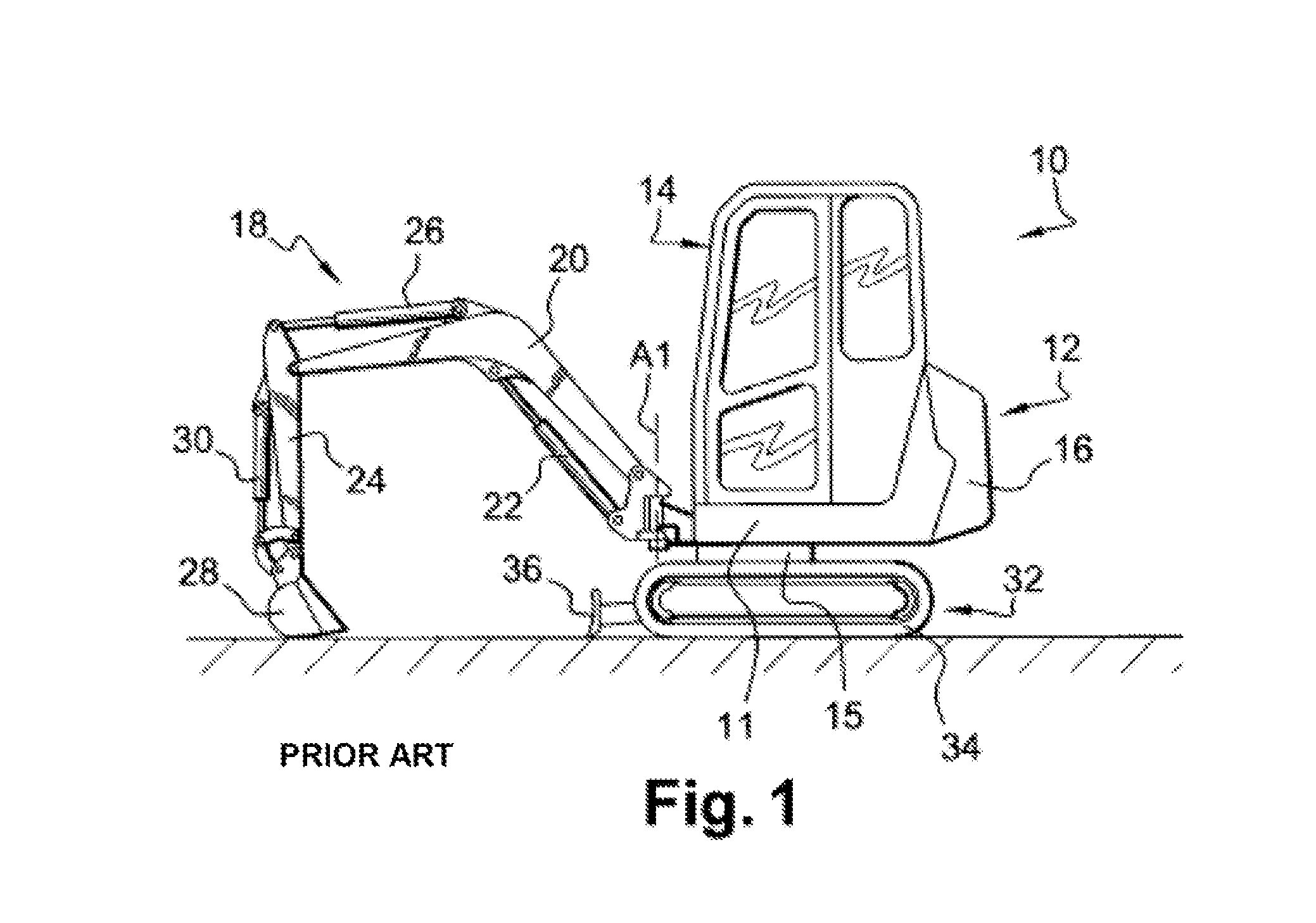

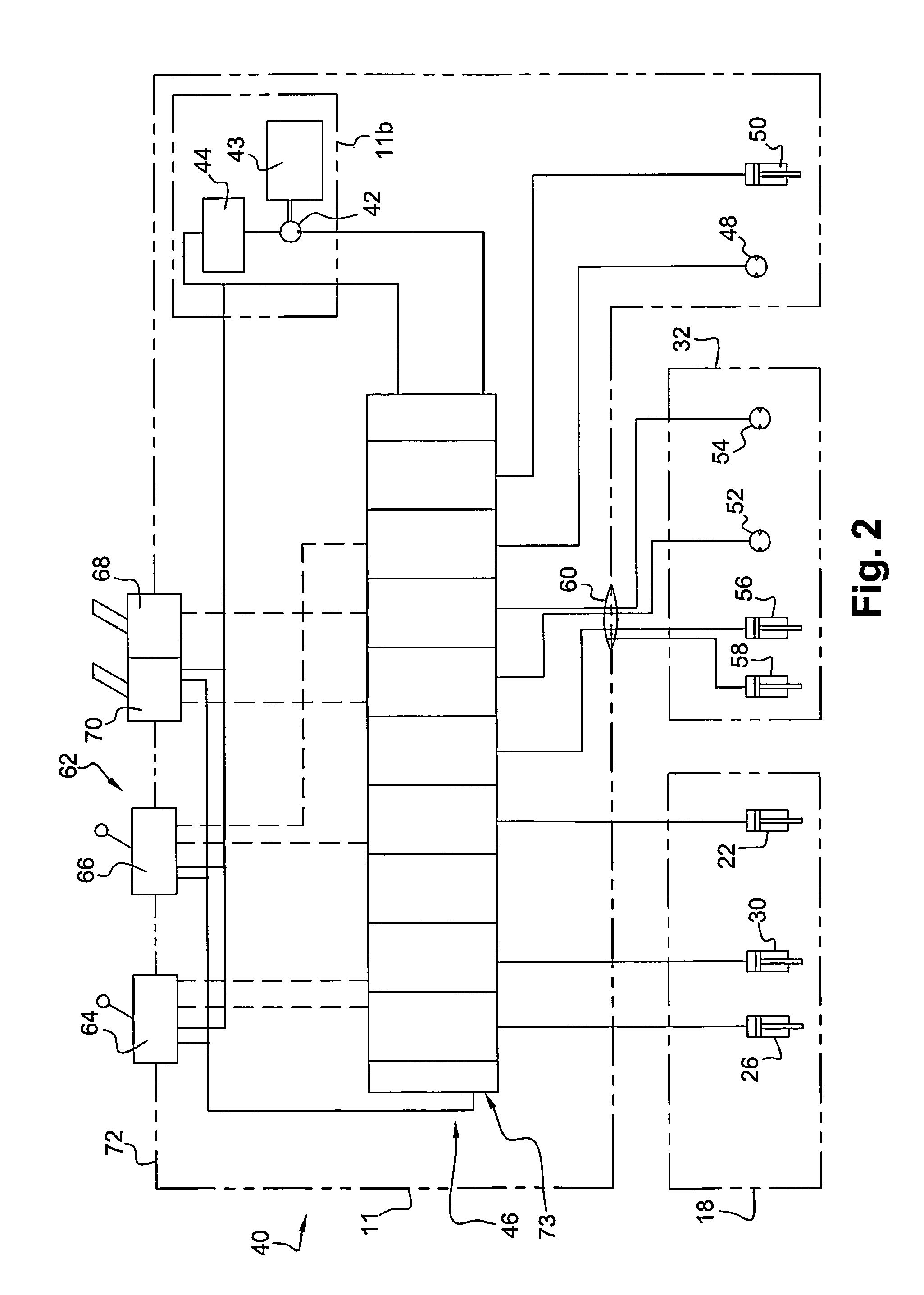

Excavator and process for assembling or dissassembling such excavator

An excavator includes a frame, and a platform on top of the frame. A hydraulic distribution system is received on top of the frame but below the platform. A pilot valve unit is at least partly received on top of the platform. The platform includes a dedicated hole capable of receiving therethrough at least that part of the pilot valve unit which is received on top of the platform. The pilot valve unit is fixed, directly or indirectly, on the platform. The pilot valve unit can be mounted from below the platform, through the dedicated hole, and is fixed on the platform from above the platform.

Owner:VOLVO COMPACT EQUIP

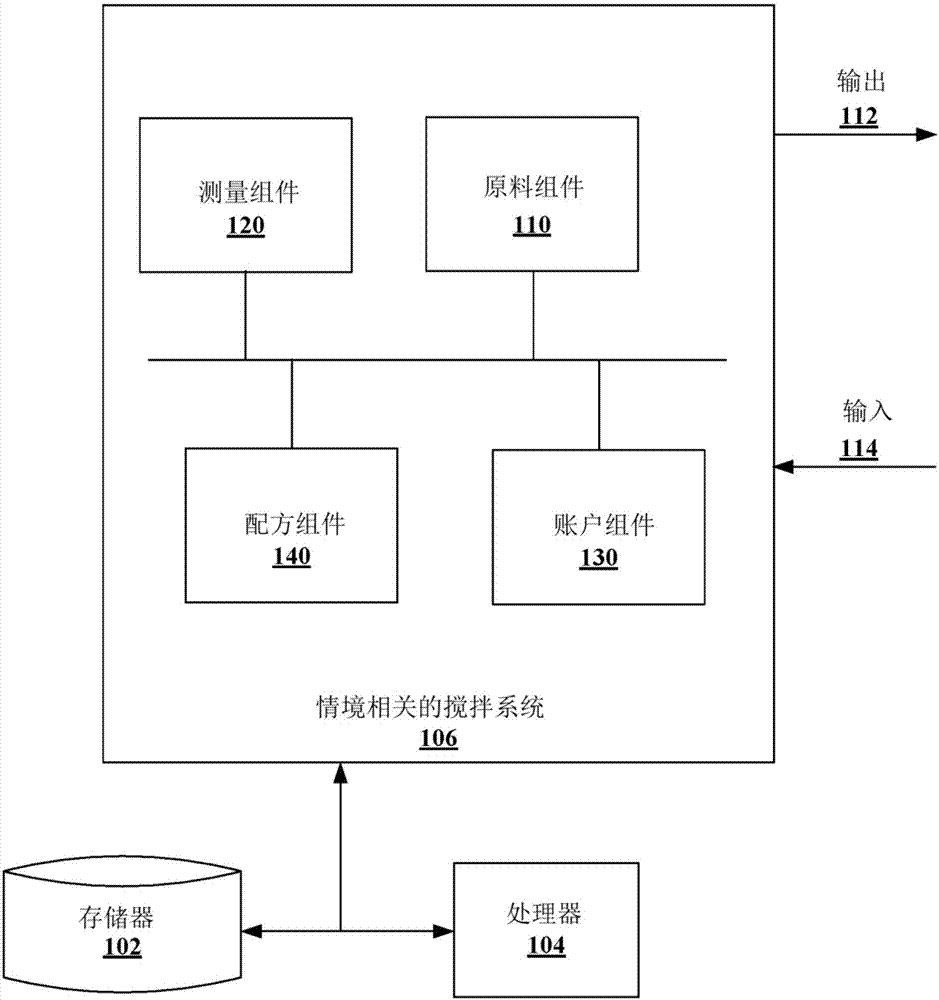

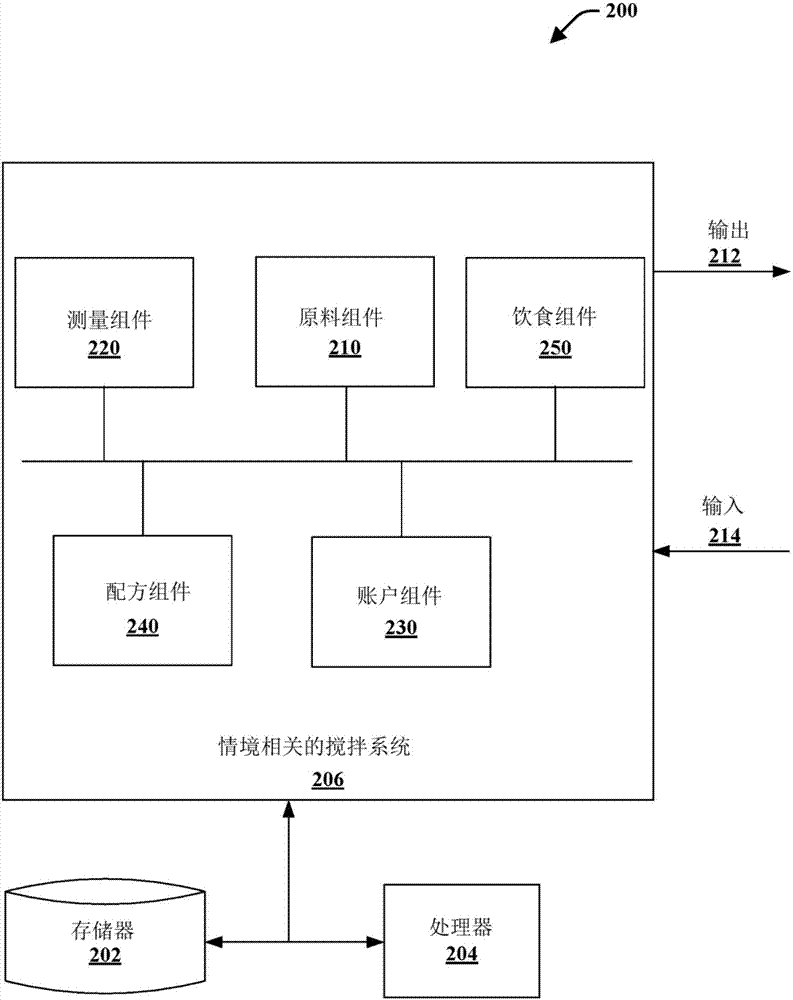

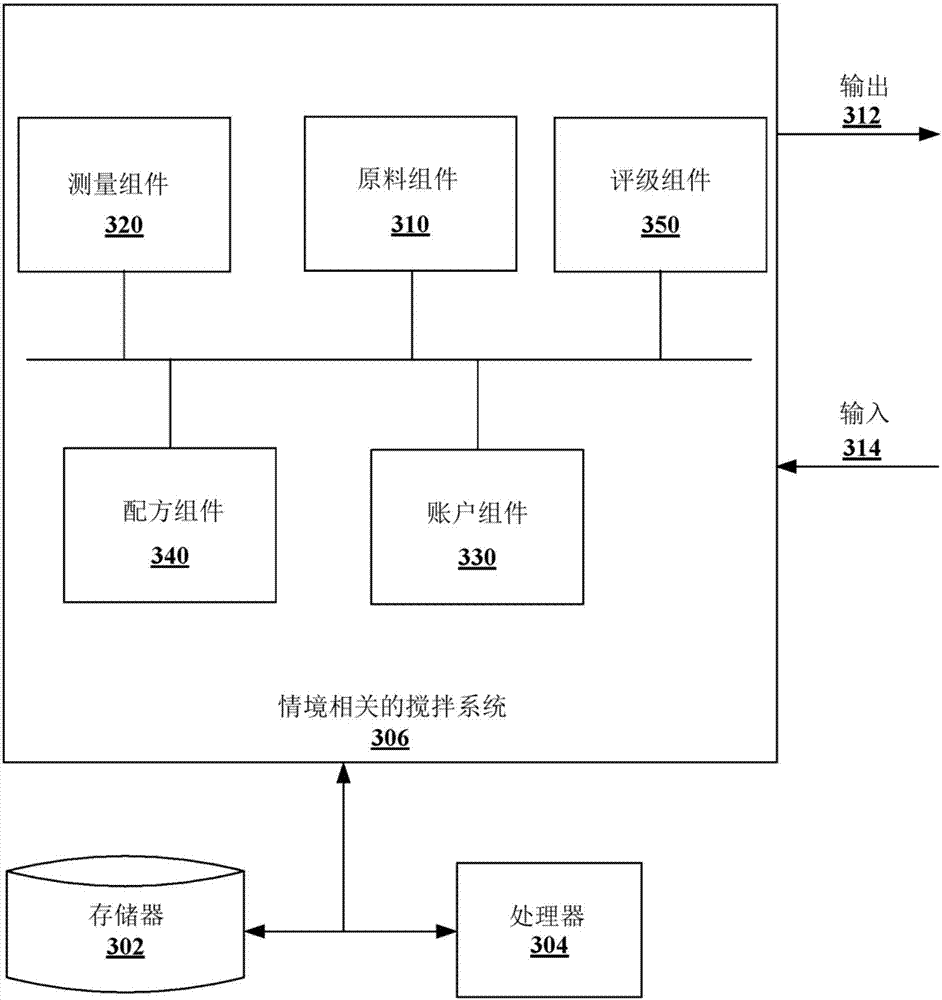

Intelligent blending system

PendingCN107533042AControlling ratio of multiple fluid flowsCooking vesselsPolymer scienceEngineering

A blending system is provided for contextual blending. The blending system may include an ingredient component and a recipe component. The ingredient component may identify ingredients and determine aquantity of each type of ingredient. The recipe component may create a recipe based on the identified ingredients and the determined quantities of the ingredients. The recipe may include instructionsfor controlling a blender device.

Owner:VITA MIX MANAGEMENT

Regulator module for a valve cluster

ActiveUS8219253B2Pressure regulation is advantageousEasy to adjustServomotor componentsRatio controlCommunication interfaceFluid control

A regulator module serves for the regulation of an actuator, in particular a pneumatic drive, and has a regulator communication interface for for output of the regulation target value and receiving an input actual value. The regulator module comprises concatenating contacts for in line arrangement on a fluid power and in particular pneumatic valve cluster with several valve modules, arranged in a row direction adjacent to each other for the fluid control of fluid power actuators and that the regulator module has an internal bus interface for connection with an internal communication bus of the valve cluster and that the regulator module is able to be connected by way of the internal communication bus with a valve cluster communication means for external communication of the valve cluster.

Owner:FESTO AG & CO KG

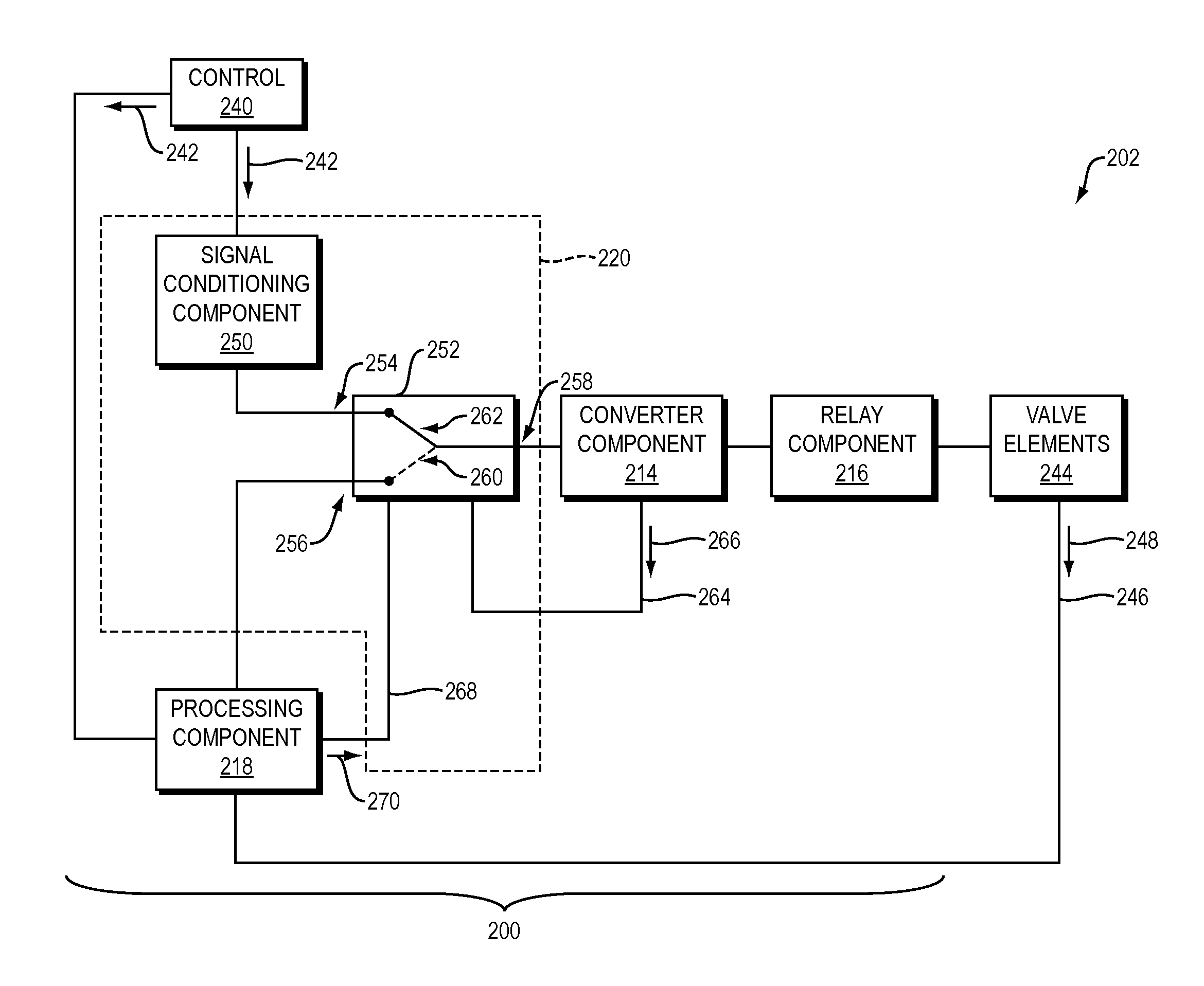

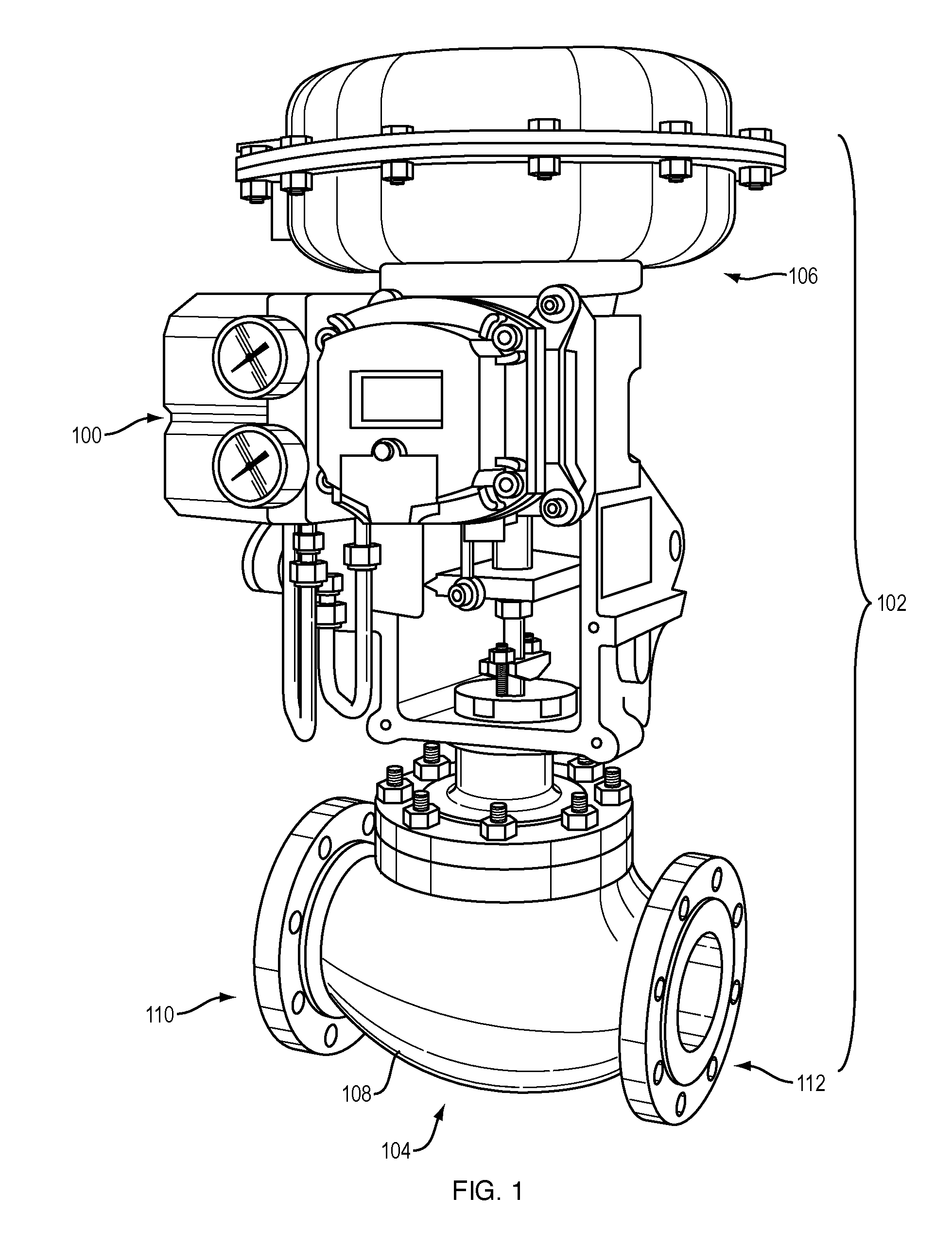

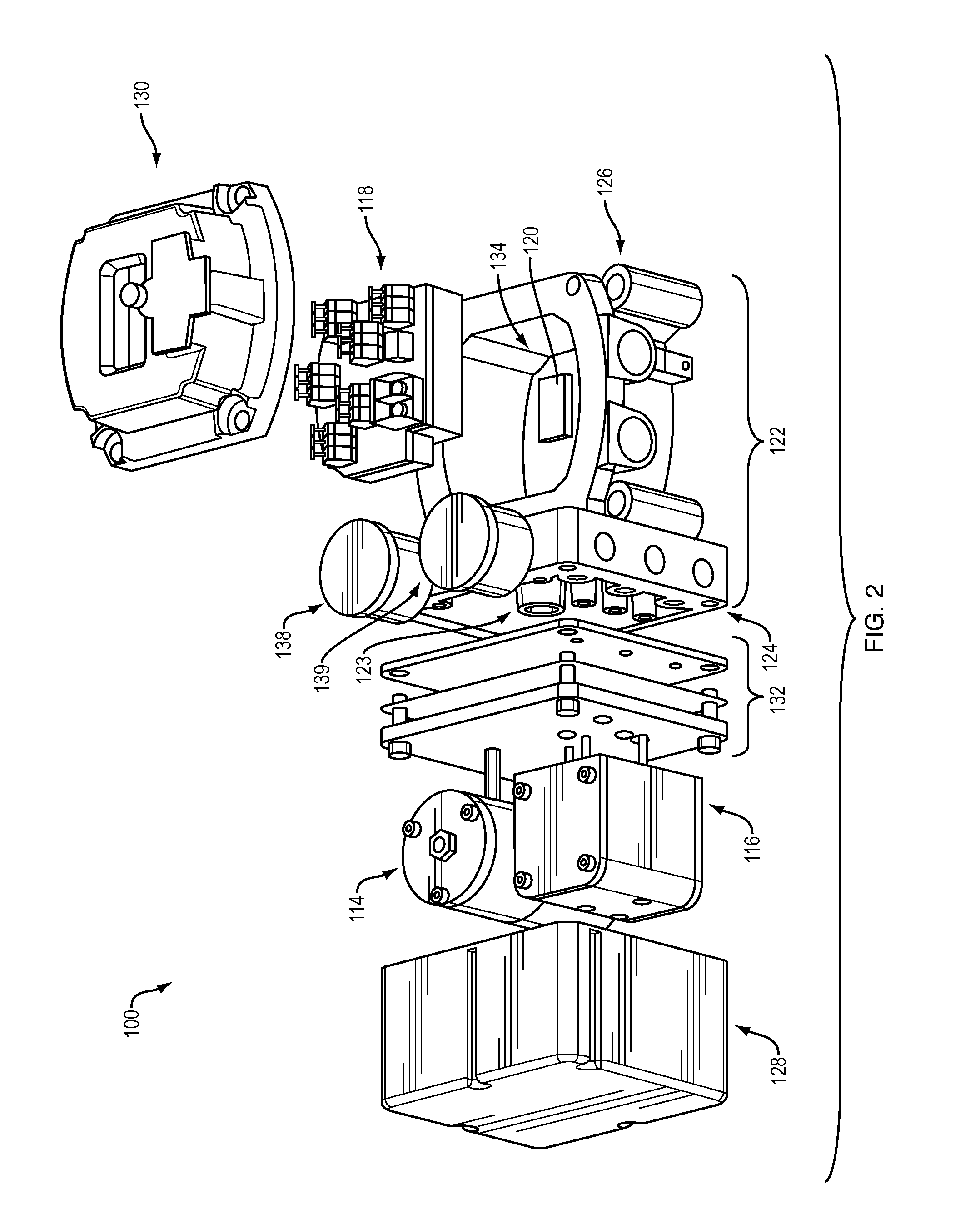

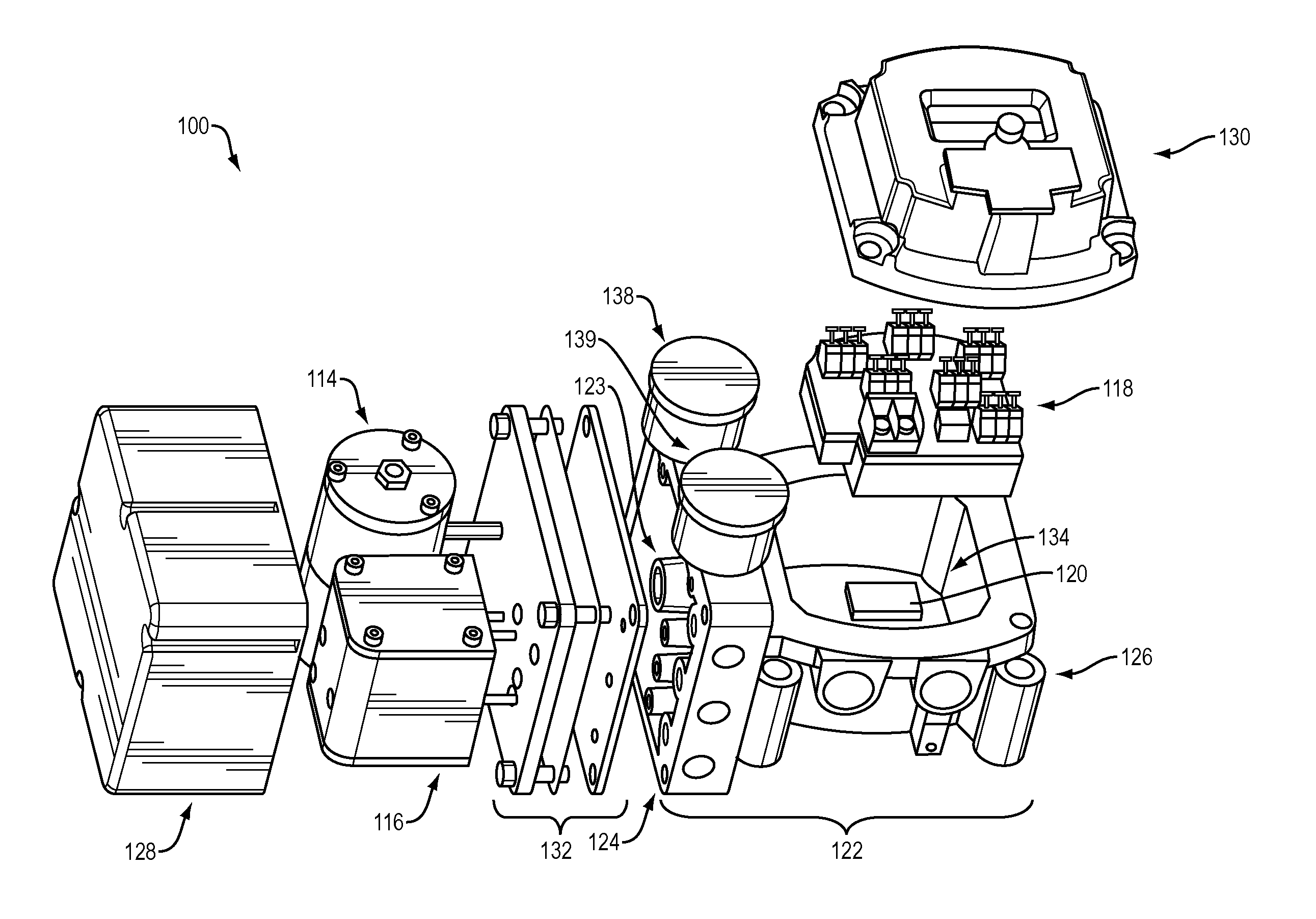

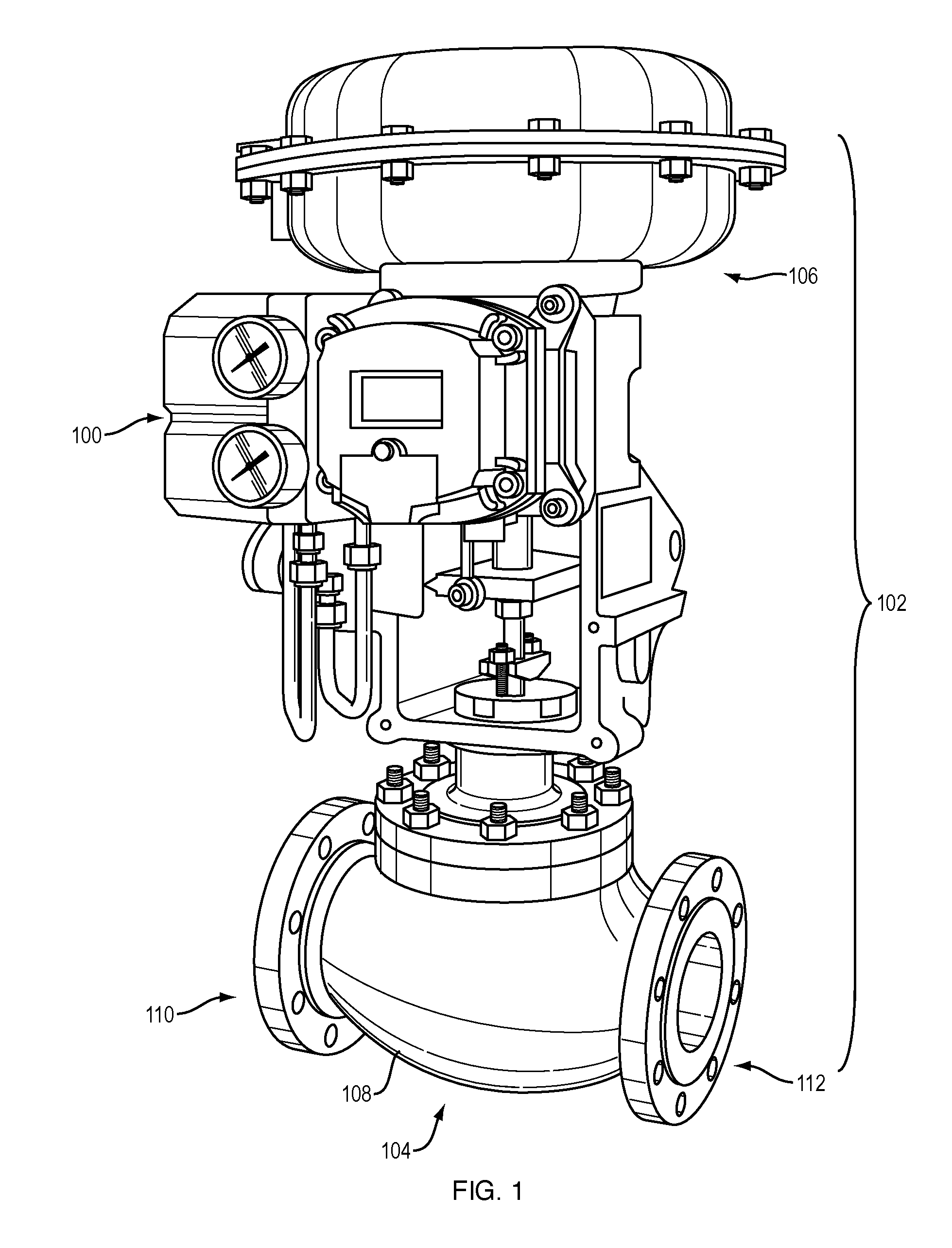

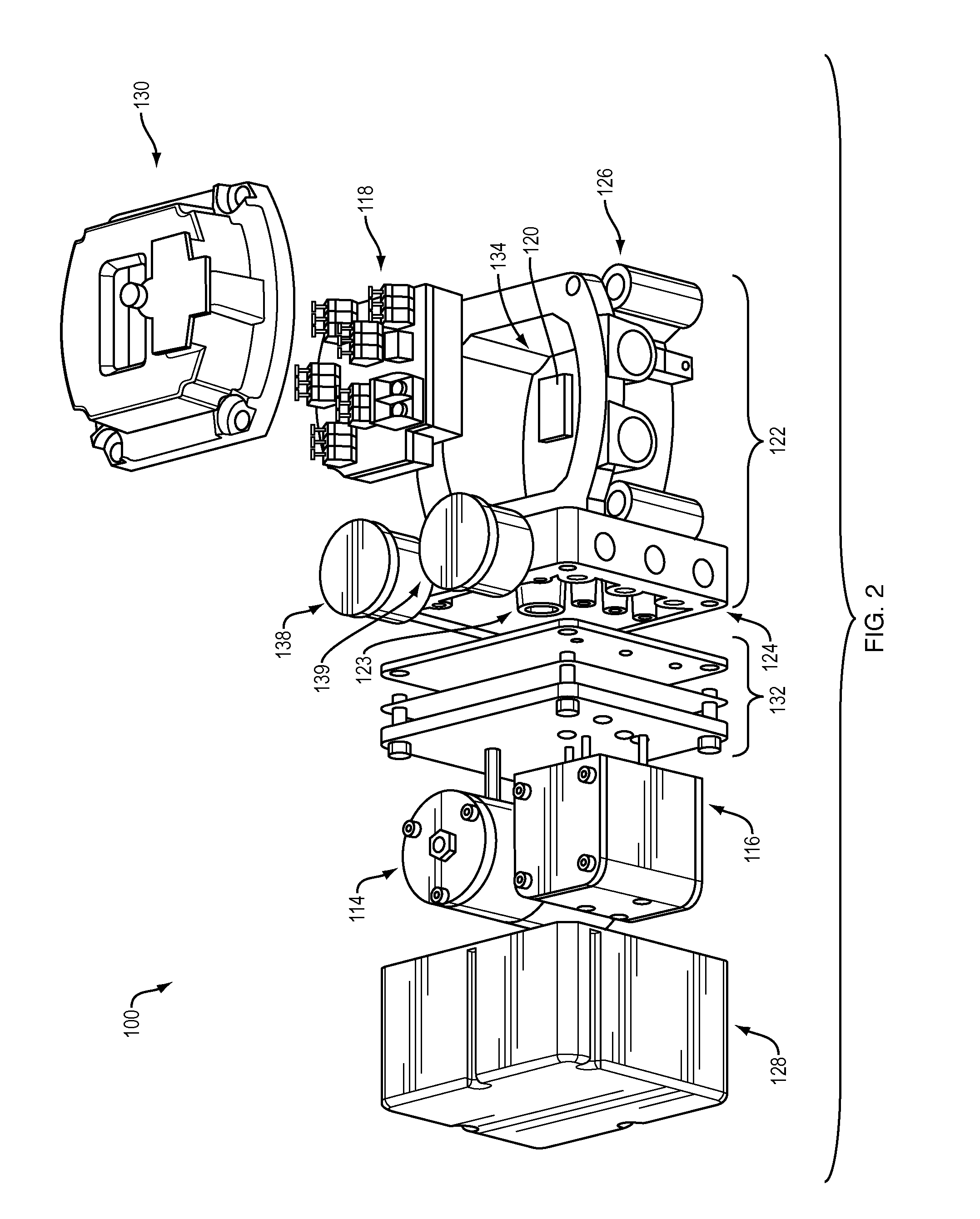

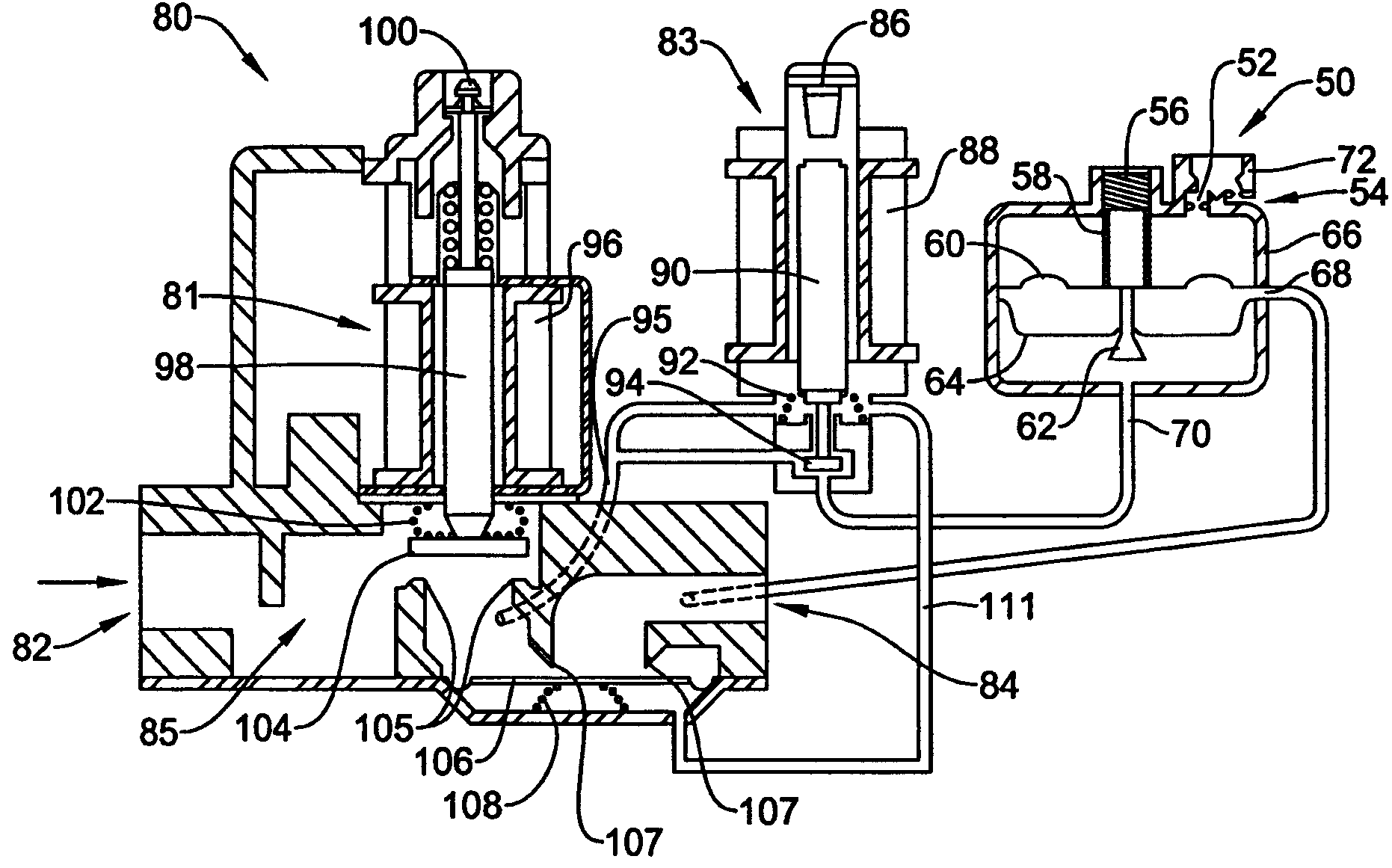

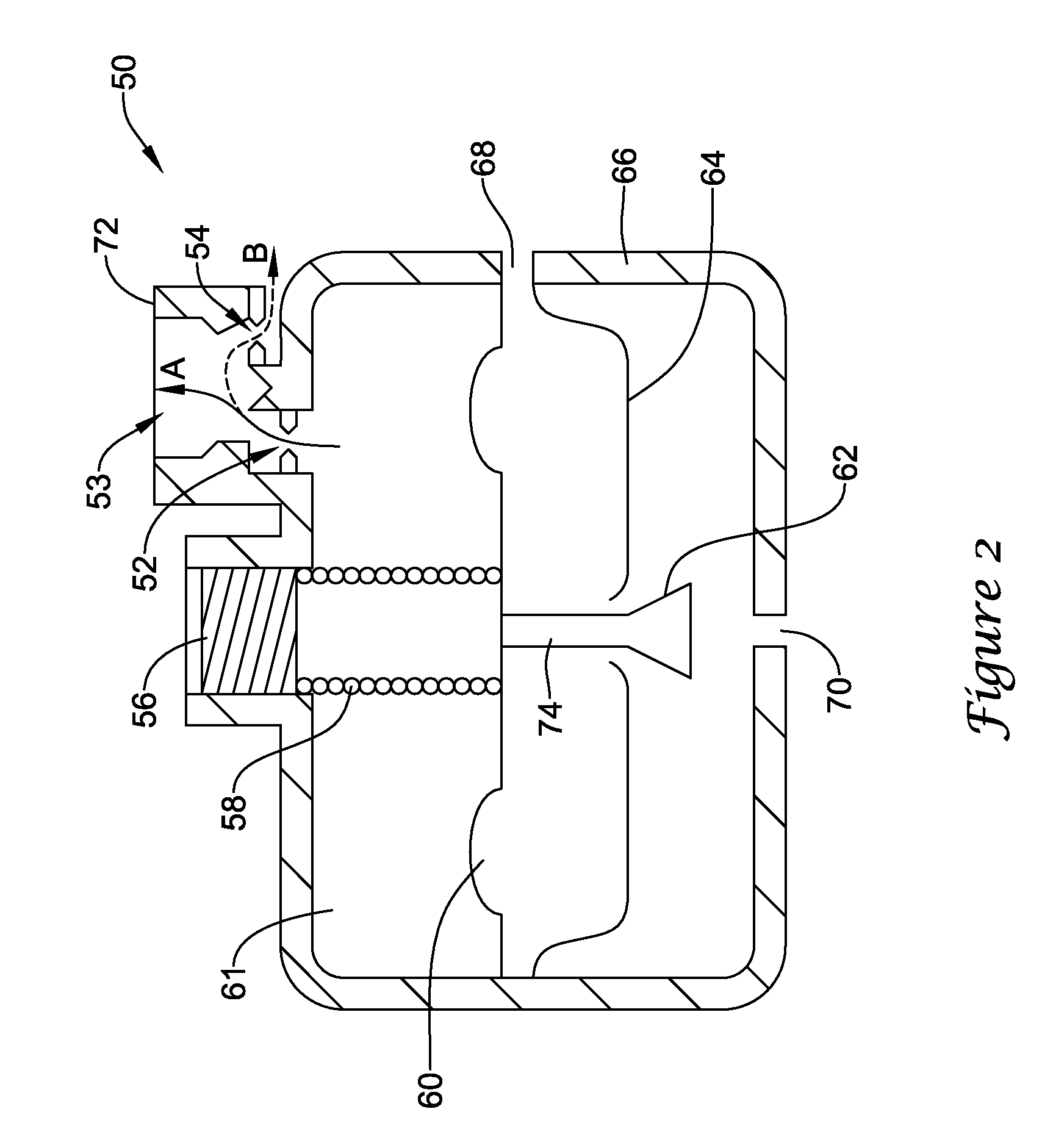

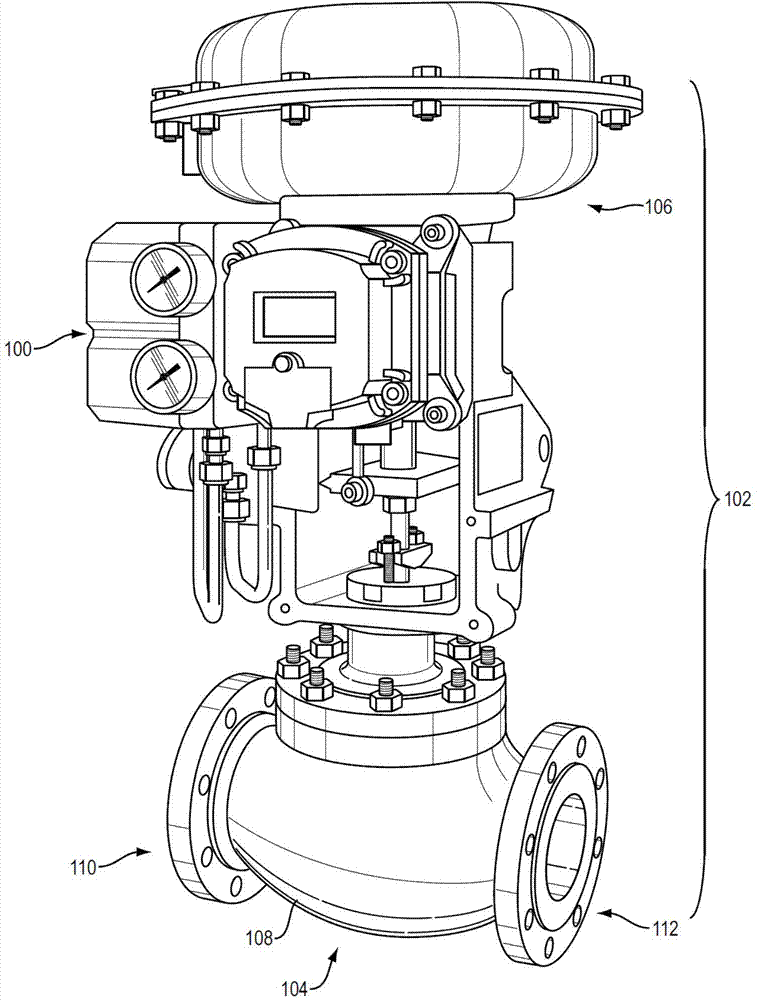

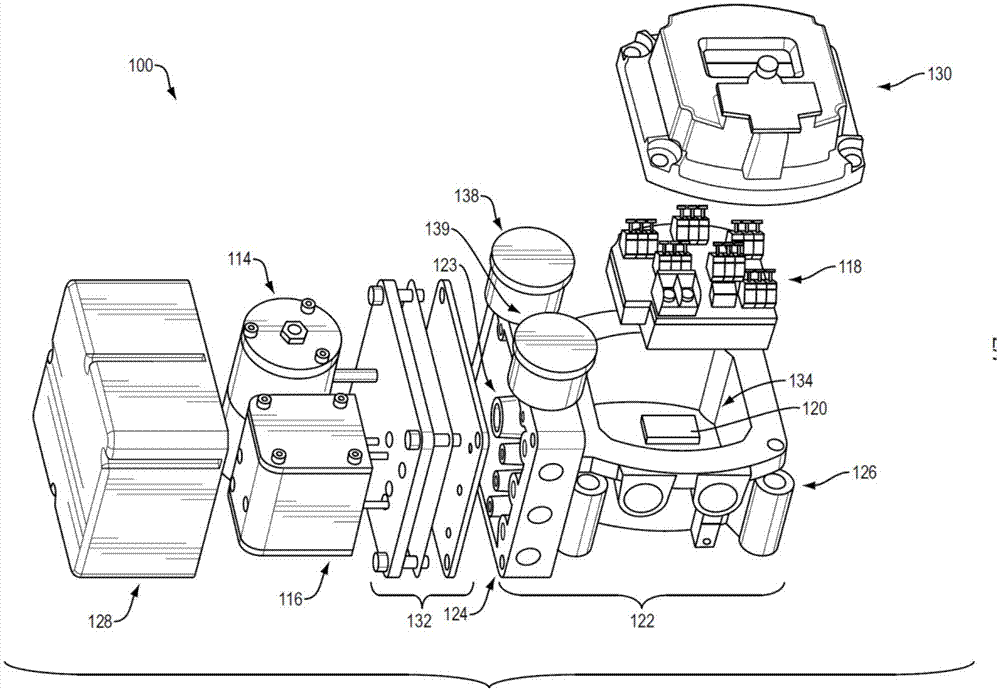

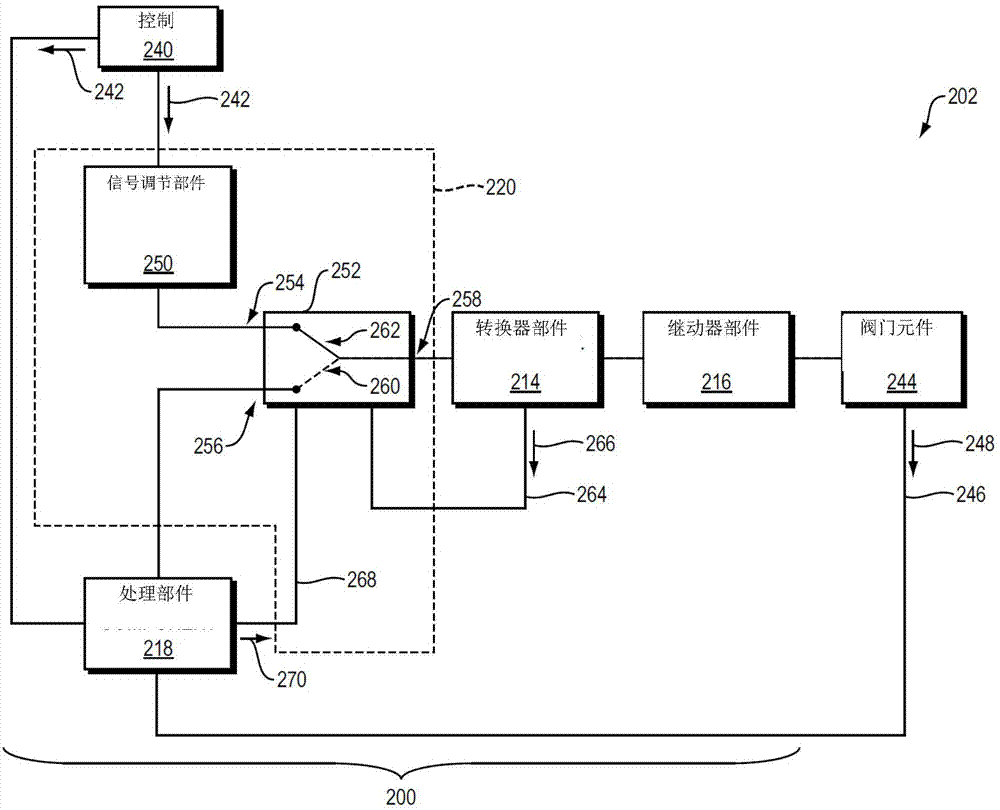

Valve positioner having bypass component and control value comprised thereof

A valve positioner that can maintain operation of the control valve despite failures in one or more components. The valve positioner may reduce downtime by allowing in-situ repair to occur on the valve positioner. The valve positioner may incorporate a by-pass component, which can utilize control input signals (e.g., a 4-20 mA signal) to energize one or more components (e.g., a current-to-pressure converter) to cause the control valve to modulate fluid flow without the digital microprocessor and / or related components.

Owner:DRESSER LLC

Valve positioner having bypass component and control valve comprised thereof

ActiveUS20150013786A1Reduce downtimeOperating means/releasing devices for valvesTransducersEngineeringControl valves

Embodiments of a valve positioner that can maintain operation of the control valve despite failures in one or more components. These embodiments reduce downtime by allowing in-situ repair to occur on the valve positioner. In one embodiment, the valve positioner incorporates a by-pass component, which can utilize control input signals (e.g., a 4-20 mA signal) to energize one or more components (e.g., a current-to-pressure converter) to cause the control valve to modulate fluid flow without the digital microprocessor and / or related components.

Owner:DRESSER LLC

Excavator and process for assembling or dissassembling such excavator

Owner:VOLVO COMPACT EQUIP

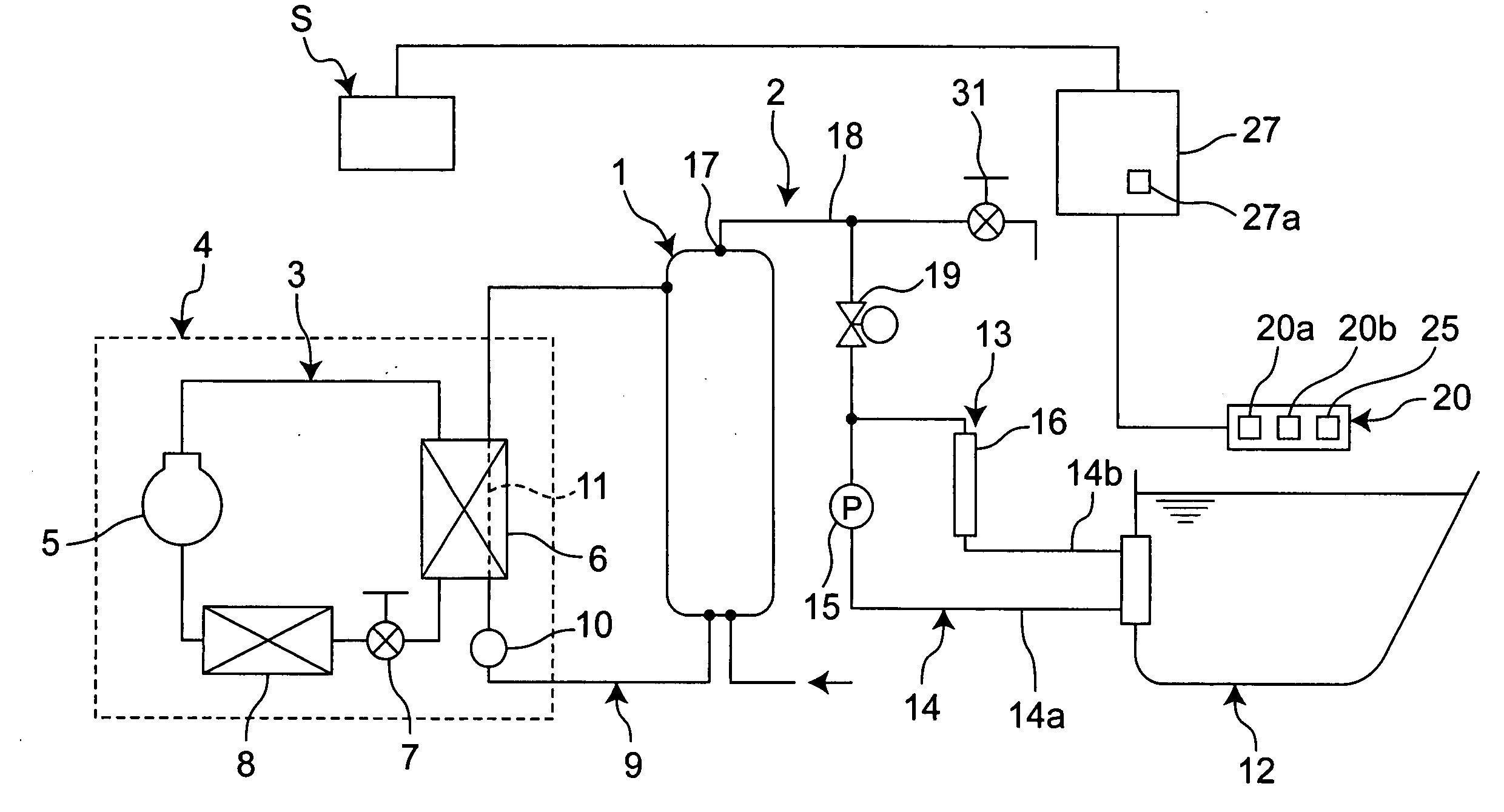

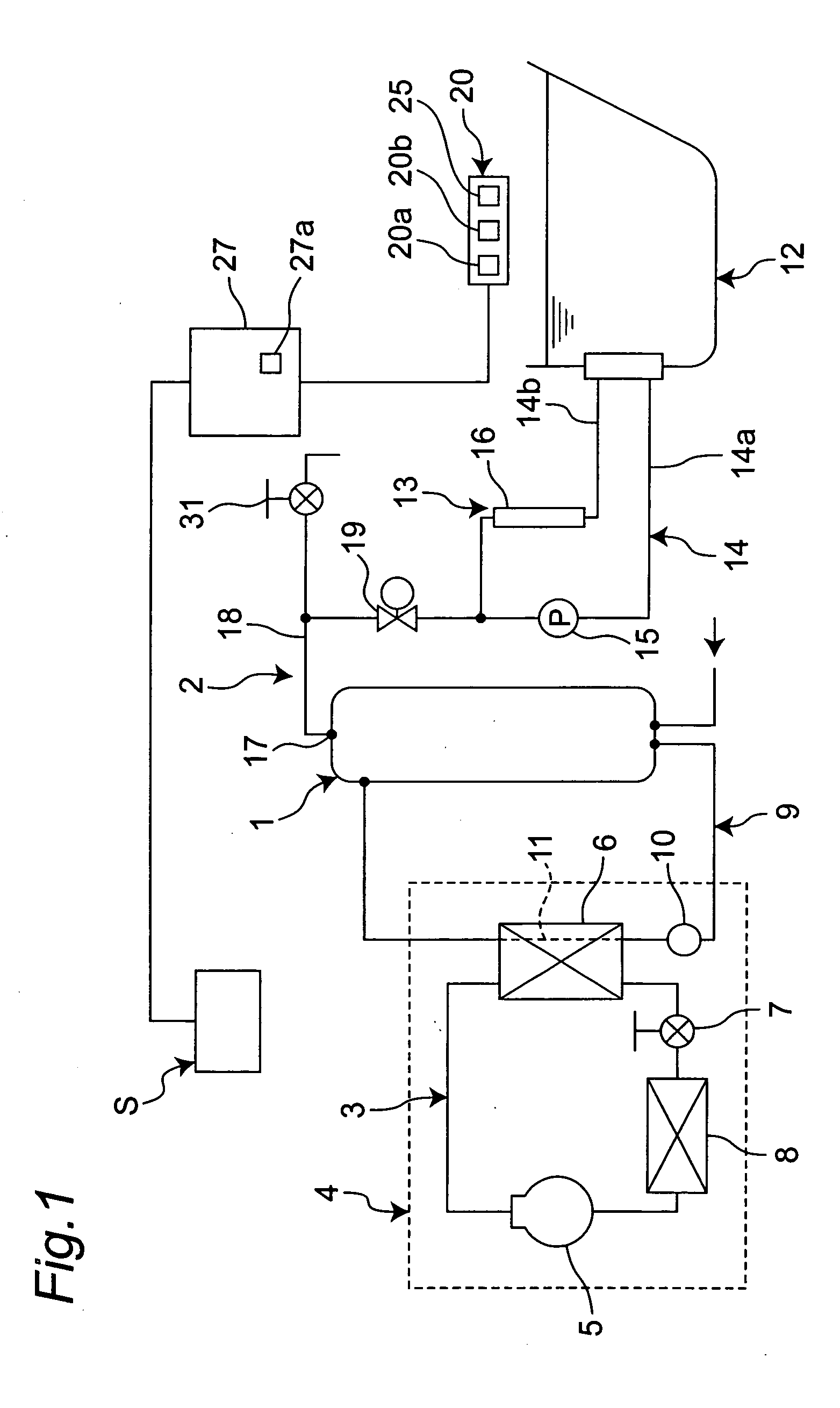

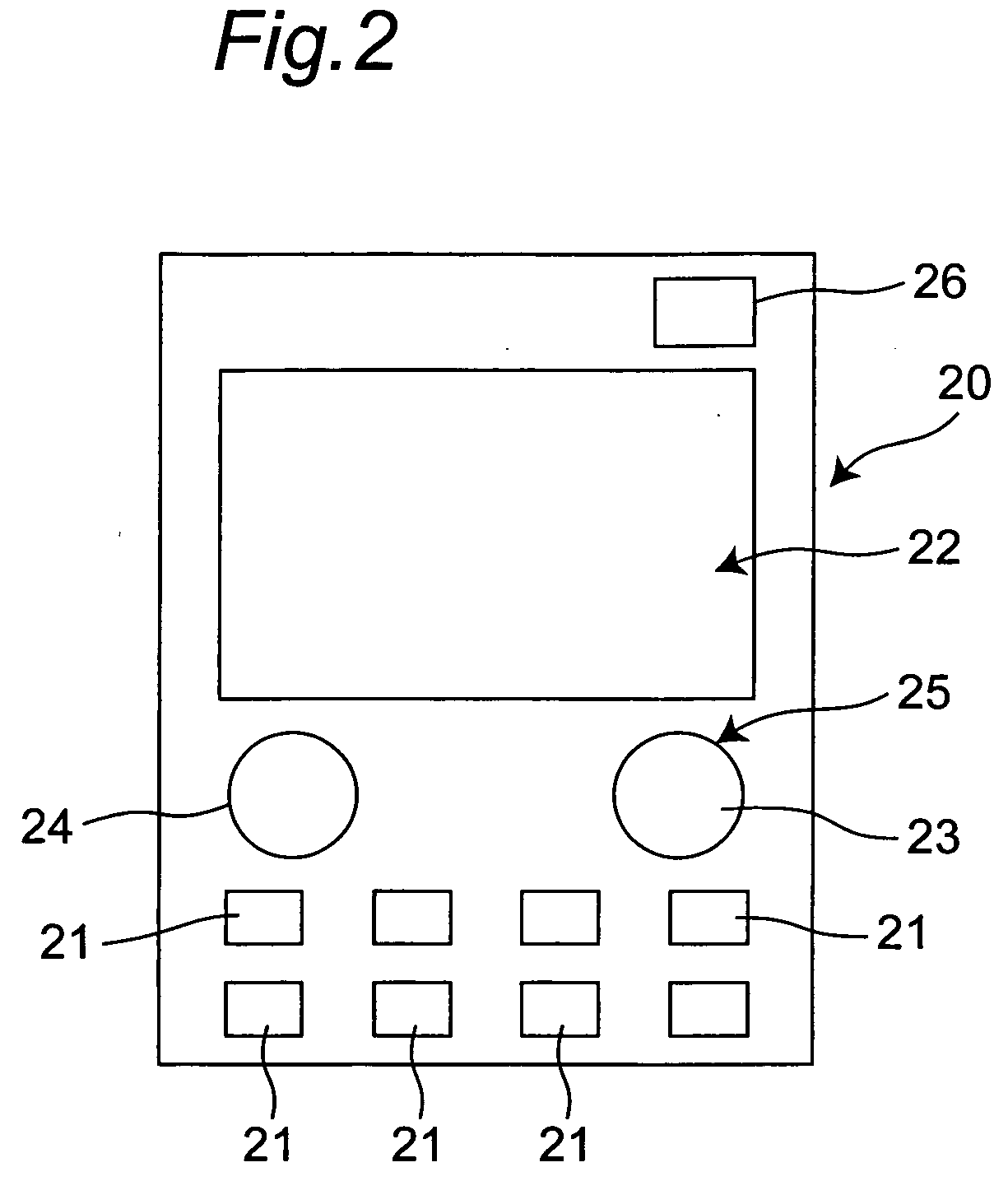

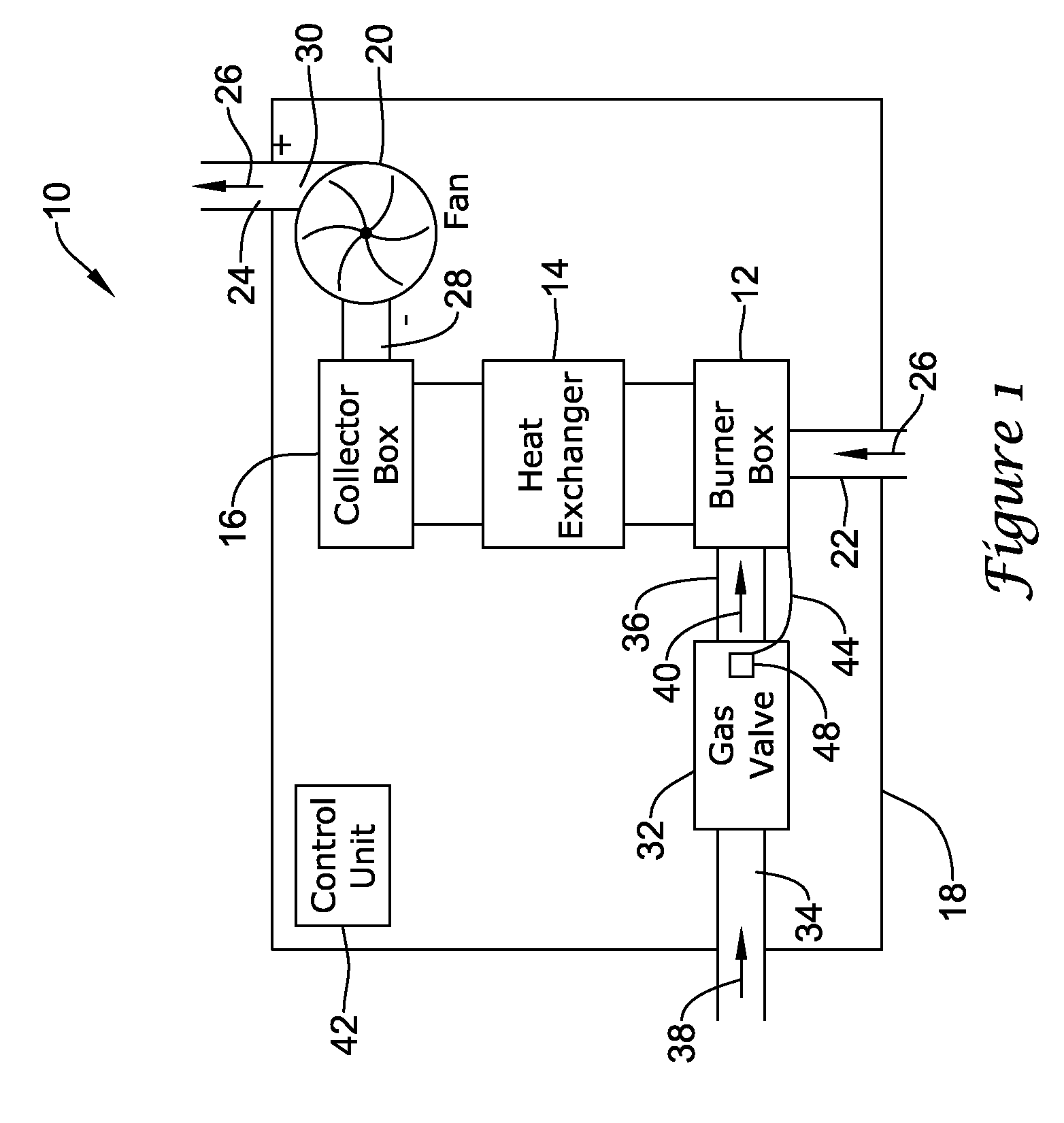

Hot Water Supply Device

InactiveUS20090222111A1Securely graspAvoid failureLevel controlLighting and heating apparatusNormal modeIntercom

A hot water supply device has a host remote controller 27 and a bath remote controller 20 capable of establishing a call with the host remote controller 27. In the normal mode, the call signal of the interphone function is prioritized over the operation signal. The operation signal is transmitted after the call signal ends. An attention calling function to output an attention calling signal during a failure or misuse is provided. The attention calling signal is prioritized over the call signal.

Owner:DAIKIN IND LTD

Intelligent Management System for Balance of Plant

InactiveUS20170336784A1Simulator controlFlow control using electric meansIntelligent managementManagement system

Systems and methods for providing intelligent management of balance of plant are provided. According to one embodiment of the disclosure, a system for determining a malfunction of a feedwater pump includes one or more processors and a database communicatively coupled to the one or more processors. The one or more processors can be configured to receive plant parameters. The one or more processors can be further configured to correlate the plant parameters to historical operational values. Based at least partially on the correlating, the one or more processors may be operable to identify a malfunction in a feedwater pump. Based at least partially on the identifying, the one or more processors may be operable to provide an advisory action concerning an operation of the feedwater pump.

Owner:GENERAL ELECTRIC CO

Intelligent fluid management system

InactiveCN104238535AAvoid wastingAvoid pollutionFluidic programme controlIntelligent managementEngineering

The invention discloses an intelligent fluid management system. The intelligent fluid management system comprises a controller and a fluid flowing state sensor, wherein the fuzzy technology is adopted in the controller, and the controller has the time calculation function. The fluid flowing state sensor comprises a flow sensor, a liquid flowing sensor and a tipping bucket type non-pressure liquid flow sensor for measuring non-pressure liquid falling in air. The controller obtains time data while obtaining flowing state data, the unusual condition occurring in the fluid flowing link is judged, controlling is carried out through alarming and the like to improve the intelligent management level and reduce waste of the fluid resource, pollution to the environment and burning and exploding accidents.

Owner:俞如

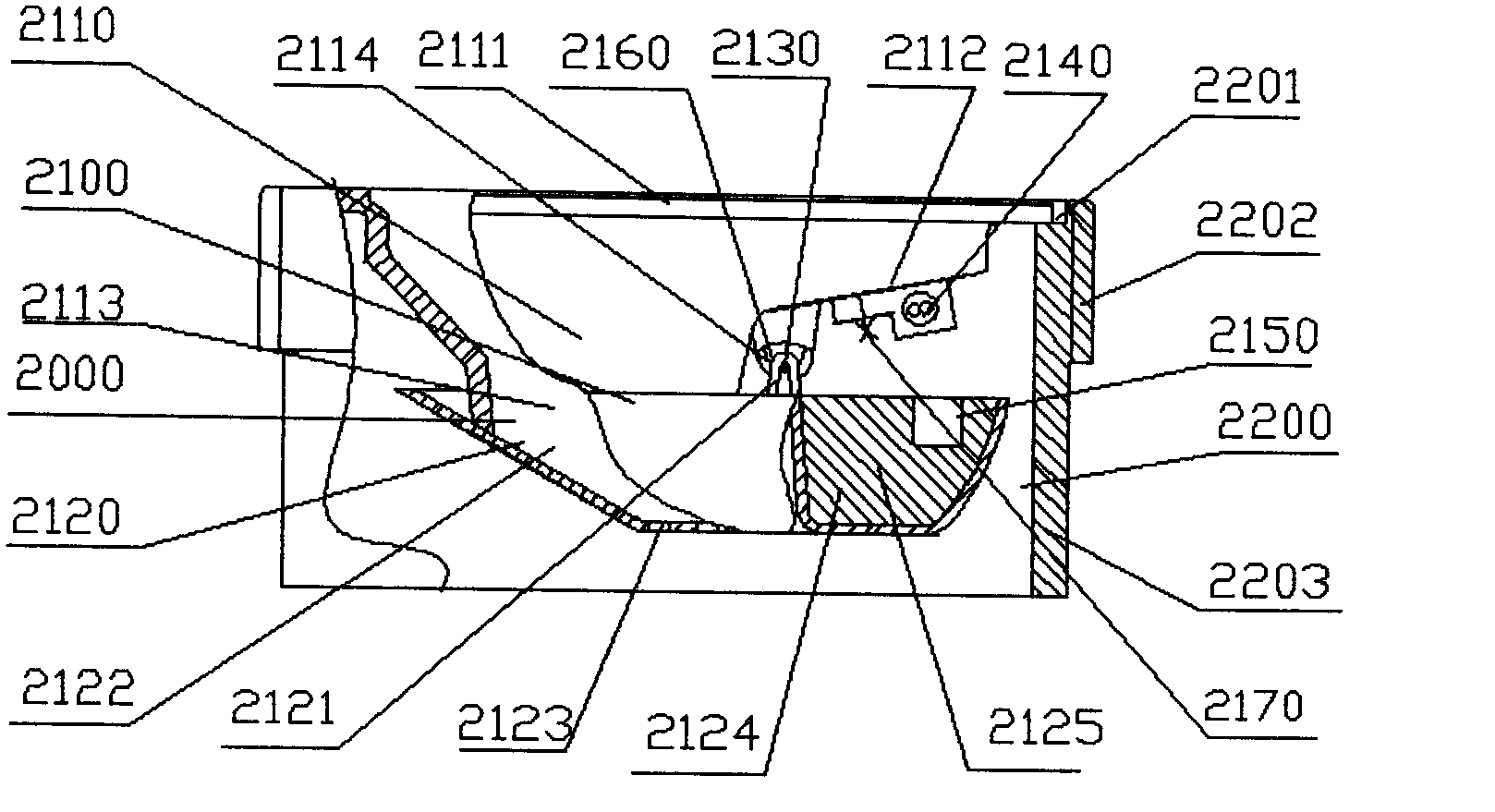

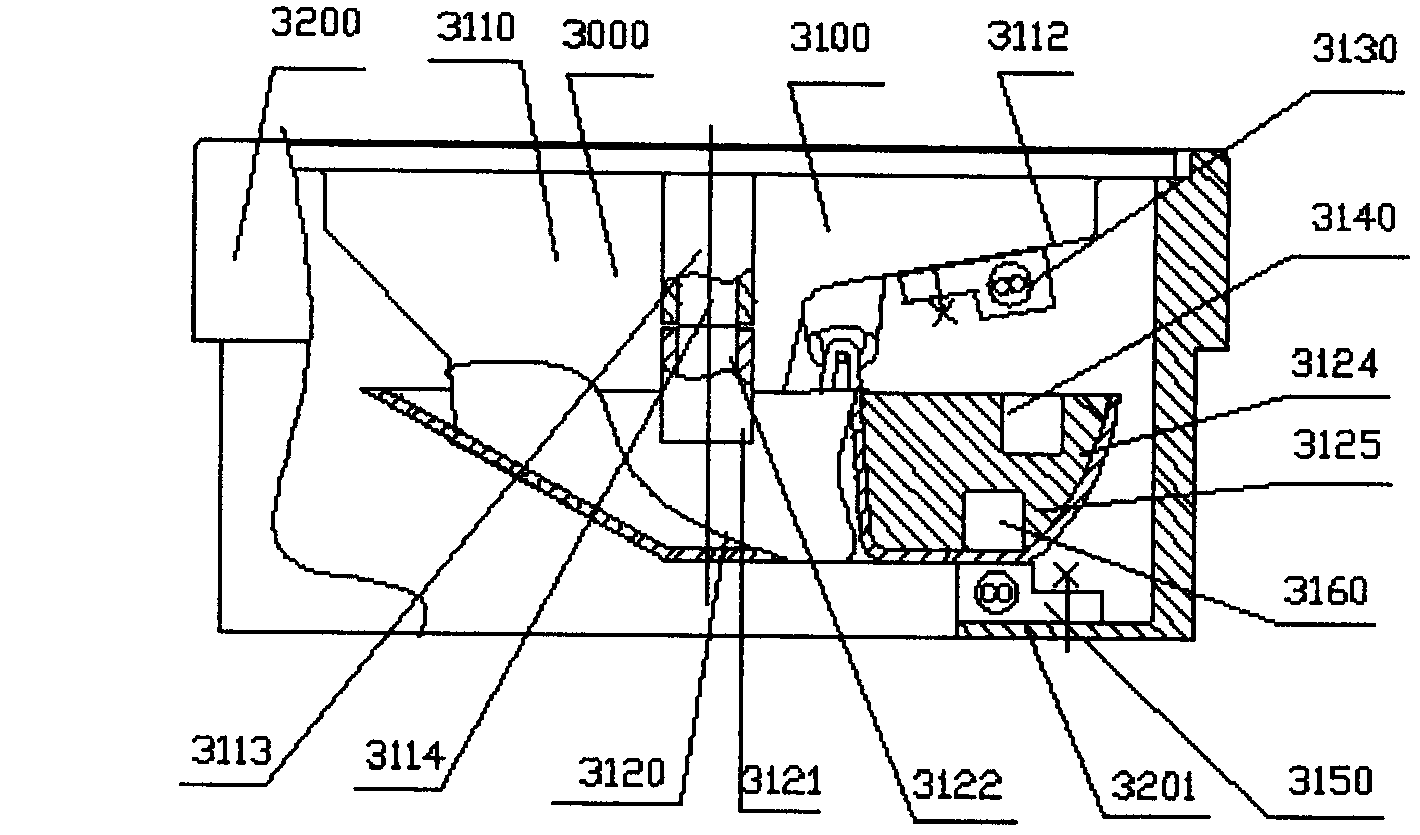

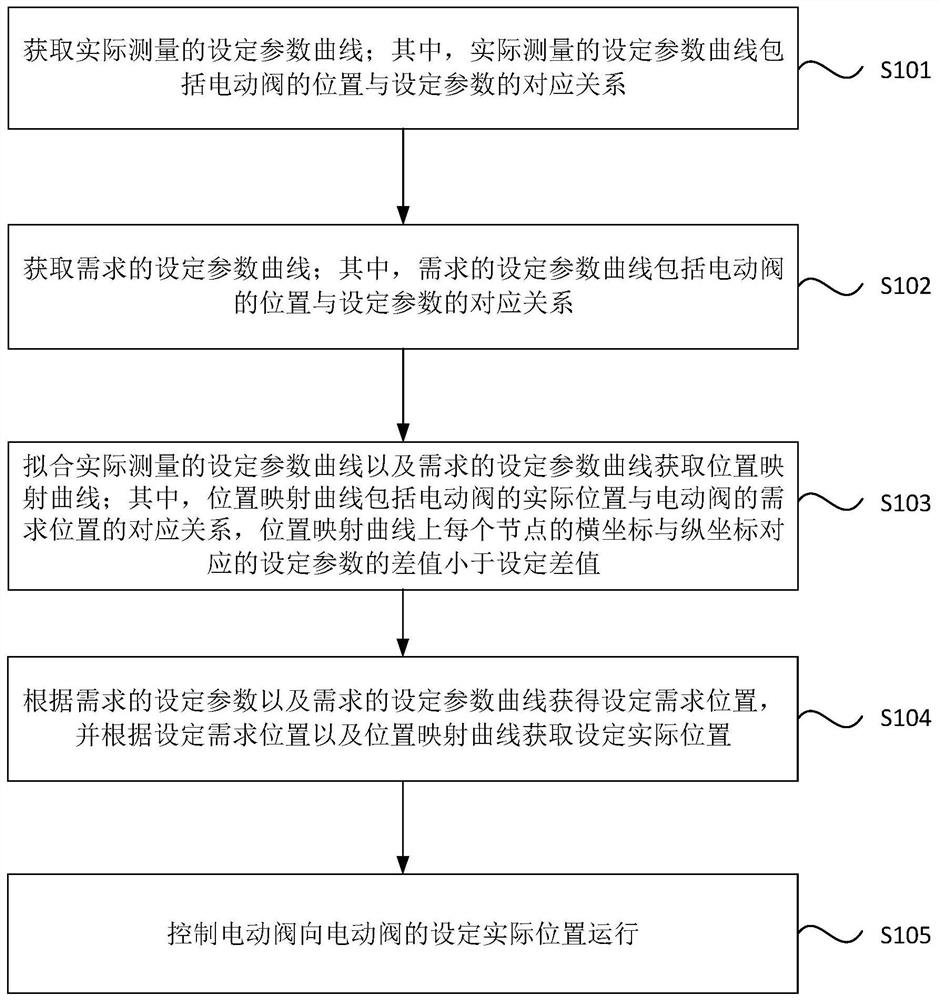

Control method, control system and electric valve

PendingCN112944007AHigh precisionImprove the problem of large deviation of control accuracyOperating means/releasing devices for valvesEfficient regulation technologiesControl systemControl engineering

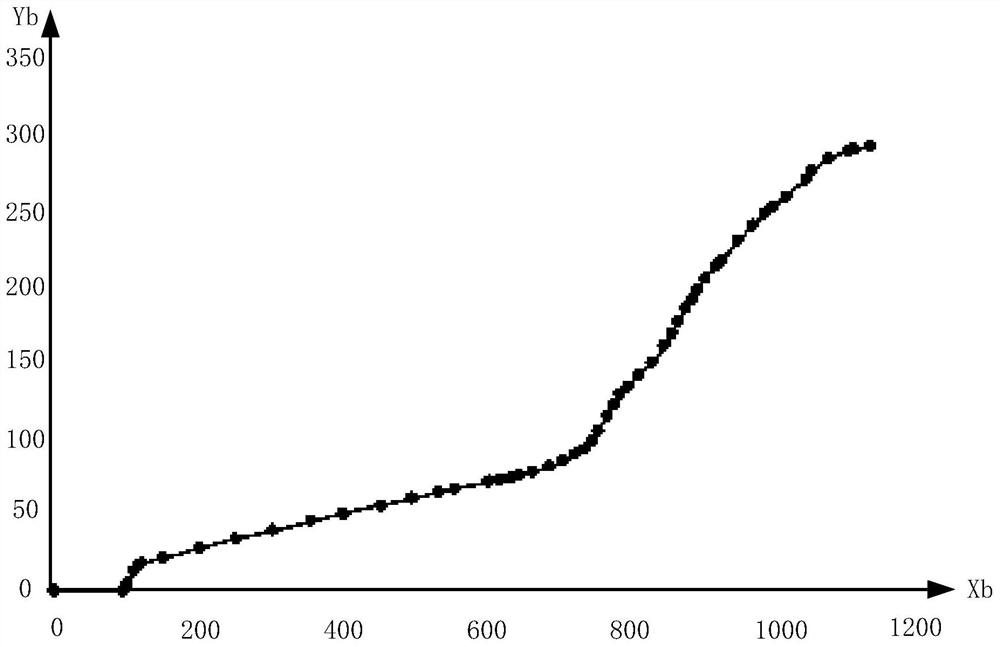

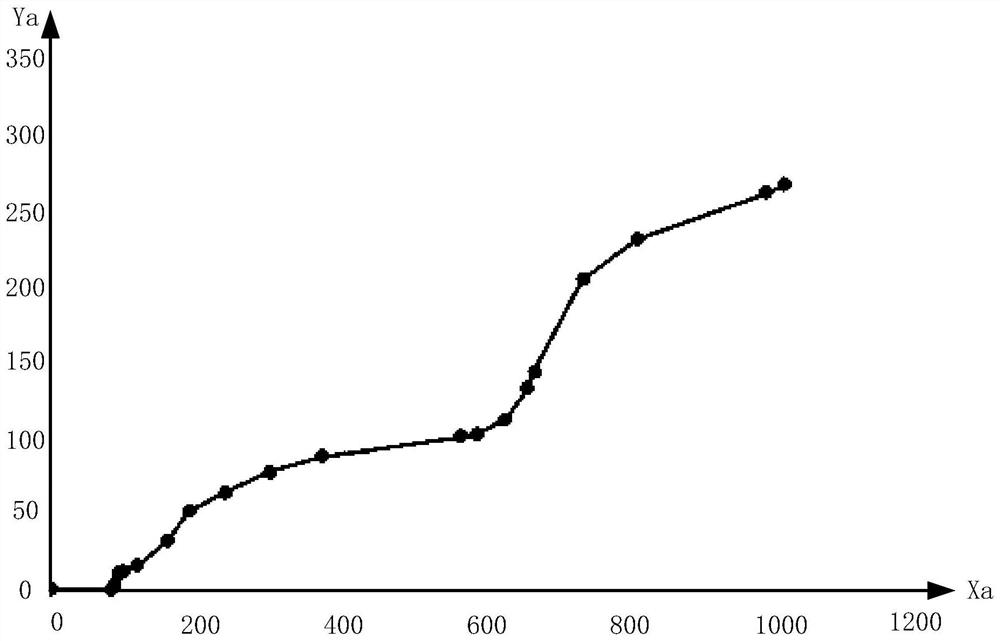

The invention discloses a control method, a control system and an electric valve. The control method comprises the steps that an actually-measured set parameter curve is acquired; a required set parameter curve is acquired; the actually-measured set parameter curve and the required set parameter curve each comprises a corresponding relation between a position of the electric valve and set parameters; the actually-measured set parameter curve and the required set parameter curve are fit to acquire a position mapping curve; the position mapping curve comprises a corresponding relation between an actual position of the electric valve and a required position of the electric valve, and a difference value of the set parameters corresponding to a horizontal coordinate and a vertical coordinate of each point on the position mapping curve is smaller than a set difference value; a set required position is obtained according to the required set parameters and the required set parameter curve, and a set actual position is acquired according to the set required position and the position mapping curve; and the electric valve is controlled to run towards the set actual position of the electric valve. Therefore, the precision of a control process of the electric valve is improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Pressure regulator with bleed orifice

A pressure regulator having a housing that defines a gas inlet, a gas outlet, and a reference pressure connector. A diaphragm is provided in the housing, where the diaphragm defines, at least in part, a reference pressure chamber. In some illustrative embodiments, the reference pressure connector fluidly references the reference pressure chamber to a first pressure via a first orifice, and to a second pressure via a second bleed orifice. A gas valve incorporating a pressure regulator is also disclosed.

Owner:ADEMCO INC

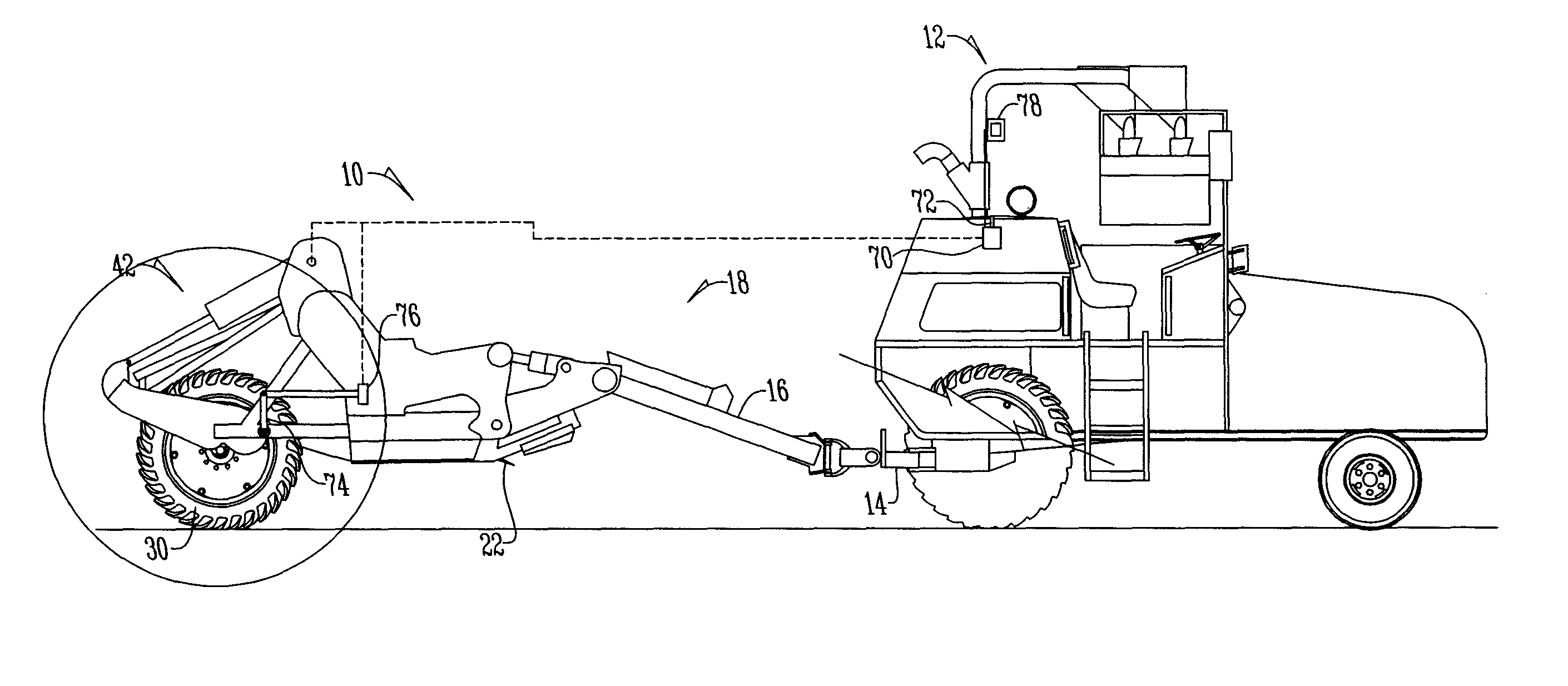

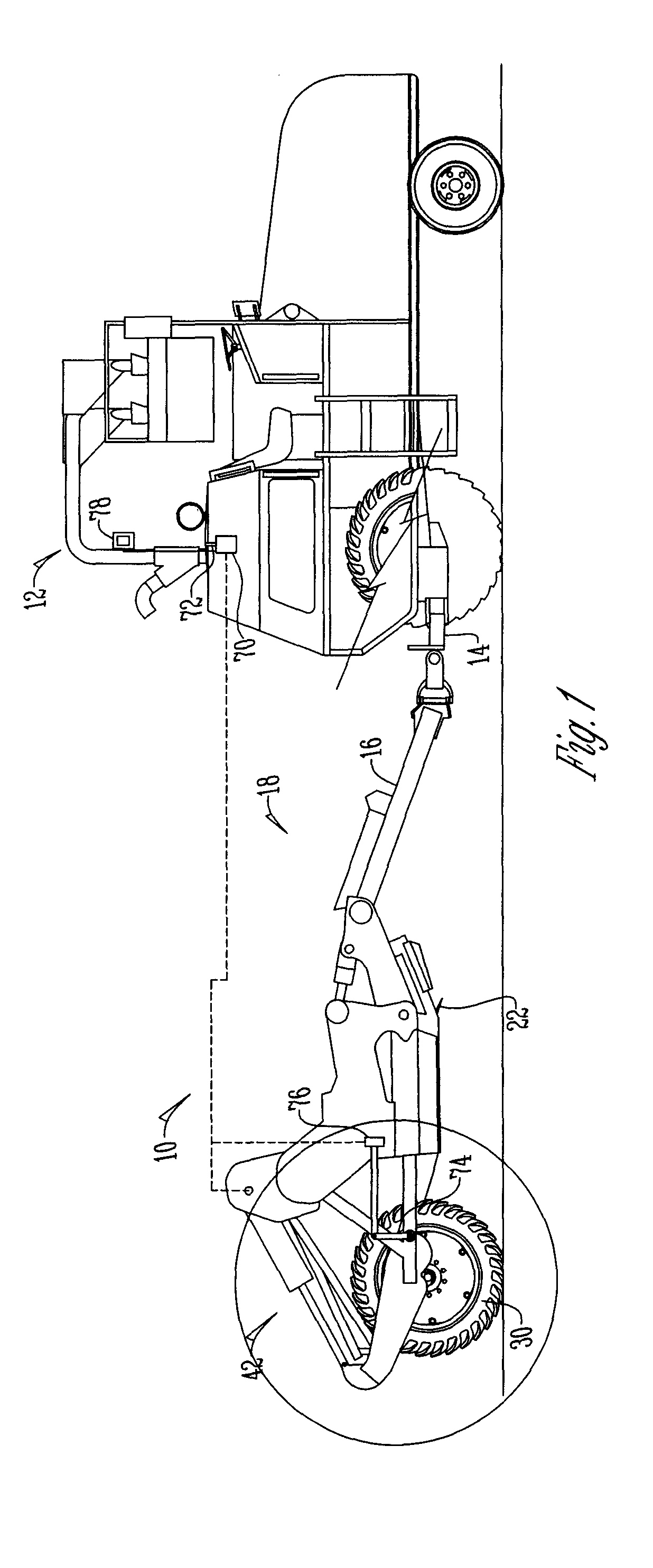

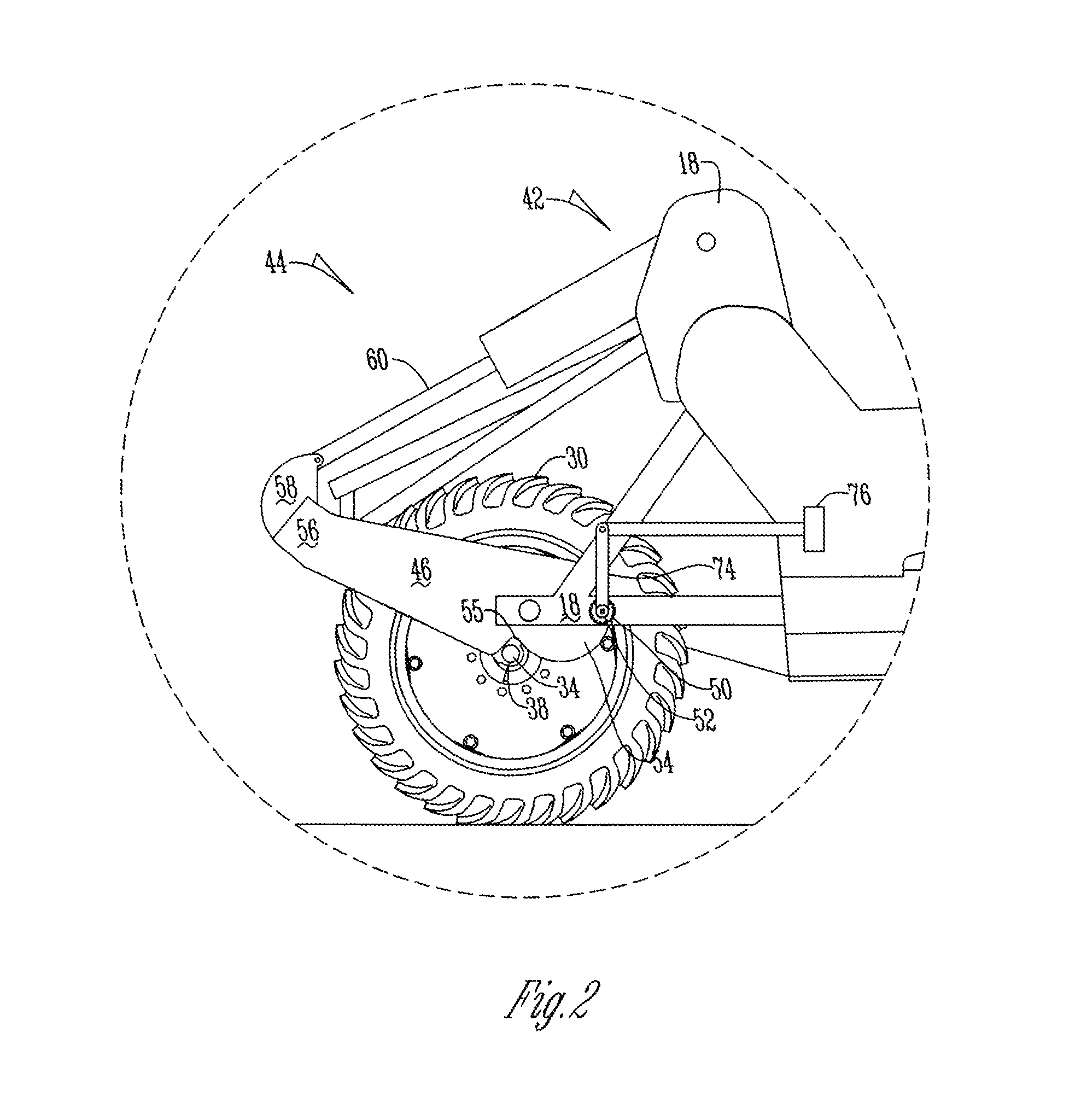

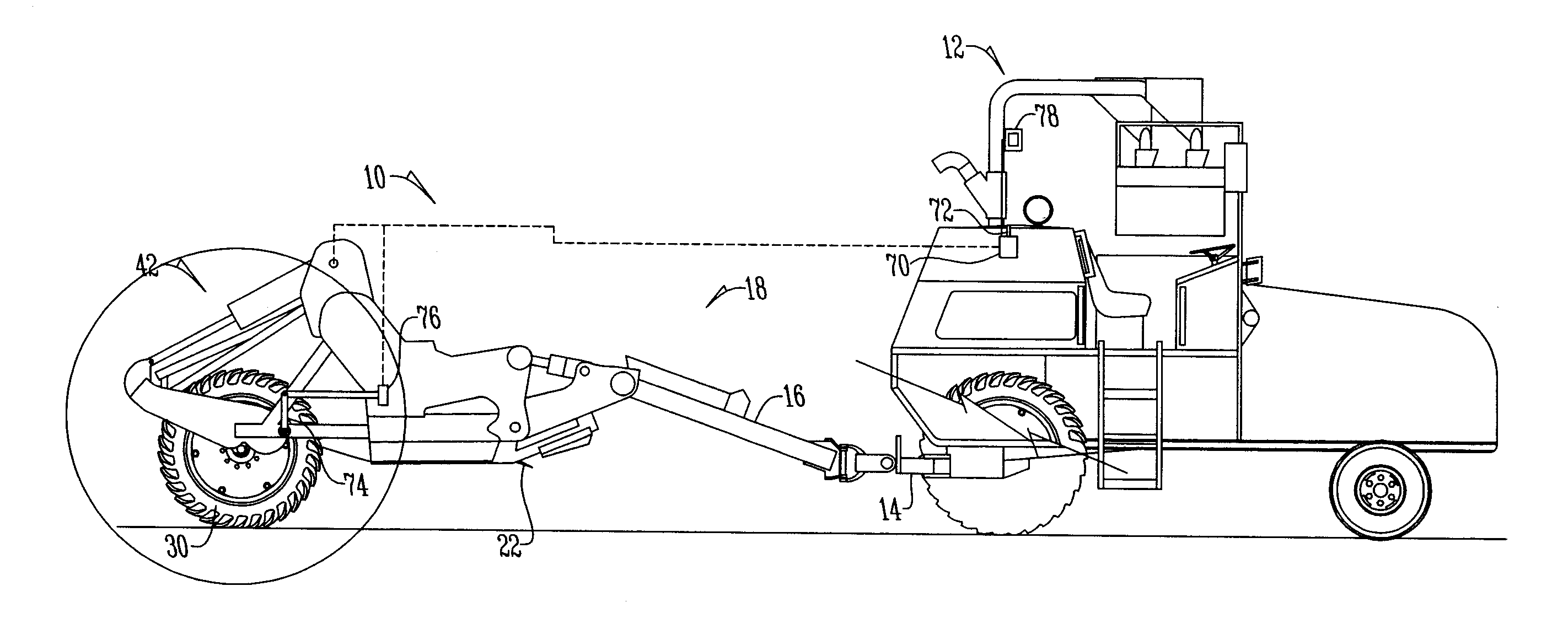

Scraper with lateral tilt

A scraper that has a frame that supports wheels. The scraper includes a blade and a blade height and tilt assembly that are connected to the frame in order to both adjust the height of the blade and the angle at which the blade cuts soil.

Owner:GUYNN LOUIS E

Valve positioner having bypass component and control valve comprised thereof

InactiveCN104279367AReduce downtimeOperating means/releasing devices for valvesTransducersDowntimeControl valves

Embodiments of a valve positioner that can maintain operation of the control valve despite failures in one or more components. These embodiments reduce downtime by allowing in-situ repair to occur on the valve positioner. In one embodiment, the valve positioner incorporates a by-pass component, which can utilize control input signals (e.g., a 4-20 mA signal) to energize one or more components (e.g., a current-to-pressure converter) to cause the control valve to modulate fluid flow without the digital microprocessor and / or related components.

Owner:DRESSER INC

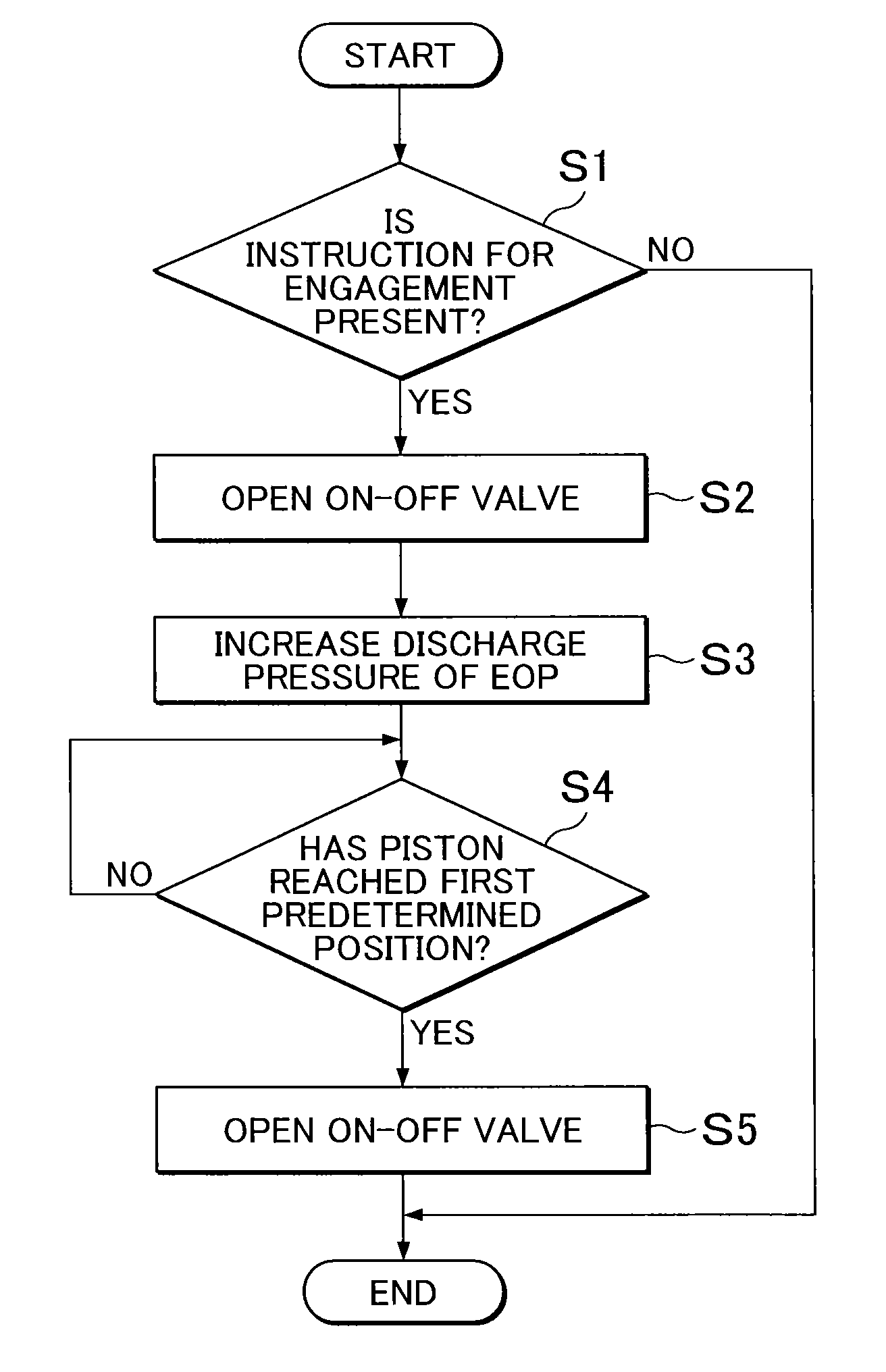

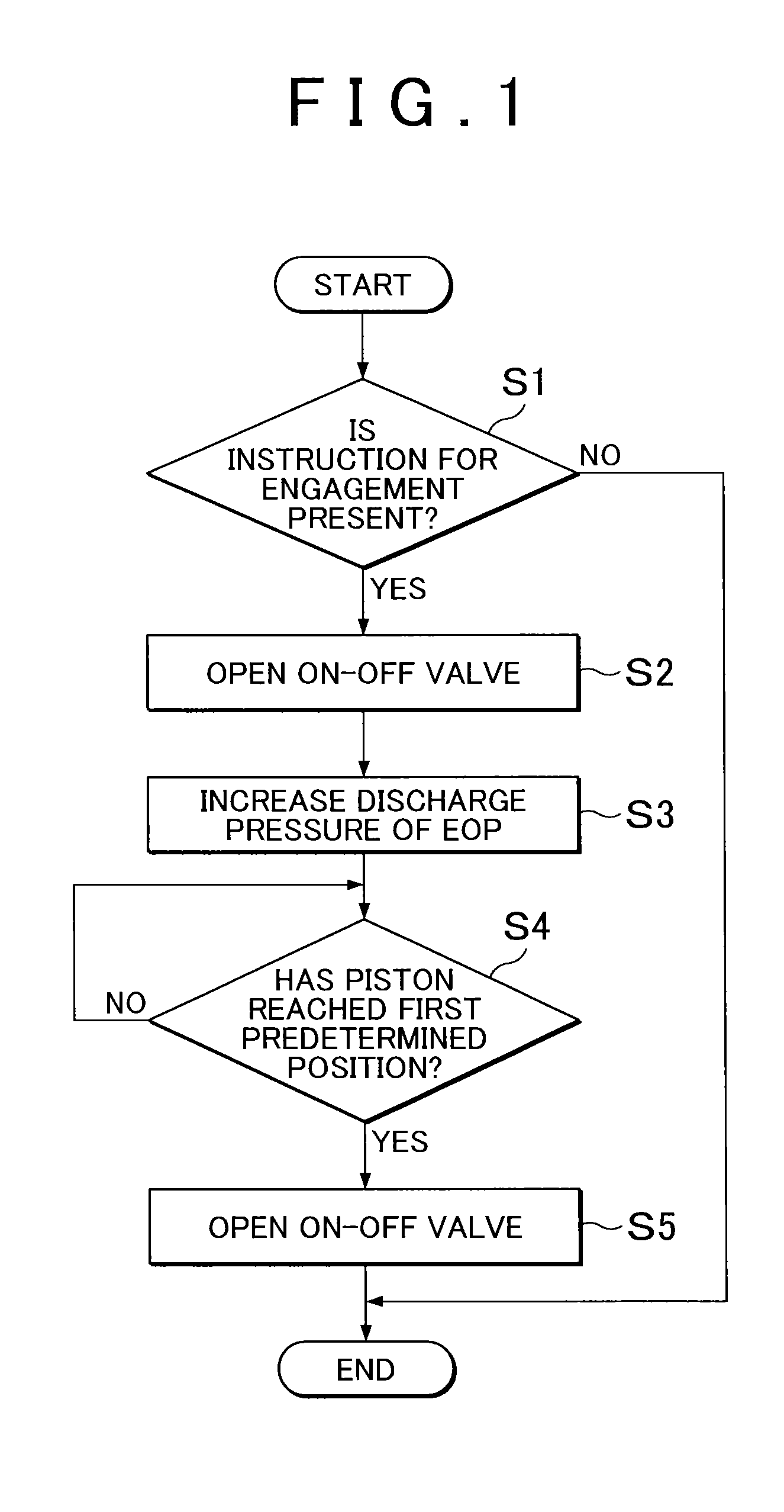

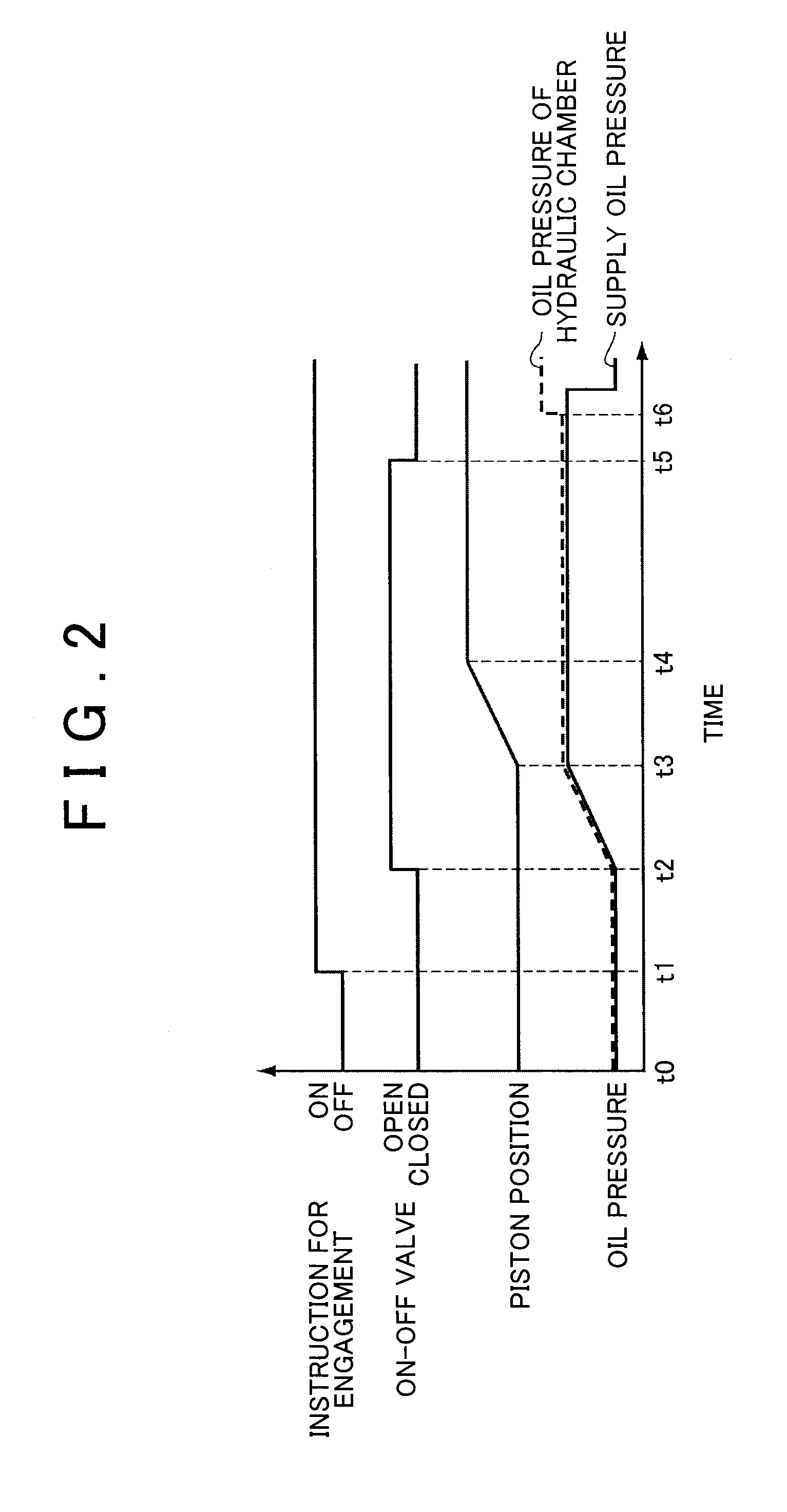

Control system for meshing type engagement mechanism

ActiveUS20160201737A1Reduce operating forceEasy to controlFluid actuated clutchesToothed gearingsControl systemEngineering

Owner:TOYOTA JIDOSHA KK

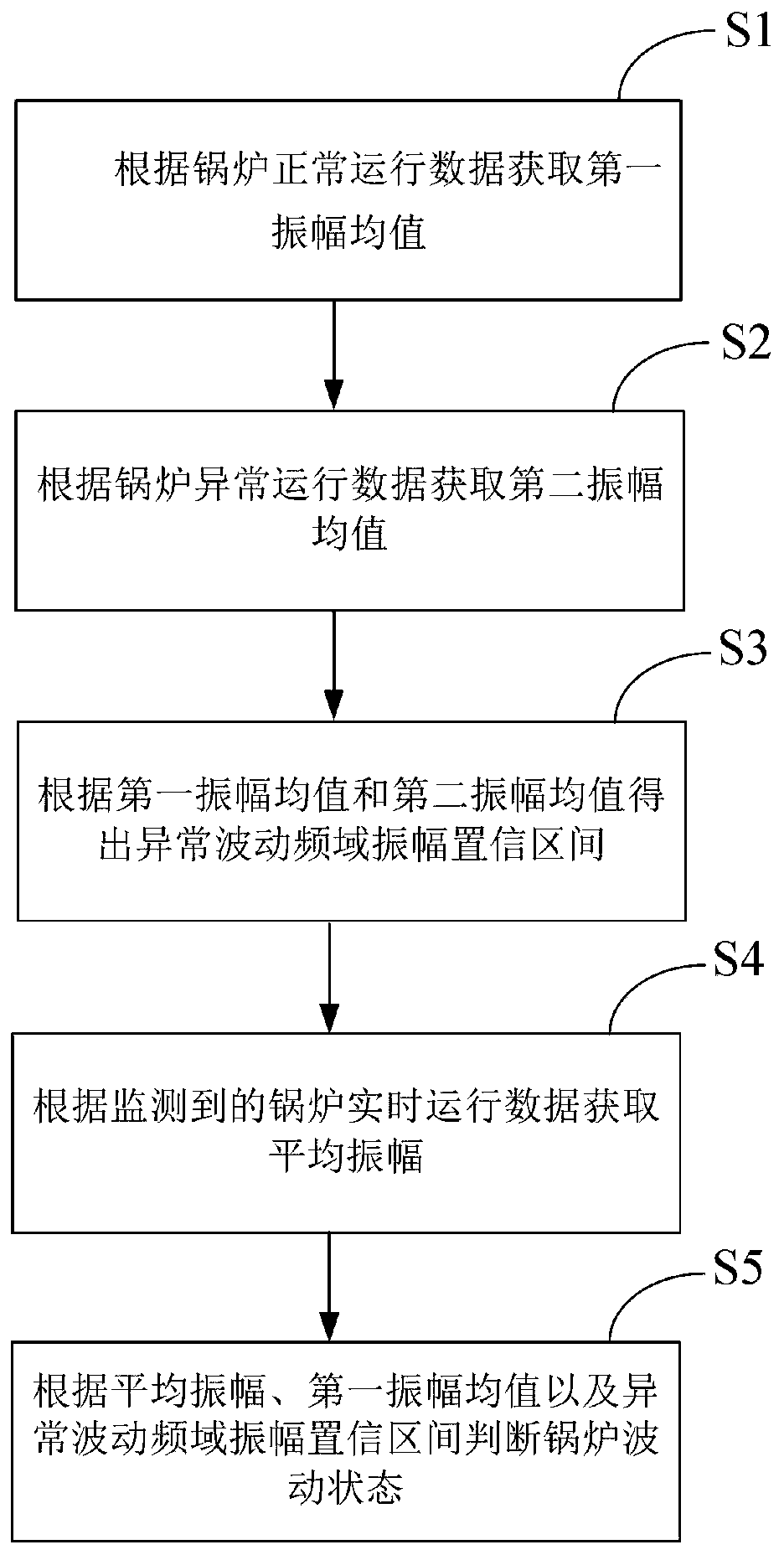

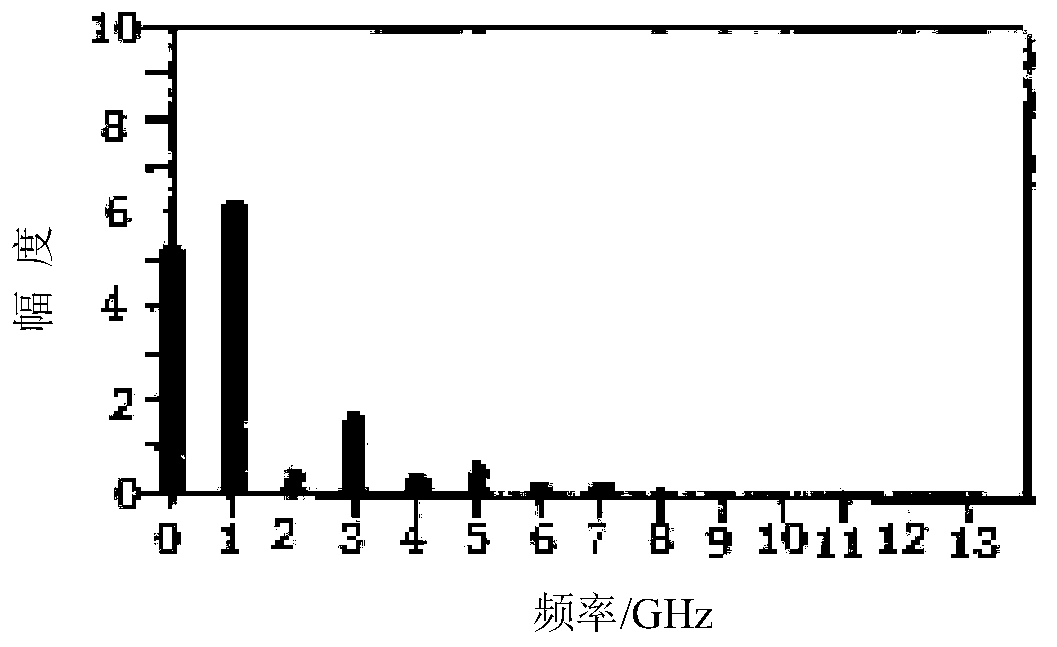

Method and device for monitoring fluctuation state of boiler

The invention is applicable to the technical field of boiler monitoring, and provides a method and device for monitoring a fluctuation state of a boiler. The method comprises the following steps: obtaining a first amplitude average value according to the normal operation data of the boiler, obtaining a second amplitude average value according to the abnormal operation data of the boiler, and obtaining an abnormal fluctuation frequency domain amplitude confidence interval sigma according to the first amplitude average value and the second amplitude average value; and obtaining an average amplitude according to the monitored real-time operation data of the boiler, and judging the fluctuation state of the boiler according to the average amplitude, the first amplitude average value and the abnormal fluctuation frequency domain amplitude confidence interval sigma. The fluctuation state of the boiler is judged according to the average amplitude, the first amplitude average value and the abnormal fluctuation frequency domain amplitude confidence interval sigma, so that the normal fluctuation and the abnormal fluctuation of the operation of the boiler can be visually quantified in the frequency domain, and whether the operation of the boiler is in an abnormal fluctuation state can be quickly identified conveniently.

Owner:XINAO SHUNENG TECH CO LTD

Lubrication unit management system

A system for remotely controlling and documenting valve lubrication. The system includes an operator unit programmed to communicate with a remote controller unit that actuates the transfer of lubricant to user-selected valves.

Owner:DUALCO INC

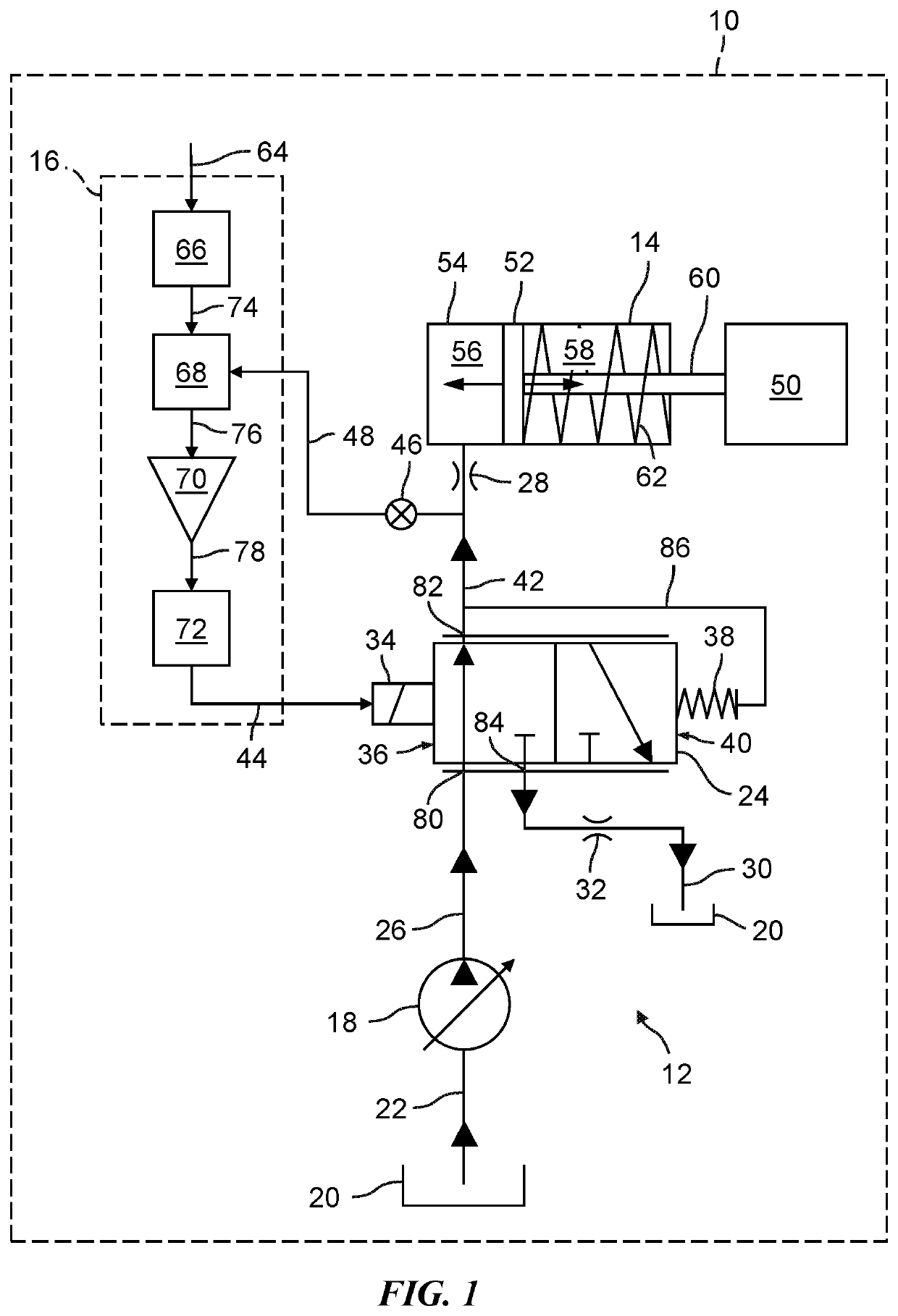

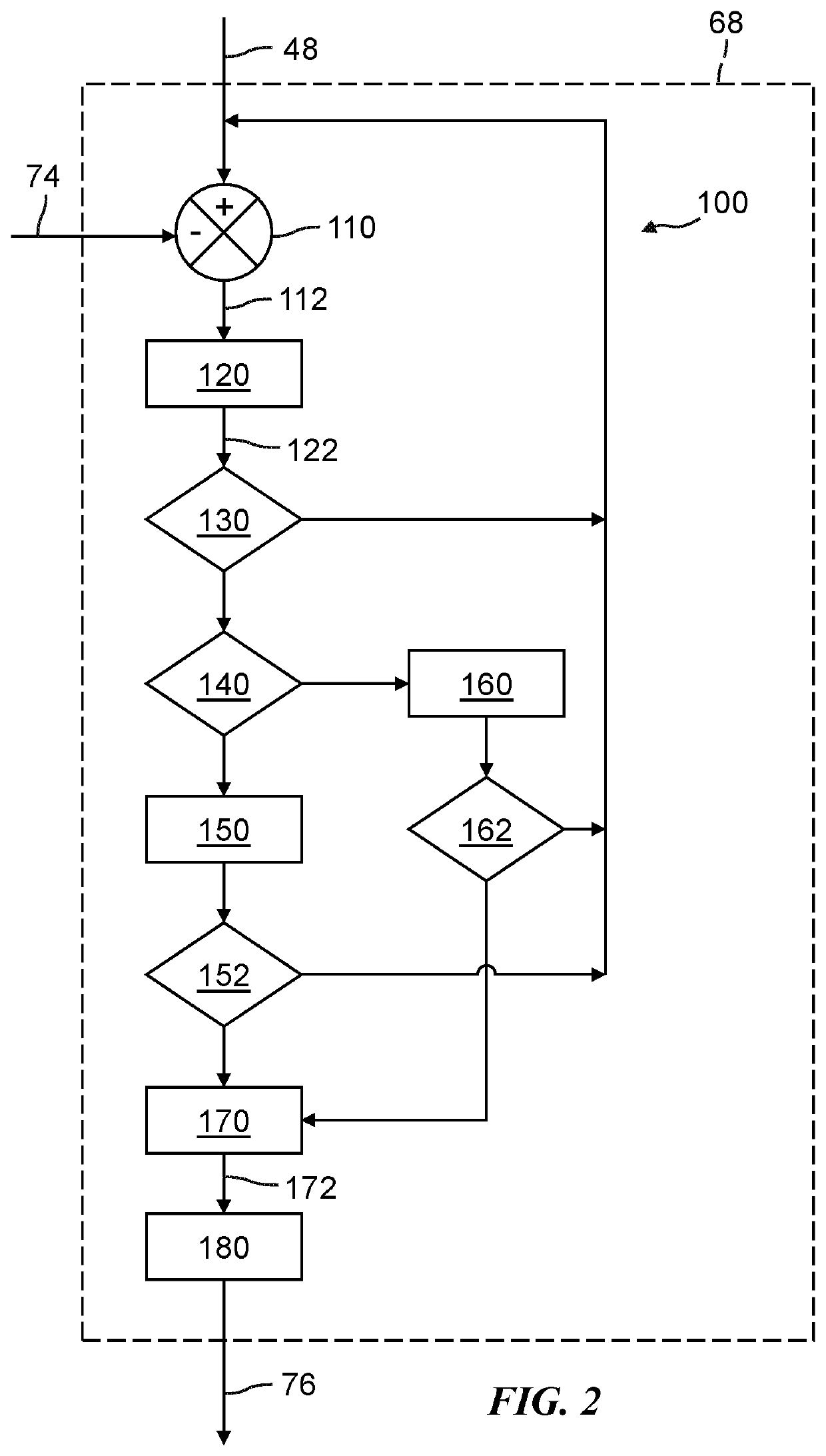

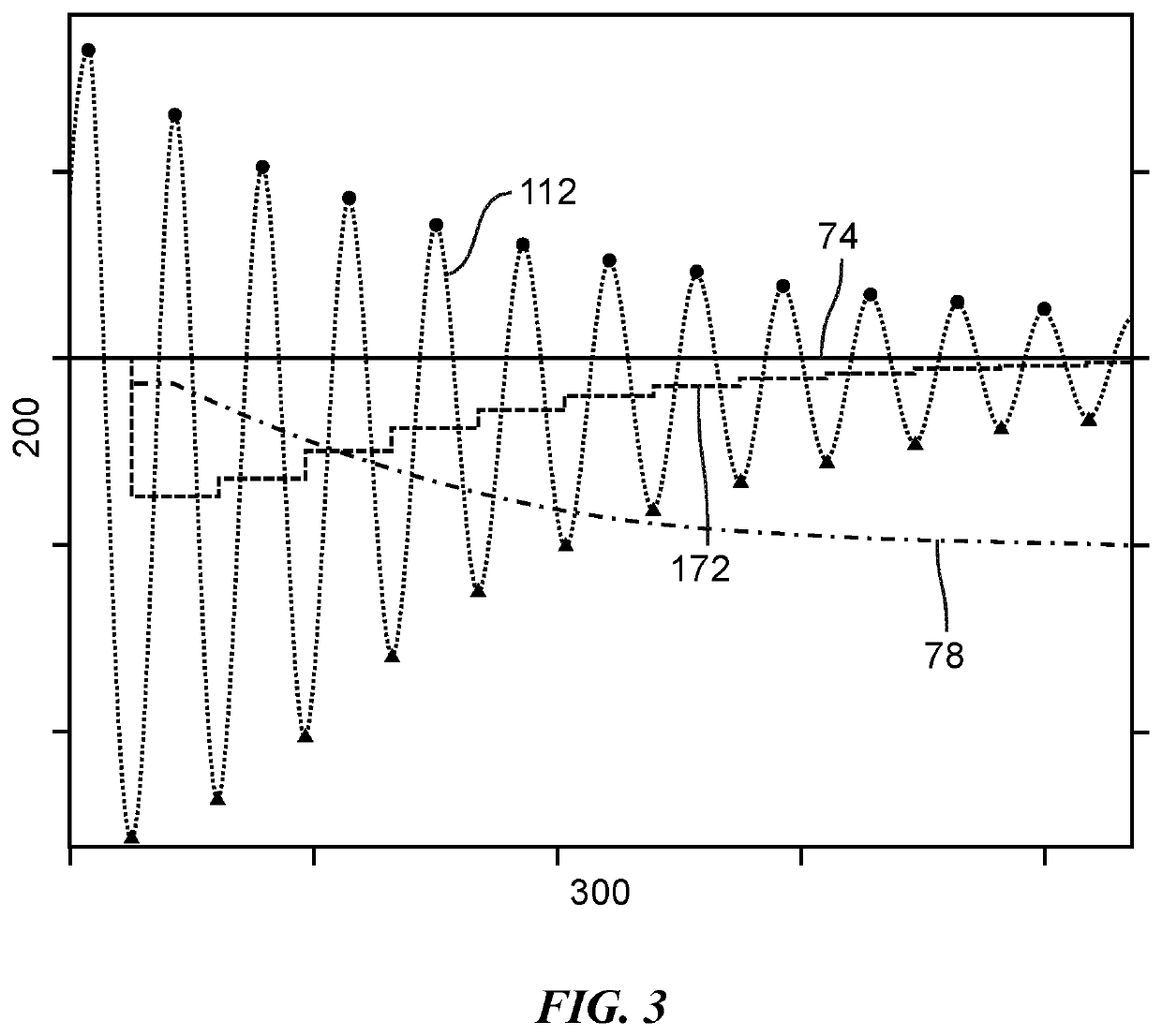

Method for controlling a hydraulic system

ActiveUS20200292071A1Offset errorFluid-pressure actuator testingServomotor componentsElectro hydraulicEngineering

A hydraulic system may include an electrohydraulic control valve disposed in fluid communication between a source of pressured fluid and a hydraulic actuator. The hydraulic system may be controlled to correct for offset errors between a target actuator pressure and a current actuator pressure output from the control valve, without amplifying pressure oscillations in the fluid between the control valve and the hydraulic actuator.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com